Page 1

0E6478

6.8LITER

GAS

ENGINE

PARTS

MANUAL

P.O. BOX 310 EAGLE WI 53119

PRINTED IN U.S.A.

Revision 0: 08/29/03

FORD

Page 2

Page 3

6.8L GAS TABLE OF CONTENTS

1

LEGEND

“AR” AS REQUIRED

“STD” STANDARD SIZE

“O.S.” OVERSIZE

“U.S.” UNDERSIZE

“NA” NOT AVAILABLE

NOTICE!

THE INFORMATION IN THIS MANUAL IS KNOWN TO BE ACCURATE AS OF THE DATE OF

RELEASE SHOWN ON THE COVER. HOWEVER, ENGINEERING CHANGES CAN OCCUR

WITHOUT NOTICE.TO OBTAIN THE PROPER PARTS, PLEASE BE SURE TO USE THE MODEL

NUMBER OF THE UNIT BEING SERVICED WHEN ORDERING FROM THIS MANUAL.

QUICK REFERENCE GUIDE .............................................................................................................................. 2

SERVICE RECOMMENDATIONS ........................................................................................................................ 3

ENGINE LOWER .................................................................................................................................................. 8

ENGINE UPPER ................................................................................................................................................ 12

ENGINE FRONT.................................................................................................................................................. 14

COOLING SYSTEM ............................................................................................................................................ 16

INTAKE AND IGNITION SYSTEM ...................................................................................................................... 18

ENGINE COMMON PARTS:

LEFT HAND SIDE (DIRECT DRIVE UNITS) .............................................................................................. 20

LEFT HAND SIDE (GEAR BOX UNITS) .................................................................................................... 22

RIGHT HAND SIDE (DIRECT DRIVE UNITS, OPEN SET - NO ENCLOSURE) ...................................... 24

RIGHT HAND SIDE (DIRECT DRIVE UNITS, CLOSED SET - W/ ENCLOSURE) .................................. 26

RIGHT HAND SIDE (GEAR BOX UNITS, OPEN SET - NO ENCLOSURE) ............................................ 28

RIGHT HAND SIDE (GEAR BOX UNITS, CLOSED SET - W/ ENCLOSURE) .......................................... 30

Page 4

6.8L GAS QUICK REFERENCE GUIDE

QUICK REFERENCE ENGINE PARTS

2

PART NUMBER DESCRIPTION QTY

0D5419 FILTER ASY. - OIL 1

0D34540114 PISTON RING SET STD (2 PISTONS) 5

0D34540115 PISTON RING SET .020"/.50MM O/S 5 AR

0D34540203 CAP - OIL FILLER 1

0D34540123 SLINGER-CRANKSHAFT OIL REAR 1

0D34540126 SEAL-CRANKSHAFT REAR 1

0D34540213 CHAIN-TIMING 2

0D34540232 PUMP ASY & SEAL-WATER 1

0D34540233 SEAL-WATER PUMP 1

0D34540235 SEAL-THERMOSTAT (O-RING) 1

0D34540238 THERMOSTAT ASSY-WATER 1

0D34540249 COIL & BOOT ASY-IGNITION 10

0D34540186 SPARK PLUG (PLATINUM) .044 GAP 10

0D3488 BELT SERPENTINE 67.5” (DIRECT DRIVE) 1

0D3488A BELT SERPENTINE 70” (GEAR BOX) 1

0A1232 D.C. ALTERNATOR ASSY 1

0D5418 STARTER MOTOR FORD V-10 ENGINE 1

0A8584 SWITCH OIL PRESSURE 1

053667 SENDER WATER TEMP 1

053666 SENDER OIL PRESSURE 1

Page 5

3

ENGINE OIL RECOMMENDATIONS

The unit has been filled with “break in” engine oil

at the factory. Use a high-quality detergent oil classified

“For Service CC, SD, SE or SF.” Detergent oils keep the

engine cleaner and reduce carbon deposits. Use oil having the following SAE viscosity rating, based on the

ambient temperature range anticipated before the next

oil change:

Engine Lubrication System:

Crankcase Oil Capacity..............................................6.8 L (7 U.S. qts.)

COOLANT

Use a mixture of half low silicate, ethylene glycol base

antifreeze and half soft water. Use only soft water and

only low silicate antifreeze. If desired, you may add a

high quality rust inhibitor to the recommended coolant

mixture. When adding coolant, always add the recommended 50-50 mixture.

Cooling System:

CCoolant Capacity

System..............................................................23.7 L (6.3 U.S. gals.)

Engine ..............................................................12.3 L (3.3 U.S. gals.)

Do not remove the radiator pressure cap while

the engine is hot or serious burns from boiling

liquid or steam could result.

Ethylene glycol base antifreeze is poisonous. Do

not use your mouth to siphon coolant from the

radiator, recovery bottle or any container. Wash

your hands thoroughly after handling. Never

store used antifreeze in an open container

because animals are attracted to the smell and

taste of antifreeze even though it is poisonous

to them.

Do not use any chromate base rust inhibitor with

ethylene glycol base antifreeze, or chromium

hydroxide (“green slime”) will form and cause

overheating. Engines that have been operated

with a chromate base rust inhibitor must be

chemically cleaned before adding ethylene glycol

base antifreeze. Using any high silicate antifreeze

boosters or additives also will cause overheating.

We also recommend that you DO NOT use any

soluble oil inhibitor for this equipment.

!

◆

◆

Temperature Oil Grade (Recommended)

Above 80º F (27º C) SAE 30W or 15W-40

30º to 80º F (-1º to 27º C) SAE 20W-20 or 15W-40

Below 32º F (0º C) SAE 10W or 15W-40

6.8L GAS SERVICE RECOMMENDATIONS

DANGER

!

!

