GE Industrial Solutions Spectra II Series Plug-in and Feeder Busway with BlueCoat Epoxy Insulation System User Manual

Page 1

GE Energy

Industrial Solutions

Spectra and Spectra II Series™

Plug-in and Feeder Busway

With BlueCoat® Epoxy Insulation System

DEH-40087

Installation and Maintenance Instructions

i

Page 2

WARNINGS, CAUTIONS AND NOTES AS USED IN THIS PUBLICATION

WARNINGS

Warning notices are used in this publication to emphasize that hazardous voltages, currents, or other

conditions that could cause personal injury are present in this equipment or may be associated with its

use.

Warning notices are also used for situations in which inattention or lack of equipment knowledge could

cause either personal injury or damage to equipment.

CAUTIONS

Caution notices are used for situations in which equipment might be damaged if care is not taken.

NOTES

Notes call attention to information that is especially significant to understanding and operating the

equipment.

This document is based on information available at the time of its publication. While efforts have been

made to ensure accuracy, the information contained herein does not cover all details or variations in

hardware, nor does it provide for every possible contingency in connection with installation, operation,

and maintenance. Features may be described herein that are not present in all busway systems. GE

Consumer & Industrial assumes no obligation of notice to holders of this document with respect to

changes subsequently made.

GE Energy makes no representation or warranty, expressed, implied, or statutory, with respect to, and

assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of the information

contained herein. No warrantees of merchantability or fitness for purpose shall apply.

To request a busway installation video or to ask questions about your installation, contact the GE

factory at (731) 645-6121.

The following are trademarks of GE Company: Spectra Series™, Spectra RMS™, BlueCoat®, Weathershield™, Joint-Guard™,

Spectra II™

© 2007 GE Company

All Rights Reserved

ii

Page 3

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Table of Contents

Contents

Installing Spectra Series Busway ............................................................... 3

Storage Precautions ......................................................................... 3

Pre-Installation Procedure ............................................................. 3

Installation of Spectra Series Busway ....................................... 3

Installing Indoor Busway ............................................................................... 5

Horizontal Mounting ......................................................................... 5

Vertical Mounting ............................................................................... 5

Joining Lengths ................................................................................... 8

Expansion Lengths ............................................................................ 9

Busway Field Check Pieces and Replacement Pieces ..... 10

Installing an End Box ...................................................................... 10

Installing and Removing Busway Plugs ................................................ 11

Installing a Plug Not Equiped with Plug-Assist.................... 12

Installing a Plug Equipped with Plug-Assist .......................... 12

Removing a Plug ............................................................................... 12

Installing Dripproof, Splashproof, and Outdoor Busway ............... 14

Installation Tips ................................................................................. 15

Installing an End Box ...................................................................... 18

Installing Spectra II Series Busway .......................................................... 21

Horizontal Mounting ....................................................................... 21

Vertical Mounting ............................................................................. 21

Installing an End Box ...................................................................... 22

Joining Lengths ................................................................................. 22

Remove the Joint or Captive Piece of Busway.................... 23

Busway Plugs ..................................................................................... 25

Busway Maintenance Procedures ........................................................... 26

Protecting the Busway from Contamination ....................... 26

Maintenance Procedures ............................................................. 26

Inspecting the Busway .................................................................. 26

Inspecting Current-Carrying Components ........................... 26

Busway Installation Checklist .................................................................... 28

1

Page 4

Spectra and Spectra II Series™ Plug-In and Feeder Busway

List of Figures and Tables

Figures

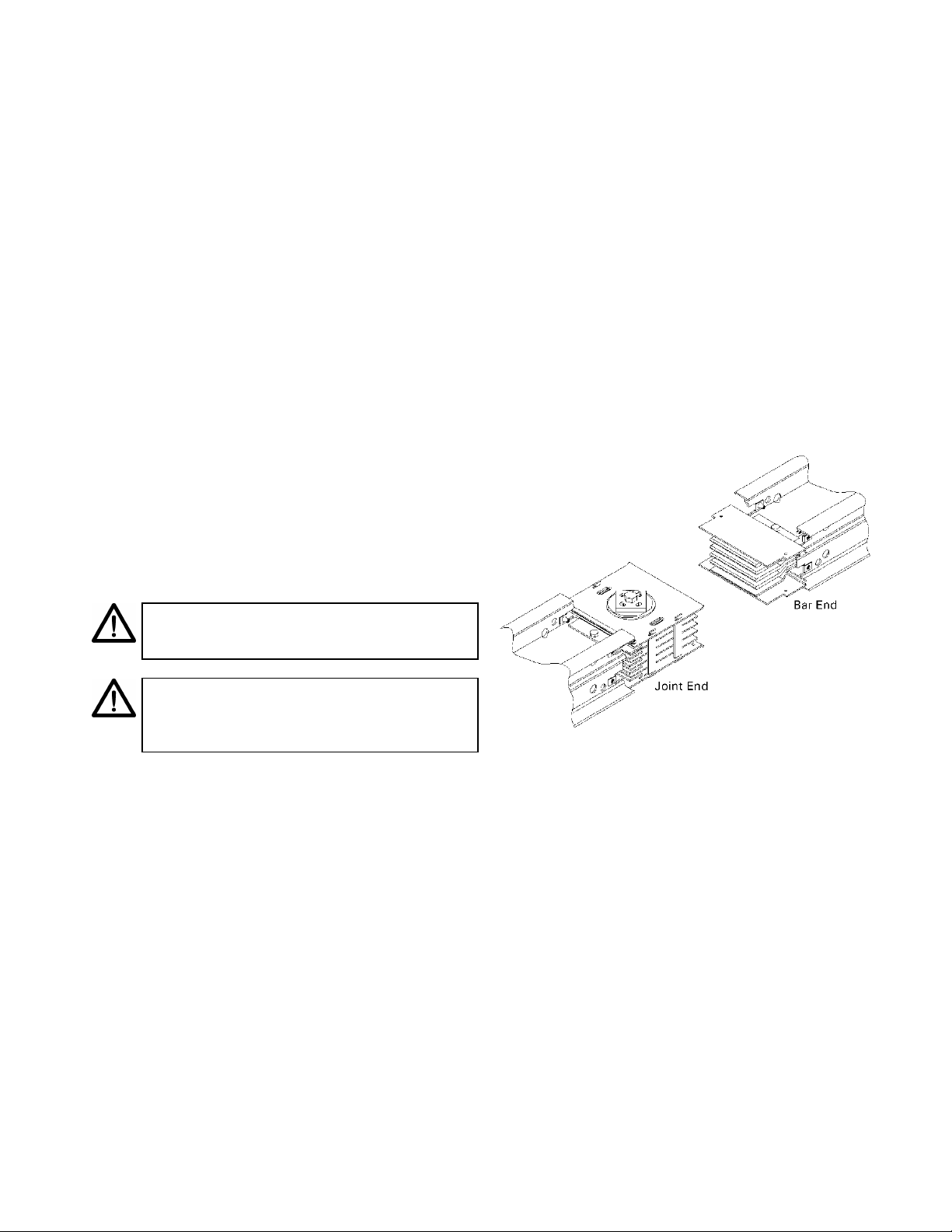

1. The bar end and joint end of the busway .................................................................................................................. 3

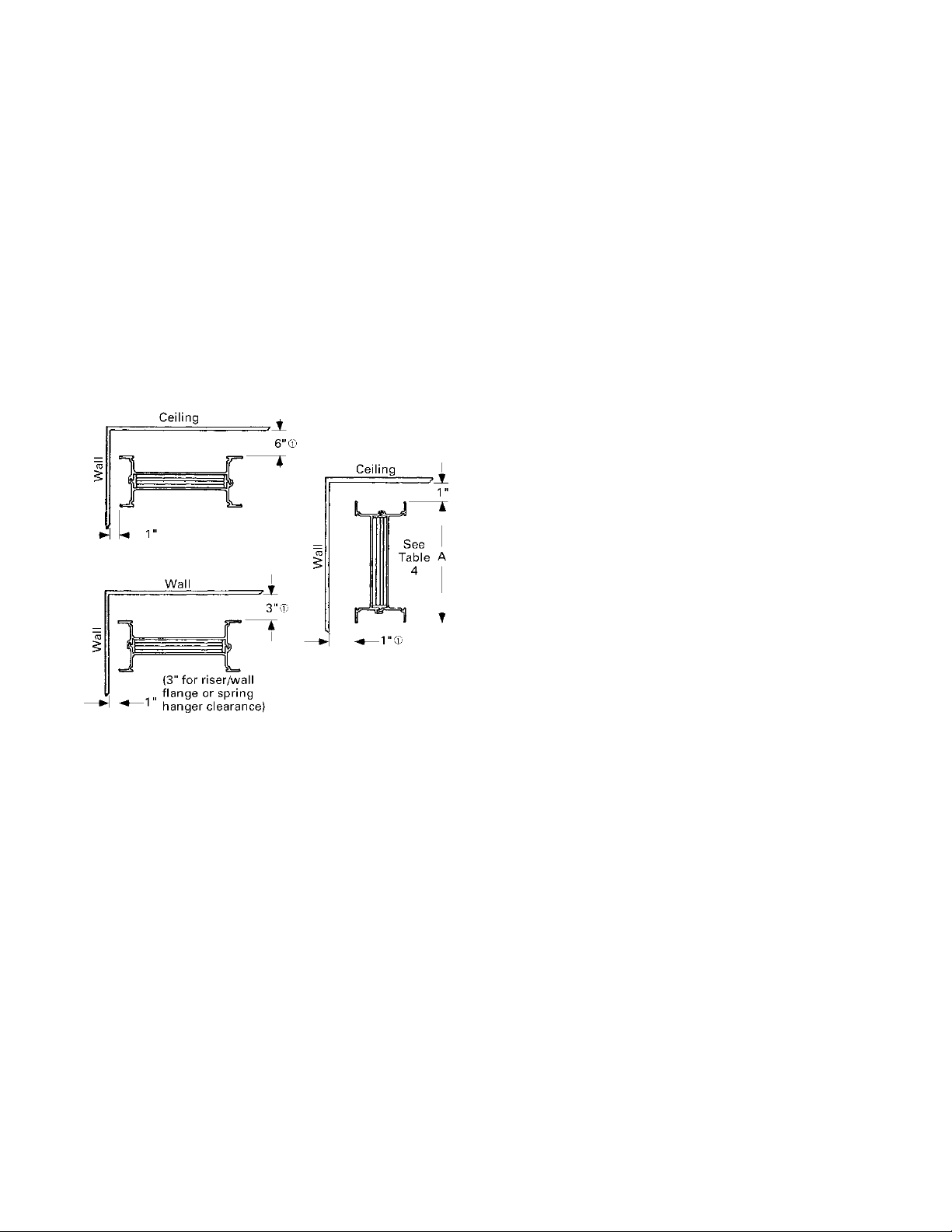

2. Minimum clearances to be maintained in various installations. ..................................................................... 4

3. Dimensions between drop rods for dual-hanger installations. ........................................................................ 5

4. Single-rod hanger with one stack (a) (standard) mounted flat and (b) mounted edgewise. ............... 5

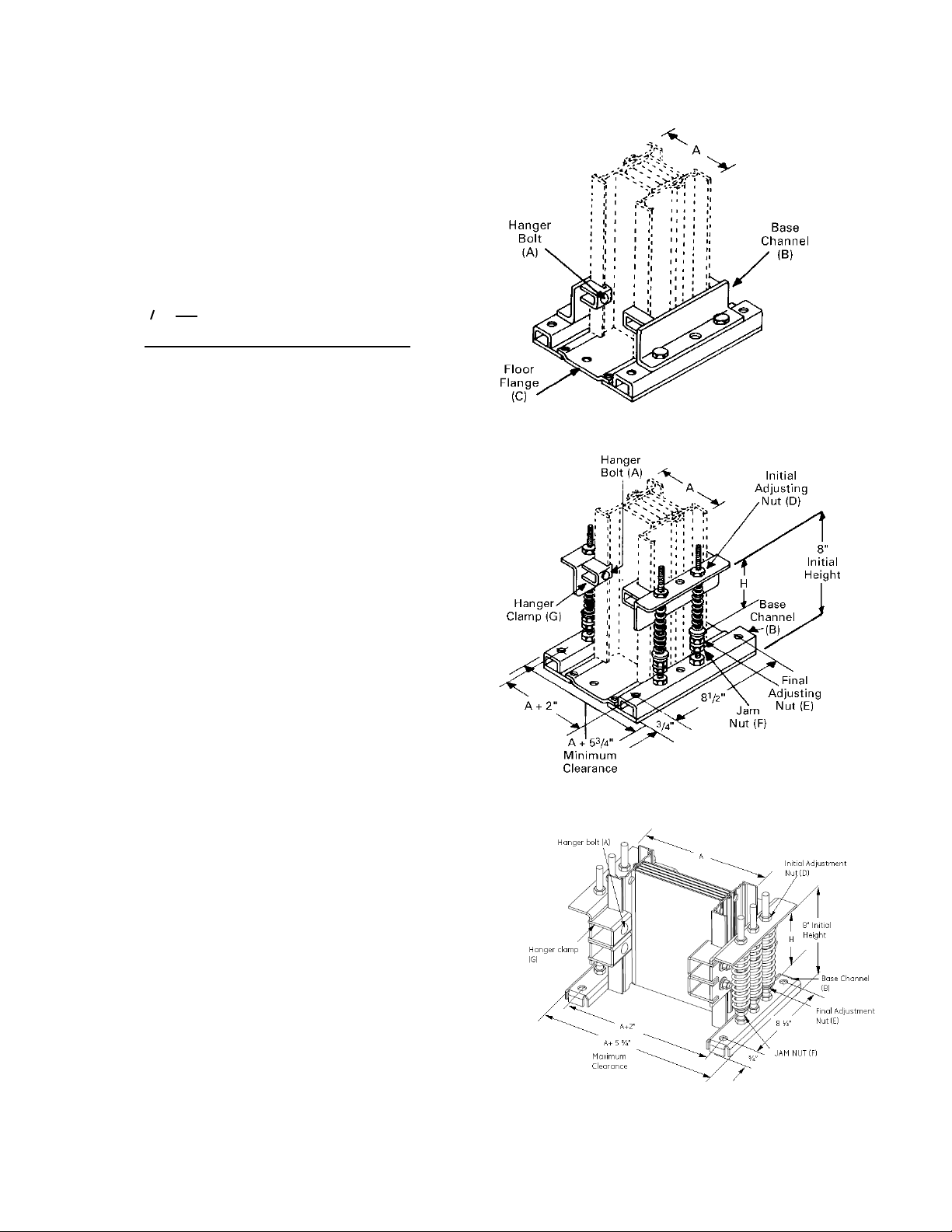

5. Rigid riser hanger installation. ......................................................................................................................................... 6

