Page 1

Page 2

Page 3

Preface

Geely “FC” is an automobile with high performance/price ratio and it meets the requirement

of national safety, energy saving, emission regulations and personal use. This automobile is

a completely new and excellent model produced by Zhejiang Geely Automobile Co., Ltd with

development in self-reliance of Geely group and with self-dominated intellectual property

right. It characterizes elegant appearance, energy conservation and environmental protection,

safety and comfort. “FC” is a product opening a completely new viewpoint of automobile

selection, because it is developed on the basis of creative design thinking that breaks through

all established customs and it features perfectly balanced performance of power, space,

safety, manipulation and comfort. “FC” is a competitive product for Geely developing brand

and exploring mid-level automobile market, which takes over the company philosophy “make

good cars that common people can afford, and let Geely cars go to the whole world” of Geely

automobile. “FC” is combination of creativity and intelligence of quite a large number of

automobile experts, who have been developing and searching with great concentration for

more than 30 months, and it fully embodies persistent Geely style of fashion appearance

and high performance/price ratio.

“FC” is equipped with engine JL4G18 completely developed and produced by Geely group.

Engine JL4G18 applies the following advanced technology such as VVT, full aluminum cylinder body, plastic intake manifold, completely new VVT inside seal method, completely new

OCV valve filtering method etc. with M7.9.7 electric injection system of BOSCH, and its

index on power efficiency, economical efficiency, and safety efficiency etc. reaches leading

level of national model with the same type. This engine features strong power, low fuel

consumption, low noise and high power per liter etc.

We start to compile “FC” Automobile Maintenance Manual, which is divided into 27 sections with detailed description of overall structure and maintenance of engine 4G18.VVT;

inspection and repair of engine BOSCH M7.9.7 electric control fuel injection system; structure and maintenance of chassis; structure and maintenance of FC electrical equipment;

structure and maintenance of ABS anti-lock brake system; structure and maintenance of

SRS air bag; structure and maintenance of auto air conditioning system; structure and maintenance of vehicle body etc. Information is detailed and accurate, contents are in systematic

coherence and description is concise and comprehensive.

This manual is compiled from structure, which prompts “FC” service personnel to master

Page 4

necessary maintenance, repair and malfunction knowledge on the basis of understanding

main structure characteristics and simple principle of vision automobile. Electric control system of “FC” automobile is particularly described with detail, and detailed steps and methods

are given for trouble shooting process. All kinds of malfunction could be eliminated quickly

and efficiently within the shortest time as long as you detect as the repair steps of this manual.

In addition, this manual is compiled with the following characteristics: in proper sequence,

clear demarcations, easy to understand, excellent in picture and its accompanying essay,

simple and clear, which is very applicable for a quite large number of “FC” automobile maintenance technicians and service personnel to refer to.

This manual is mainly compiled by Geely International Corporation; Geely Automobile Engine No. 2 Plant and engineering technicians of service corporation help complete this work.

Defects and mistakes are inevitable in this manual for limited level of compiler and limited

time, please contact Geely International Corporation if you find mistakes and careless omissions in using and we can correct in time and reverse in next version.

Geely International Corporation

Nov. 2007

Page 5

Note

This manual is mainly for qualified vehicle technicians, but it does not include all items on repair and maintenance.

In order to avoid personnel injury and vehicle damage caused by dangerous

operation, please observe the following regulations.

z Please read this manual carefully, and particularly fully master all con-

tents in “Precautions”.

z Maintenance methods described in the manual are quite useful for vehicle

maintenance. Please adopt specified or recommended tools in maintaining vehicle as steps described in this manual; maintaining vehicle with

tools or methods not specified or recommended in this manual will cause

personnel injury or vehicle damage. Therefore, please consider ensuring

the safety of technicians and vehicle at first before performing maintenance.

z If it is necessary to replace parts, please replace with parts of the same or

similar size with original ones. It is forbidden to use inferior parts.

z In order to effectively avoid technician injury and vehicle damage and hid-

den danger caused by incorrect operation, it is very important to observe

“Warning” and “Notes” in this manual. It particularly needs to mention that

not all precautions on safety are included in “Warning” and “Notes” etc. in

this manual. Therefore, please fully realize that perform maintenance not

as regulations will cause dangerous consequences.

Page 6

Contents

Brief introduction on Geely model “FC”

Basic parameters

Maintenance period

Regular maintenance items

Table on maintenance period at normal conditions5

Table on maintenance period at severe conditions..7

Engine control system

EFI system

On-vehicle inspection

Inspection

Throttle body assembly

Removing, installing and disassembling, assembling

Fuel

Fuel system

Precautions

On-vehicle inspection

Inspection

Injection nozzle assembly

Replacement

Fuel pump assembly

Removing, installing and disassembling, assembling

Fuel tank assembly

Removing, installing and disassembling, assembling

Exhaust gas control

Exhaust gas control system

On-vehicle inspection

Inspection

Engine mechanism

Engine assembly

...................................................

...................................

.............................................................

........................................

..........................................................

........................................

..........................................................

......................................................

......................................

........................................................

....................................

...................................................

...........................................

.............................................

...............................

......................................

........................................................

..................................................

...

....

.....

13

13

14

14

16

17

18

18

20

20

21

21

23

23

25

26

Inspection

1

4

8

8

9

Drive belt

Replacement

Valve clearance

Adjustment

Engine assembly

Replacement

Timing chain assembly

Replacement

Camshaft

Replacement

Crankshaft front oil seal assembly

Replacement

Crankshaft rear oil seal assembly

Replacement

Cylinder cover gasket components

Replacement

Exhaust

Exhaust pipe assembly

Removing, installing and disassembling, assembling

Cooling

Cooling system

On-vehicle inspection

Inspection

Cooling fan system

On-vehicle inspection

Inspection

Water pump assembly

Replacement

Temperature regulator components

Replacement

Radiator with electronic fan assembly

........................................................

..............................................................

...................................................

....................................................

......................................................

.................................................

...................................................

.......................................

...................................................

.............................................................

...................................................

.....................

...................................................

......................

...................................................

.....................

...................................................

........................................

.....

....................................................

......................................

........................................................

..............................................

......................................

........................................................

........................................

...................................................

...................

...................................................

................

26

29

29

30

30

36

36

45

45

52

52

60

60

62

62

63

63

65

65

66

66

66

68

68

68

69

69

71

71

72

Page 7

Replacement

Coolant

Lubrication

Lubricating system

Oil filter assembly

Oil pump assembly

Ignition

Ignition system

.................................................................

Replacement

On-vehicle inspection

Replacement

Replacement

Inspection

On-vehicle inspection

...................................................

...................................................

...............................................

......................................

.................................................

....................................................

...............................................

....................................................

.....................................................

........................................................

......................................

72

73

73

74

74

75

75

76

76

77

77

77

Front stabilizer bar

Overhaul

Front left lower control arm ball joint assembly

Replacement

Rear suspension

Rear suspension system

Table on trouble occurrence

Rear wheel alignment

Adjustment

Rear strut assembly

Overhaul

Handling

Rear stabilizer bar

Overhaul

Rear shaft assembly

Overhaul

.........................................................

...............................................

..........................................................

...................................................

....................................

..........................

.........................................

.....................................................

...........................................

........................................................

..............................................

........................................................

...........................................

........................................................

..

100

100

101

101

102

102

104

105

105

106

106

96

96

99

99

Starting and charging

Starting system

Inspection

Charging system

Precautions

On-vehicle inspection

Alternator components

Replacement

Starter components

Replacement

Front suspension

Front suspension system

Table on trouble occurrence

Front wheel alignment

Adjustment

Front absorber and helical spring

Overhaul

Handling

Lower left control arm assembly

Replacement

.....................................................

........................................................

..................................................

......................................................

......................................

..............................................

....................................................

..............................................

....................................................

.........................................

......................................................

..........................................................

..........................................................

...................................................

....................................

...........................

.......................

.........................

79

79

81

81

82

84

84

85

85

86

86

87

87

90

90

93

94

94

Tire and wheel

Wheel and tire system

Inspection

Drive shaft

Drive shaft

Notes

Malfunction phenomenon table

Inspection on automobile

Front drive shaft

Overhaul

Left front shaft hub assembly

Change

Left front shaft hub bolt

Change

Left rear shaft hub and bearing assembly

Change

Left rear shaft hub bolt

Change

......................................................

.......................................................

.............................................................

........................................................

..........................................................

..........................................................

..........................................................

..........................................................

.......................................

.............................

.................................................

............................

......................................

.......................................

....................

........

109

109

111

111

111

112

113

113

123

123

128

128

129

129

131

131

Page 8

Brake

Brake system

Notes

Remove malfunction

Malfunction phenomenon table

Brake liquid

Discharge the air in brake system

Brake pedal assembly

Adjustment

Change

Vacuum booster assembly

Inspection on automobile

Change

Front brake assembly

Overhaul

Rear brake assembly

Overhaul

Hydraulic pressure control unit (equipping with ABS)

Inspection on automobile

Change

Speed sensor of front wheel

Change

Speed sensor of rear wheels

Change

Parking brake

Parking brake system

Malfunction phenomenon table

Adjustment

Parking brake handle assembly

Change

Parking front bake pull cable assembly

Change

Parking rear brake pull cable assembly

Change

Parking brake assembly

Overhaul

......................................................

..............................................................

...........................................

.....................

.........................................................

.................

........................................

.....................................................

..........................................................

.................................

...............................

..........................................................

.........................................

........................................................

.........................................

........................................................

...............................

..........................................................

..............................

..........................................................

...........................

..........................................................

.........................................

.....................

.....................................................

.........................

..........................................................

..........................................................

..........................................................

....................................

........................................................

............

...........

Transmission

132

132

133

133

135

135

136

136

137

138

138

138

141

141

144

144

...

148

148

148

151

151

152

152

154

154

154

155

155

156

156

158

158

161

161

Disassemble assembly

Assemble the assembly

Steering column

Steering system

...............................................................

Note

Malfunction phenomenon table

Inspection on automobile

Steering column system

Overhaul

Power steering

Power steering system

...............................................................

Note

Malfunction phenomenon table

Inspection on automobile

Power steering oil pump assembly

Overhaul

Power steering gear assembly

Overhaul

Air conditioner

Air conditioning system

...............................................................

Note

Inspection on automobile

Inspection

Refrigerant

Inspection on automobile

Change

Refrigerant pipeline

...............................................................

Parts

Control assembly, air conditioner control panel (AUTO A/C)

Overhaul

Fan assembly

Overhaul

Air conditioner central heating core assembly..227

Overhaul

Compressor assembly

..................................................

........................................................

........................................................

........................................................

......................................................

..........................................................

..........................................................

........................................................

...................................................

........................................................

........................................................

...................................

....................................

.....................

...............................

.....................................

......................................

....................

.............................

..................

.........................

......................................

...............................

...............................

............................................

.....................................

165

191

192

192

192

193

194

194

198

198

199

200

203

203

205

205

213

213

213

214

215

215

221

222

222

...

223

223

224

224

227

234

Page 9

Change

Condenser Assembly

Inspection on the automobile

Overhaul

Supplemental restraint system

Note

Malfunction treatment

Repair

Inspection

Remove malfunction

Malfunction table

Diagnosis of impacted automobile

Disassemble and assemble

Electronic control unit of safety airbag (ECU)..261

Safety airbag assembly at the side of driver..261

Safety airbag assemble at the side of passenger

Scrap treatment for safety airbag

Safety belt

Safety belt

Note

Treatment

Subassembly

Change

Rear safety belt

Subassembly

Change

Light

Light System

Notes

The phenomena table

Inspect the car

Inspect

Front combination light (LH)

Subassembly

Change

..........................................................

...........................................

.......................

........................................................

....................................................................

.........................................

.................................................................

...........................................................

...........................................

............................................

.................

...............................

..................

..........................................................

...............................................................

.......................................................

.................................................

..........................................................

..................................................

.................................................

..........................................................

.......................................................

..............................................................

....................................

...............................................

...........................................................

..............................

................................................

..........................................................

....

234

236

236

236

239

244

247

249

251

251

260

261

263

264

270

270

270

273

274

275

275

277

279

279

279

281

283

286

286

287

Adjustments

Front fog light

Components

Change

Adjustment

Side turning light

Components

Rear combination light (LH)

Components

Change

Rear fog light

Components

Change

Number plate light

Change

High brake light assembly

Change

Left combination switch

Change

Wiper and cleaner

Wiper and cleaner system

Malfunction phenomena table

Inspect the car

Inspect

Right combination switch

Change

Wiper motor

Change

..................................................................

Wiper

Change

Cleaner nozzle

Adjustments

Audio system

Audio system

Notes

Radio assembly

..................................................

.....................................................

.................................................

..........................................................

....................................................

................................................

.................................................

.................................................

..........................................................

......................................................

.................................................

..........................................................