Page 6

4

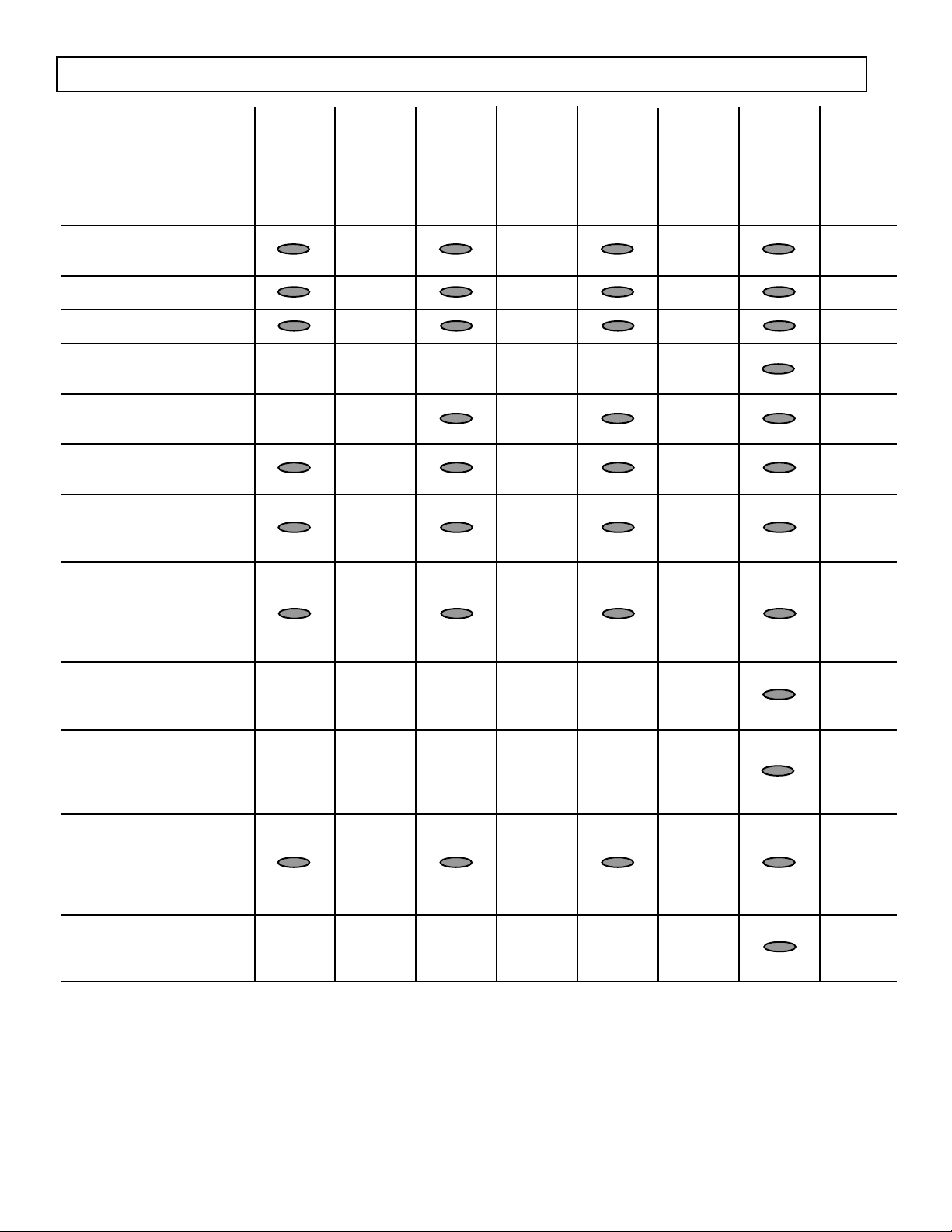

35 KW - 200 KW STANDBY GAS ENGINE DRIVEN GENERATOR SETS

Following is a recommended maintenance schedule for Generac standby gas engine driven generator sets from

35 kW to 200 kW in size. The established intervals in the schedule are the maximum recommended when the

unit is used in an average service application. They will need to be decreased (performed more frequently) if

the unit is used in a severe application. Use the unit hour meter or calendar time, whichever occurs first, from

the previous maintenance interval to determine the next required maintenance interval.

Service Maintenance Interval Information:

The various service maintenance intervals are designated by interval numbers as follows:

1 An early inspection of the generator set to insure it is ready to operate when required and to identify any

potential problem areas.

Performed monthly or following each 10 hours of operation of the unit and requires approximately .5

man-hours per unit to complete.

This inspection may be performed by the end user providing the following safety steps are taken to prevent the engine from starting automatically without warning:

To prevent injury, perform the following steps in the order indicated before starting any maintenance:

• Disable the generator set from starting and/or connecting to the load by setting the control panel

Auto-Off-Manual switch to the “OFF” position.

• Remove the control panel fuse.

• Turn off the battery charger.

• Remove the negative battery cable.

The batter

y charger m

ust be turned off BEFORE removing the battery cable to prevent an over current condi

tion from burning out sensitive control panel components and circuits.

Following all maintenance, reverse these steps to insure the unit is returned to standby setup for normal

oper ation when required.

2 A break-in service inspection of the generator set to insure it is ready to operate and carry the load when

required, and to identify any potential problem areas.

Performed ONLY ONCE following the first three months or the first 30 hours of operation after purchase

of the unit and requires approximately 2.5 man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowledge to accomplish and should be performed only by an authorized Generac Service Dealer.

3 An operational inspection of the generator set to insure it is ready to operate and carry the load when

required, and to identify any potential problem areas.

Performed semi-annually or following each 50 hours of operation of the unit and requires approximately 1.5 man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowledge to accomplish and should be performed only by an authorized Generac Service Dealer.

4 A mid-level inspection of the generator set to insure it is ready to operate and carry the load when required,

and to identify any potential problem areas.

Performed annually or following each 100 hours of operation of the unit and requires approximately 5.0

man-hours per unit to complete.

This inspection contains some maintenance tasks which require special tools, equipment, and/or knowledge to accomplish and should be performed only by an authorized Generac Service Dealer.

NOTE:

Add 20% to all times for 8 cylinder or larger engines.

6.8L GAS SERVICE RECOMMENDATIONS

Page 7

5

GENERAC POWER SYSTEMS, INC.

RECOMMENDED SCHEDULED MAINTENANCE PROGRAM

SERVICE WORK TO BE PERFORMED BY FACTORY-TRAINED PERSONNEL ONLY.

DEALER INFORMATION

NAME:

ACCOUNT #:

ADDRESS:

PHONE:

TECHNICIAN:

SIGNATURE:

OWNER INFORMA

TION

NAME:

ADDRESS:

SITE:

PHONE:

SIGNATURE:

PURCHASE DATE: START-UP DATE:

APPLICATION: Standby Power Prime Power Rental/Trailerized

GENERATOR & TRANSFER SWITCH INFORMATION

GENERA

TOR

MODEL NUMBER:

SERIAL NUMBER:

TRANSFER SWITCH

MODEL NUMBER:

SERIAL NUMBER:

HOUR METER READING

at Completion of the Inspection

:

WARNING!

To prevent injury, perform the following steps in the order indicated before starting any maintenance:

• Disable the generator set from starting and/or connecting to the load by setting the control panel

Auto-Off-Manual switch to the “OFF” position.

• Remove the control panel fuse.

• Turn off the battery charger.

• Remove the negative battery cable.

NOTE:

The battery charger must be turned off BEFORE removing the battery cable to prevent an over current condition from burning out sensitive control panel components and circuits.

Following all maintenance, reverse these steps to insure the unit is returned to standby setup for normal

operation when required.

!

!

6.8L GAS SERVICE RECOMMENDATIONS

Page 8

6

Maintenance Level 1 Level 2 Level 3 Level 4

Tasks

Recom- Task Required Task Required Task Task

mended Comp. to be done Comp. to be done Comp. Required Comp.

to be done (Date- 3 months/ (Date- Semi- (Date- to be done (Date-

monthly/ Initials) Break-in Initials) annually/ Initials) Annually/ Initials)

10 hrs. 30 hrs. 50 hrs. 100 hrs.

1. Disable the unit from

operating per the first page

warning.

2. Check the engine oil level.

Adjust as necessary.

3. Check the engine coolant

level. Adjust as necessary.

4. Check the engine coolant

thermal protection level.

Correct as necessary.

5. Check the natural gas

delivery system. Tighten

connections as necessary.

6. Check the air inlets and

outlets for debris. Clean

as necessary.

7. Check the battery

electrolyte level if

accessible. Adjust as

necessary.

8. Check the battery posts,

cables, and charger for

loose connections,

corrosion, and proper

operation. Correct as

necessary.

9. Check the unit wiring for

loose connections,

corrosion, and damage.

Correct as necessary.

10. Check the engine

accessory drive belts for

wear, weather cracking

and damage. Replace as

necessary.

11. Visually inspect the unit

looking for leaks, wear or

damage, loose connections

or components, and

corrosion. Correct as

necessary.

12. Test the engine and transfer

switch safety devices.

Correct and/or adjust as

necessary.

