Page 1

Data Sheet

January 2008

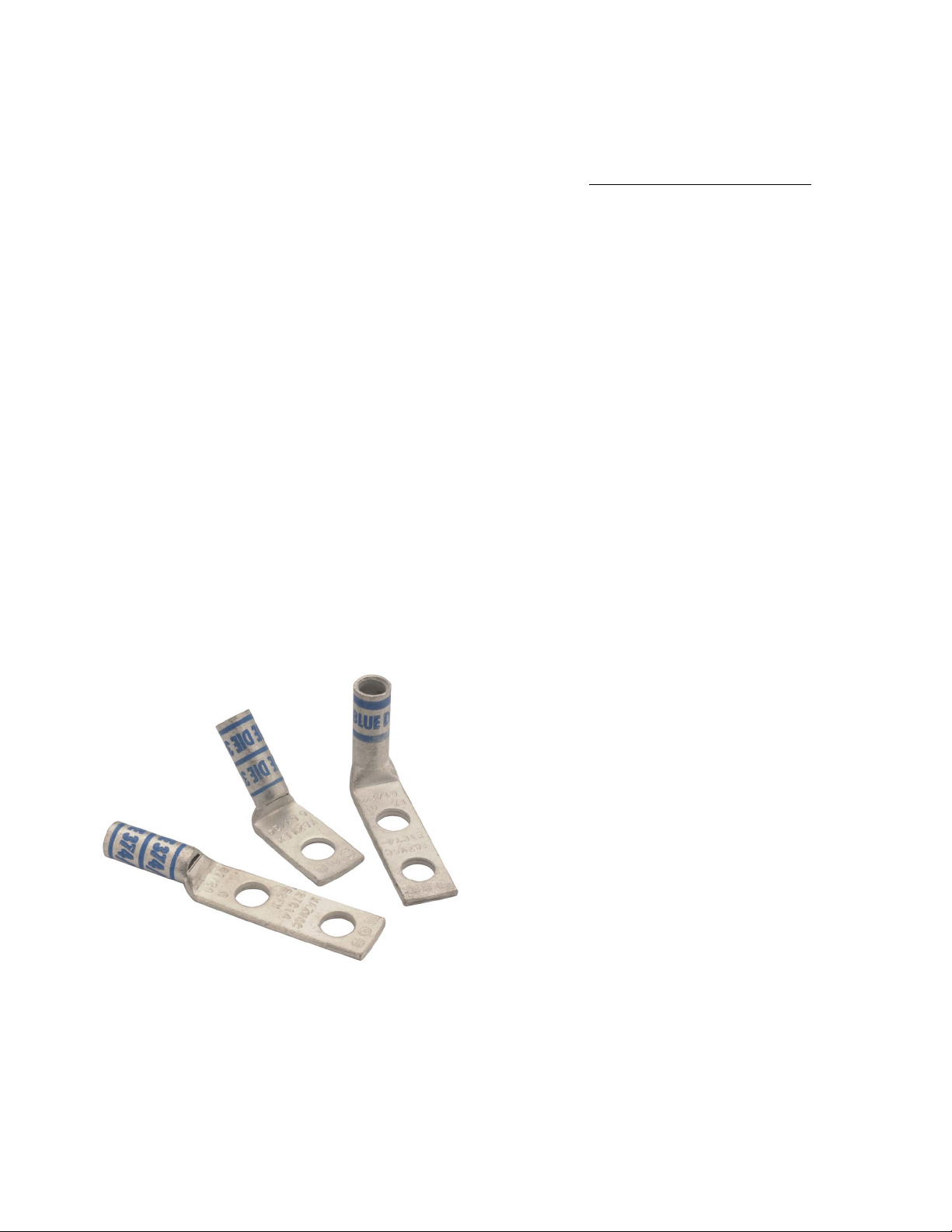

TE-20001 Connectors

Long-Barrel Lug-Type Terminations

The TE-20001 Long-barrel Connectors are

one-hole or two-hole compression-type

terminators. They are available in straight,

45° bend or 90° bend configurations and

are intended for use with copper power wire

sizes ranging from 14 AWG to750kCMil.

They can be used with both Class I and

Class B stranded flexible power wire.

Features

■ Long crimping barrel

■ High conductivity

■ Seamless, tubular copper construction

■ Corrosion-resistant, tin-plated

■ High-compression termination design

■ Accurate color-coding scheme

■ Single or dual mounting holes

■ Wire-seat inspection window

■ Exceeds commercial and UL requirements

■ Narrow tongue feature available in some sizes

Page 2

Data Sheet KS-23836

®

Connector

January 2008 Long-Barrel Lug-Type Terminations

Extra Connection Strength

The long crimping barrel of the

TE-20001 connectors provides

additional strength for

earthquake zones and other

high stress envirnments.

