Page 1

0F9765MNL

3.0 liter

G A S

P.O. BOX 310 EAGLE WI 53119

Ford

Duratec

ENGINE

PARTS

MANUAL

PRINTED IN U.S.A.

Revision 0: 09/12/06

Page 2

3.0L GAS ENGINE TABLE OF CONTENTS

QUICK REFERENCE GUIDE ................................................................................................................................... 1

SERVICE RECOMMENDATIONS ............................................................................................................................2

CYLINDER BLOCK & RELATED PARTS ................................................................................................................. 6

CYLINDER BLOCK & RELATED PARTS ................................................................................................................. 7

CYLINDER HEAD & RELATED PARTS ...................................................................................................................8

CYLINDER HEAD & RELATED PARTS ...................................................................................................................9

PISTON & CONNECTING ROD ............................................................................................................................. 10

TIMING COMPONENTS ........................................................................................................................................ 11

CRANKSHAFT & RELATED PARTS ...................................................................................................................... 12

CRANKSHAFT & RELATED PARTS ...................................................................................................................... 13

ENGINE COMMON PARTS ....................................................................................................................................14

LEGEND

“ A R ” A S R E Q U I R E D

“ S T D ” S TA N D A R D S I Z E

“ O. S .” O V E R S I Z E

“ U . S .” U N D E R S I Z E

“ N A ” N O T AVA I L A B L E

NOTICE!

THE INFORMATION IN THIS MANUAL IS KNOWN TO BE ACCURATE AS OF THE DATE OF

RELEASE SHOWN ON THE COVER. HOWEVER, ENGINEERING CHANGES CAN OCCUR

WITHOUT NOTICE. TO OBTAIN THE PROPER PARTS, PLEASE BE SURE TO USE THE

MODEL NUMBER OF THE UNIT BEING SERVICED WHEN ORDERING FROM THIS MANUAL.

Page 3

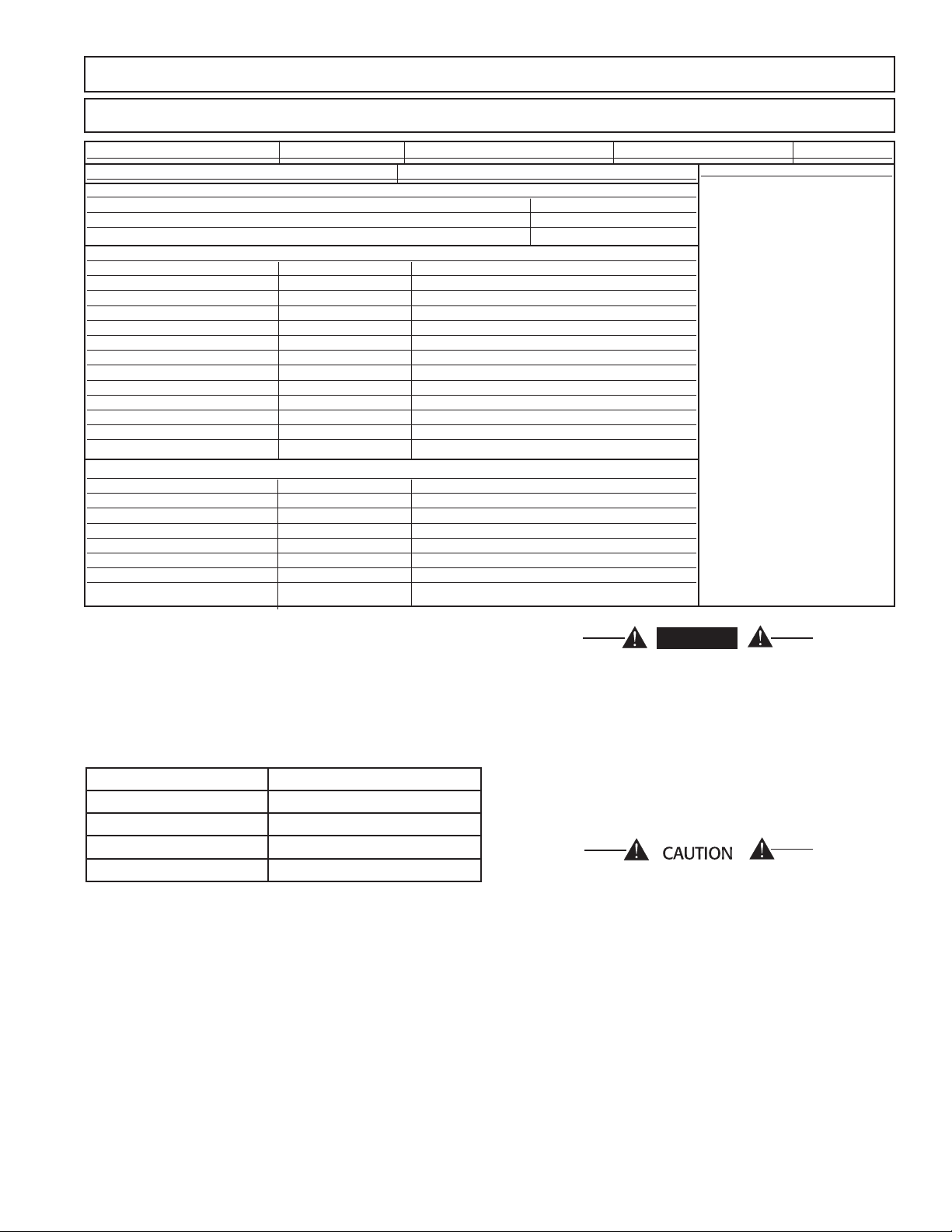

3.0L GAS ENGINE QUICK REFERENCE GUIDE

DANGER

QUICK REFERENCE ENGINE PARTS

ENGINE SIZE: 3.0 Liter FUEL: Gas MAKE: Ford ENGINE P/N: 0F9765 MODEL: —

OIL CAPACITY: 1.0 gallons (w/filter) COOLANT CAPACITY: 4.0 gallons

scheduled maintenance kits

Description Part Number

Oil/Air NA

– –

common reference parts

Description Part Number Special Notes

Oil Filter (Main) 0D5419

Fuel Filter NA

Air Cleaner Element Check BOM

V-Belt 0D3488N Serpentine

Thermostat 075885

Thermostat Gasket 048665

Water Pump 0F9225

Starter Motor 0E9747

Spark Plug 0F97650226

additional reference parts

Alternator 0E9868A

Ignition Coil 0F9228

User Notes

◆ Engine Oil Recommendations

The unit has been filled with “break in” engine oil

at the factory. Use a high-quality detergent oil classified “For Service CC, SD, SE or SF.” Detergent oils keep

the engine cleaner and reduce carbon deposits. Use oil

having the following SAE viscosity rating, based on the

ambient temperature range anticipated before the next

oil change:

