Page 1

g

GE Consumer Home Services Training

TECHNICAL SERVICE GUIDE

Monogram

Side-By-Side Refrigerators

With Electronic Controls

MODEL SERIES:

ZIS360NM

ZIS420NM

ZIS480NM

ZIS_360DM

ZIS_420DM

ZIS_480DM

PUB # 31-9091 03/02

GEA01265

Page 2

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used

to complete a path to ground are removed for service, they must

be returned to their original position and properly fastened.

GE Consumer Home Services Training

Technical Service Guide

Copyright © 2002

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

Page 3

Table of Contents

Technical Data ........................................................................................................................ 3

Model Nomenclature .............................................................................................................. 4

Rating Plate ...................................................................................................................... 4

Mini-Manual ....................................................................................................................... 4

Serial Number ...................................................................................................................5

Component Locator Views..................................................................................................... 6

Cabinet .................................................................................................................................... 9

Machine Compartment ..................................................................................................... 9

Door Closure Mechanism................................................................................................ 10

Doors and Hinges ............................................................................................................ 10

Door Gaskets..................................................................................................................... 11

Rollers and Leveling........................................................................................................11

Ice and Water Dispenser ...................................................................................................... 12

Controls ............................................................................................................................ 12

Water Valve and Water Tank ......................................................................................... 13

Airflow ................................................................................................................................... 14

Damper ............................................................................................................................ 14

Evaporator Fan ................................................................................................................ 15

Condenser Fan ................................................................................................................ 1 9

Defrost System ...................................................................................................................... 20

Adaptive Defrost .............................................................................................................. 20

Normal Operating Characteristics.................................................................................. 21

Abnormal Operating Characteristics ............................................................................. 21

Liner Protection Mode .................................................................................................... 21

Defrost Heater..................................................................................................................22

Evaporator Thermistor .................................................................................................... 23

Defrost Overtemperature Thermodisk ........................................................................... 23

Control System ...................................................................................................................... 24

Touch Panel and Temperature Control Board.............................................................. 24

Main Control Board ......................................................................................................... 25

Main Control Board Locator T ables............................................................................... 2 6

Thermistors ...................................................................................................................... 31

Climate Control Drawer........................................................................................................ 32

Strip Circuit...................................................................................................................... 32

Component Locator View............................................................................................... 33

Operation ......................................................................................................................... 34

Temperature Table .......................................................................................................... 35

Climate Control Drawer Top Panel (Mullion) ................................................................ 36

Control Board and Display ............................................................................................ 36

Fan and Fan Housing...................................................................................................... 38

Dampers ........................................................................................................................... 39

Heater............................................................................................................................... 40

Thermistor........................................................................................................................ 40

Airflow.............................................................................................................................. 42

– 1 –

Page 4

Table of Contents (cont.)

Compartment Lights ............................................................................................................. 44

FF/FZ Compartment Lights Diagnostic .......................................................................... 44

Door Switches ................................................................................................................. 45

Master Light Switch (Sabbath Switch) .......................................................................... 45

Temperature Overload Device (TOD)............................................................................. 45

Circuit Breakers............................................................................................................... 46

Transformers.................................................................................................................... 46

Light Bulb Replacement................................................................................................. 46

Schematic.............................................................................................................................. 49

Refrigeration System............................................................................................................ 50

Compressor...................................................................................................................... 50

Condenser........................................................................................................................ 50

Condenser Loop .............................................................................................................. 50

Dryer................................................................................................................................. 51

Evaporator ....................................................................................................................... 51

Refrigerant Charge ......................................................................................................... 51

Diagnostic Mode ................................................................................................................... 52

Diagnostic Flowcharts .......................................................................................................... 53

Fresh Food Warm - Freezer Normal.............................................................................. 53

Fresh Food Too Cold - Freezer Normal ......................................................................... 54

Fresh Food Warm - Freezer Warm ................................................................................ 55

Freezer Warm - Fresh Food Normal.............................................................................. 56

Compressor Not Running................................................................................................ 57

Refrigerator Dead - No Sound, No Cooling................................................................... 5 8

Damper Door Does Not Operate..................................................................................... 59

Heavy Frost on Evaporator ............................................................................................. 60

Evaporator Fan Not Running .......................................................................................... 61

Condenser Fan Not Running .......................................................................................... 6 2

Warranty ................................................................................................................................63

– 2 –

Page 5

Technical Data

WARNING: Disconnect power cord before

servicing.

Note: Reconnect all grounding devices.

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for

service, they must be returned to their original

positions and properly fastened.

Caution: To avoid personal injury when servicing

the condensing unit, stand on a ladder which will

give enough support to allow removal of the top

panel and safely allow access to service the unit.

ELECTRICAL SPECIFICATIONS

Max Defrost Control

W/No Door Openings ............60 hrs @ 35 min

Evap Overtemperature Thermodisc ..............60 °F-45 °F

Light Thermostat .....................................140 °F-90 °F

Electrical Rating: 115 VAC 60 Hz.....................9.0 amp

Maximum Current Leakage............................ 0.50 mA

Maximum Ground Path Resistance ............ 0.14 ohms

Energy Consumption (HUMID) ................................. *

Important Safety Notice:

This information is intended for use by individuals

possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt

to repair a major appliance may result in personal

injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation

of this information, nor can it assume any liability in

connection with its use.

REFRIGERATION SYSTEM

Compressor ...............................................983 Btu/hr

Minimum Compressor Capacity

Vacuum .......................................... 26 inches

Minimum Equalized Pressure

@ 70 °F............................................ 72 PSIG

@ 90 °F.............................................88 PSIG

Refrigerant Charge (R134a) .............................14.50 oz

Evaporator

Condenser

Dryer

Heat Exchanger

Suction

Tube

NO LOAD PERFORMANCE

CONTROL POSITION 37-0 °F and

AMBIENT TEMPERATURE OF

70 °F 90 °F

Fresh Food, °F ....................... 36–46 .............. 37–48

Frozen Food, °F ..................... (-6)–6 .............. (-4)–3

Percent Running Time............. 41–46 .............. 53–55

REFRIGERA TION DIAGNOSIS

To access the low-pressure side of the system,

install a WR86X0097 valve only on the process

tube extending from the compressor case.

HMI Temperature Control..........................................**

To Cabinet

To Cabinet

Wiring

Wiring

White

White

Orange

Orange

Black

Black

Run

Run Capacitor

Capacitor

*

For Models ZIS 36 & ZIS 36D: 51.2 kWh/mo. Models ZIS 42 & ZIS 42D:

54.6 kWh/mo. Model ZIS 48: 58.1 kWh/mo. Model ZIS 48D: 59.2 kWh/mo.

**

For model ZIS 36: WR55X10166. Model ZIS 36D: WR55X10165. Model ZIS 42:

WR55X10164. Model ZIS 42D: WR55X10163. Model ZIS 48: WR55X10162.

Model ZIS 48D: WR55X10158.

Overload

Overload

Green

Green

(Ground)

(Ground)

Relay ....................................................WR07X10031

Overload ............................................... WR08X10015

Run Capacitor (15 uF) ............................. WR62X0080

Overtemperature Thermodisc Light .......... WR50X10035

Overtemperature Thermodisc Evaporator .. WR50X10036

Defrost Heater ....................................... WR51X10065

Drain Trough ASM .................................. WR17X11194

Condenser Fan Motor ............................ WR60X10083

Condenser Fan Blade ............................ WR60X10049

Evaporator Fan Motor ............................ WR60X10043

Evaporator Fan Blade ............................ WR60X10050

Main Board ........................................... WR55X10167

Thermistors (2-FF , 1-FZ, 1-EV) ............... WR55X10025

Damper Assembly Fresh Food ............... WR60X10085

Evaporator ............................................ WR84X10038

Compressor .......................................... WR87X10042

Condenser............................................. WR84X10037

Filter Dryer ............................................. WR86X0096

– 3 –

High Pressure

(Do NOT use)

Process

Tube

Condenser

Loop

REPLACEMENT PARTS

Compressor

Page 6

Model Nomenclature

ZI

Brand/Product

Z - Monogram

Style

I - Built-In

Configuration

S - Side by Side

Color

S - Stainless B - Black W - White

Blank - Trim Model

Size

480 - 48 Inches Wide

S

S

480

N

MA

LH

Door T ype

F - Flat

R - Right

L - Left Door Swing

Engineering

A - Initial Design

B - 1st Revision

C - 2nd Revision

D - 3rd Revision

Etc.

Model Year

L - 2002 Pre-Energy

M - 2002 Energy

Icemaker/Exterior

N - Nondispenser

Mini-Manual and

Rating Plate

Rating Plate

The rating plate, located behind the grille panel at

the top of the refrigerator on the right side of the

evaporator box, contains the model and serial

numbers. Additionally , the rating plate specifies

the minimum installation clearances, electrical

voltage, frequency, maximum amperage rating,

refrigerant charge, and type.

Mini-Manual

The mini-manual is located behind the grille

panel at the top of the refrigerator . When done,

return the mini-manual to its original location for

future use.

– 4 –

Page 7

Serial Number

The serial number consists of two letters, followed by six numerals. The two prefix letters of the

serial number indicate the month and year the product was manufactured. The year of manufacture does not correspond with the model year of the model number.