.............................................

..........................................................

..........................................................

..........................................................

...............................................

...........................................................

..........................................................

.......................................................

..........................................................

..........................................................

...................................................

..................................................

.....................................................

.............................................................

.................................................

..............................

.................................

.....................................

.................................

......................

.................................

287

289

289

290

290

291

291

292

292

293

294

294

295

296

296

297

297

298

298

299

299

299

300

302

302

303

303

305

305

306

306

307

307

308

Page 10

Replacement

Left front door loudhailer

Change

Left front small loudhailer

Change

Rear loudhailer

Change

Outdoor antenna

Change

Circuitry

Power supply

Components

Horn system

Horn system

Position

Inspect

Windshield/window glass/wing mirror

Electric window control system

Position drawing

Inspect the car

Malfunction phenomena table

Inspect

Front windscreen

Change

Rear ventilation window

Change

Fog defrost system

Position drawing

Malfunction phenomena table

Inspect

Electric rearview mirror control system(option).329

Inspect the vehicle

Position drawing

Trouble table

INSPECT

.................................................

....................................

..........................................................

..................................

..........................................................

..................................................

..........................................................

...............................................

..........................................................

......................................................

..................................................

.......................................................

..........................................................

...........................................................

..........................

............................................

...............................................

.......................

...........................................................

................................................

..........................................................

.....................................

..........................................................

............................................

...........................................

......................

...........................................................

.........................................

...........................................

.................................................

.......................................................

308

309

309

310

310

311

311

312

312

313

313

316

316

316

317

317

317

319

319

321

321

324

324

327

327

327

328

329

331

331

332

Panel / combination panel

combination panel

Trouble table

Vehicle inspection

Inspection

..................................................................

Panel

Preparation

Change

Combination instrument assembly

Disassembly and assembly

Chair

Front chair

Subassembly

Overhaul

Rear chair (separating type)

Overhaul

Rear chair (fixing type)

Overhaul

Anti-stealing and door lock

Electric door lock control system

Position of parts

Inspection on automobile

Malfunction phenomenon table

Inspection

Electronic anti-stealing system

Electric sunroof

Sunroof

.................................................................

Overhaul

Specification for sunroof function

Inspection for sunroof function

Inspection for sunroof switch

Position of parts

Malfunction phenomenon table

..............................................

..................................................

..........................................

......................................................

....................................................

..........................................................

..........................................................

.................................................

........................................................

........................................................

.......................................

........................................................

.............................................

......................................................

........................................................

............................................

.....................

...........................

...............................

........................

...............................

.....................

...........................

......................

......................

........................

....................

334

334

335

339

340

340

340

347

347

348

348

349

352

352

354

354

355

355

355

358

359

361

362

362

364

364

365

365

365

Page 11

Engine cover/automobile door

Engine cover

Adjustment

Front automobile door

Subassembly

Overhaul

Adjustment

Rear automobile door

Overhaul

Adjustment

Trunk cover

Adjustment

Torsion spring of trunk cover

Change

Exterior/inner trim board

Front bumper

Subassembly

Change

Rear bumper

Subassembly

Change

Name plate

Change

Exterior seal tape of left front door glass (LH)

Change

Exterior seal tape of left rear door glass

Change

Light fender

Change

Top left trim tape

Replacement

Left lower fender of automobile body (LH)

Subassembly

Change

Inner trim board of top

Change

......................................................

.....................................................

........................................

.................................................

........................................................

.....................................................

.......................................

........................................................

....................................................

.........................................................

....................................................

.............................

..........................................................

....................................................

................................................

..........................................................

......................................................

................................................

..........................................................

........................................................

..........................................................

..........................................................

..........................................................

........................................................

..........................................................

.................................................

.................................................

................................................

..........................................................

........................................

..........................................................

...........

........

Automobile control system

366

366

367

367

369

372

373

373

375

377

377

378

378

379

379

380

381

381

382

383

383

...

384

384

385

385

386

386

387

387

388

388

389

390

390

Ignition switch and anti-versa lock key warning switch.394

Malfunction phenomenon table

Inspection

Electrical schematic diagram

......................................................

.....................

..............................

394

394

395

Page 12

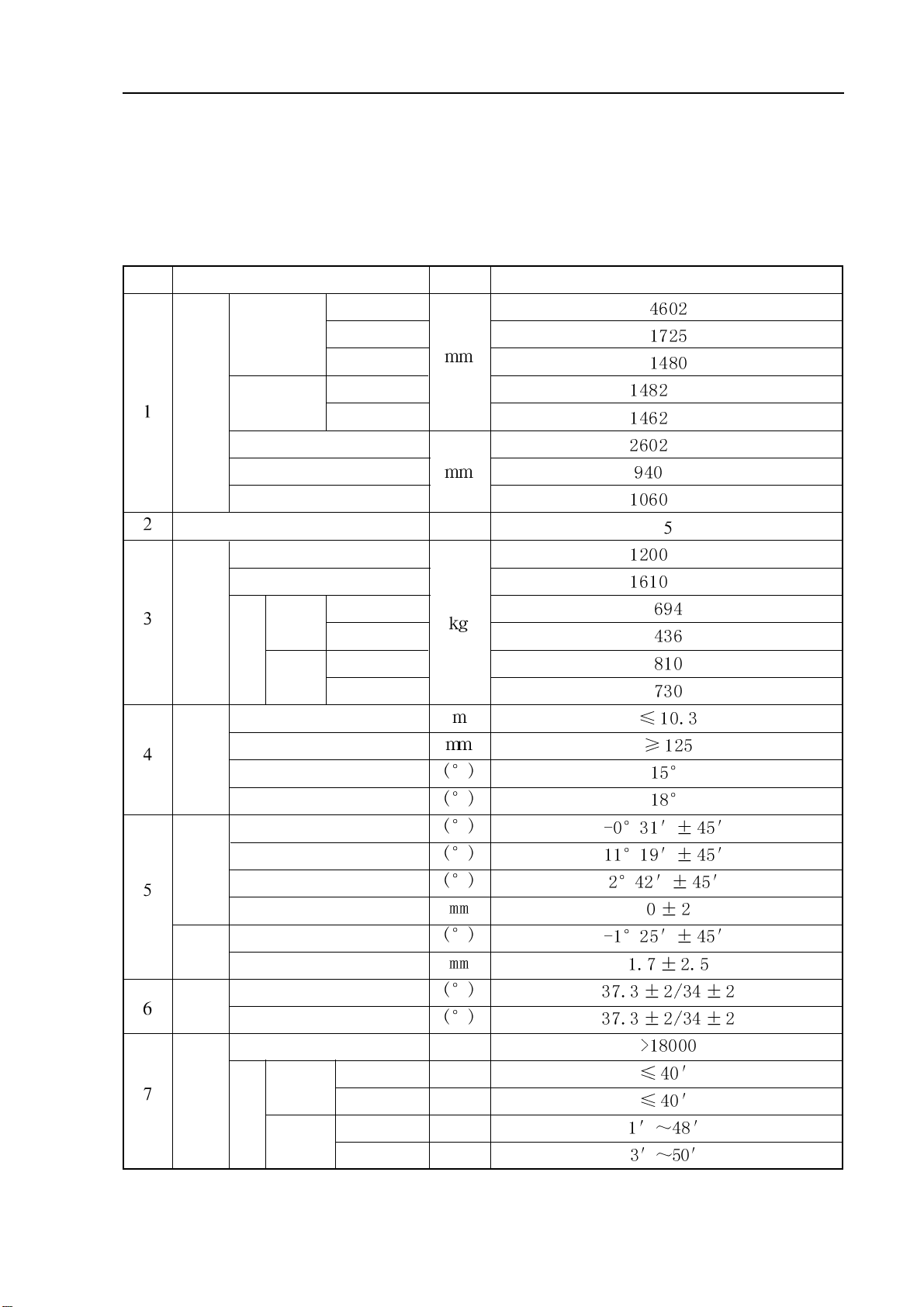

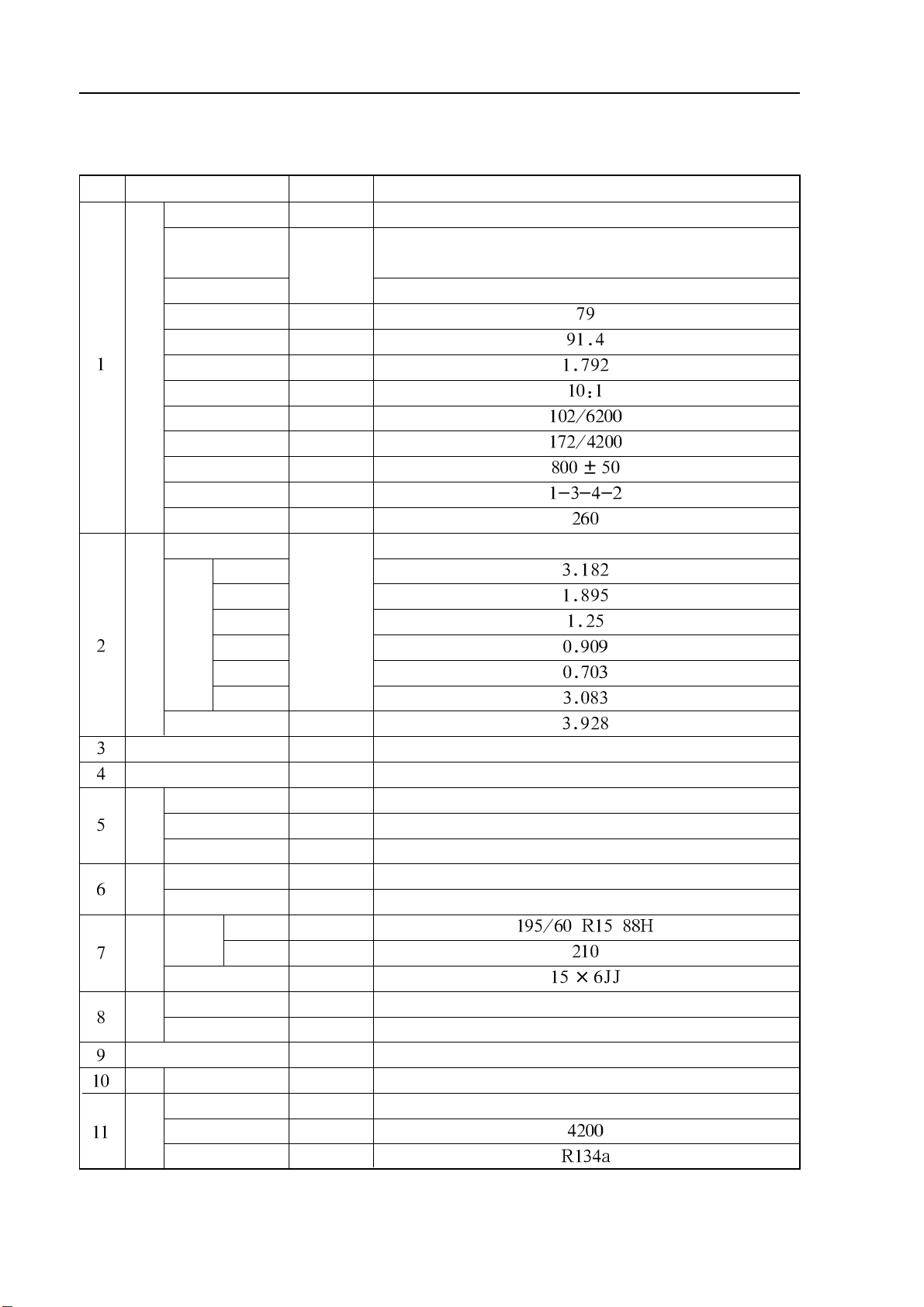

Brief introduction on Geely model “FC” Basic parameters

Brief introduction on Geely model “FC”

Basic parameters

Table 1 Complete vehicle basic parameters

Number

Item name

Length

Overall

dimension

Width

Height

Front wheel

Wheel track

Rear wheel

Wheel base

Front suspension

Dimension parameters

Rear suspension

Passenger number

Complete vehicle herb mass

Max. total mass

No

load

Full

Mass parameters

load

Weight distribution

Front axle

Rear axle

Front axle

Rear axle

Min. turning diameter

Unit

Person

Parameters

±15

±15

±20

±10

±10

±30

±30

Min. gound clearance

Approach angle (full load)

Departure angle (full load)

Traverse ability

Front wheel camber

Kingpin inclination angle

caster angle

parameters

Convergence of front wheels

Front wheel alignment

Rear wheel camber

Convergence of rear wheels

alignment

Rear wheel

parameters

Left wheel: inside/outside

wheel

steering

Right wheel:inside/outside

Front wheel

Head lamp light

Luminous intensity of

high beam of head lamp

Left and

right

inclination

Down

High beam

optical axis

inclination

Candera

Left lamp

Right lamp

Left lamp

Right lamp

1

Page 13

Brief introduction on Geely model “FC” Basic parameters

Table 2 Types and parameters of main assembly

Number

Item name

Electric injection system model

Delivery capacity

Engine

Compression ratio

Max. power

Max. torque

Idling speed

Ignition sequence

Min. fuel consumption

Each gear ratio

Transmission

Main gear box ratio

Clutch type

Steering gear

Front brake

system

Braking

Rear brake

Front suspension type

Rear suspension type

Sus-

pension

Radial

Tire

tire

Model

Type

Bore

Stroke

Type

1st gear

nd

gear

2

3rd gear

4th gear

5th gear

Reverse gear

Type

Specification

Air pressure

Unit

//

.//

/

/.

