Page 1

®

Diagnostic

RepaiR

Manual

GP Series Portable Generators

MODELS:

GP1800

GP3250

GP5000

GP5500

GP6500

GP7000

GP8000

PORTABLE GENERATORS

Page 2

Throughout this publication, “DANGER!” and “CAUTION!” blocks are used to alert the mechanic to special

instructions concerning a particular service or operation that might be hazardous if performed incorrectly or

carelessly. PAY CLOSE ATTENTION TO THEM.

DANGER! UNDER THIS HEADING WILL BE FOUND SPECIAL INSTRUCTIONS WHICH, IF NOT COMPLIED

WITH, COULD RESULT IN PERSONAL INJURY OR DEATH.

*

CAUTION! Under this heading will be found special instructions which, if not complied with, could result

in damage to equipment and/or property.

*

These “Safety Alerts” alone cannot eliminate the hazards that they signal. Strict compliance with these special

instructions plus “common sense” are major accident prevention measures.

SAFETY

NOTICE TO USERS OF THIS MANUAL

This SERVICE MANUAL has been written and published by Generac to aid our dealers' mechanics and company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with the servicing procedures for these products, or like or

similar products manufactured and marketed by Generac. That they have been trained in the recommended

servicing procedures for these products, including the use of common hand tools and any special Generac

tools or tools from other suppliers.

Generac could not possibly know of and advise the service trade of all conceivable procedures by which a

service might be performed and of the possible hazards and/or results of each method. We have not undertaken any such wide evaluation. Therefore, anyone who uses a procedure or tool not recommended by

Generac must first satisfy themselves that neither his nor the products safety will be endangered by the service procedure selected.

All information, illustrations and specifications in this manual are based on the latest product information

available at the time of publication.

When working on these products, remember that the electrical system and engine ignition system are capable of violent and damaging short circuits or severe electrical shocks. If you intend to perform work where

electrical terminals could be grounded or touched, the battery cables should be disconnected at the battery.

Any time the intake or exhaust openings of the engine are exposed during service, they should be covered to

prevent accidental entry of foreign material. Entry of such materials will result in extensive damage when the

engine Is started.

During any maintenance procedure, replacement fasteners must have the same measurements and

strength as the fasteners that were removed. Metric bolts and nuts have numbers that indicate their strength.

Customary bolts use radial lines to indicate strength while most customary nuts do not have strength markings. Mismatched or incorrect fasteners can cause damage, malfunction and possible injury.

REPLACEMENT PARTS

Components on Generac recreational vehicle generators are designed and manufactured to comply with

Recreational Vehicle Industry Association (RVIA) Rules and Regulations to minimize the risk of fire or explosion. The use of replacement parts that are not in compliance with such Rules and Regulations could result

in a fire or explosion hazard. When servicing this equipment, it is extremely important that all components be

properly installed and tightened. If improperly installed and tightened, sparks could ignite fuel vapors from fuel

system leaks.

Page 3

Specifications .......................................................... 2

Part 1 – General Information .................................. 9

Section 1.1 – Generator Fundamentals ................ 10

Magnetism .......................................................10

Electromagnetic Fields.....................................10

Electromagnetic Induction................................10

A Simple AC Generator ...................................11

A More Sophisticated AC Generator ................11

Section 1.2 – Measuring Electricity ....................... 13

Meters ............................................................13

The VOM ..........................................................13

Measuring AC Voltage .....................................13

Measuring DC Voltage .....................................13

Measuring AC Frequency ................................13

Measuring Current ...........................................14

Measuring Resistance .....................................14

Electrical Units .................................................15

Ohm's Law .......................................................15

Section 1.3 – Brushless, Capacitor

Excitation System ............................ 16

Introduction ......................................................16

Stator Assembly ...............................................16

Rotor Assembly ................................................16

Circuit Breakers ...............................................16

Operation .........................................................17

Section 1.4 – Brushed Excitation System ............. 18

Introduction ......................................................18

Stator Assembly ...............................................18

Brush Holder and Brushes ...............................18

Rotor Residual Magnetism...............................18

Voltage Regulator ............................................18

Operation .........................................................18

Section 1.5 – Testing, Cleaning and Drying .......... 20

Insulation Resistance .......................................20

The Megohmmeter...........................................20

Stator Insulation Resistance Test .....................20

Cleaning the Generator ....................................21

Drying the Generator .......................................21

Part 2 – AC Generators ......................................... 21

Section 2.1 – Brushless Capacitor

Troubleshooting Flowcharts ............. 22

Section 2.2 – Brushed Excitation

Troubleshooting Flowcharts ............. 24

Section 2.3 – AC Diagnostic Tests ........................ 26

Introduction ......................................................26

Test 1 – Check No-Load Voltage

and Frequency ....................................26

Test 2 – Check Circuit Breaker.........................26

Test 3 – Check Continuity of

Receptacle Panel ................................26

Test 4 – Field Flash Alternator

(Configuration “A” Only) .......................27

Test 5 – Check Brushed Rotor Circuit ..............28

Test 6 – Check Capacitor .................................29

Test 7 – Test Brushless DPE Winding ..............30

Test 8 – Test Brushless Stator Windings ..........30

Test 9 – Test Brushed Stator Windings ............31

Test 10 – Check Load Voltage & Frequency ....31

Test 11 – Check Load Watts & Amperage .......31

Test 12 – Adjust Voltage Regulator ..................31

Part 3 – Engine Troubleshooting .......................... 33

Section 3.1 – 389/206/163cc Troubleshooting

Flowcharts ....................................... 34

Section 3.2 – 410cc Troubleshooting Flowcharts .. 37

Section 3.3 – Diagnostic Tests .............................. 42

Test 20 – Check 1.5 Amp Fuse ........................42

Test 21 – Check Battery & Cables ...................42

Test 22 – Check Voltage at

Starter Contactor (SC) ........................42

Test 23 – Check Start-Run-Stop Switch ..........42

Test 24 – Test OFF-ON Switch .........................43

Test 25 – Check Starter Motor .........................43

Test 25 – Check Ignition Spark ........................45

Test 26 – Check Spark Plugs ...........................46

Test 29 – Check Carburetion ...........................46

Test 30 – Choke Test ........................................47

Test 33 – Check Valve Adjustment ...................47

Test 36 – Check Engine / Cylinder Leak Down

Test / Compression Test ......................48

Test 38 – Check Flywheel ................................48

Test 39 – Remove Wire 18 / Shutdown Lead ...49

Test 40 – Check / Adjust Governor

(389cc Engine) ....................................49

Test 41 – Check / Adjust Governor

(410cc Engine) ....................................50

Test 45 – Check Oil Level Switch .....................51

Test 46 – Check Oil Pressure Switch ...............51

Test 49 – Test Recoil Function .........................52

Test 50 – Test Engine Function ........................52

Part 4 – Disassembly ............................................. 53

Section 4.1 – Major Disassembly .......................... 54

Part 5 – Electrical Data .......................................... 71

Electrical Schematic, GP1850 .............................. 72

Electrical Schematic, GP3250 .............................. 73

Electrical Schematic, GP5000/5500/GP6500 ....... 74

Wiring Diagram, GP5000/5500/GP6500 ............... 75

Electrical Schematic, GP7000E/GP8000E ........... 76

Wiring Diagram, GP7000E/GP8000E ................... 77

Electrical Formulas ............................................... 78

Page 1

Page 4

AH

M

SPECIFICATIONS – GP1800

Outlets

A

Circuit Breakers

M

Other Features

H

(2) 5-20R 120V

(1) 20A

On/Off Switch

Product Series GP1800

A/C Rated Output Watts: 1800

A/C Maximum Output Watts: 2050

A/C Voltage 120VAC

A/C Frequency 60 Hz

Rated 120 VAC Amperage 7.5

Max 120 VAC Amperage 8.5

Engine Displacement 163cc

Engine Type OHV

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Splash Sump

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method Manual

Battery n/a

Battery Size n/a

Low Oil Shutdown Method Low Level

Start Switch Type On/Off Toggle

Switch Location Control Panel

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 4

Fuel Tank Capacity (Liters) 15.14

Run Time at 50% (Hours) 14

Cord Set No

Handle Style Folding

Wheel type n/a

Length (L) 23.5

Width (W) 17

Height (H) 17.5

Extended Length (EL) 23.5

Unit Weight (lbs) 79

Spark Plug Type NGK BPR4ES

or Champion

RN14YC

Spark Plug Gap 0.028"-0.031"

(0.7-0.8mm)

Oil Capacity 0.634 quart

(0.6 liter)

