Page 1

Owner's Manual

". | =*=

Generator

Wheel kit

Storage Cover

Battery charge cables

Spare Spark Plug,Air Filter, and Oil Filter

Spark PlugWrench

Locking20 Amp plug

Locking30 Amp plug

Engineoil

Owner's manual

Enginemanual

If any parts are missing or damaged, call 1-800-270-1408.

Questions? Help is just a moment away!

Call:Generac Generator Helpline - 1-800-270-1408 M-F 8-5 CT

Web: www.generac-portables.com or www.briggsandstratton.com

SafetyRules.................................... 2-4

Know Your Generator ............................. 5

Assembly...................................... 6-7

Operation .................................... 8-12

Product Specifications............................. 13

Maintenance ................................. 13-14

Storage........................................ 14

Notes ...................................... 15-16

Troubleshooting ................................. 17

Schematic...................................... 18

Wiring Diagram ................................. 19

Replacement Parts............................. 20-23

Warranty ................................. Last Page

Page 2

EQUIPMENT

DESCRIPTION

_Read this manual carefully and become

familiar with your generator. Know its

applications, its limitations and any hazards

involved.

The generators are an engine-driven, revolving field,

alternating current (AC) generator. It was designed to supply

electrical power for operating compatible electrical lighting,

appliances,tools and motor loads.Thegenerator's revolving

field is driven at about 3,600 rpm by a single-cylinder engine.

CAUTION! DO NOT exceed the generator's

wattage/amperage capacity.See"Don't Overload

Generator" on page 12.

Everyeffort hasbeenmade to ensurethat informationinthis

manualisaccurateand current. However,we reserve the

right to change,alter or otherwise improvethe product and

this document at anytime without prior notice.

The EmissionControl Systemfor this generator iswarranted

for standardsset by the Environmental Protection Agency.For

warranty informationrefer to the engineowner's manual.

In the Stateof California a spark arrester isrequired by lawI

(Section 4442 of the California PublicResourcesCode).

Other states may havesimilar laws. Federallawsapply on

federal lands.If you equip the muffler with a spark arrester,

it must be maintained ineffective working order.

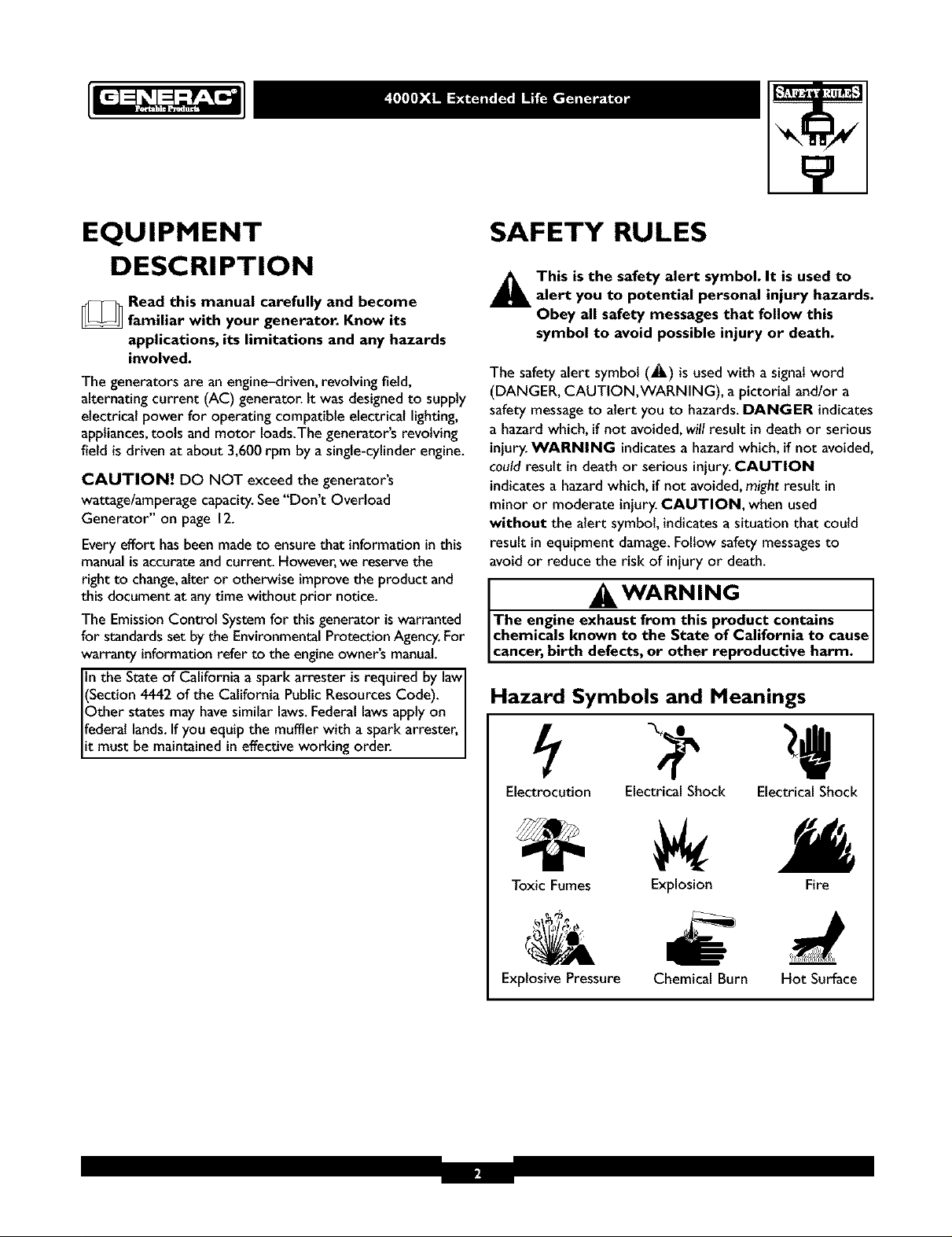

SAFETY RULES

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol (_,) isused with a signal word

(DANGER, CAUTION,WARNING), apictorial and/or a

safety messageto alert you to hazards.DANGER indicates

a hazard which, if not avoided,will result in death or serious

injury.WARNING indicatesa hazard which, if not avoided,

couldresult in death or serious injury.CAUTION

indicatesa hazard which, if not avoided,might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage.Follow safetymessagesto

avoid or reduce the risk of injury or death.

WARNING

The engine exhaust from this product contains I

chemicals known to the State of California to cause

cancer, b rth defects, or other reproduct ve harm.

Hazard Symbols and Meanings

Electrocution Electrical Shock Electrical Shock

Toxic Fumes

Explosive Pressure

Explosion Fire

Chemical Burn Hot Surface

Page 3

DANGER

, WARNING

Operate generator ONLY outdoors.