6.8L GAS SERVICE RECOMMENDATIONS

Page 9

7

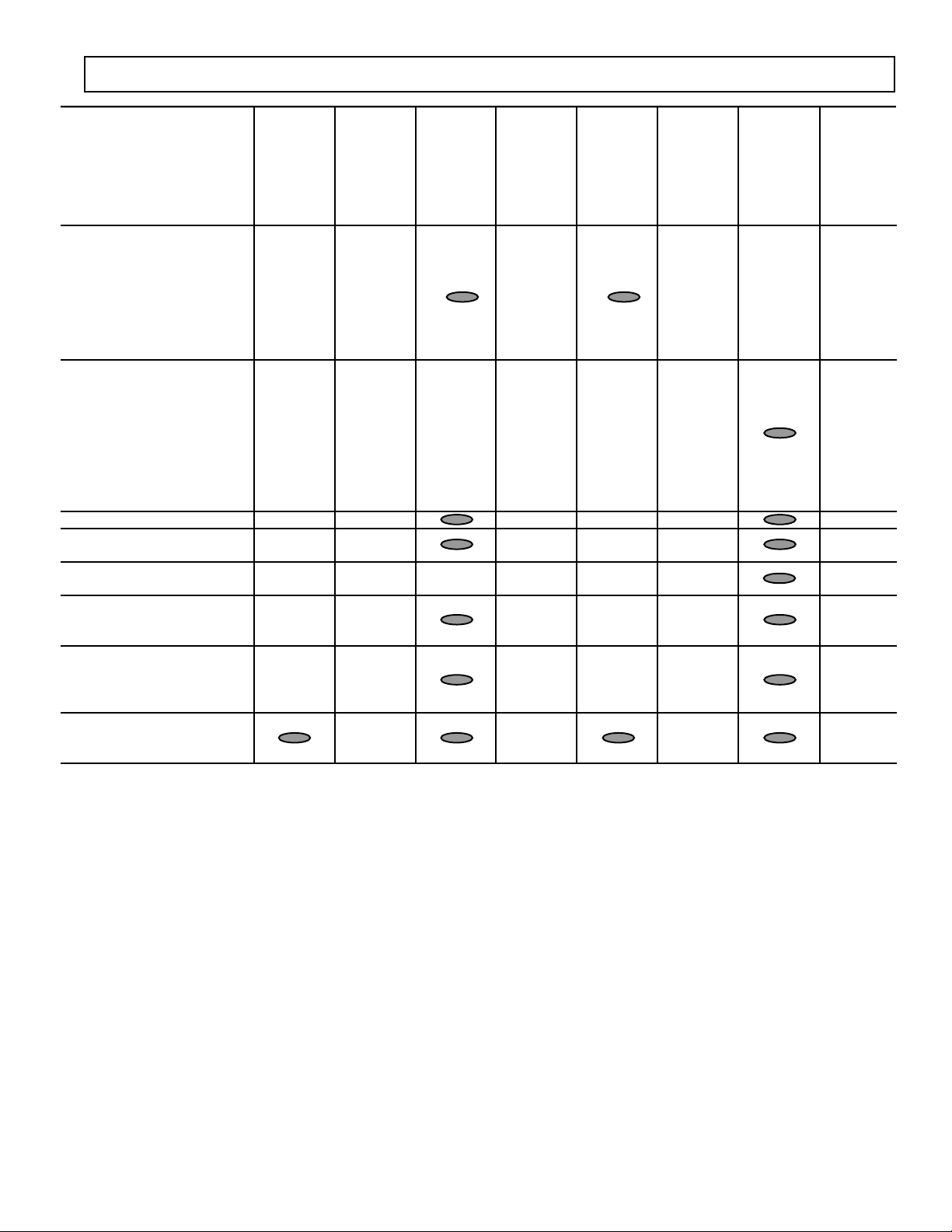

Maintenance Level 1 Level 2 Level 3 Level 4

Tasks

Recom- Task Required Task Required Task Task

mended Comp. to be done Comp. to be done Comp. Required Comp.

to be done (Date- 3 months/ (Date- Semi- (Date- to be done (Date-

monthly/ Initials) Break-in Initials) annually/ Initials) Annually/ Initials)

10 hrs. 30 hrs. 50 hrs. 100 hrs.

13. Initiate an automatic start

and transfer of the unit to

site load and exercise it for

at least 1 hour looking for

leaks, loose connections or

components, and abnormal

operating conditions.

Correct as necessary.

14. Start and exercise the unit

at full rated load (use a

load bank if the site load is

not enough) for at least 2

hours looking for leaks,

loose connections or

components, and abnormal

operating conditions.

Correct as necessary.

15. Change the engine oil.

16. Replace the engine oi

filter(s).

17. Replace the engine air

filter(s).

18. Check the engine spark

plugs. Clean and re-gap

or replace as necessary.

19. Perform a 5 minute no-load

operational run of the unit

looking for any post service

problems.

20. Return the unit to standby

setup for operation when

required.

6.8L GAS SERVICE RECOMMENDATIONS

Page 10

8

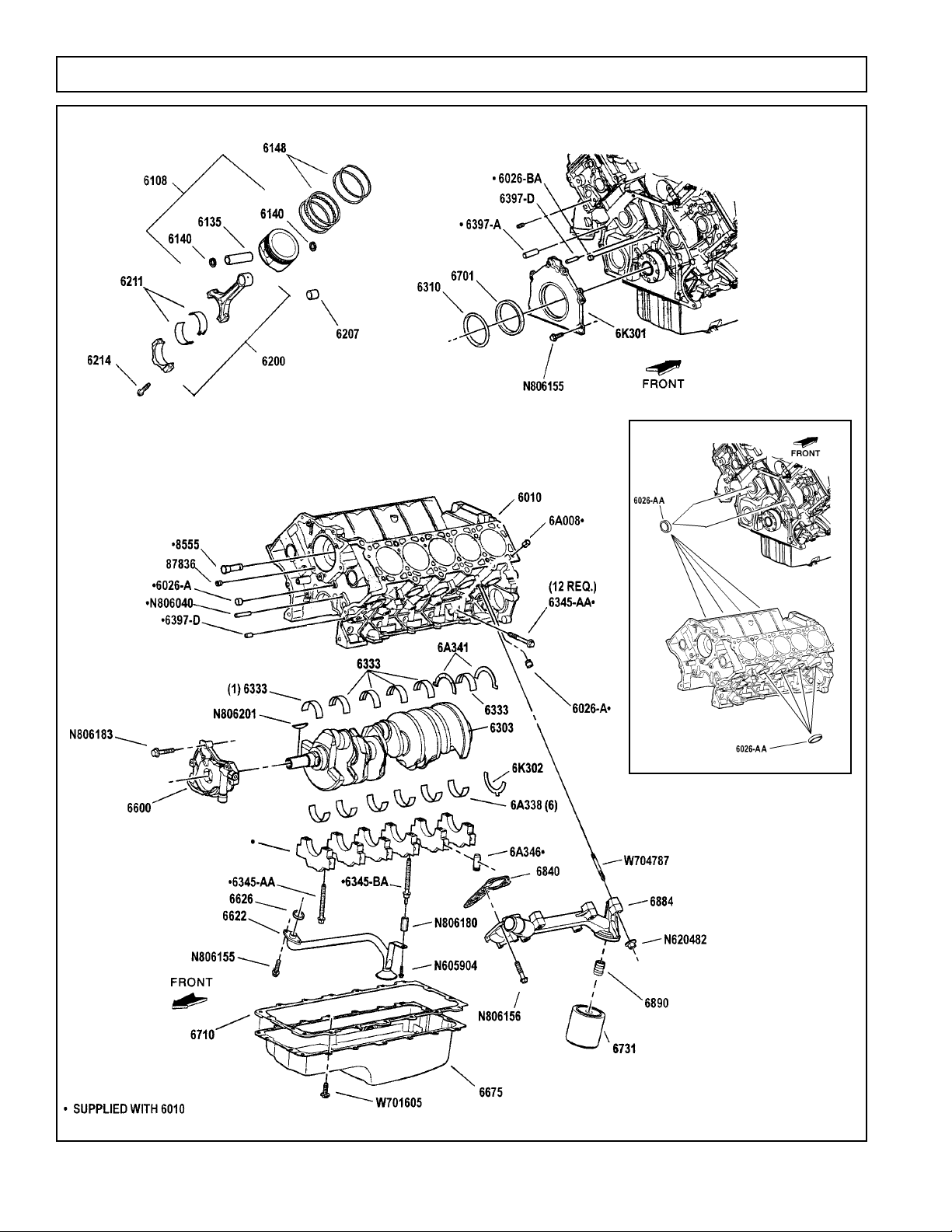

6.8L GAS ENGINE LOWER

Page 11

9

ITEM PART NUMBER DESCRIPTION QTY

6010 0D34540100 CYL BLOCK LESS CRKSHFT,PISTONS 1

6026AA 0D34540101 PLUG 1.75" STAINLESS STEEL CUP 10

(4 EA. LEFT/RIGHT, 2 REAR)

