Page 1

www.generac.com or 1-888-GENERAC

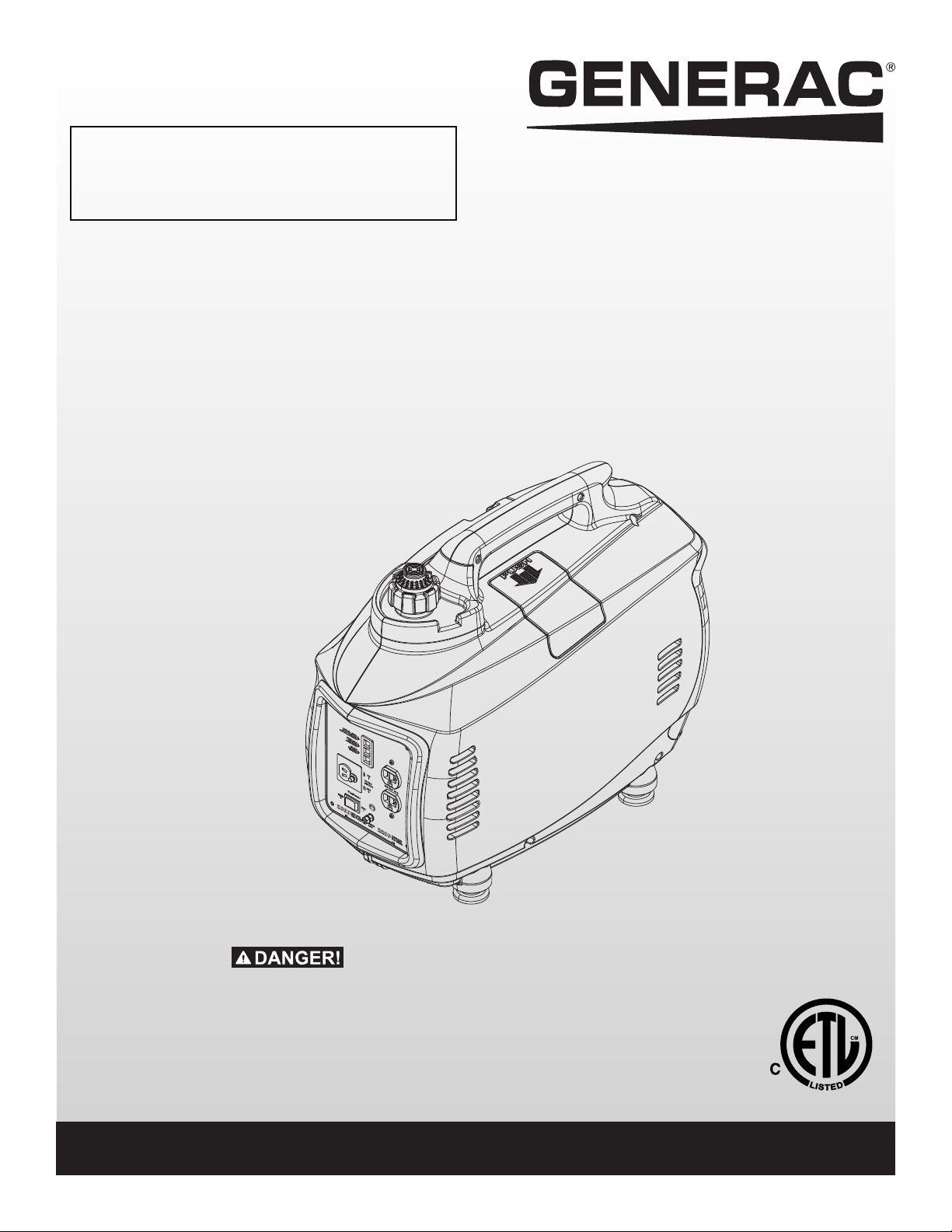

iX 1600 & iX 2000

Digital Inverter Generator Owner's Manual

MODELS: 005792-3

005793-3

006719-0

DEADLY EXHAUST FUMES! ONLY use OUTSIDE

far away from windows, doors and vents!

NOT INTENDED FOR USE IN CRITICAL LIFE

SUPPORT APPLICATIONS.

SAVE this Manual. Provide this manual to any

operator of the generator.

Page 2

Accessory Box ..............................................Inside Front Cover

Introduction ..............................................................................1

Read this Manual Thoroughly ..................................................1

Safety Rules ............................................................................1

Standards Index ...............................................................3

General Information .................................................................4

Specifications ...........................................................................4

1600 Watt ........................................................................4

2000 Watt (49 State) .......................................................4

2000 Watt (50 State) .......................................................4

Emissions Information ......................................................4

Unit Identification ......................................................................5

Control Panel....................................................................5

Operation .................................................................................6

Pre-Use Check ..........................................................................6

Starting the Generator ...............................................................7

Adding Loads ............................................................................7

Using the FlexPower

™

Switch ...................................................8

Using the 12 VDC Battery Charger ............................................8

Shutting Down ..........................................................................8

Low Oil Level Shutdown ............................................................9

Fueling the Generator ................................................................9

To Fill the Fuel Tank ..........................................................9

Adding Engine Oil ......................................................................9

To Add Engine Oil to the Crankcase ................................10

Maintenance ..........................................................................10

Generator Maintenance ...........................................................10

Generator Maintenance Schedule ............................................10

Cleaning the Generator ............................................................11

Engine Maintenance ................................................................11

Changing the Engine Oil ..........................................................11

Changing the Fuel Filter ...........................................................11

Changing the Spark Plug .........................................................12

Transportation and Storage .....................................................12

Clean Spark Arrestor Screen (50 State) ...................................13

Troubleshooting .....................................................................14

Troubleshooting Guide .............................................................14

Notes .....................................................................................15

iX 1600 & iX 2000 Manual del operador del generador

inversor digital ...................................................................17

iX 1600 et iX 2000 Manuel d'utilisation du générateur

inverseur numérique .................................................................35

ACCESSORY BOX

Check all contents. If any parts are missing or damaged locate an

authorized dealer at 1-888-436-3722.

Contents include:

• 1 bottle SAE 30 Oil • Oil Funnel

• Spark Plug Wrench • Screwdriver

• Battery Charge Cable

Table of Contents

WARNING!

California Proposition 65

Engine exhaust and some of its constituents are known to the state of California to cause cancer,

birth defects, and other reproductive harm.

WARNING!

California Proposition 65

This product contains or emits chemicals known to the state of California to cause cancer,

birth defects, and other reproductive harm.

Page 3

1

INTRODUCTION

This model is a compact, high performance, air-cooled, engine driven

generator designed to supply electrical power to operate electrical

loads where no utility power is available or in place of utility due to a

power outage.

READ THIS MANUAL THOROUGHLY

If any portion of this manual is not understood, contact the nearest

Authorized Dealer for starting, operating and servicing procedures.

The operator is responsible for proper and safe use of the equipment.

We strongly recommend that the operator read this manual and

thoroughly understand all instructions before using the equipment.

We also strongly recommend instructing other users to properly start

and operate the unit. This prepares them if they need to operate the

equipment in an emergency.

The generator can operate safely, efficiently and reliably only if it

is properly located, operated and maintained. Before operating or

servicing the generator:

• Become familiar with and strictly adhere to all local, state and

national codes and regulations.

• Study all safety warnings in this manual and on the product

carefully.

• Become familiar with this manual and the unit before use.

The manufacturer cannot anticipate every possible circumstance that

might involve a hazard. The warnings in this manual, and on tags and

decals affixed to the unit are, therefore, not all inclusive. If using a

procedure, work method or operating technique that the manufacturer

does not specifically recommend, ensure that it is safe for others.

Also make sure the procedure, work method or operating technique

utilized does not render the generator unsafe.

THE INFORMATION CONTAINED HEREIN WAS BASED ON

MACHINES IN PRODUCTION AT THE TIME OF PUBLICATION.

GENERAC RESERVES THE RIGHT TO MODIFY THIS MANUAL AT

ANY TIME.

SAFETY RULES

Throughout this publication, and on tags and decals affixed to the

generator, DANGER, WARNING, CAUTION and NOTE blocks are

used to alert personnel to special instructions about a particular

operation that may be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are as follows:

Indicates a hazardous situation or action which, if

not avoided, will result in death or serious injury.

Indicates a hazardous situation or action which, if

not avoided, could result in death or serious injury.

Indicates a hazardous situation or action which,

if not avoided, could result in minor or moderate

injury.

NOTE:

Notes contain additional information important to a procedure

and will be found within the regular text body of this manual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliance with the special

instructions while performing the action or service are essential to

preventing accidents.

Four commonly used safety symbols accompany the DANGER,

WARNING and CAUTION blocks. The type of information each

indicates is as follows:

This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

This symbol points out potential fire hazard.

This symbol points out potential electrical

shock hazard.

GENERAL HAZARDS

• NEVER operate in an enclosed area, in a vehicle, or indoors EVEN

IF doors and windows are open.

• For safety reasons, the manufacturer recommends that the

maintenance of this equipment is carried out by an Authorized

Dealer. Inspect the generator regularly, and contact the nearest

Authorized Dealer for parts needing repair or replacement.

• Operate generator only on level surfaces and where it will not be

exposed to excessive moisture, dirt, dust or corrosive vapors.

• Keep hands, feet, clothing, etc., away from drive belts, fans, and

other moving parts. Never remove any fan guard or shield while

the unit is operating.

• Certain parts of the generator get extremely hot during operation.

Keep clear of the generator until it has cooled to avoid severe

burns.

• Do NOT operate generator in the rain.

• Do not alter the construction of the generator or change controls

which might create an unsafe operating condition.

• Never start or stop the unit with electrical loads connected to

receptacles AND with connected devices turned ON. Start the

engine and let it stabilize before connecting electrical loads.

Disconnect all electrical loads before shutting down the generator.

Safety Rules

Page 4

2

• When working on this equipment, remain alert at all times. Never

work on the equipment when physically or mentally fatigued.

• Never use the generator or any of its parts as a step. Stepping on

the unit can stress and break parts, and may result in dangerous

operating conditions from leaking exhaust gases, fuel leakage, oil

leakage, etc.

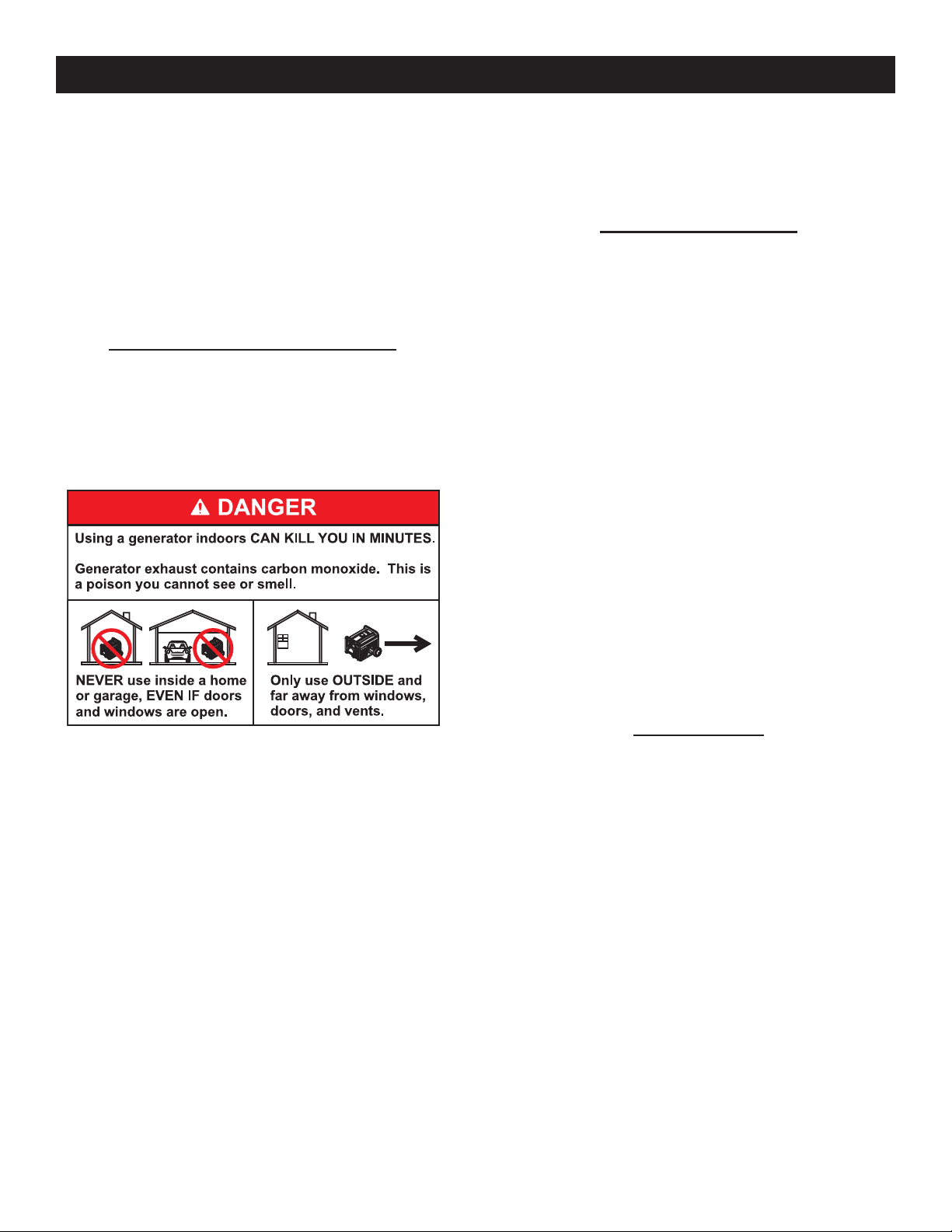

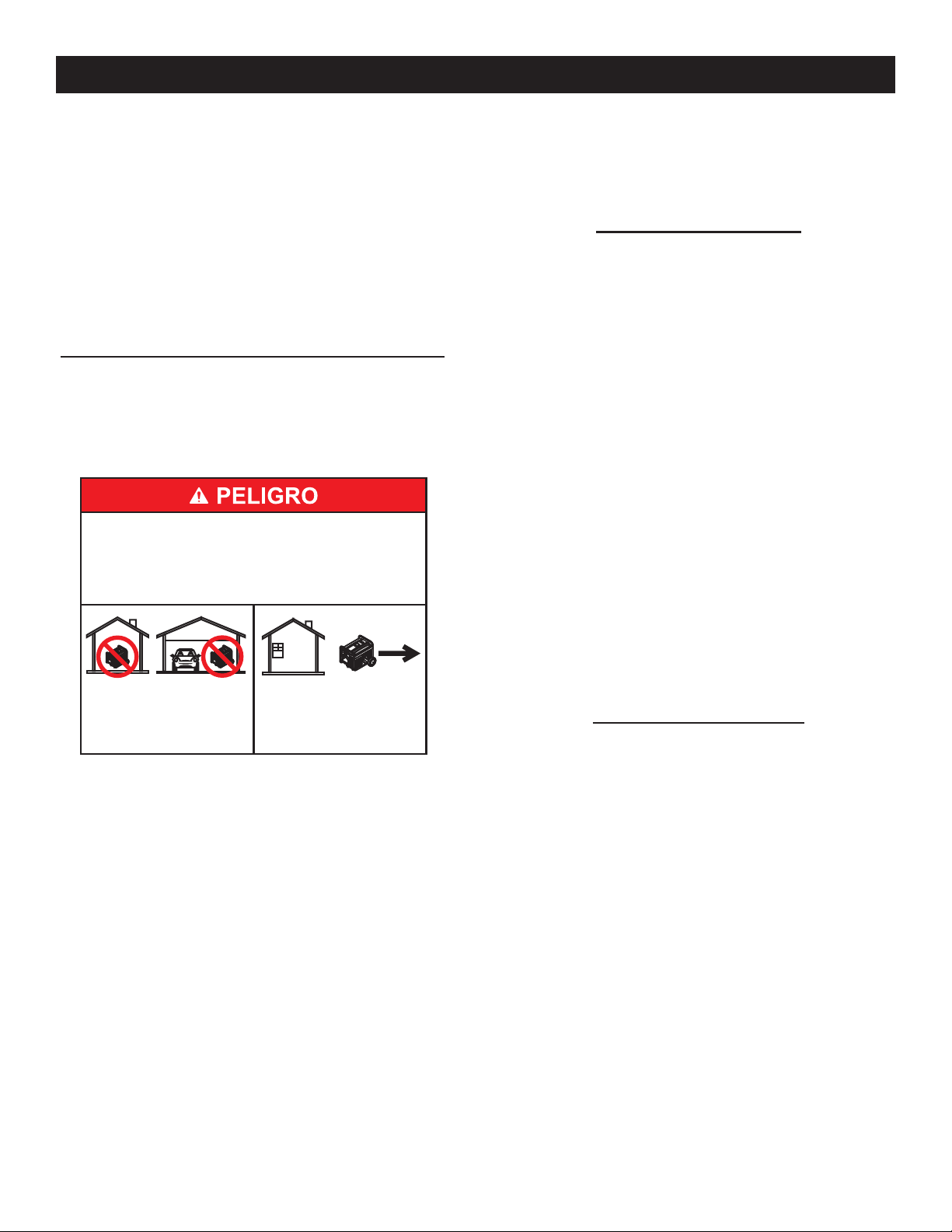

EXHAUST & LOCATION HAZARDS

• NEVER operate in an enclosed area or indoors!