Types and parameters

JL4G18

4-cylinderin-line, four-stroke, water-cooling, double over-head

camshaft, 16-valve, CVVT multipoint injection gasoline engine

United Automotive Electronic Systems Co., Ltd. M7.9.7 electric injection system

5 gears synchronizer of constant mesh gear

Dry single, diaphragm spring, constant pressure

Rack-and-pinion steering gear with hydraulic power

Double pipeline, vacuum boosterwith ABS +EBD anti-lock system

Disc brake

Disc brake

Strut-type front independent suspension

Longitudinal swinging arm and anti-twist beam compound rear suspension

2

axle

Drive

Drive shaft

Body structure

Tail gas

Catalytic converter

Air

Compressor type

condi-

Nominal refrigerating capacity

tioning

system

Refrigerant

Rim

Type

Breakaway

BalI cage and tripot type constant velocity universal joint

Loaded all-metal body

Honeycomb cordierite carrier, noble metal catalyst

Swirl or swash plate compressor

Page 14

Brief introduction on Geely model “FC” Basic parameters

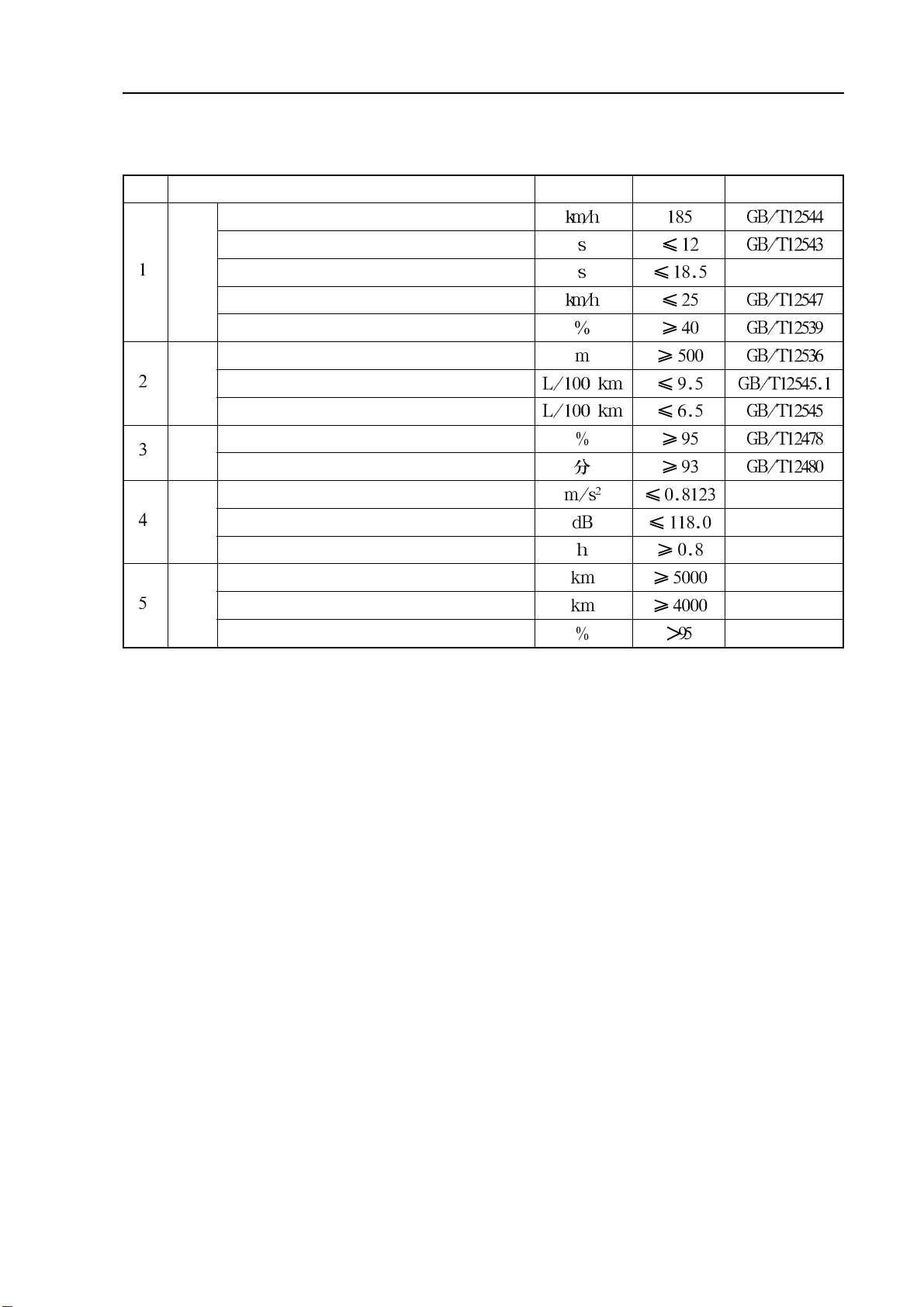

Table 3 Main performance parameters of complete vehicle

Number

Item name

Max. vehicle speed

0-100 km/h accelerating time

Accelerating time from 30km/h to 100km/h at 4th gear

Min. stable vehicle speed at 4th gear

Power performance

Slide Distance (full-load, initial speed 50km/h)

Max. climbing speed

Fuel consumption with 4 operating modes

Economy

Average fuel consumption at specified operating mode

performance

Dust sealing degree

Seal

perfor-

Ride

perfor-

mance

mance

Rain protection seal limit value

Weighted acceleration root of mean square

Equivalent mean value

Reduced comfort boundary

Average mileage to first failure

Average mileage between failures

Reliability

Efficient degree

Unit

Parameters Remarks

3

Page 15

Maintenance period-Regular maintenance items

Maintenance period

Regular maintenance items

Your precious automobile should be maintained according to maintenance period

at normal conditions (see table on maintenance period at normal conditions)

If your precious automobile is mainly driven under one or more of the following conditions, some

maintenance items must be performed more frequently (see table on maintenance period at severe

conditions).

A. Road conditions

1. Driving on rugged, muddy or melting snow road.

2. Driving on dusty road.

B. Driving conditions

1. Towing tail vehicle, equipped with camp frame or top storage racks.

2. Repeated on short-distance driving within 8 km and the temperature is below 0 .

3. Vehicles driven for long distance under idle speed or low speed over a long period of time,

such as police car, taxi or delivery truck.

4. Continuously driving at high speed for more than 2 hours frequently. (With 80% of max. vehicle speed)

5. Vehicles driven with idle speed or low speed over a long period of time or frequently accelerated or decelerated, such as training car of driving training class.

4

Page 16

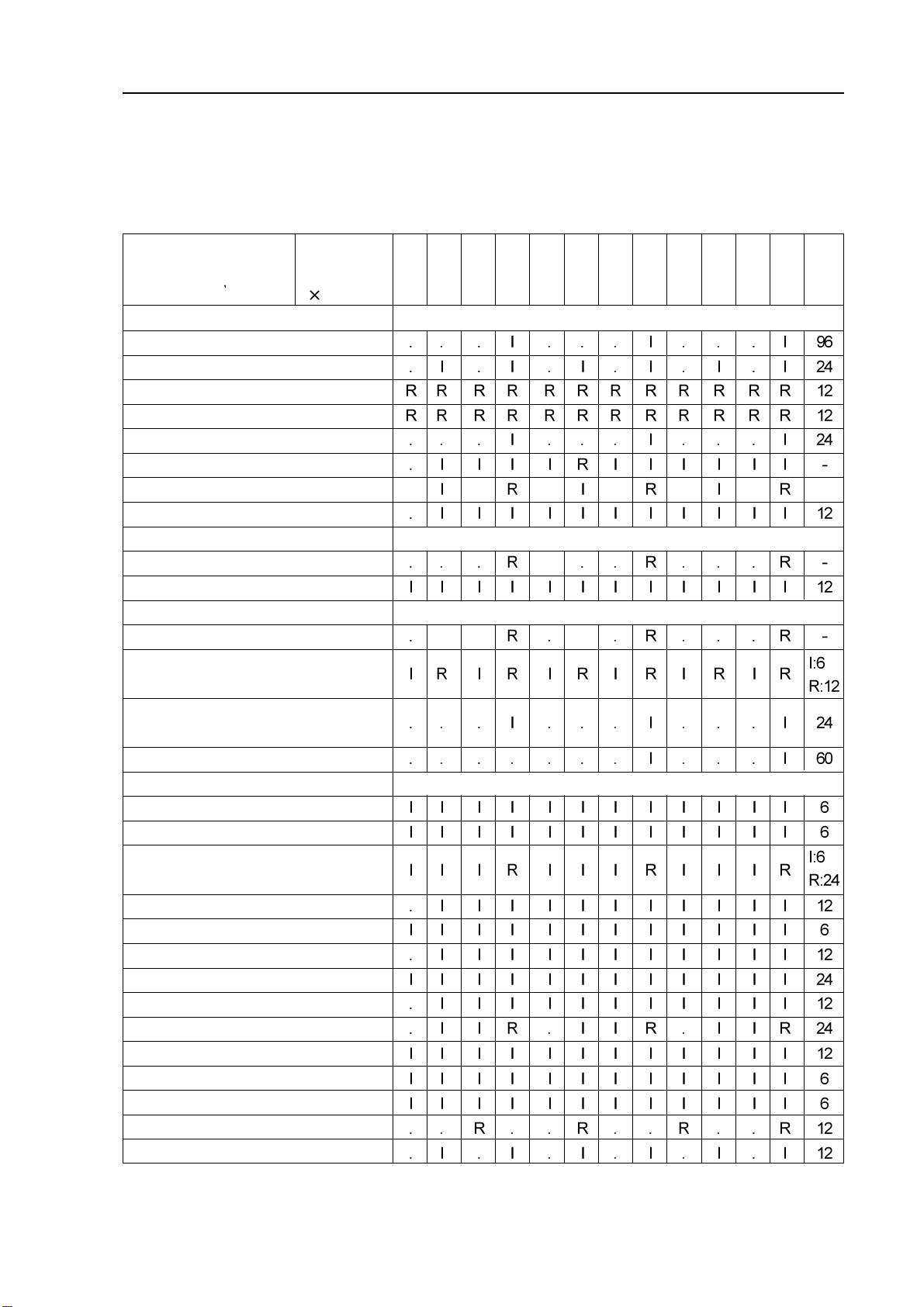

Maintenance period-Table on maintenance period at normal conditions

Table on maintenance period at normal conditions

Maintenance content:

I: Inspection and correction or replacement if necessary R: Replacement

Maintenance period

(Odometer readings or

operating months subject to

the first coming)

Engine basic elements

1. V alve clearance*

1

2. Drive belt

3. Engine oil (APLSJ,SL or ILSAC) *

4. Oil filter*

5. Cooling and heating system hose and joint*3*

6. Engine coolant*5*

2

6

7. CVVT oil duct filter screen

8. Exhaust pipe and fixed mount

Ignition system

9. Spark plug

10. Battery

Fuel and exhaust gas control system

11. Fuel filter

mileage

reading

1000km

7. 5 1 5 22.5 30 37.5 45 53.5 60 67.5 7 5 82.5 90

2

4

months

12. Air filter core

Connecting conditions of fuel tank cover,

13.

fuel pipe and fuel evaporation control valve*

7

14. Activated carbon canister

Chassis and vehicle body

15. Brake pedal and parking brake

16. Brake pad and brake disc

17. Brake fluid

18. Brake Pipe and hose

19. Power steering oil

20. Steering wheel, steering linkage and gear box oil

21. Drive shaft dust cover

22. Ball joint and dust cap

23. Transmission oil

24. Front and rear suspension

25. Tire and tire pressure

26. All light, horn, wiper and washer

27. Air conditioner cleaning filter screen

Air conditioning system/ secondary refrigerant

5

Page 17

Maintenance period-Table on maintenance period at normal conditions

Note: *1 Indicating that check valve noise and engine vibration condition, and adjust them if necessary.

*2

It is suggested that see operating modes on page 116 of operating instruction to perform.

*3

Indicating that check once every 20000km or 12 moths after 80000km or 48 months.

