Page 1

GE Energy

Industrial Solutions

GEH-6253 Installation Instructions

Power Supply Assembly

For Spectra® RMS Molded-Case Circuit Breakers

TM

with microEntelliGuard

, MicroVersaTrip® PM or MicroVersaTrip® Plus Trip Units

For Catalog Number SPSAA

Circuit Breaker Accessory

Overview

The General Electric Power Supply Assembly is used to

provide +24Vdc Control Power to Spectra

Case Circuit Breakers with microEntelliGuard

MicroVersaTrip

Cable System.

The Power Supply Assembly also provides power to the

Voltage Conditioner Assembly or Voltage Conditioner

Plate. Spectra

microEntelliGuard™ (with advanced metering) and

MicroVersaTrip

Voltage Conditioner Assembly or Voltage Conditioner

Plate to function properly.

®

RMS Molded-

TM

®

PM/Plus Trip Units via the Distribution

®

RMS Molded-Case Circuit Breakers with

®

PM Trip Units require connection to a

or

The Power Supply Assembly is rated 24 watts (+24Vdc@

1.0 amp) and has the maximum capacity to power a

Distribution Cable System consisting of either a Voltage

Conditioner Assembly or a Voltage Conditioner Plate

AND 20 Spectra

with microEntelliGuard

Trip Units with a maximum system cable length of 40

feet.

The assembly requires a minimum input voltage of

85Vac @ 60 Hz to operate properly (the maximum

voltage rating is 240Vac @ 60 Hz). This input must

be fused with 2-amp class CC fuses (not included).

The Power Supply Assembly is designed to operate in

temperatures between 0°C and 70°C.

