Page 1

Page 2

Table of Contents

Part I Engine ...........................................................................1

Chapter 1 Engine Assembly (MR479Q, MR479QA, MR481QA)...................1

Section 1 Routine Inspection.........................................................................................1

Section 2 Drive Belt Replacement ...............................................................................5

Section 3 Valve Clearance Adjustment ...........................................................................6

Chapter 2 Engine Components Replacement

(MR479Q, MR479QA, MR481QA) ................................................................10

Section 1 Engine Components ....................................................................................10

Section 2 Engine Components Replacement ............................................................13

Section 3 Timing Belt Replacement .........................................................................17

Section 4 Camshaft Replacement ............................................................................22

Section 5 Cylinder Head Gasket Replacement .........................................................28

Section 6 Oil Pump Oil Seal Replacement ................................................................33

Section 7 Engine Rear Oil Seal Replacement ............................................................34

Chapter 3 Lubrication System (MR479Q, MR479QA, MR481QA) ...............35

Section 1 Oil Pressure Gage Sensor Replacement ....................................................35

Section 2 Oil Pump Assembly Replacement ..............................................................36

Section 3 Oil Filter Replacement ................................................................................38

Section 4 Starter Replacement .................................................................................39

Section 5 Generator Replacement ............................................................................40

Chapter 4 Fuel System (MR7131A, MR7151A, MR7161A) ........................41

Section 1 Check Fuel System Pressure .....................................................................41

Section 2 Fuel Pump Inspection ...................................................................................42

Section 3 Fuel Injector Replacement .........................................................................43

Section 4 Fuel Pump Replacement ............................................................................45

Section 5 Fuel Emission Control System ....................................................................47

Section 6 Carbon Canister Replacement ....................................................................48

Chapter 5 Exhaust System (MR7131A, MR7151A, MR7161A) .................50

Page 3

Chapter 6 Cooling System Inspection

(MR7131A, MR7151A, MR7161A) .................................................................52

Section 1 System Check

Section 2 Water Pump, Thermostat and Radiator Replacement.................................... 54

...............................................................................................52

Chapter 7 Clutch (MR7131A, MR7151A, MR7161A) ....................................56

Section 1 Clutch Replacement ...................................................................................57

Chapter 8 Maunal Transaxle Assembly

(MR7131A, MR7151A, MR7161A) ................................................................59

Section 1 Manual T ransaxle Replacement ..................................................................60

Section 2 Vehicle Speed Sensor Replacement

Section 3 Transmission Case Oil Seal ..........................................................................62

Section 4 Transaxle Case Oil Seal Replacement ........................................................63

..............................................................61

Chapter 9 General Engine Troubles and Their Troubleshooting ....................64

Section 1 Overview ........................................................................................................64

Section 2 General Engine Fault and T roubleshooting .......................................................64

Section 3 Engine Noise Diagnosis and T roubleshooting ................................................77

Chapter 10 Engine Management Unit..............................................................81

Section 1 System Description .........................................................................................81

Section 2 System Component and W orking Principle ......................................................82

Part II Chassis............................................................................85

Chapter 1 Transmission Control Device .........................................................85

Section 1 Transmission Control Device .........................................................................85

Section 2 Lever Type Transmission Control Device ......................................................85

Section 3 Cable T ype Transmissi on Control Module ......................................................87

Chapter 2 Accelerator Pedal............................................................................90

Section 1 Accelerator Pedal ..........................................................................................90

Chapter 3 Clutch Control System ....................................................................91

Section 1 Clutch Control System ....................................................................................91

Section 2 Clutch Cable Control Mechanism .....................................................................91

Section 3 Clutch hydraulic Control Device .......................................................................94

Chapter 4 Propeller Shaft ...............................................................................97

Page 4

Section 1 Propeller Shaft .................................................................................................. 97

Chapter 5 Front Suspension System ............................................................... 103

Section 1 Front Suspension System ................................................................................ 103

Section 2 Front Suspension ............................................................................................105

Section 3 Front Wheel Alignment .......................................................................................106

Section 4 Front Strut Assembly ....................................................................................... 107

Section 5 Lower Swing Arm Assembly ............................................................................ 110

Section 6 Front Stabilizer Bar and Link Rod Assembly .....................................................113

Chapter 6 Rear Suspension System ................................................................116

Section 1 Rear Suspension System

Section 2 Rear Suspension ............................................................................................117

Section 3 Rear Wheel Alignment .................................................................................... 118

Section 4 Left & Right Rear Strut Assembly .....................................................................119

Section 5 Rear stabilizer bar assembly, strut rod components ..........................................121

Section 6 Left & Right Trailing Rod Assembly .............................................................. 123

Section 7 No. 1 Transverse Arm Assembly .....................................................................124

Section 8 No. 2 Transverse Arm Assembly .....................................................................125

..................................................................................116

Chapter 7 Wheel ................................................................................................126

Section 1 Tire Inspection ................................................................................................. 126

Section 2 Wheel Replacement ......................................................................................... 127

Chapter 8 Power Steering System .................................................................. 128

Section 1 Power Steering System .................................................................................... 128

Section 2 Steering Drive and Control Mechanism ......................................................... 130

Section 3 Steering Pipeline Component .......................................................................... 133

Section 4 Power Steering Gear Retaining Device

..........................................................136

Chapter 9 Brake System .................................................................................. 139

Section 1 Brake System................................................................................................... 139

Section 2 Brake Fluid ....................................................................................................... 140

Section 3 Brake Pedal...................................................................................................... 141

Section 4 Vacuum Booster with Brake Master Cylinder Assembly ....................................143

Section 5 Front Brake Assembly ..................................................................................... 144

Section 6 Rear Brake

Section 7 Brake Line ....................................................................................................... 151

.....................................................................................................147

Page 5

Section 8 Parking Brake System ..................................................................................... 155

Part III Electrical Equipment

........................................................157

Chapter 1 Survey................................................................................................157

Chapter 2 Starting and Charging System .........................................................161

Section 1 Starting System (MR479Q MR479QA MR481QA) ..........................................161

Section 2 Charging System (MR479Q, MR479QA, MR481QA) .......................................164

Chapter 3 Combination Meter System ..............................................................171

Section 1 Circuit Diagram of Combination Meter and Location of Multi-pin Plug-in

Terminal ............................................................................................................................ 171

Section 2 Malfunction Symptom T able and Solution Pr ocedure ...........................................174

Section 3 Combination Meter .......................................................................................... 187

Chapter 4 Wiper and Washer System ...............................................................193

Section 1 Wiper and W asher System Inspection ............................................................ 193

Section 2 Replacement and Adjustment ............................................................................196

Chapter 5 Light System ......................................................................................198

Section 1 Survey of Light System......................................................................................198

Section 2 Light System Symptom Inspection .................................................................. 202

Section 3 Headlamp Replacement ....................................................................................211

Section 4 Front Fog Lamp Replacement ............................................................................215

Section 5 Rear Combination Lamp Replacement ..............................................................217

Section 6 High Mounted Stop Lamp Replacement ............................................................218

Section 7 Interior Dome Lamp Replacement .....................................................................219

Section 8 Rear Row Reading Lamp Replacement ...........................................................220

Section 9 License Plate Lamp Replacement ...................................................................220

Chapter 6 Audio System......................................................................................221

Section 1 Audio System Description .................................................................................221

Section 2 Audio System Connector Terminal Layout ...........................................................224

Section 3 Audio System Inspection ................................................................................. 225

Section 4 Audio and V ideo System Replacement ........................................................... 238

Chapter 7 SRS (Supplemental Restraint System).............................................242

Section 1 SRS-General Information .................................................................................242

Section 2 Troubleshooting ................................................................................................ 251

Page 6

Section 3 Removal & Installation ................................................................................... 262

Chapter 8 MK-20 ABS System ........................................................................ 272

Section 1 ABS Diagnosis ................................................................................................. 272

Section 2 ABS System Check.......................................................................................... 276

Section 3 Removal and Installation .................................................................................292

Part IV Air Conditioner and Inside & Outside Trim ......................297

Chapter 1 A/C System ...................................................................................... 297

Section 1 The Structure & W orking Principle of Refrigeration System ...............................297

Section 2 Heating System ................................................................................................ 299

Section 3 A/C contr olling system .................................................................................... 302

Section 4 Service Caution & Notice ................................................................................ 304

Section 5 The Refrigeration System Operation Procedure ..............................................305

Section 6 Basic System.................................................................................................... 308

Section 7 A/C System Faults Check & Troubleshooting ................................................ 313

Chapter 2 Inside & outside Trim and Accessory................................................318

Section 1 Configuration Index ............................................................................................318

(I) Outside Trim And Front Accessory .................................................................................318

(II) Outside Trim and Rear Accessory .................................................................................319

(III) Front inside trim ..........................................................................................................320

(IV) Rear inside trim ............................................................................................................321

Section 2 Inside & Outside T rim and Accessories Removal and Installation .......................322

(I) Front Bumper ..................................................................................................................322

(II) Engine Hood .................................................................................................................324

(III) Outside Rear View Mirror

(IV) Rear trunk Lid ...............................................................................................................327

(V) Rear Bumper ...................................................................................................................329

(VI) Seat Removal, Installation and Adjustment ...................................................................331

(VII) Seat Belt .....................................................................................................................335

...............................................................................................326

(VIII) Instrument panel and auxiliary console .....................................................................338

(IX) A pillar inside trim and front door sill ............................................................................343

(X) B pillar inside trim ........................................................................................................344

(XI) Cpillar inside trim and rear door sill .............................................................................345

(XII) Roof inside trim

(XIII) Carpet and Heat Insulator.............................................................................................347

...........................................................................................................346

Page 7

(XIV) Rear trunk Inside Trim ............................................................................348

(XV) Engine Hood Inside Trim ...........................................................................349

(XVI) Door ..............................................................................................................350

Part V Body............................................................................359

Chapter 1 General Information .....................................................................359

Section 1 Body Structure ..............................................................................................359

Chapter 2 Body Repair..................................................................................369

Section 1 Body Damage Forms and Requirements for Repair ....................................369

Section 2 T ypical Technology Of Body Panel Repair ..................................................372

Section 3 Repair after Body Damage ..........................................................................372

Section 4 Features and Composition of Automobile Body ............................................. 377

Section 5 Painting Technique after Body Repair............................................................383

Section 6 Service Data For Body ................................................................................385

Page 8

Part I Engine

Chapter 1 Engine Assembly

(MR479Q, MR479QA, MR481QA)

Section 1 Routine Inspection

1. Check coolant

2. Check engine oil

3. Check battery

4. Check air cleaner element assembly

5. Check spark plug

6. Check drive belt

Water pump

generator

Power steering

pump

crankshaft

Belt Looseness

Notice:

Check the belt deflection at the specified point See (Figure 1).

z

Measuring Point

Figure 1

Air condition

compressor

Fan Belt 7

Power steering Belt 5~66

A/C Belt 6. 5~78

Belt deflection See (Table 1)

Belt pressure : 98N

New Belt mm Old Belt mm

~

9

11.5

~

~

~

13.5

8

9

z Set tension to specified value when installing new belt.

z Check the deflection to ensure it is below the specified value after the belt runs for over 5 minutes.

z Reinstall the belt which has been running for over 5 minutes. The deflection of the old belt is regarded as

the standard for inspection.

z Check V-belt for tension and distortion after the engine cranks for 2

turns.

7. Check ignition timing See (Figure 2)

a) Warm up the engine.

b) When using fault diagnosis tester

Connect fault diagnosis tester to fault diagnosis interface socket.

Ignition timing:

MR479Q: 10 ± 2° BTDC (before top dead center) at idle

MR479QA: 10 ± 2° BTDC at idle

MR481QA: 10 ± 2° BTDC at idle

Figure 2

1

Page 9

c) When fault diagnosis tester is not used

(1) Shorting fault diagnosis interface socket 13 (TC) terminal and 4(CG) terminal.

Notice:

z Ensure correct connection, otherwise the engine will be damaged.

z Switch off all electrical appliance system.

z Check when disconnecting cooling fan motor.

(2) Using timing light to check ignition timing.

Ignition timing: 10 ± 2° BTDC at idle

Notice:

(1) Transmission shift lever should be in neutral position when checking ignition timing.

(2) Running engine at 1,000-1,300rpm for 5s and check at idle.

(3) Remove the tester on fault diagnosis socket.

(4) Ignition timing advance angle becomes larger when the engine roate speed is higher.

(5) Remove timing light.

8. Check engine idle See (Figure 3)

(a) Warm up the engine.

(b) Connect fault diagnosis tester to fault diagnosis interface socket.

(c) Connect tachometer testing pen to fault diagnosis socket terminal

9 when not using fault tester.

(d) Check idle See (Table 2).

Table 2

MR479Q 800±50 (rpm)

MR4 79QA 800±50 (rpm)

MR 4 81QA 800±50 (rpm)

Notice:

z Check idle when cooling fan motor is disconnected.

Switch off all electrical accessories and A/C.

z

9. Check compression pressure See (Figure 4)

(a) Engine switched off.

Techometer

Battery

Figure 3

(b) Detach high voltage cable.

(c) Detach spark plug.

(d) Check the compression pressure in the cylinder.

(1) Insert pressure gauge into the hole of the spark plug.

(2) Throttle valve full open.

(3) Crank the engine, measure the compression pressure.

2

Figure 4

Page 10

The Min. compression pressure: 980 kPa

The tolerance range of the cylinders pressure: 100 kPa

Notice:

z

Ensure sufficient battery power and the engine speed is no less than 250 RPM (revolutions per minute).

z Check the compression pressure of other cylinders in the same way.

z Complete the measure as quick as possible.

(4) If the compression pressure in several cylinder is too low, fill some engine oil to the cylinder via the

hole of the spark plug. Check by repeating step 1-3.

Hint:

z If the compression pressure is improved after filling oil, the piston ring or the cylinder may be abrased

or damaged.

z If the pressure is still too low, the valve is stagnation or poor seal, or there is a leakage in gasket.

10. Check CO/HC

(a) Start engine.

(b) Running engine at 2500rpm for approximately 3 minutes.

(c) Insert CO/HC meter testing probe into tailpipe at least 40cm during idling.

(d) Check CO/HC concentration at idle and 2500rpm.

Hint:

Complete measurement within 3 minutes.

z

z Test the CO/HC emission concentration at idle and 2500 rpm on QC/T630-1999 standard.

(e) Take the following steps to diagnose the fault if the CO/HC concentration does not comply with standard .

(1) Check the oxygen sensor operation.

(2) See (Table 3) for the possible cause and check and repair.

3

Page 11

CO HC Problems Causes

1. F ault

. I ncorrect ignition timing

Table 3

Normal

Low High

High High

Rough idleHigh

Rough idle

Rough idle

(Bla c k smoke

from exhaust

pipe)

. Fouled, s hor t ed or improperly cle ara nce of spar k plug

2. Incorrect valve clearance

3. Leaky inta ke & exhaus t valves

4. Leaky cylinders

1. Air leaks

. PCV hoses, intake manifold

. Throttle body

. Brake booster circuit

2. L ean mixture gas caus ing misfire

1. Clogged air filter

2. C logged PCV valve

. Faulty ECU

. Faulty fuel pre ssure regula t or

. Faulty wa ter temperature sensor

. Faulty air compressor

. Faulty injectors

. Faulty throttle position sensor

4

Page 12

Section 2 Drive Belt Replacement

1. Disconnect all engine pipe hose and wire joint. Remove engine assembly from the engine

compartment, jack up the body, take out the engine assembly slowly (See Provision 20, Section

Two, Chapter Two for detailed information)

2. Remove generator V-belt See (Figure 5)

3. Remove No. 1 V-belt A/C compressor to crankshaft pulley

4. Remove water pump belt See (Figure 6)

5. Install water pump V-belt

6. Adjust V-belt of steering assisting pump

(a) Adjust power steering belt tension, tighten bolt B.