NEVER use in the home, in a vehicle, or in partly

enclosed areas such as garages, EVEN IF doors

and windows are open! ONLY use outdoors and far

from open windows, doors, vents, and in an area

that will not accumulate deadly exhaust.

• The engine exhaust fumes contain carbon monoxide, which you

cannot see or smell. This poisonous gas, if breathed in sufficient

concentrations, can cause unconsciousness or even death.

• Adequate, unobstructed flow of cooling and ventilating air is critical

to correct generator operation. Do not alter the installation or

permit even partial blockage of ventilation provisions, as this can

seriously affect safe operation of the generator. The generator

MUST be operated outdoors.

• This exhaust system must be properly maintained. Do nothing that

might render the exhaust system unsafe or in noncompliance with

any local codes and/or standards.

• Always use a battery operated carbon monoxide alarm indoors,

installed according to the manufacturer's instructions.

• If you start to feel sick, dizzy, or weak after the generator has been

running, move to fresh air IMMEDIATELY. See a doctor, as you

could have carbon monoxide poisoning.

ELECTRICAL HAZARDS

• The generator produces dangerously high voltage when in

operation. Avoid contact with bare wires, terminals, connections,

etc., while the unit is running, even on equipment connected to the

generator. Ensure all appropriate covers, guards and barriers are

in place before operating the generator.

• Never handle any kind of electrical cord or device while

standing in water, while barefoot or while hands or feet are wet.

DANGEROUS ELECTRICAL SHOCK MAY RESULT.

• The National Electric Code (NEC) requires the frame and external

electrically conductive parts of the generator be properly connected

to an approved earth ground. Local electrical codes may also

require proper grounding of the generator. Consult with a local

electrician for grounding requirements in the area.

• Use a ground fault circuit interrupter in any damp or highly

conductive area (such as metal decking or steel work).

• Do not use worn, bare, frayed or otherwise damaged electrical

cord sets with the generator.

• In case of accident caused by electric shock, immediately shut

down the source of electrical power. If this is not possible, attempt

to free the victim from the live conductor. AVOID DIRECT

CONTACT WITH THE VICTIM. Use a non-conducting

implement, such as a rope or board, to free the victim from the

live conductor. If the victim is unconscious, apply first aid and get

immediate medical help.

FIRE HAZARDS

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the vicinity while handling

gasoline.

• Never add fuel while unit is running or hot. Allow

engine to cool completely before adding fuel.

• Never fill fuel tank indoors. Comply with all laws regulating

storage and handling of gasoline.

• Do not overfill the fuel tank. Always allow room for

fuel expansion. If tank is over-filled, fuel can overflow onto

a hot engine and cause FIRE or an EXPLOSION. Never store

generator with fuel in tank where gasoline vapors might reach an

open flame, spark or pilot light (as on a furnace, water heater or

clothes dryer). FIRE or EXPLOSION may result. Allow unit to cool

entirely before storage.

• Wipe up any fuel or oil spills immediately. Ensure that no

combustible materials are left on or near the generator. Keep the

area surrounding the generator clean and free from debris and

keep a clearance of five (5) feet on all side to allow for proper

ventilation of the generator.

• Do not insert objects through unit’s cooling slots.

SAVE THESE INSTRUCTIONS – The manufacturer suggests that these rules for safe operation be copied and

posted near the unit's installation site. Safety should be stressed to all operators and potential operators of this

equipment.

Safety Rules

Page 5

3

• Do not operate the generator if connected electrical devices

overheat, if electrical output is lost, if engine or generator sparks or

if flames or smoke are observed while unit is running.

• Keep a fire extinguisher near the generator at all times.

STANDARDS INDEX

1. National Fire Protection Association (NFPA) 70: The NATIONAL

ELECTRIC CODE (NEC) available from www.nfpa.org

2. National Fire Protection Association (NFPA) 5000: BUILDING

CONSTRUCTION AND SAFETY CODE available from www.

nfpa.org

3. International Building Code available from www.iccsafe.org

4. Agricultural Wiring Handbook available from www.rerc.org ,

Rural Electricity Resource Council P.O. Box 309 Wilmington, OH

45177-0309

5. ASAE EP-364.2 Installation and Maintenance of Farm Standby

Electric Power available from www.asabe.org, American Society

of Agricultural & Biological Engineers 2950 Niles Road, St.

Joseph, MI 49085

This list is not all inclusive. Check with the Authority Having Local

Jurisdiction (AHJ) for any local codes or standards which may be

applicable to your jurisdiction.

MODEL NO:

SERIAL NO:

Figure 1 - Generator ID Plate

ID PLATE

Safety Rules

Page 6

4

SPECIFICATIONS

1600 WATT

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . Single Cylinder, 4-Stroke

Engine Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99cc

Starter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil

Fuel Capacity/Type. . . . . . . . . . . . . . . . . . . . . .0.69 Gal (2.6L)/Unleaded

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.63 Qt (0.6L)

Run time at 25% Rated Load . . . . . . . . . . . . . . . . . . . . . . . . . . 5.7 Hours

Spark Plug Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR7HS

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..030”

Dimensions L x W x H (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 22 x 12 x 18

Weight Lb/kg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43.5/19.7

Maximum AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1600W

Surge AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1650W

AC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 VAC

Rated AC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13.3 A

Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

THD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.0%

Insulation Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class B

Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 5-15R, (1) 12 VDC

DC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VDC

Rated DC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 A

2000 WATT (49 STATE)

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . Single Cylinder, 4-Stroke

Engine Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127cc

Starter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil

Fuel Capacity/Type. . . . . . . . . . . . . . . . . . . . . 0.85 Gal. (3.2L) Unleaded

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.63 Qt (0.6L)

Run time at 25% Rated Load . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3 Hours

Spark Plug Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR6ES

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..030”

Dimensions L x W x H (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 22 x 12 x 18

Weight Lb/kg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49.6/22.5

Maximum AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000W

Surge AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200W

AC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 VAC

Rated AC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16.7 A

Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

THD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.0%

Insulation Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class B

Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 5-20R, (1) 12 VDC

DC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VDC

Rated DC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 A

NOTE:

Power output and runtime are influenced by many factors,

some of which are fuel quality, ambient temperature and engine

condition. Output decreases approximately 3.5% for each 1,000

feet above sea level and 1% for every 10 degrees above 60°F.

2000 WATT (50 STATE)

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . . Single Cylinder, 4-Stroke

Engine Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127cc

Starter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil

Fuel Capacity/Type. . . . . . . . . . . . . . . . . . . . . 0.82 Gal. (3.1L) Unleaded

Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.63 Qt (0.6L)

Run time at 25% Rated Load . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7 Hours

Spark Plug Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR6ES

Spark Plug Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..030”

Dimensions L x W x H (in) . . . . . . . . . . . . . . . . . . . . . . . . . . 22 x 12 x 18

Weight Lb/kg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49.6/22.5

Maximum AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000W

Surge AC Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2200W

AC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 VAC

Rated AC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16.7 A

Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

THD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3.0%

Insulation Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Class B

Outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 5-20R, (1) 12 VDC

DC Volts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VDC

Rated DC Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 A

EMISSIONS INFORMATION

The Environmental Protection Agency (and California Air Resource

Board for generators certified to CA standards) requires that this

generator comply with exhaust and evaporative emission standards.

Locate the emissions compliance decal on the engine to determine

what standards the generator meets, and to determine which

warranty applies. This generator is certified to operate on gasoline.

The emission control system includes the following components (if

equipped):