Temperature Oil Grade (Recommended)

Above 75º F (24º C) SAE 30W

40º to 75º F (4.4º to 24º C) SAE 20W or 15W-40

10º to 40º F (-12º to 4.4º C) SAE 10W or 15W-40

Below 10º F (-12º C) SAE 5W-30 (Synthetic) or 5W-20

◆ Coolant

Use a mixture of half low silicate, ethylene glycol base

antifreeze and half soft water. Use only soft water and

only low silicate antifreeze. If desired, you may add a

high quality rust inhibitor to the recommended coolant

mixture. When adding coolant, always add the recommended 50-50 mixture.

Do not remove the radiator pressure cap while

the engine is hot or serious burns from boiling

*

liquid or steam could result.

Ethylene glycol base antifreeze is poisonous.

Do not use your mouth to siphon coolant from

*

the radiator, recovery bottle or any container.

Wash your hands thoroughly after handling.

Never store used antifreeze in an open container

because animals are attracted to the smell and

taste of antifreeze even though it is poisonous to

them.

Do not use any chromate base rust inhibitor with

*

ethylene glycol base antifreeze, or chromium

hydroxide (“green slime”) will form and cause

overheating. Engines that have been operated

with a chromate base rust inhibitor must be

chemically cleaned before adding ethylene glycol

base antifreeze. Using any high silicate antifreeze boosters or additives also will cause overheating. We also recommend that you DO NOT

use any soluble oil inhibitor for this equipment.

1

Page 4

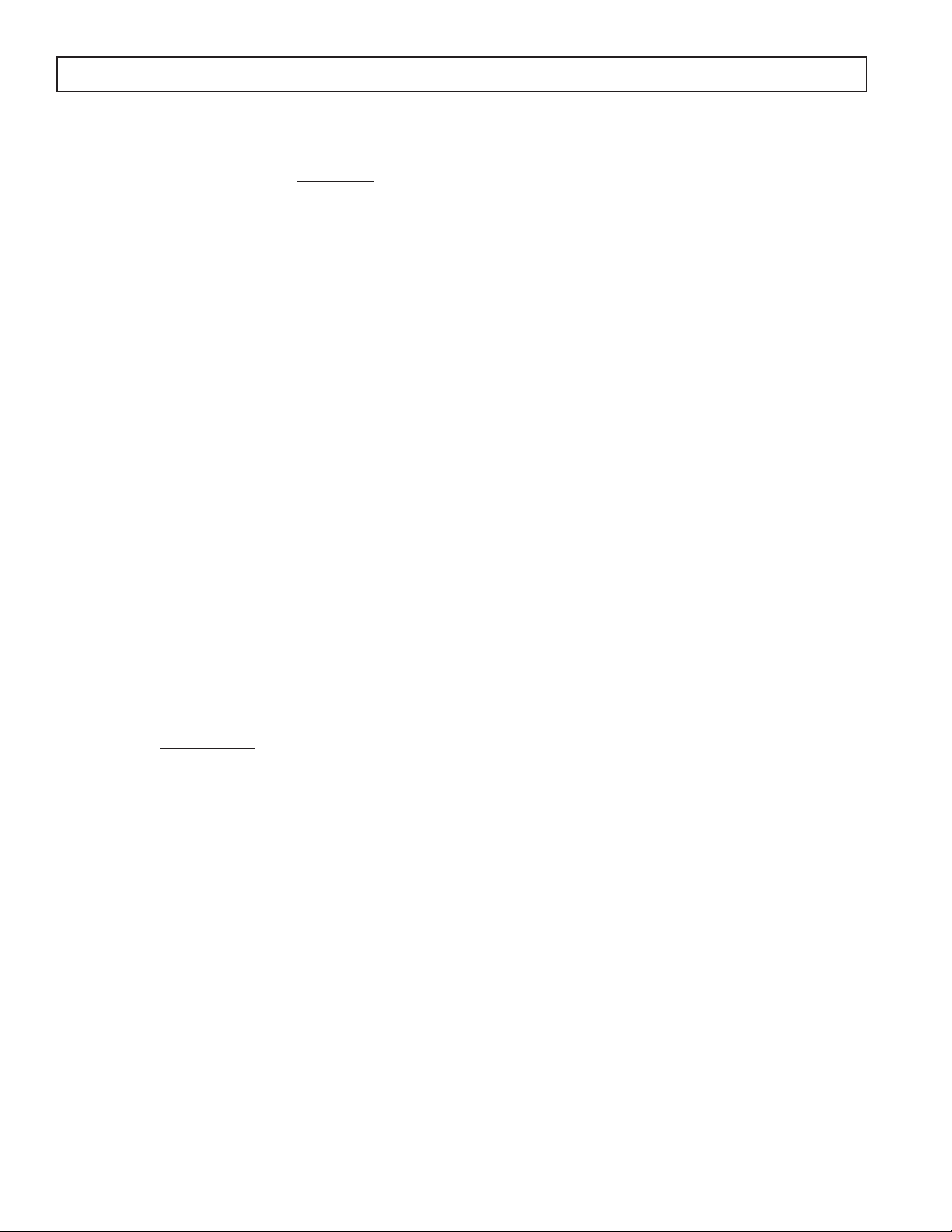

3.0L GAS ENGINE SERVICE RECOMMENDATIONS

8 kW - 35 kW Small Standby Generator Sets

Following is a recommended maintenance schedule for Generac small standby and residential generator sets

from 8 kW to 35 kW in size, and applies to both diesel engine and gas engine driven units. The established

intervals in the schedule are the maximum recommended when the unit is used in an average service application. They will need to be decreased (performed more frequently) if the unit is used in a severe application.

Use the unit hour meter or calendar time, whichever occurs first, from the previous maintenance interval to

determine the next required maintenance interval.

Service Maintenance Interval Information:

The various service maintenance intervals are designated by interval numbers as follows:

1 An early inspection of the generator set to insure it is ready to operate when required and to identify any

potential problem areas.

Performed monthly or following each 10 hours of operation of the unit and requires approximately .5

man-hours per unit to complete.