*4

Indicating that check water tank and condenser are blocked by leaves, dust or insects, and clean

hose connections.

*5

Replace at initial 60000km, and replace every 30000km in future.

*6

Only “Geely genuine ultra-long engine coolant” or equivalent high-quality ethylene glycol engine

coolant without silicate, amines, nitrite, borate and with long-life compound organic acid technology

are allowed to use, and coolant should be repeated several times until it is filled up.

*7

Indicating that check once every 20000km or 12 moths after 80000km or 48 months.

6

Page 18

Maintenance period-Table on maintenance period at severe conditions

Table on maintenance period at severe conditions

According to the driving conditions listed below, maintenance should be performed to the items that

should be maintained more frequently (for other items not listed, please see Table on maintenance

period at normal conditions)

A-1: Driving on rugged, muddy or melting snow road

Inspection of brake pad and brake disc Every 5,000 km or 3 moths

Inspection of brake pipeline and hose Every 10,000 km or 6 moths

Inspection of ball joint and dust cover Every 10,000 km or 6 moths

Inspection of drive shaft dust cover Every 10,000 km or 12 moths

Inspection of the steering wheel, steering linkage and gear box oil

Check of front and rear suspension Every 10,000 km or 6 moths

A-2: Driving on dusty road

Replacement of engine oil Every 5,000 km or 6 moths

Replacement of engine oil filter Every 5,000 km or 6 moths

Inspection or replacement of air filter core I: Every 2,500 km or 3 moths

Inspection of brake block and brake disc Every 5,000 km or 3 moths

Replacement of air conditioner cleaning filter screen Every 15,000 km

B-1: Towing tail vehicle, equipped with camp frame or top storage racks

Every 5,000 km or 3 moths

R: Every 10,000 km or 6 moths

Replacement of engine oil Every 5,000 km or 6 moths

Replacement of engine oil filter Every 5,000 km or 6 moths

Inspection of brake pad and brake disc Every 5,000 km or 3 moths

Inspection or replacement of transmission oil Every 60,000 km or 24 moths

Inspection of front and rear suspension Every 10,000 km or 6 moths

Screwing down the bolts and nuts of the chassis and vehicle body

Every 10,000 km or 6 moths

B-2: Repeated on short-distance driving within 8 km and the temperature is below 0 °C

Replacement of engine oil Every 5,000 km or 6 moths

Replacement of engine oil filter Every 5,000 km or 6 moths

Vehicles driven for long distance under idle speed or low speed over a long period of time, such as police car, taxi or delive rytruck

B-3:

.

Replacement of engine oil Every 5,000 km or 6 moths

Replacement of engine oil filter Every 5,000 km or 6 moths

Inspection of PCV valve and pipelines Every 5,000 km or 6 moths

Inspection of brake block and brake disc Every 5,000 km or 3 moths

Continuously driving at high speed for more than 2 hours frequently (With 80% of max. vehicle speed)

B-4:

Replacement of transmission oil Every 40,000 km or 12 moths

Vehicles driven with idle speed or low speed over a long period of time or frequently accelerated or

B-5:

decelerated, such as student car of driving training class.

Replacement of engine oil Every 3,000 km or 3 moths

Replacement of engine oil filter Every 3,000 km or 3 moths

Inspection of PCV valve and pipelines Every 3,000 km or 3 moths

7

Page 19

Engine control system·- EFI system

Engine control system

EFI system

On-vehicle inspection

1. Inspection of the voltage of power steering oil pres-

sure sensor

Measure the voltage between PS terminal and E2 terminal

with ohmmeter

Conditions Voltage (V)

Not turning steering wheel with

engine at idle speed

Turning steering wheel with

engine at idle speed

2. Inspection of stepping motor

(a) With engine running at idle speed, pull out the connection harness of stepping motor, and the change

of engine rotating speed indicates that the stepping motor operates normally.

(b)Pull out the connection harness of stepping motor, and measure the terminal current with universal

meter. When engine is running, there being impulse current output at the terminal indicates that there

is no trouble with ECU and stepping motor control system, and if idling is not stable at the moment

and deviates greatly from specified value, the stepping motor should be replaced. If there is no

impulse current output at the terminal, turn on air conditioner to test again, and still no impulse

current output indicates that there is trouble with ECU and stepping motor control system circuit.

(c) Check the malfunction of stepping motor circuit with diagnostic instrument.

0-1.5

8

Page 20

Engine control system·- EFI system

Inspection

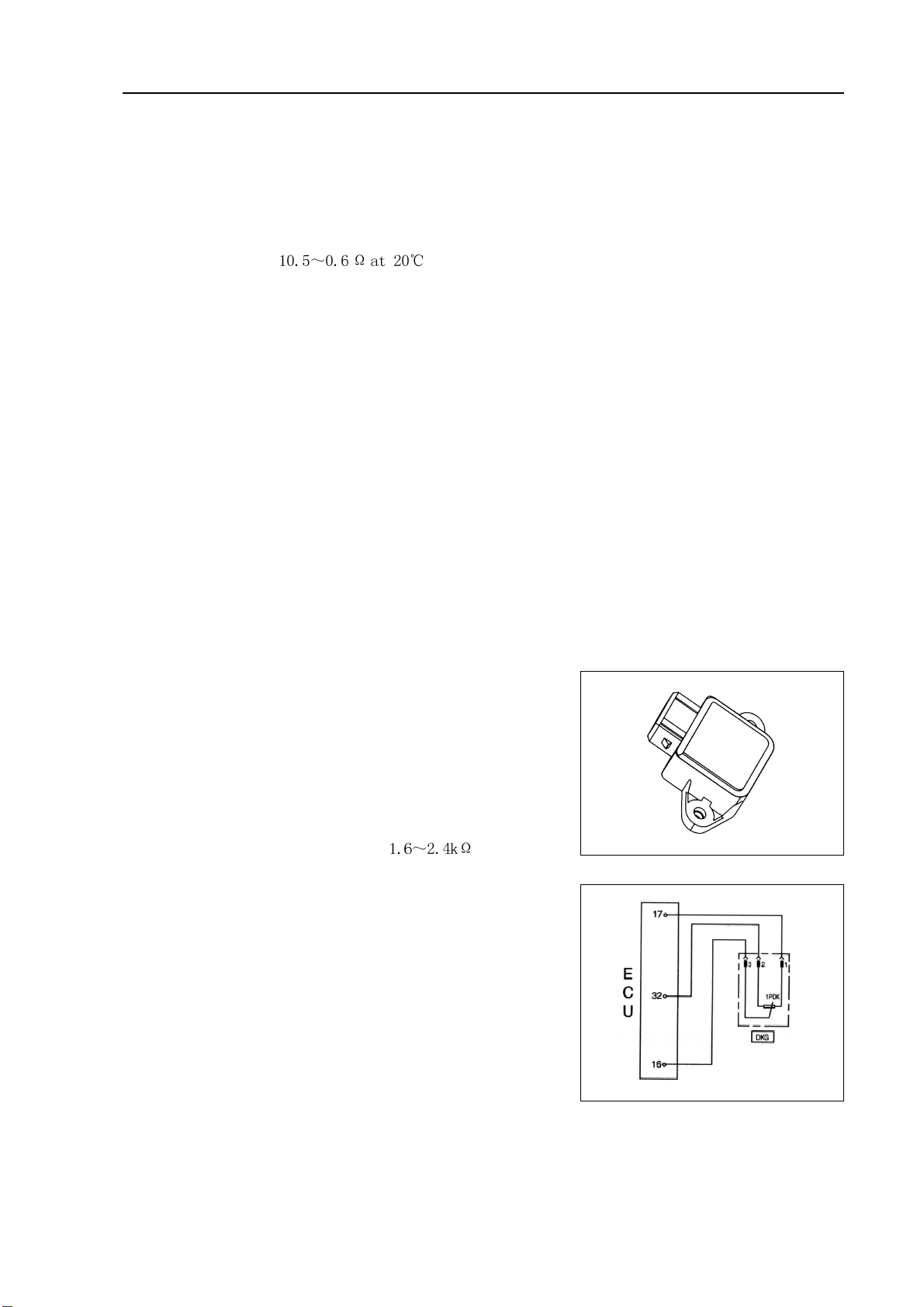

1. VVT control solenoid valve assembly (4G18-1006200)

(a)Resistance inspection

(1)Measure the resistance between terminals with ohmmeter

Resistance:

(b)Operation inspection

Connect battery positive (+) wire to No.1 terminal and negative (-) wire to No. 2 terminal, and check

valve operation.

Note: ensure that the valve is not stuck.

Hint: if there are foreign matters in the valve, the valve could not be closed tightly and will

thus result in slight pressure being lifted toward higher direction.

2. Throttle body components (4G18-1001240)

(a)Inspection of throttle body

(1)Throttle valve shaft should not swing.

(2)All channels should not be blocked.

(3)Throttle valve plate should rotate flexibly and act smoothly.

(4) When the throttle is at closed position, there should be no clearance between throttle stop bolts and

throttle lever.

Note: it is not allowed to adjust the throttle stop bolts.

3. Throttle position sensor (4G18-3600080)

(a)Resistance inspection

(1)Remove the wiring harness connectors of throttle posi-

tion sensor.

(2)Measure the resistance between 1# pin and 2# pin with

ohmmeter, resistance value: .

(3)Connect 2 terminals respectively to 1# pin and 3# pin,

and turn the throttle, the resistance value varies linearly

with the opening of throttle, but 2# pin and 3# pin are

contrary to this.

Note: pay attention whether there is great jump with

resistance value when observing resistance change.

9

Page 21

Engine control system·- EFI system

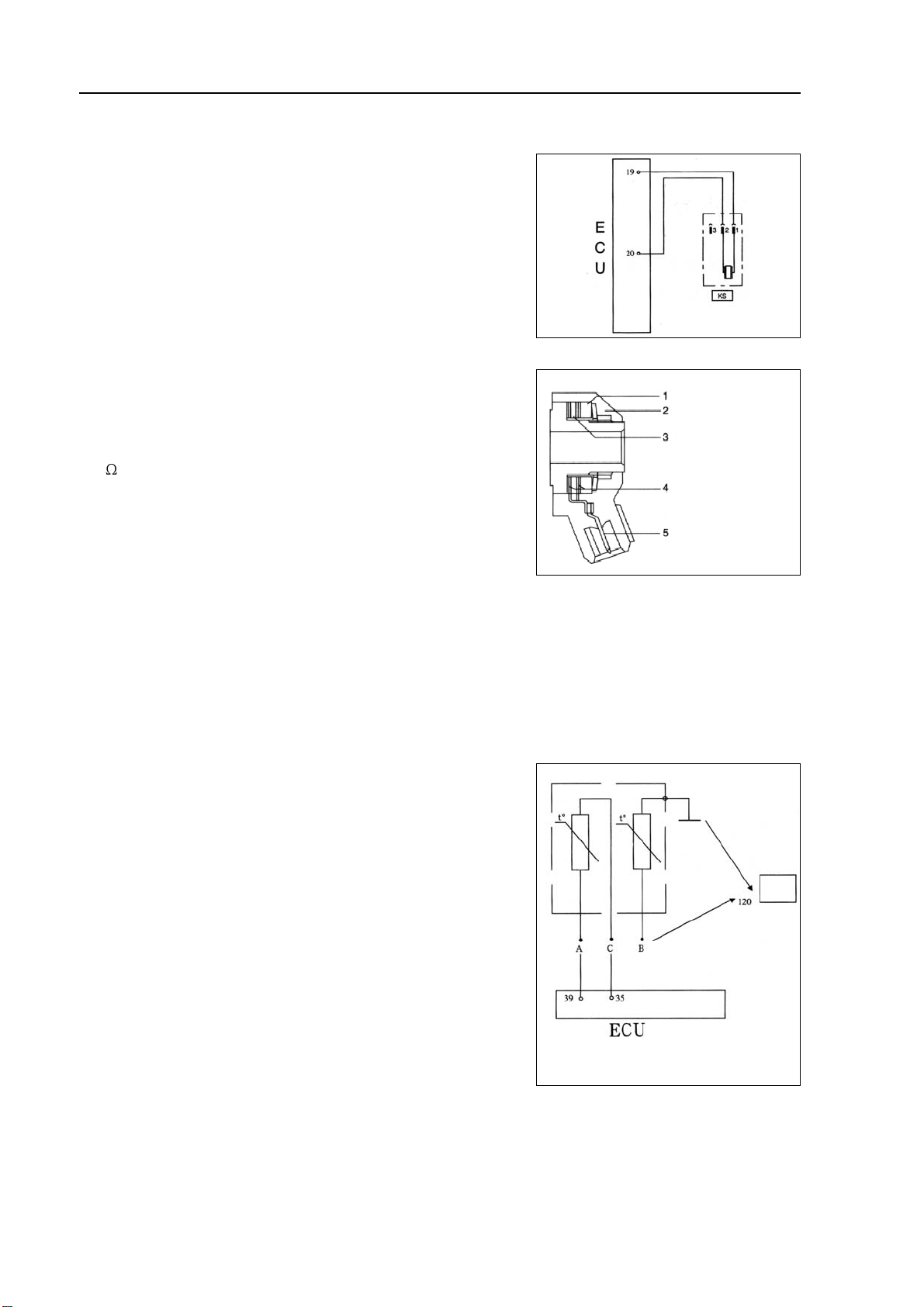

4. Knock sensor (4G18-3600020)

Measuring method:

(Removing the joint) place digital universal meter at ohm gear,

and connect 2 terminals respectively to 1# pin and 2# pin, and

the resistance under normal temperature should be more than

1M . Place digital universal meter at millivolt gear, and knock

around knock sensor with a hand hammer, there should be voltage

signal output at the moment.