(b) Tighten bolt A.

Torque : 39N. m

7. Install V-belt A/C compressor No. 1 to crankshaft pulley

8. Adjust V-belt A/C compressor No. 1 to crankshaft pulley

(a) Adjust A/C belt tension by tightening bolt B.

(b) Tighten nut A.

Torque : 39N. m

9. Install Generator V-belt See (Figure 7)

10. Adjust Generator V-belt.

Tighten bolt A and then bolt B.

Figure 6Figure 5

Torque: Bolt A 18N. m Bolt B 58N. m

11. Check driving belt for distortion and tension

Figure 7

5

Page 13

Section 3 Valve Clearance Adjustment

1. Remove right camshaft timing gear

2. Remove ignition coil and high voltage cable

3. Remove cylinder head cover sub-assembly See (Figure 8)

(a) Disconnect generator wire joint..

(b) Disconnect generator circuit.

(c) Disconnect oil pressure switch connector.

(d) Disconnect A/C compressor switch connector.

(e) Open the wire harness clip.

(f) Remove wire harness from cylinder head cover.

(g) Separate 2 ventilation hoses from cylinder head cover.

(h) Remove 4 screw nuts, 4 oil seal gaskets, cylinder head and gasket.

4. Adjust piston of Cylinder 1 to the compression position

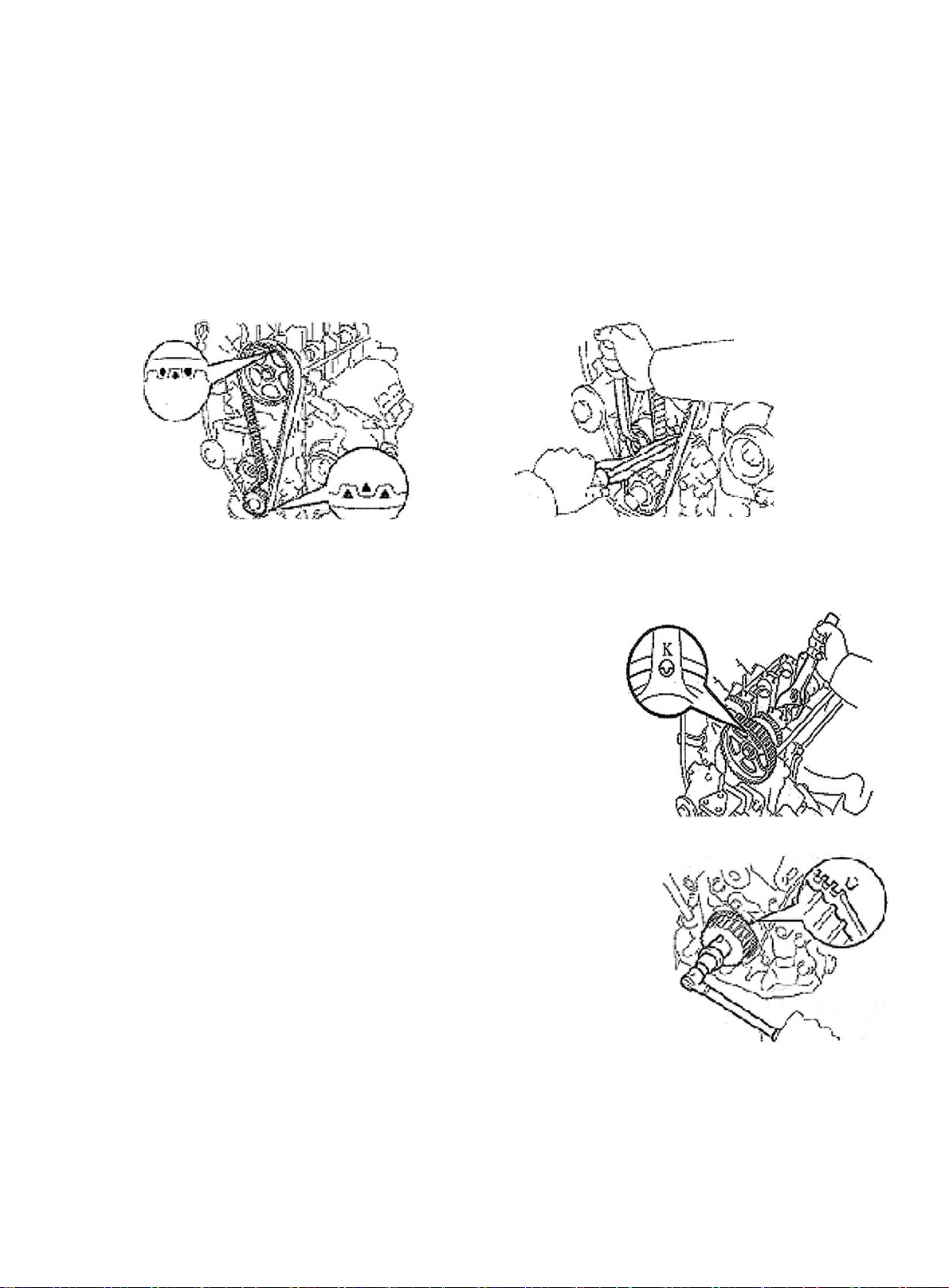

(a) Turn crankshaft pulley, align notch to timing mark "0" on Cylinder 1. See (Figure 9).

Figure 8

(b) Align mark "K" on camshaft timing pulley to the timing mark on bearing cap. See (Figure 10) Crank 360°

if it is not aligned.

Figure 9

5. Check valve clearance (cool). See (Table 5)

Table

5

Figure 10

Intake Valve mm Exha ust Valve mm

MR479Q 0.20 ± 0.05 0.30 ± 0.05

MR479Q A 0. 20 ± 0.05 0.30 ± 0.05

MR481Q A 0.20 ± 0.05 0.30 ± 0.05

(a) Turn the crankshaft pulley for 360°. Align notch to timing mark "0" on timing belt cover No. 1.

(b) Only check the valve as shown in the figure. Valve clearance measurement. See (Figure 11).

6

Page 14

Figure 11

6. Adjust intake valve clearance

(a) Detach intake camshaft

Notice:

Because the camshaft end play is quite small, keep camshaft horizontal when removing it. If not, cylinder

head may be partially damaged by the thrust force£¬it may stuck or damage camshaft when turning crankshaft.

Take the following steps to avoid the damage:

(1) Turn the pulley to access the hole on the camshaft drive gear where the counter gear is installed. See

(Figure 12).

Hint:

The above condition allows the cylinders No. 1 and No. 3 of the intake camshaft to push up the valve tappet.

Figure 12

Figure 13

(2) Remove bolt and bearing cap No. 1.

(3) Install camshaft counter gear to drive gear with service bolt. See (Figure 13).

(4) Uniformly loose and remove 8 bearing cap bolts in several passes as

shown in the figure. See (Figure 14).

(5) Remove 4 bearing caps and camshafts.

Figure 14

7

Page 15

Notice:

Due to the small end play on camshaft, the cylinder head may be damaged by the thrust force when removing

it, it may stuck or damage camshaft. Take the following steps to avoid damage:

(1) Turn the crankshaft pulley to make exhaust camshaft dowel pin is a bit higher than the cylinder head. See

(Figure 15).

(2) Align the matchmark on each gear to engage intake camshaft gear and exhaust camshaft gear. See

(Figure 16).

(3) When the gears are engaged, install the intake camshaft bearing onto bearing journal.

Install Mark

March Mark

Timing Mark

Figure 15

Figure 16

Hint:

The intake camshaft lobe of cylinder 1 and 3 can jack up their own valve tappet.

(5) Install 4 bearing caps to the right position.

(6) Apply a light layer of engine oil on the thread and under the head of bearing cap bolts.

(7) Uniformly install and tighten 8 bearing cap bolts in several times, in the sequence shown in the figure.

Torque: 13N. m

(8) Remove service screw.

(9) Install the bearing cap No. 1. in the direction of the forward arrow mark.

(10)Apply a light layer of engine oil on the thread and under the head of bearing cap bolts.

(11)Alternatively tighten and install 2 bearing bolts.

Torque: 13N. m

Cam Lobe

Upward

7. Adjust exhaust valve clearance. See (Figure 17)

Remove adjust gasket.

Front

(1) Crank to keep the camshaft head upward.

Nick

(2) Face valve tappet nick to vehicle front.

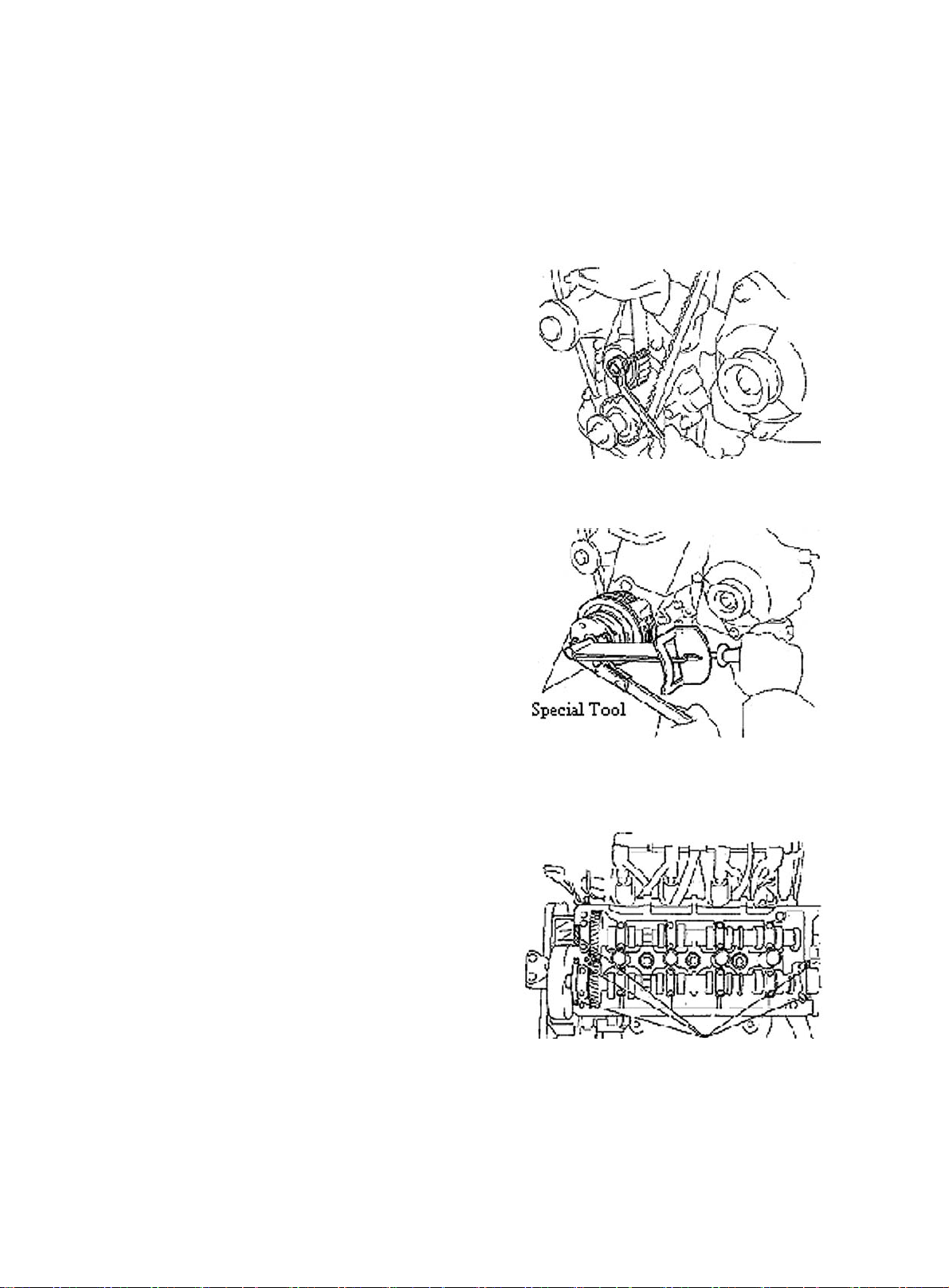

(3) Press valve tappet, put special tool between camshaft and valve tappet.

Figure 17

Hint:

z Lean the end with mark "9" into the position in (Figure 18).

8

Figure 18

Page 16

(4) Alternatively press valve tappet with the special tool (A) (B). Check

valve clearance. See (Figure 19).

8. Install cylinder head sub-assembly

(a) Remove all old gasket material.

(b) Apply the seal glue to the cylinder head.

(c) Connect wire harness and clip.

(d) Install gasket under of cylinder head.

(e) Install the cylinder head cover with 4 seal gaskets and 4 screw caps.

T orque: 7.8N. m

(f) Install 2 ventilation hoses to cylinder head cover.

(g) Connect generator wire joint.

(h) Connect generator wires.

(i) Connect oil pressure switch connector.

(j) Install wire clip.

(k) Connect A/C compressor switch connector.

9. Install electronic ignition coil and high voltage cable

10. Check engine oil for leakage

Figure 19

9

Page 17

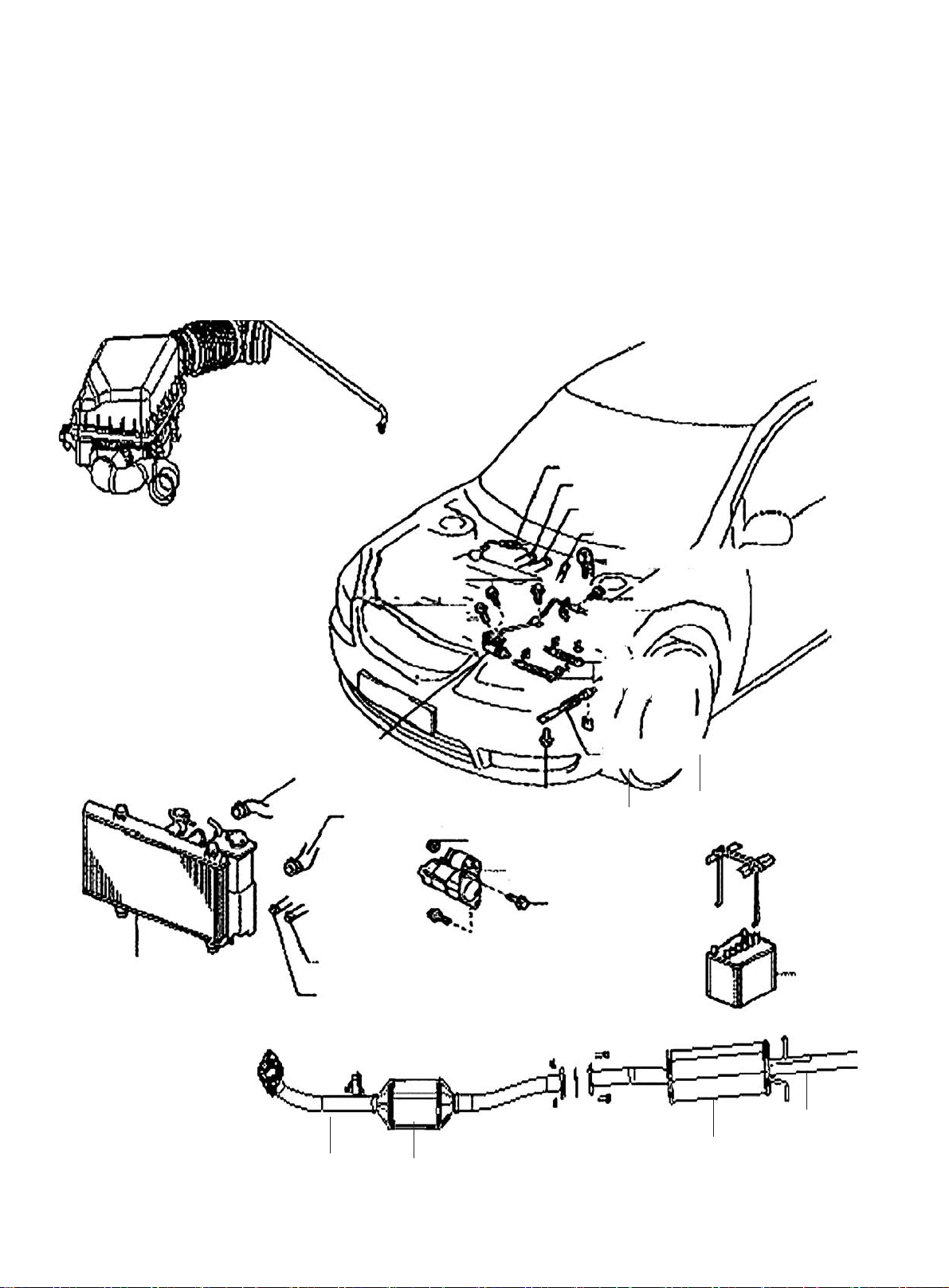

Chapter 2 Engine Components Replacement

(MR479Q, MR479QA, MR481QA)