6026A 0D34540102 PLUG-CL BLK FRT 13.84MM 2

6026A 0D34540103 PLUG-CYL BLK REAR 3/8-18X.425 2

6026BA 0D34540104 PLUG-38.3MM CUP STAINLESS STEEL 2

6397D 0D34540105 PIN-DOWEL 8.0 X 18.25 TIMING COVER 2

8555 0D34540106 TUBE ASSY - HEATER WATER 1

N806040 0D34540107 PIN-DOWELL (SOLID) 8.0 X 45.5 2

6A008 0D34540108 PIN-DOWELL, CYL HEAD 16.0 X 19.0 4

6108 0D34540109 PISTON & PIN ASSY - STD 10

6108 0D34540110 PINSTON & PIN ASSY 0.25MM O.S. AR

6108 0D34540111 PISTON & PIN ASSY 0.50MM O.S. AR

6135 0D34540112 PIN - PISTON 10

6140 0D34540113 RETAINER - PISTON PIN 20

6148 0D34540114 PISTON RING SET STD (2 PISTONS) 5

6148 0D34540115 PISTON RING SET .020"/.50MM O.S. 5 AR

6200 0D34540116 ROD-CONNECTING 10

6207 0D34540117 BUSHING-CONNECTING ROD 10

6211 0D34540118 BEARING-CONNECTING ROD 20

0D34540119 BRG-CONN ROD .020"/50MM U.S. AR

6214 0D34540120 BOLT-CONNECTING ROD 20

6K301 0D34540121 RETAINER-CRANKSHAFT OIL SEAL 1

6303 0D34540122 CRANKSHAFT ASSY 1

6310 0D34540123 SLINGER-CRANKSHAFT OIL REAR 1

N806201 0D34540124 KEY-WOODRUFF 4.76 X 49 1

6397A 0D34540125 PIN-FLYWHL 16.0X25.0 HOLLOWDWL 2

6397D 0D34540105 PIN-DOWEL 8.0 X 18.25 TIMING COVER 2

6701 0D34540126 SEAL-CRANKSHAFT REAR 1

N806155 0D34540305 SCREW & WASHER M6 X 1.0 X 27.5 6

6333 0D34540127 BRG-CRKSFT MAIN UPR STD (GRD 2) 5

6333 0D34540128 BRG-CRKSFT MAIN UPR STD (GRD 1) 5 AR

6333 0D34540129 BRG-CRKSFT MAIN UPR STD (GRD 3) 5 AR

6333 0D34540130 BRG-CRKSFT MAIN UPR .25MM U.S. 5 AR

6A341 0D34540131 BRG-CRKSFT THRUST UPPER STD 2

6333 0D34540132 BRG-CRKSFT MAIN UPR STD #1 GD2 1

6333 0D34540133 BRG-CRKSFT MN UPR STD #1 (GRD1) 1 AR

6333 0D34540134 BRG-CRKSFT MN UPR STD #1 (GRD3) 1 AR

6333 0D34540135 BRG-CRKSH MN UPR STD#1 .25MM U.S. 1 AR

6A338 0D34540136 BRG-CRKSFT MAIN LWR (GRADE 2) 6

6A338 0D34540137 BRG-CRKSFT MAIN LWR (GRADE 1) 6 AR

6A338 0D34540138 BRG-CRKSFT MAIN LWR (GRADE 3) 6 AR

6A338 0D34540139 BRG-CRKSFT MN LWR .25MM U.S. 6 AR

6K302 0D34540140 WASHER-CRKSHFT THRUST LOWER 1

6345-BA 0D34540142 STUDBOLT-CRKCS MAIN BRG CAP 1

M8 X 1.25 + M10 X 1.5 X 126

6345-AA 0D34540143 BOLT-CRKSHFT MAIN BEARING CAP 11

M10 X 1.5 X 94.5 HEX HEAD

(NOTE: Do not re-use removed bolts when replacing bearings!)