NAJBEFRAMRPAYAMNUJLUJGUAPESTCOVONCED

0002ZAZDZFZGZHZLZMZRZSZTZVZZ

1002AAADAFAGAHALAMARASATAVAZ

2002DADDDFDGDHDLDMDRDSDTDVDZ

3002FAFDFFFGFHFLFMFRFSFTFVFZ

4002GAGDGFGGGHGLGMGRGSGTGVGZ

5002HAHDHFHGHHHLHMHRHSHTHVHZ

6002LALDLFLGLHLLLMLRLSLTLVLZ

7002MAMDMFMGMHMLMMMRMSMTMVMZ

8002RARDRFRGRHRLRMRRRSRTRVRZ

9002SASDDFSGSHSLSMSRSSSTSVSZ

0102TATDTFTGTHTLTMTRTSTTTVTZ

1102VAVDVFVGVHVLVMVRVSVTVVVZ

2102ZAZDZFZGZHZLZMZRZSZTZVZZ

3102AAADAFAGAHALAMARASATAVAZ

4102DADDDFDGDHDLDMDRDSDTDVDZ

5102FAFDFFFGFHFLFMFRFSFTFVFZ

6102GAGDGFGGGHGLGMGRGSGTGVGZ

7102HAHDHFHGHHHLHMHRHSHTHVHZ

8102LALDLFLGLHLLLMLRLSLTLVLZ

9102MAMDMFMGMHMLMMMRMSMTMVMZ

0202RARDRFRGRHRLRMRRRSRTRVRZ

1202SASDDFSGSHSLSMSRSSSTSVSZ

– 5 –

Page 8

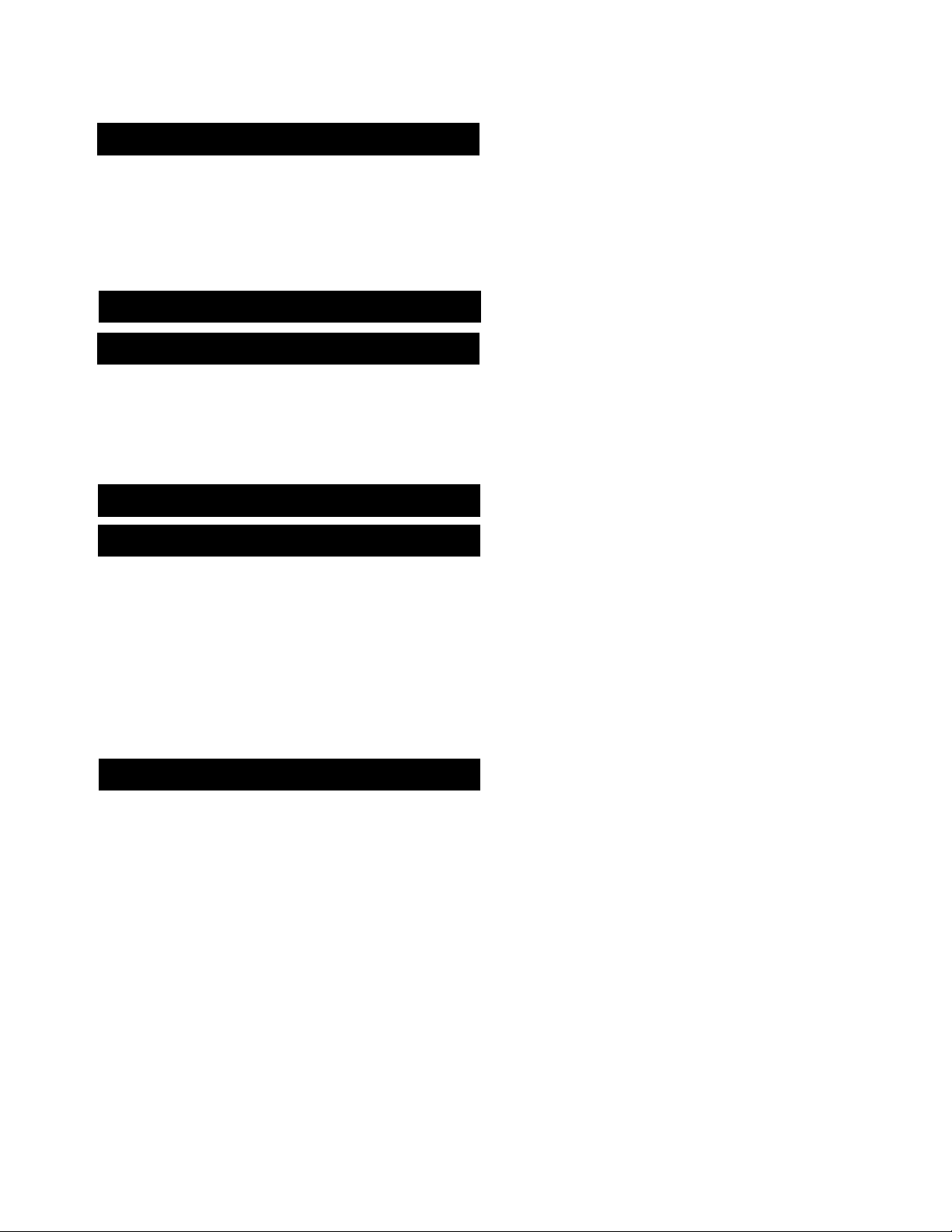

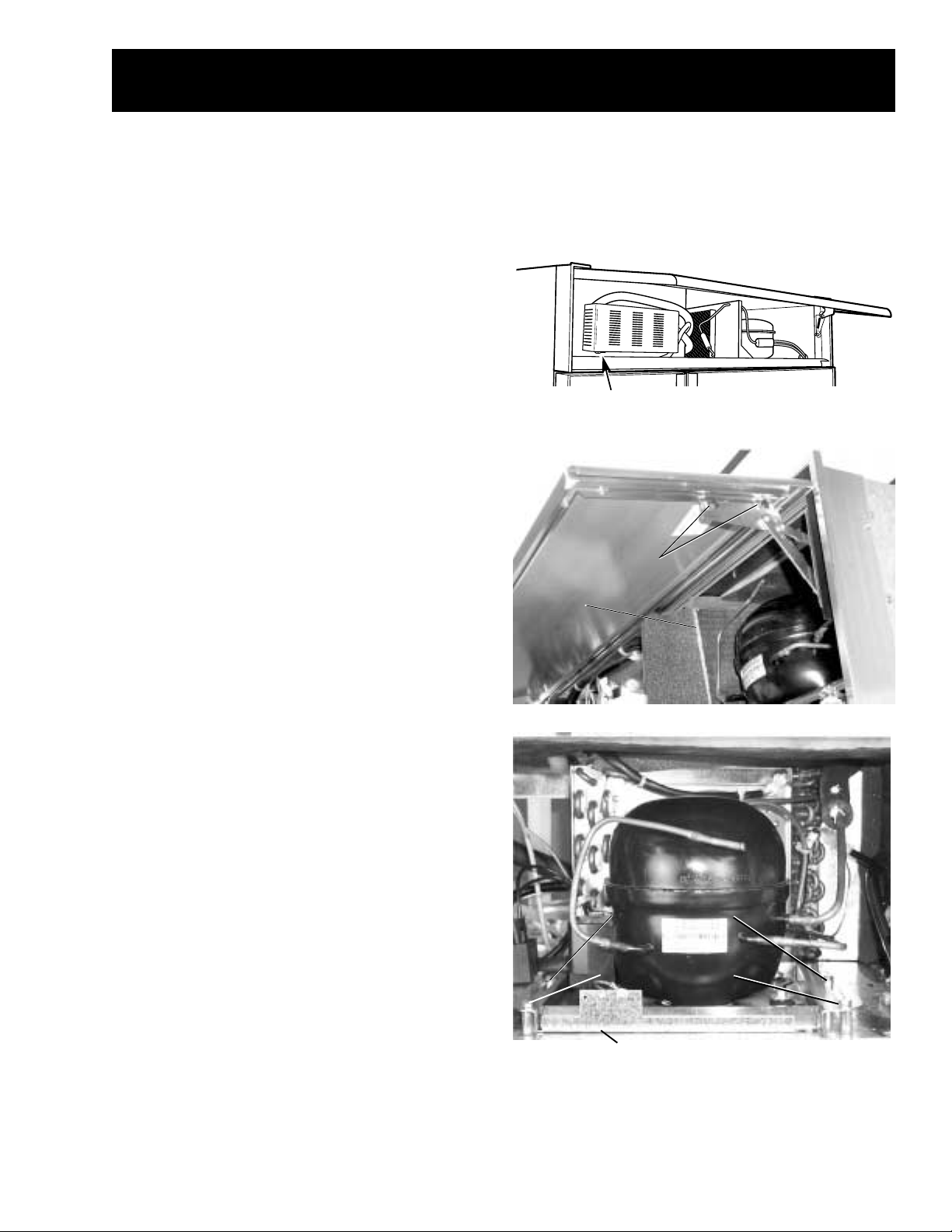

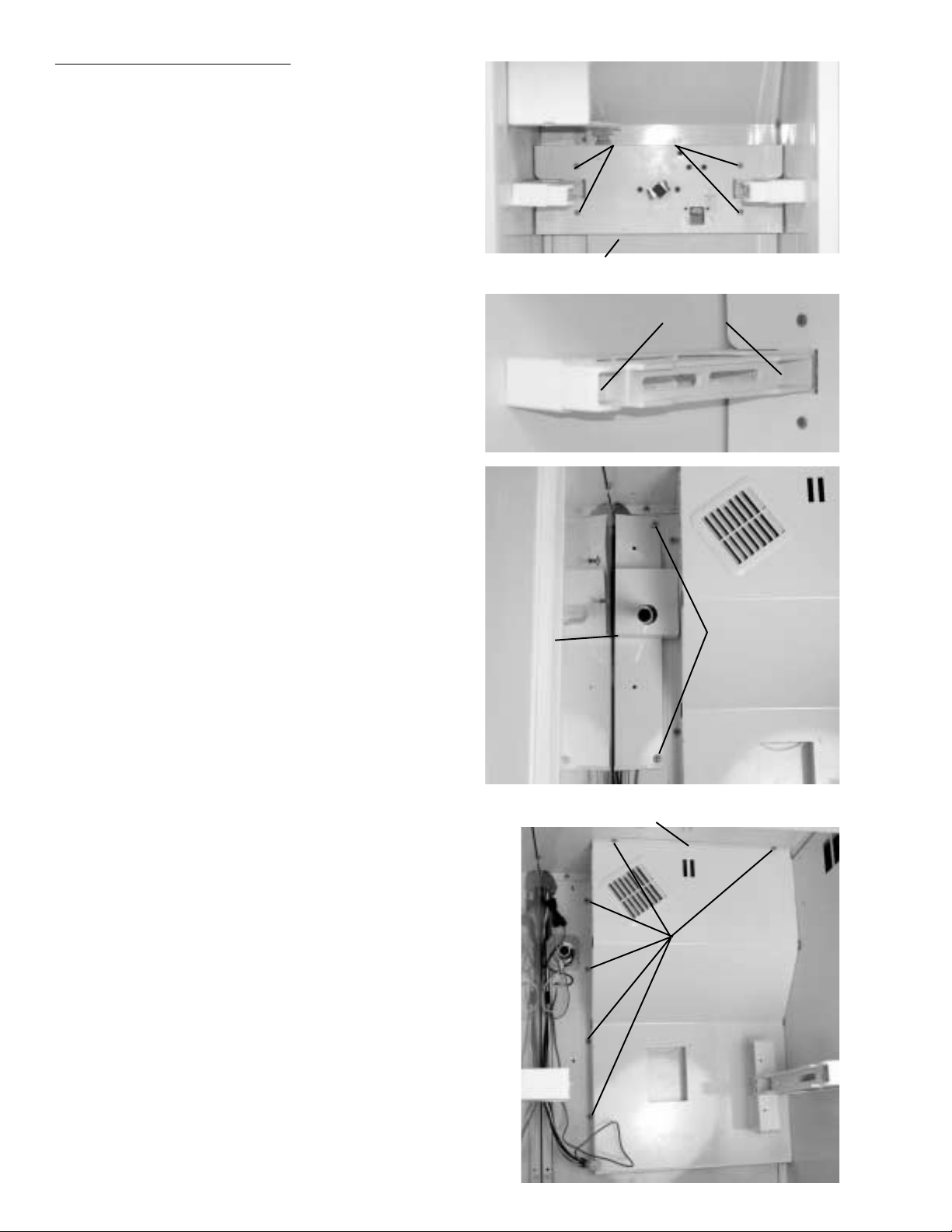

Component Locator Views

Master Light Switch

(Sabbath Switch)

Dryer

Figure 1 - Machine Compartment

Overload &

PTCR Relay

Compressor

Condenser Fan

Evaporator

Defrost Heater

Evaporator

Thermistor

Evaporator

Overtemperature

Thermodisc (TOD)

Figure 2 - Evaporator (T op of Freezer)

– 6 –

Page 9

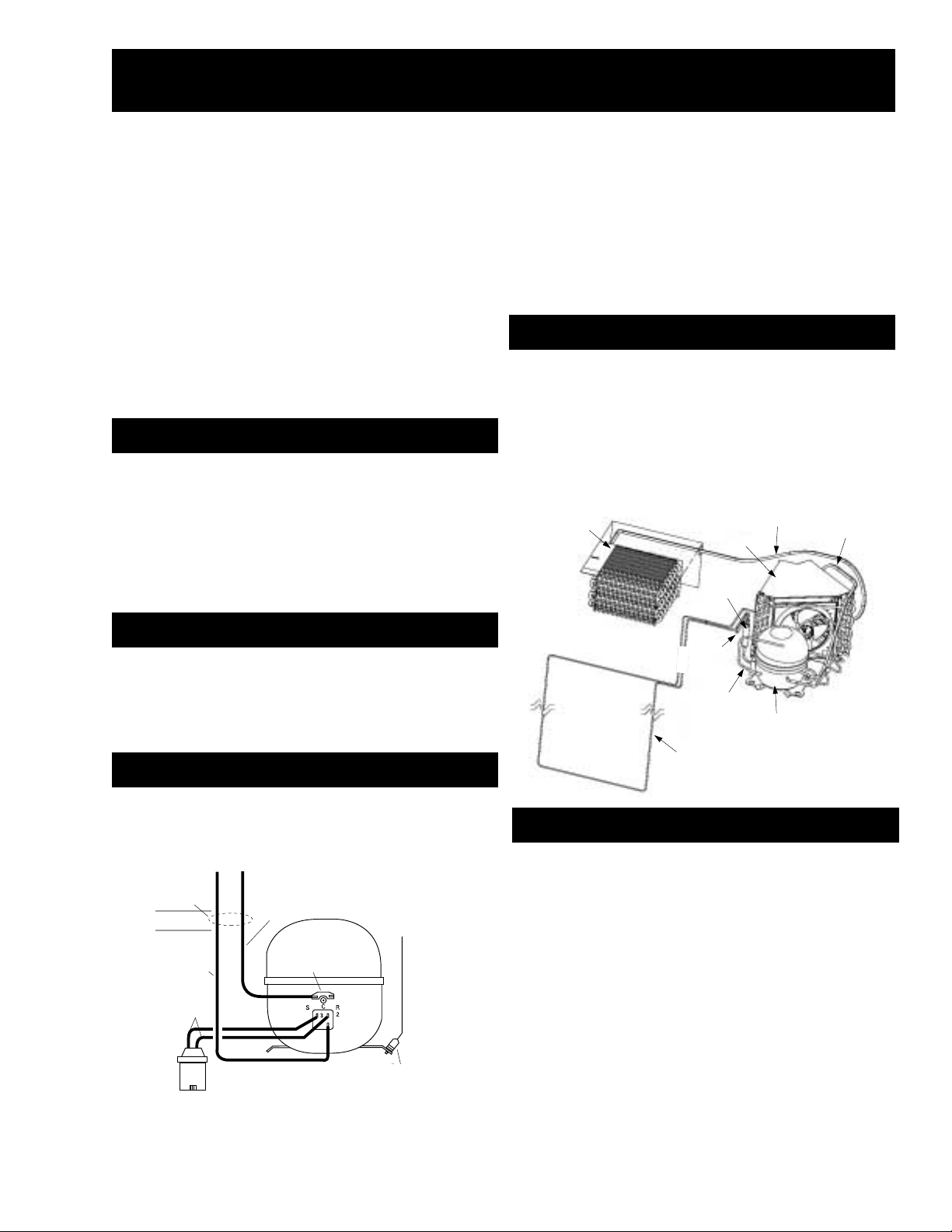

Water Valve

Evaporator Fan Motor

Capacitor

Figure 3 - Water V alve and Cap acitor

(Center of Machine Compartment)

Evaporator Fan

Connector

Figure 4 - Evaporator Fan

Circuit Breakers

Drawer Under

Center of Unit

Transformers

Figure 5 - Light Circuit Transformers

– 7 –

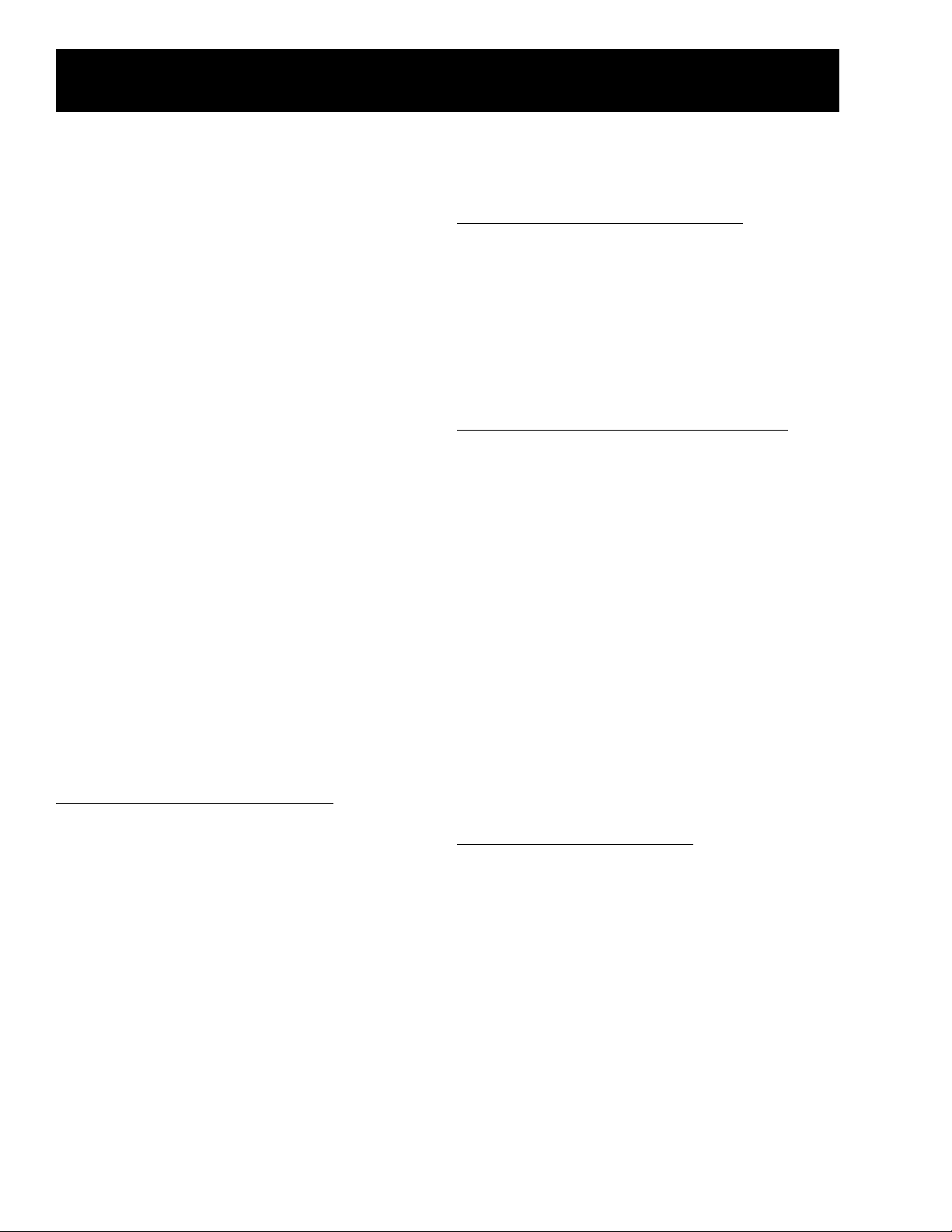

Page 10

Freezer

Door Switch

Icemaker

Fresh Food

Door Switch

Temperature Touch Pad

Damper

Airflow Grille

Auger Drive

Freezer

Thermistor

Water Filter

Cube Solenoid

Fresh Food

Thermistors

Lower

Fresh Food

Lights

Temperature

Overload Device

(TOD)

Figure 6 - Freezer Compartment

Temperature

Overload Device

(TOD)

Climate Control

Drawer Dampers

Figure 7 - Fresh Food Compartment

– 8 –

Climate Control

Drawer Fan

Page 11

Cabinet

The outer case is made of prepainted galvanized

steel. The fresh food and freezer liners are

painted metal with a smooth finish. The liners are

not removable or replaceable.