Page 2

Page 5

H

A

M

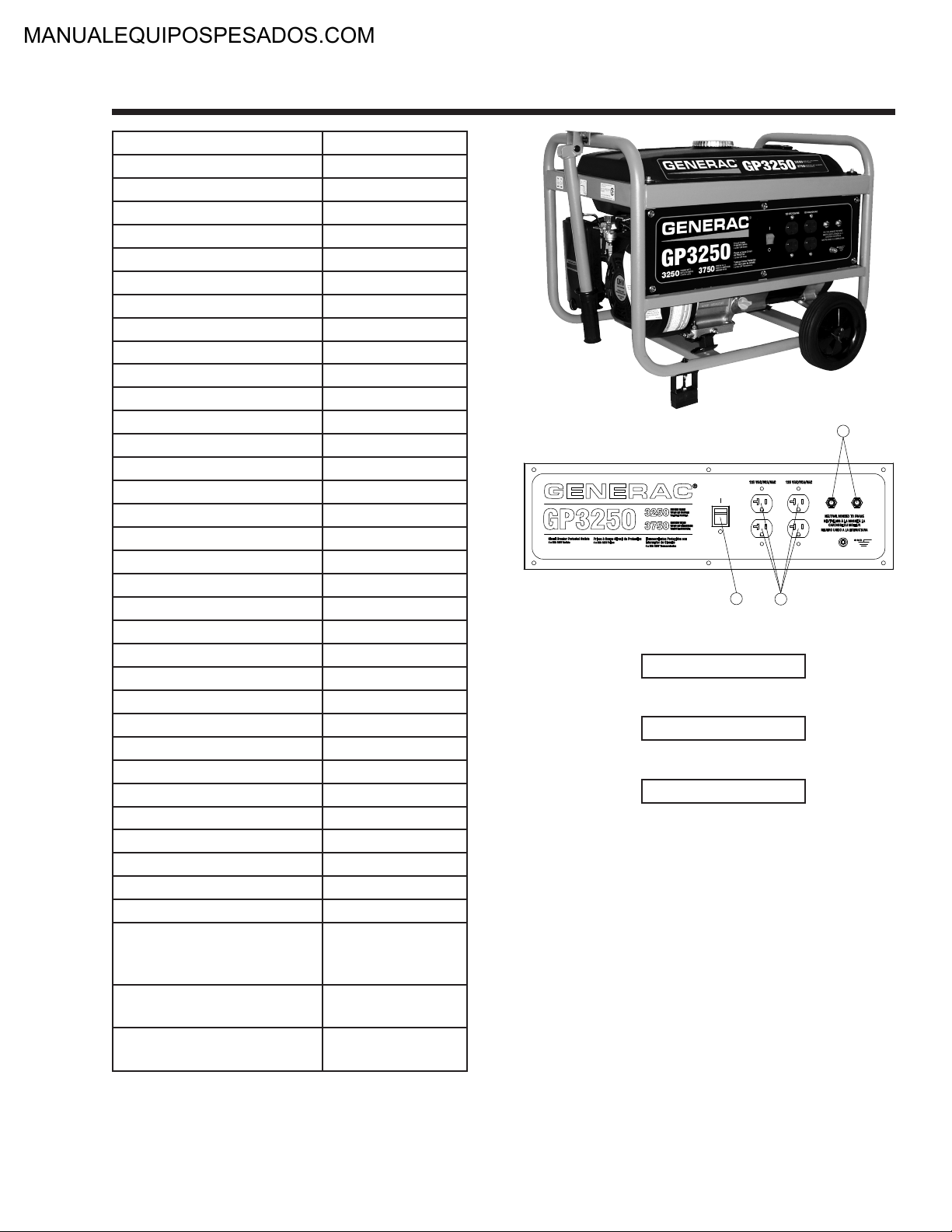

Product Series GP3250

A/C Rated Output Watts: 3250

A/C Maximum Output Watts: 3750

A/C Voltage 120VAC

A/C Frequency 60 Hz

Rated 120 VAC Amperage 13.5

Max 120 VAC Amperage 15.6

Engine Displacement 206cc

Engine Type OHV

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Splash Sump

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method Manual

Battery n/a

Battery Size n/a

Low Oil Shutdown Method Low Level

Start Switch Type On/Off Toggle

Switch Location Control Panel

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 4

Fuel Tank Capacity (Liters) 15.14

Run Time at 50% (Hours) 13.5

Cord Set No

Handle Style Folding

Wheel type 7.0" Solid Wheels

Length (L) 25.5

Width (W) 21

Height (H) 19

Extended Length (EL) 39.5

Unit Weight (lbs) 91

Spark Plug Type NGK BPR4ES

or Champion

RN14YC

Spark Plug Gap 0.028"-0.031"

(0.7-0.8mm)

Oil Capacity 0.634 quart

(0.6 liter)

