Page 1

DEH-40467

Installation Instruction for Cable

Operator Mechanisms for SE150,

RMS™ Circuit Breakers

g

SF250, SG600 & SK1200 Spectra

Type SRCM1EF, SRCM1G, SRCM1K, Cable Operated Mechanism Assemblies,

Cable Series SC3L-SC10L, SC3H-SC10H and GEPC Rotary Handles PB769780A,

PB769580A, and PB769380A.

General

General Electric Cable Operating Mechanisms are suitable

for application with GE circuit breakers mounted in a wide

variety of enclosure types and sizes.

The cable-operated mechanism can be directly mounted

inside the enclosure door and does not involve any

mounting interface with the enclosure. Standard mounting

screws for tapped holes are furnished with each mechanism

to mount the Interface Mechanism onto the enclosure door.

The cable-operated assembly is combined with one of eight

operating cables, with lengths from 3 to 10 feet, to cover a

broad range of breaker mounting locations in the

enclosure. The cable links the interface assembly to the

breaker-mounted operating mechanism and transmits the

mechanical force and motion of the handle mechanism to

the breaker-mounted mechanism. The force and motion of

cable operated mechanism is transmitted independent of

the breaker-mounting plane or location, relative to the

location of the handle assembly provided, only that the

bending radius of the cable is no less than 3 inches.

Table 1. Mechanism Selection Guide

Circuit

Breaker

Type

SE150

SF250

SG600 PB769580A SCOM1G

SK1200

Examine Table 1 below to ensure that the handle assembly,

cable, interface mechanism and breaker operating

GEPC

Rotary

Handle

PB769380A SCOM1EF SRCM1EF

PB769780A

Breaker

Operating

Mechanism

SCOM1K GEH-6291

Breaker Face

Mechanism

Installation

Instruction

GEH-6290 SC3L-SC10L

mechanism you have are correct for the job. Use Table 2 to

ensure that the cable is long enough to reach the breaker

and that the 3-inch minimum bending radius requirement

is not violated.

Installation of the handle assembly onto the enclosure door

can be performed independently from installation of the

cable-operated mechanism on to the enclosure door,

breaker-operating mechanism onto the circuit breaker and

from installation of the circuit breaker in the enclosure.

Installation of the cable between the interface mechanism

assembly and the breaker mechanism should be the final

step. The breaker operating mechanism is to be installed

onto the circuit breaker after the breaker has been mounted

in the enclosure.

Operating

Cable

Cat.No.Series

SC3H-SC10H

Handle Installation:

1

Mechanism

Cable

Operated

SRCM1G

SRCM1K

Cable Operated

Mechanism

Installation

Instruction

DEH-40467

Page 2

oles as per the instructions given in GEPC rotary

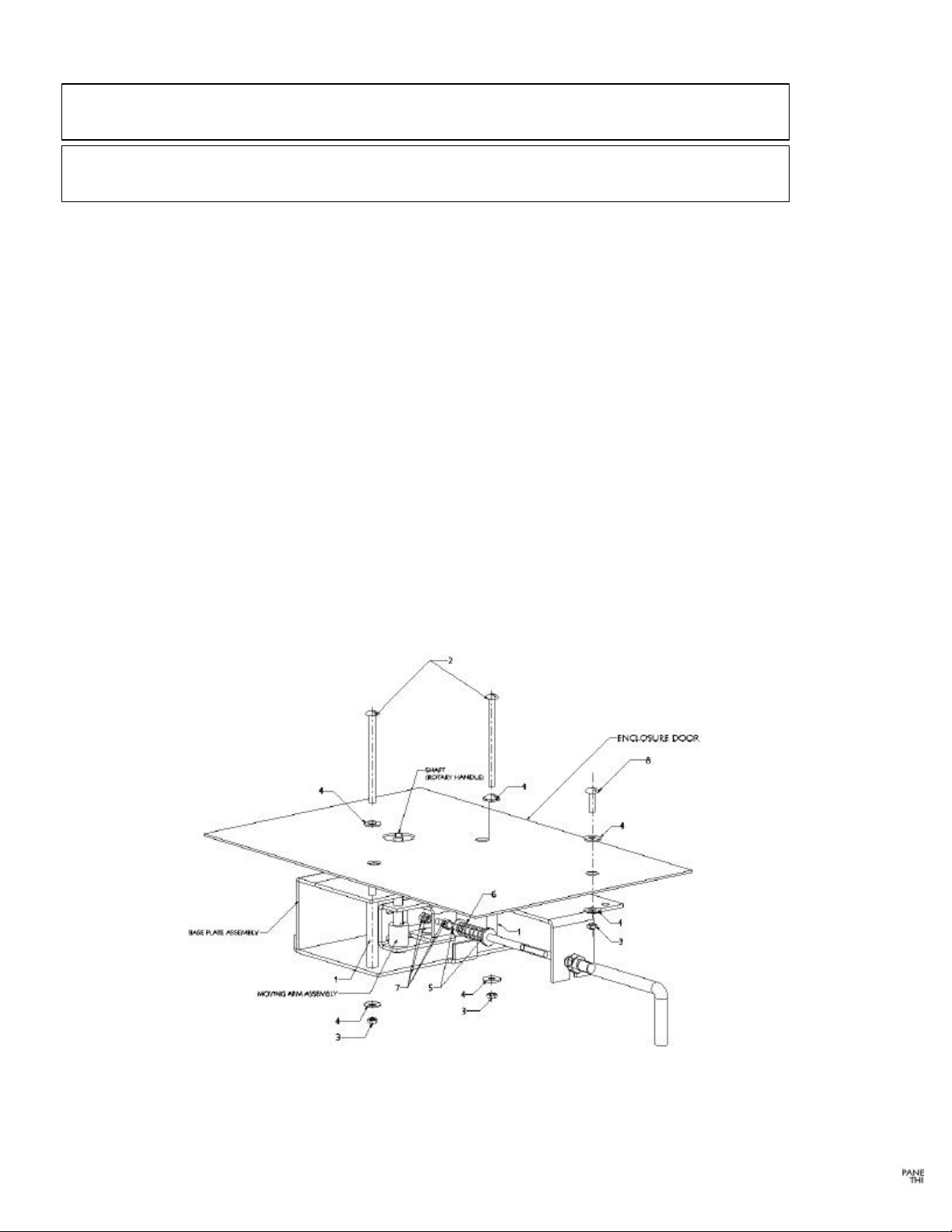

Locate and orient the moving arm assembly on the base plate assembly diameter 0.25 hole as shown in the Figures

end with (driver part) moving arm assembly as shown in Figure1 and

assemble the other end of the shaft to the rotary handle. (Keep the rotary handle in off position while doing the

Position the cable operated interface mechanism below the enclosure door and locate with the drilled holes as per

24 screws (item 2 and item 8), nuts (item 3) &

that must be met are:

WARNING: Before installing any accessories, turn the breaker off, disconnect it from all voltage sources

and discharge the closing springs.

A VERTISSEMENT: Avant d’installer tout accessoire, mettre le disjoncteur en position OFF, le

d’econnecter de toute tension d’alimentation, et d’echarger les resorts d’armement.

Cable Operated Interface Mechanism installation To Enclosure Door

1. Assemble GEPC rotary handle to the enclosure door through the h

handle instruction sheet.

2.

1, Figure 4, and Figure 5.

3. Assemble the GEPC rotary handle shaft one

shaft assembly and follow the GEPC rotary handle instruction sheet for more details on shaft assembly).

4.

the Figure 3.

5. Place and locate the spacer (item1), with base plate assembly holes of ¼ inch diameter & holes in enclosure door.

6. Install the cable-operated mechanism to the enclosure door with #12washers (item 4). Tighten the screws to 30-35 in-lb.

7. Refer Table 5 for hardware details.

Figure 1. Cable Operated Interface

Mechanism Installation to Enclosure Door.

The location of the enclosure face mounted SCRM

2

mechanism/handle with respect to the circuit breaker

mounting location is NOT fixed. The only requirements

Page 3

Table 2. Approximate Breaker Mounting Zone zone

To determine maximum mounting dimensions for

ing cables,

inch

cable maximum dimensions. (For example, add 12

inch cable

Figure 2. Shaft Length

Table 3. Shaft Length

Panel

Board

Thickness

(Inches) S/E ,S/F S/G S/K

0.075 3.0 3.0 3.0

0.125 3.0 3.0 3.0

0.1968 3.12 3.12 3.12

Shaft Length (Y)

Maximum Dimensions in Inches

Enclosure

Depth

8 13.5 4.0 15.0 25.5 16.0 27.0

10 13.0 5.0 14.8 25.0 17.0 26.8

12 12.8 6.0 14.5 24.8 17.0 26.5

16 10.5 4.5 14.2 22.5 16.5 26.2

18 8.5 3.5 12.6 20.5 15.5 24.6

20 — 0.5 10.0 22.0 15.0 24.0

24 — — — 19.5 14.0 22.0

* Maximum E dimension only if F = 4.5”.

