Page 1

Page 2

Page 3

Foreword

Geely “MK” series sedans (JL7132U,JL7132HU,JL7152U,JL7152HU,JL7162U) are brand

new superior models developed by Geely Group who has fully proprietary intellectual property

rights. As a result of the three years of involvements and ef forts of the experts from Geely Automobile Research Institute, these sedans reach international leading level in model design, power,

sense of comfort, safety and manufacturing technology while featured in beautiful appearance,

economy , environment protection and safety. The meaning of MK implied that Geely Automobile

has a great development from caterpillar to butterfly . W ith respect to the power, Geely “MK” series

sedans are equipped with 1.3L, 1.5L, and 1.6L EFI engines developed and manufactured by Geely

itself, and has reached “Chinese III” (Euro III) emission standard.

This manual contains a detailed description of the structures and principles, servicing and adjustment,

removal, assembling technology and matching clearance of the parts of the Geely “MK” sedans

with torque information of the bolts and nuts as well as schematic diagram for special tool operation.

This manual also introduces the transmission control system of the automatic transmission models,

vehicle electric circuits and elaborates ABS system, SRS, BOSCH M7.9.7 electronic control fuel

injection and ignition system, rear parking radar, sound, air conditioning and onboard hands-free

phone system. You can refer to this manual for the information about the regular maintenance,

servicing, adjustment, troubleshooting, removal and installation procedure, specific operations of

the “MK” sedans.

This manual covers the matching relation among the engine assembly, transmission assembly and

the vehicle, but does not have the further description of the structures and principles of the engine

and transmission assemblies and their servicing process. You can refer to the service manuals

solely prepared for engine assembly and transmission assembly for these information.

All information in this manual is based on the latest products released at the time of publication of

this manual. However, the specifications and procedures may need to be modified, and the subsequent change will be revealed in later versions.

This manual is prepared by Geely Automobile Research Institute under the assistance of technical

staff from Zhejiang Geely Automobile Co., Ltd and Geely International Corporation. Readers

discovering during the use of this manual the errors and careless omissions due to limited skills of

the preparers and tight schedule are encouraged and pled to contact Geely International in time for

our timely correction of the mistakes.

Geely International Corporation

Nov . 2007

Page 4

Table of Contents

Table of Contents

Part I General Information

Chapter 1 How to Use This Manual .................................................................................. 1-1

Chapter 2 Repair Instruction ............................................................................................. 1-3

Part II V ehicle Usage and Maintenance

Chapter 1 Brief Introduction of Geely MK ......................................................................... 2-1

Section 1 Major Functional and Technical Data of MK Series. ...................................... 2-1

Section 2 Vehicle System Configuration........................................................................ 2-3

I

Section 3 Main Vehicle Test Technical Specification...................................................... 2-5

Chapter 2 Usage and Maintenance of MK Series ............................................................ 2-6

Section 1 Usage of MK Series ....................................................................................... 2-6

Section 2 Maintenance Category and Content of MK Sedan..........................................2-12

Section 3 Daily Maintenance of MK Sedan.................................................................... 2-18

Part III Engine

Chapter 1 Engine Assembly ............................................................................................... 3-1

Section 1 Engine Inspection........................................................................................... 3-1

Section 2 Removal of the Engine Assembly from the Vehicle ....................................... 3- 5

Section 3 Drive Belt Replacement.................................................................................. 3 - 7

Chapter 2 Engine Mechanical ............................................................................................ 3-8

Section 1 Engine Components....................................................................................... 3-8

Section 2 Throttle Body .................................................................................................. 3-12

Section 3 Valve Clearance Adjustment .......................................................................... 3-14

Chapter 3 Fuel System ....................................................................................................... 3-15

Section 1 Check Fuel System Pressure......................................................................... 3-15

Section 2 Fuel Pump Inspection..................................................................................... 3-16

Section 3 Fuel Pump Replacement................................................................................ 3-17

Page 5

II

Section 4 Fuel Emission Control System ....................................................................... 3-18

Section 5 Carbon Canister Replacement....................................................................... 3-19

Chapter 4 Exhaust System ................................................................................................. 3-21

Chapter 5 Cooling System ................................................................................................. 3-22

Section 1 System Inspection .......................................................................................... 3-22

Section 2 Radiator Replacement................................................................................... 3-24

Chapter 6 Manual Transaxle Assembly ............................................................................. 3-25

Section 1 Frequent Problem Diagnosis.......................................................................... 3-25

Section 2 Vehicle Speed Sensor Replacement ............................................................. 3-26

Section 3 Manual Transaxle Replacement..................................................................... 3-27

Section 4 Transmission/Transaxle Case Oil Seal Replacement .................................... 3-28

Chapter 7 Automatic Transaxle Assembly ........................................................................ 3-29

Table of Contents

Section 1 Frequent Problems Diagnosis........................................................................ 3-29

Section 2 Hydraulic Torque Converter and Transaxle.................................................... 3-30

Section 3 Differential Front Oil Seal (ATM) .................................................................... 3-33

Section 4 Neutral Switch Assembly................................................................................ 3-35

Part IV Chassis

Chapter 1 Transmission Control ........................................................................................ 4-1

Section 1 Introduction of Transmission Control ............................................................. 4-1

Section 2 Cable Type Transmission Control .................................................................. 4-3

Section 3 Manual Transmission Shift Mechanism.......................................................... 4-5

Section 4 Automatic Transmission Shift Mechanism...................................................... 4 -7

Chapter 2 Accelerator Pedal Device ................................................................................. 4-11

Section 1 Introduction of Accelerator Pedal................................................................... 4-11

Chapter 3 Clutch Control System ...................................................................................... 4-12

Section 1 Introduction of Clutch Centrol......................................................................... 4-12

Section 2 Clutch Pedal ................................................................................................... 4-13

Chapter 4 Propeller Shaft/Driveshaft ................................................................................ 4-17

Section 1 Propeller Shaft, Driveshaft and Transaxle ..................................................... 4-17

Page 6

Table of Contents

Section 2 Front Driveshaft.............................................................................................. 4-19

Section 3 Front Wheel Hub ............................................................................................ 4-30

Section 4 Rear Wheel Hub and Bearing Assembly ....................................................... 4-35

Chapter 5 Front Suspension System ................................................................................ 4-38

Section 1 Front Suspension System .............................................................................. 4-38

Section 2 Front Suspension ........................................................................................... 4-40

Section 3 Front Wheel Alignment................................................................................... 4-43

Section 4 Front Strut Assembly...................................................................................... 4-46

Section 5 Front Lower Swing Arm Assembly ................................................................. 4-49

Section 6 Front Stabilizer Bar and Link Rod Assembly.................................................. 4-53

Chapter 6 Rear Suspension System ................................................................................. 4-54

Section 1 Rear Suspension System............................................................................... 4-54

III

Section 2 Rear Wheel Alignment ................................................................................... 4-56

Section 3 LH/RH Rear Suspension Coil Spring ............................................................. 4-57

Section 4 Rear Absorber Installation Assembly ............................................................. 4-60

Section 5 Rear Suspension Crossmember .................................................................... 4-62

Chapter 7 Wheel .................................................................................................................. 4-66

Section 1 Tire Inspection and Wheel Replacement....................................................... 4-66

Chapter 8 Power Steering System .................................................................................... 4-67

Section 1 Power Steering System.................................................................................. 4-67

Section 2 Steering Drive and Control Mechanism ......................................................... 4-69

Section 3 Steering Pipeline Component ........................................................................ 4-73

Section 4 Power Steering Gear...................................................................................... 4-75

Chapter 9 Brake System .................................................................................................... 4-79

Section 1 Brake System ................................................................................................. 4-79

Section 2 Brake Fluid ..................................................................................................... 4-81

Section 3 Brake Pedal.................................................................................................... 4-82

Section 4 Brake Master Cylinder Assembly ................................................................... 4-85

Section 5 Vacuum Booster ............................................................................................. 4-91

Section 6 Front Brake Disc............................................................................................. 4-94

Page 7

IV

Section 7 Rear Brake Drum............................................................................................ 4-99

Section 8 Parking Brake System.......................................................................................4-106

Table of Contents

Part V Electric System & Accessory

Chapter 1 Starting and Charging System ......................................................................... 5-1

Section 1 Starting System (MR479Q, MR479QA, MR481QA) ...................................... 5-1

Section 2 Charging System (MR479Q, MR479QA, MR481QA) .................................... 5-3

Chapter 2 Combination Instrument System ..................................................................... 5-7

Section 1

Section 2 Malfunction Symptom Table and Troubleshooting......................................... 5-10

Chapter 3 Wiper and Washer System ............................................................................... 5-21

Section 1 Wiper and Washer System Inspection........................................................... 5-21

Section 2 Replacement and Adjustment........................................................................ 5-23

Chapter 4 Light System ...................................................................................................... 5-26

Section 1 Light System Introduction............................................................................... 5-26

Section 2 Light System Malfunction Inspection ............................................................. 5-28

Section 3 Headlamp Replacement................................................................................. 5-34

Section 4 Front Fog Lamp Replacement ...................................................................... 5-35

Section 5 Rear Combination Lamp Replacement.......................................................... 5-36

Section 6 High-mounted Stop light Replacement .......................................................... 5-36

Section 7 Front Reading Lamp Replacement ................................................................ 5-37

Section 8 Rear Reading Lamp Replacement................................................................. 5-37

Wiring diagram of Combination Instrument and Location of Multi-pin Plug-in Terminal

5-7

Section 9 License Plate Lamp Replacement ................................................................. 5-37

Chapter 5 Audio System ..................................................................................................... 5-38

Section 1 Audio System Description .............................................................................. 5-38

Section 2 Audio System Connector Terminal Layout ..................................................... 5-40

Section 3 Audio System Inspection................................................................................ 5-41

Section 4 Audio System Replacement........................................................................... 5-52

Chapter 6 SRS (Supplemental Restraint System) ............................................................ 5-54

Page 8

Table of Contents

Section 1 SRS General Information ............................................................................... 5-54

Chapter 7 Air Conditioning System ................................................................................... 5-72

Section 1 General Information........................................................................................ 5-72

Section 2 Refrigerant...................................................................................................... 5-77

Section 3 A/C Operating Mechanism ............................................................................. 5-83

Section 4 Heater, Ventilation and Air Conditioning ........................................................ 5-86

Section 5 Layont of Air Conditioning Hose..................................................................... 5-92

Section 6 Multi-wedge belt (Connecting Compressor and Crankshaft Pulley).............. 5-93

Section 7 Compressor Assembly.................................................................................... 5-94

Section 8 Condenser Fan and Condenser Assembly.................................................... 5-96

Chapter 8 MK-60 ABS System ........................................................................................... 5-99

Section 1 ABS Diagnosis................................................................................................ 5-99

V

Section 2 ABS System Check ...................................................................................... 5-103

Section 3 Removal and Installation.............................................................................. 5-138

Section 2 Power Door Lock Control System ................................................................ 5-142

Part 6 Interior & Exterior Trim and Accessory

Chapter 1 Front Seat Assembly ......................................................................................... 6-1

Chapter 2 Rear Row Seat Assembly ................................................................................. 6-3

Chapter 3 Front Seat Belt ................................................................................................... 6-5

Chapter 4 Rear Seat Belt .................................................................................................... 6- 9

Chapter 5 Dashboard, Middle Console and Instrument Panel ....................................... 6-11

Chapter 6 Windshield ......................................................................................................... 6-16

Chapter 7 Rear Window Glass (with Defrosting Heater Wire) ........................................ 6-20

Chapter 8 Side Inner Panel Trim ........................................................................................ 6-22

Chapter 9 Roof Trim ............................................................................................................ 6-25

Chapter 10 Front Door Interior Trim .................................................................................. 6-27

Chapter 11 Rear Door Interior Trim ................................................................................... 6-30

Chapter 12 Front Bumper ................................................................................................... 6-33

Chapter 13 Rear Bumper .................................................................................................... 6-35

Page 9

VI

Chapter 14 Outside Rearview Mirror ................................................................................. 6-37

Chapter 15 Door Protecting Stripe .................................................................................... 6-38

Chapter 16 Carpet and Insulator ....................................................................................... 6-39

Chapter 17 Moonroof Assembly (Optional) ...................................................................... 6-40

Chapter 18 Plug List ........................................................................................................... 6-42

Table of Contents

Part 7 Body

Chapter 1 Survey ................................................................................................................ 7-1

Section 1 Body Structure................................................................................................ 7-1

Chapter 2 Body Repair ....................................................................................................... 7-9

Section 1 Body Damage Forms and Requirements for Repair...................................... 7-9

Section 2 Typical Technique of Body Panel Repair ....................................................... 7-16

Section 3 Repair After Body Damage ............................................................................ 7-16

Section 4 Features and Composition of Automobile Body ............................................ 7-24

Section 5 Painting Techniques After Body Repair ......................................................... 7-35

Section 6 Service Data For for Body.............................................................................. 7-36

Attachment: Body Key Dimensions

Appendix: T orque Table of the Fasteners for Important Assembly

Page 10

General Information - How to Use This Manual

1-1

Part 1 General Information

Chapter 1 How to Use This Manual

I. Instruction

1. General Information

(1)This manual conform to the first part of GB/T1.1--2000 Standardization Guide: The structure and preparing rule of the standard.

(2)Generally, the repairing job can be divided into the following 3 procedures:

1. Diagnosis

2. Removal and installation, replacement, disassembly and inspection, adjustment

3. Final inspection

(3) The first procedure “Diagnosis” (the details refers to each section or chapter) and second procedure “Removal and installation, replacement, disassembly and inspection, adjustment” are scattered in the chapters and

sections, and this manual omits the third procedure “Final inspection”.