6. Spring riser hanger installation ....................................................................................................................................... 6

6A. Seismic spring riser hanger installation………………………………………………………………………………….…………………..….6

7. Bus plugs with door hinges at the left end ................................................................................................................ 7

8. Bus plugs with door hinges at the top. ........................................................................................................................ 7

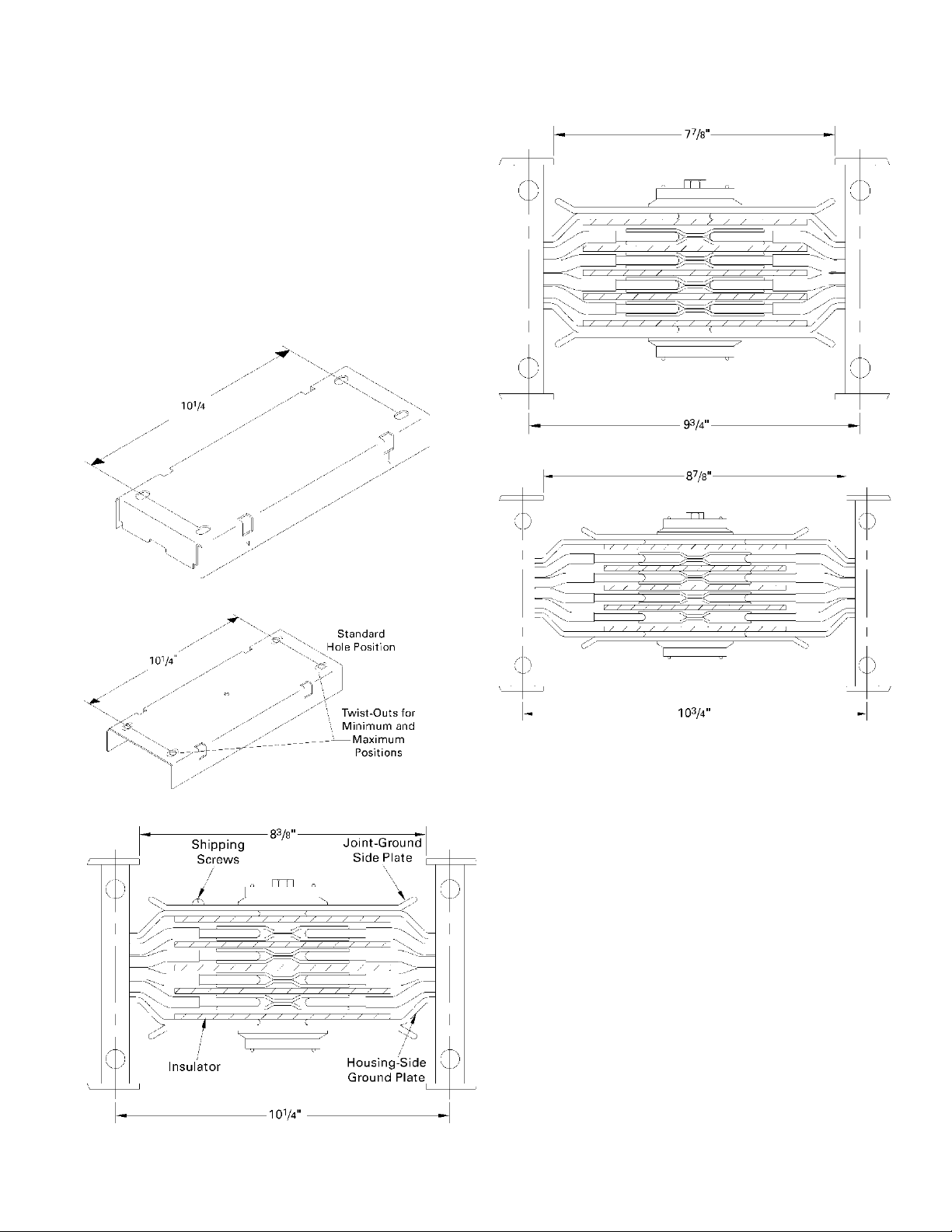

9. Indoor joint cap. ..................................................................................................................................................................... 8

10. Outdoor joint cap. ................................................................................................................................................................. 8

11. Busway joint at the standard distance ....................................................................................................................... 8

12. Busway joint at the minimum distance. ..................................................................................................................... 9

13. Busway joint at the maximum distance. .................................................................................................................... 9

14. Installing an expansion length. .................................................................................................................................... 10

15. Measuring Spectra busway for a field check ........................................................................................................ 10

16. Installing an end box. ....................................................................................................................................................... 10

17. Plug handle positions. ...................................................................................................................................................... 12

18. Mounting a bus plug on Spectra Series busway .................................................................................................. 13

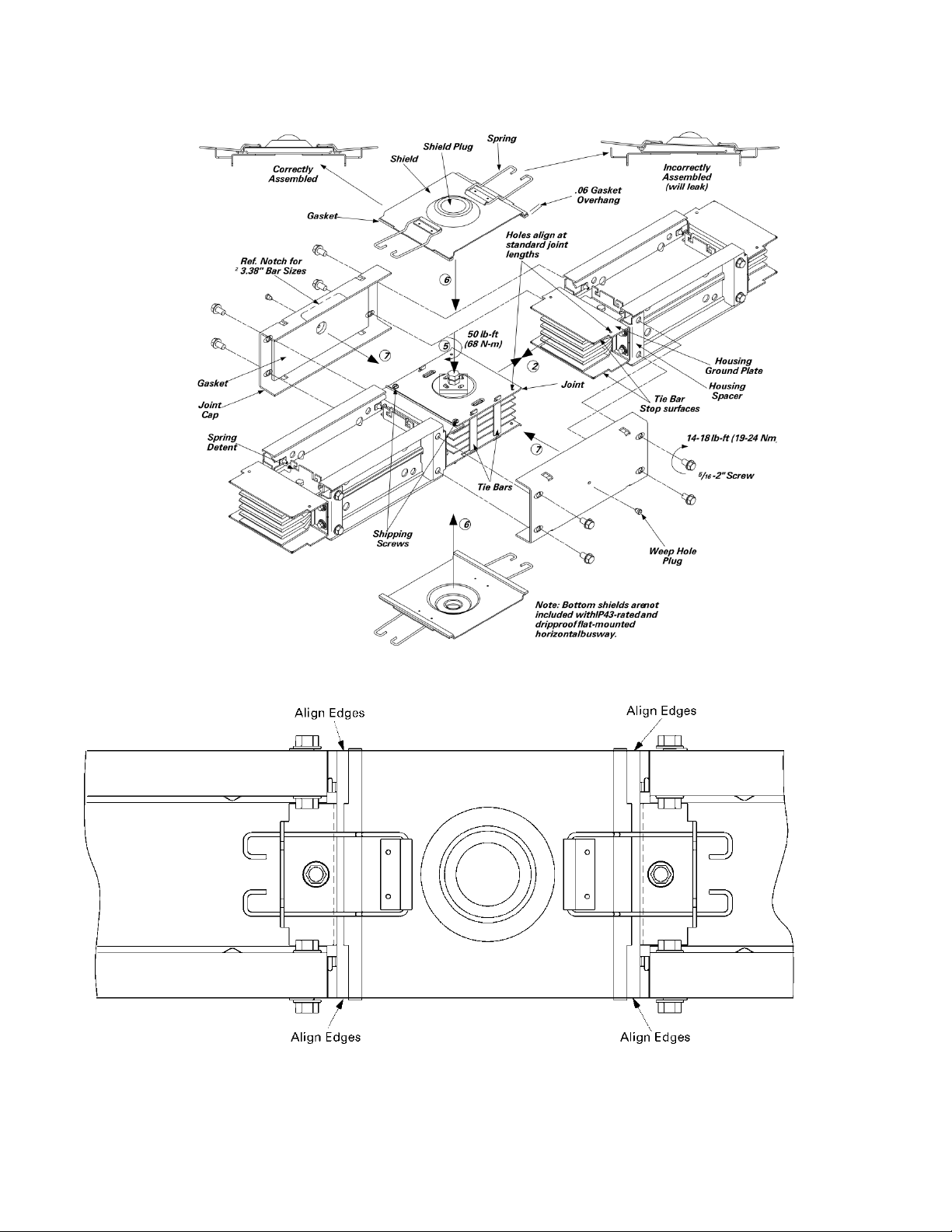

19. Assembly of a typical dripproof, splashproof, or outdoor busway joint. ................................................... 16

20. Assembly shown without joint caps, wireform springs connected. ............................................................ 16

21. View of completed joint assembly with joint caps installed. .......................................................................... 17

22. View of completed joint assembly showing joint caps. .................................................................................... 17

23. End box installed on the end of a run. ...................................................................................................................... 18

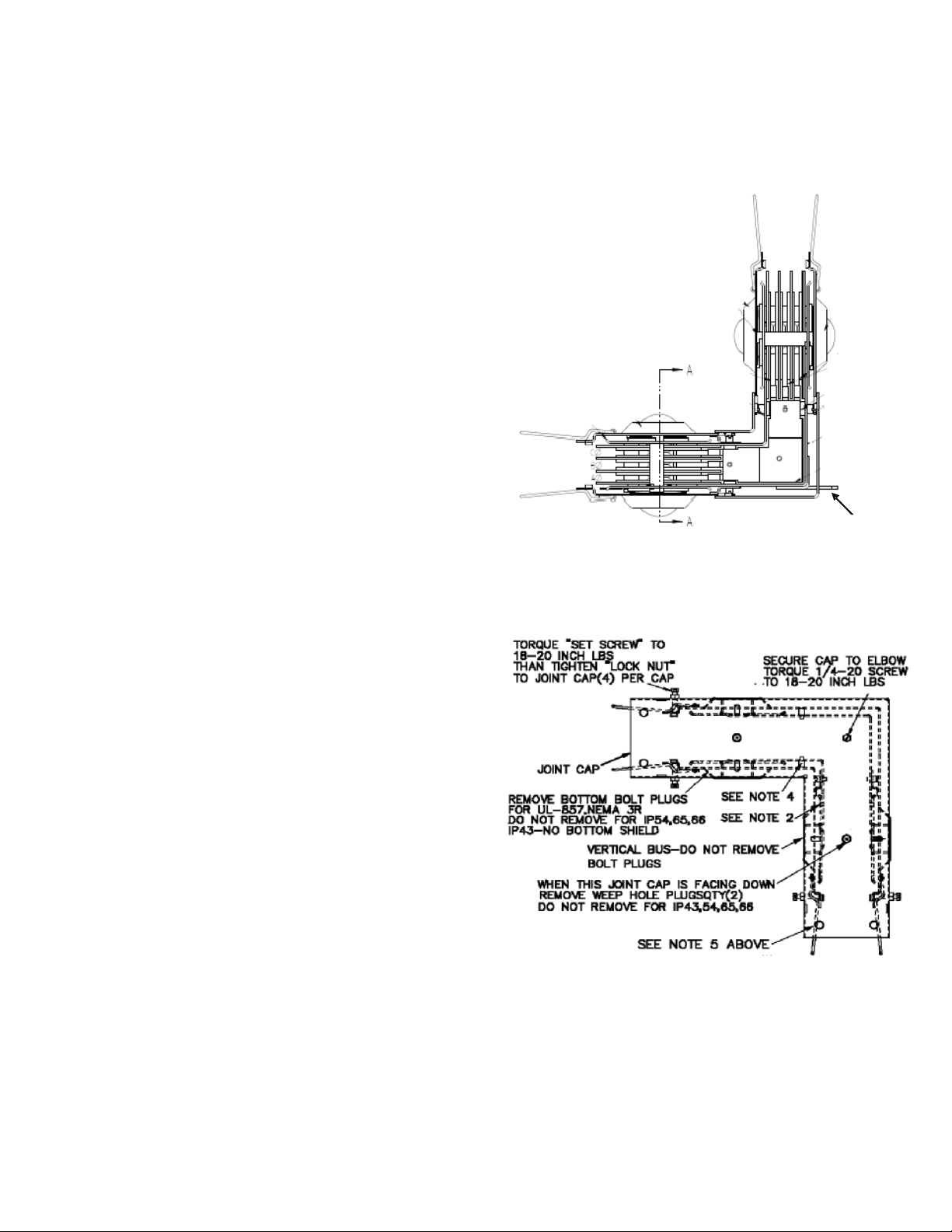

24. Edge wise outdoor Elbow Joint .................................................................................................................................... 19

25 Edge wise outdoor Elbow Joint asm instructions ................................................................................................ 19

26 Edge wise outdoor Elbow Joint .................................................................................................................................... 20

27 Edge wise outdoor Elbow Joint asm instructions ................................................................................................ 20

