Page 1

*Built in the USA using domestic

and foreign parts

Operator’s Manual

OneWASH™ Power Washer

www.generac.com or 1-888-436-3722

Page 2

WARNING!

California Proposition 65

Engine exhaust and some of its constituents are known to the state of California to cause cancer,

birth defects, and other reproductive harm.

WARNING!

California Proposition 65

This product contains or emits chemicals known to the state of California to cause cancer,

birth defects, and other reproductive harm.

ii

Page 3

Table of Contents

Section 1 - Introduction............................................. 1

1.1 Introduction.......................................................... 1

Section 2 - Safety........................ ... ... .... ..................... 3

2.1 Safety Rules................... .... ... ... ... .... ... ... ............... 3

Section 3 - General Information................................ 7

3.1 Know Your Power Washer................................... 7

3.2 Product Specifications ......................................... 8

3.3 Emissions Information.......................................... 8

3.4 High Altitude Operation........................................ 8

3.5 Unpacking............................................................ 9

Section 4 - Set-up........ ... ... ... .... ... ... ... .... ... ... ... .......... 11

4.1 Assembly ........................................................... 11

4.2 Add Engine Oil................................................... 12

4.3 Add Fuel............................................................. 13

4.4 Connect Hose and Water Supply to Pump........ 13

4.5 How to Use Nozzles........................................... 15

Section 5 - Operation........... .... ... ... ... .... ... ... ... .... ... ... 19

5.1 Operation........................................................... 19

5.2 Power Washer Location............................... ... ... 19

5.3 Checklist Before Starting Engine....................... 19

5.4 How to Start Your Power Washer...................... 19

5.5 Automatic Cool Down System

(Thermal Relief)................................................. 21

5.6 How to Stop Your Power Washer...................... 21

Section 6 - Maintenance.......................................... 23

6.1 Maintenance Recommendations ....................... 23

6.2 Maintenance Schedule ...................................... 23

6.3 Pump Oil.................................. ... ... .... ... ... ... .... ... 24

6.4 Emissions Control.............................. ... ... ... .... ... 24

6.5 Power Dial Settings ........................................... 24

6.6 Power Washer Maintenance.............................. 24

6.7 Check and Clean Inlet Screen........................... 24

6.8 Check High Pressure Hoses................. ... ... .... ... 24

6.9 Check Detergent Siphoning Tube............... .... ... 24

6.10 Check Spray Gun .............................................. 24

6.11 Chemical Tank Maintenance ............................. 24

6.12 Nozzle Maintenance .......................................... 25

6.13 Engine Maintenance.......................................... 26

6.14 Engine Oil Recommendations ........................... 26

6.15 Service Air Cleaner............................................ 27

6.16 Service Spark Plug ............................................ 28

6.17 Inspect Muffler and Spark Arrester.................... 28

6.18 After Each Use................................................... 29

6.19 Winter Storage................................................... 29

6.20 Long Term Storage............................................ 29

6.21 Other Storage Instructions................................. 30

6.22 Transporting/Tipping of the Unit ........................ 30

Section 7 - Troubleshooting ................................... 31

7.1 Troubleshooting Guide ...................................... 31

iii

Page 4

This page intentionally left blank.

iv

Page 5

Section 1 Introduction

1.1 — INTRODUCTION

Thank you for purchasing this power washer manufactured by Generac Power Systems, Inc. This model is a

high performance, air-cooled, engine-driven power

washer that operates at 3100 psi.The units feature custom designed wheels, axial cam pump with stainless

steel pistons, automatic cool down system, quick connect

nozzles, high pressure hose, detergent siphoning hose

and chemical tank.

Common sense and strict compliance with the special instructions are essential to preventing accidents. The operator must read this manual and

thoroughly understand all of the instructions and warnings before using the equipment. If any portion of the

manual is not understood, contact the nearest Au thorized

Dealer for starting, operating and servicing procedures.

The owner is responsible for proper and safe use of the

equipment.

The power washer can operate safely, efficiently and reliably only if it is properly located, operated and maintained. Before operating, servicing or storing:

• Study all warnings in this manual and on the product

carefully.

• Become familiar with this manual and the unit before

use.

• Refer to the Assembly section of the manual for

instructions on final assembly procedures. Follow the

instructions completely.

The manufacturer cannot anticipate every possible circumstance that might involve a hazard. The warnings in

this manual, and on tags and decals affixed to the unit

are, therefore, not all inclusive. If using a procedure, work

method or operating technique that the manufacturer

does not specifically recommend, ensure that it is safe for

others. Also make sure the procedure, work method or

operating technique utilized does not render the power

washer unsafe.

THE INFORMATION CONTAINED HEREIN WAS

BASED ON MACHINES IN PRODUCTION AT THE

TIME OF PUBLICATION. GENERAC RESERVES THE

RIGHT TO MODIFY THIS MANUAL AT ANY TIME.

Save these instructions for future reference. If you

loan this device to someone, always loan these

instructions and the Owner's Manual to the individual as well.

1.1.1 — Where to Find Us

You can contact Generac Customer Service by phone at

1-888-436-3722, or on the internet at www.generac.com.

Record the important information of the unit in the following chart for future reference and/or service inquiries.

Model Number

Serial Number

Date Purchased

OneWASH™ Power Washer 1

Page 6

This page intentionally left blank.

Introduction

2 OneWASH™ Power Washer

Page 7

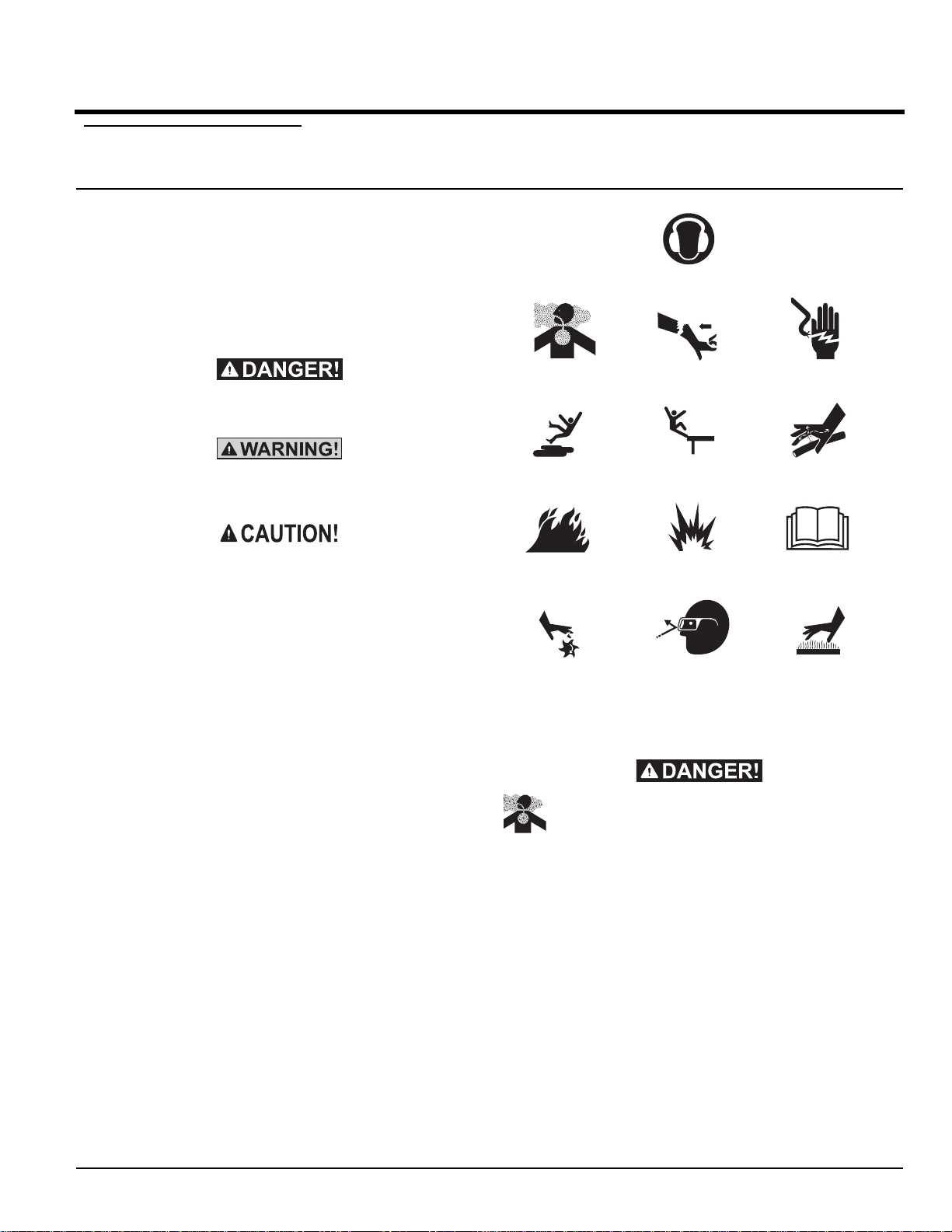

KickbackToxic Fumes Electrical Shock

Fluid InjectionFall

Fire Explosion Operator’s Manual

Slippery Surface

Moving Parts Flying Objects Hot Surface

Hearing Protection

Section 2 Safety

2.1 — SAFETY RULES

Throughout this publication, and on tags and decals

affixed to the power washer, DANGER, WARNING, CAUTION and NOTE blocks are used to alert personnel to

special instructions about a particular operation that may

be hazardous if performed incorrectly or carelessly.

Observe them carefully. Their definitions are as follows:

Indicates a hazardous situation or action which, if

not avoided, will result in death or serious injury.

Indicates a hazardous situation or action which, if

not avoided, could result in death or serious injury.

Indicates a hazardous situation or action which, if

not avoided, could result in minor or moderate injury.

NOTE:

Notes contain additional informatio n important to a

procedure and will be found within the regular text

body of this manual.

These safety warnings cannot eliminate the hazard s th at

they indicate. Common sense and strict compliance with

the special instructions while performing the action or

service are essential to preventing acciden ts.Safety

Symbols and Meanings.

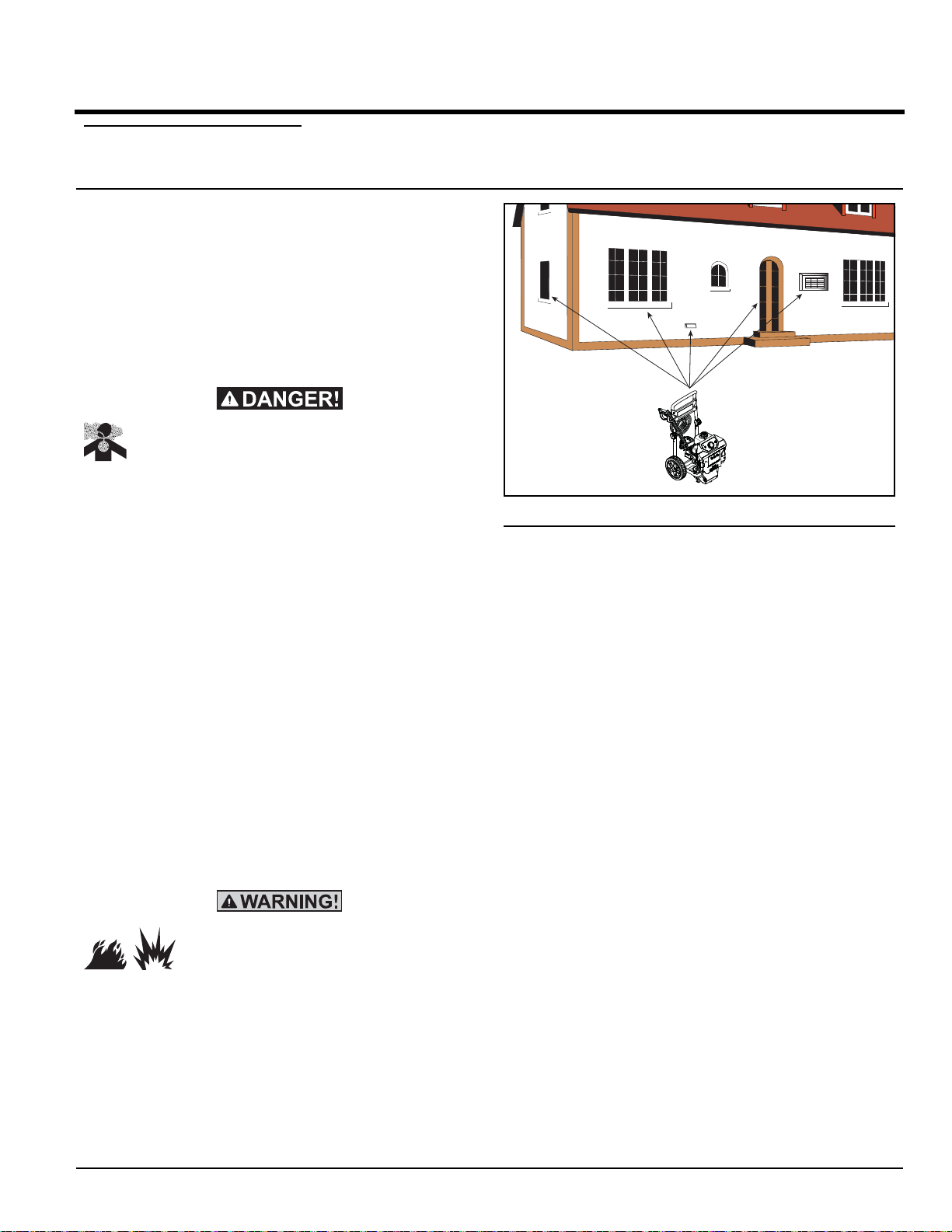

2.1.1 — Exhaust Hazards

OneWASH™ Power Washer 3

Carbon monoxide produced during use can

kill in minutes. NEVER use indoors, in a vehicle, or in other sheltered areas, EVEN IF doors

and windows are open. Only use OUTSIDE

and far away from windows, doors and vents.

Some chemicals or detergents may be harmful if inhaled or ingested, causing severe nausea, fainting, or poisoning.

• Operate power washer ONLY outdoors.

• A running engine gives off carbon monoxide.

• Carbon monoxide is an odorless, colorless, poisonous

gas. Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures, nausea, fainting or death. If you start experiencing any of

these symptoms, IMMEDIATELY move to fresh air.

Seek medical attention.

Page 8

Safety

• Keep exhaust gas from entering a confin e d ar ea

through windows, doors, ventilation intakes, or other

openings. Warn any occupants inside about the symptoms of carbon monoxide so they know to move to

fresh air if they begin to feel ill.

• The use of a carbon monoxide detector inside any

occupied premises between the power washer and the

occupant is recommended.

• NEVER start or run engine indoors, in a vehicle, or in

an enclosed area, even if windows and doors are open.

• Use a respirator or mask whenever there is a chance

that harmful gas or vapors may be inhaled.

