Page 1

INSTALLATION

INSTRUCTIONS

Side by Side Refrigerators

With Design Guide

Monogram.com

Page 2

Safety Information

BEFORE YOU BEGIN

Read these instructions completely and carefully.

IMPORTANT – Save these instructions for

•

local inspector’s use. Observe all governing codes and

ordinances.

Note to Installer – Be sure to leave these

•

instructions with the Consumer.

• Note to Consumer – Keep these instructions with

your Owner’s Manual for future reference.

If you received a damaged unit, you should immediately

contact your dealer or builder.

Skill Level – Installation of this unit requires basic

mechanical, carpentry and plumbing skills. Proper

installation is the responsibility of the installer. Product

failure due to improper installation is not covered under

the Monogram Warranty. See the Owner’s Manual for

warranty information.

WARNING

Plug into a grounded 3-prong outlet.

Do not remove the ground prong.

Do not use an adapter.

Immediately discontinue use of a damaged supply cord.

If the supply cord is damaged it must be replaced by a

qualified service professional with an authorized service

part from the manufacturer.

WARNING

These appliances are top heavy, especially with any doors open, and must be secured to prevent tipping forward

which could result in death or serious injury. Read and follow the entire installation instructions for securing the

appliance with the anti-tip system.

WARNING

Keep flammable materials and vapors, such as gasoline, away from appliance. Failure to do so can result in fire,

explosion, or death.

WARNING

access to small parts during the installation of this product.

Electrical Shock Hazard.

Do not use an extension cord with this appliance.

Failure to follow these instructions can result in death,

fire, or electrical shock.

Follow the instructions in the section Grounding the unit.

This appliance must be installed with a means in the

fixed house wiring or circuit breaker for disconnecting the

appliance from the electrical supply after installation.

Tip Over Hazard.

Explosion Hazard.

To reduce the risk associated with choking, do not allow children under 3 years of age to have

CAUTION

This refrigerator is very heavy. To reduce the risk of person injury during maneuvering and installing this refrigerator, 3

people are required for proper installation of 36” wide model and 4 people are required for proper installation of a 42”

or 48” wide model.

CAUTION

and cabinet are necessarily small. Be careful closing doors when children are in the area.

For Monogram local service in your area, call 1.800.444.1845 or visit monogram.com.

For Monogram service in Canada, call 1.800.561.3344

For Monogram Parts and Accessories, call 1.800.444.1845 or visit monogram.com.

Lifting Hazard

Keep fingers out of the “pinch point” areas; clearances between the doors and between the doors

2

31-49171

Page 3

Consignes de Sécurité

AVANT DE COMMENCER

Veuillez lire toutes ces instructions attentivement.

• IMPORTANT – Conservez ces instructions à

l’usage de l’inspecteur local. Observez tous les codes et

décrets en vigueur.

Note à l’installateur – Assurez-vous de laisser ces

•

instructions au consommateur.

Note au consommateur - Conservez ces instructions

•

avec votre manuel d’utilisation pour

Si vous avez reçu un appareil endommagé, veuillez

communiquer immédiatement avec votre revendeur ou votre

entrepreneur.

consultation ultérieure.

Niveau de compétence – L’installation de cet appareil

exige des compétences de base en mécanique, menuiserie

et plomberie. La responsabilité d’une installation adéquate

relève de l’installateur. La garantie Monogram ne couvre

pas les défectuosités du produit causées par une installation

inadéquate. Consultez le manuel d’utilisation pour des

renseignements sur la garantie.

AVERTISSEMENT

Branchez l’appareil dans une prise à 3 broches mise à la terre.

N’enlevez pas la broche de mise à la terre.

N’utilisez pas un adaptateur.

Cessez immédiatement l’utilisation d’un cordon électrique

endommagé. Si le cordon électrique est endommagé, son

remplacement doit être exécuté par un technicien en réparation

qualifié au moyen d’un cordon de rechange autorisé par le

fabricant.

AVERTISSEMENT

Ces électroménagers sont lourds du haut, notamment lorsqu’une porte est ouverte, de sorte qu’ils doivent être fixés pour

prévenir un basculement vers l’avant susceptible d’occasionner des blessures graves ou la mort. Lisez et observez la totalité des

instructions d’installation pour connaître la façon de fixer l’électroménager sur le dispositif antibasculement.

AVERTISSEMENT

Gardez les matières et les vapeurs inflammables telles que l’essence à distance de l’électroménager. L’omission de prendre cette

précaution peut entraîner un incendie, une explosion ou la mort.

AVERTISSEMENT

à la portée des enfants âgés de moins de 3 ans.

Risque d’électrocution.

N’utilisez pas un cordon de rallonge avec cet électroménager.

Le non-respect de ces instructions peut occasionner un décès,

un incendie ou un choc électrique

Suivez les instructions de la section Mise à la terre de l’appareil.

Le circuit électrique auquel cet électroménager sera raccordé

doit comporter un disjoncteur ou un autre dispositif permettant

de couper l’alimentation électrique à l’appareil après l’installation.

Risque de basculement.

Risque d’explosion.

Pour réduire le risque d’étouffement pendant l’installation de ce produit, ne pas laisser les petites pièces

ATTENTION

Ce réfrigérateur est très lourd. Pour réduire le risque de blessure lors de la manutention de ce réfrigérateur, trois (3) personnes

sont nécessaires pour procéder à l’installation appropriée du modèle 36 pouces, quatre (4) pour l’installation des modèles 42 ou 48

pouces.

ATTENTION

l’armoire sont particulièrement restreints. Soyez prudent lorsque vous fermez les portes en présence d’enfants.

Risque lié à la manipulation d’un objet lourd

Gardez vos doigts éloignés des points de pincement. Les espaces entre les portes et ceux entre les portes et

Pour joindre le service Monogram de votre région, composez le 1.800.444.1845 ou visitez monogram.com.

Pour le service Monogram au Canada, composez le 1.800.561.3344.

Pour le service des Pièces et accessoires Monogram, composez le 1.800.444.1845 ou visitez monogram.com.

31-49171

3

Page 4

Contents

Safety 2, 3

Instructions for Standard Installation 5-22

Planning Guide

The Installation Space 6

Dimensions and Clearances 6

Customization Basics 7

Side Panels 7

Refrigerator Location 7

1/4” Framed Panel Dimensions 8

3/4” Overlay Panel Dimensions 9

130° Door Swing 10

90° Door Swing 11

Dispenser Trim 12

Installation Instructions

Tools, Hardware, Materials 13

Grounding the Unit 13

Step 1. Remove Packaging 14

Step 2. Move the Refrigerator into the House 14

Step 3. Install Water Line 14

Step 4. Installation with Filtration System 15

Step 5. Install Side Panels 15

Step 6. Anti-Tip Procedures 15

Step 7. Level Refrigerator 16

Step 8. Alternate Anti-Tip Procedure 16

Step 9. Adjust Door Swing 17

Step 10. Install Grille Panel 17

Step 11. Install 1/4” Framed Panels 18

Step 11A. Install Overlay Panels 19, 20

Step 12. Connect Water Supply 20, 21

Step 13. Connect Power, Close Grille Panel 21

Step 14. Start Icemaker 21

Step 15. Install Toekick 21

Inspect Final Installation 22

Instructions for Flush Installation 23-40

Planning Guide

The Installation Space 24

Dimensions and Clearances 24

Customization Basics 25

Custom Handle Design Guide 25

Refrigerator Location 25

Side Panels 25

1/2” Overlay Panel Dimensions 26

3/4” Raised Panel Dimensions 27

3/4” Raised Door Panel Routing 28

3/4” Raised Grille Panel Routing 29

Dispenser Trim 30

Side Cleats 30

Installation Instructions

Tools, Hardware, Materials 31

Grounding the Unit 29

Step 1. Remove Packaging 32

Step 2. Move the Refrigerator into the House 32

Step 3. Install Water Line 32

Step 4. Installation with Water Filtration System 33

Step 5. Install Side Panels 33

Step 6. Install Case Trim 33

Step 7. Anti-Tip Procedure 33-34

Step 8. Level Refrigerator 34

Step 9. Adjust Door Swing 35

Step 10. Install Grille Panel 36

Step 11. Install 1/4” Framed Panels 37

Step 11A. Install Overlay Panels 38

Step 12. Connect Water Supply 39

Step 13. Connect Power, Close Grille Panel 39

Step 14. Start Icemaker 39

Step 15. Install Toekick 40

Inspect Final Installation 40

Instructions for Stainless Steel Installation 41-49

Planning Guide

The Installation Space 42

Dimensions and Clearances 42

Customization Basics 43

Side Panels 43

Refrigerator Location 43

130° Door Swing 44

90° Door Swing 45

Installation Instructions

Tools, Hardware, Materials 46

Grounding the Unit 46

Step 1. Remove Packaging 47

Step 2. Moving the Refrigerator into the House 47

Step 3. Install Water Line 47

Step 4. Installation with Water Filtration System 48

Step 5. Install Side Panels 48

Step 6. Anti-Tip Procedure 48

Step 7. Level Refrigerator 49

Step 8, Alternate Anti-Tip Procedure 49

Step 9. Adjust Door Swing 49

Step 10. Connect Water Supply 50

Step 11. Connect Power, Close Grille Panel 50

Step 12. Start Icemaker 50

Step 13. Install Toekick 51

Inspect Final Installation 51

4

31-49171

Page 5

Instructions for Standard Installation

31-49171

5

Page 6

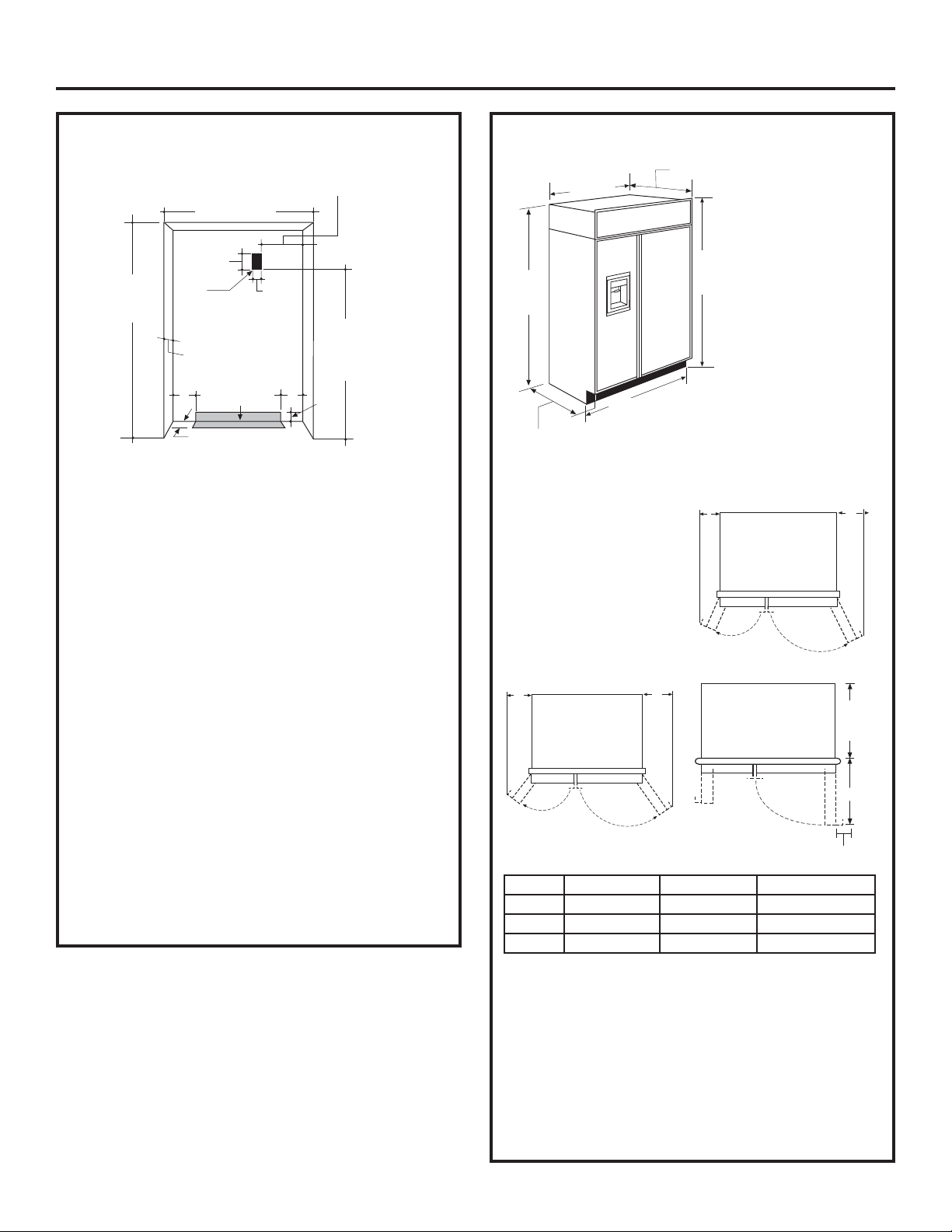

Design Guide - Standard Installation

THE INSTALLATION SPACE

36" Models 12"

42" Models 18"

48" Models 20"

*Finished Width

6"

85" max

Finished

Opening

*The finished cutout width must be:

35-1/2” (90.17 cm) for 36” models

41-1/2” (105.41 cm) for 42” models

47-1/2” (120.65 cm) for 48” models

Water And Electrical Locations

The opening must be prepared with the electrical and

the cold water supply located as shown.