Keepat least 2 feet of clearance on all sidesof generator for

adequate ventilation.

DO NOT operategenerator insideanybuildingor enclosure,

includingthegenerator compartmentof arecreationalvehicle(RV).

DANGER

When usinggenerator for backup power, notify utility

company.Use approved transfer equipment to isolate

generator from electric utility.

Use aground circuit fault interrupter (GFCi) in anydamp or

highly conductive area,such asmetal decking or steel work.

DO NOT touch bare wires or receptacles.

DO NOT use generator with electrical cords which are worn

frayed,bare or otherwise damaged.

DO NOT operate generator in the rain.

DO NOT handle generator or electrical cords while standing

inwater, while barefoot, or while handsor feet are wet.

DO NOT allow unqualified persons or children to operate or

service generator.

WHEN ADDING FUEL

Turn generator OFF and let it cool at least 2 minutes before

removing gas cap. Loosen cap slowly to relieve pressure in tanlc

Fill fuel tank outdoors.

DO NOT overfill tank.Allow space for fuel expansion.

Keep fuel away from sparks, open flames, pilot lights, heat, and

other ignition sources.

DO NOT light a cigarette or smoke.

eVHEN OPERATING EQUIPMENT

DO NOT tip engine or equipment at angle which causes fuel

to spill.

This generator is not for use in mobile equipment or marine

applications.

'HEN TRANSPORTING OR REPAIRING EQUIPMENT

Transportlrepair with fuel tank EMPTY or with fuel shutoff

valve OrE

Disconnect spark plug wire.

_HEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

DANGER

DO NOT allow any open flame, spark, heat, or lit cigarette

during and for several minutes after charging a battery.

Wear protective goggles, rubber apron, and rubber gloves.

, WARNING

Thisgenerator does not meet U. S.Coast Guard Regulation

33CFR-183 and should not be used on marine applications.

Failure to use the appropriate U. S.Coast Guard approved

generator could result in bodily injury and/or property

damage.

Page 4

WARNING

;ENERATOR

Disconnect the spark plug wire from the spark plugand place

the wire where it cannot contact spark plug.

, WARNING

CAUTION

See"Don't Overload Generator" on page 12.

Start generator and let engine stabilize before connecting

electrical loads.

Connect electrical loads in OFF position, then turn ON for

operation.

Turn electrical loads OFF and disconnect from generator

before stopping generator.

CAUTION

DO NOT touch hot surfaces.

Allow equipment to cool before touching.

CAUTION

DO NOT tamper with governed speed.Generator supplies

correct rated frequency and voltage when running at governed

speed.

DO NOT modify generator in any way.

Use generator only for intended uses.

tf you have questions about intended use,askdealer or call

1-800-270-1408.

Operate generator only on level surfaces.

DO NOT expose generator to excessive moisture, dust, dirt,

or corrosive vapors.

DO NOT insert anyobjects through cooling slots.

if connected devices overheat, turn them off and disconnect

them from generatoc

Shut off generator if.'

-electrical output is lost;

-equipment sparks,smokes,or emits flames;

-unit vibrates excessively.

Page 5

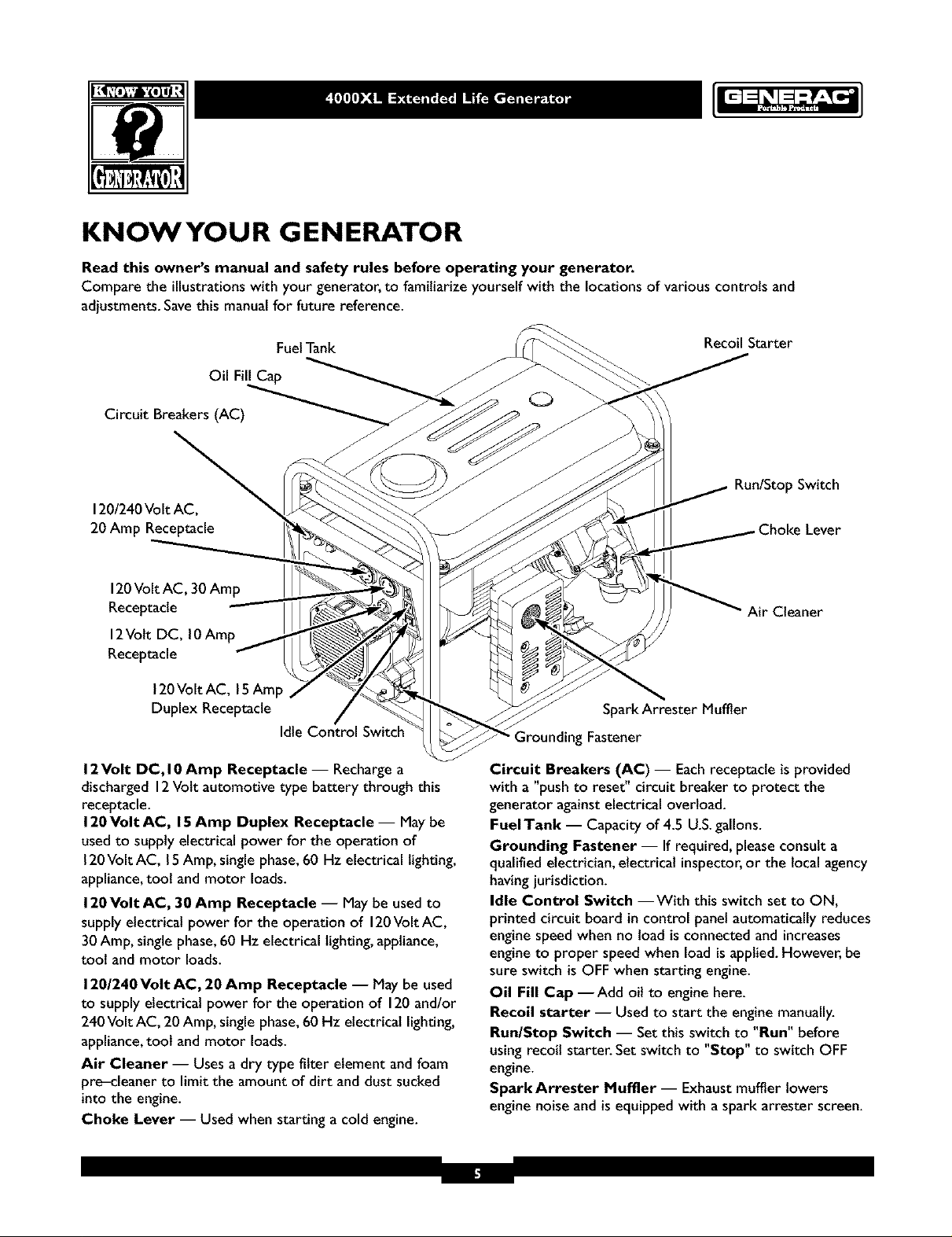

KNOWYOUR GENERATOR

Reacl this owner's manual and safety rules before operating your generator.