Section 1 Engine Components

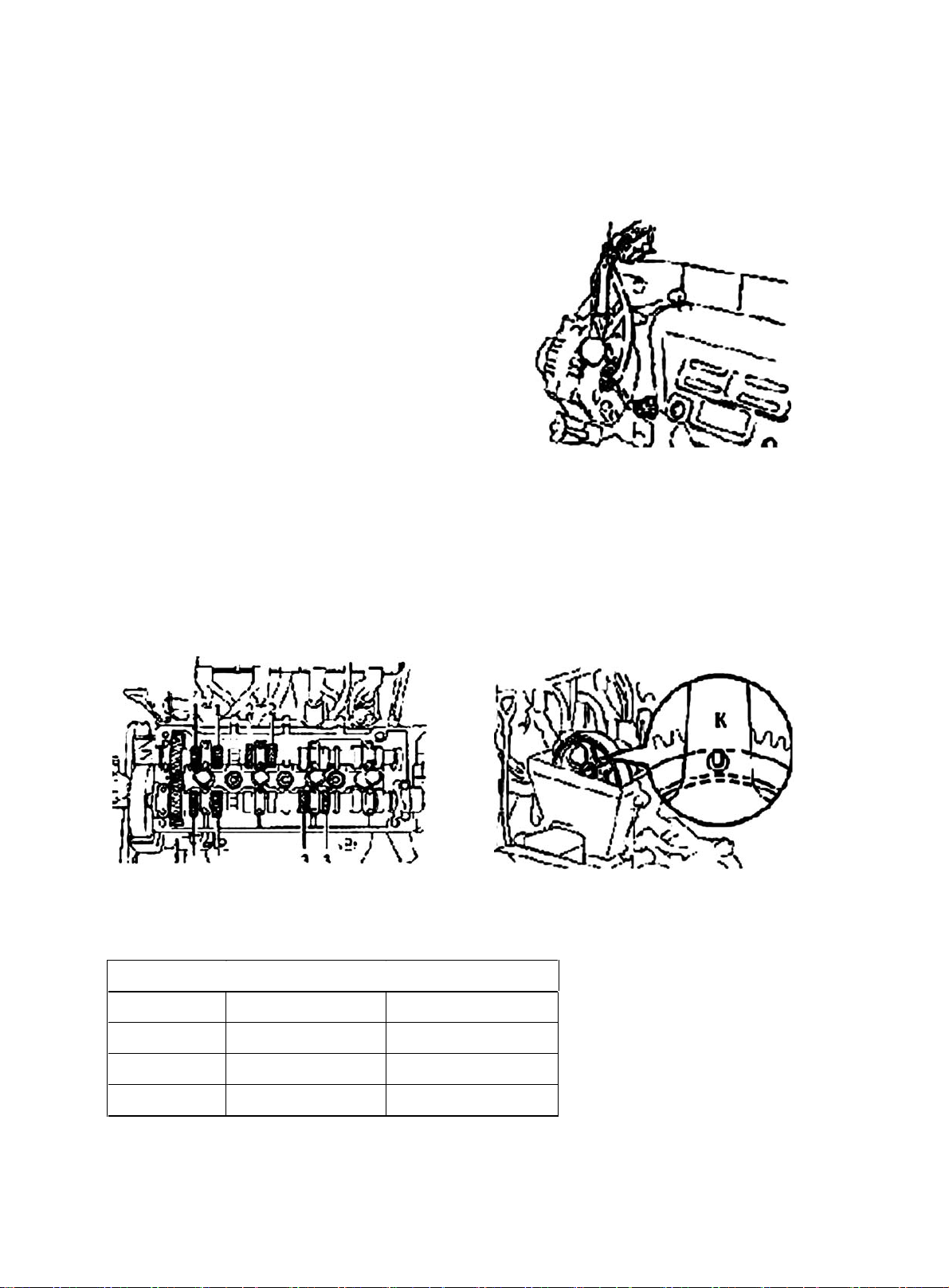

Component 1

Air Filter Assembly W/ Hose

Accelerator Control

Cable Assembly

Heater Inlet Hose

Heater Outlet Hose

Fuel Sub-Assembly

Efi Fuel Pipe Clamp

Radiator Assembly

MT:

Clutch Release

Cylinder Assembly

Radiator Inlet Pipe

AT: Oil Cooler

AT: Oil Cooler

Outlet

Pipe

Inlet

Pipe

Radiator Outlet Pipe

Starter Assembly

MT:

Transmission

Control Cable

Assembly

AT:

Transmission Control Cable Assembly

Battery

10

Front Exhaust

Pipe Assy.

Tail Pipe

Muffler

3-way catalytic

converter

Figure 20

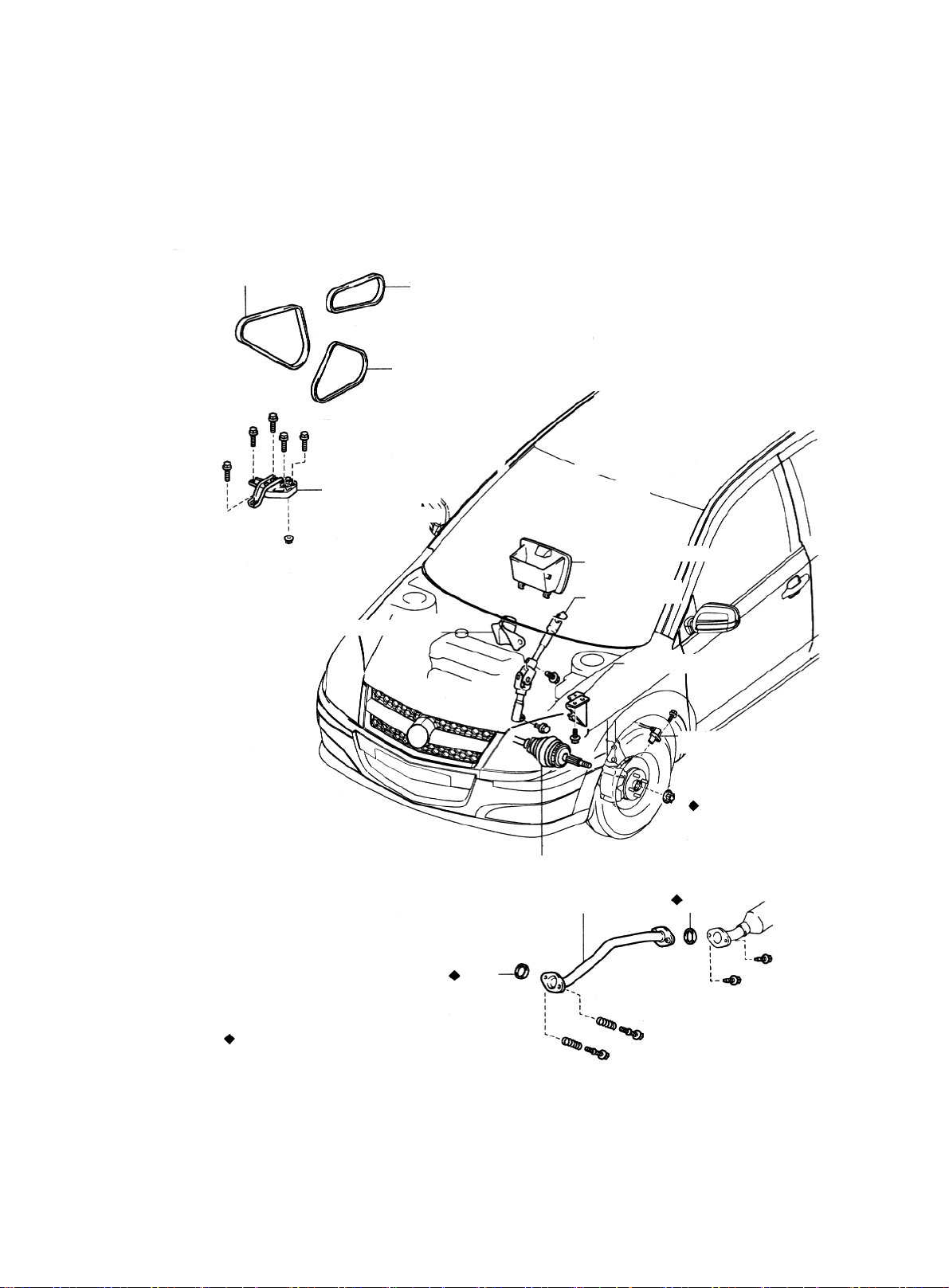

Page 18

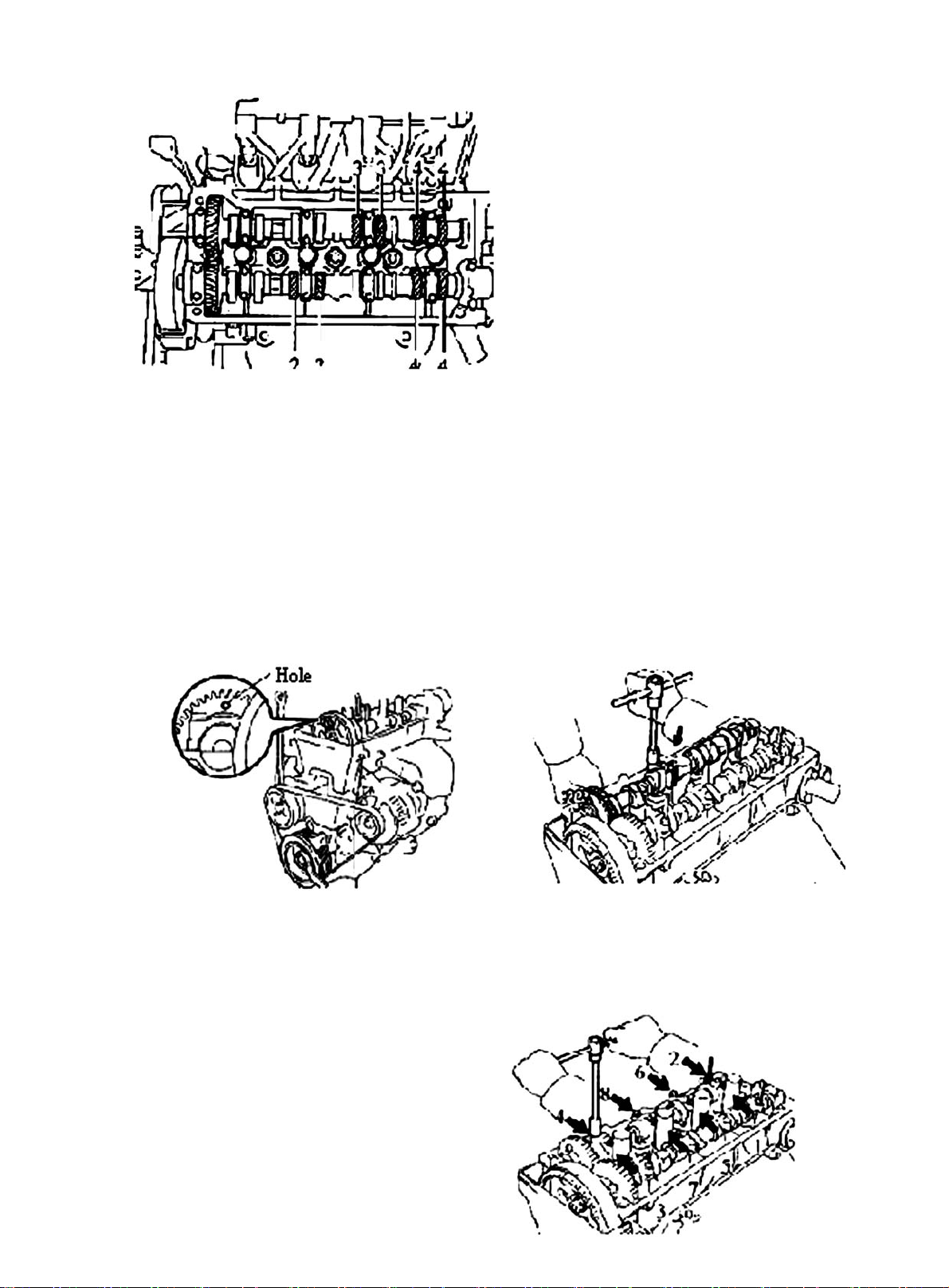

Component 2

Fan & Generator V-Belt

Vane-Type Pump V-Belt (V/ Power Steering)

