Page 1

GE

g

READ THOROUGHLY BEFORE INSTALLING

W1LR, W1SR, W1LG, W1SG, W25C (cutoff optics)

Lighting Solutions

WARNING

Risk of electric shock

• Turn power off before servicing

– see instructions

GEH-5794

INSTRUCTIONS

Wallighter 175 and

Wallighter 250 Cutoff Luminaires

A. MOUNTING

CAUTION

WARNING

Risk of fire

• Use supply wire specified on

nameplate

GENERAL

This luminaire is designed for outdoor lighting

applications, and should not be used in areas of limited

ventilation, or in high ambient temperature enclosures.

For optimum performance, it should be installed and

maintained according to the following recommendations.

UNPACKING

This luminaire has been properly packed so that no parts

should have been damaged during transit. Inspect to

confirm.

INSTALLATION

The refractor must be removed to access two bolts (on

each side of the reflector) which secures front housing to

back plate. Removal of the front housing allows access for

mounting and wiring.

Unit will fall if not installed properly

• Follow installation instructions

Outlet Box Mounting: The luminaire can be mounted to

a suitable surface-mounted outlet box (3'’ or 4'’ octagon, or

2'’x4'’ rectangular). The back plate may be attached to the

outlet box with two 10-24 screws (not provided), approximately ‘’ long. An alternate method of mounting the back

plate over a surface-mounted outlet box is to position back

plate over box and mount with two 3/8'’ bolts (not

provided) through the knock-out holes provided in the back

plate (see figure 2). Wire the unit (see Wiring). Reattach

the front housing/reflector over the back plate. For W25C

having socket mounted in front housing, plug wire assembly

must be re-connected as front housing is installed.