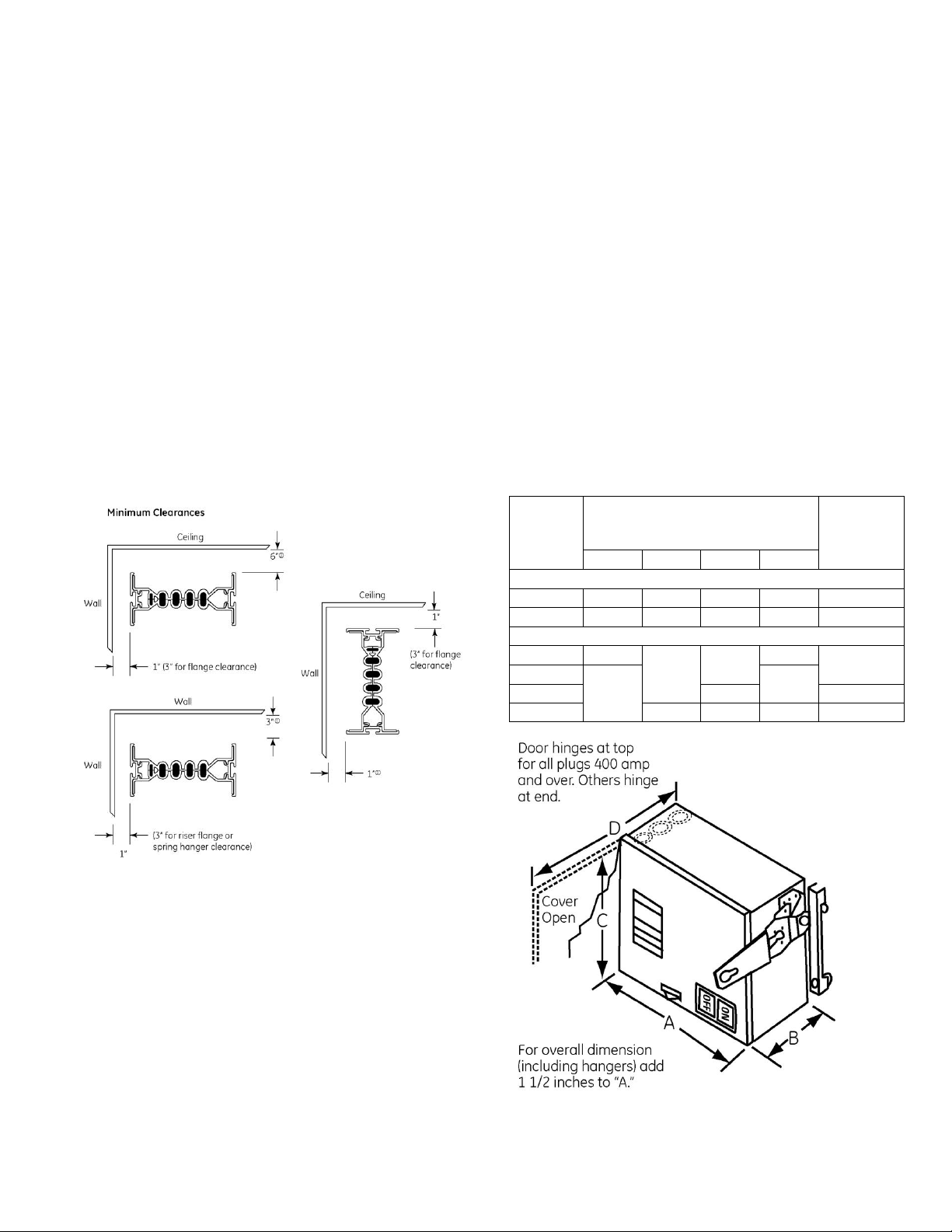

28. Minimum clearances Spectra II ................................................................................................................................... 21

29. Lowamp busplug data ..................................................................................................................................................... 21

30. Spectra II flatwise hanger .............................................................................................................................................. 22

31. Spectra II edgewise hanger ........................................................................................................................................... 22

32. Spectra II trapeze edgewise hanger .......................................................................................................................... 22

33. Spectra II trapeze flatwise hanger ............................................................................................................................. 22

34. Spectra II cross section.................................................................................................................................................... 22

35. Spectra II end box .............................................................................................................................................................. 22

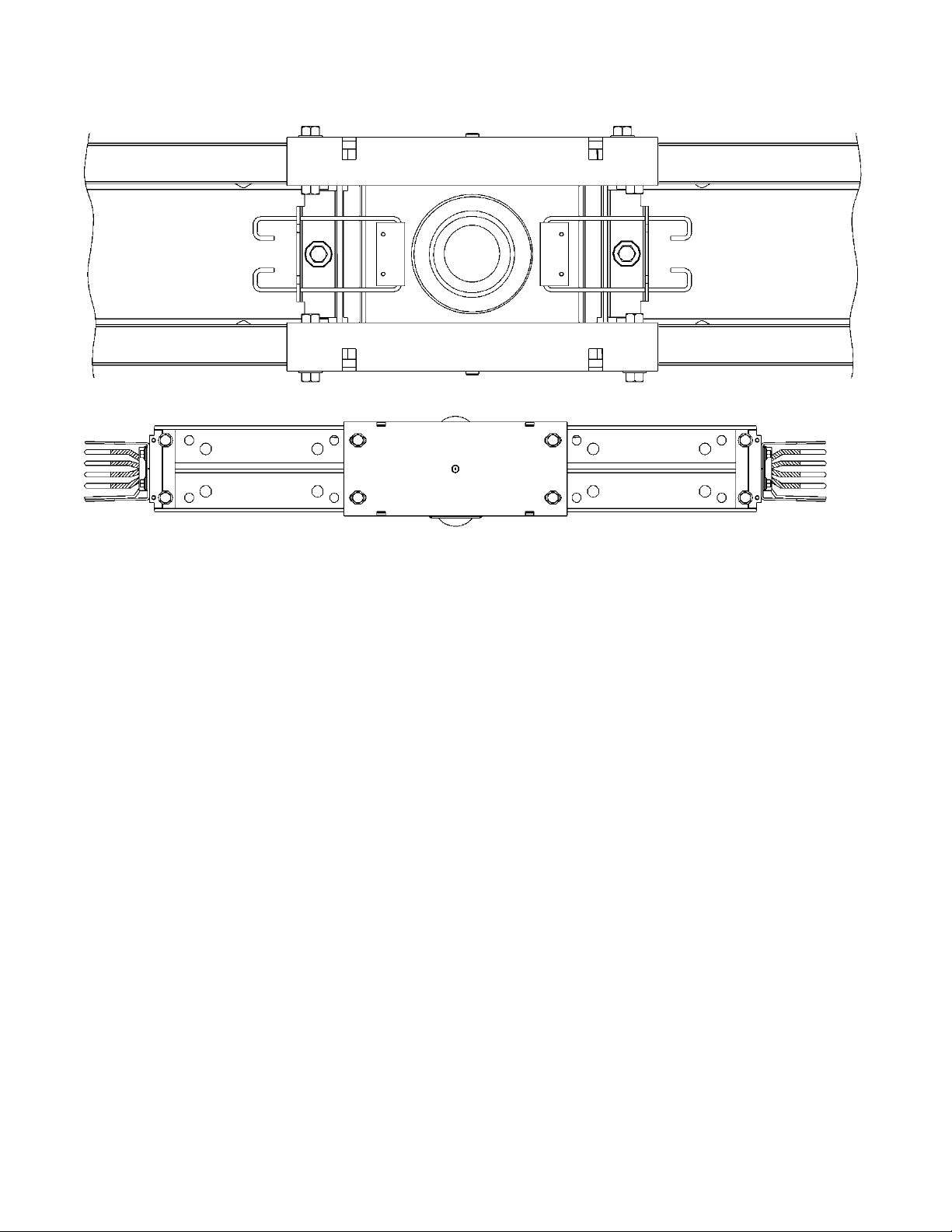

36. Spectra II busway joint at minimum .......................................................................................................................... 23

37. Spectra II busway joint at standard ........................................................................................................................... 23

38. Spectra II busway joint at maximum ........................................................................................................................ 24

39. Joint cap ................................................................................................................................................................................ 24

40. Bus plug mounting ............................................................................................................................................................ 24

Tables

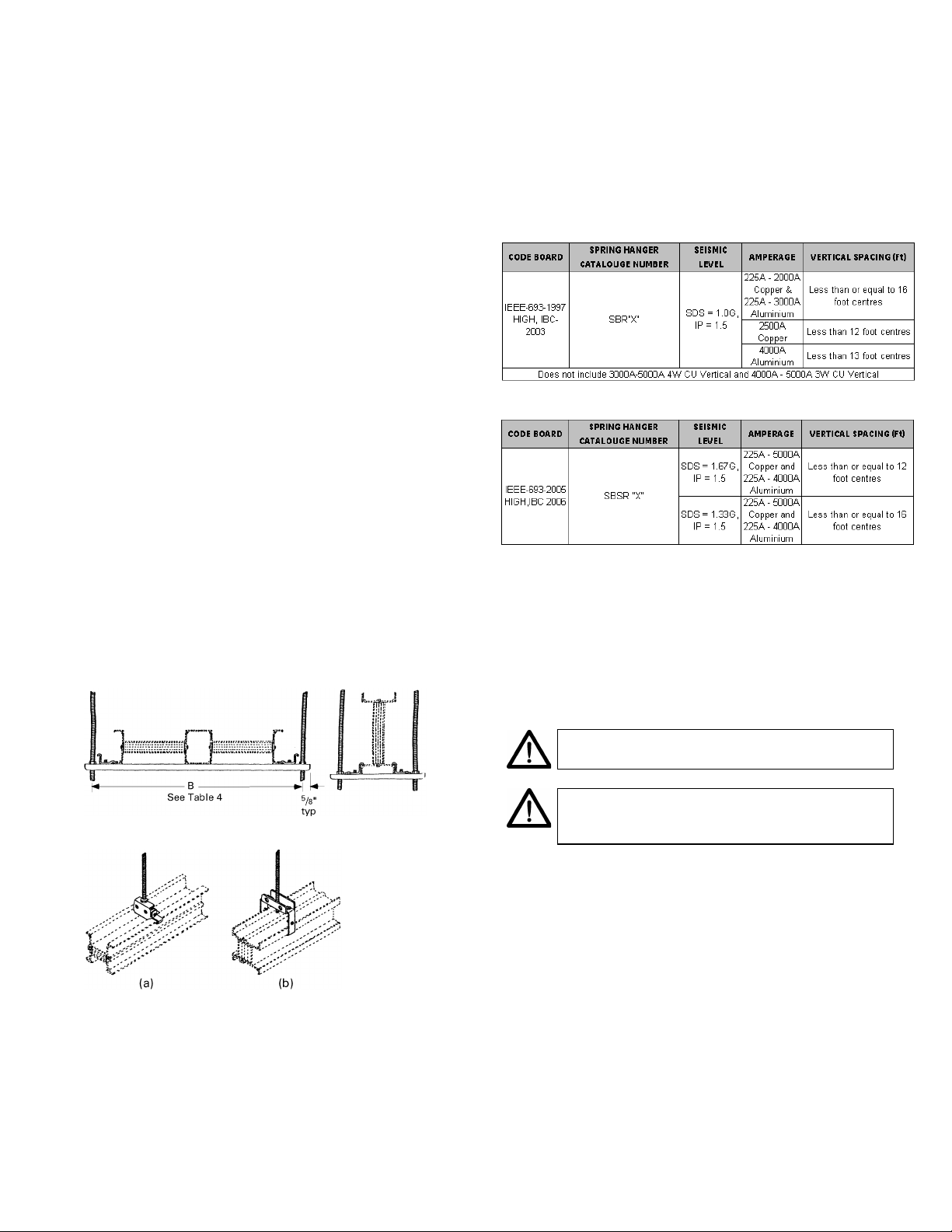

1. Selection of spring hanger based on Seismic load……………………………………………………………………………………..5

2. Selection of spring hanger based on Seismic load……………………………………………………………………………………..5

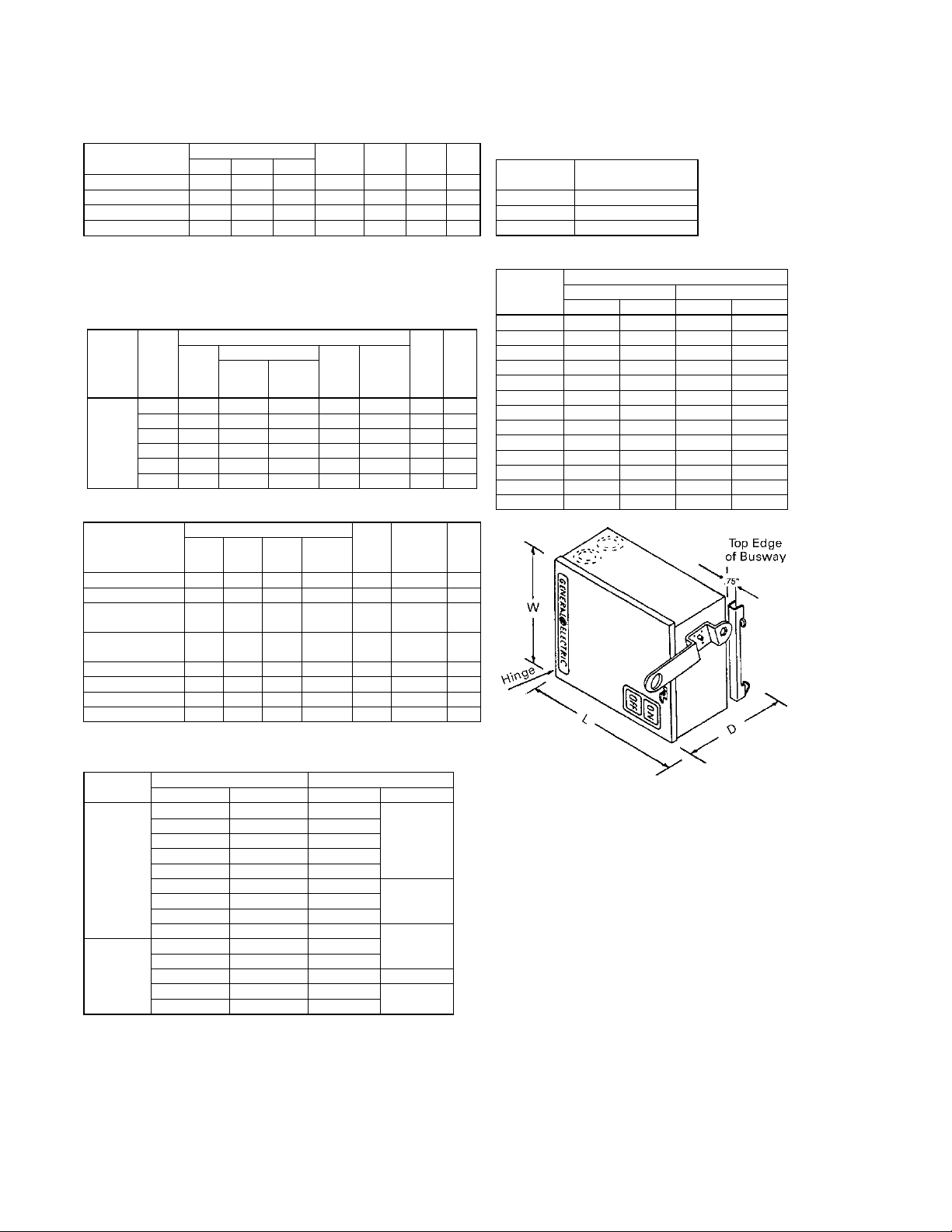

3. Dimensions for Spectra RMS™ circuit breaker bus plugs ................................................................................... 7

