Gx

770

intra-oral

installation/maintenance

manual

x-ray

system

|

THIS

GENDEX

MANUAL

AT

INSTALLATION

MUST

BE

RETAINED

SITE.

|

X-ray

equipment

The

instructions

read

and

followed

dex

dealers

GX-770

The

unnecessary

can

tors

sary

in

operation.

GX-770

provide

from

exposing

radiation.

may

cause

contained

when

operating

will

be

glad

to

provides a high

X-radiation.

complete

However,

protection,

themselves

IMPORTANT!...

injury

if

used

improperly.

in

this

assist.

you

degree

no

nor

or

others

manual

the

of

protection

practical

GX-770.

in

placing

prevent

to

unneces-

must

design

opera-

be

Gen-

the

from

X-RAY

PROTECTION

Itis

Important

ble

government

provisions

recommendations

Protection

dental

Number

30175,

Personal

are

available.

against

that

you

radiation

of

these

and

Measurements.

X-ray

protection

35

available

Washington,

radiation

You

unnecessary

be

fully

acquainted

protection

regulations

the

National

are

published

from

NCRP

D.C.

20014.

monitoring

are

urged

X-radiation

with

regulations.

are

based

Council

Recommendations

Publication,

and

to

use

exposure.

on

in

NCRP

protective

them

applica-

Many

on

the

Radiation

for

Report

P.O.

Box

devices

to

protect

GENDEX

This

direction

assembly,

This

direction

through

Basic

service

CORPORATION

provides

check-out,

also

6)

data

information

adjustment

provides

is

also

and

procedures

provided

to

assemblers

certification

to

to

include

FOREWARD

for

installation

procedures.

be

followed

basic

theory,

of

the

GX-770.

(Sections 2 through

for

periodic

scheduled

troubleshooting

and

The

installation

6)

maintenance.

parts.

(Sections 9 and

GX

data

includes

(Sections

10)

770

3

Section

1

2

Step-by-step

3

4

Preinstallation

This

information

installers

the

installation

preinstallation

remote

special

Installation

station,

mounting

Data

is

as

reference

site

preparation.

4X4

.......................

instructions

assembly,

paration

support)

4X4

procedures.

Electrical

This

checking

electrical

tion

check-out

tion

intervals

System

providing

requirements

are

mount

Calibration

section

and

calibrations.

is

performed

procedure

and

also

as

and

completed.

and

special

provides

adjusting

at

periodic

requested

Function

...............

provided

for

mount

procedures.

for

data

to

completion

Includes

and

for

that

site

pre-

(power

Includes

mounting

..............

instructions

the

GX-770

This

calibra-

as

part

of

the

during

by

(1

the

installa-

year)

owner.

Checks

TABLE

check

of

and

for

......

OF

Page

1-1

CONTENTS

Section

6

Final

This

final

Mechanical

This

check

and

ease

suspension

Remote

This

assembly

the

Electrical

This

operation

troubleshooting

10

This

number

components

Assembly

section

provides

assembly

Adjustments...........

section

and

provides

adjust

tubehead

in

positioning

and

Station

section

provides

and

GX-770

Remote

Troubleshooting

section

section

provides

of

the

identifies

of

major

and

...................

instructions

and

trimout

of

the

unit.

procedures

the

suspension

to

obtain

the

maximum

GX-770

tubehead.

Installation.........

instructions

wiring

connections

Station.

.........

information

GX-770

and

basic

information.

the

ordering

GX-770

other

exchange

service

parts.

Page

6-1

for

7-1

to

8-1

for

of

9-1

on.

To

check-out

tem

compliance

standards.

for

tenance.

5

Certification

This

the

Product

Government

form.

following

This

periodic

section

assembler

Locator

and

test a GX-770

assembly,

with

performance

section

(1

year)

......................

provides

to

fill

cards

FD-2579

to

insure

also

is

used

scheduled

instructions

out

the

and

“Certification”

main-

GENDEX

the

US

sys-

5-1

for

GENDEX

CORPORATION

GX

770

The

purpose

information

SECTION

INTRODUCTION

of

this

for

the

Section

GX-770

is

to

provide

Intra

Oral

1

—

preinstallation

X-ray

System.

PREINSTALLATION

CERTIFIED

COMPATIBILITY

The

GX-770

compatible

Component

Tubehead

Master

120V

60HZ

8"

focal

cone

12” focal

cone

Remote

The

suspension

required

System

components,

Control

length

length

Station

to

be

consists

Model

46-404650G1

46-404600G1

46-404653G2

46-404653G1

46-404725G1

is

Model

certified.

COMPONENT

ofthe

following

manufactured

No.

No.

Label

back

bottom

around

around

left

side

46-404770G1

by

GENDEX.

Location

of

tubehead

base

base

and

certified,

is

not

F59829-174

The

A0771A

A

A

D

О

А

A

ACCESSORIES

following

0772

0773

0774

0774

0778

8108

are

A

A

A 12

В

А

AA

available

for

optional

Remote

4X4

Mount

Special

inch

8

inch

Cone

Special

Cable

Remote

purchase:

Station

Kit

Mounting

Cone

Length

Remote

Switch

Fixture

GENDEX

CORPORATION

GX

770

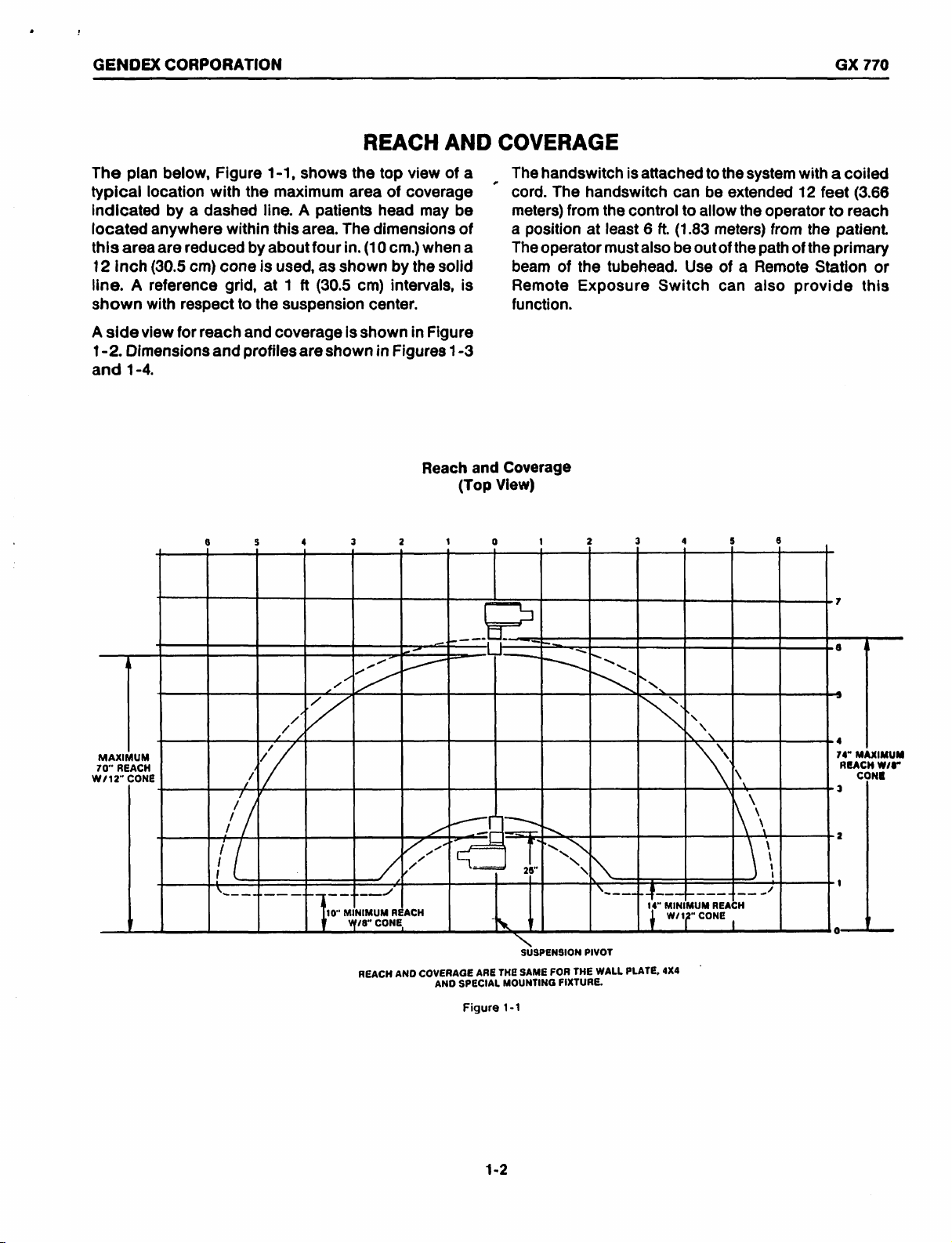

The

plan

below,

typical

indicated

located

this

12

line. A reference

shown

A

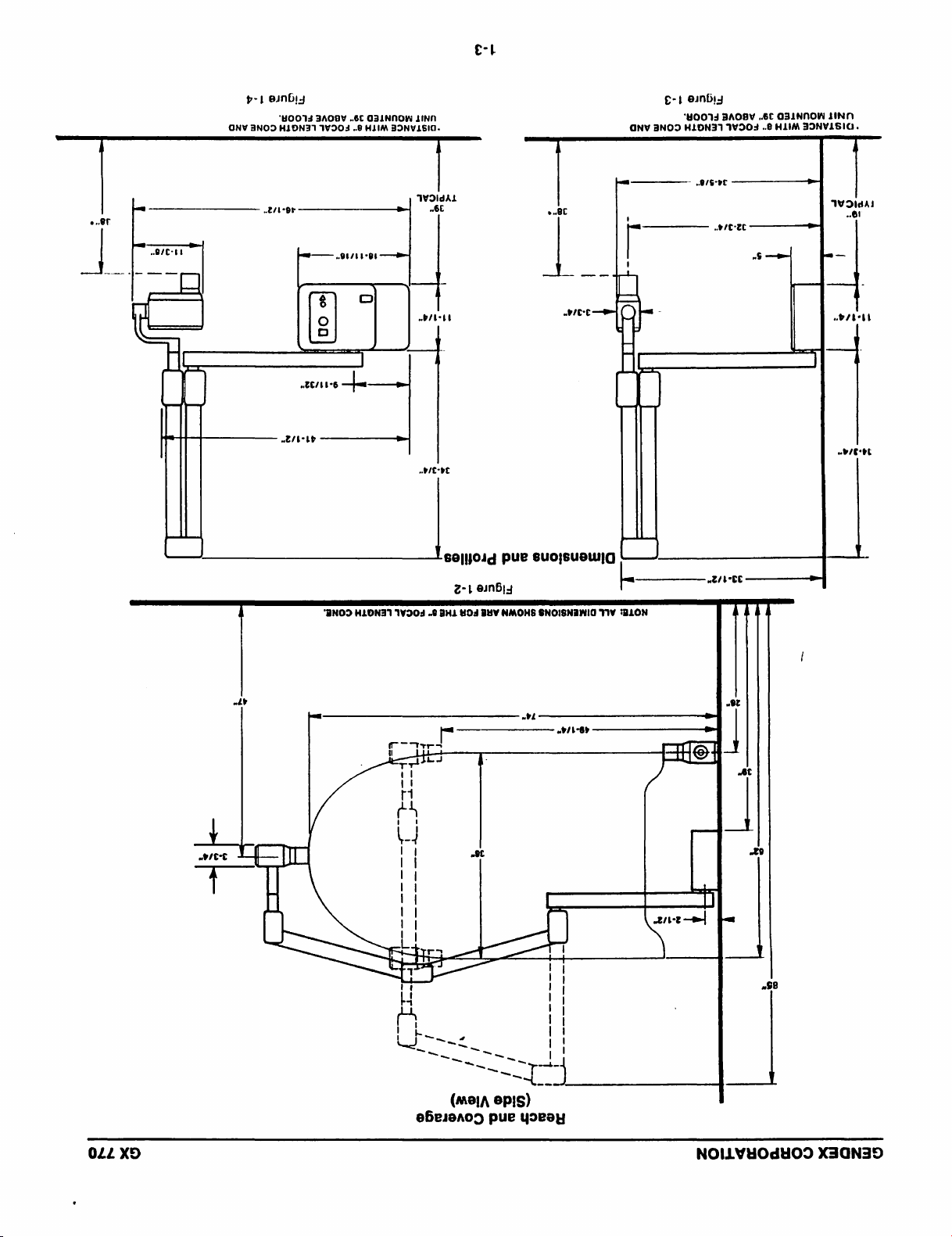

1-2.

and

location

anywhere

area

inch

(30.5

with

side

view

Dimensions

1-4.

with

by a dashed

are

reduced

cm)

respect

for

reach

and

8

Figure

the

within

by

cone

grid,

to

the

and

profiles

5

REACH

1-1,

shows

maximum

line. A patients

this

area.

about

is

used,

at 1 ft

suspension

coverage

are

4

The

four

as

shown

(30.5

shown

the

area

in.