• Air Induction System

– Intake Pipe / Manifold

– Air Cleaner

• Fuel System

– Carburetor

– Fuel Tank / Cap

– Fuel Lines

– Evaporative Vent Lines

– Carbon Canister

• Ignition System

– Spark Plug

– Ignition Module

• Exhaust System

– Exhaust Manifold

– Muffler

– Pulsed Air Valve

– Catalyst

General Information

Page 7

5

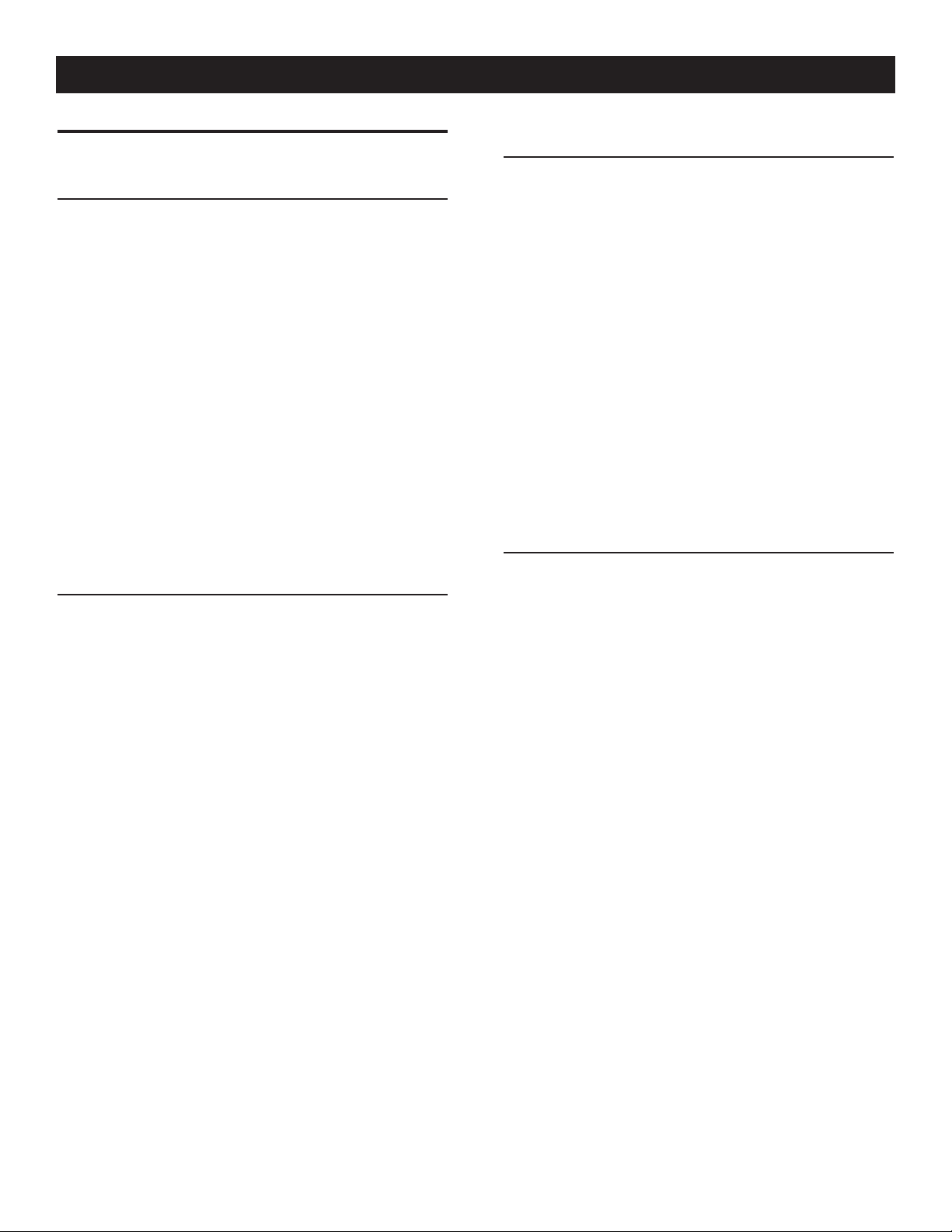

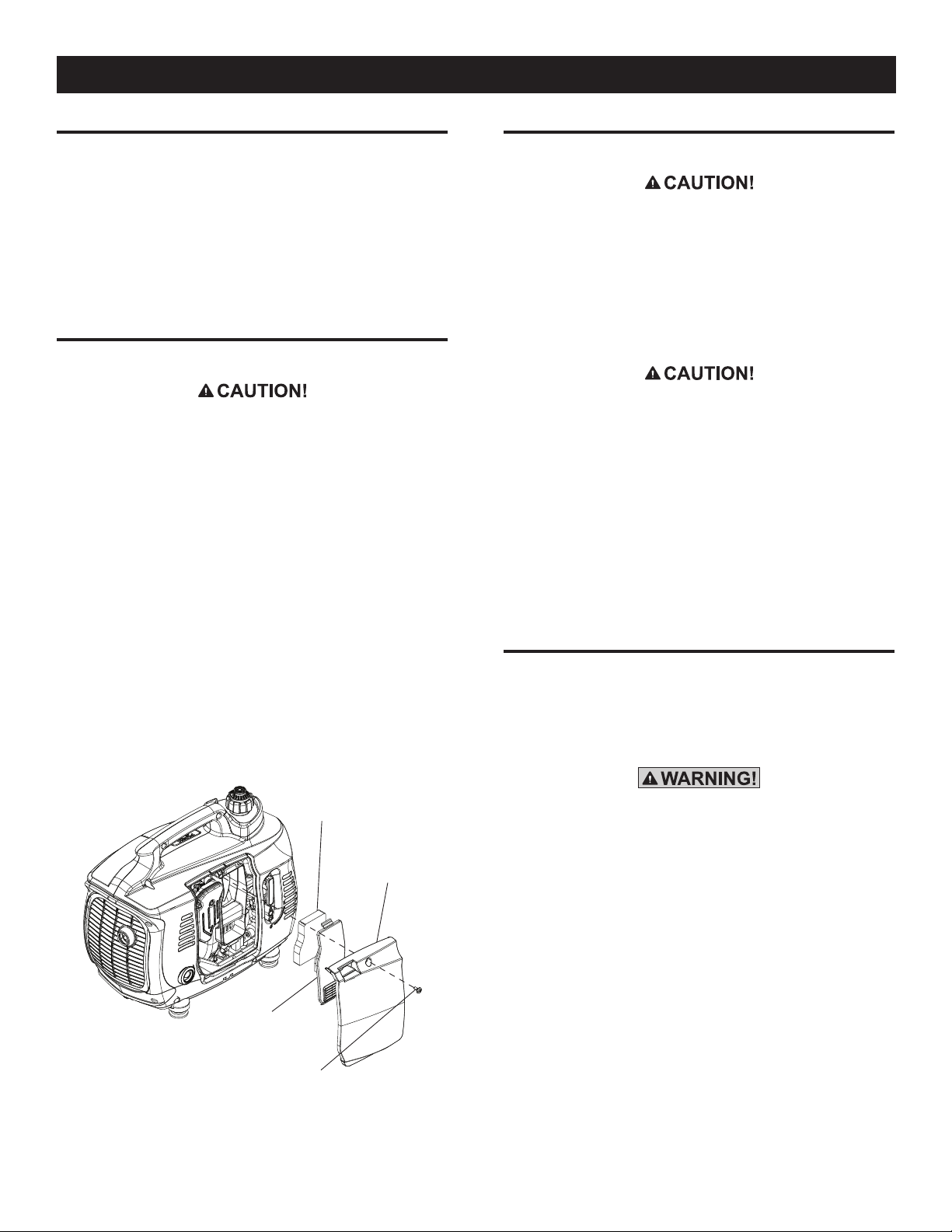

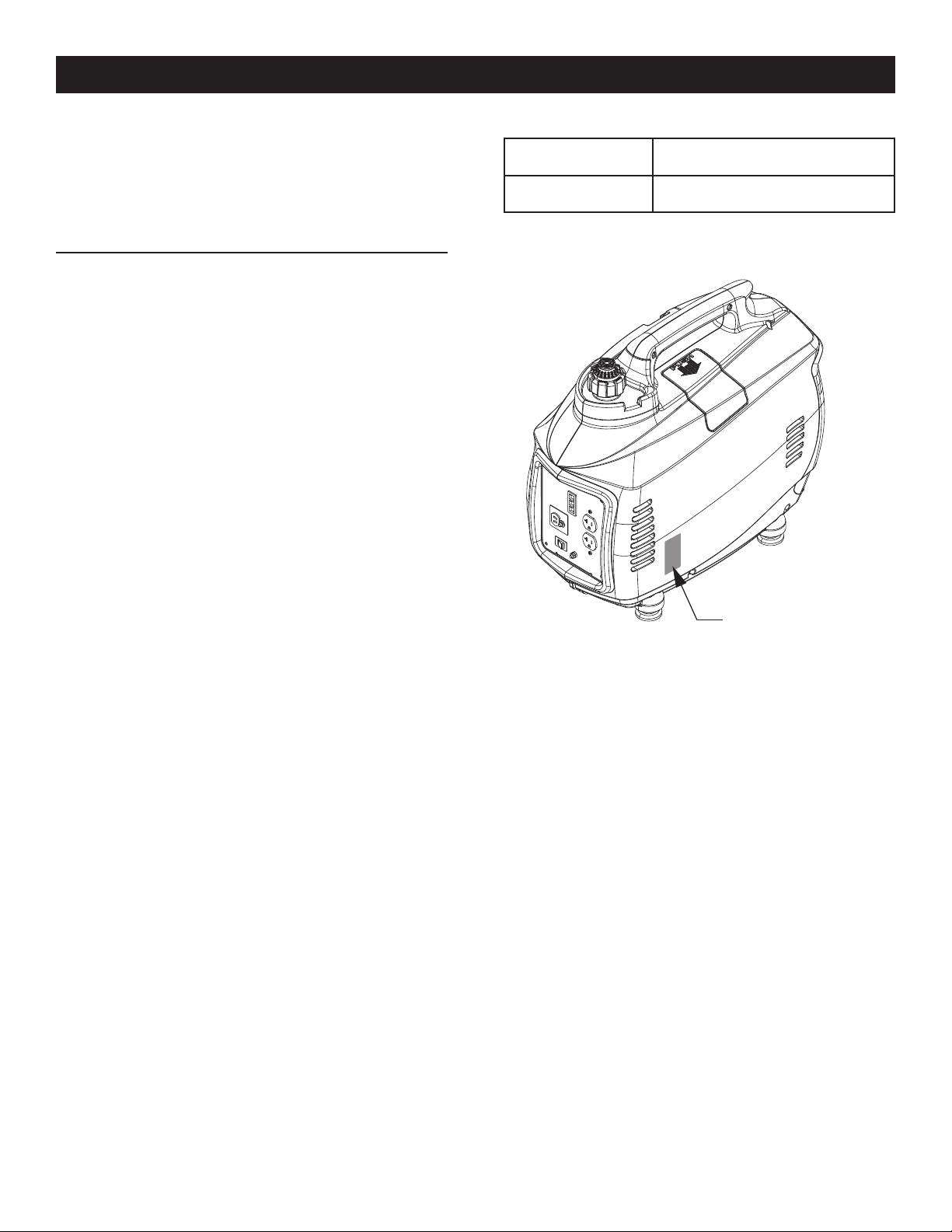

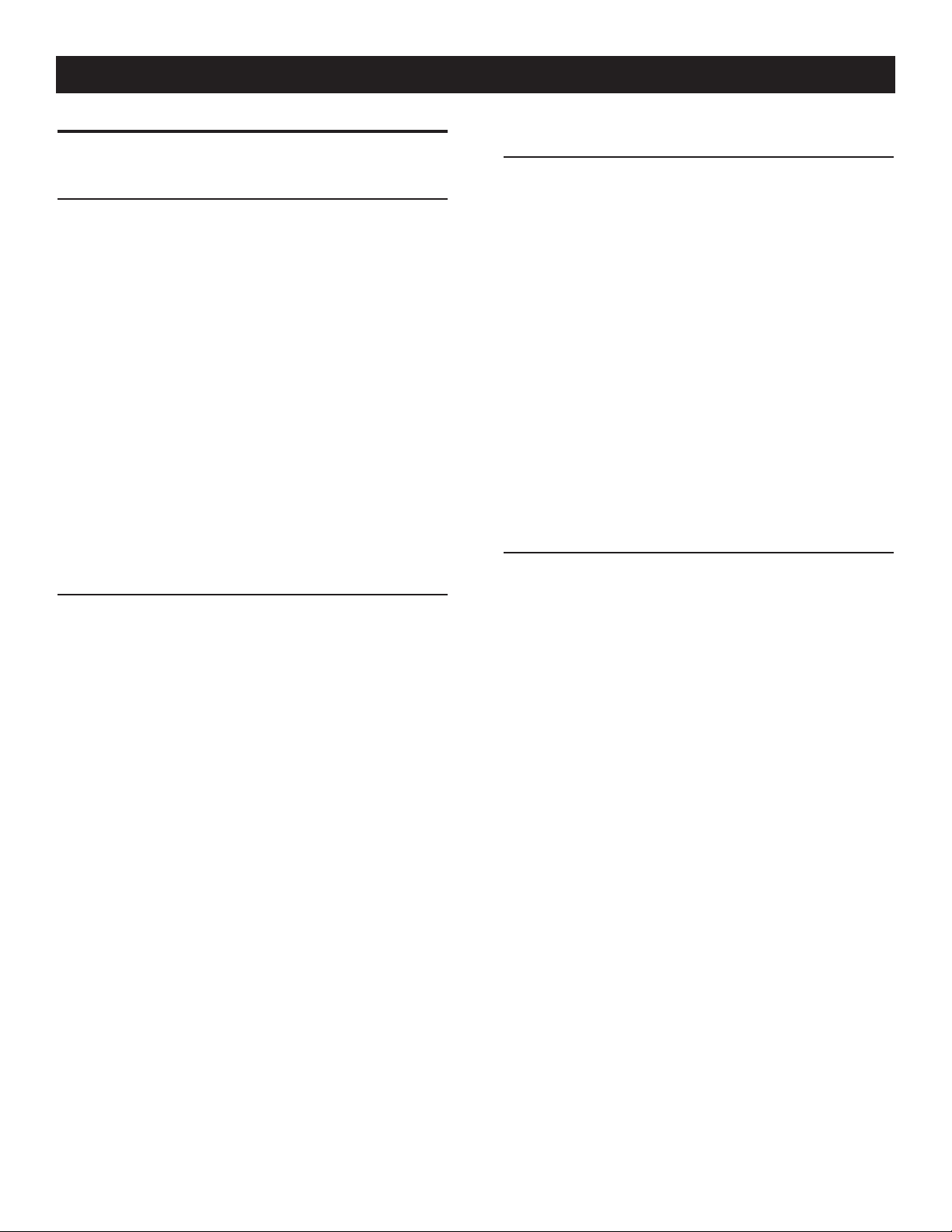

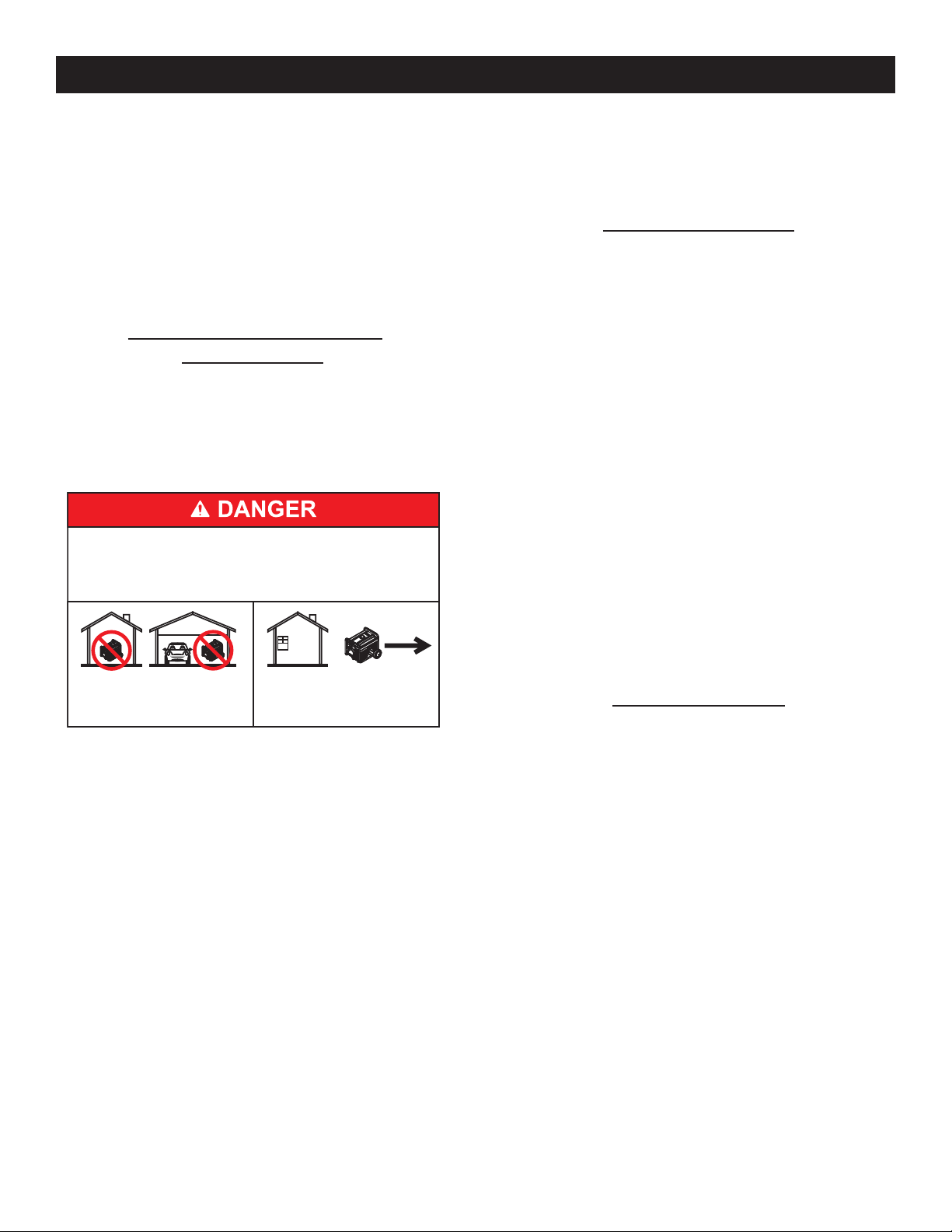

UNIT IDENTIFICATION

(Figure 2)

1. Carrying Handle: Lift the generator by this handle only.

2. Spark Plug Cover: Allows access to the engine spark plug.

3. Primer Bulb: Used to prime the fuel system for starting.

4. Fuel Tank Cap: Access to fuel tank for filling.

5. Control Panel: location of generator controls and output

receptacles.

6. Air Intake Slats: Allows for cooling air to enter the housing.

7. Muffler: Lowers engine exhaust noise (includes the spark

arrestor).

8. Choke: Cold engine starting aid

9. Left Side Service Cover: Allows access to air filter, fuel filter and

oil fill.