6345-AA 0D34540144 BOLT-CRKSFT MAIN BEARING CAP 12

M9 X 1.25 X 53 HEX HEAD

6A346 0D34540145 DOWEL-MAIN BRG CAP TO BLOCK 12

6600 0D34540146 PUMP ASSY-OIL 1

6.8L GAS ENGINE LOWER

Page 12

10

6.8L GAS ENGINE LOWER

Page 13

11

ITEM PART NUMBER DESCRIPTION QTY

6622 0D34540147 SCREEN & COVER ASY-OIL PUMP 1

6626 0D34540148 SEAL-SCREEN & COVER ASSY 1

6675 0D34540150 PAN ASY-ENGINE OIL 1

6710 0D34540151 GASKET-OIL PAN 1

6731 0D5419 FILTER ASY. - OIL 1

6840 0D34540154 GASKET-OIL FILTER ADAPTOR 1

6884 0D34540155 ADAPTER-OIL FILTER 1

6890 0D34540156 INSERT-OIL FILTER MOUNTING 1

87836 0D34540187 PLUG-PIPE 1/8-27SOCKET HEX 1

N620482 0D34540158 NUT ADTR REAR/ENG STUD M10X1.5 1

N806155 0D34540305 SCREW & WASHER M6 X 1.0 X 27.5 6

N806156 0D34540159 BOLT-ADPTR/ENG M8X1.25X41 HEX 4

N806180 0D34540160 SPACER-SCRN & CVR M8X1.25X37.9 1

N806183 0D34540161 BOLT-OIL PUMP M6X1.0X42.5 HEX 3

N605904 0D34540162 BOLT-SCRN&CVR/SPACR M8X1.25X19 1

W701605 0D34540163 BOLT&WASHER M8X30 HEX FLANGE 18

W704787 0D34540164 STUD-ADAPTOR REAR TO ENGINE 1

6.8L GAS ENGINE LOWER

Page 14

12

6.8L GAS ENGINE UPPER

Page 15

13

ITEM PART NUMBER DESCRIPTION QTY

6A008 0D34540108 PIN-DOWEL, CYL HEAD 16.0X19.0 4

6026C 0D34540166 PLUG-CYL HD PRESS RELIEF 4

6026BA 0D34540104 PLUG-38.3MM CUP STAINLESS STEEL 2

6026K 0D34540167 PLUG-CYL HD MAIN OIL GALLERY 4

6049 0D34540168 CYL HD,RH W/O VLV W/INSRTS/GDS 1

6049 0D34540169 CYL HD,LH W/O VLVS W/INSRTS/GDS 1

6051 0D34540170 GASKET-CYLINDER HEAD RH 1

6051 0D34540171 GASKET-CYLINDER HEAD LH 1

6057 0D34540172 INSERT-VALVE SEAT INTAKE 10

6057 0D34540173 INSERT-VALVE SEAT EXHAUST 10

6065 0D34540174 BOLT-CYL HD HEX FLANGE HEAD 24

6L293 0D34540175 BOLT-CAM CAPS M6X1.0X42.5 HXFL 26

N808777 0D34540176 BOLT-CAP BALANCE SHAFT 6

6C501 0D34540177 ADJUSTER ASSY-VALVE LASH 20

6505 0D34540178 VALVE - EXHAUST 10

6507 0D34540179 VALVE - INTAKE 10

6510 0D34540180 GUIDE-INT & EXH VALVE STD 20

6513 0D34540181 SPRING - VALVE 20

6514 0D34540182 RETAINER-VALVE SPRING 20

6518 0D34540183 KEY-VALVE SPRING 40

6564 0D34540184 ARM-VALVE ROCKER 20

6571 0D34540185 SEAL-VALVE STEM 20

AGSF-22F-M1 0D34540186 SPARK PLUG (PLATINUM) .044 GAP 10

87836 0D34540187 PLUG-PIPE 1/8-27SOCKET HEX 2

6250 0D34540188 CAMSHAFT - RH 1

6250 0D34540189 CAMSHAFT - LH 1

6256 0D34540190 SPROCKET-CAMSHAFT RH 1

6256 0D34540191 SPROCKET-CAMSHAFT LH 1

6265 0D34540192 SPACER-CAMSHAFT SPROCKET RH 1

6278 0D34540193 WASHER-CAMSHAFT, FLAT HARDENED 2

6A303 0D34540194 GEAR-BALANCE SHFT (ON CAMSHFT) 1

6A304 0D34540195 GEAR, BAL SHFT DRV (ON BAL SHF) 1

6A311 0D34540196 SHAFT & GEAR ASY - BALANCE 1

6582 0D34540199 CVR & GASKET ASY-ROCKER ARM RH 1

6582 0D34540200 CVR & GASKET ASY-ROCKER ARM LH 1

6584 GASKET-ROCKER COVER (USE SEALANT *) NA

NOT SHOWN 0D34540202* SILICONE GASKET & SEALANT AR

6766 0D34540203 CAP - OIL FILLER 1

6279 0D34540204 BOLT-CAMSHFT SPROCKET, HEX 2

N808897 NA NOT SERVICED — PART OF CYLINDER HEAD NA

•6B280 NA SUPPLIED WITH CYLINDER HEAD, ITEM 6049

•6B284 NA SUPPLIED WITH CYLINDER HEAD, ITEM 6049

•6C266 NA SUPPLIED WITH CYLINDER HEAD, ITEM 6049

•6C267 NA SUPPLIED WITH CYLINDER HEAD, ITEM 6049

•6C272 NA SUPPLIED WITH CYLINDER HEAD, ITEM 6049

6.8L GAS ENGINE UPPER

Page 16

14

6.8L GAS ENGINE FRONT

Page 17

15

ITEM PART NUMBER DESCRIPTION QTY

6019 0D34540205 COVER & GASKETS ASSY-FRONT 1

6020 0D34540206 GASKET-COVER LH 1

6020 0D34540207 GASKET-COVER CENTER 1

6020 0D34540208 GASKET-COVER RH 1

6K255 0D34540209 ARM-TIMING CHAIN TENSIONER RH 1

6M256 0D34540210 GUIDE-TIMING CHAIN RH 1

6L266-CA 0D34540211 TENSIONER-TIMING CHAIN LH 1

6L266-DA 0D34540212 TENSIONER-TIMING CHAIN RH 1

6268 0D34540213 CHAIN-TIMING 2

6M274 0D34540214 ARM-TIMING CHAIN TENSIONER LH 1

6K297 0D34540215 GUIDE-TIMING CHAIN LH 1

6306 0D34540216 SPROCKET-CRANKSHAFT 1

6700 0D34540217 SEAL-CRANKSHAFT FRONT 1

12A227 0D34540218 RING-IGN PULSE CRKSHFT SENSOR 1

N605892 0D34540219 BOLT-TIMING CHAIN GUIDES 3

N606527 0D34540220 BOLT-TIMING CHAIN GUIDE LH, HEX 1

N606543 0D34540221 BOLT-TIMING CHAIN TENSIONERS 4

N806177 0D34540222 BOLT-FRONT CVR M8X1.25X53, HEX 5

N808140 0D34540223 STUD & WASHER-FRONT COVER 5

N808142 0D34540224 SCREW & WASHER-FRONT COVER 3

N808529 0D34540225 STUD-FRONT CVR M10X1.5X103 2

6312 0D34540226 DAMPER ASSY-CRANKSHAFT 1

6A340 0D34540227 BOLT-CRANKSHAFT DAMPER 1

6378 0D34540228 WASHER-CRKSHFT DAMPER,FLAT HRD 1

6B288 0D34540230 SENSOR ASSY-CAMSHAFT POSITION 1

6C315 0D34540231 SENSOR ASSY-CRANKSHAFT 1

N806155 0D34540305 SCREW & WASHER M6 X 1.0 X 27.5 2

6.8L GAS ENGINE FRONT

Page 18

16

6.8L GAS COOLING SYSTEM

Page 19

17

ITEM PART NUMBER DESCRIPTION QTY

8501 0D34540232 PUMP ASY & SEAL-WATER 1

8507 0D34540233 SEAL-WATER PUMP 1

N808794 0D34540234 BOLT & WASHER-WATER PUMP 4

8255 0D34540235 SEAL-THERMOSTAT (O-RING) 1

8555 0D34540236 TUBE-WATER 1

8575 0D34540238 THERMOSTAT ASSY-WATER 1

8592 0D34540239 CONNECTION ASY-WATER OUTLET 1

18599 0D34540241 TUBE-INT MNFLD HEATER INLET 1

18663 0D34540242 TUBE-WATER HEATER 1

N806178 0D34540243 BOLT-THERMOSTAT/OUTLET CONNECT 2

N811415 0D34540244 STUD-HEATER TUBE, HEX 2

6.8L GAS COOLING SYSTEM

Page 20

18

6.8L GAS INTAKE & IGNITION SYSTEM

Page 21

19

ITEM PART NUMBER DESCRIPTION QTY

9424 0D34540245 MANIFOLD ASY-INTAKE UPPER 1

9424 0D34540246 MANIFOLD-INTAKE LOWER 1

9439 0D34540247 GASKET-INT MNFLD TO CYL HEAD 2

18599 0D34540304 TUBE - INT MAN HEATER INLET 1

N806156 0D34540159 BOLT - M8 X 1.25 X 43MM 11

12029 0D34540249 COIL & BOOT ASY-IGNITION 10

W706175 0D34540252 BOLT-COIL ON PLUG M5 X 25 HEX 10

6.8L GAS INTAKE & IGNITION SYSTEM

Page 22

20

6.8L GAS ENGINE COMMON PARTS LH (DIRECT DRIVE UNITS)