This inspection may be performed by the end user providing the following safety steps are taken to pre-

vent the engine from starting automatically without warning:

To prevent injury, perform the following steps in the order indicated before starting any maintenance:

• Disable the generator set from starting and/or connecting to the load by setting the control panel

Auto-Off-Manual switch to the “OFF” position.

• Remove the control panel fuse.

• Turn off the battery charger.

• Remove the negative battery cable.

The battery charger must be turned off BEFORE removing the battery cable to prevent an over current con-

dition from burning out sensitive control panel components and circuits.

*

Following all maintenance, reverse these steps to insure the unit is returned to standby setup for normal

operation when required.

2 A break-in service inspection of the generator set to insure it is ready to operate and carry the load when

required, and to identify any potential problem areas.

Performed ONLY ONCE following the first three months or the first 30 hours of operation after purchase

of the unit and requires approximately 2.5 man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowl-

edge to accomplish and should be performed only by an authorized Generac Service Dealer.

3 An operational inspection of the generator set to insure it is ready to operate and carry the load when

required, and to identify any potential problem areas.

Performed semi-annually or following each 50 hours of operation of the unit and requires approximately

1.5 man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowl-

edge to accomplish and should be performed only by an authorized Generac Service Dealer.

4 A mid-level inspection of the generator set to insure it is ready to operate and carry the load when required,

and to identify any potential problem areas.

Performed annually or following each 100 hours of operation of the unit and requires approximately 4.0

man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowl-

edge to accomplish and should be performed only by an authorized Generac Service Dealer.

2

Page 5

!

!

3.0L GAS ENGINE SERVICE RECOMMENDATIONS

GENERAC POWER SYSTEMS, INC.

RECOMMENDED SCHEDULED MAINTENANCE PROGRAM

SERVICE WORK TO BE PERFORMED BY FACTORY-TRAINED PERSONNEL ONLY.

DEALER INFORMATION

NAME: ____________________________________

ACCOUNT #: _______________________________

ADDRESS: _________________________________

PHONE: ___________________________________

TECHNICIAN: ______________________________

SIGNATURE: _______________________________

PURCHASE DATE: ____________________ START-UP DATE: ____________________

APPLICATION: ____ Standby Power ____ Prime Power ____ Rental/Trailerized

NAME: ____________________________________

ADDRESS: _________________________________

SITE: _____________________________________

PHONE: ___________________________________

SIGNATURE: _______________________________

OWNER INFORMATION

GENERATOR & TRANSFER SWITCH INFORMATION

GENERATOR

MODEL NUMBER:___________________________

SERIAL NUMBER:___________________________

MODEL NUMBER:___________________________

SERIAL NUMBER:___________________________

TRANSFER SWITCH

HOUR METER READING at Completion of the Inspection:___________________________

WARNING!

To prevent injury, perform the following steps in the order indicated before starting any maintenance:

• Disable the generator set from starting and/or connecting to the load by setting the control panel

Auto-Off-Manual switch to the “OFF” position.

• Remove the control panel fuse.

• Turn off the battery charger.

• Remove the negative battery cable.

NOTE:

The battery charger must be turned off BEFORE removing the battery cable to prevent an over current

condition from burning out sensitive control panel components and circuits.

Following all maintenance, reverse these steps to insure the unit is returned to standby setup for normal

operation when required.

3

Page 6

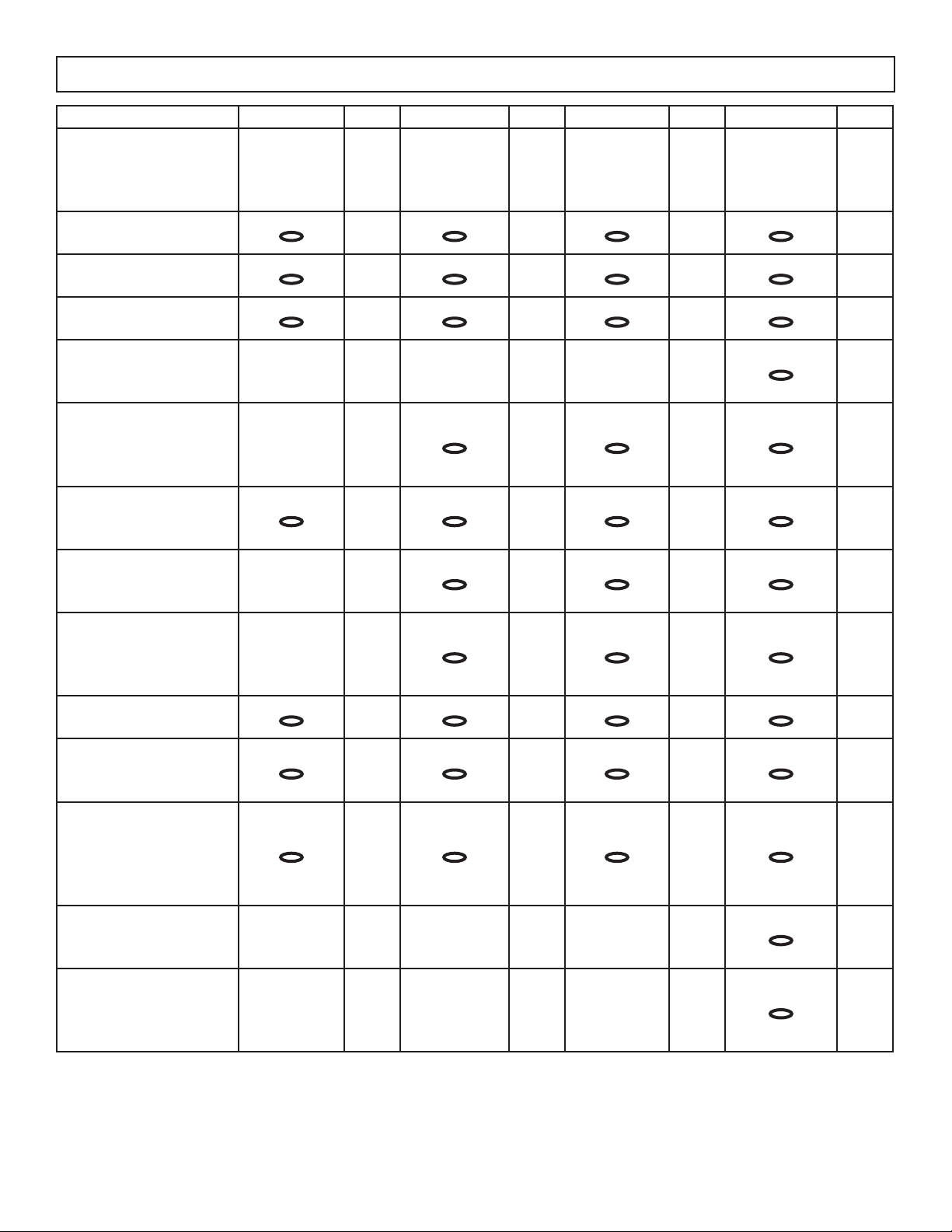

3.0L GAS ENGINE SERVICE RECOMMENDATIONS

Maintenance Tasks Level 1 Level 2 Level 3 Level 4

1. Disable the unit from operating

per the first page warning.