Providing maximum reliability,

the connection strength far

exceeds minimum UL*

requirements.

High Conductivity

The connectors are fabricated

using seamless, tubular copper

for excellent conductivity and

reliability. Tin plating preserves

connector integrity and also

prevents corrosion. In addition,

the connectors are specified for

extra margins of safety to

minimize the risk of overheating.

Easy, Accurate Installation

Intended for use in power

equipment and central office

power system installations,

TE-20001 connectors are

designed to be installed using

UL- or CSA†-approved

compression tools and dies. A

color-coding scheme matches

terminal and die sets to provide

the correct number and location

of crimps, reducing errors and

ensuring proper installation.

Color-coded barrels are

matched with Class I and Class

B stranding, which are UL-listed

with tooling, as indicated by the

specification.

Benefits

■ Extra connection strength for

earthquake zones and other

hight stress environments

■ Provides highly reliable

electromechanical

connections for high-energy

applications

■ Minimizes the risk of

overheating

■ Designed for fast, simple,

error-free installation

■ High quality ensured by strict

testing and qualification

procedures

■ Exceeds applicable

Telecordia requirements

■ UL-listed with Lineage

Power’s KS power wires for

Class I stranding and

standard Class B Stranding

■ Compatible with UL or

CSA-approved crimp

compression tools

■ UL-listed with tooling

identified in the power data

sheets of the TE-20001

specification

* UL is a registered trademark of

Underwriters Laboratories, Inc.

† CSA is a registered trademark of the

Canadian Standards Association, Inc.

Lineage Power offers

TE-20001 in one-hole or

two-hole, 90°, 45°, and

straight configurations

2 Lineage Power

Page 3

Data Sheet KS-23836® Connector

January 2008 Long-Barrel Lug-Type Terminations

Ordering Information

Class B

TE-20001

List No.