®

RMS Molded-Case Circuit Breakers

TM

or MicroVersaTrip® PM/Plus

Page 2

GEH-6253 Installation Instructions

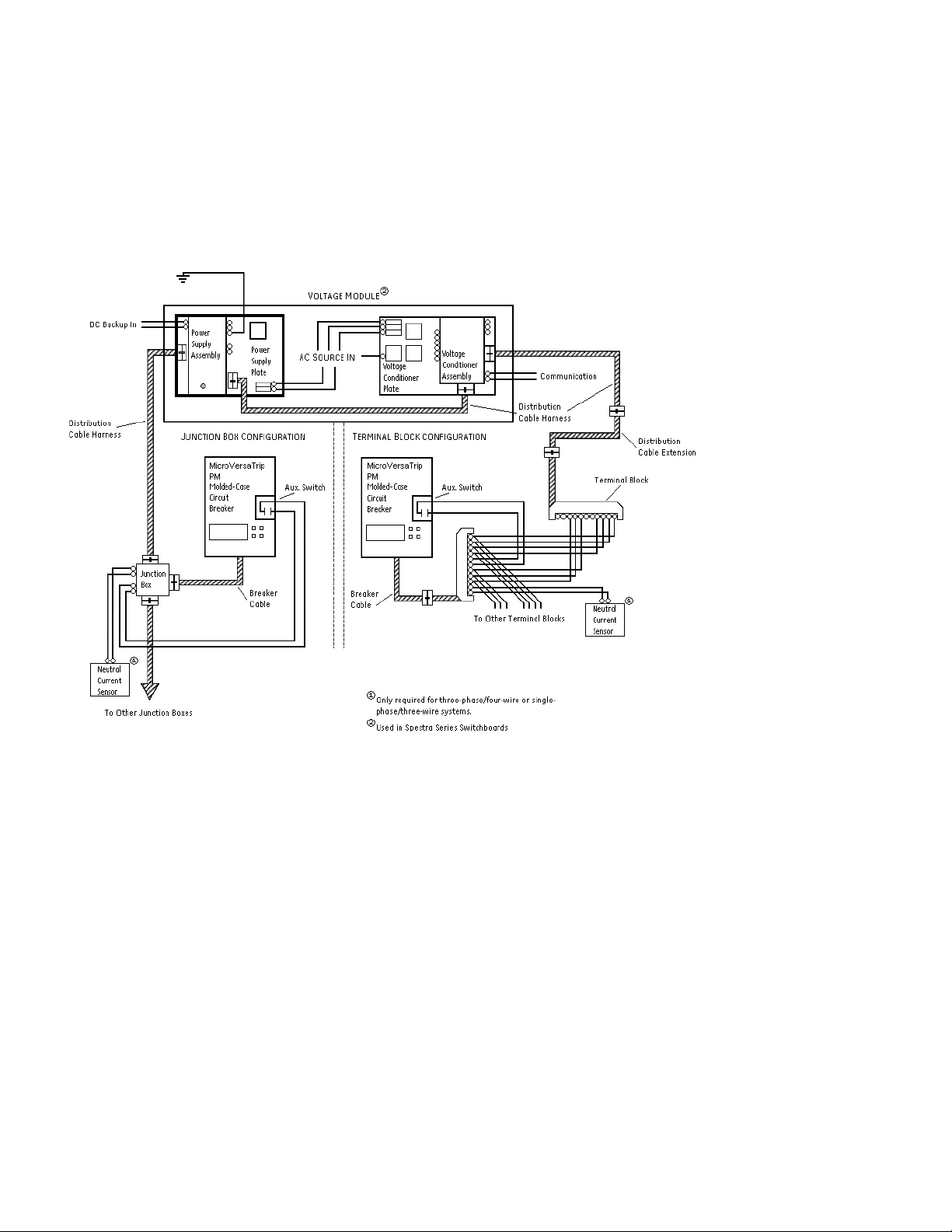

Figure 1 shows how the Power Supply Assembly is used in a typical MicroVersaTrip® PM system. Figure 2 shows

how the Power Supply Assembly is used in a typical MicroVersaTrip

®

Plus system. The microEntelliGuard

TM

Trip Unit

can be used with either configuration, i.e. Figure 1 or Figure 2. The connection diagram shown in Figure 2 applies

TM

to microEntelliGuard

Trip Units with Basic Metering.

Figure 1. Typical MicroVersaTrip® PM Trip Unit System detailing the Power Supply Assembly.

