Page 1

g

p

g

quip

y

DEH223 Installation Instructions R06

Spectra Series™ Power Panelboards &

Switchboard Panels

ATVS Tranquell® Transient-Voltage Surge Suppressors

Application

This kits are provided for installation of ATVS Tranquell

and Tranquell VII transient-voltage surge suppressors in

Spectra bolt-on and plug-in panels and switchboards. The

catalog numbers and descriptions of the available units

are listed in Table 1. The K suffix denotes field-installable

kits. The catalog number for the mounting and cover kit is

ATVSHK.

5

All TVSS units are 7x (9

equipment width is 27-inch wide Spectra panelboard or

35-inch wide Spectra switchboard

Catalog Number

ATVS0501LACSK 480Y/277 3Ø, 4W 50

ATVS0502LACSK 208Y/120 3Ø, 4W 50

ATVS0503LACSK 480 ∆ 3Ø, 3W 50

ATVS0504LACSK 240/120 ∆ 3Ø, 4W 50

ATVS0505LACSK 120/240 1Ø 50

ATVS0801LACSK 480Y/277 3Ø 80

ATVS0802LACSK 208Y/120 3Ø 80

ATVS0803LACSK 480 ∆ 3Ø, 3W 80

ATVS0804LACSK 240/120 ∆ 3Ø, 4W 80

ATVS0805LACSK 120/240 1Ø 80

ATVS1001LACSK 480Y/277 3Ø 100

ATVS1002LACSK 208Y/120 3Ø 100

ATVS1003LACSK 480 ∆ 3Ø, 3W 100

ATVS1004LACSK 240/120 ∆ 3Ø, 4W 100

ATVS1005LACSK 120/240 1Ø 100

ATVS3004WK 480Y/277 3Ø, 4W 100

ATVS3002WK 208Y/120 3Ø, 4W 100

ATVS3004DK 480 ∆ 3Ø, 3W 100

ATVS2002DK 240/120 3Ø, 4W 100

ATVS3002SK 240/120 1Ø, 3W 100

Table 1. Catalog numbers and specifications for Tranquell transient-

Voltage, Vac Configuration

voltage surge suppressor kits.

/8") high and the minimum

System

Surge

Current per

Mode, kA

Installation

WARNING: Danger of electrical shock or injury.

OFF

Turn

switchboard before workin

e

ment or removing any component.

Equipment is to be installed and maintained b

properly trained and qualified personnel only.

The numbers in brackets in the text and circled in the

figures refer to the items in Tables 1 and 2.