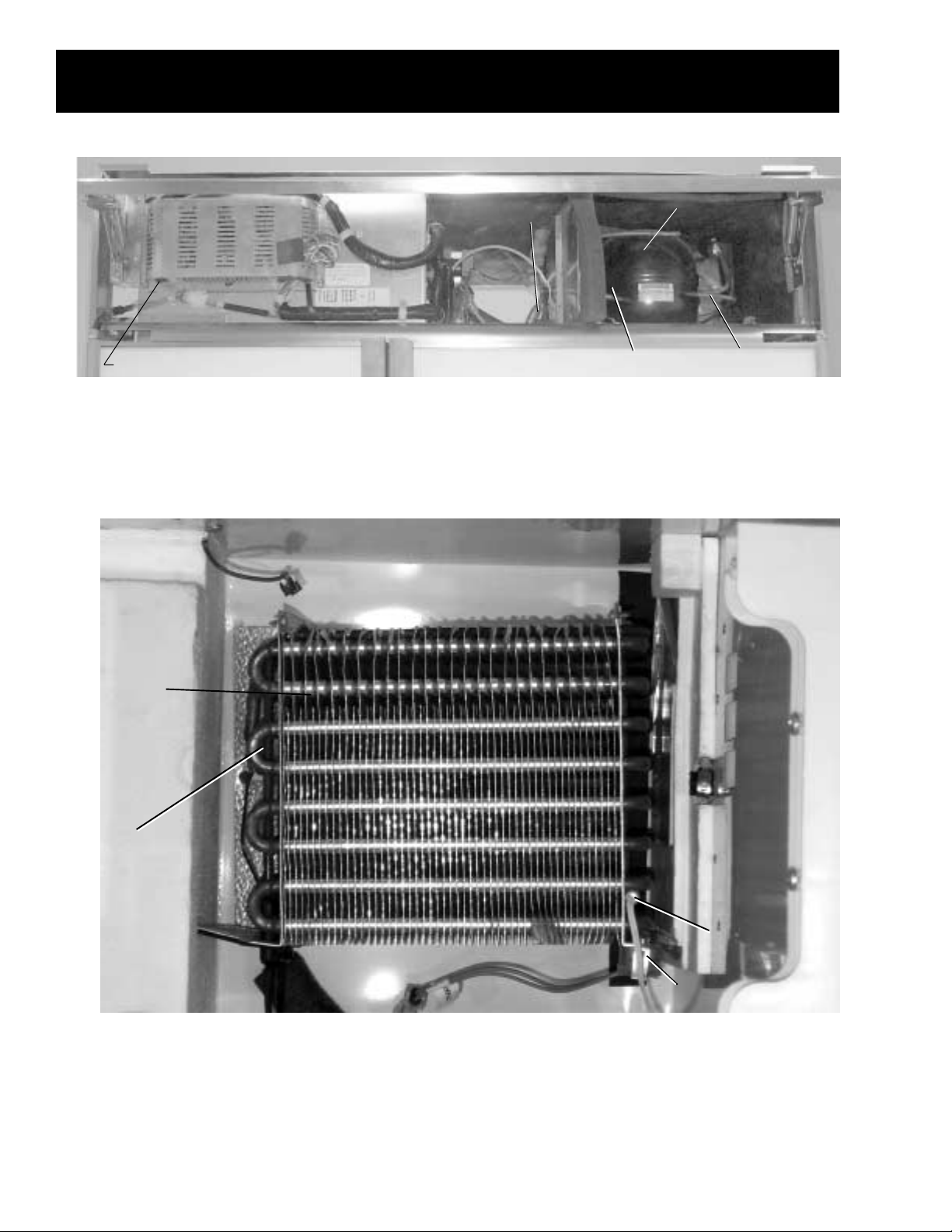

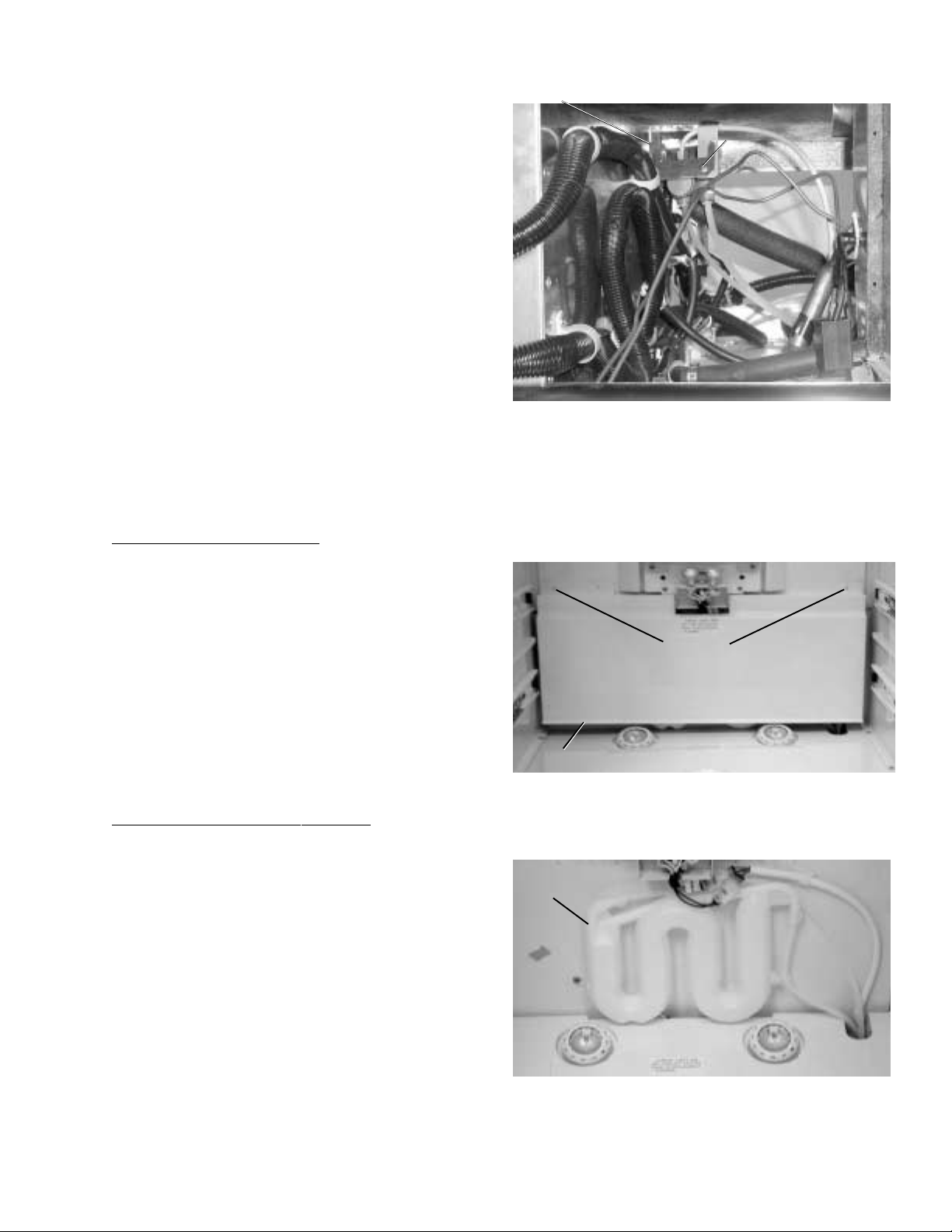

Machine Compartment

The machine compartment is located on the top of

the unit and has a movable chassis that can be

extended from the front of the unit to provide

access to the refrigeration system components.

Machine Compartment

Caution: Avoid kinking the refrigeration lines when

sliding the chassis out and back in.

To extend the chassis:

1. Remove the grille panel by removing 2 screws

from each side (see photo).

2. Remove the wire guard and rocker switch

panel.

3. Remove the condenser baffle.

4. Loosen 2 (7/16-in.) track bolts from the front of

the chassis track.

5. Remove 2 (7/16-in.) rear track bolts and the

spacers under the rear of the chassis track.

6. Pull the chassis forward until it reaches the

stops in the tracks, working the refrigeration

tubing as you pull the chassis out.

Note.

• When sliding the chassis back into position, be

certain the lines and wiring have not fallen

behind the chassis.

The Master Light Switch (Sabbath switch) is

located behind the grille panel.

2 Screws

Condenser

Baffle

• Use the grille screws for adjustment when

realigning the grille.

– 9 –

Rear Track Bolt s

Rear T rack Bolts

Front Track Bolt s

Front Track Bolt s

Chassis

Page 12

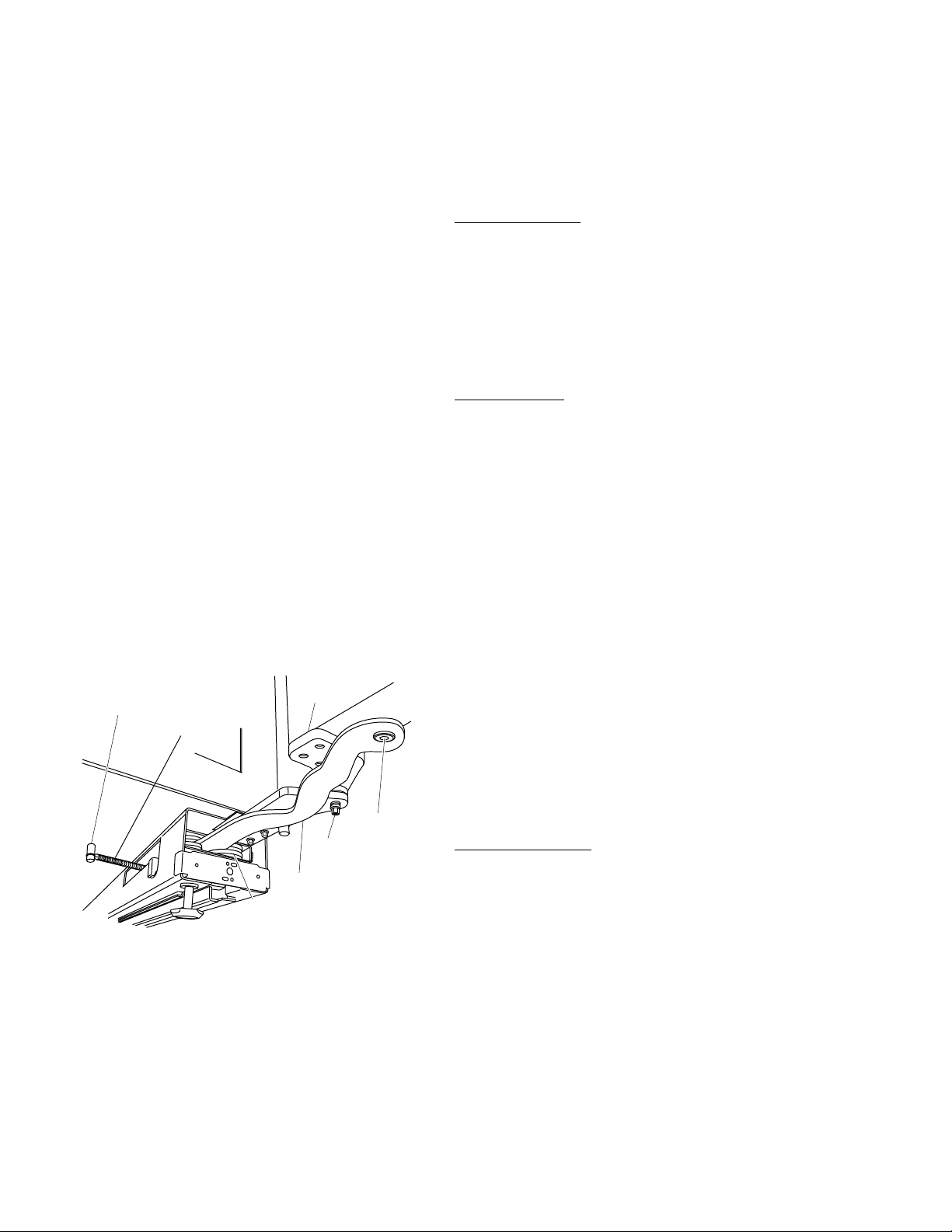

Door Closure Mechanism

Doors and Hinges

The door closure mechanism uses a spring to

provide positive door closure from approximately

60 degrees. The door closure mechanism

actuator arm has a spring attached to the rear and

is supported by guide rollers on either side of the

base channel. The roller circumferences and the

actuator arm detents are matched for smooth

operation. The arm is attached to the door with an

Allen head shoulder bolt.

The closure mechanism allows easy opening to

approximately 90 degrees, where the arm has a

detent to permit the door to remain open at 90

degrees with minimal tension. Once the door is

opened beyond 90 degrees, the closure

mechanism pulls the door open until the closure

arm engages the door stop at approximately 130

degrees (factory setting, the door stop can be field

set to 90 degrees). The reverse action occurs

when the door is closed.