The Cutout Depth Must Be 24” (60.96 cm)

The refrigerator will project forward, slightly beyond

adjacent cabinetry for standard installation.

Additional Specifications

• A 115 volt 60Hz., 15 or 20 amp power supply is

required. An individual properly grounded branch

circuit or circuit breaker is recommended. Install

a properly grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must be

located on the rear wall as shown.

• The water line can enter the opening through the

floor or back wall. The water line should be 1/4”

O.D. copper tubing or SmartConnect™ kit between

the cold water line and water connection location,

long enough to extend to the front of the refrigerator.

Installation of an easily accessible shut-off valve in

the water line is required.

Electrical

Area

24"

5"

Water Supply

3 1/2"

5"

75" From Floor

to Bottom

of Electrical

Area

5"

3 1/2"

DIMENSIONS AND CLEARANCES

35", 41", or 47"

Case Width

*83-1/2"

at

Rear

36", 42" or 48"

Frame to Frame

Depth Including Handles 26-7/8”

Product Clearances

These refrigerators are

equipped with a 3-position

door stop. The factoryset 115° door swing can

be adjusted to 130°, or

to 90° on panel models

or 90° on stainless steel

models if clearance to

adjacent cabinets or walls

is restricted.

130° Door Swing

(Panel Models Only)

A

Models A B C

36” 13”

42” 13” (33.02 cm) 19” (48.26 cm) 26-5/8” (67.63 cm)

48” 15” (38.1 cm) 20” (50.8 cm) 28-5/8” (72.71 cm)

(33.02 cm) 15” (38.1 cm) 20-5/8” (52.39 cm)

Panel Models Only: Allow minimum clearances for

the freezer door (Dimension A) and fresh food door

(Dimension B) for a full 130° door swing and to allow for

pan removal.

For a 90° door swing, allow 4” (10.16 cm) min.

clearance to a wall. If the 90° door stop position is used,

pan access is maintained, but pan removal is restricted.

See the illustrations on pages 10 and 11 to determine

door swing interaction with adjacent cabinets or

countertops.

25-3/8" Framed Models

* Shipping height. The

*84"

From

Floor

115° Door Swing

A

90° Door Swing

B

refrigerator can be

adjusted to fit into a

cutout that is 84-1/2”

214.63 cm) in

height. Use leveling

legs and wheels

for a maximum 1”

(2.54 cm) height

adjustment.

B

23-7/8"

Behind

Frame

C

4”

*Min. Distance

to Wall

6

31-49171

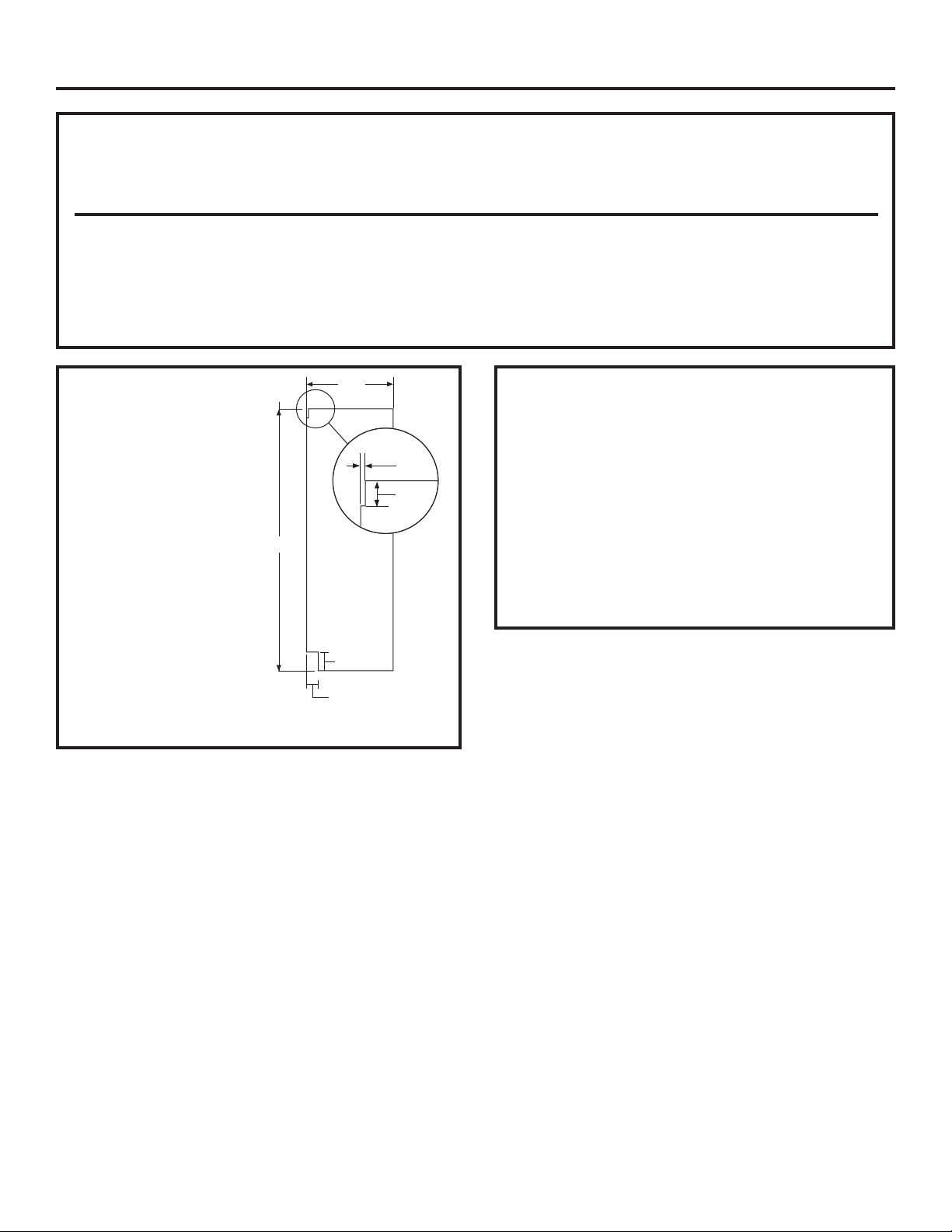

Page 7

Design Guide - Standard Installation

CUSTOMIZATION BASICS:

These refrigerators are designed to be customized with decorative panels. Field installed custom door and grille

panels are required.

Optional Accessory Kits

ZKHSS2: Monogram Tubular Stainless Steel handles

designed to fit 3/4” (1.91 cm) overlay panels.

ZKHPSS1: Professional Tubular Stainless Steel

handles designed to fit 3/4” (1.91 cm) overlay panels.

Kit includes one handle. Order 2 kits for side-by-side

refrigerator models from your Monogram supplier

SIDE PANELS

Side panels must be used

whenever the sides of

the refrigerator will be

exposed. The 1/4”

(0.63 cm) side panels will

slip into the side case trim.

Secure the panels to the

refrigerator with stick-on

hook and loop fastener

strips. Order the side

panels from the cabinet

manufacturer.

• Cut a notch in the top

front corner as shown

to allow clearance for

corner keys in the front

side trim.

* Depending on installation height.

*84"

24"

*3" to 4"

2-9/16"

3/16"

1-7/8"

REFRIGERATOR LOCATION

• Do not install the refrigerator where the

temperature will go below 55°F (13°C). It

will not run often enough to maintain proper

temperatures.

• Do not install the refrigerator where temperatures

will go above 100°F (37°C). It will not perform

properly.

• Do not install the refrigerator in a location

exposed to water (rain, etc.) or direct sunlight.

• Install it on a floor strong enough to support it

fully loaded.

31-49171

7

Page 8

"

Design Guide - Standard Installation

1/4” (0.63 cm) FRAMED PANEL DIMENSIONS

5/16"

If you choose to install framed panels, they must be cut to the

dimensions shown. The panels will slide into the frame on the

Door

door and grille.

Non-Dispenser Models

If the custom panel is less than 1/4” (0.63 cm) thick and it fits

loosely in the door frame it can be backed up with a piece of filler

material or foam tape to improve the fit.

IMPORTANT NOTE: Maximum total panel weight:

• Fresh food door panel – 75 lbs.(34.0 kg)

• Freezer door panel – 53 lbs. (24.0 kg)

• Grille Panel – 18 lbs. (8.16 kg)

IMPORTANT NOTE – DISPENSER MODELS

The refrigerator is supplied with two dispenser trims, one for framed panels and one for overlay panels.

• If the panel is less than 0.250” (0.63 cm) thick, a noticeable gap may be created around the dispenser trim. Foam

tape may be applied on the door to improve the fit.

• If the panel is more than 0.250” (0.63 cm) thick, the dispenser trim cannot be secured to the door.

See Dispenser Trim Fit Example, page 12.

Trim

Reveal

1/4"

Panel

Grille Panel

Dispenser

Cutout

G

Freezer

Panel

D

A

B

F

C

Dispenser Cutout

The framed panel must be 1/4” (0.63 cm) nominal

thickness to fit the dispenser trim.

15-3/8

9-5/8"

Dispenser Cutout

Fresh

Food

Panel

Side-by-Side (in inches)

ABCD E F G

36” Models 33-7/8 9 68-3/8 14-9/16 18-9/16 17-13/16 3-1/8

Position

42” Models 39-7/8 9-1/2 68-3/8 14-9/16 24-9/16 17-13/16 3-1/8

E

48” Models 45-7/8 9-1/2 68-3/8 18-9/16 26-9/16 17-13/16 5-1/8

8

31-49171

Page 9

"

Design Guide - Standard Installation

3/4” (1.91 cm) OVERLAY PANEL

DIMENSIONS

For a more custom appearance, overlay panels may

be installed on trimmed models. The overlay panel

must be secured to a 1/4” (0.63 cm) thick backer

panel which slides into the trim. A spacer panel 0.10”

(0.25 cm) thick must be placed between the overlay

Door

3/4"

Overlay

Panel

Overlay Panel

Spacer Panel

Backer Panel

and backer panel.

Assemble the panels with glue and screws:

• Center the spacer panel on the backer panel, left to

right and top to bottom. Secure the panels with glue.

• Center the spacer and backer panel on the overlay

panel and secure with glue and screws. Screws

must be countersunk into the backer panel.

1/4"

Backer

Panel

.250” + .10” + .750” = 1.100” Total Panel Thickness

0.63 + 0.25 + 1.91 = 2.79 cm

.10"

Spacer

NOTE: Left-to-right offset

is not always equal to topto-bottom offset.

IMPORTANT NOTE – DISPENSER MODELS

The refrigerator is supplied with two dispenser trims, one for framed panels and one for overlay panels. The

overlay dispenser trim is designed to fit a total panel thickness of 1.100”.

• If the panel is less than 1.100” (2.79 cm) a noticeable gap may be created around the dispenser trim.

• If the panel is more than 1.100” (2.79 cm) the dispenser trim cannot be secured to the door.

See Dispenser Trim Fit Example, page 12.

• The overlay panel must be constructed according to the specifications shown to achieve the correct total

thickness.

• Alternative panel construction methods such as securing a 3/4” (1.91 cm) panel to a 1/4” (0.63 cm) backer

panel cannot be used. Another method, routing a 3/4” (1.91 cm) thick panel on all sides, cannot be used.

These methods will not result in the required 1.100” (2.79 cm) panel thickness.

Grille Panel

Dispenser

Cutout

G

Freezer

Panel

D

A

B

F

Dispenser Cutout

15-3/8

*Cut the dispenser opening after the backer, spacer and overlay

panels have been assembled.