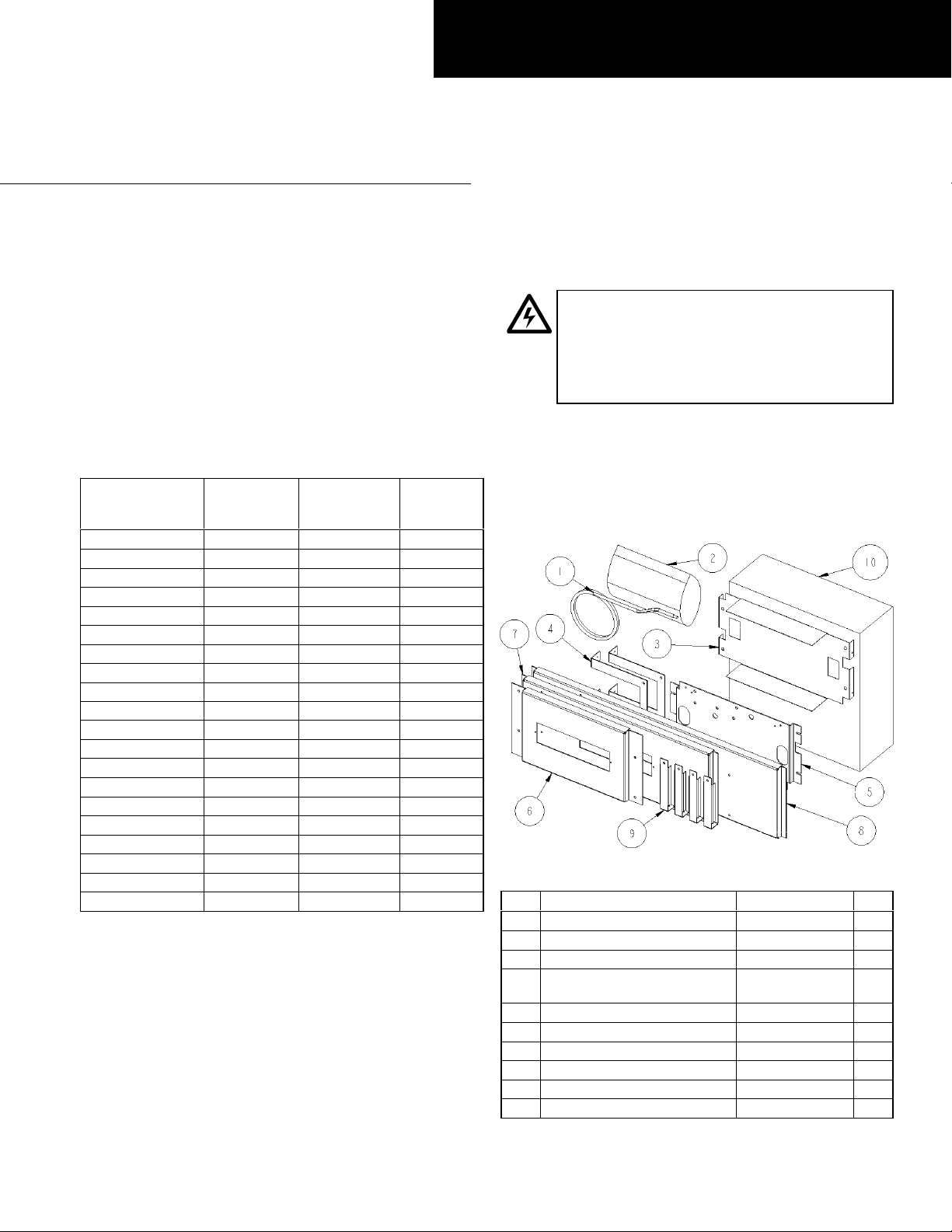

1. Confirm the contents of the kit. Figure 1 illustrates the

contents of the kit, with the parts listed in Table 2.

Figure 2 illustrates the hardware included in the kit

([2] in Table 2), with the parts listed in Table 3.

Figure 1. Typical TVSS kit contents.

Item Description Part # Qty.

1 Cable, #6 stranded 10080819P2 1

2 TVSS kit hardware 10082305G2 1

3 Barrier 10082331P1 1

Cover support for 36W,

4

40W, 44W, 45W

5 Mounting plate 208C4326P1 1

6 Cover for 27W, 31W, 35W 208C4331P1 1

7 Cover for 36W, 40W 208C4331P2 1

8 Cover for 44W, 45W 208C4331P3 1

9 Cover support for 27W, 31W 252B1477P4 4

10 TVSS in package TVSS_UNIT 1

ower ahead of the panelboard or

inside the

10083033P1 2

Table 2. Parts list for TVSS kit.