Note: The actuator arm is spring loaded with

moderate spring tension.

1. Disconnect the spring from the pin and the

actuator arm.

2. Remove the 3/16-in. Allen head bolt, bushing,

and spacer from the door and actuator arm.

Door

Pin

Spring

Hinge

The doors are of one-piece construction with foam

insulation.

The inner door panel and outer door panel cannot

be separated and must be replaced as an

assembly.

Door Adjustment

Be sure the top hinge does not hit the cabinet trim.

Adjust the door up or down by turning the threaded

hinge pin on the bottom hinge of the fresh food

door.

The upper hinge on the freezer door is slotted to

allow the freezer door to be adjusted left or right.

Door Removal

WARNING: Use the appropriate safety equipment

and lifting techniques. Two persons may be

required for door removal.

Caution: Use wood or a heavy plastic sheet to

protect the floor where the door will be placed.

1. Remove all food and bins from the inner door

liner and tape door to cabinet.

2. Disconnect the spring from the pin and the

actuator arm.

3. Remove the Allen head bolt, bushing, and

spacer from the door and actuator arm.

4. If removing the freezer door, shut of f the water

supply , and disconnect the water line and

electrical connector.

3/16"

Bolt

Allen

Head

Bolt

GEA01267

5/16"

Actuator

Arm

Roller

Assembly

3. Remove 2 screws and the roller assembly

from the rail. Replace roller if excessively

worn.

5. Remove the upper hinge.

6. Lift door up and out to remove.

Lower Door Hinge

Note: If replacing lower door hinge, note the

placement of the door stop (pin).

1. Remove the door .

Note: Note the placement of spacers and washers

for reassembly.

2. Remove 3/8-in. hex screws (4) and hinge from

the underside of the cabinet.

– 10 –

Page 13

Hex Nut

Wheel

Leveling Leg

3. Remove T-27 Torx screws (4) and hinge from the

bottom of the door .

Hinge

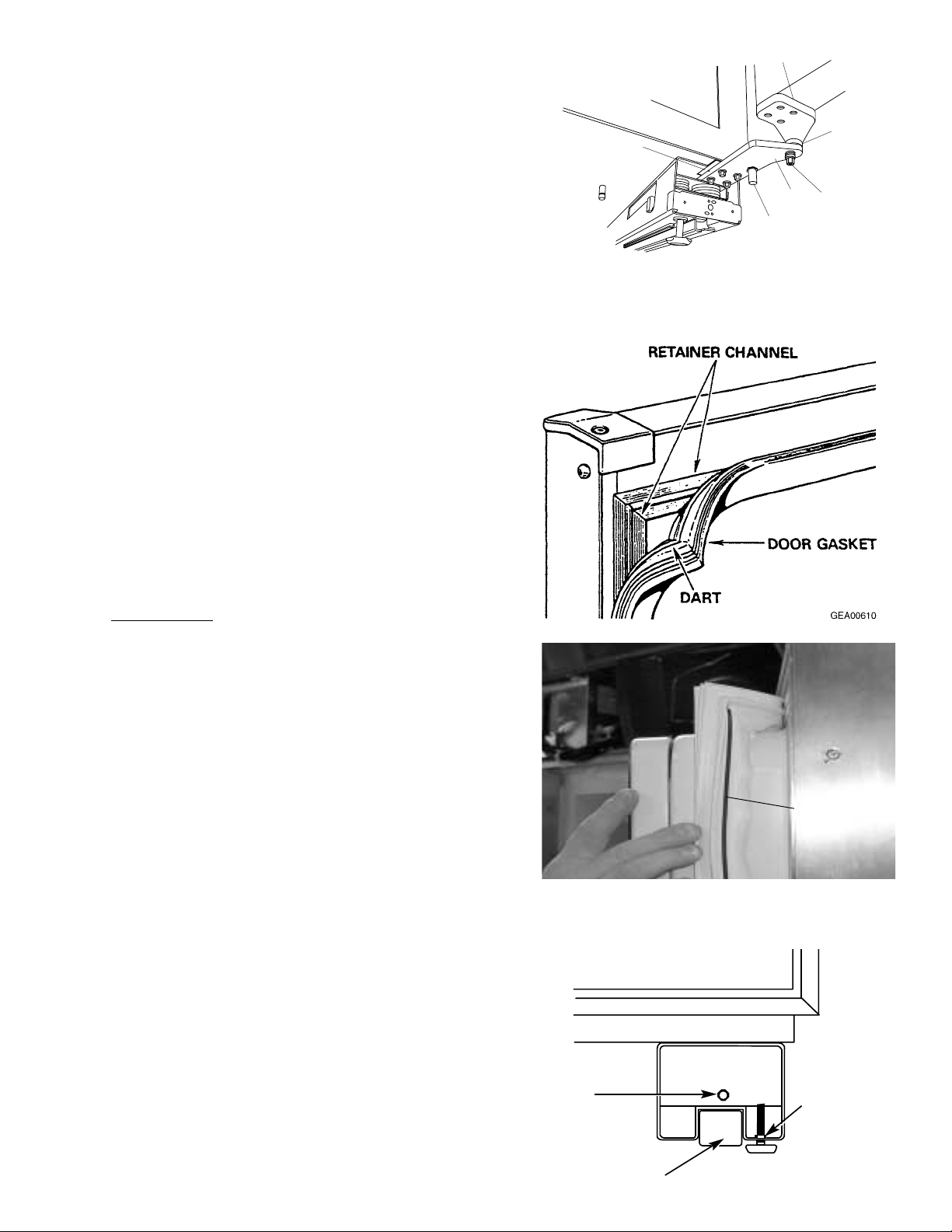

Door Gaskets

The fresh food and freezer doors have magnetic

gaskets that create a positive seal to the front of the

steel cabinet. The center mullion also has magnets to

assist in door sealing. Improper installation of the door

gasket will cause same-poled magnets to oppose one

another, preventing the door from closing tightly.

The magnetic door gaskets are secured to the doors

by a barbed edge that locks into a retainer channel.

The side of the gasket that is nearest the handle of the

door has a stripe on the inside of the barb (see photo).

Base Channel Spacer

Hinge

Door Stop

Bushing

5/16"

Bolt

GEA01268

Replacement

1. Starting at any corner, pull the old gasket out of the

retaining channel.

2. Soak the new gasket in warm water to make it

pliable.

3. Push the barbed edge of the gasket into the

retainer channel.

Rollers and Leveling

This model has 4-point leveling provided by adjustable

rollers on the rear and leveling legs on the front. It also

has 2 nonadjustable front rollers that are used only for

unit positioning.

T o level the unit:

1. Turn the 7/16-in. hex nut, located above the front

rollers, to adjust the roller on the rear of the unit.

Turn clockwise to raise, counterclockwise to lower.

2. Turn the front legs with a 1-1/4

wrench to adjust the front of the unit. T urn

clockwise to raise, counterclockwise to lower.

in. open end

Stripe

(Handle Side

of Door)

– 11 –

Page 14

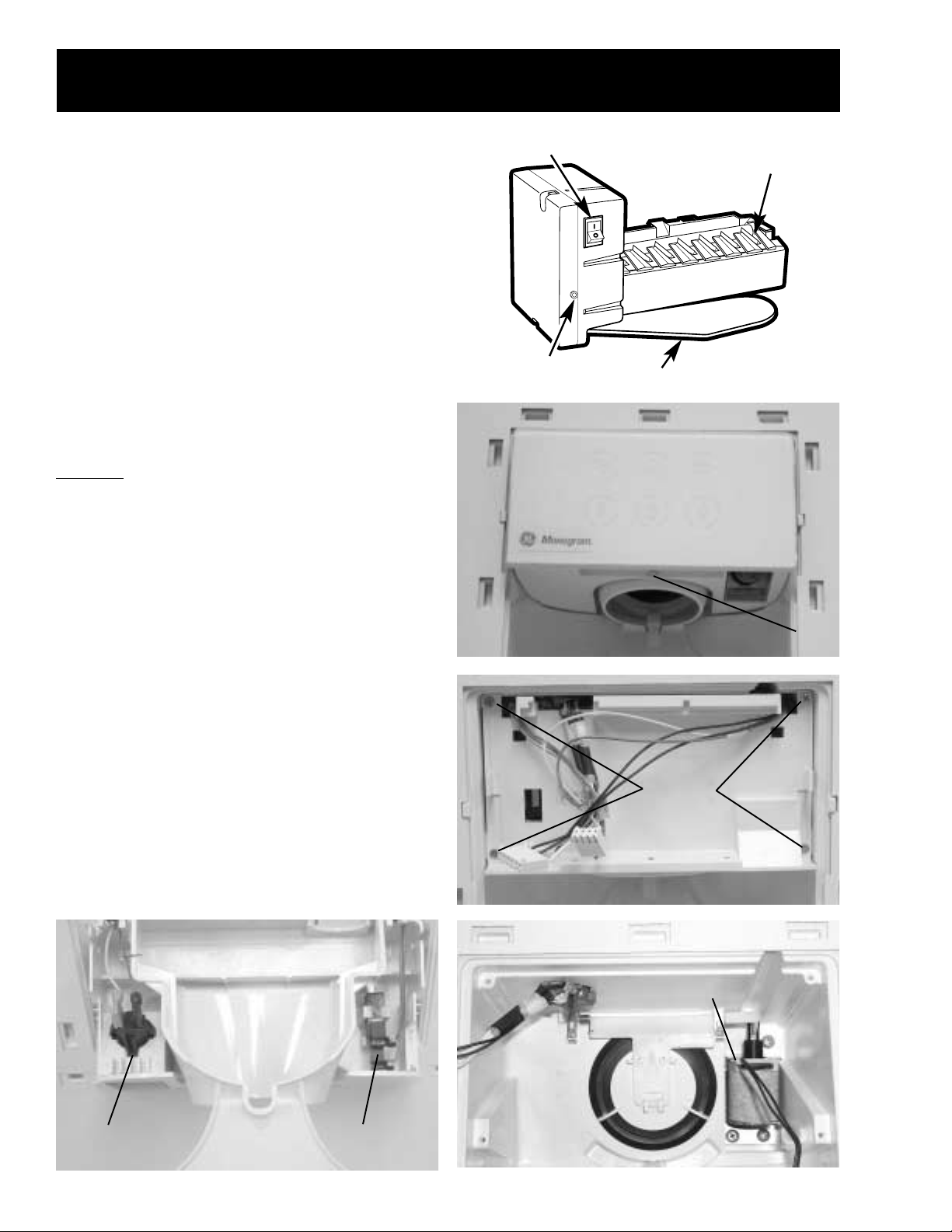

Icemaker

Feeler Arm

Power Switch

Green

Power Light

Ice and W ater Dispenser

The icemaker is mounted to the upper left wall of

the freezer cabinet. Under normal operating

conditions, temperatures, door openings, and food

load, the icemaker is capable of producing

approximately 100 to 130 cubes in a 24-hour

period.

To service the icemaker, refer to GE Publication

31-9063.

Controls

The electronic controls on the dispenser are

interactive. The control panel is equipped with a

proximity sensor that causes the panel to light up

as you approach the dispenser (approx. 2 inches).

Removal

1. Remove the bezel from the outside of the

freezer door.

Note: On stainless steel models, the front panel

must be removed. Remove screws from top,

bottom, and hinge side. Pull out on hinge side.

2. Remove the screw from the bottom of the

control panel. Lift up and pull the bottom of the

panel out. Disconnect the connectors, and

remove the control panel.

3. Remove 4 screws and the backing panel.

4. From the back side of the panel, remove the

water switch and the light socket.

5. Remove 3 screws and the duct door solenoid.

Screw

4 Screws

Duct Door

Solenoid

Light Socket

Water Switch

– 12 –

Page 15

Water V alve and Water Tank

The water valve is mounted in the left side of the

machine compartment.

A plastic water line is routed from under the unit,

up the back of the cabinet, into the machine

compartment, and to the water filter . A line then

goes from the water filter to the water valve.

Two low-pressure plastic water lines supply water

to the icemaker and door dispenser from the water

valve. A plastic water line is routed from the water

valve, out the back of the machine compartment,

down the back of the cabinet through the bottom of

the unit, and into the fresh food compartment

where it is attached to the cold water tank. A line is

routed from the cold water tank through the bottom

of the unit into the freezer door to supply the water

dispenser. The icemaker water line is routed from

the water valve through the machine compartment

to the icemaker. The icemaker fill tube is also

plastic.

To Replace the Water V alve

Water Valve

Screw

Screw

Note: Some water may leak from the water supply

line and valve when they are disconnected.

1. Shut off the water supply to the unit.

2. Open the grille panel.

3. Remove 1 Phillips screw attaching the water

valve to the filter bracket.

4. Disconnect the wiring harness connector and

3 water lines from the water valve and remove.

To Replace the Chilled Water Tank

Note: Some water may leak from the water supply

line and valve when they are disconnected.

1. Shut off the water supply to the unit.

2. Remove 2 screws and the chilled water tank

cover inside the fresh food compartment.

3. Remove 2 screws from the chilled water tank.

4. Cut the water lines leaving enough line to

reconnect. Use union WR02X10471

(5/16 x 5/16).