(4) This manual does not include the following basic operations which are imperative in real scenarios.

a.

operate the jack or lifter

b. clean the removed parts if necessary.

c. inspect the appearance

2. Preparation

SST (Special Service Tools) and SSM (Special Service Materials) may be required and correctly used based

on the repairing condition, make sure the job procedure is followed.

3. Repair Procedure

(1) The disassembly illustration is placed under the title.

(2) The illustration shows the disassembly of the parts to help you understand the assembly of the parts.

(3) Non-reusable parts need to be coated with grease, and the precoated parts and torque are specially shown

in the disassembly illustration.

(4) Sometimes, the illustrations of the similar model are used where there may be some details differently

from the actual vehicle.

(5)The operational procedure is described in the following ways:

a. The illustration shows what to do and where to do it.

b. The task heading tells what to do.

c. The detailed text tells how to perform the task and gives other information such as specifications and

warnings.

4. Specification

Specifications are presented in bold type throughout the manual.

5.Term Definition

Caution indicates there is a possibility of injury to you or other people.

Notice indicates the possibility of damage to the components being repaired.

Tip provides additional information to help you perform the repair efficiently.

6. International System of Unit

The Units given in this manual are primarily expressed according to the International System of Unit.

Page 11

1-2

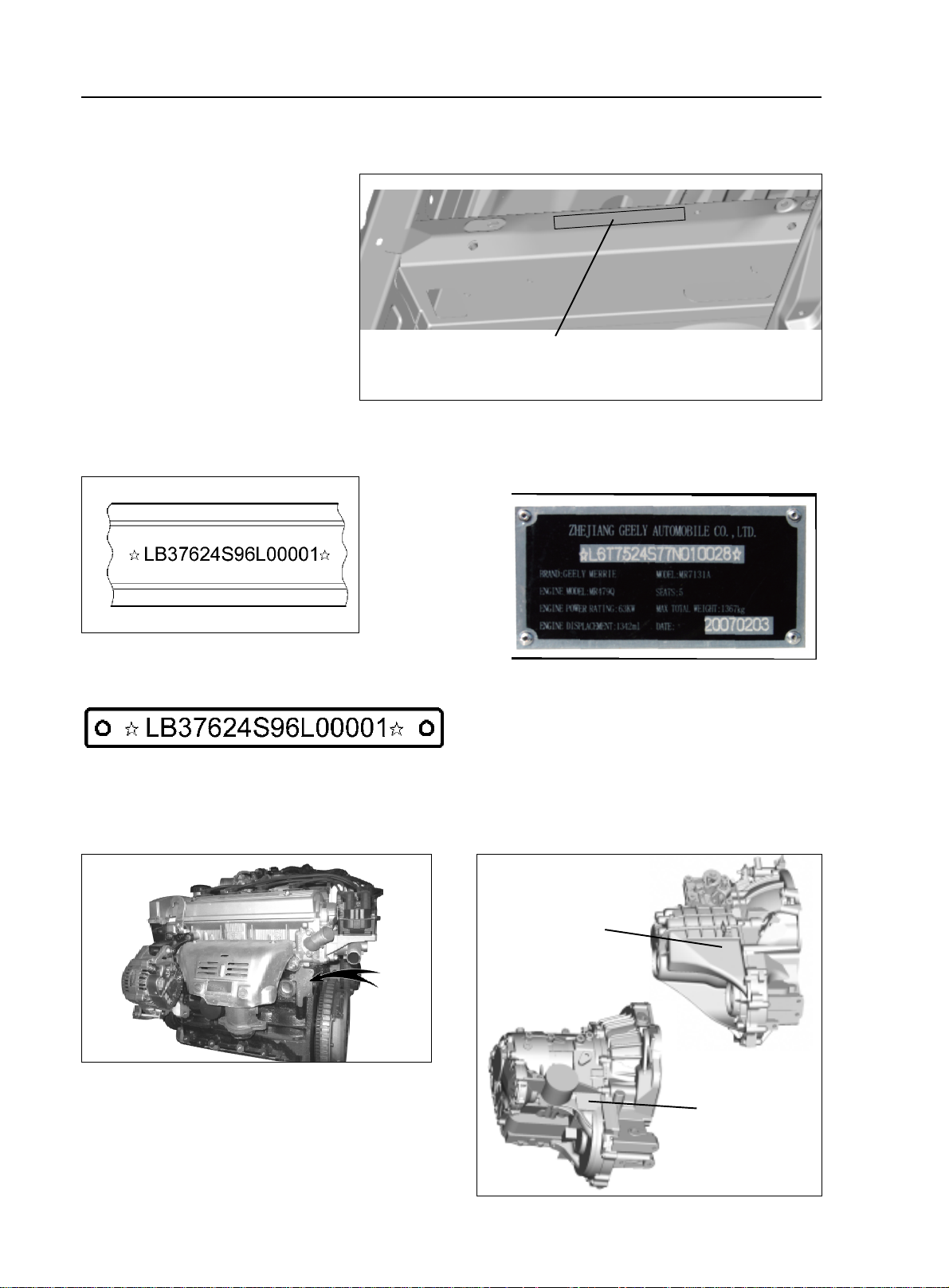

II. Vehicle Identification

1. Vehicle Identification Number

(VIN):

Vehicle Identification Number

(VIN) is the legal identification of the

vehicle which is printed on the middle

of the engine compartment cowl (as

shown in the illustration).

General Information - How to Use This Manual

VIN code position

2. VIN Code

4. VIN Code: on the left lower corner of the front windshield.

5. Engine Number:

marked on the engine block as shown in the illustration

3. Ex-work Nameplate: on the middle of the engine

compartment cowl

6. Transmission Mark:

printed on the left side of the transmission

Mark position

Mark position

Page 12

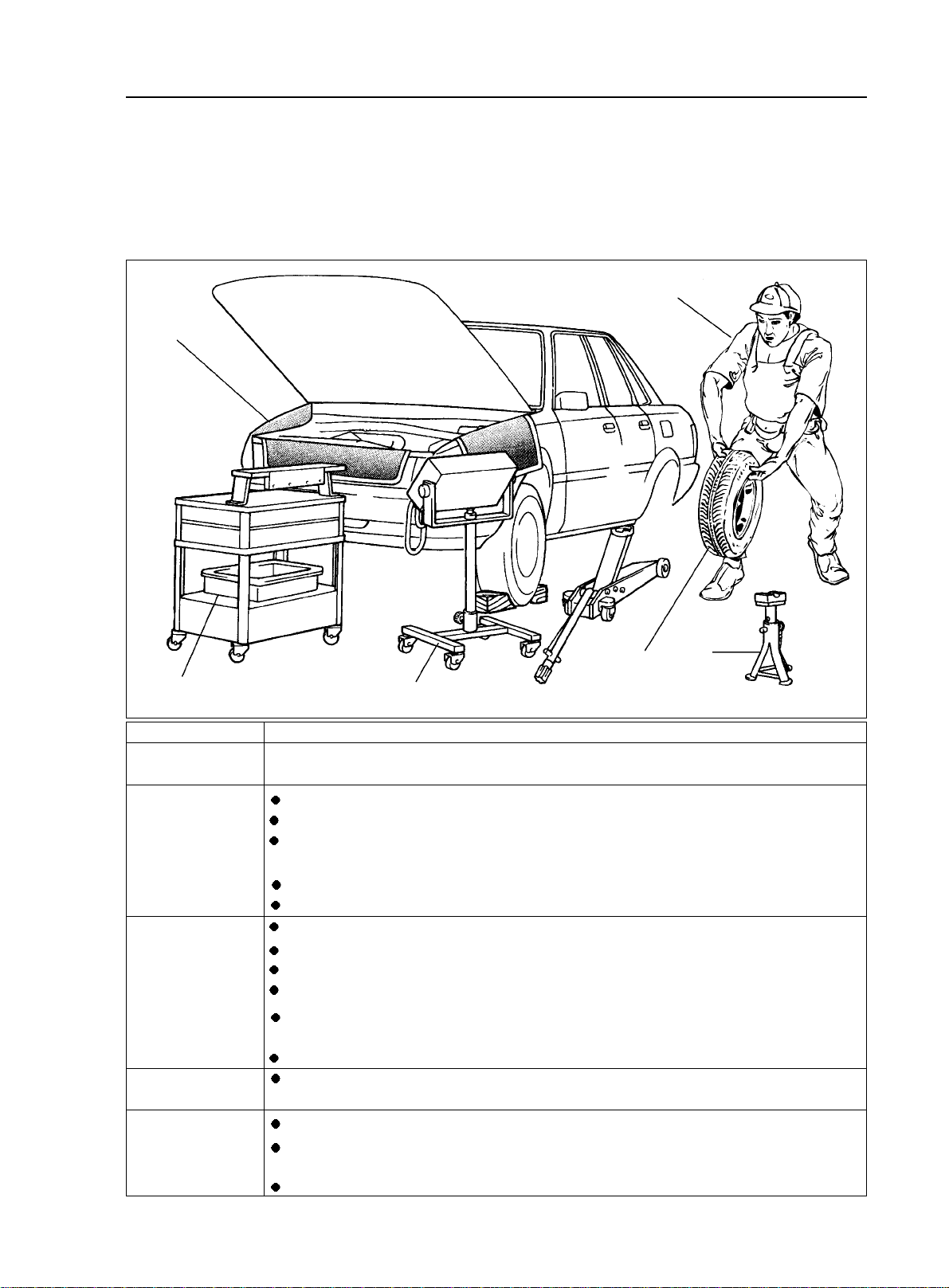

I. Precautions

1. Basic Repair Hint

(1)Operation Hint

1

General Information - Repair Instruction

Chapter 2 Repair Instruction

1-3

2

6

Vehicle Protection

Appearance

Safe Operation

Removal and

installation, disassemble and inspection

Prepare the tools and

measuring instrument

Removed parts

4

5

Before the work, place radiator fascia cloth, fender cloth, seat cover and mat.

Always wear clean uniform

Make sure to wear the helmet and safety shoe

when more than 2 persons work together, be sure to pay mutual attention to the safety.

when it is required to run the engine, you have to pay attention to the ventilation of the workshop.

When handling the high-temperature, rotating, moving and vibrating parts, be careful not to be scalded

or hurt.

When lifting the vehicle, safety stand should be used to support the specified position.

When lifting the vehicle, safety devices should be used.

The diagnosis requires full understanding of the trouble and effective operation.

Before the parts are removed, check the assembly for distortion and damage.

The diagnosis requires full understanding of the trouble and effective operation.

Before the parts are removed, check the assembly for distortion and damage.

If the structure is complicated, notes or marks should made to avoid mistake and impact of the part

function.

If needed, clean the removed parts and reassemble them after careful inspection.

Before the work, prepare the tool fixture, special tools, instrument, oil, workshop cloth and required

parts for replacement.

arrange the removed parts in correct sequence, do not confuse or contaminate them.

For non-reusable parts such as gasket, O ring and self-locking nut, replace them with new ones in

accordance with the instruction described in this manual.

Pick up replaced parts, put them in the containers, and show them to the customers.

3

Page 13

1-4

(2)Lift and support the vehicle

Be careful to lift and support the vehicle. Make sure that the vehicle is appropriately supported.

(3)Precoated Parts

a. Precoated parts are bolts, nuts, etc. that are coated with a seal

lock adhesive at the factory.

b. If a precoated part is retightened, loosened or caused to move

in any way, it must be recoated with the specified adhesive.

c. When reusing precoated parts, clean off the old adhesive and

dry with compressed air. Then apply the specified sealing adhesive

to the bolt, nut or threads.

Notice: the torque should achieve the lower limit of the allowed torque range.

d. The precoated parts should be kept intact for a period of time for induration based on the requirement of

the sealing adhesive.

(4)Gasket

If necessary, apply the sealant to the gasket to prevent disclosure.

(5)Bolt, nut and screw

Be careful to follow all torque specification and torque wrench should be used.

General Information - Repair Instruction

Sealing Adhesive

(6)Fuse

When replacing fuses, be sure the new fuse has the correct amperage rating. Do not exceed the rating or use one with a lower rating.