4. Dimensions for Types QMR and QMW fusible switch bus plugs ...................................................................... 7

5. Dimensions for molded-case circuit breaker bus plugs. ..................................................................................... 7

6. Busway and hanger mounting dimensions .............................................................................................................. 7

7. Number of busway springs required per busway weight .................................................................................. 7

8. Busway weights ..................................................................................................................................................................... 7

9. Busway torque requirements ....................................................................................................................................... 10

10. Lowamp plug sizes ............................................................................................................................................................ 21

11. Spectra II busway cross section .................................................................................................................................. 22

12. Lowamp plug weight ........................................................................................................................................................ 22

13. Spectra II busway weight ............................................................................................................................................... 22

2

Page 5

Spectra and Spectra II Series™ Plug-In and Feeder Busway

NOTE: No busway, including outdoor rated, is

weatherproof until completely and properly

installed.

NOTE: Aucune canalisation pour barres omnibus,

incluant celles classées pour l'extérieur, n'est à

l'épreuve de l'eau jusqu'à ce qu'elle soit installée

complètement et correctement.

Installing Spectra Series Busway

Installing Spectra Series™ Busway

Storage Precautions

Before storing, unpack sufficiently to make a

check of the busway for possible concealed

damage resulting from shipping and handling. If

damage has occurred, notify the shipper

immediately. If the busway is free of damage,

restore the packing until ready for installation.

Store indoors in a clean, dry area, preferably close

to the installation points.

Protect the busway from mechanical damage and

any contact with or exposure to corrosive fumes,

Installation of Spectra Series Busway

Establish the bus bar phase sequence (Ø side is

labeled) to determine how the busway is to be

installed, so that correct phasing is maintained

throughout the system. Note that phase

transposition lengths, when furnished, may

relocate the Ø to the opposite side of a busway

run.

Each busway piece has a ―bar end‖ and a ―joint

end,‖ as illustrated in Figure 1. Normally the

busway is oriented end for end with bar ends

pointing away from the source. Also, the ø side

should be oriented down for horizontal plug-in

applications.

liquids, salts, or concrete.

Failure to store and protect the busway properly

can cause serious damage and will void the

warranty.

Pre-Installation Procedure

When possible, deliver the busway to its

installation location before unpacking. Large

labels on each shipping carton or crate designate

the items contained. Additionally, each busway

piece is identified with an item number label.

Inspect each busway piece for possible damage

or contamination. Contact surfaces must be clean.

However, do not attempt to polish tarnished

contact surfaces.

Check to ensure that joint insulators are not

damaged or cracked and are firmly in place.

Megohm test each piece before installation.

Figure 1. The bar end and joint end of the busway.

In vertical riser installations, it is easier to lower

the busway into place than it is to raise it.

If installation drawings have been furnished,

information regarding the orientation of the

busway and location of the ø side, as well as other

pertinent data, will be furnished. These drawings

should be followed carefully to ensure a proper

busway system.

Where to Start

Start the installation, if at all possible, at the most

critical point, such as a main feed box,

switchboard or switchgear, elbow, or other critical

fitting or termination.

3

Page 6

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Spectra Series Busway

Obstructions

Where a busway run must pass through a wall or

floor, an opening one inch larger than the busway

cross-section should be provided. Joints may not

occur inside walls or floors per the NEC. A flange is

available to mask the opening after the busway is

installed.

Minimum Clearances

Figure 2 illustrates the minimum clearances that

must be maintained in various installation

situations.

4‖ minimum provides clearance for 30–100 A fusible plugs. 7‖ minimum for 200

A fusible plugs. 8‖ minimum for all other plugs. See Tables 1, 2, and 3.

Figure 2. Minimum clearances to be maintained in various

installations.

4

Page 7

Spectra and Spectra II Series™ Plug-In and Feeder Busway

NOTE: Check that the initial height is 8 inches, as

shown in Figure 6.

NOTE: Veuillez vous assurer que la hauteur

initiale est de 8 pouces, tel que montré à la Figure

6.

Installing and Removing Spectra Busway Plugs

Installing Indoor Busway

Horizontal Mounting

Overhead Support

For overhead-supported busway, 1/2-inch drop

rods are recommended with a maximum 10-foot

spacing. Drop rods and other hardware must be

furnished by the installer. Figure 3 illustrates

mounting dimensions for typical installations.

• Maintain good alignment of the drop rods

along the busway run.

• Do not support busway at the joints.

• After the busway is secured in the hangers,

adjust the hangers on the rods for the correct

elevation.

• Sway braces (furnished by the installer) may be

required to keep the run straight or to prevent

rotation.

Wall or Column Support

Table 4, Table 5 and Table 8. Select the spring

hanger based on the seismic load; amperage and

Vertical support spacing mentioned in table 1 & 2.

Table 1: Selection of spring hanger based on Seismic load and

amperage.

Table 2: Selection of spring hanger based on Seismic load.

Single-rod hangers, as shown in Figure 4, may be

used for mounting busway on walls or columns

with the addition of an angle support supplied by

the installer.

the floor, follow this procedure to assemble

hangers to the busway, as illustrated in Figure 5

Figure 6 & 6A. For convenience in assembly, step 8

may be completed before the hangers are

attached to the busway.

After placing the length of busway through

Figure 3. Dimensions between drop rods for dual-hanger

installations.

Figure 4. Single-rod hanger with one stack (a) (standard) mounted

flat and (b) mounted edgewise.

Vertical Mounting

Support Busway on maximum 16-foot centers.

Use Table 7 to determine the number of springs

required based on busway weight, as listed in

1. Loosen the hanger bolt A, shown in Figure 5.

2. Assemble the hangers to each side of the

busway.

3. Position the hangers on the busway so that

the base channel (B) rests on the floor or other

support. A floor flange (C) may be placed under

the hanger, but it will not support the busway

weight.

4. Fit the hanger clamps (G) to the busway

housing and hand tighten the hanger bolts (A).

5. Anchor the base channels to their supports.

6. Tighten the hanger bolts (A).

5

Page 8

Spectra and Spectra II Series™ Plug-In and Feeder Busway

H = 5

585

8 –

W

150

W =

Busway wt /ft ft/floor + devices on floor

Total number of springs/floor

Installing and Removing Spectra Busway Plugs

7. Install the next length and make the joint

assembly (see the instructions for joining

lengths below).

8. If springs are furnished, they must be adjusted

as shown in Figure 6 at this time. Determine

the required dimension H of the hanger

springs, found on the layout drawing or by

using the formula,

Using the final adjusting nuts (E), set the

springs on the hangers to the dimension H.

With the springs adjusted, hold nut (E) in

position and tighten jam nut (F) against nut (E)

Figure 5. Rigid riser hanger installation.

to retain the spring setting. Tighten all jam

nuts (F) using this procedure.

Note that when you are calculating the

dimension H for the bottom floor of a riser with

an elbow and busway directly below the floor,

the following must be included in the footage

calculation:

• Busway below the floor to the elbow,

• The elbow,

• 8 feet of horizontal busway.

For the riser to function as a free end, the last

horizontal hanger must be 8 feet from the

bottom elbow.

9. After the busway run is installed and all ―H‖

dimensions are set to the required settings,

starting at the top hanger raise the initial

Figure 6. Spring riser hanger installation

adjusting nuts (D) of all hangers to the top of

the spring studs. The studs are crimped to hold

the nuts in the uppermost position.

NOTE: Failure to properly adjust the spring

hangers could damage the bus and void the

warranty.

Figure 6A. Seismic Spring riser hanger installation (Cat No:

SBSR”X”)

6

Page 9

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Frame

Dimensions, in.

Handle

Ht.

Wt.,

lb.

Outlets

Fig.

W L D

SED, SEH, SEL, SEP

11.00

13.00

8.00

11.00

25 1 7

SFH, SFL, SFP

11.00

21.25

9.00

12.00

41 1 7

SGH, SGL, SGP

16.75

26.50

12.50

20.50

91 2 8

SKH. SKL, SKP

16.75

36.50

12.50

20.50

160 2 8

Rating,

Volts

Amps

Dimensions, in.

Wt.,

lb

Fig.

W L D

Handle

Ht.

Std

Gutter

Ext

Gutter

240 &

600

30

11.25

13.00

18.63

8.75

11.00

24 7 60

11.25

13.00

18.63

8.75

11.00

25 7 100

11.25

18.75

NA

8.75

11.00

28 7 200

16.00

18.75

24.50

8.75

11.00

46 7 400

20.50

18.75

NA

18.75

24.00

135 8 600

20.50

24.50

NA

18.75

28.00

160

8

Frame

Dimensions, in.

Wt.,

lb

Outlets

Fig.

W L D

Handle

Height

TEB, TED, THED

11.00

13.00

8.00

11.00

24 1 7

TFJ, TFK, THFK

11.00

18.50

9.50

12.00

44 1 7

TJJ, TJK4, TJK6,

THJK4, THJK6

16.75

24.50

12.50

20.50

95 2 8

TKM8, THKM8,

THK

16.75

36.50

12.50

20.50

160 2 8

TB1 (fused)

11.00

18.50

8.00

11.00

29 1 7

TB4 (fused)

16.75

30.50

12.50

20.50

65 2 8

TB6 (fused)

16.75

45.25

12.50

20.50

175 2 8

TB8 (fused)

16.75

45.25

12.50

20.50

185 2 8

Bars per

Phase

Ampere Rating

Dimensions, in.

Copper

Aluminum

Busway A

Hanger B

1

225–800

225–600

43/8

101/4

1000 — 5

1200

800

55/8

1350

1000

61/8

1600

1200

7

2000

1350

81/2

14

—

1600

91/4

2500

—

101/4

—

2000

11

181/2

2

3000 — 15

—

2500

151/2

4000

3000

18

221/2

5000

—

211/2

26

—

4000

23

Busway

Weight, lb

No. of Springs

Required per Floor

0–600

2

601–1200

4

Over 1200

6

Amperes

Busway Weight, lb/ft

Copper

Aluminum

3 Wire

4 Wire

3 Wire

4 Wire

225 8 9 5 6

400 8 9 5 6

600 8 9 5 6

800 8 9 6 7

1000

10

12 7 8

1200

12

15 8 9

1350

14

17 9 10

1600

16

20

10

12

2000

21

26

12

15

2500

26

33

17

20

3000

32

40

19

23

4000

42

52

25

30

5000

52

66 — —

Installing and Removing Spectra Busway Plugs

Table 3. Dimensions for Spectra RMS™ circuit breaker bus plug.

Table 7. Number of busway springs required per busway weight.

Maximum distance from the busway housing to the handle tip.

For ground fault option, increase width by 2.125 inches and length by 6.00

inches.

Table 4. Dimensions for Types QMR and QMW fusible switch bus

plugs, as illustrated in Figure and Figure 8.

Table 5. Dimensions for molded-case circuit breaker bus plugs.

Table 8. Busway weights.

Table 6. Busway and hanger mounting dimensions, as illustrated in

Figure 2 and Figure 3.

The door hinges at the left end. The L and W dimensions are shown over

the largest part of the plug.

Figure 7. Bus plugs with door hinges at the left end.

Important Note:

On vertical riser applications use a Minimun of 18‖ of

un-supported flexible conduit connecting to bus plugs.

7

Page 10

Spectra and Spectra II Series™ Plug-In and Feeder Busway

WARNING: The housing-ground side plates must pass

between the outside insulators and the joint-ground side

plates to avoid a phase-to-ground short circuit.

AVERTISSEMENT: Les plaques de côté reliant le boîtier à

la mise à la terre doivent passer entre les isolateurs

extérieurs et les plaques de côté du joint à la terre pour

éviter un court -circuit de phase à la terre.

NOTE: If any adjustments are made in Step 5, remove

the shipping screws and center the joint between the

two housings.

NOTE: Retirer les vis d'expédition et centrer le raccord

entre les deux habitacles sitout ajustement est

apporté à la fiche-boîtier à l'étape 5.

Installing and Removing Spectra Busway Plugs

Joining Lengths

Use the following procedure to join two lengths of

busway.

1. Remove at least one joint cap, shown in Figure

9 and Figure 10, from the two pieces to be

joined, retaining the bolts.

2. Align the sections to be joined by matching up

the Ø SIDE labels attached to the ends of each

section.

3. If necessary, loosen the joint bolt slightly.

The door hinges at the top. The L and W dimensions are shown over the

largest part of the plug.

