Page 1

Manual Part No. 86640

SERVICE

Manual

NP and IM Series

RECREATIONAL

VEHICLE AND

INDUSTRIAL MOBILE

AC GENERATORS

Liquid-Cooled 1.2 Liter

Gas Engine Models

CORPORATION

♦ P. O. Box 8

♦ Phone: (414) 544-4811

♦Waukesha, Wisconsin 53187

♦ FAX: (414) 544-4851

Original laaua (02/28/93)

Printed In U.SJt.

Page 2

Foreword

PURPOSE OF MANUAL:

This Service Manual has been written and published by Generac Corporation to aid our Dealers" mechanics and

company service personnel In the maintenance, servicing, troubleshooting and repair of the products described

herein. All information, illustrations and specifications are based on the latest product Information available at the

time of publication.

Proper service and repair Is important to the safe, economical and reliable operation of all recreational vehicle

and Industrial mobile generators. Troubleshooting, testing and servicing procedures recommended by Generac

and described In this manual are effective methods of performing such operations. Some of these operations or

procedures may require the use of specialized equipment Such equipment should be used when and as

recommended.

Generac could not possibly know of and advise the generator service trade of all conceivable procedures by

which a service or repair might be performed or of the possible hazards and/or results of each method. We have

not undertaken any such wide evaluation. Therefore, anyone who uses a service procedure, method or tool not

recommended by Generac must first completely satisfy himself that neither his nor the product’s safety will be

endangered by the procedure or method selected.

USER’S RESPONSIBILITY:

It Is assumed that service personnel are familiar with the servicing procedures of these products or like or similar

products manufactured and marketed by Generac. It Is further assumed that such personnel have been trained In

the recommended servicing procedures for these products; and that such training Includes the use of mechanic’s

common hand tools, special Generac tools, and tools from other suppliers.

li

■-!

SAFETY:

When working on this product, it must be remembered that the generator AC electrical system produces high

and dangerous voltages that can cause severe electrical shock. Contact with high voltage terminals, bare wires,

etc., can result In dangerous and even fatal Injury.

To prevent accidental engine cranking and startup, always disconnect battery cables before working on or

around the generator.

Cover all openings Into the engine-generator, to prevent entry of foreign materials. Such materials could enter

the engine cylinders and cause extensive damage when the engine Is started.

It Is Important to note that the manual contains various DANGER, CAUTION and NOTE blocks. These should be

read carefully In order to minimize the risk of personal Injury or to prevent methods or practices from being used

which could damage equipment or render It unsafe.

FASTENERS:

Replacement fasteners must have the same measurements and strength as the fasteneres they will replace.

Numbers on the heads of metric bolts and on surfaces of metric nuts indicate their strength. Customary nuts do

not have strength markings. Mismatched or incorrect fasteners can cause damage, equipment malfunction or

possible Injury.

REPLACEMENT PARTS:

Many parts used on recreational vehicle generators and engines are designed and manufactured to comply with

rules and regulations established by the Recreational Vehicle Industry Association (RVIA), American National

Standards Institute (ANSI), and the National Fire Protection Association (NFPA). Strict compliance with such rules

and regulations help to minimize the risk of fire or an explosion. Use of any replacement part that does not comply

with such rules and regulations could result in fire or explosion hazard and should be avoided.

Page 3

SERVICE

MANUAL

NP and IM Series

RECREATIONAL

VEHICLE &

INDUSTRIAL

TABLE OF CONTENTS

PART

1

2 ENGINE MECHANICAL

3 ENGINE LUBRICATION SYSTEM

4

5 GASOLINE FUEL SYSTEM

6 GASEOUS FUEL SYSTEM

7 ENGINE SPEED CONTROL SYSTEM

8

9 ENGINE DC ELECTRICAL SYSTEM

10

11 SPECIFICATIONS & ELECTRICAL DATA

ENGINE COOLING SYSTEM

ENGINE IGNITION SYSTEM

OPTIONS AND ACCESSORIES

TtTLE

THE AC GENERATOR

MOBILE

AC

GENERATORS

1.2 Liter, Liquid-Cooled

Gas/Gasoline Engine Models

Page 4

Part 1

THE

AC

SECTION

1.1

1.2

1.3

1.4

1.5

1.6

TABLE OF CONTENTS

TITLE

How Generators Produce Electricity

Major Generator Components

Insulation Resistance Tests

Introduction to Troubleshooting

Troubleshooting Flow Chart

Troubleshooting Test Procedure

GENERATOR

NP and IM Series

RECREATIONAL

VEHICLE &

INDUSTRIAL

MOBILE

AC GENERATORS

Liquid Cooled 1.2 Liter

Gas Engine Models

Manual Familiarization

This Service Manual has baan dividad Into alevant (11) PARTS.'

Each PART consists of ons or mors SECTIONS. Each SECTION

Is divided Into two or more SUBSECTIONS. Each SUBSECTION

may be made up of one or more PARAGRAPHS.

A DIVIDER page separates each PART of the Manual. The

DIVIDER page provides a TABLE OF CONTENTS which lists the

SECTIONS that may be found In that PART.

Page numbers at the bottom of each page Identify the PART

number, SECTION number, and the specific page. For example.

Page 2.3-4 Indicates PART 2, SECTION 2 J, and Page 4 of that

SECTION. This type of numbering system allows Individual SEC

TIONS to be kept current without affecting page numbers In the

entire Manual.

Page 5

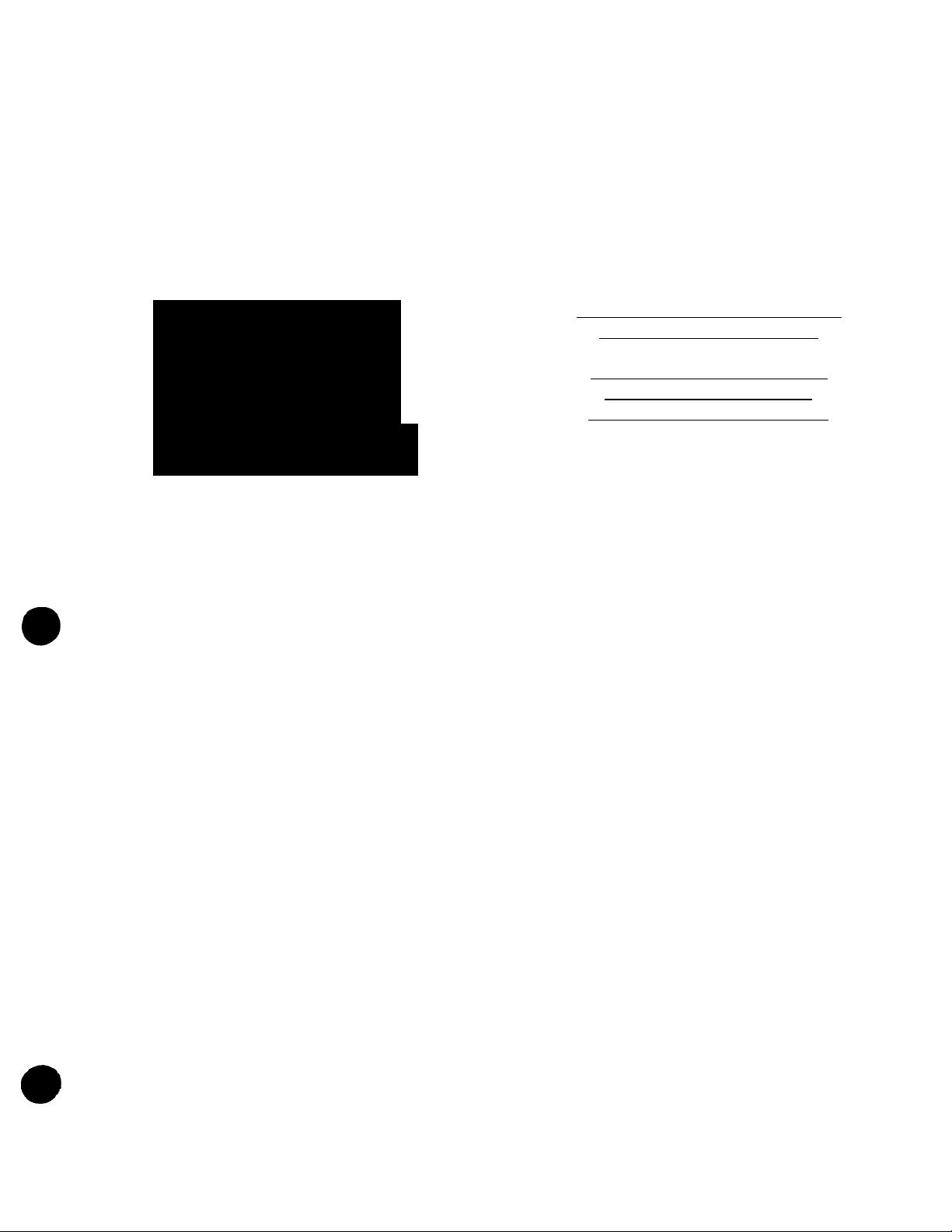

Section 1.1- HOW GENERATORS PRODUCE ELECTRICITY

It has long been №own that a relationship exists between

Magnetic Induction

magnetism and electricity. Revolving field AC generators

depend on this relationship for their operation. If generator

problems are to be properly diagnosed, the service techriician

must understand this relationship. Magnetism can be used to

create an electrical voltage in a conductor. Conversely, elec

trical current flow through a conductor will create a magnetic

field around that conductor.

See Figure 1, below. When a conductor is moved

through a magnetic field, an electromotive force (EMF or

voltage) is induced Into the conductor. Movement of the

magnetic field so that It cuts across the conductor will also

create a voltage In the conductor. If the ends of the conductor

are connected to form a complete circuit, current will flow

through the conductor. The direction in which the current

flows depends on the polarity of the magnetic field and the

direction in which the magnetic field (or conductor) is moved.

The amount of voltage Induced into the conductor depends

on the strength or concentration of the magnetic field, i.e., the

stronger the magnetic field, the higher the induced voltage.

See Rgure 2. When current flows through a conductor,

a magnetic field is created around that conductor. The

strength of the magnetic field depends on (a) the amount of

current flow, (b) the number of turns or loops in the conductor.

The polarity of the magnetic field depends on the direction of

current flow through the wire. The following facts should be

evident:

□ If current flow through a conductor can be regulated, the

strength of the magnetic field around the conductor can

be regulated.

D If the strength of a magnetic field can be regulated, the

amount of voltage induced into a conductor by such a

magnetic field can also be regulated.

Figure 3 represents a simple AC generator, in which the

A Simple AC Generator

rotating magnetic field (Rotor) Is a permanent magnet. As the

magnet rotates, its magnetic field cuts across a stationary coil

of wires called a STATOR. When the magnet’s North mag

netic pole moves past the stator windings, current moves

through the wire in one direction. As the South magnetic pole

of the magnet passes the stator wires, current reverses itself

and moves through the stator in the opposite direction.

in the simple generator shown, the strength of the mag

net is fixed. That \ the magnetic field strength cannot be

changed since a permanent magnet is used. Because the

magnetic field strength is fixed, the voltage induced into the

stator coil is constant

If some method of regulating the magnetic field strength

of the magnetic could be found, the voltage induced into the

stator coil could be regulated as well.

Figure 3. A Simple Revolving Field Generator

Paga 1.1-1

Page 6

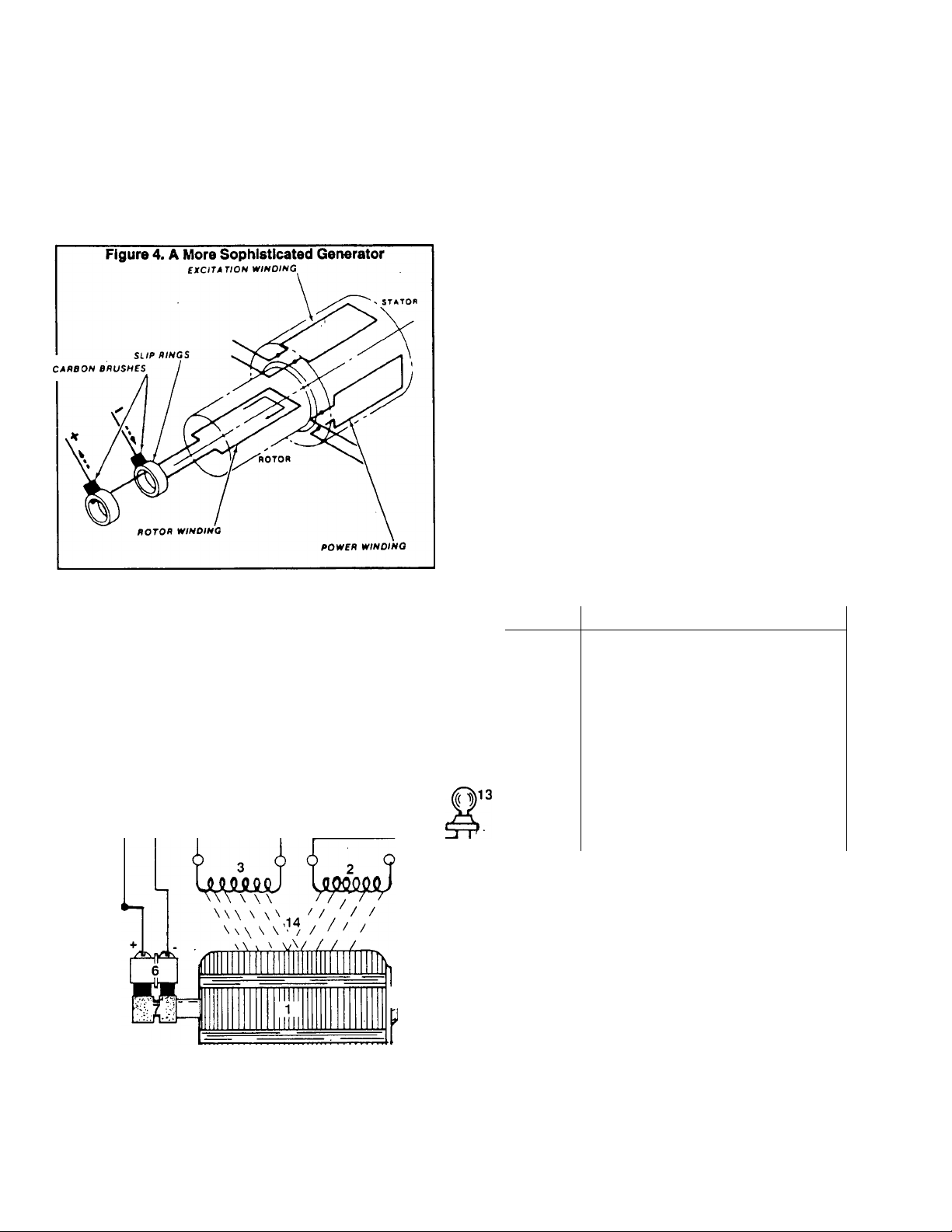

A More Sophisticated Generator

Figure 4 Is a diagram of a more sophisticated generator.

A regulated direct current (DC) is delivered to the rotating

magnet (Rotor), via CARBON BRUSHES and SUP RINGS.

This creates a regulated magnetic field around the Rotor

which cuts across the stationary Stator windings to Induce a

regulated voltage into those windings. When the Stator circuit

is corfipleted by connecting a load, current will flow through

the Stator windings to the load.

Rgure 5, below, Is an operating diagram of a typical AC

A Typical AC Generator

generator. Operation of this typical generator may be briefly

described as follows:

D The ROTOR is attached to the engine’s power takeoff

(PTO) shaft and turns at the same speed as the engine.

D As the ROTOR turns, its magnetic field cuts across the

stationary coils of a STATOR EXCITATION WINDING

and dual STATOR AC POWER WINDINGS. A voltage is

induced into these stationary widings.

□ Unregulated alternating current (AC) is delivered from

the STATOR EXCITATION WINDING to the VOLTAGE

REGULATOR, via an EXCITATION CIRCUIT

BREAKER.

n "Sensing" leads deliver a signal of ACTUAL AC POWER

WINDING voltage to the VOLTAGE REGULATOR.

n The VOLTAGE REGULATOR electronically compares

the ACTUAL AC POWER WINDING voltage to a preset

REFERENCE VOLTAGE and changes №e STATOR

EXCITATION WINDING output to direct current (DC).

□ If ACTUAL POWER WINDING voltage Is less than the

REGULATOR’S preset REFERENCE voltage, REGU

LATOR action will increase direct current flow to the

ROTOR windings. The ROTOR magnetic field strength

will then increase and the voltage induced into the STA

TOR AC POWER WINDINGS will then increase.

□ When ACTUAL POWER WINDING voltage is greater

than the REGULATOR’S preset REFERENCE voltage,

direct current flow to the ROTOR will be decreased by

REGULATOR action to reduce ROTOR magnetic field

strength.

12

-S-

Rgure 5. Operating Diagram of a Typical AC Generator

ITEM

i

2

3

4

5

6

7 SLIP RINGS

11

4^

8

9

10

11

12

13

14

DESCRIPTION

RÓTOF1

STATOR POWER WINDING

STATOR EXCITATION WINDING

FIELD BOOST

ENGINE

BRUSHES

VOLTAGE REGULATOR

SENSING LEADS

THERMAL PROTECTOR

THERMAL PROTECTOR BYPASS

EXCITATION CIRCUIT BREAKER

ELECTRICAL LOAD

MAGNETIC FIELD

Page 1.1-2

Page 7

□ The VOLTAGE REGULATOR will continue to increase

or decrease direct current flow to the ROTOR, In an

attempt to maintain STATOR AC POWER WINDING

voltage at the same value as the REGULATOR’S preset

REFERENCE voltage.

□ When the STATOR AC POWER WINDING circuit is

completed by connecting a load to the winding's AC

output leads, current will flow through the windings and

to the load.

Rotor Residual Magnetism

The Rotor may be considered a permanent magnet since

some residual magnetism is always normally present In the

Rotor windings. As a general rule. Rotor residual magnetism

atone (without regulated excitation current and without field

boost current) will produce a STATOR AC POWER WINDING

output of approximately 2 to 7 volts.

Field Boost

When the engine Is being cranked, direct current is

delivered to the Rotor windings from a source other than the

Stator excitation windings and Voltage Regulator. This direct

current, in effect, Hashes the field" every time the engine is

cranked. By applying field boost current to the Rotor during

cranking, an early "pickup" voltage Is induced into the Stator

windings to turn the Regulator on sooner and provide AC

output more quickly.