Illustration Symbol Part Name

Equal Rated Ampere Value

Fuse

Medium Current

Fuse

High Current Fuse

Page 14

General Information - Repair Instruction

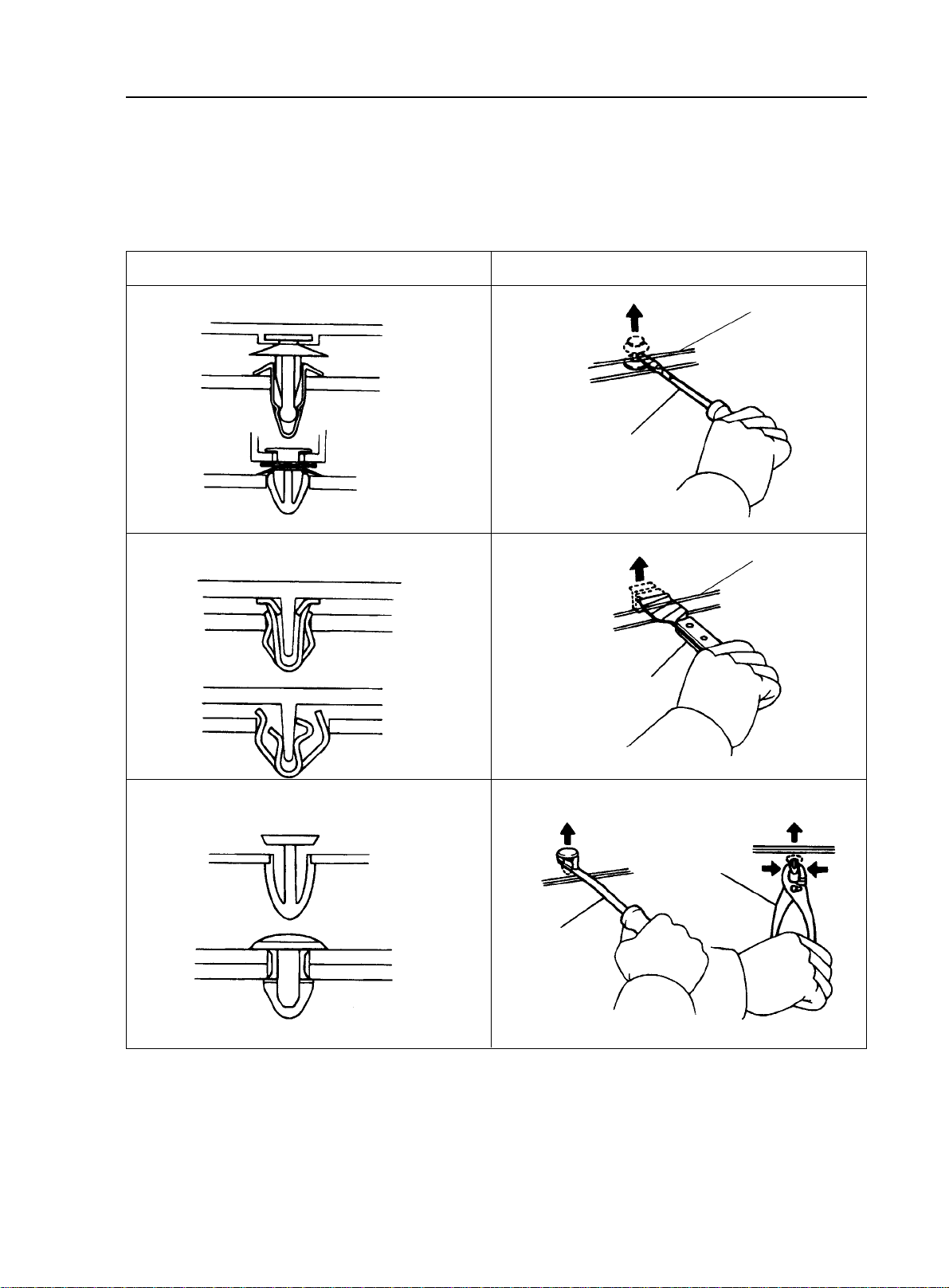

(7)Clip

The following illustration shows the typical removal and installation of the clip for body parts.

Tip:

If the clip is damaged during the operation, you have to replace it with a new one.

1-5

Illustration

Removal/installation

Protective Band

Screwdriver

Protective Band

Scraper

Clip Remover

Slip-joint

Pliers

Page 15

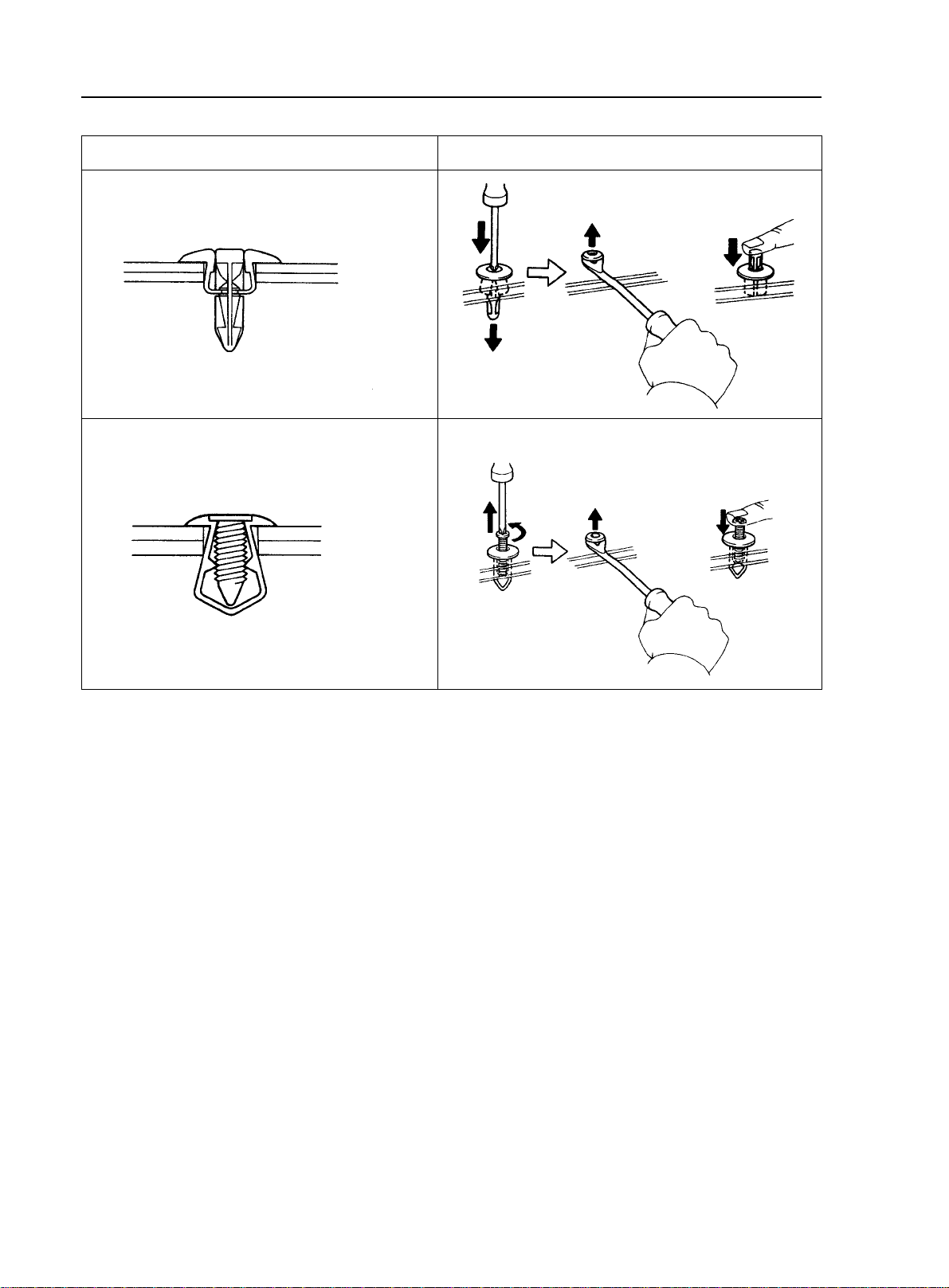

1-6

General Information - Repair Instruction

Illustration

Remove

Remove

Removal/installation

Install

Install

2. For Vehicles Equipped With SRS Airbag and Seat Belt Pretensioner

Tip: This is equipped with an SRS (Supplemental Restraint System), such as the driver airbag assembly,

front passenger airbag assembly airbag ECU and seat belt pretensioner. Failure to carry out service operations in

the correct sequence could cause the supplemental restraint system to unexpectedly deploy during servicing,

possibly leading to a serious accident. Further, if a mistake is made in servicing the supplemental restraint

system, it is possible the SRS may fail to operate when required. Before servicing (including removal or installation of parts, inspection or replacement), be sure to read the following items carefully, then follow the correct

procedure described in this manual.

(1) General Notice

a. Malfunction symptoms of the supplemental restraint system are difficult to confirm, so the diagnostic

trouble codes become the most important source of information when troubleshooting. When troubleshooting

the supplemental restraint system, always inspect the diagnostic trouble codes before disconnecting the battery.

b. Work must be started after 90 seconds from the time the ignition switch is turned to the "LOCK"

position and the negative (-) terminal cable is disconnected from the battery. (The supplemental restraint system

is equipped with a back--up power source so that if work is started within 90 seconds of disconnecting the

negative (-) terminal cable from the battery, the SRS may deploy.) When the negative (-) terminal cable is

disconnected from the battery, memory of the clock and audio systems will be cancelled. So before starting

work, make a record of the contents memorized by the each memory system. Then when work is finished, reset

the clock and audio systems as before. To avoid erasing the memory of each memory system, never use a backup power supply from another battery.

Page 16

General Information - Repair Instruction

1-7

c. Even in cases of a minor collision where the SRS does not deploy, the driver airbag assembly, front

passenger airbag assembly and seat belt pretensioner should be inspected.

d.

e. Never use SRS parts from another vehicle. When replacing parts, replace them with new parts.

f. Before repairs, remove the airbag ECU if shocks are likely to be applied to the sensor during repairs.

g. Never disassemble and repair the airbag ECU assembly, driver airbag assembly, front passenger airbag

assembly or seat belt pretensioner.

h. If the airbag ECU assembly, driver airbag assembly, front passenger airbag assembly or seat belt

pretensioner has been dropped, or if there are cracks, dents or other defects in the case, bracket or connector,

replace them with new ones.

i. Do not directly expose the airbag ECU assembly, driver airbag assembly, front passenger airbag assembly or seat belt pretensioner to hot air or flames.

j. Use a volt/ohmmeter with high impedance (10 k ohm/ V minimum) for troubleshooting of the electrical

circuit.

Information labels are attached to the periphery of the SRS components. Follow the instructions on the

notices.

k.

After work on the supplemental restraint system is completed, check the SRS warning light

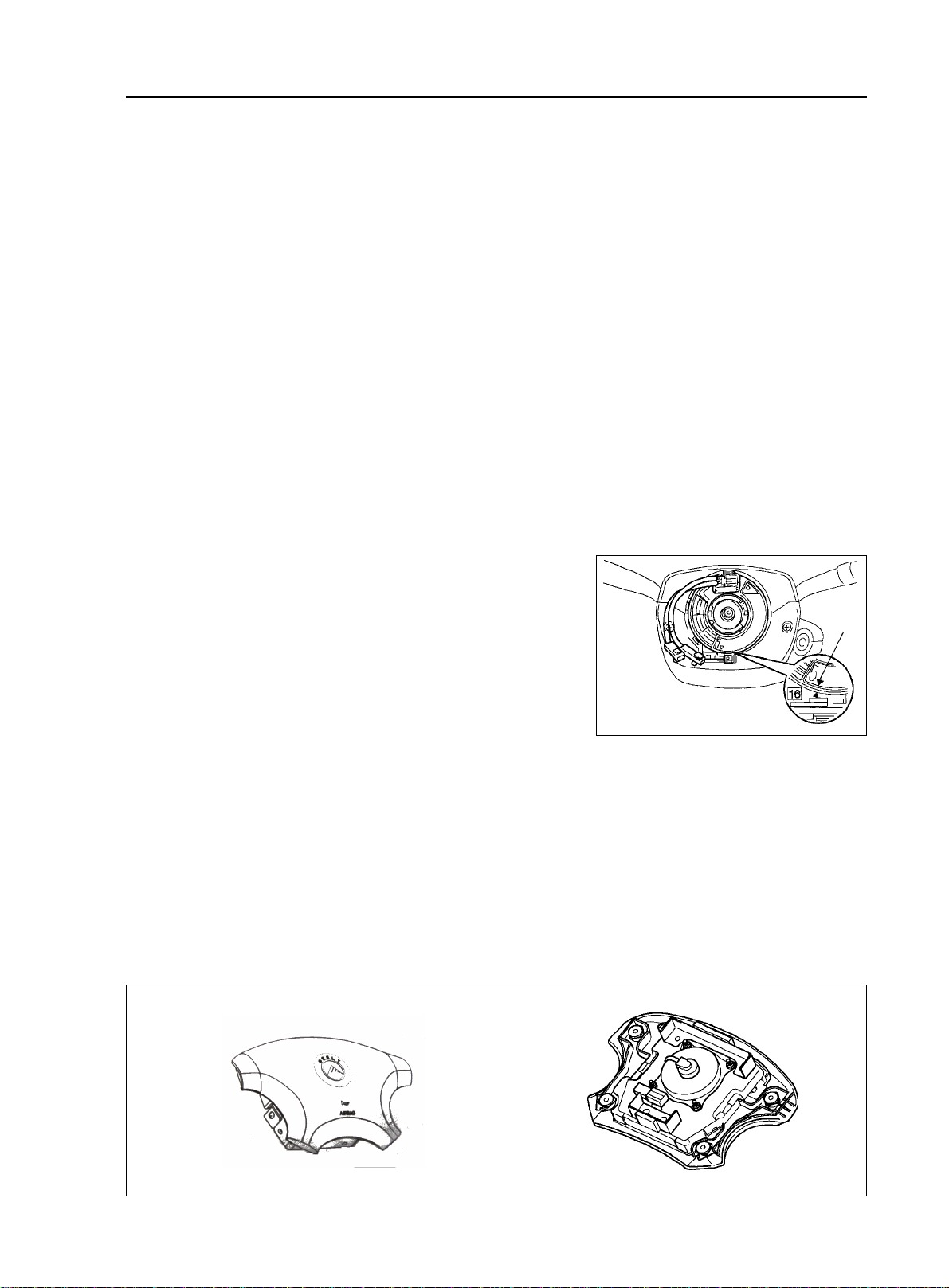

(2) Clock Spring (in combination switch)

The steering wheel must be fitted correctly to the steering column with the clock spring at the neutral position, otherwise clock

spring disconnection and other troubles may result.