IMPORTANT NOTE: Maximum total weight for the

assembled panels:

• Fresh food door panel – 75 lbs. (34.0 kg)

• Freezer door panel – 53 lbs. (24.0 kg)

• Grille Panel – 18 lbs. (8.16 kg)

9-5/8"

Dispenser Cutout

Position

Fresh

Food

Panel

E

C

36” Side-by-Side (in inches)

ABCD E F G

1/4” Backer Panel 33-7/8 9 68-3/8 14-9/16 18-9/16

.10” Spacer Panel 33 8-3/8 67 13-1/4 17-1/4

3/4” Overlay Panel 34-1/8 9-1/4 68-5/8 14-13/16 18-13/16 17-13/16 3-1/4

42” Side-by-Side (in inches)

ABCD E F G

1/4” Backer Panel 39-7/8 9-1/2 68-3/8 14-9/16 24-9/16

.10” Spacer Panel 39 8-5/8 67 13-1/4 23-1/4

3/4” Overlay Panel 40-1/8 9-3/4 68-5/8 14-13/16 24-13/16 17-15/16 3-1/4

48” Side-by-Side (in inches)

ABCD E F G

1/4” Backer Panel 45-7/8 9-1/2 68-3/8 18-9/16 26-9/16

.10” Spacer Panel 45 8-5/8 67 17-1/4 25-1/4

3/4” Overlay Panel 46-1/8 9-3/4 68-5/8 18-13/16 26-13/16 17-15/16 5-1/4

31-49171

9

Page 10

Refrigerator

Design Guide - Standard Installation

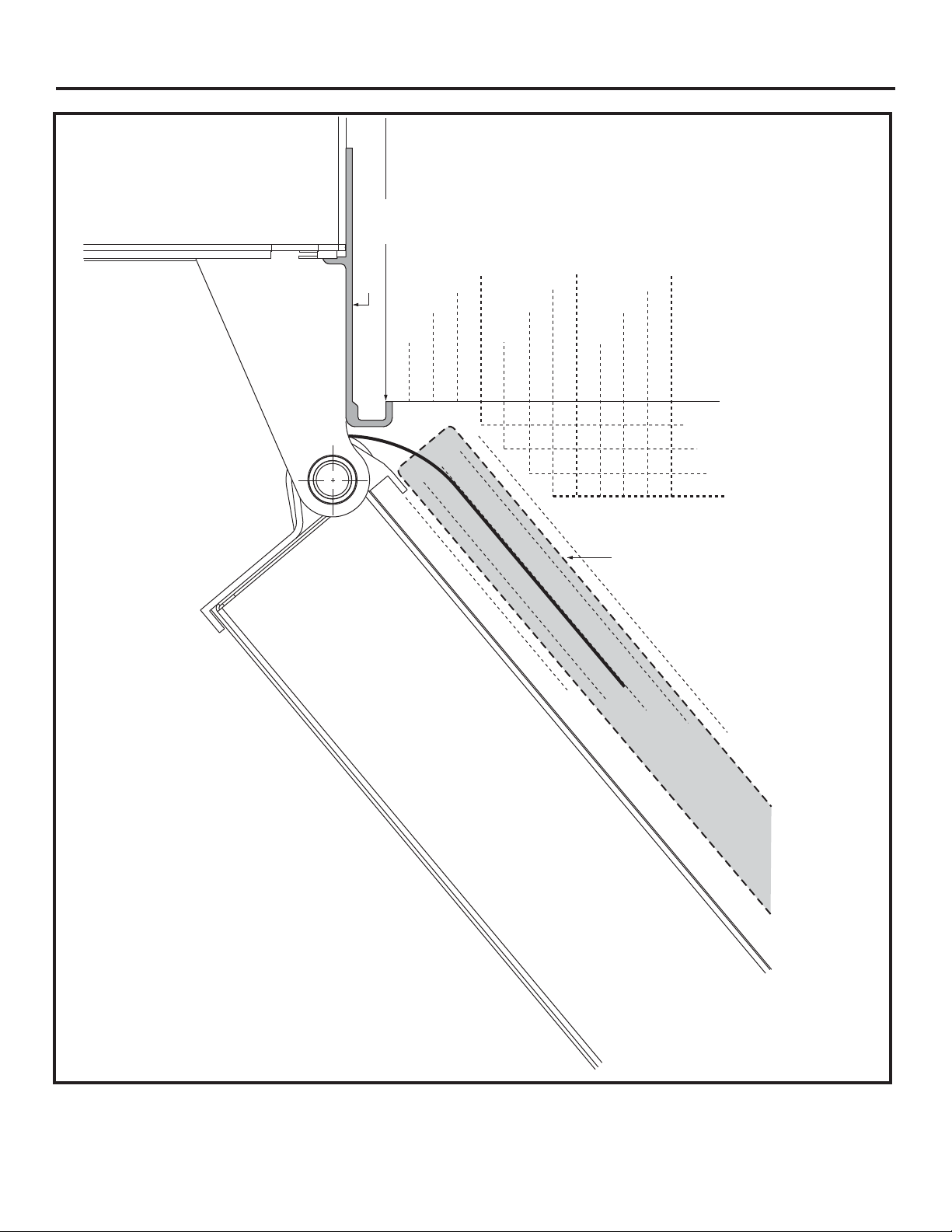

Frameless Cabinets: The case trim

overlaps cabinets at the top and sides.

Therefore, frameless cabinets may require

23-7/8" From

Rear of

Refrigerator

filler strips to prevent interfeence with

cabinet door swing. The opening must

allow for filler strips.

Top View

130° DOOR SWING

Scale 1:1

Case

Trim

Door

1/4"

1/2"

3/4"

1"

1-1/4"

2"

1-3/4"

1-1/2"

Stainless Steel

1/4"

2-1/2"

2-1/4"

3/4" Overlay

(Nominal Size)

1/2"

2-3/4"

Panel

3/4"

3"

1/4"

1/2"

3/4"

1"

1"

1-1/4"

IMPORTANT NOTE –

FOR DISPENSER MODELS:

Dispenser models are supplied with two

dispenser trims, one to fit framed panels

and one for overlay panels. Dispenser

trim fit to the custom panel depends on

correct panel thickness. Framed panels

must be 1/4” (0.63 cm) nominal. Overlay

panels should be constructed as shown

to accomplish a total 1.100” (2.79 cm)

thickness. See pages 19 and 20 for details.

10

31-49171

Page 11

Design Guide - Standard Installation

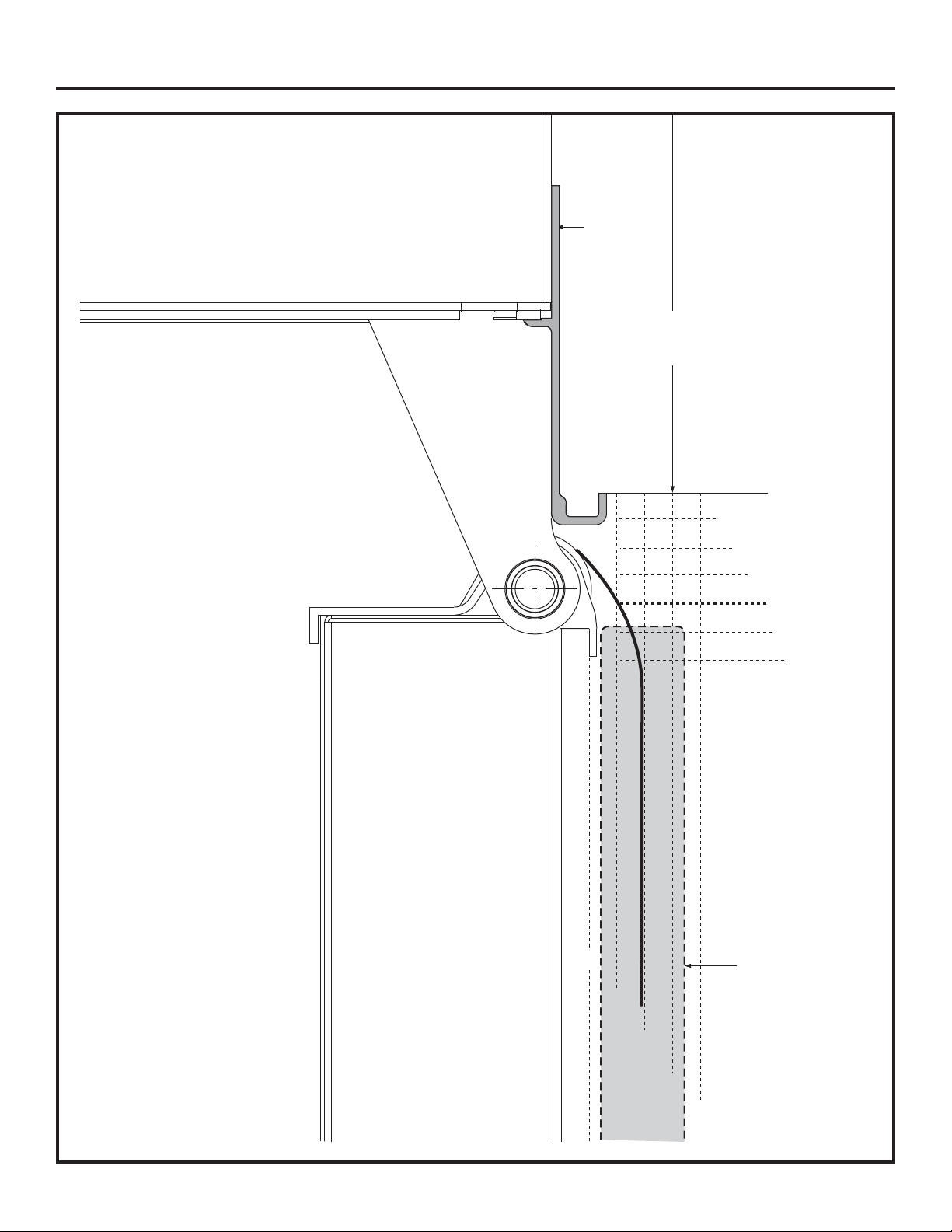

Frameless Cabinets:

The case trim overlaps

cabinets at the top

Refrigerator

Case Trim

23-7/8"

From Rear of

Refrigerator

and sides. Therefore,

frameless cabinets may

require filler strips to

prevent interference with

cabinet door swing. The

opening must allow for

filler strips.

1/4"

Top View

90° DOOR SWING

Scale 1:1

IMPORTANT NOTE –

FOR DISPENSER MODELS:

Dispenser models are supplied

with two dispenser trims, one

to fit framed panels and one for

overlay panels. Dispenser trim

fit to the custom panel depends

on correct panel thickness.

Framed panels must be 1/4”

(0.63 cm) nominal. Overlay

panels should be constructed

as shown to accomplish a total

1.100” (2.79 cm) thickness

pages 19 and 20 for details.

. See

Door

1/4"

1/2"

3/4"

1"

1-1/4"

1-1/2"

Stainless Steel

3/4" Overlay

Panel

(Nominal Size)

1/2"

3/4"

31-49171

1"

1-1/4"

11

Page 12

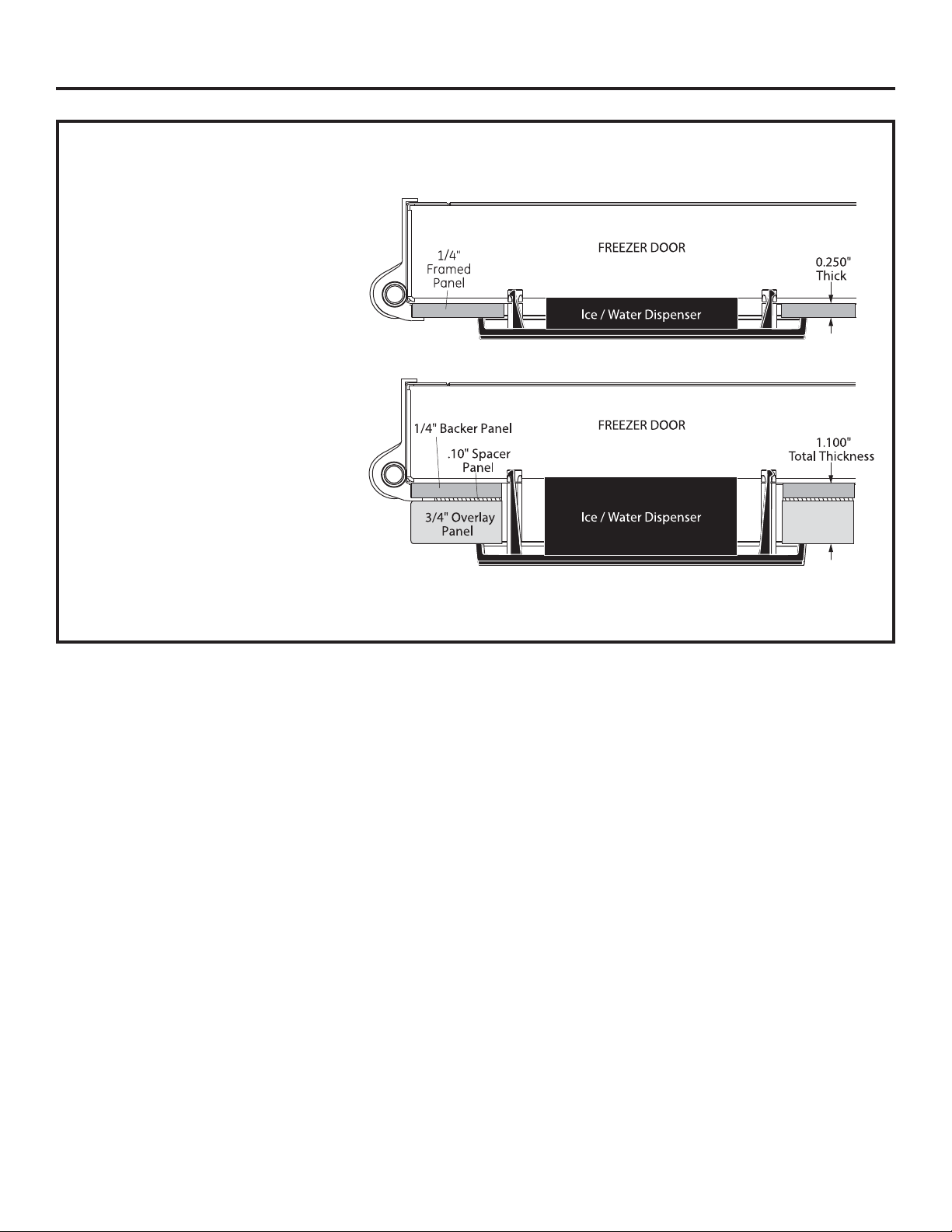

Design Guide - Standard Installation

DISPENSER TRIM FIT EXAMPLES:

(NOT TO SCALE)

1/4” (0.63 cm) FRAMED

PANEL

• The dispenser trim fits over the

custom panel and snaps into the freezer

door.