Failure of the field boost circuit rrray or may not result In

toss or dropout of AC power winding output voltage, depend

ing on the characteristics of the Individual generator. The

following general rules apply:

D If Rotor residual magnetism atone (without field boost) is

sufficient to turn the Voltage Regulator on and provide

the required pickup voltage, the generator will operate

normally with normal AC output voltage.

G If Rotor residual magnetism atone (without field boost) Is

NOT sufficient to turn the Regulator on and provide the

needed pickup voltage, generator AC output voltage will

not build and will be commensurate with Rotor residual

magnetism (about 2 to 7 volts AC).

G If regulated excitation current to the Rotor is lost. Stator

AC power winding output voltage will drop to a value that

is commensurate with Rotor residual magnetism (2 to 7

volts AC). The magnetic field strength created by field

boost current cannot be considered since it is available

only while cranking.

Figure 6. Field Boost Circuit (Gasoline Fuel System)

STARTER

CONTACTOR

-TO STARTER

§

11 CHOKE

* MODULE

° 1 FROM

*

TO ROTOR •

Figure 7. Field Boost Circuit (LP Gas Fuel System)

BATTERY

-Q)

ENGINE CONTROL

CIRCUIT BOARD

La/v-J

RESISTOR

47 OHM. 2 WATT

TO IGNITION COIL

9 RESISTOR ^9°^

9

-----

W\ T-

9

too OHM 200V.

1 WATT 1 WATT

W-

ENGINE CONTROL

CIRCUIT BOARD

DIODE

AMPY 1 AMf

TO

ROTOR

#

UNITS WITH GASOLINE FUEL SYSTEM;

See Figure 6. Units equipped with a gasoline fuel system

use a choke module (CM) which closes and opens a choke

solenoid (CS) during engine cranking to open and close the

carburetor choke.

UNITS WITH LP GAS FUEL SYSTEM:

Units equipped with a gaseous fuel system do not require

a carburetor choke and do not have a choke module. The field

boost circuit for such units Is shown in Rgure 7. While

cranking, battery voltage is delivered to Terminal No. 8 of an

engine control circuit board, to Wire No. 9, a field boost

assembly. Wire No. 4, and to the Rotor via brushes and slip

rings.

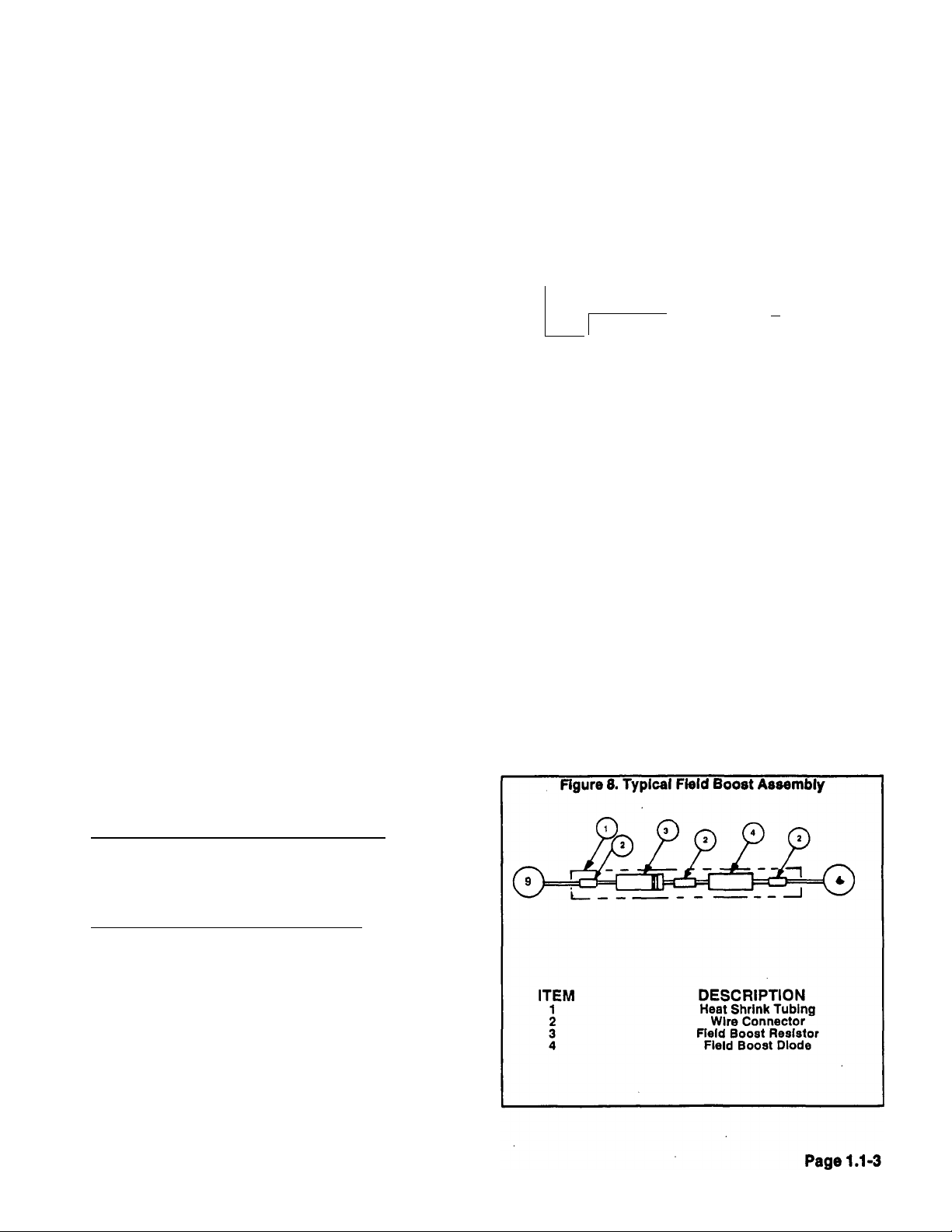

The field boost assembly, shown In Figure 8, consists of

a 100 ohm, 1 watt resistor (1^) and a 200 volt, 1 amp diode

(D2). The diode ensures that current will flow in one direction

only in the circuit. The resistor reduces the battery voltage

(12 volts DC) to approximately 9-10 volts DC.

Page 8

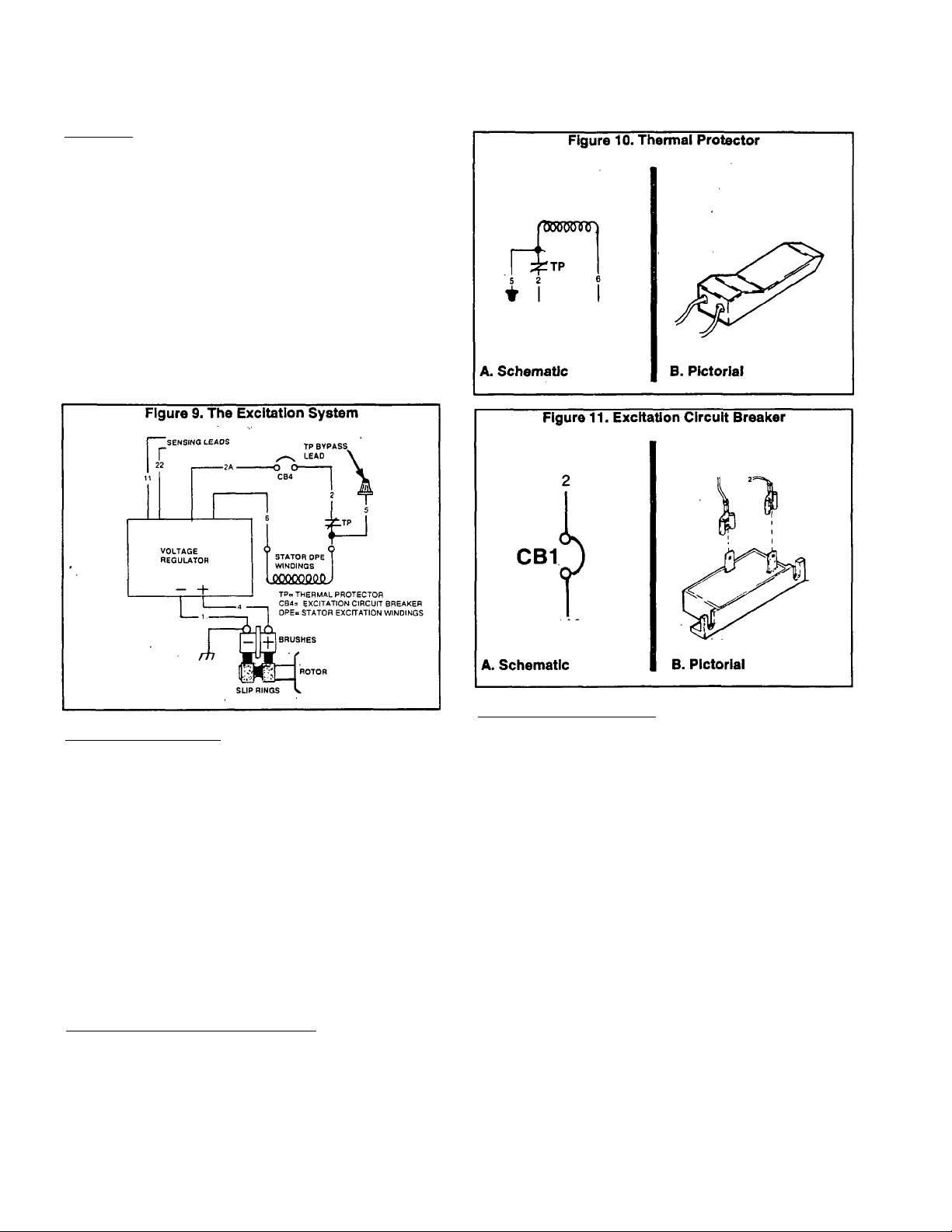

GENERAL:

The excitation system is shown schematically in Figure

9. During operation, unregulated AC current from the Stator

excitation winding is delivered to the Voltage Regulator via a

Thermal Protector, Wires 2 and 6, an excitation circuit

breaker (CB4), and Wires 2A and 6. The Voltage Regulator

rectifies and regulates the current flow, which is then deliv

ered to the Rotor windings via Wires 4 and 1, and the brushes

and slip rings. Major components of the excitation system

include the following;

D Stator Excitation (DPE) Winding,

n Thermal Protector (TP).

D Excitation Circuit Breaker (CB4).

D AC Voltage Regulator.

D Brushes and Slip Rings,

n Rotor Assembly.

Excitation System

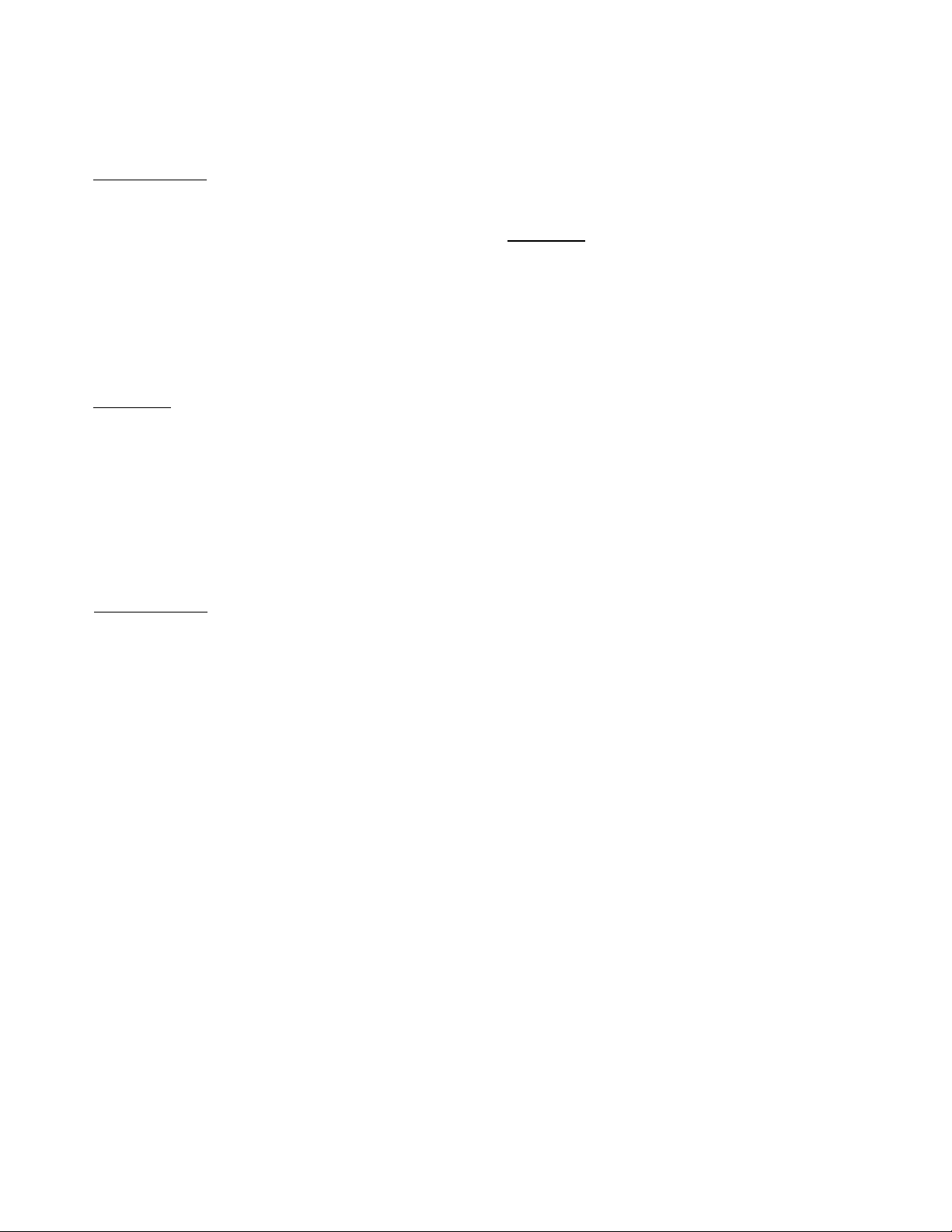

THERMAL PROTECTOR:

A Thermal Protector (tP) is physically imbedded in the

wire windings of the Stator assembly and electrically con

nected in series with the excitation winding AC output leads

to the Voltage Regulator. The device is a normally-closed (N.

C.), temperature sensitive switch. Should Stator tempera

tures exceed a preset level, the switch contacts will open. The

switch is self-resetting. That is, its contacts will close when

Stator temperatures decrease below a safe, preset level.

If the switch contacts open, excitation winding output to

the Regulator will terminate and the Regulator will shut down.

Generator AC output voltage will then drop to a value com

mensurate with the Rotor’s residual magnetism (about 2 to 7

volts AC).

The thermal protector is NOT accessible and cannot be

replaced. If it has failed open, it can be bypassed by connect

ing excitation lead No. 2 to a bypass lead No. 5. Once the

switch has been bypassed, overtemperature protection is no

longer available.

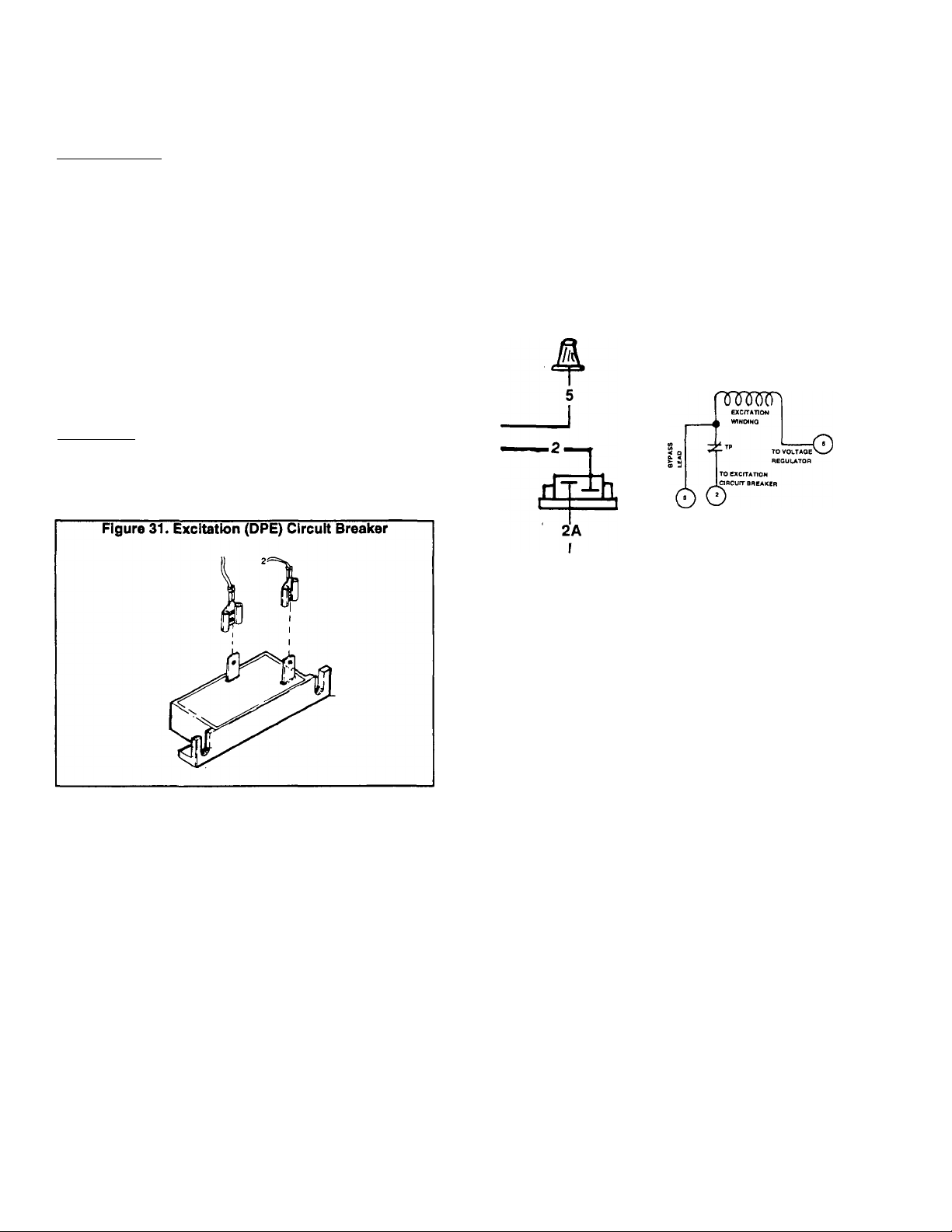

EXCITATION CIRCUIT BREAKER (CB4):

If this circuit breaker has failed open, the results will be

the same as a Thermal protector that has failed open. That

is, generator AC output will drop to about 2-7 volts AC

(residual).