• Read all instructions with respirator or mask so you are

certain the respirator or mask will provide the necessary protection against inhaling harmful gas or vapors.

If you begin to experience any of the CO sympto m s

listed above, IMMEDIATELY move to fresh air.

2.1.2 — Fluid Injection Hazard

NEVER aim spray gun at people, animals, or

electrical devices. Serious injury or death will

result. ALWAYS point spray gun in safe direction, squeeze spray gun trigger to release

high pressure, every time you stop engine.

Engage trigger lock when not in use.

• The high pressure stream of water that this equipment

produces can cut through skin and its underlying tissues, leading to serious injury, possible amputation or

death. Spray gun tra ps high water pressure, even

when engine is stopped and water is disconnected,

which can cause injury.

• NEVER allow CHILDREN to operate power washer or

play nearby. This is NOT a toy.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any

kind. Replace o-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connec ted to pump and

spray gun while system is pressurized.

• NEVER secure spray gun in open position.

• NEVER leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

2.1.3 — Electrical Shock Hazard

Risk of electrocution.

Contact with power source can cause ele ctric

shock or burn.

• NEVER spray near power source.

2.1.4 — Hot Surfaces Hazard

Contact with muffler area can result in

serious burns. Exhaust heat/gases can

ignite combustibles, structures or

damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust

gases.

• Allow equipment to cool before touching.

• Keep at least five (5) feet (152 cm) of clearance on all

sides of power washer including overhead.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark

arrester , as defined in Section 4442, maintained in

effective working order. Other states or federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a spark

arrester designed for the exhaust system installed on

this engine.

• Replacement parts must be the same and installed in

the same position as the original parts.

4 OneWASH™ Power Washer

Page 9

Safety

2.1.5 — Fire Hazards

Fuel and its vapors are extremely flammable and explosive. Fire or explosion

can cause severe burns or death.

WHEN ADDING OR DRAINING FUEL

• Turn power washer OFF and let it cool at least two (2)

minutes before removing fuel cap. Loosen cap slowly

to relieve pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting

engine.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleaner

are in place.

• DO NOT crank engine with spark plug removed.

WHEN OPERATING EQUIPMENT

• DO NOT tip engine or equipment at angle which

causes fuel to spill.

• DO NOT spray flammable liquids.

WHEN TRANSPORTING OR REPAIRING EQUIPMENT

• Transport/repair with fuel tank EMPTY.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters,

clothes dryers, or other appliances that have pilot light

or other ignition source because they can ignite fuel

vapors.

2.1.6 — Hearing Protection Hazard

Hearing Protection Recommended.

2.1.7 — Fall Hazard

Use of power washer can create puddles and slippery surfaces. Kickback

from spray gun can cause you to fall.

• Use only on a level surface.

• The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery surfaces.

• Do not use on elevated surfaces where chance of kickback could result in a serious fall.

• Firmly grasp spray gun with both hands when using

high pressure spray to avoid injury when spray gun

kicks back.

2.1.8 — Moving Parts Hazard

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

• NEVER operate power washer without protective

housing or covers.

• DO NOT wear loose clothing, jewelry or anything that

may be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

2.1.9 — Kickback Hazard

Starter cord kickback (rapid retraction) can

result in bodily injury . Kickback will pull hand

and arm toward engine faster than you can

let go. Broken bones, fractures, bruises, or

sprains could result.

• NEVER pull starter cord without first relieving spray

gun pressure.

• To relieve trapped pressure, point gun in safe direction

and release pressure by pulling/actuating trigger on

spray gun.

• When starting engine, pull cord slowly until resistance

is felt and then pull rapidly to avoid kickback.

• After each starting attempt, where engine fails to run,

always point spray gun in safe direction, and squeeze

spray gun trigger to release high pressure.

• Firmly grasp spray gun with both hands when using

high pressure spray to avoid injury when spray gun

kicks back.

OneWASH™ Power Washer 5

Page 10

Safety

2.1.10 — Spark Hazards

Unintentional sparking can result in

fire or electric shock.

WHEN ADJUSTING OR MAKING

REP AIRS TO YOUR Power washer.

• Disconnect the spark plug wire from the sp ark plug and

place the wire where it cannot contact sp ark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

2.1.11 — Splash Hazards

Risk of eye injury. Spray can splash back or

propel objects.

• Always wear safety goggles when using this equipment or in vicinity of where equipment is in use.

• Before starting the power washer, be sure you are

wearing adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

NOTE:

High pressure spray may damage fragile items

including glass.

• DO NOT point spray gun at glass when using red (0°)

MAX nozzle.

• NEVER aim spray gun at people, animals, electrical

devices or plants.

NOTE:

Improper treatment of power washer can damage it

and shorten its life.

• If you have questions about intended use, ask dealer

or contact qualified service center.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DO NOT operate power washer above rated pressure.

• DO NOT modify power washer in any way.

• Before starting power washer in cold weather , check all

parts of the equipment to be sure ice has not formed

there.

• NEVER move machine by pulling on hoses. Use handle provided on unit.

• Check fuel system for leaks or signs of deterioration,

such as chafed or spongy hose, loose or missing

clamps, or damaged tank or cap. Correct all defects

before operating power washer.

• This equipment is designed to be used with Generac

authorized parts ONLY. If equipment is used with parts

that DO NOT comply with minimum specifications, user

assumes all risks and liabilities.

6 OneWASH™ Power Washer

Page 11

I

U

O

Q

P

S

D

R

S

W

V

F

H

B

A

Section 3 General Information

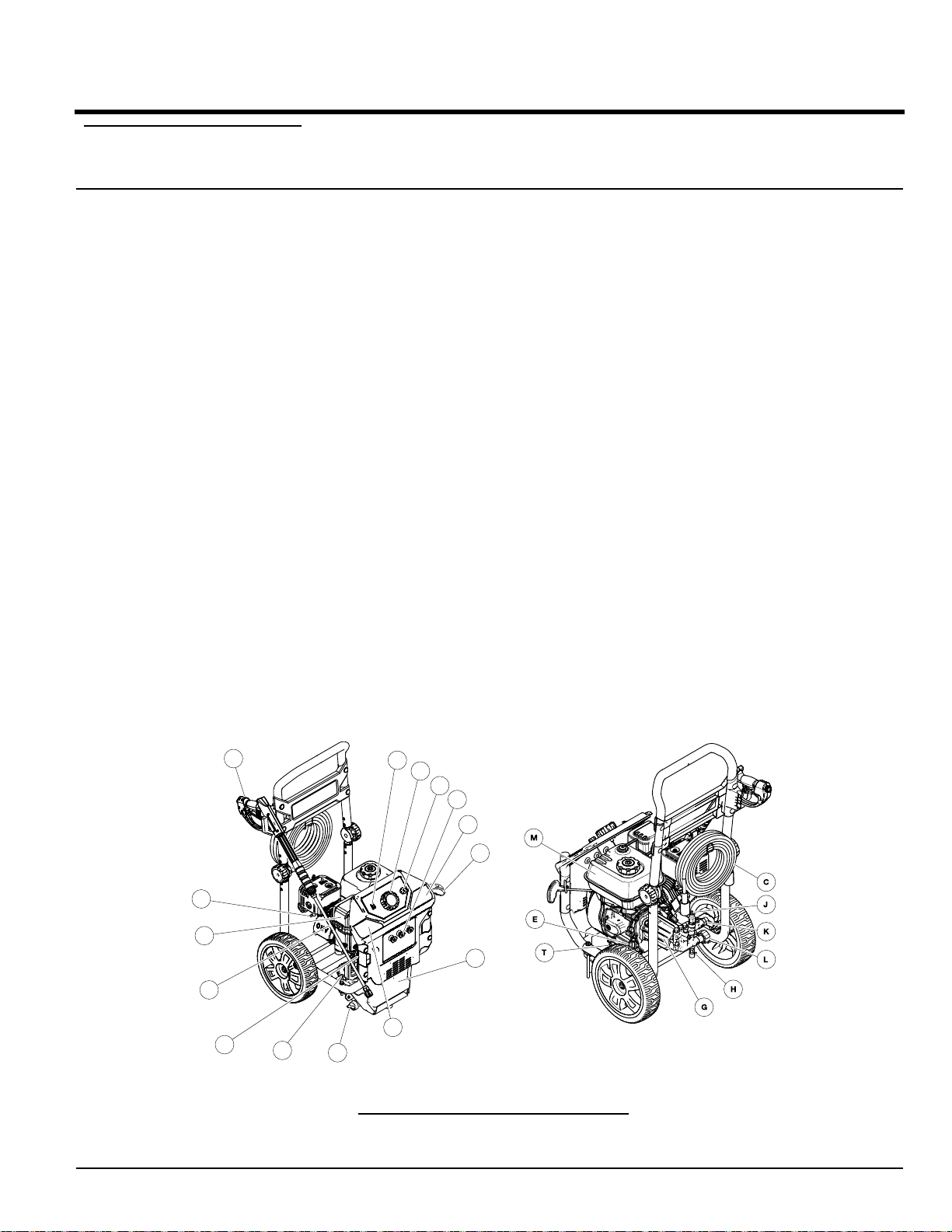

3.1 — KNOW YOUR POWER WASHER

Read this owner’s manual and safety rules before operating your high power washer. If you loan this device to

someone, ALWAYS loan these instructions AND the

owner’s manual to the individual as well. Compare the

illustrations with your high power washer to familiarize

yourself with the locations of various controls

(Figure 3-1). Save this manual for future reference.

Replacement owner’s manuals can be printed from the

Generac Web site.

A-Spray Gun – Controls the application of water onto

the cleaning surface with trigger device. Includes a

trigger lock.

B -Lance with Quick Connect – Allows you to switch

between different nozzles.

C -High Pressure Hose – Connect one end to water

pump and the other to the spray gun.

D -Recoil Starter – Use for starting the engine.

E -Oil Fill – Check and add engine oil.

F-Air Filter – Protects engine by filtering dust and

debris out of the intake air.

G-Pump – Develops high pressure.

H -Thermal Relief Valve – Cycles water through the

pump when water reaches 125°F warm water w ill

discharge from pump onto ground. This prevents

internal pump damage.

I -Engine On/Off Switch – Turn this switch to “ON”

before using the recoil starter. Turn the switch to

“OFF” to stop the engine.

J -Unloader Valve – Controls the high pressure output.

K -High Pressure Outlet – Connection for high pres-

sure hose.

L -Water Inlet – Connection for Garden Hose.

M -Fuel Tank – Fill tank with regular unleaded fuel.

Always leave room for fuel expansion.

O -Choke – Prepares a cold engine for starting.

P-Power Dial – Provides optimal cleaning power for

each desired application.

Q -Nozzles – Chemical injection, Blast (0°), Wash (25°),

Detergent for various high pressure cleaning applications.

R -Chemical Tank – A drain-able tank used to hold

power washer safe detergents to be siphoned into

the low pressure stream.

S -Prepare/Start Instruction – Identifies proper proce-

dure to set up and start/stop power washer.

T -Drain Plug – Used to drain engine oil.

U -Serial Number Location

V -Chemical Tank Fill Cap

W -Chemical Tank Drain Cap

OneWASH™ Power Washer 7

Figure 3-1. Features and Controls

Page 12

General Information

3.1.1 — ITEMS NOT SHOWN

Identification Label (on engine blower housing) –

Provides model and serial number of power washer.

Please have these readily available if calling for assistance.

Detergent Siphoning T ube/Filter – Use to siphon power

washer safe detergents into the low pressure stream.

3.2 — PRODUCT SPECIFICATIONS

Pressure - (PSI / BAR) .............................. 3100/213 Max

Flow Rate - (GPM / LPM)............................ 2.8/10.6 Max

Water supply temperature - (°F / C°)............. 100/38 Max

Hose length - (Feet / Meters)..................................30/9.1

Chemical Tank(s) - Number per unit...............................1

Chemical Tank - Capacity (Gal) N/A..........................0.75

Nozzles - Number per unit..............................................3

Lance Length (Inches / cm).....................................20/51

Gun.....................................................................Standard

Engine Displacement - (Cubic Inch / cc) ............12.9/212

Spark Plug Type .................................F7TC or equivalent

Spark Plug Gap - (Inches / mm) ....0.028-0.031/0.70-0.80

Fuel Capacity - (Quarts / Liters) ............................ 3.7/3.5

Oil Capacity - (Oz / Liters)...... ... ... .... ... ... ... .... ... ... ... 20/0.6

On/Off Switch ............................................................. Yes

• Hard starting or stalling after starting

• Rough idle

• Misfiring or backfiring under load

• Afterburning (backfiring)

• Black exhaust smoke or high fuel consumption

3.4 — HIGH ALTITUDE OPERATION

The fuel system on this engine may be influenced by

operation at higher altitudes. Proper operation can be

ensured by installing an altitude kit when required. See

the table below to determine when an altitude kit is

required. Operating this engine without the proper altitude kit installed may increase the engine’s emissions

and decrease fuel economy and performance. Kits may

be obtained from any Dealer and should be inst alled by a

qualified individual.