• The clips will not engage the door if

the panel is more than 0.250”

(0.63 cm) thick.

• If the panel is less than 0.250”

(0.63 cm) thick, a noticeable gap may

be created around the dispenser trim.

3/4” (1.91 cm) OVERLAY

PANEL

• The dispenser trim fits over the

custom panel and snaps into the

freezer door.

• The clips will not engage the door if

the panel is more than 1.100” (2.79

cm) thick.

• If the panel is less than 1.100” (2.79

cm) thick, a noticeable gap may be

created around the dispenser trim.

1/4” Dispenser Trim

3/4” Overlay Dispenser Trim

12

31-49171

Page 13

Installation Instructions - Standard Installation

TOOLS AND MATERIALS REQUIRED

• Tinsnips to cut banding

• Stepladder

• 1” Bit extension

• Tape measure

• Gloves

• 1/4” Drywall screws

• 5-Gal. Bucket with cover

• 6” Spirit level

• Appliance hand truck

• Tubing cutter

• 7/16” open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 5/16”, 7/16” socket

• Safety glasses

• 1-1/8” open end wrench

• Pliers

• 1/4”, 5/16” Combo Rachet

• 35” long 2x4 for Anti-Tip support

• 1/4” copper water line tubing or SmartConnect™

Refrigerator Tubing kits

• Water shut-off valve

• Custom panels for doors and grille panel

• Screws to secure refrigerator to cabinetry

• Stick-on hook and loop fastener strips for 1/4” side

panels

GROUNDING THE REFRIGERATOR

WARNING

Failure to follow these instructions can result in death,

fire, or electrical shock.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall receptacleto minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet

is encountered, it is your personal

responsibility and obligation to have

it replaced with a properly grounded

3-prong wall outlet.

DO NOT, UNDER ANY

CIRCUMSTANCES, CUT OR REMOVE THE THIRD

(GROUND) PRONG FROM THE POWER CORD.

DO NOT USE AN ADAPTER PLUG TO CONNECT

THE REFRIGERATOR TO A 2-PRONG OUTLET.

DO NOT USE AN EXTENSION CORD WITH THIS

APPLIANCE.

Electrical Shock Hazard.

HARDWARE SUPPLIED

• Water filter bypass plug

• Toekick

• 1/4” nut and ferrule

• Dispenser trim for overlay panels (for use with

Custom Panel models).

FLOORING

For proper installation, this refrigerator must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should

be strong enough to support a fully loaded refrigerator,

or approximately 1,500 lbs.(680.39 kg).

NOTE: Protect the finish of the flooring. Cut a large

section of the cardboard carton and place under

the refrigerator where you are working.

31-49171

MISE À LA TERRE DU RÉFRIGÉRATEUR

AVERTISSEMENT

électrique.

Le non-respect de ces instructions peut entraîner des

risques d’incendies, des chocs électriques ou la mort.

Le cordon d’alimentation de cet appareil est équipé

d’une fiche à trois broches (pour une mise à la terre)

qui s’adapte à la prise de courant standard à 3 broches

(pour une mise à la terre) pour minimiser les risques de

chocs électriques par cet appareil.

Faites vérifier la prise murale et le circuit électrique par

un électricien qualifié pour s’assurer que le système est

correctement mis à la terre.

Dans le cas d’une prise biphasée,

l’installateur a la responsabilité et

l’obligation de la remplacer par une prise

triphasée correctement mise à la terre.

NE COUPEZ PAS OU N’ENLEVEZ

PAS, SOUS AUCUN PRÉTEXTE, LA

TROISIÈME BROCHE DE MISE À LA TERRE DU

CORDON D’ALIMENTATION.

N’UTILISEZ PAS D’ADAPTATEUR POUR BRANCHER

LE RÉFRIGÉRATEUR À UNE PRISE BIPHASÉE.

N’UTILISEZ PAS DE RALLONGE AVEC CET

APPAREIL.

13

Risque de choc

Page 14

Installation Instructions - Standard Installation

STEP 1 REMOVE PACKAGING

WARNING

The refrigerator is much heavier at the top than at the

bottom—be careful when moving. When using a hand

truck, handle from the side only.

AVERTISSEMENT

basculement Le réfrigérateur est beaucoup plus

lourd en haut qu’en bas. Il faut être prudent lors des

déplacements. Si un diable est utilisé, il faut soulever

le réfrigérateur sur le côté seulement.

• Carefully cut banding at the top and bottom, remove

the outer carton.

• Slide out the back corner posts (2).

• Slide the carton off the top of the cabinet.

NOTE: IT IS NOT NECESSARY TO LAY THE

CABINET DOWN IN ORDER TO REMOVE THE

SKID!

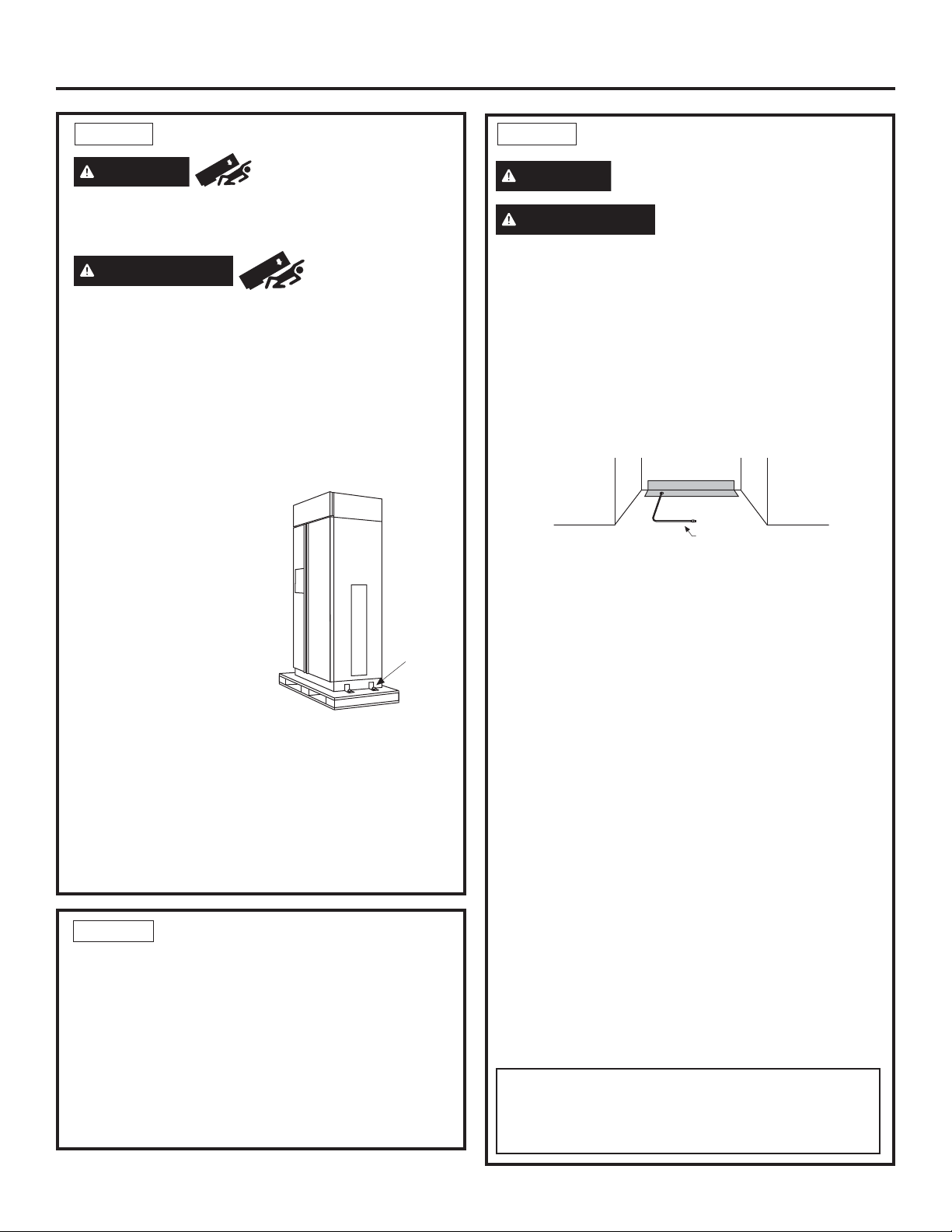

• The unit is secured to the

skid with 4 slotted tie-down

straps. Remove the six

7/16” bolts from the base

channels in the tie-downs.

• Remove the six 7/16” bolts

securing the straps to the

skid.

NOTE: DO NOT ATTEMPT

TO ROLL UNIT OFF SKID.

• The support blocks on the

bottom of the refrigeration

case must be removed before the refrigerator is

taken off the skid or damage will occur. Carefully

tilt the refrigerator and slide the blocks out from

beneath.

• Remove the toekick and set aside for final

installation.

• Lift the refrigerator off the skid with an appliance

dolly. Handle from the sides.

Tip Over Hazard.

Risque de

Remove

Toekick

Tie Downs

STEP 2 MOVE THE REFRIGERATOR

INTO THE HOUSE

• Re-use the corner posts from the packaging to

protect stainless steel models. Run the appliance

dolly straps over the posts and under the handles.

• Leave the protective film on the refrigerator until

installation is complete. IMPORTANT: Never lift the

refrigerator by the handle or push against the grille

panel; this could cause damage or misalignment.

• Avoid laying the unit on its back or side to prevent

sealed system restrictions.

STEP 3 INSTALL WATER LINE

WARNING

AVERTISSEMENT

alimentation d’eau potable seulement.

• A cold water supply is required for automatic

icemaker operation. The water pressure must be

between 40 and 120 p.s.i. (275-827 kPa).

• Route 1/4” OD copper or SmartConnect™ plastic

tubing between house cold water line and the water

connection location.

• The tubing should be long enough to extend to the

front of the refrigerator. Allow enough tubing to

accommodate the bend leading into the water line

connection.

NOTE: The only Monogram approved plastic tubing is

supplied in the SmartConnect™ Refrigerator Tubing kits.

Do not use any other plastic water supply line because

the line is under pressure at all times. Other types of

plastic may crack or rupture with age and cause water

damage to your home.

SmartConnect™ Refrigerator Tubing Kits are available

in the following lengths:

2’ (.6 m) WX08X10002

8’ (2.4 m) WX08X10006

15’ (4.6 m) WX08X10015

25’ (7.6 m) WX08X10025

Shut off the main water supply.

Turn on the nearest faucet long enough to clear the line

of water.

• Install a shut-off valve between the icemaker water

valve and cold water pipe in a basement or cabinet.

The shut-off valve should be located where it will be

easily accessible.

• Turn on the main water supply and flush debris.

Run about a quart of water through the tubing into a

bucket. Shut off the water supply at the shut-off valve.

NOTE: Saddle type shut-off valves are included in

many water supply kits. Before purchasing, make sure

a saddle type valve complies with your local plumbing

codes.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

Connect to potable water supply

only.

Raccordez l’appareil à une

Floor

Cold Water Line

14

31-49171

Page 15

Installation Instructions - Standard Installation

STEP 4 INSTALLATION WITH

HOUSEHOLD WATER

FILTRATION SYSTEM

Skip this step if you do not have a household

water filtration system

If the water supply to the refrigerator is from any

household water filtration system, the filter cartridge

should be removed. For better ice and water

performance, remove the filter and install the filter

bypass plug.

Rotate Counterclockwise

to Remove

Filter Bypass

Plug

STEP 5 INSTALL SIDE PANELS

Skip this step when not using side panels.

If you are using 1/4” (0.63 cm) side panels, they

should be inserted into the case trim. Fasten the

panels to the refrigerator with stick-on hook and loop

fastener strips before setting the refrigerator in place.

STEP 6 ANIT-TIP PROCEDURE (Cont.)