(10

cm)

is

shown

3 2

top

view

of

coverage

head

may

dimensions

cm.)

when

by

the

solid

intervals,

center.

in

Figure

in

Figures

Reach

AND

of

a

be

of

a

is

1-3

and

(Top

1

COVERAGE

The

handswitch

cord.

The

meters)

a

The

beam

Remote

function.

Coverage

View)

from

position

operator

of

1

the

Exposure

is

attached

handswitch

the

control

at

least 6 ft.

mustalso

tubehead.

Switch

2

3 4 5

can

to

allow

(1.83

be

outof

Use

to

be

the

system

extended

the

operator

meters)

of a Remote

can

the

from

path

also

6

with a coiled

12

feet

(3.66

to

reach

the

patient.

of

the

primary

Station

provide

this

or

MAXIMUM

W/12"

1

CONE

VÆ

и

/

/

/

7

7

/

/

/

/

/

1

|

i

XL]

ルー

2

7

4

+

Ш

10"

MINIMUM

W/8"

CONE

REACH

esa

[一 一 一

>

lati

レー

|

ンプ

Papa

ンズ

レ

и

REACH

COVERAGE

AND

AND

”|

-|

一

ARE

SPECIAL

Figure

|

|

」

THE

MOUNTING

1-1

ο

ος.

mn

—

26"

SUSPENSION

SAME

= に

「

TA

SN

N

THE

FOR

FIXTURE.

m

S

NS

N

N

\

NON

N

\

N

N

q

\

N

N

ュー

PIVOT

WALL

r

ニー 上 ーー

|

| — 4

14"

MINIMUM

|

ΜΜ

REACH

o

CONE

|

4X4

PLATE,

|

в

|

a

-

4

74"

MAXIMUM

REACH

W/8°

CONE

3

\

\

1

【

à

2

1

;

p-1

esnbiy

‘40074

3A08Y

..6£

ONV

3NOD

HJONA1

14303

..6

CIINNON

HJIM

¿INN

JINVI6I0.

£-1

01nbi3

‘40015

BAOBY

„6C

NY

3ANOD

HLON37

1W303

„6

OJINNOW

HLIM

JINN

JINVISIG.

0.81

pe

WOIdAL

.6E

©

]

HLON ヨ 1

que

、

„bh

À

ge

vit

1YO0』

。0

1

tt

selloid

2-1

@JnB5』

HI

HO

BUY

pue

NMOHS

¿LN

k

|

|

ож

$)

o

o

——

a-

|

ζει 6 Le

I

NOO

„915-18

=

ec

„HCP

euoijsueuulgd

SNOISNINIO

TV

'

トー

ОН

一

-

ис

——————ş

WWDidAi

/CC

一

5

—|

|

pe

—

.

|

KT

W/E

«¿NE

ÁS]

44

022

XD

ος

~

dl

y

に

-一

一

一

+

”个

一

个

一

-全

一

一

一

一

一

一

一

一

一

一

一

一

ビー

-

—

}

——

-<

—

e6e10005

一

—

(쓰이,

—

pue

0016)

yoreay

„dě

AT

fan

|

BY

一

十

一

一

一

一

一

一

一

一

一

1

一

2/12]

S

NOILVHOdHOO

X ヨ QN ヨ り

GENDEX

CORPORATION

GX

770

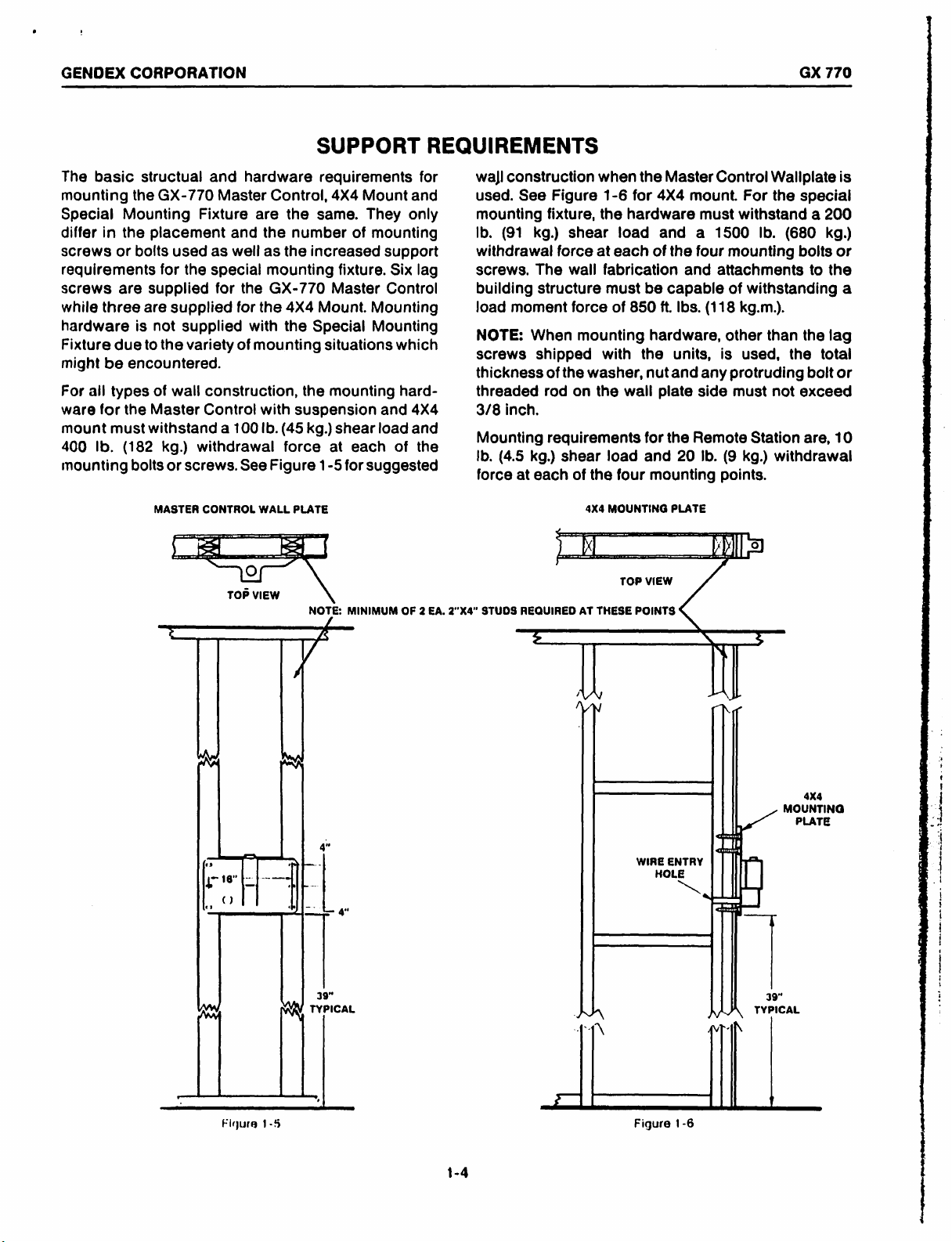

The

basic

structual

mounting

Special

differ

screws

requirements

screws

while

hardware

Fixture

might

For

ware

mount

400

mounting

Mounting

in

the

or

are

three

due

be

encountered.

all

types

for

the

must

Ib.

(182

the

bolts

supplied

are

is

to

withstand a 100

bolts

and

GX-770

Fixture

placement

used

as

for

the

special

for

supplied

not

supplied

the

variety

of

wall

construction,

Master

MASTER

kg.)

or

screws.

Control

withdrawal

CONTROL

hardware

Master

are

and

well

the

for

the

with

of

mounting

See

WALL

TOP

VIEW

Control,

the

the

number

as

the

increased

mounting

GX-770

4X4

the

the

with

suspension

Ib.

(45

kg.)

force

Figure

PLATE

NOTE:

SUPPORT

requirements

4X4

Mount

same.

Mount.

Special

They

of

mounting

fixture.

Master

Mounting

Mounting

situations

mounting

shear

load

at

each

1-5

for

suggested

MINIMUM

support

Control

and

REQUIREMENTS

and

only

Six

which

hard-

4X4

and

of

OF 2 EA.

for

lag

the

wall

used.

mounting

Ib.

withdrawal

screws.

building

load

NOTE:

screws

thickness

threaded

3/8

Mounting

Ib.

force

2"X4"

STUDS

construction

See

Figure

fixture,

(91

kg.)

shear

force

The

wail

structure

moment

inch.

(4.5

at

REQUIRED

force

When

kg.)

mounting

shipped

of

the

rod

on

requirements

shear

each

of

<

И

)

AT

e

when

the

1-6

for

the

hardware

load

at

each

fabrication

must

of

850

with

washer,

the

wall

load

the

four

4X4

MOUNTING

TOP

THESE

POINTS

Master

4X4

mount.

must

and a 1500

of

the

four

and

be

capable

ft.

Ibs.

hardware,

the

units,

nutand

plate

side

for

the

Remote

and

20

mounting

PLATE

VIEW

Control

For

withstand a 200

Ib.

mounting

attachments

of

withstanding

(118

kg.m.).

other

is

used,

any

protruding

must

Station

Ib.

(9

kg.)

points.