2. Check the engine oil level. Adjust

as necessary.

3. Check the engine coolant level.

Adjust as necessary.

4. Check the engine coolant ther-

mal protection level. Correct as

necessary.

5. Check the natural gas delivery

system on gas engine driven

units. Tighten connections as

necessary.

6. Check the diesel fuel supply

level for diesel engine driven

units. Fill as necessary.

7. Drain water and sediment from

the diesel fuel tank on diesel

engine driven units.

8. Drain water from the fuel line

water separator on diesel

engine driven units if the unit is

equipped with one.

9. Check the air inlets and outlets

for debris. Clean as necessary.

10. Check the battery electrolyte

level if accessible. Adjust as

necessary.

11. Check the battery posts,

cables, and charger for loose

connections, corrosion, and

proper operation. Correct as

necessary.

12. Check the unit wiring for loose

connections, corrosion, and

damage. Correct as necessary.

13. Check the engine accessory

drive belts for wear, weather

cracking, and damage. Replace

as necessary.

Recommended to

be done monthly/

10 hrs.

Task

Comp.

(Date-

Initials)

Required to be

done 3 months/

Break-in /30 hrs.

• • • •

• • • •

• • • •

• • •

• • • •

• • •

• • •

• • • •

• • • •

• • • •

Task

Comp.

(Date-

Initials)

Required to

be done Semi-

Annually/50 hrs.

Task

Comp.

(Date-

Initials)

Required to be done

Annually/ 100 hrs.

•

•

•

Task

Comp.

(Date-

Initials)

4

Page 7

3.0L GAS ENGINE SERVICE RECOMMENDATIONS

Maintenance Tasks Level 1 Level 2 Level 3 Level 4

14. Visually inspect the unit look-

ing for leaks, wear or damage,

loose connections or compo-

nents, and corrosion. Correct

as necessary.

15. Test the engine and transfer

switch safety devices. Correct

and/or adjust as necessary.

16. Initiate an automatic start and

transfer of the unit to site load

and exercise it for at least 1

hour looking for leaks, loose

connections or components,

and abnormal operating condi-

tions. Correct as necessary.

17. Start and exercise the unit at

full rated load (use a load bank

if the site load is not enough)

for at least 2 hours looking

for leaks, loose connections

or components, and abnormal

operating conditions. Correct as

necessary.

Recommended to

be done monthly/

10 hrs.

Task

Comp.

(Date-

Initials)

Required to be

done 3 months/

Break-in /30 hrs.

• • • •

• •

Task

Comp.

(Date-

Initials)

Required to

be done Semi-

Annually/50 hrs.

Task

Comp.

(Date-

Initials)

Required to be done

Annually/ 100 hrs.

•

•

Task

Comp.

(Date-

Initials)

18. Change the engine oil.

19. Replace the engine oil filter(s).

20. Replace the engine air filter(s).

21. Replace the engine fuel filter(s)

on diesel engine driven units

and re-prime the fuel system.

22. Check the engine spark plugs

on gas engine driven units.

Clean and re-gap orreplace as

necessary.

23. Perform a 5 minute no-load

operational run of the unit

looking for any post service

problems.

24. Return the unit to standby

setup for operation when

required.