SPECIFICATIONS – GP3250

Outlets

A

Circuit Breakers

M

Other Features

H

(4) 5-20R 120V

(2) 20A

On/Off Switch

Page 3

Page 6

H

B

N

M

A

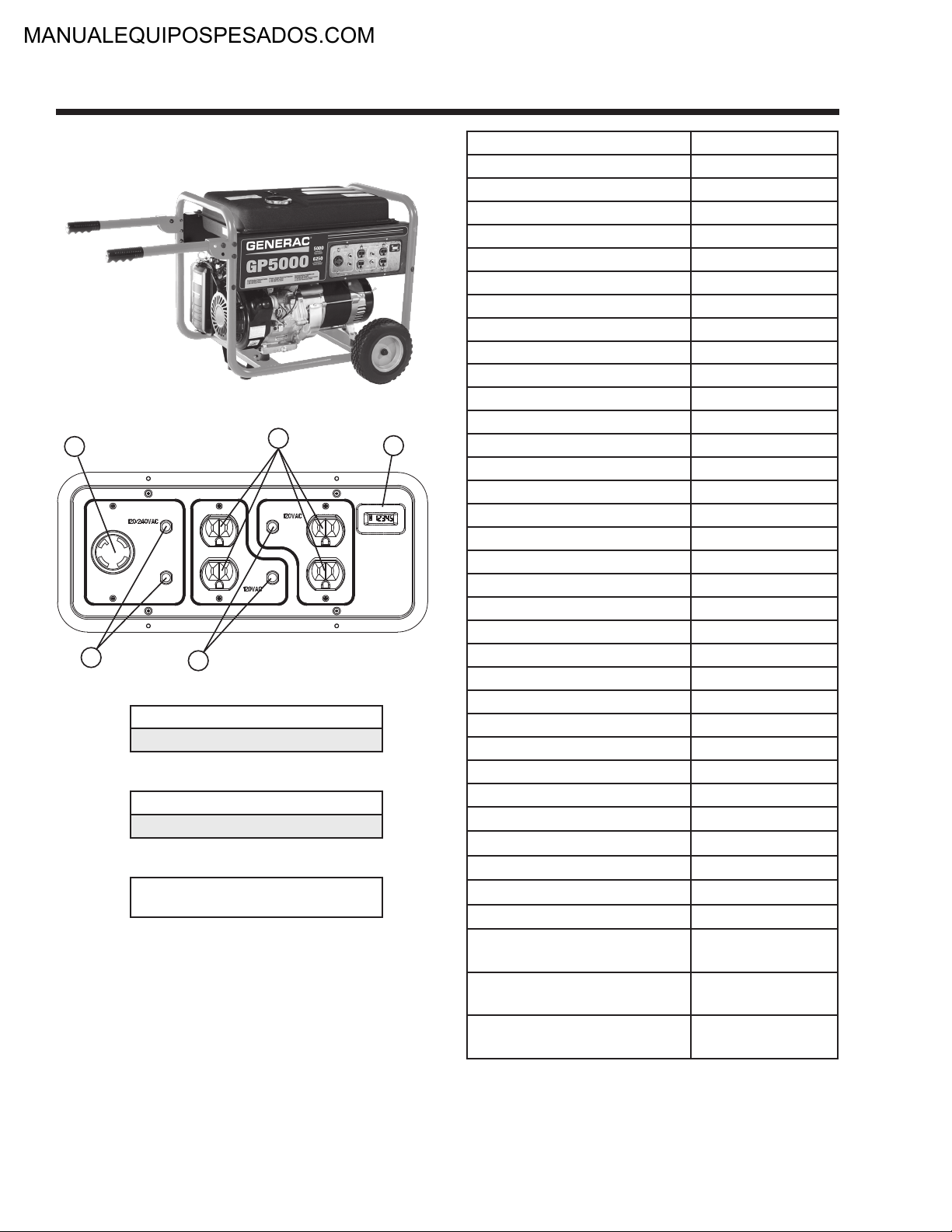

SPECIFICATIONS – GP5000

Receptacles

A

B

Circuit Breakers

M

N

Other Features

H

(4) 5-20R 120V

L14-30R Twist-Lock 120/240V

(2) 20A

(2) 25A

Hour Meter with

Maintenance Reset

Product Series GP5000

A/C Rated Output Watts: 5000

A/C Maximum Output Watts: 6250

A/C Voltage 120/240VAC

A/C Frequency 60 Hz

Rated 120/240 VAC Amperage 20.8

Max 120/240 VAC Amperage 26.0

Engine Displacement 389cc

Engine Type OHV

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Splash Sump

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method Manual

Battery n/a

Battery Size n/a

Low Oil Shutdown Method Low Level

Start Switch Type 3-Position

Switch Location On Engine

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 6.6

Fuel Tank Capacity (Liters) 24.981

Run Time at 50% (Hours) 10

Cord Set No

Handle Style Folding Interlocked

Wheel type 9.5" Solid Wheels

Length (L) 33.5

Width (W) 26.5

Height (H) 27.5

Extended Length (EL) 47

Unit Weight (lbs) 167

Spark Plug Type NHSP F7RTC or

Champion RN9YC

Spark Plug Gap 0.028"-0.031"

(0.7-0.8mm)

Oil Capacity 1.16 quart

(1.1 liter)

Page 4

Page 7

H

B

N

M

A

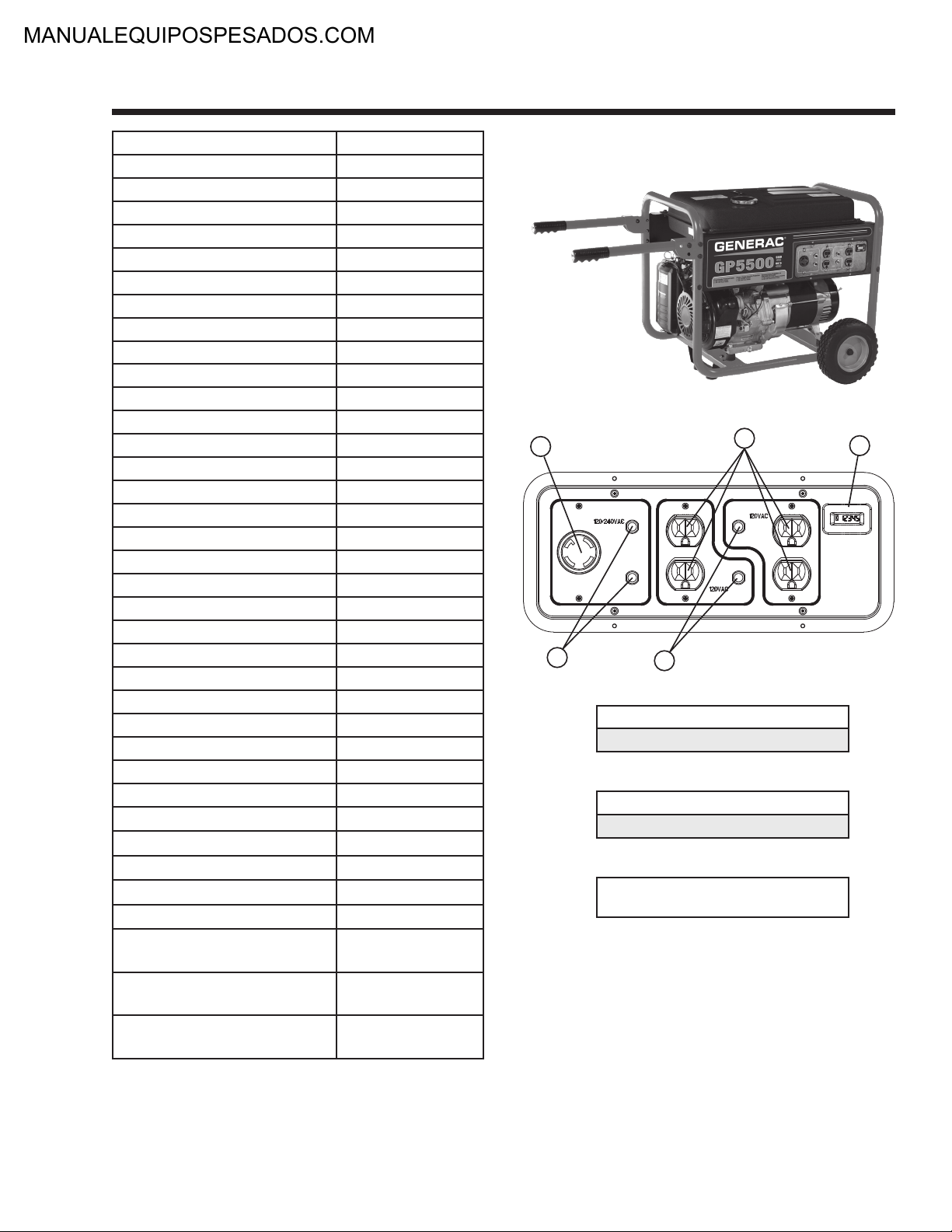

Product Series GP5500

A/C Rated Output Watts: 5000

A/C Maximum Output Watts: 6875

A/C Voltage 120/240VAC

A/C Frequency 60 Hz

Rated 120/240 VAC Amperage 22.9

Max 120/240 VAC Amperage 28.6

Engine Displacement 389cc

Engine Type OHV

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Splash Sump

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method Manual

Battery n/a

Battery Size n/a

Low Oil Shutdown Method Low Level

Start Switch Type 3-Position

Switch Location On Engine

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 6.6

Fuel Tank Capacity (Liters) 24.98

Run Time at 50% (Hours) 10

Cord Set No

Handle Style Folding Interlocked

Wheel type 9.5" Solid Wheels

Length (L) 33.5

Width (W) 26.5

Height (H) 27.5

Extended Length (EL) 47

Unit Weight (lbs) 167

Spark Plug Type NHSP F7RTC or

Champion RN9YC

Spark Plug Gap 0.028"-0.031"

Oil Capacity 1.16 quart

(0.7-0.8mm)

(1.1 liter)