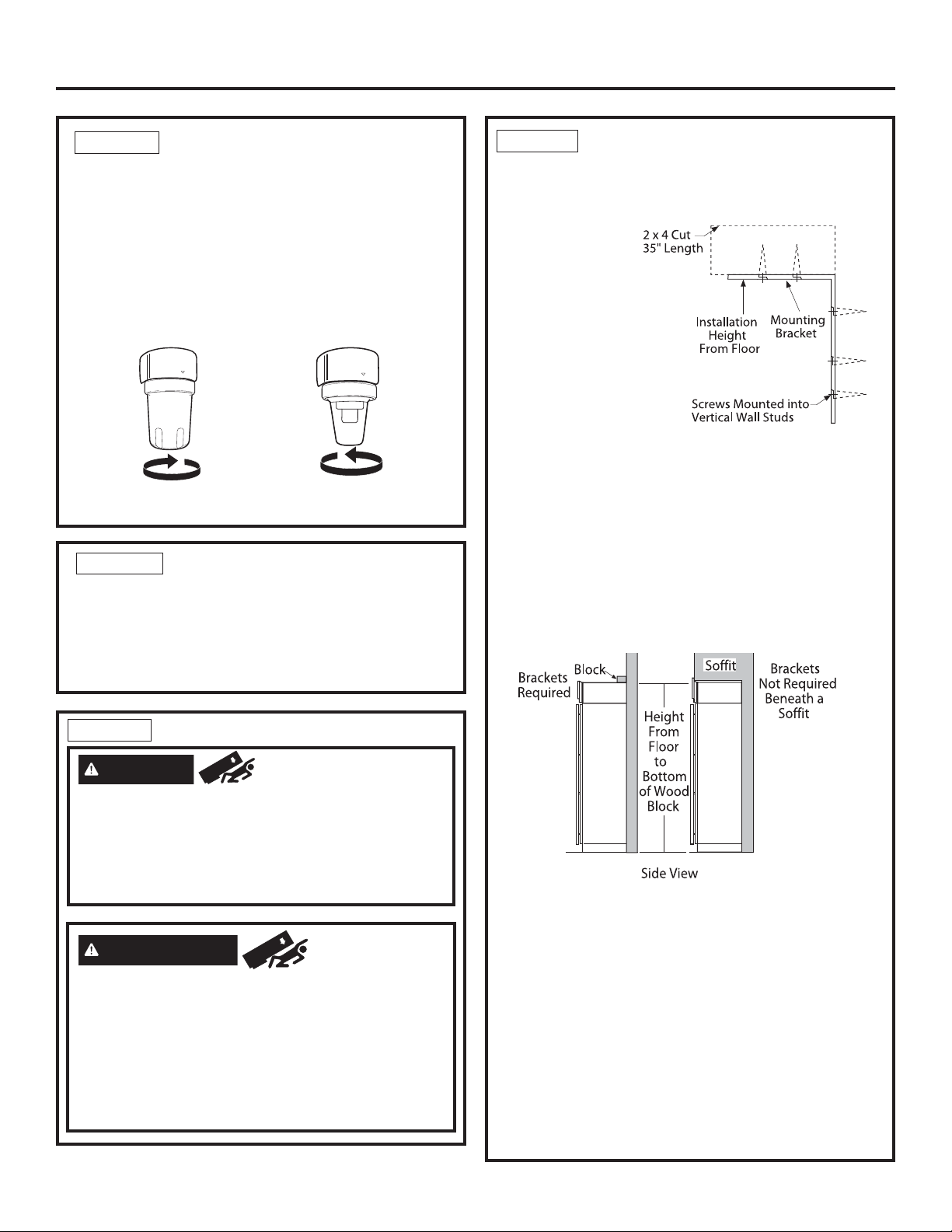

• Cut a 2” x 4” block, 35” (88.9 cm) long and secure

the block to the mounting brackets provided using

#12 or #14 wood screws.

• Secure the

bracket with

wood block to

the back wall

so that it is 84”

(213.36 cm)

from the finished

floor. Use #12

or #14 wood

screws. See the

illustration.

• The screws must

penetrate at least one inch into the vertical wall

studs.

• If metal wall studs, use self-tapping sheet metal

screws in place of wood screws.

IMPORTANT: When the refrigerator is installed under

a soffit or if there is not enough height for this method

of security, brackets cannot be used. Proceed to step

7 to level the refrigerator and then to step 8 to secure

refrigerator to cabinets.

secured to prevent tipping.

The refrigerator must be

STEP 6

WARNING

These refrigerators are top heavy, especially with

any doors open, and must be secured to prevent

tipping forward which could result in death or

serious injury. Read and follow the entire installation

instructions for securing the refrigerator with the antitip system.

AVERTISSEMENT

basculement

Ces réfrigérateurs présentent une partie supérieure

lourde, en particulier avec une porte ouverte; ils

doivent donc être fixés pour prévenir le basculement

vers l’avant et le risque concomitant de blessure

grave ou fatale. Lisez et suivez les instructions

d’installation complètes pour l’installation du système

anti-basculement.

ANTI-TIP PROCEDURE

Tip Over Hazard.

Risque de

Connect Power Cord:

• Before pushing the refrigerator into the opening,

plug the power cord into the receptacle. The water

filter guard will need to be removed for access

(some models). Remove the 3 screws holding it

in place. If access is still too tight, remove the 2

screws holding the water filter bracket and move

aside. Open the grille panel and reach into the

opening at the back to grasp the power cord. Pull

the power cord into the opening as you push the

refrigerator back. Secure the bracket and guard with

the original screws.

• Gently push refrigerator into the opening with hands

against front corners.

31-49171

15

Page 16

Installation Instructions - Standard Installation

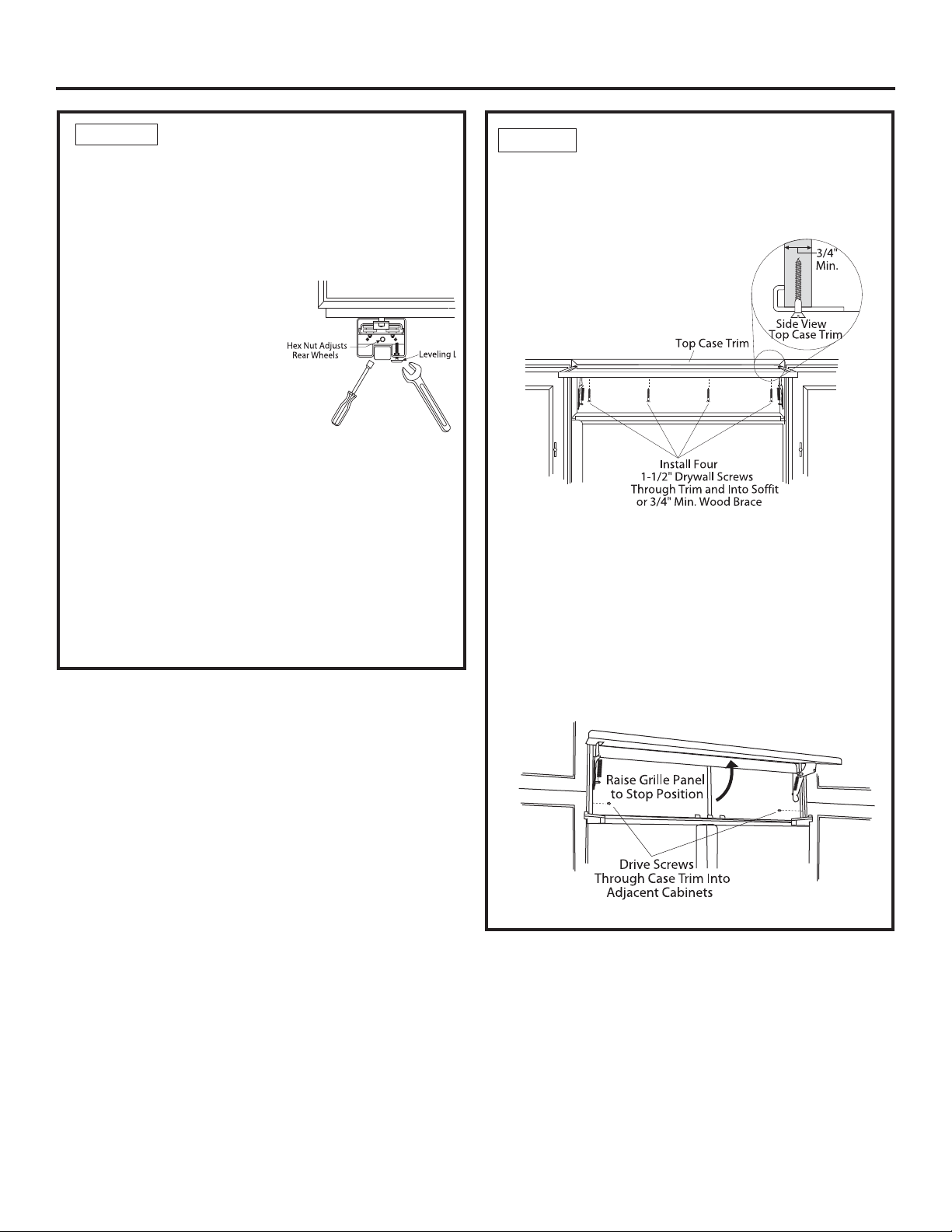

STEP 7 LEVEL REFRIGERATOR

All models have 4-point leveling. The front is

supported by leveling legs, the rear is supported by

adjustable wheels. Both are accessible from the front

of the refrigerator.

• To level the back of the refrigerator, turn the 7/16”

hex nut located above the front wheels. Turn

clockwise to raise or counterclockwise to lower the

refrigerator.

• For front leveling, use a

1-1/4” open-end wrench.

• Adjust height of refrigerator

to match installation cutout

opening 84-1/2”

(214.63 cm). The refrigerator

should be level and plumb

with cabinetry.

NOTICE: The rear leveling wheels and front leveling

legs are limited to a maximum height adjustment of

1” (2.54 cm). If the installation requires more than

84-1/2” (214.63 cm) height, the installer should

elevate the refrigerator on a sheet of plywood or

runners. Cabinetry trim could also be added across

the top of the opening to shorten the opening. If you

attempt to raise the refrigerator more than 1”

(2.54 cm), you will damage the front leveling legs

and the rear leveling wheels. Make adjustments in

small increments.

STEP 8 ALTERNATE ANTI-TIP

PROCEDURE

The refrigerator must be secured to prevent tipping.

• Raise the grille panel to access case trim.

• Use a 3/16” bit to drill four evenly spaced clearance

holes through the metal top case trim.

• Use a 1/16” bit to drill to pilot holes through the metal

clearance holes and into the wood soffit. The holes

should be centered in the soffit or a 3/4” (1.91 cm)

min. wood brace. The brace spanning the enclosure

must be securely fastened to cabinets on both sides.

• Install four, 1-1/2” drywall screws into the pilot holes.

• Drill screws into adjacent cabinets through side case

trim.

16

31-49171

Page 17

Installation Instructions - Standard Installation

STEP 9 ADJUST DOOR SWING

NOTE: This refrigerator has a 3-position door stop:

90°, 115°, and 130°. When space does not allow the

door to swing open fully to 115°, you may change

the door swing to a 90° opening. A 130° door swing

option is available for standard installation only. Skip

this step if door opening is satisfactory for your

installation situation.

• Open the door to view the bottom hinge. Note the

door stop pin locations. The pin is factory installed in

the 115° position.

• Close the door. From below, use pliers to unscrew

the door stop and reinstall into the 130° or 90°

position.

STEP 10 INSTALL GRILLE PANEL

To insert the framed or overlay panel into the

grille:

• Raise the grille panel to the stop position.

Loosen

Side

Trim

Screw

Adjust Nut Below

Spring to Accommodate

Panel Weight

• Loosen the screws on the side trim behind the frame.

Remove the bottom trim.

Loosen

Side

Trim

Screw

CAUTION

The metal panel may be slippery. Grip the metal

panel firmly so the panel does not slip out of the

frame and cause personal injury or damage to the

frame.

ATTENTION

ATTENTION AUX ARÊTES VIVES

Le panneau en métal peut bêtre glissant. Tenir

fermement le panneau en métal, de manière à ce

que le panneau ne glisse pas en dehors du cadre

en provoquant des blessures corporelles ou des

dommages au cadre.

• Slide the panel over the metal backer panel and into

the trim.

• If necessary, tap with a wood block until the panel

slips under the top trim piece.

• Reassemble the bottom trim. Tighten the screws.

• Adjust the hinge spring to accommodate the panel

weight, if necessary.

SHARP EDGE HAZARD

RISQUE DE COUPURE :

31-49171

17

Page 18

Installation Instructions - Standard Installation

STEP 11 INSTALL 1/4” (0.63 cm) FRAMED PANELS

Install door panels:

• Open the door to 90°. Remove the 6 Phillips head

screws from the door handle.

• Remove the handle. Retain all screws.

• Remove the 6 screws holding the trim, then lift off the

trim. Retain the screws.

• Slide the framed panel into the door trim.

Dispenser Models Only:

• The dispenser controls protrude beyond the face of the

freezer door. To avoid damage to the dispenser, the

trim at the top of the door should be removed.

• Remove the screws holding the top trim in place.

• Place the freezer panel into the bottom channel and

slide into the hinge side trim.

• Reinstall the top trim piece with screws.

Go to Step 12A for Overlay Panels

Supplied Handle

Shown in 1/4”

Panel Position

• There are two sets of holes in the handle side trim.

Replace the handle side trim by installing the original

screws in the FRONT screw holes.

• Secure the handle to the door using the REAR screw

holes.

• Follow the same procedures to install the opposite

panel.

• Check to be sure the handles are evenly aligned with

each other at the top. To adjust, loosen the handle

screws and slide up or down. Tighten the screws.

NOTE: Aluminum cover trim is supplied for use with

custom handles on overlay panels. It is not intended for

use with 1/4” (0.63 cm) panels. Discard the cover trim

when using 1/4” (0.63 cm) framed panels.

18

31-49171

Page 19

Installation Instructions - Standard Installation

STEP 11A INSTALL OVERLAY PANELS

Install door panels:

• Open door to 90°. Remove the 6 Phillips head screws

from the door handle.

• Remove the handle. Retain all screws.

• Remove the 6 screws holding the trim, then lift off the

trim. Retain the screws.

• Slide the overlay panel into the door trim.