Page 1.1-4

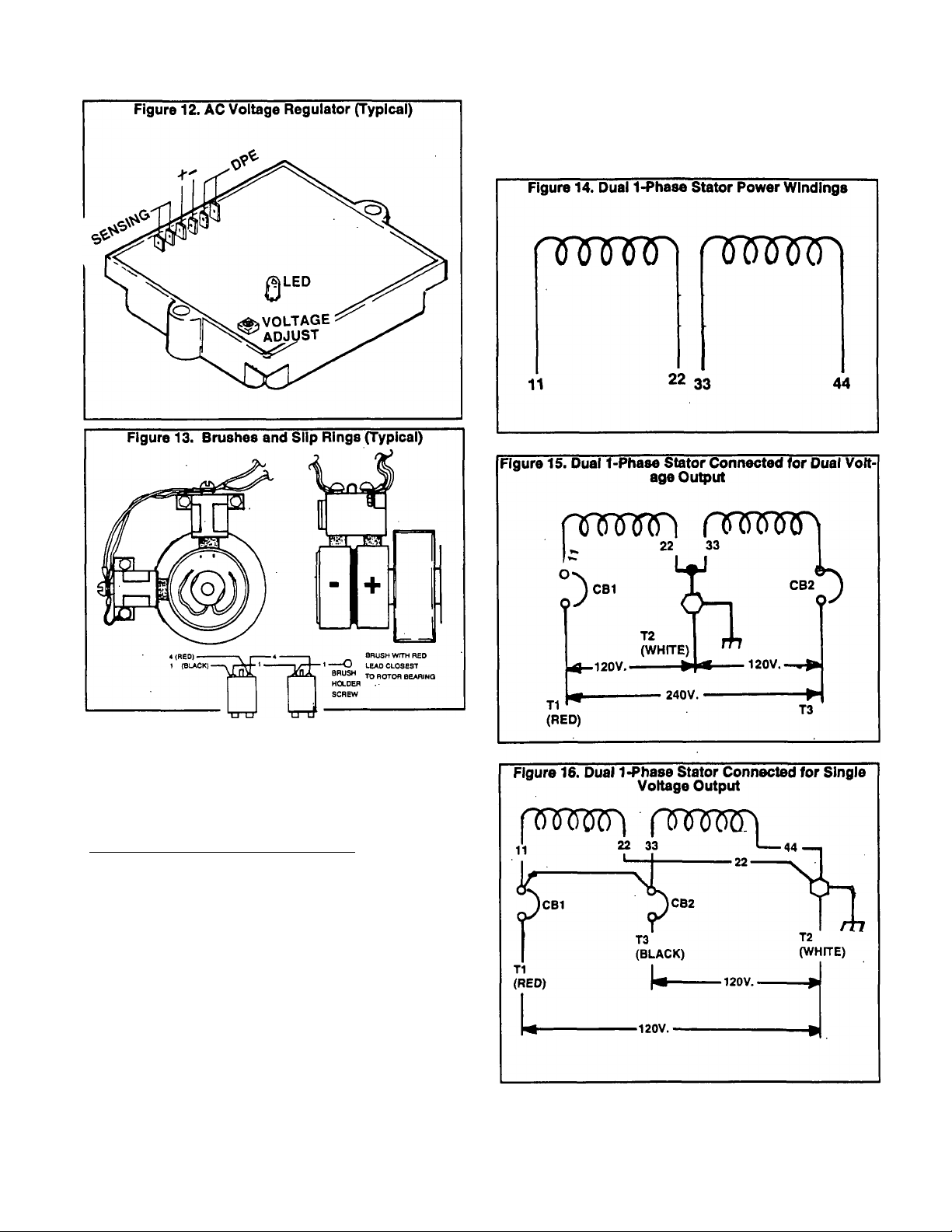

AC VOLTAGE REGULATOR:

See Figure 12. Sensing leads deliver ACTUAL AC power

winding voltage signals to me Regulator via Leads 11 and 22

and Regulator terminals 5 and 6. The Regulator electronically

compares this ACTUAL signal to a preset REFERENCE

voltage, then acts to maintain an ACTUAL voltage that Is

equal to the REFERENCE voltage.

If ACTUAL voltage is less than the preset REFERENCE

voltage, the Reoulator will increase excitation current flow to

the Rotor. The Rotor's magnetic field will then strengthen and

the AC output voltage will increase.

If ACTUAL voltage is greater than preset REFERENCE

voltage. Regulator action will decrease excitation current flow

to the Rotor. The Rotor’s magnetic field strength will drop and

ACTUAL voltage will decrease.

The typical AC Voltage Regulator shown in Figure 12 has

a single amustable potentiometer, used to establish the de

sired REFERENCE voltage.

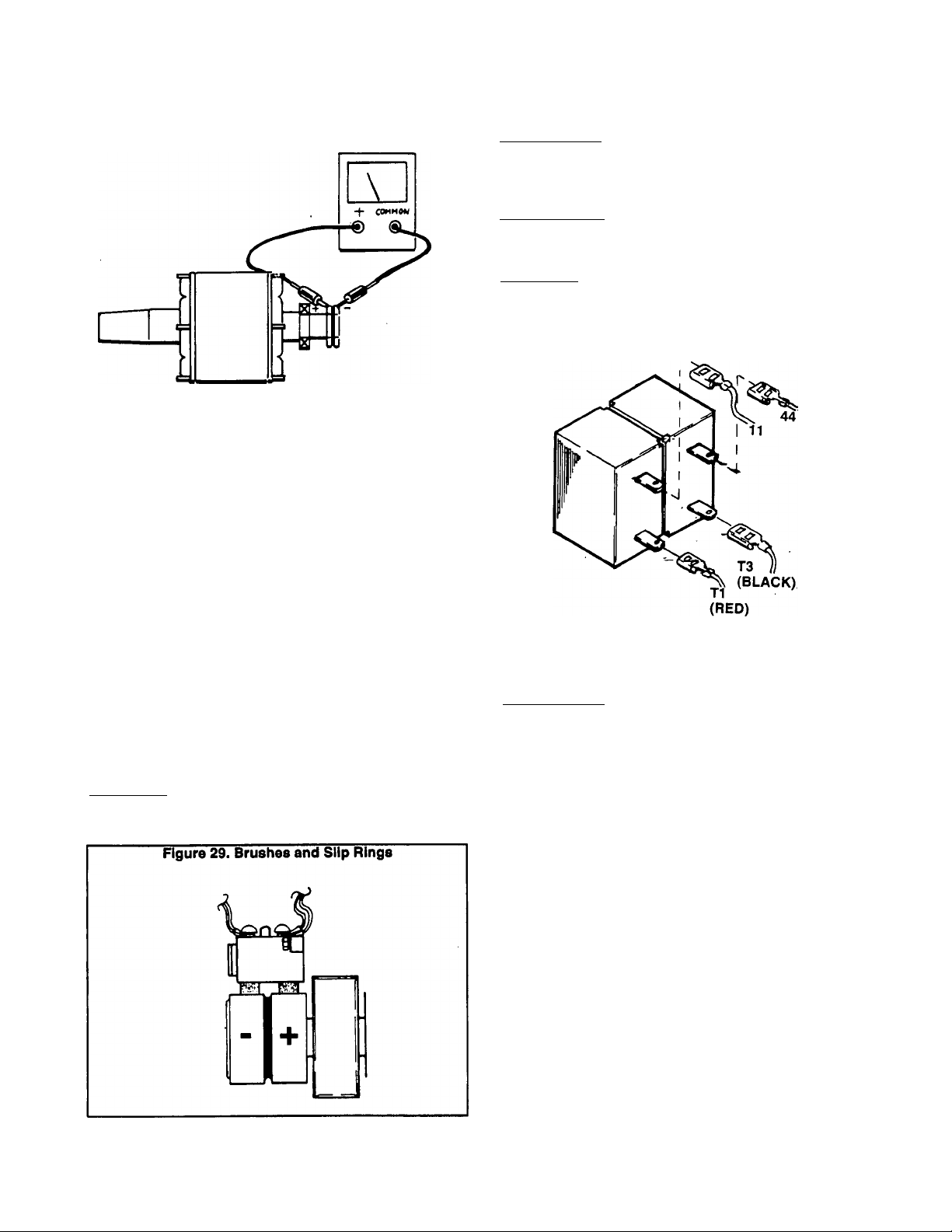

BRUSHES AND SLIP RINGS:

The Brushes and Slip Rings (Figure 13) allow excitation

current flow to be transmitted rrom a stationary member to a

rotating member. The Slip Rings are actually a part of the

Rotor assembly. As a general rule, the positive slip ring is the

one nearest the Rotor bearing. Wire No. 4 is the positive

brush lead; Wire No. 1 is the negative baish lead.

Page 9

NOTE: At the time thie Manual was written, all NP/IM

Series generators were equipped with the dual, 1-phasa

stator configuration. Some other possible stator config

urations will be mentioned here to cover future possibil

ities.

Stator AC Power Connection Systems

GENERAL:

Any one of several different connection systems are

used on NP and IM Series generators. Theses are(a) dual

1-phase, (b) 3-phase Delta, and (c) 3-phase Wye-Connected

systems.

DUAL WINDING. 1-PHASE SYSTEM:

Figure 14 is a schematic representation of dual 1-phase

Stator AC power windings. Each Stator winding can supply a

120 volts AC output. When the two windings are connected

In series to form a 3-wire connection system, a 240 volts AC

output results.

Connected for Dual Voltage Output Some dual wind

ing systems may have been connected to provide a dual

voltage output (120 and/or 240 volts AC). See Figure 15.

Stator AC output leads 11 (T1) and 44 (T3) form the two hot

leads. The Junction of Stator leads 22 and 33 form the

"Neutral’ line (T2).

Connected for Single Voltage Output: If desired, the

Stator AC ou^ut leads can be reconnected for single voltage

output only (Figure 16). When this Is done, a jumper wire must

be connected between the two main circuit breakers (CB1

and CB2).

Page 1.1-5

Page 10

stator AC Power Connection Systems (Continued)

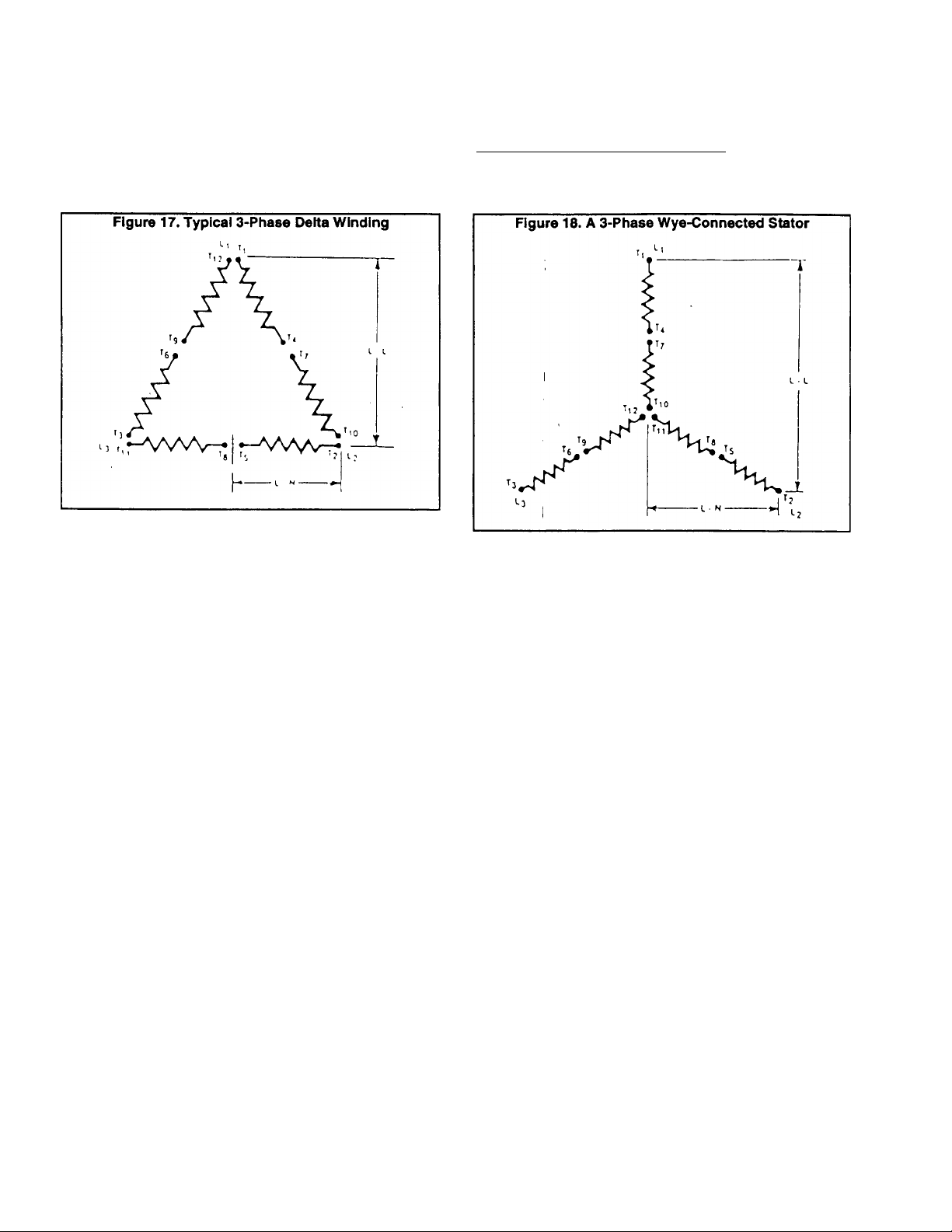

3-PHASE DELTA STATOR SYSTEM:

Figure 17 is a schematic representation of a 3-phase

Delta Stator configuration. Phase rotation is L1-L2-L3. The

“Neutral" line is designated “LO".

3-PH^ASE WYE-CONNECTED SYSTEM:

See Figure 18. This type of Stator consists of six (6) coils

and twelve (12) leads coming out of the Stator. The twelve

leads are reconnectable to supply several different voltages.

Page 1.1-6

Page 11

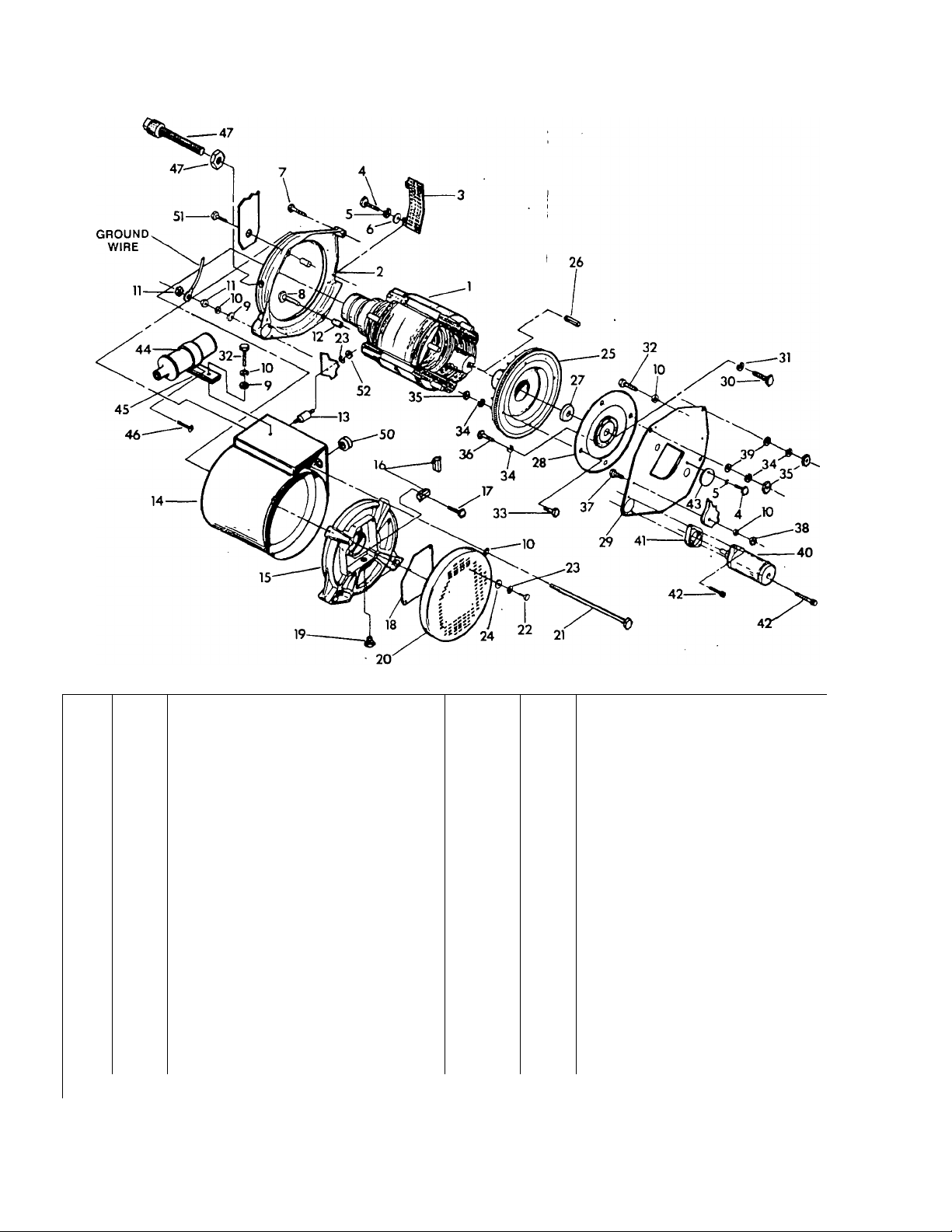

Section 1.2- MAJOR GENERATOR COMPONENTS

This section will discuss generator disassembly, Inspec

tion of components, and reassembly. See Figure 21 on Page

1.2-2.