Compare the illustrationswith your generator, to familiarize yourself with the locationsof variouscontrols and

adjustments. Savethis manual for future reference.

FuelTank

Oil Fill Cap

Circuit Breakers (AC)

120/240Volt AC,

20 Amp Receptacle

120Volt AC, 30 Amp

Receptacle

12Volt DC, 10Amp

Receptacle

120VoltAC, 15Art

Duplex Receptacle

Idle Control Switch

12Volt DC, I 0 Amp Receptacle -- Rechargea

discharged 12Volt automotive type battery through this

receptacle.

120Volt AC, 15Amp Duplex Receptacle -- May be

usedto supply electrical power for the operation of

120Volt AC, 15Amp, single phase,60 Hz electrical lighting,

appliance,tool and motor loads.

120Volt AC, 30 Amp Receptacle -- Maybe usedto

supply electrical power for the operation of 120Volt AC,

30 Amp, singlephase,60 Hz electrical lighting,appliance,

toot and motor loads.

120/240 Volt AC, 20 Amp Receptacle -- May be used

to supply electrical power for the operation of 120and/or

240 Volt AC, 20 Amp, single phase,60 Hz electrical lighting,

appliance,toot and motor loads.

Air Cleaner -- Usesa dry type filter element and foam

pre-cleaner to limit the amount of dirt and dust sucked

into the engine.

Choke Lever -- Used when starting a cold engine.

Recoil Starter

Run/Stop Switch

Air Cleaner

SparkArrester Muffler

Grounding Fastener

Circuit Breakers (AC) -- Eachreceptacle is provided

with a "push to reset" circuit breaker to protect the

generator againstelectrical overload.

FuelTank -- Capacity of 4.5 U.S.gallons.

Grounding Fastener -- If required, pleaseconsulta

qualified electrician, electrical inspector,or the local agency

havingjurisdiction.

Idle Control Switch --With this switch set to ON,

printed circuit board in control panel automatically reduces

engine speedwhen no load isconnected and increases

engine to proper speed when loadis applied.However, be

sure switch isOFF when starting engine.

Oil Fill Cap --Add oil to engine here.

Recoil starter -- Used to start the engine manually.

Run/Stop Switch -- Setthis switch to "Run" before

using recoil starter. Set switch to "Stop" to switch OFF

engine.

Spark Arrester Muffler -- Exhaust muffler lowers

engine noise and is equipped with a spark attester screen.

Page 6

ASSEMBLY

Your generator requires some assemblyand is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any problems with the assembly of your

generator, please call the generator helpline at

1-800-270-1408.

Remove Generator From Carton

I. Set carton on a rigid flat surfacewith "This SideUp"

arrows pointing upward.

2. Carefully open top flaps of shipping carton. Review

"Cold Weather Operation" on page I0.

3. Cut down corners at one end of carton from top to

bottom and laythat side of carton down flat.

4. Remove all packing material, carton fillers, etc.

5. Remove generator from shipping carton.

Cap Screw

\

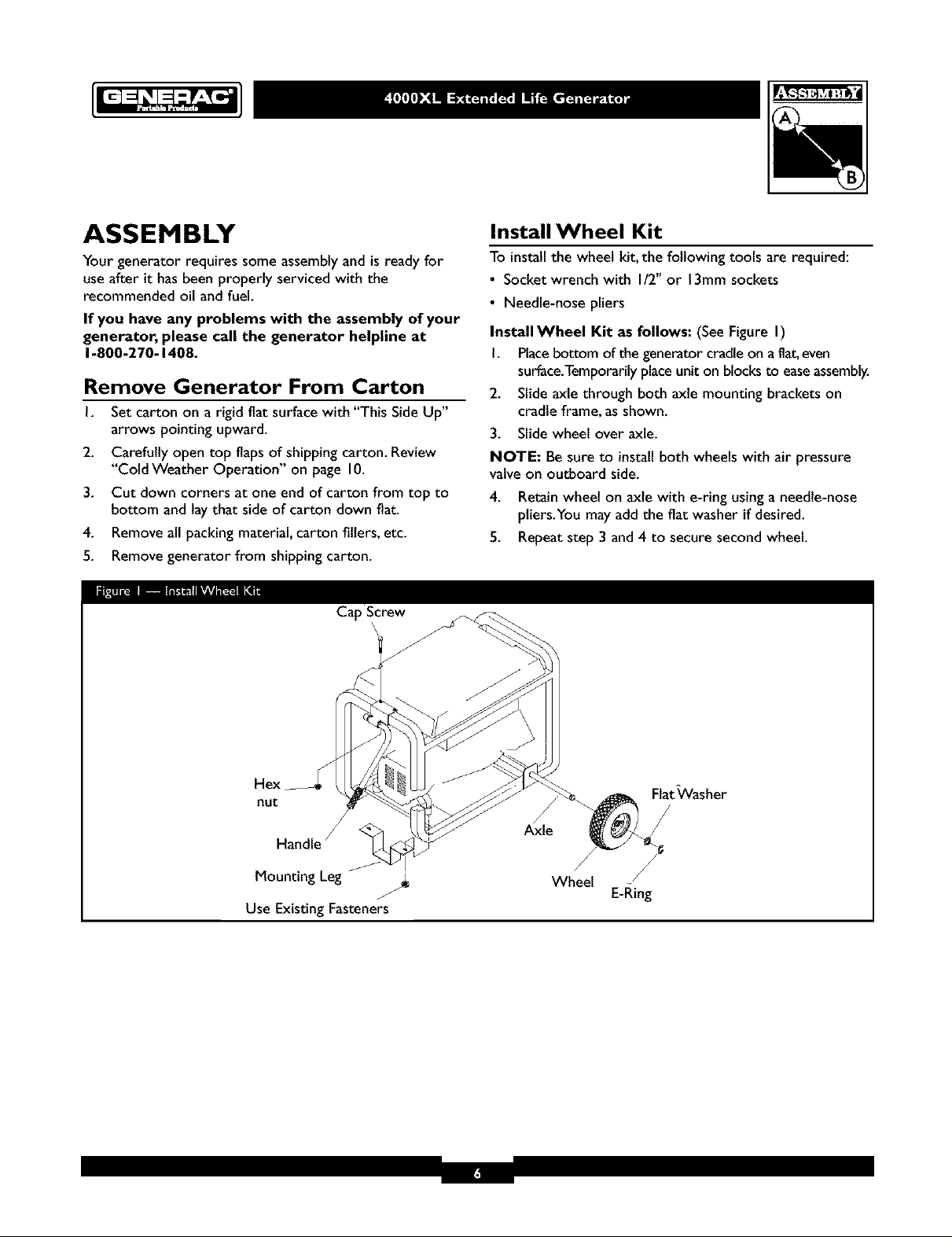

Install Wheel Kit

To installthe wheel kit, the following tools are required:

• Socket wrench with I/2" or 13mm sockets

• Needle-nose pliers

Install Wheel Kit as follows: (SeeFigure I)

I. Placebottom of the generator cradleon aflat,even

surface.Temporarilyplaceunit on blocksto easeassembly.