60-inch through 120-inch-long operat

add the respective additional lengths to the 48-

E* F G E* F G

36” Cable 48” Cable

Figure 3. Drilling Diagram

Table 4. Drilling Diagram

X Y Z

SE & SF

SG 1.00 7.27 3.46

SK 0.54 9.02 4.60

0.82 7.13 3.06

inches to E, F, and G dimensions for 60length.)

3

Page 4

toute tension d’alimentation, et d’echarger les ressorts

d’armement.

Figure 4. Cable Installation – SE, SF, and SG.

Cable Installation-SE, SF, SG

WARNING: Before installing any accessories, turn the

breaker off, disconnect it from all voltage sources, and

discharge the closing springs.

A VERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjoncteur en position OFF, le d’econnecter de

Use the following procedure to first install one end of the

operating cable to the interface mechanism, then the other

end to the breaker operating mechanism.

1. Slide a 7/16-20 hex nut onto the end of the cable with

the #10-32 x 7/8" thread. Install the nut onto the

threaded cable shank beyond the groove at the middle

of the shank. Install a 7/16" lock washer onto the hex

nut. Do not tighten.

2. Place the operating handle in the OFF position. Slide

a washer, a spring, a second washer, and thread two

#10-32 hex nuts on #10-32 x 7/8” thread. Ensure the

spring is between two washers. Set the nuts to 3/8

inches (SE, and SF) and 7/16 inches for SG onto the

thread end of the cable as shown in Figure 4. Rotate

the pivot bracket into position as shown in Figure 1 &

Figure 4. Insert the end of the cable through the pivot

bracket, thread two #10-32 hex nuts and tighten until

it is snug. Insert the groove of the cable into the slot on

the base plate. Tighten the 7/16" hex nut against the

cable operating mechanism base plate assembly until

it is snug.

3. Slide a 7/16-20 hex nut over the cable end with the

#10-32 x 3" thread. Install the nut onto the threaded

cable shank beyond the groove at the middle of the

shank. Install a 7/16" lock washer onto the hex nut.

Thread two #10-32 hex nuts approximately 23/4” onto

the threaded end of the cable. Rotate the pivot bracket

into position, as shown in Figure 4, and insert the end

of the cable through the pivot bracket. Insert the

groove of the cable into the slot on the base plate.

Tighten the 7/16-20 hex nut against the base plate

flange until snug. With the breaker in the OFF

position, move the #10-32 hex nut up on the cable

shaft against the pivot bracket. Note the position of the

pivot bracket in Figure 4.

4. Verify that the power to the circuit breaker has been

turned off. Move the operating handle on the circuit

breaker to the ON position. Place the spring over the

cable end. Thread the spring retainer onto the end of

the cable and tighten to the installed height of 17/16".

Do not over tighten the retainer.

5. Move the operating handle ON and then OFF. If the

breaker does not turn ON, then, with the handle in the

OFF position, adjust the #10-32 hex nut toward the

pivot bracket until the breaker turns ON.

6. Trip the circuit breaker by pushing the TRIP button.

Move the operating handle to the OFF/RESET

position, then to ON. If the breaker reset, lock both

#10-32 hex nuts against the pivot bracket. If the

breaker does not reset, adjust the # 10-32 hex nut away

from the pivot bracket until the breaker resets.

4

Page 5

cable shank beyond the groove at the middle of the

shank. Install a 5/8” lock washer onto the hex nut.

28” hex nuts approximately 2 ¾”

onto the threaded end of the cable. Rotate the pivot

cket into position, as shown in Figure 5, and insert

the end of the cable through the pivot bracket. Insert

the groove of the cable into the slot on the base plate.

18” hex nut against the base plate

n the off

28” hex nut upon the cable

shaft against the pivot bracket. Note the position of

rcuit

breaker to the ON position. Place the spring over the

cable end. Thread the spring retainer onto the end of

the cable and tighten to the installed height of 3

Breaker does not turn ON, then, with the handle in

28” hex nut toward

From the pivot bracket until the breaker resets.

toute

d’armement.