Page 3

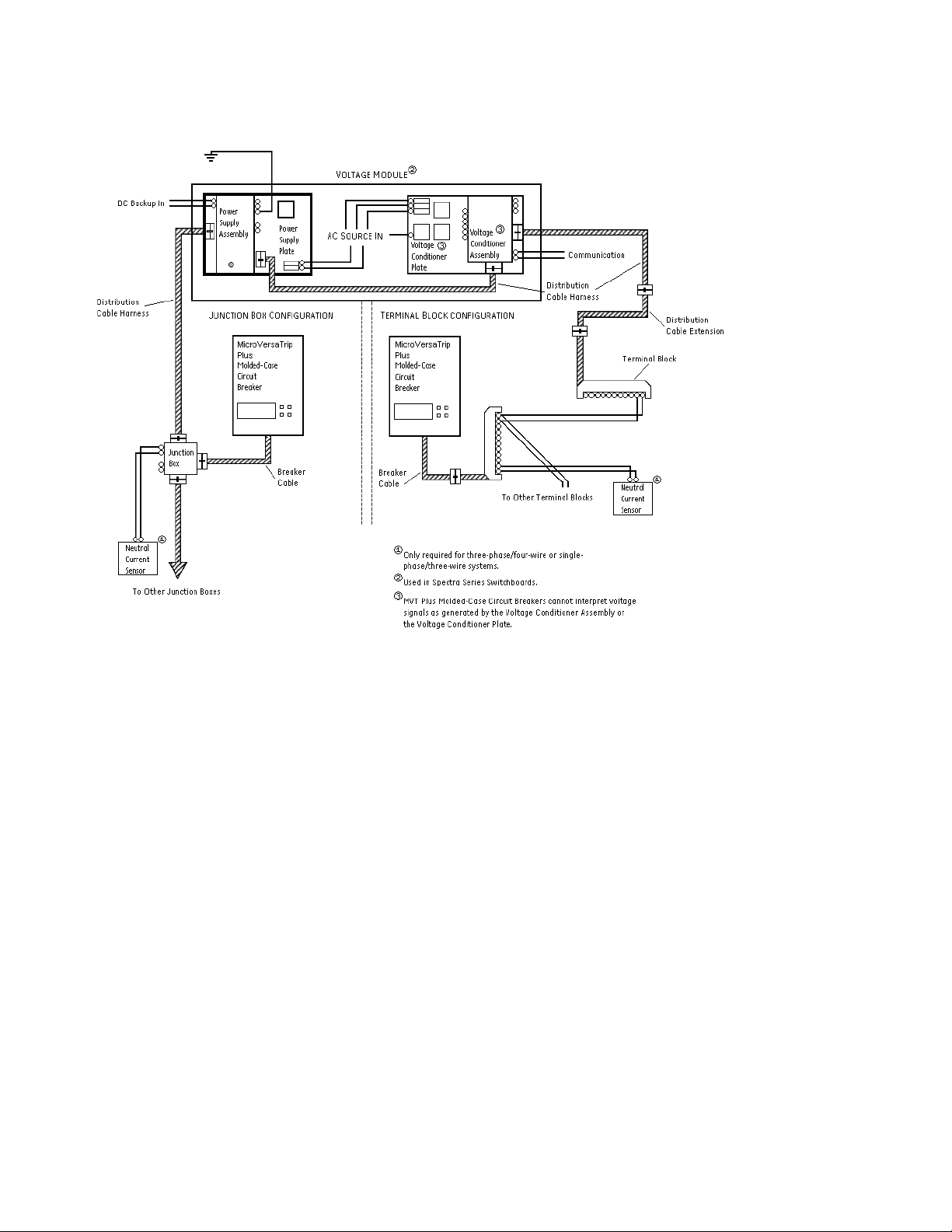

GEH-6253 Installation Instructions

Figure 2. Typical MicroVersaTrip® Plus Trip Unit System detailing the Power Supply Assembly.

Page 4

GEH-6253 Installation Instructions

Supplemental 24Vdc input terminals are provided for

systems that have access to an external +24Vdc power

supply. If this supplemental input is connected, the

assembly will continue to pass the control power to

breakers and accessories connected to the Distribution

Cable System if the primary AC power is lost or drops

below the 85Vac minimum requirement. This backup

input must meet ANSI C37.90.1 for oscillatory and fast

transient surges (the Power Supply Assembly provides

this protection for the primary AC input).

Additional 24Vdc output connections are supplied for

applications where +24Vdc control power is required

independent of the Distribution Cable System (i.e. feeding

an Air Circuit Breaker or Insulated Case Breaker with a

®

MicroVersaTrip

PM/Plus or EntelliGuardTM TU Trip Unit).

NOTE: THE POWER SUPPLY ASSEMBLY IS SIZED FOR A

MAXIMUM OF 20 BREAKERS. Use of the Power Supply

Assembly to provide voltage sensing signals and/or

+24Vdc control power to a main Air Circuit Breaker or

®

a main Insulated Case Breaker with a MicroVersaTrip

TM

PM/Plus or EntelliGuard

total quantity of 20 Spectra

Breakers with microEntelliGuard

TU Trip Unit reduces the

®

RMS Molded-Case Circuit

TM

or MicroVersaTrip®

PM/Plus Trip Units by one. The overall maximum cabling

length of the system remains 40 feet.

• “Output to 24Vdc”

– Two-screw terminal block for optional control power

output (in lieu of using the Distribution Cable System).

• “Supplemental Input 24Vdc”

– Two-screw terminal block for connection of an

external +24Vdc power supply.

By plugging the Power Supply Assembly into the

Distribution Cable System, you create system wide

signals that are available to all breakers connected to

the system; a list of those functions appears in Table 2.

Table 2. Signals Available on the Distribution Cable System by

connection of the Power Supply Assembly.