Mark

(3) Driver Airbag Assembly

a. When removing the driver airbag assembly or handling a new driver airbag assembly, it should be placed

with the steering wheel top surface facing up. Storing the steering wheel with its top surface facing downward

may lead to a serious accident if the airbag deploys for some reason. In addition do not store a driver airbag

assembly on top of another one.

b. Never measure the resistance of the airbag squib. (This may cause the airbag to deploy, which is very

dangerous.)

c. Grease should not be applied to the driver airbag assembly and the pad should not be cleaned with

detergents of any kind.

Correct

Wrong

Page 17

1-8

d. Store the driver airbag assembly where the ambient temperature remains below 93°C , without

high humidity and away from electrical noise.

e. When using electric welding, first disconnect the airbag connector (yellow color and 2 pins) under the

steering column near the combination switch connector before starting work.

f. When disposing of a vehicle or the driver airbag assembly alone, the airbag should be deployed using an

SST before disposal. Perform the operation in a safe place away from electrical noise.

(4) Front Passenger Airbag Assembly

a. Always store a removed or new front passenger airbag assembly with the airbag rupture surface facing

up. Storing the airbag assembly with the airbag rupture surface facing down could cause a serious accident if the

airbag inflates.

b. Never measure the resistance of the airbag squib. (This may cause the airbag to deploy, which is very

dangerous.)

c. Grease should not be applied to the front passenger airbag assembly and the airbag door should not be

cleaned with detergents of any kind.

d. Store the airbag assembly where the ambient temperature remains below 93°C , without high humidity

and away from electrical noise.

e. When using electric welding, first disconnect the airbag connector (yellow color and 2 pins) installed on

the assembly before starting work.

f. When disposing of a vehicle or the airbag assembly alone, the airbag should be deployed using an SST

before disposal. Perform the operation in a safe place away from electrical noise.

General Information - Repair Instruction

Correct

(5) Seat Belt Pretensioner

a. Never measure the resistance of the seat belt pretensioner. (This may cause the seat belt pretensioner to

activate, which is very dangerous.)

b. Never disassemble the seat belt pretensioner.

c. Never install the seat belt pretensioner in another vehicle.

d. Store the seat belt pretensioner where the ambient temperature remains below 80°C and away from

electrical noise without high humidity.

e. When using electric welding, first disconnect the connector (yellow color and 2 pins) before starting

work.

f. When disposing of a vehicle or the seat belt pretensioner alone, the seat belt pretensioner should be

activated before disposal. Perform the operation in a safe place away from electrical noise.

g. The seat belt pretensioner is hot after activation, so let it cool down sufficiently before the disposal.

However never apply water to the seat belt pretensioner.

h. There should be no oil or water on the seat belt, no cleanser should be used to wash it.

Wrong

Page 18

General Information - Repair Instruction

1-9

(6) Airbag ECU

a. Never reuse the airbag ECU involved in a collision when the SRS has deployed.

b. The connectors to the airbag sensor assembly should be connected or disconnected with the airbag ECU

mounted on the floor. If the connectors are connected or disconnected while the airbag ECU is not mounted to

the floor, it could cause undesired inflation of the supplemental restraint system.

c. Work must be started after 60 seconds from the time the ignition switch is turned to the "LOCK" position

and the negative (-) terminal cable is disconnected from the battery, even if only loosing the set bolts of the

airbag ECU.

(7) Wire Harness and Connector

The SRS wire harness is integrated with the instrument panel wire harness assembly. All the connectors in

the system are a standard yellow color. If the SRS wire harness becomes disconnected or the connector becomes

broken due to an accident, etc., repair or replace it.

3. Electronic Control Device

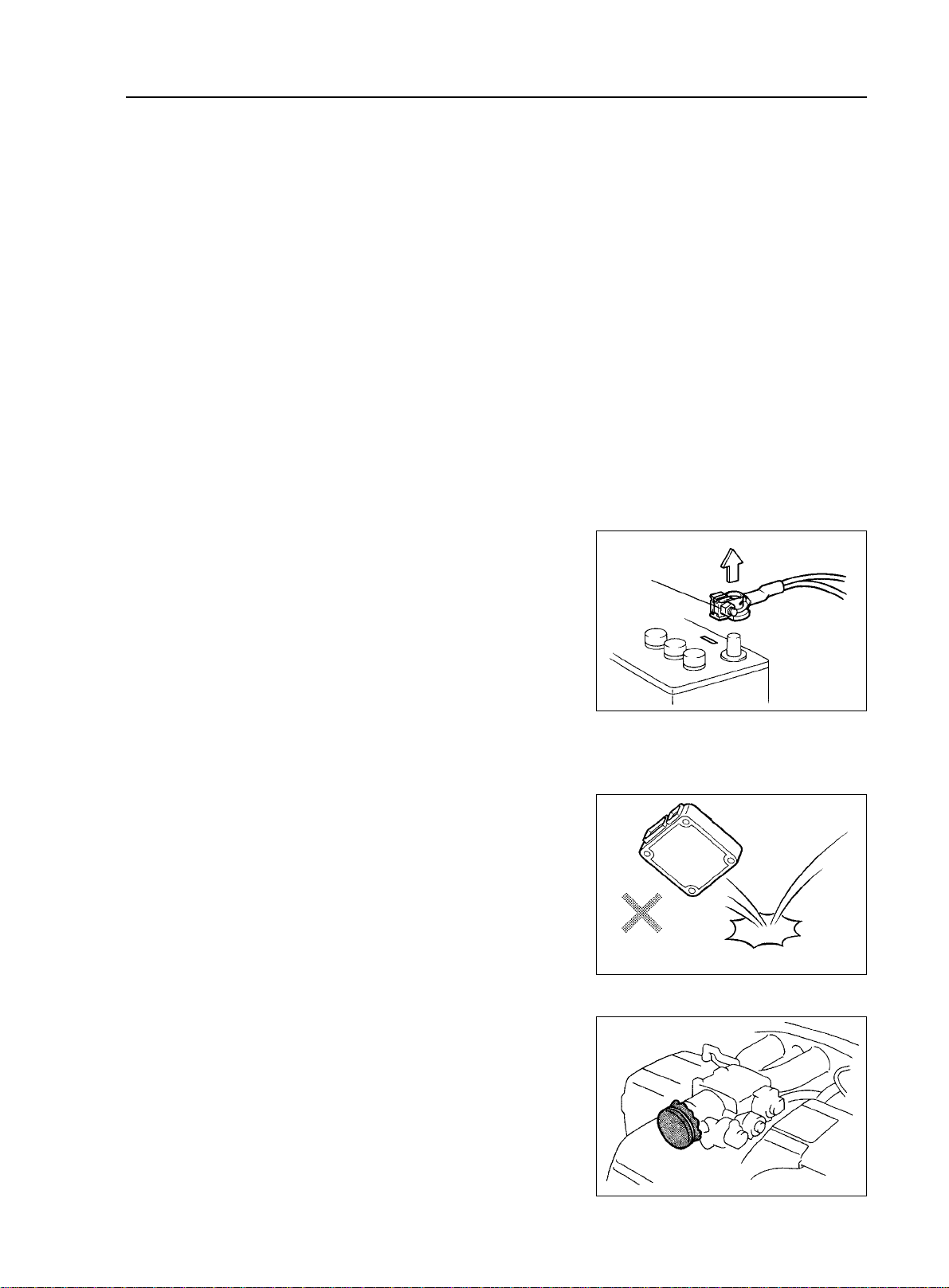

(1) Removal of the battery terminal cable

a. Before performing electrical servicing, disconnect the negative (-) cable from the battery in order to avoid short for burnout.

b. When disconnecting the terminal cable, turn of f the ignition

Negative(-)

Cable

and light switches, loosen the cable nut and raise the cable straight

up without twisting or prying it.

c. When disconnecting the terminal cable from the battery, all

information stored in the clock, radio and DTC shall be deleted,

therefore, these information shall be checked before disconnection.

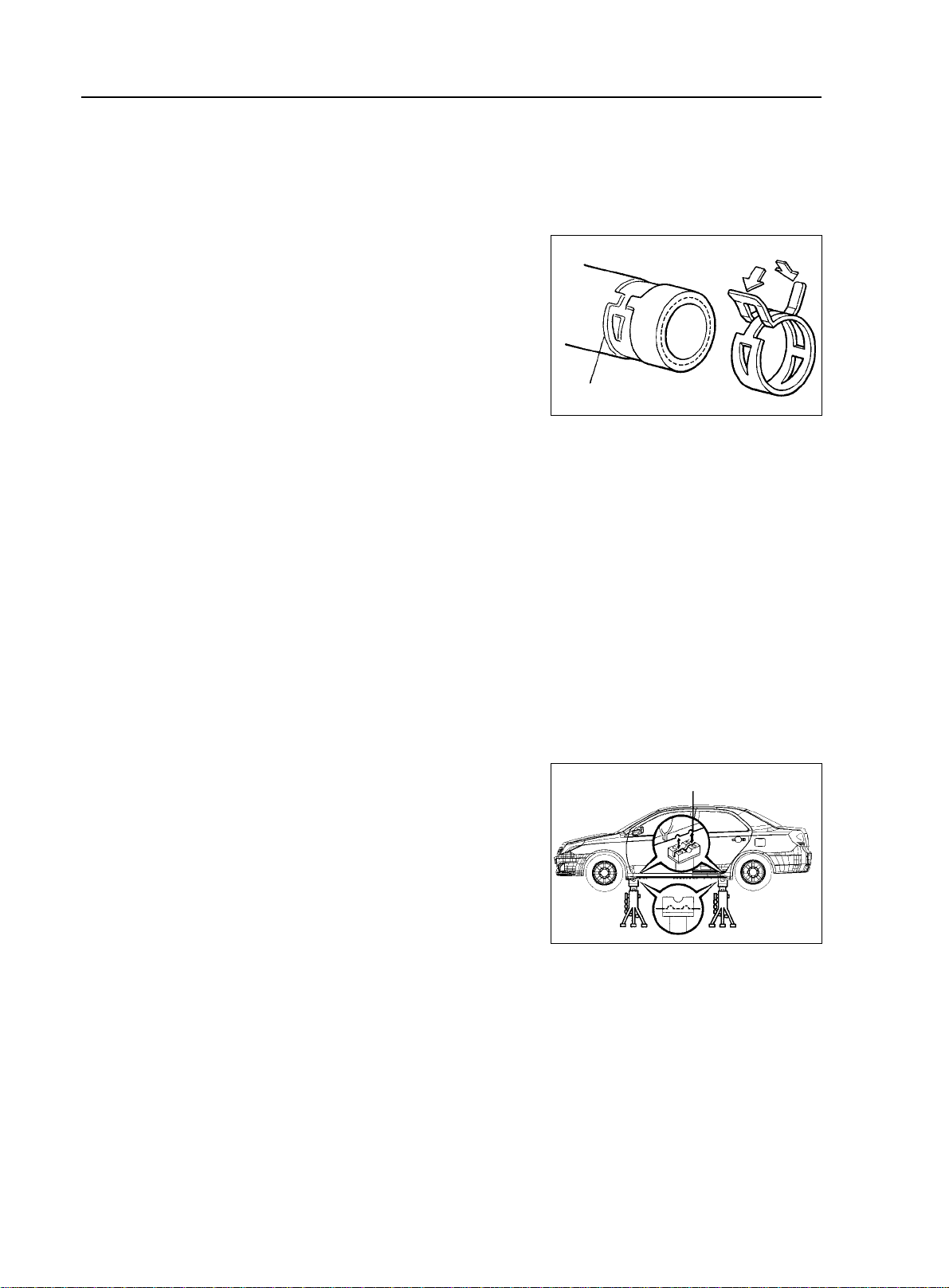

(2) Processing of Electronic Parts

a. Do not open the cover or case of the ECU unless absolutely

necessary. (If the IC terminals are touched, the IC may be destroyed

by static electricity.)

b. To pull apart electrical connectors, pull on the connector itself,

not the wires.

c. Be careful not to drop electrical components, such as ECU

or relays. If they are dropped on a hard floor, they should be replaced

and not reused.

d. When steam cleaning an engine, protect the electronic

Wrong

components, air filter and emission-related components from water.

e. Never use an impact wrench to remove or install temperature switches or temperature sensors.

f. When checking continuity at the wire connector, insert the

tester probe carefully to prevent terminals from bending.

4. Remove and Installation of Engine Intake Parts

(1) If any metal scrap is mixed in the inlet pass, that may give

a bad effect to the engine.

(2) When removing and installing of the inlet system parts, close

Page 19

1-10

the opening of the removed inlet system parts and the engine with a

clean shop lag or gum tape.

(3)When installing the inlet system parts, check that there is no

mixing of a metal scrap.