Dispenser Models Only:

• The dispenser controls protrude beyond the face of

the freezer door. To avoid damage to the dispenser,

the trim at the top of the door should be removed.

• Remove the screws holding the top trim in place.

• Place the assembled freezer panel into the bottom

channel and slide into the hinge side trim.

• Reinstall the top trim piece with the screws.

• There are two sets of holes in the handle side trim.

Replace handle side trim by installing the original

screws in the REAR screw holes.

• Secure the handle to the door using the FRONT

screw holes.

• Follow the same procedures to install the opposite

panel.

• Check to be sure the handles are evenly aligned with

each other at the top. To adjust, loosen the handle

screws and slide up or down. Tighten the screws.

Supplied Handle

Shown in Overlay

Panel Position

31-49171

19

Page 20

Installation Instructions - Standard Installation

STEP 11A INSTALL OVERLAY PANELS

(continued)

Custom Handles

• If you are using custom handles, the handle must e

properly secured to the overlay panel before sliding

the panel into the trim.

• The cabinet manufacturer will supply the custom

handle and hardware.

• Discard the supplied handle.

Reinstall all original screws.

• Reinstall the handle side trim, using all 12 supplied

flat-head screws, plus the 12 flat-head screws

originally installed in the handle trim.

• Install a supplied end cap onto the top of the door,

using a Phillips head screwdriver and the 2 screws

provided. Hand-tighten the screws into the end

caps. Do not overtighten; damage will occur.

• Clean the aluminum trim with rubbing alcohol—

do not use alcohols with oil or lanolin that will prevent

adhesion of double-sided tape.

• Slip the aluminum cover onto the top bracket to check

the fit. The aluminum cover trim has a slot on each

end which fits the bracket.

STEP 11A INSTALL OVERLAY

PANELS (continued)

• Carefully place the aluminum cover trim onto the top

bracket so that the bracket is inside the cover trim.

Use the top to bottom grooves along the handle side

to align the cover trim accurately. Align the bracket

with the screw holes in the top of the door. Pull the

tape a few inches at a time while pressing the trim

against the door. Press and hold approximately 10

seconds before continuing along the length of the

door.

• Install another bracket at the bottom of the door to

secure the cover trim. Use a stubby Phillips head

screwdriver and the 2 screws provided.

• NOTE: Make sure there are no gaps in the

installation.

• Follow the same procedure on the opposite door.

STEP 12 CONNECT WATER SUPPLY

Refrigerator

Water Supply

House

Water Supply

Top Bracket

Slide aliminum

trim over top

bracket.

Top Bracket

Secure top

bracket with

2 screws.

• Remove the trim. Peel away a few inches of the

adhesive backing.

IMPORTANT: The tape is very sticky and strong.

Once it adheres to a surface, it cannot be removed

without damaging both surfaces. Do not install the

trim before the final wood panels are in place. Be

sure to align the trim carefully before removing the

paper backing.

• Locate and bring the tubing to the front of the

cabinet.

• Turn the water on to flush debris from the line. Run

about a quart of water through the tubing into a

bucket, then shut off the water.

Copper Tubing:

• Slip a 1/4” nut and ferrule (provided) over both ends

of the copper tubing. Insert the tube into the union

fitting on the unit and tighten the nut to the union.

• Turn on the water to check for leaks.

SmartConnect™ Tubing:

NOTE: The only Monogram-approved plastic tubing

is supplied in the SmartConnect™ Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other

types of plastic may crack or rupture with age and

cause water damage to your home.

20

31-49171

Page 21

Installation Instructions - Standard Installation

STEP 12 CONNECT WATER SUPPLY

(continued)

SmartConnect™ Refrigerator Tubing Kits are available

in the following lengths:

2’ (.6 m) WX08X10002

8’ (2.4 m) WX08X10006

15’ (4.6 m) WX08X10015

25’ (7.6 m) WX08X10025

• Insert the molded end of the tubing into the

refrigerator connection. Tighten the compression nut

until it is just hand tight.

• Tighten one additional turn with a wrench.

Overtightening can cause leaks!

• Turn on the water to check for leaks.

NOTE: Make sure excess tubing length does not

interfere with the toekick installation.

STEP 13 CONNECT POWER, CLOSE

GRILLE PANEL

• Open the grille panel.

• Plug in the power cord (if necessary) by reaching

into the opening next to the water filter. The water

filter guard will need to be removed for access (some

models). Remove the 3 screws holding it in place. If

access is still too tight, remove the 2 screws holding

the water filter bracket and move aside. Plug in the

power cord. Secure the bracket and guard with the

original screws.

Screws

Bracket

Screws

Water Filter

Guard in Front of

Electric Outlet

Access

STEP 14 START ICEMAKER

CAUTION

of the ejector mechanism, or with the heating element

(located on the bottom of the icemaker) that releases

the cubes. Do not place fingers or hands on the

automatic ice making mechanism while the refrigerator

is plugged in.

ATTENTION

pièces mobiles du mécanisme d’éjection ou l’élément

chauffant (situé dans le bas de la machine à glaçons)

qui libère les cubes. Ne placez pas les doigts ou

les mains sur le mécanisme de production de glace

automatique lorsque le réfrigérateur est branché dans

la prise électrique.

• Slide the power switch to ON.

• The icemaker will begin operation automatically.

• Be sure nothing interferes with the sweep of the feeler

arm.

• Discard the first full bucket of ice cubes.

• To turn the icemaker off, slide the switch to OFF.

Avoid contact with the moving parts

Évitez tout contact avec les

Icemaker

Power

Switch

Feeler Arm

STEP 15 INSTALL TOEKICKS

• Locate the supplied toekicks (shipped taped to the

side of the refrigerator.

• The narrower set of toe kicks will be used with

standard installation. You can discard the other set of

toe kicks.

• Attach the LARGER toekick to the refrigerator using

ONLY the top center hole (1).

• Attach the toekick skirt to the refrigerator using the

three lower slots (2).

• Check to make sure power to refrigerator is on by

opening refrigerator door to see if interior lights are on.

• The temperature controls are preset at 37°F (3° C) for

the fresh food section and 0°F (-18°C) for the freezer.

• Allow 24 hours to stabilize before making adjustments.

31-49171

1

2

• A custom toekick can be installed to match or

complement the surrounding cabinetry. Use the

supplied toekick as a template to cut the shape.

21

Page 22

Installation Instructions - Standard Installation

INSPECT FINAL INSTALLATION

Check door alignment. Stand back away from the

refrigerator to inspect the final installation.

• Check to be sure the handles are evenly aligned with

each other at the top. To adjust, loosen the handle

screws and slide up or down. Tighten the screws.

• Shipping or the addition of heavy door panels may

have caused the doors to move slightly out of

alignment.

Door Out of

Alignment

Bushing

Door Hinge

Case Hinge

Raise

• If necessary, the fresh food door may be adjusted

up or down to align with the freezer door.

• Use a 5/16” wrench to adjust the hinge pin as

shown.

5/16" Wrench

22

31-49171

Page 23

Instructions for Flush Installation

31-49171

23

Page 24

Design Guide - Flush Installation

THE INSTALLATION SPACE

36" Models 12"

42" Models 19"

48" Models 22-1/4"

*Finished Width

6"

85" max

Finished

Opening

*Finished cutout width must be:

39” (99.06 cm) for 36” models

45” (114.3 cm) for 42” models

51” (129.54 cm) for 48” models

Water And Electrical Locations

The opening must be prepared with the electrical and

the cold water supply located as shown.

The Cutout Depth Must Be 26-3/16” (66.99 cm)

Wooden cleats are required for flush installation. See

Side Cleats on page 27. If 3/4” (1.91 cm) Overlay

panels w/ 90 degree door swing are to be used

then cutout depth must be 26-1/4” (66.68 cm)

Additional Specifications

• A 115 volt 60Hz., 15 or 20 amp power supply is

required. An individual properly grounded branch

circuit or circuit breaker is recommended. Install

a properly grounded 3-prong electrical receptacle

recessed into the back wall. Electrical must be

located on the rear wall as shown.

• The water line can enter the opening through the

floor or back wall. The water line should be 1/4”

O.D. copper tubing or SmartConnect™ kit between

the cold water line and water connection location,

long enough to extend to the front of the refrigerator.

Installation of an easily accessible shut-off valve in

the water line is required.

Electrical

Area

26-3/16"

7"

Water Supply

3 1/2"

5"

75" From Floor

to Bottom

of Electrical

Area

7"

3 1/2"

DIMENSIONS AND CLEARANCES

35", 41", or 47"

Case Width

83-1/2"

at

Rear

36", 42" or 48"

Frame to Frame

Depth Including Handles 26-7/8”

Product Clearances

These refrigerators are equipped with a 3-position door

stop. The factory-set 115° door swing can be adjusted

to 90° if clearance to adjacent cabinets or walls is

restricted. Only standard installation can be adjusted to

130°.

115° Door Swing

A

Models A B C

36” 13”

42” 13” (33.02 cm) 19” (48.26 cm) 26-5/8” (67.63 cm)

48” 15” (38.1 cm) 20” (50.8 cm) 28-5/8” (72.71 cm)

(33.02 cm) 15” (38.1 cm) 20-5/8” (52.39 cm)

Allow minimum clearances for the freezer door

(Dimension A) and fresh food door (Dimension B) for

a full 115° door swing and to allow for pan removal.

25-3/8" Framed Models

* Shipping height.

*84"

From

Floor

90° Door Swing

B

The refrigerator can

be adjusted to fit

into a cutout that is

85” (215.9 cm) in

height. Use leveling

legs and wheels

for a maximum 1”

(2.54 cm) height

adjustment.

23-7/8"

Behind

Frame

C

*Min. Distance

to Wall

*4” Stainless and

Trimmed Models.

5” Pro Series

For a 90° door swing, allow 4” (10.16 cm) min.

clearance to a wall, for framed and stainless steel

models. Allow 5” (12.7 cm) min. clearance for

professional series models. If the 90° door stop

position is used, pan access is maintained, but pan

removal is restricted.

24

31-49171

Page 25

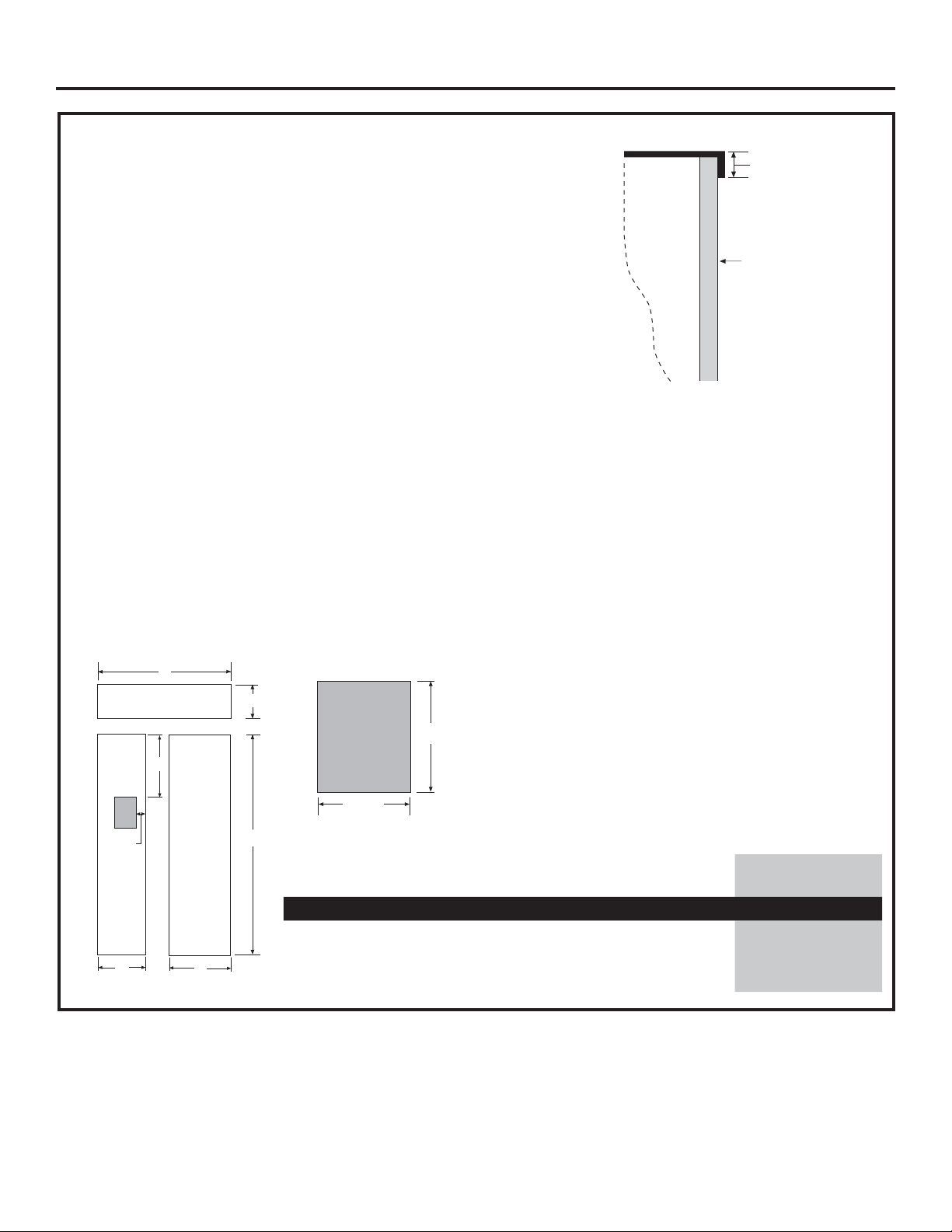

Design Guide - Flush Installation

CUSTOMIZATION BASICS:

These refrigerators are designed to be customized with decorative panels. Field installed custom door and grille

panels are required.