Page 2

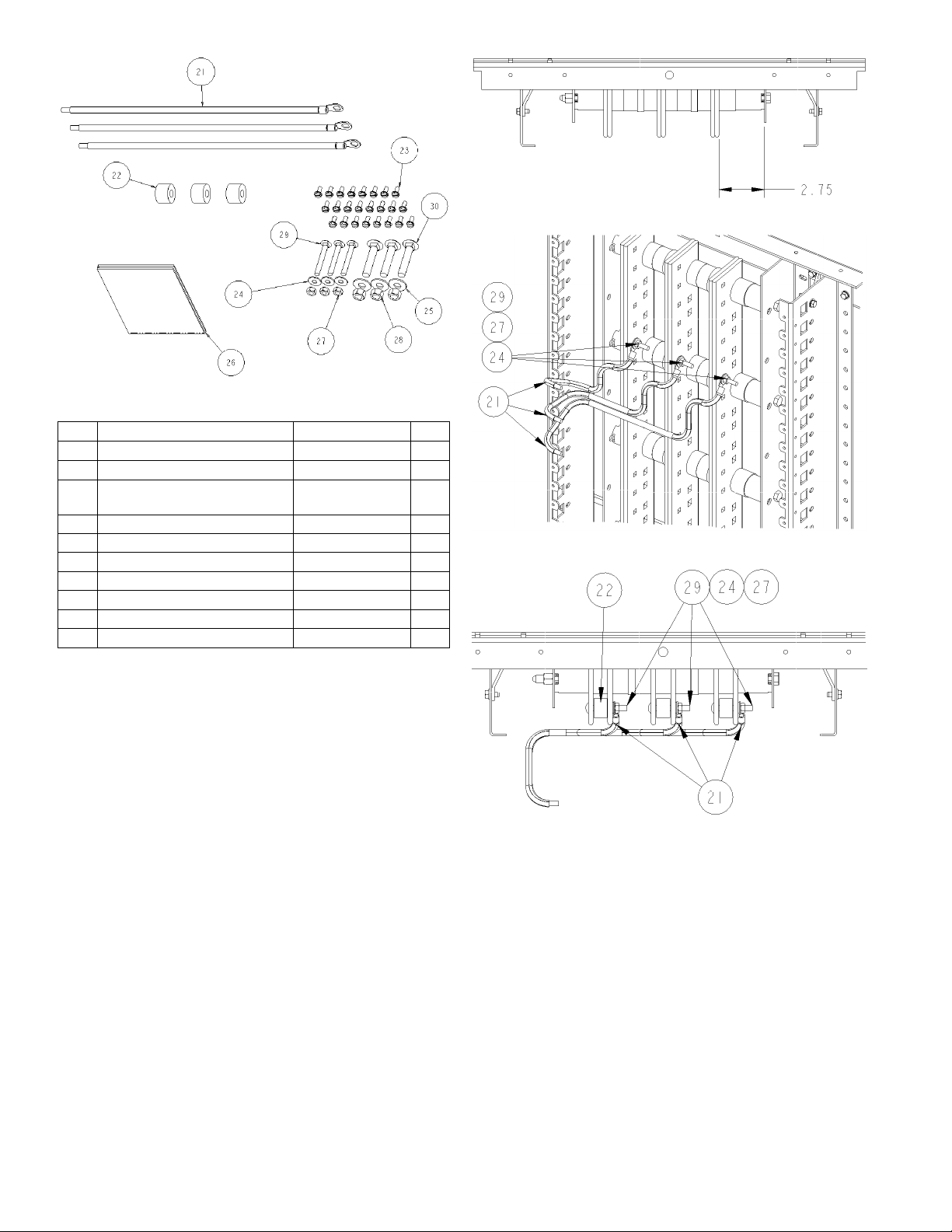

Figure 2. Hardware included in [2].

Item Description Part # Qty.

21 Cable assembly 10080819P2 3

22 Spacer, .70 inch 188A4381P9 3

Thread-forming screw,

23

10-32x

24 Conical spring washer, 1/4" 75A105503P101 3

25 Conical spring washer, 3/8" 75A105503P102 3

26 TVSS instruction sheet DEH223 1

27 Nut, 1/4-20 N245P21B6 3

28 Nut, 3/8-16 N245P25B6 3

29 Carriage bolt, 1/4-20 x 2" N657P21032B6 3

30 Carriage bolt, 3/8-16 x 2" N657P25032B6 3

7

/16"

192A6976P189 24

Table 3. Parts list for the hardware package [2].

Figure 3. Top view of a bolt-on interior.

Figure 4. Bolt-on and single-bus plug-in assemblies.

2. Install TVSS-bus cable assembly. (For connecting a

TVSS to a disconnect, go to step 2.)

• Bolt-on and single bus of plug-in assemblies, switchboard

panels, and powerpanel. Before installing, locate the

side of the panel interior for which the dimension

from the nearest vertical bus face to the inner face

of the bus support rail is 2.75 inches, as indicated

in Figure 3. The cable terminals will be mounted

on this side of the bus.

1

For each phase install a

/4-20 x 2" carriage bolt

[29] into a .281-inch square hole of the interior

vertical bus, as shown in Figure 4. Use the

5

uppermost holes in the 7X (9

/8") space that the

TVSS unit can reach. Slide a terminal of the cable

assembly [21] onto each carriage bolt and rotate it

so that the terminal barrel is located below the front

1

edge of the vertical bus. Install a

1

[24] and a

/4-20 nut [27] onto each bolt and

/4" spring washer

tighten to 75 in-lb.

• Plug-in assemblies, switchboard panels, and panelboards

with .281-inch square holes available (double bus). For

each phase, slide a spacer [22] between the vertical

1

bus bars and install a

/4-20 x 2" carriage bolt [29]

into a .281-inch square hole located towards the

front of interior vertical bus, as shown in Figure 5.

5

Use the uppermost holes in the 7X (9

/8") space

that the TVSS unit can reach.

Figure 5. Plug-in assemblies with .281-inch square holes.

Slide a terminal of the cable assembly [21] onto

each carriage bolt and rotate it so that the terminal

barrel is located below the front edge of the vertical

1

bus. Install a

/4" spring washer [24] and a 1/4-20

nut [27] onto each bolt and tighten to 75 in-lb.