2. Slide axle through both axle mounting brackets on

cradle frame, as shown.

3. Slide wheel over axle.

NOTE: Be sure to installboth wheels with air pressure

valve on outboard side.

4. Retain wheel on axle with e-ring using a needle-nose

pliers.You may add the fiat washer ifdesired.

5. Repeat step 3 and 4 to secure second wheel.

Hex

nut

J

Mounting Leg j_

Use Existing Fasteners

Flat_/asher

Axle

/

Wheel E.l_i/ng

Page 7

6. Removeexistinghardwarefrom vibration mountswith

13mmwrench.Use samehardwareto attach mountingleg.

7. Remove temporary blocks.

8. Center handle bracket on generator frame at control

panel end of cradle.

9. Attach handlebracket with two capscrews andtwo hex

nuts.Use two 13mm wrenches to tighten hardware.

10. Check that all fasteners are tight and tires are inBate_

between 15-40 PSI.

BEFORE STARTING

ENGINE

Add Engine Oil and Fuel

• Placegenerator on a levelsurface.

CAUTION

- Refer to engine manual for oil and fuel fill information.

- Damage to equipment resulting from failure to follow this

instruction will void warranty.

• Refer to engine owner's manualand follow oil and fuel

recommendations and instructions.

NOTE: Check oil often during engine break-in. Refer to

engine owner's manual for recommendations.

NOTE: The generator assembly rotates on a prelubricated

and sealed ball bearing that requires no additional

lubrication for the life of the bearing.

Page 8

USING THE GENERATOR

System Ground

The generator has a system ground that connects the

generator frame components to the ground terminals on

the AC output receptacles.The system ground isconnected

to theAC neutral wire (the neutral is bonded to the

generator frame).

Special Requirements

There may be Federalor State Occupational Safety and

Health Administration (OSHA) regulations, localcodes,or

ordinances that apply to the intendeduse of the generator.

Pleaseconsult a qualified electrician, electrical inspector,or

the localagencyhaving jurisdiction.

• In some areas,generators are required to be registered

with local utility companies.

• If the generator is usedat a construction site,there may

be additional regulations which must be observed.

Connecting to a Building's Electrical

System

Connections for standby power to a building's electrical

system must be made by a qualified electrician.The

connection must isolate the generator power from utility

power, and must comply with all applicable laws and

electrical codes.

OPERATING THE

G EN ERATO R

CAUTION

See"Don't Overload Generator" on page 12.

Start generator and let engine stabilize before connecting

electrical loads.

Connect electrical loads in OFF position, then turn ON for

operation.

Turn electrical loads OFF and disconnect from generator

before stopping generator.

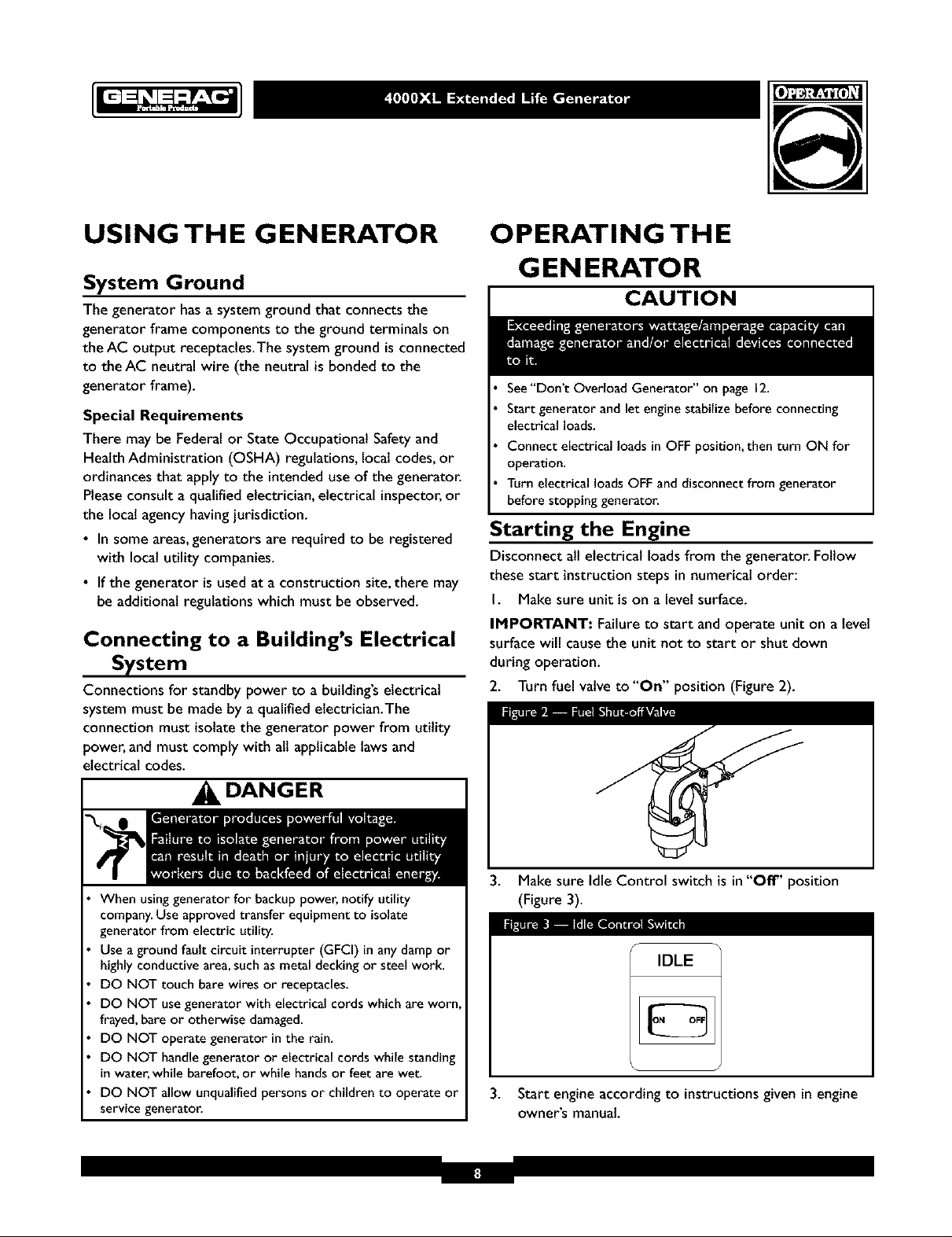

Starting the Engine

Disconnect all electrical loads from the generator. Follow

these start instruction steps in numerical order:

I. Make sure unit is on a level surface.

IMPORTANT: Failure to start and operate unit on a level

surface will cause the unit not to start or shut down

during operation.

