GE Industrial Solutions Spectra Series Power Panelboards 30–200 Ampere Fusible Switch User Manual

Page 1

g

p

g

quip

p

y

p

GEH5548 Installation Instructions R02

Spectra Series™ Power Panelboards

30–200 Ampere Fusible Switch

WARNING: Danger of electrical shock or injury.

OFF

Turn

switchboard before workin

ment or removing any component. Do

e

not remove circuit

other component until the power is turned

OFF.

ower ahead of the panelboard or

inside the

rotective devices or an

General

To comply with the National Electrical Code and

Underwriters Laboratories, the Canadian Electrical Code

and the Canadian Standards Association, the load center

must be installed in accordance with the information

included on the label on the inside of the equipment.

This must also be done in accordance with the applicable

local electrical codes and by a qualified electrical

contractor or licensed electrician.

WARNING: Hazard of electrical shock or burn.

Turn off

before working inside.

ower supplying this equipment

Installation

Use the following instructions to install a 30–200 ampere

fusible switch.

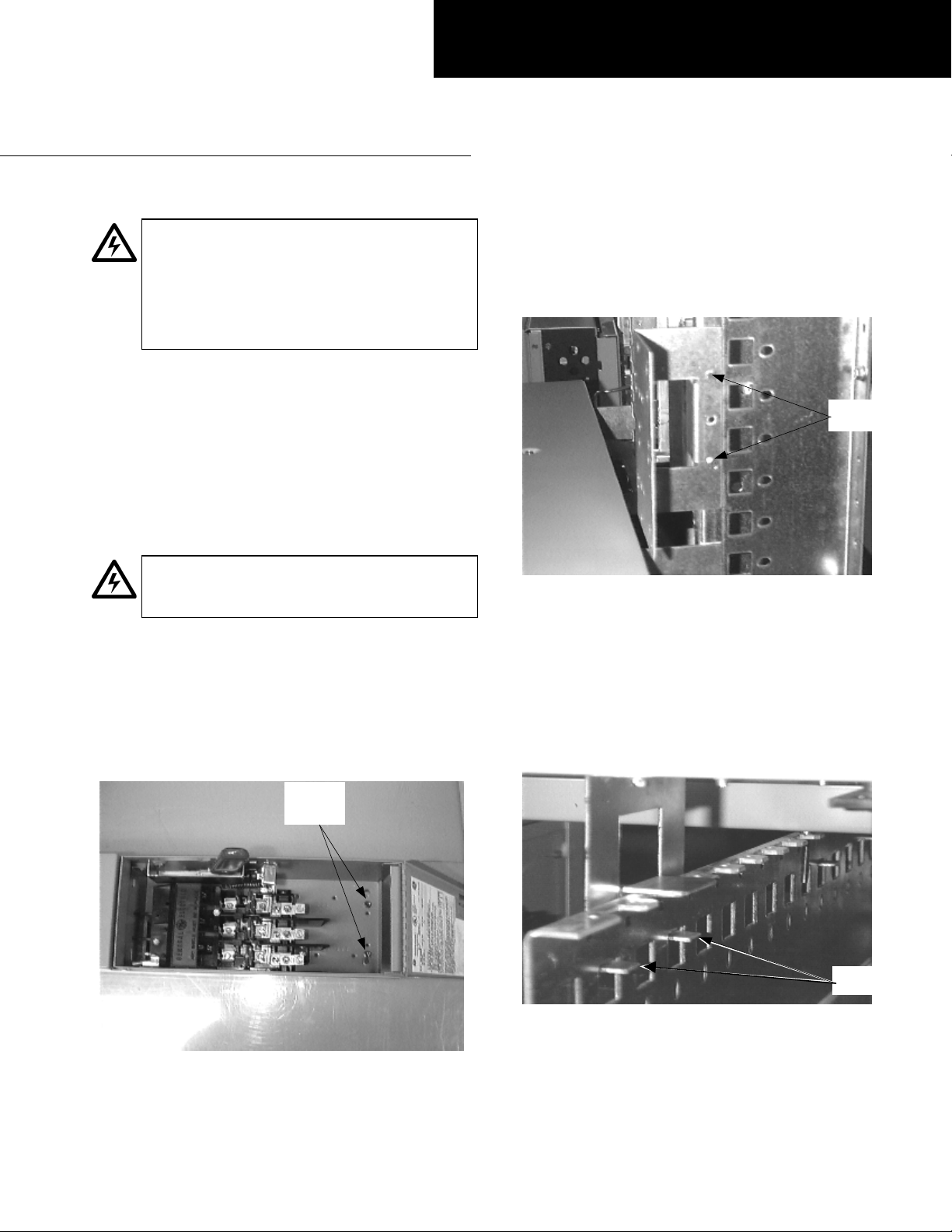

1. Remove the mounting bracket. Remove the two screws

shown in Figure 1 and remove the mounting bracket

from the switch.

2. Mount the removable mounting bracket. Install the

mounting bracket (removed from the switch in step 1)

on the power panelboard with the two self-tapping

screws provided, as shown in Figure 2. Tighten the

screws to 27–32 in-lb.

Mounting

Screws

Figure 2. Installing the mounting bracket in the panelboard.

3. Install the switch. Align the locating hook tabs on the

bottom of the switch into the square holes in the

support rails on the panelboard interior, as shown in

Figure 3. Open the switch door and reattach the

screws removed in step 1 to the mounting bracket

installed on the panel in step 2. Tighten the screws to

27–32 in-lb.

Mounting

Bracket

Screws

Figure 1. Removing the mounting bracket from the switch.

Locating

Tabs

Figure 3. Switch locating tabs aligned in the panelboard interior.

Page 2

4. Wire the circuits. Refer to the label inside for the

g

quip

y

p

switch cover for the proper tightening torques.

5. Filler plates. Install filler plates in all unused spaces

from the filler kits included with the switch. Order

replacement filler plates from the list in Table 1.

Current,

A Voltage

30 240/600 H, J, K, R 26 AFP4X

60

100 240/600

200 240/600

240 H, K, R AFP4X

600 H, J, K, R

Fuse

Type

H, J, K, R AFP5X

T, J 26 AFP7T

H, J, K, R 26 AFP7X

H, K, R 32 AFP7X2

T

Switch Encl.

Width, in.

26

26

Filler Kit

Cat. No.

AFP5X

AFP7T

Table 1. Replacement filler plate kits.

Procedure for Aluminum Terminations

1. Strip the insulation, being careful to not nick the wire.

2. Clean the wire strands with a wire brush.

3. Thoroughly coat the stripped conductor with a

suitable antioxidant compound, such as ALNOX or

PENETROX A13.

4. Insert the conductor and tighten the connector screw

to the torque indicated on the rating label.

For Two-Pole Devices on Three-Phase

Systems Only

To balance the panelboard load, remove the screws on the

appropriate bus clip, reposition the bus clip as shown in

Figure 8, then reinstall and tighten the screws to 27–32 inlb.

A & C Phase

As Received

A & B Phase

B & C Phase

Figure 4. Repositioning the bus clip to balance the load.

These instructions do not cover all details or variations in e

ma

be met in connection with installation, operation, or maintenance. Should further information be desired or should

articular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

ment nor do they provide for every possible contingency that

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

GEH5548 R02 0901 © 2001 General Electric Company

Loading...

Loading...