10. Vent Hoses: Hoses allow venting of the carburetor.

11. Fuel Shutoff: Controls fuel supply to the carburetor.

12. Starter Rope: Pull rope for starting engine.

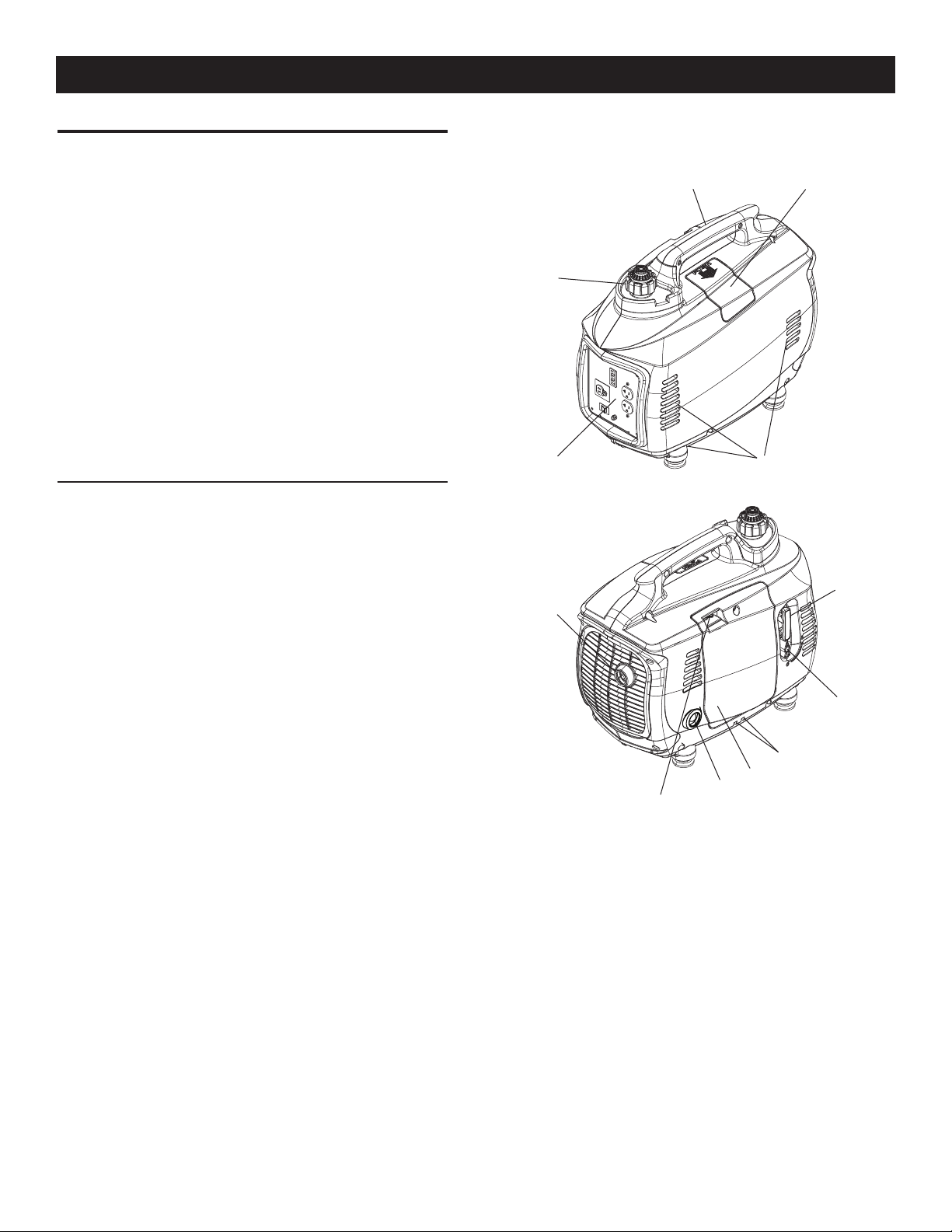

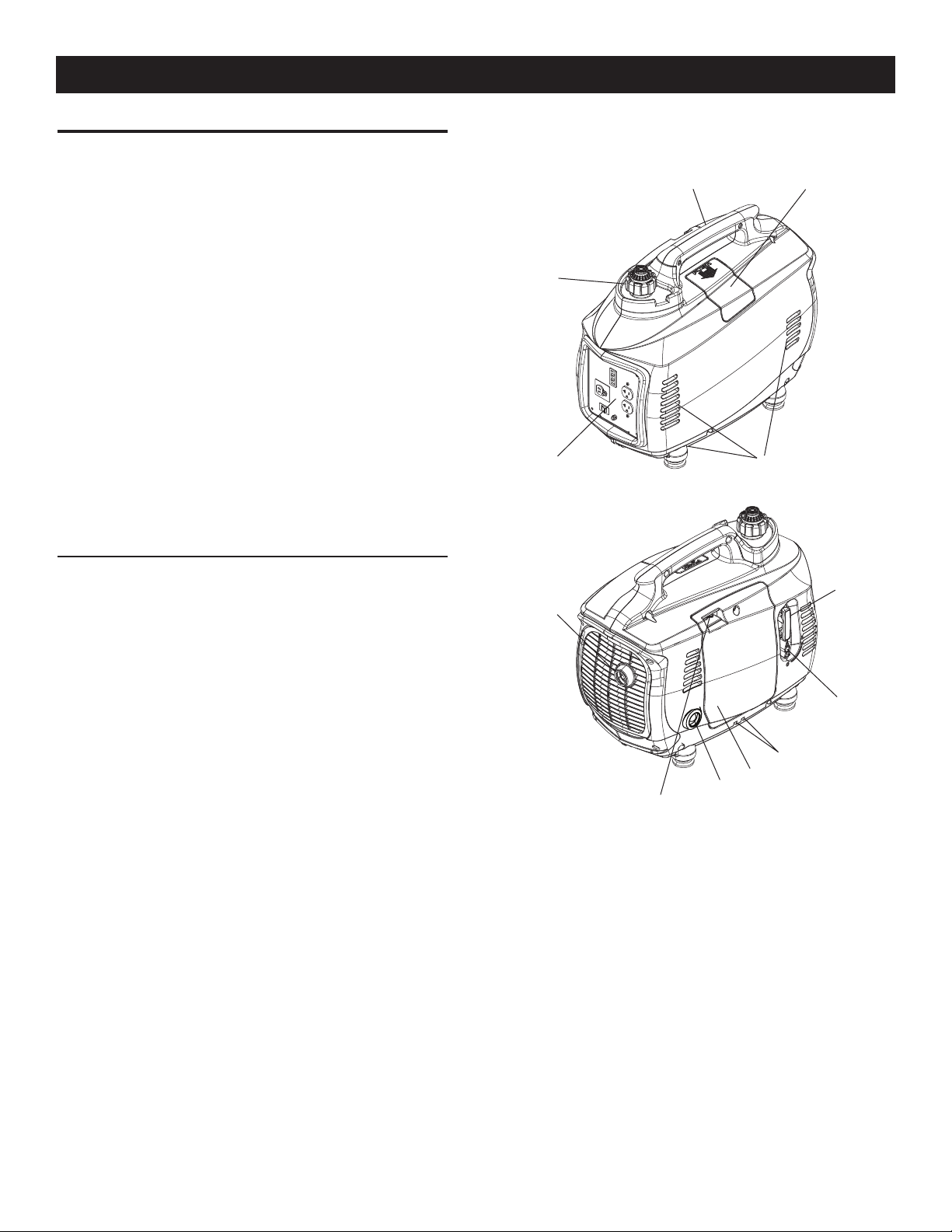

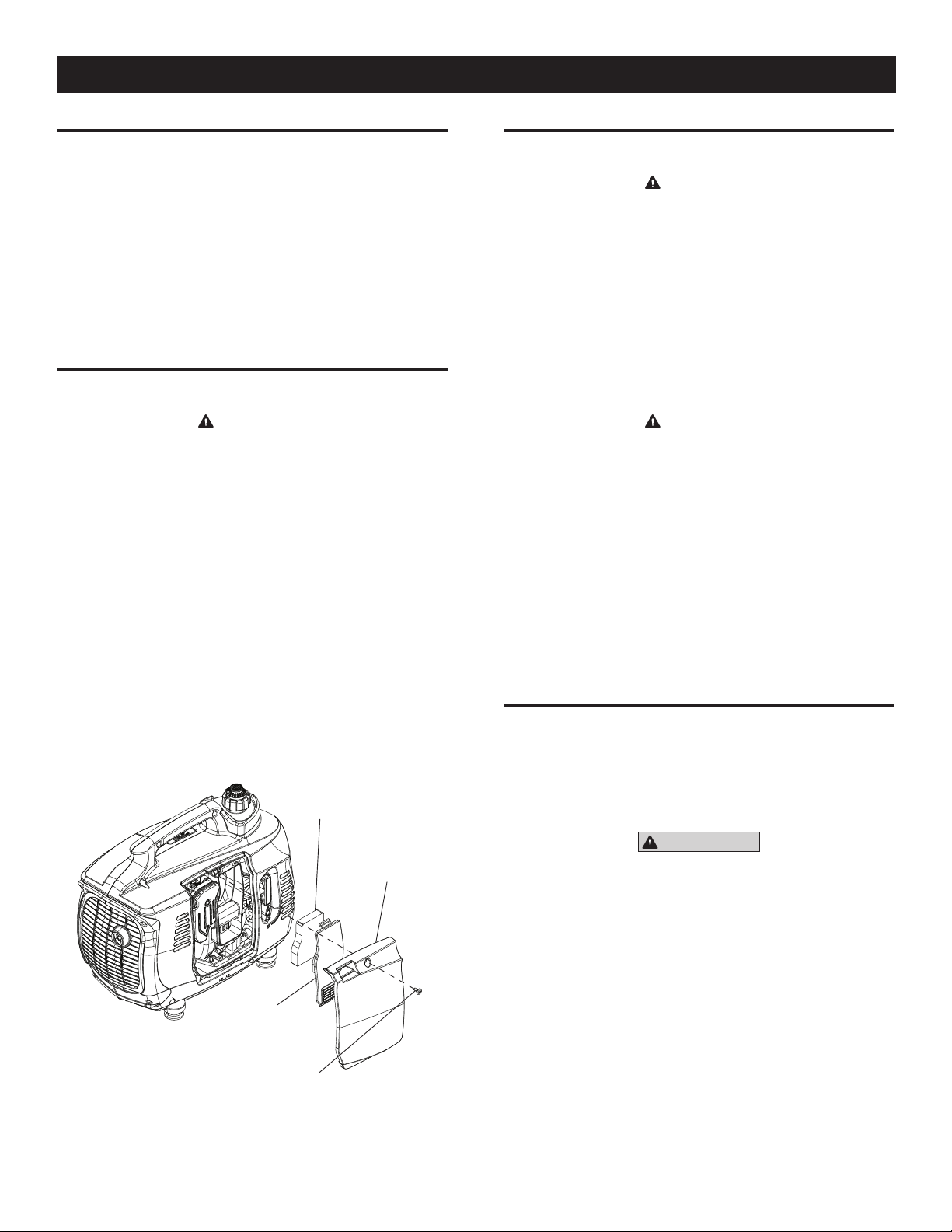

CONTROL PANEL

(Figure 3)

13. LOW OIL LEVEL LED (yellow): Lights up when oil level is below

safe operating level and the engine shuts down.

14. OVERLOAD LED (red): This LED indicates a system overload.

This LED should be used in conjunction with the READY LED

which will flash an error code, see No. 15.

15. READY LED (green): Indicates output from the generator unless

there is a low oil or overload condition. In the event of a system

overload the Ready LED will provide an indication of the overload

condition. The indication consists of a series of flashes separated

by a pause. These indications are as follows:

1 Flash = Low Voltage. The unit has been overloaded to the point

where the output voltage has dropped to less than

100V AC.

2 Flashes = High Temperature of the Inverter System. The unit

has been overloaded to the point where the internal

temperature of the inverter has exceeded 212° F.

3 Flashes = Overload. The unit has been overloaded to the point

that the output power required has exceeded 110%

of rated power.

4 Flashes = Short Circuit. This indicates the unit's output has

been short circuited by the load connected to it.

Figure 2 - Unit Identification

1

2

3

4

5

6

7

8

9

10

11

12

16. 12 VDC Plug: Connection for re-charging 12VDC automotivestyle batteries while generator is in operation.

17. FlexPower™ Switch: This switch slows the engine speed when

the load is reduced to save fuel and engine wear.

18. 12 VDC Circuit Breaker: Overload protection for the 12 VDC

charging system.

19. Ground (Earth) Connection Lug: Grounding point for the

generator; consult state and local electrical codes before use

(floating ground).

20. 120 VAC Receptacles: Two (2) receptacles for connecting

devices.

NOTE:

Do not exceed the rated output of the generator.

General Information

Page 8

6

Figure 3 - Control Panel

13

14

15

16

17

18

19

20

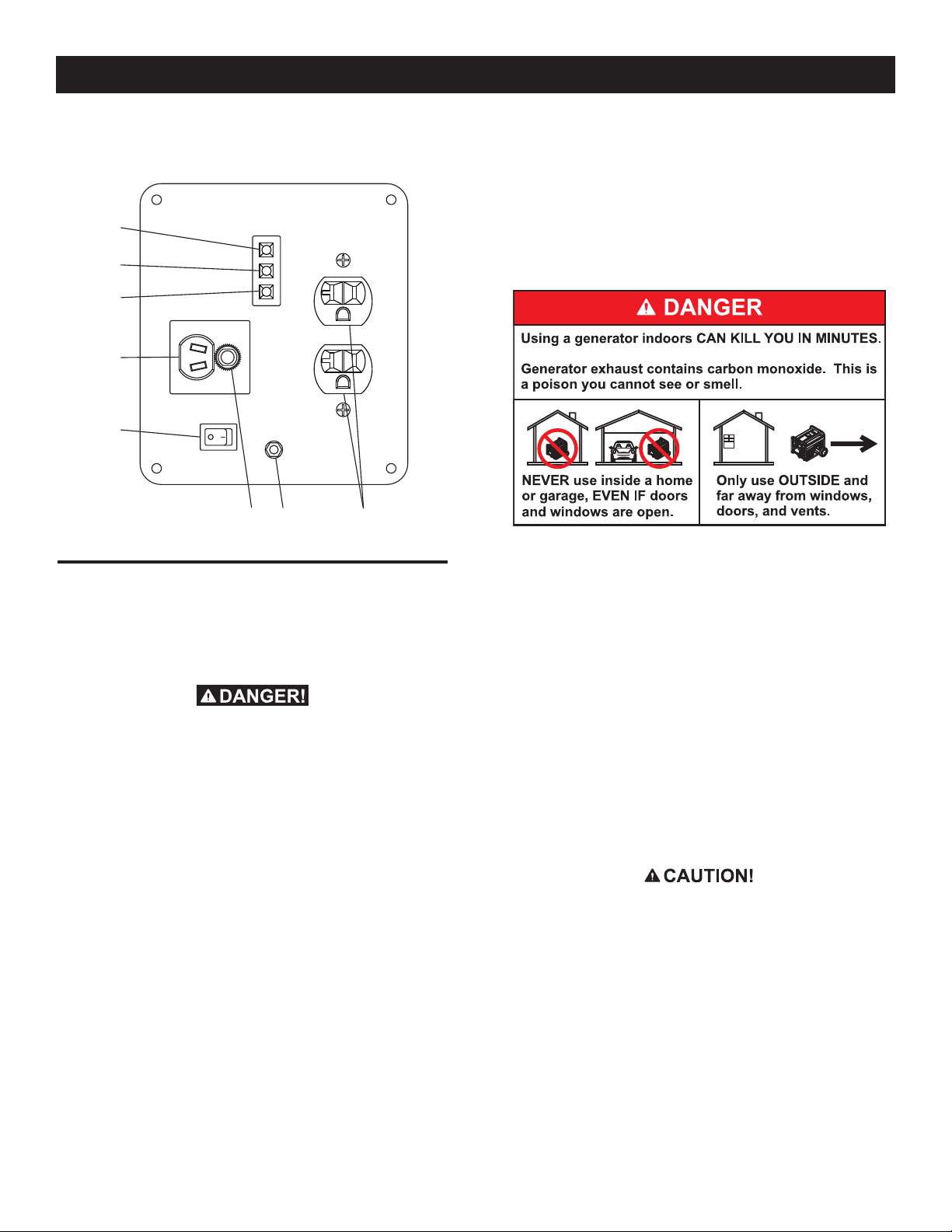

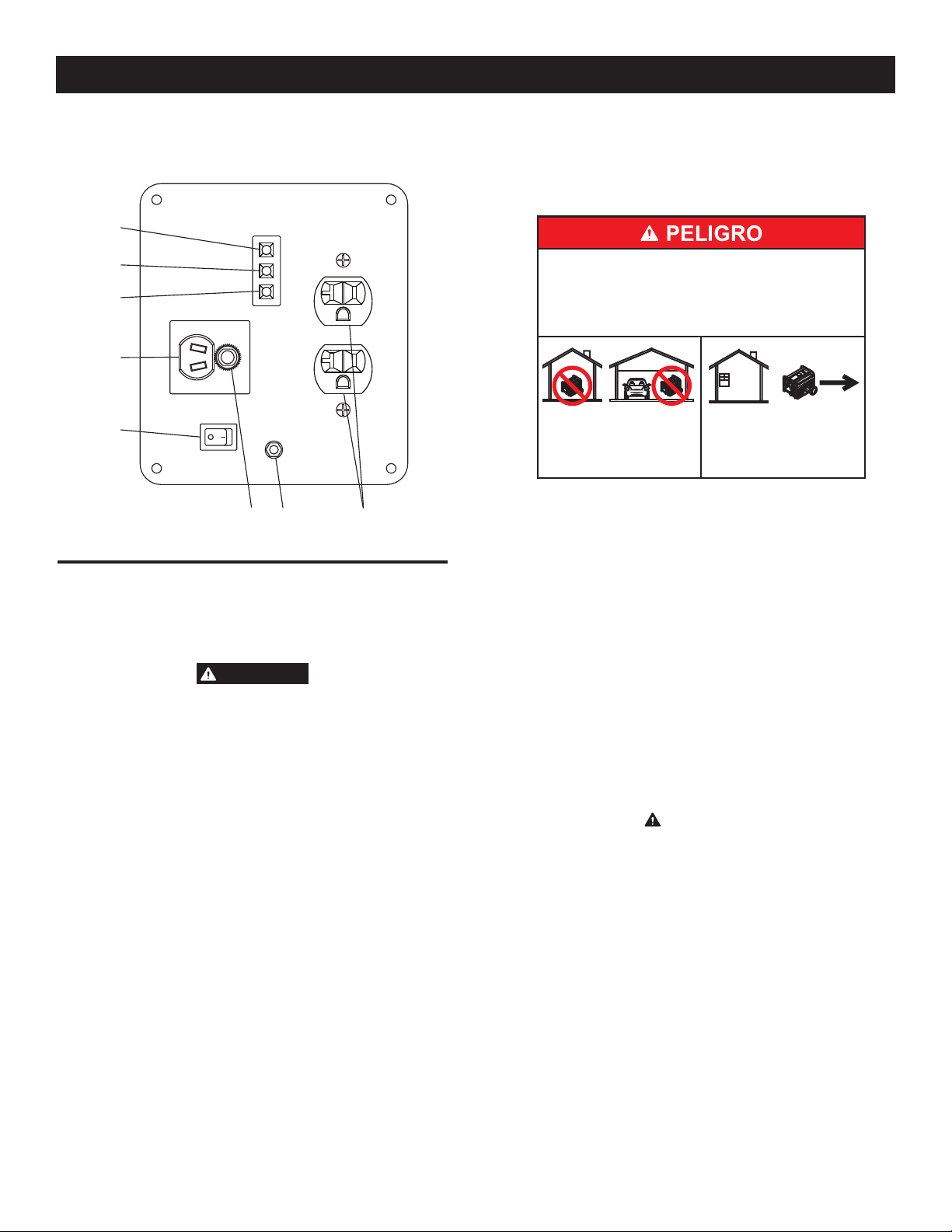

PRE-USE CHECK

Prior to starting the generator and adding loads, perform the following

tasks:

1. Make sure the generator in on a firm, level, non-combustible

surface with at least five (5) feet of clearance on all sides.

Never operate in an enclosed area or indoors!

NEVER use in the home, in a vehicle, or in

partly enclosed areas such as garages, even

if doors and windows are open! ONLY use

outdoors and far from open windows, doors,

vents, and in an area that will not accumulate

deadly exhaust.

The engine exhaust fumes contain carbon

monoxide, which you cannot see or smell.

This poisonous gas, if breathed in sufficient

concentrations, can cause unconsciousness

or even death.

Adequate, unobstructed flow of cooling and

ventilating air is critical to correct generator

operation. Do not alter the installation or

permit even partial blockage of ventilation

provisions, as this can seriously affect safe

operation of the generator. The generator

MUST be operated outdoors.

This exhaust system must be properly

maintained. Do nothing that might render the

exhaust system unsafe or in noncompliance

with any local codes and/or standards.

The manufacturer recommends installing

a battery operated carbon monoxide alarm

indoors, according to the manufacturer's

instructions.

NEVER use in the home, or in partly enclosed areas

such as garages, campers or trailers. ONLY use

outdoors and far from open windows, doors, vents.

2. Remove the fuel cap and check the fuel level. If fuel is needed,

see the section “FUELING THE GENERATOR”.

3. Remove the left side service cover and check the oil level by

removing the oil filler cap. The oil level should be to the bottom

of the threads on the oil fill pipe. If oil is needed, see the section

“ADDING ENGINE OIL”.

4. Replace and secure the left side service cover.

5. Make sure there are no loads connected to the generator.

6. The National Electric Code (NEC) requires the frame and

external electrically conductive parts of the generator be properly

connected to an approved earth ground. Proper grounding of the

generator will prevent electrical shock in the event of a ground

fault condition in the generator or in connected electrical devices.

Proper grounding also helps dissipate static electricity, which

often builds up in unguarded devices.

7. Local electrical codes may also require proper grounding of the

generator.

Starting the generator with accessories

connected to the 120 VAC outlets will damage

the generator and the connected devices.

Operation

Page 9

7

STARTING THE GENERATOR

Once the fuel and oil levels have been checked and it has been

verified there are no loads connected, the generator may be started.

Turn the FlexPower Switch OFF (O).

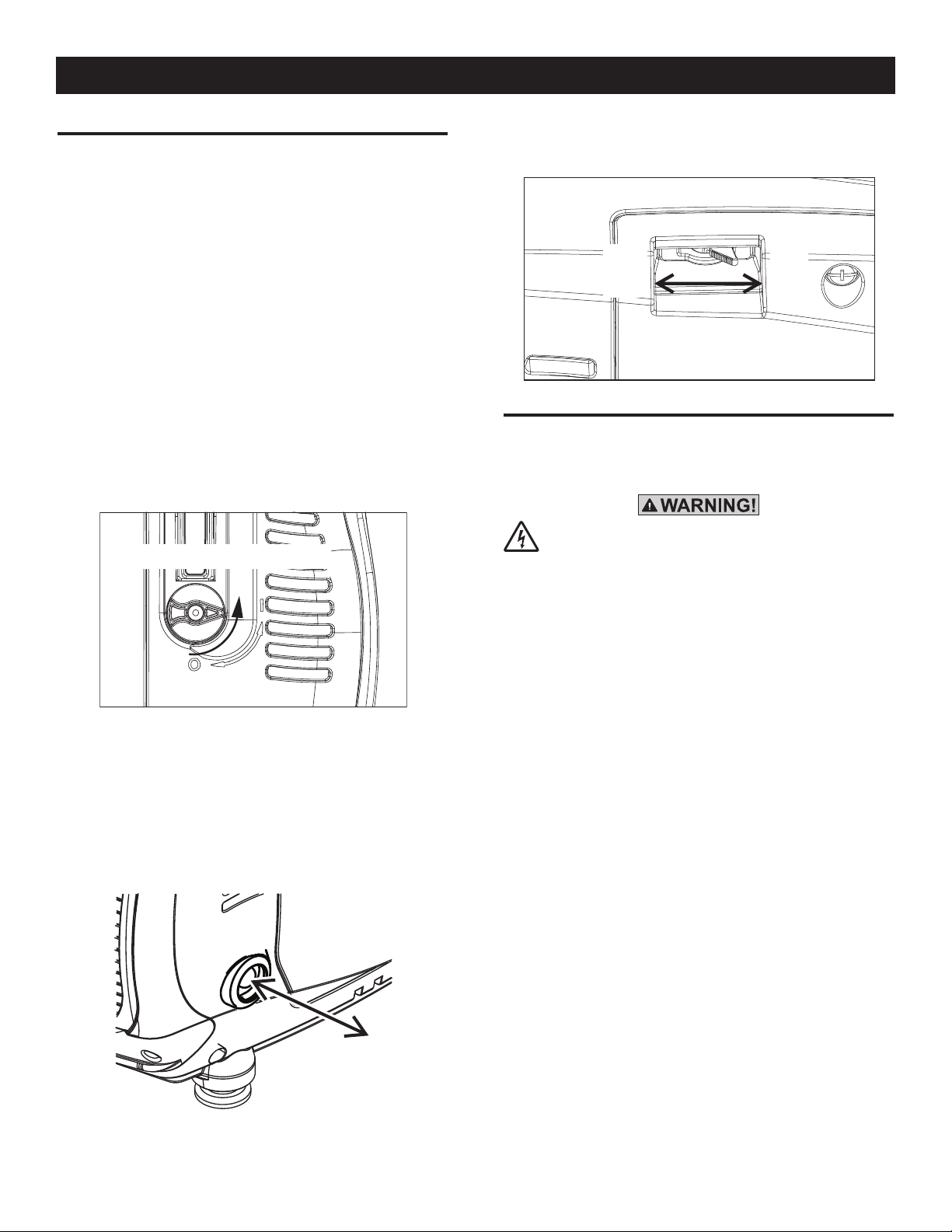

1. Open the fuel valve (Figure 4), located below the starter rope

pull, by turning to the valve 90° counter-clockwise to the “ON” (I)

position.