Page 23

21

ITEM PART NUMBER DESCRIPTION QTY

1 0D3293A FAN, COOLING 22" DIA KYSOR 1

2 0D2149 SPACER, FAN 6.8L 1

3 0D2843 BRKT, LWR, ALT 6.8L 1

4 0D2844 BRKT, UPR, ALT 6.8L 1

5 0D5419 OIL FILTER, FORD V-10 ENGINE 1

6 0D7055 DIPSTICK TUBE, FORD 6.8L 1

7 0D3488 BELT SERPENTINE 67.5” (DIRECT DRIVE) 1

8 057795 CONNECTOR C/C VENT 1

9 0A6283 HOSE PREFORMED BLOCK HEATER 1

10 046526 WASHER LOCK M10 2

11 0D1744 6.8L,IGN CONTROL,SCH ASSY 1

12 0A1232 D.C. ALTERNATOR ASSY 1

13 031678 SCREW HHC 3/8-16 X 3-3/4 G5 1

14 022241 NUT HEX 3/8-16 STEEL 1

15 055476 BUSHING REDUCER 3/8 TO 1/8 GAL 1

16 053666 SENDER OIL PRESSURE 1

17 0D6658 DIPSTICK, 6.8L FORD 1

18 047411 SCREW HHC M6-1.0 X 16 G8.8 2

19 022097 WASHER LOCK M6-1/4 8

20 022473 WASHER FLAT 1/4 ZINC 3

21 042568 SCREW HHC M6-1.0 X 20 G8.8 2

22 022129 WASHER LOCK M8-5/16 6

23 022142 SCREW HHC 5/16-18 X 3/4 G5 4

24 039253 SCREW HHC M8-1.25 X 20 G8.8 2

25 022145 WASHER FLAT 5/16 ZINC 2

26 057796 GROMMET 1

27 0A5737B SPACER, DC ALT. 25LG 1

28 0D3507 ALTERNATOR PULLEY 84 O.D. 1

29 022237 WASHER LOCK 3/8 1

30 022131 WASHER FLAT 3/8-M10 ZINC 4

31 0D3784 HARNESS, 6.8L ENGINE (E-PANEL) (NOT SHOWN) 1

0D3784A HARNESS,ENGINE 6.8L (C-PANEL) (NOT SHOWN) 1

32 049814 SCREW HHC M10-1.5 X 25 G8.8 2

33 0D7801 WIRE HARNESS, 6.8L IGN. SYSTEM (NOT SHOWN) 1

34 032300 HOLDER FUSE 3

35 086310 FUSE 2A X AGC2 1

36 028578 FUSE 10A X AGC10 2

37 034125 VIB MNT .5 X .62 X #10-32 4

38 033121 SCREW HHC #10-32 X 1/2 4

39 022152 WASHER LOCK #10 4

40 023897 WASHER FLAT #10 ZINC 4

41 0D8031 DECAL, GOVERNOR 10 AMP 1

42 0D8032 DECAL, COIL 10 AMP 1

43 0D8033 DECAL, PCB 2 AMP 1

44 0D8027 BOLT, WATER PUMP PULLEY 4

45 0D8025 BOLT, GROOVED IDLER PULLEY 1

46 0D8026 BOLT, BELT TENSIONER 3

47 0D8030 TENSIONER, ENG. AUTOMATIC BELT 1

48 0D8029 PULLEY, ENGINE WATER PUMP 1

49 0D8028 PULLEY, GROOVED ENGINE IDLER 1

50 0D8450 BRACKET, TERMINAL BLOCK 1

51 048766 BLOCK TERM 20A 2 X 6 X 1100V REF

52 049815 SCREW HHC M5-0.8 X 16 G8.8 2

53 049226 WASHER LOCK M5 5

54 051713 WASHER FLAT M5 5

55 051716 NUT HEX M5-0.8 G8 YEL CHR 5

56 0D8991 MODULE COVER 1

57 0D8614 COVER, FUSE PANEL 1

58 055934B CLAMP VINYL 1 X .281 Z 7

59 029107 GROMMET 7/8 X 3/16 X 5/8 2

60 0E5333 SCREW PHTT M5-0.8 X 8 ZINC 4

61 0D6575D DEUTSCH,MOUNTING CLIP F/DT'S 3

62 043146 SCREW HHC M6-1.0 X 10 G8.8 4

63 091526 SCREW PPHM M5-0.8 X 12 ZNC 3

64 058441 SCREW CRIMPTITE 1/4-20 X 3/8 1

65 035578 NIPPLE CLOSE 1/8 NPT 1

66 035430 PIPE TEE 1/8 NPT 1

67 0A8584 SWITCH OIL PRESSURE HOBBS 1

68 056739 RELAY SOLENOID 12VDC PNL MNT (NOT SHOWN) 1

69 074908 SCREW HHTT M5-0.8 X 10 BP 2

6.8L GAS ENGINE COMMON PARTS LH (DIRECT DRIVE UNITS)

Page 24

22

6.8L GAS ENGINE COMMON PARTS LH (GEAR BOX UNITS)

Page 25

23

ITEM PART NUMBER DESCRIPTION QTY

1 049814 SCREW HHC M10-1.5 X 25 G8.8 2

2 0D3784 HARNESS 6.8L ENGINE (E-PANEL) (NOT SHOWN) 1

3 0D2843 BRKT LOWER ALT 6.8L 1

4 0D2844 BRKT UPPER ALT 6.8L 1

5 0D5419 OIL FILTER, FORD V-10 ENGINE 1

6 0D7055 DIPSTICK TUBE, FORD 6.8L 1

7 0D3488A BELT SERPENTINE 70” (GEAR BOX) 1

8 057795 CONNECTOR C/C VENT 1

9 0A6283 HOSE PREFORMED BLOCK HEATER 1

10 046526 WASHER LOCK M10 2

11 022237 WASHER LOCK 3/8 1

12 0A1232 D.C. ALTERNATOR ASSY 1

13 031678 SCREW HHC 3/8-16 X 3-3/4 G5 1

14 022241 NUT HEX 3/8-16 STEEL 1

15 055476 BUSHING REDUCER 3/8 TO 1/8 GAL 1

16 053666 SENDER OIL PRESSURE 1

17 0D6658 DIPSTICK 6.8L FORD 1

18 047411 SCREW HHC M6-1.0 X 16 G8.8 2

19 022097 WASHER LOCK M6-1/4 8

20 022473 WASHER FLAT 1/4 ZINC 3

21 042568 SCREW HHC M6-1.0 X 20 G8.8 2

22 022129 WASHER LOCK M8-5/16 2

23 022131 WASHER FLAT 3/8-M10 ZINC 4

24 039253 SCREW HHC M8-1.25 X 20 G8.8 2

25 022145 WASHER FLAT 5/16 ZINC 2

26 057796 GROMMET 1

27 0A5737B SPACER DC ALT. 25LG 1

28 0D3507A ALTERNATOR PULLEY 140 O.D. 1

29 0D1744 6.8L IGN CONTROL SCH ASSY 1

30 0D7801A WIRE HARNESS 6.8L (GEAR BOX) (NOT SHOWN) 1

31 032300 HOLDER FUSE 2

32 086310 FUSE 2A X AGC2 1

33 028578 FUSE 10A X AGC10 1

34 034125 VIB MNT .5 X .62 X #10-32 4

35 033121 SCREW HHC #10-32 X 1/2 4

36 022152 WASHER LOCK #10 4

37 023897 WASHER FLAT #10 ZINC 4

38 0D8991 MODULE COVER 1

39 0D8032 DECAL COIL 10 AMP 1

40 0D8033 DECAL PCB 2 AMP 1

41 0D8025 BOLT GROOVED IDLER PULLEY 1

42 0D8026 BOLT BELT TENSIONER 3

43 0D8027 BOLT WATER PUMP PULLEY 4

44 0D8028 PULLEY GROOVED ENGINE IDLER 1

45 0D8030 TENSIONER ENG. AUTOMATIC BELT 1

46 0D8029 PULLEY ENGINE WATER PUMP 1

47 0D8614 COVER FUSE PANEL 1

48 055934B CLAMP VINYL 1 X .281 Z 7

49 029107 GROMMET 7/8 X 3/16 X 5/8 2

50 0E5333 SCREW PHTT M5-0.8 X 8 ZINC 4

51 0D6575D DEUTSCH,MOUNTING CLIP F/DT'S 3

52 043146 SCREW HHC M6-1.0 X 10 G8.8 4

53 091526 SCREW PPHM M5-0.8 X 12 ZNC 3

54 051713 WASHER FLAT M5 5

55 049226 WASHER LOCK M5 5

56 051716 NUT HEX M5-0.8 G8 YEL CHR 5

57 058441 SCREW CRIMPTITE 1/4-20 X 3/8 1

58 049815 SCREW HHC M5-0.8 X 16 G8.8 2

59 048766 BLOCK TERM 20A 2 X 6 X 1100V REF

60 0D8450 BRACKET TERMINAL BLOCK 1

61 035578 NIPPLE CLOSE 1/8 NPT 1

62 035430 PIPE TEE 1/8 NPT 1

63 0A8584 SWITCH OIL PRESSURE HOBBS 1

64 056739 RELAY SOLENOID 12VDC PNL MNT (N0T SHOWN) 1

65 074908 SCREW HHTT M5-0.8 X 10 BP 2

6.8L GAS ENGINE COMMON PARTS LH (GEAR BOX UNITS)

Page 26

24

6.8L GAS ENGINE COMMON PARTS RH (DIRECT DRIVE UNITS, OPEN SET - NO ENCLOSURE)