5

Wallplate

the

special

(680

kg.)

bolts

to

than

the

the

total

bolt

not

exceed

are,

withdrawal

is

or

the

a

lag

or

10

を

Figura

1-5

TYPICAL

I

Y

WA

HAN

WIRE

HOLE

Figure

A

Rh

~

ENTRY

<

<

L

T

1-6

\

MOUNTING

39”

TYPICAL

|

4X4

PLATE

1-4

GENDEX

CORPORATION

GX

770

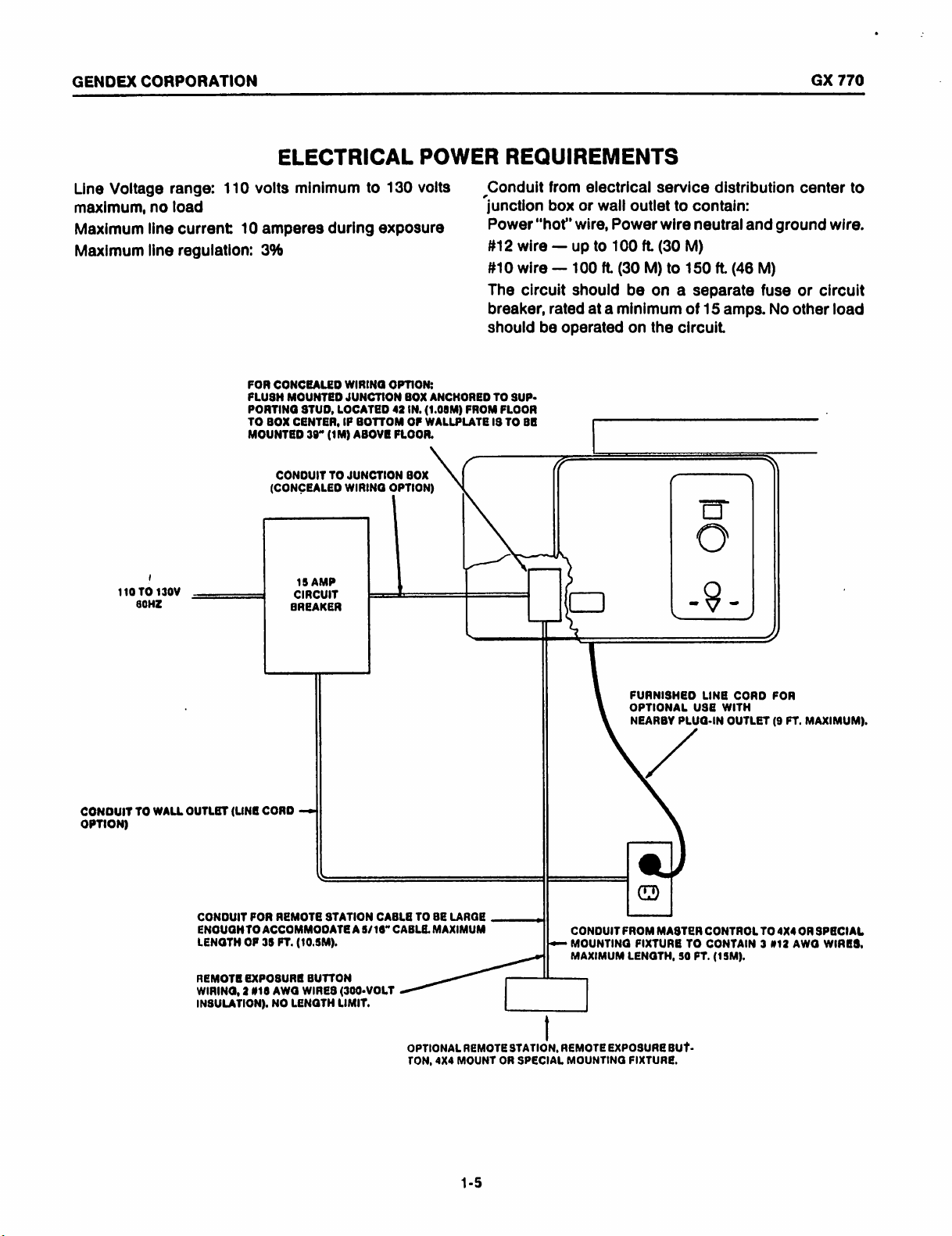

Line

Voltage

maximum,

Maximum

Maximum

110TO130V

line

line

'

60HZ

range:

no

load

110

volts

current:

regulation:

10

FOR

FLUSH

PORTING

TO

MOUNTED

|

ELECTRICAL

minimum

amperes

3%

CONCEALED

BOX

CONDUIT

(CONCEALED

during

MOUNTED

STUD,

CENTER,

39”

(1M)

TO

15

AMP

CIRCUIT

BREAKER

WIRING

JUNCTION

LOCATED

IF

JUNCTION

WIRING

to

exposure

BOTTOM

ABOVE

POWER

130

volts

OPTION:

BOX

42

IN.

GF

FLOOR,

BOX

OPTION)

ANCHORED

(1.08)

FROM

WALLPLATE

REQUIREMENTS

Conduit

junction

Power

#12

#10

The

breaker,

should

TO

FLOOR

19

from

box

“hot”

wire — up

wire — 100

circuit

rated

be

operated

SUP-

TO

BE

electrical

or

wire,

should

at a minimum

service

wall

outlet

to

to

ft.

Power

100

wire

ft.

(30

(30

M)

to

be on a separate

on

the

circuit.

distribution

contain:

neutral

M)

150

ft.

(46

of

15

amps.

and

M)

fuse

center

ground

or

No

other

to

wire.

circuit

load

CONDUIT

OPTION)

TO

WALL

OUTLET

(LINE

CONDUIT

ENGUGH

LENGTH

REMOTE

WIRING,

INSULATION).

CORD

FOR

REMOTE

TO

ACCOMMODATE

OF

35

FT.

EXPOSURE

2

#16

AWG

NO

—=

(10.5).

BUTTON

WIRES

LENGTH

STATION

A

(300-VOLT

LIMIT.

CABLE

5/16"

TO

CABLE.

OPTIONAL

TON,

SE

MAXIMUM

一

4X4

LARGE

REMOTE

MOUNT

STATION,

OR

|

re

一

REMOTE

SPECIAL

MOUNTING

FUANISHED

OPTIONAL

NEARBY

PLUG-IN

Je

CONDUIT

MOUNTING

MAXIMUM

EXPOSURE

FROM

CD

MASTER

FIXTURE

LENGTH,

FIXTURE.

BUT.

LINE

USE

WITH

OUTLET

CONTROL

TO

CONTAIN 3 #12

30

FT.

(15M).

CORD

TO

FOR

(9

4X4

FT.

MAXIMUM).

OR

AWG

SPECIAL

WIRES,

1-5

GENDEX

CORPORATION

GX

770

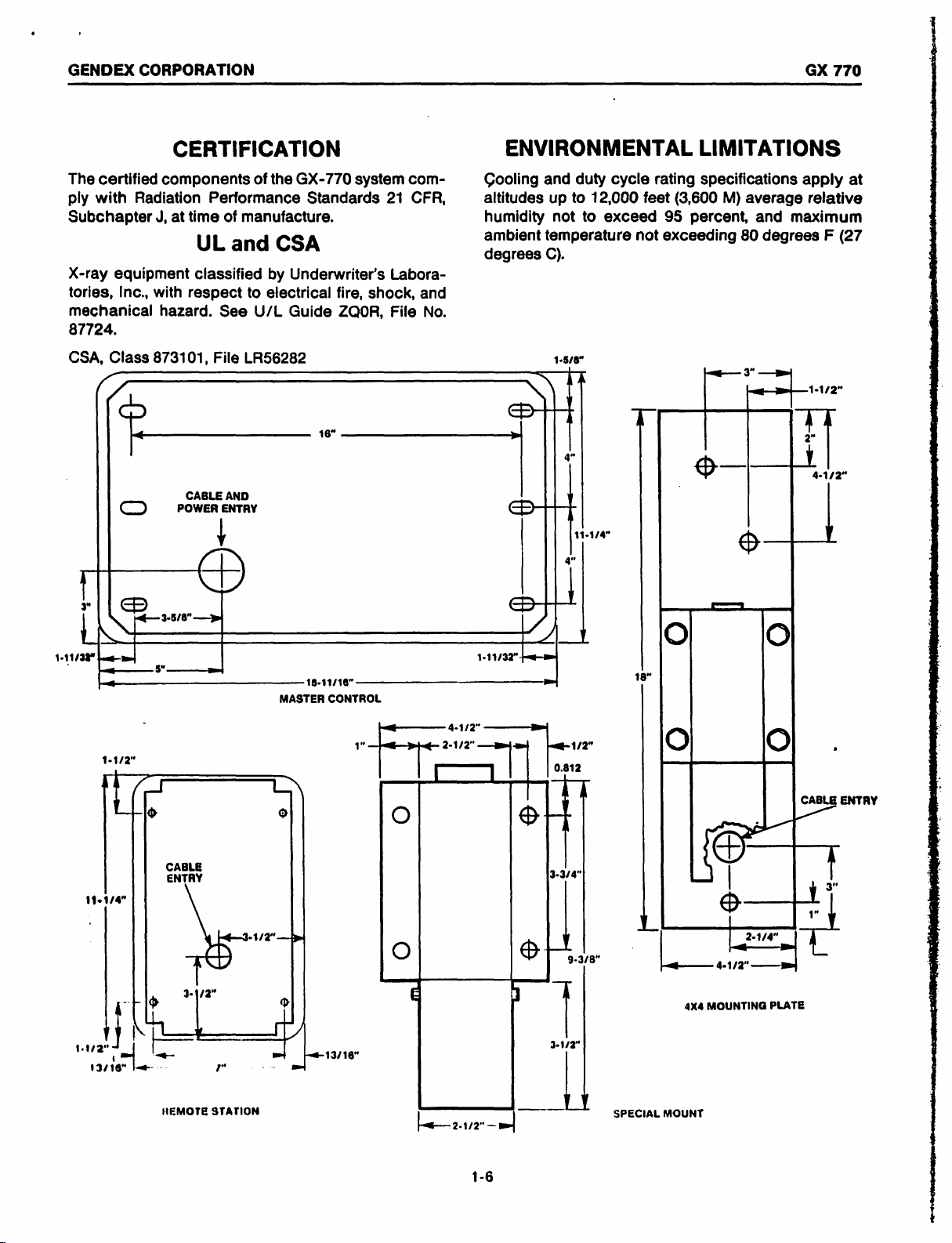

The

certified

ply

with

Subchapter

X-ray

equipment

tories,

mechanical

87724.

CSA,

Class

(/

|

1.11/32"

:

m

<

components

Radiation

J,

Inc.,

with

hazard.

873101,

中

<

C

СВ

ыы

5“

CERTIFICATION

of

the

GX-770

Performance

at

time

UL

classified

respect

See U/L

File

CABLE

POWER

of

manufacture.

and

to

LR56282

AND

ENTRY

Standards

CSA

by

Underwriter’s

electrical

Guide

|

D

ыы

18-11716"

MASTER

system

fire,

ZQOR,

。

CONTROL

com-

21

Labora-

shock,

File

CFR,

and

No.

ENVIRONMENTAL

Cooling

altitudes

humidity

ambient

degrees

and

duty

up

to

not

to

temperature

C).

1-5/8"

NH

1-11/32"

9

y

C]

a

|

4

|

+

cycle

12,000

exceed

rating

feet

not

exceeding

1

18"

LIMITATIONS

specifications

(3,600

95

M)

average

percent,

80

に

©

©

apply

relative

and

maximum

degrees F (27

Le

A

3

n

LI.

0

at

1-4/2"

nm

11174“

.

|

/J

o

CABLE

ENTRY

NEMOTE

5

STATION

LN

o

at

13/16"

(4-12

1°

bag

2.1/2

[그

O

O

Bo

一

mm

|

|

©

Side

—

112

0.812

|

”

°

|

3/8"

|

1

0

0

.