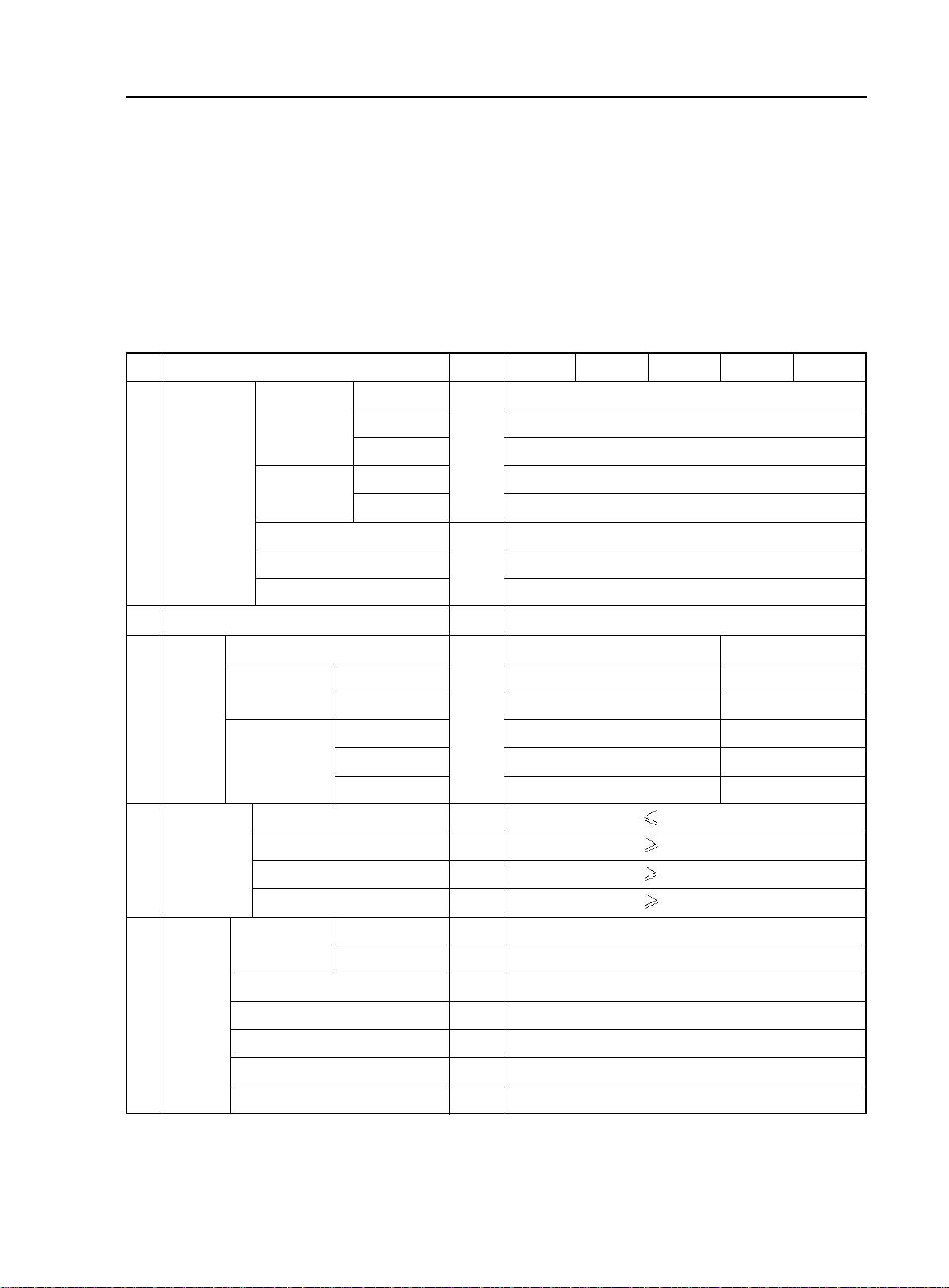

5. Handling of Hose Clamp

(1)Before removing the hose, check the clamp position to re-tighten

it for sure.

(2)Replace a deformed or dented clamp with a new one.

(3)In case of reusing the hose, install the clamp on the hose where

it has a clamp track.

(4)For a steel band circlip, make it adjust by adding force to the

arrow mark direction after the installation.

General Information - Repair Instruction

Steel Band Circlip

Clamp Trace

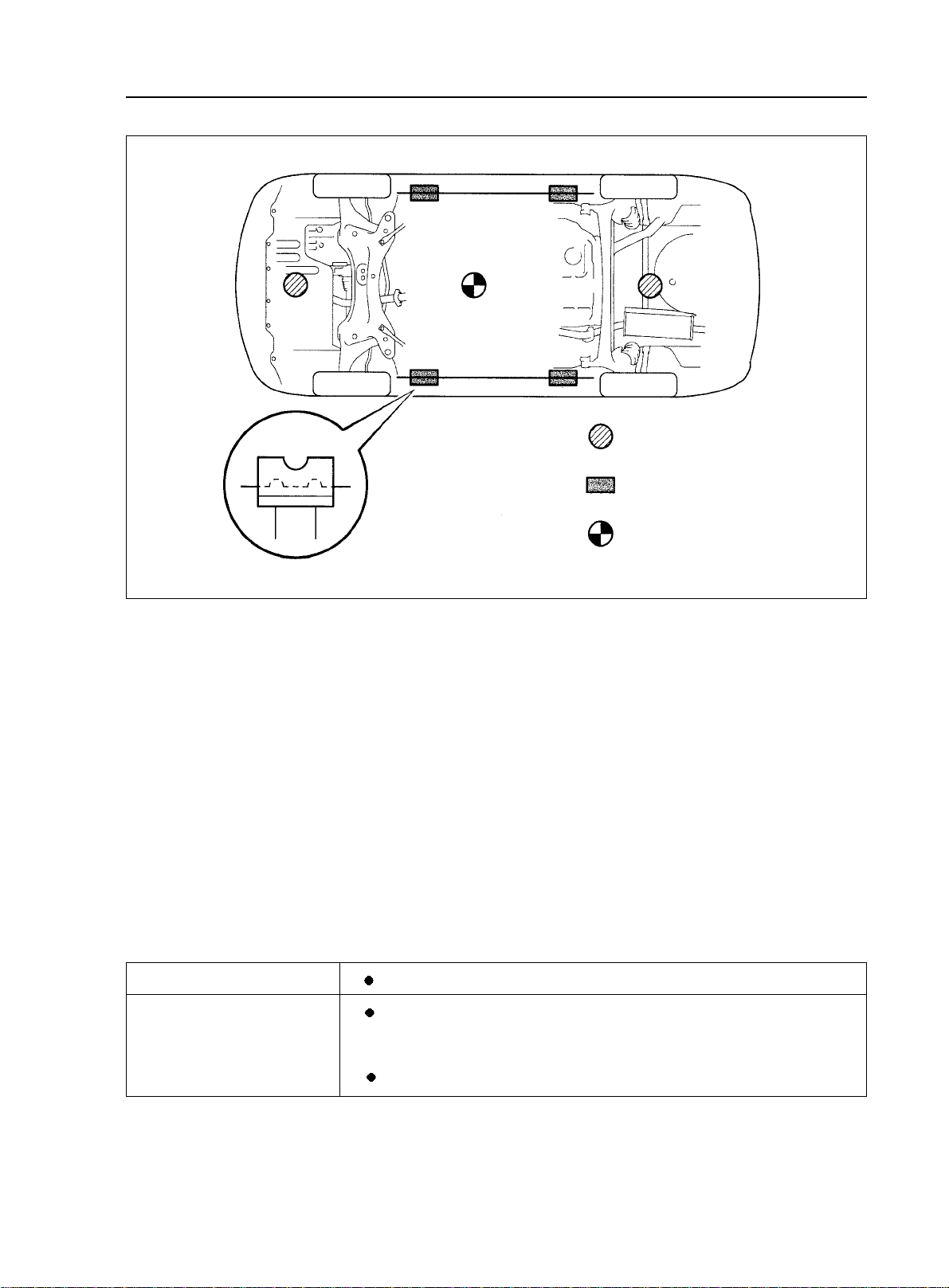

II. Vehicle Lift and Support Location

1. Vehicle Conditions To Be Under Attention During Lift

(1)Generally speaking, when being lifted, the vehicle should be empty, do not lift the heavily loaded vehicles.

(2)When removing heavy parts such as engine and transmission, the center of gravity of the vehicle will move.

Place balance weight to prevent the vehicle from rolling or use special jack to support the vehicle.

2. Precautions for Use of Four-tappet Lift

(1)follow the safe operation instruction described in this manual.

(2)do not damage the tire or rim.

(3)use wheel stopper to retain the vehicle.

3.Precautions for Use of Jack and Safety Stand

(1)always use the wheel stoppers when performing servicing on

level ground.

(2)use safety stand and rubber support as shown in the illustration.

(3)use the jack and safety stand to support specified location.

(4)When jacking up the front wheels of the vehicle, release the

park brake and place stoppers only behind the rear wheels. When

jacking up the rear wheels, place stoppers only before the front wheels.

(5)During the job, make sure to use safety stand instead of jack

only to support the vehicle.

(6)When only jacking up the front wheels or rear wheels, place

stoppers before or after the wheels touching the ground.

(7)when lowering the vehicle with its front wheels lifted, release

the park brake, and place the stopper only before the rear wheels.

When lowering the vehicle with its rear wheels lifted, place the stopper only after the front wheels.

Rubber Suport

Page 20

General Information - Repair Instruction

Jack Position

Center of Gravity of the Vehicle

1-11

Support Position

Jack Lifting Position

(empty load)

4. Precautions for Use of Swing Arm Type Lift

(1) follow the safe operation instruction described in this manual.

(2) use bracket with rubber support as shown in the illustration.

(3) make the center of gravity of the vehicle as close as possible to that of the lift ("L" should be smaller).

(4) adjust the bracker height, level the vehicle, align the groove of the bracket with the safety stand

support location.

(5) the arm should be locked during the job

(6) lift the vehicle until the tires become round.Swing the vehicle to make sure of stable vehicle.

5. Precautions for Use of Plate Type Lift

(1) follow the safe operation instruction described in this manual.

(2) use the support of the plate type lift.

(3) make sure to secure the vehicle in the specified position.

Left and right set position

Front and rear set position

•

Place the vehicle over the center of the lift.

•

Align the cushion gum ends of the plate with the attachment

lower ends (A, C).

•

Align the attachment upper end (B) with the front jack supporting point.

Page 21

1-12

General Information - Repair Instruction

(3)lift the vehicle until the tires become a little bit round. Swing the vehicle to make sure of stable vehicle.

Lift Center

Swing Arm Type Lifter

Plate T ype Lift

Cener of Gravity of the Vehicle

(Empty Load)

Support

rubber support

Support Dimension

Page 22

Vehicle Usage and Maintenance - Brief Introduction of Geely MK

Part II Vehicle Usage and Maintenance

Chapter 1 Brief Introduction of Geely MK

Section 1 Major Functional and Technical Data of MK Series.

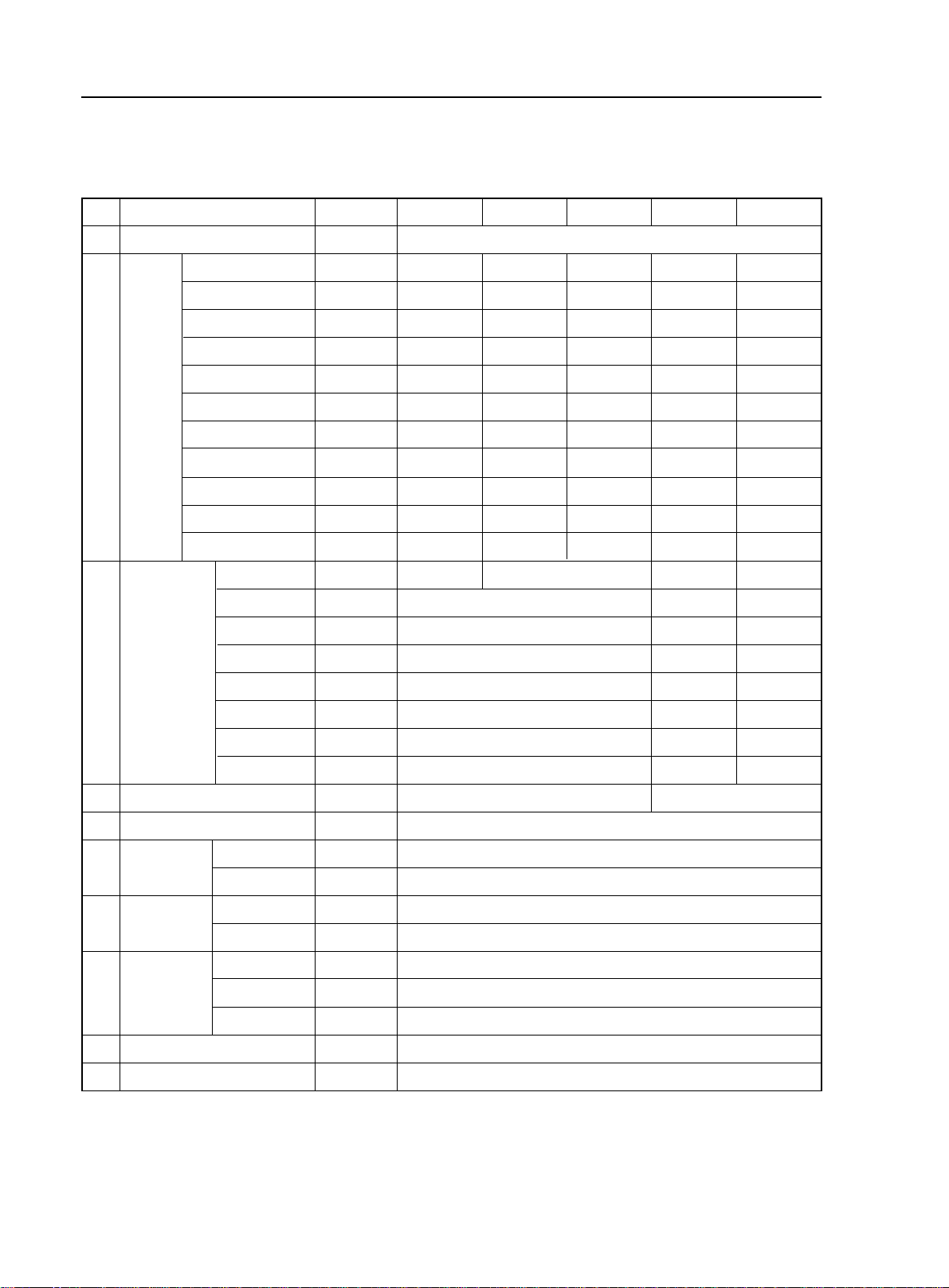

I. Vehicle performance and structural data

Table 1 vehicle data

2-1

ID

Dimension

1

2

Number of passengers

Curb weight

Weight

3

Road

4

adaptability

Curb

Gross Vehicle

W eight

Max turning angle

of front wheel

Item

Length

Dimension

Axle

Wheelbase

Front Suspension

Rear suspension

Minimum turning diameter

Minimum Ground Clearance

Approach angle

Deviation angle

Width

Height

Front

Rear

Front Axle

Rear Axle

V ehicle

Front

Rear

Left: Inner/out

Right: inner/out

Unit

mm

mm

person

kg

m

mm

°

°

°

°

JL7132U

JL7152U

1090(1040)