Generator Disassembly

To disassemble the generator, proceed as follows. See

Figure 21.

1. Remove the four capscrews, lockwashers and flatwashers

(Items 22, 23 and 24) that retain the REAR BEARING CAR

RIER PLATE (Item 20) to the REAR BEARING CARRIER

(Item 15). Remove the REAR BEARING CARRIER PLATE

(Item 20).

2. Remove the Rear Bearing Carrier GASKET (Item 18).

3. Disconnect wires from BRUSH HOLDERS (Item 16).

4. Remove SCREWS (Item 17) that retain the BRUSH HOLD

ERS (Item 16) to the Rear Bearing CARRIER (Item 15).

Remove the BRUSH HOLDERS (Item 16).

5. Remove hardware that retains the Rear Bearing CARRIER

(Item 15) to the generator mounting base.

6. Remove the four long CAPSCREWS (Item 21), along with

four LOCKWASHERS (Item 10).

7. A REAR BEARING CARRIER PULLER tool Is available.

See Figure 19. To order the tool, specify Part No. 74078.

a. Retain the PULLER TOOL to the Rear Bearing CAR

RIER (Item 15) using the same M6-1.00 x 8mm screws

ltem 22) that were used to retain the Rear Bearing Carrier

»LATE (Item 20).

i

b. Turn the center bolt on the PULLER TOOL (Figure 19)

clockwise until the Rear Bearing CARRIER (Item 15) is

free of the Rotor bearing.

c. Completely remove the Rear Bearing CARRIER (Item

' 15).

8. Free the STATOR ASSEMBLY (Item 14) from the

BLOWER HOUSING (Item 2). Completely remove the STA

TOR ASSEMBLY (Item 14).

Introduction

12. Remove the ROTOR ASSEMBLY (Kern 1) with the FAN

& RING GEAR (Item 25) attached.

13. Remove CAPSCREWS and LOCKWASHERS (Items 34

and 36) that retain the FLEX PLATE (Item 28) to the engine

flywheel. Remove the FLEX PLATE (Item 28).

14. If the FAN & RING GEAR is to be removed from the

ROTOR (Item 1), proceed as follows:

a. Remove CAPSCREW and LOCKWASHER (Items 30

and 31) that retain the FAN & RING GEAR to the ROTOR.

b. Remove the SPACER (Item 27).

c. Remove the FAN & RING GEAR (Item 25) from the

ROTOR.

NOTE: The FAN & RING GEAR ASSEMBLY (Item 25) Is

retained to the ROTOR shaft by a KEY (Item 26).

Inspection of Major Components

REAR BEARING CARRIER Pj^TE:

Air slots in the Rear Bearing Carrier Plate allow cooling

air to be drawn into the generator by fan action during

operation. These air slots must be kept open and unob

structed. Clean the plate and check for cracks, obvious

damage. Replace the Plate, If necessary.

BRUSHES:

Inspect both Brush Holders and their Brushes. Look for

cracks, chipping, excessive wear. Replace any damaged

Brush Holder. Brushes should be replaced as a complete set.

Inspect Boish Leads No. 1 and 4, replace any damaged or

defective Brush Lead.

Figure 20. Brush Holders, Brushes and Leads

I

9. Remove the hardware that retains the STARTER (Item 40)

to the ENGINE PLATE (Item 29). Remove the STARTER.

10. Remove all fasteners that retain the BLOWER HOUSING

(Item 2). Remove the BLOWER HOUSING.

11. Remove CAPSCREWS (Item 33) that retain the FLEX

PLATE (Item 28) to the FAN & RING GEAR (Item 25).

-

+'

BRUSH WITH RED

LEAD CLOSEST

BRUSH

TO ROTOR BEARING

HOLDER

SCREW

n-rf

REAR BEARING CARRIER:

The Rear Bearing Carrier is an aluminum casting. Clean

the casting and blow dry with compressed air. Inspect care

fully for cracks, damage. An insert is pressed into the bearing

carrier center bore, to accept the Rotor bearing. Use an Inside

micrometer to check the diameter of the Insert. Replace the

Rear Bearing Carrier If its insert’s inside diameter (I.D.) is not

within the following limits:

2.384-2.386 Inches (71.996-72.012mm)

Page 1.2-1

Page 12

Figure 21. Exploded View of AC Generator Assembly

ITEM

1 1

2 1

3

4 5

5 5

6

7

8

9

10 9

11 3

12 2

13*

14 1

15

16 2

17

18

19

20

21

22

23

24 4

25

26

* User

QTY

i to mount the generator control panel. ** Part of Engine Governor system.. See Part 7.

DESCRIPTION ITEM QTY DESCRIPTION

Rotor Assembly 27

Blower Housing

1

4

1

1

2

4

1

4

1

1

1

4

4

8

1

1

Air Outlet Screen 29 1

Pan Head Machine Screw 30 1

Lockwasher

Flatwasher 32

Hex Head Capscrew 33 4

Hex Head Capscrew

Flatwasher

Lockwasher 36

Hex Nut

Dowel Sleeve

Vibration Dampener 39 3

Stator Assembly

Rear Bearing Carrier 41 1

Brush Holder

Hex Head Screw 43 1

Rear Bearing Carrier Gasket

Flame Arrestor

Rear Bearing Carrier Plate

Hex Head Capscrew

Hex Head Capscrew

Lockwasher 51

Flatwasher

Rywheel & Ring Gear Assembly

3/8* square x 1" Key

28 1

31

34

35 7

37 1

38 1

40

42

44

45

46

47- 1

50 1

52

12

1

1

4

5

1

2

1

1

1

1

4

Magnetic Pickup Assembly

Spacer

Flex Plate

Engine Plate

Hex Head Capscrew

Lockwasher

Hex Head Capscrew

Hex Head Capscrew

Lockwasher

Hex Nut

Hex Head Capscrew

Hex Head Capscrew

Hex Nut

Flatwasher

Starter Motor

Starter Adapter

Hex Head Capscrew

Fan Access Cover

Ignition Coll

Ignition Coll Bracket

Screw

Rubber Grommet

Hex Head Capscrew

Hex Nut

Page 1.2-2

Page 13

STATOR ASSEMBLY;

Clean the Stator can exterior surfaces with a soft brush

or cloth. Use clean, dry, low pressure air (25 psi maximum)

to clean the Stator.

Use an ohmmeter or a volt-ohm-milliammeter (VOM) to

test the resistance of Stator AC power windings and excita

tion (DPE) windings. See Section 1.6.

Use an insulation resistance tester (megohmmeter or

hi-pot tester) to check the condition of stator insulation (see

Section 1.3). If stator insulation is breaking down, dry the

stator by blowing warm, dry air across it for several hours. Do

NOT exceed 185* F. (85‘ C.). If insulation resistance Is still

low after drying, replace the stator assembly.

BLOWER HOUSING:

Clean the cast aluminum blower housing. Inspect the

housing carefully for cracks, damage.

FLEX PLATE;

The flex plate is of 16 gauge steel. Clean the flex plate,

then inspect it carefully for cracks, damage, wear. Check all

holes for elongation and wear.

ROTOR ASSEMBLY;

Use clean, dry, low pressure air (25 psI maximum) to

clean the rotor. Use a volt-ohm-mllliammeter ^OM) to check

the resistance of Rotor windings (Section 1.6).

Check the Rotor bearing for binding, seizing, roughness.

The bearing is pre-lubricated and sealed; It requires no addi

tional lubrication for the life of the bearing. If the bearing Is

defective, replace the Rotor assembly.

Check the keyway in the Rotor’s tapered shaft for wear

or damage. Also, inspect the drive key.

Inspect the slip rings. A dull or tarnished appearance

indicates oxidation on the slip ring surface. If necessary,

clean the slip rings with fine sandpaper. DO NOT USE ANY

METALLIC GRIT TO CLEAN SLIP RINGS.

Use an Insulation resistance tester (megohmmeter or

hi-pot tester) to check fhe Rotor for Insulation breakdown. If

insulation resistance Is low, dry the Rotor with heated, dry air.

DO NOT EXCEED 165* F. (85 C.). If the insulation resistance

is still low after drying, replace the Rotor assembly.

FAN AND RING GEAR ASSEMBLY:

During factory assembly, the ring gear is heated to 400*

F. and the blower fan is installed. The entire assembly is then

statically balanced. If the fan and ring gear must be replaced,

replace It as an assembly.

Page 1.2-3

Page 14

Section 1.3- INSULATION RESISTANCE TESTS

Effects of Moisture and Dirt

The insulation in RV and IM generators is moisture

resistant. However, prolonged exposure to moisture will grad

ually decrease the resistance of Stator and Rotor insulation.

If moisture is allowed to remain in contact with generator

windings, some of the moisture will be retained in cracks and

voids of the iunsulation. This will result in a reduced insulation

resistance and, eventually, the unit’s AC output will be af

fected.

Dirt can make the problem worse since it tends to hold

the moisture Into contact with the windings.

Salt, as from sea air, can also worsen the problem since

salt absorbs moisture from the air. When salt and moisture

combine, they make a good electrical conductor.

Because of the detrimental effects of dirt and moisture,

the generator should be kept as clean and dry as possible.

Stator and Rotor windings should be tested periodically with

an insulation resistance tester such as a megohmmeter or

hi-pot tester. If the insulation resistance is excessively low,

drying may be required to remove moisture. After drying, a

second test of the Insulation should be performed. If resis

tance Is still low after drying, replacement of the defective

windings may be necessary.

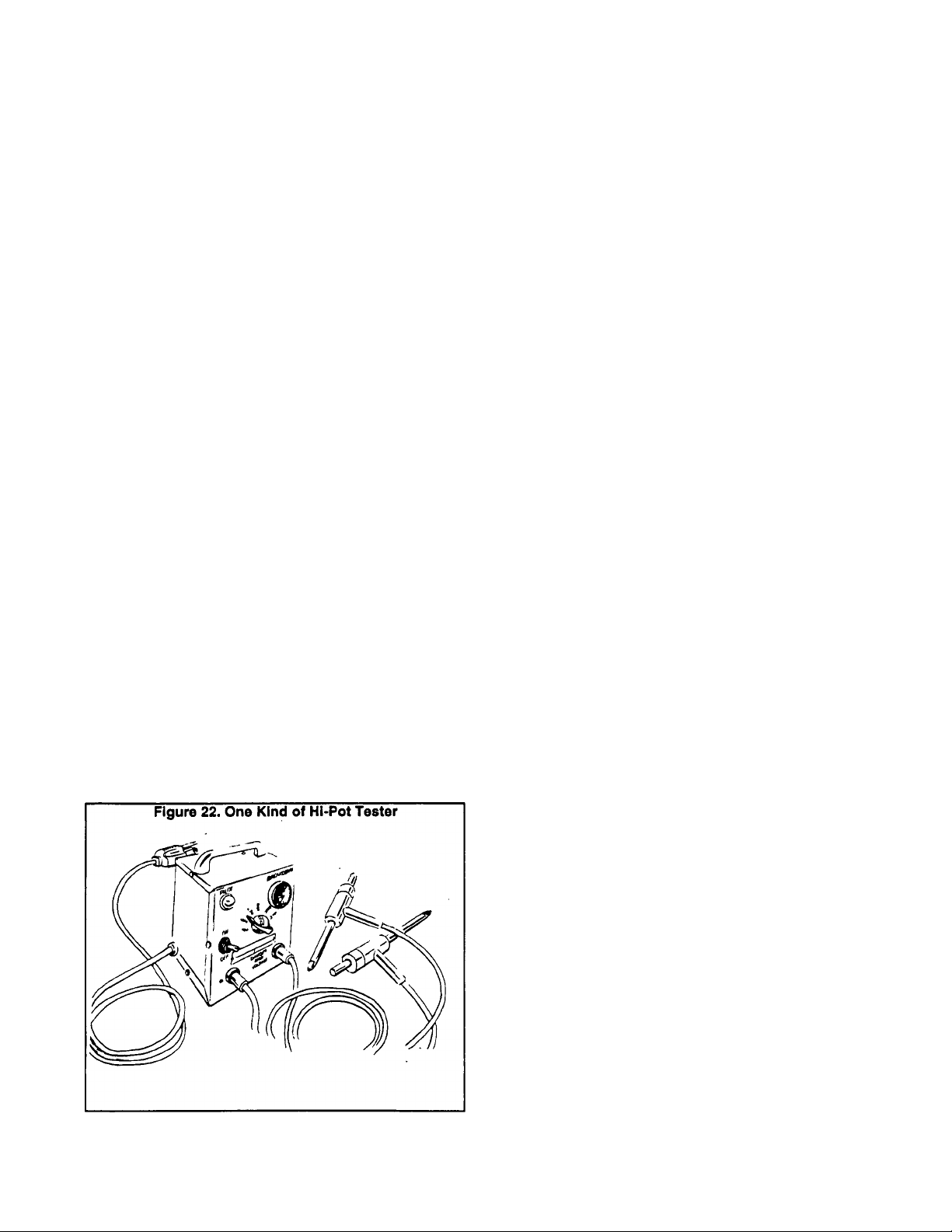

Insulation Resistance Testers

Figure 22 shows Just one type of hi-pot tester. The tester

shown is one of many brands that are commercially available.

It has a "Breakdown^ lamp which will glow to Indicate insula

tion breakdown during the test.

Normally, the resistance of insulation is measured on the

order of millions of ohms, it can be measured w'rth a device

called a 'megger', which is a megohm meter (meg is for

million) and a power supply. The power supply voltage varies

but the most common Is 500 volts. A megger voltage over 500

is NOT recommended.

When using a hi-pot tester or megger to measure Insu

lation resistance, be sure to follow the manufacturer's instruc

tions carefully.

CAUTION: Before attempting to measure Insula

tion resistance In any winding, first disconnect

any electronic components, regulators, diodes,

surge protectors, protective relays, etc., from the

circuit. Such components will be destroyed by the

high voltages generated by a megger or hl-pot

tester.

To measure Insulation resistance, connect one tester

lead to the leads for the winding to be tested and the other

tester lead to the generator frame. Make sure no leads of the

part being tested are touching any metal parts of the gener

ator. If the 'Neutral' is grounded, it must be disconnected.

Follow the tester manufacturer’s instructions and perform the

resistance test.

Insulation Resistance- Main Stator

All stator leads (No. 11, 22, 33, 44, 2 and 6) must be

Isolated from ground and connected together. Connect one

hi-pot or megger test lead to the main stator leads. Connect

the other hi-pot or megger lead to the generator grounding

stud. Set the hi-pot tester or megger voltage to '500'. Follow

the tester manufacturer’s Instructions and take the reading.

Do not apply the voltage for longer than one (1) second.

If a hi-pot tester like the one shown in Figure 22 is being

used, a 'Breakdown' lamp on the tester will glow during the

one second test to indicate an Insulation breakdown.

If a megger is used to perform the test, the minimum

acceptable value can be calculated using the following for

mula:

Minimum Insulation в

Resistance (Megohms)

Example: For a generator rated 240 volts AC:

2^+1b 1.24 Megohms

Generator Voltage +1

-------------TOOO

------

1000

H the reading Is below the recommended value, the

winding must be dried out

Rotor insuiation Resistance

Before testing Rotor insulation, гтшке sure the Rotor Is

completely Isolated. This can be done by removing both

brush holders with their brushes.

Connect one hi-pot tester or megger lead to the positive

Rotor slip ring, the other test lead to a clean frame ground

(such as the Rotor shaft). Set the tester to '500' volts and

apply voltage - DO NOT APPLY VOLTAGE LONGER THAN

ONE SECOND.

If a hi-pot tester is used. Its 'Breakdown' lamp will come

on to Indicate an insulation breakdown.

If a megger Is used, the minimum acceptable value Is 1.5

megohms. ,

If insulation Is breaking down under the applied voltage,

the Rotor must be dried out. After drying, retest the Rotor. If

insulation still breaks down after drying, replace the Rotor

assembly.

Greasy dirt or dirt that Is caked may be loosened with a

soft brush or a clean, damp cloth. A vacuum system may be

used to clean up loosened dirt. Loose dust and dirt may also

be blown away with clean, dry, low pressure air (25 psi

maximum).

Drying the Generator

To dry the generator without disassembling it, proceed

as follows:

1. Open the generator’s main circuit breaker. NO ELECTRI

CAL LOADS MUST BE APPLIED TO THE UNIT WHILE

DRYING.

Page 1.3-1

Cleaning the Generator

Page 15

Drying the Generator (Continued)

2. Disconnect Wires No. 4 from the Voltage Regulator.

3. Provide an external source to blow warm, dry air through

the generator. DO NOT EXCEED 185* F. (85* C.).

4. Start the generator and iet it run for 2 or 3 hours.

5. Stop the engine and retest Stator and Rotor insulation for

breakdown.

Page 1.3-2

Page 16

Section 1.4- INTRODUCTION TO TROUBLESHOOTING

A revolving field RV/IM type generator does not have a

Introduction

large number of parts. However, the parts are expensive. For

that reason, a 'parts replacement' method of troubleshooting

Is not cost effective. A basic understanding of generators is

required if one Is to achieve effective troubleshooting and

repair. The technician must understand why generators be

have or don’t behave as they should. This section is Intended

to introduce the service technician to some of the fundamen

tals of troubleshooting generator problems.

DANGER: RV AND IM TYPE GENERATORS PRO

DUCE EXTREMELY HIGH AND DANGEROUS

VOLTAGES. CONTACT WITH LIVE WIRES AND

TERMINALS MAY RESULT IN HAZARDOUS AND

POSSIBLY FATAL ELECTRICAL SHOCK. ONLY

PERSONNEL WHO HAVE BEEN TRAINED IN THE

SERVICING AND REPAIR OF RV/IM GENERA

TORS SHOULD ATTEMPT TO TROUBLESHOOT,

TEST OR REPAIR SUCH EQUIPMENT.