V-Belt No.1

Right Engine

Glove Compartment

Steering Column

Hole Cover

Mounting Insulator

Door Assembly

Steering Column

Assembly

Steering Column Hole Cover

One-off accessory

Front Shaft Hub Left Nut

Front exhauxt pipe assembly

Gasket

Figure 21

Left Engine Mounting Bracket

Left Front Speed Sensor

Gasket

11

Page 19

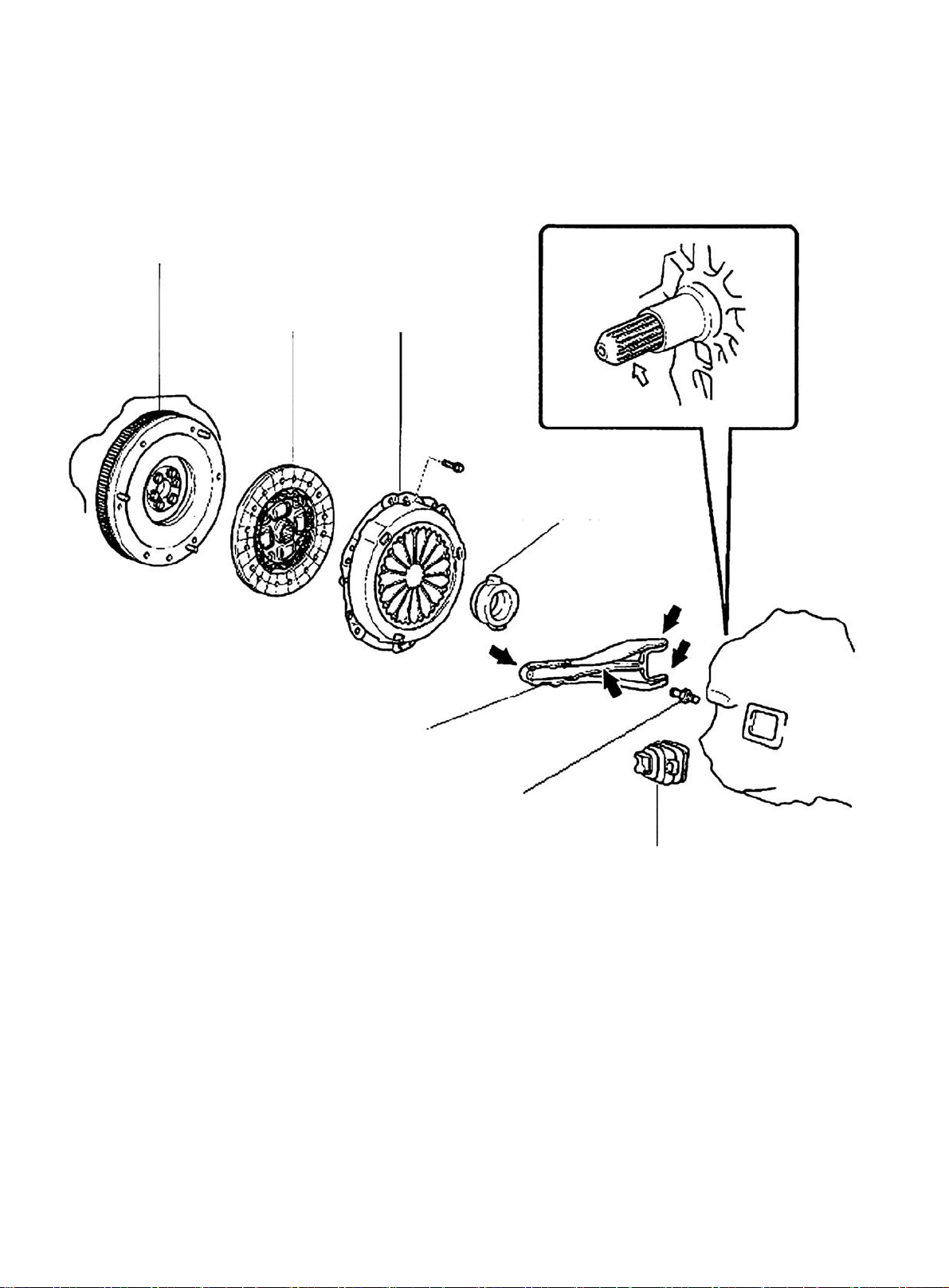

Flywheel

Component 3

Clutch Disc

Clutch Release Fork

Clutch Cover

Clutch Release Bearing

12

Release Fork Support

Release Fork Boot

Figure 22

Page 20

Section 2 Engine Components Replacement

1. Avoid gasoline ejection when work.

2. Drain the coolant to empty.

3. Remove air filter assembly with hose. See (Figure 23)

4. Remove battery

5. Remove fuel delivery pipe sub-assembly

6. Disconnect water hoses, disconnect heater outlet hose

from A/C hose.

7. Loose nut, remove accelerator control cable

8. Remove throttle body assembly

9. Remove power steering pump reservoir assembly

10. Remove front exhaust pipe assembly

11. Remove steering gear boot

12. Seperate steering column assembly. See (Figure 24)

13. Remove front wheel hub nut

Figure 23

14. Disconnect front wheel vehicle speed sensor (with ABS)

15. Detach steering tie rod ball stud pin assembly

16. Detach front lower swing arm sub-assembly

17. Detach front propeller assembly. See (Figure 25)

Detach front propeller from the shaft hub with plastic hammer.

18. Disconnect transmission shift cable or gear shift level assembly

19. Disconnect clutch cylinder assembly or disconnect clutch cable

20. Detach engine assembly and transaxle

(a) Hoisting engine ;

(b) Remove 3 bolts. Detach the right engine mounting bracket. See (Figure 26) ;

(c) Remove 1 bolt. Detach the left engine mounting bracket;

(d) Remove 1 bolt. Detach the rear engine mounting bracket;

(e) Remove engine and transaxle and put them on the pallet;

(f) Jack up the boday.

Figure 24

Figure 25 Figure 26

13

Page 21

21. Remove radiator assembly

22. Remove engine V-belt

23. Remove No. 1 V- belt (A/C compressor to crankshaft pulley)

24. Remove generator assembly

25. Remove A/C compressor

26. Remove compressor installing No. 1 bracket. Remove 4 bolts and compressor installing No.

1 bracket.

27. Remove starter assembly

28. Remove power steering pump V- belt

29. Detach power steering pump assembly

30. Remove power steering pump, adjust the bracket

31. Detach manual transaxle assembly (Separate automatic transaxle assembly)

32. Detach clutch cover panel assembly.

33. Detach clutch pressure plate assembly.

34. Detach flywheel sub-assembly.

35. Remove engine rear end cover.

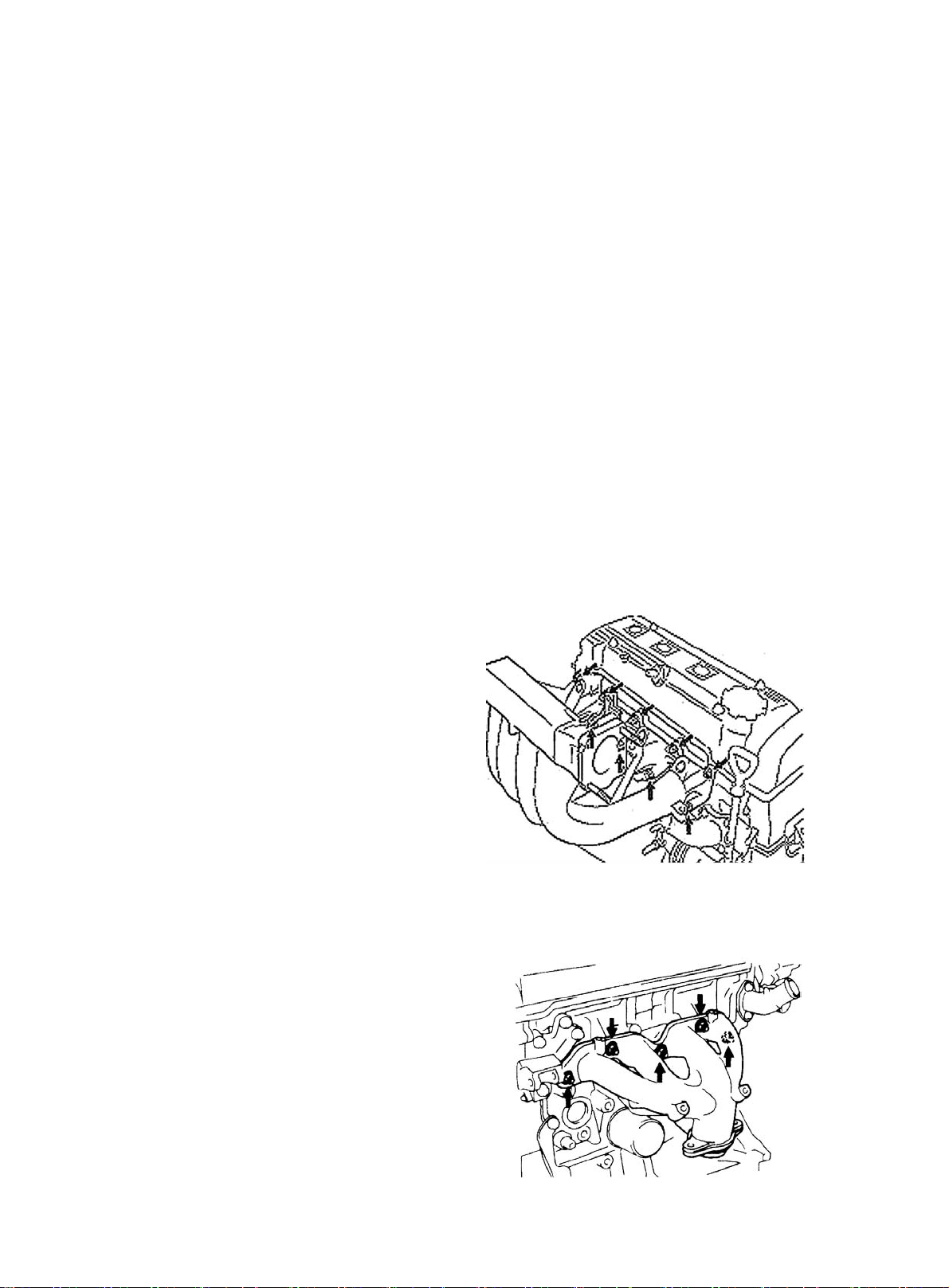

36. Remove injector assembly and remove intake manifold.

Remove 2 bolts and intake manifold support and remove 7 bolts,

2 nuts, intake manifold and gasket. See (Figure 27).

37. Remove knock sensor

38. Remove water temperature gauge sensor

39. Remove crankshaft position sensor

40. Remove engine oil pressure switch

41. Remove water inlet hose housing

42. Remove water outlet hose joint

43. Detach exhaust manifold. See (Figure 28)

44. Remove engion oil filter sub-assembly

45. Remove ignition coil and high voltage cable

46. Install engine sub-assembly

47. Install ignition coil and high voltage cable

48. Install engine oil filter sub-assembly

49. Install exhaust manifold

Figure 27

(a) Install new gasket and exhaust manifold stay with

5 nuts, Torque: 34N. m

(b) Install exhaust manifold stay with two bolts.

Torque: 59N. m

(c) Install upper heat shield with 4 bolts.

14

Torque: 17N. m

Figure 28

Page 22

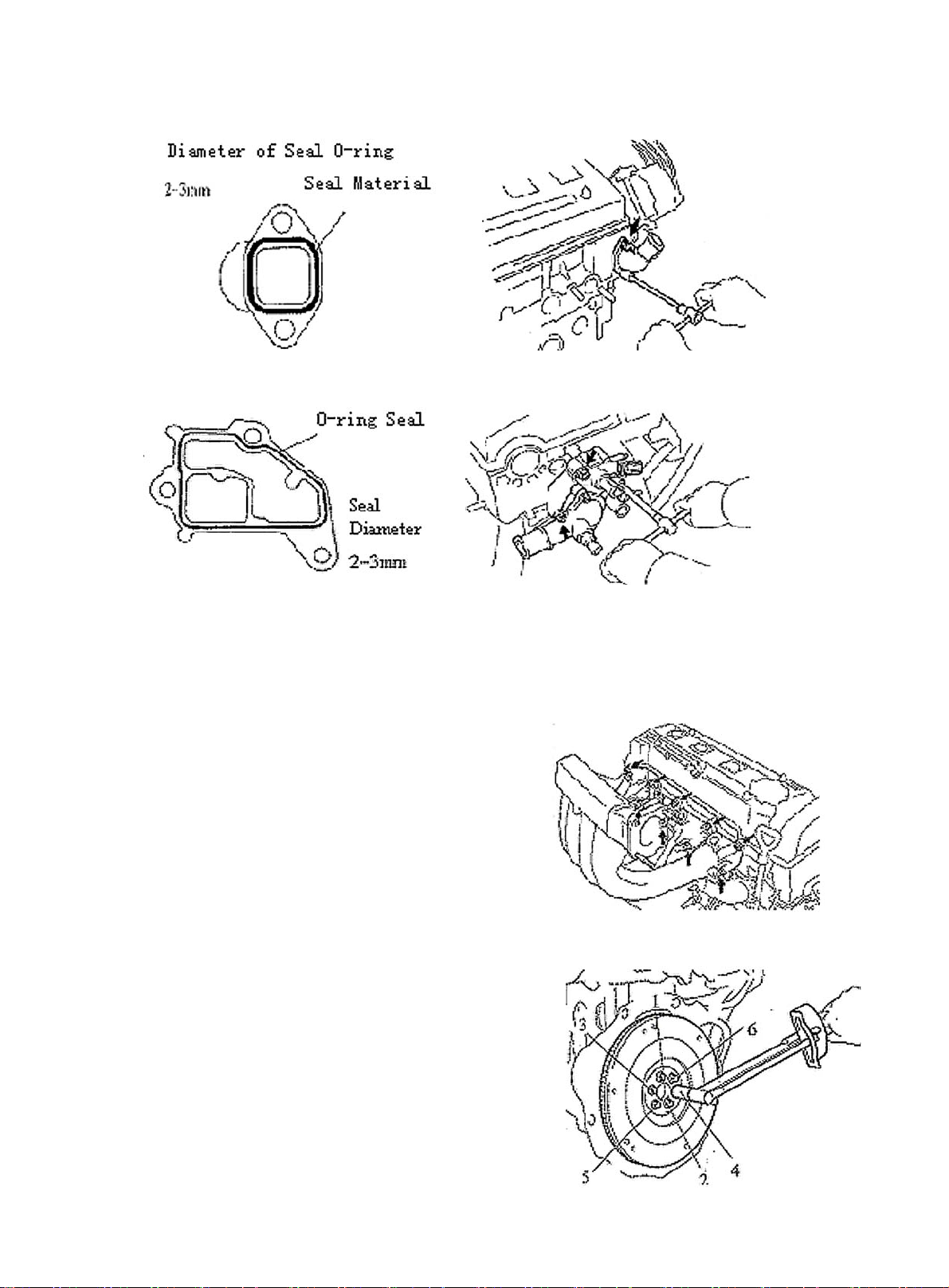

50. Install water outlet hose joint. See (Figure 29, 30)

Figure 29

Figure 30

51. Install water inlet hose housing. See (Figure 31, 32)

Figure 31 Figure 32

52. Install engine oil pressure switch

53. Install crankshaft position sensor

T orque: 9, 3N. m

54. Install water temperature gauge and water temperature sensor

T orque: 15N. m

55. Install knock sensor

Torque: 44N. M

56. Install intake manifold. See (Figure 33)

Install the intake manifold with new gasket with 7 bolts and 2

nuts. Uniformly tighten bolts and nuts in several time.