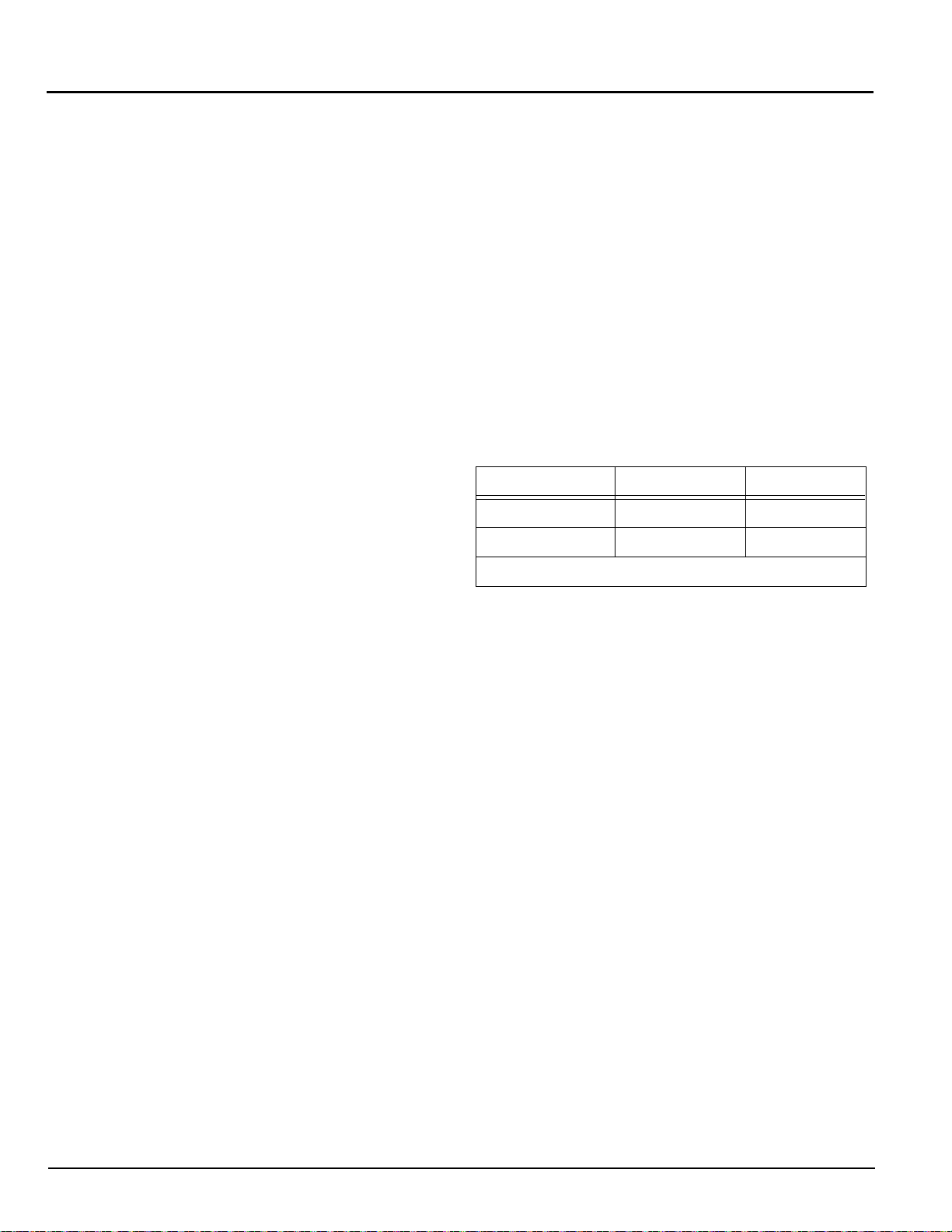

Altitude* Kit Number PSI

0 - 5000 Feet Not Required 3100

5000 - 7000 Feet 0K2016 3100

* Elevation above sea level.

3.3 — EMISSIONS INFORMATION

The U.S. Environmental Protection Agency (and California Air Resource Board for equipment certified to CA

standards) requires that this engine comply with exhaust

and evaporative emission standards. Locate the emissions compliance decal on the engine to determine what

standards the engine meets, and to determine which

emissions warranty applies. The engine is certified to

meet the applicable emission standards on gasoline. It is

important to follow the maintenance specifications in the

Maintenance section to ensure that the engine com plie s

with the applicable emission standards for the duration of

the product’s life. This engine utilizes lean carburetion

settings and other systems to reduce emissions. Tampering with or altering the emission control system may

increase emissions and may be a violation of Federal or

California Law. Act s that co nstitute t amper ing include but

are not limited to:

• Removal or alteration of any part of the intake, fuel, or

exhaust systems

• Altering or defeating the governor linkage or speedadjusting mechanism to cause the engine to operate

outside its design parameters

NOTE:

If the altitude kit has been installed and the engine

will be operated at an altitude where the kit is not

required, the engine should be returned to the original factory configuration. Operating the engine at

lower altitudes with the kit installed may cause the

engine to overheat and result in serious engine damage, and may result in decreased performance and

increased emissions.

If you are aware of any of the following symptoms, have

your engine inspected and repaired by your servicing

dealer:

8 OneWASH™ Power Washer

Page 13

General Information

3.5 — UNPACKING

1. Remove the parts bag, accessories, and inserts

included with power washer.

2. Open carton completely by cutting each corner from

top to bottom.

3. Ensure you have all included items prior to assembly.

• Main Unit

• Handle Assembly

• High Pressure Hose

• Siphon Hose & Filter

• Spray Gun

• Lance with Quick Connect Fitting

• Oil Bottle

• Hose Hook Wire form

• Parts Bag (which includes the following):

— Operator’s Manual

— Warranty Statement

— Emission Warranty Statement

— CARB Emission Warranty Statement

— Owner’s Registration Card

— Bag containing Color-coded Nozzles

— 4mm Allen wrench

— Screw (Qty 4)

— Tree clips (Qty 4)

— Plastic Gun Holder

— Plastic Lance Holder

4. If you are missing any items from your carton, please

call Generac Customer Service at 1-888-436-3722.

When calling for assistance, please have the model

and serial number from the data tag available.

5. Fill out and send in registration card. Write Model

number , Serial number & date of purchase in the

table located in the “Where to Find Us” section.

OneWASH™ Power Washer 9

Page 14

This page intentionally left blank.

General Information

10 OneWASH™ Power Washer

Page 15

B

A

Section 4 Set-up

4.1 — ASSEMBLY

Read entire operator’s manual before you attempt to

assemble or if you have any problems with the assembly

of your power washer, please call Generac Customer

Service at 1-888-436-3722. When calling for assistance,

please have the model and serial number from the data

tag available.

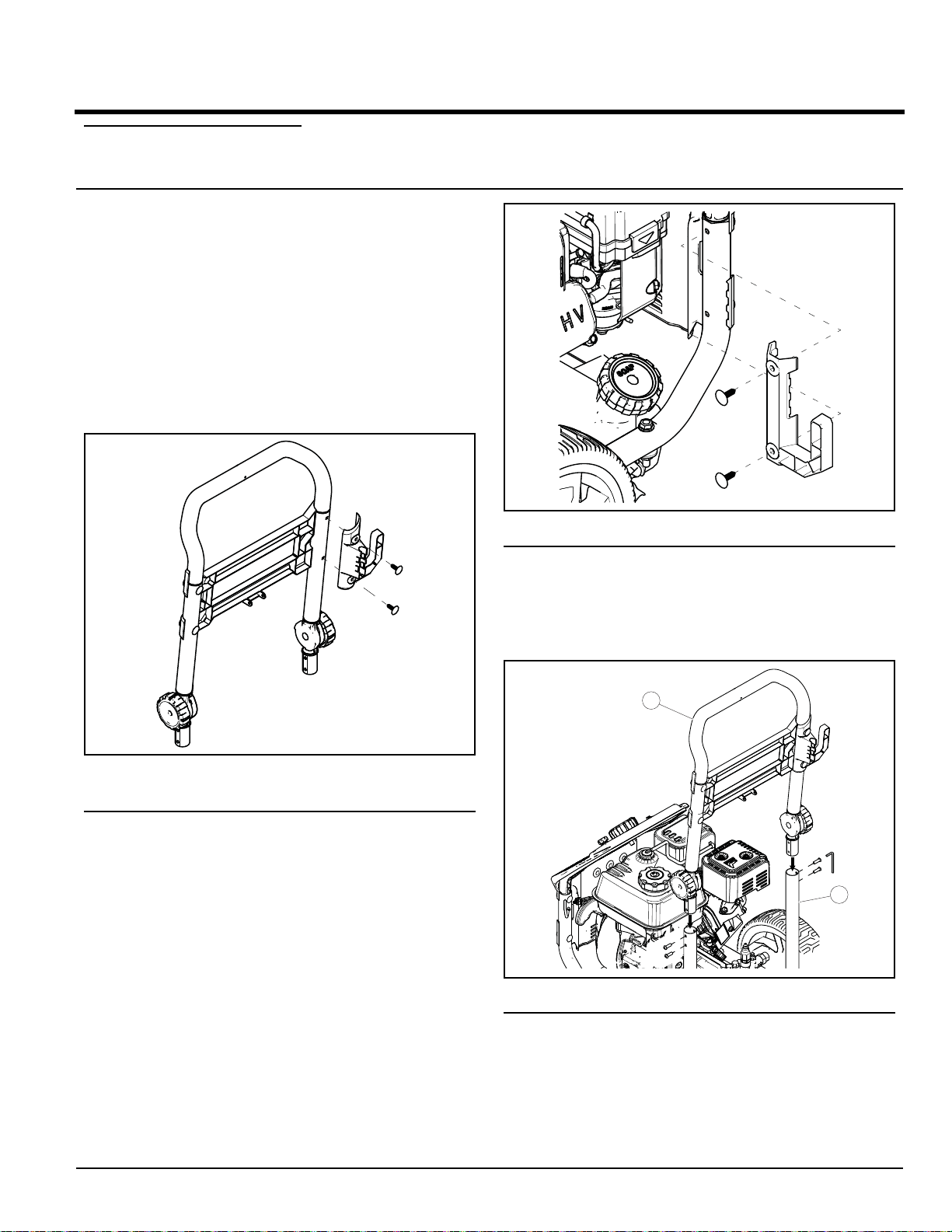

1. Install gun hook to handle assembly using the (2)

supplied tree clips. Align holes and push the tree

clips into holes until they sit flush with gun hook

(Figure 4-1).

Figure 4-2. Attach Lance Hook to Unit

3. Place handle assembly (A) onto cradle supports (B).

Allow handle to slide into position. Locate the (4)

screws and Allen wrench. Install the four screws

using supplied Allen wrench as shown in

(Figure 4-3).

Figure 4-1. Attach Gun Hook to Handle

Assembly

2. Install lance hook to unit frame using (2) supplied

tree clips. Align holes and push the tree clips into

holes until they sit flush with gun hook (Figure 4-2).

Figure 4-3. Attach Handle to Unit

OneWASH™ Power Washer 11

Page 16

Set-up

A

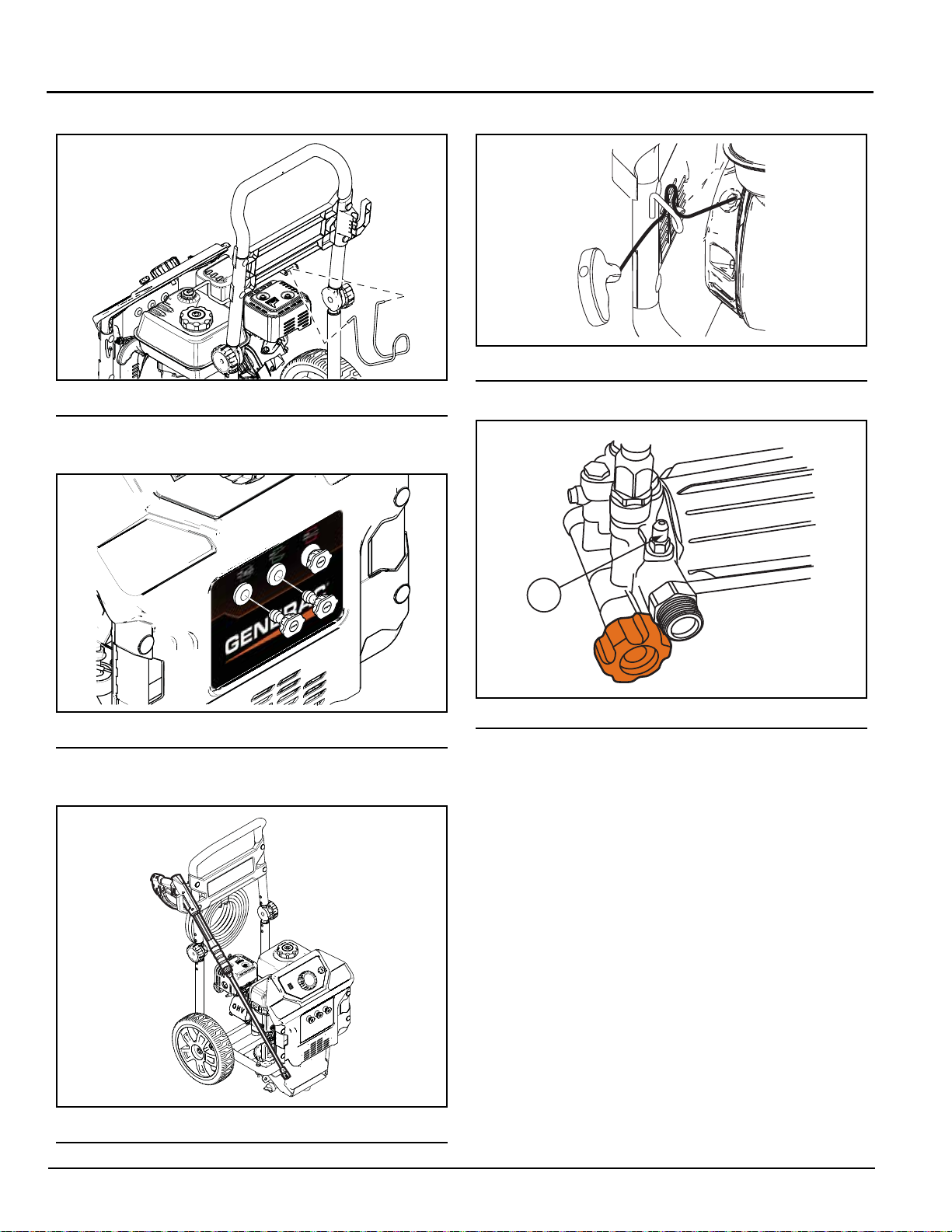

4. Install hose hook (Figure 4-4).

Figure 4-4. Install Hose Hook

5. Insert color–colored nozzles in spaces provided in

front panel (Figure 4-5).

7. Place recoil rope into holder as shown (Figure 4-7).

Figure 4-7. Recoil Rope Hook

8. Attach siphon tube to location A (Figure 4-8).

Figure 4-5. Insert Nozzles

6. Place spray gun/lance extension onto spray gun

holder as shown (Figure 4-6).