2. Turn fuel valve to "On" position (Figure 2).

DANGER

When usinggenerator for backup power, notify utility

company. Use approved transfer equipment to isolate

generator from electric utility.

Use a ground fault circuit interrupter (GFCI) in any damp or

highly conductive area, such as metal decking or steel work.

DO NOT touch bare wires or receptacles.

DO NOT use generator with electrical cords which are worn

frayed, bare or otherwise damaged.

DO NOT operate generator in the rain.

DO NOT handle generator or electrical cords while standing

in water, while barefoot, or while hands or feet are wet.

DO NOT allow unqualified persons or children to operate or

service generator.

3. Make sure Idle Control switch is in"Off" position

(Figure 3).

I_ll"_lc:iliL_l_ [OL_l _"_a

IDLE

.

Start engine according to instructions given in engine

owner's manual

I:|

Page 9

NOTE: If engine still fails to start after 3 pulls,check for

proper oil level in crankcase.This unit is equipped with a

Low Oit Shutdown System.Seeengine manual.

Connecting Electrical Loads

• Let engine stabilize and warm up for a few minutes after

starting.

• Plugin and turn on the desired 120and/or 240 VottAC,

single phase,60 Hz electrical loads.

• DO NOT connect 240Volt loadsto the 120Volt

receptacles.

• DO NOT connect 3-phase loadsto the generator.

• DO NOT connect 50 Hz loadsto the generator.

• DO NOT OVERLOADTHE GENERATOR. See

"Don't Overload Generator" on page 12.

Stopping the Engine

I. Unplug ALL electrical loads from generator panel

receptacles.NEVER start or stop engine with electrical

devices plugged in and turned ON.

2. Move idle control switch to "Off" position.

3. Let engine run at no-load for several minutes to

stabilize internaltemperatures of engine and generator.

4. Turn engine off according to instructionsgiven in the

engine owner's manual.

5. Move fuel valve to "Off' position.

Operating Automatic Idle Control

This switch isdesignedto greatly improve fuel economy.

When this switch is turned ON, the engine will only

run at its normal high governed engine speed when

electrical loads are connected.When an electrical load is

removed,the enginewill run at a reduced speed.

With the switch off, the engine will run at the normal

high engine speed.Always have the switch off when

starting and stopping the engine.

Charging a Battery

Your generator hasthe capability of recharging adischarged

12Volt automotive or utility style storage battery. DO

NOT use the unitto charge any 6Volt batteries. DO NOT

usethe unit to crank an engine havinga discharged battery.

DANGER

DO NOT allow anyopen flame, spark, heat,or lit cigarette

during andfor several minutes after charginga battery.

Wear protective goggles,rubber apron, and rubber gloves.

To recharge 12Volt batteries, proceed as follows:

I. Check fluid level in atl battery cells. If necessary,add

ONLY distilled water to cover separators in battery

cells.DO NOT use tap water.

2. If battery isequipped with vent caps,make sure they

are installedandare tight.

3. If necessary,clean battery terminals.

4. Connect battery charge cable connector plug to panel

receptacle identified by the words "12-VOLTS D.C".

5. Connect battery charge cable clamp with red handle

to the positive (+) battery terminal (Figure4).

12VOLT D.C.

RECEPTACLE

._ PO_2 VOLT BATI'ENE'-G J

Page 10

6. Connect battery chargecableclamp with black handle

to the negative (-) battery terminal (Figure4).

7. Start engine. Let engine run while battery recharges.

8. When battery has charged,shut down engine

NOTE: Use an automotive hydrometer to test battery

state of charge andcondition. Follow the hydrometer

manufacturer's instructionscarefully.Generally,a battery is

considered to be at 100%state of chargewhen specific

gravity of itsfluid (as measured by hydrometer) is 1.260or

higher.

COLD WEATH ER

OPERATION

Under certain weather conditions (temperaturesbelow

40°F [4°C] and a high dew point),your generator may

experience icingof the carburetor and/or the crankcase

breather system.

Build a structure that will enclose three sides and the top

of the generator:

I. Makesure entire muffler-side of generator is exposed.

Note that your generator may appear different from

that shown in Figure 5.

Wind

DANGER

Operate generator ONLY outdoors.

Keep at least 2 feet of clearance on all sides of generator for

adequate ventilation.

DO NOT operate generator inside any building or enclosure,

including the generator compartment of a recreational vehicle (RV).

Remove generator from shelter when temperature is above

40°F [4°C].

RECEPTACLES

CAUTION

NEVER attempt to power a device requiring more

amperagethan generator or receptacle can supply.

DO NOT overload the generator. See"Don't Overload

Generator".

120 Volt AC, 15 Amp Receptacles

Eachof these outlets is protected againstoverload by

15Amp push-to-reset type circuit breakers (Figure 6).

J

2. Ensure a minimum of two feet clearance between

open side of box and nearest object.

3. Face exposed end away from wind and elements.

4. Enclosure should hold enough heat created by

generator to prevent problems.

Use each outlet to operate 120Volt, 60 Hz,single phase

loads requiring 1,800(I.8 kW) watts at 15Amps of current.

Page 11

120/240 Volt AC, 20 Amp Locking

Receptacle

Use a NEMA LI4-20 plug with this receptacle. Connect a

4-wire cord set rated for 250Volts at 20 Amps (or greater)

(Figure 7).You canuse the same 4-wire cord if you plan to

run a 120Volt load.

4-WireCord Set

3-Wire Cord Set

i NEMA L5-30

Neutral

120V

Hot

(Neutral)

Y (Hot) X (Hot)

NEMA L14-20

This receptacle powers 120/240Volt AC, 60 Hz,single

phaseloads requiring up to 2,400 watts of power at

20 Amps for 120Volts;4,000 watts of power (4.0 kW) at

16.7Amps for 240Volts.The outlet is protected by a

20 Amp push-to-reset circuit breaker.

Ground (Green)

120 Volt AC, 30 Amp Locking

Receptacle

Use a NEMA L5-30 plug with this receptacle. Connect a

3-wire cord set rated for 125Volts AC at 30 Amps to the

plug (Figure8).