57. Install injector assembly

58. Install rear end cover

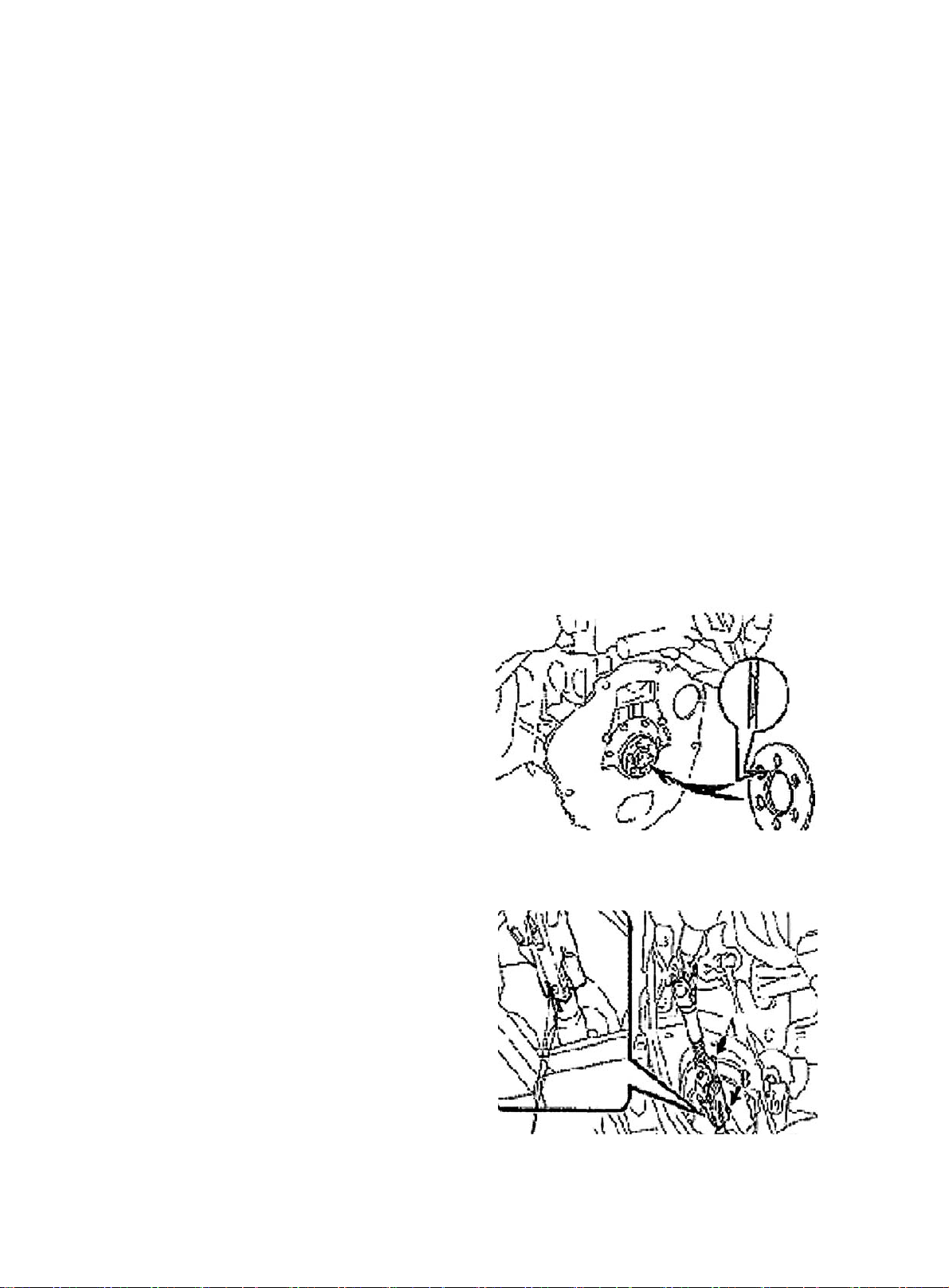

59. Install flywheel sub-assembly. See (Figure 34)

(a) Install flywheel to crankshaft.

(b)Install and uniformly tighten and connect bolt as shown in the

figure. Torque: 78N. m

60. Install clutch assembly

61. Install flywheel and ring gear. See (Figure 35)

(a)Install the oil thrower, it’s chamfer side on crankshaft in

the axie direction.

(b) Install flywheel and ring gear on crankshaft.

Figure 33

Figure 34

15

Page 23

(c) Install and uniformly tighten connecting bolt in the sequence shown in

the figure.

Torque: 64N. m

62. Install manual transaxle assembly

63. Install starter assembly

64. Install power steering pump bracket

65. Install power steering pump adjusting bracket with 2 bolts.

66. Connect power steering pump assembly

67. Install engine assembly and transaxle

68. Connect left, right, front and rear lower suspension arm sub-assembly

69. Connect left and right tie rod ball stud pin assembly

70. Connect left, right and front vehicle speed sensor (with ABS)

71. Install left & right nuts on the front shaft hub

72. Install front exhaust pipe assembly

73. Connect steering shaft assembly and steering column hole cover. See (Figure 36)

74. Connect wire harness

75. Install belt adjusting bracket of A/C compressor

76. Connect A/C compressor

77. Install generator assembly

78. Install A/C compressor to crankshaft pulleyV-belt

79. Install generator belt

80. Install engine assembly with transaxle

81. Install radiator assembly

82. Install throttle body assembly

83. Install fuel delivery pipe sub-assembly

84. Install battery

85. Install air filter assembly with hose

86. Install front wheel

87. Fill engine oil

88. Fill coolant

89. Check engine oil for leakage

90. Check engine coolant for leakage

Figure 35

91. Check fuel for leakage

92. Check idle and ignition timing

93. Check CO/HC

94. Check and adjust front wheel alignment

95. Check ABS vehicle speed sensor signal

16

Figure 36

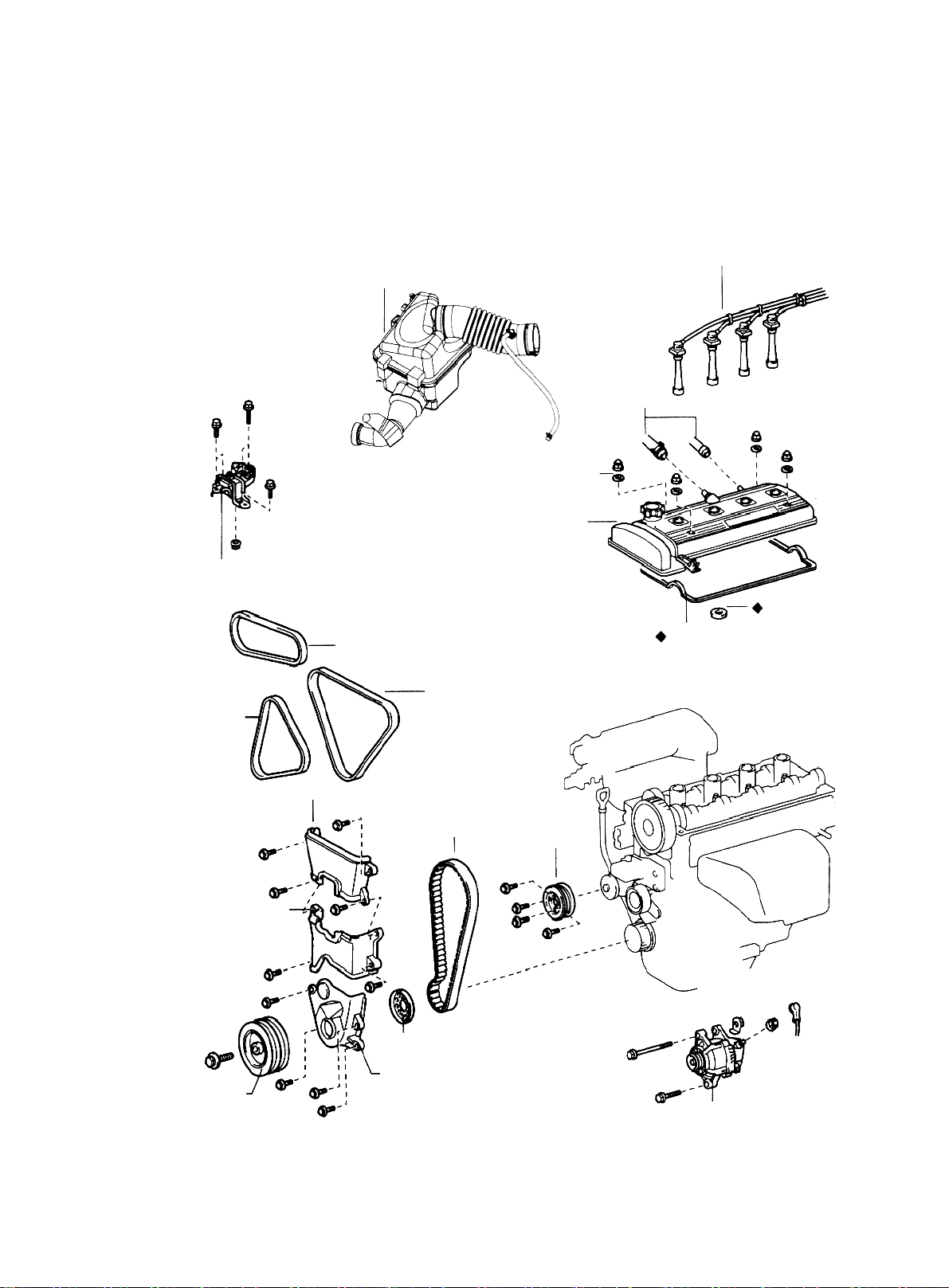

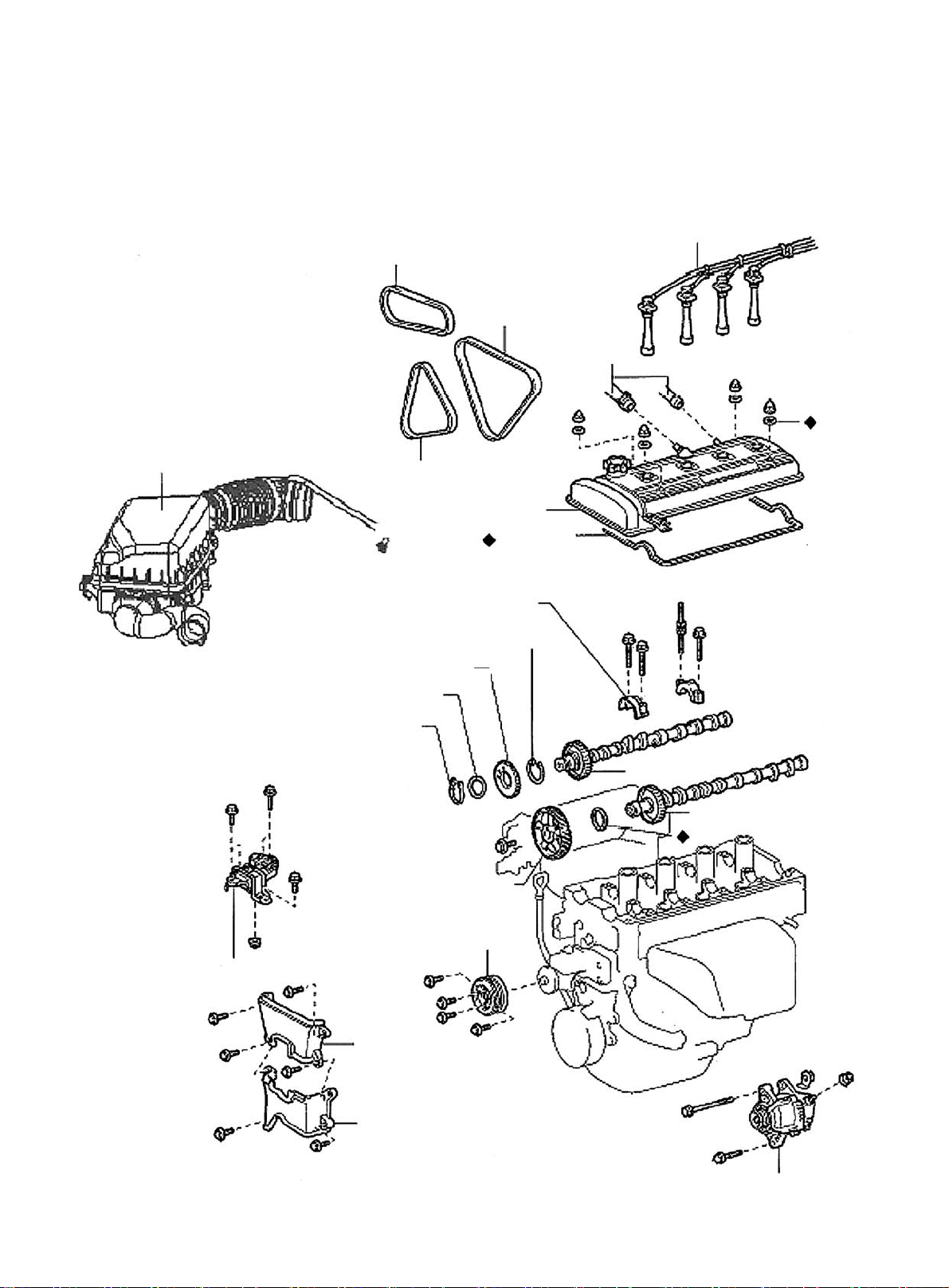

Page 24

Right Engine Mounting

Section 3 Timing Belt Replacement

Air Filter Assembly W/ Hose

Ventilation Pipe

Seal

Cylinder Head

Vane-Type Pump V-Belt V/ Power Steering

Cylinder Head Gasket

High Pressure Cable

Gasket

V-Belt No.1

Timing Chain Or Timing Belt Cover Assembly No. 2

Crankshaft Or Pulley

Cover Sub-Assembly

Timing Chain Timing Belt

Crankshaft Pulley

Cover Sub-Assembly

Fan & Generator V-Belt

Timing Belt

Timing Belt Guide

Fan Pulley

Generator Assembly

Figure 37

17

Page 25

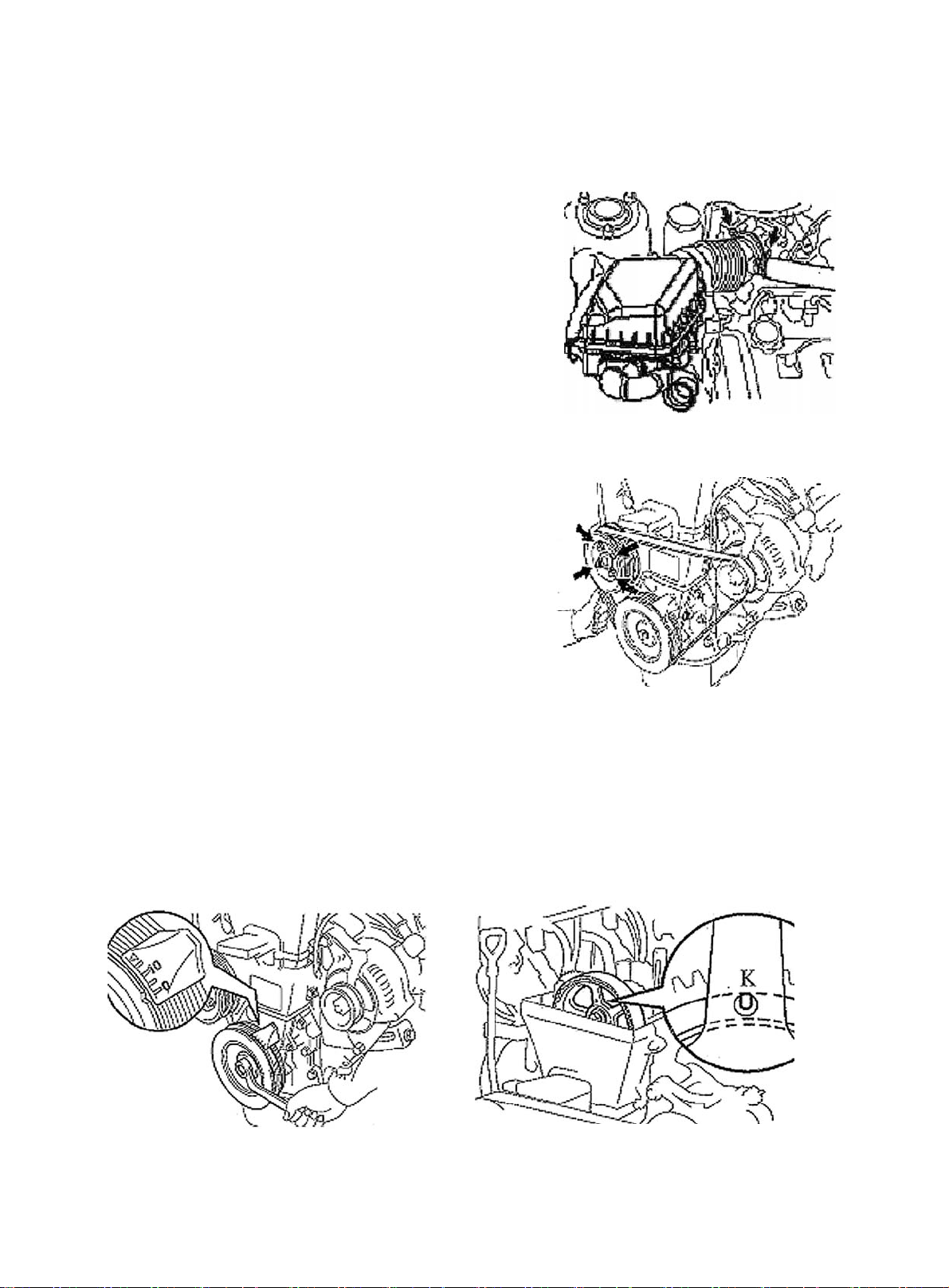

1. Disconnect engine from all the wire harnesses and cables connected to body.

2. Remove air filter assembly with hose. See (Figure 38)

3. Disconnect oil pipe and water hoses

4. Loose positive and negative cables on battery

5. Detach propeller shaft

6. Loose engine left & right rear brackets after hoisting engine

7. Disconnect all the connectors of engine and the body

8. Remove engine per "Provision 20, Section 2, Chapter 2"

9. Remove A/C compressor to crankshaft pulley V-belt

10. Remove power steering pump V-belt

11. Remove water pump fan pulley

12. Remove high pressure cable.

13. Remove cylinder head cover sub-assembly

14. Remove generator assembly. See (Figure 39)

15. Put the piston in Cylinder 1 to TDC compression position

(a)Turn crankshaft pulley to align its notch to the timing mark "0"

on the timing belt cover. See (Figure 40).