Tools and Equipment

The generator service technician should have a well

stocked tool box having a good selection of common hand

tools. Such a tool box should be equipped with wrenches in

both english and metric sizes. A selection of nut drivers

(english and metric) is also recommended. In addition to

common hand tools, the following specialized equipment

should be available;

Figure 24. A Typical Frequency Meter

1. Volt-Ohm-Milliammeter or VOM

a. An accurate VOM Is necessary fortesting, adjusting and

troubleshooting.

b. Simply having a VOM is not enough- the technician must

be familiar with electrical circuits, must be able to read

wiring diagrams and electrical schematics, and must be

able to use the VOM effectively.

C. An accurate digital type VOM is recommended.

2. Frequency Meter

a. Frequency meter reads alternating current (AC) fre

quency, in HERTZ or CYCLES PER SECOND.

b. Generator AC output frequency must be known in order

to check and adjust engine-generator operating speed.

See "ROTOR ROTATIONAL SPEECt in this section.

3. Insulation Resistance Tester

a. See Section 1.3, ‘INSULATION RESISTANCE TESTS".

b. This tester will allow the user to test Rotor and Stator

Insulation for breakdown under an applied voltage.

4. Load Bank- will permit a known electrical load to be applied

to the generator, i.e., fortesting and adjustment of the gener

ator under load.

Rotor Rotational Speed

The revolving field (Rotor) is directly connected to the

engine crankshaft and will rotate at the same speed as the

engine. Engine speed is held nearly constant by an engine

governor. Some generator models utilize a constant speed,

MECHANICAL governor; other models may be equipped with

an ELECTRONIC governor. See Part 7, "ENGINE SPEED

CONTROL SYST^Kr.

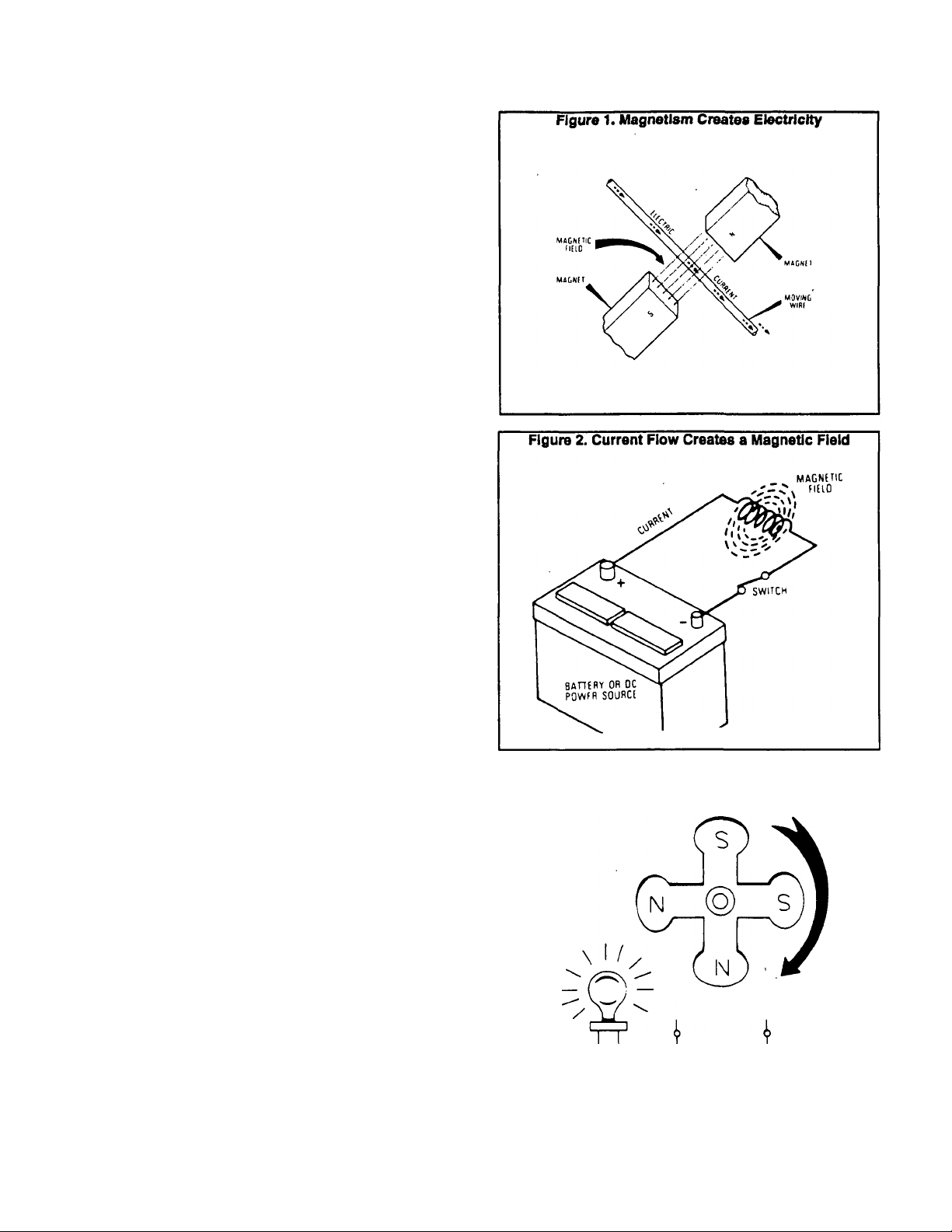

Generators may be equipped with either a 2-pole or a

4-pole Rotor. A 2-poie Rotor has a single North magnetic pole

and a single South magnetic pole. A 4-pole Rotor has two

North magnetic poles and two South magnetic poles. The

following apply to 2 and 4-pole Rotor assemblies:

A. 2-Pole

Figure 25. Typical 2 and 4-Pole Rotors

B. 4-Pole

Page 1.4-1

Page 17

Rotor Rotational Speed (Continued)

1. A 4-Pole Rotor must be operated at 1800 rpm to supply a

60 Hertz AC output frequency: or at 1500 rpm for a 50 Hertz

AC output frequency.

2. A 2-pole Rotor must be operated at 3600 rpm for a 60 Hertz

AC output frequency: or at 3000 rpm for a 50 Hertz frequency.

The following formulas apply to (a) frequency, (b) rpm, and

(c) number of Rotor poles:

FREQUENCY = RPM X NO. OF ROTOR POLES

2x60

RPM o

NO. OF ROTO№ 2 X 60 X FREQUENCY

POLES RPM

2 X 60 X FREQUENCY

NO. OF ROTOR POLES

Relationship of Voltage & Frequency

The generator’s AC voltage regulator mounts a single

adjustable potentiometer, used for adjustment of tne

Regulator’s REFERENCE voltage (see ’EXCITATION S/S-

TEAf on Page 1.1-4). The potentiometer is called simly a

'Voltage Adjust Potentiometer* and is adjusted with the gen

erator running at no-load and at a specific operating speed.

It is important that the engine speed governor be properly

adjusted before the Voltage Adjust Potentiometer setting is

attempted. The no-load AC frequency and voltage settings

should be as follows:

1. Shut the generator engine down.

2. Connect a voltmeter to the generator’s AC output

leads.

3. Disconnect Wires No. 4 and 1 from the Voltage Reg

ulator.

4. Connect a jumper wire from terminal #1 (Wire #15) of

the engine control circuit board to the terminal end of Wire #4

(just disconnected from the Reguiator).

5. Connect a jumper wire from terminal #2 of the engine

control circuit board (Wire #0, ground) and to the terminal end

of Wire #1 Gust disconnected from the Regulator).

6. Start the generator and let It run at no-load (main

breakers open) and at its rated speed.

7. Read the generator’s AC output voltage from the

voltmeter connected In Step 2. Reading should be approxi

mately one-half rated voltage (about 40-60 volts line-to-neutral or 80-120 volts line-to-line).

8. Shut the generator down.

9. Reconnect Wires No. 1 and 4 to the Voltage Regulator.

If voltage reading is normal in Step 7, the Wires #1 and

4 circuit, brushes and slip rings. Rotor and Stator are working

satisfactorily. The problem is In the circuit that Includes (a)

stator excitation windings, (b) thermal protector, (c)excitation

circuit breaker (CB4), (d) Wires 2 and 6, and (e) Voltage

Regulator.

NOTE: Field boost current la available to the Rotor only

while the engine Is cranking. Loss of excitation current

flow to the Rotor will result In a decrease In generator AC

output voltage to a value commensurate with Rotor re

sidual magnetism (about 2 to 7 volts AC),

1. For Units Rated 120/240 Volts at 60 Hertz: Set AC

frequency to 60.5-63.5 Hertz and Voltage to 121-127 volts

AC (line-to-neutral), or 242-254 volts AC (line-to-line).

2. For units rated 110/220 volts at 50 Hertz: Set AC fre

quency to 49-52 Hertz and voltage to 108-112 volts (line-toneutral).

Visuai inspection

Quite often problems that occur in the generator can be

detected by making a thorough visual inspection. Remove

covers and look for any obvious problems. Burned windings,

broken connections, leads, mounting brackets, etc., can usu

ally be Identified. Also look for loose or frayed insulation,

loose or dirty electrical connections, broken wires.

Verify that the generator AC output leads are properly

connected for (a) single voltage outpiut, or (b) dual voltage

output. See 'STATOR AC POWER CONNECTION SV%-

TEMSr on Page 1.1-5.

Check for any foreign objects, loose nuts, bolts, and

electrical connectors. Clear away paper, leaves, snow, build

ing materials, etc., that might be sucked into the generator.

Constant Excitation Test

The generator’s AC output voltage will vary with Rotor

speed, generator design, connected loads, and excitation

current to the Rotor, if the generator speed and excitation

cunenttothe Rotor are known, the no-load AC output voltage

can be measured and compared to the design value. A

problem can be isolated to (a) Stator Excitation (OPE) wind

ings to Voltage Regulator circuit, including the Regulator, or

(b) Voltage Regulator to Rotor circuit, excluding the Regula

tor, or (c) the Stator assembly. Perform the test as follows:

a DC or AC voltage.

The DC voltage most often measured will be battery

voltage (12 volts DC).

When measuring AC voltages, the generator will have to

be running at rated speed and may have some of the protec

tive guárete and covers removed. BE CAREFUL. It is best to

shut the unit down when connecting meters. Use the meter’s

instruction manual to verify its operation and limitations.

Page 1.4-2

Page 18

Alternating current measurements can be taken with a

Measuring Current

'clamp-on* type ammeter. Amperage should never exceed

the nameplate rating when running the intended electrical

load(s).

Resistance of the main stator windings is very low. Some

meters are not able to read such a low resistance and, for that

reason, use of a very sensitive digital type meter is recom

mended. A standanj VOM can be used to check for continuity,

shorts or grounded condition.

Effects of Engine Power

The generator engine must provide adequate power to

operate the generator at rated load. The greater the load

current (amperage) or load watts, the greater the engine

power that is needed. As a general rule, approximately 2

engine horsepower is needed for each 1000 watts (1.0 kW)

of generator power.

If the generator’s wattage/amperage capacity is ex

ceeded, engine power may not be sufficient to handle the

Increased load. The result will be a decrease in engine speed

(rpm) and a corresponding reduction int AC output frequency

and voltage.

A badly worn engine, one that has lost compression, or

one with a mechanical problem may not be able to handle a

load within the generator’s rated capacity. Problems with

generator AC output are often the direct result of an engine

problem, rather than a generator problem.

If engine speed, AC frequency and voltage are normal

when the generator Is running aty no load, but deteriorate

when electrical loads are applied, an underpowered engine

may be the cause of the problem.

Measuring Resistance

Page 1.4-3

Page 19

Section 1.5- TROUBLESHOOTING FLOW CHART

TEST 1-CHECK NO-LOAD

VOLTAGE AND FREQUENCY

VOLTAGE &

FREQUENCY

BOTH GOOD

VOLTAGE &

FREQUENCY

BOTH HIGH

IVQEVOLTAGE LOW,

FREQUENCY

GOOD

VOLTAGE

AND

FREQUENCY

Page 1.5-1

Page 20

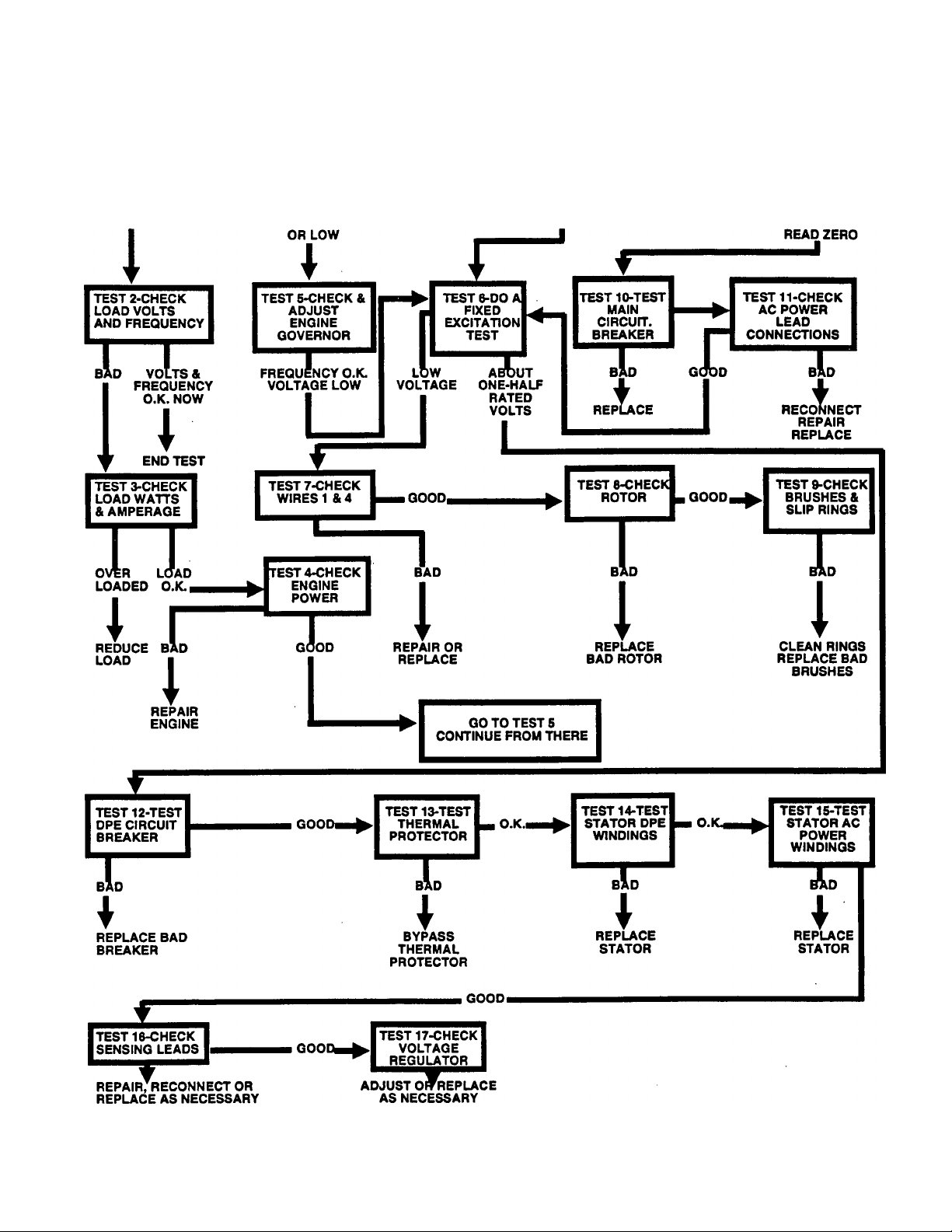

Using the Troubleshooting Flow Chart

When a problem occurs with an RV/IM series generator

set, the first step is to determine exactiy what that problem is.

The nature of the problem can usually be found by checking

the unit’s no-load AC output voltage and frequency. This is

Test 1 in the Flow Chart. A check of the no-load voltage and

frequency will usually end with one of the following results;

1. Voltage and frequency are both good. If this is the case,

the next step is to check voltage and frequency with electrical

load applied.

2. Voltage and frequency are both high or bw, usually an

engine governor problem, I.e., governed speed too high or

too low.

3. Voltage is low, but AC frequency is good. The cause of

this problem can often be found by perfomiing a "Fixed

Excitation" test

4. Voltage and frequency read "zero".

Once the nature of the problem is defined, the cause of

the problem can usually be found by following the explana

tions and arrows in the Flow Chart

Use the'TROUBLESHOOTING FLOWCHART in con

junction with test instructions in Section 1.6, 'TROUBLE

SHOOTING TEST PROCEDURES'.

r-\

Page 1.5-2

Page 21

Section 1.6- TROUBLESHOOTING TEST PROCEDURES

The following numbered tests may be performed in con

Introduction

junction with identically numbered tests in the "TROUBLE

SHOOTING FLOW CHART (Section 1.5). The "FLOW

CHART* has been carefully planned to prevent guesswork

and to locate most common generator problems.

NOTE: Quite often the cause of a problem can be deter

mined by completing a close visual Inspection of the

generator. See "VISUAL INSPECTION" on Page 1.4-2.

Test 1> Check No-Load Voltage and Fre

quency

DISCUSSION:

When a generator problem occurs, the first step Is to

identify the problem. This can usually be accomplished

quickly by checking the no-load AC ouÿut voltage and fre

quency. Once the exact problem has been identified, the

cause of the problem can usually be isolated by continuing

orderly tests as shown in the "TROUBLESHOOTING FLOW

CHART".