Screws

Water Tank Cover

Chilled Water Tank

– 13 –

Page 16

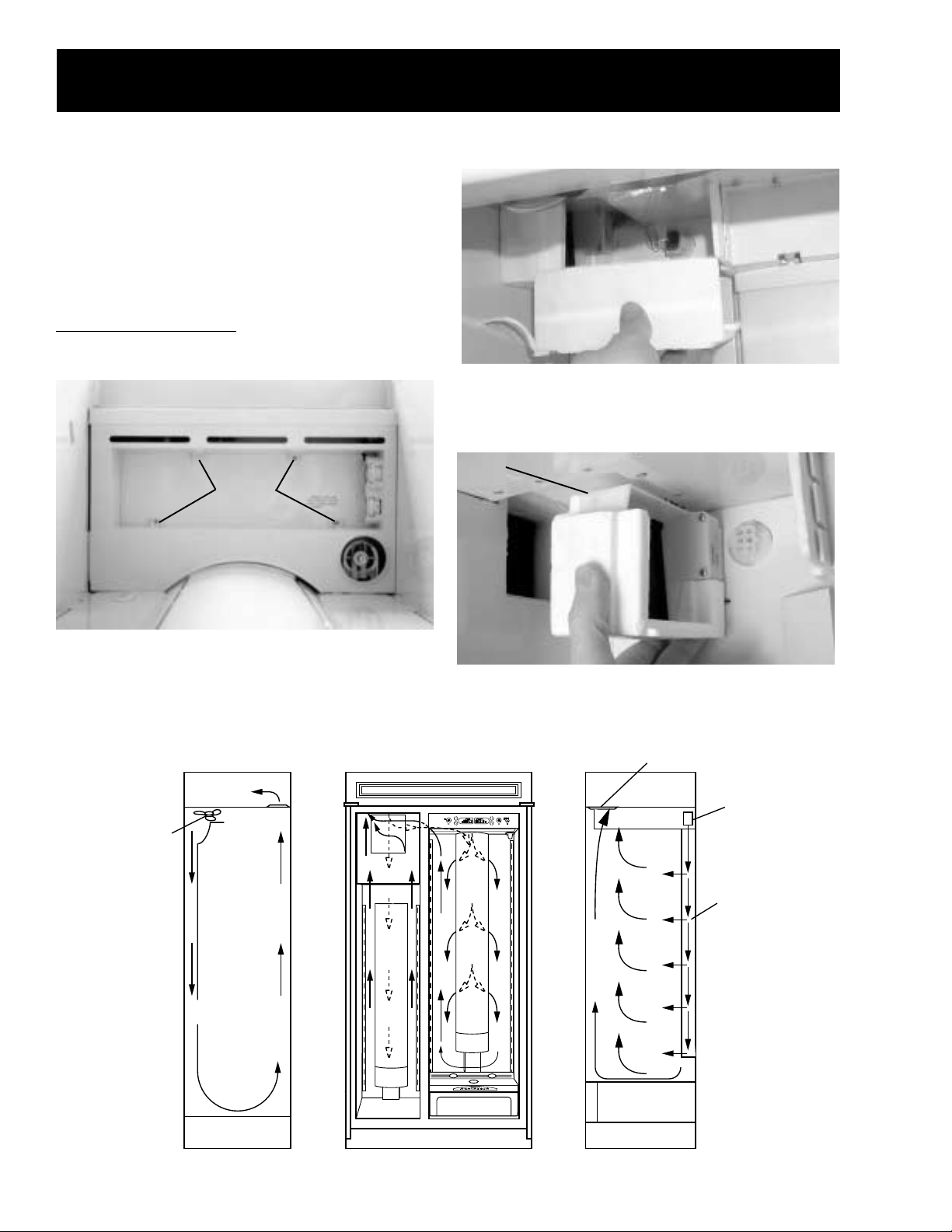

Airflow

Damper

The fresh food compartment receives chilled air

via an electronic damper that is positioned at the

top rear of the fresh food compartment. The

damper is controlled by the main control board and

when open, allows the evaporator fan to push

chilled air from the evaporator into the fresh food

compartment.

To Remove the Damper

1. Remove the light cover .

Screws

3. Remove the Styrofoam section covering the

damper.

4. Disconnect the damper wiring connector.

Damper

2. Remove 4 Phillips screws and the light

assembly.

Evaporator

Evap.

Fan

Front FrontBack Back

5. Carefully pull the damper out of the mullion and

remove.

Top

Return

Damper

Air

Tower

BottomFreezer Side Fresh Food Side

– 14 –

GEA01269

Page 17

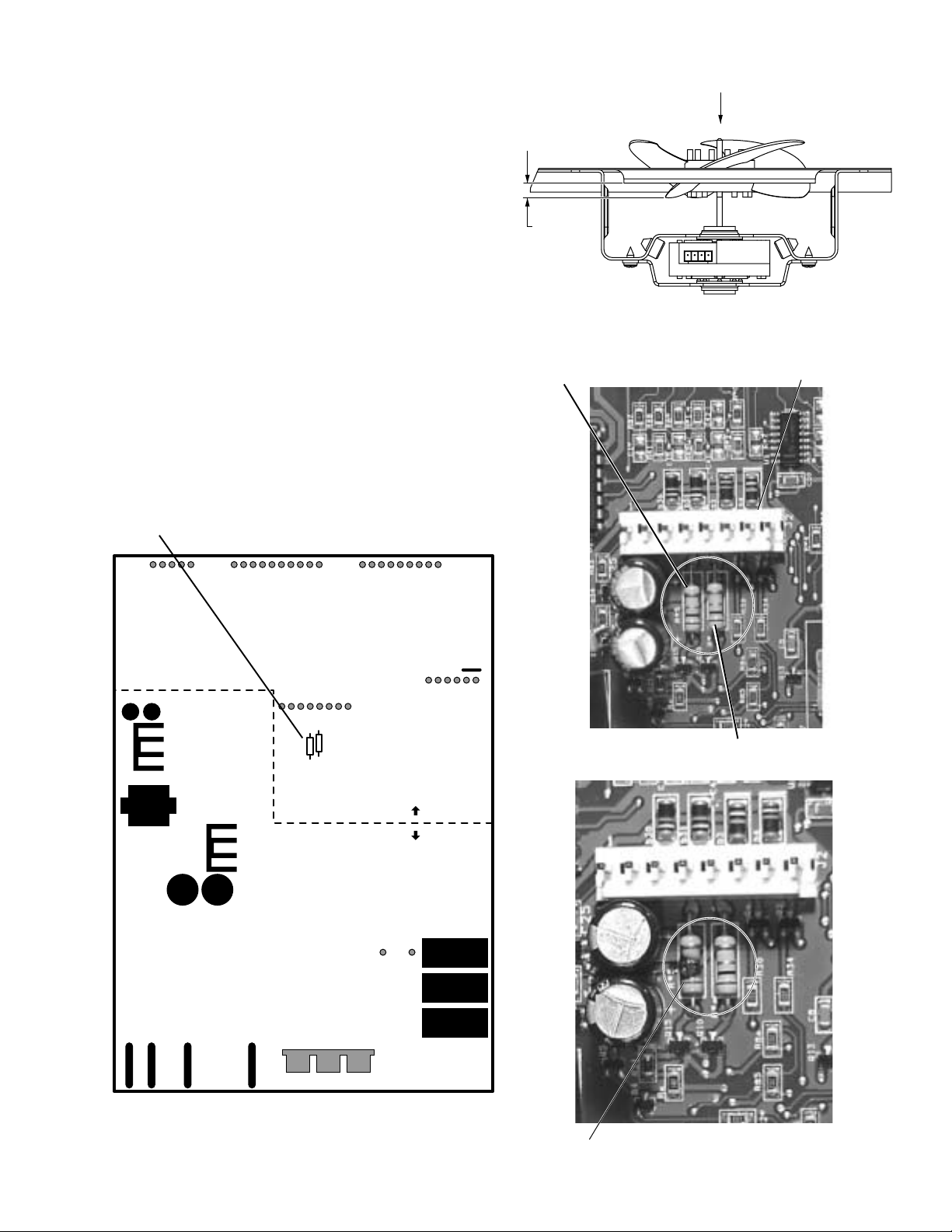

Evaporator Fan

Evaporator Fan Adjustment

The position of the fan blade in relation to the

shroud is critical. Refer to evaporator fan

adjustment graphic for specifications.

If the fan shorts, it may damage the main control

board. If the resistor on the main control board is

burnt, you must replace the fan and the board (see

photo).

The evaporator fan utilizes a permanent magnet,

4-pole, DC motor that can operate at three

different speeds: high, medium, and low (medium

and low are the same speed, controlled by the

main control board). The speed of the fan is

controlled by the voltage output from the main

control board. V oltage output from the control

board to the fan is 12.6 VDC; however, in order to

regulate the speed of the fan, the control board

uses Pulse Width Modulation (PWM) during low-

Evaporator and Condenser Fan Resistors

5/16

5/16 +/- .03

+/- 0.03

Evaporator Fan Resistor

Airflow

J2 Connector

GEA01140

Compressor

Defrost Heater

Pin 2

Pin 3

J4 Pin 1

Comm. Tx/Rx

Comm. +12V

Comm. Common

Pin 4

Pin 5

Discrete Disp. Input 1

Discrete Disp. Input 2

Line

Pin 2

Pin 3

Pin 4

Pin 5

J3 Pin 1

Damper - Blue

Pin 6

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

J2 Pin 1

Evaporator Fan Tach.

Monogram Drain Pan Heater

Pin 7

Pin 8

Pin 9

Pin 10

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

Pin 2

Pin 3

Pin 4

Pin 5

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

Neutral

NIC

FZ Door Switch

FF Door Switch

J1 Pin 1

FF1 Thermistor

Pin 6

Pin 7

Pin 8

FF Fan

QuickChill Fan

Fan +12V

QuickChill Heater

Auger Motor Interlock

Water Valve

Crusher Solenoid

Auger Motor

Pin 2

Pin 3

Pin 4

Pin 5

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

QuickChill Htr.

Pin 1

Pin 6

Pin 7

Pin 8

Pin 9

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

Pin 2

Pin 3

J5 Pin 1

QuickChill Damper1 +

QuickChill Damper1 -

QuickChill Damper2 +

Low Voltage DC

120 VA C

QuickChill Htr.

Pin 2

Pin 4

Pin 5

Pin 6

QuickChill Damper2 -

+5V

QuickChill Thermistor

Condenser Fan Resistor

Pin 1 J8

Pin 1 J9

Pin 1 J11

Pin 9 J7

Pin 8

Pin 7

Pin 6

Pin 5

Pin 4

Pin 3

Pin 2

Pin 1 J12

Pin 1

GEA01196

Bad Evaporator Fan Resistor

– 15 –

Page 18

speed and medium-speed operation. When operating in low and medium speeds, voltage is sent in

pulses (much like a duty cycle) as opposed to an uninterrupted flow. This pulsing of 12.6 VDC produces

effective voltage being received at the motor , which is the equivalent to a reduction in voltage. Fan speed

will be selected and maintained by the control board regulating the length and frequency of the 12.6 VDC

pulse.

One complete revolution of the motor is comprised of all 4 poles. To determine the rpm of the fan:

Measure the frequency being applied to the motor . Multiply this number by 15 (60 seconds divided by 4

poles). For example, a frequency measurement of 200 Hz multiplied by 15 would show a fan speed of

3000 rpm (15 x 200 = 3000). Temperature may cause some fan speed variation. Fan speed may vary

+/- 5%, depending on the temperature, with higher temperatures causing slightly higher speeds.

The evaporator fan motor uses a 4-wire connection, utilizing a common wire (white), feedback/rpm

wire (blue), supply wire (red), and a signal wire (yellow).

12 VDC

12 VDC

8 VDC

4 VDC

0 VDC

12VDC

0 VDC

12 VDC

0 VDC

High S peed (12 VDC measured)

Medium and Low S peed (8 VDC measured)

EVAPORATOR FAN SPEEDS

High Speed (12 VDC measured)

Medium Speed (8 VDC measured)

Low Speed (4 VDC measured)

GEA01139

– 16 –

Page 19

White Wire (DC Common)

The white wire is the DC common wire used for

testing. During repairs, DC polarity must be

observed. Reversing the DC polarity will cause a

shorted motor and/or board.

Red Wire (Supply)

Each motor uses an internal electronic controller

to operate the motor. Supply volt age from the

main control board remains at a constant

12 VDC.

Blue Wire (Feedback/RPM)

The blue wire feeds rpm (speed) information to

the main control board, allowing the board to

maintain consistent fan speeds. Loss of feedback

from the blue wire will result in the fan accelerating

to maximum speed. Measure the fan rpm using

the frequency between the blue and white wires.

High speed - 195 to 200 Hz

Medium speed - 145 to 160 Hz

Note: Fan operates at the same speed in low and

medium.

Low speed - 145 to 160 Hz (same as medium)

Yellow Wire (Signal)

The yellow wire is the input wire from the main

control board. The main control board provides

8.1 VDC effective voltage for low speed, 8.1 VDC

effective voltage for medium speed, and 12.6 VDC

for high speed. The fan will operate in low speed

only when the fresh food thermistor is satisfied.

Compressor

Pin 1 J8

Pin 2

Pin 3

J4 Pin 1

Comm. Tx/Rx

Comm. +12V

Comm. Common

Defrost Heater

Pin 1 J9

Pin 4

Pin 5

Discrete Disp. Input 1

Discrete Disp. Input 2

Line

Pin 1 J11

Pin 2

Pin 3

Pin 4

Pin 5

J3 Pin 1

Damper - Blue

Pin 6

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

J2 Pin 1

Evaporator Fan Tach.

Monogram Drain Pan Heater

Pin 1 J12

Pin 7

Pin 8

Pin 9

Pin 10

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

Pin 2

Pin 3

Pin 4

Pin 5

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

Neutral

NIC

FZ Door Switch

FF Door Switch

Pin 9 J7

Pin 8

Pin 7

Pin 6

J1 Pin 1

FF1 Thermistor

Pin 6

Pin 7

Pin 8

FF Fan

QuickChill Fan

Fan +12V

QuickChill Heater

Auger Motor Interlock

Water Valve

Crusher Solenoid

Auger Motor

Pin 5

Pin 4

Pin 3

Pin 2

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

QuickChill Htr.

Pin 1

Pin 6

Pin 7

Pin 8

Pin 9

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

Pin 2

Pin 3

J5 Pin 1

QuickChill Damper1 +

QuickChill Damper1 -

QuickChill Damper2 +

Low Voltage DC

120 VA C

QuickChill Htr.

Pin 2

GEA01196

Pin 4

Pin 5

Pin 6

QuickChill Damper2 -

+5V

QuickChill Thermistor

Note: When testing these motors:

• You cannot test with an ohmmeter.

• DC common is not AC common.

• Verify 2 volt age potentials:

a. Red to white - power for internal controller.

b. Yellow to white - power for fan.

• Observe circuit polarity.

• Motors can be run for short periods using a

9-volt battery . Connect the white wire to the

negative (-) battery terminal only. Connect the

red and yellow wires to the positive (+) battery

terminal.

– 17 –

Page 20

To Remove the Evaporator Fan

1. Remove the ice bucket.

2. Disconnect the icemaker connector. Loosen 2

screws and remove icemaker.

3. Remove 4 screws and slide the icemaker drive

motor assembly forward. Disconnect the wiring

connector and remove the assembly.

4. Remove 2 screws and inner section of left ice

bucket track.

Screws

Icemaker Drive

Motor Assembly

Screws

5. Remove 2 screws and wiring cover.

6. Remove 6 screws and evaporator fan cover.

Wiring

Cover

Evaporator Fan Cover

Screws

Screws

– 18 –

Page 21

7. Disconnect the evaporator fan wiring

connector.