CABLE

A

|

©

L

a

— —

4X4

SPECIAL

MOUNT

ーー

4-172

MOUNTING

— вы

ry

|":

し

PLATE

ENTAY

|

|

GENDEX

CORPORATION

GX

770

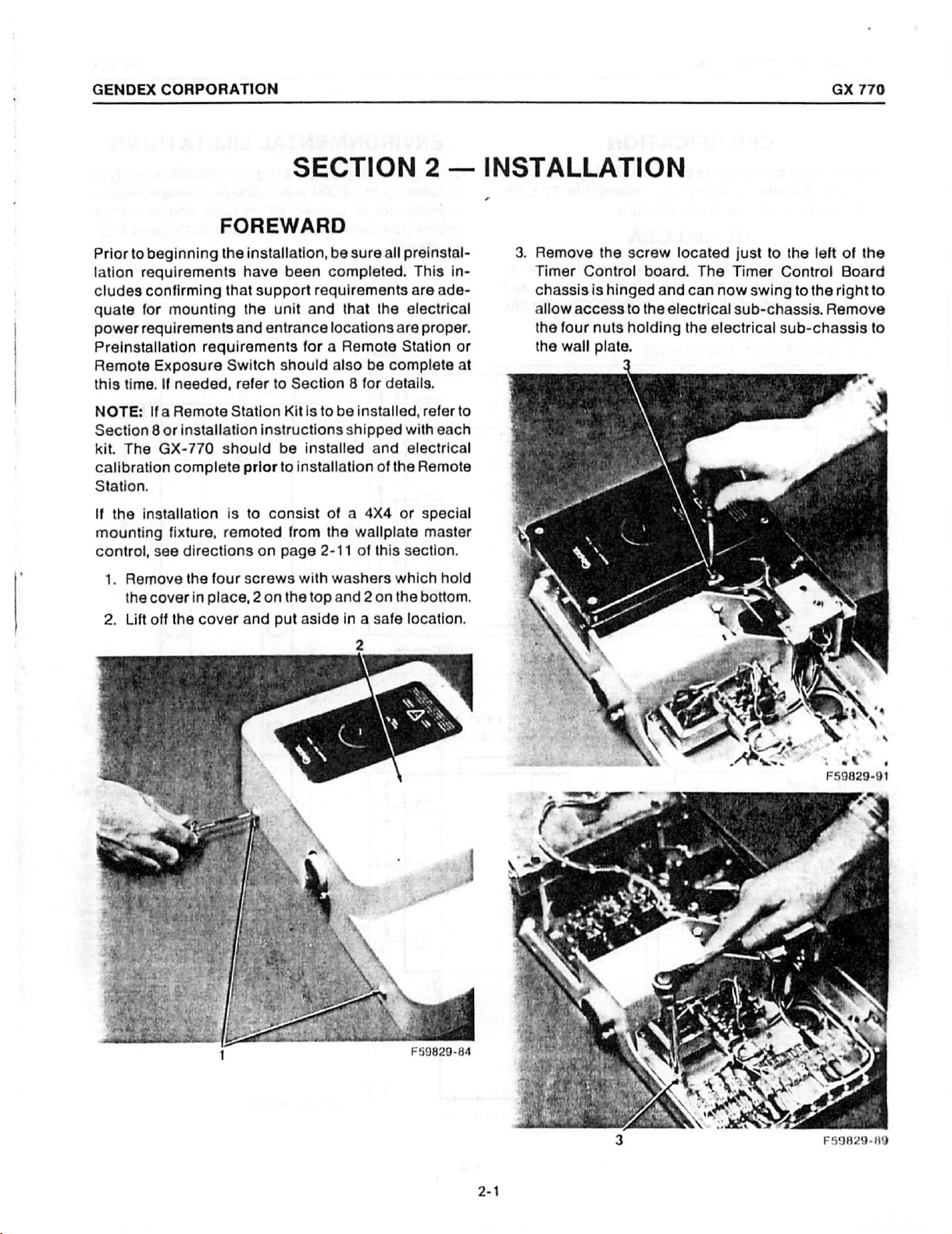

Prior

to

beginning

lation

requirements

cludes

quate

power

confirming

for

mounting

requirements

Preinstallation

Remote

this

NOTE:

Section 8 or

kit.

calibration

Station.

If

mounting

control,

1.

2.

Exposure

time.

Ifa

The

the

installation

see

Remove

the

cover

Lift

off

If

needed,

Remote

installation

GX-770

complete

fixture,

directions

the

in

the

FOREWARD

the

installation,

have

that

support

the

unit

and

entrance

requirements

Switch

Station

should

is

remoted

four

place, 2 on

cover

should

refer

to

instructions

be

prior

to

to

consist

on

page

screws

and

put

SECTION

be

sure

been

completed.

requirements

and

that

locations

for a Remote

also

be

Section 8 for

Kitis

to

be

installed,

shipped

installed

installation

from

2-11

with

the

top

aside

and

of a 4X4

the

wallplate

of

washers

and 2 on

in a safe

all

preinstal-

This

are

the

electrical

are

Station

complete

details.

with

electrical

of

the

or

this

section.

which

the

location.

2

—

in-

ade-

proper.

or

at

refer

to

each

Remote

special

master

hold

bottom.

INSTALLATION

3.

Remove

Timer

chassis

allow

the

the

Control

access

four

wall

the

screw

is

hinged

to

nuts

holding

plate.

board.

the

located

The

and

can

now

electrical

the

electrical

just

to

the

Timer

Control

swing

to

sub-chassis.

sub-chassis

left

the

Remove

of

the

Board

right

to

to

F59829-84

2-1

3

oe”

4

F59829-91

F59829-89

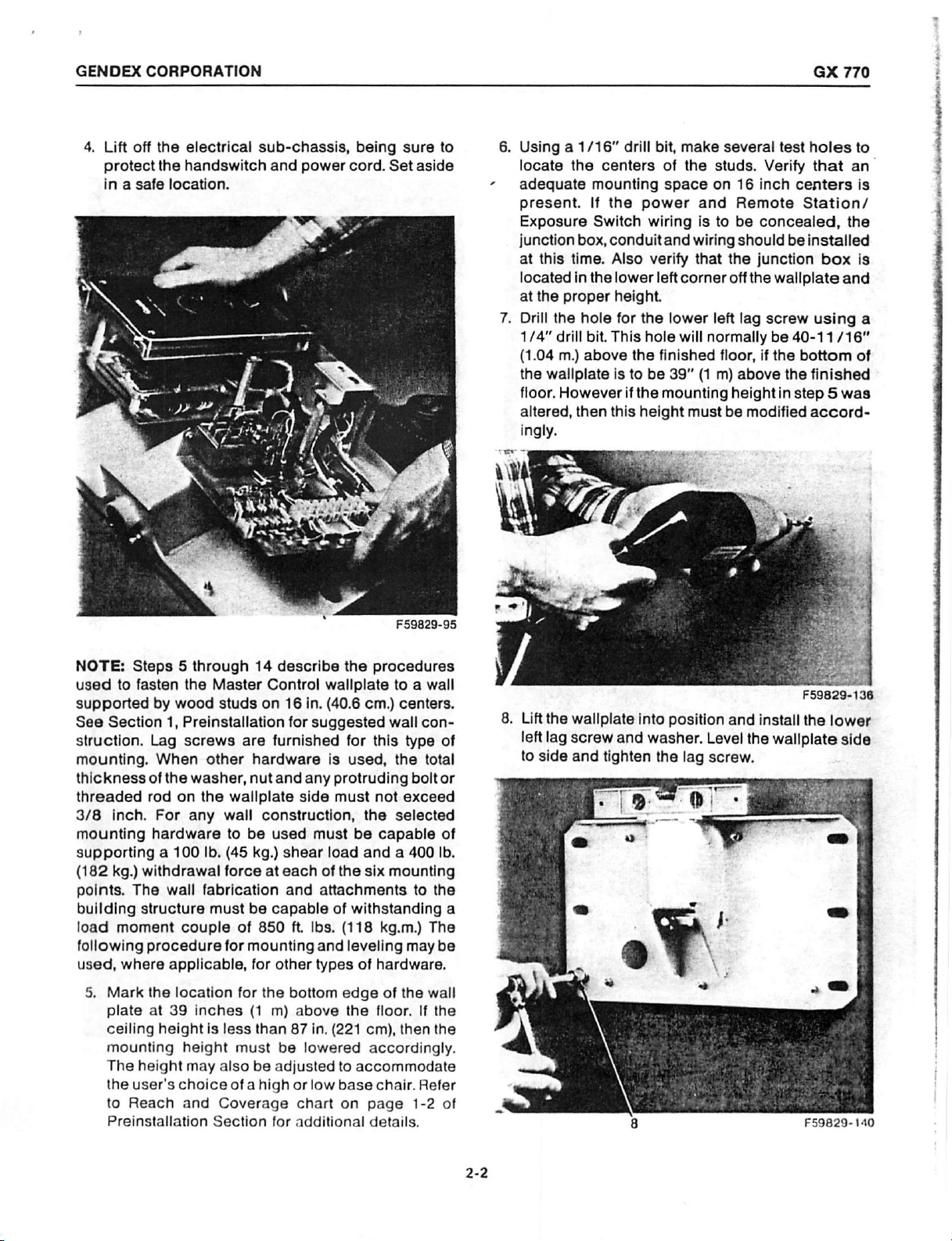

GENDEX

4.

Lift

protect

in a safe

CORPORATION

off

the

electrical

the

handswitch

location.

sub-chassis,

and

power

being

cord.

sure

Set

to

aside

6.

Using a 1/16”

locate

adequate

present.

Exposure

junction

at

this

located

at

the

proper

7.

Drill

the

1/4"

drill

(1.04

m.)

the

wallplate

floor.

However

altered,

the

centers

mounting

If

Switch

box,

time.

in

the

hole

bit.

above

then

drill

bit,

of

space

the

power

wiring

conduit

Also

lower

height.

This hole

is

this

for

the

to

if

the

and

verify

left

the

finished

be

mounting

height

make

the

and

is

wiring

that

corner

lower

will

39"

(1

must

several

studs.

on

16

Remote

to

be

should

the

junction

off

the

left

lag

normaliy

floor,

m)

above

heightin

be

modified

GX

test

holes

Verify

inch

concealed,

if

that

centers

Station/

be

installed

wallplate

screw

be

40-11

the

bottom

the

finished

step 5 was

accord-

using

box

770

to

an

is

the

is

and

/16”

of

CEE

isi

a

F59829-95

NOTE:

used

supported

See

struction.

mounting.

thickness

threaded

3/8

mounting

supporting a 100

(182

points.

building

load

following

used,

Steps 5 through

to

fasten

by

Section

Lag

When

of

rod

inch.

For

hardware

kg.)

withdrawal

The

structure

moment

procedure

where

5.

Mark

the

plate

at

ceiling

mounting

The

the

to

Preinstallation

height

height

user's

Reach

14

the

Master

wood

studs

1,

Preinstallation

screws

the

washer,

on

any

wall

couple

applicable,

location

39

inches

height

may

choice

and

are

other

hardware

nut

the

wallplate

wall

to

be

Ib.

(45

kg.)

force

fabrication

must

be

of

850

for

mounting

for

for

(1

is

less

than

must

also

be

ofa

high

Coverage

Section

describe

Control

on

16

for

furnished

and

construction,

used

shear

at

each

and

capable

ft.

other

the

bottom

m)

above

87

be

adjusted

orlow

chart

for

additional

the

wallplate

in.

(40.6

suggested

for

is

used,

any

protruding

side

must

must

load

of

the

attachments

of

withstanding

Ibs.

(118

and

leveling

types

edge

the

in.

(221

lowered

to

base

on

be

of

accommodate

procedures

to a wall

cm.)

centers.

wall

con-

this

type

the

total

bolt

not

exceed

the

selected

capable

and a 400

six

mounting

to

the

kg.m.)

hardware.

floor.

cm),

accordingly.

chair.

page

details.

of

may

the

If

then

Refer

1-2

The

wall

the

the

of

or

of

Ib.

a

be

of

8.