Figure 4-6. Gun/Lance

Figure 4-8. Siphon Tube Location

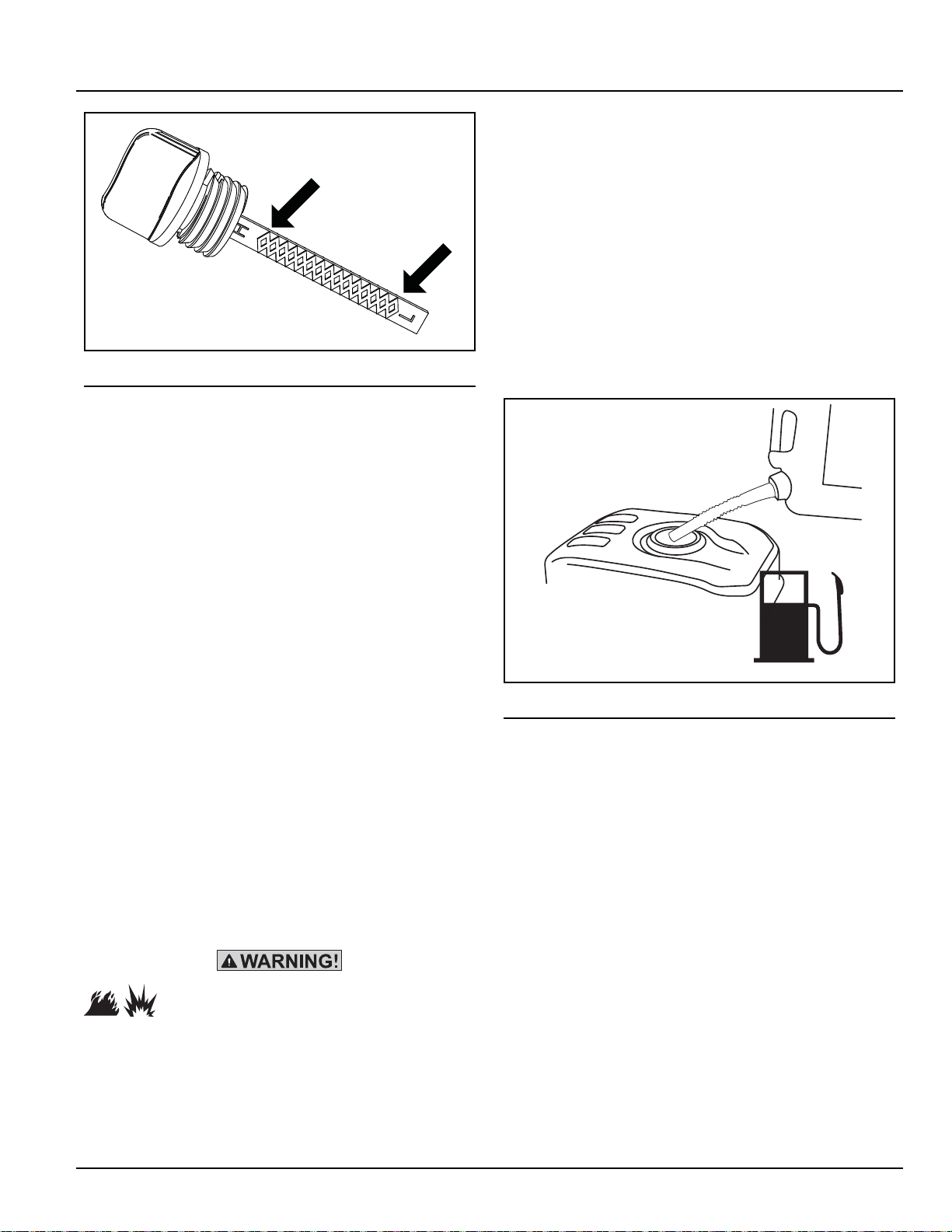

4.2 — ADD ENGINE OIL

1. Place power washer on a flat, level surface.

2. Clean area around oil fill and remove orange oil fill

cap/dipstick.

3. Using oil funnel, slowly pour oil into fill opening. See

“Maintenance” section for oil type recommendation.

NOTE:

On some units there is more than one oil fill location.

In these instances it is only necessary to use one of

the oil fill points.

4. Check periodically until the oil level is between “L”

and “H” on the dipstick (Figure 4-9). Do not overfill.

12 OneWASH™ Power Washer

Page 17

Set-up

Acceptable Oil

Level Range

Figure 4-9. Dipstick

NOTE:

Any attempt to crank or start the engine before it has

been properly serviced with the recommend oil may

result in engine failure.

5. Replace oil fill cap/dipstick and fully tighten.

• Fill fuel tank outdoors.

• DO NOT overfill tank. Allow space for fuel expansion.

• If fuel spills, wait until it evaporates before starting

engine.

• Keep fuel away from sparks, open flames, pilot lights,

heat, and other ignition sources.

• DO NOT light a cigarette or smoke.

1. Clean area around fuel fill cap, remove cap.

2. Slowly add regular unleaded fuel to fuel tank. Be

careful not to overfill. Fill to bottom of filter screen,

this will allow for fuel expansion (Figure 4-10).

3. Install fuel cap and let any spilled fuel evaporate

before starting engine.

4.3 — FUEL

Fuel must meet these requirements:

• Clean, fresh, unleaded gasoline.

• A minimum of 87 octane/87 AKI (91 RON).

• Gasoline with up to 10% ethanol (gasohol) is acceptable.

NOTE:

Avoid power washer damage. Failure to follow Operator’s Manual for fuel recommendations voids warranty.

• DO NOT use unapproved gasoline such as E85.

• DO NOT mix oil in gasoline.

• DO NOT modify engine to run on alternate fuels.

To protect the fuel system from gelling, mix in a fuel stabilizer when adding fuel. See Storage. All fuel is not the

same. If you experience starting or performanc e pr ob lems after using fuel, switch to a different fuel pro vider or

change brands.

Fuel and its vapors are extremely flammable and explosive. Fire or explosion can

cause severe burns or death.

4.3.1 — WHEN ADDING FUEL

• Turn power washer OFF and let it cool at least two (2)

minutes before removing fuel cap. Loosen cap slowly

to relieve pressure in tank.

Figure 4-10. Adding Fuel

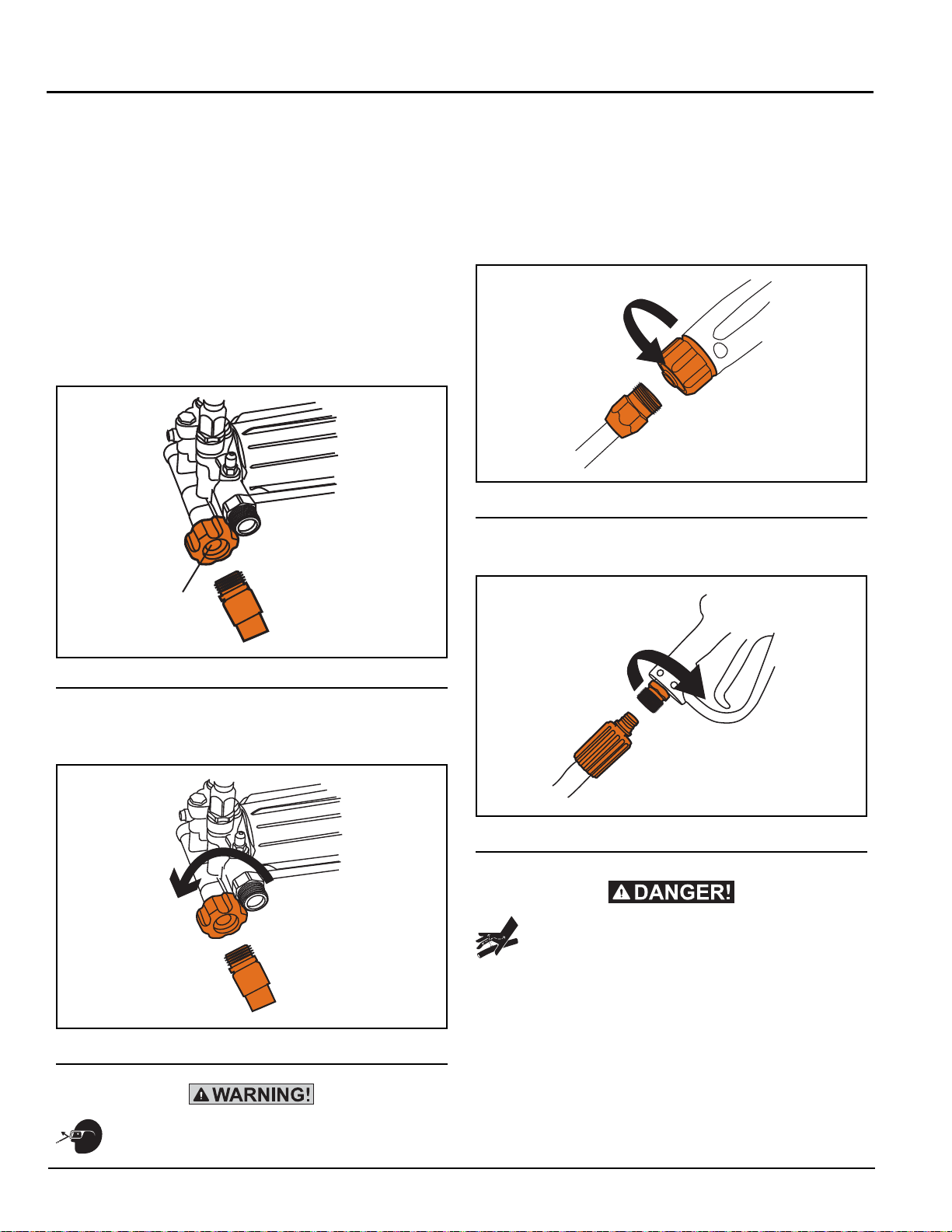

4.4 — CONNECT HOSE AND WATER

UPPLY TO PUMP

S

NOTE:

DO NOT run the pump without the water supply connected and turned on. Damage to equipment resulting from failure to follow this instruction will void

warranty.

NOTE:

Remove and discard the shipping cap from the

pump’s water inlet before attaching hose.

1. Run water through your garden hose for 30 seconds

to clean out any debris.

2. Before connecting garden hose to water inlet, inspect

inlet screen (A) (Figure 4-11). Clean screen if it contains debris or have it replaced if damaged . DO NOT

run power washer if inlet screen is damaged.

OneWASH™ Power Washer 13

Page 18

Set-up

A

IMPORTANT: DO NOT siphon standing water for the

water supply. Use ONL Y cold water (less than 100°F).

Water supply must be adequate to handle greater than

3.8 gallons per minute and no less than 30 psi.

NOTE:

Using a One Way Valve (vacuum breaker or check

valve) at pump inlet can cause pump or inlet connector damage.

• There MUST be at least ten feet of unrestricted garden

hose between the power washer inlet and any device,

such as a vacuum breaker or check valve.

• Damage to equipment resulting from failure to follow

this instruction will void warranty.

• Always wear safety goggles when using this equipment or in vicinity of equipment in use.

• Before starting the power washer, be sure you are

wearing adequate safety goggles.

• NEVER substitute safety glasses for safety goggles.

4. Connect lance to spray gun (Figure 4-13). T ighten b y

hand.

Figure 4-13. Attach Lance

5. Attach end of high pressure hose to base of spray

gun (Figure 4-14). Tighten by han d.

Figure 4-11. Inspect Inlet Screen

3. Connect the garden hose (not to exceed 50 feet in

length) to the water inlet (Figure 4-12). Tighten by

hand.

Figure 4-12. Connect Garden Hose

Risk of eye injury. Spray can splash back or

propel objects.

Figure 4-14. Connect Hose to Spray Gun

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation.

• NEVER connect high pressure hose to lance.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

14 OneWASH™ Power Washer

Page 19

Set-up

6. Connect high pressure hose to pump (uncoil hose

before connecting to pump or spray gun)

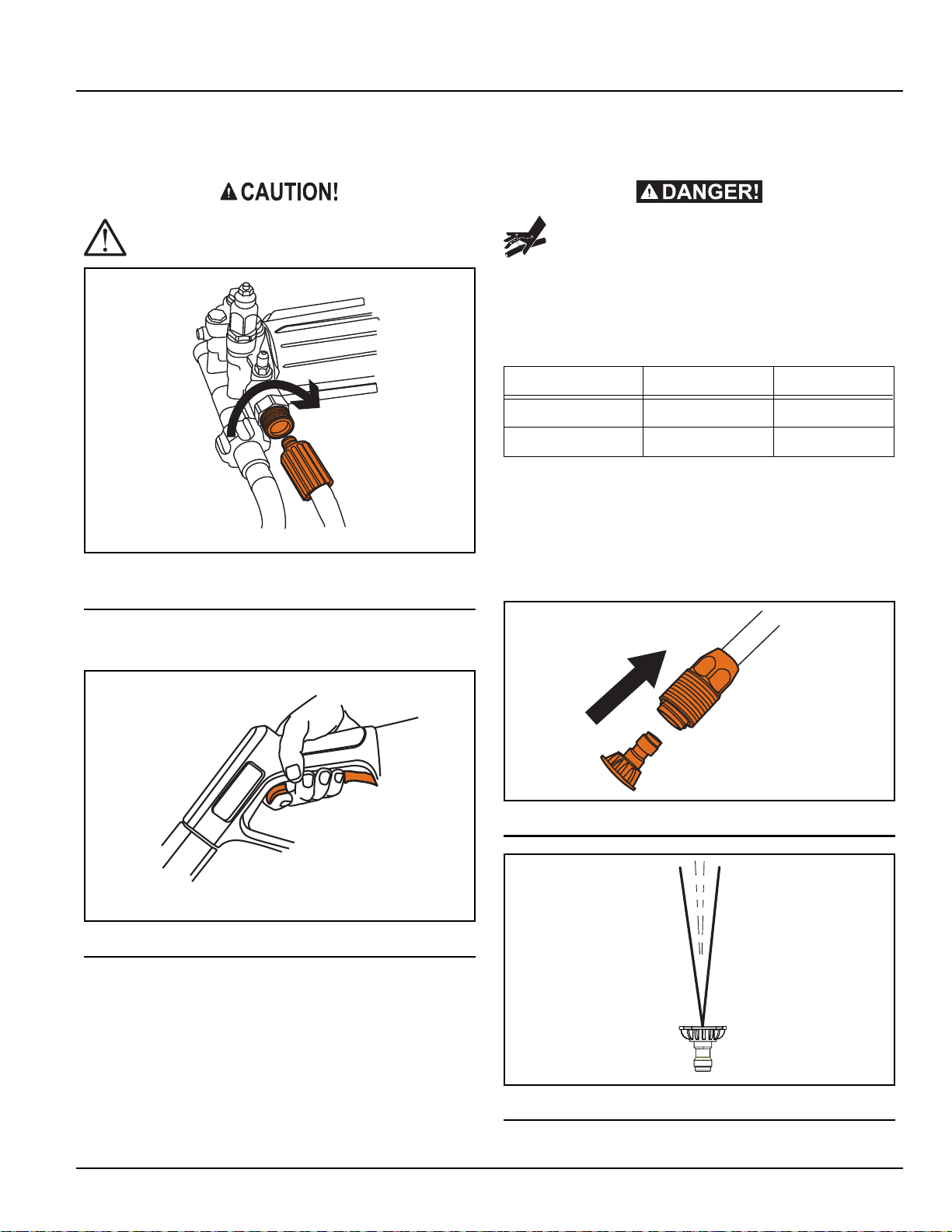

(Figure 4-15). Tighten by hand.

The hose can be damaged if it comes in contact with a hot engine or muffler.

Figure 4-15. Connect High Pressure Hose

to Pump

• If you get nozzle too close, especially using a high

pressure nozzle (RED), you may damage surface

being cleaned.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation.

• NEVER exchange nozzles without the trigger lock

being engaged on the spray gun.

• DO NOT twist nozzles while spraying.

NOZZLE PSI GPM

Blast 3100 2.4

Wash 2600 2.8

The OneWash power washer is equipped with a Power

dial to provide optimal cleaning power for each application (Figure 5-4).

1. Pull back collar on quick–connect lance (Figure 4-17)

and install the GREEN wash nozzle (Figure 4-18) for

the following cleaning applications.

7. Turn ON the water, squeeze the trigger to purge the

pump system of air (Figure 4-16) .