1 Vibration block

2 Housing

3 Piezoelectric ceramics

4 Contact

5 Electric connection

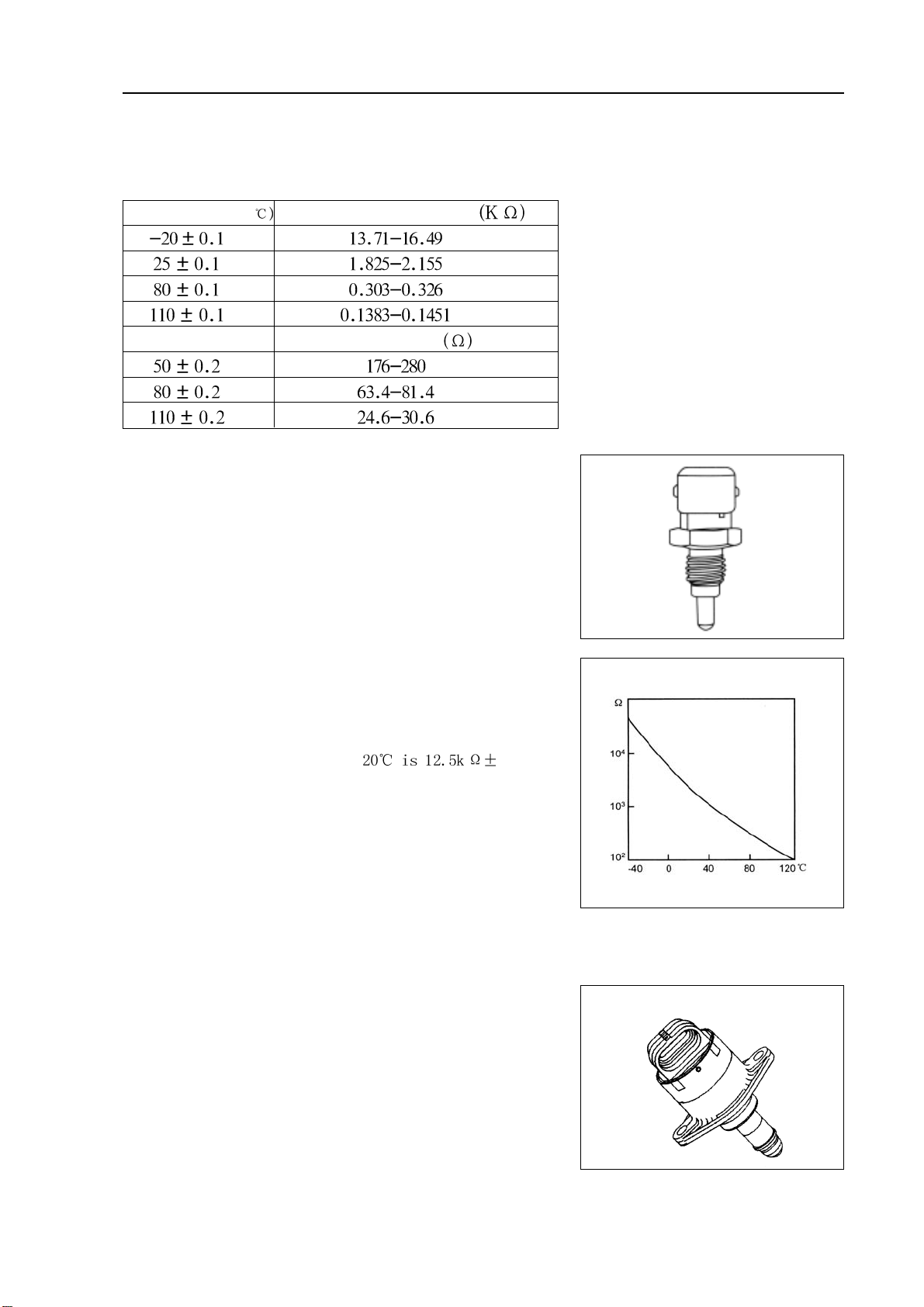

5. Water temperature sensor (4G18-3600040)

This sensor applies sealing NTC thermal resistor in temperature sensor, and resistance value varies with

ambient temperature, thus slight change of outside temperature could be measured. Measuring its output resistance could reflect the temperature of contact media. Signals from A and C are sent to ECU,

and Signals from B and earth are sent to instrument.

Operating principle (Fig. 1):

Fig. 1

Note: A, B and C represent 3 pins of sensor, and see pin root for the mark.

10

Page 22

Engine control system·- EFI system

Use digital universal meter to measure:

Resistance-temperature characteristics of temperature sensor

Temperature range(

Resistance at A and C

Resistance at B

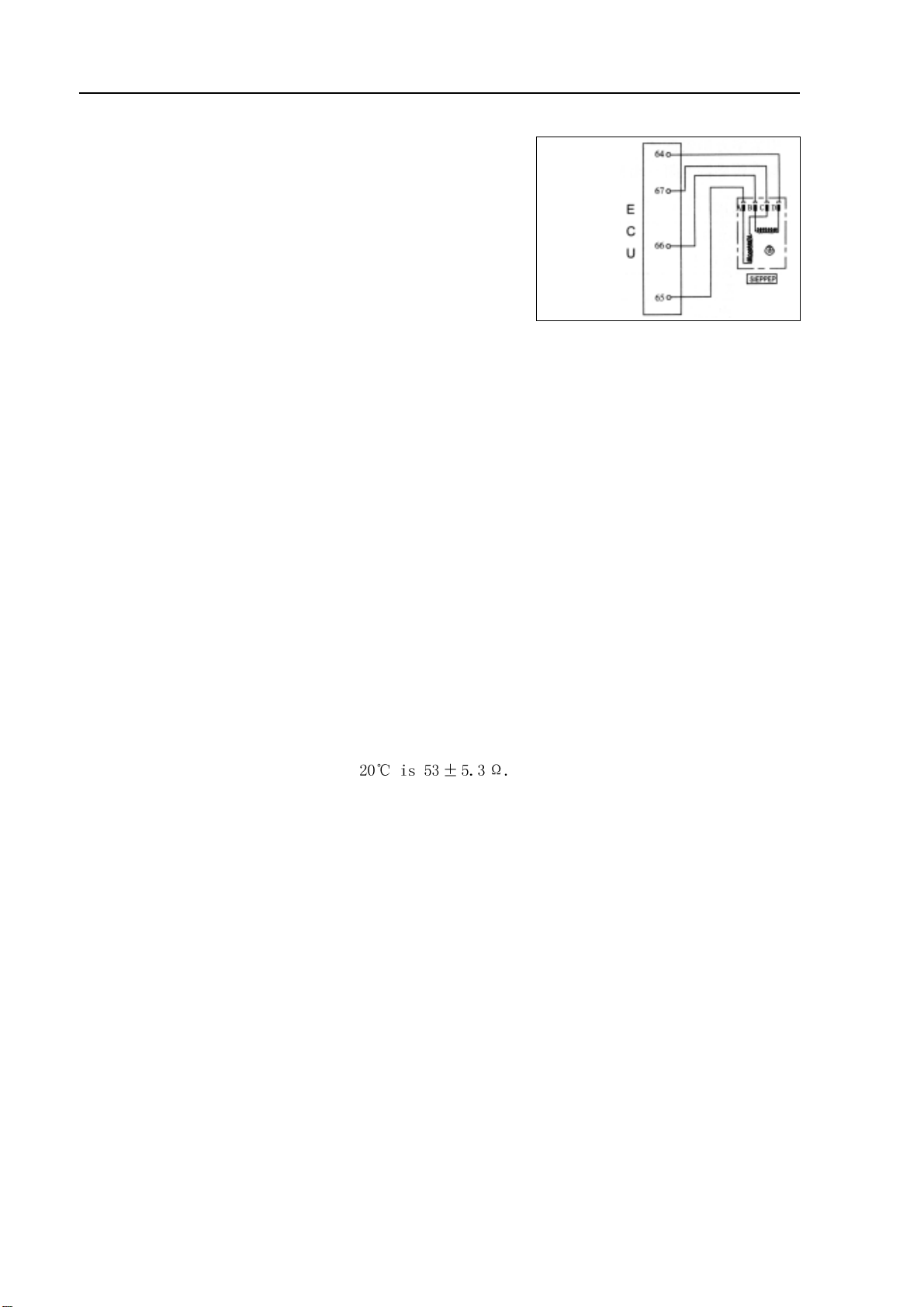

6. Intake air temperature sensor (4G18-3600090)

Intake air temperature sensor is a resistor with negative temperature coefficient (NTC), resistance varies with intake air

temperature, and this sensor sends a voltage indicating change

of intake air temperature to controller.

Simple measuring method:

(Removing the joint) place digital universal meter at ohm gear,

and connect 2 terminals respectively to 1# pin and 2# pin of

sensor, and rated resistance at 5%, and

other corresponding resistance values could be measured according to the characteristic curve in above drawing. Analog

method could also be applied in measurement. Use an electric blower to blow air into the sensor (pay attention not to

keep them too near), and observe the change of resistance,

which should decrease at the moment.

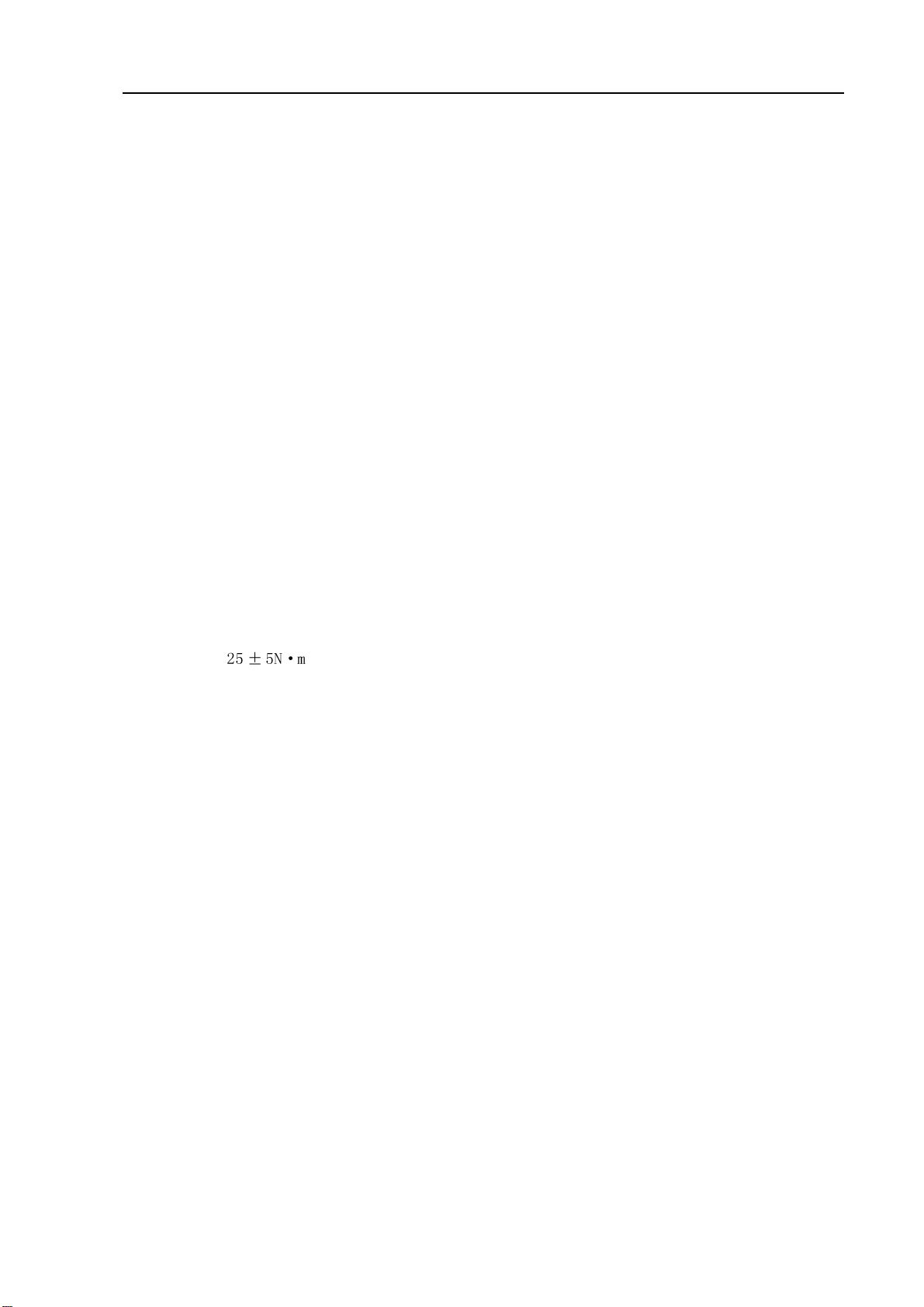

7. Stepping motor (4G18-3600070)

Schematic diagram and pins

Characteristic curve of

temperature sensor

Characteristic curve of intake air

temperature sensor NTC resistor

Stepping motor of idle speed actuator

11

Page 23

Engine control system·- EFI system

Electrical

Pins: Pin A is connected to ECU No. 65 pin

Pin B is connected to ECU No. 66 pin

Pin C is connected to ECU No. 67 pin

Pin D is connected to ECU No. 64 pin

wiring

diagram

on stepping motor

of idle

speed

actuator

Maintenance precautions:

1. It is not allowed to apply any force at axial direction with the purpose of pressing into or pulling out the

axle;

2. Before idle speed regulator with stepping motor is mounted into throttle body, its shaft must be at fully

retractive position;

3. Pay attention to clean and maintain bypass air passage frequently;

4. After removing battery or ECU, pay attention to self-teach stepping motor in time.

Self-teach method of M7 system: turn on ignition switch but not start engine immediately, and start it

after 5 seconds. If engine idle speed is found bad at the moment, it is

necessary to repeat the above steps.

Simple measuring method: (removing the joint) place digital universal meter at ohm gear, and connect

2 terminals respectively to Ad pin and BC pin of regulator, and rated resistance at

12

Page 24

Engine control system·- Throttle body assembly

Throttle body assembly

Removing, installing and disassembling, assembling

1. Discharge coolant (see Page 73).

2. Remove air cleaner hose assembly.

3. Remove engine plastic hood components [4G18-1000310].

4. Remove throttle pull cable assembly.

5. remove throttle body assembly [4G18-1008240].

(a ) Uncouple throttle position sensor joint and stepping motor joint.

(b)Disassemble ventilation hose.

(c) Remove 2 bolts and throttle control pull cable bracket.

(d)Remove 2 preheating water inlet and outlet hoses of throttle.

(e)Remove 2 bolts and 2 nuts, and remove throttle body from intake air manifold.

6. Remove stepping motor of throttle body [4G18-3600070].

Remove 3 screws and stepping motor.

7. Install stepping motor of throttle body.

Install stepping motor.

8. Install throttle body assembly.

(a)Install new seal gasket on intake air manifold.

(b)Install throttle body, 2 bolts and 2 nuts.

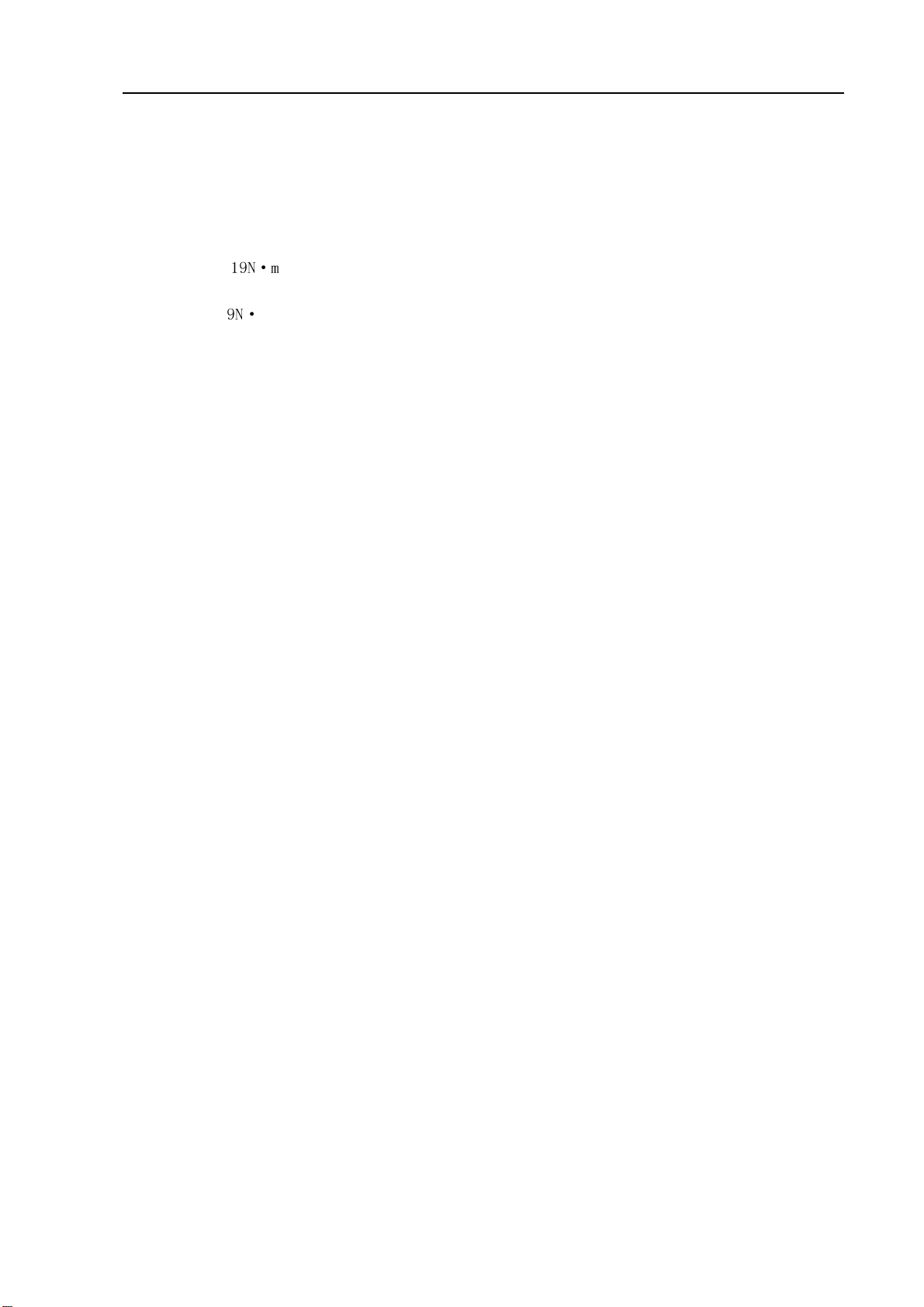

Torque:

9. Refill coolant.

10.Check there is leakage with coolant.

13

Page 25

Fuel-Fuel system

Fuel

Fuel system

Precautions

1. Before repairing fuel system, uncouple battery negative (-) wire at first.

2. When operating on fuel system, do not smoke or repair near fire area.

3. Do not let gasoline come into contact with rubber or leather parts.

4. Take measures to prevent gasoline leaking.

(a)Uncouple electric fuel pump joint.

(b)Start engine and turn ignition switch to LOCK position

after the engine flames out.

(c) Uncouple battery negative (-) wire.

(d)Couple electric fuel pump joint.

5. Fuel system

(a ) There will be a great amount of gasoline flowing out

when disassembling high-pressure fuel pipe,

therefore, it is required to observe the following

procedures.

(1 ) T ake measures to prevent gasoline leaking.

(2 ) Disassemble fuel pipe.

(3 ) Completely discharge the oil in fuel pipe.

(4 ) Cover the fuel pipe with plastic bag to avoid pipe

damage and foreign matters entering.

(5 ) Place a container under the joint.

(b)When removing and installing injection nozzle, always

observe the following precautions.

14

Page 26

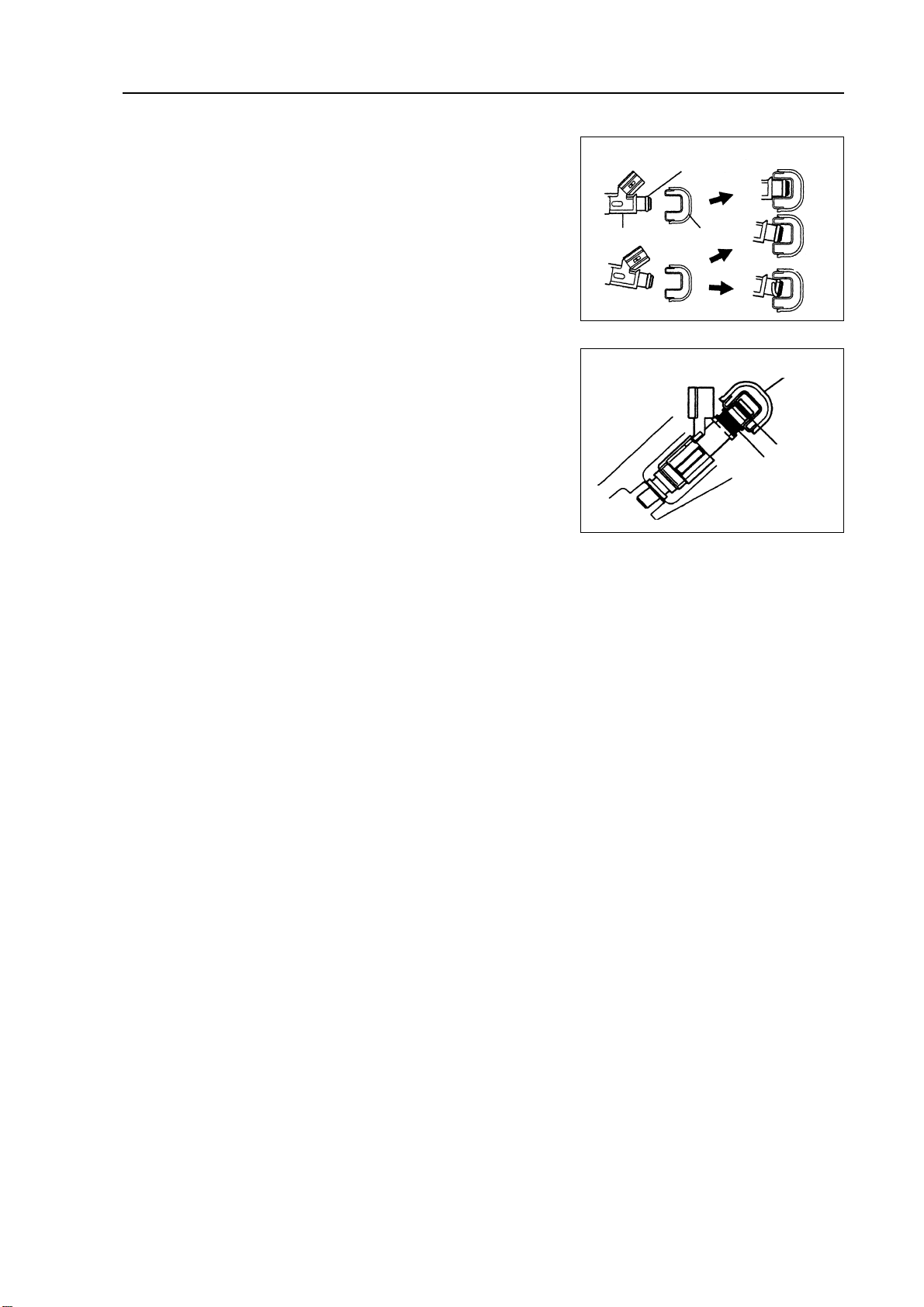

Fuel-Fuel system

(1)It is not allowed to use o-ring repeatedly.

(2)When installing o-ring, always be careful to avoid dam-

aging o-ring.

(3) Before installing, coat o-ring with spindle oil or gasoline.

It is not allowed to coat with engine oil, gear oil or

brake fluid.

(c) As shown in the diagram, install injection nozzle to oil feed

pipe and cylinder head.

Before installing, ensure that spindle oil and gasoline are

coated at the contact position between o-ring and oil feed

pipe.

injection nozzle

o-ring

oil feed pipe

Correct

Wrong

oil feed pipe

o-ring

washer

(d) When disassembling oil feed pipe, always observe the fol-

lowing precautions.

(1)Remove oil feed pipe clips.

(2)Remove oil feed hose.

(3)Cover oil inlet of fuel distribution pipe with plastic bag

to avoid foreign materials entering the fuel distribution

pipe.

6. Inspection of fuel leakage

(1)After completing maintenance, check there is leakage with the whole fuel system.