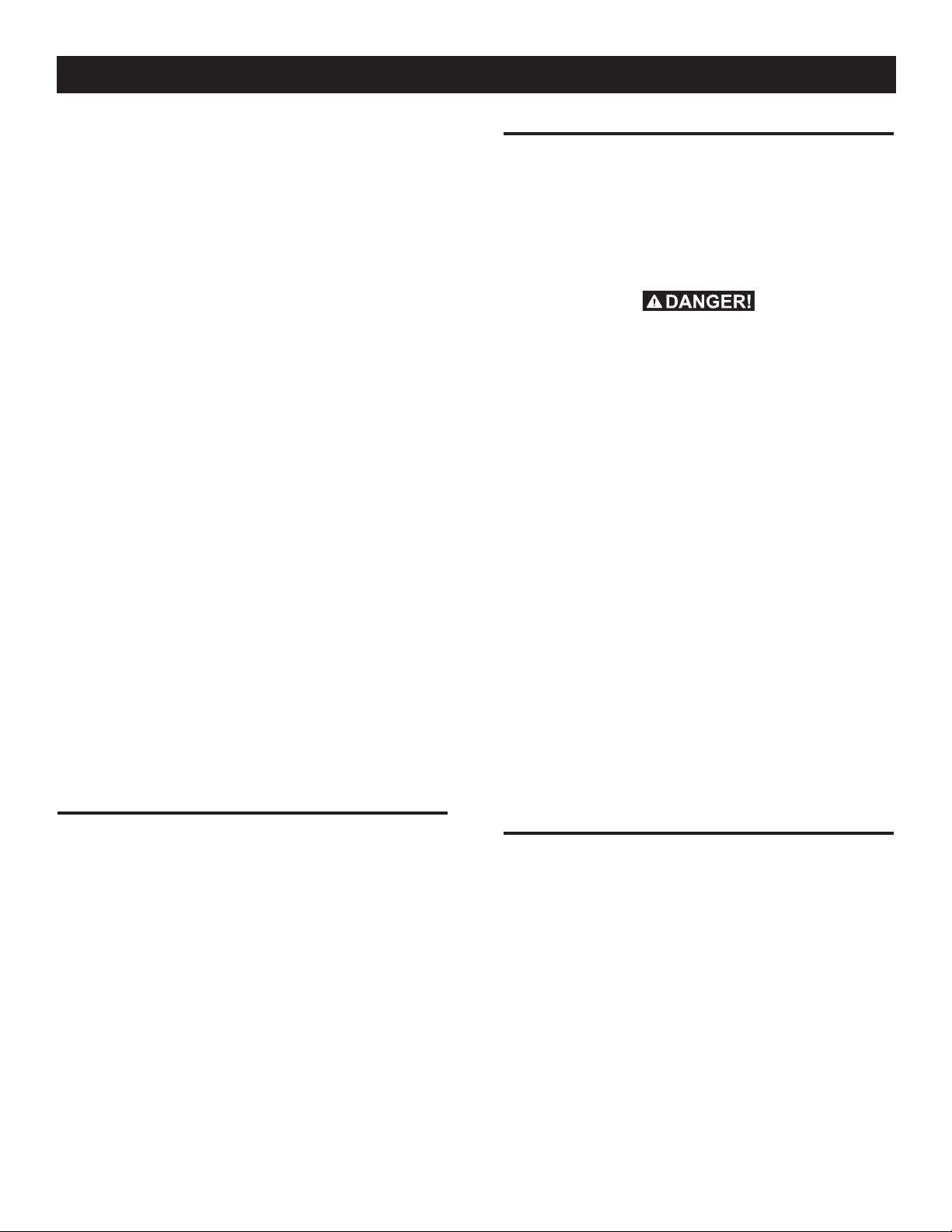

2. Locate the primer bulb (See Figure 5). Slowly, fully depress the

primer bulb and release. Allow the primer bulb to return to its

original state. Repeat this six (6) more times.

3. If the engine is cold or has not been run for some time, engage

the choke by pushing the choke lever to the right (Figure 6).

4. Grip the handle for the pull starter and brace your other hand

against the generator. Pull the rope slowly until resistance is felt,

then pull the rope rapidly up to three (3) times.

5. If the engine does not start, repeat steps 2-4 until the engine fires

and begins to run.

Figure 4 - Fuel Valve

TURNING THE FUEL ON

6. Carefully adjust the choke to approximately the ½ position until

the engine begins to run smoothly, then push the lever all the way

to the left (Figure 6).

7. Make sure the bottom of the generator is not blocked by sand,

leaves, grass, etc. as the cooling vents are located on the bottom

of the unit.

Figure 5 - Prime Fuel System

Figure 6 - Adjust Choke

ENGINE CHOKE

OPERATION

ON

I

OFF

O

ADDING LOADS

Once the generator has been running smoothly for 2-3 minutes,

electrical loads can be added.

Do not use worn, bare, frayed or otherwise

damaged electrical cord sets with the

generator. Do not handle any kind of electrical

device while standing in water, while barefoot,

or while hands or feet are wet.

1. There are two grounded 120 VAC duplex outlets on the front of

the generator.

2. DO NOT overload the generator; if the red “overload” LED lights

up and the devices attached to the generator stop operating, stop

the engine and reduce the load to the generator. Restart and

apply reduced loads.

3. Consult the following table to estimate what can be powered by

the generator.

Device . . . . . . . . . . . . . . . . . . . . . . . . . .Running Watts

*Air Conditioner (12,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1700

*Air Conditioner (24,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3800

*Air Conditioner (40,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6000

Battery Charger (20 Amp). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500

Belt Sander (3") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1000

Chain Saw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200

Circular Saw (6-1/2") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 to 1000

*Clothes Dryer (Electric). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5750

*Clothes Dryer (Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700

*Clothes Washer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1150

Coffee Maker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1750

*Compressor (1 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000

*Compressor (3/4 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1800

*Compressor (1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1400

Curling Iron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 700

*Dehumidifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650

Disc Sander (9") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200

Edge Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500

Electric Blanket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400

Electric Nail Gun. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200

Electric Range (per element) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1500

Operation

Page 10

8

Electric Skillet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1250

*Freezer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700

*Furnace Fan (3/5 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .875

*Garage Door Opener . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 500 to 750

Hair Dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200

Hand Drill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 to 1100

Hedge Trimmer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .450

Impact Wrench . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .500

Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200

*Jet Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .800

Lawn Mower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1200

Light Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Microwave Oven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 700 to 1000

*Milk Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1100

Oil Burner on Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300

Oil Fired Space Heater (140,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . .400

Oil Fired Space Heater (85,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . .225

Oil Fired Space Heater (30,000 Btu) . . . . . . . . . . . . . . . . . . . . . . . . .150

*Paint Sprayer, Airless (1/3 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .600

Paint Sprayer, Airless (handheld) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 to 200

*Refrigerator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .700

Slow Cooker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

*Submersible Pump (1-1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2800

*Submersible Pump (1 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000

*Submersible Pump (1/2 HP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1500

*Sump Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 800 to 1050

* Allow three (3) times the listed running watts for starting theses

devices.

NOTE:

When an electric motor is started, the "OVERLOAD" LED may

light up for up to five (5) seconds (this is normal). If it stays on, a

fault has occurred. Remove all loads and shut down generator to

reset the alarm. Restart the generator. If the "OVERLOAD" LED

remains lit, contact a Generac Dealer for assistance.

USING THE FLEXPOWER™ SWITCH

When the accessories connected to the generator are going to be

used intermittently (such as a hand drill), the FlexPower™ switch

can be pushed to the “ON” (I) position. This will lower the generator

engine speed when loads are not being applied, saving fuel, reducing

engine wear and extending runtime.

USING THE 12 VDC BATTERY CHARGER

The 12 VDC receptacle may be used to recharge 12 VDC automotive

batteries only. The DC charging output is not regulated. The circuit

protector does not prevent over-charging a battery.

1. Connect the charging cable to the generator first, then the

battery, ALWAYS connecting the red lead to positive (+) and the

black to negative (-).

Do not permit smoking, open flame, sparks or

any other source of heat around a battery. Wear

protective goggles, rubber apron and rubber

gloves when working around a battery. Battery

electrolyte fluid is an extremely corrosive

sulfuric acid solution that can cause severe

burns. If a spill occurs, flush area with clear

water immediately.

Storage batteries give off explosive hydrogen

gas while recharging. An explosive mixture will

remain around the battery for a long time after

it has been charged. The slightest spark can

ignite the hydrogen and cause an explosion.

Such an explosion can shatter the battery and

cause blindness or other serious injury.

NEVER reverse the polarity when connecting

the battery terminals to the charging jack.

Severe damage may occur to the generator

and battery.

2. Keep the FlexPower™ switch in the “OFF” (O) position.

3. Start the generator and use it as normal. Charging time will vary

with battery size and condition. Check the voltage at the battery

terminals once the charging cable has been unplugged or the

generator has been shut down.

NOTE:

This receptacle can not recharge 6-Volt batteries and can not be

used to crank an engine having a discharged battery.

SHUTTING DOWN

Once the generator is no longer needed it can be shut down.

1. Switch off any devices connected to the generator. Unplug any

cords to the 120 VAC duplex outlets or the 12 VDC plug.

2. Turn the fuel valve to the “OFF” (O) position (Figure 7). A switch

behind the fuel valve grounds the ignition system, stopping the

engine and the fuel supply is shut off.

3. Close the vent on the fuel cap.

4. Allow the generator to cool before moving or storing.

Operation

Page 11

9

Always allow the generator to cool off before

storing. High temperatures will be present

at the rear of the unit for some time after

shutdown.

Figure 7 - Turn Off Fuel

TURNING THE FUEL OFF

LOW OIL LEVEL SHUTDOWN

This generator is equipped with a low oil level shut down. If the oil

level in the engine crankcase drops below a pre-determined level,

the engine will stop automatically and the “LOW OIL LEVEL” LED

will light up.

Remove the Left Side Service Cover and check the oil level of

the engine. Add or drain oil as necessary; refer to see the section

“ADDING ENGINE OIL”.

FUELING THE GENERATOR

Use care when fueling the generator. Only fill the fuel tank when the

generator has cooled entirely. Use fresh unleaded gasoline with a

minimum Research Octane Number (RON) of 87.

NOTE:

Do not use any gasoline containing more than 10% Ethanol.

NEVER fill the fuel tank with E85 or a mixture of oil and gasoline

designated for two-cycle engines.

Do not light a cigarette or smoke when filling the

fuel tank.

Gasoline is highly FLAMMABLE and its vapors

are EXPLOSIVE. Do not permit smoking, open

flames, sparks or heat in the vicinity while

handling gasoline.

Never fill fuel tank indoors. Never fill fuel tank

when engine is running or hot. Avoid spilling

gasoline on a hot engine. Allow engine to cool

entirely before filling fuel tank.

Do not overfill the fuel tank. Always allow

room for fuel expansion. If tank is over-filled,

fuel can overflow onto a hot engine and cause

FIRE or an EXPLOSION. Wipe up fuel spills

immediately!

TO FILL THE FUEL TANK

1. Remove the fuel tank cap.

Figure 8 - Fuel Tank Cap

FUEL

TANK

CAP

FILL TANK UNTIL

FUEL IS TWO (2)

INCHES BELOW

THE TOP

2. Add fuel slowly, stopping about two (2) inches below the top of

the filler neck.

3. Replace the fuel tank cap. Make sure the valve on the fuel cap

is in the “OFF” position.

4. If the generator is going to be started, refer to the section

“STARTING THE GENERATOR” for additional directions on

priming the fuel system.

ADDING ENGINE OIL

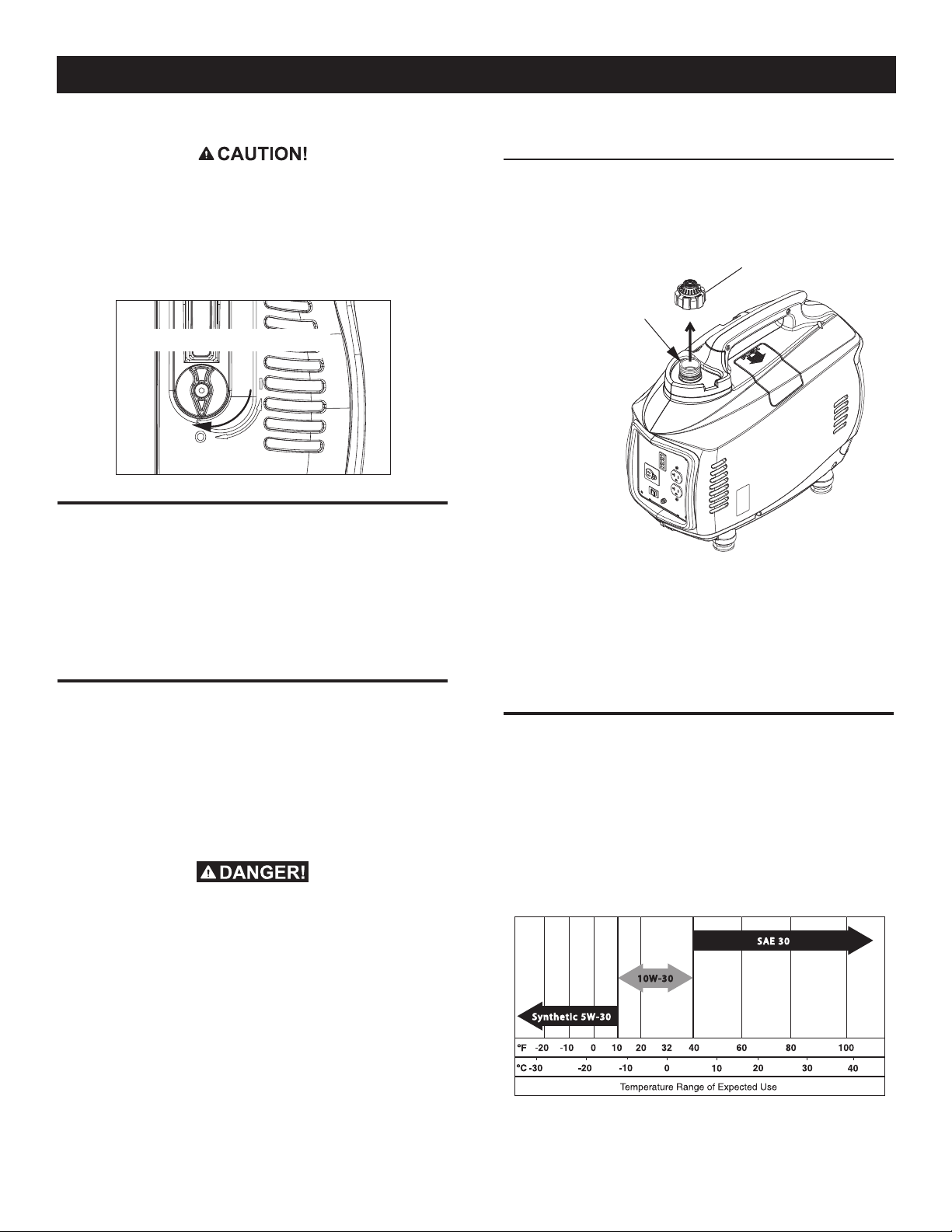

All oil should meet minimum American Petroleum Institute (API)

Service Class SJ, SL or better. Do not use any aftermarket additives.

Select the oil's viscosity grade according to the expected operating

temperature, only a little more than one-half quart is needed.