Figure 4-16. Squeeze T rigger

4.5 — HOW TO USE NOZZLES

The quick–connect on the nozzle lance allows you to

switch between different nozzles. Nozzles can be

changed while power washer is running once spray gun

trigger is locked in the safety position. The nozzles vary

the pressure and spray pattern.

• For most effective cleaning, keep nozzle from 8 to 24

inches (20 to 61 cm) away from cleaning surface.

Figure 4-17. Nozzles

Figure 4-18. Wash Pressure Nozzle (Green)

OneWASH™ Power Washer 15

Page 20

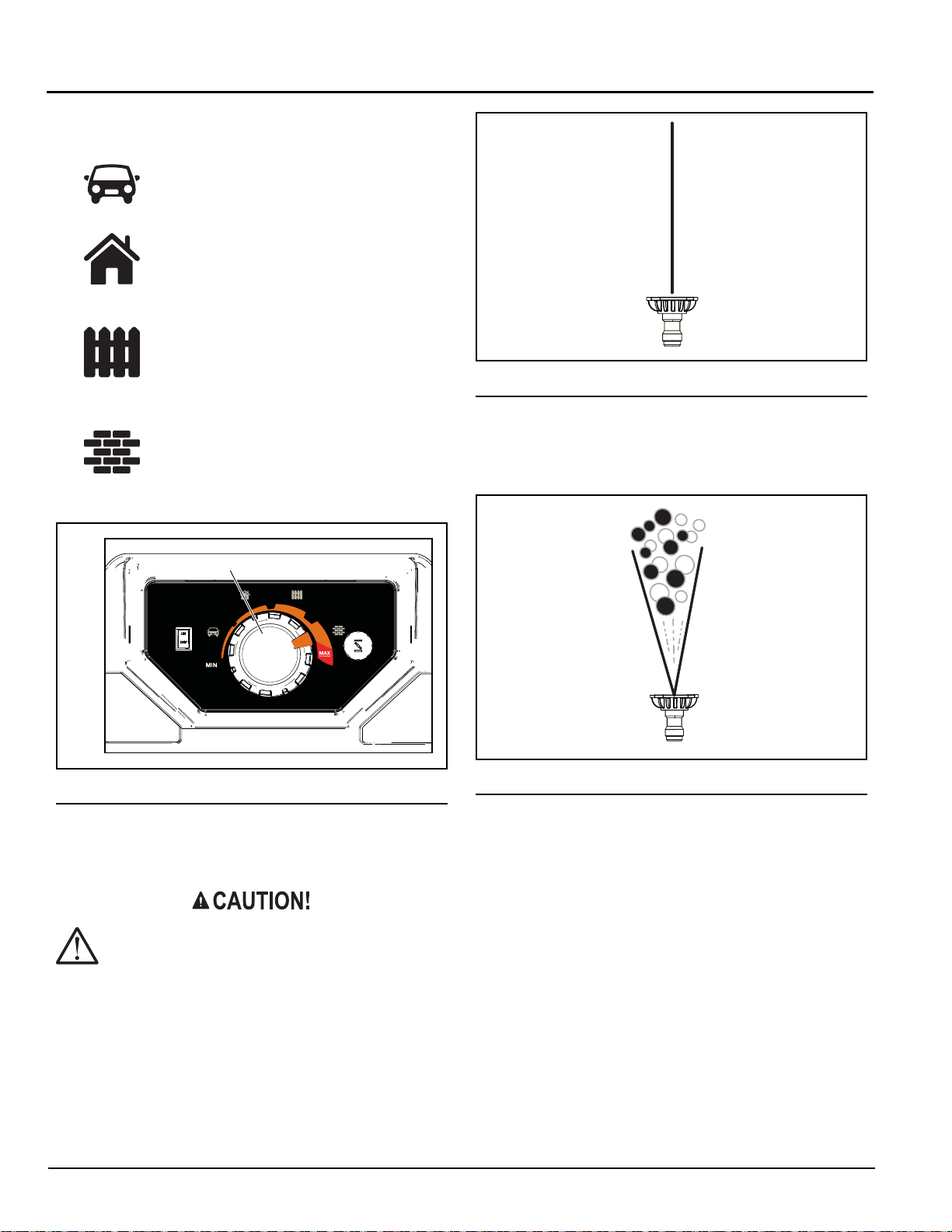

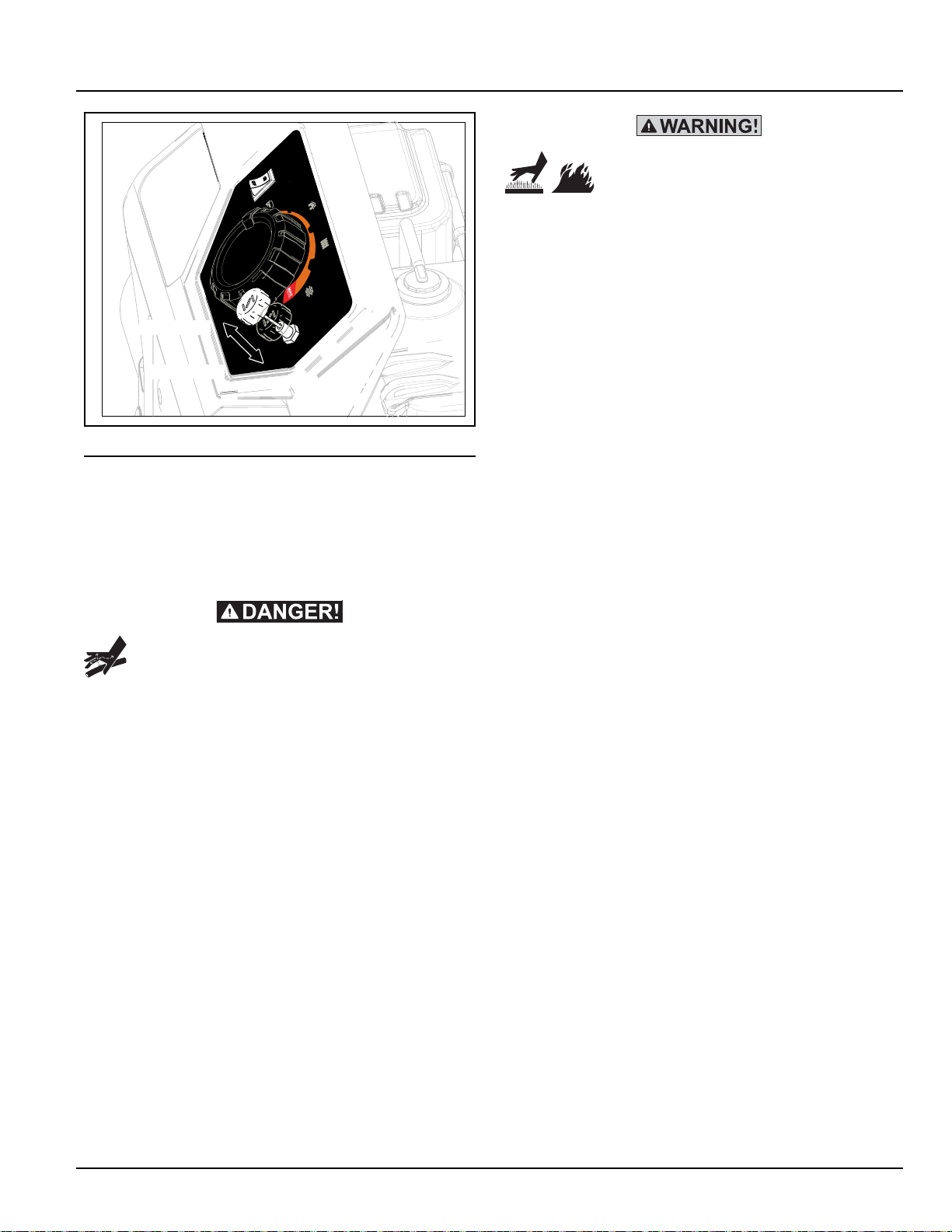

2. Turn the Power Dial so that it matches the material

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

PRESSURE CONTROL

you would like to clean (Figure 4-19).

Car icon - This setting is best for cleaning

cars, boats and RV’s as it delivers the right

balance of power and flow to clean these

types of surfaces effectively.

House Icon - This setting is best for cleaning vinyl and aluminum siding on your

home, as it delivers the right balance of

power and flow to clean these types of surfaces effectively.

Wood Fence Icon - This setting is best for

cleaning wood decks fences and siding on

your home, as it delivers the right balance

of power and flow to clean these types of

surfaces effectively.

Brick Icon - This setting is best for cleaning brick, concrete and masonry materials,

as it delivers the right balance of power and

flow to clean these types of surfaces effectively.

Set-up

Figure 4-20. Blast Pressure Nozzle (Red)

• When applying detergent, use only the black nozzle

(Figure 4-21). Only use power washer safe detergents/

soaps to help break down stubborn dir t and g rime on a

variety of surfaces.

Figure 4-19. Power Dial

Figure 4-21. Detergent Nozzle (Black)

3. To remove persistent stains on concrete or masonry

surfaces, use the red blast nozzle within the stained

area (Figure 4-20).

This tip (Red Nozzle) can damage work surface if it is too close or held in one position for

an extended time.

16 OneWASH™ Power Washer

Page 21

Set-up

4.5.1 — Cleaning and Applying Detergent

Chemicals can cause bodily injury, and/or

property damage.

• NEVER use caustic liquid with power washer.

• Use ONLY power washer safe detergents/soaps. Fol-

low all manufacturer's instructions.

To apply detergent, follow these steps:

1. Review use of nozzles.

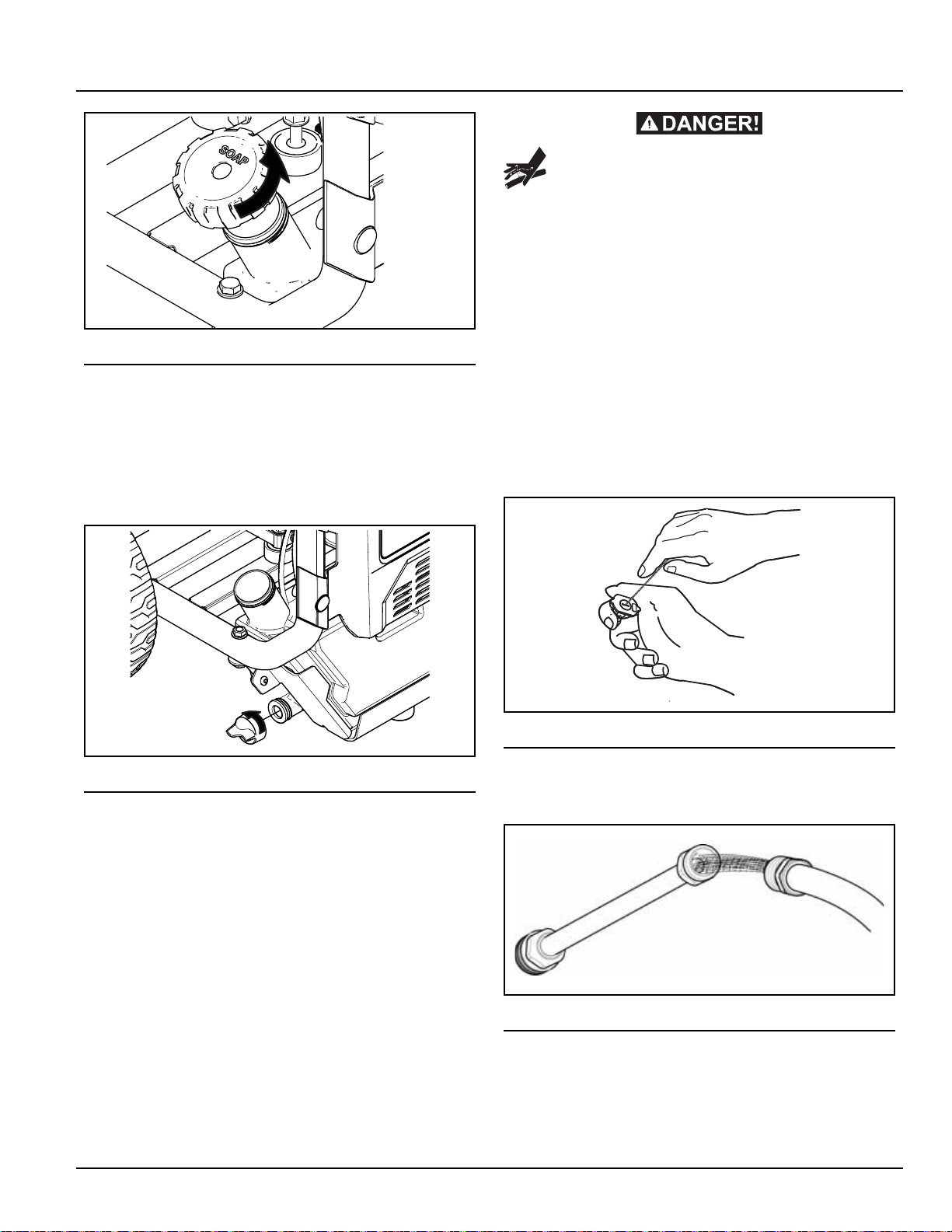

2. Remove chemical tank cap (Figure 4-22).

3. Prepare detergent solution as required by job.

Figure 4-22. Chemical Tank & Cover

4. Insert filter on end of siphoning tube through the hole

in the chemical tank cap (Figure 4-23).

5. Make sure siphoning tube remains fully submerged

into detergent.

NOTE:

Make sure the filter remains fully submerged in

detergent while applying detergent.

NOTE:

Contact with the hot muffler can damage detergent

siphoning tube.

• When inserting the siphon into a detergent solution

bottle, route the tube so as to keep it from inadvertently

contacting the hot muffler.

6. Make sure black detergent nozzle is installed.

NOTE:

Detergent cannot be applied with the high pressure

nozzle (Green or Red). Only use the Black nozzle with

detergent.

7. Confirm set-up instructions have been followed.

NOTE:

You must attach all hoses before you start the

engine.

• Starting the engine without all the hoses connected

and without the water turned ON will damage the

pump.

• Damage to equipment resulting from failure to follow

this instruction will void warranty.

8. Start engine following instructions How to Start Your

Power Washer.

9. Apply detergent to a dry surface, starting at lower

portion of area to be washed and work upward using

long, even, overlapping strokes.

10. Allow detergent to “soak in” for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent

surface from drying. DO NOT allow detergent to dry

on surface being cleaned (prevents streaking).

IMPORTANT: You must flush the detergent siphoning

system after each use by placing the filter into a bucket of

clean water, then run the power washer in low pressure

for 1-2 minutes.

4.5.2 — Power Washer Rinsing

1. Remove black detergent nozzle from lance.

2. Select and install desired high pressure nozzle fol-

lowing instructions How to Use Nozzles.

3. Point spray gun in safe direction and away from pe o-

ple, animals and plants. Squeeze trigger to flush a ny

Figure 4-23. Install Siphoning Tube

OneWASH™ Power Washer 17

remaining chemical from system.