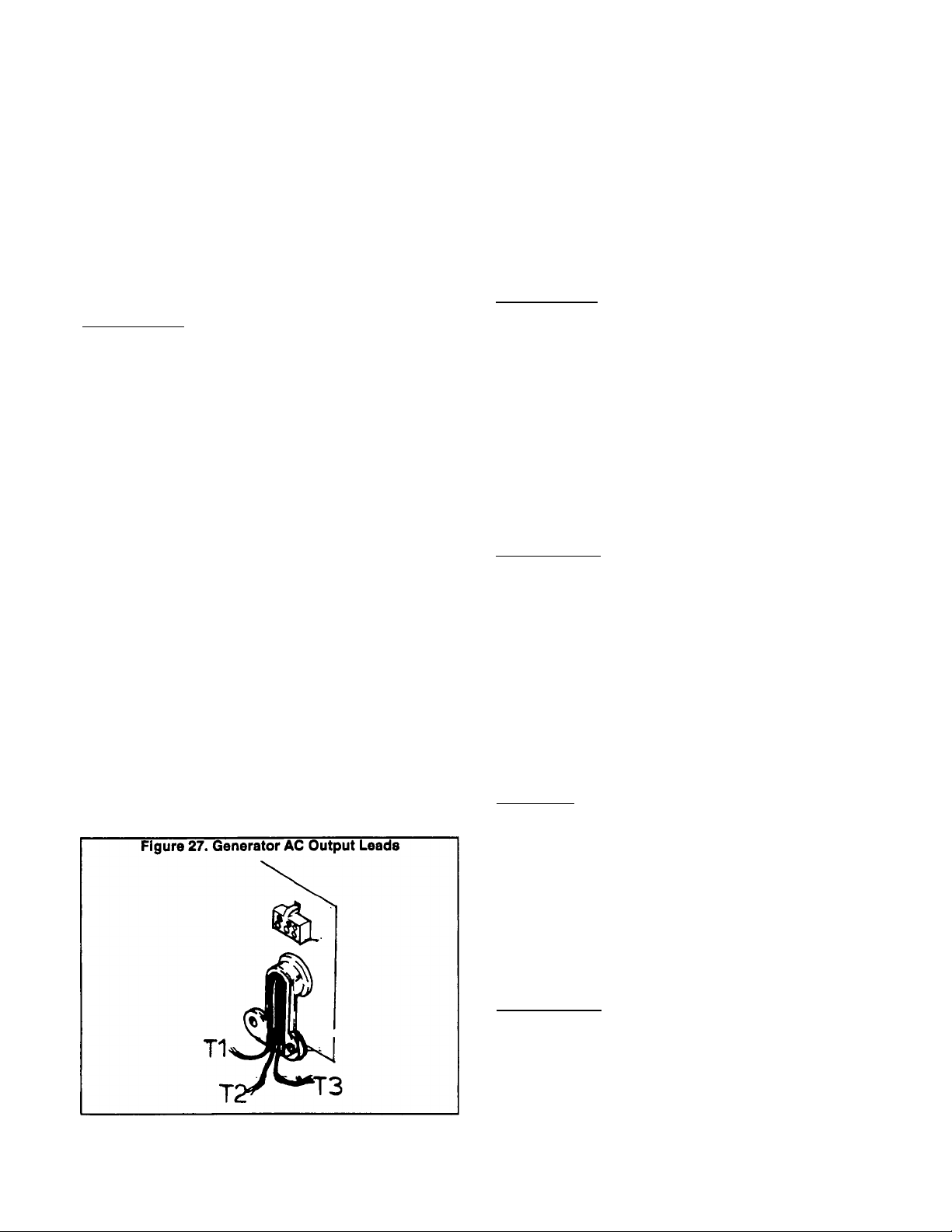

NOTE: You will have to determine whether the AC leads

have been connected for single voltage output only (120

volts, 60 Hertz orilo volts, SO Hertz); or for dual voltage

output (120/240 volts, 60 Hertz or 110/220 volts, 50 Hertz).

See "STATOR AC POWER CONNECTION SYSTEMS" on

Page 1.1-5.

PROCEDURE:

1. Connect an AC voltmeter and AC frequency meter across

the generator’s AC output leads. Open main circuit breaker.

a. If connected for single voltage AC output, connect the

meters across leads T1 and 12.

b. If connected for dual voltage output, connect meters

across leads T1 and 12 or 12 and T3 for a 120 volts, 60

Hertz (or 110 volts, 50 hertz) reading. For a 240 volts, 60

Hertz (or 220 volts, 50 hertz) reading, connect meter test

leads across generator leads T1 andT3.

2. Start the generator engine, let It stabilize and wami up.

3. Read the AC output voltage and frequency. Readings

should be as follows:

a. For units rated 120/240 volts, 60 hertz; readings should

be 121 -126 volts at 61 -63 Hertz; or 242-252 volts at 61 -63

Hertz.

b. For units rated 110/220 volts, 50 hertz; readings should

be 111 -113 volts at 51 -53 Hertz; or 222-226 volts at 51 -53

Hertz.

RESULTS:

1. If the no-load voltage and frequency are good, go to Test

2.

2. If no-load voltage and frequency are both high or low, go

to Test 5.

3. If frequency reads good but voltage Is low, go to Test 6.

4. If voltage and frequency read "zero", go to Test 1.0.

Test 2- Check Load Voltage and Fre

quency

DISCUSSION:

Generator problems are sometimes caused by exceed

ing the wattage/amperage capacity of the unit. What appears

to be a generator problem may, in fact, be caused by an

engine that has lost power. The following facts apply:

D Quite often, the maximum wattage that can be supplied

by a generator Is limited by available engine power.

When connected loads exceed a critical point, engine

speed will droop. With a reduction in engine speed will

come a voltage and frequency loss.

O It is possible that an engine can lose power to the extent

that even normal rated generator output power can be

achieved. Engine speed, frequency and voltage can then

droop before a unit's rated maximum capacity has been

reached.

PROCEDURE:

If no-load AC output voltage and frequency were within

limits, but operational problems occur when electrical loads

are applied, check the output voltage and frequency under

load as follows:

1. Connect an AC voltmeter and frequency meter across the

generator’s AC output leads. Close the main circuit breaker.

2. Start the generator, let it stabilize and warm up.

3. Apply an electrical load to the generator equal to its rated

maximum wattage/amperage capacity.

4. Read the voltage and frequency.

a. Units rated 120/240 volts, 60 Hertz: Readings should

be at least 116 volts and 58 Hertz (or higher).

b. Units rated 110/220 Volts, 50 Hertz: Readings should

be at least 107 volts, 48 Hertz (or greater).

RESULTS:

1. If load voltage and frequency are below limits, go to Test

3.

2. If voltage and frequency are good, discontinue tests.

Test 3- Check Load Watts and Amperes

DISCUSSION:

If the unit's AC output frequency and voltage drop below

limits when electrical loading is applied, it is possible that the

rated capacity of the generator has been exceeded.

PROCEDURE:

Add up wattage ratings of all electrical loads applied to

the generator at one time. This total should not be greater

than the unit’s rated maximum wattage capacity. If desired, a

clamp-on ammeter may be used to measure load current. The

unit’s rated maximum amperage capacity should not be ex

ceeded.

Page 1.6-1

Page 22

Test 3- Check Load Watts and Amperes

(Continued)

NOTE; The best way to check load wattage and amperage

la to use a load bank. A load bank will allow the operator

to apply a known wattage/amperage load to the generator

and win permit voltage, frequency and amperage to be

read directly from the load bank.

RESULTS;

1. If the generator Is overloaded, reduce the load to the unit’s

rated capacity.

a. If voltage and frequency are excessively low at the unit’s

rated capacity or less, go on to Test 4.

b. If voltage and frequency are acceptable at the unit’s

rated capacity, discontinue tests.

2. If the load Is within the unit’s rated capacity, but load

voltage and frequency are excessively low, go on to Test 4.

Test 4- Check Engine Power

DISCUSSION:

If excessive rpm and frequency droop occurs when

electrical loads are applied, the engine may be underpowered

due to a malfunction.

PROCEDURE:

Check the engine for (a) adequate air flow, (b) clogged

air cleaner, (c) incorrect timing, (d) mechanical failure, etc.

RESULTS:

1. If engine problems are found, repair the engine as neces

sary.

2. If engine checks good, go on to Test 5.

Test 5- Check & Adjust Engine Governor

DISCUSSION:

If engine speed (and frequency) droop excessively under

load, the engine governor may require adjustment

PROCEDURE:

Refer to Part 7, "ENGINESPEED CONTROL SYSTEM-.

Governor adjustment procedures for both the mechanical and

electronic type governors can be found in Part 7.

RESULTS:

1. It, after governor adjustment, voltage and frequency output

at no-load and under load are good, discontinue tests.

2. If, after governor adjustment, frequency Is good, but volt

age is excessively low, go on to Test 6.

Test 6- Do a Fixed Excitation Test

DISCUSSION:

See "CONSTANTEXCITATION TEST on Page 1.4-2.

PROCEDURE:

’TEST" on Page 1.4-2.

RESULTS:

1. If voltage is excessively low, go to Test 7.

2. If about 1/2 rated volts is indicated, go to Test 12.

Test 7- Check Wires 1 and 4

DISCUSSION:

the fixed or constant excitation test (Test 6) consisted

of applying battery direct current to the Rotor windings (12

volts DC). With the normal excitation circuit disconnected,

application of battery current should result In approximately

one-half rated voltage output (about 60-80 volts AC).

If batteiy current is applied and AC output voltage te

excessively low, a problem exists in Wires 1 and 4 from the

Regulator, or the brushes and slip rings, or the Rotor or stator

windings.

If the application of battery current results in an AC output

of about one-half rated volts, but AC output voltage is low

during normal operation, a problem exists in the stator exci

tation (DPE) windings, in the excitation circuit between the

stator DPE windings and the Regulator, or in the Regulator

itself.

PROCEDURE:

1. Visually inspect Wires 1 and 4, between the Voltage

Regulator and the brushes.

2. Use a VOM to test Wire 1 (between the brushes and

Regulator) for continuity.

3. Check Wire 4 (between the brushes and Regulator) for

continuity.

4. Check that Wires No. 1 and 4 are properly connected at

the Regulator and at the brushes.

RESULTS:

1. Repair, replace or reconnect wires 1 and 4 as necessary.

2. If Wires 1 and 4 are good, go to Test 8.

Test 8- Check Rotor

DISCUSSION:

Problems will be encountered if the Rotor Is (a) open, (b)

shorted, or (c) grounded. This test will determine If any of

these problems exist in the Rotor.

PROCEDURE:

1. If Rotor Is installed, remove the bearing carrier cover to

gain access to the Rotor brushes and slip rings.

2. Disconnedct Wires 1 and 4 from the brushes, to prevent

Interaction.

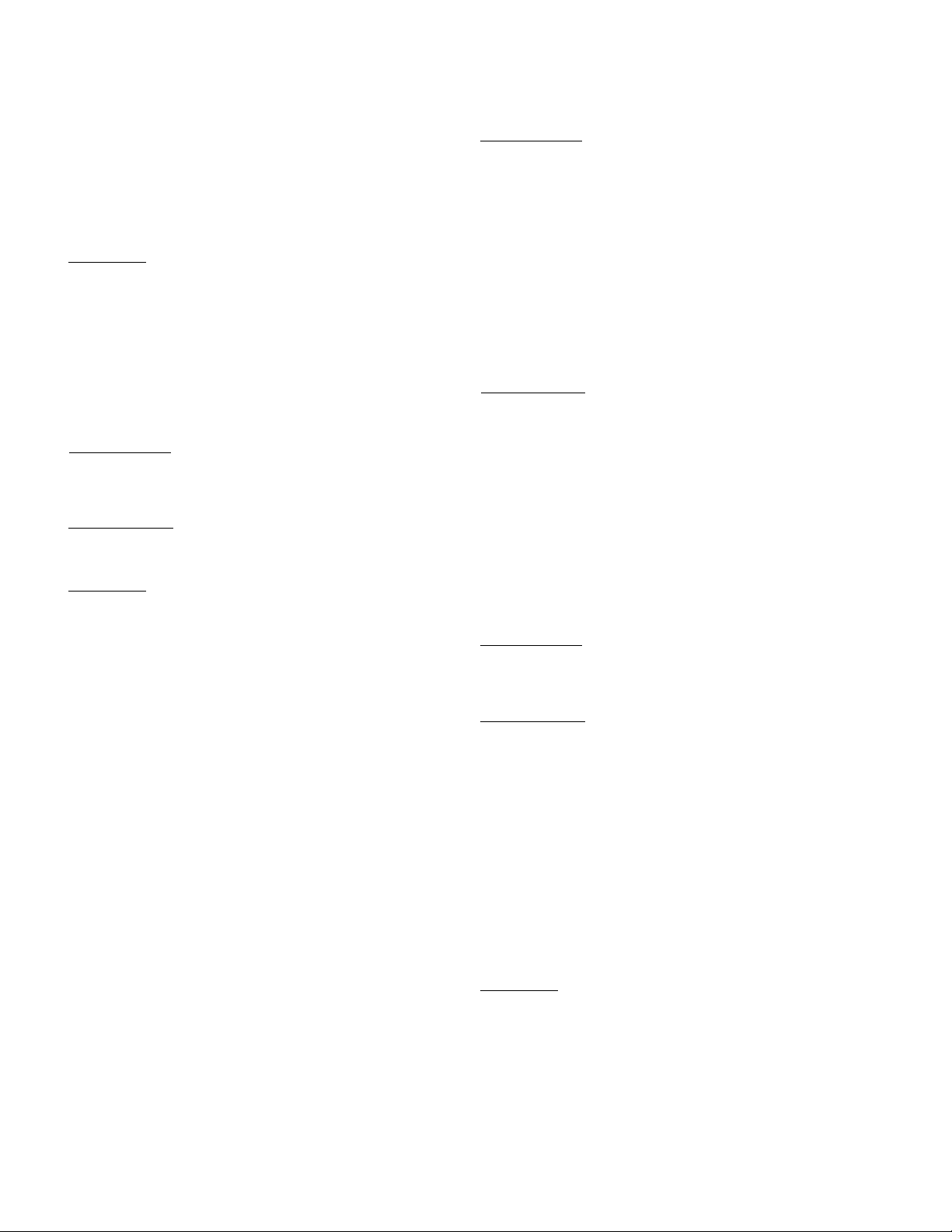

3. Connect the positive test lead of an ohmmeter to the

positive slip ring, the common test lead to the negative slip

ring. The positive slip ring Is the one nearest the Rotor bearing

(see Figure 28). The meter should indicate the resistance of

the Rotor windings, approximately 8.5 ohms (plus or minus

10%) for both 8 and 10 kW models.

4. Set a VOM to a very high resistance scale, such as

■Rxl 0,000" or "RxlK". Zero the meter. Connect the positive

VOM test lead to the positive slip ring. Connect the negative

VOM test lead to a clean frame ground, such as the Rotor

shaft. The meter should read "infinity".

RESULTS:

1. In Step 3, a very high resistance or "infinity" Indicates an

open or partially open condition. Replace the Rotor.

2. In Step 3, a very low resistance indicates a shorted or

groundea condition. Replace the Rotor.

3. In Step 4, any reading other than "infinity" Indicates a

groundea condition. Replace the Rotor.

4. If all Rotor readings are good, go to Test 9.

Page 1.6-2

Page 23

Figure 28. Checking Rotor Resistance

Test 9> Check Brushes and Slip Rings

DISCUSSION:

if the fixed (constant) excitation test did not result in an

AC output voitage of approximateiy one-haif rated voits, one

possibie cause of the probiem might be defective brushes

and/or slip rings.

Test 10- Test Main Circuit Breaker

DISCUSSION:

■ If AC output voltage and frequency are "zero", one pos

sible cause of the problem is an open or failed main circuit

breaker.

PROCEDURE:

Make sure the main circuit breaker Is set to Its ’Closed’

position, if the breaker Is closed, check it for continuity.

RESULTS:

1. Replace main circuit breaker. If It Is defective.

2. If main breaker is good, go to Test 11.

Figure 30. Main Circuit Breaker (Typical)

PROCEDURE:

Remove Wires 1 and 4 from the brushes. Then, remove

the brush holders from the rear bearing carrier. Inspect the

brushes and brush holders. Replace, It cracked, damaged,

worn excessively, etc.

Inspect the slip rings. If they are dull or tarnished, they

can be cleaned with fine sandpaper. DO NOT USE ANY

METALLIC GRIT TO CLEAN SLIP RINGS. Use low pressure

air (25 psi or less) to blow away cleaning residue.

Reassemble brushes and brush holders to rear bearing

carrier. Make sure brushes are properly seated in brush

holders and are contacting the slip rings properly. Reconnect

Wires 1 and 4 to brushes. Rotate the Rotor several times to

seat the brushes against the slip rings.

RESULTS:

Clean slip rings, replace bad brushes or brush holder(s)

as necessary.

Test 11- Check AC Power Lead Connec

tions

DISCUSSION:

The stator's AC output leads must be property connected

as outlined under ‘STATOR AC POWER CONNECTION

SYSTEMSr (Page 1.1-5).

PROCEDURE:

Check that Stator AC output leads 11,22,33 and 44 (as

well as T1, T2 and T3) are property connected as shown In

the appropriate wiring diagram/schematic. Reconnect wires

as necessary.

RESULTS:

Reconnect, repair or replace stator AC output leads as

necessary.

Test 12- Test DPE Circuit Breaker

DISCUSSION:

The excitation (DPE) circuit breaker is connected in

series with lead 2 (or 2A) between the stator excitation (DPE)

windings and the voltage regulator. If the breaker should

open, excitation winding AC output to the Regulator will be

lost and AC ou^ut from the generator will drop to a voltage

that is commensurate with the Rotor’s residual magnetism

(about 2 to 7 volts AC). Application of fixed excitation current

p est 6) will result in an AC output voltage equal to approxi

mately one-half rated voltage.

Page 1.6-3

Page 24

Test 12< Test DPE Circuit Breaker (Con

tinued)

PROCEDURE:

1. With the generator shut down, disconnect the leads from

the two breaker terminals, to prevent interaction. Then,

connect the test leads of a volt-ohm-milliammeter (VOM)

across the two circuit breaker terminals. The meter should

read continuity or a very small resistance.

a. If meter indicates 'continuity' or a small resistance, go

to Step 2.

b. If the meter reads 'infinity' replace the circuit breaker.

2. Reconnect the two leads to the circuit breaker terminals.

3. Start the generator engine.

4. Check the generator's AC output voltage (see Test 1).

a. if AC output voltage is excessively low, go to Step 5.

b. If AC output voltage is normal, discontinue tests.

5. Connect a jumper wire across the two terminals of the

excitation (DPE) circuit breaker. Again, check the unit’s AC

output voltage.

RESULTS:

1. In Step 1, if the meter reads 'infinity' it should be replaced.

2. If AC output voltage was excessively low in Step 4, but

normal in Step 5, replace the excitation (DPE) circuit breaker.

RESULTS:

1. If the VOM indicated excitation winding resistance in Step

4, but read 'infinity' in Step 6, the thermal protector will have

to be bypassed as follows:

a. Cut Wire 2 as close as possible to the end of Wire 5.

b. Strip the Insulation from the end of Wire 2 that goes to

the excitation circuit breaker.

c. Strip the iunsulation from the end of Wire 5.

d. Connect the stripped ends of Wire 2 and 5, retain with

the wire nut.