L-1 848659074 10-14 10-14 8-10 M5 — — — 0.41

L-2 848659165 10-14 10-14 1/4” M6 5/8” 15.88 — 0.41

L-3 848659173 10-14 10-14 1/4” M6 5/8” 15.88 90 0.41

L-4 848659181 10-14 10-14 1/4” M6 3/4” 19.05 — 0.41

L-5 848659199 #8 #8 #10 M5 — — — 0.41

L-6 848659207 #8 #8 1/4” M6 — — — 0.44

L-7 848659215 #8 #8 #10 M5 5/8” 15.88 — 0.41

L-8 848659223 #8 #8 #10 M5 3/4” 19.05 — 0.41

L-9 848659231 #8 #8 1/4” M6 5/8” 15.88 — 0.44

L-10 848659249 #8 #8 1/4” M6 3/4” 19.05 — 0.44

L-11 848659256 #8 #8 1/4” M6 1” 25.4 — 0.44

L-12 848659264 #8 #8 3/8” M10 1” 25.4 — 0.58

L-13 848659280 #6 #6 1/4” M6 — — — 0.48

L-14 848659298 #6 #6 1/4” M6 — — 45 0.48

L-15 848659306 #6 #6 1/4” M6 — — 90 0.48

L-16 848659314 #6 #6 3/8” M10 — — — 0.58

L-17 848659322 #6 #6 #10 M5 3/4” 19.05 — 0.48

L-18 848659330 #6 #6 1/4” M6 5/8” 15.88 — 0.48

L-19 848659348 #6 #6 1/4” M6 5/8” 15.88 90 0.48

L-20 848659355 #6 #6 1/4” M6 3/4” 19.05 — 0.48

L-21 848659363 #6 #6 1/4” M6 1” 25.4 — 0.48

L-22 848659371 #6 #6 3/8” M10 1” 25.4 — 0.58

L-23 848659413 #4 #4 1/4” M6 — — — 0.55

L-24 848659421 #4 #4 1/4” M6 — — 90 0.55

L-26 848659447 #4 #4 1/4” M6 5/8” 15.88 — 0.55

L-25 848659439 #4 #4 3/8” M1 — — — 0.58

L-27 848659470 #4 #4 3/8” M10 1” 25.4 — 0.58

L-28 848659488 #2 — 1/4” M6 — — — 0.60

L-29 848659496 #2 — 1/4” M6 — — 45 0.60

L-30 848659504 #2 — 1/4” M6 — — 90 0.60

L-32 848659520 #2 — 1/4” M6 5/8” 15.88 — 0.60

L-33 848659538 #2 — 1/4” M6 3/4” 19.05 — 0.60

L-34 848659546 #2 — 1/4” M6 1” 25.4 — 0.60

L-35 848659553 #2 — 5/16” M8 1” 25.4 — 0.60

L-31 848659512 #2 — 3/8” M10 — — — 0.60

L-36 848659561 #2 — 3/8” M10 1” 25.4 — 0.60

L-37 848659579 #2 — 1/2” M12 1-3/4” 44.45 — 0.83

L-38 848659587 #2 #2 1/4” M6 — — — 0.68

L-40 848659603 #2 #2 1/4” M6 5/8” 15.88 — 0.68

L-39 848659595 #2 #2 3/8” M10 — — — 0.68

L-41 848659611 #2 #2 3/8” M10 1” 25.4 — 0.68

L-42 848659629 1/0 — 1/4” M6 5/8” 15.88 — 0.75

L-43 848659637 1/0 — 3/8” M10 1” 25.4 — 0.75

L-44 848659645 1/0 — 3/8” M10 1” 25.4 90 0.75

L-45 848659652 1/0 — 1/2” M12 1-3/4” 44.45 — 0.83

L-46 848659660 1/0 1/0 3/8” M10 1” 25.4 — 0.83

L-47 848659678 1/0 1/0 1/2” M12 1-3/4” 44.45 — 0.83

L-48 848659686 2/0 — 3/8” M10 — — — 0.83

Comcode

Wire Size

(AWG)

Class I

Wire Size

(AWG)

Bolt

Size

(ASTM)

Bolt Size

2

)

(mm

Hole

Spacing

(inches)

Hole

Spacing

2

)

(mm

Degree

of Bend

Tongue

Width

Lineage Power 3

Page 4

Data Sheet KS-23836

©

®

Connector

January 2008 Long-Barrel Lug-Type Terminations

Ordering Information (continued)

Hole

Spacing

2

)

(mm

Degree

of Bend

TE-20001

List No. Comcode

Class B

Wire Size

(AWG)

Class I

Wire Size

(AWG)

Bolt

Size

(ASTM)

Bolt Size

2

)

(mm

Hole

Spacing

(inches)

L-49 848659694 2/0 — 1/4” M6 5/8” 15.88 — 0.83

L-50 848659702 2/0 — 1/4” M6 3/4” 19.05 — 0.83

L-51 848659710 2/0 — 3/8” M10 1” 25.4 — 0.83

L-52 848659728 2/0 — 1/2” M12 1-3/4” 44.45 — 0.83

L-53 848659736 2/0 2/0 3/8” M10 1” 25.4 — 0.93

L-54 848659744 2/0 2/0 1/2” M12 1-2/4” 44.45 — 0.93

L-55 848659819 4/0 — 1/4” M6 3/4” 19.05 — 1.02

L-56 848659827 4/0 — 3/8” M10 1” 25.4 — 1.02

L-57 848659843 4/0 — 1/2” M12 1-3/4” 44.45 — 1.02

L-58 848659850 — 4/0 1/4” M6 3/4” 19.05 — 1.12

L-59 848659868 — 4/0 3/8” M10 1” 25.4 — 1.12

L-60 848659876 — 4/0 1/2” M12 1-3/4” 44.45 — 1.20

L-61 848659884 350 kcmil — 3/8” M10 1” 25.4 — 1.29

L-62 848659892 350 kcmil — 1/2” M12 1-3/4” 44.45 — 1.29

L-63 848659900 — 350 kcmil 3/8” M10 1” 25.4 — 0.96

L-64 848659934 — 350 kcmil 3/8” M10 1” 25.4 — 1.55

L-65 848659942 — 350 kcmil 1/2” M12 1-3/4” 44.45 — 1.55

L-66 848659959 500 kcmil — 3/8” M10 1” 25.4 — 1.55

L-67 848659975 500 kcmil — 1/2” M12 1-3/4” 44.45 — 1.55

L-68 848659991 — 500 kcmil 3/8” M10 1” — 1.63

L-69 848660015 — 500 kcmil 1/2” M12 1-3/4” 44.45 — 1.63

L-70 848660023 — 500 kcmil 1/2” M12 1-3/4” 44.45 90 1.63

L-71 848660049 750 kcmil — 3/8” M10 1” 25.4 — 1.63

L-72 848660072 750 kcmil — 1/2” M12 1-3/4” 44.45 — 1.63

L-73 848660080 — 750 kcmil 3/8” M10 1” 25.4 — 1.63

L-74 848660106 — 750 kcmil 1/2” M12 1-3/4” 44.45 — 1.63

Tongue

Width

LINEAGE POWER

World Wide Headquarters

3000 Skyline Drive, Mesquite, TX 75149, USA

2008 Lineage Power. Lineage Power reserves the right to make changes to the product(s) or information contained herein without notice. No liability is assumed as a result of

their use or application. No rights under any patent accompany the sale of any such product(s) or information.

4 Lineage Power

January 2008

DS03-016 Rev 4

+1-800-843-1797

Outside U.S.A.: +1-972-284-2626

http://www.lineagepower.com

e-mail: techsupport1@lineagepower.com

Loading...

Loading...