4. Keep spray gun a safe distance from area you plan

to spray.

Page 22

Kickback from spray gun can cause

you to fall.

• Use only on a level surface.

• Do not use on elevated surface to prevent the risk of a

serious fall.

• Firmly grasp spray gun with both hands when using

high pressure spray to avoid injury when spray gun

kicks back.

5. Apply a high pressure spray to a small area and then

check surface for damage. If no damage is found,

you can assume it is okay to continue rinsing.

6. Start at top of area to be rinsed, working down with

same overlapping strokes as you used for cleaning.

4.5.3 — Cleaning Detergent Siphoning Tube

If you used the detergent siphoning tube, you must flush

it with clean water before stopping the engine.

Set-up

1. Place detergent siphoning tube/filter in a bucket full

of clean water.

2. Remove high pressure nozzle from nozzle extension.

3. Select and install black detergent nozzle following

instructions “How to Use Nozzles”.

4. Flush for 1-2 minutes.

5. Shut off engine following instructions How to Stop

Power Washer and turn off water supply.

6. AL W A YS point spray gun in a safe direction, squeeze

spray gun trigger to release retained high wa te r pres sure. Engage trigger lock when not in use.

IMPORTANT: S pray gun trap s high water pressur e, even

when engine is stopped and water is disconnected.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation. Spray gun

traps high water pressure, even when engine

is stopped and water is disconnected, which

can cause injury.

• Keep high pressure hose connec ted to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, and

squeeze spray gun trigger to release high pressure,

every time you stop engine. Engage trigger lock when

not in use.

18 OneWASH™ Power Washer

Page 23

5 Foot Minimum

Section 5 Operation

5.1 — OPERATION

If you have any problems operating your power washer,

please call Generac customer service at

1-888-436-3722.

5.2 — POWER WASHER L OCATION

5.2.1 — Clearances and Air Movement

Running engine gives off carbon monoxide,

an odorless, colorless, poisonous gas.

Breathing carbon monoxide can caus e he ad ache, fatigue, dizziness, vomiting, confusion,

seizures, nausea, fainting or death. For more

information, reference the CO warnings in the

“Safety” section.

Figure 5-1. Building Clearances

Place power washer outdoors in an area that will not

accumulate deadly exhaust gas. NEVER place power

washer where exhaust gas could accumulate and enter

inside or be drawn into a potentially occupied building.

Ensure exhaust gas is kept away from any windows,

doors, ventilation intakes, or other openings that can

allow exhaust gas to collect in a confined area. Prevailing

winds and air currents should be ta ken into consideration

when positioning power washer (Figur e 5-1).

• Operate power washer ONLY outdoors.

• Keep exhaust gas from entering a co nf in e d ar ea

through windows, doors, ventilation intakes, or other

openings.

• NEVER start or run engine indoors, in a vehicle or in

an enclosed area, EVEN if windows and doors are

open.

Exhaust heat/gases can ignite combustibles, structures or damage fuel tank

causing a fire.

• Keep at least 5 ft. (152 cm) clearance on all sides of

power washer including overhead.

5.3 — CHECKLIST BEFORE STARTING

NGINE

E

1. Be sure to read and understand the “Safety” section

and “Operation” section before using power washer.

2. Check that the oil is at the full mark on the dipstick,

and that fuel has been added to the fuel tank.

3. Review the unit’s assembly and ensure fitting are

properly secured and make sure there are no kinks,

cuts, or damage to high pressure hose.

4. Provide a proper water supply at an adequate flow,

clear screens of debris, and confirm that the system

is purged of air.

5. Confirm unit is secure on level ground and surrounding work area is clear.

5.4 — HOW TO START YOUR POWER

ASHER

W

NOTE:

DO NOT run the pump without the water supply connected and turned on. Damage to equipment resulting from failure to follow this instruction will void

warranty.

OneWASH™ Power Washer 19

Page 24

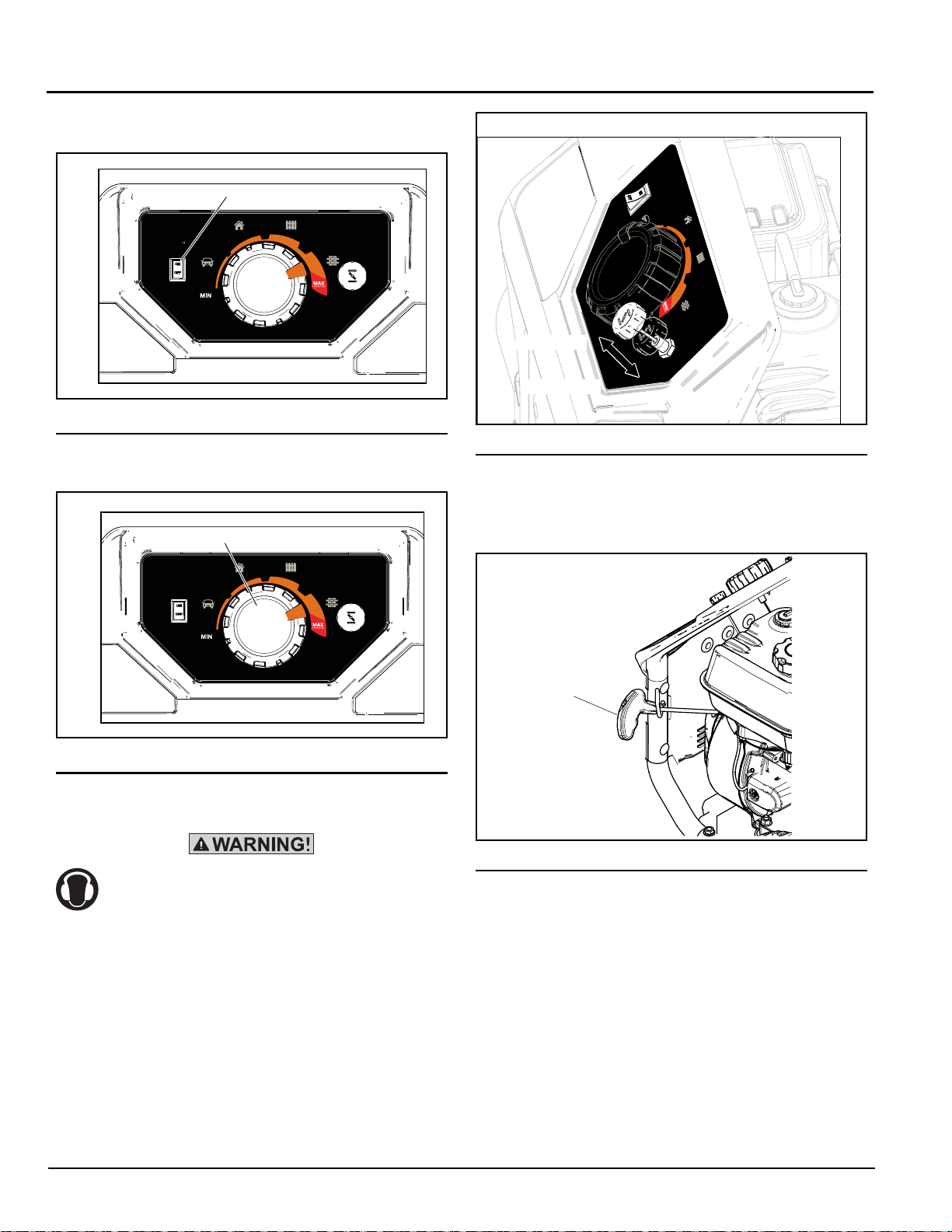

1. Turn the ON/OFF switch to the “ON” position

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

ON/OFF SWITCH

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

PRESSURE CONTROL

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

CHOKE “ON”

CHOKE “OFF”

STARTER

GRIP

(Figure 5-2).

Figure 5-2. ON/OFF Switch

2. Rotate pressure control knob to the position show n

on “Start” decal (Item #2) (Figure 5-3).

Operation

Figure 5-4. Choke Knob

4. Secure unit from movement when pulling recoil.

5. When starting the engine, grasp starter grip handle

(Figure 5-5) and pull slowly until you feel some resistance. Then pull rapidly to start engine.

Figure 5-3. Power Dial

3. Choke the engine by slowly pulling out on the choke

knob until it stops in the “ON” position (Figure 5-4).

Figure 5-5. Starting the Engine

Hearing Protection Recommended.

6. Return starter grip handle slowly. DO NOT let rope

“snap back” against holder.

NOTE:

For a warm engine, push the choke knob down until

it stops in the “OFF” position (Figure 5-4).

20 OneWASH™ Power Washer

7. When engine starts, slowly push the choke knob in to

the “OFF” position as engine warms. If engine falters,

pull choke knob out to the “ON” position, then push in

to the “OFF” position (Figure 5-6).

Page 25

Operation

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

CHOKE “ON”

CHOKE “OFF”

Figure 5-6. Choke Knob

8. After each starting attempt, where engine fails to run,

always point gun in safe direction, and squeeze

spray gun trigger to release high pressure.

9. If engine fails to start after six pulls, push choke knob

in to the “OFF” position, and repeat steps 6 through

10.

Contact with muffler area can result in

serious burns. Exhaust heat/gases can

ignite combustibles, structures or

damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust

gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (152 cm) of clearance on all sides

of power washer including overhead.

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark

arrester , as defined in Section 4442, maintained in

effective working order. Other states or federal jurisdictions may have similar laws.

• Replacement parts must be the same and installed in

the same position as the original parts.

5.5 — AUTOMATIC COOL DOWN SYSTEM

HERMAL RELIEF)

(T

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation. Spray gun

traps high water pressure, even when engine

is stopped and water is disconnected, which

can cause injury.

• DO NOT allow CHILDREN to operate power washer or

play nearby.

• Keep high pressure hose connec ted to pump and

spray gun while system is pressurized.

• NEVER aim spray gun at people, animals or electrical

devices. Serious injury will result.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories

are correctly attached.

If you run the engine on your power washer for 3-5 min utes without pressing the trigger on the spray gun, circulating water in the pump can reach temperatures above

125°F. The system engages to cool the pump by discharging the warm water onto the ground.

5.6 — HOW TO STOP YOUR POWER

ASHER

W

1. Release spray gun trigger.

2. Turn the engine ON/OFF switch to the “OFF” position

(Figure 5-7).

3. ALWAYS point spray g un in a safe direction, and

squeeze spray gun trigger to release retained high

water pressure. Engage trigger lock when not in use.

4. Turn OFF water supply.

OneWASH™ Power Washer 21

Page 26

Figure 5-7. ON/OFF Switch

DELICATE

2000 PSI

HEAVY DUTY

3100 PSI

ON/OFF SWITCH

IMPORTANT: S pray gun trap s high water pressur e, even

when engine is stopped and water is disconnected.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation. Spray gun

traps high water pressure, even when engine

is stopped and water is disconnected, which

can cause injury.

Operation

• Keep high pressure hose connec ted to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, squeeze

spray gun trigger to release high pressure, every time

you stop engine. Engage trigger lock when not in use.

22 OneWASH™ Power Washer

Page 27

Section 6 Maintenance

6.1 — MAINTENANCE RECOMMENDATIONS

Regular maintenance will improve the performance and

extend the life of the power washer. See any qualified

dealer for service.

The power washer’s warranty does not cover items that

have been subjected to operator abuse o r negligence. To

receive full value from the warranty, the operator must

maintain the power washer as instructed in this manual,

including proper storage as detailed in “Winter Storage”

and “Long Term Storage”.

NOTE:

Should you have questions about replacing components on your power washer, please call

1-888-436-3722 for assistance.

Some adjustments will need to be made periodically to

properly maintain your power washer.

All service and adjustments should be made at least

once each season. Follow the requireme nts in the “Maintenance Schedule” chart.

NOTE:

Once a year you should clean or replace the spark

plug, clean or replace the air filter, and check the

spray gun and nozzle extension assembly for wear. A

new spark plug and clean air filter assure prop er fuelair mixture and help your engine run better and last

longer.

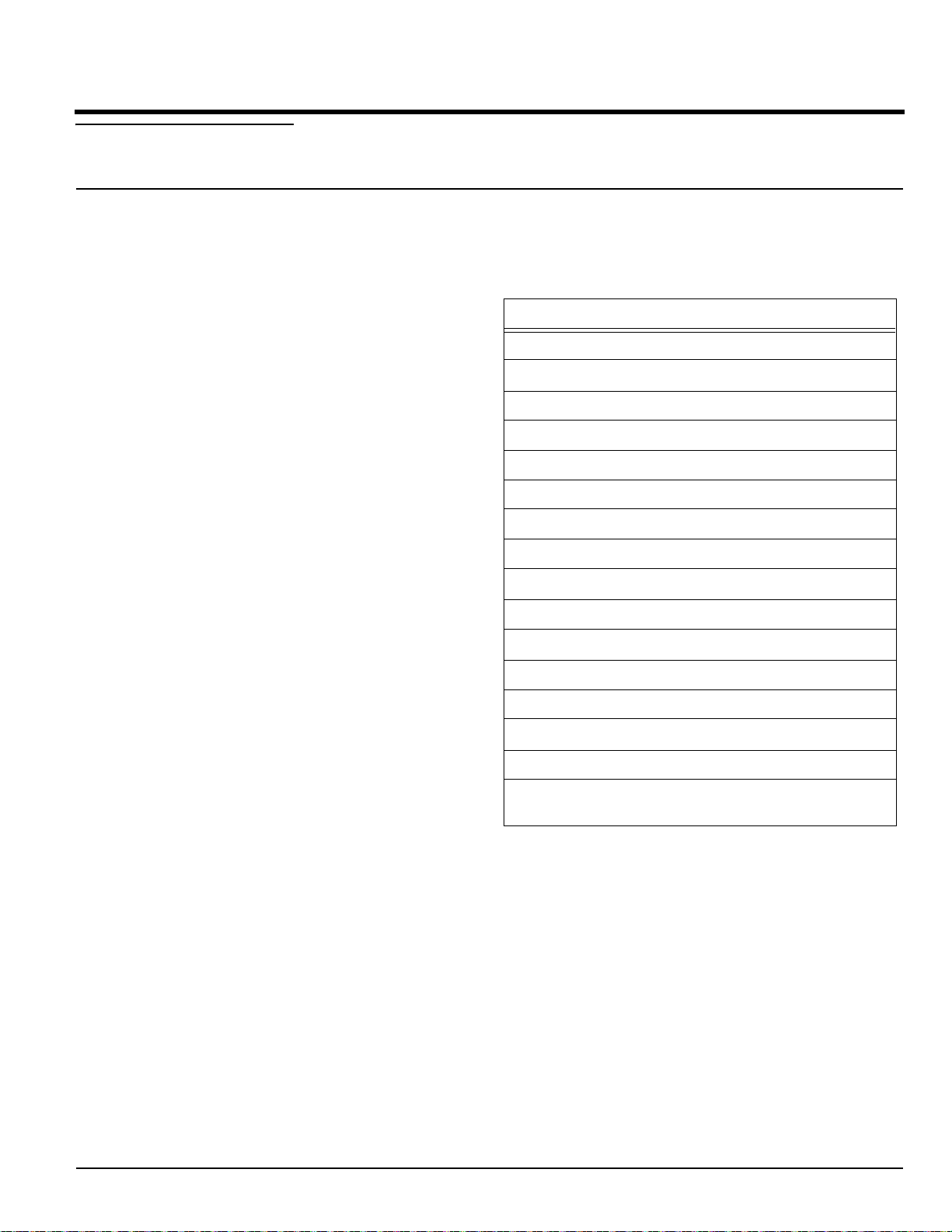

6.2 — MAINTENANCE SCHEDULE

Follow the hourly or calendar intervals, whichever occurs

first. More frequent service is required when operating in

adverse conditions.