Ground (Green)

Use this receptacle to operate 120Volt AC, 60 Hz, single

phaseloads requiring up to 3,600 watts (3.6 kW) of power

at 30Amps.The outlet is protected by a 30Amp

push-to-reset circuit breaker.

12Volt DC, I 0 Amp Receptacle

Thisreceptacle (Figure9) allows you to recharge a 12Volt

automotive or utility style storage battery with the battery

chargecables provided.

_lP&V_'Jfl _ I[*]r__l

Thisreceptacle can not recharge 6Volt batteries and can

not be usedto crank an engine havinga discharged battery.

See"Charging a Battery" on page9 before attempting to

recharge a battery.This outlet is protected by a 10Amp

self resetting circuit breaker.

Page 12

DON'T OVERLOAD YOU R

GENERATOR

Capacity

You must make sure your generator can supply enough

rated (running) and surge (starting) watts for the itemsyou

wilt power at the same time. Follow these simple steps:

I. Select the items you will power at the same time.

2. Total the rated (running) watts of these items.Thisis

the amount of power your generator must produce to

keep your items running.SeeFigure 10.

3. Estimate how many surge (starting) watts you will

need.Surge wattage isthe short burst of power

needed to start electric motor-driven tools or

appliancessuch asa circular saw or refrigerator.

Becausenot all motors start at the same time, total

surge watts can be estimated by adding only the

item(s) with the highest additional surge watts to the

total rated watts from step 2.

Example:

Tool or Appliance

Window Air

Conditioner

Refrigerator

Deep Freezer

Television

Light (75 Watts)

Total Rated (Running)Watts = 3075

Highest Additional SurgeWatts = 1800

Total Generator Output Required = 4875

Rated (Running)

Watts

1200

800

50O

500

75

3075 Total

Running Watts

Power Management

To prolong the life of your generator and attached devices,

it is important to take care when addingelectrical loads to

your generator.There should be nothing connected to the

generator outlets before starting it's engine.The correct

and safeway to managegenerator power is to sequentially

add loads as follows:

I. With nothingconnected to the generator, start the

engine asdescribed in this manual.

2. Plugin and turn on the first load,preferably the largest

load you have.

3. Permit the generator output to stabilize (engine runs

smoothly and attached device operates properly.

Additional Surge

(Starting)Watts

1800

1600

5O0

1800 Highest

SurgeWatts

4. Plug in and turn on the next load.

5. Again, permit the generator to stabilize.

6. Repeat steps 4 and 5for each additional load.

NEVER add more loads than the generator capacity.Take

specialcare to consider surgeloads in generator capacity,

asdescribed above.

Rated*

Tool or Appliance

Essentials

LightBulb - 75 watt

Deep Freezer

SumpPump

Refrigerator/Freezer - 18Cu. Ft.

Water Well Pump- I/3 HP

Heating/Cooling

Window AC - 10,000BTU

Window Fan

FurnaceFanBlower - I/2 HP

Kitchen

Microwave Oven - 1000Watt

Coffee Maker

Electric Stove - SingleElement

Hot Plate

Family Room

DVD/CD Player

VCR

Stereo Receiver

Color Television - 27"

Personal Computer w/I 7" monitor

Other

Security System

AM/FM Clock Radio

GarageDoor Opener - I/2 HP

Electric Water Heater - 40 Gallon

DIY/Job Site

Quartz Halogen Work Light

Airless Sprayer - I/3 HP

Reciprocatin_ Saw

Electric Drill - I/2 HP

Circular Saw- 7 I/4"

Miter Saw - 10"

Planer/Jointer - 6"

Table Saw/RadialArm Saw - 10"

Air Compressor - I-I/2 HP

*Wattages listed are approximate only. Check toot or

appliance for actual wattage.

(Running)

Watts

75

500

8O0

8O0

1000

12O0

3OO

8O0

1000

1500

1500

25O0

100

100

450

5o0

8o0

18o

3O0

480 520

40O0

1000

600 1200

960 960

1000 1000

1500 1500

1800 1800

1800 1800

2000 2000

2500 2500

Additional

Surge

(Starting)

Watts

500

1200

1600

20O0

1800

6O0

1300

Page 13

SPECIFICATIONS

Maximum SurgeWatts ................. 6,600 watts

Continuous Wattage Capacity ........... 4,000 watts

Power Factor .............................. 1.0

Rated Maximum Continuous AC Load Current:

At 120Volts ....................... 33.3Amps

At 240 Volts ....................... 16.7Amps

Phase................................. I-phase

Rated Frequency ....................... 60 Hertz

FuelTank Capacity................... 4 U.S.gallons

ShippingWeight ......................... 134 Ibs.

NOTE: DO NOT use agarden hose to clean generator.

Water can enter engine fuel system and causeproblems. In

addition, ifwater enters generator through cooling air slots,

some of the water witl be retained in voids and cracks of

the rotor and stator winding insulation.Waterand dirt

buildup on the generator internalwindings wilt eventually

decreasethe insulationresistanceof these windings.

WARNING

GENERAL MAINTENANCE

RECOMMENDATIONS

The Owner/Operator is responsible for making sure that

all periodic maintenance tasks are completed on a timely

basis;that all discrepancies are corrected; and that the unit

iskept clean and properly stored. NEVER operate a

damaged or defective generator.

Engine Maintenance

Seeengine owner's manualfor instructions.

CAUTION

Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

Thoroughly wash exposed areas with soapandwater.

POLLUTE.CONSERVE RESOURCES.RETURN

USED OILTO COLLECTION CENTERS.

KEEPOUT OF REACH OF CHILDREN. DON'T

ENERATOR

Disconnectthe sparkplugwire from the sparkplugandplace

thewire whereit cannotcontactsparkplug.

Fuel Valve Maintenance

The fuel valve isequipped with a fuel sediment cup,screen,

retaining ring and o-ring that need to be cleaned every

6 months or IO0 hours (whichever occurs first).

I. Move fuel valve to "Off' position.

2. Remove sediment cup from fuel valve. Removeo-ring,

retaining ring and screen from fuel valve (Figure I I).

_ - Screen

_1{ Retaining Ring

Generator Maintenance

Generator maintenanceconsists of keeping the unit clean

and dry. Operate and store the unit in a clean dry

environment where it witl not be exposed to excessive

dust, dirt, moisture or any corrosive vapors.Cooling air

slots in the generator must not become clogged with

snow, leavesor anyother foreign material.

_'_ O-ring

Sediment Cup

3. Wash sediment cup,o-ring, retaining ring, and screen in

a nonflammable solvent. Dry them thoroughly.