SPECIFICATIONS – GP5500

Receptacles

A

B

Circuit Breakers

M

N

Other Features

H

(4) 5-20R 120V

L14-30R Twist-Lock 120/240V

(2) 20A

(2) 25A

Hour Meter with

Maintenance Reset

Page 5

Page 8

H

B

N

M

A

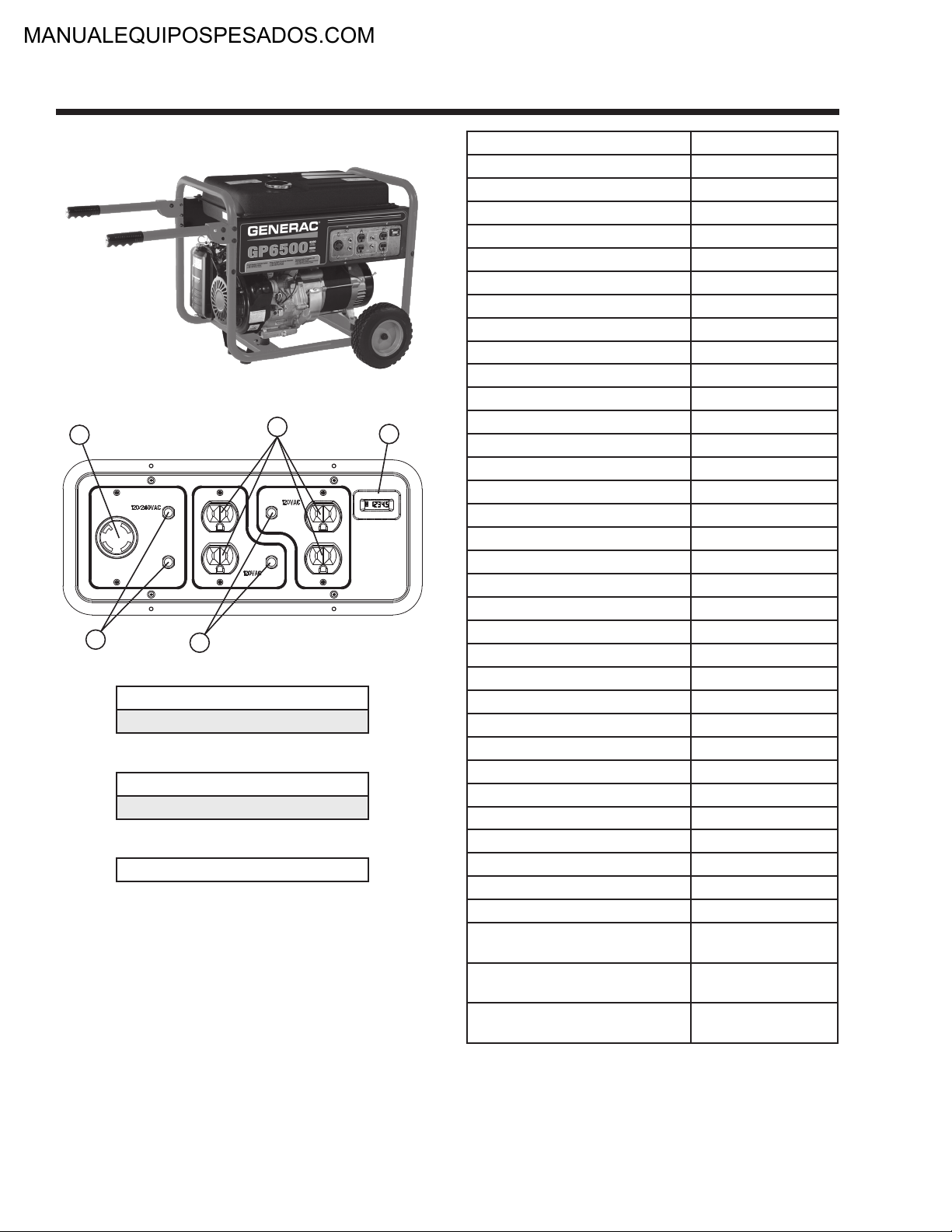

SPECIFICATIONS – GP6500

Outlets

A

B

Circuit Breakers

M

N

Other Features

H

Hour Meter with Maintenance Reset

(4) 5-20R 120V

L14-30R Twist-Lock 120/240V

(2) 20A

(2) 30A

Product Series GP6500

A/C Rated Output Watts: 6500

A/C Maximum Output Watts: 8000

A/C Voltage 120/240VAC

A/C Frequency 60 Hz

Rated 120/240 VAC Amperage 27.1

Max 120/240 VAC Amperage 33.3

Engine Displacement 389cc

Engine Type OHV

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Splash Sump

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method Manual

Battery n/a

Battery Size n/a

Low Oil Shutdown Method Low Level

Start Switch Type 3-Position

Switch Location On Engine

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 6.6

Fuel Tank Capacity (Liters) 24.98

Run Time at 50% (Hours) 9

Cord Set No

Handle Style Folding Interlocked

Wheel type 9.5" Solid Wheels

Length (L) 33.5

Width (W) 26.5

Height (H) 27.5

Extended Length (EL) 47

Unit Weight (lbs) 172

Spark Plug Type NHSP F7RTC or

Champion RN9YC

Spark Plug Gap 0.028"-0.031"

(0.7-0.8mm)

Oil Capacity 1.16 quart

(1.1 liter)

Page 6

Page 9

H

B

N

M

A

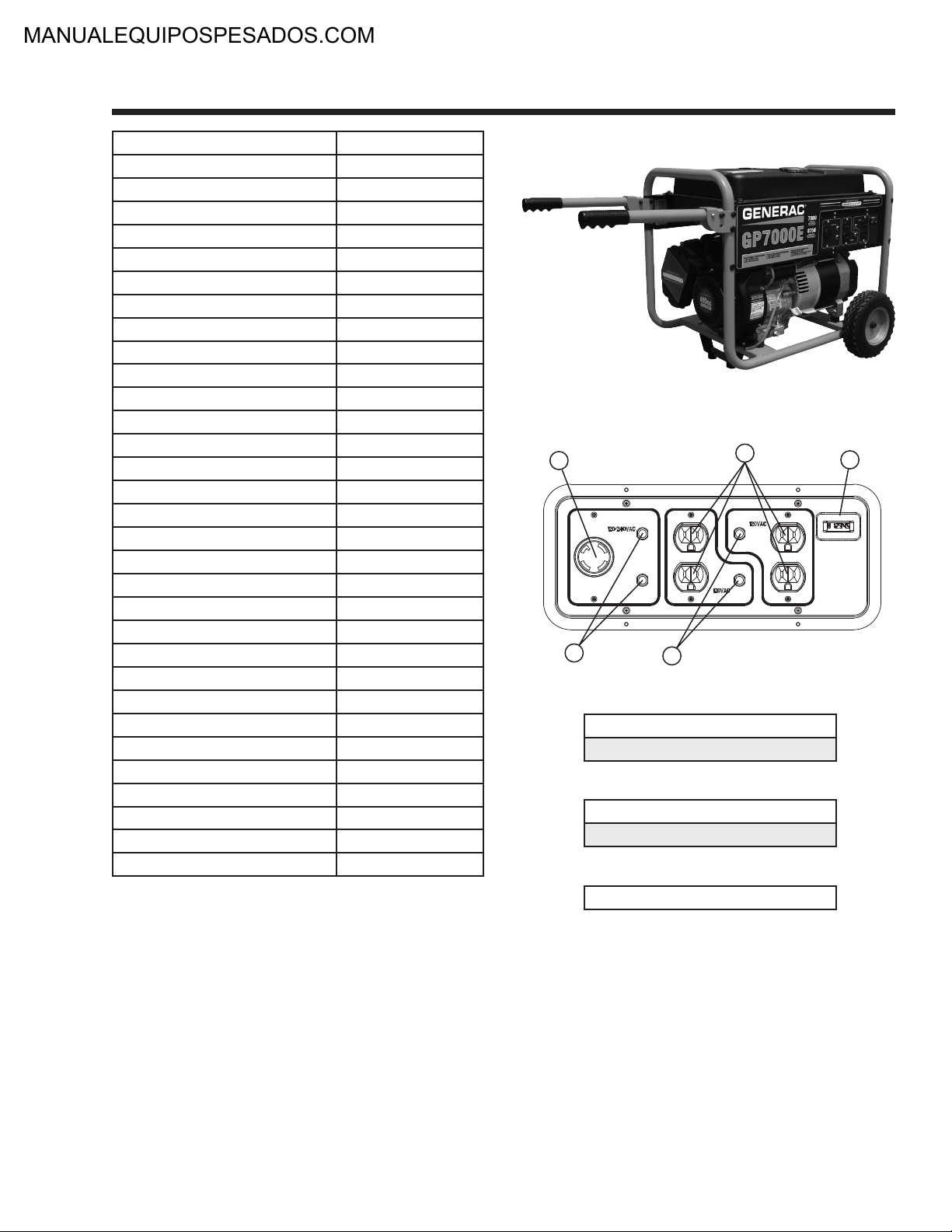

Product Series GP7000

A/C Rated Output Watts: 7000

A/C Maximum Output Watts: 8750

A/C Voltage 120/240VAC

A/C Frequency 60 Hz

Rated 120/240 VAC Amperage 29.2

Max 120/240 VAC Amperage 36.5

Engine Displacement 410cc

Engine Type OHVI

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Full Pressure

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method GP7000 Manual

Starting Method GP7000E Manual or Electric

Battery Size (if equipped) 12VDC 10 Ahr

Low Oil Shutdown Method Low Pressure

Start Switch Type 3-Position

Switch Location On Engine

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 8

Fuel Tank Capacity (Liters) 30.28

Run Time at 50% (Hours) 11

Cord Set No

Handle Style Folding Interlocked

Wheel type 9.5" Solid Wheels

Spark Plug Type Champion RC14YC

Spark Plug Gap 0.030" (0.76mm)