8. Remove 2 screws from the fan mounting

bracket and remove the fan.

Condenser Fan

The condenser fan utilizes a DC motor that

operates at a single speed and is mounted in the

machine compartment. When the fan is

operating, air is pulled through the condenser ,

drawing air through the coils. The air is then

exhausted past the compressor and out the front

of the refrigerator on the right side.

Evaporator Fan

Screws

Wire Connector

Inlet air is available through the left front and left

rear of the machine compartment.

If the fan shorts, it will damage the main control

board. If the resistor on the main control board is

burnt, you must replace the fan and the board (see

photo page 15).

The condenser fan is mounted with screws to a

fan shroud and mounting bracket in back of the

condenser.

To Remove the Fan

1. Extend the chassis (see Machine

Compartment in the Cabinet chapter).

2. Pull the blade off the motor shaft.

3. Cut the wire tie securing the fan wiring to the

fan bracket.

Caution: Fan connector can be separated into 3

segments (center, left side, and right side).

Disconnect the fan connector at the center only.

Fan Bracket

Fan Bracket

Condenser Fan Motor

Screws

4. Disconnect the fan connector.

5. Feed wiring through the hole in the fan shroud.

6. Remove 2 screws, top section of fan bracket,

and motor.

– 19 –

Page 22

Defrost System

Adaptive Defrost

Adaptive Defrost can be described as a defrost

system that adapts to a refrigerator’s surrounding

environment and household usage.

Unlike conventional defrost systems that use

electromechanical timers with a fixed defrost cycle

time, Adaptive Defrost utilizes an intelligent,

electronic control to determine when the defrost

cycle is necessary. In order to accomplish the

correct defrost cycle time, the main control board

monitors the following refrigerator operations:

• Length of time the refrigerator doors were open

since the last defrost cycle

• Length of time the compressor has run since

the last defrost cycle

• Amount of time the defrost heaters were on in

the last defrost cycle

Adaptive Defrost is divided into 4 separate cycles.

Those operations are:

• Cooling Operation

• Pre-Chill Operation

• Defrost Heater Operation

• Dwell Period

(See Pub. #31-9062 for more information on

Adaptive Defrost.)

Adaptive Defrost (Cooling Operation)

During the cooling operation, the main control

board monitors door opening (fresh food door and

freezer drawer) and compressor run times. The

board counts the time the doors are open. It

reduces the length of time between defrosts by

300 seconds (multiplication factor) for each

second that each door is open (if both doors are

open, it reduces it by twice the amount). The

multiplication factor reduces compressor run time.

If the doors are not opened, the compressor will

run up to 60 hours between defrosts. If the doors

are opened frequently and/or for long periods of

time, the compressor run time between defrosts

will be reduced to as little as 8 hours.

Adaptive Defrost (Pre-Chill Operation)

When the main control board determines that

defrost is necessary, it will force the refrigerator

into a continuous cool mode (pre-chill). During prechill, the freezer temperature may be driven below

the set point. However, the fresh food temperature

will be regulated by the evaporator fan running at

low speed. Pre-chill will last for 30 minutes. These

models do have an 8-hour defrost holdoff.

Adaptive Defrost (Defrost Heater Operation)

After 30 minutes of pre-chill operation, the main

control board turns off the compressor, condenser

fan, and evaporator fan.

During defrost operation, the main control board

monitors the evaporator temperature using

evaporator thermistor inputs. T ypically, the

evaporator thermistor will sense a temperature of

38 °F within 16 minutes. When the thermistor

senses 38 °F, the main control board will terminate

defrost heater operation. Maximum defrost cycle

(heater on) time is 35 minutes (main control board

time out).

The defrost system is protected by a defrost

overtemperature thermodisc (bimetal switch). The

thermostat opens when the evaporator

temperature raises to 60 °F and closes when the

evaporator temperature lowers to 45 °F.

Adaptive Defrost (Dwell Period)

After defrost heater operation has been terminated

by the main control board, a 20-minute dwell

period occurs. During this period, the

compressor, condenser fan, and evaporator fan

remain off. The remaining frost melting from the

evaporator will continue to drip and drain so that,

prior to the cooling operation, the evaporator will be

totally clear of any moisture. The pan heater is on

for the entire 20 minute dwell period.

– 20 –

Page 23

Normal Operating Characteristics

• Evaporator fan running, without compressor or

condenser fan.

• Liner Protection Mode, fan comes on when the

doors are open for 3 minutes.

• Different sound levels can be heard when the

fan changes speed; however, the fan should

never be heard oscillating between speeds.

• Response time for drastic temperature change

is 2 to 10 minutes. The main control board will

only respond to 8 °F of temperature change

per minute as determined by resistance of

sensor.

Abnormal Operating Characteristics

(Incorrect Operation)

• Rapid fan speed changes, fan takes at least

1 minute to change speeds.

• Compressor running without the condenser

fan. The compressor and condenser fan

should always run at the same time.

Liner Protection Mode

The liner protection mode will activate if either of

the doors has been open for 3 minutes. This

mode will start the evaporator fan on high speed.

This mode is controlled by 2 timers. Timer #1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If

3 minutes elapse before the door is closed, the

liner protection mode will become active. Once

the door is closed, timer #1 resets and liner

protection mode goes into standby. In standby,

normal fan and damper operations resume and

timer #2 begins a 3-minute door-closed count.

If 3 minutes elapse without a door opening, liner

protection mode will completely deactivate. If a

door is opened within the timer #2 door-closed

count, the remaining time in the door-closed count

will be deducted from the timer #1 door-open

count.

– 21 –

Page 24

Defrost Heater

Caution: Use care to avoid scratching the finish

on unit walls.

The defrost heater is a single calrod-type, radiant

heater mounted on the evaporator .

To remove the defrost heater:

1. Remove the evaporator fan (see Evaporator

Fan procedure in the Airflow chapter).

2. Remove 8 screws and freezer ceiling panel.

3. Remove Styrofoam insulation from the bottom

of the evaporator drain pan.

4. Loosen evaporator drain hose clamp.

5. Lower left side of evaporator drain pan and

slide right side out of drain hose and remove.

6. Disconnect the heater wiring.

Styrofoam

Insulation

Evaporator Drain Pan

Hose Clamp

7. Remove 2 screws from the left and right heater

fasteners.

8. Slide the heater toward the front of the freezer

compartment and remove.

Heater

Screws

– 22 –

Page 25

Evaporator Thermistor

The evaporator thermistor is mounted on the

upper left side of the evaporator. The defrost

cycle will terminate when the main control board

detects 38 °F from the evaporator thermistor. The

main control board must sense 38 °F in less than

35 minutes, or the defrost cycle will time out.

Average time to defrost is less than 16 minutes.

Defrost time should not exceed 35 minutes.

Defrost time does not include dwell period.

Defrost Overtemperature Thermodisc

The defrost overtemperature thermodisc (bimetal

switch) is mounted on the evaporator and

provides overtemperature protection during

defrost. This thermostat will open at 60 °F and

will close at 45 °F.

Evaporator

Thermistor

Note: The main control board will not know if the

heater does not come on due to a broken heater ,

open defrost overtemperature thermodisc, or

open wiring harness. The defrost heater is

controlled by maximum time on the main control

board or temperature at the evaporator thermistor .

Defrost

Overtemperature

Thermodisc

– 23 –

Page 26

Control System

Touch Panel and

Temperature Control Board

The temperature control assembly is located at

the top front of the fresh food compartment and

contains the touch panel and temperature control

board.

The temperature control board receives switched

DC voltage from the main control board. Input

consists of pins 2 to 3. Failure of input results in

default to most recent setting. Pin 1 provides

digital communication between the temperature

control board and the main control board. Failure

of communication results in erratic control.

To remove the temperature control assembly:

1. Remove the light cover .

2. Remove 4 Phillips screws and the light

assembly.

Temperature Control Assembly

Light Assembly

Touch Panel

Note: Temperature control assembly is mounted

on 3 slotted fasteners. Fasteners do not need to

be loosened or removed.

3. Cut the RTV around the edge of the

temperature control assembly.

Note: Old RTV must be removed from the inside

of the fresh food compartment and from the

temperature control assembly. RTV 102 must be

put in place when the temperature control panel is

installed.

4. Disconnect the temperature control assembly

wiring connector.

5. Slide the temperature control assembly back

to release it from the slotted fasteners and

lower the assembly.

6. Disconnect the wiring connector from the

temperature control board.

7. Slide the touch panel out of the temperature

control assembly.

Screws

8. Remove 2 screws and the temperature control

board.

– 24 –

Page 27

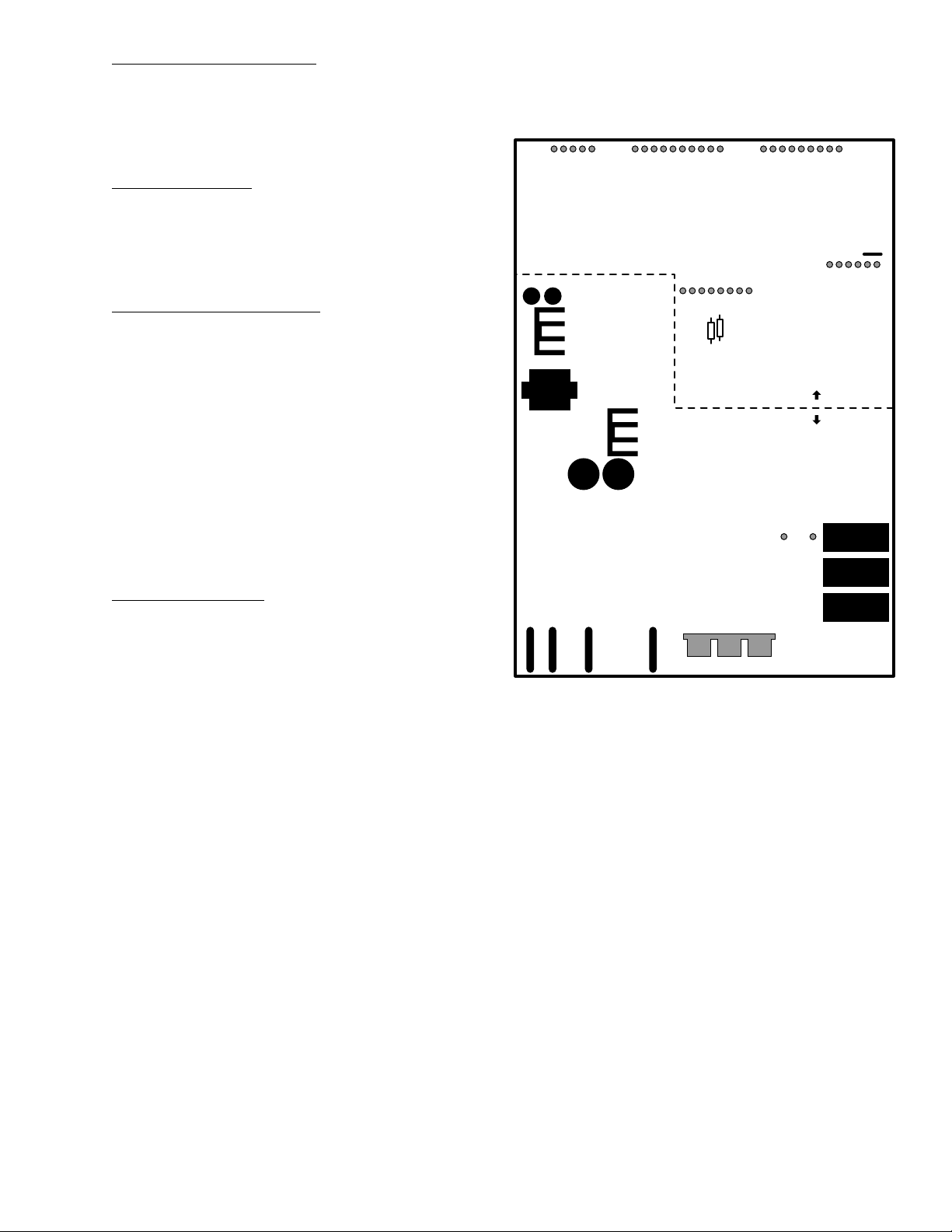

Main Control Board

The main control board, located behind a metal cover at the top of the refrigerator in the machine

compartment, manages the operation of the refrigerator by calculating response from various inputs.

Pin 1 J8

Pin 1 J9

Pin 1 J11

Pin 1 J12

– 25 –

GEA00859

Pin 9 J7

Pin 8

Pin 7

Pin 6

Pin 5

Pin 4

Pin 3

Pin 2

Pin 1

Compressor

Defrost Heater

Line

Monogram Drain Pan Heater

Neutral

NIC

FZ Door Switch

FF Door Switch

QuickChill Heater

Auger Motor Interlock

Water Valve

Crusher Solenoid

Auger Motor

Pin 1

Pin 2

QuickChill Htr.

QuickChill Htr.

Evaporator Fan Tach.