(b) Check if the "K" mark on camshaft timing pulley and the timing mark

on the bearing cap are aligned. Crank the crankshaft for 360 degrees

if not. See (Figure 41).

16. Remove crankshaft pulley

17. Remove timing belt cover

18. Remove crankshaft gear or pulley cover sub-assembly

19. Remove timing belt cover sub-assembly

Figure 38

Figure 39

18

Figure 40

Figure 41

Page 26

20. Remove timing belt guide wheel

Hint:

(a) Mark on pulley and belt (in engine turning direction) if re-using timing belt (See Figure 42).

(b) Install bolt to the idler pulley. Move pulley to its far left and tighten it temperarily (See Figure 43).

21. Remove spark plug and gasket

Figure 42

22. Install spark plug and gasket

23. Put the piston in Cylinder 1 to TDC compression position.

See (Figure 44)

(a) Turn camshaft hexagon part. Align the mark "K" on the camshaft

timing pulley to the mark on the bearing cap.

(b) Using the crankshaft pulley bolt, turn the crankshaft, align the mark

on crankshaft timing pulley to the oil pump.

24. Install timing belt. See (Figure 45)

Notice: The engine must be cool.

(a) Install timing belt. Check the tension force between crankshaft timing

pulley and camshaft timing pulley.

Hint: Align the marks if re-using the timing belt when removing. The

engine's rotating direction should be the same with the arrow's when

installing belt.

Figure 43

Figure 44

(b) Check valve timing. Loose idler bolt.

(1) Turn crankshaft from TDC to BDC slowly.

Notice: Crank always in clockwise.

Figure 45

(2) Align each pulley to timing mark as shown in the figure. If the timing mark is not aligned,

remove timing belt and reinstall it.

(3) Tighten idler bolt.

T orque: 37N. m

(4) Remove crankshaft pulley bolt.

19

Page 27

(c) Check timing belt for deflection

Check the belt distorn as shown in the figure.

Belt deflection:

20N: 5~6mm

Re-adjust the idler if the deflection does not comply with the regulation.

25. Install timing belt guide wheel. See (Figure 46)

Install guide, place the cup side outward.

26. Install timing belt cover sub-assembly

Torque: 9.3N. m

27. Install crankshaft gear or pulley cover sub-assembly

Torque: 9.3N. m

28. Install timing belt cover

Torque: 9.3N. m

29. Install crankshaft pulley. See (Figure 47)

(a) Align pulley lock key and pulley key groove. Install pulley .

Figure 46

(b) Install pulley bolt T orque: 127N. M

30. Install generator assembly

31. Install water pump pulley

32. Install power steering pump V-belt

33. Install A/C compressor fan to crankshaft pulleyV-belt

34. Install cylinder head cover sub-assembly.

(a) Wipe off all seal packing material.

(b) Apply the seal glue on cylinder head cover as shown in Figure 48.

(c) Install gasket onto cylinder head cover.

(d) Install cylinder head cover with 4 seal gaskets and 4 nuts.

Torque: 7.8N. M

(e) Install 2 ventilation hoses onto cylinder head cover.

(f) Install engine wire harness onto cylinder head cover.

(g) Connect generator wire joint.

(h) Connect generator wire.

Figure 47

(i) Connect oil pressure switch connector.

(j) Install wire clip.

(k) Connect A/C compressor switch connector.

35. Hoist the engine back into the compartment

36. Install left & right rear engine mounting brackets

37. Install ignition coil and high pressure cable

38. Install air filter assembly with hose

20

Figure 48

Page 28

39. Install oil pipe and water hose

40. Install left & right propeller shaft

41. Install left & right front wheel

42. Check engine oil for leakage

43. Install all connected wire harnesses and the cables on engine and vehicle body

21

Page 29

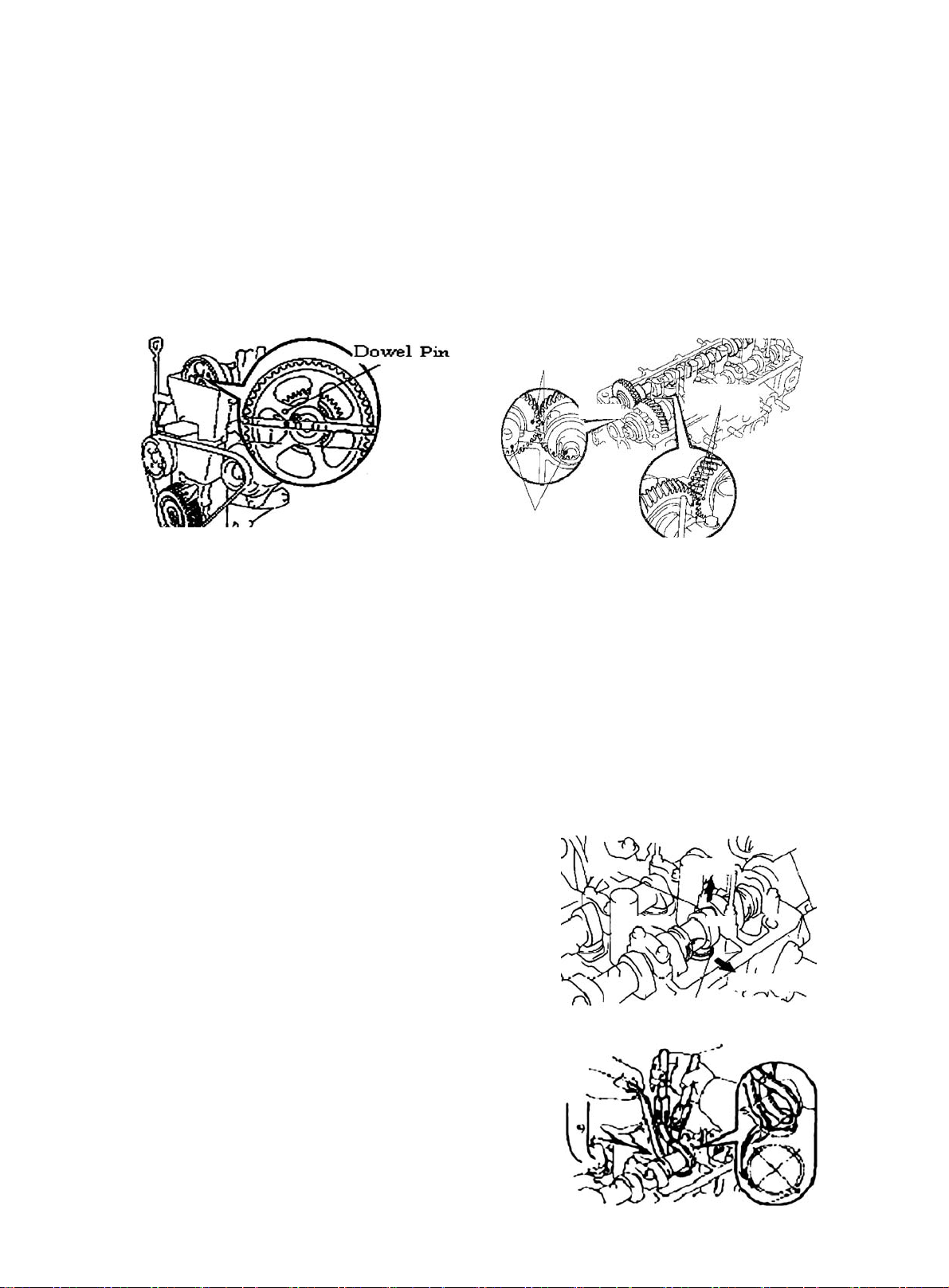

Section 4 Camshaft Replacement

Air Filter Assembly W/ Hose

Vane-Type Pump V-Belt

V/ Power Steering

Fan & Generator V-Belt

V-Belt No.1

Cylinder Head

Crankshaft Bearing Cap

Crankshaft Timing Belt Washer

Crankshaft Counter Gear

Wave Gasket

Ventilation Pipe

Cylinder

Head Gasket

High Pressure Cable

Seal

Right Engine Mounting

Snap Ring

Camshaft Timing Pulley

Fan Pulley

Timing Belt

Cover No. 2

Crankshaft Or Pulley

Cover Sub-Assembly

Figure 49

Camshaft

Camshaft No. 2

Oil Seal

Generator Assembly

22

Page 30

1. Disconnect all connected wire harnesses and the cable on the engine and the vehicle body

2. Remove air filter assembly with hose

3. Disconnect oil pipe and water hose

4. Loose positive and negative cables of the battery

5. Detach propeller shaft

6. Loose left & right rear engine mounting bracket after hoisting the engine.

7. Disconnect all other connectors between the engine and the vehicle body.

8. Remove engine per "Provison 20, Section 2, Chapter 2"

9. Remove A/C compressor to crankshaft pulleyV-belt

10. Remove power steering pump V- belt

11. Remove water pump fan pulley

12. Disconnect ignition coil and high voltage cables

13. Remove cylinder head cover sub-assembly

14. Remove generator assembly

15. Remove cylinder head cover sub-assembly

(a) Disconnect generator wire joint.

(b) Disconnect generator circuit

(c) Disconnect A/C compressor switch connector.

(e) Open wires clips.

(f) Disconnect wire harness from the cylinder head cover.

(g) Disconnect 2 ventilation PCV hoses from cylinder head cover.

(h) Remove 4 screws, 4 seal gaskets, cylinder head and gasket.

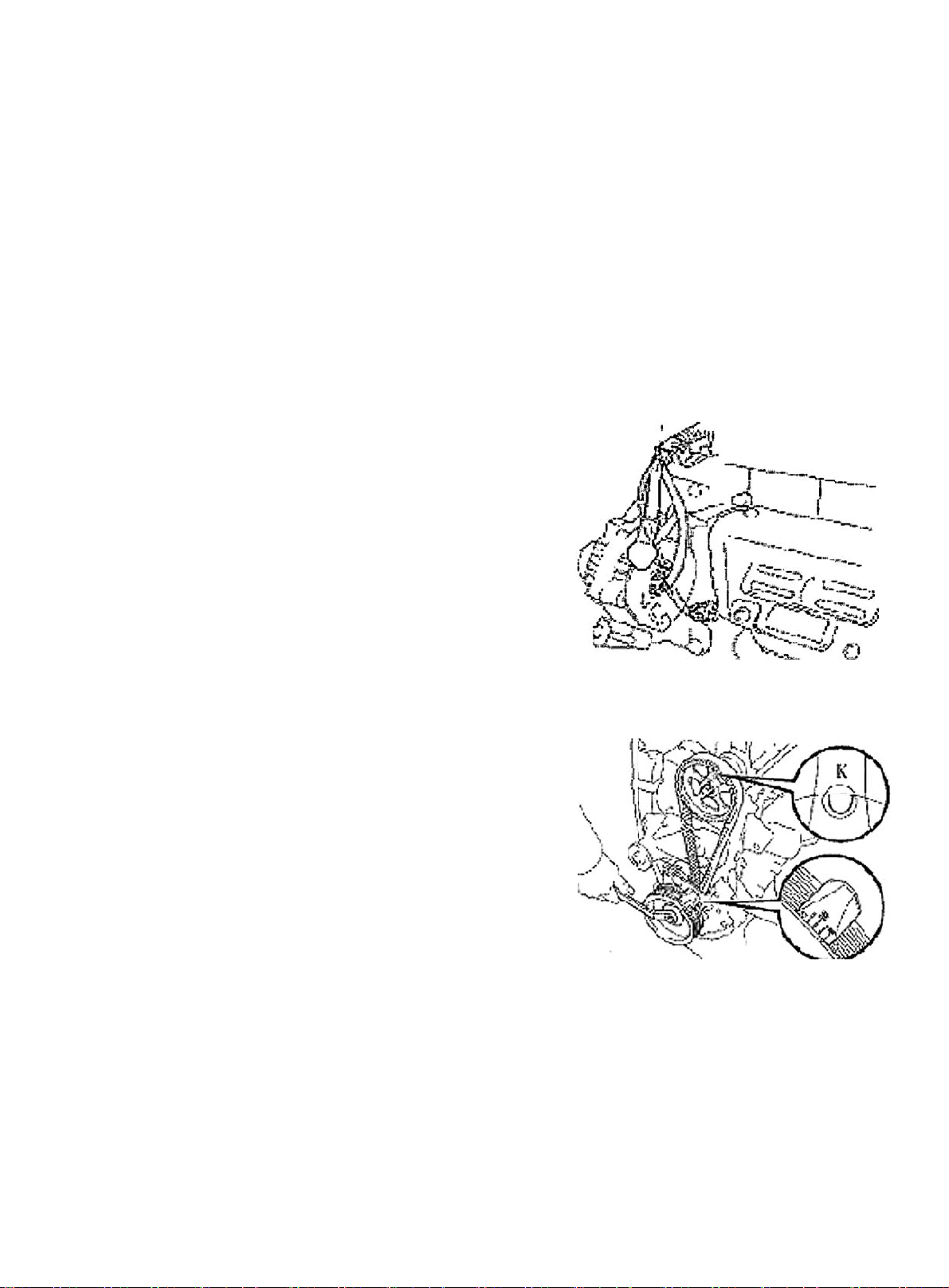

16. Remove generator assembly. See (Figure 50)

17. Remove timing belt cover

18. Remove crankshaft gear or pulley cover sub-assembly

19. Put the piston on Cylinder 1 to TDC compression position.

(a) Turn crankshaft pulley. Align its notch to the timing mark "O" on the

timing belt cover.

(b) Check if the mark "K" on camshaft timing pulley is aligned to the

timing mark on the bearing cap. Turn crankshaft 360° if not.

20. Remove ignition coil assembly

Figure 50

Figure 51

21. Remove timing belt. See (Figure 51)

(a) Mark on the timing belt and the camshaft pulley. The mark on the

timing belt to the timing belt cover No. 1 should match.

(b) Remove rubber gasket from timing belt cover.

23

Page 31

(c) Loose installing bolt of the idler. See (Figure 52). Move the pulley to

its far left and tighten it temporarily.

(d) Remove the belt from the camshaft timing pulley.

Notice:

z Hold the timing belt, the engagement of the crankshaft timing

pulley and timing belt will not move.

z Be careful not to drop anything into the timing belt cover.

z Do not let the belt contact oils, water or dirt.

Figure 52

Figure 53

22. Remove the camshaft and the timing pulley. See (Figure 53)

(a) Turn the camshaft hexagon head and loose pulley bolt.

(b) Remove pulley bolt and timing pulley.