•

• •

• •

• •

• •

• •

• • • •

5

Page 8

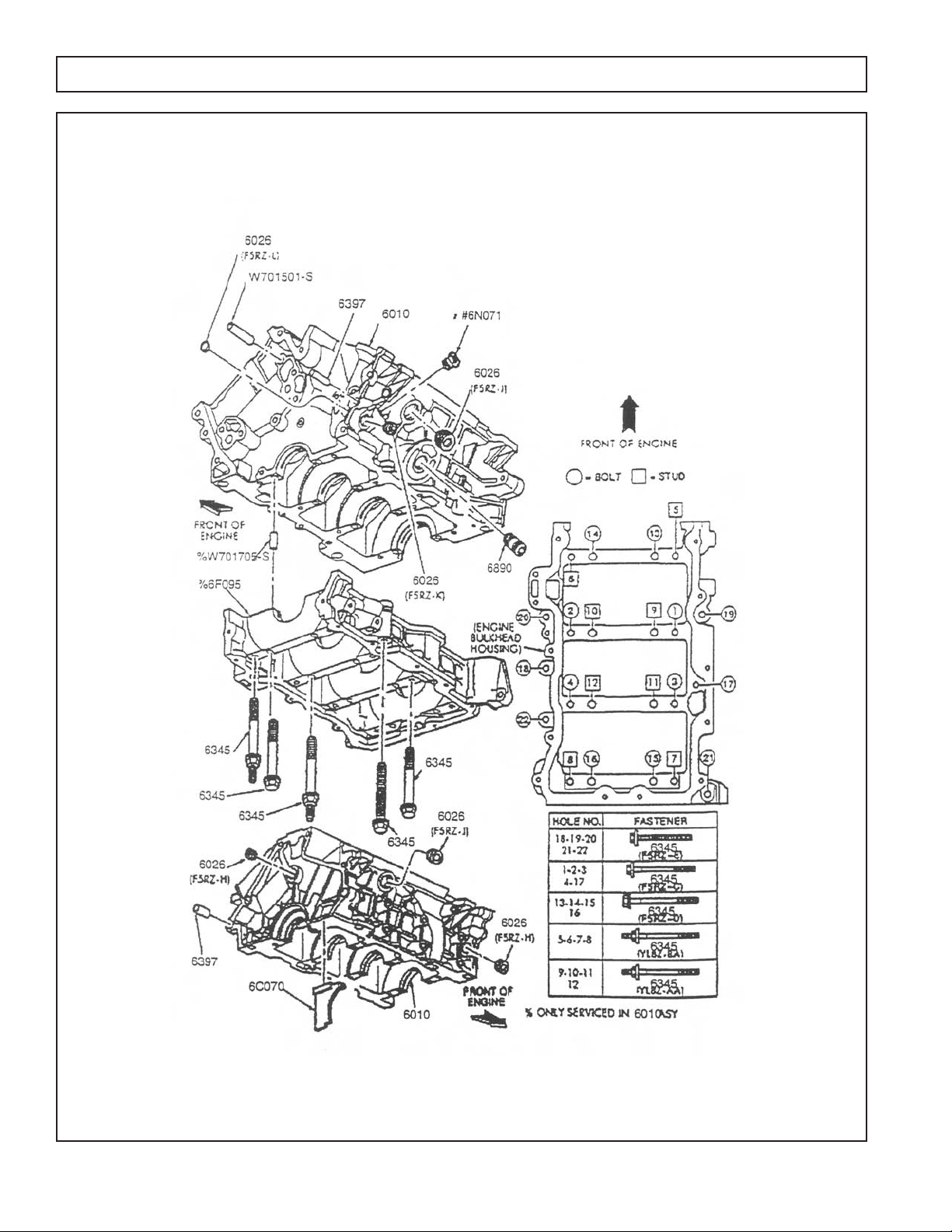

3.0L GAS ENGINE CYLINDER BLOCK & RELATED PARTS

6

Page 9

3.0L GAS ENGINE CYLINDER BLOCK & RELATED PARTS

ITEM PART NUMBER DESCRIPTION QTY

ENGINE BLOCK

0F9765 SHORT BLOCK 1

REMAN ENGINE ASSY 1

6890 0F97650100 OILFILTER MOUNTING INSERT 1

W701501 0F97650101 DOWEL, TIMING CHAIN GUIDE 1

TIMING COVER

6019 0F97650102 FRONT TIMING COVER 1

6020 0F97650103 TIMING COVER GASKET, RH 1

6020 0F97650104 TIMING COVER GASKET, CENTER 1

6020 0F97650105 TIMING COVER GASKET, LH 1

6700 0F97650106 TIMING COVER SEAL 1

W701525 0F97650107 BOLT,M8 X 51MM POS.4,10,13,14,15 & 16 6

W701240 0F97650108 BOLT, M8 X 34MM POS.7 & 9 2

W701581 0F97650109 STUD M8 X 68MM X M8 X 2MM POS.2,3,5,6,8,11, &12 7

W701712 0F97650110 STUD M6 X 20 M8 X 47.5 POS. 1 1

W701228 0F97650111 DOWEL TIMING COVER TO BLOCK 2

PLUGS-CYLINDER BLOCK

6026 0F97650112 1/2" X 14 MM PIPE, RG & CENTER REAR OF BLOCK 2

6026 0F97650113 3/4" X 14MM PIPE RH & LH SIDE OF BLOCK 2

6026 0F97650114 3/8" X 18MM PIPE LH SIDE OF BLOCK 1

6026 0F97650115 19.35MM CUP LH SIDE OF BLOCK 1

6026 0F97650116 1 X 11.5MM PIPE RH & LH CYLINDER HEAD 2

6026 0F97650117 1/4" X 18 MM PIPE RH & LH CYLINDER HEAD 9

6391 0F97650118 DOWEL TRANY TO BLOCK 2

OIL PRESSURE SENDING UNIT

9278 0F97650119 OIL PRESSURE SENDING UNIT 1

6N071 0F97650120 OIL PRESSURE SENDING UNIT TO BLOCK ADAPTER 1

MAIN BOLTS

6345 0F97650121 HOLE # 1,2,3,4 &17 5

6345 0F97650122 HOLE # 13,14,15,& 16 4

6345 0F97650123 HOLE # 18,19,20,21,& 22 5

6345 0F97650124 HOLE #9,10,11 & 12 4

6345 0F97650125 HOLE #5,6,7,& 8 4

7

Page 10

3.0L GAS ENGINE CYLINDER HEAD & RELATED PARTS

8

Page 11

3.0L GAS ENGINE CYLINDER HEAD & RELATED PARTS

ITEM PART NUMBER DESCRIPTION QTY

CYLINDER HEAD ASSEMBLY

6049 0F97650126 CYL., HEAD, COMPLETE WITH VALVES, LESS CAMS 1

6049 0F97650127 CYL., HEAD, COMPLETE WITH VALVES, LESS CAMS 1

6051 0F97650128 HEAD GASKET, LH 1

6051 0F97650129 HEAD GASKET, RH 1

6065 0F97650130 HEAD BOLT,M10 X 156MM, PKG OF 8 16

VALVES

6505 0F97650131 EXHAUST VALVE, STANDARD 6

6507 0F97650132 INTAKE VALVE, STANDARD 6

6571 0F97650133 VALVE STEM SEAL, INTAKE 6

VALVE TRAIN

6513 0F97650134 VALVE SPRING 6

6514 0F97650135 VALVE SPRING RETAINER 12

6518 0F97650136 VALVE SPRING LOCK KEY 24

6564 0F97650137 ROCKER ARM 24

6C501 0F97650138 LASH ADJUSTER 24

6L293 0F97650139 CAMSHAFT BEARING CAP BOLT (NOT REPLACED 11-97) A/R

CAMSHAFT

6250 0F97650140 CAMSHAFT, RH INTAKE 1

6250 0F97650141 CAMSHAFT, LH INTAKE 1

6250 0F97650142 CAMSHAFT, RH EXHAUST 1

6250 0F97650143 CAMSHAFT, LH EXHAUST 1

6L253 0F97650144 ARM, TINING CHAIN TENSIONER 2

OIL FILLER / BREATHER / PCV VALVE

6A785 0F97650145 OIL SEPERATOR ASSEMBLY 1

W701504 0F97650146 BOLT, OIL SEPERATOR 1

6A664 0G0607 CRANKCASE ASPIRATOR HOSE ASSEMBLY 1

6762 0F97650147 ELBOW 1

6A666 0F97650148 PCV VALVE 1

9

Page 12

3.0L GAS ENGINE PISTON & CONNECTING ROD

ITEM PART NUMBER DESCRIPTION QTY

PISTON & PIN ASSEMBLY

6100 0F97650149 PISTON, PIN, RINGS & CONNECTING ROD, STANDARD 6

6148 0F97650150 RINGSET, STANDARD 3

CONNECTING ROD

6200 0F97650151 CONECTING ROD 6

6135 0F97650152 PISTON PIN 6

6207 0F97650153 BUSHING, PISTON PIN 6

6140 0F97650154 PISTON PIN RETAINING CLIP 12

6214 0F97650155 BOLT, ROD 12

ROD BEARINGS

(SOLD IN PACKS OF TWO HALVES)