660(640)

430(400)

1460(1410)

780(760)

680(650)

JL7162U

4342

1692

1435

1450

1431

2502

848

992

10.4m

150mm

15°

20°

37.2°±2°/ 32°±2°

37.2°±2°/ 32°±2°

JL7132HU JL7152HU

5

1450(1455)

780(785)

1080

665

415

670

5

Wheel

Positioning

Front wheel leaning angle

Kingpin inward leaning angle

Kingpin rearward leaning angle

Left front wheel toe-in

Rear wheel outward

°

°

mm

°

°

-0°30'±45'

10°0'±45'

2°0'±45'

1±2mm

-0°56'±45'

Page 23

2-2

Brief Introduction of Geely MK - Major Functional and Technical Data of MK Series.

II. Introduction of major systems

Table 2 Models and technical data of major systems.

ID

1

Engine

2

3

Transmission

Item Description

Unit

Drive Type

Model

Type

Bore Diameter

Piston play

mm

mm

Displacement

Compression Ratio

Max Power

Max Torque

Idle Speed

kw/r/min

N.m/r/min

r/min

Ignition Sequence

minimum fuel consumption rate

Model

1st gear

2nd gear

3rd gear

4th gear

g/kw.h

JL7132U JL7152U JL7162U JL7132HU JL7152HU

›‹

Front Wheel Drive

2

4

MR479Q MR479QA MR481QA MR479Q MR479QA

In-line 4 cylinderIn-line 4 cylinder In-line 4 cylinder In-line 4 cylinder In-line 4 cylinder

78.7 78.7 81.0 78.7 78.7

69.0 77.0 77.0 69.0 77.0

L

1.342 1.498 1.587 1.342 1.498

9.3 : 1 9.8 : 1 9.6 : 1 9.3 : 1 9.8 : 1

63/6000 69/6000 78.7/6000 63/6000 69/6000

110/5200 128/3400 137/4400 110/5200 128/3400

800±50

800±50 800±50

800±50

800±50

1-3-4-2 1-3-4-2 1-3-4-2 1-3-4-2 1-3-4-2

259 279 269 259 279

JL-S160 JL-S160A JL-Z110 JL-Z130

3.182 3.087 3.087

1.895 1.634 1.634

1.250 1 1

0.909 / /

4

Clutch Type

5

Steering type

Braking

6

system

7

suspension

8

Tire

9

Fuel Tank Capacity

10

Body structure

5th gear

Reverse gear

Final Drive Ratio

Model

Booster type

Front

Rear

Specification

Tire pressure

Wheel

KPa

L

0.703 / /

3.083 2.29 2.29

4.308 3.317 3.317

Single disc, Plate and dry Spring

Hydraulic Gear-rack

Hydraulic, X-type pipe

Vacuum booster, Front Wheel Disc, Rear Wheel Drum

McPherson suspension strut system

Twist beam independent suspension system

85/60R15(1175/65R14)

230(Front)/210(Rear)

Aluminum 15X6J (Iron 14X5 1/2JJ)

45

Unitary construction body

/

Page 24

Brief Introduction of Geely MK - Vehicle Configuration

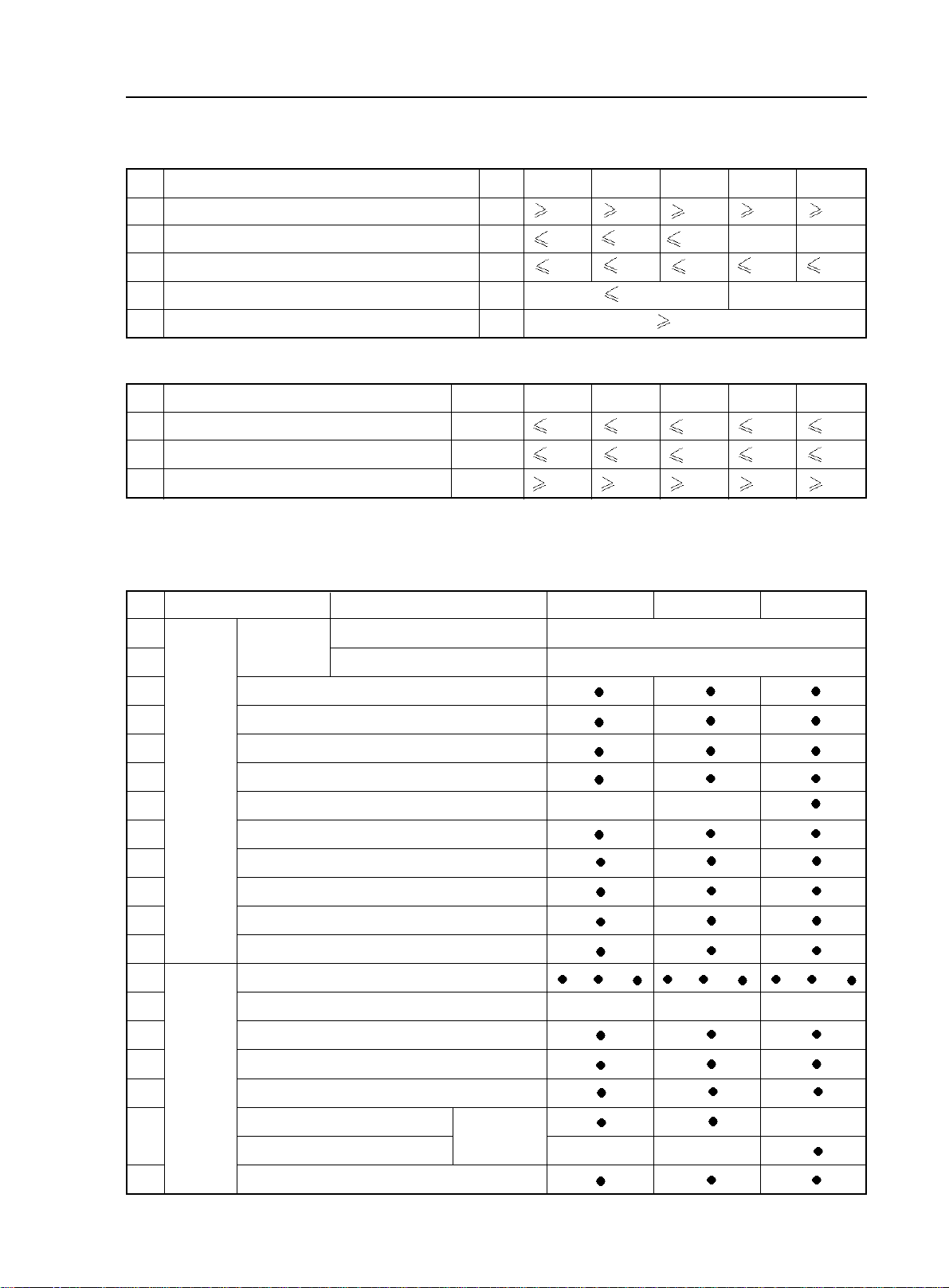

Table 3 Power Performance Parameter

No.

Item Name

Unit

JL7132U JL7152U JL7162U JL7132HU JL7152HU

2-3

1

Maximum vehicle speed

Acceleration time within the fourth gear from 30km/h to 120km/h

2

Acceleration time from 0-100km/h

3

Minimum stable vehicle speed within the fourth gear

4

Maximum gradeability

5

Table 4 Economic Performance Parameter

No.

1

Fuel consumption at constant speed (60km/h)

2

Fuel consumption at constant speed (90km/h)

3

Coasting distance (fully loaded, initial speed 50km/h)

Item Name

Unit

L/100km

L/100km

Section 2 Vehicle Configuration

No.

1

2

Item Name

Body color

Type

Common color

Uncommon color

km/h

km/h

%

m

33

s

s

20

30

18

25

JL7132U JL7152U JL7162U

4.5

4.6 5.0

6.2

550

550

Standard Comfortable Luxury

Chinese red, snow mountain white, pearl black, sky blue, ribbon silver

Crystal diamond silver, golden sand green, pineapple yellow

155175165155

28

16.5

30

22

165

//

20

/

JL7132HU JL7152HU

4.7

6.3

550

6.66.2

550

5.1

6.7

550

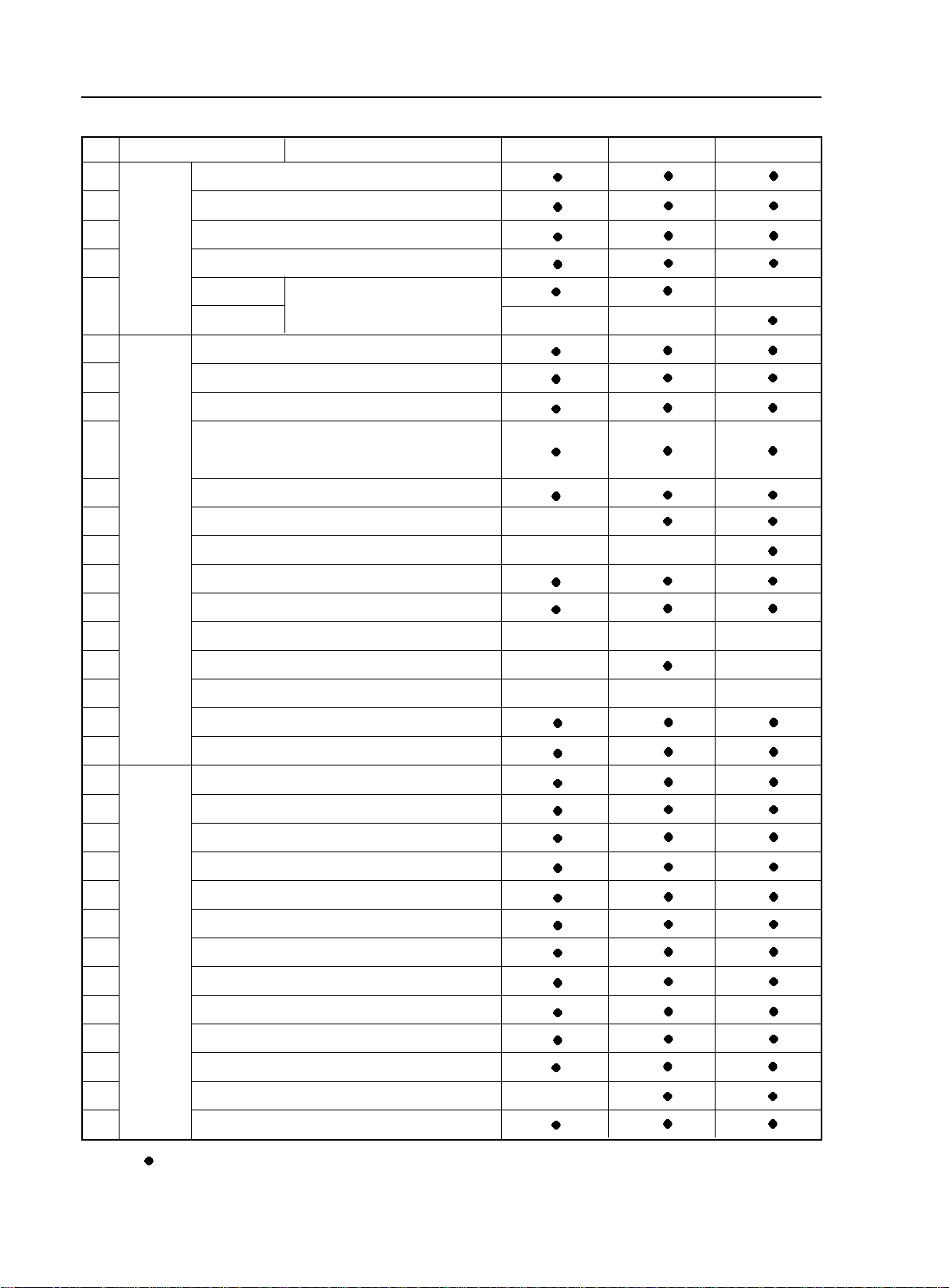

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Exterior

device

Interior

device

Front chromeplated trim molding

Diamond-shape headlight

Crystal diamond taillight

Highly penetrable front fog light

Green heat insulating four-door glass

Scuff strip with same color as that of the body

Aluminum alloy wheel rim

Tire (185/60R15) (with spare tire)

Retractive antenna (A pillar)

Bumper with same color as that of the body

Light color (T)deep color(S)mixed color(R)interior trim

Central control panel

Firry red Firry red

A/C outlet vent + trim ring

Chromeplated inner handle

Sun shade (with ticket folder)

High-grade flannelette

Seat

Luxury leather

/ /

/ / / /

Titanium silver

19

Front seat headrest front and rear angle/height adjustable function

Page 25

2-4

Brief Introduction of Geely MK - Vehicle Configuration

No.