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

FF Fan

QuickChill Fan

Fan +12V

Low V oltage DC

120 V AC

J2 Pin 1

QuickChill Damper1 +

QuickChill Damper1 QuickChill Damper2 +

QuickChill Damper2 +5V

QuickChill Thermistor

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

J5 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Comm. Tx/Rx

Comm. +12V

Comm. Common

Discrete Disp. Input 1

Discrete Disp. Input 2

Damper - Blue

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

FF1 Thermistor

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

J4 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

J3 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

J1 Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Page 28

Main Control Board Locator Tables

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

1J1CDV

1J2CDV

1J3CDV

1J4CDV

1J5 CDV.1JnosnipytilanosrepdnasrotsimrehtrofCDV5sedivorP

SNOITINIFEDNIPDRAOBLORTNOC

ecnatsiser,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtdoofhserffokcabdeeF

nehw(nafdoofhserfelcycotdesusieulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulav

8otdnopserotderetlifsikcabdeeF.nafrosnednocdna,rosserpmoc,nafrotaropave,)desu

.etunimrepegnahcfoseerged

nehw,CTNsirotsimrehT.)desunehw(eulavrotsimrehtdoofhserfdnocesfokcabdeeF

desusieulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulavecnatsiser,sporderutarepmet

sikcabdeeF.nafrosnednocdna,rosserpmoc,nafrotaropave,)desunehw(nafdoofhserfelcycot

.etunimrepegnahcfoseerged8otdnopserotderetlif

ecnatsiser,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtrezeerffokcabdeeF

,nafrotaropaveelcycotdesusieulavsihT.noitcuderegatlovnrutergnisuac,sesaercnieulav

deretlifsikcabdeeF.)desunehw(nafdoofhserfelcyctonlliwdna,nafrosnednocdna,rosserpmoc

.etunimrepegnahcfoseerged8otdnopserot

ecnatsiser,sporderutarepmetnehw,CTNsirotsimrehT.eulavrotsimrehtrotaropavefokcabdeeF

retaehehtelcycotdesusieulavrotsimrehtsihT.noitcuderegatlovnrutergnisuac,sesaercnieulav

evobasierutarepmetehtnehwffodnaeulavtsorfedwolebsierutarepmetnehwtsorfedgnirudno

otniseogrotaregirferfienimretedotpu-rewopgniruddaeroslasieulavsihT.eulavtsorfed

.yletaidemmisdnopser,deretlifnusikcabdeeF.noitaunitnocelcycroedomnwodllup

1J9CDV

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

2J1zH

2J3 CDV.dnuorgCDV-nommocnaF

2J4 CDV .MWPybdenimretedsiegatlovevitceffE.noitareporotomrofnafrotaropaveottuptuO

2J5 CDV

2J7 CDV

2J8 CDV.egatlovtnatsnoc,snafllaotegatlovylppusCDV-21sedivorP

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

.sdeeps

.MORPEEni

.MWP

.ylnopu-rewopnonoitanibmocsdaeR.desugnimmargorpdna

ledomsenimreted,snipytilanosreprehtohtiwnoitanibmocnidetcennocnehw,tahtnipnoitceleS

SNOITINIFEDNIPDRAOBLORTNOC

nafrofMWPehtlortnocotdesusiycneuqerfkcabdeefsihT.nafrotaropavemorfkcabdeeF

tesdeeps,MWPybdenimretedsiegatlovevitceffE.noitareporotomrofnafrosnednocottuptuO

ybdenimretedsiegatlovevitceffE.noitareporotomrofnaf)llihCkciuQ(llihCsserpxEottuptuO

SNOITINIFEDNIPDRAOBLORTNOC

3J1 CDV.rotomreppetsrepmaD

3J2 CDV.rotomreppetsrepmaD

3J3 CDV.rotomreppetsrepmaD

3J4 CDV.rotomreppetsrepmaD

– 26 –

Page 29

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

4J1

4J2 CDV.ylppusCDV-21

4J3 CDV.nommocCD

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

5J1 CDV

5J2 CDV

5J5 CDV.rotsimreht)llihCkciuQ(llihCsserpxErofCDV5sedivorP

latigiD

noitacinummoC

latigiD

noitacinummoC

SNOITINIFEDNIPDRAOBLORTNOC

lortnocerutarepmet,draoblortnocniamneewtebnoitacinummoclatigidyaw-owT

.draobllihCkciuQdna,draobresnepsid,)draob(

SNOITINIFEDNIPDRAOBLORTNOC

.detcelessi)llihCkciuQ(llihCsserpxEnehwrepmadrewarDlortnoCetamilCotCDV21

.detcelessiwahtsserpxenehwdnuorgCDV-nommoC

.detcelessiwahTsserpxEnehwrepmadrewarDlortnoCetamilCotCDV21

.detcelessi)llihCkciuQ(llihCsserpxEnehwdnuorgCDV-nommoC

5J6CDV

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

7J1 CAV.CAV021-rotomreguaehtotegatlov1LdehctiwS

7J2 CAV.CAV021-dionelosrehsurcehtotegatlov1LdehctiwS

7J3 CAV.CAV021-evlavretawehtotegatlov1LdehctiwS

7J4CAV .desolcsiroodrezeerfnehwhctiwsroodrezeerfmorftupni1LsevieceR

7J5 CAV .CAV021-retaeh)llihCkciuQ(llihCsserpxEehtotegatlov1LdehctiwS

7J6CAV

.snoitaluclactsorfedevitpada

7J7CAV

.egatlovnruterninoitcuderagnisuac,sesaercnieulavecnatsiser

,sporderutarepmetnehw,CTNsirotsimrehT.rotsimreht)llihCkciuQ(llihCsserpxEfokcabdeeF

SNOITINIFEDNIPDRAOBLORTNOC

desusitupnisihT.)neporood(sesolchctiwsnehwhctiwsrooddoofhserfmorftupni1LsevieceR

dna,snoitaluclacmralarood,snoitaluclacedomnoitcetorprenil,lortnocnafrotaropaverof

desusitupnisihT.)neporood(sesolchctiwsnehwhctiwsroodrezeerfmorftupni1LsevieceR

rood,snoitaluclactsorfedevitpada,snoitaluclacedomnoitcetorprenil,lortnocnafrotaropaverof

desolcroodnidesolcebtsumhctiwS.snoitcnufkcolretniroodemosdna,snoitaluclacmrala

.ezigreneottengamroodtcuddnathgilresnepsidrof)desserpedhctiws(noitisop

7J9CAV.nilartuenCA

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

8J1 CAV

– 27 –

SNOITINIFEDNIPDRAOBLORTNOC

dnadezigrenesitiucricgnolwohstnuocremitA.tiucricrosserpmocotegatlov1LdehctiwS

.ruccolliwtsorfedtxenehtnehwenimretedotnoitamrofnisihtsesu

Page 30

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

9J1 CAV

.evitpadanon

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

11J1CAV .slanimret1LdehctiwsroflaitnetoptupniCAV021-stiucricdraoblortnocotegatlov1LtnatsnoC

ROTCENNOC NIP TUPNI TUPTUO NOITCNUF

21J1 CAV.retaehnapniardehtotegatlov1L

SNOITINIFEDNIPDRAOBLORTNOC

sitiucricsihtgnolwohstnuocremitA.CAV021-tiucrictsorfedehtotegatlov1LdehctiwS

roevitpadasielcyctsorfedtxenehtfienimretedotnoitamrofnisihtsesudnadezigrene

SNOITINIFEDNIPDRAOBLORTNOC

SNOITINIFEDNIPDRAOBLORTNOC

– 28 –

Page 31

draoBlortnoCniaM

)ediSCAV021(rotcennoC7J

niP roloCeriW

tnenopmoC

noitanimreT

/tupnI

tuptuO

1kcalBrotomreguAtuptuO

2elpruPdionelosrehsurCtuptuO

3eulBevlavretaWtuptuO

4deR

5teloiV

6eulB

7wolleY

roodrezeerF

hctiws

llihCkciuQ

retaeH

rooddoofhserF

hctiwsthgil

thgilroodrezeerF

hctiws

tupnI

tuptuO

tupnI

tupnI

9egnarOlartueNlartueNlartueN

gnidaeRegatloVniP-ot-niP

021=9nip7Jot1nip7J

CAV

021=9nip7Jot2nip7J

CAV

021=9nip7Jot3nip7J

CAV

021=9nip7Jot4nip7J

)desolcroodZF(CAV

021=9nip7Jot5nip7J

CAV

021=9nip7Jot6nip7J

)neporoodFF(CAV

021=9nip7Jot7nip7J

)neporoodZF(CAV

Compressor

Defrost Heater

Line

Pin 1 J8

Pin 1 J9

Pin 1 J11

Monogram Drain Pan Heater

Pin 1 J12

niP roloCeriW tuptuO/tupnI gnidaeRegatloVniP-ot-niP

Neutral

Pin 9 J7

NIC

Pin 8

FZ Door Switch

FF Door Switch

QuickChill Heater

Auger Motor Interlock

Pin 7

Pin 6

Pin 5

Pin 4

11J,9J,8JdraoBlortnoCniaM

)ediSegatloV-hgiH(srotcennoC

Water Valve

Crusher Solenoid

Auger Motor

Pin 3

Pin 2

Pin 1

QuickChill Htr.

QuickChill Htr.

Pin 1

Pin 2

Low V oltage DC

120 VA C

GEA01194

8JetihWtuptuOCAV021=9nip7Jot8J

9JdeRtuptuOCAV021=9nip7Jot9J

11JnworBtupnICAV021=9nip7Jot11J

21JkcalBtuptuOCAV021=9nip7Jot21J

– 29 –

Page 32

niP roloCeriW tnenopmoC

1deRerutarepmeT

2nworBerutarepmeT

3egnarOerutarepmeT

Pin 2

Pin 3

Pin 4

Pin 5

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Discrete Disp. Input 1

Discrete Disp. Input 2

J3 Pin 1

Damper - Blue

Damper - White

Damper - Red

Damper - Yellow

FF Encoder Select

FZ Encoder Select

J2 Pin 1

Evaporator Fan Tach.

J4 Pin 1

Comm. Tx/Rx

Comm. +12V

Comm. Common

Pin 7

Pin 8

Pin 9

Pin 10

Encoder Signal

Encoder Signal

Encoder Signal

Encoder Signal

Pin 2

Pin 3

Pin 4

Pin 5

Personality Input 5

Fan Common

Evaporator Fan

Condenser Fan

lortnoc

lortnoc

lortnoc

Pin 6

Pin 7

FF Fan

QuickChill Fan

noitanimreT

J1 Pin 1

FF1 Thermistor

Pin 8

Fan +12V

Pin 2

Pin 3

Pin 4

Pin 5

FF2 Thermistor

FZ Thermistor

Evaporator Thermistor

+5V

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC4J

tuptuO/tupnI gnidaeRegatloVniP-ot-niP

noitacinummoCnoitacinummoclatigidyaw-owT

CDV.ylppusCDV-21

CDV.nommocCD

Pin 6

Pin 7

Pin 8

Pin 9

Personality Input 1

Personality Input 2

Personality Input 3

Personality Input 4

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

J5 Pin 1

QuickChill Damper1 +

QuickChill Damper1 -

QuickChill Damper2 +

QuickChill Damper2 -

+5V

QuickChill Thermistor

Low Voltage DC

120 VAC

GEA01195

,draoblortnocniamneewteb

,)draob(lortnocerutarepmet

dna,draobresnepsid

.draobllihCkciuQ

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC3J

niP roloCeriW tnenopmoC

noitanimreT

/tupnI

tuptuO

1eulBrotoMreppetSrepmaD=3nip4Jot1nip3J

2etihWrotoMreppetSrepmaD=3nip4Jot2nip3J

3deRrotoMreppetSrepmaD=3nip4Jot3nip3J

4wolleYrotoMreppetSrepmaD=3nip4Jot4nip3J

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC1J

niP roloCeriW tnenopmoC

1elpruPdoofhserF

2eulBdoofhserF

noitanimreT

1rotsimreht

2rotsimreht

/tupnI

tuptuO

tupnI5.3ot8.2=5nipot1nip1J

tupnI5.3ot8.2=5nipot2nip1J

3deRrotsimrehtrezeerFtupnI5.3ot8.2=5nipot3nip1J

4kcalBrotaropavE

5nworBylppusrotsimrehT

niP

1wolleY

2yarG

5nworB

6eulB

eriW

roloC

tnenopmoC

noitanimreT

llihCkciuQ

)looCmotsuC(

repmaD

llihCkciuQ

)looCmotsuC(

repmaD

egatloVylppuS

)CDV5(

llihCkciuQ

)looCmotsuC(

rotsimrehT

rotsimreht

/tupnI

tuptuO

/tupnI

tuptuO

/tupnI

tuptuO

tuptuOCDV5=3nip2Jot01nip5J

tupnIA/N

tupnI5.3ot8.2=5nipot4nip1J

)CDV5(egatlov

tuptuOCDV5=3nip4Jot5nip1J

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC5J

gnidaeRegatloVniP-ot-niP

CDV3.2egatloVgnidnatS

CDV0.6=egatloVgnilevarT

CDV3.2egatloVgnidnatS

CDV0.6=egatloVgnilevarT

CDV3.2egatloVgnidnatS

CDV0.6=egatloVgnilevarT

CDV3.2egatloVgnidnatS

CDV0.6=egatloVgnilevarT

gnidaeRegatloVniP-ot-niP

CDV

CDV

CDV

CDV

gnidaeRegatloVniP-ot-niP

)ytiralopgnisrever(CDV21=2nipot1nip5J

)ytiralopgnisrever(CDV21=1nipot2nip5J

draoBlortnoCniaM

)ediSCDegatloV-woL(rotcennoC2J

niP roloCeriW tnenopmoC

1eulBnafrotaropavE

noitanimreT

retemohcat

/tupnI

tuptuO

tupnICDV3.6=3nipot1nip2J

3etihWnommocnaFnommoCCDV21=8nipot3nip2J

4wolleYnafrotaropavEtuptuOCDV6.21=3nipot4nip2J

5kniPnafresnednoCtuptuOCDV4.31=3nipot5nip2J

6kcalBnafnapniarDdnuorGdnuorgCDV

7kcalBnafllihCkciuQnommoCCDV21=7nipot8nip2J

8deRegatlovylppusnaF

)CDV21(

tuptuOCDV21=3nipot8nip2J

)wol(CDV1.8

elgnissinafresnednoc(

)deeps

– 30 –

gnidaeRegatloVniP-ot-niP

,).dem(CDV1.8,)hgih(

Page 33

Thermistors

This main control board uses input from 4 thermistors. These thermistors are located in the fresh food

section, the freezer section, and on the evaporator. The main control board monitors the thermistors to

determine the temperature in these areas of the unit and determines which components to run and

when to run them based on this information.

seulaVrotsimrehT

erutarepmeT

)C(seergeD

04-04-k8.661 Ω

03-22-k88 Ω

02-4-k4.84 Ω

01-41k6.72 Ω

023k3.61 Ω

0105k01 Ω

0286k2.6 Ω

0368k4 Ω

04401k6.2 Ω

05221k8.1 Ω

06041k2.1 Ω

dooFhserF

lortnoC

gnitteS

erutarepmeT

)F(seergeD

dooFhserF

rotsimrehT

egnaRerutarepmeT

ecnatsiseR

smho-oliKni

trahCtnioPteSerutarepmeT

rezeerF

lortnoC

gnitteS

rotsimrehTrezeerF

egnaRerutarepmeT

muminiMmumixaMmuminiMmumixaM

F°43F°23F°63F°5-F°01-F°0

F°53F°33F°73F°4-F°9-F°1

F°63F°43F°83F°3-F°8-F°2

F°73F°53F°93F°2-F°7-F°3

F°83F°63F°04F°1-F°6-F°4

F°93F°73F°14F°0F°5-F°5

F°04F°83F°24F°1F°4-F°6

F°14F°93F°34F°2F°3-F°7

F°24F°04F°44F°3F°2-F°8

F°34F°14F°54F°4F°1-F°9

F°44F°24F°64F°5F°0F°01

F°54F°34F°74F°6F°1F°11

– 31 –

Page 34

Climate Control Drawer

The Climate Control Drawer can chill or thaw items

quickly. It can also store items at their optimum

temperatures. This Climate Control Drawer

contains the following components:

• Control Board

• Thermistor

• Dampers (2)

• Fan

• Heater

The main control board controls the dampers, fan,

and heater based on input from the Climate Control

Drawer’s control board and the thermistor.