Figure 8. Bus plugs with door hinges at the top.

4. Slide the sections together. Ensure that the

busbars interweave the insulators, as shown in

Figure 11, Figure 12, and Figure 13.

5. In nominal position, the standard distance

between the joint cap bolt holes is 10 1/4

inches for outdoor busway, as shown in Figure

11. On indoor busway, the standard distance

between the two housings is 8 3/8 inches, in

nominal position, as shown in Figure 11. An

alignment line marked ―N‖ on the joint cap

window should line up with the edge of the

housing at nominal position. However, the joint

is also adjustable, as shown in Figure 12 and

Figure 13. Simply move the sections in or out

to the desired length, as shown, and remove

the twist-outs in both joint caps (outdoor only)

if needed, as shown in Figure 10.

6. If the joint caps are not already in place,

reattach them and hand-tighten the mounting

screws.

7. When joining old-style indoor to new-style

indoor busway, use a 3/8" x 1/2" bolt to attach

8

Page 11

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing and Removing Spectra Busway Plugs

the joint cap to the housing spacer of old-style

indoor and the 5/16" x 2" bolt provided on the

new-style indoor and attach to the U clip.

8. When joining Spectra Series Busway to

Spectra II Plug-in Busway, a combination joint

cap will be provided, use the 5/16‖ X 2‖ bolt to

attach this joint cap to the Spectra Series

Busway and the M10 X 16 bolts to attach the

cap to the Spectra II Busway.

Figure 9. Indoor joint cap.

Figure 10. Outdoor joint cap.

Figure 11. Busway joint at the standard distance.

Figure 12. Busway joint at the minimum distance.

Figure 13. Busway joint at the maximum distance.

9. When joining Style II outdoor to new-style

indoor busway, use the existing 3/8" x 1/2" bolt

to attach the joint cap to the housing spacer of

Style II outdoor and the 5/16" x 2" bolt

provided on the new-style indoor and attach

to the U clip.

10. Inspect the busway run for straightness in all

planes and make any adjustments necessary

for good alignment.

11. Grease has been applied to the joint bolt head

and threads to reduce friction. Do not remove

this grease.

12. Tighten the joint bolt with a 5/8‖ or 16-mm

socket wrench until the smaller, top head

breaks off. When the Belleville washers on

both sides are flattened, the bolt is fully

tightened. If the optional Joint-Guard™

9

Page 12

Spectra and Spectra II Series™ Plug-In and Feeder Busway

NOTE: The bolt head may be relocated to the

opposite side of the busway to improve

accessibility.

NOTE: La tête du boulon peut être repositionnée

sur le côté opposé de la canalisation pour barres

omnibus pour la rendre plus accessible.

Installing and Removing Spectra Busway Plugs

torque-indicating bolt is used, tighten using a

3/4‖ or 19-mm socket torque wrench set at

50ft-lb (68N-m). The color indicator should turn

fully black and can be viewed periodically to

insure proper torque.

Use a

socket wrench to remove the 1/4-20 shipping

screws.

An elbow below a riser that is supported by a

drop rod less than 8 feet from the elbow

should be considered rigidly mounted.

3

/8" (6- or 12-point) or 10-mm (6-point)

13. Tighten all

3

/8" joint cap screws to 25 lb-ft (34

N-m) with a 9/16" or 14-mm socket wrench

and all 5/16" joint cap screws to 10 lb-ft (14 N-

m) with a 1/2" or 12-mm socket wrench.

14. During installation, occasionally megohm test

the assembly to check for any improperly

made joints. Resistance should not drop below

1 megohm per 100 feet of busway.

15. Megohm test the complete run before

energizing.

Expansion Lengths

Expansion lengths compensate for thermal

expansion of a long busway run or for differential

expansion between two buildings spanned by a

busway run. One end wall of the expansion box is

free to move, but only after the eight 1/4-20

shipping screws are removed.

Install the expansion length and the remaining

busway run, as shown in Figure 14. All but the

farthest busway supports beyond the box’s free

end must be nonrigid, such as spring hangers for

riser (vertical) busway or drop rod assemblies on a

horizontal run. Before energizing the run, remove

the eight 1/4-20 shipping screws, four on each

side of the box, as identified by two labels.

Tips for installing expansion lengths

The label and shipping screws are near the

box’s free end.

Figure 14. Installing an expansion length.

Busway Field Check Pieces and Replacement

Pieces

A field check piece is a length of busway inserted

into a run after the major portion of that run has

been installed. To determine the length of the

piece to be inserted, measure the opening length

L between the ends of the bars and the center of

the joint of the adjacent piece and subtract .875

inches, as shown in Figure 15. This is equal to the

busway length X measured from the center lines

of joint to joint and is the way to measure all

Spectra Series busway pieces.

10

Page 13

Spectra and Spectra II Series™ Plug-In and Feeder Busway

L Dimension

X Dimensions (L -.875)

Example

36.875

36.000

FC – 1

______

______

FC – 2

______

______

FC – 3

______

______

FC - 4

______

______

Bolt Size

Torque (ft-lbs)

¼-20 low carbon

6-10

¼-20 med carbon

8-12

5/16-18 med carbon

14-18

3/8-16 low carbon

14-18

3/8-16 med carbon

22-26

½-13 low carbon

32-36

½-13 med carbon

32-36

½-13 joint thru bolt

50-55

WARNING: HAZARD OF ELECTRICAL SHOCK OR

BURN! The plug must be turned OFF before

installing on or removing from the busway.

Failure to do so may cause serious injury or

death! It is a good safety practice to de-energize

the busway before inserting or removing bus

plugs. In the United States, it is necessary to

comply with all Federal and local safety

procedures, including NFPA 70E 2-1.3 directing

the use of appropriate PPE (Personal Protective

Equipment) such as face shield, insulating gloves,

and flame-resistant clothing. In Canada, be sure

to comply with the appropriate requirements of

the Canadian Electrical Code. Only properly

trained personnel may install bus plugs on or

remove them from energized busway. In addition,

all bus plug installation instructions must be

followed completely.

Installing and Removing Spectra Busway Plugs

Figure 15. Measuring Spectra busway for a field check.

Provide “X” dimension to plant for field check.

Table 9. Spectra busway torque requirements.

Installing an End Box

An end box, as shown in Figure 16, is available to

isolate phases and seal the end of a run. The

installation process is as follows:

1. Place the box over the end of the busway.

2. Insert the housing spacer and align it with the

U-type clip and the end box mounting holes.

3. Secure the end box to the busway with the

5

/16" x 2" screws provided.

Figure 16. Installing an end box.

Installing and Removing Busway Plugs

11

Page 14

Spectra and Spectra II Series™ Plug-In and Feeder Busway

AVERTISSEMENT: DANGER DE CHOC ÉLECTRIQUE

OU DE BRÛLURE! La fiche-boîtier doit être à OFF

avant de l'installer ou de la retirer de la barre

blindée. Le non-respect de cette directive

pourrait causer une blessure sérieuse ou la mort!

C'est une pratique sécuritaire de mettre hors

tension la barre blindée avant d'insérer ou de

retirer les fiches-boîtiers de barre omnibus. Il est

nécessaire aux États-Unis de respecter toutes les

procédures de sécurité tant fédérales que locales

y compris le NFPA 70E 2-1.3 réglementant

l'utilisation d'équipement de protection individuel

(ÉPI) tel qu'écran facial, gants isolants et

vêtements ignifuges. Au Canada, assurez-vous

d'observer les exigences appropriées du Code

électrique canadien. Seul un personnel

correctement entraîné peut installer des fichesboîtiers ou les retirer d'une barre blindée

alimentée. De plus, toutes les instructions quant à

l'installation de fiches-boîtiers de barre omnibus

doivent être suivies entièrement.

CAUTION: Do not rest the weight of the bus plug

on the alignment pin during installation. The pin

must be used for alignment only. The plug must

be adequately supported by independent means

until all the hanger bolts are tightened.

ATTENTION: Le poids de la fiche-boîtier de barre

omnibus ne doit pas reposer sur la tige

d'alignement durant l'installation. La tige doit être

utilisée uniquement pour l'alignement. La ficheboîtier doit être soutenue adéquatement par des

moyens indépendants jusqu'à ce que les

boulons-vis soient serrés.

WARNING: Perform all of the following steps to

insure proper plug-to-bus engagement. Failure to

do so may cause injury, death, or damage to

equipment.

Shipping Position

Operating Position

Installing and Removing Spectra Busway Plugs

the handle 90 CW to access the lock-out

feature. Reinsert the screw to secure the

handle. NEC requires the ON handle position to

be up and the OFF handle position to be down,

as shown in Figure 17.

Plugs are interlocked, permitting engagement

and disengagement with the busway only

when in the OFF position.

Place the operating handle at the desired

position on the plug and secure it with the

screw provided. The NEC requires the ON

handle position to be up and the OFF handle

position to be down.

If plug-assist has been furnished on the plug,

the operating handle may be used as a

wrench to operate the mechanism.

To install a plug where the rear plug hanger

interferes with a joint cap, it is necessary to

Note the following points concerning busway

plugs:

Inspect the plug before installing on the

busway.

Stab fingers have been lubricated with grease,

which should not be removed.

remove the break-off tabs, as shown in Figure

18.

See the note below Figure 18 concerning the

hanger hooks kit.

On large plugs, drop rod brackets are provided

for auxiliary support of the plug on horizontal

runs.

Busway plug-in outlets are made accessible

by hinging the outlet cover 180°. A highfriction hinge holds the cover open.

An alignment pin polarizes and locates the

plug in the correct position only.

The plug handle is originally in the shipping

position. Remove the center screw and rotate

Figure 17. Plug handle position.

12

Page 15

Spectra and Spectra II Series™ Plug-In and Feeder Busway

AVERTISSEMENT: Accomplissez tout ce qui suit

pour assurer un accouplement correct entre la

fiche-boîtier et la barre omnibus. Le non-respect

de cette directive peut entraîner des blessures, la

mort ou endommager l'équipement.

Installing and Removing Spectra Busway Plugs

2. Loosen the four bolts on the hanger hooks.

3. Insert the alignment pin into the housing hole.

4. Push the stabs into full contact with the

5. Engage the four hanger hooks with the

Insure that all hangers are fully seated on

busway, hanger hooks are latched on the

busway rail, and all bolts are tight.

Insure that the Plug Assist pointer (if equipped)

is lined up with the IN position before turning

the plug ON.

Installing a Plug Equipped with Plug-Assist

Use the following procedure, as illustrated in

Figure 18.

1. Make sure the device is in the OFF position and

Insure that the alignment pin is in the

alignment hole and extends past the busway

housing on the back side by 1 3/16" ± 1/16".

Insure that the plug-to-bus interlock (black

hook) is in the busway housing slot and is free

2. Loosen the four bolts on the hanger hooks.

3. Insert the alignment pin into the housing hole.

4. Engage the four hanger hooks with the

to move.

Insure that the bus plug is parallel with the bus

housing (line end to load end and across the

5. Rotate the plug-assist indicator fully toward

busway rail).

Installing a Plug not Equipped with Plug-Assist

Use the following procedure, as illustrated in

Figure 18.

Removing a Plug

First, turn the device OFF. Then follow the

appropriate procedure above in reverse order.

1. Make sure the device is in the OFF position.

busway.

busway rails and tighten the bolts.

the plug-assist indicator is rotated fully toward

the stabs-out position.

busway rails. Tighten the bolts and wire the

device.

the stabs-in position.

13

Page 16

Spectra and Spectra II Series™ Plug-In and Feeder Busway

WARNING: Be sure that the plug-assist pointer is

lined up with the IN position before turning the

plug on. Failure to do so may result in serious

death or injury.

AVERTISSEMENT: Assurez-vous que le repère du

mécanisme ( Plug-assist pointer) qui aide à

connecter la fiche boîtier est enligné avec la

position IN avant de la brancher. Il y a risques de

blessures graves ou de mort, si cette procédure

n'est pas respectée.

NOTE: Un nécessaire de crochets de suspension

est disponible: le numéro de catalogue est DP2PK

et contient des crochets plus courts et des vis

plus longues. Ce nécessaire n'est requis que

lorsqu'on monte des fiches boîtiers pour barres

omnibus fabriquées avant septembre 1999 sur

des barres omnibus à fiches boîtiers anti-gouttes

avec une barre d'une largeur de 3.375 pouces ou

moins et avec les crochets positionnés sur le

capuchon à rainures du joint. Voir la Figure 19.

NOTE: A hanger hooks kit, Catalog Number

DP2PK, containing shorter hooks and longer

screws, is available. This kit is required only when

mounting bus plugs made before September

1999 onto drip-proof plug-in bus with a bar width

of 3.375 inch or less and with hooks positioned

on the notched joint cap. Refer to Figure 19.

CAUTION: Make sure that the bus plug is level in

all orientations with the busway after all

connections are completed. Failure to level the

plug could result in overheating of the plug

connection.

ATTENTION: Assurez-vous, après que tous les

raccords soient complétés, que la fiche boîtier

pour barres omnibus est de niveau avec la

canalisation dans toutes les directions. Il existe

un risque de surchauffement du raccord de la

prise si celle-ci n'est pas mise à niveau.

Installing Dripproof, Splashproof, and Outdoor Busway

Figure 18. Mounting a bus plug on Spectra Series busway..

14

Page 17

Spectra and Spectra II Series™ Plug-In and Feeder Busway

WARNING: Be sure that the busbars interleave

the insulators, as shown in Figure 11, Figure 12,

and Figure 13. The housing-ground side plates

must pass between the outside insulators and

the joint-ground side plates to avoid a phase-toground short circuit.

AVERTISSEMENT: Asssurez-vous que les barres

omnibus intercalent les isolteurs, tel que montré

aux Figure 11, Figure 12 et Figure 13. Les plaques

de côté reliant le boîtier à la mise à la terre

doivent passer entre les isolateurs extérieurs et

les plaques de côté du joint à la terrre pour éviter

un court -circuit de phase à la terre.