4. Place screen,retaining ring,and o-ring into fuel valve.

Install sediment cup and tighten securely.

Page 14

5. Movefuelvalveto"On"position,andcheckforleaks.

Replaceo-ringifthere isanyleakage.

Generator Cleaning

• Use a damp cloth to wipe exterior surfacesclean.

CAUTION

DO NOT expose generator to excessive moisture, dust, dirt,

or corrosivevapors.

DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt or oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use tow pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and opening on

generator.These openings must be kept clean and

unobstructed.

STO RAG E

The generator should be started at least once every seven

claysand allowed to run at least 30 minutes. If this cannot

be done and you must store the unit for more than

30 days,use the following guidelinesto prepare it for

storage.

Generator Storage

• Clean the generator asoutlined in"Generator Cleaning".

• Check that cooling air slots and openingson generator

are open and unobstructed.

WARNING

_'-,l[(*_L'-ltl_'] [1_.1|1 l|lilill_!l-I

DO NOT place a storage cover over a hot generator.

Let equipment cool for a sufficient time before placing the

cover on the equipment.

Engine Storage

See engine owner's manual for instructions.

Other Storage Tips

• To prevent gum from forming in fuel system or on

essentialcarburetor parts, addfuel stabilizer into fuel

tank and fill with fresh gasoline.Run the unit for several

minutes to circulate the additive through the carburetor.

The unit and fuel can then be stored for up to

24 months. Fuelstabilizer can be purchasedlocally.

DO NOT store gasolinefrom one seasonto another

unless it has been treated asdescribed above.

Replacefuel container if it startsto rust. Rust and/or dirt

in fuel can cause problems if it's usedwith this umt.

Store in clean and dry area.

Page 15

NOTES

Page 16

NOTES

Page 17

TROUBLESHOOTING

Problem

Cause

I. One of the circuit breakers is

open.

2. Fault in generator.

No AC output is available, but

generator is running.

3. Poor connection or defective

cord set.

4. Connected device is bad.

I. Short circuit in a connected load.

Generator runs good at no-load

but "bogs" down" when loads are

connected.

Generator will not start; or starts

2. Generator is overloaded.

3. Shorted generator circuit.

Low oillevel.

and runs rough.

Generator shuts down during

I. Out of gasoline.

2. Low oitlevel.

operation.

Generator lacks power. Load is too high.

Correction

I. Resetcircuit breaker.

2. Contact Authorized service

facility.

3. Check and repair.

4. Connect another device that is in

good condition.

I. Disconnect shorted electrical

load.

2. See "Don't Overload Generator".

3. Contact Authorized service

facility.

Fill crankcaseto proper level or place

senerator on level surface.

I. Fillfuel tank.

2. Fill crankcase to proper level or

place generator on level surface.

See "Don't Overload Generator".

Page 18

SCHEMATIC

PB/#ER POWER

mH O_Oj

>X

oxoJ L_W

R

m H

D •

S D

G

A

T

E

S

O

N

A

SPARK

PLUG

ENG

IGNITION

BATTERY CHARGE

BRN BLK BRN

66 55 77

RED BLK

AUTO 13 55

3

o/

RED

Page 19

WIRING DIAGRAM

GRY

44A

BLU

llB

I

IDLE

CONTROL

SWITCH

GRN

0

RED

13

RED

RED

22

RED

t5

BLU

ii

GRN

0

GRN

L2V/IOA DC

BLK

RED

13

IDLE CONTROL

TRANSFORMER

GRY

GRN

GRY

CONTROL

BOARD

I_ C I,

Is B I,

BATTERY

CHARGE

RECTIFIER

LOb/ OIL

GATE

SIGNAL

pq

3 PIN S _!ITCH

ENGINE CATHODE

RUN

SWITCH

NUT ON ENGINE BLOCK

PRE££URE

LOW OIL

PRESSURE

LED

Page 20

_rs

EXPLODED VIEW

51

- MAIN UNIT

5O

\

57

40

59

52

56 48

47

SEE

DETAIL " y "

5

7

8

6

52

27

DETAIL " y "

14

58

16

24

Page 21

2 ¸

_rs

PARTS LIST- MAIN UNIT

Item Part # Description Item Part #

I MI89159GS CRADLE 40 22145GS

2 M84021GS SUPPORT,Engine,Red 41 86494GS

3 NSP ENGINE 42 86292GS

4 66365GS HOUSING, EngineAdapter 43 52858GS

5 8414 IJGS ASSY,Rotor (Includes Item 7) 44 189134GS

6 83540JGS ASSY,Stator 45 93826GS

7 65791GS BEARING 46 5W31GS

8 96796GS WASHER 47 189133GS

9 73054GS DECAL, FuelShut Off 48 189759GS

10 86307GS SCREW 49 189135GS

I I 47480GS SCREW 50 193574GS

12 84508GS MOUNT,Vibration

13 B2153GS SCREW 51 J84042GS

14 83208GS BRACKET,Muffler 52 84687GS

15 B4986GS DECAL, Ground 53 85000GS

16 66476GS SCREW 54 14353621GS

17 89476GS GASKET,Exhaust 55 23762GS

18 70644GS SCREW 56 189568GS

19 84346GS SCREW 57 92982GS

20 40976GS SCREW 58 BI797GS

21 83083GS SCREEN,Spark Arrest 59 189137GS

Oescription

WASHER

SCREW,Wing

SCREW

NUT, Lock

GROMMET,Tank

DECAL, Operating Instructions

SCREW

VALVE,Tank(Includes Item 48)

KIT,FuelValveRepair

CAP,Tank Fuel,Vented

ASSY,Tank,Fuel

(Includes Items 47 & 48)

SHIELD,Heat

INSULATION

CLIP,Insulation

WIRE, Ground

WASHER

CLAMP,Hose

DECAL, Danger

CLIP,Tree

SPACER

22 83071GS MUFFLER

23 81917GS PIN,Roll Items Not Shown:

24 77816GS DECAL, Caution Hot Muffler BB3061GS

25 SRV66825DGS CARRIER,Rear Bearing 43483GS

26 85652GS MOUNT, Vibration 37806GS

27 67989GS NUT 70185GS

28 26850GS WASHER 78601GS

29 84409GS SLEEVING,Flexo 65787GS

30 74908GS SCREW 193524GS

31 87116GS ASSY,Control Panel(see page22) A8926GS

32 86308GS BOLT 84882GS

33 65795GS RECTIFIER,Battery Charge 72347GS

34 66849AGS SCREW 84895GS

35 67022GS GROMMET,Rubber 193575GS

OIL BOTTLE

PLUG, 250V 20A 4-Prong

PLUG, 125V 30A 3-Prong

OIL FILTER

AIR CLEANER

CABLE, Battery Charge

MANUAL, Owners

MANUAL, Engine

WRENCH, Spark Plug

SPARKPLUG

COVER,Storage

KIT,Decals

36 84132GS ASSY,Drive Module Pwr Reg.