Oil Capacity 1.5 quart w/filter

SPECIFICATIONS – GP7000/GP7000E

Outlets

A

B

Circuit Breakers

M

N

Other Features

H

Hour Meter with Maintenance Reset

(4) 5-20R 120V

L14-30R Twist-Lock 120/240V

(2) 20A

(2) 30A

Page 7

Page 10

H

B

N

M

A

SPECIFICATIONS – GP8000/GP8000E

Outlets

A

B

Circuit Breakers

M

N

Other Features

H

Hour Meter with Maintenance Reset

(4) 5-20R 120V

L14-30R Twist-Lock 120/240V

(2) 20A

(2) 30A

Product Series GP8000/GP8000E

A/C Rated Output Watts: 8000

A/C Maximum Output Watts: 10000

A/C Voltage 120/240VAC

A/C Frequency 60 Hz

Rated 120/240 VAC Amperage 33.3

Max 120/240 VAC Amperage 41.7

Engine Displacement 410cc

Engine Type OHVI

Engine RPM 3600

Recommended Oil 5W30

Lubrication Method Full Pressure

Choke Type Manual Lever

Fuel Shut Off Manual Lever

Idle Control Full Speed

Starting Method GP8000 Manual

Starting Method GP8000E Manual or Electric

Battery Size (if equipped) 12VDC 10 Ahr

Low Oil Shutdown Method Low Pressure

Start Switch Type 3-Position

Switch Location On Engine

Single-Point Lifting Eye N/A

Fuel Gauge Built-In

Fuel Tank Capacity (Gal) 8

Fuel Tank Capacity (Liters) 30.28

Run Time at 50% (Hours) 8

Cord Set No

Handle Style Folding Interlocked

Wheel type 9.5" Solid Wheels

Spark Plug Type Champion RC14YC

Spark Plug Gap 0.030" (0.76mm)

Oil Capacity 1.5 quart w/filter

Page 8

Page 11

PART 1

GENERAL

INFORMATION

GP Series Portable Generators

TABLE OF CONTENTS

PART TITLE PAGE

1.1 Generator Fundamentals 10

1.2 Measuring Electricity 13

1.3 Brushless, Capacitor Excitation

System

1.4 Brushed Excitation System 18

1.5 Testing, Cleaning and Drying 20

16

Part 1 – General Information .................................. 9

Section 1.1 – Generator Fundamentals ................ 10

Magnetism .......................................................10

Electromagnetic Fields.....................................10

Electromagnetic Induction................................10

A Simple AC Generator ...................................11

A More Sophisticated AC Generator ................11

Section 1.2 – Measuring Electricity ....................... 13

Meters ............................................................13

The VOM ..........................................................13

Measuring AC Voltage .....................................13

Measuring DC Voltage .....................................13

Measuring AC Frequency ................................13

Measuring Current ...........................................14

Measuring Resistance .....................................14

Electrical Units .................................................15

Ohm's Law .......................................................15

Section 1.3 – Brushless, Capacitor

Excitation System ............................ 16

Introduction ......................................................16

Stator Assembly ...............................................16

Rotor Assembly ................................................16

Circuit Breakers ...............................................16

Operation .........................................................17

Section 1.4 – Brushed Excitation System ............. 18

Introduction ......................................................18

Stator Assembly ...............................................18

Brush Holder and Brushes ...............................18

Rotor Residual Magnetism...............................18

Voltage Regulator ............................................18

Operation .........................................................18

Section 1.5 – Testing, Cleaning and Drying .......... 20

Insulation Resistance .......................................20

The Megohmmeter...........................................20

Stator Insulation Resistance Test .....................20

Cleaning the Generator ....................................21

Drying the Generator .......................................21

Page 9

Page 12

SECTION 1.1

GENERATOR FUNDAMENTALS

MAGNETISM

Magnetism can be used to produce electricity and

electricity can be used to produce magnetism.

Much about magnetism cannot be explained by our

present knowledge. However, there are certain patterns of behavior that are known. Application of these

behavior patterns has led to the development of generators, motors and numerous other devices that utilize magnetism to produce and use electrical energy.

See Figure 1. The space surrounding a magnet is permeated by magnetic lines of force called “flux”. These

lines of force are concentrated at the magnet's north

and south poles. They are directed away from the

magnet at its north pole, travel in a loop and re-enter

the magnet at its south pole. The lines of force form

definite patterns which vary in intensity depending on

the strength of the magnet. The lines of force never

cross one another. The area surrounding a magnet in

which its lines of force are effective is called a “magnetic field”.

Like poles of a magnet repel each other, while unlike

poles attract each other.

PART 1

NOTE: The “right hand rule” is based on the “current flow” theory which assumes that current

flows from positive to negative. This is opposite

the “electron” theory, which states that current

flows from negative to positive.

Figure 2. The Right Hand Rule

GENERAL INFORMATION

Figure 1. Magnetic Lines of Force

ELECTROMAGNETIC FIELDS

All conductors through which an electric current is

flowing have a magnetic field surrounding them. This

field is always at right angles to the conductor. If a

compass is placed near the conductor, the compass

needle will move to a right angle with the conductor.

The following rules apply:

• Thegreater thecurrent flowthrough theconductor,

the stronger the magnetic field around the conductor.

• The increase inthe number of linesof force is

directly proportional to the increase in current flow

and the field is distributed along the full length of

the conductor.

• Thedirectionofthelinesofforcearoundaconductor can be determined by what is called the “right

hand rule”. To apply this rule, place your right hand

around the conductor with the thumb pointing in

the direction of current flow. The fingers will then be

pointing in the direction of the lines of force.

ELECTROMAGNETIC INDUCTION

An electromotive force (EMF) or voltage can be produced in a conductor by moving the conductor so that

it cuts across the lines of force of a magnetic field.

Similarly, if the magnetic lines of force are moved so

that they cut across a conductor, an EMF (voltage)

will be produced in the conductor. This is the basic

principal of the revolving field generator.

Figure 3, below, illustrates a simple revolving field

generator. The permanent magnet (Rotor) is rotated

so that its lines of magnetic force cut across a coil of

wires called a Stator. A voltage is then induced into

the Stator windings. If the Stator circuit is completed

by connecting a load (such as a light bulb), current

will flow in the circuit and the bulb will light.

Figure 3. A Simple Revolving Field Generator

Page 10

Page 13

S

TATOR

ROT

OR

MAGNETIC FIEL

D

CURRENT

VOLTAGE

ONE CYCLE

0

180

360

(+)

(-)

STATOR

ROTOR

GENERATOR

120 VAC

120 VAC

+

-

AC OUTPUT

STATOR

240 VAC

CAPACITOR

STATOR

BRUSHES

120 V

120 V

+

-

SLIP

RINGS

AC OUTPUTDC CURRENT

STATOR

240 V

GENERAL INFORMATION

PART 1

A SIMPLE AC GENERATOR

Figure 4 shows a very simple AC Generator. The generator consists of a rotating magnetic field called a

ROTOR and a stationary coil of wire called a STATOR.

The ROTOR is a permanent magnet which consists of

a SOUTH magnetic pole and a NORTH magnetic pole.

As the MOTOR turns, its magnetic field cuts across

the stationary STATOR. A voltage is induced Into

the STATOR windings. When the magnet's NORTH

pole passes the STATOR, current flows in one direction. Current flows in the opposite direction when the

magnet's SOUTH pole passes the STATOR. This constant reversal of current flow results in an alternating

current (AC) waveform that can be diagrammed as

shown in Figure 5.

The ROTOR may be a 2-pole type having a single

NORTH and a single SOUTH magnetic pole. Some

ROTORS are 4-pole type with two SOUTH and two

NORTH magnetic poles. The following apply:

1. The 2-pole ROTOR must be turned at 3600 rpm to produce an AC frequency of 60 Hertz, or at 3000 rpm to

deliver an AC frequency of 50 Hertz.

SECTION 1.1

GENERATOR FUNDAMENTALS

A MORE SOPHISTICATED AC GENERATOR

Figure 6 and 7 show two methods of creating alternating current that are implemented on GP Series portable generator product.

Figure 6 shows a consistent voltage being induced to

the rotor from a capacitor which is installed in series

with the DPE winding. As a result a regulated voltage

is induced into the STATOR.

2. The 4-pole ROTOR must operate at 1800 rpm to deliver

a 60 Hertz AC frequency or at 1500 rpm to deliver a 50

Hertz AC frequency.

Figure 4. A Simple AC Generator

Figure 6. Capacitive Discharge

Figure 7 shows a regulated direct current being delivered into the ROTOR windings via carbon BRUSHES

AND SLIP RINGS. This results in the creation of

a regulated magnetic field around the ROTOR. As

a result, a regulated voltage is induced into the

STATOR. Regulated current delivered to the ROTOR

is called “EXCITATION” current.

Figure 5. Alternating Current Sine Wave

Figure 7. Direct Excitation

Page 11

Page 14

CAPACITOR

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE DIRECT

DRIVE

AUTOMATIC

VOLTAGE

REGULATOR

+-

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

SENSING

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE DIRECT

DRIVE

120 VAC 120 VAC

240 VAC

120 VAC 120 VAC

240 VAC

A B

CAPACITIVE DISCHARGE DIRECT EXCITATION

SECTION 1.1

GENERATOR FUNDAMENTALS

PART 1

GENERAL INFORMATION

Figure 8. Generator Operating Diagram

The revolving magnetic field is driven by the engine

at constant speed. This constant speed is maintained

by a mechanical engine governor. Units with a 2-pole

rotor require an operation speed of 3600 rpm to deliver a 60 Hertz AC output.