• Above 40° F, use SAE 30

• Below 40° F to 10° F, use 10W-30

• Below 10° F, use synthetic 5W-30

10W-30

SAE 30

Synthetic 5W-30

Operation

Page 12

10

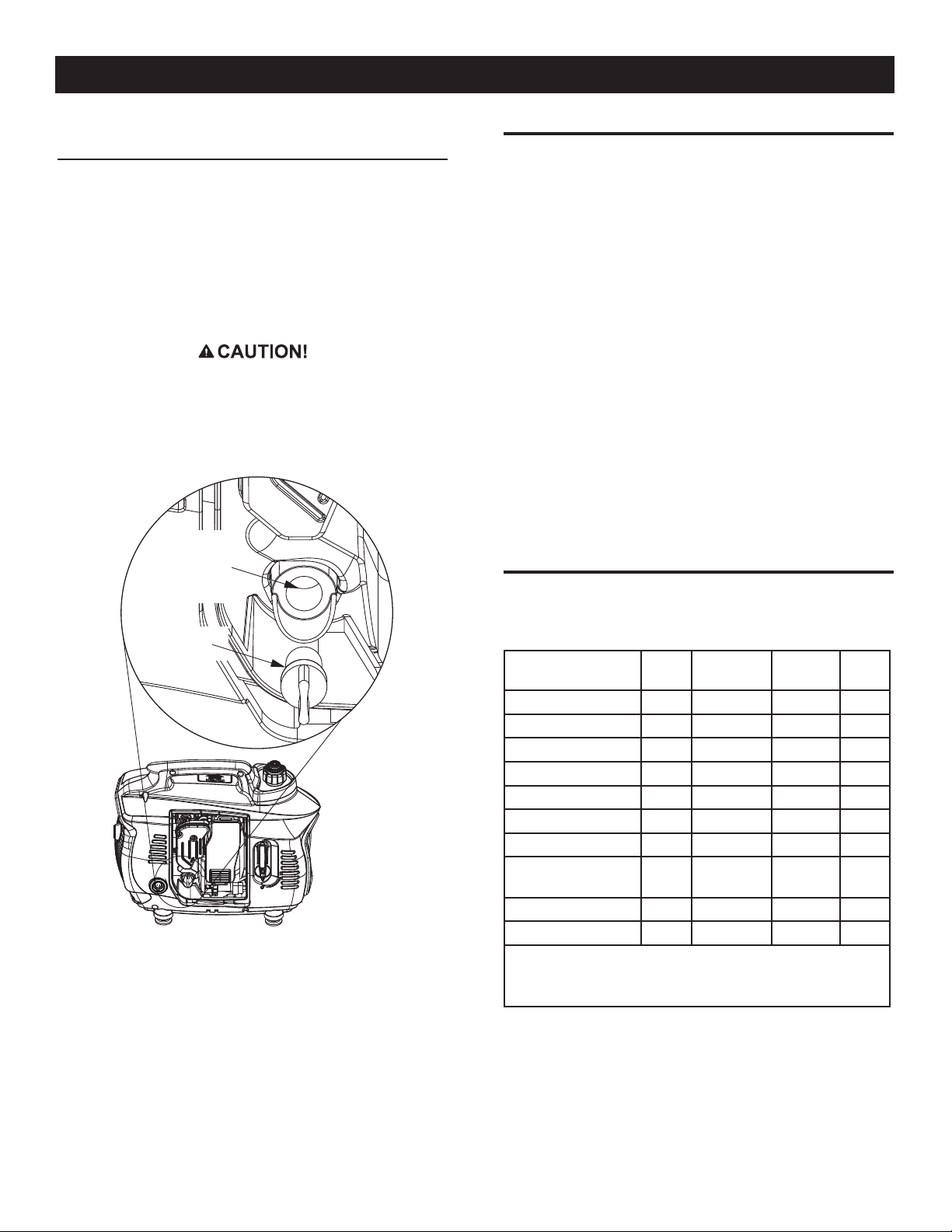

TO ADD ENGINE OIL TO THE CRANKCASE

1. Place the unit on a firm, level surface.

2. Remove the Left Side Service Cover.

3. Remove the oil fill cap located on the bottom of the engine

crankcase.

4. Add the recommended engine oil slowly, stopping frequently to

check the level. The full level is the base of the threads in the filler

neck. DO NOT OVERFILL!

5. Replace the oil fill cap and tighten.

6. Always check the oil level before starting the generator engine.

DO NOT overfill the engine crankcase with

oil. High oil pressure may result, causing

premature engine wear and damage.

Figure 9 - Oil Fill

FULL OIL LEVEL

IS THE BOTTOM

OF THESE

THREADS

OIL FILL

CAP

GENERATOR MAINTENANCE

Proper care will ensure maximum performance of your generator.

Generator maintenance consists of keeping the unit clean and dry.

Operate and store the unit in a clean dry environment where it will not

be exposed to excessive dust, dirt, moisture or any corrosive vapors.

Cooling air slots in the generator must not become clogged with snow,

leaves, or any other foreign material.

Check the cleanliness of the generator frequently and clean when

dust, dirt, oil, moisture or other foreign substances are visible on its

exterior surface.

NOTE:

Never insert any object or tool through the air cooling slots, even

if the engine is not running.

NOTE:

DO NOT use a garden hose to clean the generator. Water

can enter the engine fuel system and cause problems. In

addition, if water enters the generator through cooling air

slots, some water will be retained in voids and crevices of the

rotor and stator winding insulation. Water and dirt buildup on

the generator internal windings will eventually decrease the

insulation resistance of these windings.

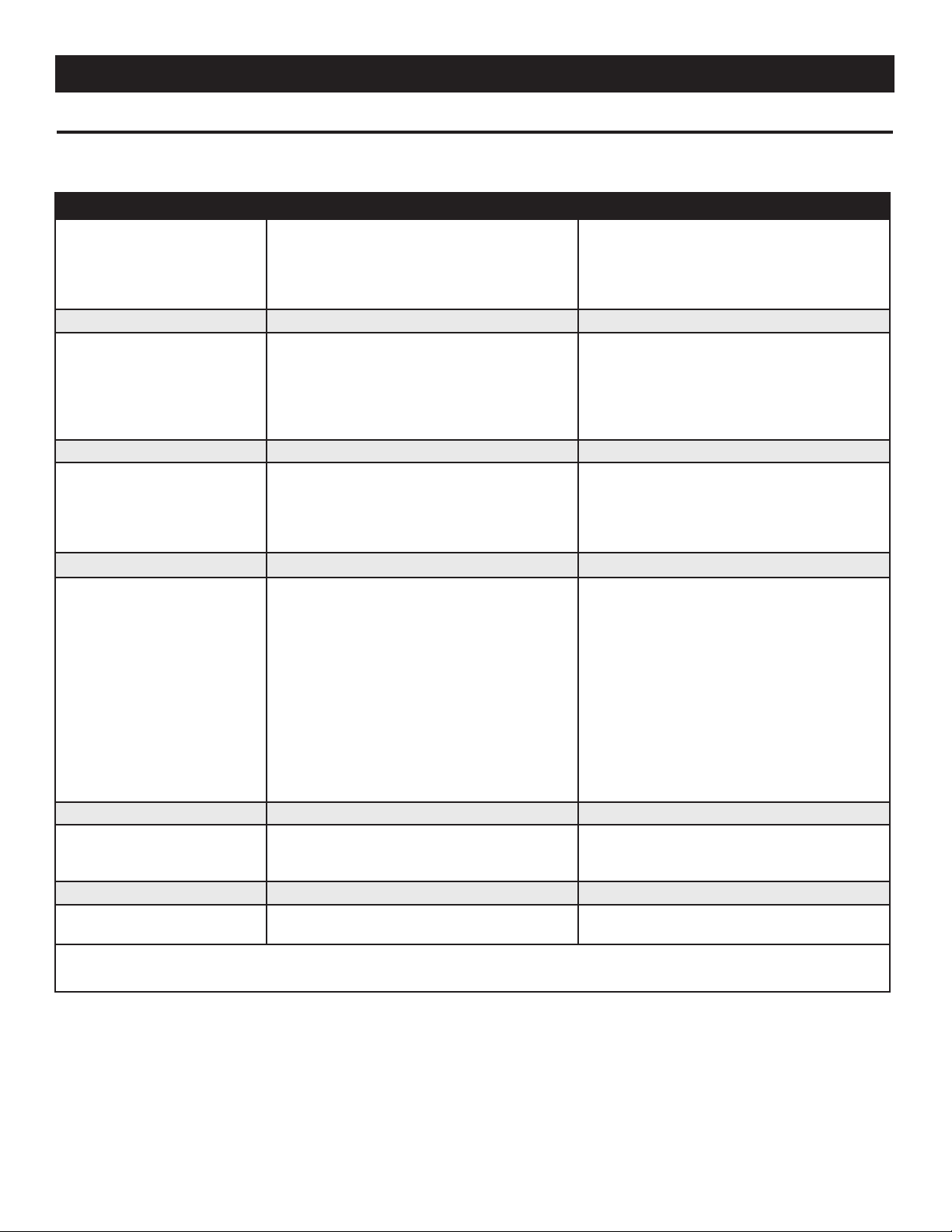

GENERATOR MAINTENANCE SCHEDULE

Follow the recommended service schedule; to order replacement

parts call 1-888-436-3722.

Each

Use

Every 100

Hours

Every 6

Months

Each

Year

Fuel Level X

Oil Level X

Check Air Filter X

*Change Engine Oil X

**Clean Air Filter X

Check Spark Plug X

Check Muffler X

Inspect and Clean

Spark Arrestor

X

Replace Spark Plug X

Replace Fuel Filter X

* Perform initial oil change after the first five (5) hours of operation

** Clean the air filter more often if operating in dusty or sandy conditions.

Replace as necessary.

Maintenance

Page 13

11

CLEANING THE GENERATOR

1. Use a damp cloth to wipe exterior surfaces clean.

2. A soft, bristle brush may be used to loosen caked on dirt, oil, etc.

3. A vacuum cleaner may be used to pick up loose dirt and debris.

4. Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspect cooling air slots and openings on the

generator. These openings must be kept clean and unobstructed.

5. Inspect the vent hoses on the left side of the generator. Make

sure the hoses protrude through the slots below the door and that

the ends are open and free of debris.

ENGINE MAINTENANCE

Only work on a generator that has cooled

completely.

Inspect the oil level and air filter condition each time you are going

to use the generator. To check the air filter and oil level the left side

service cover must be removed; use a screwdriver to loosen the

screw securing the cover and remove.

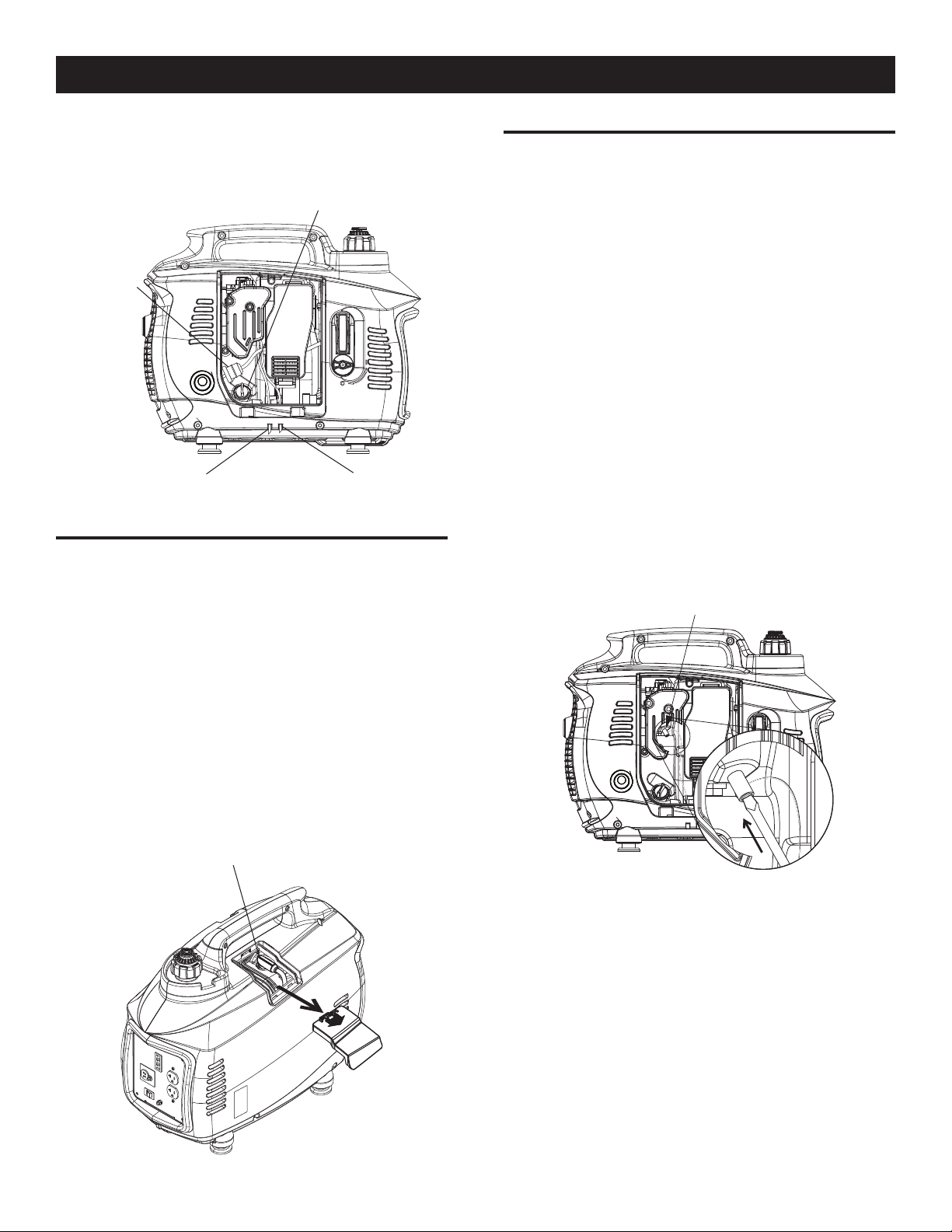

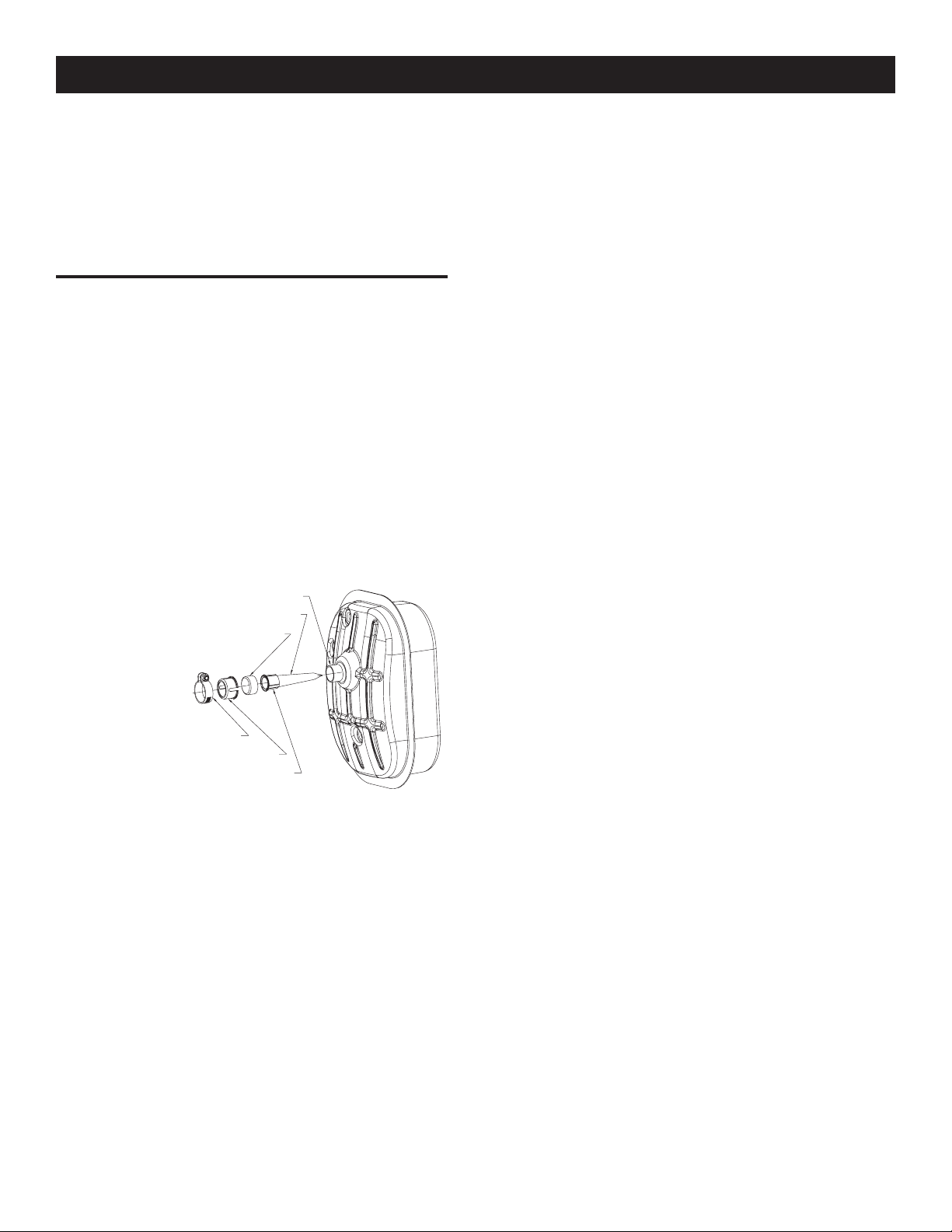

The air filter is located behind a cover for the air box (Figure 10). Push

the tab on the bottom of the air box upwards to release the cover. To

service the air cleaner:

1. Remove the air cleaner. Tap the element to shake loose any

large particles.