Spectra® RMS ™ Breaker

with microEntelliGuard™ or

MicroVersaTrip

Control Power (+24Vdc) Control Power (+24Vdc)

Control Power (-common) Control Power (-common)

®

PM Trip Unit

Spectra

MicroVersaTrip

microEntelliGuard™ with

Basic Metering Trip Unit

®

RMS Breaker with

®

Plus or

Dimensions, Weights and Wiring Diagrams

A Power Supply Assembly dimensioned drawing is

provided in Figure 3 to assist in mounting the assembly.

The maximum unit weight is two and a half pounds.

The Power Supply Assembly contains five connection

points. The following list contains a description and

type of connection points.

• “To Distribution Cable”

– 12-pin plug connector that mates with the 12-pin

receptacle of a Distribution Cable Harness (catalog

number SDCHA11, SDCHA30 or SDCHA60).

• “To Voltage Conditioner”

– 12-pin plug connector that mates with the 12-pin

receptacle of a Distribution Cable Harness (catalog

number SDCHA11, SDCHA30 or SDCHA60). For

®

Spectra

MicroVersaTrip

RMS Molded-Case Circuit Breakers with

®

PM Trip Units, the other end of

the harness MUST connect to either a Voltage

Conditioner Assembly (catalog number SVCAA)

or a Voltage Conditioner Plate (catalog number

SVCA120Y, SVCA208Y, SVCA240D, SVCA277Y,

SVCA480Y, SVCA480D or SVCA600D) for the breaker

to function properly.

• “Input”

– Three-screw terminal block for connection of the

primary AC source (85Vac to 240Vac @ 50/60 Hz)

AND a ground connection.

Figure 3. Dimensioned drawing of the Power Supply Assembly

(dimensions shown in inches).

Page 5

GEH-6253 Installation Instructions

Figure 4 shows how the Power Supply Assembly is used in a typical MicroVersaTrip® PM system. Figure 5 shows

how the Power Supply Assembly is used in a typical MicroVersaTrip® Plus system. The microEntelliGuard

TM

Trip Unit

can be used with either configuration, i.e. Figure 4 or Figure 5. The connection diagram shown in Figure 5 applies

to microEntelliGuardTM Trip Units with Basic Metering.

Figure 4. Wiring connections to the Power Supply Plate for a typical MicroVersaTrip® PM System.

Page 6

GEH-6253 Installation Instructions

Figure 5. Wiring connections to the Power Supply Plate for a typical MicroVersaTrip® Plus System

Page 7

GEH-6253 Installation Instructions

Connections

The screw terminals on the Power Supply Assembly

are labeled by function for clarity. The terminal strip

pocket will accommodate a spade lug or ring terminal

with a tongue width up to 0.320 inches. The terminal

screw size is 10-32. To make the connection, attach

an appropriate spade lug or ring terminal to the wire,

then slip the fastener beneath the terminal screw and

tighten.

The Power Supply Assembly also contains two 12-pin

plug connectors. The connectors are keyed so they

cannot be inserted incorrectly into a mating 12-pin

receptacle connector.

To connect to the Power Supply Assembly plugs, align

the receptacle interlock connector of a Distribution

Cable Harness with the plug hook connector of the

Power Supply Assembly. Insert the receptacle until the

interlock and hook catch (see Figure 6). To disconnect

from the Power Supply Assembly, press down at the

rear of the receptacle interlock until the interlock clears

the plug hook and withdraw the receptacle interlock

(see Figure 7).

PARTS AND OPTIONS

There are no user-serviceable components or parts

within the Power Supply Assembly; however, in order

for the unit to be properly protected the 85Vac to

240Vac 60Hz INPUT must be fused. Table 3 lists the

fuses and fuse holders that are recommended for use

with the Power Supply Assembly.

Table 3. Recommended replacement fuses for use with the

Power Supply Assembly.

Class CC Current limiting Fuse Fuse Holder

Gould-Shawmut ATMR 2 Gould-Shawmut 3012R & DFC3M

If the incoming AC power supply is greater than the

240 Vac @ 60 Hz maximum rating of the Power Supply

Assembly, then refer to Table 4 for a listing of GE control

power transformers that are recommended for use

with the Power Supply Assembly. The INPUT to the

Power Supply Assembly must always be protected. It

is recommended that the primary side of the control

power transformer be fused with the fuses previously

described.