NOTE: Remove the shipping screws and center

the joint between the two lengths of busway

when adjusting to the maximum length.

NOTE: Enlever les vis de l'expédition et centrer le

joint entre les deux longueurs de la canalisation

pour barres omnibus lorsque vous faites

l'ajustement de la longueur maximale.

Installing Dripproof, Splashproof, and Outdoor Busway

Installing Dripproof, Splashproof, and

Outdoor Busway

Install busway according to the instructions for

indoor busway, with the following exceptions for

outdoor joints. Figure 19 illustrates the assembly

of a typical dripproof, splashproof, or outdoor

busway joint. Sequence numbers on the figure

refer to the steps below.

1. Inspect the ends of the bus and joint assembly

for damage. Outdoor and splashproof joints

should have green Weathershield™ epoxy

insulators. (Red insulators are for indoor and

drip-proof applications.) Joint caps and shields

are packed separately.

2. Maintain the proper phasing of the sections to

be joined by matching up the Ø SIDE labels

attached to the ends of each section. Loosen

the joint bolt slightly, if necessary, and slide the

sections together.

3. The joint cap can be used as a gage (reversed,

with the gasket out) to set the desired length

dimension across the joint.

4. The joint is

1

/8" narrower than the housing

ground plates and should be kept within the

width of the ground plates to ensure the best

seal to the joint cap gasket. The joint will be

centered laterally if the tie bars are flush

against the tie bar stop surfaces of the housing

ground plates and the bus is in good edge-wise

alignment across the joint.

5. Inspect the busway run for straightness in all

planes and make any adjustments necessary

for good alignment. Tighten the joint bolt to 50

lb-ft (68 N-m). If the optional Joint-Guard™

torque-indicating bolts are used, tighten the

bolt until the color indicator turns fully black

±1/4 turn.

6. Set the shields in place bridging the joint. Align

the edges of the shields with the edges of the

housing ground plates and fasten the shields

with the wire-form springs onto the spring

detents, as shown in Figure 20. (To secure

larger shields, first attach two diagonally

opposite spring legs, slide the shield into

alignment, then fasten the remaining legs.)

Note that lower shields are not required and

are not provided with IP43 and dripproof

horizontal flat-mounted busway.

7. Attach the two joint caps (gaskets inward) with

the four bolts provided. Depending on which

bolt is provided, tighten the 3/8-16 x 5/8" bolts

to 25 lb-ft (34 N-m) or the 5/16" x 2" bolt to 14-

18ft/lbs (19-24 N-m) . Exception: 5000 ampere

busway uses eight bolts per joint cap.

Assembled joint caps are illustrated in Figure

21 and Figure 22.

8. During installation, megohm test at 1000 VDC

the assembly occasionally to check for

improperly connected joints. The resistance

should not drop below one megohm per 100

feet of busway.

9. Before energizing, the complete run of bus

should be megohmed at 1000 VDC. Resistance

15

Page 18

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Dripproof, Splashproof, and Outdoor Busway

should not drop below one megohm per 100

feet of busway.

10. For UL Outdoor, NEMA 3R, and GM Drip-Proof

rated installations: Remove only downward-

facing weep-hole plugs and shield plugs so

that condensation and accumulated moisture

can drain out as suggested by these

standards.

11. For IEC 529 IP43, IP54, IP65, or IP66 rated

installations: Do not remove the weep-hole

plugs during installation if the busway is to

meet any of these water-spray ratings.

Remove (and be sure to reinstall) the plugs

only as a maintenance procedure to

determine if water has entered the busway.

Use a

joint bolts, and tighten to 50 lb-ft (68 N-m).

Depending on which cap bolt is provided, use

a 9/16-inch (14-mm) socket wrench and

tighten to 25 lb-ft (34 N-m) for the 3/8 bolts or

a ½-inch (12-mm) socket wrench and tighten

to 14-18 lb-ft (19-24 N-m) for the 5/16 bolts.

Do not adjust the joint length with the shields

or caps installed, as this will damage the

gaskets.

Cap gaskets should be replaced whenever a

joint cap is removed, except that if a cap

gasket has been compressed and taken a set,

it may be reused if:

– It is reinstalled in exactly the same location

Installation Tips

Outdoor busway is only rated as such when it

is completely and properly installed. GE

– It has recovered to 80% of its original

normally recommends setting and tightening

joints at the nominal length and sealing each

joint as the installation proceeds. The

contractor should consider the weather and

the need to seal each joint versus the need to

make length adjustments later.

Use a reversed joint cap (gasket side out) as a

joint-length gauging tool or align the holes in

the joint and housing ground plates.

Use a straight edge, string, level, plumb line,

and square to set runs.

Spare gaskets are provided.

Call the GE factory at (731) 645-6121 to

request a free Busway Installation video or to

ask questions about your installation.

If any parts are damaged during shipment or

installation, replacement parts should be

ordered from the factory. On-site repairs of

damaged parts should not be attempted.

3

/4-inch or 19-mm socket wrench on

and orientation without any joint

readjustment. Use the compressed outline

in the gasket to set this location.

thickness within 12 hours. In this case, it

may be reused in any location as if it were

new.

16

Page 19

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Dripproof, Splashproof, and Outdoor Busway

Figure 19. Assembly of a typical dripproof, splashproof, or outdoor busway joint. Correct and incorrect assembly of joint shields is illustrated.

Figure 20. Assembly shown without joint caps, wireform springs connected.

17

Page 20

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Dripproof, Splashproof, and Outdoor Busway

Figure 21. View of completed joint assembly with joint caps installed.

Figure 22. View of completed joint assembly showing joint caps.

18

Page 21

Spectra and Spectra II Series™ Plug-In and Feeder Busway

WARNING: Failure to fasten the isolation joint

with screws may result in serious injury or death.

AVERTISSEMENT: Il y a risques de blessures

graves ou même de mort si le joint d'isolation

n'est pas attaché avec des vis.

Installing Dripproof, Splashproof, and Outdoor Busway

Installing an End Box

An end box, as shown in Figure 23, is available to

isolate phases and seal the end of a run. The

installation process is as follows:

1. Fasten the isolation joint to the end of the run

with two screws.

2. Assemble the box over the isolation joint but

do not fasten the wireform springs.

3. Loosely assemble the gasketed joint caps to

set the box position to 10 1/4 inches long. Do

not remove the joint cap knockouts.

4. Fasten the springs and then tighten the cap

bolts.

Figure 23. End box installed on the end of a run.

19

Page 22

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Lifting Bracket

See Note # 8

Lifting Bracket

See Note # 8

Installing Spectra II Series Busway

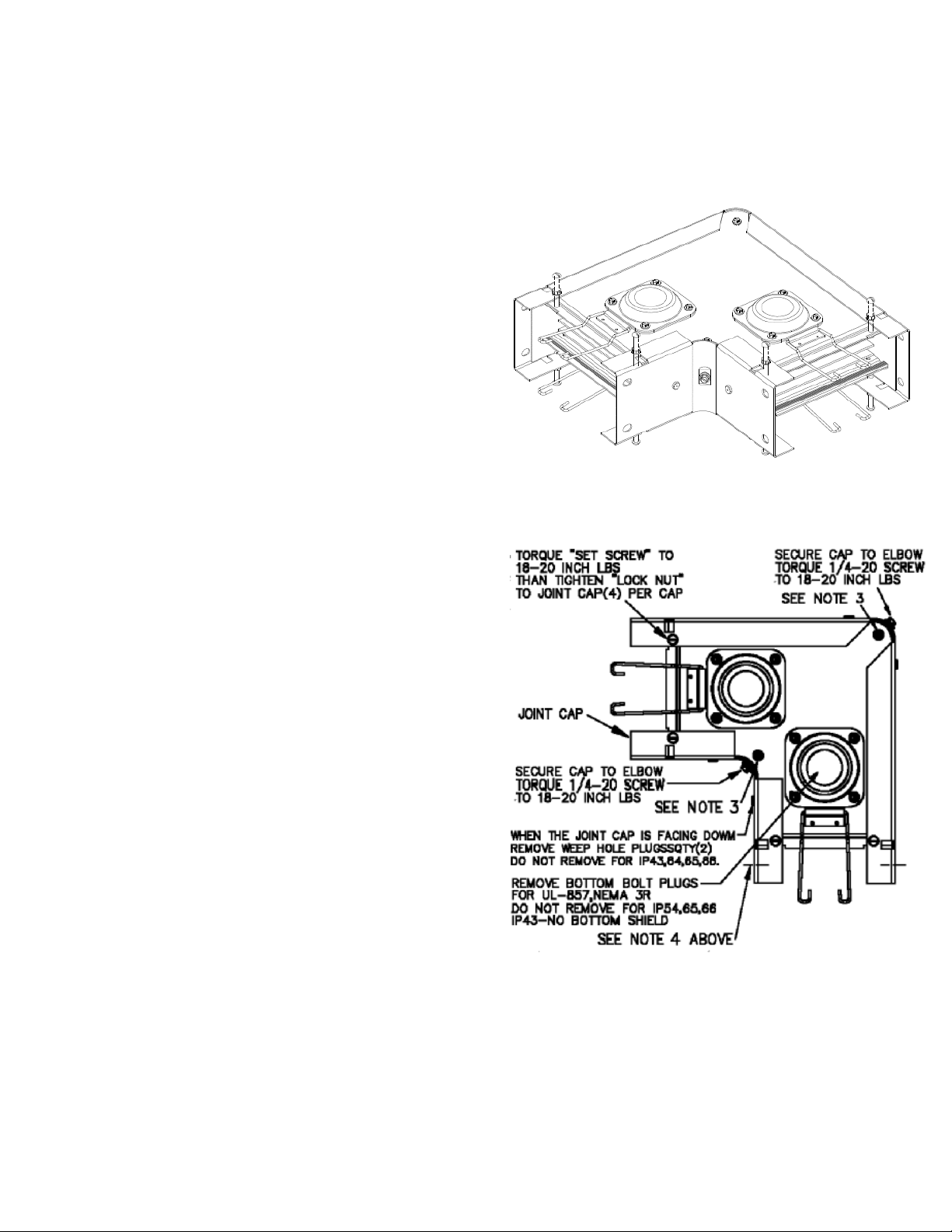

Spectra SeriesTM Busway - Edge wise Outdoor

Elbow Joint

Installation and Maintenance Instructions.

1. Maintain phase alignment using ø side

labels.

2. Do not remove joint attachment screws.

3. Align bus within limits shown in the

installations torque joint bolt to 50 Lb-ft (68

N-M)

4. Set shield in place and align outside edges

with edges of elbow side plates and secure

springs.

5. Important: Insert hole in shield ―Z‖ bracket

over alignment pin on elbow.

6. Attach joint caps:

7. A. Secure joint cap corner with ¼-20 screw

provided

8. B. Torque bolts: 3/8-25 lb-ft

5/16-14-19 Lb-ft

9. Torque ―Set screw‖ to 18-20 inch Lbs then

tighten ―lock nut‖ to joint cap (4) per cap

10. Mega ohm test run before energizing.

Note: 8 – Remove lifting bracket prior to

installing joint shields.

Figure 24. Edge wise outdoor Elbow Joint

Figure 25. Edge wise outdoor Elbow Joint asm. Instructions.

20

Page 23

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Spectra II Series Busway

Spectra SeriesTM Busway - Flat wise Outdoor

Elbow Joint

Installation and Maintenance Instructions.

1. Maintain phase alignment using ø side

labels.

2. Align bus within limits shown in the

installations torque joint bolt to 50 Lb-ft (68

N-M)

3. Set shield in place and align outside edges

with edges of elbow side plates and secure

springs.

4. Important: Attach shields to C-Brackets

using 10/32 screws.

5. Attach joint caps:

6. A. Secure joint cap corner with ¼-20 screw

provided

7. B. Torque bolts: 3/8-25 lb-ft

5/16-14-19 Lb-ft

8. Torque ―Set screw‖ to 18-20 inch Lbs then

tighten ―lock nut‖ to joint cap (4) per cap

9. Mega ohm test run before energizing.

Figure 26. Flat wise outdoor Elbow Joint.

Figure 27. Flat wise outdoor Elbow Joint asm. Instructions.

