Page 1

g

p

g

quip

y

DEH071 Installation Instructions R02

Spectra Series™ Power Panelboards

Bolt-On Main Lug Kits

Application

These instructions apply to main lug kits with the

following catalog numbers. An “F” suffix indicates that the

kit includes all cover plates.

AMB2120N(F) AMB3120N(F) AMB2120DN(F)

AMB3120DN(F) AMB2250CA(F) AMB3250CA(F)

AMB2600CA(F) AMB3600CA(F) AMB2800CA(F)

AMB3800CA(F) AMB2120CA(F) AMB3120CA(F)

AMB2250DCA(F) AMB3250DCA(F) AMB2600DCA(F)

AMB3600DCA(F) AMB2800DCA(F) AMB3800DCA(F)

AMB2120DCA(F) AMB3120DCA(F)

Installation

WARNING: Danger of electrical shock or injury.

OFF

Turn

switchboard before workin

e

Equipment is to be installed and maintained b

properly trained and qualified personnel only.

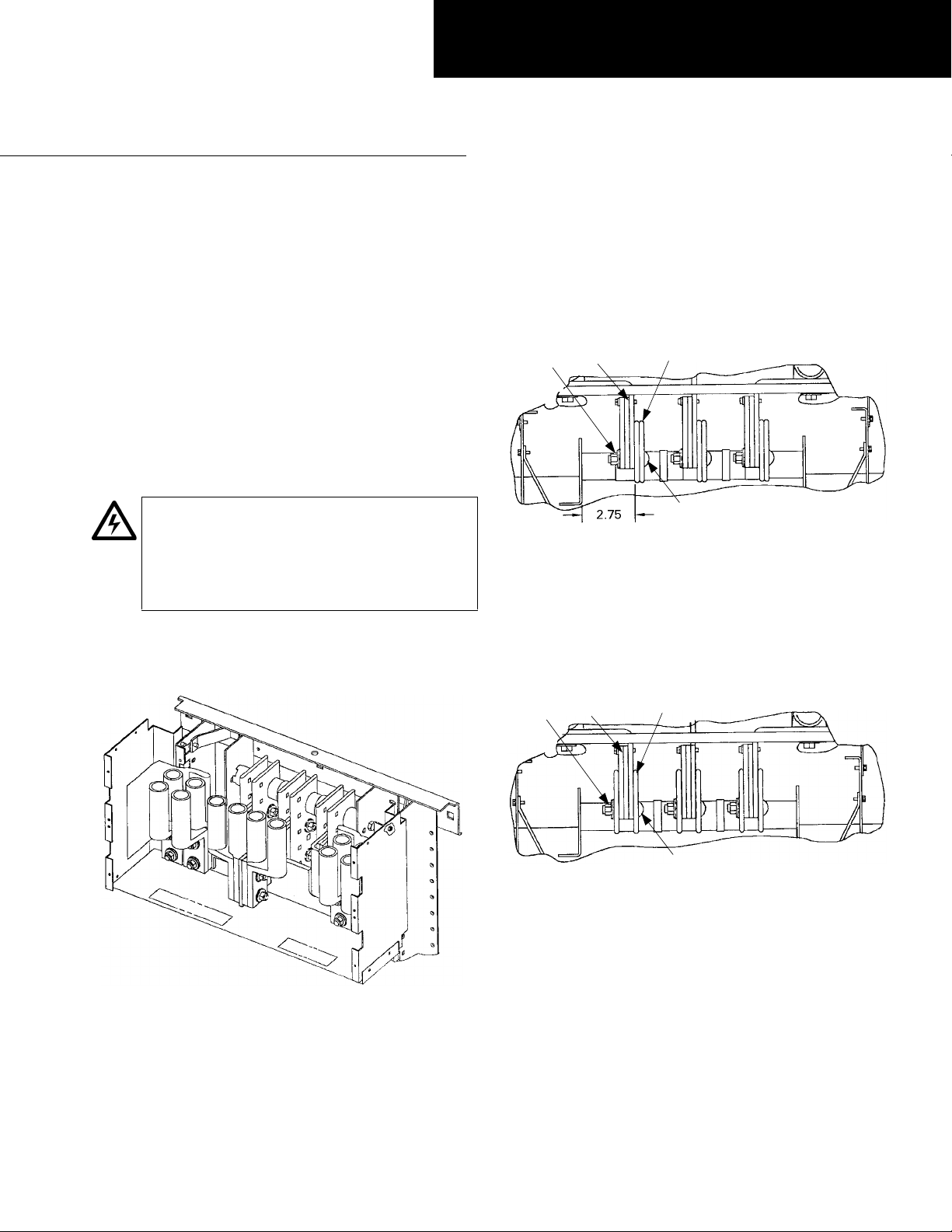

1. Orient the lug base with the lug wire holes facing the

end of the box stamped

the interior, as illustrated in Figure 1.

ower ahead of the panelboard or

inside the

ment or removing any component.

LINE or toward the line side of

Line Side

2. Locate the mounting position. For Spectra APNB bolton style interiors, locate the side of the panelboard

interior in which the dimension from the nearest bus

face to the inner face of the bus support rail is 2.75

inches, as shown in Figure 2. The lug straps will be

mounted on this side of each phase of the bus.

Nut, Flat

Washer,

Conical

Washer

Figure 2. Lug strap positions relative to the bus bars of a Spectra

For Spectra APN plug-in style interiors, the lug straps

are positioned between the buses for each phase, as

shown in Figure 3. For Spectra APN interiors rated at

600 A or less, the lug tangs are positioned as described

above for Spectra APNB interiors.

Nut, Flat

Washer,

Conical

Washer

Lug

Strap

Lug

Strap

Bus

Carriage

Bolt

APNB bolt-on interior.

Bus

Carriage

Bolt

Figure 3. Lug strap positions relative to the bus bars of a Spectra

APN plug-in interior.

Figure 1. Lug assembly orientation.