2. Wash the element in soapy water. Squeeze the filter dry in clean

cloth (DO NOT TWIST).

3. Soak the filter element in clean engine oil. Squeeze the excess

oil from the filter, leaving a light coating.

4. Clean air cleaner housing and cover before re-installing the filter

element.

Figure 10 - Air Filter

AIR

FILTER

FILTER

HOUSING

COVER

LEFT SIDE

SERVICE COVER

SCREW

LEFT SIDE

SERVICE

COVER

CHANGING THE ENGINE OIL

Hot oil may cause burns. Allow engine to cool

entirely before draining oil. Avoid prolonged

or repeated skin exposure with used oil.

Thoroughly wash exposed areas with soap.

Change the engine oil after the first five (5) hours of operation. Change

the engine oil every 100 hours thereafter. To change the engine oil:

1. Run the generator briefly to warm the engine oil; this also loosens

any engine deposits and makes the used oil flow easier.

Change the oil only when the fuel tank is low

or nearly empty. Tipping the generator with a

full fuel tank may cause fuel leakage.

2. Place the generator over a drain pan and remove the drain

plug. Tip the generator on its side to drain the used oil from the

crankcase.

NOTE:

To make draining the oil easier, a 6” length of vinyl (PVC) hose

with an inside diameter of 1.25” (32mm) any be placed over the

drain lip.

3. Tip the generator upright once the oil has finished draining.

Replace the engine oil with the proper grade called out in Section

“ADDING ENGINE OIL”, then replace the drain plug.

CHANGING THE FUEL FILTER

Locate the fuel filter, just below the engine intake housing (Figure 11).

Make sure the Fuel Shutoff is in the “OFF” (O) position.

1. Remove the pinch clamps securing the fuel filter. Pull the hoses

free.

Wipe up any fuel spills immediately! Do not

smoke or replace the fuel filter near sparks or

open flame!

2. Replace the used filter with a new one. Push the fuel hoses onto

the barbed filter fittings until they are seated completely.

3. Replace the clamps, making sure they are seated on the fittings.

Maintenance

Page 14

12

Maintenance

Figure 11 - Fuel Filter

FUEL

FILTER

OIL FILL PLUG/

OIL DRAIN

CRANKCASE

VENT HOSE

CARBURETOR

VENT HOSE

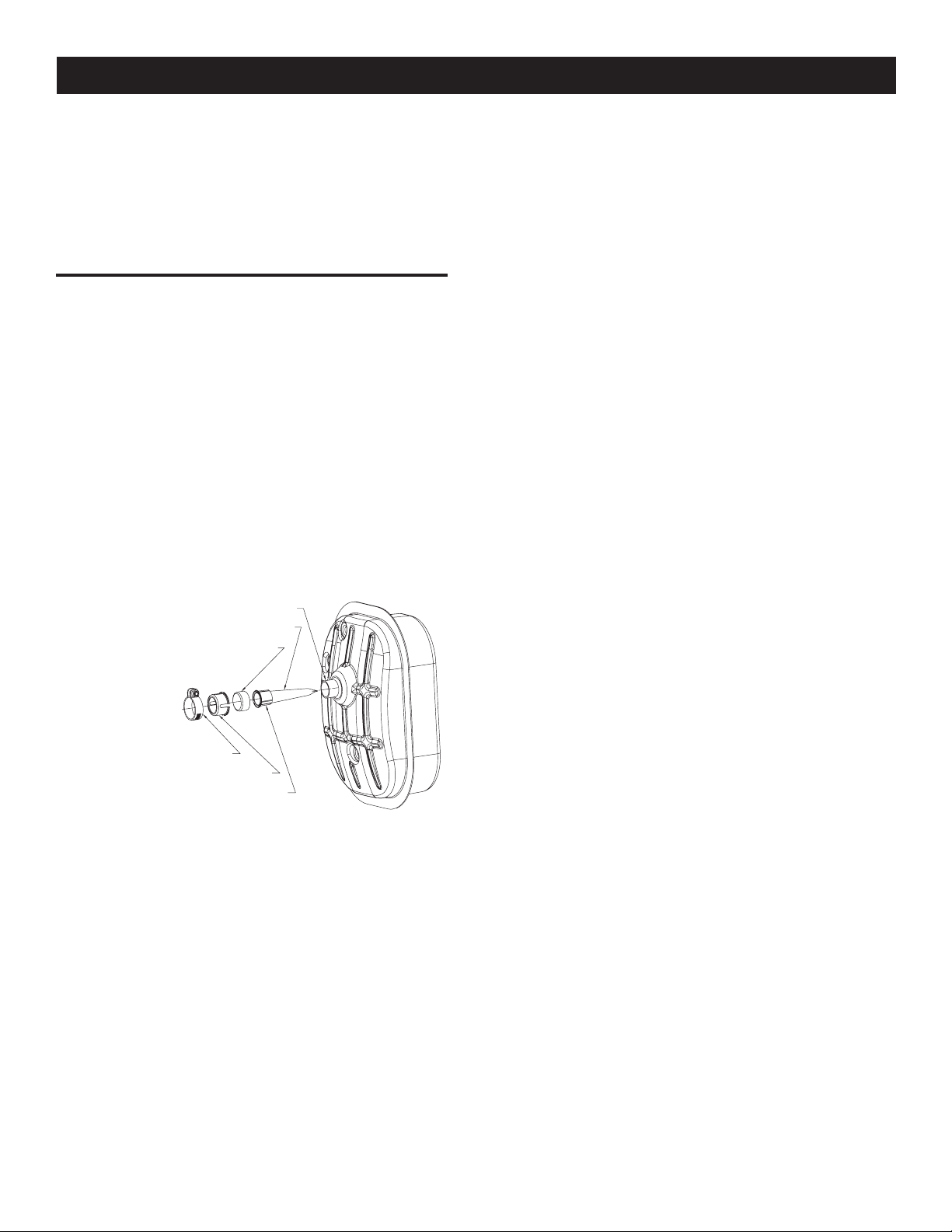

CHANGING THE SPARK PLUG

Replace the spark plug each year, regardless of how many hours the

generator has been run. Use a NGK BPR7HS that has be gapped to

.030” (.76mm). To replace the spark plug:

1. Remove the spark plug cover on the top right side of the

generator, just below the handle (Figure 12).

2. Carefully pull the spark plug lead from the spark plug. Use a

socket wrench to remove the spark plug.

3. Install the new spark plug into the cylinder head. Tighten the

spark plug to 15 ft/lb.

4. Replace the spark plug lead, making sure it is fully seated.

5. Replace the spark plug cover.

Figure 12 - Replace Spark Plug

SPARK PLUG

LOCATION

TRANSPORTATION AND STORAGE

Transport or store the generator only if it has cooled completely. Make

sure the fuel valve and the vent on the fuel cap are both in the OFF

(“O”) position.

It is important to prevent gum deposits from forming in essential fuel

system parts such as the carburetor, fuel hose or tank during longterm storage. Also, experience indicates that alcohol-blended fuels

(called gasohol, ethanol or methanol) can attract moisture, which

leads to separation and formation of acids; these acids can damage

the fuel system of an engine while in storage.

To avoid engine problems, the use of a commercial fuel stabilizer prior

to storage is recommended. Follow the manufacturer’s instructions

when adding the fuel stabilizer.

If the generator is going to be stored for more than six (6) months, the

generator should be prepared as follows:

1. Remove all gasoline from the fuel tank.

2. Start and run engine until engine stops from lack of fuel or open the

valve on carburetor bowl (Figure 13), and allow gasoline to drain

down tube into a receptacle. Discard appropriately. Be sure to close

the valve once the gasoline has drained.

Figure 13 - Carburetor Drain Valve

CARBUREATOR DRAIN

VALVE LOCATED BEHIND

AIR INTAKE

TURN VALVE COUNTER-

CLOCKWISE TO DRAIN FUEL,

CLOCKWISE TO CLOSE

3. While engine is still warm, drain oil from crankcase. Refill with

recommended grade.

4. Remove spark plugs and pour about 1/2 ounce (15 ml) of engine

oil into the cylinders. Cover spark plug hole with rag. Pull the

starting rope several times to coat the cylinder walls with engine

oil.

5. Install and tighten the spark plug.

6. Clean the generator outer surfaces. Check that cooling air slots

and openings on generator are open and unobstructed.

7. Store the unit in a clean, dry place.

Do not store gasoline from one season to another.

If possible, store the unit indoors and cover it to give protection from

dust and dirt.

Page 15

13

Maintenance

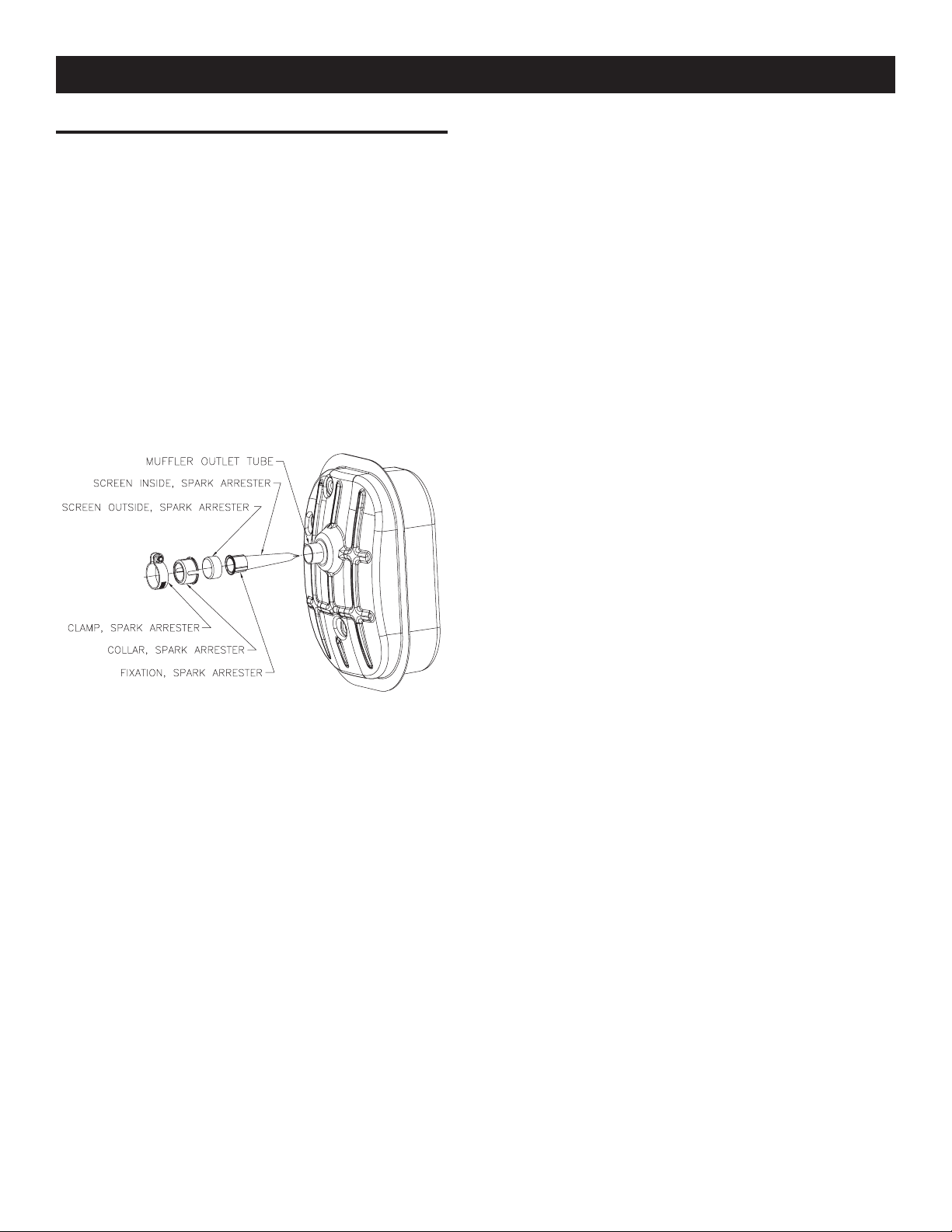

CLEAN SPARK ARRESTOR SCREEN (50 STATE)

The engine exhaust muffler has a spark arrestor screen. Inspect and

clean the screen every 50 hours of operation or once each year,

whichever comes first.

Clean and inspect the spark arrestor as follows:

• Remove the screen retainer by removing the retainer clamp.

• Slide the spark arrestor screen out from the muffler outlet tube.

• Inspect screen and replace if torn, perforated or otherwise

damaged. Do NOT use a defective screen. If screen is not

damaged, clean with a commercial solvent.

• Replace the screen and retainer and secure with retainer clamp.

Figure 12 - Spark Arrestor Screen

Page 16

14

Troubleshooting

TROUBLESHOOTING GUIDE

PROBLEM CAUSE CORRECTIVE ACTION

Engine won't start. 1. No fuel in tank.

2. Fuel valve turned off.

3. Defective spark plug.

4. Plugged fuel filter.

5. Defective or stuck engine stop switch.

1. Add fuel to tank.

2. Turn fuel valve on.

3. Replace spark plug.

4. Replace fuel filter.

5. Replace engine start switch.

Engine starts, then shuts down. 1. Low fuel level.

2. Fuel tank vent closed.

3. Incorrect engine oil level.

4. Contaminated fuel.

5. Defective low oil level switch.

6. Defective ignition coil.

1. Add fuel to tank.

2. Open fuel tank vent.

3. Check engine oil level, add or drain as needed.

4. Replace fuel filter.

5. Replace Low Oil Level switch.

6. Replace ignition coil.

Engine starts, then runs rough.* 1. Choke is stuck or left on.

2. Dirty or clogged air filter.

3. Defective or dirty spark plug.

4. Dirty fuel filter.

5. Defective EcoMode switch.

1. Turn choke off.

2. Clean or replace the air filter element.

3. Replace spark plug.

4. Replace fuel and fuel filter.

5. Replace EcoMode switch.

No AC output.

1. Generator is overloaded (OVERLOAD LED is on

and READY LED is flashing, See control Panel

Identification section).

2. AC voltage is low (OVERLOAD LED is on and

READY LED is flashing, See control Panel

Identification section).

3. Inverter module is overheated (OVERLOAD LED is

on and READY LED is flashing, See control Panel

Identification section).

4. Short circuit in electrical device (OVERLOAD LED

is on and READY LED is flashing, See control Panel

Identification section).

5. Defective inverter assembly.

1. Shut down generator to reset module. Reduce

loads and restart generator.

2. Verify that the choke is OFF.

3. Verify service door is ON. Let cool for 15 minutes

and restart generator.

4. Verify condition of any extension cords and all

items being powered.

5. Replace inverter assembly.

No DC output. ** 1. DC circuit breaker is open.

2. Defective DC circuit breaker.

3. Defective rectifier.

1. Reset DC circuit breaker.

2. Replace DC circuit breaker.

3. Replace rectifier.

Fuel leaks from drain hoses. 1. Fuel system over primed (flooded).

2. Carburetor drain in bowl is not closed.

1. Let generator sit 15 minutes before restarting.

2. Turn valve clockwise to close.

* Engine speed increases and decreases — This is normal as the generator starts up and as loads vary.

** Verify EcoMode Switch is in the "O" OFF position.

Page 17

15

Notes

15

Page 18

Manual Part No. 0J9694 Rev F (09/19/14) Printed in China

Page 19

17

www.generac.com o 1-888-GENERAC

iX 1600 & iX 2000

Manual del Usuario del Generador

Inversor Digital

MODELOS: 005792-3

005793-3

006719-0

PELIGRO

¡GASES DE ESCAPE MORTALES! ¡Utilícelo SOLAMENTE

al AIRE LIBRE y lejos de ventanas, puertas y

respiraderos!

No diseñado para uso en aplicaciones de soporte de

vida crítica.

GUARDE este Manual. Proporcione este manual a

cualquier operador del generador.

Page 20

18

Caja de accesorios ................................................................18

Introducción ...........................................................................19

Lea este manual en su totalidad ............................................19

Reglas de Seguridad .............................................................19

Índice de normas ...........................................................21

Información general...............................................................22

Especificaciones .....................................................................22

1600 Vatios ...................................................................22

2000 Vatios (49 Estado) ................................................22

2000 Vatios (50 Estado) ................................................22

Información de las emisiones .........................................22

Identificación de la unidad .......................................................23

Panel de control .............................................................23

Operación ..............................................................................24

Verificación antes de arrancar .................................................24

Cómo arrancar el generador ....................................................25

Cómo agregar cargas..............................................................25

Cómo usar el interruptor FlexPower

™

......................................26

Cómo usar el cargador de batería de 12 VCD ..........................26

Cómo apagarlo .......................................................................26

Paro por bajo nivel de aceite ...................................................27

Cómo cargar combustible al generador ...................................27

Para llenar el depósito de combustible ............................27

Cómo agregar aceite al motor .................................................27

Para añadir aceite de motor al cárter del motor ..............28

Mantenimiento .......................................................................28

Mantenimiento del generador ..................................................28

Programa de mantenimiento del generador ..............................28

Limpieza del generador ...........................................................29

Mantenimiento del motor.........................................................29

Cambio del aceite de motor ....................................................29

Cambio del filtro de combustible .............................................29

Cambio de la bujía ..................................................................30

Transporte y almacenamiento .................................................30

Limpieza del tamiz del supresor de chispas (50 Estado) ..........31

Localización y corrección de fallas .......................................32

Guía de localización y corrección de fallas ..............................32

Notas .....................................................................................33

CAJA DE ACCESORIOS

Compruebe todo el contenido. Si algunas piezas faltan o están

dañadas, localice a un distribuidor autorizado llamando al

1-888-436-3722.