Page 27

25

ITEM PART NUMBER DESCRIPTION QTY

1 0D3454 6.8L FORD (V-10) 1

2 0D5418 STARTER MOTOR FORD V-10 ENGINE 1

3 0D4162 MANIFLD BLK COOLANT TEMP & LEVEL 1

4 0D4312 BRACKET MANIFOLD BLOCK 1

5 050968 HOSE 3/4 ID SAE-20R3 .25 FT

6 083982 HOSE 3/8 ID 100R6 OIL LINE 2 FT

7 0E0561 ASSEMBLY WATER LEVEL SENSOR 1

8 053667 SENDER WATER TEMP 1

9 0D2696 ADAPTOR THROTTLE BODY 1

10 0D2698 GASKET ADAPTOR THROTTLE BODY 1

11 057823 CLAMP HOSE #10 .56 - 1.06 2

12 049120 BARBED EL 90 1/2 NPT X 3/4 1

13 049340 BARBED EL 90 1/4 NPT X 3/8 3

14 0C7649 CLAMP HOSE .38 - .87 2

15 049821 SCREW SHC M8-1.25 X 30 G12.9 3

16 022129 WASHER LOCK M8-5/16 3

17 043146 SCREW HHC M6-1.0 X 10 G8.8 1

18 055816 SCREW HHC M6-1.0 X 70 G8.8 1

19 022097 WASHER LOCK M6-1/4 8

20 045757 SCREW HHC M6-1.0 X 25 G8.8 4

21 022473 WASHER FLAT 1/4 ZINC 3

22 049226 WASHER LOCK M5 3

23 052618 SCREW HHC M5-0.8 X 12 G8.8 2

24 051713 WASHER FLAT M5 2

25 0D3808 EXH MANIFOLD MACH 6.8L V-10 2

26 0D4255 GASKET EXHAUST MANIFOLD 2

27 070010 SCREW HHC M8-1.25 X 35 SS G8.8 2

28 0D6344 ASSEMBLY 6.8L FLYWHEEL - DIRECT 1

29 0D3803 FLYWHEEL HOUSING MACH 6.8L V10 1

30 0D3805 COVER FLYWHEEL MACH 6.8L V-10 1

31 0A8240 FLEX PLATE SAE10 2.2 3

32 0D2608 SCREW HHC 5/16-18 X 1/2 SSTL 10

33 070006 WASHER LOCK M8 SSTL 30

34 070008 WASHER FLAT M8 SS 10

35 046526 WASHER LOCK M10 21

36 022131 WASHER FLAT 3/8-M10 ZINC 8

37 0D5417 SCREW HHC M10-1.0 X 25 G10.9 REF

38 057822 CLAMP HOSE #8 .53 - 1.00 1

39 083982 HOSE 3/8 ID 100R6 OIL LINE 1.25 FT

40 047411 SCREW HHC M6-1.0 X 16 G8.8 2

41 0D6742 VALVE PCV (FORD 6.8L) 1

42 0D2244M ASSY MAG PICKUP (3/8-24 MALE) 1

43 052647 SCREW SHC M10-1.5 X 25 G12.9 15

44 035606 SENSOR HI COOLANT SHUTDOWN 1

45 087599 PLUG PLASTIC 3/8 NPT 1

46 077996 CAP HOSE 1

47 055934M CLAMP VINYL .75 X .343 Z 1

48 0D5623 HEAT SHIELD EXHAUST 2

49 0D6575D DEUTSCH MOUNTING CLIP F/DT'S 1

50 0D9423 BRACKET MAG-PICKUP CONNECTORS 1

51 0D9913 SCREW SHC M8-1.25 X 35 SS 18

52 052648 SCREW SHC M10-1.5 X 20 G12.9 8

53 049813 NUT HEX M6 X 1.0 G8 YEL CHR 1

54 051716 NUT HEX M5-0.8 G8 YEL CHR 1

55 091526 SCREW PPHM M5-0.8 X 12 ZNC 1

6.8L GAS ENGINE COMMON PARTS RH (DIRECT DRIVE UNITS, OPEN SET - NO ENCLOSURE)

Page 28

26

6.8L GAS ENGINE COMMON PARTS RH (DIRECT DRIVE UNITS, CLOSED SET - W/ ENCLOSURE)

Page 29

27

ITEM PART NUMBER DESCRIPTION QTY

1 0D3454 6.8L FORD (V-10) 1

2 0D5418 STARTER MOTOR FORD V-10 ENGINE 1

3 0D4162 MANIFLD BLK COOLANT TEMP & LEVEL 1

4 0D4312 BRACKET MANIFOLD BLOCK 1

5 050968 HOSE 3/4 ID SAE-20R3 (3") 1

6 047290 HOSE 3/8 ID SINGLE BRAID (24") 1

7 0E0561 ASSEMBLY WATER LEVEL SENSOR 1

8 053667 SENDER WATER TEMP 1

9 0C3433A CLAMP BAND 2.5" 4

10 0D2696 ADAPTOR THROTTLE BODY 1

11 0D2698 GASKET ADAPTOR THROTTLE BODY 1

12 057823 CLAMP HOSE #10 .56 - 1.06 2

13 049120 BARBED EL 90 1/2 NPT X 3/4 1

14 049340 BARBED EL 90 1/4 NPT X 3/8 3

15 0C7649 CLAMP HOSE .38 - .87 2

16 049821 SCREW SHC M8-1.25 X 30 G12.9 3

17 022129 WASHER LOCK M8-5/16 3

18 043146 SCREW HHC M6-1.0 X 10 G8.8 1

19 055816 SCREW HHC M6-1.0 X 70 G8.8 1

20 022097 WASHER LOCK M6-1/4 8

21 045757 SCREW HHC M6-1.0 X 25 G8.8 4

22 022473 WASHER FLAT 1/4 ZINC 3

23 049226 WASHER LOCK M5 3

24 052618 SCREW HHC M5-0.8 X 12 G8.8 2

25 051713 WASHER FLAT M5 2

26 0D3808 EXH MANIFOLD MACH 6.8L V-10 2

27 0D4255 GASKET EXHAUST MANIFOLD 2

28 070010 SCREW HHC M8-1.25 X 35 SS G8.8 2

29 0D6344 ASSEMBLY 6.8L FLYWHEEL - DIRECT 1

30 0D3803 FLYWHEEL HOUSING MACH 6.8L V10 1

31 0D3805 COVER FLYWHEEL MACH 6.8L V-10 1

32 0A8240 FLEX PLATE SAE10 2.2 3

33 0A6765 RING GASKET 2.5 DIA. 2

34 0D3649 TUBE R/H EXHAUST MANIFOLD 1

35 0A5215B PIPE FLEX (2.5") 2

36 0D3159 FLANGE EXHAUST 2

37 0D3651 TUBE R/H EXHAUST MUFFLER INLET 1

38 0D3648 TUBE L/H EXHAUST MANIFOLD 1

39 0D3650 TUBE L/H EXHAUST MUFFLER INLET 1

40 0D5623 HEAT SHIELD EXHAUST 2

41 0D2608 SCREW HHC 5/16-18 X 1/2 SSTL 10

42 070006 WASHER LOCK M8 SSTL 30

43 070008 WASHER FLAT M8 SS 10

44 0A7387 SCREW HHC M10-1.5 X 40 G10.9 6

45 046526 WASHER LOCK M10 21

46 022131 WASHER FLAT 3/8-M10 ZINC 8

47 0D5417 SCREW HHC M10-1.0 X 25 G10.9 REF

48 057822 CLAMP HOSE #8 .53 - 1.00 1

49 047290 HOSE 3/8 ID SINGLE BRAID (15") 1

50 047411 SCREW HHC M6-1.0 X 16 G8.8 2

51 0D6742 VALVE PCV (FORD 6.8L) 1

52 0D2244M ASSEMBLY MAGPICKUP (3/8-24 MALE) 1

53 052647 SCREW SHC M10-1.5 X 25 G12.9 23

54 035606 SENSOR HI COOLANT SHUTDOWN 1

56 077996 CAP HOSE 1

57 055934M CLAMP VINYL .75 X .343 Z 1

58 0D6575D DEUTSCH MOUNTING CLIP F/DT'S 1

59 0D9423 BRACKET MAG-PICKUP CONNECTORS 1

60 0D9913 SCREW SHC M8-1.25 X 35 SS 18

61 052648 SCREW SHC M10-1.5 X 20 G12.9 8

62 091526 SCREW PPHM M5-0.8 X 12 ZNC 1

63 051716 NUT HEX M5-0.8 G8 YEL CHR 1

64 049813 NUT HEX M6 X 1.0 G8 YEL CHR 1

65 087599 PLUG PLASTIC 3/8 NPT 1

6.8L GAS ENGINE COMMON PARTS RH (DIRECT DRIVE UNITS, CLOSED SET - W/ ENCLOSURE)

Page 30

28

6.8L GAS ENGINE COMMON PARTS RH (GEAR BOX UNITS, OPEN SET - NO ENCLOSURE)