Page 2

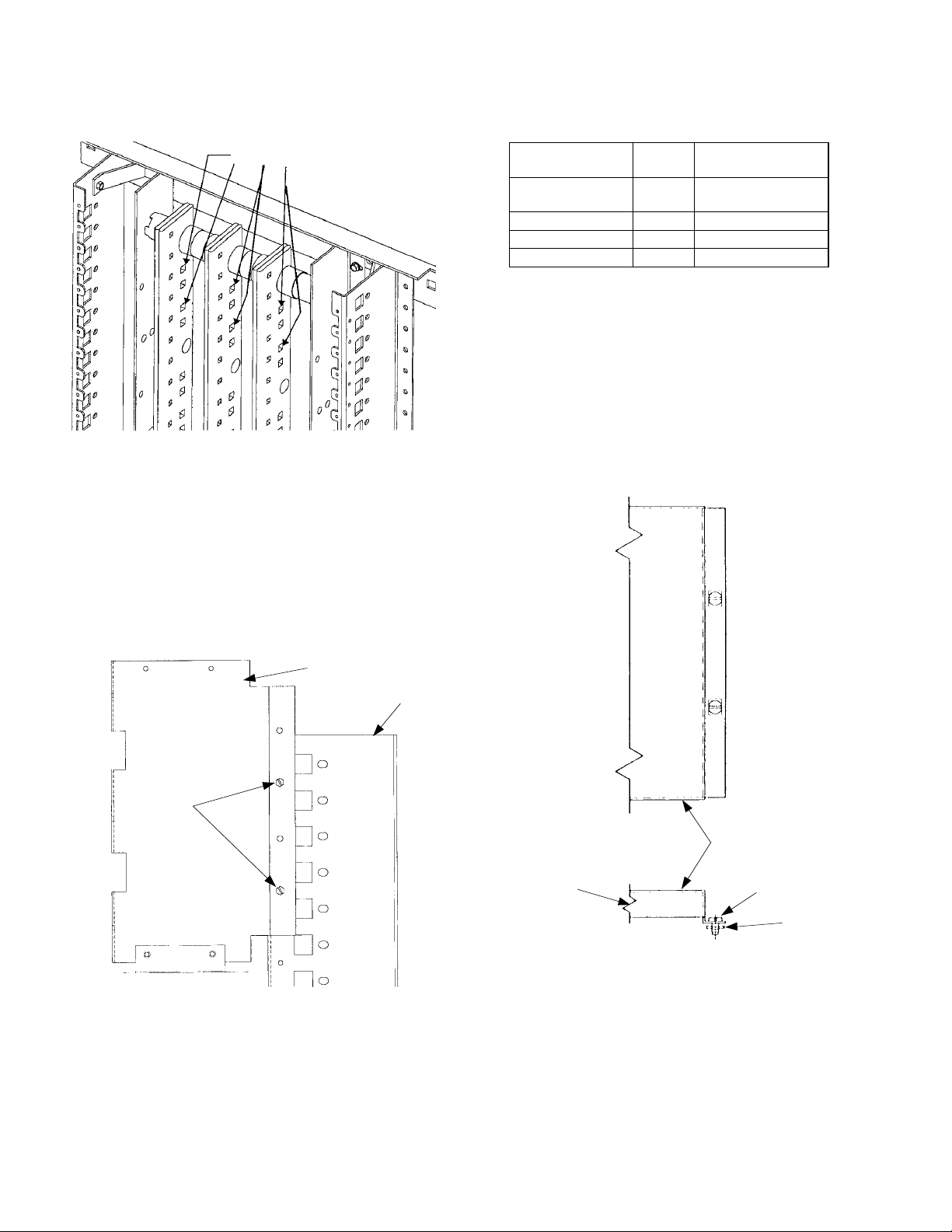

3. Align the mounting holes. Align the lug strap

mounting holes with the first and third bus holes from

the box end stamped

LINE on the rear row of holes, as

shown in Figure 4.

6. Wire the lugs using the conductor sizes and tightening

torques listed in Table 1. If compression lugs are used,

follow the tool and wire information stamped on the

lugs.

Mounting Holes

Figure 4. Bus bar mounting holes.

4. Fasten the lug straps to the bus using a carriage bolt,

flat washer, Belleville washer, and nut, as shown in

Figures 2 and 3. Tighten these bolted connections to

200–250 in.-lb.

5. Install the wire barriers. Position the wire barriers so

that the second and fourth holes from the top of the

wire barrier align with the first and fourth holes of the

panel side rails or Z rails, as shown in Figure 5. Secure

the wire barriers to the panel side rails or Z rails using

the thread-forming screws supplied.

Wire

Barrier

Panel Side

Rail

Torque,

Lug Part No.

252B3638G9–10 375

252B3638G1–2 450 2/0–600 kcmil (4)

252B3638G3–8 450 2/0–600 kcmil (8)

GEA2-750 475 3/0–750 kcmil (2)

in.-lb.

Wire Size

(# of wires)

8–500 kcmil (1)

#2/0–600 kcmil (1)

Table 1. Recommended tightening torque and wire sizes.

7. Install the cover. Lug kits whose catalog numbers have

an F suffix include cover plates. Two covers are

included: one for 36"- and 40"-wide boxes and one for

44"-wide boxes. Choose the appropriate cover for the

box to be used.

Attach the cover to the barriers in four places with the

screws and nut fasteners provided, as shown in Figures

6 and 7. Also use the black spacers for the style of

cover shown in Figure 7. Tighten the screws to 25–30

in.-lb.

Thread-

Forming

Screws

Figure 5. Wire barrier installation.

Barrier

Cover

Screw

Nut

Fastener

Figure 6. Installing the cover.

Page 3

Screw

Black

Spacer

Cover

Nut

Fastener

Figure 7. Installing the cover with black spacers.

Barrier

Page 4

g

These instructions do not cover all details or variations in e

quip

y

p

ma

be met in connection with installation, operation, or maintenance. Should further information be desired or should

articular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

ment nor do they provide for every possible contingency that

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH071 R02 1001 © 2001 General Electric Company

Loading...

Loading...