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Interior

device

Electric

device

Safety

device

Item Name

Front seat back trash bag

6/4 split foldable rear seat

Cable-controlled oil tank cap

Cable-controlled trunk

plastic

leather

Power window (with one-touch function)

Remote control central door lock

Power rearview mirror with turn signal light

Smart remote control key (control the closure of the

door and window and the delay of the vehicle lights)

Adjustable intermittent wiper

On-board handsfree handset

Anti-clamp retractive power window

Central pointer type instrument

Temperature display

Hi-fi CD audio

MP3 function

Speaker

Freon-free A/C system

Air cleaner

ABS + EBD

Driver side airbag

Front passenger side airbag

Telescopic steering column

Front seat belt pretensioner /height adjustable

Rear row triple-person seat belt

Anti-glaze inner rearview mirror

Anti-explosion and anti-leak plastic oil tank

Rear windshield defroster function

High-mounted stop light

Four-door anti-impact beam

Digital display rear parking radar

Adjustable steering wheel

Type

Follow me home light delay system

Standard Comfortable Luxury

Single Disc Single Disc 6 Discs

6 speakers (2 Tweeters) 6 speakers (2 Tweeters) 6 speakers (2 Tweeters)

Remark: - denote standard configuration Z - standard C - comfortable D - luxury S - dark interior trim

T - light colored interior trim R - mixed color

Page 26

Brief Introduction of Geely MK - Main Vehicle Test Technical Specification

Section 3 Main Vehicle Test Technical Specification

2-5

Item

Inspection

line items

Description

Front wheel outward leaning angle

Kingpin inward leaning angle

Kingpin rearward leaning angle

Left front wheel toe-in (mm)

Rear wheel outward leaning angle

% of braking total power vs. gross vehicle weight

% of front wheel braking power vs. front axle load

% of gap between left and right wheel brake power vs. the

greater braking power of them two

rolling resistance of each wheel should not be larger than the axle load by

parking brake total power should be lighter than the test vehicle weight by

sliding distance of front/rear wheels

when vehicle speed meter shows 40km/h, vehicle speed

monitor indicates

brightness of left/right headlamps

tolerance of close lamps is

tolerance of distant lamps is

(0.6-0.8)H, H refers to the central

height of headlamps.

-0°30'± 45'

10°0'± 45'

2°0'± 45'

-0°56'± 45'

60% (no load),

60% (no load, and full load)

20%(Front Axis),

24%(Rear Axis)

33.3 Km/h-42.1Km/h

Harsh brake at 50km/h. the stop distance is

Rain test. 100 points is full mark. Minus one point for each

Specification

1±2

50% (full load)

5%

20%

2 m/km

15000 cd

10cm/10m

19m

Regular

quality

inspection

items

Emission

seepage. Minus 3 points for slow seepage 3 points, and minus

6 for a quick seepage. The limit of vehicle sealing is

Check leaks of the vehicle. When vehicle has run 50km, stop it and

inspect for leaks. Check if there is oil/water marks at static joints,

or if there is oil/water drops dripping down at dynamic joints

nose

10min after the vehicle is stopped, there is a leak; if there is oil/

water marks/drops, but it does not drip down, there is seepage.

Measure the temperature of transmission oil inspection hole.

Usually it is not higher than ambient temperature.

Check the surface temperature of wheel trim column. Usually

it is no higher than ambient temperature.

vehicle should be slightly steering insufficient i.e. driving on

a circle with same steering wheel angle, and accelerate from

low to high speed, the diameter of the circle increases gradually.

Maximum front wheel turning angle (inner/outer)

Specification: GB18352.3-2005

93 points

Daily inspection and smell with

70°C

40°C

Inspect regularly

37.2°±2°/ 32°±2°

Page 27

2-6

Usage and Maintenance of MK Series - Usage of MK Series

Chapter 2 Usage and Maintenance of MK Series

Section 1 Usage of MK Series

1. Instrument Panel Overview

1.Instrument Panel Outlet Vent

2. Instrument Panel

3.Upper Glove Compartment

(Front Passenger Airbag Cover)

4.Sunshade

5.Dome Light And Sunroof

Switch

6.Inside Rearview Mirror

7.Glove Box

8. Power Window Regulator

Switch

9. Manual Transmission Shift

Lever Or Automatic Transmission Shift Lever

10.Parking Brake Control Lever

11.Engine Hood Release Handle

12.Power Window Lock

13.Power Door Lock Switch

1.Left Combination Switch

2.Right Combination Switch

3.Display

4.Audio

5.Short-Distance Odometer

Adjustment Button

6.Instrument Panel Brightness

Adjustment Switch

7.Hazard Warning Light

8.A/C Control Panel

9.Ash Tray

10.Defroster Switch

11.Cigarette Lighter

12.”A/C“ Switch

13.Ignition Switch

14.Tilt Steering Adjustment

Handle

15.Theft-Deterrent Indicator

16.Power Outside Rearview

Mirror Control Switch

Page 28

Usage and Maintenance of MK Series - Usage of MK Series

2-7

2.How to use ignition switch

(1) LOCK when key is at this position, it can be pulled out and inserted in easily. The function of this position

is to lock steering wheel. If the key cannot be turned from LOCK to ACC, please rotate the steering wheel slightly

while turning the ignition key.

(2) ACC radio and cigarette lighter is turned on when key is at this position.

(3) ON when key is at this position, the following indicator is on: battery charging, ABS, brake fluid level,

park brake, engine coolant temperature, engine MIL, airbag oil pressure.

(4) START Turn the key to this position to start the engine. When engine is started, release the key

immediately. It returns to ON automatically. When engine is on, do not turn the key to this position.

Notice:

(1) Do not pull the key out or turn it to LOCK before the car is fully stopped, or there will be dangers caused

by locking steering wheel or disabling some safety functions.

(2) It is prohibited to drive the car with engine turned off to ensure functioning of braking and steering booster.

(3) Do not let the key stay at ON for a long time when engine is off, or the battery fully discharged.

(4) Shift to neutral gear before ignition key is switched to START.

(5) Turn the steering wheel lightly after the car is fully stopped to make sure it is locked.

3.Unlock Steering Wheel

How to unlock steering wheel: insert ignition key, turn the steering wheel lightly and switch the ignition key.

Steering wheel is unlocked.

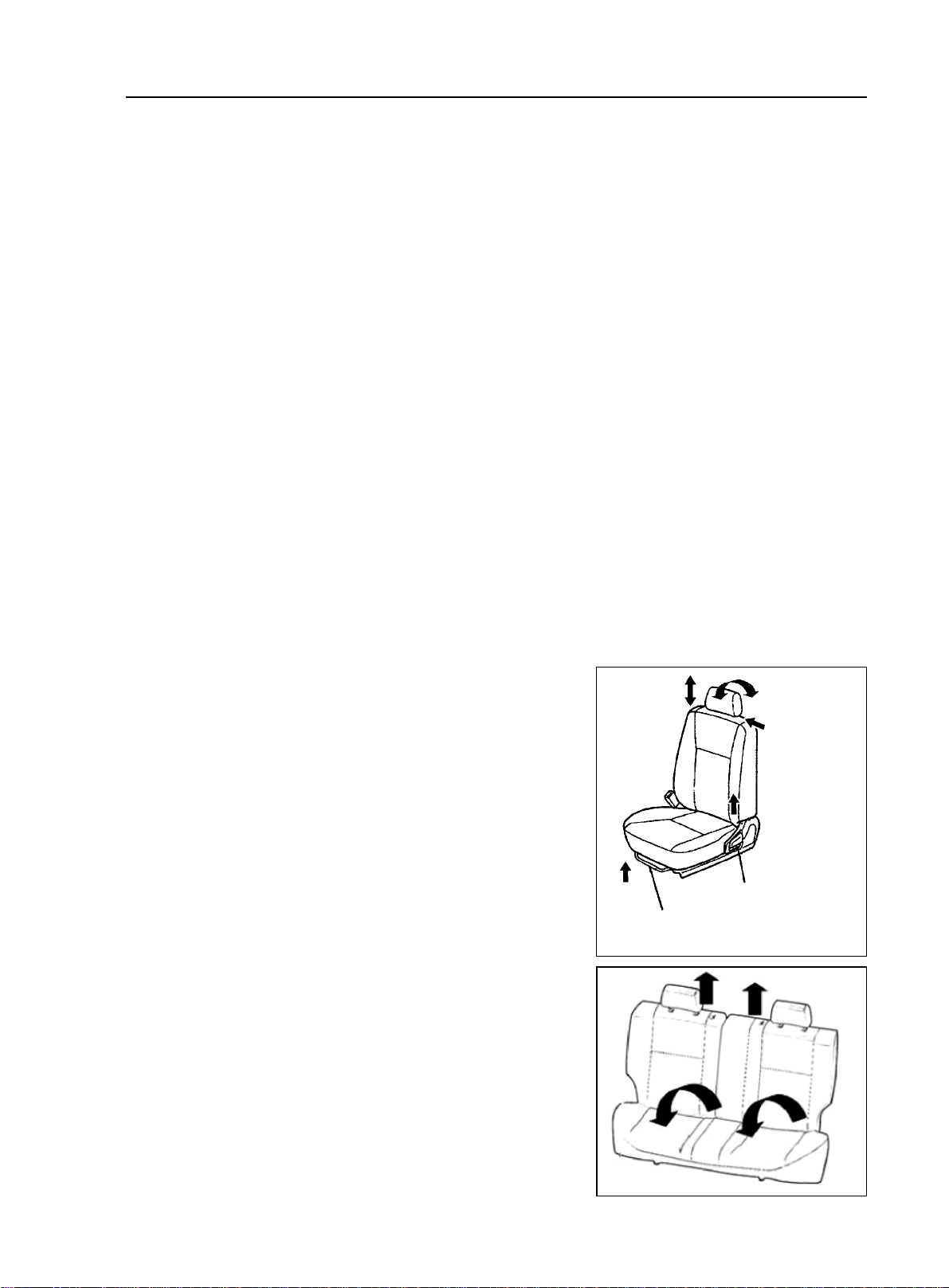

4.Adjust seat position

Seat back angle and cushion angle of front seats in MK-1 sedan can be adjusted.

(1) Adjust seat back angle

Turn around adjusting handle, and adjust seat back to appro

priate position.

(2) Move seat forward or backward

Steps:

a. pull adjusting handler up

b. Move the seat forward or backward, and adjust the seat to

appropriate position.

c. Put the handler down and move the seat again till it is

locked.

Attention: adjust the seat only when the car is fully stopped

to ensure safety.

(3) Front head rest can be adjusted in two ways.

Push the head rest from back to front, there are three fixed

positions to lock.If pushed over the final locking position,the

head rest can return to the original position after hand

withdraws.

(4) Fold Rear Row Seat

The seat back can be tilted forward so that the trunk will be

used to the last degree.

a. Remove the head rest

b. Unlock the seatback and fold it down.

Split seatback can be folded separately on demand.

2

Move seat forward or backward angle

1

Adjust seat back angle

Page 29

2-8

5. Actions to ensure vehicle working condition and safe driving.

(1) To make sure of driving safety, execute the following inspections before driving.

a. Inspect fuel level, and add fuel when necessary.

b. Inspect illuminating lights, turning signal lights, braking signal lights to see if they work.

c.Check the position of rearview mirrors.

d.Check if breaking system functions well.

e.Check if glass of all the lights, windshield is clean.

(2) Regular inspection Perform the following regular inspections to ensure the vehicle work condition and

driving safety.

a. Check engine oil level. Park the vehicle on flat road; check the oil level with engine oil level indicator

at least 10 minutes after the engine is stopped. The oil level should be between the two marks. If it is

lower than "L" mark, add some oil; if it is higher than "F" mark, there is excessive oil, so release it.

Or investigate the cause of high oil level.

The volume between the lowest oil level ("L") and highest oil level ("F") is 1.4L.

b. Check engine coolant level. Check the level when the engine is cool. The coolant level should be between

LOW and FULL. If it is lower than "LOW", add coolant. If the coolant is much lower than Min (every

coolant fill is more than 1L) or the vehicle requires frequent fills,investigate if there is any problem with

the cooling system.

To keep the function of coolant, replace coolant every two years at the beginning of cold winter.

c. Check brake and clutch fluid level (sharing a reservoir). Brake fluid level should between the Max and

Min marks. And it is better to keep it close to the Max mark. Add fluid in time when there is not enough

fluid.

d. Check power steering fluid tank. The level should be between Max and Min marks. Refill when there

is not enough steering fluid to avoid pump stuck. It is strictly prohibited to run the vehicle without

steering fluid in any circumstances.

e. Check the charging status of battery and if the connection of battery wires is good.

f. Check tire status and pressure

g. Check the status of wipers.

(3) Observe warning lights and indicators on instrument panel.

a. There are various warning lights and indicators on the instrument panel of MK-1 sedans to indicate and

warn abnormal operations of engine, braking, and charging systems.

b. Pay attention to these lights when driving.When the warning lights or indicators are on,stop the vehicle,

check the vehicle and resolve the causes to make sure the vehicle works well or drives safely.