Generator operation may be described briefly as follows.

1. Some “residual” magnetism is normally present in the

Rotor, which is sufficient to induce approximately 1 to 2

Volts AC in to the Stator’s AC Power Windings and DPE

winding.

2. See Figure 8.

A. Dur ing startup, the “residual” voltage that

is induced into the DPE winding will initially

charge the capacitor to a greater potential.

When the capacitor is discharged the voltage

is in turn induced back into the Rotor which will

exponen tially raise the voltage to 120/240.

B. During startup, the “residual” voltage that is

induced into the DPE winding will turn on the

voltage regulator allowing DC excitation current

to be delivered to the rotor and raise the voltage

to 120/240.

Page 12

Page 15

GENERAL INFORMATION

PART 1

METERS

Devices used to measure electrical properties are called

meters. Meters are available that allow one to measure

(a) AC voltage, (b) DC voltage, (c) AC frequency, and

(d) resistance in ohms. The following apply:

• TomeasureACvoltage,useanACvoltmeter.

• TomeasureDCvoltage,useaDCvoltmeter.

• UseafrequencymetertomeasureACfrequencyin

“Hertz” or “cycles per second”.

• Use an ohmmeter to read circuit resistance, in

“Ohms”.

THE VOM

A meter that will permit both voltage and resistance to

be read is the “volt-ohm-milliammeter” or “VOM”.

Some VOMs are of the “analog” type (not shown).

These meters display the value being measured by

physically deflecting a needle across a graduated

scale. The scale used must be interpreted by the user.

“Digital” VOMs (Figure 1) are also available and are

generally very accurate. Digital meters display the

measured values directly by converting the values to

numbers.

NOTE: Standard AC volt me te rs react to the

AVERAGE value of alternating current. When working with AC, the effective value is used. For that

reason a different scale is used on an AC voltmeter. The scale is marked with the effective or “rms”

value even though the meter actually reacts to the

average value. That is why the AC voltmeter will

give an incorrect reading if used to measure direct

current (DC).

SECTION 1.2

MEASURING ELECTRICITY

MEASURING AC VOLTAGE

An accurate AC voltmeter or a VOM may be used to

read the generator's AC output voltage. The following

apply:

1. Always read the generator's AC output voltage only at

the unit's rated operating speed and AC frequency.

2. The generator's Voltage Regulator can be adjusted for

correct output voltage only while the unit is operating at

its correct rated speed and frequency.

3. Only an AC voltmeter may be used to measure AC

voltage. DO NOT USE A DC VOLTMETER FOR THIS

PURPOSE.

DANGER! GENERATORS PRODUCE HIGH

AND DANGEROUS VOLTAGES. CONTACT

*

WITH HIGH VOLTAGE TERMINALS WILL

RESULT IN DANGEROUS AND POSSIBLY

LETHAL ELECTRICAL SHOCK.

MEASURING DC VOLTAGE

A DC voltmeter or a VOM may be used to measure

DC voltages. Always observe the following rules:

1. Always observe correct DC polarity.

a. Some VOM's may be equipped with a polar-

ity switch.

b. On meters that do not have a polarity switch,

DC polarity must be reversed by reversing

the test leads.

2. Before reading a DC voltage, always set the meter to a

higher voltage scale than the anticipated reading. If in

doubt, start at the highest scale and adjust the scale

downward until correct readings are obtained.

Figure 1. Digital VOM

3. The design of some meters is based on the “current

flow” theory while others are based on the “electron flow”

theory.

a. The “current flow” theory assumes that direct

current flows from the positive (+) to the

negative (-).

b. The “electron flow” theory assumes that cur-

rent flows from negative (-) to positive (+).

NOTE: When testing generators, the “current flow”

theory is applied. That is, current is assumed to

flow from positive (+) to negative (-).

MEASURING AC FREQUENCY

The generator's AC output frequency is proportional to

Rotor speed. Generators equipped with a 2-pole Rotor

must operate at 3600 rpm to supply a frequency of 60

Hertz. Units with 4-pole Rotor must run at 1800 rpm to

deliver 60 Hertz.

Page 13

Page 16

1.00 A

BATTERY

+-

RELAY

SECTION 1.2

MEASURING ELECTRICITY

Correct engine and Rotor speed is maintained by an

engine speed governor. For models rated 60 Hertz,

the governor is generally set to maintain a no-load frequency of about 62 Hertz with a corresponding output

voltage of about 124 volts AC line-to-neutral. Engine

speed and frequency at no-load are set slightly high

to prevent excessive rpm and frequency droop under

heavy electrical loading.

MEASURING CURRENT

CLAMP-ON:

To read the current flow, in AMPERES, a clamp-on

ammeter may be used. This type of meter indicates

current flow through a conductor by measuring the

strength of the magnetic field around that conductor.

The meter consists essentially of a current transformer with a split core and a rectifier type instrument connected to the secondary. The primary of the current

transformer is the conductor through which the current

to be measured flows. The split core allows the instrument to be clamped around the conductor without

disconnecting it.

Current flowing through a conductor may be measured

safely and easily. A line-splitter can be used to measure

current in a cord without separating the conductors.

PART 1

NOTE: If the physical size of the conductor or ammeter capacity does not permit all lines to be measured

simultaneously, measure current flow in each individual line. Then, add the individual readings.

IN-LINE:

Alternatively, to read the current flow in AMPERES, an

in-line ammeter may be used. Most Digital Volt Ohm

Meters (VOM) will have the capability to measure

amperes.

This usually requires the positive meter test lead to be

connected to the correct amperes plug, and the meter

to be set to the amperes position. Once the meter is

properly set up to measure amperes the circuit being

measured must be physically broken. The meter will

be in-line or in series with the component being measured.

In Figure 4 the control wire to a relay has been

removed. The meter is used to connect and supply

voltage to the relay to energize it and measure the

amperes going to it.

GENERAL INFORMATION

Page 14

Figure 2. Clamp-On Ammeter

Figure 3. A Line-Splitter

Figure 4. A VOM as an In-line meter

MEASURING RESISTANCE

The volt-ohm-milliammeter may be used to measure

the resistance in a circuit. Resistance values can be

very valuable when testing coils or windings, such as

the Stator and Rotor windings.

When testing Stator windings, keep in mind that the

resistance of these windings is very low. Some meters

are not capable of reading such a low resistance and

will simply read CONTINUITY.

If proper procedures are used, the following conditions

can be detected using a VOM:

• A“short-to-ground”condition inanyStatoror Rotor

winding.

•

Shorting together of any two parallel Stator windings.

•

Shorting together of any two isolated Stator windings.

• AnopenconditioninanyStatororRotorwinding.

Page 17

-

+

AMPERE - Unit measuring rate of

current flow (number of electrons

past a given point)

OHM - Unit measuring resistance

or opposition to flow

VOLT - Unit measuring force or

difference in potential

causing current flow

Conductor of a

Circuit

VOLTS

(E)

AMPS

(I)

OHMS

(R)

GENERAL INFORMATION

Component testing may require a specific resistance value or a test for INFINITY or CONTINUITY.

Infinity is an OPEN condition between two electrical

points, which would read as no resistance on a VOM.

Continuity is a CLOSED condition between two electrical points, which would be indicated as very low resistance or “ZERO” on a VOM.

PART 1

ELECTRICAL UNITS

AMPERE:

The rate of electron flow in a circuit is represented

by the AMPERE. The ampere is the number of electrons flowing past a given point at a given time. One

AMPERE is equal to just slightly more than six thousand million billion electrons per second (6.25 x 1018).

With alternating current (AC), the electrons flow first in

one direction, then reverse and move in the opposite

direction. They will repeat this cycle at regular intervals. A wave diagram, called a “sine wave” shows that

current goes from zero to maximum positive value,

then reverses and goes from zero to maximum negative value. Two reversals of current flow is called a

cycle. The number of cycles per second is called frequency and is usually stated in “Hertz”.

SECTION 1.2

MEASURING ELECTRICITY

OHM:

The OHM is the unit of RESISTANCE. In every circuit

there is a natural resistance or opposition to the flow

of electrons. When an EMF is applied to a complete

circuit, the electrons are forced to flow in a single

direction rather than their free or orbiting pattern. The

resistance of a conductor depends on (a) its physical

makeup, (b) its cross-sectional area, (c) its length, and

(d) its temperature. As the conductor's temperature

increases, its resistance increases in direct proportion.