Lift

the

left

lag

to

side

wallplate

screw

and

and

tighten

8

into

position

washer.

the

lag

and

Level

screw.

install

the

wallplate

이진

『59829-136

the

lower

side

F59829-140

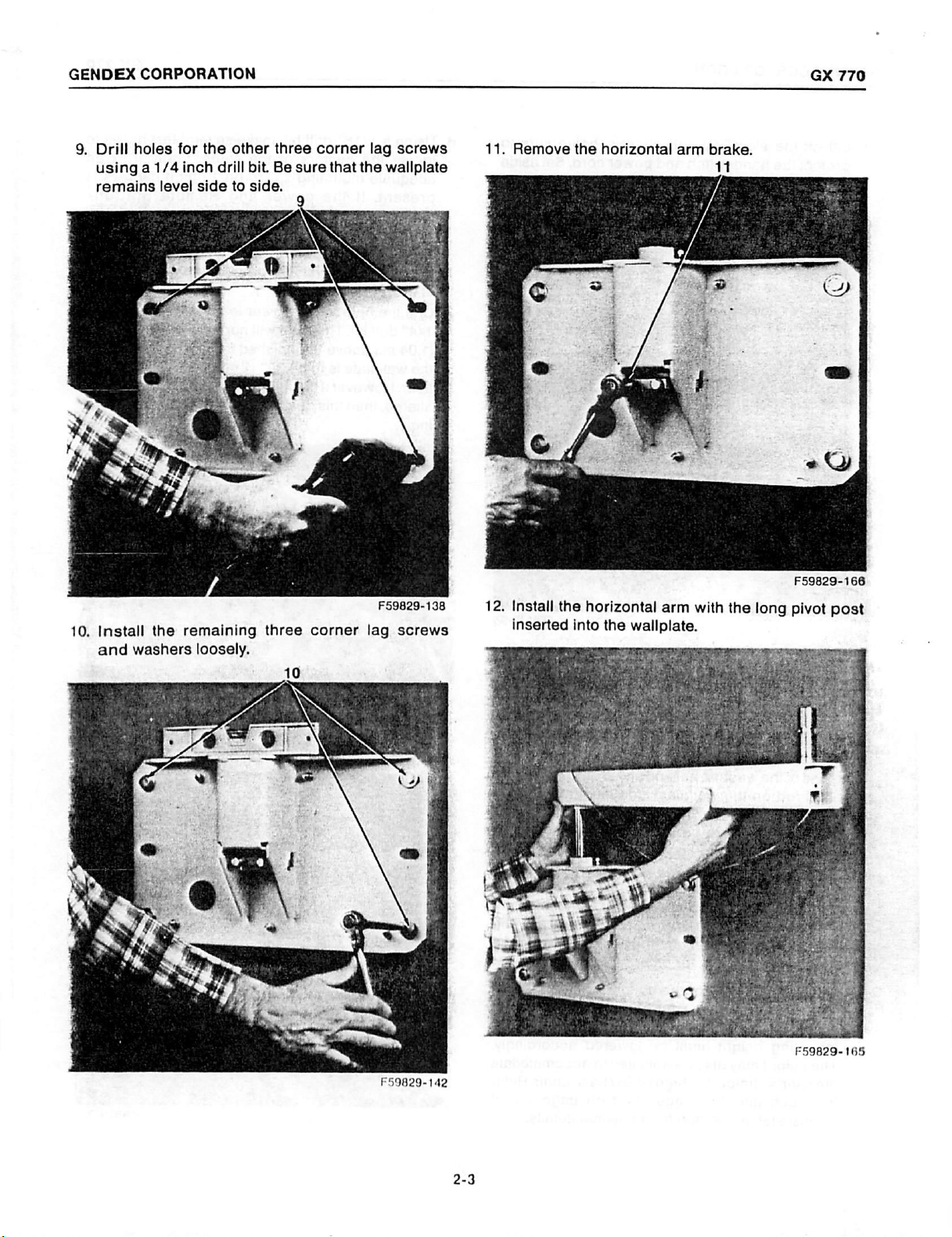

GENDEX

9.

Drill

using a 1/4

remains

CORPORATION

holes

for

the

inch

level

side

other

drill

to

three

bit.

Be

side.

corner

sure

that

lag

the

wallplate

screws

11.

Remove

the

horizontal

arm

brake.

11

GX

770

long

F59829-166

pivot

post

Install

10.

and

the

washers

remaining

loosely.

three

10

corner

F59829-138

screws

lag

12.

Install

inserted

the

horizontal

into

arm

wallplate.

the

with

the

F59829-142

F59829-165

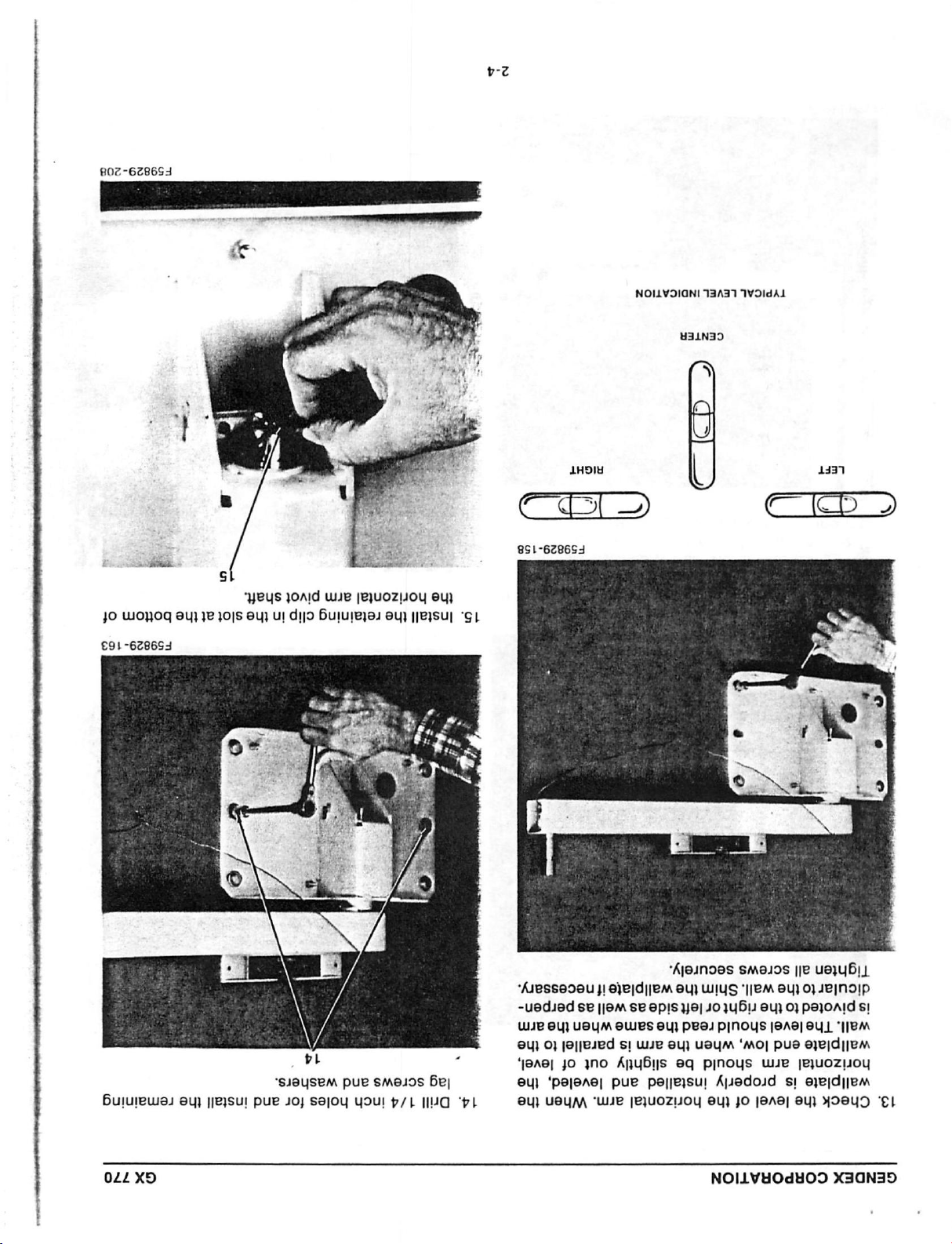

802-6278654

vee

Jo

uohoq

€91-6286S3

5

BUS

euileiols

eui

1OAId

UUJB

ul

dllo

6ululeleledl

IBJUOZIJOU

llelsul

041

“SL

8S1-6286S4

NOILVOIQNI

H31N39

13437

1VOIdAI

Buiuieuu8」

044

ХЭ

eui

IIBJSUI

PUP

*SJ8USEM

』O』

SSIOU

PUR

SM819S

UOUI ヤ /L

Ge|

IIUO

“pl

*

人 ん

eSSeo8u』I

-uedied

Je

ey]

se

[jem

ueym

SBIdIIBA

ey) 이 | 비 16160

Челе!

30

¿no

edl'peleAel

eu}

UBUM

pue

“WE

AleJno9S

9U!

UUIUS

SB

9DIS

Je]

10

eules

ey,

pea.

61

uuJg

eui

usuA

ÁpyBbis

eq

рпоц$

paellelsul 人 AlJedo』d

[E}UOZIIOY

OU}

SA9』oS

"IIBA

8U1 0 JBInoIP

}uB1

8U1

O)

p¡noys

'mo]

|[8A8]

pue

uue

SI

Jo

jane]

NOILVHOdH09

IIB

U81U5I」

PS1OAId

EUL

SI

‘EM

ejejd¡em

jejuozuou

ejejdijem

ey]

HOEY

X30N359

“EL

GENDEX

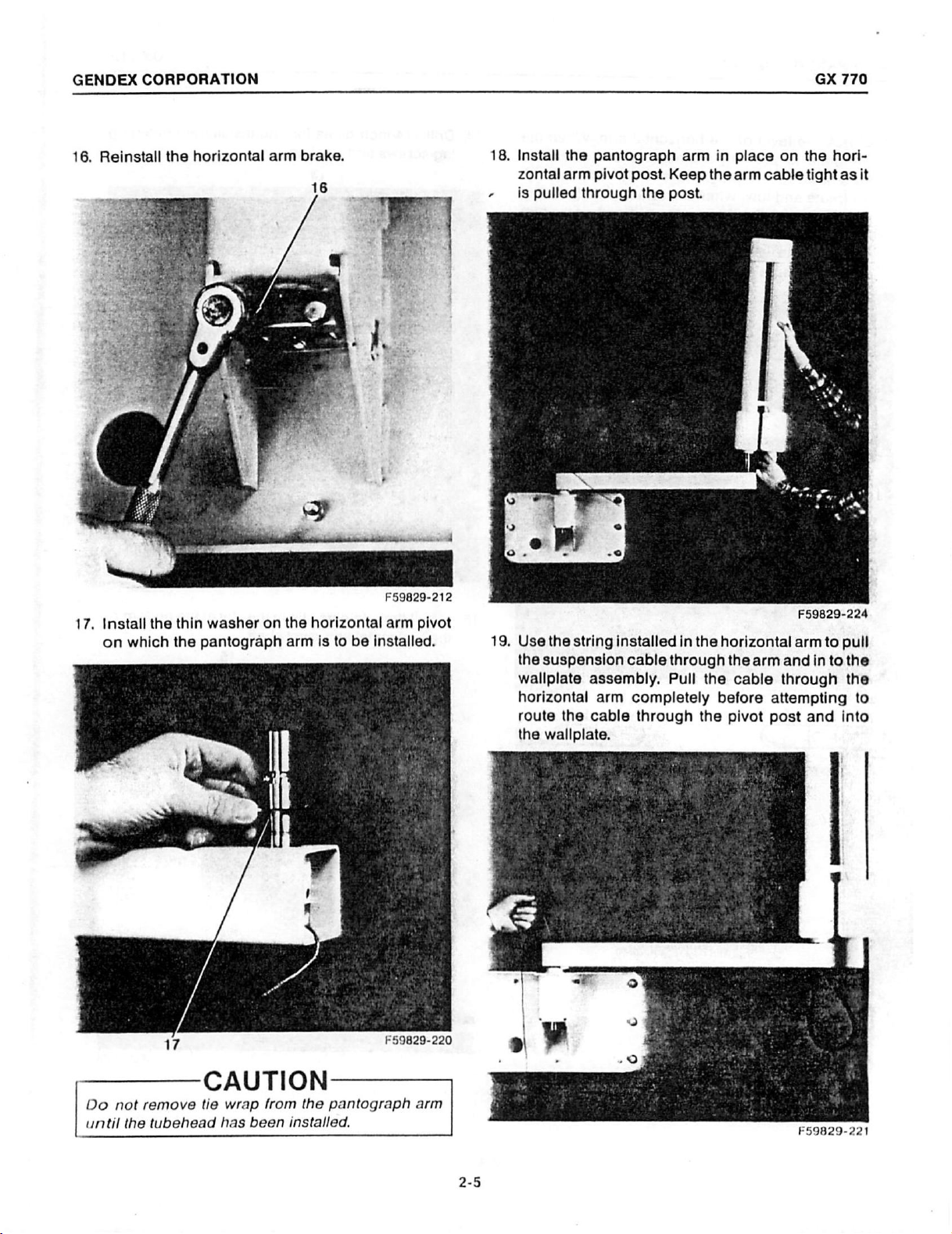

16.