Figure 5. Cable Installation- SK.

Cable Installation -SK

WARNING: Before installing any accessories, turn the

breaker off, disconnect it from all voltage sources, and

discharge the closing springs.

A VERTISSEMENT: Avant d’installer tout accessoire,

mettre le disjonctur en position OFF, le d’econnecter de

tension d’alimentation, et d’echarger les ressorts

Use the following procedure to first install one end of the

operating cable to the interface mechanism, then the other

end to the breaker operating mechanism.

1. Slide a 5/8-18” hex nut onto the end of the cable with

the #1/4-28 x 1” thread. Install the nut onto the

threaded cable shank beyond the groove at the middle

of the shank. Install a 5/8” lock washer onto the hex

nut. Do not tighten.

2. Place the operating handle in the OFF position. Slide a

washer, a spring, a second washer, and thread two #1/428 hex nuts on #1/4-28 x 1” thread. Ensure the spring

in between the two washers. Set the nuts to 7/16 inches

onto the threaded end of the cable as shown in figure 5.

Rotate the pivot bracket into position as shown in

Figure 1 & Figure 5. Insert the end of the cable through

the pivot bracket, thread two #1/4-28 nuts, and tighten

until it is snug. Insert the groove of the cable into the

slot on the base plate. Tighten the 5/8-18" hex nut

against the cable operating mechanism base plate

assembly until it is snug.

3. Slide a 5/8-18” hex nut over the cable end with the

#1/4-28” thread. Install the nut onto the threaded

Thread two #1/4bra

Tighten the 5/8flange until snug. With the breaker i

position, move the #1/4-

the pivot bracket in Figure 5.

4. Verify that the power to the circuit breaker has been

Turned off. Move the operating handle on the ci

5/16”. Do not over tighten the retainer.

5. Move the operating handle ON and then OFF. If the

the OFF position, adjust the #1/4-

the pivot bracket until the breaker turns ON.

6. Trip the circuit breaker by pushing the TRIP button

Move the operating handle to the OFF/RESET

Position, then to ON. If the breaker reset, lock both

#1/4-28” hex nuts against the pivot bracket. If the

Breaker does not reset, adjust the # ¼-28 hex nut away

5

Page 6

6

E

CATALOGU

NO.

SRCM1EF

SRCM1G

S.NO. PART NO. NAME OF THE PART QTY/ASSY. Breaker

1 10087146P1 Steel pipe 2

2 N66P19056B #12-24 x 3 ½” Steel Screws 2

3 N210P19B6 # 12-24 Nut 3

4 N402P10B6 Washer, Steel Plate 6

5 N402P40B6 Washer 2

6 10086816P1 Compression Spring 1

7

8 N37P19012B6 #12-24 x 3/4” Steel Screw 1

1 10087146P2 Steel pipe 2

2 N66P19056B #12-24 x 3 ½” Steel Screws 2

3 N210P19B6 #12-24 Nut 3

4 N402P10B6 Washer, Steel Plate 6

5 N402P40B6 Washer 2

6 10086816P1 Compression Spring 1

7 10087374P1 #10-32 Hex Nut (Cable) 4

8 N37P19012B6 #12-24 x 3/4” Steel Screw 1

1 10087146P2 Steel pipe 2

2 N66P19056B 12-24 x 3 ½” Steel Screws 2

Table 5. Hardware Details

SE150/ SF250

10087374P1 #10-32 Hex Nut (Cable) 4

SG600

3 N210P19B6 #12-24 Nut 3

SRCM1K

These instructions do not cover all details or variations in equipment nor do they provide for every possible

contingency that may be met in connection with installation, operation, or maintenance. Should further

information be desired or should particular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the GE Company.

g

4 N402P10B6 Washer, Steel Plate 6

5 N402P41B6 Washer 2

6 10086816P2 Compression Spring 1

7 10087374P2 Hex Thin Jam Nut (Cable) 4

8 N37P19012B6 #12-24 x 3/4” Steel Screw 1

SK1200

GE Industrial Systems

General Electric Company

41 Woodford Ave., Plainville, CT 06062

DEH-40467 R02 0198© 2001 General Electric Company

Loading...

Loading...