23. Remove camshaft. See (Figure 54)

Because the camshaft end play is quite small, keep camshaft horizontal

when removing it.Take the following steps to avoid the damage:

(a) Remove the camshaft

(1) Turn the camshaft to access the hole of the counter gear installed on camshaft drive gear.

Hint: The intake camshaft lobe of Cylinder 1 and 3 can push up their

own valve tappet.

(2) Remove 2 bolts and bearing cap No. 1.

(3) Install the counter gear on the intake camshaft with the service

bolt onto the drive gear.

(4) Uniformly loose and detach 8 bearing cap bolts in several times

in the sequence shown in Figure 55.

Figure 54

Figure 55

(5) Remove 4 bearing caps and camshaft.

If the camshaft can not be kept horizontal, lift it vertically. Reinstall the

bearing cap with 2 bolts. Alternatively loose and detach the bearing cap

bolts and lift the camshaft gear. See (Figure 56)

24

Figure 56

Page 32

(b) Remove the counter gear of the camshaft.

(1) Clamp the camshaft's hexagon on the vise.

(2) Turn the counter gear cloclwise, Remove the service bolt.

(3) Remove the snap ring with a circlip pliers. See (Figure 57).

(4) Remove waved gasket, camshaft counter gear and the camshaft gear spring. See (Figure 58)

24. Remove and install spark plug hole gasket. See Provision 15 and 16, Section 3 Timing Belt

Replacement for detailed information. See (Figure 44, 45).

Rotate

Figure 57

Figure 58

25. Install camshaft

(a) Install exhaust camshaft and turn camshaft counterclockwise to make the dowel pin cross the vertical

line a little. See (Figure 59).

(b) Apply grease to a new oil seal lip and install it into the oil seal. See (Figure 60).

Figure 59

Figure 60

(c) Install camshaft counter gear.

Figrue 61

(1) Clamp the camshaft's hexagon head with a vise.

(2) Install camshaft gear spring, camshaft counter gear and waved washer. (Figure 61).

Hint: Align the pin on the gear to the spring end of the counter gear.

(3) Install the snap ring with a circlip plier.

(4) Turn the counter gear clockwise with the special tool. Align the

holes on the camshaft drive gear. Install the service bolt.

25

Page 33

(d) Install intake camshaft.

(1) Make the exhaust camshaft dowel pin a bit higher than the top of the cylinder head.

(2) Apply grease to camshaft's contact surface.

(3) Install intake camshaft gear to exhaust camshaft gear ,

Align the matchmarks on each gear. See (Figure 62).

(4) Check the timing marks on the camshaft gear for

alignment.See (Figure 63).

Hint: Matchmark is on the top.

26. Adjust valve clearance

Install Mark

Timing Mark

27. Install camshaft timing pulley

Turn the camshaft's hexagon head. Tighten the timing pulley bolt. See (Figure 64).

Torque: 59N. M

Install Mark

Timing Mark

Install Mark

Figure 62

Figure 63

5-6mm

Figure 65

Figure 64

Figure 66

28. Install the timing belt

(a) Align the marks on timing belt and the one on camshaft timing pulley.

(b) Install timing belt. Check tension force between the crankshaft timing pulleys. See (Figure 65).

29. Check valve timing

(a) Loose idler bolt.

(b) Turn crankshaft from TDC clockwise for 2 cycles.

(c) Check and align each pully to the timing mark as shown in Figure 66. Remove timing belt and reinstall it

if not.

30. Install crankshaft gear or pulley cover sub-assembly

Torque: 9.3N. m

26

Page 34

31. Install timing belt cover

Torque: 9.3N. m

32. Install generator assembly

33. Install right engine mounting bracket. See (Figure 67)

34. Install cylinder head cover sub-assembly

(a) Install 2 ventilation PCV hoses to the cylinder head cover.

(b) Connect the generator wire.

(c) Install the wire clip.

(d) Connect A/C compressor switch connector.

35. Install water pump pulley

36. Install power steering pump V-belt

37. Install A/C compressor to crankshaft pulleyV-belt

38. Install generator V-belt

39. Install left & right rear mounting bracket of engine.

40. Install ignition coil and high voltage cable

41. Hoist the engine back into the compartment

42. Install propeller shaft

43. Install air filter assembly with hose

44. Install oil pipe and water hoses

45. Install left and right front tires.

Figure 67

46. Check engine oil for leakage

47. Install all the wire harnesses and the cables on the engine connected to car body

27

Page 35

Section 5 Cylinder Head Gasket Replacement

Component 1

Vane Pump Assembly V/ Power Steering

Throttle Body Assembly

Dipstick

Fuel Delivery Pipe No.1

Inlet Pipe

Gasket

O-Ring

Timing Chain Or Timing Belt Cover No. 2

Crankshaft Or Pulley Cover Sub-Assembly

Fan Pulley

Gasket

Wire Harness

28

Figure 68

Page 36

Component 2

High Pressure Cable

Camshaft Bearing Cap

Oil Seal

Camshaft Timing Pulley

Cylinder Head Sub-Assembly

Cylinder

Head Gasket

Camshaft

Camshaft

No.2

Ventilation Pipe

Seal

Cylinder Head Cover

Cylinder Head

Cover Gasket

Exhaust Manifold

Insulator No. 1

Figure 69

Gasket

Exhaust Manifold

Manifold Mounting

29

Page 37

Air Filter Assembly W/ Hose

Right Scuttle Ventilation Grille

Component 3

Engine Hood

Right Wiper Arm

Left Wiper Arm

Right Engine Mounting Bracket

Left Scuttle Ventilation Grille

Vane-Type Pump

V-Belt V/ Power Steering

V-Belt No.1

Accelerator Cable Assembly

Generator

Assembly

Heater Inlet Hose

Radiator Inlet Hose

Fan & Generator V-Belt

Wiper Arm Subassembly

EFI Fuel Hose Clamp

Fuel Pipe Sub-Assembly

Heater Outlet Hose A

Radiator Outlet Hose

Figure 70

30

Page 38

Replacement

1. Disconnect all the wire harnesses and the cables on the engine connected to the car body.

2. Detach air filter assembly with hose

3. Disconnect oil pipe and water hose

4. Loose positive and negative cables of the battery.

5. Detach propeller shaft. Detach front exhaust pipe assembly

6. Loose engine left & right rear brackets after hoisting the engine.

7. Disconnect all the other connectors between the engine and the car body.

8. See "Provision 20, Section 2, Chapter 2". Lift the car body and take out the engine assembly.

9. Remove A/C compressor to the crankshaft pulleyV-belt.

10. Remove power steering pump V-belt.

11. Detach water pump fan pulley.

12. Disconnect ignition coil and high voltage cable.

13. Detach cylinder head cover sub-assembly.

14. Detach generator assembly.

15. Detach the camshaft.

16. Detach the throttle body assembly

17. Detach intake manifold stay No. 2.

18. Take out the dipstick

19. Detach No. 1 fuel delivery pipe

20. Detach the wire harness.

21. Detach the steering assisting pump assembly

22. Detach exhaust manifold. See (Figure 71)

23. Pry cylinder head from the dowel pin on the cylinder block.

See (Figure 72)

24. Remove the cylinder head gasket.

25. Install cylinder head gasket

26. Install cylinder head sub-assembly

27. Install exhaust pipe assembly.

(a) Install the new gasket and exhaust manifold with 5

bolts. Torque: 34N. m

Figure 71

(b) Install exhaust manifold stay with 2 bolts.

(c) Install upper heat shield with 4 bolts

T orque: 17N. m

Figure 72

31

Page 39

28. Install power steering adjusting pole

29. Install power steering pump assembly

30. Install wire harness.

31. Install No. 1 fuel delivery pipe

32. Set the new gasket on cylinder head with flange upward. Install water inlet hose. See

(Figure 73)

33. Install manifold stay No. 2

34. Connect front exhaust pipe assembly

35. Install throttle body assembly

36. Install camshaft

37. Install engine cylinder head cover

38. Hoist the engine back to the compartment.

39. Install engine right left and rear brackets

40. Install propeller shaft

Figure 73

41. Install ignition coil and high pressure cables. Install air filter assembly with hose

42. Install oil pipe and water hose

43. Install left & right front tire

44. Install all the wire harnesses and cables on the engine connected to car body

45. Check compression pressure

46. Check CO/HC. Check idle and ignition timing

32

Page 40

Section 6 Oil Pump Oil Seal Replacement

1. Pry with 2 screwdrivers. Detach crankshaft timing pulley.

See (Figure 74)

2. Remove oil pump oil seal. See (Figure 75)

(a) Using a knife, cut off oil seal lip.

(b) Using a screwdriver, pry out the oil seal.

3. Install oil pump oil seal. See (Figure 76)

(a) Smear grease to a new oil seal lip.

(b) on the oil seal with hammer until the edge of the oil pump

case is filled with the seal packing.

4. Install crankshaft timing pulley. See (Figure 77)

(a) Align pulley set key to the key groove.

(b) Place the flange face inward. Install timing pulley.

5. Install timing belt

6. Check engine oil for leakage

Figure 74

Figure 75

Figure 76

Figure 77

33

Page 41

Section 7 Engine Rear Oil Seal Replacement

1. Detach engine and manuel transaxle assembly on "Provision 20, Section 2, Chapter 2"

2. Detach clutch case assembly

3. Remove clutch plate assembly

4.Fix the front end of crankshaft. Detach flywheel.

See (Figure 78)

5. Remove rear crankshaft end cover

6. Remove engine rear oil seal. See (Figure 75)

7. Install engine rear oil seal. See (Figure 76)

8. Install flywheel sub-assembly. See (Figure 79)

(a) Fix crankshaft.

(b) Install flywheel to crankshaft. as the sequence shown in the figure,

(c) Install and uniformly tighten and install bolt

T orque: 78N. m

9. Install clutch plate assembly

10. Install clutch case assembly

11. Install manual transaxle assembly

Figure 78

Figure 79

34

Page 42

Chapter 3 Lubrication System

(MR479Q, MR479QA, MR481QA)

Section 1 Oil Pressure Gage Sensor Replacement

1. Check oil level

Warm up the engine. Check the dipstick to ensure oil level between "L" and "F" after engine stopped

5 minutes. Check for leakage if it is too low. Fill oil to "F.

2. Check oil for deterioration. Water entry, discolor and dilution. Replace oil if it is obviously

deteriorated.

3. Detach oil pressure sensor assembly. See (Figure 80)

4. Install oil pressure gage sensor. See (Figure 81) Start engine to

normal operation temperature.

5. Check for oil pressure

6. Smear adhesive on 2 or 3 threads of the oil pressure sensor.

Install oil pressure sensor. See (Figure 82)

Figure 80

Figure 82

Figure 81

35

Page 43

Section 2 Oil Pump Assembly Replacement

1. Remove timing belt

2. Remove timing belt idler sub-assembly

3. Detach crankshaft timing pulley. See (Figure 74)

4. Remove the dipstick guide

5. Detach oil sump sub-assembly. See (Figure 83)

6. Detach oil strainer sub-assembly. See (Figure 84)

7. Detach oil pump assembly. See (Figure 85)

8. Remove oil pump oil seal

9. Install oil pump oil seal

10. Install oil pump assembly

11. Install oil strainer sub-assembly

12. Install oil sump assembly. See (Figure 86)

Figure 84

Figure 83

36

Figure 86

Figure 85

Page 44

13. Install the dipstick guide. See (Figure 87)

14. Install crankshaft timing pulley. See (Figure 77)

15. Install timing belt idler sub-assembly No.1

16. Install timing belt

17. Fill in engine oil

18. Check oil for leakage

Figure 87

37

Page 45

Section 3 Oil Filter Replacement

1. Detach oil filter sub-assembly. See (Figure 88)

2. Install oil filter sub-assembly. See (Figure 89)

Figure 88 Figure 89

3. Install drain plug

Clean and use new washer to install drain plug.

Torque: 54N. m

4. Oil fill

Capacity:

Oil refill amount with the filter replaced: 3.0L

Oil refill amount without the filter dry fill replaced: 2.80L

Dry fill: 3.3L

5. Check oil for leakage

38

Page 46

Section 4 Starter Replacement

1. Detach starter assembly. See (Figure 90)

2. Install starter assembly

Torque:

Bolt 37N. m

Figure 90

39

Page 47

Section 5 Generator Replacement

1. Detach V-belt of generator

2. Detach generator assembly

(a) Disconnect wire joint of generator.

(b) Remove wire of generator.

(c) Disconnect oil pressure switch interface.

(d) Disconnect A/C compressor switch connector.

(e) Open wire clips.

(f) Detach 2 bolts and generator.

3. Install generator assembly

Torque:

M12 bolt 18N. m

M14 bolt 58N. m

4. Transmit belt tilt and tension state inspection

40

Page 48

Chapter 4 Fuel System

(MR7131A, MR7151A, MR7161A)

Section 1 Check Fuel System Pressure

1. Remove the fuel tank from the vehicle

2. Check the fuel pump running

(a) Connect the positive and negative battery terminal to the concerned

fuel pump connector. See (Figure 91).

Notice: Do not start engine

The sound of fuel flowing can be heard if there is pressure.

Check fusible link, fuse, EFI open circuit relay, fuel pump, ECU and

wire connector if there is no pressure.

(b) Turn the ignition switch to "OFF" position.

3. Check fuel pressure

(a) Check battery electrical pressure to be above 12V.

(b) Detach negative terminal cable from the battery.

(c) Install pressure gage from the fuel delivery pipe. See (Figure 92).

(d) Connect battery negative terminal.

(e) Measure fuel pressure

Fuel pressure:

304-343kPa

Check fuel pipe & union, fuel pump, fuel filter if the pressure is too

low.

(f) Start engine. Measure fuel pressure at idle. Fuel pressure: 304-343kPa

(g) Check fuel pressure and retain the pressure for approximately 5min after the engine stopped.

Fuel pressure: 147kPa

Figure 91

Figure 92

41

Page 49

Section 2 Fuel Pump Inspection

1. Fuel pump

at 20°. Replace fuel pump if the resistance is not as specified.

(a) Check fuel pump resistance, 0.2~3.0

See (Figure 93)

(b) Fuel pump running:

Check fuel pump by connecting with battery. Replace fuel pump or wire if the running is not as specified.

See (Figure 94).

The test should be conducted within 10s to prevent coil from damage.

2. Fuel injector assembly

3

Injection V olume: 40~50cm

/s

Error between each injector: less than 10 cm

Replace injector if the injection volume is not as specified.

(a) Check for leakage: Disconnect the cable from the battery. The fuel drop/min is no more than 1 drop.

Ohmmeter

Ω

3

42

Battery

Figure 93 Figure 94

Page 50

Section 3 Fuel Injector Replacement

1. Check fuel for ejection.

2. Remove PCV ventilation hoses. See (Figure 95). Remove fuel pipe clamp.

3. Detach fuel hose sub-assembly

4. Detach fuel delivery pipe sub-assembly. See (Figure 96)

(a) Press the connector to lock the spring and pull the connector from the injector.

(b) Remove 2 screws and detach fuel delivery pipe with injector.

5. Remove fuel injector assembly

6. Install injector assembly

(a) Smear a light layer of oil on two O-rings and install them to injector. See (Figure 97).

(b) Install 4 injectors to feul delivery pipe by rotating them left and right. See (Figure 98).

(c) Install retain frame to each injector.

New O-ring

Figure 95 Figure 96

Upward

Rotate

Ratain Frame

Push

Figure 97 Figure 98

43

Page 51

7. Install fuel delivery pipe sub-assembly

(a) Install two washers in intake manifold. See (Figure 99).

(b) Install 4 injectors and fuel delivery pipe assembly into intake manifold .

(c) Temperarily install 2 bolts to attach the fuel delivery pipe to intake

manifold .