One (1) ohm of resistance will permit one (1) ampere

of current to flow when one (1) volt of electromotive

force (EMF) is applied.

OHM'S LAW

A definite and exact relationship exists between VOLTS,

OHMS and AMPERES. The value of one can be calculated when the value of the other two are known. Ohm's

Law states that in any circuit the current will increase

when voltage increases but resistance remains the

same, and current will decrease when resistance

Increases and voltage remains the same.

VOLT :

The VOLT is the unit used to measure electrical

PRESSURE, or the difference in electrical potential

that causes electrons to flow. Very few electrons will

flow when voltage is weak. More electrons will flow as

voltage becomes stronger. VOLTAGE may be considered to be a state of unbalance and current flow as

an attempt to regain balance. One volt is the amount

of EMF that will cause a current of 1 ampere to flow

through 1 ohm of resistance.

Figure 5. Electrical Units

Figure 6. Ohm's Law

If AMPERES is unknown while VOLTS and OHMS are

known, use the following formula:

OHMS

If VOLTS is unknown while AMPERES and OHMS are

known, use the following formula:

If OHMS is unknown but VOLTS and AMPERES are

known, use the following:

AMPERES

AMPERES =

VOLTS = AMPERES x OHMS

OHMS

VOLTS

VOLTS

=

Page 15

Page 18

STATOR

ROTOR

ENGINE

CAPACITOR

DIODE B

COIL 2

COIL 1

DIODE A

CAPACITOR

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE DIRECT

DRIVE

AUTOMATIC

VOLTAGE

REGULATOR

+-

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

SENSING

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE -

DIRECT

DRIVE

120 VAC 120 VAC

240 VAC

120 VAC 120 VAC

240 VAC

SECTION 1.3

BRUSHLESS, CAPACITOR EXCITATION SYSTEM

INTRODUCTION

A typical brushless type portable generator will need

4 major components to function—a prime mover, a

stator, a rotor, and a capacitor.

As the engine starts to crank, residual magnetism

from the rotor creates magnetic lines of flux. The

lines begin to cut the excitation winding and induce

a small voltage into the winding. The voltage causes

the capacitor to charge. When the capacitor has fully

charged it will discharge a voltage that will be induced

back into the rotor. The AC voltage induced into the

rotor is rectified using a diode. The magnetic lines of

flux from the rotor will increase, causing output voltage to increase. The charge and discharge relationship that the capacitor and rotor share is the voltage

regulation system that allows the generator to maintain 240 volts.

Figure 1 shows the major components of a typical GP

Series brushless AC generator.

a tapered crankshaft and is held in place with a single

through bolt.

Note: Some Rotors have a magnet placed inside

to help excite the rotor after it has been left idle

for a long period of time.

PART 1

GENERAL INFORMATION

The stator has three windings wound separately

inside the can. Two are the power windings and are

located on Wire 44 (Hot) and Wire 33 (Neutral), the

other winding is located on Wire 11 (Hot) and Wire 22

(Neutral). The third winding is called the DPE winding

or Displaced Phase Excitation winding and is located

on Wire 2 and Wire 6.

The 2-pole rotor must be operated at 3600 rpm to

supply a 60 Hertz AC frequency. The term “2-pole”

means the rotor has a single north magnetic pole and

a single south magnetic pole. It spins freely inside

the stator can and is excited by the charging and discharging of the capacitor. It has two diodes that rectify voltage induced from the Excitation winding to DC

voltage. The rotor bearing is pressed onto the end of

the rotor shaft. The tapered rotor shaft is mounted to

Page 16

Figure 1. AC Generator Exploded View

STATOR ASSEMBLY

ROTOR ASSEMBLY

Figure 2. Rotor and Diodes

CIRCUIT BREAKERS

Each individual circuit on the generator is protected

by a circuit breaker to prevent overload.

Figure 3. Generator Operating Diagram

Page 19

CAPACITOR 28µf

WIRE 2

WIRE 6

RED (R2 – 33)

BLUE (R1 – 44)

BROWN (L2 – 22)

WHITE (L1 – 11)

WIRE 2

WIRE 6

11 22 33 44

CAPACITOR 47µf (440 VAC)

GENERAL INFORMATION

PART 1

BRUSHLESS, CAPACITOR EXCITATION SYSTEM

OPERATION

STARTUP:

When the engine is started, residual magnetism from

the rotor induces a voltage into (a) the stator AC

power windings, (b) the stator excitation or DPE windings. In an “On-speed” (engine cranking) condition,

residual magnetism is capable of creating approximately one to three Volts AC.

ON-SPEED OPERATION:

As the engine accelerates, the voltage that is induced

into the stator windings increases rapidly, due to the

increasing speed at which the rotor operates.

SECTION 1.3

FIELD EXCITATION:

An AC voltage is induced into the stator excitation

(DPE) windings. The DPE winding circuit is completed

to the capacitor where the charging and discharging

causes a voltage to be induced back in to the rotor

which will regulate voltage. The greater the current

flow through the rotor windings, the more concentrated the lines of flux around the rotor become. The

more concentrated the lines of flux around the rotor

that cut across the stationary stator windings, the

greater the voltage that is induced into the stator

windings. Initially, the AC power winding voltage is

low, but as the capacitor is charged and discharged

this relationship between the rotor and the capacitor

is what will regulate voltage at a desired level.

AC POWER WINDING OUTPUT:

A regulated voltage is induced into the stator AC

power windings. When electrical loads are connected

across the AC power windings to complete the circuit,

current can flow in the circuit.

A

Figure 4. Alternator Configuration A

B

Figure 5. Alternator Configuration B

Page 17

Page 20

STATOR

ROTOR

ENGINE

BRUSHES

VOLTAGE REGULATOR

Section 1.4

BRUSHED EXCITATION SYSTEM

INTRODUCTION

A typical brushed type portable generator will need 4

major components to function: a prime mover, a stator, a rotor, and a voltage regulator.

As the engine starts to crank, residual magnetism

from the rotor creates magnetic lines of flux. The lines

begin to cut the excitation winding and induce a small

voltage into the voltage regulator. The excitation voltage will power the voltage regulator and the voltage

regulator will start to sense AC voltage from Wires

S15 and S16. The lower voltage from the sensing

wires will cause DC excitation to the rotor to be driven

up until AC output is at desired level of 240VAC. Once

the generator has reached 240VAC it will maintain the

DC voltage, regulating the alternator when loads are

applied and removed.

PART 1

to the negative (-) slip ring and brush on Wire 0. This

current flow creates a magnetic field around the rotor

having a flux concentration that is proportional to the

amount of current flow.

GENERAL INFORMATION

ROTOR RESIDUAL MAGNETISM

The generator revolving field (rotor) may be considered to be a permanent magnet. Some “residual”

magnetism is always present in the rotor. This residual magnetism is sufficient to induce a voltage into the

stator AC power windings that is approximately 2-5

volts AC.

Note: Some Rotors have a magnet placed inside

to help excite the rotor after it has been left idle

for a long period of time.

VOLTAGE REGULATOR

Refer to Figure 3 for the proper identification of the

voltage regulator. Unregulated AC output from the

stator excitation winding is delivered to the regulator’s

DPE terminals, via Wire 2 and Wire 6. The voltage

regulator rectifies that current and, based on stator

AC power winding sensing, regulates it. The rectified

and regulated excitation current is then delivered to

the rotor windings from the positive (+) and negative

(-) regulator terminals, via Wire 4 and Wire 0. Stator

AC power winding “sensing” is delivered to the regulator via Wires S15 and S16.

Figure 1. AC Generator Exploded View

STATOR ASSEMBLY

The stator has three windings wound separately

inside the can. Two are the power windings and are

located on Wire 44 (Hot) and Wire 33 (Neutral); the

other winding is located on Wire 11 (Hot) and Wire 22

(neutral). The third winding is called DPE winding or

Displaced Phase Excitation winding and is located on

Wire 2 and Wire 6.

BRUSH HOLDER AND BRUSHES

The brush holder is retained to the rear bearing carrier by means of two Taptite screws. A positive (+) and

a negative (-) brush are retained in the brush holder.

Wire 4 connects to the positive (+) brush and Wire

0 to the negative (-) brush. Rectified and regulated

excitation current are delivered to the rotor windings

via Wire 4, and the positive (+) brush and slip ring.