First 5 Hours

Change engine oil

Every 8 Hours or Daily

Check/clean water inlet screen*

Check high pressure hose

Check detergent siphoning hose/filter

Check spray gun and assembly for leaks

Clean debris

Check engine oil level

Every 20 Hours or Every Season

Change engine oil**

Every 50 Hours or Every Season

Check/clean air cleaner filter**

Inspect muffler and spark arrester*

Every 100 Hours or Every Season

Service spark plug

* Clean if clogged. Replace if perforated or torn.

** Service more often under dirty or dusty conditions.

OneWASH™ Power Washer 23

Page 28

Maintenance

6.3 — PUMP OIL

DO NOT attempt any oil maintenance on this pump. The

pump is pre-lubricated and sealed from the factory,

requiring no additional maintenance for the life of the

pump.

6.4 — EMISSIONS CONTROL

Maintenance, replacement, or rep air of the emissions

control devices and systems may be performed by

any non-road engine repair establishment or individual. However, to obtain “no charge” emissions control

service, the work must be performed by a factory authorized dealer. See the Emissions Warranty.

6.5 — POWER DIAL SETTINGS

Tampering, maintenance, adjustment or replacement of

the throttle settings will impact the performance and may

void the warranty of the unit.

6.6 — POWER WASHER MAINTENANCE

6.6.1 — Clean Debris

Daily or before use, clean accumulated debris from

cleaning system. Keep linkage, spring and controls

clean. Keep area around and behind muffler free from

any combustible debris. Inspect cooling air slots and

openings on the power washer. These openings must be

kept clean and unobstructed.

Power washer parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces c lea n.

NOTE:

Improper treatment of power washer can damage it

and shorten its life.

• DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

6.7 — CHECK AND CLEAN INLET SCREEN

Examine the screen on the pump’s water inlet. Clean it if

the screen is clogged or replace it if screen is damaged.

6.8 — CHECK HIGH PRESSURE HOSES

The high pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect the hoses each time before

using them. Check for cuts, leaks, abrasions or bulging of

cover, damage or movement of couplings. If any of these

conditions exist, replace the hose immediately.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation.

• NEVER repair high pressure hose. Replace it.

• Replacement hose rating MUST meet or exceed maximum pressure rating of unit.

6.9 — CHECK DETERGENT SIPHONING

UBE

T

Examine the filter on the detergent tube and clean if

clogged. The tube should fit tightly on the barbed fitting.

Examine the tube for leaks or tears. Replace the filter or

tube if either is damaged.

6.10 — CHECK SPRAY GUN

Examine the hose connection to the spray gun and make

sure it is secure. Test the trigger by pressing the trigg er , it

“springs back” into place when you release it. Replace

spray gun immediately if it fails to “spring back”.

6.11 — CHEMICAL TANK MAINTENANCE

Periodically you will need to drain and clean the chemical

tank.

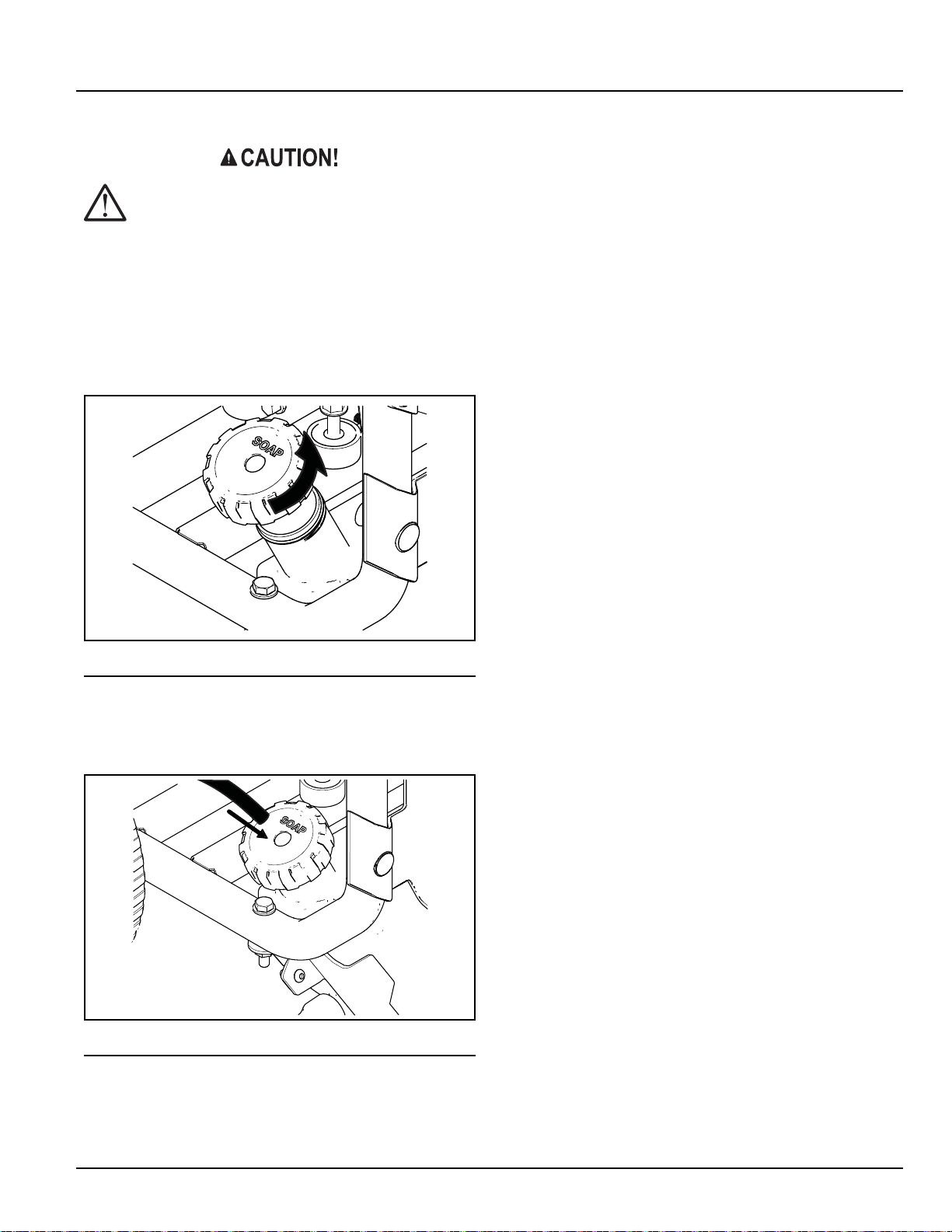

Use the following these instructions:

1. Shut off engine and turn off water supply.

2. AL W A YS point spray g un in a safe direction, squeeze

spray gun trigger to release retained high water pressure.

3. Remove chemical fill cap and siphon hose

(Figure 6-1).

4. Obtain a container to drain the excess chemical into.

24 OneWASH™ Power Washer

Page 29

Maintenance

Figure 6-1. Chemical Cap/Siphon Hose

5. Place container under the chemical tank drain.

(Figure 6-2).

6. Remove drain cap and allow chemical to drain.

7. Insert garden hose into fill neck allow water to flush

out tank.

8. Once tank is clean re install drain cap with gasket, do

not over tighten.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation. Spray gun

traps high water pressure, even when engine

is stopped and water is disconnected, which

can cause injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, and

squeeze spray gun trigger to release high pressure

every time you stop engine. Engage trigger lock when

not in use.

3. Remove nozzle from end of nozzle extension.

4. Use a small paper clip to free any foreign material

clogging or restricting nozzle (Figure 6-3).

5. Remove lance from spray gun.

Figure 6-3. Free Foreign Material

Figure 6-2. Chemical Drain Cap

6. Using a garden hose, remove additional debris by

back flushing water through lance (Figure 6-4). Back

flush between 30 to 60 seconds.

6.12 — NOZZLE MAINTENANCE

A pulsing sensation felt while squeezing the spray gun

trigger may be caused by excessive pump pressure. The

principal cause of excessive pump pressure is a nozzle

clogged or restricted with foreign materials, such as dirt,

etc. To correct the problem, immediately clean the nozzle

following these instructions:

1. Shut off engine and turn off water supply.

2. AL W A YS point spray gun in a safe direction, squeeze

spray gun trigger to release retained high water pressure.

OneWASH™ Power Washer 25

7. Reinstall nozzle into lance.

8. Reconnect lance to spray gun.

9. Make sure garden hose is connected to pump water

Figure 6-4. Back Flush Lance

inlet. Check that high pressure hose is connected to

spray gun and pump. Turn on water.

Page 30

Maintenance

SA E 30 *

10 W- 30 **

5W -3 0

Acceptable Oil

Level Range

10. Start engine following instructions “How to Start Your

Power Washer”.

11. Test power washer by operating with each quick connect nozzle.

6.13 — ENGINE MAINTENANCE

Unintentional sparking can result in fire

or electric shock.

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

POWER WASHER

• Disconnect the spark plug wire from the sp ark plug and

place the wire where it cannot contact sp ark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

6.14 — ENGINE OIL RECOMMENDATIONS

We recommend the use of high-quality detergent oils

acceptable if classified for service SF, SG, SH, SJ or

higher. DO NOT use special additives.

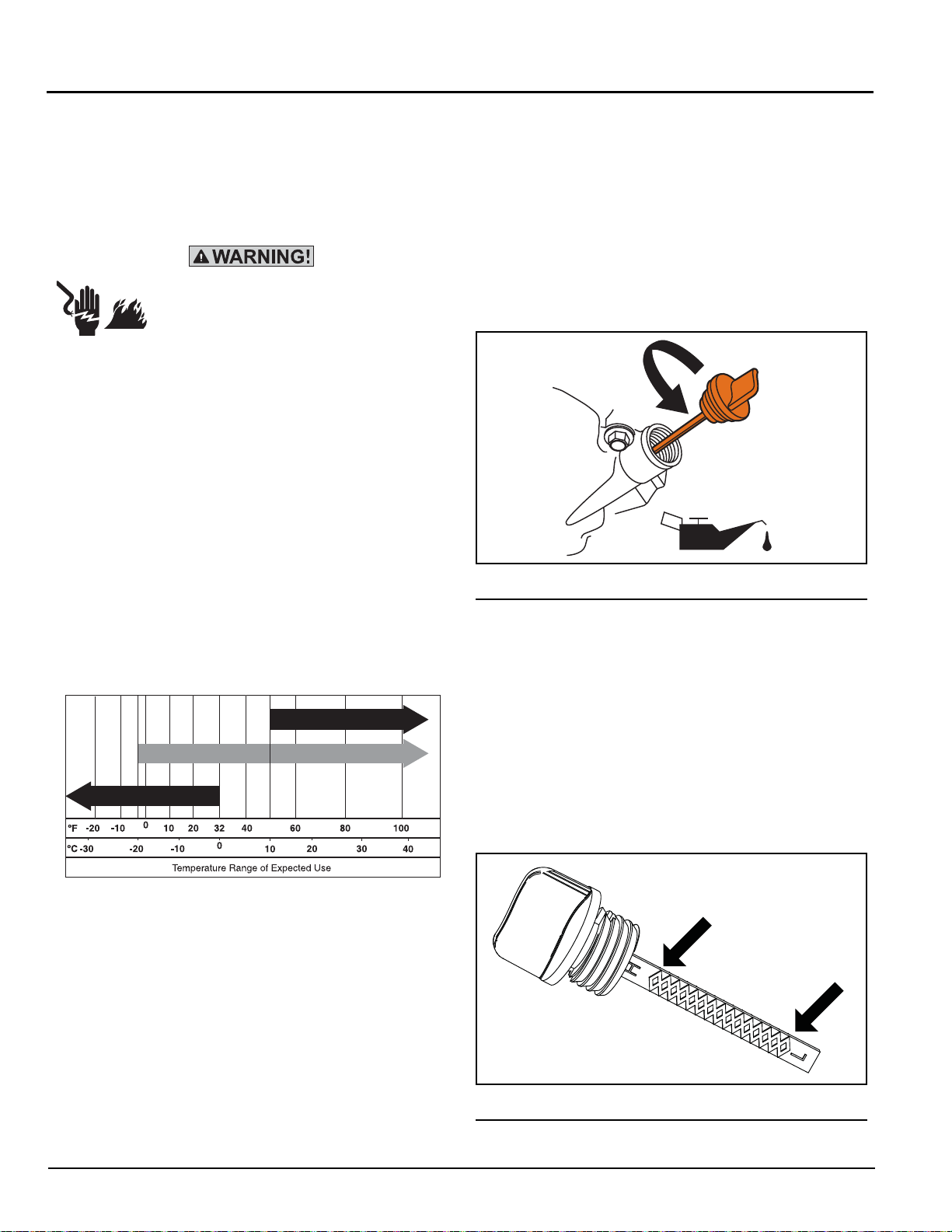

Outdoor temperatures determine the proper oil viscosity

for the engine. Use the chart to select the best viscosity

for the outdoor temperature range expected.

SAE 30*

10W-30**

5W-30

6.14.1 — Check Oil Level

Oil level should be checked prior to each use or at least

every 8 hours of operation. Keep oil level maintained.

1. Make sure power washer is on a flat, level surface.

2. Clean area around oil fill and wipe dipstick clean

remove oil fill cap (Figure 6-5).

3. Verify oil is at the proper level on the dipstick.

4. Insert the dipstick into filler neck but do not screw it

in.

5. Replace and tighten oil fill cap.

Figure 6-5. Fill Engine Oil

6.14.2 — Adding Engine Oil

1. Make sure power washer is on a flat, level surface.

2. Check oil level as described in Checking Oil Level.

3. If needed, slowly pour oil into oil fill opening until the

proper level on the dipstick is reached.

4. Insert the dipstick into filler neck but do not screw it

in.

5. If level is low, fill until the oil level is between “L” and

“H” on the dipstick (Figure 6-6).

6. Replace and tighten oil fill cap.

* Below 50°F (10°C) the use of SAE 30 will result in hard start-

ing.