Reinstall

CORPORATION

the

horizontal

arm

brake.

18...

ыы

18.

-

Install

zontal

is

pulled

the

pantograph

arm

pivot

through

post.

the

arm

Keep

post.

in

the

place

arm

on

cable

GX

the

hori-

tight

770

as

it

F59829-212

17.

Install

on

which

the

thin

washer

the

pantográph

on

the

horizontal

arm

is

)

to

be

arm

pivot

installed.

19,

Use

the

wallplate

horizontal

route

the

the

string

installed

suspension

assembly.

arm

the

cable

wallplate.

in

cable

through

Pull

completely

through

the

horizontal

the

the

cable

before

the

pivot

F59829-224

arm

arm

and

through

attempting

post

in

and

to

to

pull

the

the

into

to

Do

until

not

the

remove

tubehead

CAUTION

tie

wrap

from

has

been

installed.

the

pantograph

F59829-220

arm

F59829-221

2-5

GENDEX

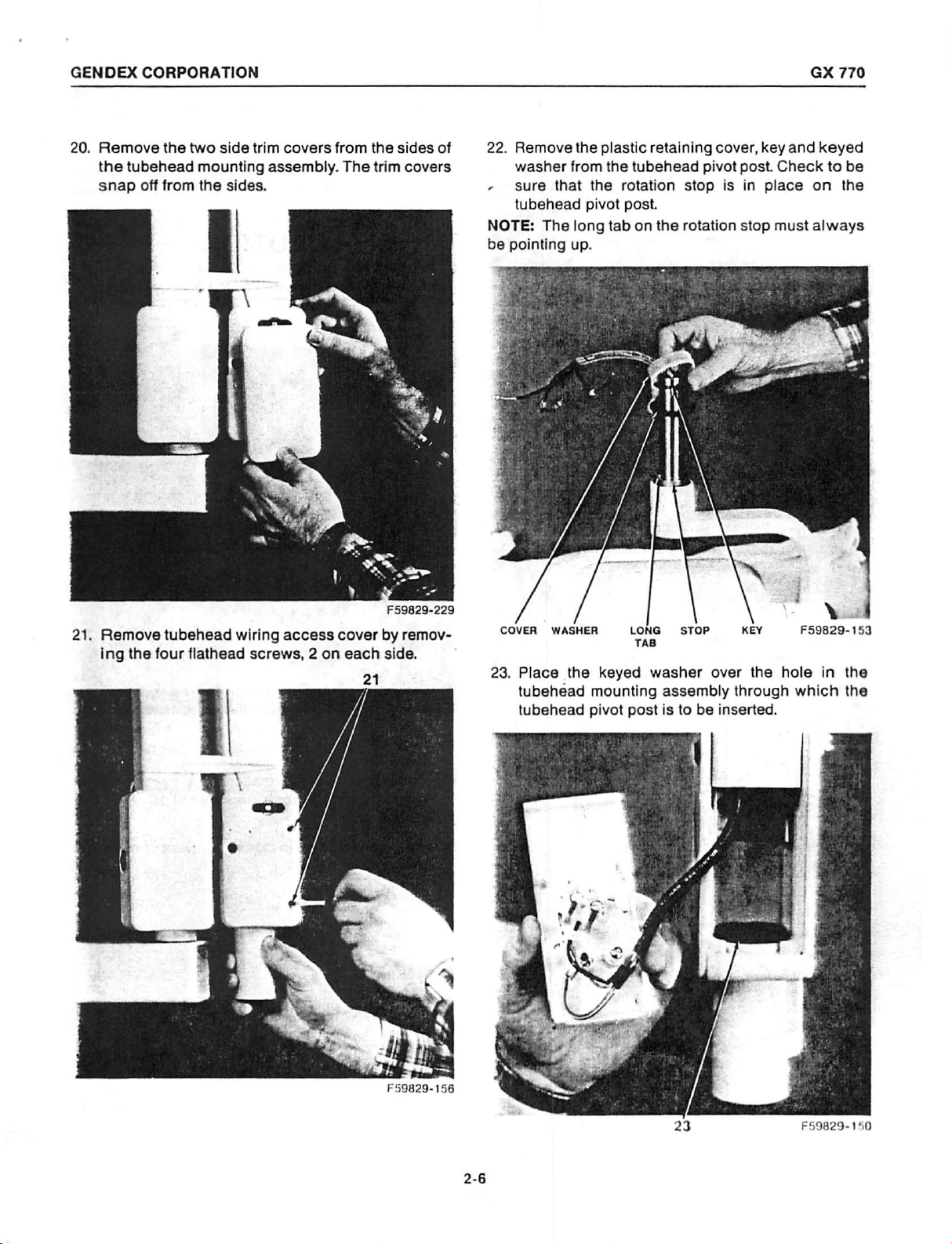

20.

Remove

the

tubehead

snap

CORPORATION

the

two

mounting

off

from

the

side

sides.

trim

covers

assembly.

from

The

4

the

trim

sides

covers

of

22.

Remove

washer

~

sure

tubehead

NOTE:

be

pointing

that

The

the

from

the

pivot

long

up.

plastic

the

tubehead

rotation

post.

tab

on

retaining

pivot

stop

the

rotation

cover,

post.

is

in

stop

key

Check

place

must

and

GX

770

keyed

to

be

on

the

always

21.

Remove

ing

the

tubehead

four

flathead

wiring

access

screws, 2 on

cover

each

21

F59829-229

by

remov-

side.

COVER

23.

WASHER

Place

tubehead

tubehead

the

LONG

TAB

keyed

mounting

pivot

post

STOP

washer

assembly

is

to

over

be

inserted.

KEY

the

through

F59829-153

hole

which

Y

in

the

the

F59829-156

F59829-150

2-6

GENDEX

24.

Install

mounting

CORPORATION

the

tubehead

assembly

pivot

and

post

through

into

the

the

keyed

tubehead

washer.

26.

<

The

prevent

Install

wires

and

washer.

plastic

the

the

plastic

snap

retaining

tubehead

retaining

into

place

cover

over

CAUTION

cover

from

MUST

falling

over

the

be

out

GX

the

tubehead

key

and

installed

during

use.

770

keyed

to

25.

Install

the

tubehead

pivot

shaft

—

p

— A

the

(OX

key

and

AS

@\

24

on

the

until

the

the

Y

NIDA)

||

,

tubehead

key

slots

WV)

on

fits

the

リ

O

A

É

pivot

into

keyed

shaft.

the

washer.

F59829-

Rotate

hole

|

f

in

147

the

27.

NOTE:

rotation.

Check

tubehead

stop

the

to

Stop

26

tubehead

through

stop.

MUST

rotation

approximately

be

in

place

stops

to

prevent

by

470

F59829-193

rotating

degrees

continuous

from

the

F59829-195

GENDEX

28.

Connect

strip

access

and 4 on

connect

sion

CORPORATION

the

four

and

ground

cover.

ground

Wires 3 and 4 connect

the

terminal

to

the

ground

wire

tubehead

screw

strip.

stud

is

already

wires

on

the

tubehead

Both

to

which

connected.

to

the

ground

the

terminal

wiring

to

wires

wires

suspen-

3

30.

Remove

counter

~

movement

arms.

Adjustment

31.

Reinstall

the

the

balance

ofthe

If

adjustments

the

two

side

tiewrap

of

inboard

Section.

tubehead

trim

panels.

from

the

tubehead

and

are

required,

wiring

the

arm

outboard

access

and

and

pantograph

see

Mechanical

GX

check

for

proper

cover

770

the

and

F59829-197

29.

Attach

cone

to

the

tubehead.

F59829-202

F59829-156

F59829-229

GENDEX

32.

Install

covers

CORPORATION

the

two

arm

on

the

horizontal

end

and

arm.

two

pivot

post

access

-

34,

35.

Check

stop

of

Tighten

wrench,

until

it

brake

the

pantograph

approximately

the

lower

located

firms

up.

This

for

the

pantograph

set

on

arm

240

screw,

the

screw

for

rotation

degrees.

requires

lower

adjusts

arm.

rear

from

5/32”

arm

the

horizontal

GX

770

stop

to

allen

casting,

33.

Tighten

wrench,

then

rotation

graph

NOTE:

additional

36.

Refer

the

top

located

back

off

and

stop

assembly.

Mechanical

to

calibration

32

set

screw,

on

the

1/2

turn.

out

lift

information

requires a 5/32"

lower

rear

screw

for

steps

arm

This

prevention

Adjustment

on

F59829-209

allen

casting,

provides

the

Section

33,

a

panto-

for

35

and

36.

Tighten

wrench

NOTE:

so

horizontal

The

that

35

the

horizontal

socket,

or

horizontal

pantograph

the

arm

moves.

arm

desired.

as

arm

brake

section

brake,

is

normally

opens

36

requires

F59829-34

a

7/16"

adjusted

before

the

F59829-214

2-9

F59829-212

GENDEX

CORPORATION

GX

770

NOTE:

counter

would

Electrical

be

37.

If

the

where

not

sub

visible

after

Reinstall

nuts

removed

the

chassis

be

possible.

NOTE:

cord

wiring

and

Switch

the

If

the

should

connected

GND1.

electrical

is

to

be

If a Remote

components.

-—————_

The

unit

must

building

ground.

Master

visible,

chassis

the

Control

the

serial

they

final

assembly.

electrical

earlier.

should

chassis

be

part

calibration

is

removed

to

the

of

the

CAUTION

be

properly

Conduit

is

and

must

and

placed

sub

Before

be

shifted

to

be

“hard

at

this

appropriate

Station

system,

prior

grounded

grounding

to

be

installed

model

chassis

number

be

removed

in a location

using

tightening

to

the

wired”,

time

and

terminals

or

Remote

you

should

to

connecting

via a wire

is

not

over

labels

from

the

that

will

the

four

the

nuts,

left

as

far

the

power

the

conduit

on

TS1

Exposure

complete

these

to

the

sufficient.

a

as

38.

Connect

ate

terminals

the

suspension

on

oR?

ς

κ.