6211 0F97650156 ROD BEARING,STANDARD, UPPER & LOWER 12

10

Page 13

3.0L GAS ENGINE TIMING COMPONENTS

ITEM PART NUMBER DESCRIPTION QTY

6268 0F97650157 TIMING CHAIN, RH OR LH 2

6L253 0F97650158 TENSIONER ARM, RH OR LH 2

6K297 0F97650159 TIMING CHAIN GUIDE, RH 1

6K297 0F97650160 TIMING CHAIN GUIDE, LH 1

6L266 0F97650161 TIMING CHAIN TENSIONER, RH OR LH 2

W701524 0F97650162 BOLT TENSIONER 4

W701232 0F97650163 BOLT, TENSIONER ARM 6

6306 0F97650164 CRANKSHAFT SPROCKET, TWO ROW 1

11

Page 14

3.0L GAS ENGINE CRANKSHAFT & RELATED PARTS

12

Page 15

3.0L GAS ENGINE CRANKSHAFT & RELATED PARTS

ITEM PART NUMBER DESCRIPTION QTY

CRANKSHAFT ASSEMBLY

6303 0F97650165 CRANKSHAFT 1

6B316 0F97650166 CRANKSHAFT KEY 1

12A227 0F97650167 PULSATOR RING, CRANKSHAFT SENSOR 1

6C315 0F97650168 CRANKSHAFT TIMING SENSOR 1

12257 0F97650169 BRACKET, IGNITION MOUNTING 1

18801 0F97650170 CAPACITOR 1

CRANKSHAFT PULLEY

6316 0F97650171 CRANKSHAFT DAMPER 1

6A340 0F97650172 BOLT, CRANKSHAFT DAMPER 1

6378 0F97650173 WASHER, PULLEY TO CRANKSHAFT 1

6A312 0F97650174 PULLEY, CRANKSHAFT 1

CRANKSHAFT MAIN BEARING KITS

6D309 0F97650175 MAIN BEARING KIT, STANDARD 1

6D309 0F97650176 MAIN BEARING KIT, .010" UNDERSIZE(25MM) 1

6D309 0F97650177 MAIN BEARING KIT, .020" UNDERSIZE (50MM) 1

13

Page 16

3.0L GAS ENGINE OIL PUMP, OIL PAN & RELATED PARTS

14

Page 17

3.0L GAS ENGINE OIL PUMP, OIL PAN & RELATED PARTS

ITEM PART NUMBER DESCRIPTION QTY

OIL PUMP

6600 0F97650178 OIL PUMP ASSEMBLY 1

W500300 0F97650179 BOLT,PUMP TO BLOCK 4

W700005 0F97650180 BOLT, PICK UP TO PUMP 2

6622 0F97650181 OIL PUMP PICK UP TUBE & SCREEN 1

6626B 0F97650182 OIL PUMP INLET TUBE GASKET 1

OIL PAN

6675 0F97650183 OIL PAN 1

6687 0F97650184 BAFFLE, OIL PAN 1

W701542 0F97650185 NUT,M6 X 1MM 5

6730 0F97650186 OIL PAN DRAIN PLUG 1

6734 0F97650187 OIL PAN DRAIN PLUG GASKET 1

6710 0F97650188 OIL PAN GASKET 1

W701605 0F97650189 BOLT, OIL PAN A/R

W701606 0F97650190 STUD OIL PAN A/R

6754 0F97650191 DIPSTICK TUBE 1

6750 0F97650192 DIPSTICK 1

W701585 0F97650193 BOLT, TUBE TO BLOCK 1

6C629 0F97650194 OIL PAN SPACER,SELECT FIT,YELLOW (#SILVER) 1

6C629 0F97650195 OIL PAN SPACER,SELECT FIT,BLUE (#GOLD) 1

OIL FILTER

6731 0D5419 OIL FILTER 1

15

Page 18

3.0L GAS ENGINE ROCKER COVER & RELATED PARTS

ITEM PART NUMBER DESCRIPTION QTY

6582 0F97650196 ROCKER COVER, RH 1

6582 0F97650197 ROCKER COVER, LH 1

6584 0F97650198 ROCKER COVER GASKET, RH 1

6584 0F97650199 ROCKER COVER GASKET, LH 1

6C519 0F97650200 STUD & GROMMET 1

6C519 0F97650201 BOLT & GROMMET 1

6766 0F97650202 OIL FILLER CAP 1

16

Page 19

3.0L GAS ENGINE COOLING SYSTEM

ITEM PART NUMBER DESCRIPTION QTY

8501 0F9225 WATER PUMP 1

8A507 0F97650203 WATER PUMP OUTLET CONNECTION 1

8508 0F97650204 COVER WATER PUMP 1

8A505 0F97650205 INLET WATER TUBE 1

8555 0F97650206 WATERTUBE, CROSSOVER 1

6A312 0F97650207 ACCESSORY DRIVE PULLEY 1

8620 0F9562 BELT, WATER PUMP 1

17

Page 20

3.0L GAS ENGINE INTAKE AND EXHAUST MANIFOLD

ITEM PART NUMBER DESCRIPTION QTY

INTAKE MANIFOLD

9424 0F9222 UPPER INTAKE MANIFOLD ASSEMBLY 1

9424 0F9221 LOWER INTAKE MANIFOLD ASSEMBLY 2

9H486 0F9224 GASKETS, UPPER TO LOWER INTAKE MANIFOLD 6

9439 0F9223 GASKETS, LOWER MANIFOLD TO HEAD (PKG OF 6) 2

9E470 0F97650208 TUBE ASSY,EGR VALVE OUTLET 1

W701504 0F97650209 BOLT, EGR TUBE TO UPPER INTAKE MANIFOLD 2

9S479 0F97650210 ISOLATOR ASSY, INTAKE MANIFOLD 1

9F593 0F97650211 INJECTOR 6

9F792 0F97650212 FUEL RAIL 1

9H321 0F97650213 FUEL PRESSURE RELIEF VALVE 1

9H323 0F97650214 FUEL PRESSURE RELIEF VALVE CAP 1

9F972 0F97650215 FUEL INJECTOR SENSOR 1

W500203 0F97650216 SCREW, SENSOR TO RAIL 2