If there is a preference to purchase a +24Vdc Power

Supply that has factory-mounted AC line fuses and/

or a higher AC voltage rating, Table 5 contains a listing

of GE Power Supply Plates. These Power Supply Plates

contain the Power Supply Assembly as an integral

part of the plate and are factory-wired from the Power

Supply Assembly to the control power transformer

(where required) and to the fuse holders (one set of

fuses is included).

Figure 6. Slide view of receptacle-plug insertion into the

Power Supply Assembly.

Figure 7. Side view of receptacle-plug removal from the

Power Supply Assembly.

Table 4. Recommended GE Control Power Transformers for use

with the Power Supply Assembly.

Input Rating Pri / Sec Rating Catalog Number

480Vac @ 50/60 Hz 480Vac / 120Vac 9T58K2802

600Vac @ 50/60 Hz 600Vac / 120Vac 9T58K2824

Table 5. Available GE Power Supply Plates.

Voltage

Rating

120 Vac SPSA120 1,2 amp larger mounting plate with fuse holder

208 Vac SPSA208 2,2 amp larger mounting plate with fuse holder

240 Vac SPSA240 2,2 amp larger mounting plate with fuse holder

480 Vac SPSA480 2,2 amp

600 Vac SPSA600 2,2 amp

Catalog

Number

AC line

Fuses

Comments

larger mounting plate with fuse holders

and 480Vac to 120Vac transformer

larger mounting plate with fuse holders

and 600Vac to 120Vac transformer

Page 8

GEH-6253 Installation Instructions

Additional Information

Refer to these other user’s manuals for more details·:

®

GEH-5934 MicroVersaTrip

PM Trip Units in Spectra

Plus and MicroVersaTrip®

®

RMS Molded-

Case Circuit Breakers

®

GEH-700 Spectra

G Breaker w/

microEntelliGuard™ Trip Unit

®

GEH-701 Spectra

K Breaker w/

microEntelliGuard™ Trip Unit

GEH-702 microEntelliGuard™ Trip Unit Users Manual

DEH-41318 Universal Rating Plug

GEH-6250 Voltage Module

GEH-6251 Power Supply Plate

GEH-6252 Voltage Conditioner Plate

GEH-6254 Voltage Conditioner Assembly

GEH-703 MET Battery Pack Adapter

GEH-704 MET Advanced Distribution Cable

Junction Box

DEH-006 Distribution Cable Junction Box

GEH-705 MET Distribution Cable Extension (20-pin)

GEH-6256 Distribution Cable Extension (12-pin)

GEH-6255 Distribution Cable Harness (12-pin)

GEH-706 MET Distribution Cable Terminal Blocks

(11 point & 22 point)

GEH-6257 Distribution Cable Terminal Block (11 point)

GEH-6491 POWER LEADER™ Modbus Concentrator

GEH-6502 POWER LEADER™ PMCS 5.0 Network

Architecture Guide

GEH-707 MET Sealable Cover kits

DEH-4568 GTU digital test kit (GTUTK20)

GEH-5551 Shunt Trip and UVR instructions

GEH-5593 Aux switch and bell alarm

GEK-64467 TIM-1 Zone Selective Interlock Module

Spectra and MicroVersaTrip are registered trademarks and EntelliGuard and

microEntelliGuard are trademarks of the General Electric Company.

These instructions do not cover all details or variations in equipment nor do they

provide for every possible contingency that may be met in connection with installation,

operation, or maintenance. Should further information be desired or should particular

problems arise that are not covered sufficiently for the purchaser’s purposes, the

matter should be referred to the GE Company.

GE Energy

41 Woodford Avenue, Plainville, CT 06062

www.geelectrical.com

© 2011 General Electric Company

imagination at work

GEH-6253 Rev. 4 (11/11 M45)

Loading...

Loading...