The Climate Control Drawer compartment is sealed to reduce the effect that the drawer temperature

has on the rest of the refrigerator. When the drawer features are not being used, the temperature inside

the drawer will be the same as the fresh food compartment.

Strip Circuit

DAMPER

DAMPER

1

2

1

2

WHITE

YELLOW

WHITE

YELLOW

CONTROL

BOARD

(CONTROL HMI)

RED

1

BROWN

3

ORANGE

5

THERMISTOR

FAN

RED

BROWN

ORANGE

BLUE

BROWN

GRAY

YELLOW

WHITE RED

BLACK

J4

1 DATA

2 + 12 VDC

3 COM

J5

6

5

2

1

J2

8 +12 VDC

7 FAN

HEATER 5

MAIN

CONTROL

BOARD

J7

VIOLET ORANGE

HEATER

438 Ω

ORANGEORANGE

BROWN

EMI/RF

FILTER

GREEN

BROWN

AC POWER CORD

GEA01264

– 32 –

Page 35

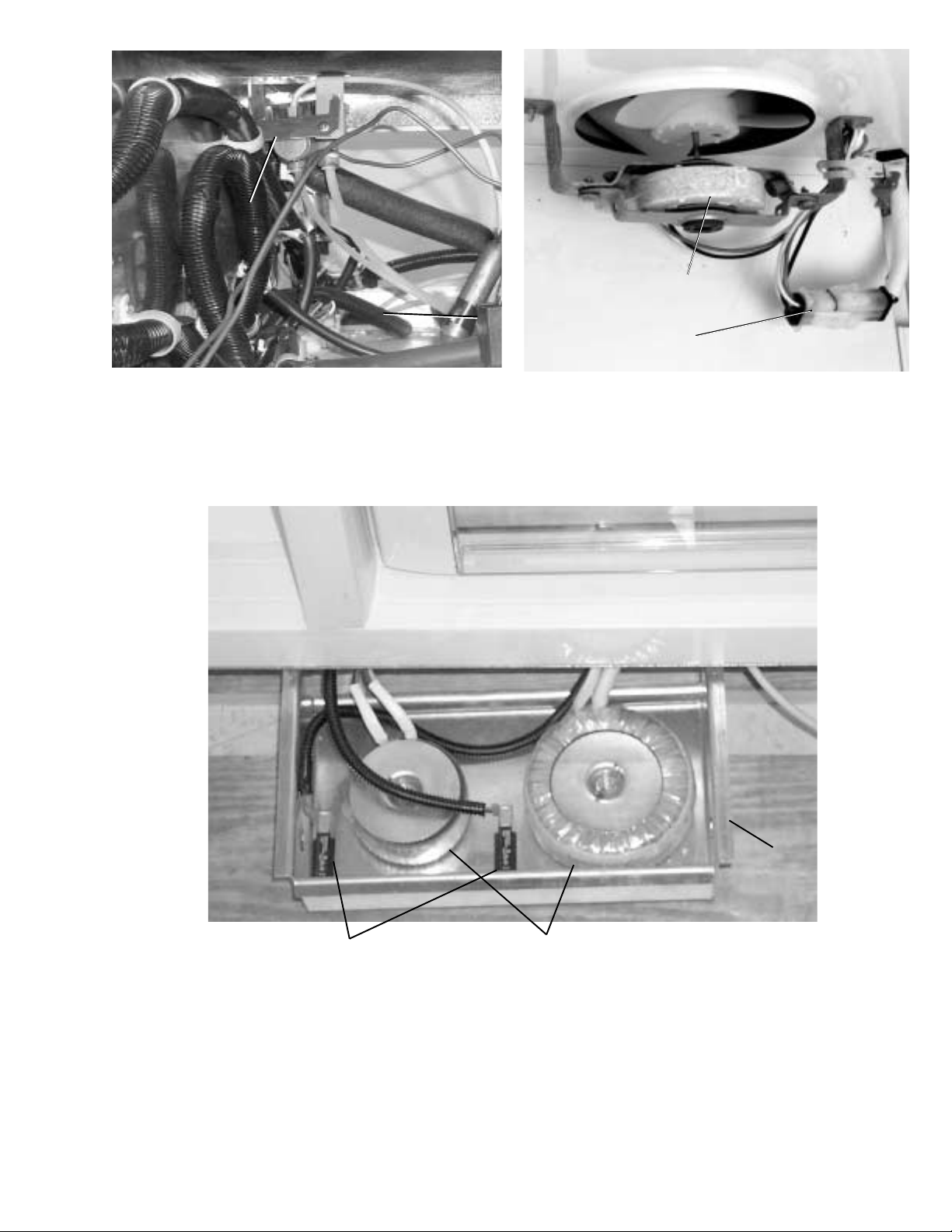

Component Locator View

Air

Diffuser

Dampers

Fan

(in Fan Housing)

Light

Connector

Thermistor

(in Fan Housing)

Top Panel

(Mullion)

Heater

(in Fan Housing)

Fan Connector

9-Pin

Connector

Heater

Connector

Control Board

(in T op Panel)

Climate Control Drawer compartment shown with top panel moved out

– 33 –

Page 36

Operation

During all modes of operation, the main control board will cycle the dampers, fan, and heater as

necessary to maintain the desired temperature. Typical operation is as follows:

Select Temp

This feature maintains optimum temperatures for specific items.

The CITRUS setting will maintain a drawer temperature of 43 °F by circulating warmed air or cooled

air as needed. The dampers will close and the heater will turn on if warmed air is required to maintain

43 °F. The dampers will open if cooled air is required.

The PRODUCE setting will maintain a drawer temperature of 34 °F by circulating warmed air or cooled

air as needed. The dampers will close and the heater will turn on if warmed air is required to maintain

34 °F. The dampers will open if cooled air is required.

The MEA T setting will maintain a drawer temperature of 32 °F by circulating warmed air or cooled

air as needed. The dampers will close and the heater will turn on if warmed air is required to maintain

32 °F. The dampers will open if cooled air is required.

The Climate Control drawer display will show the selected temperature for approximately 4 seconds

after a Select Temp mode has been selected. After approximately 4 seconds, the actual temperature of

the drawer will be displayed. Refer to the Temperature Table for drawer temperatures.

Express Chill

This feature cools items by opening the dampers and circulating air from the freezer compartment

throughout the drawer . The fan will be on at all times during Express Chill.

The Climate Control Drawer display will show the number of minutes (or minutes remaining) for the

Express Chill mode selected on the control panel. The display will not show the temperature of the

drawer . Refer to the Temperature Table for drawer temperatures.

Express Thaw

This feature thaws items by circulating warmed air throughout the drawer. Temperature is maintained in

the drawer by cycling a small heater on and off as needed. The dampers will be closed during Express

Thaw . The fan will be on at all times during Express Thaw .

When the Express Thaw cycle is complete, the drawer will automatically adjust to 30 °F.

The Climate Control Drawer display will show the number of hours (or hours remaining) for the Express

Thaw mode selected on the control panel (.5 LBS = 4 HRS, 1.5 LBS = 8 HRS, 3 LBS = 12 HRS). The

display will not show the temperature of the drawer. Refer to the Temperature Table for drawer

temperatures.

– 34 –

Page 37

Temperature Table

When using the Temperature Table, please note the following:

• FF and FZ compartments should be within 3 °F of the temperature set point when checking drawer

temperature.

• All temperatures listed are as measured by the thermistor and displayed by the Climate Control

Drawer display.

• Actual drawer temperature will be displayed in Select Temp mode only . The Climate Control Drawer

display will show the selected temperature for approximately 4 seconds after a Select Temp mode

has been selected. Af ter approximately 4 seconds, the actual temperature of the drawer will be

displayed.

• The actual-temperature display is based on the temperature that the main control board sees from

the thermistor. The selected-temperature (example: CITRUS – 43 °F) is based on the logic of the

Climate Control Drawer control board. If the actual temperature that is displayed is incorrect, the

thermistor and main control board are suspect. If the temperature associated with the Select Temp

mode is incorrect, the Climate Control Drawer control board is faulty.

WAHTSSERPXE LLIHCSSERPXE PMETTCELES

EDOM PMET EDOM PMET EDOM PMET

.SBL5.F°64ot24

.SBL5.1F°64ot24

.SBL3F°64ot24

1

1

1

.NIM51F°52

.NIM03F°02ot51

.NIM54F°02ot51

2

2

2

SURTICF°34

ECUDORPF°43

TAEMF°23

3

4

5

Note 1 Climate Control Drawer may take up to 1 hour and 45 minutes to achieve

temperature with no load in drawer (except metal tray) and minimal or no door openings.

When the Express Thaw cycle is complete, the drawer will automatically adjust to 30 °F.

Note 2 Temperature should lower to 25 °F or less within 15 minutes with no load in

drawer (except metal tray) and minimal or no door openings. Temperature should lower

to a temperature between 15 °F to 20 °F within 30 minutes with no load in drawer

(except metal tray) and minimal or no door openings. If refrigerator is defrosting,

temperature in drawer may go below 15 °F.

Note 3 Climate Control Drawer may take up to 1 hour and 45 minutes to achieve

temperature with no load in drawer (except metal tray) and minimal or no door openings.

Note 4 Climate Control Drawer may take up to 1 hour to achieve temperature with no

load in drawer (except metal tray) and minimal or no door openings.

Note 5 Climate Control Drawer may take up to 45 minutes to achieve temperature with

no load in drawer (except metal tray) and minimal or no door openings.

– 35 –

Page 38

Climate Control Drawer Top Panel

(Mullion)

Removal

Styrofoam Insert

1. Remove 2 storage bins and the glass panel

over Climate Control Drawer.

2. Remove 4 screws from climate control top

and slide back to access wire connectors.

3. Disconnect the connectors and remove the

top panel.

Note: Note that there is a Styrofoam insert in the

slot at the back, right-hand corner of the top

panel.

Control Board and Display

The control board and display are located in the

Climate Control Drawer top panel (mullion). The

control board and display are part of the mullion

and cannot be replaced separately .

Input from the Climate Control Drawer’s control

board and the thermistor is used by the main

control board to control the dampers, fan, and

heater.

Screws

Top Panel

(Mullion)

Actual drawer temperature will be displayed in

Select Temp mode only. The Climate Control

Drawer display will show the selected temperature

for approximately 4 seconds after a Select Temp

mode has been selected. After approximately 4

seconds, the actual temperature of the drawer will be displayed.

The actual-temperature display is based on the temperature that the main control board sees from the

thermistor. The selected temperature (example: CITRUS – 43 °F) is based on the logic of the Climate

Control Drawer control board. If the actual temperature that is displayed is incorrect, the thermistor and

main control board are suspect. If the temperature associated with the Select Temp mode is incorrect,

the Climate Control Drawer control board is faulty.

– 36 –

Page 39

Caution: When assembling the top panel, use care to prevent pinched wires.

Troubleshooting

Use this diagnostic flowchart if the Climate Control Drawer control panel and display are not operating

properly.

If the problem is drawer temperature and the control panel and display appear to be operating normally ,

check the thermistor, damper, fan, and heater first.

If the actual drawer temperature displayed is incorrect, suspect the thermistor and main control board.

Check

communication

using diagnostic

mode.

Communication

pass?

YES

Replace Climate

Control Drawer

control board.

YES

Replace Climate

Control Drawer control

board. If problem is not

corrected, replace the

main control board.

Is a temperature or time

NO

displayed or are any

indicator lights illuminated

on the Climate Control

Drawer control panel?

Display and/or lights

Replace Climate

Control Drawer

control board.

Check for continuity on

data circuit between

J4-1 and Climate Control

Drawer control board

connector terminal 5.

Circuit OK?

Repair circuit.

NO

Disconnect connector J4

from main control board.

No display

or lights

YES

Check for 12 VDC at

main control board

between J4-2 and J4-3.

12 VDC present?

YES

Reconnect connector J4 to

main control board.

Check for 12 VDC at J4-2 at

main control board between

J4-2 and J4-3.

12 VDC present?

YES

Disconnect connector from Climate

Control Drawer control board.

Check for 12 VDC at the Climate

Control Drawer control board

connector between terminals 3 and 5.

12 VDC present?

NO

NO

NO

Replace main

control board.

Replace Climate

Control Drawer

control board.

Open wiring between Climate

Control Drawer control board and

main control board.

9-Pin Connector

Behind Climate

Control Drawer

ORANGE

– 37 –

Page 40

Fan and Fan Housing

The 12 VDC fan is controlled by the main control board. The main control board turns the fan on and off

based on input from the Climate Control Drawer control board and thermistor. The fan should always

come on any time Express Chill or Express Thaw is selected.

Troubleshooting

Turn on Express Chill.

Check for 12 VDC at

main control board

between J2-8 and J2-7.

12 VDC present?

NO

Check communication

using diagnostic mode.

Communication pass?

NO

YES

Replace main

control board.

Check for 12 VDC

at fan connector.

12 VDC present?

YES

· Open circuit between

fan connector and fan.

· Faulty fan.

NO

Open circuit

between main

control board and

fan connector.

Removal

1. Remove Climate Control Drawer top panel.

2. Loosen 2 bottom screws, remove 2 top

screws, and remove air diffuser from fan

housing.

YES

· Open circuit between J4-1 and

Climate Control Drawer control

board terminal 1.

· Faulty Climate Control drawer

control board.

· Faulty main control board.

Screws (Remove)

Screws (Loosen)

Flat Surface

– 38 –

Air

Diffuser

T abs

Page 41

3. This step for fan removal only: Remove

screen from front of fan and fan from housing.

4. Remove 2 screws and the sheet metal cover

from the right-hand side of the housing.

5. Disconnect fan connector.

9-Pin

Connector

Fan Connector

6. This step for fan removal only: Cut fan wires

Screen and Fan

at fan to remove.

Note: When installing new fan, fan wires do not

Fan Housing

Heater Connector

have to be installed under plastic wire holders.