6. Correct ways to use new cars

Reliability and stability of components in new cars and recently repaired cars still need to be confirmed, and

relative parts are not broken-in, so they must be used carefully to ensure driving safety, to avoid abnormal damage,

and to extend the useful life of the car.

(1) Before driving inspection The following inspections must be performed on the new car to ensure car safety

and reliable operation:

a. Check if instrument panel, warning lights, and indicator, front and rear wiper and washer, and switches

work.

b. Check if the fastening of driveline, steering, suspension, wheels and other connection parts is good.

Usage and Maintenance of MK Series - Usage of MK Series

Page 30

Usage and Maintenance of MK Series - Usage of MK Series

c. Check levels of braking fluid, engine coolant, engine oil, transmission oil, power steering fluid, and

washing fluid to see if there is any leaking.

d. Inspect if brake pedal, clutch pedal, accelerator pedal, transmission shifter, steering wheel, choke are

loose or stuck. The free travel of clutch pedal is 5~15mm, the free travel of brake pedal is 1~6mm and

the free play of steering wheel is less than 30mm(measurement point at margin of steering wheel). if it

is out of this normal range, the clutch needs to be tuned.

e. Inspect if the connection of battery, lamps and signal lights are normal, and if the wire routing and

position are correct and not loose.

f. Inspect if the tire pressure is correct.

(2) On-road inspection If the inspection result of the above items is good, start the engine and test the car on

road, and perform the following inspections.

a. Acceleration pedal, see if the operation is smooth and if it is loose.

b. Clutch, see if there is any stuck or abnormal noise, and slip when driving.

c. Transmission,check if shifting is smooth,or rough and wrong shifting.Inspect if the display of A/T

shift lever is normal.

d. Steering, check if steering is light and smooth, and if the steering wheel turns back after steering.

e. Brake pedal, apply brake pedal to check if the braking functions well when vehicle speed is at

40km/h and if the vehicle runs off track.

f. Park brake, when parking brake handler is pulled, there should be 6~9 clicking sounds. Pull park brake

when vehicle is running at the speed of 20km/h and transmission is at neutral gear to see if it brakes.

g. Vehicle speed meter, observe the vehicle speed meter while driving. When speed changes, check if the

indicator is moving steadily or shakes.

h. Heating and air-conditioning.Try every control button to see if both heating and cooling system work

well.

i. Abnormal noise, listen carefully to see if there is any abnormal noise from engine, drive line system or

any other parts of the vehicle at a steady speed and during accelerating, and decelerating.

(3) Inspection after test ride check if there is anything abnormal in the vehicle while driving and conduct the

following inspections after the vehicle is parked.

a. Check electrical fan When engine coolant temperature is beyond 92.5°C, the radiator fan should be

running; When A/C is on and the pressure of refrigerant is more than 1.5 cooling ton, air conditioning

cooling fan should be running.

b. Check headlamp, method: park the car 5m away from the inspection surface (inspection board, curtain,

or wall) to the front bumper, and check if the beam from headlamp is good. The upper level if headlamp

should be 540mm above the ground, and the distance between headlamps on the two sides is 900mm.

c. Inspect engine idle speed,idle speed of hot engine is 800r/min±50r/min,when A/C compressor works,

the idle speed should be 900r/min±50r/min. If idle speed is abnormal, adjust the idle speed adjust

ment screw to adjust it.

(4) Usage of new cars in breaking-in period Follow the instructions below in the first 1500~2500km breaking

mileage to avoid wear and abnormal damage in breaking-in period, and to improve vehicle performance, fuel

economy and to extend vehicle useful life.

a. Drive steadily during breaking-in; do not accelerate harshly to avoid running engine at high speed.

Engine should not exceed 4500r/min in any gears. Especially at the early stage of breaking-in, vehicle

2-9

Page 31

2-10

must be running at medium speed without load. Increase the speed and load gradually with the

accumulation of breaking-in mileage.

b. Because the brake plat is not broken in on a new vehicle,in order to ensure safety and reduce wear,avoid

harsh brake, and brake for multiple times to break in the brake plate faster.

c. It is better to avoid driving vehicle on steep roads or in bad conditions during breaking-in period.

d. Pay special attention to engine coolant temperature meter and oil pressure meter.Check engine oil level

frequently and make sure engine works in normal temperature and good lubrication.

e. Maintain the vehicle strictly according to first-time maintenance requirements to bring the vehicle into

normal usage life under good condition.

7.vehicle towing

There are towing facilities both in the front and rear end of MK-1 sedan for towing other vehicles and being towed.

To ensure safety, pay attention to the following instructions when towing.

(1) Towing car Towing car should be started and shifted steadily.The speed should be no more than 40km/h.

(2) Follow the instructions below when being towed:

a. Steering system of the vehicle being towed works well.

b. Braking system of the vehicle being towed works well or it cannot be towed with a rope and must be

towed with the towing shaft instead.

c. Release park brake and shift the transmission to neutral gear when the vehicle is being towed.

d. Turn the ignition switch to ACC to allow turning signal lights,braking indicator to be turned on when

necessary.

e. The towing rope must be tensioned in the towing process.

f. If the purpose of towing is to start the engine, shift the transmission to the 2nd or 3rd gear to increase

engine speed. It is good for starting the engine.

8. Instructions to save fuel when using the vehicle

(1) Reasonable load Do not store useless articles in luggage compartment because they consumes fuel for

nothing.

(2) Correct driving style Instructions as follows:

a. When engine is started, do not heat it but press the accelerator pedal slightly, drive the vehicle slowly

and accelerate gradually.

b. Shift to higher gears when driving to allow the engine to work at appropriate engine speed and avoid

running the engine at low or high speed. The engine speed should be higher than 2500r/min when

driving, and higher than 3000r/min when up-shifting.

c. Keep the vehicle speed stable, and avoid harsh acceleration and frequent braking.

d. Pay attention to vehicle speed. Drive at high speed results in excessive fuel consumption.

(3) Organize vehicle usage well Pay attention to the following two instructions.

a. Organize vehicle usage time and avoid short trips. Because at the beginning when the vehicle is started

(around 1km), the engine has not reached its efficiency point, and the fuel consumption doubles

compared to regular.

b. Select a good driving route, avoid driving through the city or blocks with heavy traffic.

(4) Keep the vehicle under good work condition Strictly follow instructions to maintain the vehicle to make

sure the vehicle is under good technical working condition, and inspect and replace key parts that affect vehicle

fuel consumptions. For example:

Usage and Maintenance of MK Series - Usage of MK Series

Page 32

Usage and Maintenance of MK Series - Usage of MK Series

a. Keep air filter clean, Block of air filter affects engine air induction efficiency and increases fuel

consumption. So it must be cleaned and replaced in time.

b. Keep ignition system under good work condition. Bad connection or electricity leak of ignition coil and

power distributor or inappropriate gap or carbon residue of spark plug decreases ignition power supply

and efficiency, which leads to engine fuel consumption increase. So they need regular inspection and

repair to keep their good work condition.

c. Fuel feeding system works well. Often check if fuel feeder pipe leaks, and check if injectors and other

parts perform well on regular basis (electrical injection engines).

d. Keep regular tire pressure. If the tire pressure is not enough, vehicle rolling resistance increases and

engine fuel consumption increases accordingly. So tire pressure must be checked on time (around once

a week).

2-11

Page 33

2-12

Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

Section 2 Maintenance Category and Content of MK Sedan

As the vehicle is being used, its technical performance changes as the mileage accumulates and being affected by

various factors, which results in decrease of power, fuel economy, safety, and increase of emission pollutions,

noise and incidents. So timely maintenance during vehicle usage eliminates potential risks and prevents incidents

from happening, improves vehicle integrity and technical functionality, and prolongs useful life of the vehicle.

According to the vehicle technical requirements and usage history, maintenance of freedom Cruiser sedan can be

classified into several categories.

I. first time maintenance

First time maintenance is also called breaking-in maintenance. It is performed when the vehicle mileage has

accumulated to 1500~2500km in breaking-in period. First time maintenance must be conducted at the appointed

service shops. It includes:

1. Check if there is any leak in engine, transmission, and differential. Fix if there is any.

2. Replace engine oil filter, engine oil and ATF for A/T.

3. Check the level of engine coolant, braking fluid, windshield washing fluid, power steering fluid and if there

is any leak. Refill if the level is too low and repair if there is any leak.

4. Check if there is any damage in triangle arm and ball joint, connection ball joint, triangle arm flexible hinge,

or the ball joint is loose. If there is, fix or replace it.

5. Check if the drive shaft dust cover is damaged. If there is, replace it.

6. Check if there is any leak in steering mechanism, or front and rear absorber and fix it there is any.

7. Check the tire pressure, front 230kpa, and rear 210kpa.

II. Regular maintenance

After first time maintenance, the vehicle is in regular usage life. During regular use, the vehicle needs to be

maintained regularly according to the way it is used in.

1.Regular maintenance for vehicles used under extreme bad conditions. Any of the condition below is defined

as extreme bad condition:

(1) Frequent start.

(2) Often drive the vehicle in dusty circumstances.

(3) Drive the vehicle in hot areas (such as in summer in the south).

(4) Often drive in cold areas (often runs short trips, engine temperate cannot reach regular work temperature).

Vehicles ran under extreme bad conditions need to be maintained every 5000km.

2. Regular maintenance for vehicles Vehicles that have not been through extreme bad conditions need to be

maintained every 7500km.

Regular maintenance is required to be performed at Geely service shop, too.

List of parts that need to be replaced regularly is in table 1.

Maintenance timetable is in table2.

III. Geely maintenance program

Geely recommends following Geely maintenance program.

The intervals of maintenance schedules are determined by mileage meter or time periods. Maintain the vehicle

when either meets the schedule. For details, please refer to the schedule.

Page 34

Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

For servicing items whose deadlines have expired, they should be maintained at the same intervals as before. The

intervals are recorded in maintenance schedule.

Rubber hoses

Used in cooling and heating system, braking and fuel-feeding systems should be inspected by qualified Geely

technicians according to Geely maintenance schedule.

There are all very important maintenance items. Hoses must be replaced immediately should there be any aging

or damage. Please pay attention, rubber hoses age as time goes by, and they may have problems of inflation, wear,

or crack.

Special Tips

If the vehicle is driven under one or more of the following circumstances, the maintenance items should be

carried out more frequently. See attached maintenance schedule.

A Road condition

1. drive on rough, muddy or skiddy roads

2. drive on dusty roads.

B driving condition

1. Repeat driving within 8km a few times, or when the outdoor temperature is below 0 degree centigrade.

2. Idle the car drive at a low speed for a long time, such as police car, taxi, or door to door delivery vehicles.

3. Continuously drive the car at high speed for more than 2 hours (80% of the max speed).

2-13

IV. Regular inspections

1. weekly schedule

inspect engine oil level and cleanness

inspect engine coolant level

inspect brake fluid level

inspect windshield wash fluid level

inspect power steering fluid level

2. monthly inspections

inspect water pump belt

inspect electrolyte level in battery

inspect tire air pressure and wear

inspect steering wheel

inspect brake

inspect acceleration pedal

3. inspection when driving (low speed)

inspect speed meter and water temperature

check steering wheel power and if vehicle runs off-track

check if the front wheels skid or swing

inspect if brake functions or if the vehicle runs off-track when brake is functioning

4. other inspection items

Eliminate problems immediately when there is anything abnormal

Page 35

2-14

Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

V. Table 1 List of parts to be replaced regularly

System

Braking

System

Driveline

Steering System

A/C System

Engine

Parts need to be replaced regularly

1

Brake master cylinder cup valve and dust cover

2

Brake master cylinder cup

3

Brake hose

4

Brake caliper valve

5

Brake booster rubber

6

Brake booster vacuum hose

7

Brake fluid

8

MT Transmission oil

9

AT Transmission oil

10

Steering fluid

11

Air Cleaner

12

Air c leaner f ilter

13

14

15

16

17

18

19

Lubricant

Oil filter

Fuel filter

Coolant

All hoses

Canister

Timing belt

(API) SG or above

(Table 1)

Intervals

Every 2 years (or as required)

Every 2 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years (or as required)

Every 4 years (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

Every 2 years,or 40000km (or as required)

To be cleaned every 10,000km and changed

every 30,000km (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

First 2500km or 2 months. Every 7500km or

6 months afterward (or as required)

Every 5000km (or as required)

Every 40000km (or as required)

Every year (or as required)

Every 2 years (or as required)

Every 60000km (or as required)

Every 120000km (or as required)

Wedge belt (including the power steering pump,

20

air conditioner compressor and generator belts)

21

PCV system

22

Spark plug

The intervals in the part list are for cars driven under normal condition. If the car is driven in special circumstances,

the replacement can be advanced from the schedule above.

Every 50000km (or as required)

Every 20000km or 12 months (or as required)

Every 20000km (or as required)

Page 36

Usage and Maintenance of MK Series - Maintenance Category and Content of MK Sedan

2-15

VI. Table 2 Maintenance Timetable of Geely Freedom Cruiser Sedan

Maintain the vehicle when either mileage or time has reached maintenance requirements. User should keep

maintaining the vehicle to no less than 100000km. User can send the vehicle for inspection and repair in advance

if it has been through special conditions.

System Inspection item

Steering

System

Drive

line

Drive

Train

Braking

System

Steering

Wheel

Steering

Gear

Steering

Link and

Joint

Knuckle

Front

Wheel

Wheel

Clutch