Optional Accessory Kits

ZKHSS2: Monogram Tubular Stainless Steel handles

designed to fit 3/4” (1.91 cm) overlay panels.

ZKHPSS1: Professional Tubular Stainless Steel

handles designed to fit 3/4” (1.91 cm) overlay panels.

Kit includes one handle. Order 2 kits for side-by-side

refrigerator models from your Monogram supplier

ZUG2: For side-by-side installation of two trimmed

models. This kit provides for the installation of a unified

custom grille panel to span the width of two units using

a framed or overlay panel.

CUSTOM HANDLE DESIGN GUIDE

Custom handles must be used for flush installation. For

custom handle installation, counterbore holes in rear of

decorative panels must ensure 1/2” (1.27 cm) material

thickness remains for handle support.

NOTE: The counterbore must not exceed 1” (2.54 cm)

in diameter.

1/2”

1/4”

3/4”

REFRIGERATOR LOCATION

• Do not install the refrigerator where the

temperature will go below 55°F (13°C). It

will not run often enough to maintain proper

temperatures.

• Do not install the refrigerator where temperatures

will go above 100°F (37°C). It will not perform

properly.

• Do not install the refrigerator in a location

exposed to water (rain, etc.) or direct sunlight.

• Install it on a floor strong enough to support it

fully loaded.

Minimum distance from handle

side edge to handle center

should be 1-1/4” (3.18 cm) as

shown.

7/8"

0.85"

1/2"

SIDE PANELS

Side panels must be used

whenever the sides of

the refrigerator will be

exposed. The 1/4”

(0.63 cm) side panels will

slip into the side case trim.

Secure the panels to the

refrigerator with stick-on

hook and loop fastener

strips. Order the side

panels from the cabinet

manufacturer.

• Cut a notch in the top

front corner as shown

to allow clearance for

corner keys in the front

side trim.

1-1/4”1-1/4”

24"

3/16"

1-7/8"

*84"

*3" to 4"

2-9/16"

* Depending on installation height.

31-49171

25

Page 26

Design Guide - Flush Installation

1/2"

Overlay

Panel

1/4"

Backer

Panel

Door

.10"

Spacer

D

1/2” (1.27 cm) OVERLAY PANEL DIMENSIONS

For a more custom appearance, overlay panels may be installed on trimmed models. The

overlay panel must be secured to a 1/4” (0.63 cm) thick backer panel which slides into the

trim. A spacer panel 0.10” (0.25 cm) thick must be placed between the overlay and backer

panel.

Assemble the panels with glue and screws:

• Center the spacer panel on the backer panel, left to right and top to bottom. Secure the

panels with glue.

• Refer to the following chart for locating the backer panel to the overlay panel. Secure the

overlay panel to the backer panel with glue and screws. Screws must be countersunk into

the backer panel.

Hinge Side

C

Freezer

Back

Backer with

Overlay Panel

Assembly

C

Fresh Food

Back

SxS Fresh Food 2-1/16” 1/16” 1/8” 1/8”

D

D

SxS Freezer 2-1/16” 1/16” 1/8” 1/8”

SxS Grille 2-1/16” 2-1/16” 1-15/32”* 7/32”

A

AB

B

IMPORTANT NOTE – DISPENSER MODELS

The refrigerator is supplied with 3 dispenser trims; 2

for standard installation and 1 for flush installation. The

flush installation trim is designed to fit a total panel

thickness of 0.85” (2.16 cm) or 0.75” (1.91 cm).

• If the panel is less than 0.75” (1.91 cm) a noticeable

gap may be created around the dispenser trim.

• If the panel is more than 0.85” (2.16 cm) the dispenser

.250” + .10” + .50” = .85”

0.63 + 0.25 + 1.27 = 2.16 cm

Total Panel Thickness

Grille Back

C

A B

AB CD

*2” for 36” models

trim cannot be secured to the door.

• The overlay panel must be constructed according to

the specifications shown to achieve the correct total

thickness.

• Cut the dispenser opening after the backer, spacer

and overlay panels have been assembled.

See Dispenser Trim Fit Example, page 28.

Panel Dimensions

36” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

E

1/4” Backer Panel 68-3/8” x 18-9/16” 68-3/8” x 14-9/16” 33-7/8” x 9”

.10” Spacer Panel 67” x 17-9/16” 67” x 13-9/16” 33” x 8-3/8”

EF

1/2” Overlay Panel 68-5/8” x 20-7/8” 68-5/8” x 16-7/8” 38” x 11-3/16” 17-23/32” 3-3/8”

15-3/8”

F

42” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

1/4” Backer Panel 68-3/8”x 24-9/16” 68-3/8” x 14-9/16” 39-7/8” x 9-1/2”

.10” Spacer Panel 67” x 23-9/16” 67” x 13-9/16” 39” x 8-5/8”

EF

1/2” Overlay Panel 68-5/8” x 26-7/8” 68-5/8” x 16-7/8” 44” x 11-3/16” 17-23/32” 3-3/8”

9-5/8”

48” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

1/4” Backer Panel 68-3/8” x 26-9/16” 68-3/8” x 18-9/16” 45-7/8” x 9-1/2”

.10” Spacer Panel 67” x 25-9/16” 67” x 17-9/16” 45” x 8-5/8”

EF

1/2” Overlay Panel 68-5/8” x 28-7/8” 68-5/8” x 20-7/8” 50” x 11-3/16” 17-23/32” 5-3/8”

IMPORTANT NOTE: Maximum total weight for the assembled panels:

• Fresh food door panel – 75 lbs.(34 kg) • Freezer door panel – 53 lbs.(24 kg) • Grille Panel – 18 lbs. (8.16 kg)

26

31-49171

Page 27

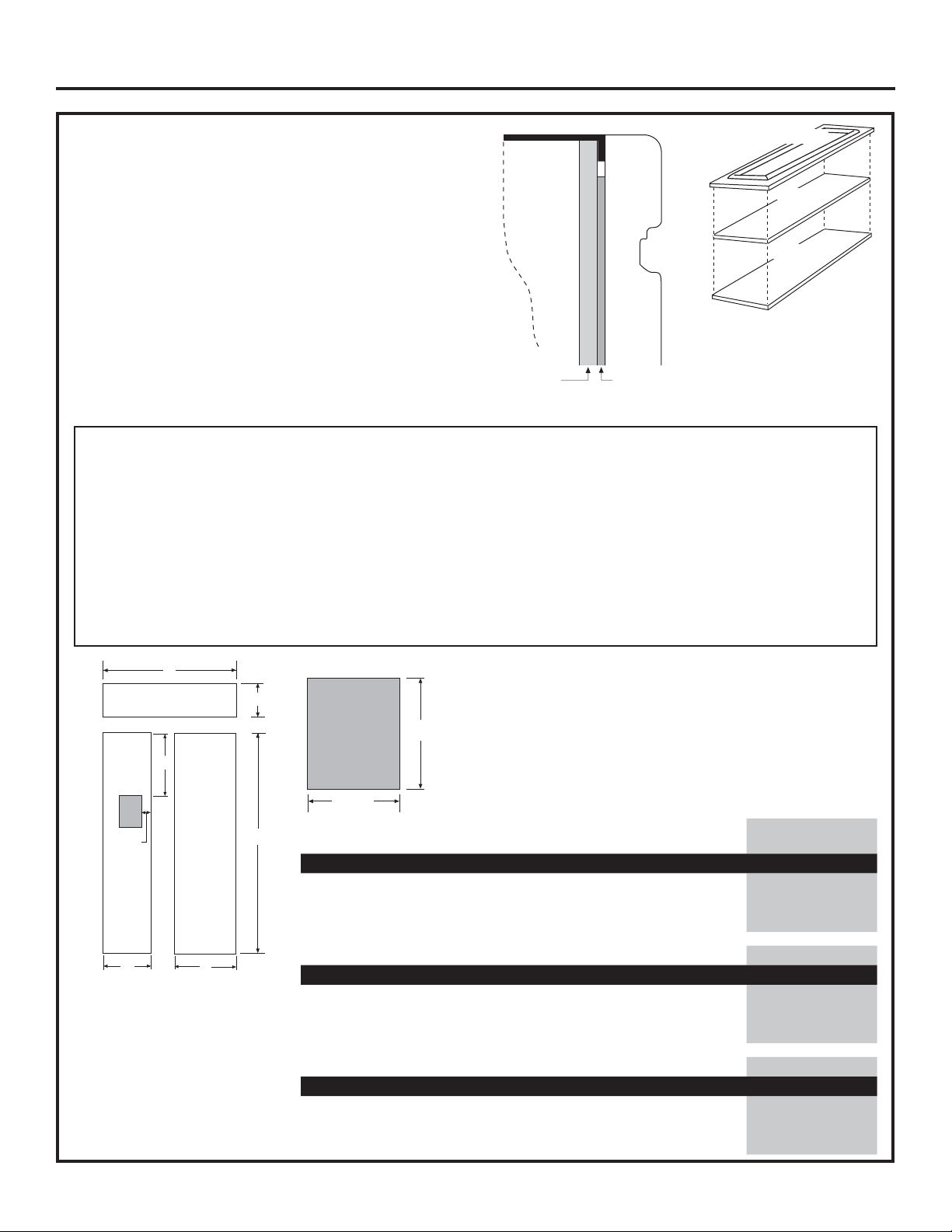

Design Guide - Flush Installation

3/4” (1.91 cm) RAISED PANEL DIMENSIONS

For a more custom appearance raised panels may be installed

on trimmed models. The panels must be 3/4” (1.91 cm) thick

at and routed per the instructions below in order to guarantee

proper operation

IMPORTANT NOTE – DISPENSER MODELS

The refrigerator is supplied with 3 dispenser trims; 2 for

standard installation and 1 for flush installation. The overlay

dispenser trim is designed to fit a total panel thickness of 0.85”

(2.16 cm) or 0.75” (1.91 cm).

• If the panel is less than 0.75” (1.91 cm) a noticeable gap may

be created around the dispenser trim.

• If the panel is more than 0.85” (2.16 cm) the dispenser trim

cannot be secured to the door.

• The overlay panel must be constructed according to the

specifications shown to achieve the correct total thickness.

See Dispenser Trim Fit Example, page 30.

Panel Dimensions

Door

3/4"

Raised

Panel

15-3/8”

36” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

E

3/4” Raised Panel 68-5/8” x 20-7/8” 68-5/8” x 16-7/8” 38” x 11-3/16” 17-23/32” 3-3/8”

42” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

F

3/4” Raised Panel 68-5/8” x 26-7/8” 68-5/8” x 16-7/8” 44” x 11-3/16” 17-23/32” 3-3/8”

48” Side-by-Side Fresh Food Freezer Grille Dispenser Cutout Position

3/4” Raised Panel 68-5/8” x 28-7/8” 68-5/8” x 20-7/8” 50” x 11-3/16” 17-23/32” 5-3/8”

9-5/8”

WARNING

E F

E F

E F

IMPORTANT NOTE: Maximum total weight

for the assembled panels:

• Fresh food door panel – 75 lbs. (34 kg)

• Freezer door panel – 53 lbs. (24 kg)

• Grille Panel – 18 lbs. (3.16 kg)

AVERTISSEMENT

Door Trim Pinch Point Hazard

Improper installation can lead to a finger pinch point

hazard between the side door trim and the cabinets

when operating the door, especially with children.

To minimize this risk you must follow the installation

instructions for cabinet dimensions, trim assembly,

and door stop angle.

31-49171

Risque de pincement de la garniture de porte

Une installation incorrecte représente un risque de pincement

pour les doigts entre le côté de la garniture de porte et les

armoires lors de l’ouverture ou de la fermeture de la porte,

spécialement pour les enfants. Pour réduire ce risque, vous

devez suivre les instructions d’installation selon les dimensions

des armoires, l’assemblage de garniture et l’angle de butée de

la porte.

27

Page 28

Design Guide - Flush Installation

3/4” (1.91 cm) RAISED DOOR PANEL ROUTING

For 3/4” (1.91 cm) raised door panel, routing is required. The router depth is 1/4” (0.63 cm) all the way around the

panel back. Additional panel width reductions are required per the diagrams below. This will create a “picture frame”

routing that will slide onto the attached door trim.

Back

TOP DETAIL TOP

3/4”

11/32”

1/4”

Front

3/32”

DETAIL BOTTOM

1/4”

11/32”

NOTE: Routed areas should be

finished as they may be visible

when assembled.

Front

Back

CORNER VIEW SHOWING

“PICTURE FRAME” ROUTING

DETA

IL HANDLE

SIDE

HANDLE

SIDE

BOTTOM

3/4” PANEL SIDE VIEW

(AFTER ROUTING)

DETAIL HINGE

SIDE

HINGE

SIDE

ROUTER DEPTH 1/4”

2-1/16”

3/4” PANEL BOTTOM VIEW

3/16”

Front

Back

(AFTER ROUTING)

NOTE: For panels constructed with rails and stiles (5-panel), the minimum width is 3” (7.62 cm) for rails and 4” (10.16 cm)

for stiles.