21

Page 24

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Device

Plug Dimensions

Plug

Overhang

Busway

Each Side

A B C

D

Circuit Breakers

E-Line

13 8 11

21

2 ½

SF

21 ¼

9

11

30 ¼

2 ½

Fusible Switches

30A,60A

13

8 ¾

11 ¼

21 ¾

2 5/8

100A

18 ¾

27 ½

200A

16 5 400A

18 ¾

20 ½

37 ½

7 ¾

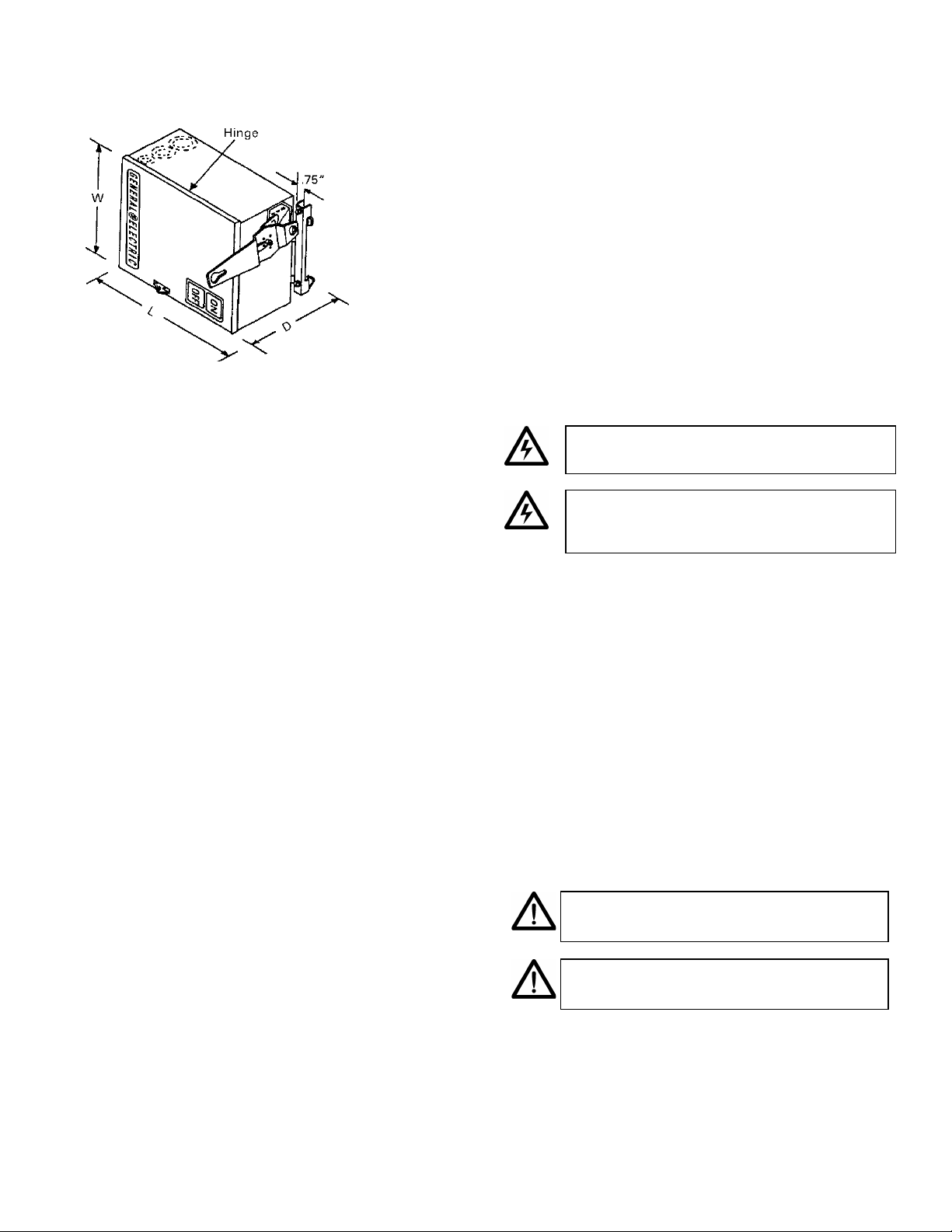

Installing Spectra II Series Busway

Installing Spectra II Series™ Busway

Where To Start

Start the installation, if at all possible, at the

most critical point; such as a main feed box,

switchboard or switchgear, an elbow, or other

critical fitting or termination.

Obstructions

Where a busway run must pass through a wall

or floor, an opening one-inch larger than the

busway cross-section should be provided.

Joints may not occur inside the walls or floors

per N.E.C. A flange is available to mask the

opening after the busway is installed.

After the busway is secured in the hangers,

adjust the hangers on the rods for correct

elevation.

Locate the Ø side down on the busway so

the plugs will be properly oriented.

Sway braces may be required to keep the

run straight or to prevent rotation (furnished

by the installer).

Wall or Column Support: Single rod hangers

(Figure 30 and 31) may be used for mounting

busway on walls or columns by the addition of

an angle support furnished by the installer.

Table 10. Lowamp plug sizes (inches).

Figure 28

4‖ minimum provides clearance for 30-100 amp fusible plugs. 7‖

Minimum for 200 amp fusible plugs. 8‖ Minimum for all other plugs.

See Table 8.

Horizontal Mounting

Overhead Support: ½‖ drop rods are

Maintain a good alignment of the drop rods

Avoid hanging drop rods at a busway joint.

recommended. Max. 10 foot spacing. Drop

rods and other hardware must be furnished

by the installer.

along the busway run.

Figure 29. Lowamp plug data.

22

Page 25

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Bar Material

Rated Load

Amps

Dimension “A”

In.

Aluminum

225

3

400

3 3/8

600

4

Copper

225

3

400 3 600

3 3/8

Amperes

Weight

30

24

60

25

100

28

200

46

400

135

Plug Weight (lbs.) – Circuit Breakers

Frame Type

Weight

E

28

SF

39

Ampere

Copper

Aluminum

3-wire

4-wire

3-wire

4-wire

225 7 8 5 6

400 7 8 6 7

600 8 9 7 8

800

11

12 9 10

Figure 31. Edgewise.

Figure 30. Flatwise (Standard).

Figure 32. Trapeze Edgewise.

Figure 33. Trapeze Flatwise.

Installing Spectra II Series Busway

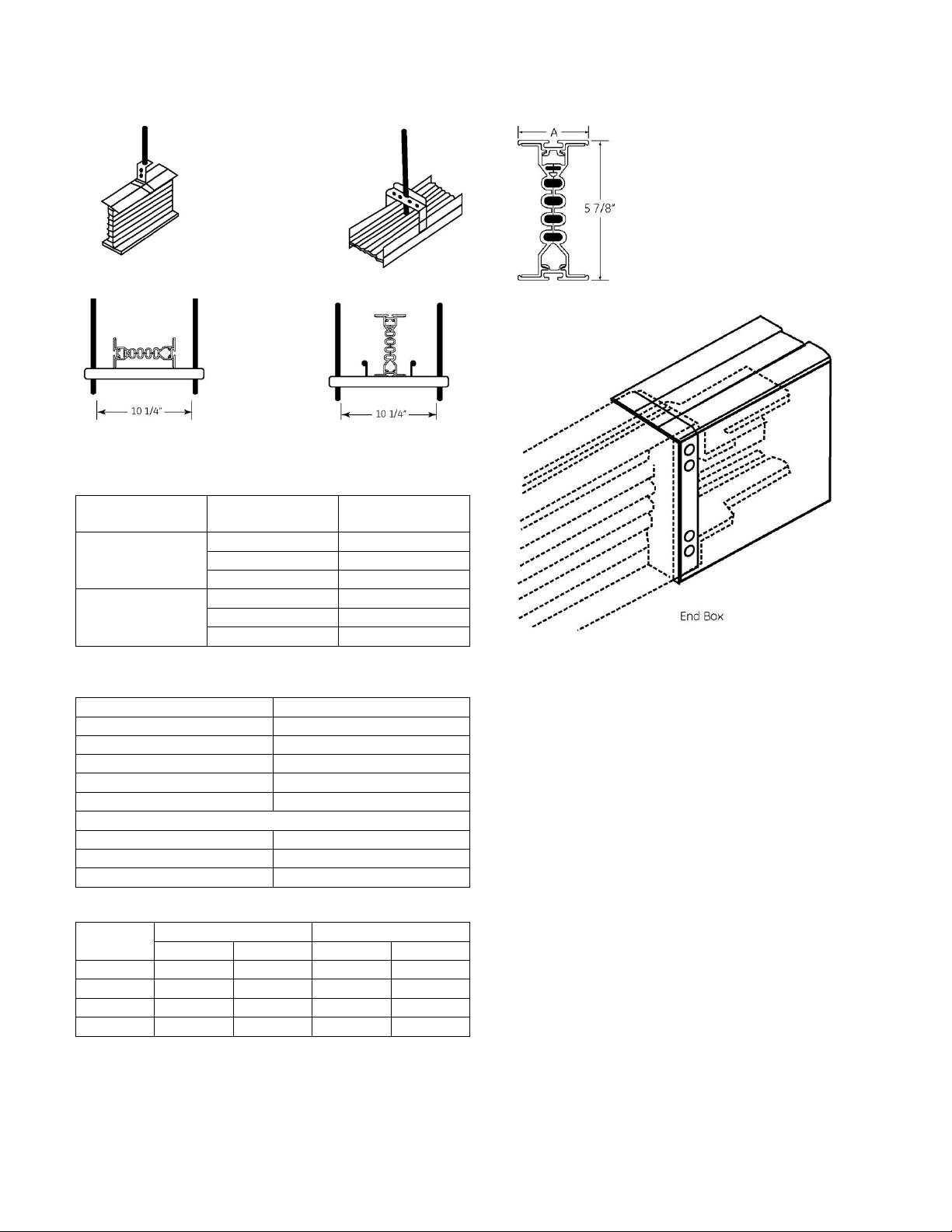

Figures 26-29

Table 11 Busway Cross Section

Table 12 Plug Weight (lbs)

QMR Fusible Switches

Table 13 Weight (lbs./ft.) – Busway

Figure 34. Busway Cross-Section.

Figure 35. End Box.

Installing End Box

Loosen the screw on back of the end box

and separate the end box cap from the end

box.

Slide the end box over the end of the

busway and bolt it to the busway. Note:

make sure the end box is tightly against the

busway.

Place the end box cap on the end box and

bolt it to the busway.

Tighten the screw on the back of the end

box.

Joining Lengths

1. Remove shipping caps from bar end and

discard, but retain the bolts.

2. Remove one joint cap from the two pieces

to be joined, retaining the bolts. Note that

joint pack may be wider than bus.

23

Page 26

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Installing Spectra II Series Busway

3. Align sections to be joined by matching up

―Ø side‖ labels attached at ends of each

section.

4. If necessary, loosen joint bolt slightly.

5. Slide sections together. Make sure that the

busbars interweave the insulators as shown

in Figure 36-38. NOTE: the housing ground

side plates must pass between the outside

insulators and the joint sides.

6. The standard distance between the

housings is 9‖ as shown in Figure 37.

However, the joint is also adjustable as

shown in Figures 36-38. Simply move the

sections in or out to the desired length as

shown and remove the twist outs in both

joint caps. See Figure 39 NOTE: Remove

shipping screw to center joint when

adjusting to max. and min. length.

7. Insert mounting screws into the joint cap

which is already attached and tighten to

align centerlines of the two bus sections.

8. Inspect busway run for the straightness in

all planes, and make adjustments, if

necessary, for good alignment.

9. Lubrication grease has been applied to the

joint is designed for easy removal either during

or after installation.

1. De-energize the busway. Remove either

joint cap.

2. Remove the shipping screw, illustrated in

Figure 37.

3. Grasp the joint sides and pull toward the

narrow side of the busway. A gently rocking

motion may necessary to aid the joint in

sliding out.

NOTE: With the joint removed the busway is

segmented and section of the run away

from the source is electrically isolated from

the source.

4. To reinstall the joint, simply slide the joint

back into place. CARE MUST BE TAKEN TO

ASSURE SPLICE PLATES AND INSULATORS

ARE PROPERLY POSITIONED. It is not

necessary to reinstall the shipping screw.

5. Install joint cap(s), as required.

6. Megger at 1000VDC the complete run of

busway before energizing.

Joints With +/- .50 Inch Adjustability

joint bolt head and thread to reduce friction.

Do not remove this grease.

10. Tighten the joint bolt to 50 foot-pounds.

When the Belleville springs on both sides are

flattened, the bolt is fully torqued. The bolt

head may be relocated to the opposite side

of the busway if it is inaccessible.

11. Install second joint cap and tighten the joint

cap screws.

12. During installation occasional meggering

Figure 36 “Minimum”

should reveal any improperly made

assemblies. Resistance should not drop

below one megohm for 100 feet of busway.

Megger the complete run before energizing.

To Remove the Joint or Captive Piece of

Busway

Should it become necessary to isolate for

testing or troubleshooting a piece or run off

Spectra and Spectra II Series ™ busway the

Figure 37 “Standard”

24

Page 27

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Figure 40. Plug mounting.

Figure 40B. Break-Off Tabs

WARNING: HAZARD AND ELECTRICAL SHOCK OR

BURN! The plug must be turned OFF before

installing on or removing from the busway.

Failure to do so may cause serious injury or

death! It is a good safety to de-energize the

busway before inserting or removing bus plugs.

In the United States, it is necessary to comply

with all Federal and local safety procedures,

including NFPA 70E 2-1.3 directing the use of

appropriate PPE (Personal Protective Equipment)

such as face shield, insulating gloves, and flame

resistant clothing. In Canada, be sure to comply

with the appropriate requirements of the

Canadian Electrical Code. Only properly trained

personnel may install bus plugs on or remove

them from energized busway. In addition, all bus

plug installation instructions must be followed

completely.

Installing Spectra II Series Busway

Figure 38. “Maximum”

Figure 39. Joint Cap

Note the following points concerning busway

plugs:

Inspect the plug before installing on the

busway.

Stab fingers have been lubricated with

grease, which should not be removed.

Dripproof plug-in busway has a dripproof

cover over the outlet. Unscrew the cover

and reattach the cover to the left side of the

outlet, using the screw on the right side of

the cover. This relocates the cover so it is

out of the way for plug insertion.

The actuator bar polarizes and locates the

plug in the correct position only.

Plugs are interlocked, permitting

engagement and disengagement with the

busway only when in the OFF position.

Place the operating handle at the desired

position on the plug and secure it with the

screw provided. The NEC requires the ON

25

Page 28

Spectra and Spectra II Series™ Plug-In and Feeder Busway

CAUTION: Make certain that the bus plug is level

in all orientations with the busway after all

connections are completed. Failure to level the

plug could result in overheating of the plug

connection.

NOTE: On the vertically mounted plugs, push up

on the plug to remove the weight of the plug

from the alignment pin before tightening the

bolts in step 4.

WARNING: Be sure that the plug-assist pointer is

lined up with the IN position before turning the

plug on. Failure to do so may result in serious

injury or death.

Installing Spectra II Series Busway

handle position to be up and the OFF handle

position to be down. If plug-assist has been

furnished on the plug, the operating handle

may be used as a wrench to operate the

mechanism.

5. Engage bus plug by rotating the plug assist

mechanism, the shutter should open and

the bus stabs fingers will engage the bus

bars. The pointer should indicate ―Stabs-IN‖.

To install a plug where the rear plug hanger

interferes with a joint cap, it is necessary to

remove the break-off tabs, as shown in the

Figure 40B.