Sat mom

TS1

and

arm

GND2.

cable

to

the

appropri-

F59829-29

The

unit

to

Section

function

is

now

3, 4,

5,

checks,

capable

and 6 for

certification

of

electrical

producing

and

final

F59829-37

X-rays.

calibration,

Proceed

assembly.

system

GENDEX

CORPORATION

GX

770

The

following

begin

modifications

4X4

wallplate

NOTE:

WITHOUT

load

four

on

or

1.

Steps 1 through 4 remain

and

mounting

2.

Step 5 -

3.

Steps 6 through 9 remain

4.

Step

loosely.

securely.

5.

Step

the

6.

Remove

special

7.

Install

the

lation

steps

page

2-1

noted

Special

master

Mounting

90

10 - Install

11 - Remove

wallplate.

appropriate

the

suspension

Ib.

(40.9

points.

Height

Level

the

mounting

the

4X4

Section

Mounting

control.

wiring

of

requirements

may

the

Set

or

mounting

for

INSTALLATION

4X4

OR

the

installation

of

this

section

are

applicable

Fixture,

are:

kg.)

withdrawal

be

modified

the

remaining 3 corner

wall

plate.

the

horizontal

aside

for

access

fixture.

special

hardware.

mounting

procedure

for

remoted

the

same.

for

the

30

Ib.

force

to

the

same.

Tighten

reinstallation.

cover

mounting

requirements.

DIRECTIONS

SPECIAL

which

along

(13.6

suit

arm

from

with

installation

from

Master

Control

kg.)

at

each

preference.

lag

screws

all

lag

screws

brake

the

4X4

fixture

See

Preinstal-

shear

of

using

MOUNTING

the

of

a

the

the

from

or

FOR

8.

Step

pivot

fixture.

SYSTEM

FIXTURE

12 - Install

post

inserted

WITH

the

horizontal

into

the

8

4X4

arm

or

special

with

mounting

F59829-104

the

long

9.

Step

13 - Correct

mounting

in

Step

7

F59829-99

fixture

13,

Page

the

to

achieve

2-4.

position

the

of

the

level

4X4

as

described

or

special

F59829-107

2-11

GENDEX

10.

Omit

11.

Install

the

CORPORATION

Step

14.

the

retaining

horizontal

arm

clip

pivot

in

the

shaft.

slot

at

the

bottom

of

13.

14.

Steps

Connect

necting

special

17

through

the

wires

mounting

37

remain

suspension

and

ground

fixture.

the

cable

screw

same.

to

the

on

GX

intercon-

the

4X4

770

or

12.

Step

16 - Install

4X4

or

NOTE:

wallplate.

Use

special

brake

11

the

horizontal

mounting

removed

arm

fixture.

from

the

brake

master

12

F59829-110

onto

the

control

TS1

MASTER

[의

[$

[의

[$]

[의

[$]

의

©]

15.

一

Do

sion

IN

GX-770

CONTROL

|

]

GND2

Connect

ate

terminals

一

not

reverse

cable.

CUSTOMER

WIRING,

the

interconnecting

on

TS1

一

CAUTIOM

red

and

50

3 #

FT.

X

and

black

SUSPENSION

CABLE

FURNISHED

12

AWG

MAX.

wires

GND2.

wires

一

in

to

the

the

F59829-37

SCREW

ON

OR

MOUNTING

FIXTURE

appropri-

suspen-

GND

4X4

SPECIAL

一

F59829-109

2-12

GENDEX

16.

CORPORATION

Install

pivot hole. bolts on

the

plug

button

in

place

on

the

wallplate

17.

Install

the

three

the

4X4

plug

mount.

buttons

to

cover

the

mounting

GX

770

16

“

18.

Reinstall

wiring

the

access

4X4

cover.

or

special

mounting

fixture

F59829-119

GENDEX

CORPORATION

GX

770

SECTION

ELECTRICAL

THE

KEY

LOCK

MUST

ALLOW

CANNOT

THE

“ON”

X-RAY

BE

REMOVED

POSITION.

EXPOSURE.

r——

Radiation

the

electrical

be

placed

available

100108.

Itis

recommended

ments

titled

ibration

copy

form

will

over

from

be

recorded

“Product

Record

should

FD2579

be

calibration.

location/Identification

be

and

BE

TURNED

WHEN

WARNING

produced

the

tubehead

GENDEX

CAUTION

that

by

is

provided

attached

the

numerous

Therefore a lead

Corporation.

all

of

the

installer. A separate

to

the

other

to

NOTE

THE

port.

the

following

for

this

owners

the

90

DEGREES

THAT

THE

SWITCH

——

times

plug

These

plugs

Part

EL

measure-

Log

and

purpose.

copy

installers

IS

during

must

are

No.

sheet

Cal-

One

of

copy.

CALIBRATION

TO

KEY

IN

©

the

Suggested

AC/RMS,

Impulse

Va

2.

3.

4.

3

Instruments:

DC

Voltmeter

Fluke

8030

or

8060

Beckman

Kessler-Ellis

ESD

Make

Plug

distribution

With

Voltmeter

and

Counter

XR201

ιο LO

sure

in

the

the

Master

TP-13

Tech

KT293

the

Master

line

panel.

to

read

on

the

1

Digital

330

Digital

È

Iné

cord

or

Control

100

Relay

к

È

and

Control

DC

Voltmeter

Voltmeter

behead

turn

turned

to

130

Circuit

TP-1

Milliameter

port.

is

turned

on

the

power

off,

connect

VAC

between

Board.

ТР-13

off.

at

an

TP-1

the

AC

These

insure

regulations.

be

advise

calibration

the

installation

obtained,

the

user

INSTRUMENT

The

following

accuracies

tion

is

fully

compliant

Type

of

AC

or

DC

DC

Impulse

Instrument

Voltmeter,

True

RMS

Milliameter

Voltmeter

Counter

If

the

contact

not

measuring

are

needed

Iron

Digital

procedures

is

fully

required

GENDEX

to

operate

to

with

Vane

Meter

must

be

followed

compliant

measurement

the

with

applicable

values

for

guidance,

equipment.

REQUIREMENTS

instruments

insure

applicable

Range

0-150

RMS

0-10

0-20V

0-999

Impulses

80-120V

RMS

with

the

GX-770

regulations:

VAC | +/-1.5V

mA

DC | +/-0.1mA

DC

60HZ

to

cannot

and

required

installa-

Accuracy

+/-0.02V

+/-0

Impulse

i

5.

Turn

reading.

Calibration

110

on

the

and

Master

Record

Record.

130.

Control

the

“No-Load”

This

and

note

line

voltage

voltage

must

F59829-44

the

voltmeter

be

between

on

the

3-1

GENDEX

6.

Set

sure

Control

tion

NOTE:

The

voltage,

CORPORATION

exposure

using

S2

Board.

record.

voltage

must

not

time

to

99

impulses.

(Calibration

Record

variation,

exceed 3 VAC.

“Load”

“No-Load”

Switch)

voltage

Make

on

minus

an

the

on

calibra-

“Load”

expo-

Timer

Turn

ing.

calculated

correct,

obtain

Load”

Turn

10.

11.

With

Voltmeter,

used

on

on

Meter

reading

off

the

in

the

Timer

the

the

Master

reading

in

step

adjust

R6

correct

on

Master

Master

step 8 and

Control and

using

Control

Control.

should

7,

+/-0.05

on

the

value.

the

Calibration

Control

the

same

9,

between

Board.

Note

be

equal

VDC.

Timer

Record

remove

turned

meter

TP-2

voltmeter

to

the

If

voltage

Control

the

final

Record.

meter

off,

connect a DC

and

meter

(+)

and

GX

read-

voltage

is

Board

“Vcal

leads.

scale

TP-4

770

not

to

(-)

7.

Calculate

following

“Load”

EXAMPLE

8.

With

Voltmeter

and

Voltage

10

the

TP-4

Vcal

formula:

Master

to

read

(-)

on

(load),

-

Vcal

11808

0

Control

10

to

the

Timer

from

“Load”

turned

20

VDC

Control

step

11.8

off,

connect a DC

between

Board.

R6

6,

using

TP-4

F59829-47

the

TP-3

(+)

TP-3

NOTE:

selector

in

these

Removal

knob

is

photos

R11

of

the

front

not

required

to

provide a better

TP-2

(graphic

for

calibration.

view.

panel)

TP-4

F59829-16

and

time

Removed

F59829-19

3-2

12.

13.

Turn

should

the

Timer

Record

Turn

on

off

the

be

2.00

Control

final

Master

Master

+/-0.01

“Vref”

Control

Control.

VDC.

Board

reading

and

Voltmeter

If

not,

to

obtain

on

Calibration

remove

reading

adjust

R11

2.00

VDC.

Record.

meter leads.

on

GENDEX

14.

With

Voltmeter

and

CORPORATION

the

Master

to

read

TP-13

on

TP-13

the

Control

100

to

Relay

TP-11

turned

130

VAC

Circuit

off,

connect

between

Board.

S2

an

AC

TP-11

GX

770

17.

With

the

tubehead

read 5 to

ground

(-).

Master

pivot

10

mA

Control

cover.

between

turned

Connect a DC

the

mA

off,

test

remove

mA

meter

point

(+)

the

to

and

15.

Turn

99

impulses.

bration

"regulated"

should

If

“No

TP-1

110

115

16.

Turn

Record

Record.

on

the

Switch)

be:

Load”

to

to

to

off

Master

final

Master

Make

on

voltage

voltage

TP-13

115

VAC

130

VAC

Control

“regulated”

Control.

an

the

between

is:

Set

exposure

Timer

Control

TP-11

“Regulated”

during

105

109

and

remove

voltage

exposure

using

TP-11

to

exposure

should

to

115

to

117

on

F59829-23

time

S2

(Cali-

Board.

and

TP-13

be:

meter

Calibration

The

TP-13

voltage

VAC

VAC

leads.

to

F59829-71

mA

TEST

POINT

(17)

3-3

18.

Turn

on

99

impulses.

tion

Switch)

reading

is

not

port.

Record

cord.

the

Master

Make

on

should

obtained,

final

Control.

an

exposure

the

Timer

be 7 +/-1.0mA.

contact

reading

Set

Control

GENDEX

on

exposure

using

Board.

If

the

Technical

the

Calibration

S2

(Calibra-

The

proper

time

value

Sup-

Re-

to

mA

GENDEX

19.

Turn

leads.

20.

With

impulse

Relay

CORPORATION

the

Master

the

Master

counter

Circuit

Board.

Control

Control

between

off

and

turned

TP-6

remove

off,

and

TP-13

the

meter

connect

on

an

the

22.

Remove

reinstall

Ifa

Remote

installed,

For

Remote

Section 8 or

Station

To

install a Remote

handswitch

Control

and

cord,

terminals 6 and 7 on

Station

it

may

Kit.

wires from

Board

2)

connect

the

Station

the

lead

cone.

or

be

instructions

and

completely

plug

from

the

Remote

installed

installation

Exposure

Remote

the

Exposure

at

this

instructions,

shipped

Switch,

terminals 6 and 7 on

remove

Exposure

Timer

Control

tubehead

Switch

time.

with

each

1)

the

Switch

Board.

GX

770

port

and

is

to

refer

Remote

disconnect

the

Timer

handswitch

wires

be

to

to

一

recommended

used.

一

Use

of

any

770. п no

一

CAUTION

switch

case

other

by

GENDEX

should a “lighted”

F59829-62

21.

Turn

on

the

3

impulses.

switch

counter

pulses

Check

Impulse

plus

Record.

NOTE:

than

calculated,

and

impulse

counter

posure

or

should

of

exposure

counter

22

impulses.