W701572 0F97650217 BOLT,FUEL RAILTO LOWER INTAKE MANIFOLD 4

W708187 0F97650218 BOLT,FUEL RAILTO LOWER INTAKE MANIFOLD 4

EXHAUST MANIFOLD

9448 0G0100 EXHAUST MANIFOLD GASKET 2

9E498 0F97650219 CONNECTOR, EMMISSION VACUMN CNTRL 1

9D476 0F97650220 GASKET EGR VALVE 1

9D477 0F97650221 TUBE , EGR TO EXHAUST MANIFOLD 1

W701732 0F97650222 STUD, EXHAUST MANIFOLD TO HEAD 12

W701706 0F97650223 NUT, EXHAUST MANIFOLD TO HEAD 12

18

Page 21

3.0L GAS ENGINE IGNITION

ITEM PART NUMBER DESCRIPTION QTY

12029 0F9228 COIL 1

18801 0F97650224 IGNITION INTERFERENCE CAPACITOR 1

W701547 0F97650225 BOLT, COIL TO ENG,3/8" 16X.75" 4

0F97650226 SPARK PLUG 6

12259 0F9556 WIRESET, SPARK PLUGS 1

12297 0F97650227 SEPERATOR, IGNITION WIRE 1

12297 0F97650228 SEPERATOR, IGNITION WIRE 1

12A581 0F97650229 ENGINE CONTROL WIRE HARNESS 1

14536 0F97650230 BRACKET, WIRING 1

19

Page 22

G-8403-C

6/21/06

ENGINE COMMON PARTS

0F9766

D

DRAWING #:

EXPLODED VIEW:

REVISION:

DATE:

PAGE 1 OF 3

GROUP

SPECIFIC

AT

I

ON

S

FOR ENGINE

OI

L

OW

N

ERS MANU

AL

REFER

T

O

0

F

5

1

1

4

WIRE

GRD.

85

84

82

83

11

50

24

"B"

25

51

96

32

45

31

102

97

47

46

59

15

62

39

63

98

9

58

43

42

49

64

2

32

45

31

"C"

65

18

44

19

2

66

55

105

32

75

35

73

21

76

53

52

77

76

"TO A"

35

56

100

36

99

20

104

1

61

74

32

17

72

56

LOWER

RADIATOR

HOSE

31

30

8

"TO B"

82

2

42

"A"

27

28

92

87

32

49

90

35

36

91

31

36

68

79

88

80

82

81

82

4

68

79

82

UPPER

RADIATOR

HOSE

70

41

26

2

48

44

14

ROUTED UNDER STATOR

CAN

"TO C"

67

28

35

103

16

12

34

84

83

86

28

94 (GRD. SCREW)

89

43

36

3.0L GAS ENGINE COMMON PARTS

20

Page 23

3.0L GAS ENGINE COMMON PARTS

ITEM PART NUMBER DESCRIPTION QTY

1 0F9765X ENGINE FWD MAKE 1

2 022131 WASHER FLAT 3/8-M10 ZINC 5

4 085662D TIE WRAP UL 17.7 X .35 BLK HT 1

8 0F9258 SUPPORT COOLANT TUBE 1

9 0D5419 (REF.) OIL FILTER 1

11 0F8931 SPACER FLEX PLATE 1

12 027482 WASHER SHAKEPROOF EXT 5/16 STL 1

14 0A6751 SWITCH HI-TEMP 245D X 3/8 NPT 1

15 033472 RIVET POP .125 X .400 AL 6

16 0E9747 STARTER 12 VOLT 1

17 0E6585 COVER IAC ACTUATOR 1

18 0F8425 ADAPTER ENGINE 1

19 0F9965C FLEX PLATE 2 POLE 1

20 055476 BSHG RDCR HEX 3/8 TO 1/8 GALV 1

21 0A8584 SWITCH OIL PRESSURE 10 PSI 2 POL 1

24 083896 WASHER LOCK 1/4-M6 SS 6

25 084929 WASHER FLAT 1/4 SS 6

26 0F3844 WASHER FLAT .45 X 1.00 8

27 077996 CAP ANTIFREEZE RUBBER 1

28 057823 CLAMP HOSE #10 .56-1.06 3

30 047411 SCREW HHC M6-1.0 X 16 G8.8 2

31 022097 WASHER LOCK M6-1/4 8

32 022473 WASHER FLAT 1/4-M6 ZINC 16

34 0G0153 BARBED EL 90 1/2 NPT X 3/4 HOSE 1

35 022129 WASHER LOCK M8-5/16 14

36 022145 WASHER FLAT 5/16-M8 ZINC 14

39 067989 NUT HEX FL WHIZ M8-1.25 12

41 0D5417 SCREW HHC M10-1.0 X 25 G10.9 8

42 046526 WASHER LOCK M10 3

43 049226 WASHER LOCK M5 8

44 064416 SCREW HHC M10-1.5 X 45 G8.8 FT 6

45 043116 SCREW HHC M6-1.0 X 12 G8.8 5

46 051769 WASHER LOCK M12 1

47 049808 WASHER FLAT M12 1

48 025507 WASHER SHAKEPROOF EXT 7/16 STL 5

49 045772 NUT HEX M10-1.5 G8 YEL CHR 3

50 085296 SCREW HHC 1/4-20 X 1/2 SS 6

51 0E7202 HEAT SHIELD 260 X 80 HOT 2

52 0F8795A MANIFOLD EXHAUST LH 1

53 0G0100 GASKET EXHAUST 2 (REF.)

55 0E0992A PLUG EXPANSION 14 OD 6

56 039253 SCREW HHC M8-1.25 X 20 G8.8 5

58 051713 WASHER FLAT M5 2

59 052617 SCREW HHC M12-1.75 X 20 G8.8 1

60 0F9556 WIRES, SPARK PLUG 1

21

Page 24

G-8403-C

6/21/06

ENGINE COMMON PARTS

0F9766

D

DRAWING #:

EXPLODED VIEW:

REVISION:

DATE:

PAGE 1 OF 3

GROUP

SPECIFIC

AT

I

ON

S

FOR ENGINE

OI

L

OW

N

ERS MANU

AL

REFER

T

O

0

F

5

1

1

4

WIRE

GRD.