28

31-49171

Page 29

Design Guide - Flush Installation

3/4” (1.91 cm) RAISED GRILLE PANEL ROUTING

For 3/4” (1.91 cm) raised grille panel, routing is required. The router depth is 1/4” (0.63 cm) all the way around the

panel back. Additional panel width reductions are required per the diagrams below. This will create a “picture frame”

routing that will slide onto the attached grille trim.

DETAIL TOP

TOP

NOTE: Routed areas should be

finished as they may be visible

when assembled.

Front

Back

Back

Front

1-1/2”

2” for 36”

models

ROUTER DEPTH 1/4”

BOTTOM

3/4” PANEL SIDE VIEW

(AFTER ROUTING)

LEFT

SIDE

DETAIL

LEFT SIDE

CORNER VIEW SHOWING

“PICTURE FRAME” ROUTING

3/16”

DETAIL BOTTOM

DETAIL RIGHT

SIDE

ROUTER DEPTH 1/4” ROUTER DEPTH 1/4”

2-1/16” 2-1/16”

Front

RIGHT

SIDE

Back

3/4” PANEL BOTTOM VIEW

(AFTER ROUTING)

NOTE: For panels constructed with rails and stiles (5-panel), the minimum width is 3” (7.62 cm) for rails and 4” (10.16 cm)

for stiles.

29

31-49171

Page 30

Design Guide - Flush Installation

DISPENSER TRIM FIT EXAMPLES:

(NOT TO SCALE)

CUSTOM PANEL

• The dispenser trim fits over the custom

panel and snaps into the freezer door.

SIDE CLEATS

Wood cleats are required to be installed vertically

down both sides of the cabinet opening to provide

depth stop for the refrigerator when installed into the

opening.

The cleat should be installed per the diagrams below

based on the type of panel being used.

TOP VIEW

Finished

Cleat

Custom Panel

FREEZER DOOR

Ice / Water Dispenser

3/4”Overlay Dispenser Trim

5-1/4”

Finished

Cleat

5-3/8”

DOOR

3/4” Panel

Case Trim

TOP VIEW

DOOR

1/2” Panel

Case Trim

1/2”

1/2”

30

31-49171

Page 31

Installation Instruction - Flush Installation

TOOLS AND MATERIALS REQUIRED

• Tinsnips to cut banding

• Stepladder

• 1” Bit extension

• Tape measure

• Gloves

• 1/4” Drywall screws

• 5-Gal. Bucket with cover

• 6” Spirit level

• Appliance hand truck

• Tubing cutter

• 7/16” open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 5/16”, 7/16” socket

• Safety glasses

• 1-1/8” open end wrench

• Pliers

• 1/4”, 5/16” Combo Rachet

• 35” long 2x4 for Anti-Tip support

• 1/4” copper water line tubing or SmartConnect™

Refrigerator Tubing kits

• Water shut-off valve

• Custom panels for doors and grille panel

• Screws to secure refrigerator to cabinetry

• Stick-on hook and loop fastener strips for 1/4” side

panels

HARDWARE SUPPLIED

• Water filter bypass plug

• Toekick

• 1/4” nut and ferrule

• Dispenser trim for overlay panels (for use with

Custom Panel models).

•

Flush inset case trim

FLOORING

For proper installation, this refrigerator must be placed

on a level surface of hard material that is at the same

height as the rest of the flooring. This surface should

be strong enough to support a fully loaded refrigerator,

or approximately 1,500 lbs.(680.39 kg).

NOTE: Protect the finish of the flooring. Cut a large

section of the cardboard carton and place under the

refrigerator where you are working.

GROUNDING THE REFRIGERATOR

WARNING

Failure to follow these instructions can result in death,

fire, or electrical shock.

The power cord of this appliance is equipped with a

3-prong (grounding) plug which mates with a standard

3-prong (grounding) wall receptacle to minimize the

possibility of electric shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered,

it is your personal responsibility and obligation to have

it replaced with a properly grounded 3-prong wall outlet.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD.

DO NOT USE AN ADAPTER PLUG TO CONNECT

THE REFRIGERATOR TO A

2-PRONG OUTLET.

DO NOT USE AN EXTENSION

CORD WITH THIS APPLIANCE.

Electrical Shock Hazard.

MISE À LA TERRE DU RÉFRIGÉRATEUR

AVERTISSEMENT

électrique.

Le non-respect de ces instructions peut entraîner des

risques d’incendies, des chocs électriques ou la mort.

Le cordon d’alimentation de cet appareil est équipé

d’une fiche à trois broches (pour une mise à la terre)

qui s’adapte à la prise de courant standard à 3 broches

(pour une mise à la terre) pour minimiser les risques de

chocs électriques par cet appareil.

Faites vérifier la prise murale et le circuit électrique par

un électricien qualifié pour s’assurer que le système est

correctement mis à la terre.

Dans le cas d’une prise biphasée, l’installateur a la

responsabilité et l’obligation de la remplacer par une

prise triphasée correctement mise à la terre.

NE COUPEZ PAS OU N’ENLEVEZ PAS, SOUS

AUCUN PRÉTEXTE, LA TROISIÈME BROCHE DE

MISE À LA TERRE DU CORDON

D’ALIMENTATION.

N’UTILISEZ PAS D’ADAPTATEUR

POUR BRANCHER LE

RÉFRIGÉRATEUR À UNE PRISE

BIPHASÉE.

N’UTILISEZ PAS DE RALLONGE AVEC CET

APPAREIL.

Risque de choc

31-49171

31

Page 32

Installation Instructions - Flush Installation

STEP 1 REMOVE PACKAGING

WARNING

The refrigerator is much heavier at the top than at the

bottom—be careful when moving. When using a hand

truck, handle from the side only.

AVERTISSEMENT

basculement Le réfrigérateur est beaucoup plus

lourd en haut qu’en bas. Il faut être prudent lors des

déplacements. Si un diable est utilisé, il faut soulever

le réfrigérateur sur le côté seulement.

• Carefully cut banding at the top and bottom, remove

the outer carton.

• Slide out the back corner posts (2).

• Slide the carton off the top of the cabinet.

NOTE: IT IS NOT NECESSARY TO LAY THE

CABINET DOWN IN ORDER

TO REMOVE THE SKID!

• The unit is secured to the

skid with 4 slotted tie-down

straps. Remove the six

7/16” bolts from the base

channels in the tie-downs.

• Remove the six 7/16” bolts

securing the straps to the

skid.

NOTE: DO NOT ATTEMPT

TO ROLL UNIT OFF SKID.

• The support blocks on the

bottom of the refrigeration case must be removed

before the refrigerator is taken off the skid or

damage will occur. Carefully tilt the refrigerator and

slide the blocks out from beneath.

• Remove the toekick and set aside for final

installation.

• Lift the refrigerator off the skid with an appliance

dolly. Handle from the sides.

Tip Over Hazard.

Risque de

Remove

Toekick

Tie Downs

STEP 2 MOVE THE REFRIGERATOR

INTO THE HOUSE

• Re-use the corner posts from the packaging to

protect stainless steel models. Run the appliance

dolly straps over the posts and under the handles.

• Leave the protective film on the refrigerator until

installation is complete. IMPORTANT: Never lift the

refrigerator by the handle or push against the grille

panel; this could cause damage or misalignment.

• Avoid laying the unit on its back or side to prevent

sealed system restrictions.

STEP 3 INSTALL WATER LINE

WARNING

AVERTISSEMENT

alimentation d’eau potable seulement.

• A cold water supply is required for automatic icemaker

operation. The water pressure must be between 40

and 120 p.s.i. (275-827 kPa).

• Route 1/4” OD copper or SmartConnect™ plastic

tubing between house cold water line and the water

connection location.

• The tubing should be long enough to extend to the

front of the refrigerator. Allow enough tubing to

accommodate the bend leading into the water line

connection.

NOTE: The only Monogram approved plastic tubing

is supplied in the SmartConnect™ Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Other

types of plastic may crack or rupture with age and

cause water damage to your home.

SmartConnect™ Refrigerator Tubing Kits are available

in the following lengths:

2’ (.6 m) WX08X10002

8’ (2.4 m) WX08X10006

15’ (4.6 m) WX08X10015

25’ (7.6 m) WX08X10025

Shut off the main water supply.

Turn on the nearest faucet long enough to clear the line

of water.

• Install a shut-off valve between the icemaker water

valve and cold water pipe in a basement or cabinet.

The shut-off valve should be located where it will be

easily accessible.

• Turn on the main water supply and flush debris.

Run about a quart of water through the tubing into a

bucket. Shut off the water supply at the shut-off valve.

NOTE: Saddle type shut-off valves are included in

many water supply kits. Before purchasing, make sure

a saddle type valve complies with your local plumbing

codes.

NOTE: Commonwealth of Massachusetts Plumbing

Codes 248CMR shall be adhered to. Saddle valves

are illegal and use is not permitted in Massachusetts.

Consult with your licensed plumber.

Connect to potable water supply

only.

Raccordez l’appareil à une

Floor

Cold Water Line

32

31-49171

Page 33

Installation Instructions - Flush Installation

STEP 4 INSTALLATION WITH

HOUSEHOLD WATER

FILTRATION SYSTEM

Skip this step if you do not have a household water

filtration system

If the water supply to the refrigerator is from any

household water filtration system, the filter cartridge

should be removed. For better ice and water performance,

remove the filter and install the filter bypass plug.

Rotate Counterclockwise To

Remove

Filter Bypass

Plug

STEP 5 INSTALL SIDE PANELS

Skip this step when not using side panels.

If you are using 1/4” (0.63 cm) side panels, they should

be inserted into the case trim. Fasten the panels to the

refrigerator with stick-on hook and loop fastener strips

before setting the refrigerator in place.

STEP 7 ANTI-TIP PROCEDURE

WARNING

These refrigerators are top heavy, especially with any

doors open, and must be secured to prevent tipping

forward which could result in death or serious injury.

Read and follow the entire installation instructions for

securing the refrigerator with the anti-tip system.

AVERTISSEMENT

basculement

Ces réfrigérateurs présentent une partie supérieure

lourde, en particulier avec une porte ouverte; ils

doivent donc être fixés pour prévenir le basculement

vers l’avant et le risque concomitant de blessure

grave ou fatale. Lisez et suivez les instructions

d’installation complètes pour l’installation du système

anti-basculement.

• Cut a 1” x 4” block, 35” (88.9 cm)

long.

• Measure and mark under the soffit,

5-1/4” (13.34 cm) from the front edge

of the cabinet.

• Secure the wood block under the

soffit. From the bottom of the block to

the finished floor should measure 84”

(213.36 cm). See the illustration.

Tip Over Hazard.

Risque de

STEP 6 INSTALL CASE TRIM

The unit arrives with case trim for standard installation

attached. Flush installation case trim is provided.

Remove the three pieces of factory installed case

trim (both sides and top). Install new case trim using

supplied right hand and left hand case trim pieces

and case trim screws. A top piece of case trim is not

required for flush installation. Attach case trim to each

side of case as shown in illustration using case trim

screws in holes provided down each side of the case.

Connect Power Cord:

• Before pushing the refrigerator into the opening, plug

the power cord into the receptacle. The water filter

guard will need to be removed for access (some

models). Remove the 3 screws holding it in place. If

access is still too tight, remove the 2 screws holding

the water filter bracket and move aside. Open the

grille panel and reach into the opening at the back

to grasp the power cord. Pull the power cord into the

opening as you push the refrigerator back. Secure the

bracket and guard with the original screws.

• Gently push refrigerator into the opening with hands

against front corners.

• Once the refrigerator is pushed into the opening,

use leveling legs to raise the refrigerator until it rests

against the block installed at the top of the opening.

31-49171

33

Page 34

Installation Instructions - Flush Installation

STEP 7 ANIT-TIP PROCEDURE

(continued)

We recommend units for flush installation be

installed under a soffit. If this is not possible, follow

these instructions using the mounting brackets.

• Cut a 2” x 4” block, 35” (88.9 cm) long and secure the

block to the mounting brackets provided using #12 or

#14 wood screws.

• Secure the bracket with wood block to the back wall

so that it is 84” (213.36 cm) from the finished floor.

Use #12 or #14 wood screws. See the illustration.

• The screws must

penetrate at least

one inch into the

vertical wall studs.

• If metal wall studs

then use selftapping sheet metal

screws in place of

the wood screws

to secure the block

and brackets to the

wall.

STEP 8 LEVEL REFRIGERATOR

All models have 4-point leveling. The front is supported

by leveling legs, the rear is supported by adjustable

wheels. Both are accessible from the front of the

refrigerator.

• To level the back of the refrigerator, turn the 7/16”

hex nut located above the front wheels. Turn

clockwise to raise or

counterclockwise to lower

the refrigerator.

• For front leveling, use a

1-1/4” open-end wrench.

• Adjust height of refrigerator

to match installation cutout

opening 84-1/2”

(214.63 cm). The refrigerator

should be level and plumb

with cabinetry.