On large plugs, drop rod brackets are

provided for auxiliary support of the plug on

the horizontal runs.

Removing a Plug

Installing a Plug Not Equipped with PlugAssist

First turn the device OFF. Then follow the

appropriate procedure above in reverse order.

1. Make sure the device is in the OFF position.

2. Loosen the four bolts on the hanger hooks.

3. Align the actuator bar of the bus plug with

the vertical actuator bar slot on the shutter

and push firmly, the shutter will open and

the bus plug stabs fingers will engage the

bus bars.

4. Push the stabs into the full contact with the

busway.

5. Engage the four hanger hooks with the

busway rails and tighten the bolts.

Installing a Plug Equipped with the Plug-Assist

1. Make sure the device is in the OFF position

and the plug-assist indicator is rotated fully

toward the stabs-OUT position.

2. Loosen the four bolts on the hanger hooks.

3. Align the actuator bar of the bus plug with

the vertical actuator bar slot on the shutter

and attach the line end hanger hooks to the

bus rail and tighten.

4. Recheck alignment of actuator and vertical

slot and attach load end hanger hooks to

bus rail and tighten.

26

Page 29

Spectra and Spectra II Series™ Plug-In and Feeder Busway

WARNING: De-energize the busway before

performing any of the following operations.

Failure to do so may result in serious injury or

death.

AVERTISSEMENT: Mettez hors tension la

canalisation pour barres omnibus avant

d'entreprendre n'importe laquelle des opérations

suivantes. Il y a risques de blessures graves ou de

mort, si cette procédure n'est pas respectée.

NOTE: It is important to press the center of the

plug inward several times to center it in the hole.

Liquid soap can be used to lubricate the plug for

re-installation.

NOTE: Il est important de presser plusieurs fois le

centre de la fiche boîtier pour le centrer dans le

trou. On peut utiliser du savon liquide pour

lubrifier la fiche boîtier si on la réinstalle.

Busway Maintenance Procedures

Busway Maintenance Procedures

Protecting the Busway from Contamination

Be particularly careful during installation to

protect the busway from contaminants. Should

the busway become contaminated with water, it

should be baked dry or replaced. Contact GE for

instructions.

Maintenance Procedures

A periodic maintenance schedule should be

established to obtain the best service from the

busway. An annual check and overall

maintenance procedure for the busway, busplug

devices, and all connections should be followed as

a minimum requirement. Equipment subject to

highly repetitive operation may require more

frequent maintenance.

Keep a permanent record of all maintenance

work. The record should include a list of periodic

checks and tests, the dates they were performed,

the condition of the equipment, and any repairs or

adjustments. Maintenance employees should

follow all recognized safety practices, such as

those contained in the National Electrical Code,

OSHA, and in company or other safety regulations.

Inspecting the Busway

The busway should be periodically inspected

to spot trouble areas or changes in operating

condition.

Remove any accumulations of dust, dirt, or

other foreign matter.

Eliminate moisture from leaks or condensation

dripping from pipes.

Check for any equipment installed near the

busway that might cause damage because of

external heating.

Inspect the Belleville washers at the joint to

ensure that the springs are flat. Flat washers

indicate that proper joint pressure is being

maintained. It is not necessary to recheck the

torque on joint bolts so long as the visual

check is satisfactory. If the washers are not

flat, it is recommended to de-energize the

Busway, completely loosen the joint bolt and

re-tighten.

Inspecting Current-Carrying Components

To check joints covered by a shield, as shown

in Figure 19, carefully pry out the rubber plug

by sliding a screwdriver tip under the plug,

pressing in slightly toward the hole center, and

prying out. (The bolt head is usually on the side

of the bus marked Ø SIDE, but the installer

may have reversed the bolt). Tighten the bolt

to 50 lb-ft (68 N-m). Clean the outer surface of

the shield. Reinstall the rubber plug by hooking

in one edge and pressing the plug in place.

Carefully inspect all visible electrical joints and

terminations for tightness of bolts, nuts, and

other fasteners.

Check for signs of overheating at joints,

terminations, and fuse clips.

Check for deterioration in insulating material

or melting of sealing compound.

Ensure that the condition that caused any

overheating has been eliminated.

27

Page 30

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Busway Maintenance Procedures

Check for missing or broken parts, proper

spring tension, free movement, rust or

corrosion, dirt, excessive wear, arc spatter,

sooty deposits, and tracking. Clean or replace

parts as required.

After Seismic event check for proper spring

tension and yielding of spring hanger parts.

Replace parts as required.

Megohm test at 1000 VDC the system before

re-energizing. The resistance should not be

below 1 megohm per 100 feet of busway.

For general instructions regarding handling,

installation, operation, and maintenance or

busway systems rated at 600 volts or less, see

NEMA Publication BU1.

Additional procedures for inspection, thermal

scanning, safety practices, and maintenance are

described in ANSI/NFPA Standard 70B,

"Recommended Practice for Electrical Equipment

Maintenance" available from the National Fire

Protection Association, Quincy, Massachusetts.

28

Page 31

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Busway Installation Checklist

GE Job Number Customer ID Number

Run Identification Amp Rating Service

1. Was there any shipping damage? Report any minor damage or missing parts to the factory. No

Be sure to include the item number.

2. Proper storage before actual installation.

a. Were bus components kept clean and dry? Yes

b. Were bus components exposed to corrosive fumes, liquids, salts, or concrete materials? No

3. Have you read this installation instruction book? Yes

4. Bus exposure during installation.

a. Were bus components kept clean and dry? Yes

b. Were bus components exposed to corrosive fumes, liquids, salts, or concrete materials? No

c. Was there any mechanical damage due to handling? No

5. Did each piece of bus get a pre-installation megohm test? Yes

(Individual pieces should megohm test as infinite resistance.

Consult the factory if you experience a lower reading.)

6. Mounting and support.

a. Is each 10 feet of bus run supported, including any vertical sections? Yes

(Closer supporting may be required, based on job specifications.)

b. Does any support interfere with a bus joint? No

c. Are any bus terminations to other equipment used as support? No

(Busway weight should not bear on equipment, such as switchgear,

switchboards, or transformers.)

7. Is the bus installed level and plumb? Yes

8. Was a periodic megohm test performed as this run was installed? Yes

(After every two or three items or as critical items are installed.

Joints should be tightened for all megohm testing.)

9. Has the bus been inspected for proper phasing? Yes

10. Are all joint bolts properly tightened to 50 lb-ft (68 N-m) torque? Yes

11. On vertically mounted bus using spring hangers, were the correct settings verified? Yes

(See Figure 6 in the installation instructions.)

12. Did you check for proper clearances for the bus at floors, walls, ceilings,

other bus, and trades? (Never use cement to seal between the bus and floors or walls.) Yes

13. Have all shipping screws been removed from expansion lengths? Yes

14. Have nonrigid hangers been used beyond the free end of expansion lengths

(except at the farthest end) to allow the busway to expand toward the expansion box? Yes

15. Was all foreign material removed from the installed bus? Yes

16. Was a final megohm test performed when all bus was installed? Yes

(Record readings on the separate sheet provided.)

29

Page 32

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Busway Installation Checklist

Outdoor and Dripproof Bus

17. Verify the orientation of weep holes. Are all open weep holes in joint caps,

elbows and shields facing downward? Yes

(Do not remove shield plugs or weep-hole plugs in top or side positions.)

18. Are all drain holes clear in both bus and joint caps? (All construction debris removed.) Yes

19. Were joints assembled within the width of the housing ground plates? (See outdoor step 4.) Yes

20. Are 3/8" joint cap bolts properly tightened to 25 ft-lb (34 N-m), and all 5/16" joint cap

bolts tightened to 14-18 ft-lb (19-24 N-m)? Yes

21. Were shields aligned at the edges of housing ground plates and all springs seated properly? Yes

22. Were isolation joints screwed in place before end boxes (when present) were installed? Yes

23. Were joint cap knockouts left in to set end boxes to 10 1/4 inches,

as shown in Figure 23 of DEH-40087? Yes

Note: Please list any exceptions made to this checklist and any other comments related to the installation of this run of bus:

This checklist is intended to insure a sound installation of GE busway. It is not intended to cover all items related to the

installation, successful startup, and long-term use of the product and in no way relieves the contractor of his obligation to

meet all specification and code requirements.

Installation Contractor

Signed Date

30

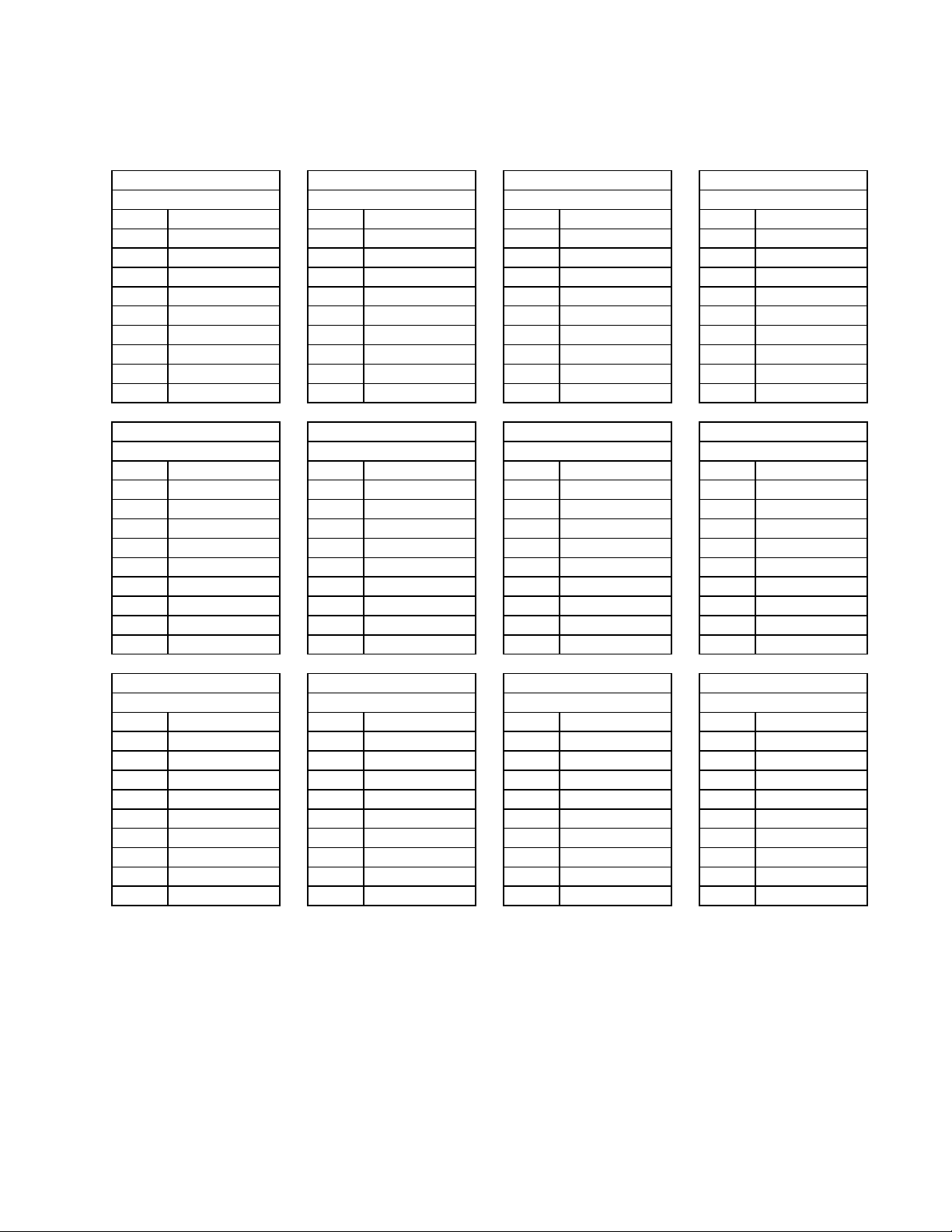

Page 33

Spectra and Spectra II Series™ Plug-In and Feeder Busway

Date

Date

Date

Date

Run ID

Run ID

Run ID

Run ID

A-G

A-G

A-G

A-G

B-G

B-G

B-G

B-G C-G

C-G

C-G

C-G

N-G

N-G

N-G

N-G

A-B

A-B

A-B

A-B A-C

A-C

A-C

A-C

B-C

B-C

B-C

B-C

A-N

A-N

A-N

A-N B-N

B-N

B-N

B-N

C-N

C-N

C-N

C-N

Date

Date

Date

Date

Run ID

Run ID

Run ID

Run ID

A-G

A-G

A-G

A-G B-G

B-G

B-G

B-G

C-G

C-G

C-G

C-G

N-G

N-G

N-G

N-G A-B

A-B

A-B

A-B

A-C

A-C

A-C

A-C

B-C

B-C

B-C

B-C A-N

A-N

A-N

A-N

B-N

B-N

B-N

B-N

C-N

C-N

C-N

C-N

Date

Date

Date

Date

Run ID

Run ID

Run ID

Run ID

A-G

A-G

A-G

A-G B-G

B-G

B-G

B-G

C-G

C-G

C-G

C-G

N-G

N-G

N-G

N-G A-B

A-B

A-B

A-B

A-C

A-C

A-C

A-C

B-C

B-C

B-C

B-C A-N

A-N

A-N

A-N

B-N

B-N

B-N

B-N

C-N

C-N

C-N

C-N

Busway Installation Checklist

Pre-Energizing Megohm Readings

31

Page 34

These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that

may be met in connection with installation, operation, or maintenance. Should further information be desired or should

particular problems arise that are not covered sufficiently for the purchaser’s purposes, the matter should be referred to the

GE Company.

General Electric Company

41 Woodford Ave. Plainville CT 06062

DEH40087 R08 03/26/2012 ©2012 General Electric Company CR # R0914489

Loading...

Loading...