The excitation current passes through the windings

Page 18

OPERATION

STARTUP:

When the engine is started, residual magnetism from

the rotor induces a voltage into (a) the stator AC

power windings, (b) the stator excitation or DPE windings. In an “on-speed” (engine cranking) condition,

residual magnetism is capable of creating approximately one to three volts AC.

ON-SPEED OPERATION:

As the engine accelerates, the voltage that is induced

into the stator windings increases rapidly, due to the

increasing speed at which the rotor operates.

FIELD EXCITATION:

An AC voltage is induced into the stator excitation

(DPE) windings. The DPE winding circuit is completed to the voltage regulator, via Wire 2 and Wire

6. Unregulated alternating current can flow from the

winding to the regulator. The voltage regulator “senses” AC power winding output voltage and frequency

via stator Wires S15 and S16.

The regulator changes the AC from the excitation

winding to DC. In addition, based on the Wire S15

and Wire S16 sensing signals, it regulates the flow of

direct current to the rotor. The rectified and regulated

current flow from the regulator is delivered to the rotor

windings, via Wire 4, and the positive brush and slip

ring. This excitation current flows through the rotor

Page 21

AUTOMATIC

VOLTAGE

REGULATOR

+-

STATOR

EXCITATION

WINDING

STATOR

POWER

WINDING

STATOR

POWER

WINDING

MAGNETIC

FIELD

MAGNETIC

FIELD

SENSING

MLB = MAIN LINE

CIRCUIT BREAKER

ROTOR

TO LOAD

MLB

ENGINE DIRECT

DRIVE

120 VAC 120 VAC

240 VAC

VOLTAGE REGULATOR

AVR SENSING

DPE

NOT USED

RED (R2 – 11)

BLUE (R1 – 22)

BLUE

BLUE

4 (+) RED

S15

2

S16

6

0 (-) WHITE

BROWN (L2 – 33)

WHITE (L1 – 44)

WHITE

GREEN

C1 FEMALE

C1 MALE

GENERAL INFORMATION

PART 1

windings and through the negative (-) slip ring and

brush on Wire 0.

The greater the current flow through the rotor windings, the more concentrated the lines of flux around

the rotor become. The more concentrated the lines

of flux around the rotor that cut across the stationary

stator windings, the greater the voltage that is induced

into the stator windings.

Initially, the AC power winding voltage sensed by the

regulator is low. The regulator reacts by increasing

the flow of excitation current to the rotor until voltage increases to a desired level. The regulator then

maintains the desired voltage. For example, if voltage

exceeds the desired level, the regulator will decrease

the flow of excitation current. Conversely, if voltage

drops below the desired level, the regulator responds

by increasing the flow of excitation current.

AC POWER WINDING OUTPUT:

A regulated voltage is induced into the stator AC

power windings. When electrical loads are connected

across the AC power windings to complete the circuit,

current can flow in the circuit.

Section 1.4

BRUSHED EXCITATION SYSTEM

Figure 2. 240 VAC Sensing Alternator

C

Figure 3. Alternator Configuration C

Page 19

Page 22

NOTES

Page 20

Page 23

PART 2

AC GENERATORS

GP Series Portable Generators

TABLE OF CONTENTS

PART TITLE PAGE#

2.1 Brushless Excitation

Troubleshooting Flowcharts

2.2 Brushed Capacitor

Troubleshooting Flowcharts

2.3 AC Diagnostic Tests 26

22

24

Part 2 – AC Generators ......................................... 21

Section 2.1 – Brushless Capacitor

Troubleshooting Flowcharts ............. 22

Section 2.2 – Brushed Excitation

Troubleshooting Flowcharts ............. 24

Section 2.3 – AC Diagnostic Tests ........................ 26

Introduction ......................................................26

Test 1 – Check No-Load Voltage

and Frequency ....................................26

Test 2 – Check Circuit Breaker.........................26

Test 3 – Check Continuity of

Receptacle Panel ................................26

Test 4 – Field Flash Alternator

(Configuration “A” Only) .......................27

Test 5 – Check Brushed Rotor Circuit ..............28

Test 6 – Check Capacitor .................................29

Test 7 – Test Brushless DPE Winding ..............30

Test 8 – Test Brushless Stator Windings ..........30

Test 9 – Test Brushed Stator Windings ............31

Test 10 – Check Load Voltage & Frequency ....31

Test 11 – Check Load Watts & Amperage .......31

Test 12 – Adjust Voltage Regulator ..................31

Page 21

Page 24

GO TO PROBLEM 2 GO TO PROBLEM 1GO TO PROBLEM 4 VERIFY ROTOR IS SPINNING,

GO TO PROBLEM 1

GO TO PROBLEM 3

VOLTAGE &

FREQUENCY BOTH

HIGH OR LOW

FREQUENCY GOOD

VOLTAGE HIGH

ZERO VOLTAGE

ZERO FREQUENCY

FREQUENCY GOOD,

LOW OR RESIDUAL

VOLTAGE

TEST 1 - CHECK

NO LOAD VOLTAGE

& FREQUENCY

NO LOAD VOLTAGE &

FREQUENCY GOOD -

VOLTAGE/FREQUENCY

FALLS OFF UNDER LOAD

If Problem Involves AC Output

REPLACE

ALTERNATOR

REPLACE

ROTOR

STOP TESTING

BAD

BAD

GOOD

GOOD

CONFIGURATION “B”

GOOD

CONFIGURATION “A”

BAD

CONFIGURATION “B”

BAD

CONFIGURATION “A”

Problem 1 – Generator Produces Zero Voltage or Residual Voltage

TEST 2 – CHECK

MAIN CIRCUIT

BREAKER

RESET TO “ON”

OR REPLACE IF BAD

REPLACE COMPONENT

AS NEEDED

STOP

TESTING

TEST 3 – CHECK

CONTINUITY OF

RECEPTACLE PANEL

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

TEST 4 – FIELD

FLASH

ALTERNATOR

REPLACE

BAD

BAD

BAD

REPLACE

S TATO R

BAD

REPLACE

ALTERNATOR

REPLACE

CAPACITOR

ON

GOOD

GOODGOODGOOD

TEST 6 –

CHECK

CAPACITOR

TEST 7 – TEST

BRUSHLESS

DPE WINDING

TEST 8 – TEST

BRUSHLESS

STATOR

WINDINGS

TEST STATOR

FOR SHORTS

TO GROUND

GOOD

SECTION 2.1

BRUSHLESS CAPACITOR TROUBLESHOOTING FLOWCHARTS

The GP series portable generators currently use

three different types of alternators. Two of the alternators are brushless capacitor type with different style of

capacitors (Configuration “A” and “B”). The third utilizes a voltage regulator and a brushed excitation system (Configuration “C”). To help with troubleshooting,

two sets of flow charts have been created for these

different styles of alternators.

Identify the configuration of the alternator being serviced using Sections 1.3 and 1.4 of this manual and

proceed to the appropriate flowchart section.

Configuration “A” – Brushless Capacitor, use Section 2.1

Configuration “B” – Brushless Capacitor, use Section 2.1

Configuration “C” – Brushed Excitation, use Section 2.2

PART 2

AC GENERATORS

Page 22

Page 25

ELECTRICAL FORMULAS

TO FIND KNOWN VALUES 1-PHASE

KILOWATTS (kW)

KVA

AMPERES

WATTS

NO. OF ROTOR POLES

FREQUENCY

RPM

kW (required for Motor)

Volts, Current, Power Factor

Volts, Current

kW, Volts, Power Factor

Volts, Amps, Power Factor Volts x Amps

Frequency, RPM

RPM, No. of Rotor Poles

Frequency, No. of Rotor Poles

Motor Horsepower, Efficiency

E x I

1000

E x I

1000

kW x 1000

E

2 x 60 x Frequency

RPM

RPM x Poles

2 x 60

2 x 60 x Frequency

Rotor Poles

HP x 0.746

Efficiency

RESISTANCE

VOLTS

AMPERES

E = VOLTS I = AMPERES R = RESISTANCE (OHMS) PF = POWER FACTOR

Volts, Amperes

Ohm, Amperes I x R

Ohms, Volts

E

I

E

R

Page 78

Page 26

NOTES

Page 27

NOTES

Page 80

Page 28

Page 29

Part No. 0H0285 rev. A / Printed in USA 02.09

© 2009 Generac Power Systems, Inc. All rights reserved.

Generac Power Systems, Inc.

S45 W29290 Hwy. 59 • Waukesha, WI 53189

1-888-GENERAC (1-888-436-3722) • generac.com

Loading...

Loading...