• Plug-in assemblies and powerpanels without .281-inch

square holes (double bus). For each phase, slide a

spacer [22] between the vertical bus bars and

3

install a

/8-16 x 2" carriage bolt [30] into a .406inch square hole located towards the rear of

interior vertical bus, as shown in Figure 6. Use the

5

uppermost holes in the 7X (9

/8") space that the

TVSS unit can reach. Slide a terminal of the cable

assembly [21] onto each carriage bolt. Install a

3

spring washer [25] and a

/8-16 nut [28] onto each

3

/8"

bolt and tighten to 200 in-lb.

2

Page 3

Figure 6. Plug-in assemblies without .281-inch square holes. (Interior

spools are not shown for clarity.)

3. Install barrier. Route the cable assemblies through the

rectangular holes in the barrier [3]. Secure the barrier

7

to the side of the “Z” rail with 10-32x

/16" threadforming screws [23], as shown in Figure 7 and tighten

to 22 in-lb.

4. Mounting plate. Route the cable assemblies through

the oblong slot in the mounting plate [5]. Secure the

mounting plate to the interior “Z” rail with

7

10-32x

/16" thread-forming screws [23], as shown in

Figure 8 and tighten to 22 in-lb.

5. Mount the TVSS unit. Remove the two screws securing

the plastic cover to the TVSS unit and lift off the

cover. Save the screws for later reinstallation. Mount

7

the unit to the mounting plate with six 10-32x

/16"

thread-forming screws [23] and tighten to 22 in-lb.

6. Make cable connections to the TVSS. Trim the cable

assemblies to the minimum required and strip

1

/2

inch from the end of the cable. Connect the cable

assemblies to the lugs provided in the TVSS unit and

tighten the lug screws to 110 in-lb. Insure that the A

location is connected to the top lug, the B location (if

required) to the middle lug, and the C location to the

bottom lug, as shown in Figure 9.

a. Install ground (and neutral cable if required).

Measure the length required for the ground and

1

neutral cables and cut from the cable [1]. Strip

/2

inch from the end of the cable and connect to the

TVSS ground and neutral lugs and panel lugs, as

shown in Figure 9. Tighten the lug screws to 110

in-lb. Reinstall the plastic cover on the TVSS.

b. Install the cable connections from the circuit

breaker to the TVSS. Trim the cable [21] to the

length required and strip the ends as required.

Connect the cable to the appropriate connection

points on the circuit breaker and the TVSS, as

shown in Figure 10. Install the ground and neutral

cables as in step a. above.

Figure 7. Barrier installation.

Figure 8. Mounting plate installation.

Figure 9. Installing the cable connections to the TVSS.

3

Page 4

Figure 10. TVSS with a circuit breaker disconnect.

7. Install the TVSS monitor plate to the filler plate.

Mount the monitor plate, provided with the TVSS, to

the cover plate [6, 7, or 8], as shown in Figure 11.

Secure with two 10-32x

7

/16" thread-forming screws

[23] and tighten to 22 in-lb.

8. Install the filler supports. For 27W, 31W, and 35W

panels, mount four filler supports [9] to the Z rail of

the vertical bus interior, as shown in Figure 12. For

36W, 40W, 44W, and 45W panels, mount two filler

supports [4] to the Z rail, as shown in Figure 13.

7

Secure the supports with 10-32x

/16" thread-forming

screws [23] and tighten to 22 in-lb.

9. Install the filler plate assembly. Plug the cable harness

into the TVSS and monitor panel. Mount the filler

plate assembly to the filler supports, as shown in

Figure 14. Secure with four 10-32x

7

/16" thread-

forming screws [23] and tighten to 22 in-lb.

Figure 11. TVSS monitor plate mounted to the cover.

Figure 12. Filler supports for 27 and 31 wide panelboard or 35 wide

switchboard.

Figure 13. Filler supports for 36, 40, and 44 wide panelboard or 40

and 45 wide switchboard.

4

Page 5

Figure 14. Mounting the filler plate assembly on the supports.

5

Page 6

g

These instructions do not cover all details or variations in equipment nor do they provide for every possible

g

p

contin

information be desired or should

purposes, the matter should be referred to the GE Company.

ency that may be met in connection with installation, operation, or maintenance. Should further

articular problems arise that are not covered sufficiently for the purchaser’s

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH223 R06 0501 © 2001 General Electric Company

Loading...

Loading...