Page 31

29

ITEM PART NUMBER DESCRIPTION QTY

1 0D3454 6.8L FORD (V-10) 1

2 0D5418 STARTER MOTOR FORD V-10 ENGINE 1

3 0D4162 MANIFLD BLK COOLANT TEMP & LEVEL 1

4 0D4312 BRACKET MANIFOLD BLOCK 1

5 050968 HOSE 3/4 ID SAE-20R3 (3”) 1

6 047290 HOSE 3/8 ID SINGLE BRAID (24”) 1

7 0E0561 ASSEMBLY WATER LEVEL SENSOR 1

8 053667 SENDER WATER TEMP 1

9 055934M CLAMP VINYL .75 X .343 Z 1

10 0D2696 ADAPTOR, THROTTLE BODY 1

11 0D2698 GASKET ADAPTOR THROTTLE BODY 1

12 057823 CLAMP HOSE #10 .56 - 1.06 2

13 049120 BARBED EL 90 1/2 NPT X 3/4 1

14 049340 BARBED EL 90 1/4 NPT X 3/8 3

15 0C7649 CLAMP HOSE .38 - .87 2

16 049821 SCREW SHC M8-1.25 X 30 G12.9 3

17 022129 WASHER LOCK M8-5/16 3

18 043146 SCREW HHC M6-1.0 X 10 G8.8 1

19 055816 SCREW HHC M6-1.0 X 70 G8.8 1

20 022097 WASHER LOCK M6-1/4 8

21 045757 SCREW HHC M6-1.0 X 25 G8.8 4

22 022473 WASHER FLAT 1/4 ZINC 3

23 049226 WASHER LOCK M5 4

24 052618 SCREW HHC M5-0.8 X 12 G8.8 2

25 051713 WASHER FLAT M5 2

26 0D3808 EXH MANIFOLD MACH 6.8L V-10 2

27 0D4255 GASKET EXHAUST MANIFOLD 2

28 070010 SCREW HHC M8-1.25 X 35 SS G8.8 2

29 0D6686 ASSEMBLY 6.8L G-BOX FLYWHEEL 1

30 0D3803 FLYWHEEL HOUSING MACH 6.8L V10 1

31 0D3805 COVER FLYWHEEL MACH 6.8L V-10 1

32 021113 PLATE DAMPNER RETNR 1

33 077996 CAP HOSE 1

34 022131 WASHER FLAT 3/8-M10 ZINC 8

35 0C9785 GASKET POWER FLOW 50 & 60 ADAPTOR 1

36 052647 SCREW SHC M10-1.5 X 25 G12.9 15

37 0D2244M ASSY MAGPICKUP (3/8-24 MALE) 2

38 0D6742 VALVE PCV (FORD 6.8L) 1

39 047411 SCREW HHC M6-1.0 X 16 G8.8 2

40 0D5623 HEAT SHIELD EXHAUST 2

41 0D2608 SCREW HHC 5/16-18 X 1/2 SSTL 10

42 070006 WASHER LOCK M8 SSTL 30

43 070008 WASHER FLAT M8 SS 10

44 049541 SCREW HHC M10-1.5 X 35 G8.8 (NOT SHOWN) 6

45 046526 WASHER LOCK M10 21

46 0C9730 PWR FLO 60 - ACTUATOR, POWERFLOW 60MM 1

47 0D5417 SCREW HHC M10-1.0 X 25 G10.9 REF

48 057822 CLAMP HOSE #8 .53 - 1.00 1

49 047290 HOSE 3/8 ID SINGLE BRAID (15”) 1

50 052625 SCREW SHC M10-1.5 X 35 G12.9 6

51 0D6575D DEUTSCH,MOUNTING CLIP F/DT'S 2

52 0D9423 BRACKET, MAG-PICKUP CONNECTORS 1

53 0D9913 SCREW SHC M8-1.25 X 35 SS 18

54 091526 SCREW PPHM M5-0.8 X 12 ZNC 2

55 049813 NUT HEX M6 X 1.0 G8 YEL CHR 1

56 051716 NUT HEX M5-0.8 G8 YEL CHR 2

6.8L GAS ENGINE COMMON PARTS RH (GEAR BOX UNITS, OPEN SET - NO ENCLOSURE)

Page 32

30

6.8L GAS ENGINE COMMON PARTS RH (GEAR BOX UNITS, CLOSED SET - W/ ENCLOSURE)

Page 33

31

ITEM PART NUMBER DESCRIPTION QTY

1 0D3454 6.8L FORD (V-10) 1

2 0D5418 STARTER MOTOR FORD V-10 ENGINE 1

3 0D4162 MANIFLD BLK COOLANT TEMP & LEVEL 1

4 0D4312 BRACKET MANIFOLD BLOCK 1

5 050968 HOSE 3/4 ID SAE-20R3 (3”) 1

6 047290 HOSE 3/8 ID SINGLE BRAID (24”) 1

7 0E0561 ASSEMBLY WATER LEVEL SENSOR 1

8 053667 SENDER WATER TEMP 1

9 0C3433A CLAMP BAND 2.5" 4

10 0D2696 ADAPTOR THROTTLE BODY 1

11 0D2698 GASKET ADAPTOR THROTTLE BODY 1

12 057823 CLAMP HOSE #10 .56 - 1.06 2

13 049120 BARBED EL 90 1/2 NPT X 3/4 1

14 049340 BARBED EL 90 1/4 NPT X 3/8 3

15 0C7649 CLAMP HOSE .38 - .87 2

16 049821 SCREW SHC M8-1.25 X 30 G12.9 3

17 022129 WASHER LOCK M8-5/16 3

18 043146 SCREW HHC M6-1.0 X 10 G8.8 1

19 055816 SCREW HHC M6-1.0 X 70 G8.8 1

20 022097 WASHER LOCK M6-1/4 8

21 045757 SCREW HHC M6-1.0 X 25 G8.8 4

22 022473 WASHER FLAT 1/4 ZINC 3

23 049226 WASHER LOCK M5 4

24 052618 SCREW HHC M5-0.8 X 12 G8.8 2

25 051713 WASHER FLAT M5 2

26 0D3808 EXH MANIFOLD MACH 6.8L V-10 2

27 0D4255 GASKET EXHAUST MANIFOLD 2

28 070010 SCREW HHC M8-1.25 X 35 SS G8.8 2

29 0D6686 ASSEMBLY 6.8L G-BOX FLYWHEEL 1

30 0D3803 FLYWHEEL HOUSING MACH 6.8L V10 1

31 0D3805 COVER FLYWHEEL MACH 6.8L V-10 1

32 021113 PLATE DAMPNER RETNR 1

33 0A6765 RING GASKET 2.5DIA. 2

34 0D3166 PIPE R/H EXHAUST MANIFOLD 1

35 0A5215B PIPE FLEX 2.5" 2

36 0D3159 FLANGE EXHAUST 1

37 0D3196 PIPE R/H MUFFLER INLET 1

38 0D3160 PIPE L/H EXHAUST MANIFOLD 1

39 0D3195 PIPE L/H MUFFLER INLET 1

40 0D5623 HEAT SHIELD EXHAUST 2

41 0D2608 SCREW HHC 5/16-18 X 1/2 SS 10

42 070006 WASHER LOCK M8 SS 30

43 070008 WASHER FLAT M8 SS 10

44 0A7387 SCREW HHC M10-1.5 X 40 G10.9 6

45 046526 WASHER LOCK M10 21

46 0C9730 THROTTLE BODY PWR FLO 60 1

47 0D5417 SCREW HHC M10-1.0 X 25 G10.9 (NOT SHOWN) REF

48 057822 CLAMP HOSE #8 .53 - 1.00 1

49 047290 HOSE 3/8 ID SINGLE BRAID (15”) 1

50 047411 SCREW HHC M6-1.0 X 16 G8.8 2

51 0D6742 VALVE PCV (FORD 6.8L) 1

52 0D2244M ASSY MAGPICKUP (3/8-24 MALE) 2

53 052647 SCREW SHC M10-1.5 X 25 G12.9 15

54 0C9785 GASKET POWER FLOW 50 & 60 ADAPTOR 1

55 022131 WASHER FLAT 3/8-M10 ZINC 8

56 077996 CAP HOSE 1

57 055934M CLAMP VINYL .75 X .343 Z 1

58 052625 SCREW SHC M10-1.5 X 35 G12.9 6

59 0D9913 SCREW SHC M8-1.25 X 35 SS 18

60 0D6575D DEUTSCH MOUNTING CLIP F/DT'S 2

61 0D9423 BRACKET MAG-PICKUP CONNECTORS 1

62 051716 NUT HEX M5-0.8 G8 YEL CHR 2

63 049813 NUT HEX M6 X 1.0 G8 YEL CHR 1

64 091526 SCREW PPHM M5-0.8 X 12 ZNC 2

65 0C9748 PLUG M18-1.50 1

6.8L GAS ENGINE COMMON PARTS RH (GEAR BOX UNITS, CLOSED SET - W/ ENCLOSURE)

Page 34

Notes

Page 35

Notes

Page 36

Loading...

Loading...