(2)Connect hand-held tester to diagnostic joint.

(3)Turn ignition switch to ON and turn main switch of hand-held tester to ON.

(4)Switch hand-held tester to function test state.

(5)For further details, please see hand-held tester operating instruction.

(6)If there is no hand-held tester, connect battery anode and cathode to electric fuel pump joint.

(7)Ensure that there is no leakage with all parts of electric fuel pump.

(8)Turn ignition switch to LOCK.

(9)Disassemble hand-held tester from diagnostic interface joint.

15

Page 27

Fuel-Fuel system

On-vehicle inspection

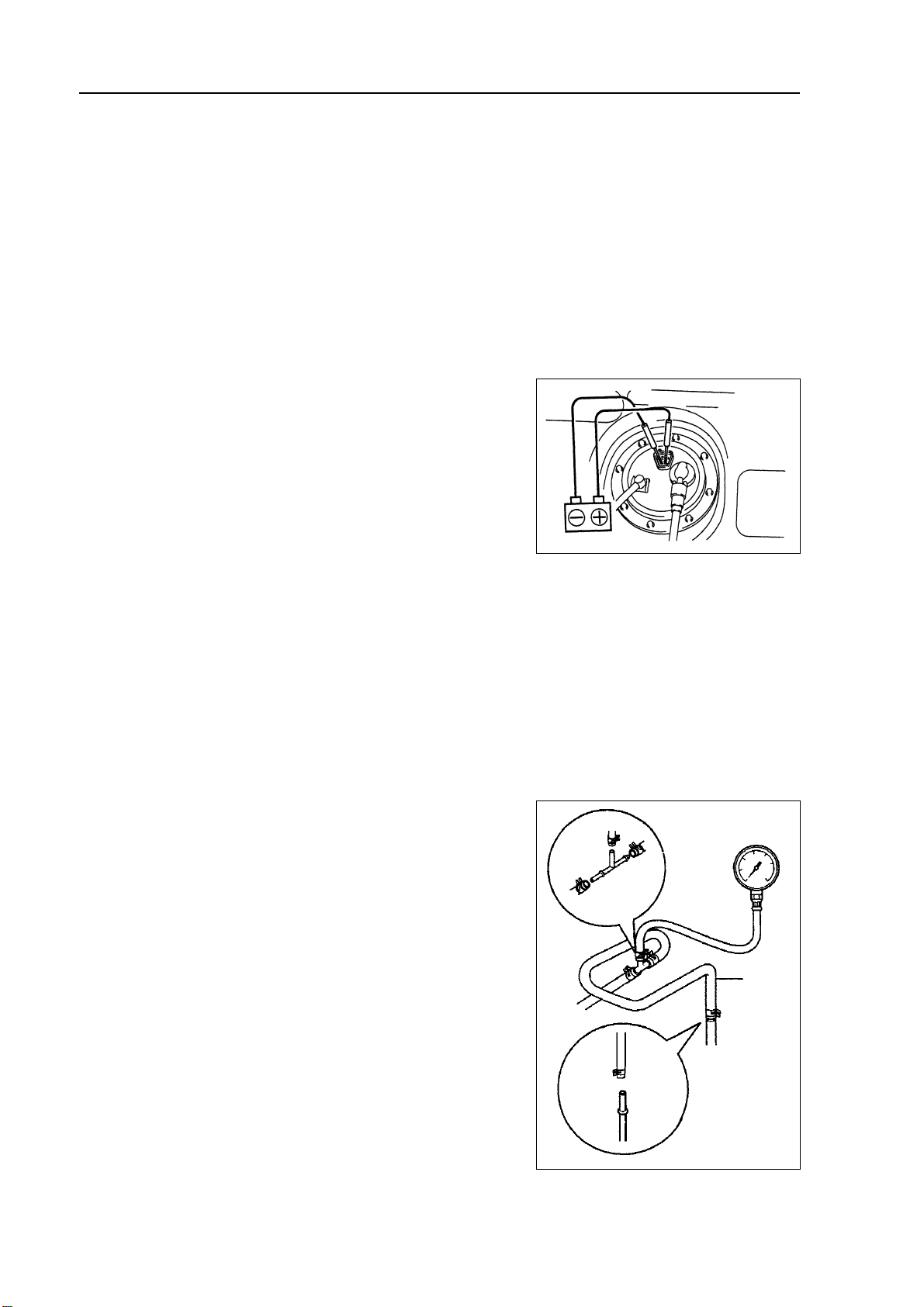

1. Inspection of fuel pump function

(a)Connect hand-held tester to diagnostic joint.

(b)Turn ignition switch to ON and turn main switch of hand-

held tester to ON.

Note: do not start the engine.

(c) Switch hand-held tester to function test state.

(d)For further details, please see hand-held tester operating

instruction.

(e)If there is no hand-held tester, connect battery positive (+)

wire to P+ terminal and negative (-) wire to P- terminal.

2. Inspection of fuel pressure

(a)Preparation of inspection.

Purchase new fuel hose and take out fuel pipe joint.

(b)Take measures to prevent gasoline leaking.

(c) Disassemble fuel pipe clamp at fuel pipe joint of fuel rail

component.

(d) Disassemble fuel hose from fuel pipe of fuel rail component.

(e)As shown in the diagram, install special tool (pressure

gauge) with special tool and fuel pipe joint.

(f) Check there is fuel leakage.

(g)Start engine.

(h)Measure the fuel pressure at idle speed state.

Fuel pressure: 390~400Pa

(i) Take measures again to prevent gasoline leaking.

(j) After measuring the fuel pressure, remove special tool.

(k) Connect back fuel hose.

(l) Install fuel hose fixing clip to fuel pipe joint.

(m)Check there is fuel leakage.

16

Special

tool

Page 28

Fuel-Fuel system

Inspection

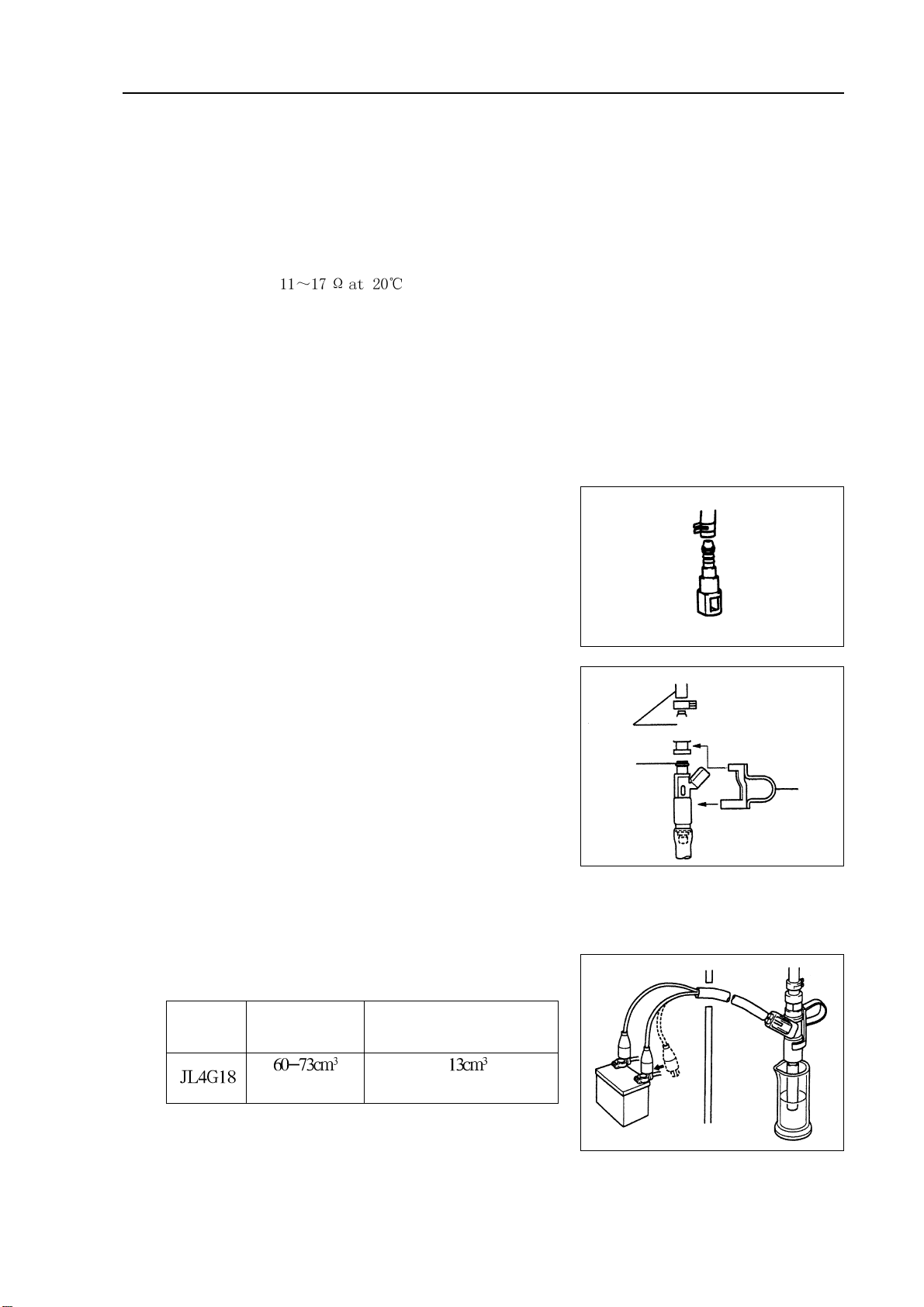

1. Fuel injector components [4G18-1112120]

(a)Check injection nozzle resistance.

(1) Measure the resistance between terminals with

ohmmeter.

Resistance:

Hint: if resistance is not within specification, replace injection nozzle.

(b)Injection nozzle test.

Warning: there should be no sparks during testing.

(1 ) Purchase new fuel pipe and take out fuel hose joint.

(2 ) Install special tool and fuel hose joint to fuel pipe.

Note: Only after performing precautions could the

connection operation of fuel hose joint (fastjoint mode) be allowed to perform.

Warning: before connecting fuel pipe joint (fast-joint

mode), please read precautions carefully

(3)Install o-ring to injection nozzle.

(4) Connect special tool (joint and hose) to injection nozzle,

and hold down the injection nozzle to prevent fuel splash.

(5 ) Place injection nozzle into measuring cup.

Hint: install proper hose on injection nozzle to prevent

gasoline injecting out of the cup.

(6)Connect special tool to injection nozzle joint.

(7)Connect special tool to battery for 15 seconds, and measure the injection volume with measuring

cup, each injection nozzle should be test for 2~3 times.

Injection volume:

Engine Injection volume Uneven volume between

each injection nozzle

Every 15 seconds

Hint: if injection volume is not within specification, replace

injection nozzle.

or less

Special

tool

o-ring

Special

tool

17

Page 29

Fuel-Injection nozzle assembly

Injection nozzle assembly

Replacement

1. Take measures to prevent gasoline leaking.

2. Remove engine plastic hood components.

3. Uncouple engine wire harness [4G18-3724100].

(a)Remove injection nozzle joint.

(b)Remove exhaust gas hose.

4. Remove fuel pipe assembly

(a)Loosen oil feed hose clips.

(b)Pull oil feed hose away from fuse distribution pipe.

Notes:

z

Check there is dirt on fuel pipe and its joint before removing, and clean it off in the case of dirt.

z

It is only allowed to remove with hands.

z

Check there are foreign matters with the removed fuel pipe seal surface, and clean them off in the

case of foreign matters.

z

Cover the fuel pipe with plastic bag to avoid pipe damage and foreign matters entering.

5. Remove fuel pipe assembly

Remove 2 bolts and oil feed pipe (together with injection nozzle).

6. Remove injection nozzle components.

Pull out 4 injection nozzles from oil feed pipe.

7. Install injection nozzle components.

Coat a thin layer of gasoline on o-ring and rotate left and right to push injection nozzle into oil feed pipe.

Notes:

z Be careful not to rotate o-ring.

z Check injection nozzle could rotate smoothly after it is installed, and if not replace with new o-ring.

8. Install fuel hose assembly.

Install fuel hose to oil feed pipe.

Notes:

z Check there are damage or foreign matters in the binding site of fuel pipe.

z After installing, pull the fuel pump with hands to check the fuel pipe is bound firmly with joint.

18

Page 30

Fuel-Injection nozzle assembly

9. Install fuel rail component [4G18-1112110].

(a)Check injection nozzle o-ring and replace if there is damage.

(b)Install isolator on cylinder head.

(c) Install fuel rail component together with injection nozzle.

Torque:

(d ) Install fuel pipe fixing clip.