(d) Check injector for smooth rotation. See (Figure 100).

Hint: If injector doesn't rotate smoothly, replace O-ring with the injector

connector upward.

(e) Tighten the 2 bolts and attach the fuel delivery pipe to intake manifold

See (Figure 101).

Torque: 15N. m

Upward

Rotate

Washer

Figure 99

Figure 100 Figure 101

44

Page 52

Section 4 Fuel Pump Replacement

Figure 102

45

Page 53

1. Avoid fuel ejection

2. Disconnect fuel tank hose

3. Disconnect fuel tank return hose

4. Disconnect fuel tank gas exhaust hose

5. Detach fuel pump assembly with filter screen. See (Figure 103)

Using special tool, loose fuel tank cap. Be careful not to bend the fuel

level sensor arm when pulling out fuel pump.

6. Install fuel pump assembly. See (Figure 104). Replace ring seal .

Align the tab on the fuel pump to the notch on the fuel tank port. Tighten

the fuel tank cap with special tool.

Torque: 40N. m

7. Install fuel gas exhaust hose

(a) Install return hose;

(b) Install fuel hose;

(c) Check fuel for leakage.

Figure 104

Figure 103

New Washer

46

Page 54

Section 5 Fuel Emission Control System

1. Check the operation when the fuel is cut off.

(a) Warm up the engine for at least 2500rpm. Using sound grade meter , check injector's noise when running.

See (Figure 105).

(b) The noise from the injector should stop immediately after loosing the throttle. Repeat for several times.

2. Check fuel vapor emission control system. See (Figure 106)

(a) Disconnect vacuum pipe after starting the engine.

(b) Select "ACTIVE TEST" and "PURGE VSV (Vacuum Solenoid Valve)" from the display on the fault

diagnosis tester. Confirm vacuum at VSV port.

(c) Connect the vacuum pipe after completing "ACTIVE TEST".

(d) After conducting "ECM DATA MONITOR"on the fault diagnosis tester, select "PURGE VSV" to

check operation.

(e) Start the vehicle after warming up the engine to confirm the VSV status is changed from disconnected to

connected. See (Figure 107).

3. Check the fill fuel port cap and gasket for distortion or damage. See (Figure 108)

Sound Grade Meter

Figure 105 Figure 106

Figure 107 Figure 108

Gasket

47

Page 55

Section 6 Carbon Canister Replacement

1. Check and replace carbon canister

(a) Eye-inspect the carbon canister for crack or damage. See (Figure 109).

(b) Check the carbon canister's operation.

1. Plug the exhaust hole. See (Figure 110).

2

2. Blow air in through (4.71kpa, 48kgf/cm

hole is closed. Check and ensure air is blew out from the blow purge hole.

) fuel tank hole when the exhaust

Replace the carbon carnister if the operation is not as specified.

Figure 109

3. Blow air in through the fuel tank hole. Check and ensure air flows out from

the other hole without resistance.

Replace the carbon carnister if the operation is not as specified.

(c) Clean the carbon carnister: Plug the blowing tube, bleed air in through (4.71kpa,) fuel tank hole and goes

out from the exhaust port. See (Figure 111).

Figure 110 Figure 111

2. Vacuum Solenoid Valve (VSV)

(a) Using ohmmeter, check VSV open circuit. The resistance is 27-33 ¸ when the temperature is 20°. See

Ω

(Figure 112).

Ohmmeter

Trigger

Ohmmeter

No trgger

Figure 112 Figure 11 3

(b) Using ohmmeter, check VSV grounding. Replace VSV if it is continuity. See (Figure 113).

48

Page 56

(3) Check VSV operation from hole E to F and that the air flow should be difficult. See (Figure 114).

3. PCV sub-assembly

It should be easy for air to pass through the cylinder head.

Notice:

z Do not suck air through valve.

z Never put any object into the valve. Replace PCV if the operation is

not as specified.

z Blow air in from the intake manifold side. Check that the air flow

should be difficult. Replace PCV if the operation is not as specified. See

(Figure 115).

Near cylinder head

Cleaning pipe

Figure 115

Near the intake manifold

Air

Figure 114

49

Page 57

Chapter 5 Exhaust System

(MR7131A, MR7151A, MR7161A)

Component1

50

Figure 116

Page 58

1. Detach tail exhaust pipe assembly

Remove 2 bolts and the tail exhaust pipe assembly.

2. Remove intermediate exhaust pipe assembly

Replace exhaust system

Detach 2 bolts and intermediate exhaust pipe assembly.

3. Detach front exhaust pipe assembly

Remove 2 bolts and front exhaust pipe assembly.

4. Install front exhaust pipe assembly

Using vernier calipers, measure the free length of the spring.

Free length: 42mm

Using the new gasket, install the front exhaust pipe to the exhaust manifold.

Notice:

z Do not use removed gasket any more.

5. Install front exhaust pipe assembly.

Torque: 43N. m

6. Install intermediate exhaust pipe assembly

Using the new gasket, install the intermediate exhaust pipe to the front exhaust pipe.

Torque: 44N. m

7. Install tail exhaust pipe assembly

Using the new gasket, install the tail exhaust pipe to the intermediate

exhaust pipe. See

T orque: 43N. m

(Figure 117).

Tail Pipe side

8. Check exhaust for leakage

Washer

Figure 117

51

Page 59

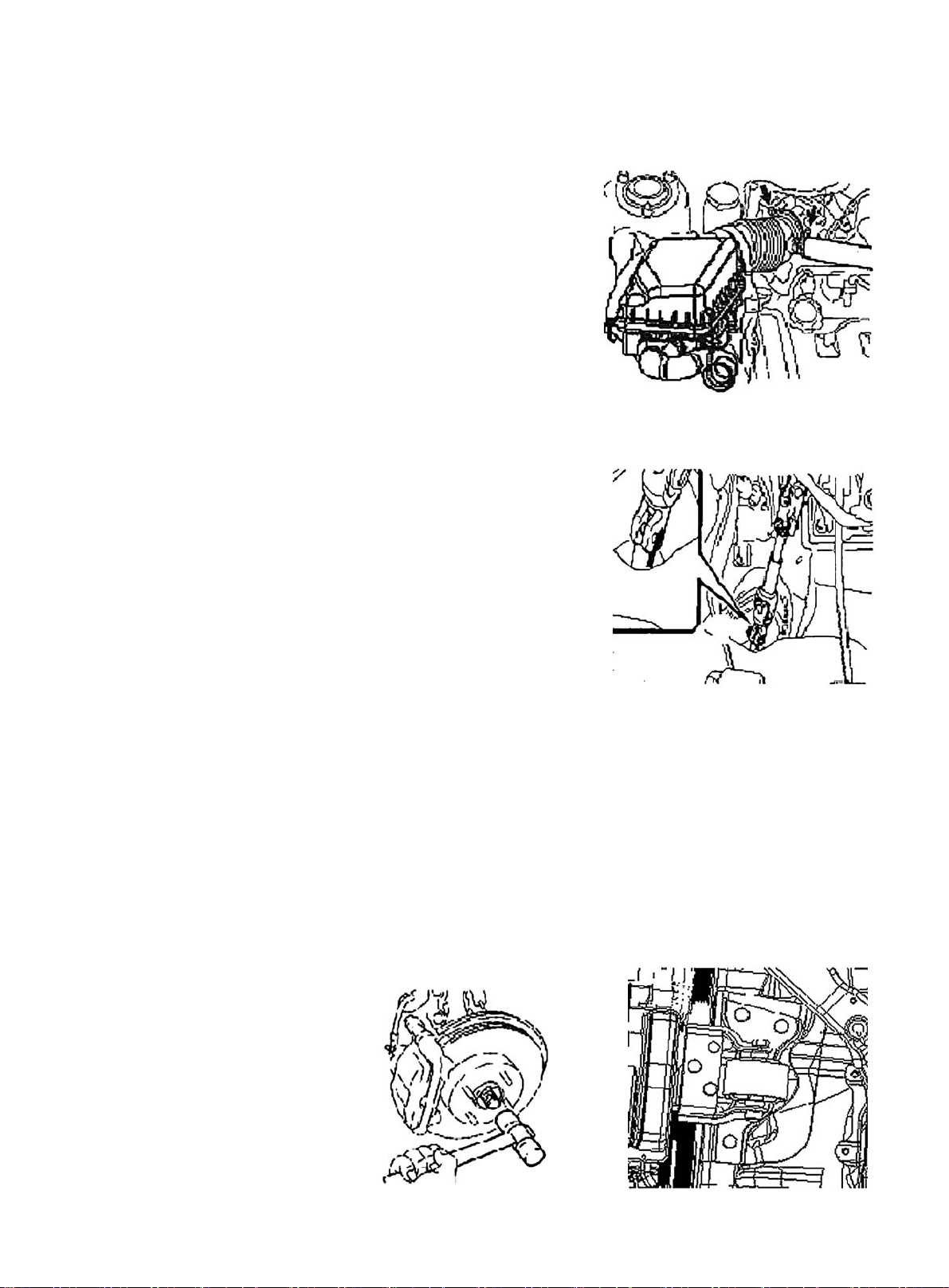

Chapter 6 Cooling System Inspection

(MR7131A, MR7151A, MR7161A)

Section 1 System Check

1. Check the cooling system for leakage. See (Figure 118)

(a) Fill coolant into radiator. Install the tester onto the radiator cap port.

(b) Start engine.

(c) The water pump pressure is 118Kpa. Check the pressure and ensure the

pressure will not drop. If the pressure drops, check the port, radiator and

water pump for leakage. If there is no leakage, check the heat exchanger,

cylinder block and cylinder head.

2. Check the engine coolant level in the reservoir.

The coolant level should be between low and full marks.

3. Check coolant quality

Radiator Cap Tester

Figure 118

(a) Remove radiator cap.

To avoid being scalded, do not remove radiator cap while the engine and

radiator are still hot, as fluid and steam can be sprayed under pressure.

(b) There should not be excessive deposits of rust or scale around the radiator,

and the coolant should be free from oil.

(c) Reinstall the radiator cap.

4. Thermostat

Hint:

The thermostat temp indicates the valve opening temperature.

See (Figure 119).

(a) Immerse the thermostat in water and gradually heat the water.

(b) Check the valve opening temperature. Valve opening temperature: 80 -- 84°C

(c) Check the valve lift. See (Figure 120, Figure 121). V alve lift: 8mm or mor at

95°C

(d) Check the thermostat is fully closed when the thermostat is at low temperature

( 77°C).

≤

5. Radiator cap valve

Figure 119

Figure 120

8.0mm or

More

Standard opening pressure: 93-123kpa

Minimum opening pressure: 78kpa

If the opening pressure is less thanminimum, replace the radiator cap.

52

Figure 121

Page 60

6. Fan

(1) Check the cooling fan operation with low temperature (Lower than

83°C)

(a) Turn the ignition switch to “ON” position.

(b) Check that the cooling fan stops.

(c) Pull out the water temperature sensor connector. See (Figure

122)

(d) Connect the water temperature sensor to car body with the

wire and ground the wire.

(e) Check the cooling fan operation.

(f) Insert water temperature sensor connector.

(2) Check the cooling fan operation with high temperature (over 93°C)

See (Figure 123)

(a) Start engine and make the coolant temp. higher than 93°C.

Disconnest

Figure 122

> 93°C

(b) Check that the cooling fan turns.

Replace it with water temperature switch if it doesn't run)

(3) Check the cooling fan. See (Figure 124)

(a) Disconnect the cooling fan connector.

(b) Connect the battery and ammeter to the connector.

(c) Check that the cooling fan rotates smoothly and check

the reading on the ammeter.

Standard amperage: 5.7 - 7.7A

(d) Reconnect the cooling fan connector.

Figure 123

Amperometer

Battery

Figure 124

53

Page 61

Section 2 Water Pump, Thermostat and Radiator Replacement

Hoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Replace water pump. See (Figure 125)

(1) Drain the coolant.

(2) Detach timing belt.

(3) Detach power steering pump assembly.

(4) Remove the oil dipstick guide.

(5) Detach water pump assembly.

(6) Install water pump assembly.

(7) The installation is in the reverse order of the removal.

2. Replace thermostat

(1) Remove thermostat (See Figure 126).

(2) Install thermostat.

a. Install a new gasket to the thermostat. See (Figure 127).

Figure 125

b.Align the main valve of the thermostat to the top of the

stud. Insert the thermostat into the water inlet case.

Hint:

The main valve is set at around 10°C as shown in the figure. See (Figure 128).

(3) Install inlet connector.

Figure 127 Figure 128

3. Replace radiator

(1) Open radiator cap.

(2) Open the drain valve and drain the coolant.

Figure 126

(3) Detach radiator water inlet hose.

(4) Detach radiator water outlet hose.

54

Page 62

(5) Disconnect auto-transmission oil cooler input pipe (Auto-transmission).

(6) Disconnect auto-transmission oil cooler output pipe (Auto-transmission).

(7) Remove 4 bolts from the radiator mounting bracket. See (Figure 129).

(8) Detach radiator assembly, Remove 3 bolts. Detach the fan and fan shroud. See (Figure 130).

Figure 127 Figure 128

(9) Install the cooling fan assembly

(a) Fix the reservoir assembly on the cooling fan bracket with the bolt. Torque: 16 N. m.

(b) Install the fan and fan shroud with 3 bolts. Torque: 7.5N. m.

(c) Install the cooling fan assembly to radiator assembly with 3 bolts. Torque: 16N. m.

(d) Connect the overflow pipe on the reservoir assembly and radiator assembly. Fix it with the spring

band.

(f) The installation of the radiator assembly is in the reverse order of the removal.

55

Page 63

Chapter 7 Clutch

(MR7131A, MR7151A, MR7161A)

Component 1 (Hydraulic Manipulation)

56

Figure 131

Page 64

Section 1 Clutch Replacement

Hoist the engine from the compartment. See "Provison 20, Section 2, Chapter 2".

1. Remove manual transaxle assembly

2. Remove the clutch release fork. See (Figure 132)

3. Detach clutch release fork boot.

4. Detach clutch release bearing

5. Detach clutch release bearing fixed clamp

6. Remove clutch fork pivot pin

7. Align the clutch cover to the mark on the flywheel. Detach clutch cover. See (Figure 133)

8. Remove clutch plate

9. Check and remove clutch plate assembly. See (Figure 134)

10. Check clutch cover. See (Figure 135)

Depth wear: A: 0.6mm

Width wear: B: 5mm

Figure 132 Figure 133

Figure 134 Figure 135

57

Page 65

11. Using the dial gauge, check the flywheel runout. See

(Figure 136).

The maximum runout: 0.3mm

12. Check clutch release bearing

The bearing is permanently lubricated. There is no need to

lubricate or clean.

13. Check clutch plate

14. Install clutch cover. See (Figure 137)

Align the Clutch cover to the mark on the flywheel.

Hint:

(1) Uniformly tighten the bolt in the sequence shown.

Torque: 19 N. m

(2) Shake the clutch plate up and down, left and right to ensure

it is centered, then tighten the bolt.

15. Check and adjust the clutch cover. See (Figure 138)

Check the diaphragm tip flatness with the dial gauge with roller.

Max. roughness: 0.5mm.

16. Install the release fork pivot pin

17. Install clutch release fork boot

18. Install clutch release bearing fixed clamp

19. Install clutch release fork

20. Install clutch release bearing

21. Install manual transaxle assembly

Figure 136

Figure 137

58

Figure 138

Page 66

Chapter 8 Maunal Transaxle Assembly

(MR7131A, MR7151A, MR7161A)

Component 1

Figure 139

59

Page 67

Section 1 Manual Transaxle Replacement

1. Open the engine hood

2. Remove the battery

3. Remove clutch cylinder sub-assembly. See (Figure 140)