37 66386GS ASSY,Brush Holder Optional Accessories Not Included:

38 66849GS SCREW 84883GS CordWrap

39 B4871GS COVER,BearingCarrier

Page 22

_rs

EXPLODED VIEW AND PARTS LIST - CONTROL PANEL

14

2

f

1

'\ 7

\

\

\

\

8

18

17 F 24

19 \

Item PaX #

I 83976GS

2 83975GS

3 66818GS

4 66821GS

5 68867CGS

6 68868CGS

7 75207AGS

8 75207GGS

9 82538GS

10 84134GS

II 83514GS

12 83970GS

12 24 4

25.

9

\\ 16 _ 3

13

Description Item Part #

PANEL,Control 13 84028GS

BOX, Control 14 67022GS

OUTLET, 120VAC, 15A Duplex 15 85584GS

OUTLET, 12V DC 16 84543AGS

OUTLET, 120/240V AC, 20 A 17 84543CGS

Locking 18 84198GS

OUTLET, 120VAC, 30A Locking 19 84197GS

BREAKER,Circult 21 75476GS

BREAKER,Circuit 22 22264GS

SWITCH, On/Off Rocker 23 51715GS

GROMMET,Rubber 24 84543BGS

BREAKER,Circuit 25 84335GS

CONTROL BOARD,System 26 82542GS

17

26

10

Description

TRANSFORMER, Idle Control

GROMMET,Rubber

BAR, Bus

SCREW

SCREW

SHIELD,Circuit Breaker

BAR, Circuit Breaker Retaining

SCREW

WASHER, Lock

NUT

SCREW

HARNESS,Wire

BAR, DC Outlet Retaining

Page 23

_rs

EXPLODED VIEWAND PARTS LIST-WHEEL KIT

8

/

1

USE EXISTING FASTENERS

TD SECURE ITEM #8

Item Part #

I 189715GS

2 BI764GS

3 52858GS

4 39287GS

5 191267FGS

6 B4966GS

7 191265GS

8 22247GS

/

Description

ASSY,Handle

LEG,Mounting

NUT, Locking

SCREW

AXLE

WHEEL

E_RING

WASHER

Page 24

GENERAC PORTABLE PRODUCTS OWNERWARRANTY POLICY Effective January I, 2003

LIMITED WARRANTY

"Generac Portable Products isa licensedtrademark of Briggs& Stratton Power Products. Briggs& Stratton Power Products will

repair or replace,free of charge,any part, or parts of the equipment** that are defective in material or workmanship or both.

Transportation charges on parts submitted for repair or replacement under this warranty must be borne by purchaser.This

warranty iseffective for the time periods and subject to the conditions provided for in this policy. For warranty service,find your

nearest Authorized service dealer by calling 1-800-270-1408.Warranty service may only be performed by a Briggs& Stratton

Power ProductsAuthorized service dealer.

THERE IS NO OTHER EXPRESSWARRANTY. IMPLIEDWARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESSFOR A PARTICULAR PURPOSE,ARELIMITED TO THE TIME PERIOD SPECIFIED,OR TO THE EXTENT PERMITTED

BY LAW.ANY AND ALL IMPLIEDWARRANTIES ARE EXCLUDED. LIABILITY FOR CONSEQUENTIAL DAMAGES UNDER

ANY AND ALL WARRANTIES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some countries or

states do not allow limitationson how long an impliedwarranty lasts,and some countries or states do not atlow the exclusion

or limitationof incidentalor consequential damages,sothe above limitation and exclusion may not apply to you.This warranty

givesyou specific legal rights and you mayalso haveother rights that vary from country to country or state to state."

WARRANTY PERIOD*

Equipment ** Consumer Use Commercial Use

PressureWasher I Year 90 Days

Portable Generator 2Years (2rid year parts only) I Year

*The warranty period beginson the date of purchaseby the first retail consumer or commercial end user,and continues for the

period of time stated in the table above."Consumer use" meanspersonal residential household use by a retail consumer.

"Commercial use" meansall other uses,includingusefor commercial, income producing or rental purposes. Once equipment has

been used commercially, it shallthereafter be considered to be in commercial usefor purposes of this warranty.

**The engine and starting batteries are warranted solely by the manufacturers of those products.

WARRANTY REGISTRATION IS NOT NECESSARYTO OBTAIN WARRANTY ON BRIGGS & STRATTON

POWER PRODUCTS EQUIPMENT. SAVEYOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE

PROOF OFTHE INITIAL PURCHASE DATEATTHETIMEWARRANTY SERVICE IS REQUESTED, THE

MANUFACTURING DATE OFTHE EQUIPMENTWlLL BE USEDTO DETERMINETHEWARRANTY PERIOD.

About your equipment warranty:

We welcome warranty repair and apologize to you for being inconvenienced.AnyAuthorizedservice dealer may perform warranty

repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For

example,warranty service would not apply if equipment damageoccurred becauseof misuse,lackof routine maintenance,shipping,

handling,warehousing or improper installation.Similarly,the warranty is void if the manufacturing date or the serial number on the

equipment hasbeen removed or the equipment has been altered or modified. During the warranty period, the Authorized service

dealer,at its option, will repair or replace any part that, upon examination, isfound to be defective under normal use and service.

This warranty will not cover following repairs and equipment:

• Normal Wear: Outdoor power equipment, like all mechanical devices,needs periodic parts, service and replacement to

perform well.This warranty does not cover repair when normal use has exhausted the lifeof a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that havebeen subjected to improper or

unauthorized installationor alteration and modification, misuse,negligence,accident, overloading, overspeeding, improper

maintenance, repair or storage so as,in our judgment, to adverselyaffect itsperformance and reliability.This warranty also does

not cover normal maintenance suchas adjustments,fuel system cleaning and obstruction (due to chemical,dirt, carbon or time,

etc.).

• Other Exclusions: Also excludedfrom this warranty are wear items suchas quick couplers, oil gauges,belts, o-rings,filters,

pump packing,etc., pumps whichhave been run without water supplied or damageor malfunctions resulting from accidents,

abuse, modifications, alterations, or improper servicing or freezing or chemical deterioration.Accessory parts such asguns,

hoses, wands and nozzles are excluded from the product warranty.Also excluded is used, reconditioned, and demonstration

equipment; equipment used for prime power in place of utility power and equipment used in llfe support applications.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Loading...

Loading...