2. If the meter indicated excitation winding resistance In both

Steps 4 and 5, go to Test 14.

Figure 32. Thermal Protector In the Circuit

Test 13- Test Thermal Protector

DISCUSSION:

Also see 'THERMAL PROTECTOR' on Page 1.1-4. A

thermal protector that has failed open will cause the same

effects as an excitation circuit breaker that has failed open.

PROCEDURE:

1. Disconnect lead 2 from the excitation circuit breaker.

2. Disconnect lead 6 from the Voltage Regulator.

3. Locate lead 5. This lead is brought out of the Stator and is

unattached. A wire nut covers its end.

4. Connect the test leads of a VOM across leads 5 and 6. The

meter should read a small resistance (the resistance of the

Stator excitation winding).

5. Now, connect the VOM test leads across leads 2 and 6.

Again, the resistance of the Stator excitation windings shouid

be indicated (about 0.73 ohm for 10 kW units; 1.00 ohm for 8

kW units).

A. Pictorial

Figure 33. Thermal Protector Bypassed

B. Schematic

CXCrTATtON

rr*T)ON I

^ ^ WINDINO

-.-t

ÓO

TO EXCrTATION

2A

A. Pictorial

Test 14- Test Stator DPE Windings

DISCUSSION:

An open condition in the stator excitation windings wiii

result in loss of excitation output to the Voltage Regulator.

The Regulator will then shut down and generator AC output

voltage will drop to a value commensurate with Rotor residuai

magnetism (about 2-7 volts).

A grounded or shorted condition will also result in prob

lems with generator AC output. This test will test the Stator

excitation windings for (a) open condition, and (b) for a

grounded condition.

ClftClHT BBBAKER

B. Schematic

Page 1.6-4

Page 25

NOTE: Before attempting to test the Stator excitation

winding, be sure the thermal protector has not failed

open. See Teat 13.

PR^OCEDURE:

1. Disconnect Wire 2 from the excitation circuit breaker (CB4).

2. Disconnect Wire 6 from the Voltage Regulator.

3. Use a VOM to test the resistance of the excitation windings.

Connect the VOM test leads across leads 2 and 6. The VOM

should indicate the resistance of the excitation windings.

a. For 8 kW units, reading should be approximately 1.00

ohm (plus or minus 10%).

b. For 10 kW units, resistance should be approximately

0.73 ohm (plus or minus 10%).

4. Now, set the VOM to a high resistance scale such as

"Rxl 0,000’ or *Rx1 K’. Zero the meter. Connect one VOM test

lead to Wire 6, the other test iead to a clean frame ground on

the Stator. The meter should read 'Infinity'.

RESULTS:

1. If stator excitation windings fall the test, replace the Stator

assembly.

2. If excitation windings check good, go to Test 15.

Test 15- Test Stator AC Power Windings

DISCUSSION:

An open or shorted condition in the Stator will adversely

affect generator AC voltage output. This test will check the

AC power windings for (a) open condition, (b) grounded

condition, and (c) short between parallel windings.

PR^OCEDURE:

1. Disconnect and isolate Stator leads 11,22,33 and 44. Also

disconnect and isolate Stator leads 5 and 6.

2. Set a VOM to Its 'Rxl' scale and zero the meter.

3. Connect the VOM test leads across stator leads 11 and

22.

a. For 8 kW units, the meter should read approximately

0.21 ohm.

b. For 10 kW units, the VOM should indicate approximately

0.14 ohm.

NOTE: The actual realatance will vary slightly with tem

perature, with a nominal variation as much as plus or

mlnua 10 percent.

4. Connect the VOM test leads across stator leads 33 and 44.

Resistance readings should be the same as In Step 3(a) and

3(b).

5. Now, set the VOM to a high resistance scale, such as

’Rx10,000' or 'RxlK'. Zero the meter. Connect one meter

test lead to stator lead 11, the other test lead to stator lead

33.

a. The meter should read 'infinity'.

b. Any reading other than 'infinity' Indicates a short be

tween parallel windings.

6. With VOM still set for a high resistance, connect one VOM

test lead to stator lead 11, the other test lead to a clean frame

ground on the stator. Repeat the test with one test lead

attached to stator lead 33 and the other connected to a clean

frame ground on the stator.

a. The VOM should read '1011011/.

b. Any reading other than 'Infinity' Indicates a grounded

condition.

7. With the VOM still set for a high resistance, connect one

VOM test lead to stator lead 11, the other to stator lead 5.

Repeat the test with one VOM test lead connected to stator

lead 33, the other to stator lead 5.

a. In both cases, the meter should read 'Infinity'.

b. Any reading other than 'infinity' Indicates a short be

tween windings.

RESULTS:

1. If any reading is bad, replace the stator assembly.

2. If stator checks good, go to Test 16.

Test 16- Check Sensing Leads

DISCUSSION:

The Voltage Regulator must sense ACTUAL AC power

winding voltage. Itr must then electronically 'compare' the

ACTUAL voltage to a REFERENCE voltage that is preset In

the Regulator. The Regulator acts to maintain an actual

voltage that is the same as the reference voltage by regulat

ing excitation current flow to the Rotor.

If ACTUAL voltage sensing signals to the Regulator

become lost for any reason, the normal reaction of most

Regulators would be to think' that ACTUAL voltage Is too

low. The Regulator would then Increase excitation current

flow to the Rotor in an attempt to increase the ACTUAL

voltage. That is, the Regulator and Rotor would go to a 'Full

Field''^ condition and the generator’s AC output vdtage would

go to a very high maximum value.

However, the Voltage Regulator used on RV/IM models

is equipped with a 'sensing loss cutout' feature. That is, when

loss of sensing signals occurs, the Voltage Regulator will shut

down. When the Regulator shuts down, a complete loss of

excitation current flow to the Rotor will occur. The actual AC

output voltage will then drop dramatically to a value commen

surate with Rotor residual magnetism (about 2 to 7 volts AC).

PROCEDURE:

1. With the generator running, observe the red LED (light

emitting diode) on the AC voltage regulator. If sensing voltage

is available to the regulator, the light should be ON.

a. if the light is OUT, complete Step 2 below.

b. If the light is ON, go to Test 17.

2. Connect an accurate AC voltmeter across the Voltage

Regulator sensing terminals (leads 11 and 22). The meter

should Indicate line-to-neutrai voltage. If not, complete the

following:

a. Carefully Inspect sensina leads 11 and 22, between the

engine control circuit board and the Voltage Regulator.

b. Inspect leads 11 and 22 between the engine control

circuit board and the AC connection panel.

c. Use a VOM to check sensing leads 11 and 22 for an

open or shorted condition.

RESULTS:

1. Reconnect, repair or replace any damaged, open, shorted

or defective sensing leads.

2. If sensing leads are good, go to Test 17.

Test 17- Check Voltage Regulator

DISCUSSION:

The Voltage Regulator Is discussed under Test 16 above, as

well as on Page 1.1-4. The Regulator Is equipped with two

safety features, as follows:

Page 1.6<^

Page 26

Test 17- Check Voltage Regulator (Con

tinued)

1. Sensing loss shutdown- if sensing is not availabie to the

Regulator (sensing leads 11 and 22), the Regulator will shut

down.

a. With the Regulator shut down, loss of regulated excita

tion current to the Rotor will occur.

b. The generator’s AC output voltage will drop to a value

commensurate with Rotor residual magnetism (approxi

mately 2-7 volts AC).

c. The red LED (light emitting diode) on the Regulator is a

sensing indicator. The light will go OUT when sensing

signals to the Regulator (wires 11 and 22) are not avail

able. It should remain ON during operation, indicating that

sensing voltage is available.

2. Voltage limiting- maximum AC output voltage is limited to

a maximum of approximately 140-145 volts AC (llne-to-neutral).

PROCEDURE:

If a zero or low AC output voltage condition exists and

you have completed all previous tests Indicated in the Trou

bleshooting Flow Chart", you might try adjusting the Voltage

Regulator. If attempts to adjust the Regulator do not produce

positive results, replace the Regulator. Then, adjust the

Regulator and test generator operation.

Page 1.6-6

Page 27

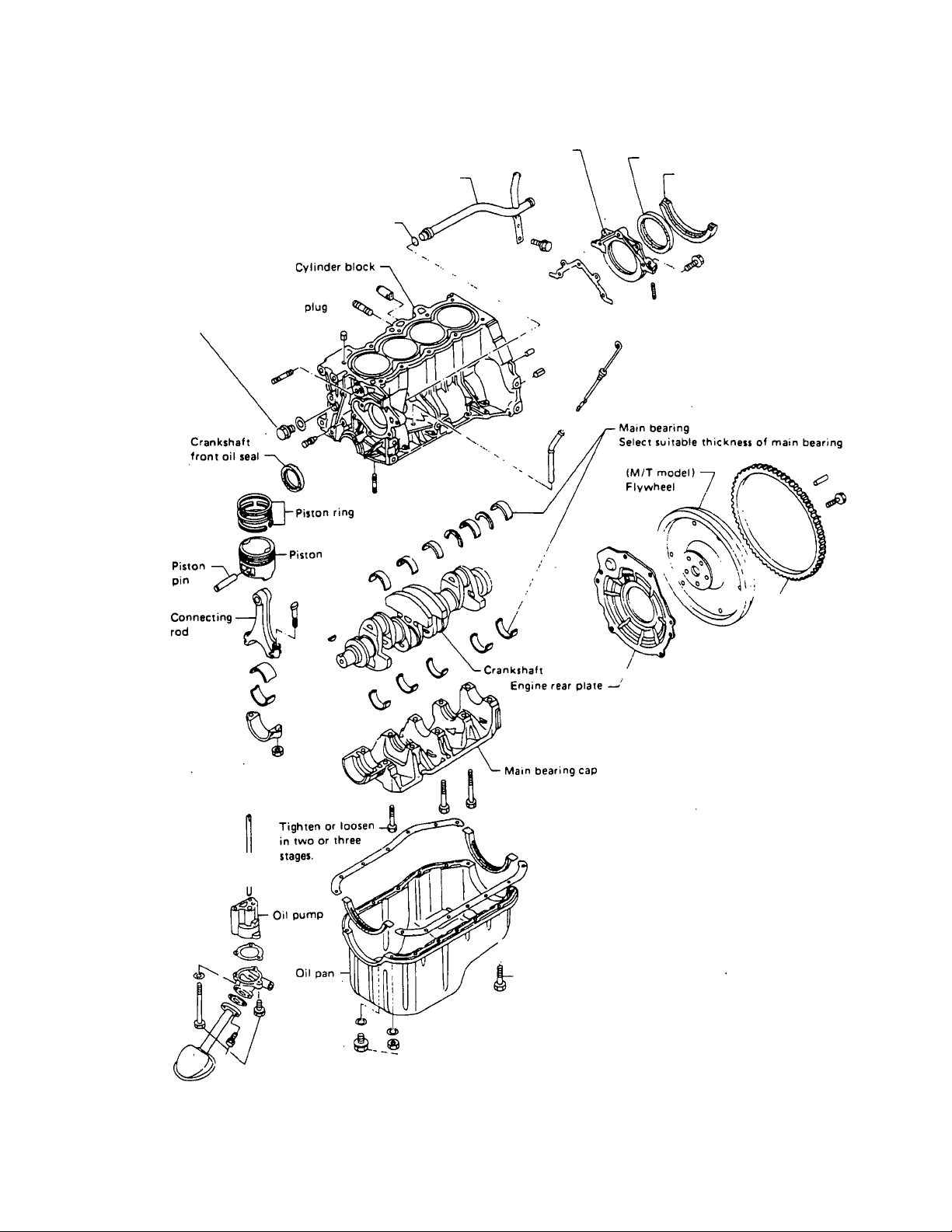

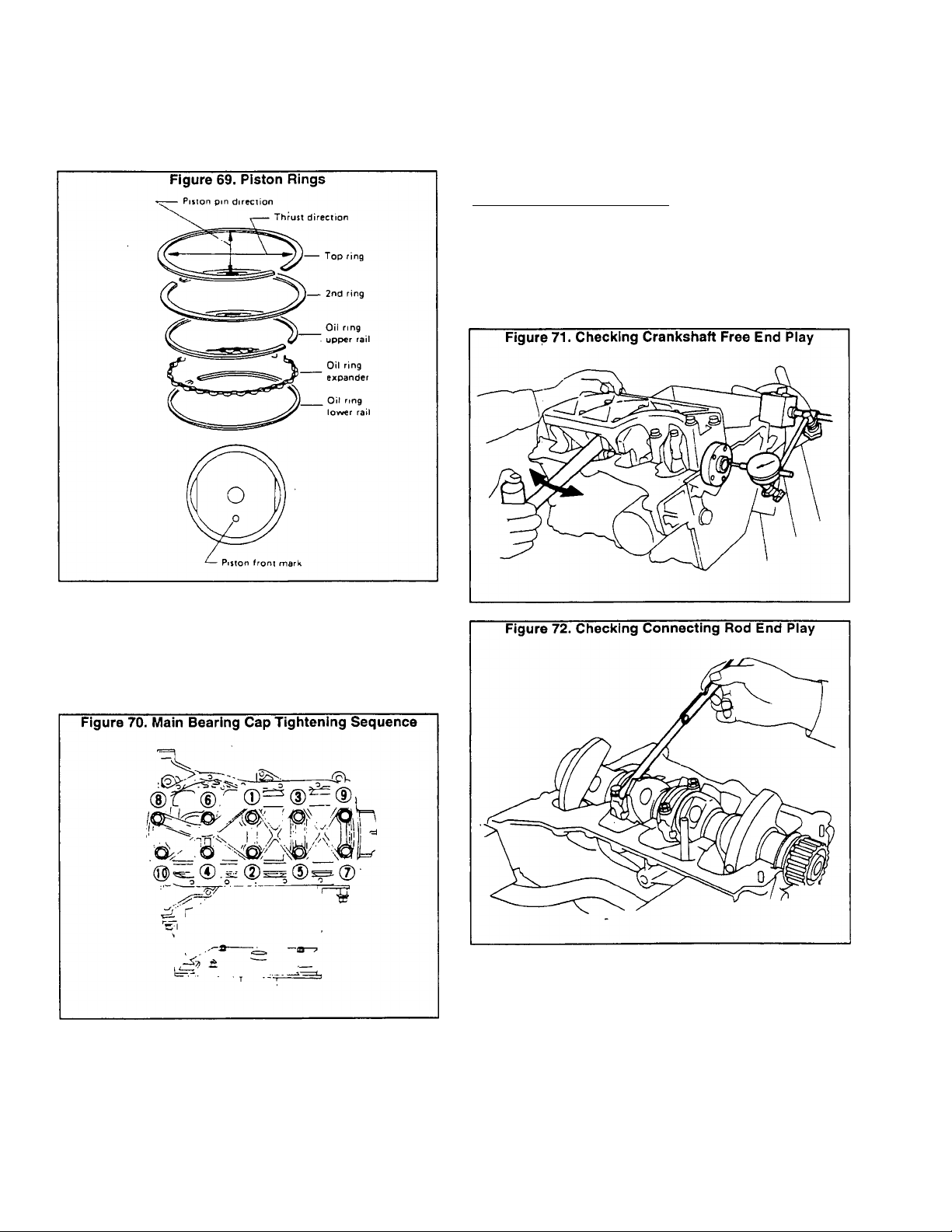

Part 2

ENGINE

MECHANICAL

NP and IM Series

RECREATIONAL

VEHICLE &

INDUSTRIAL

MOBILE

AC GENERATORS

Liquid Cooled 1.2 Liter

Gas Engine Models

SECTION

2.1

2.2

2.3

2.4

2.5

2.6

TABLE OF CONTENTS

TITLE

Basic Engine Mechanical

Timing Belt

Cylinder Head

Oil Pan and Oil Pump

Oil Seal Replacement

Engine Overhaul

Page 28

Section 2.1- BASIC ENGINE MECHANICAL

This section covers some of the basic engine servicing

Introduction

tasks. Included In the Section are commonly used tightening

procedures for cylinder head bolts, manifold nuts and carbu

retor bolts. Also covered are valve clearance adjustment and

drive belt checking procedures.

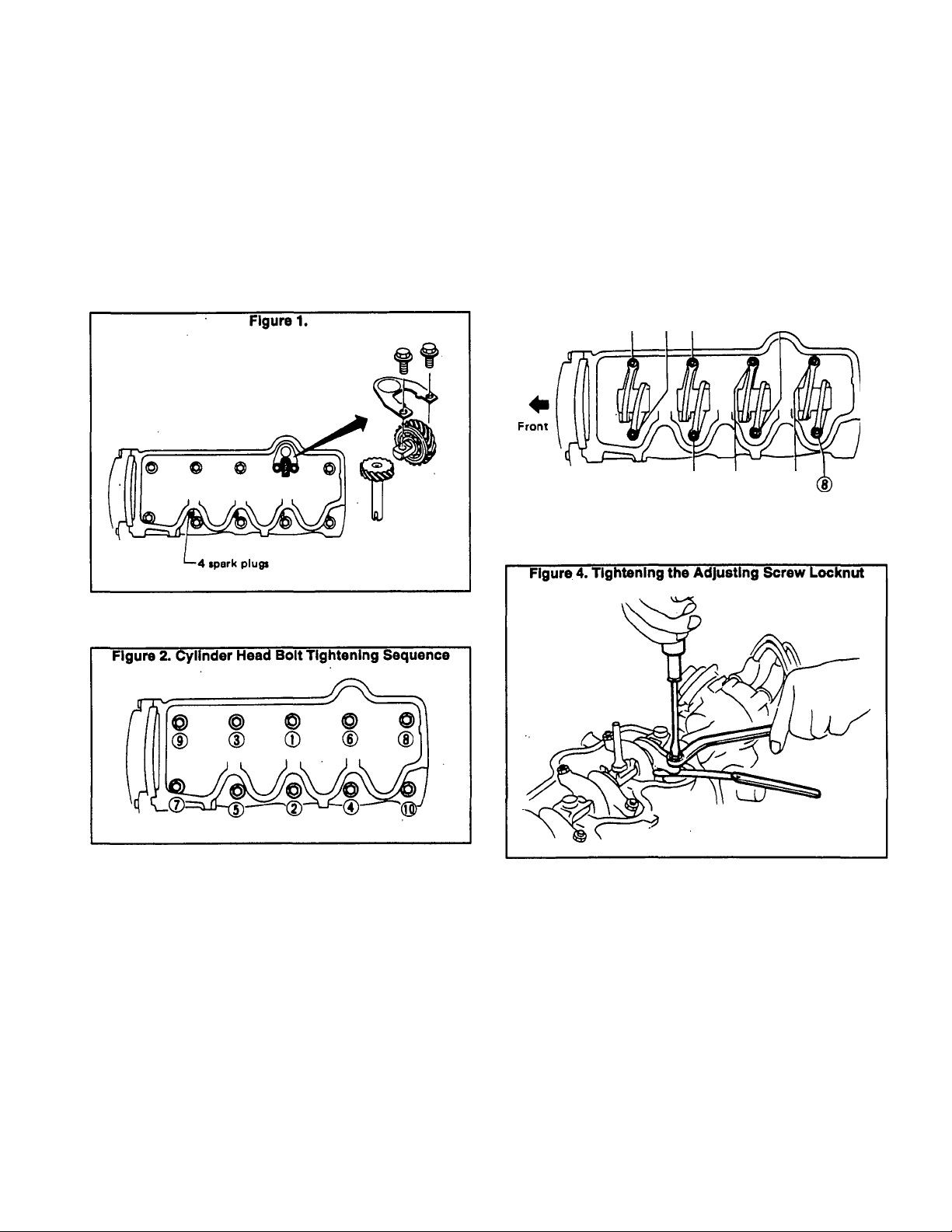

Tightening Cylinder Head Boits

RetIghten cylinder head bolts while the engine Is cold, at

approximately 68* F. (20* C.). Tighten the bolts as follows:

1. Remove all spark plugs, oil pump drive gears, retainer and

bolts (Figure 1).