El paquete incluye:

• 1 bote de aceite SAE 30 • Embudo para aceite

• Llave para bujías • Destornillador

• Cable de carga de batería

Contenido

ADVERTENCIA!

Proposición 65 de California

El escape del motor y algunos de sus componentes son conocidos pore el Estado de California como

causa de cáncer, defectos congénitos y otros daños reproductivos.

ADVERTENCIA!

Proposición 65 de California

Este producto contiene o emite sustancias químicas que son conocidas por el Estado de California como

causa de cáncer, defectos congénitos y otros daños reproductivos.

Page 21

19

INTRODUCCIÓN

Este modelo es un generador compacto, de alto rendimiento, enfriado por

aire y accionado por un motor que está diseñado para suministrar corriente

eléctrica para impulsar cargas eléctricas donde no esté disponible el servicio

público eléctrico o en lugar del servicio público eléctrico por un apagón.

LEA ESTE MANUAL EN SU TOTALIDAD

Si cualquier parte de este manual no se entiende, contacte al

Distribuidor Autorizado más cercano para obtener información sobre los

procedimientos de arranque, operación y mantenimiento.

El operador es responsable del uso apropiado y seguro del equipo.

Recomendamos encarecidamente que el operador lea este manual y

comprenda a fondo todas las instrucciones antes de usar el equipo.

También recomendamos encarecidamente darle instrucciones a otros

usuarios sobre cómo arrancar y operar correctamente la unidad. Esto los

preparará en caso de que necesiten operar el equipo en una emergencia.

El generador puede operar de forma segura, eficiente y confiable

solamente si se sitúa, opera y mantiene correctamente. Antes de operar

o dar mantenimiento al generador:

• Familiarícese con todos los códigos y regulaciones locales, estatales

y nacionales, y sígalas al pie de la letra.

• Estudie cuidadosamente todas las advertencias de seguridad en este

manual y en el producto.

• Familiarícese con este manual y con la unidad antes de usarla.

El fabricante no puede anticipar cada circunstancia posible que pueda

implicar un riesgo. Las advertencias en este manual, y en las etiquetas

y calcomanías en la unidad son, por lo tanto, no exhaustivas. Si usa

un procedimiento, método de trabajo o técnica de operación que el

fabricante no recomiende específicamente, cerciórese de que es seguro

para otros. También asegúrese de que el procedimiento, método de

trabajo o técnica de operación utilizada no haga que el generador sea

inseguro.

LA INFORMACIÓN INCLUIDA EN EL PRESENTE SE BASA EN LAS

MÁQUINAS EN PRODUCCIÓN A LA HORA DE LA PUBLICACIÓN.

GENERAC SE RESERVA EL DERECHO DE MODIFICAR ESTE

MANUAL EN CUALQUIER MOMENTO.

REGLAS DE SEGURIDAD

En esta publicación, y en las etiquetas y calcomanías en el generador, los

recuadros de PELIGRO, ADVERTENCIA, PRECAUCIÓN y NOTA se utilizan

para alertar al personal de instrucciones especiales sobre una operación en

particular que pueda ser peligrosa si se realiza incorrecta o negligentemente.

Obsérvelos cuidadosamente. Sus definiciones son como sigue:

PELIGRO

Indica una situación o acción peligrosa que, si no se

evita, puede ocasionar la muerte o una lesión grave.

ADVERTENCIA

Indica una situación o acción peligrosa que, si no se

evita, podría ocasionar la muerte o una lesión grave.

CUIDADO

Indica una situación o acción peligrosa que, si no se

evita, podría ocasionar una lesión menor o moderada.

NOTA:

Las Notas contienen información adicional importante para un

procedimiento y se incluyen dentro del cuerpo del texto de este manual.

Estas advertencias de seguridad no pueden eliminar los peligros que

indican. El sentido común y el estricto cumplimiento con las instrucciones

especiales mientras realiza la acción o el servicio son esenciales para la

prevención de accidentes.

Cuatro símbolos de seguridad de uso frecuente acompañan los cuadros

de PELIGRO, ADVERTENCIA y PRECAUCIÓN. El tipo de

información que cada uno indica es como sigue:

Este símbolo señala información de seguridad

importante que, si no se sigue, podría poner en

peligro la seguridad personal y/o las propiedades de

terceros.

Este símbolo indica el riesgo de posible explosión.

Este símbolo indica el riesgo de posible incendio.

Este símbolo indica el riesgo de posible descarga

eléctrica.

PELIGROS GENERALES

• NUNCA usar en interiores o áreas cubiertas, INCLUSO SI ventanas

y puertas están abiertas.

• Por razones de seguridad, el fabricante recomienda que

el mantenimiento de este equipo se realice por un Distribuidor

Autorizado. Examine el generador regularmente, y contacte al

Distribuidor Autorizado más cercano para las piezas que necesitan

repararse o reemplazarse.

• Sólo opere el generador en superficies niveladas y donde no esté

expuesto a humedad, suciedad, polvo o vapores corrosivos, en

exceso.

• Mantenga las manos, pies, ropa, etc., alejados de las bandas de

impulsión, de los ventiladores y de otras piezas móviles. Nunca quite

alguna guarda o blindaje de los ventiladores mientras la unidad está

en operación.

• Ciertas piezas del generador se calientan demasiado durante la

operación. Manténgase alejado del generador hasta que se haya

enfriado para evitar quemaduras graves.

• NO opere el generador en la lluvia.

• No modifique la estructura del generador ni cambie los controles

puesto que podría crear una condición de funcionamiento insegura.

• Nunca arranque o pare la unidad con las cargas eléctricas conectadas

a los tomacorrientes Y con los dispositivos conectados ENCENDIDOS.

Arranque el motor y déjelo estabilizarse antes de conectar las cargas

eléctricas. Desconecte todas las cargas eléctricas antes de apagar

el generador.

Reglas de seguridad

Page 22

20

• Al trabajar en este equipo, permanezca alerta todo el tiempo. Nunca

realice trabajos en el equipo cuando esté cansado físicamente o

mentalmente.

• Nunca utilice el generador o ninguna de sus piezas como escalón. Si se

para sobre la unidad puede ejercer presión y romper piezas, y esto puede

generar condiciones de funcionamiento peligrosas como fugas de gases

de escape, fugas de combustible, fugas de aceite, etc.

PELIGROS DEL ESCAPE Y DE LA UBICACIÓN

• ¡Nunca opere el equipo en un área cerrada o en interiores! ¡NUNCA

lo

utilice en el hogar, en un vehículo, ni en áreas parcialmente

cerradas como garajes, incluso si las puertas y las ventanas están

abiertas! Utilícelo SOLAMENTE al aire libre y lejos de las ventanas

abiertas, puertas, respiraderos, y en un área que no acumule los

mortales gases de escape.

Si usa un generador en interiores, MORIRÁ EN

POCOS MINUTOS.

El escape del generador contiene monóxido de

carbono. Es un veneno que no tiene olor ni se

puede ver.

Sólo úselo EN

EXTERIORES y lejos de

ventanas, puertas y

ductos de ventilación.

NUNCA lo use dentro de

una casa o garaje, AUN

si las puertas y ventanas

están abiertas.

• Los gases de escape del motor contiene monóxido de carbono, que no se

puede ver ni oler. Este gas venenoso, si es inhalado en concentraciones

altas, puede causar inconsciencia o aun la muerte.

• El flujo adecuado y sin obstrucciones del aire de enfriamiento y de

ventilación es esencial para el correcto funcionamiento del generador.

No modifique la instalación ni permita algún bloqueo, incluso parcial, de

los componentes de la ventilación, como esto puede afectar seriamente

la operación segura del generador. El generador DEBE ser operado al

aire libre.

• Este sistema de escape debe recibir el mantenimiento correcto. No haga

nada que pueda hacer que el dispositivo de escape sea inseguro o que

no cumpla con los códigos o normas locales.

• Utilice siempre una alarma a pilas para detección del monóxido de

carbono en interiores, siguiendo las instrucciones del fabricante.

• Si comienza a sentirse enfermo, mareado o débil después de que el

generador esté en funcionamiento, trasládese a un lugar con aire fresco

INMEDIATAMENTE. Visite a un doctor, pues podría sufrir de intoxicación

por monóxido de carbono.

PELIGROS ELÉCTRICOS

• El generador produce un voltaje peligrosamente alto cuando está

en funcionamiento. Evite tocar alambres pelados, los terminales, las

conexiones, etc. mientras la unidad está en funcionamiento, incluso en

el equipo conectado al generador. Asegúrese de que todas las cubiertas,

guardas y barreras adecuadas estén colocadas en su sitio antes de hacer

funcionar el generador.

• Nunca manipule ningún tipo de cable o dispositivo eléctrico mientras

esté parado en agua, mientras esté descalzo, o mientras tenga las

manos o los pies mojados. PUEDE SUFRIR UNA DESCARGA

ELÉCTRICA PELIGROSA.

• El Código Eléctrico Nacional (NEC) requiere que el marco y las partes

conductoras del exterior del generador estén conectadas correctamente

a una tierra aprobada. Los códigos eléctricos locales pueden también

requerir que el generador se ponga a tierra adecuadamente. Consulte

con un electricista local sobre los requerimientos de puesta a tierra en su

área.

• Utilice un interruptor de circuito por falla a tierra en áreas húmedas

o altamente conductivas (como los trabajos en pisos metálicos o en

herrería).

• No use cables eléctricos gastados, pelados, quemados o dañados de

alguna otra forma con el generador.

• En caso de un accidente ocasionado por descarga eléctrica, corte

inmediatamente la fuente de corriente eléctrica. Si esto no es posible,

intente liberar a la víctima del conductor vivo. EVITE EL CONTACTO

DIRECTO CON LA VÍCTIMA. Utilice un instrumento no conductor,

tal como una cuerda o una tabla, para liberar a la víctima del conductor

vivo. Si la víctima está inconsciente, aplique los primeros auxilios y

consiga ayuda médica inmediatamente.

RIESGOS DE INCENDIOS

• La gasolina es altamente INFLAMABLE y sus vapores

son

EXPLOSIVOS. No permita fumar, llamas abiertas,

chispas o calor a su alrededor mientras manipula la

gasolina.

• Nunca añada combustible mientras la unidad está en

funcionamiento o caliente. Permita que el motor se enfríe

totalmente antes de añadir combustible.

• Nunca llene el depósito de combustible en interiores.

Cumpla con todas las leyes que regulan el almacenamiento y el manejo

de la gasolina.

• No sobrellene el depósito de combustible. Siempre

deje espacio para la dilatación del combustible. Si se

sobrellena el depósito, el combustible puede desbordarse sobre el motor

caliente y causar un INCENDIO o una EXPLOSIÓN. Nunca almacene el

generador con combustible en el depósito donde los vapores de gasolina

pueden llegar a una llama abierta, una chispa o un piloto (como en

un horno, calentador de agua o un secadora de ropa). Puede suceder

un INCENDIO o una EXPLOSIÓN. Permita que la unidad se enfríe

totalmente antes de almacenarla.

• Limpie los derrames de combustible o aceite inmediatamente. Asegúrese

de que no se dejen materiales combustibles sobre o cerca del generador.

Mantenga el área alrededor del generador limpia y libre de desechos y

deje un espacio de cinco (5) pies a cada lado para permitir la adecuada

ventilación del generador.

• No inserte objetos a través de las ranuras de enfriamiento de la unidad.

GUARDE

ESTAS INSTRUCCIONES – El fabricante sugiere que estas reglas para la operación segura se copien

y se coloquen cerca del sitio de instalación de la unidad. Se debe hacer hincapié de la seguridad a todos los

operadores y a los posibles operadores de este equipo.

Reglas de seguridad

Page 23

21

• No opere el generador si los dispositivos eléctricos conectados se

recalientan, si se pierde la corriente de salida, si el motor o el generador

generan chispas o si se observan llamas o humo mientras la unidad está

en funcionamiento.

• Tenga un extintor cerca del generador en todo momento.

ÍNDICE DE NORMAS

1. Asociación nacional de protección contra incendios (NFPA) 70: El

CÓDIGO ELÉCTRICO NACIONAL (NEC) disponible en www.nfpa.org

2. Asociación nacional de protección contra incendios (NFPA) 5000:

CÓDIGO DE EDIFICACIÓN Y SEGURIDAD disponible en www.nfpa.org

3. El Código internacional de la construcción disponible en www.iccsafe.

org

4. Manual de Cableado Agrícola disponible en www.rerc.org , Consejo de

Recursos de Electricidad Rural P.O. Box 309 Wilmington, OH 451770309

5. ASAE EP-364.2 Instalación y mantenimiento de energía eléctrica de

respaldo en granjas disponible en www.asabe.org, Sociedad Americana

de Ingenieros Agrícolas y Biológicos 2950 Niles Road, St. Joseph, MI

49085.

Esta lista no es inclusiva. Verifique con la Autoridad con jurisdicción local

(AHJ) cualesquiera códigos locales o normas que puedan ser aplicables a

su jurisdicción.

N.º DE MODELO:

N.º DE SERIE:

Figura 1 - Placa de identificación del generador

PLACA DE

IDENTIFICACIÓN

Reglas de seguridad

Page 24

22

ESPECIFICACIONES

1600 VATIOS

Tipo de motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Un cilindro, 4 tiempos

Tamaño del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99 cc

Tipo de arrancador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retroceso

Capacidad de combustible/Tipo . . . . . . . 0,69 galones (2,6 L)/Sin plomo

Capacidad de aceite. . . . . . . . . . . . . . . . . 0,63 Cuartos de galón (0,6 L)

Tiempo de operación a 25% de carga . . . . . . . . . . . . . . . . . . . 5.7 Horas

Tipo de bujía. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR7HS

Separación entre bujías . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0,030"

Dimensiones Largo x Ancho x Alto (pulg.) . . . . . . . . . . . . . . 22 x 12 x 18

Peso Lb/kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43,5/19,7

Salida Máxima de CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1600 W

Salida de sobretensión de CA . . . . . . . . . . . . . . . . . . . . . . . . . . .1650 W

Voltios de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120 VCA

Corriente nominal de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13,3 A

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

Distorsión armónica total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3,0%

Tipo de aislamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clase B

Tomacorrientes. . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 5-15R, (1) 12 VCD

Voltios de CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VCD

Corriente nominal de CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 A

2000 VATIOS (49 ESTADO)

Tipo de motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Un cilindro, 4 tiempos

Tamaño del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 cc

Tipo de arrancador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retroceso

Capacidad de combustible/Tipo . . . . . . . 0,85 galones (3,2 L)/Sin plomo

Capacidad de aceite. . . . . . . . . . . . . . . . . 0,63 Cuartos de galón (0,6 L)

Tiempo de operación a 25% de carga . . . . . . . . . . . . . . . . . . . 5,3 Horas

Tipo de bujía. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR6ES

Separación entre bujías . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0,030"

Dimensiones Largo x Ancho x Alto (pulg.) . . . . . . . . . . . . . . 22 x 12 x 18

Peso Lb/kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49,6/22,5

Salida Máxima de CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 W

Salida de sobretensión de CA . . . . . . . . . . . . . . . . . . . . . . . . . . .2200 W

Voltios de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120 VCA

Corriente nominal de CA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16,7 A

Frecuencia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 Hz

Distorsión armónica total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3,0%

Tipo de aislamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clase B

Tomacorrientes. . . . . . . . . . . . . . . . . . . . . . . . . . . (2) 5-20R, (1) 12 VCD

Voltios de CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VCD

Corriente nominal de CD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 A

NOTA:

La energía generada y el tiempo de operación son influenciados por

muchos factores, algunos de los cuales son la calidad del combustible,

la temperatura ambiente y la condición del motor. La corriente de salida

disminuye aproximadamente en 3,5% por cada 1.000 pies sobre el nivel

del mar y en 1% por cada 10 grados sobre 60° F.

2000 VATIOS (50 ESTADO)

Tipo de motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Un cilindro, 4 tiempos

Tamaño del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 cc

Tipo de arrancador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Retroceso

Capacidad de combustible/Tipo . . . . . . . 0,82 galones (3,1 L)/Sin plomo

Capacidad de aceite. . . . . . . . . . . . . . . . . 0,63 Cuartos de galón (0,6 L)

Tiempo de operación a 25% de carga . . . . . . . . . . . . . . . . . . . 4,7 Horas

Tipo de bujía. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NGK BPR6ES

Separación entre bujías . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0,030"

Dimensiones Largo x Ancho x Alto (pulg.) . . . . . . . . . . . . . . 22 x 12 x 18

Peso Lb/kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49,6/22,5

Salida Máxima de CA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2000 W

Salida de sobretensión de CA . . . . . . . . . . . . . . . . . . . . . . . . . . .2200 W