If

impulse

leads.

times,

Master

Make

remote

preheat

i.e.,

counter

If

you

contact

Control.

an

exposure

station

read

will

counter

exposure

are

exposure

25

plus 3 impulses

times

always

Record

reads

reads

26,

unable

GENDEX

Set

exposure

using

switch.

+/- O impulses

of

at

32

and

62

read

exposure

readings

time

reverse

Technical

one

to

obtain

on

impulse

set

at 3 impulses

your

time

for

the

hand-

Impulse

(22

im-

exposure.

impulses.

time

Calibration

higher

impulse

proper

Services.

ex-

than

could

those

damage

doorbell

furnished

the

button

or

GX-

be

GENDEX

CORPORATION

SECTION4

GX

770

The

following

installation

performed

12

month

may

result

U.S.

Radiation

of

as

intervals,

in

an

J.

—

Ifthe

GX-770

as

follows,

manual

Advise

USED.

1.

Complete

before

2.

Labels — Insure

labels

of

This

Master

Tubehead

Remote

12

8

Inch

The

not

3.

Tubehead — Check

that

head

4.

Check

tubehead

5.

Cone

properly

surface

cone

6.

Handswitch

and

housing

see

or

the

owner

proceeding.

thatinclude

manufacture,

is

required

Control

Station

Inch

Focal

Length

Focal

Length

suspension

required

could

if

necessary.

thatthe

—

of

is

at

coiled

is

SYSTEM

must

be

performed

the

GX-770.

part

of

the

Failure

installation

Performance

These

PERIODIC

to

that

Standard

IMPORTANT

System

contact

the

...............

Cone

Cone

indicate

port

Check

installed,

the

least

cord

cracked

does

not

the

Troubleshooting

GENDEX

that

the

system

Electrical

that

all

certified

model

and a statement

and

on:

ο

00060

..........

..........

is

Model

to

be

certified.

for

oil

internal

aluminum

and

that

tubehead

2.5

—

Inspect

for

shows

the

and

that

port

in.

(6.5

damage

or

the

filter

the

cord

Calibration

to

complete

are

MAINTENANCE,

perform

does

these

not

CFR

——

perform

Model

Model

Model

Model

Model

#46-404770G1

leaks

damage.

no

cone

the

to

cm).

or

the

Section

Technical

is

NOT

components

serial

numbers,

of

#46-404600G1

#46-404650G1

#46-404725G1

#46-404653G1

#46-404653G2

or

other

Replace

is

in

place

sign

of

is

distance

the

distal

handswitch

wear.

Replace

is

frayed

FUNCTION

the

also

to

be

at

checks

comply

with

Subchapter

functions

of

this

Support.

TO

BE

(Section

certification.

evidence

inside

damage.

undamaged,

end

or

3)

bear

date

and

is

tube-

the

from

the

of

the

housing

if

the

cracked.

CHECKS

7.

Mounting — Be

or

the

Special

ed

to

the

wall

8.

Key

Lock

Switch — Turn

remove

that

and

verify

.

Power

position.

Remote

sure

Indication

10.

kVp

Master

the

Premature

11.

of

exposure

automatically.

soon

Exposure

12.

exposures

operation

Control

Station,

at

X-ray

13.

packs

placed

the

containable

Suspension — Should

14.

and

either

Information

15.

previous

Manual

NOTE:

user

user

with

recommended.

the

an

exposure

turn

that

On

Station

Time

-7mA”

Control

“Warning”

99

impulses.

as

the

or

verify

the

Remote

Beam

(taped

square

film

quietly.

side.

over

All

required

is

included

the

key.

the

an

Lamp — Turn

Verify

Readout

of

Technic

is

Termination — Select

button

exposure

Indicators — Make

of

of

the

Size — Expose

and

in a 2.5

Should

(see

for

checks,

Installation/

sure

the

Mounting

or

other

Press

key

exposure

that

is

legible

or

Fixture

supporting

exposure

can

not

lock

to

can

the

Power

connected,

is

operating.

Factors — Verify

on

the

Remote

statement.

Make

an

before

The

exposure

switch

less

than

30

the

“X-RAY”

Remote

that

Station

together)

just

verify

Station.

the

audible

location.

or a panoramic

at

the

that

in.

(6.5

extend

not

drift

Mechanical

User — After

be

sure

to

the

owner/user.

information

in

the

User

Maintenance

Wall

Support,

is

securely

key

to

“OFF”

be

made.

the

“ON”

be

made.

key

lock

On

verify

the

front

Station.

an

exposure,

the

exposure

should

is

released.

several

impulses

lamp

If

there

signal

several

end

of

the

the

resulting

cm)

circle.

and

out

from

Adjustment

completing

to

turn

the

to

be

Manual.

4X4

Mount,

mount-

structure.

position

switch

to

Insert

verify

the

position

to

the

Lamp

lights.

that

the

Expo-

that

the

panel

of

Also

check

exposure

but

release

terminates

terminate

additional

and

verify

at

the

Master

is a Remote

can

be

heard

occlusal

cassette,

cone.

Process

image

retract

smoothly

the

wall

Section).

all

GX-770

furnished

Providing

Manual

to

is

and

key

and

“ON”

Ifa

“70

the

time

the

as

the

film

or

to

the

User

the

the

also

is

4-1

GENDEX

CORPORATION

GX

770

The

GX-770

the

United

Standards

according

It

is

therefore

1.

Assemble

tions.

2.

Perform

Function

A

preprinted

ized

component,

Locator

ranty.

returned

Product

serialized

System

Each

to

Locator

is

certified

States

when

to

the

the

the

the

Checks.

“IBM”

should

GENDEX.

GX-770

to

comply

Government

assembled,

instructions

Radiation

calibrated

given

responsibility

system

Electrical

as

and

cards

components:

card

part

for

be

completed

are

according

Calibration

is

furnished

of

the

extended

provided

SECTION

CERTIFICATION

CERTIFICATION

with

provisions

Performance

and

checked

in

this

publication.

of

the

to

PRODUCT

the

GENDEX

by

installer

previous

with

tubehead

the

for

to:

and

System

each

serial-

Product

installer

the

following

Sec-

war-

and

5

RESPONSIBILITY

3.

of

LOCATOR

Complete

States

United

5-2).

4.

Maintain

ing

to

States

Log

and

CARDS

Component

Tubehead

Master

Remote

12

8

Suspension

Inch

Inch

Control

Station

Cone

Cone

and

Form

FD2579

States

the

law.

jurisdiction

the

records

applicable

See

Calibration

distribute

for

installations

(see

of

eguipmentlocation

provisions

Product

Location/Identification

Record.

Model

46-404650G1

46-404600G1

46-404725G1

46-404653G1

46-404653G2

No.

46-404770G1

copies

example

of

the

United

subject

to

on

accord-

of

the

United

Certified*

Yes

Yes

Yes

Yes

Yes

No

the

page

—

—

—

—.-_——

GENDEX

vt

Corporation | PRODUCT

800

INSTALLATION

uu

A.B.

ans,

915

Waukesha

cate

.…

414

—

—

—

HE

Rankin,

West

Edgerton

555-4911

e

——P 一 一 … ーー

TARE

Te

ony

GX-770

D.M.D.

P.C.

BOX

MILWAUKEE,

CONT

Avenue

WI . 53207

stat

ee

ーー

LOCATOR

21004

Wi

DOM

----

53221

ee

ーー 一 一

FILE

*Certified

components

and/or a separate

installer.

and

—

—. — ---

Moni.

46-40460061

И

|

una

sao

un.

ーー- 一 一

ーーー

See

Calibration

----

Z.

アン

Progressive

1204

E.

Waukesha

414 . 555-1194

ne

ーー

ーー

——

list

Product

Record.

---- — --- 1—

чина

Dental

Main

Street

wan

—

must

be

listed

on

the

of

must

be

maintained

Location/Identification

—

ーー

ーー

—-

—

800101

ЕР

4125/84

Equip.

ーー

ーー

WI

Co.

.

————Pr

53151

—— 一 一

FD2579

by

the

Log

GENDEX

CORPORATION

GX

770

Upon

completion

checks

is

to

and

be

provisions

of

calibration,

completed

of

U.S.

Law.

CERTIFICATION

installation,

the

certification

and

distributed

system/function

form

according

COMPLETED

s.

Neme

A.0,

D.

Street

€.

City

Milwaukee

e.

Zip

53207

3.

GENERAL

s.

This

О

5.

intended

À

©

O

©.

The

o

4,

COMPONENT

6.

The

b.

Control

GENDEX

Complete

|

menutecturet

Insteiled

ο.

o

E

§ 9 | Menutecturer

3

på | GENDEX

3

j

r

5.

ASSEMSLER

+

atfirm

Inatructions

modilled

and

sech

4.

Printed

J.P.

6.

COMMENTS

+

**8

ene

FORM

FOR

MENT

of

Hospital

Goodrich,

Autres

Code

report

A

complete

A

replacement

да

года

uses)

General

Purpose

Generst

Purposs

tomography

angiography

Podistry

X-ray

Stationery

le

end

complete

master

Manutacturer

the

totiowing

and

in

chls

Menutecturor

|

GENDEX

Menufscturet

Manufacturer

Manufacturer

thet

ef)

provided

to

edvertaty

other

Infarmetion

copy

of

this

Name

Smith

12

inch

inch

FOA

2579

は

FDA

USE

ONLY

LOCATION

Doctor

or

0.M.0.

【

414-555-4911

INFORMATION

is

107

etsembly

u~ray

system

ol

components)

to

the

sastilng

{Check

applicable

Radiogrenhy

Fiuoroscony

(Other

than

System

fs

(check

INFORMATION

items. 4 end 3 onlyj

control

is

information

model

number

system,

Selected

CERTIFICATION

certified

component

by

the

affect

performance,

required

renort

will

be

focal

length

focal

length

(8/82)

office

where

Number

of

certified

components

(inches

x-ray

in

the

system

baxfrs))

CT)

one)

(If

addirionel

KI A new

for

the

In

the

indiceted

Components

Modes

16-40465361*

Model

6-40465362**

Model

Model

Model

steembied

menufacturer(s|

and

by

21

CER

Part

distributed

ss

cone

cone

(FD2579)

to

DEPARTMENT

Inztalied

q.

control,

existing

9.

space

instaitetion

€,

certitied

speces.

Number

Number

Number

Mumber

Number

or

were

were

1020

indicated

OF

FOOD

AND

REPORT

OF À DIAGNOSTIC

State

HI

which

are

(Check

tube

housing

system

D

urotogy

С]

Mammography

О

che:

O

Cnirooractic

O

cT

介

CT

The

Master

Control

R

2

00m

és

needed

for

Control

Model

46-40460081

campanenti

listed

For

other

cardfied

installed

by

me

of

the

type

required

installed

In

accordance

for

chis

sssembly

at

the

bottom

>. re

7)

this

Number

for

7

FORM

NOTE:

below

all

sponsible

ents.

bration

Even

does

not

certified

components,

for

See

Product

Record.

though

request

location

Location/Identification

EXAMPLE

ーー

Form

Approved;

HEALTH

AND

HUMAN

X—RAY

SYSTEM

Progressive

dos

(es))

limiting

Scenner

enother

form,

O

existing

you

instatied.

enter

1,

soy

[son

O

Vertical

Tube

O

С

Gente

report

le

disgnostic

provisions

furniched

to

Sly

Copy

-

FOA,

SERVICES | AE

device.

(Certified)

in

(Enter

vortsge

Housing

(Medicas)

being

n-ray

ot

21

the

HPKLIO

DAUG

ADMINISTRATION

OF

ASSEMBLY

eporapriate

assembly,

beam

Head