85

84

82

83

11

50

24

"B"

25

51

96

32

45

31

102

97

47

46

59

15

62

39

63

98

9

58

43

42

49

64

2

32

45

31

"C"

65

18

44

19

2

66

55

105

32

75

35

73

21

76

53

52

77

76

"TO A"

35

56

100

36

99

20

104

1

61

74

32

17

72

56

LOWER

RADIATOR

HOSE

31

30

8

"TO B"

82

2

42

"A"

27

28

92

87

32

49

90

35

36

91

31

36

68

79

88

80

82

81

82

4

68

79

82

UPPER

RADIATOR

HOSE

70

41

26

2

48

44

14

ROUTED UNDER STATOR

CAN

"TO C"

67

28

35

103

16

12

34

84

83

86

28

94 (GRD. SCREW)

89

43

36

3.0L GAS ENGINE COMMON PARTS

22

Page 25

3.0L GAS ENGINE COMMON PARTS

ITEM PART NUMBER DESCRIPTION QTY

61 0F5114 DECAL REFER TO OWNERS MANUAL 1

62 0F5966 REFLECTIVE HEAT SHIELD 2

63 022985 WASHER FLAT #6 ZINC 6

64 0F9225 PUMP WATER 1.(REF.)

65 0F9227 TENSIONER WATER PUMP 1

66 0F9562 BELT WATER PUMP 1

67 050968 HOSE COOL 3/4 ID 20R3 (51.5” LG) 1

68 0F6746 TUBE UPPER COOLANT 2

70 052243 SCREW HHC M10-1.5 X 60 G8.8 1

72 0F9563 GASKET IDLE AIR CONTRL ACT CVR 1.(REF.)

73 0F9564 GASKET INTAKE ADAPTER 1.(REF.)

74 0F9222 MANIFOLD INTAKE UPPER 1

75 0F9224 GASKET INTAKE MANIFOLD UPPER 6(REF)

76 0F9221 MANIFOLD INTAKE LOWER 2

77 0F9223 GASKET INTAKE LOWER 6

79 055934V CLAMP VINYL 1.5 X .281 Z 2

80 0F9220 HOSE UPPR RAD REAR 1

81 0F9239 HOSE,LOWR RAD REAR 1

82 035685 CLAMP HOSE #28 1.32-2.25 6

83 0A2711A ADAPTER THERMOSTAT 2

84 048665 GASKET THERMOSTAT 2

85 075885 THERMOSTAT 195 DEG 1

86 0F9252 MACHINING,THERMOSTAT ADPTR 1

87 0F9259 BRACKET,THERMOSTAT 1

88 0C2454 SCREW THF M6-1X16 N WA Z/JS 2

89 052207 SCREW HHC M8-1.25 X 80 G8.8 2

92 0F9232 HOSE UPPR RAD REAR 1

96 0F9271 GUARD WATER PUMP REAR 1

97 0F9270 GUARD WATER PUMP FRNT 1

98 0F9314 BRKT WATERPUMP GUARD 1

99 0F7695 EGR GASKET 1

100 0F6658 COVER EGR 1

102 051716 NUT HEX M5-0.8 G8 CLEAR ZINC 4

103 049821 SCREW SHC M8-1.25 X 30 G12.9

104 0G0607 ASSEMBLY HOSE PCV VALVE 3

23

Page 26

G-8403-C

6/21/06

ENGINE COMMON PARTS

0F9766

D

EXPLODED VIEW:

DRAWING #:

REVISION:

DATE:

PAGE 2 OF 3

GROUP

35

36

2

*REFERENCE COOLING PACKAGE EXP. VW. 0F9367.

6

93

36

6

7

71

35

38

40

60

STUD. STUD SUPPLIED

REMOVE & REPLACE

53

51

W / ENGINE.

25

50

24

78

38

15

62

63

39

22

23

36

35

33

29

37

101

95

43

13

43

102

57

49

42

5

38

35

36

36

*3

10

1

69

3.0L GAS ENGINE COMMON PARTS

24

Page 27

3.0L GAS ENGINE COMMON PARTS

ITEM PART NUMBER DESCRIPTION QTY

1 0F9765X ENGINE FWD MAKE 1

2 022131 WASHER FLAT 3/8-M10 ZINC 5

3* 0F8046 ADAPTER CRANKSHAFT (REF.)

5 0F9625 BRACKET DC ALTERNATOR 1

6 0E9868A ALTERNATOR DC W/OUT PULLEY 1

7 0F3216 PULLEY 80 OD DC ALTERNATOR 1

10 0D3488N BELT SERPENTINE 28.92” 1

13 029187 SPACER .19 X .31 X .50 PL 2

15 033472 RIVET POP .125 X .400 AL 6

22 0C7649 CLAMP HOSE .38-.87 1

23 069860E HOSE DRAIN ASSY 28" 1

24 083896 WASHER LOCK 1/4-M6 SS 6

25 084929 WASHER FLAT 1/4 SS 6

29 055596 BARBED STR 3/8 NPT X 3/8 1

33 077456 ADAPTER M12-1.75 X 3/8 NPT 1

35 022129 WASHER LOCK M8-5/16 14

36 022145 WASHER FLAT 5/16-M8 ZINC 14

37 052677 WASHER NYLON .50 X .87 X .06 1

38 043107 SCREW HHC M8-1.25 X 25 G8.8 3

39 067989 NUT HEX FL WHIZ M8-1.25 12

40 0F9228 COIL IGNITION 1

42 046526 WASHER LOCK M10 3

43 049226 WASHER LOCK M5 8

49 045772 NUT HEX M10-1.5 G8 YEL CHR 3

50 085296 SCREW HHC 1/4-20 X 1/2 SS 6

51 0E7202 HEAT SHIELD 260 X 80 HOT 2

53 0G0100 GASKET EXHAUST 2 (REF.)

57 0F9617 SPACER ALTERNATOR 1

60 0F9556 WIRES, SPARK PLUG 1

62 0F5966 REFLECTIVE HEAT SHIELD 2

63 022985 WASHER FLAT #6 ZINC 6

69 051731 SCREW HHC M8-1.25 X 50 G8.8 1

93 057645 SCREW HHC M10-1.5 X 50 G8.8 1

95 055440 SCREW HHC M5-0.8 X 25 G8.8 3

101 0F9498 BRACKET COIL 1

102 051716 NUT HEX M5-0.8 G8 CLEAR ZINC 4

25

Page 28

Loading...

Loading...