** Above 80°F (27°C) the use of 10W30 may cause increased

oil consumption. Check oil level more frequently.

NOTE:

Synthetic oil meeting ILSAC GF-2, API certification

mark and API service symbol with “SJ/CF ENERGY

CONSERVING” or higher, is an acceptable oil at all

temperatures. Use of synthetic oil do e s no t alte r

required oil change intervals.

26 OneWASH™ Power Washer

Figure 6-6. Dipstick

Page 31

Maintenance

A

Air Cleaner

Cover

Paper Filter

Element

Foam Filter

Element

Gasket

Wing Nut

Latch

6.14.3 — Changing Engine Oil

If you are using your power washer under extremely dirty

or dusty conditions, or in extremely hot weather, change

the oil more often.

Avoid prolonged or repea ted skin cont act with

used motor oil.

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

KEEP OUT OF REACH OF CHILDREN.

• Don’t pollute. Conserve resources. Return used oil to

collection centers.

Allow the engine to cool down and then change oil as follows:

1. Make sure power washer is on a flat, level surface.

2. Disconnect the spark plug wire from the spark plug

and place the wire where it cannot contact spark

plug.

3. Clean area around oil drain plug (A) (Figure 6-7). The

oil drain plug is located at base of engine, opposite

carburetor.

4. Remove oil fill cap (Figure 6-6).

5. Remove oil drain plug and drain oil completely into a

suitable container.

6. Reinstall oil drain plug and tighten securely.

7. Slowly pour oil (about 20 oz.) into oil fill opening to

the proper level on the dipstick. DO NOT overfill.

8. Reinstall oil fill cap. Finger tighten cap securely.

9. Wipe up any spilled oil.

10. Properly dispose of oil in an accordance with all local

regulations.

6.15 — SERVICE AIR CLEANER

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner. Service more often if

operating under dirty or dusty conditions.

To service the air cleaner, follow these step s:

1. Pull on air cleaner cover latch and remove cover

(Figure 6-8).

Figure 6-8. Service the Air Cleaner

2. Loosen wing nut.

3. Carefully remove filter assembly.

4. Remove foam filter.

5. To clean cartridge, gently tap on a flat surface.

6. Reinstall foam filter.

7. Reinstall clean or new cartridge assembly.

8. Reinstall wing nut and tighten.

9. Install cover by snapping latch closed.

Figure 6-7. Oil Drain Plug

OneWASH™ Power Washer 27

Page 32

6.16 — SERVICE SPARK PLUG

A

A

B

Changing the spark plug will help your engine to start

easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug (Figure 6-9).

3. Check electrode gap with wire feeler gauge and reset

spark plug gap to recommended gap if necessary

(see Specifications).

4. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use the recommended replacement plug. See Specifications.

5. Install spark plug and tighten firmly.

Maintenance

Figure 6-10. Remove Heat Shield

Figure 6-9. Change the Spark Plug

6.17 — INSPECT MUFFLER AND SPARK

RRESTER

A

Inspect the muffler for cracks, corrosion, or other damage. Remove the spark arrester, if equipped, and inspect

for damage or carbon blockage. If replacement parts are

required, make sure to use only original equipment

replacement parts.

6.17.1 — Remove Spark Arrester Screen

Tools Required: 8mm Box Wrench

1. Remove heat shield from the muffler by loosening

the four (4) Bolts (A) (Figure 6-10).

2. Remove the spark arrester from the muffler by loosening the two (2) Bolts (B) (Figure 6-11).

3. Inspect the spark arrester, replace if torn, perforated

or otherwise damaged (part number 0K1851). DO

NOT USE A DEFECTIVE SCREEN.

4. If screen is not damaged, clean it with a commercial

solvent and replace.

Figure 6-11. Remove Spark Arrester

Contact with muffler area can result in

serious burns. Exhaust heat/gases can

ignite combustibles, structures or damage fuel tank causing a fire.

• DO NOT touch hot parts and AVOID hot exhaust

gases.

• Allow equipment to cool before touching.

• Keep at least 5 feet (152 cm) of clearance on all sides

of power washer including overhead.

28 OneWASH™ Power Washer

Page 33

Maintenance

• It is a violation of California Public Resource Code,

Section 4442, to use or operate the engine on any forest-covered, brush-covered, or grass-covered land

unless the exhaust system is equipped with a spark

arrester, as defined in Section 4442, maintained in

effective working order. Other states or federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a spark

arrester designed for the exhaust system installed on

this engine.

• Replacement parts must be the same and installed in

the same position as the original parts.

6.18 — AFTER EACH USE

Water should not remain in the unit for long periods of

time. Sediments or minerals can deposit on pump parts

and freeze pump action. Follow these procedures after

every use:

1. Shut off engine, turn off water supply, point gun in a

safe direction, and squeeze trigger to relieve trapped

pressure, and let engine cool.

The high pressure stream of water that this

equipment produces can cut through skin and

its underlying tissues, leading to serious

injury and possible amputation. Spray gun

traps high water pressure, even when engine

is stopped and water is disconnected, which

can cause injury.

• Keep high pressure hose connec ted to pump and

spray gun while system is pressurized.

• AL WAYS point spray gun in safe direction and squeeze

spray gun trigger, to release high pressure, every time

you stop engine. Engage trigger lock when not in use.

2. Disconnect hoses from spray gun and high pressure

outlet on pump. Drain water from hoses, spray gun,

and lance. Use a rag to wipe off the hose.

3. Empty pump of all pumped liquids. Check that the

engine ON/OFF switch is in the OFF position. Then

pull the recoil handle about six times. This should

remove most liquid in pump.

4. Store unit in a clea n, dry area.

5. If storing for more than 30 days, see the “Long Term

Storage ” on page 29.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters,

clothes dryers, or other appliances that have pilot light

or other ignition source because they can ignite fuel

vapors.

Fuel and its vapors are extremely flammable and explosive. Fire or explosion

can cause severe burns or death.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters,

clothes dryers, or other appliances that have pilot light

or other ignition source because they can ignite fuel

vapors.

6.19 — WINTER STORAGE

NOTE:

You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your pump

and render your unit inoperable.

• Freeze damage is not covered under warranty.

To protect the unit from freezing temperatures:

1. Follow steps 1-3 in the previous section “After Each

Use”.

2. Use pump saver to treat pump. This minimizes

freeze damage and lubricates pistons and seals .

3. If pump saver is not available, connect a 3-foot sec-

tion of garden hose to water inlet adapter. Pour RVantifreeze (antifreeze without alcohol) into hose. Pull

recoil handle twice. Disconnect 3-foot hose.

4. Store unit in a clean, d ry area.

6.20 — LONG TERM STORAGE

If you do not plan to use the power washer for more than

30 days, you must prepare the engine and pum p for lo ng

term storage.

Fuel and its vapors are extremely flammable and explosive. Fire or explosion

can cause severe burns or death.

OneWASH™ Power Washer 29

Page 34

Maintenance

6.20.1 — Protect Fuel System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel system or on essential carburetor parts. To keep fuel fresh,

use a fuel stabilizer, available as a liquid additive or a drip

concentrate cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throughout

the fuel system. The engine and fuel can then be stored

up to 24 months.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container.

Run the engine until it stops from lack of fuel. The use of

a fuel stabilizer in the storage container is recommended

to maintain freshness.

Hearing Protection Recommended.

6.20.2 — Protect Engine

1. Change engine oil.

2. Remove spark plug.

3. Pour a tablespoon (5-10 cc) of clean engine oil into

the cylinder.

4. Pull the starter rope several times to distribute the oil

in the cylinder.

5. Reinstall the spark plug.

6. Pull the starter rope slowly until resistance is felt.

This will close the valves so moisture cannot enter

the engine cylinder. Return the starter rope gently.

• Freeze damage is not covered under warranty.

To protect the unit from freezing temperatures:

1. Follow steps 1-3 in the previous section “After Each

Use” on page 29.

2. Use pump saver to treat pump. This minimizes

freeze damage and lubricates pistons and seals .

3. If pump saver is not available, connect a 3-foot section of garden hose to water inlet adapter. Pour RVantifreeze (antifreeze without alcohol) into hose. Pull

recoil handle twice. Disconnect 3-foot hose.

4. Store unit in a clean, d ry area.

6.21 — OTHER STORAGE INSTRUCTIONS

1. DO NOT store fuel from one season to another

unless it has been treated as described in Protect

Fuel System.

2. Replace fuel container if it starts to rust. Rust and/or

dirt in fuel can cause problems if it’s used with this

unit.

3. Cover unit with a suitable protective cover that does

not retain moisture.

Storage covers can be flammable.

• DO NOT place a storage cover over a hot power

washer.

• Let equipment cool for a sufficient time before placing

the cover on the equipment.

4. Store unit in a clean and dry area.

6.20.3 — Change Oil

Allow the engine to cool down and then drain oil from

crankcase. Refill with recommended grade. See “Changing Engine Oil” on page 27.

Hot oil may cause burns. Allow engine to cool

before draining oil. Avoid prolonged or

repeated skin exposure with used oil. Thoroughly wash exposed areas with soap.

6.22 — TRANSPORTING/TIPPING OF THE

NIT

U

Do not operate, store or transport the unit at an angle

greater than 15 degrees.

6.20.4 — Protecting the Pump

To protect the pump from damage caused by mineral

deposits or freezing, use PumpSaver or RV-antifreeze to

treat the pump. This prevents freeze damage and lubricates pistons and seals.

• Failure to do so will permanently damage your pump

and render your unit inoperable.

30 OneWASH™ Power Washer

Page 35

Section 7 Troubleshooting

7.1 — TROUBLESHOOTING GUIDE

PROBLEM CAUSE CORRECTION

Detergent fails to mix with

spray.

Engine runs well at no-load

but bogs when load is

added.

Engine will not start; or

starts and runs rough.

Engine shuts down during

operation.

1. Detergent siphoning tube is not

submerged.

2. Detergent siphoning tube/filter is clogged

or cracked.

3. High pressure nozzle installed.

1. Engine speed is too slow. 1. Contact a local service facility to adjust throttle

1. Dirty air cleaner.

2. Out of fuel.

3. Stale fuel.

4. Spark plug wire not connected to spark

plug.

5. Bad spark plug.

6. Water in fuel.

7. Excessively rich fuel mixture.

1. Out of fuel. 1. Fill fuel tank.

1. Insert detergent siphoning tube into detergent.

2. Clean or replace fil ter/detergent siphoning

tube.

3. Replace with low pressure nozzle.

mechanism.

1. Clean or replace air cleaner.

2. Fill fuel tank.

3. Drain fuel tank; fill with fresh fuel.

4. Connect wire to spark plug.

5. Replace spark plug.

6. Drain fuel tank; fill with fresh fuel.

7. Contact local service facility.

Engine lacks power. 1. Dirty air filter. 1. Replace air filter.

OneWASH™ Power Washer 31

Page 36

Part No. 0K6212 Rev B 02/12/14 © Generac Power Systems, Inc. All rights reserved Specifications are subject to change without notice. No reproduction allowed in any form without prior written consent from Generac Power Systems, Inc.

Generac Power Systems, Inc.

S45 W29290 Hwy. 59

Waukesha, WI 53189

1-888-GENERAC (1-888-436-3722)

generac.com

Page 37

*Construido en EE. UU. usando

piezas locales y extranjeras

Manual del operador

Hidrolavadora OneWASH™

www.generac.com o 1-888-436-3722

Page 38

¡ADVERTENCIA!

Proposición 65 de California

¡ADVERTENCIA!

Proposición 65 de California

El escape del motor y algunos de sus componentes son conocidos por el estado de California como

causantes de cáncer, defectos congénitos y otros daños reproductivos.

Este producto contiene o emite sustancias químicas que son conocidas por el estado de California

como causantes de cáncer, defectos congénitos y otros daños reproductivos.

ii

Page 39

Índice

Sección 1 - Introducción ........................................... 1

1.1 Introducción ......................................................... 1

Sección 2 - Seguridad ............................................... 3

2.1 Reglas de seguridad ............................................ 3

Sección 3 - Información general............................... 7

3.1 Conozca su hidrolavadora ................................... 7

3.2 Especificaciones del producto ............................. 8

3.3 Información sobre emisiones ............................... 8

3.4 Funcionamiento a gran altitud.............................. 8

Sección 4 - Configuración...................................... 11

4.1 Armado .............................................................. 11

4.2 Cómo añadir aceite de motor............................. 12

4.3 Combustible ....................................................... 13

4.4 Conexión de la manguera y suministro

de agua a la bomba ........................................... 13

4.5 Cómo usar las boquillas..................................... 15

Sección 5 - Operación ............................................. 19

5.1 Operación .......................................................... 19

5.2 Ubicación de la hidrolavadora............................ 19

5.3 Lista de comprobación antes de dar arranque al

motor 19

5.4 Cómo poner en marcha su hidrolavadora.......... 19

5.5 Sistema de enfriamiento automático

(Alivio térmico) ...................................................21

5.6 Cómo parar su hidrolavadora ............................ 21

Sección 6 - Mantenimiento...................................... 23

6.1 Recomendaciones de mantenimiento ............... 23

6.4 Control de emisiones ......................................... 24

6.5 Ajustes del cuadrante de potencia..................... 24

6.6 Mantenimiento de la hidrolavadora.................... 24

6.7 Comprobación y limpieza de la rejilla

de entrada .......................................................... 24

6.9 Comprobación del tubo para sifón

de detergente ..................................................... 24

6.10 Comprobación de la pistola de pulverización .... 24

6.11 Mantenimiento del tanque para sustancias

químicas ............................................................ 24

6.12 Mantenimiento de la boquilla ............................. 25

6.13 Mantenimiento del motor ................................... 26

6.14 Recomendaciones sobre el aceite de motor ..... 26

6.15 Servicio del filtro de aire .................................... 27

6.16 Servicio de la bujía ............................................ 28

6.17 Inspección del silenciador y el supresor

de chispas .......................................................... 28

6.18 Después de cada uso ........................................ 29

6.19 Almacenamiento en el invierno.......................... 29

6.20 Almacenamiento a largo plazo .......................... 29

6.21 Otras instrucciones de almacenamiento............ 30

6.22 Transporte e inclinación de la unidad ................ 30

Sección 7 - Resolución de problemas ................... 31

7.1 Guía de resolución de problemas...................... 31

iii

Page 40

Esta página se ha dejado en blanco intencionalmente.

iv

Page 41

Sección 1 Introducción

1.1 — INTRODUCCIÓN

Muchas gracias por haber comprado esta hidrolavadora

fabricada por Generac Power Systems, Inc. Este modelo es

una hidrolavadora accionada por motor, de alto

rendimiento, enfriada por aire, que funciona a 3100 psi. Las

unidades presentan ruedas de diseño personalizado,

bomba de cámara axial con pistones de acero inoxidable,

sistema de enfriamiento automático, boquillas de conexión

rápida, manguera de alta presión, manguera de sifón para