1. Set No. 1 cylinder at top dead center (TDC) of Its compres

sion stroke. Then, adjust valve clearance 1,2,3 and 6.

2. Set No. 4 cylinder at top dead center (TDC) of its compres

sion stroke and adjust valve clearance 4, 5, 7 and 8.

3. Set valve clearance as follows:

VALVE CLEARANCE HOT

INTAKE s 0.010 Inch (0.25mm)

EXHAUST = 0.012 Inch (0.30mm)

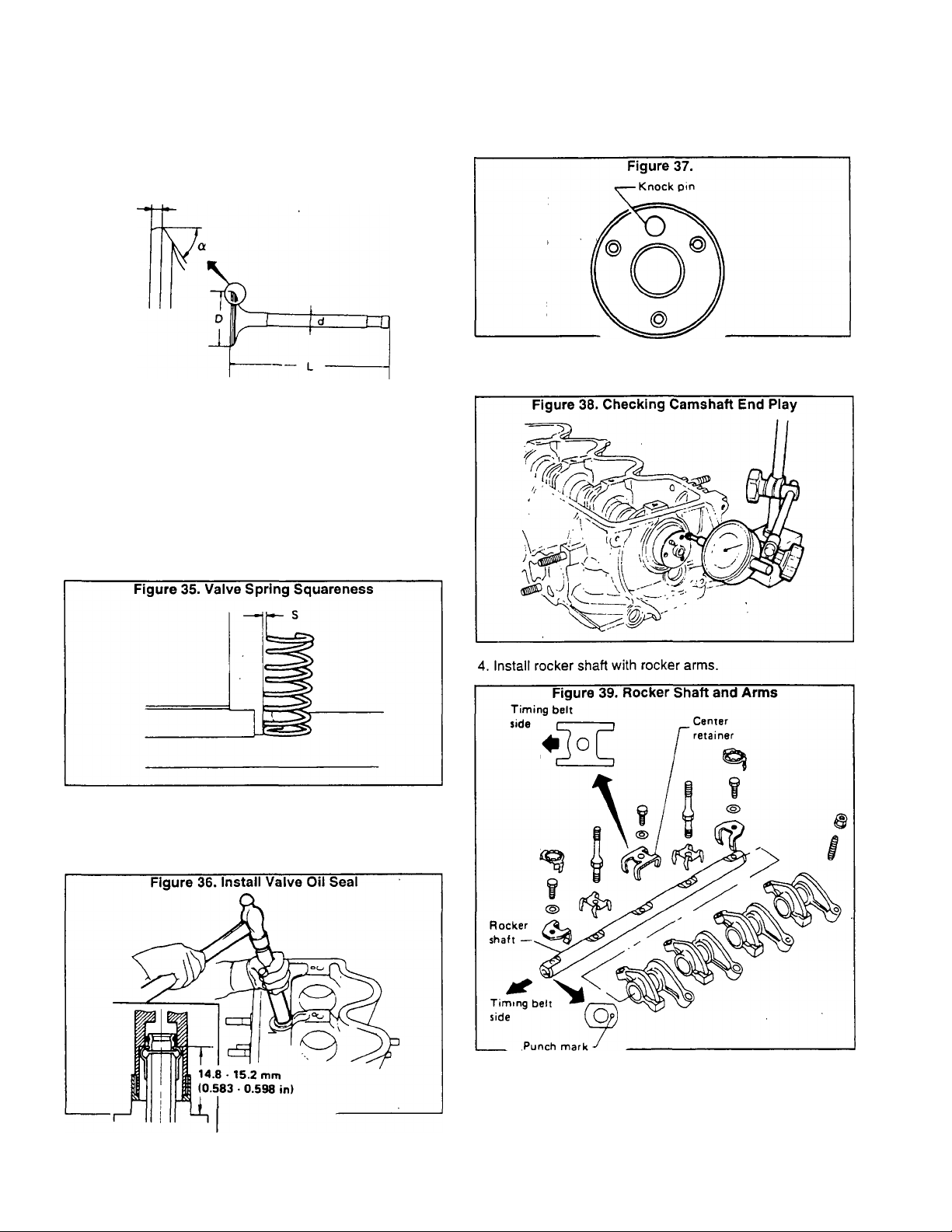

Figure 3. Valve Clearance Adjustments

© (2) (?) (6)

(i) d) (z)

4. When valve clearances are properly set, tighten the adjust

ing screw locknut to 8-11 foot-pounds (11-15 N-m).

2. Tighten bolts to 47-51 foot-pounds (64-69 N-m) in the

sequence shown below.

Tighten Manifoid, Exhaust Manifoid and

Carburetor Fasteners

INTAKE MANIFOLD NUTS:

Tighten to 12-15 foot-pounds (16-21 N-m).

EXHAUST MANIFOLD NUTS:

Tighten to 12-15 foot-pounds (16-21 N-m).

CARBURETOR BOLTS:

Tighten to 4.3-5.8 foot-pounds (6-8 N-m).

Adjusting Vaive Clearance

Adjust valves while engine is warm, but not running, as

foltows:

Inspect drive belts for cracks, fraying, wear, ollllness.

Checking Drive Beits

Replace, if necessary. The belts should not touch the bottom

of the pulley groove. To check belt tension, apply a force of

approximately 22 pounds (10 kg) midway between pulleys.

Belt deflection should be as follows:

NEW BELT a 0.59^).75 inch (15-19m)

USED BELTaO.71-0.87 inch (18-22mm)

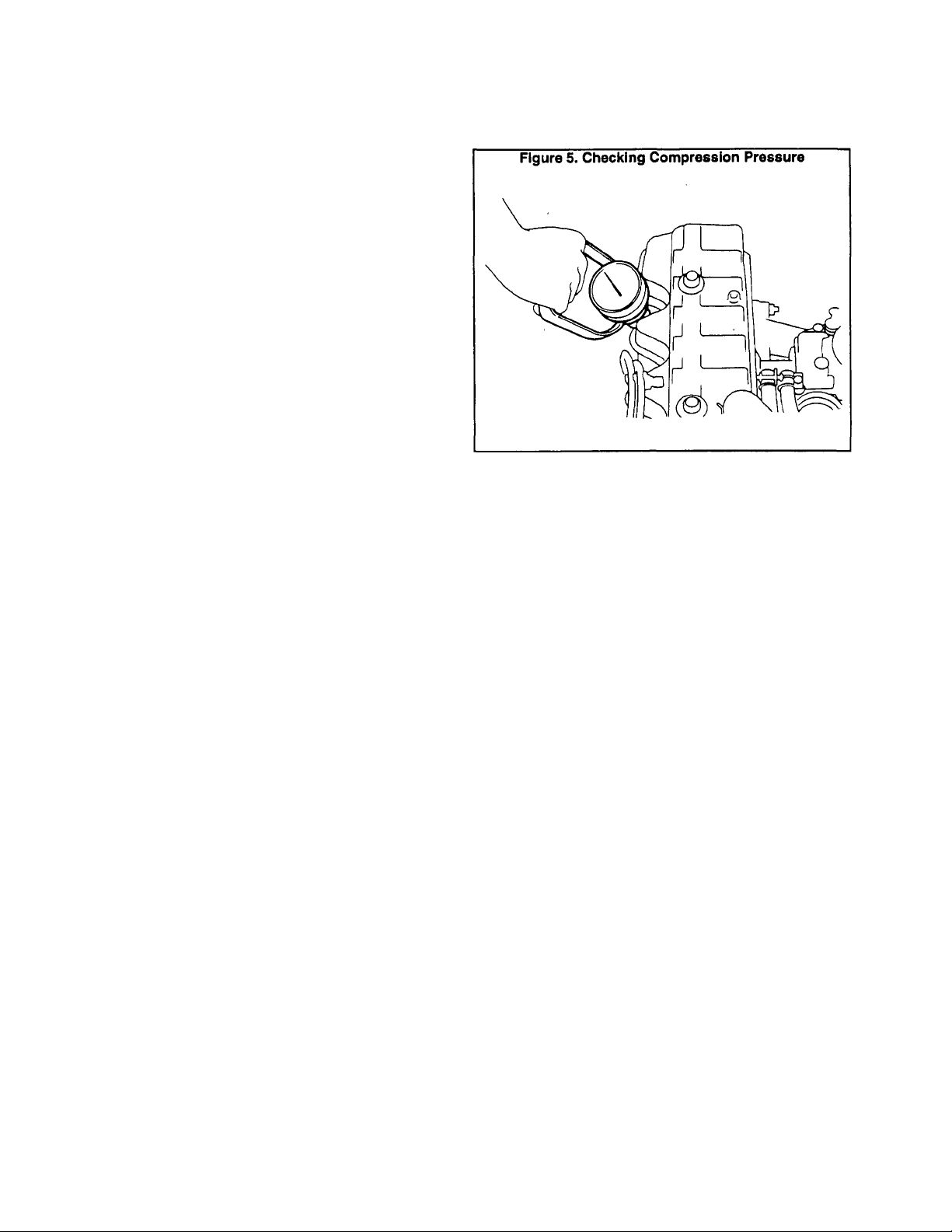

Measuring Compression Pressure

Warm up the engine. Then, shut down and remove ail spark

plugs. Use a standard automotive type compression gauge.

Hold the throttle and choke valves on carburetor wide open.

Page 2.1-1

Page 29

Measuring Compression Pressure (Continued)

then crank the engine and read the compression pres

sure. The pressure reading shouid be as follows:

^TANDAR^^^9278MiT5kg7clT?)at35^^

MINIMUM n 164 psi (11.5 kg/cm^) at 350 rpm

DIFFERENCE BETWEEN CYLINDERS SHOULD NOT

EXCEED 14 PSI (1.0 kg/cm^)

If the compression reading is low in any cylinder, pour a

small amount of clean engine oil into the cylinders through

the spark plug opening. Then, retest compression and eval

uate as follows:

D If compression pressure increased after adding the oil,

check for worn or damaged piston rings or worn cylinder

walls.

n If pressure did NOT increase after adding oil, valve(s)

may be sticking or seating improperly.

D If compression in any two adjacent cylinders is low and

adding oil did not increase compression, check for a

leaking head gasket

Page 2.1-2

Page 30

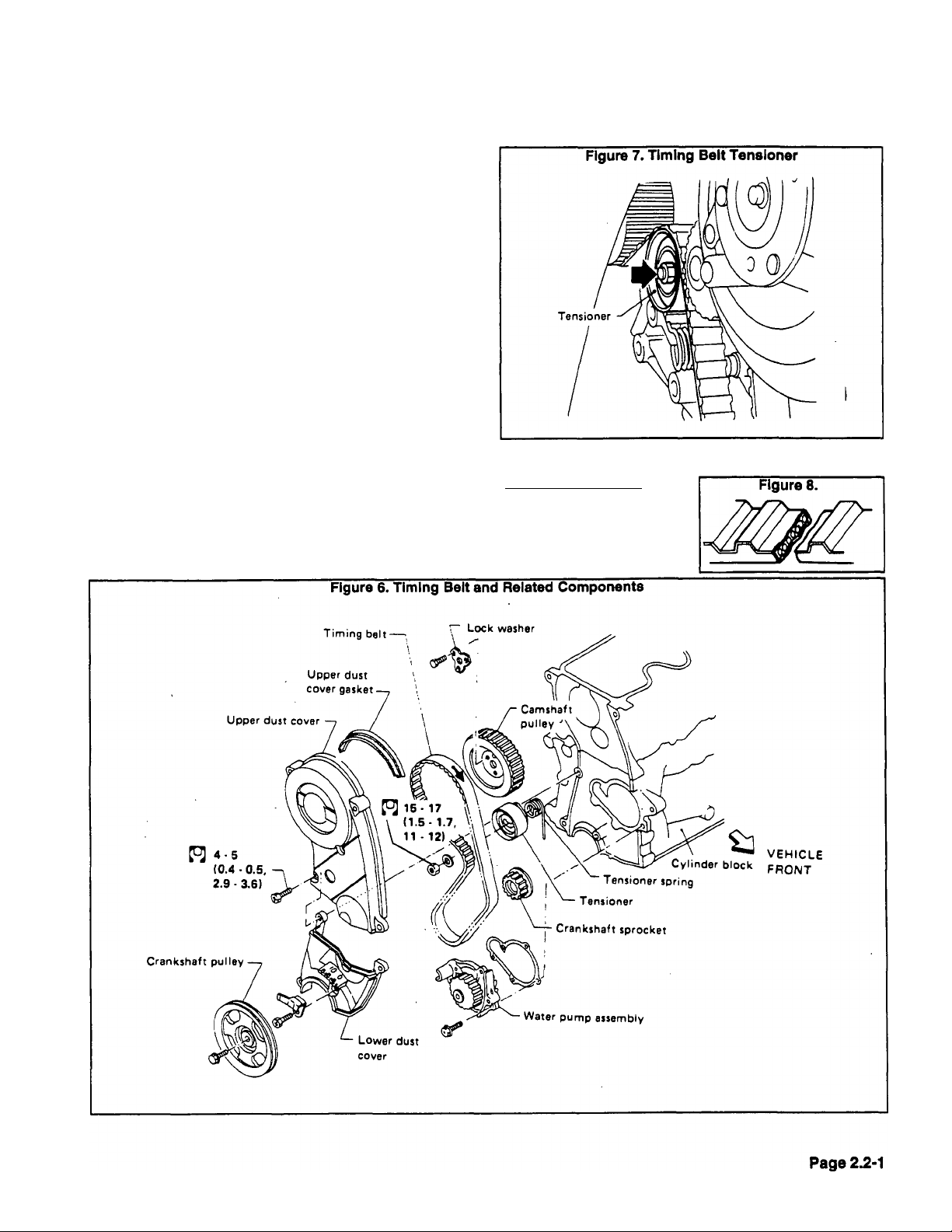

Section 2.2- TIMING BELT

Timing Belt Precautions

Comply with the following precautions when removing,

Installing or inspecting the timing belt:

D Make sure the timing belt, pullies and belt tensioner are

free of oil and water.

□ Prior to installing the timing belt, make sure that No. 1

cylinder is at top dead center (TDC) of its compression

stroke.

D Align the arrow on the timing belt in the direction of

engine rotation.

G Remove all spark plugs before adjusting timing belt

tension.

□ Once the timing belt has been removed, DO NOT rotate

the crankshaft and camshaft separately, or the valves

will strike the piston heads.

Q Do NOT bend or twist the timing belt too tightly.

Timing Beit Removai

1. Drain the radiator.

2. Remove the radiator, fan guard and fan. See Part 4,

“ENGINE COOLING SYSTEM".

3. Remove tension from the drive belt, then remove the drive

belt.

4. Remove the crankshaft pulley.

5. Set No. 1 cylinder at top dead center (TDC) of its compres

sion stroke. Then, remove upper and lower dust covers and

gaskets.

6. Loosen timing belt tensioner and return spring, then re

move timing belt.

Timing Beit Inspection

BELT IS BROKEN;

Caused by improper han

dling, poor belt cover sealing,

coolant leakage at water

pump.

Page 31

Timing Belt Inspection (Continued)

TOOTH BROKEN OR TOOTH ROOT CRACKED:

Caused by camshaft jamming,

distributor jamming, damaged

crankshaft or camshaft oil seal.

BACK SURFACE CRACKED OR WORN:

Caused by tensioner jamming,

overheated engine, interference with

belt cover.

SIDE SURFACE WORN:

Caused by Improper belt instal

lation, defective crank pulley and/or

timing belt plate.

CAUTION: The timing belt must be clean and free

of oil and water. Do NOT bend the belt. Arrow on

belt must point In normal direction of rotation.

Figure 14. Tensioner and Return Spring

NOTE: Replace the timing belt If (a) side surface Is worn

to such an extent that cutoff performed during the man

ufacturing process cannot be seen, (b) belt comers are

worn or rounded, or (c) belt fibers are frayed and coming

out.

BELT TEETH ARE WORN:

Caused by poor belt cover seal

ing, coolant leakage at water pump,

defective camshaft, defective distrib

utor, excessive belt tension. Some

problems that might be found under

Belt Teeth are Worn” include (a) can

vas on tooth face worn, (b) canvas on

tooth is fluffy, (c) rubber layer worn or

faded white, or (d) weft worn or invis

ible.

Timing Belt Installation

1. Check that No. 1 cylinder is at top dead center (TDC) of Its

compression stroke. Align the camshaft and crankshaft pulley

marks. See Figure 13.

2. See Figure 14. Install tensioner and return spring. Hook

the return spring to its stopper.

3. Slide the tensioner to the left and tighten the lock nut

temporarily (Figure 15).

4. Check that the water pump and tensioner pulleys can be