Torque: m

10. Check the function of electric fuel pump and check there is fuel leakage.

19

Page 31

Fuel - Fuel pump assembly

Fuel pump assembly

Removing, installing and disassembling, assembling

1. Take measures to prevent gasoline leaking

2. Remove rear seat cushion assembly

3. Remove rear floor repairing hole cover

4. Remove No. 2 fuel evaporation assembly

Notes:

z Check there is contaminant looked like dirt around the joint before operating and clean it off in the

case of contaminant.

z Be careful of the contaminant looked like dirt, because fast-joint depends on o-ring to seal fuel pipe

and joint.

z Do not perform this operation with tools.

z Do not bend or distort nylon hose.

z Cover the joint with plastic bag after removing the fuel hose.

z When the joint is stuck with fuel pipe, clip the hose with fingers and rotate carefully to release the

hose, and then remove it.

5. Remove fuel tank main fuel hose and oil return pipe assembly

Notes:

z Check there is contaminant looked like dirt around the joint before operating and clean it off in the

case of contaminant.

z Be careful of the contaminant looked like dirt, because fast-joint depends on o-ring to seal fuel pipe

and joint.

z Do not perform this operation with tools.

z Do not bend or distort nylon hose.

z Cover the joint with plastic bag after removing the fuel hose.

z When the joint is stuck with fuel pipe, clip the hose with fingers and rotate carefully to release the

hose, and then remove it.

6. Remove fuel pump assembly

(a ) Screw off fuel pump tighten nut (plastic fuel tank) or remove

6 screws (iron fuel tank).

(b)Pull out fuel pump assembly.

Notes:

z Do not damage fuel pump filter screen.

z Be careful not to bend the measuring oil arm of fuel gauge

float unit.

7. Install fuel pump assembly

Torque: 8 N.m

8. Install rear floor repairing hole cover

Install rear floor repairing hole cover with butyl rubber cloth.

9. Check there is fuel leakage.

20

Page 32

Fuel - Fuel tank assembly

Fuel tank assembly

Removing, installing and disassembling, assembling

1. Take measures to prevent gasoline leaking

(see Page 14)

2. Remove rear seat cushion assembly

3. Remove rear floor repairing hole cover

4. Remove No. 2 fuel evaporation assembly

5. Remove fuel tank main fuel hose and oil return pipe

assembly

6. Remove fuel pump assembly

7. Discharge fuel

8. Remove front floor bracket

9. Remove front exhaust pipe assembly

(a)Move away carpet and remove oxygen sensor joint.

(b)Remove front exhaust pipe assembly

10.Disassemble the vent pipe of fuel hose

11.Disassemble filler pipe from fuel tank

12.Remove No. 2 fuel evaporator hose assembly

Press fuel hose joint and then pull out the hose.

Notes:

Check there is contaminant that looked like dirt around the

joint before operating and clean it off in the case of

contaminant.

Be careful of the contaminant that looked like dirt, because

fast-joint depends on o-ring to seal fuel pipe and joint.

Do not perform this operation with tools.

Do not bend or distort nylon hose.

Cover the joint with plastic bag after removing the fuel hose.

When the joint is stuck with fuel pipe, clip the hose with

fingers and rotate carefully to release the hose, and then

remove it.

13.Disassemble fuel tank main fuel hose assembly

Clip the protrusion part of fixing ring and move lock claw toward

open direction, and then pull out the hose as shown in the

diagram.

Notes:

Check there is contaminant looked like dirt around the joint

before operating and clean it off in the case of contaminant.

Nylon pipe

Fuel pipe clip

O-ring

Pipe

21

Page 33

Fuel - Fuel tank assembly

Be careful of the contaminant that looked like dirt, because

fast-joint depends on o-ring to seal fuel pipe and joint.

Do not perform this operation with tools.

Do not bend or distort nylon hose.

Cover the joint with plastic bag after removing the fuel hose.

When the joint is stuck with fuel pipe, clip the hose with

fingers and rotate carefully to release the hose, and then

remove it.

14. Remove fuel tank assembly

(a ) Remove parking brake pull cable retaining clip.

(b)Place jack under fuel tank. Remove fuel tank band harness and fuel

tank assembly.

15. Remove fuel tank main fuel hose and oil return pipe

assembly

16. Remove No. 2 fuel evaporation hose assembly

17. Remove No. 1 fuel tank gasket

18. Remove No. 1 fuel tank protector

Remove rivet with electric drill and then remove fuel tank protector.

19. Install No. 1 fuel tank protector

Install fuel tank protector with rivet.

20. Install No. 1 fuel tank gasket

As shown in the diagram, install new fuel tank gasket.

21. Install fuel tank assembly

Torque: 39 N.m

22. Install front exhaust pipe assembly

Torque: 40 N.m

23. Install front floor bracket

Torque: 30 N.m

24. Install rear floor repairing hole cover

Install rear floor service hole cover with butyl rubber cloth.

25. Check fuel leakage (see Page 14)

26. Check gas leakage of exhaust system

22

Page 34

Exhaust gas control - Exhaust gas control system

Exhaust gas control

Exhaust gas control system

On-vehicle inspection

1. Check oxygen sensor.

(a)Let the engine run at idle speed for 3 minutes to ensure oxygen sensor reaches operating tempera-

ture of 350

(b)Place digital universal meter at DC voltage gear, and connect 2 terminals respectively to (gray) pin

and (black) pin of sensor, and voltage should fluctuate

quickly between 0.1-0.9V at the moment.

Warning:

Perform inspection immediately after warming

up vehicle.

If voltage change could not be confirmed,

it is necessary to heat oxygen sensor again.

2. Check rotating speed after fuel cut off.

(a)Accelerate engine at least to 3500rpm.

(b)Check the operating noise of injection nozzle with listening device.

(c) When throttle is released, check the operating noise of injection nozzle recovers after stop.

3. Check fuel evaporation exhaust control system.

(a)Check the pipe clamps of connecting pipeline between

charcoal canister and carbon canister solenoid valve are

firmly clipped and check there is leakage.

(b)Check there is trouble with fuel evaporation exhaust con-

trol system with failure diagnostic instrument.

4. Visually check hose, joint and hot fin.

Check cracks, leakage and damage.

Hint: the disconnecting of engine oil level gauge, oil opening

cover and PCV hose may cause running failure of engine.

The cracks, looseness and not connecting at the intake

system between throttle and cylinder head will result in

redundant air entering and running failure of engine.

23

Page 35

Exhaust gas control - Exhaust gas control system

5. Check heater resistance of heated oxygen sensor.

(a)Uncouple oxygen sensor joint.

(b) Place digital universal meter at ohm gear, and connect 2 terminals respectively to 1# (white) pin and

2# (black) pin, and the resistance under normal temperature is 1 6

Oxygen sensor

Main relay

6. Check fuel tank cover.

Visually check fuel tank cover and gasket are distorted or damaged.

24

Page 36

Exhaust gas control - Exhaust gas control system

Inspection

1. Carbon canister assembly [4G18-1129020]

Carbonl canister assembly. Check the function of carbon canister according to the following tables.

Standard:

Inspection Methods Standard

Close B hole and C hole and then

supply vacuum to A hole No leakage

Close C hole and then supply vacuum Air flown out

to A hole from B hole

Close C hole and then blow air Air flown out

into A hole from B hole

Blow air into A hole Air flown out from B hole

and C hole

2. Carbon canister control valve

(a ) For carbon canister control valve, check the conduction be-

tween terminals.

Resistance:

(b)Check the control valve operates.

(1) Supply battery voltage to its terminal.

(2) Check air is flown as the arrow direction on valve body.

3. PCV valve assembly [4G18-1014110]

(a)Blow air into valve from cylinder side and check the air is

easy to get through.

Warning: do not suck against the valve, because the

gasoline left in the valve will make you be

injured.

(b)Blow air into valve from intake manifold side and check

the air is hard to get through.

Hint: if the function does not conform to the standard, PCV

valve should be replaced.

Cylinder side

Clean hose

Intake manifold side

25

Page 37

Engine mechanism - Engine assembly

Engine mechanism

Engine assembly

Inspection

1. Check coolant.

2. Check engine oil.

3. Check battery.

4. Check air filter assembly.

5. Check spark plug [4G18-3705113].

6. Check drive belt [4G18-1307107].

Hint: do not check belt tension, because automatic tensioner is applied.

7. Check ignition timing.

(a)Warm up engine.

(b)Connect timing lamp to engine.

(c) Check ignition timing at idle speed.

Ignition timing: before top dead center

Note: when checking ignition timing, place

transmission at neutral position.

Hint: After run the engine for 5 seconds with rotating

speed of 1000-1300rpm, check the engine could

recover to idle running.

8. Check engine idle speed.

(a)Warm up engine and run it at idle speed.

(b)Read engine rotating number in data flow with diagnostic instrument.

(c) Check idle speed.

Idle speed: about 750-850rpm

Notes:

When checking idle speed, place cooling fan at OFF position.

Turn off all auxiliary devices and air conditioner.

K-line

26

Page 38

Engine mechanism - Engine assembly

9. Check compression pressure.

(a)Warm up engine.

(b)Remove ignition coil.

(c) Remove spark plug.

(d)Check cylinder compression pressure.

(1)Install cylinder compression pressure gauge on spark plug hole.

(2 ) Wide open throttle.

(3)Measure the pressure during crankshaft rotating.

Notes:

Ensure to use fully charged battery to make the rotating speed of engine reach or exceed 250rpm.

When measuring other items, please repeat steps (1) to (3).

Finish the measurement as soon as possible.

Compression pressure: 1080kPa

Min pressure: 1000kPa

Difference among cylinders: 100kPa

(4) If the compression pressure of one or more cylinders is too low, inject a small amount of engine oil

from spark plug hole into the cylinder with low pressure, and repeat steps (1) to (3) to check

pressure.

If the pressure increases after engine oil is injected, the piston ring of this cylinder or the

cylinder has been worn or scratched.

If the pressure is still too low, the valve may be stuck or not fully closed, or the cylinder head

gasket leaks.

10. Check CO/HC.

(a)Start engine.

(b)Keep the rotating speed of engine at 2500rpm for about 180 seconds.

(c) When the engine is idle running, insert the test bar of CO/HC gauge into exhaust pipe at least 40cm.

(d)Immediately check idle speed and CO/HC concentration at 2500rpm.

Hints:

Finish test within 3 minutes.

Perform the test under 2 analog states (idle speed and 2500rpm) according to measuring methods and sequences specified by Emission Regulations.

(e)If CO/HC concentration is not within specified value, perform trouble shooting according to the

following sequences.

(1)Check the function of oxygen sensor.

(2)See possible failure causes listed in the table below, and repair and correct if necessary.

27

Page 39

Engine mechanism - Engine assembly

CO HC Trouble occurrence Possible causes

1. Ignition system malfunction

Ignition timing incorrect

Normal High Unstable idle speed

Low High Unstable idle speed

(HC readings not stable)

Spark plug too dirty, short circuit or clearance

incorrect

2. Valve clearance incorrect

3. Air inlet and exhaust valve leaky

4. Cylinder leaky

1. Vacuum leak:

PCV hose

Intake manifold

Throttle body

Idle speed stepping motor

Vacuum booster and pipelines

2. Fire caused by too thin mixing ratio

1. Air filter core blocked

High High Unstable idle speed

(black smoke emission)

2. PCV valve blocked

3. EFI system malfunction

Fuel pressure regulator malfunction

Water temperature sensor malfunction

Intake pressure sensor malfunction

ECU malfunction

Injection nozzle malfunction

Throttle position sensor malfunction

28

Page 40

Engine mechanism - Drive belt

Drive belt

Replacement

1. Remove engine right bottom shield.

2. Remove drive belt

Slowly turn drive belt tensioner clockwise to loosen it.

Then remove drive belt and put back drive belt tensioner slowly

and gently.

3. Install drive belt

Slowly turn drive belt tensioner clockwise to loosen it.

Then install drive belt and put back drive belt tensioner slowly

and gently.

29

Page 41

Valve clearance

Adjustment

Engine mechanism - Valve clearance

1. Remove engine plastic hood components.

2. Remove ignition coil components [4G18-3705110].

3. Remove cylinder head cover components [4G181003130].

4. Remove engine right bottom shield.

5. T urn crankshaft to cylinder 1 compression top dead

center position.

(a)Turn crankshaft pulley to align its groove with “o” mark on

timing chain hood.

(b)Check dot marks on camshaft timing sprocket and VVT

timing sprocket, and they should be in a line on timing chain

hood surface as shown in the diagram.

Hint: if not, turn crankshaft for one circle again

and align the above marks.

6. Check valve clearance.

(a)Only check the valves shown in the diagram.

(1 ) Measure the clearance between valve tappet and cam-

shaft with plug gauge.

(2)Record valve clearance measuring value exceeding

specification, and this value will be used to determine

valve tappet thickness that needs change.

Valve clearance (cold vehicle)

Mark

Groove

Mark

Mark

Timing chain

hood surface