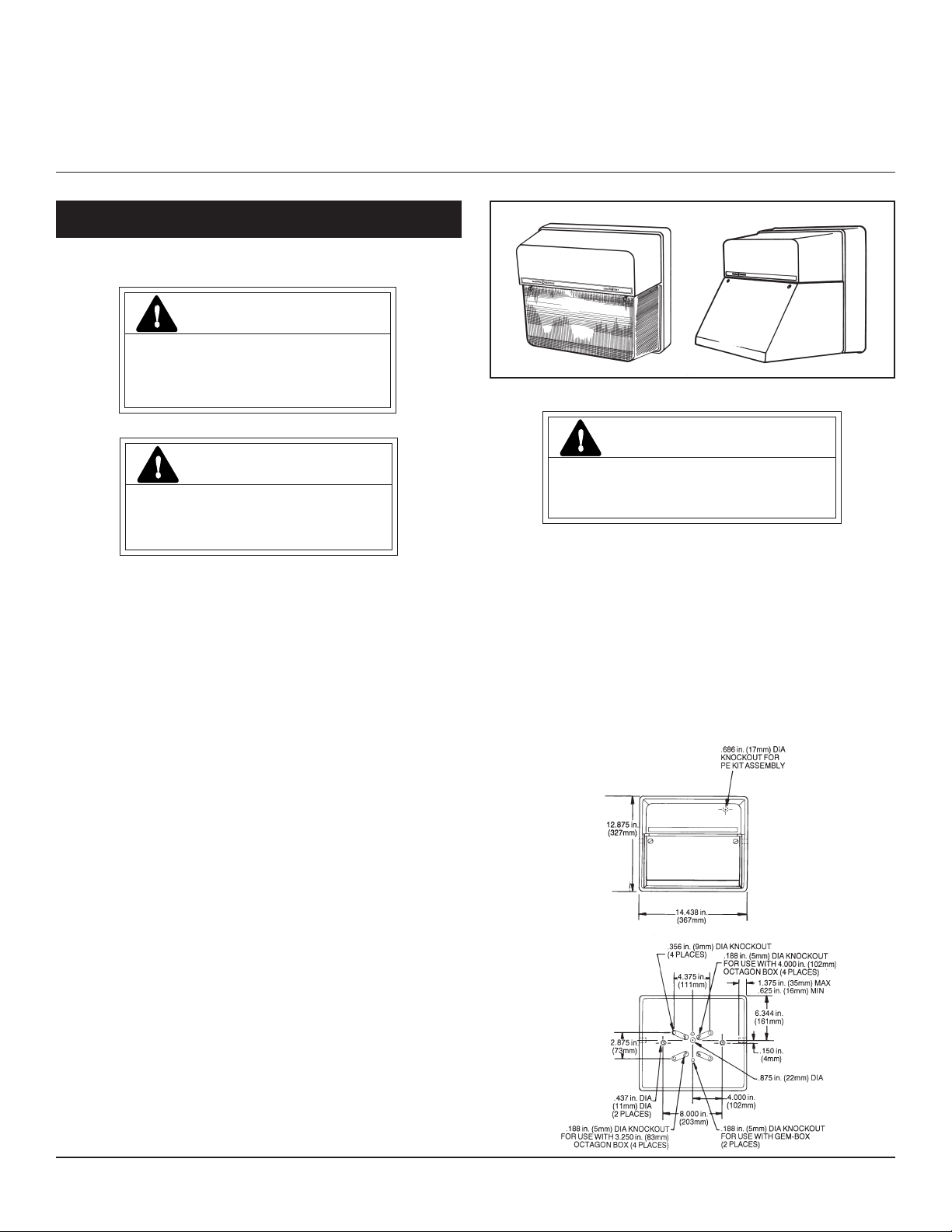

Figure 1

NOTE: For units marked W25C having socket

mounted in front housing, plug wire assembly

located in center top of back plate must be un-

plugged while removing front housing.

A gasket is provided with the unit to be used when

mounting over an outlet box, and should be installed

between rear of back plate and the mounting surface. If

additional sealing is desired, caulk back of housing with

generic non-hardening sealant (not provided) across the

top and down both sides.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or

maintenance. Should further information be desired or should particular problems arise which are not covered sufficiently for the purchaser’s purposes, the matter should be referred

to GE Lighting Solutions.

Figure 2

2

Page 2

Through-Feed Conduit:

Note: Some units may not allow this mounting or

may require special high temperature cable. See

labels on back plate for instruction.

Knock-out holes are provided to permit mounting of the

back plate on vertical surfaces with two 3/8'’ bolts (not

provided). The -inch conduit is then positioned in the

cradles on each side of back plate and secured to back plate

with clips and screws provided (see figure 2). The conduit

may also be secured to the wall on either side of the fixture

with conduit straps (not provided). Wire the unit (see

Wiring). Knock-out the sections on each side of the front

housing using pliers, twisting inwardly. Re-attach the front

housing/reflector over the back plate. For W25C having

socket mounted in front housing, plug wire assembly must

be re-connected as front housing is installed.

Install lamp (see LAMP INSTALLATION) and re-install

refractor or cut-off optical assembly.

NOTE: Do not overcompress the gasket on acrylic

lens units as this may cause the lens to crack around

the screw holes.

B. WIRING

Make all electrical connections in accordance with

the National Electrical Code and any applicable local

code requirements.

Verify that supply voltage is correct by comparing it

to nameplate.

Customer wiring enters either through the center hole in

the back plate or through the conduit entrance knock-outs

on the sides of the front housing. In either case, an easy

access wiring area (see figure 2) is provided for electrical

connections.

LAMP INSTALLATION

CAUTION

Risk of burn

• Allow lamp/fixture to cool before

handling

WARNING

Risk of burn

• Do not touch operating luminaire

Use only lamps specified on nameplate. Observe

lamp manufacturer’s recommendations and

restrictions on lamp operation, particularly ballast

type, burning position, etc.

Lamp Tightness-Mogul Base Lamp: The lamp should be

securely inserted to the NEMA-EEI specified torque of 35

inch-pounds, which is best achieved by very firm tightening

sufficient to fully depress and load the center contact of the

socket.

Lamp Tightness-Medium Base Lamp: The lamp should

be tightened to a light firmness sufficient to depress the

center contact.

MAINTENANCE AND CLEANING

It will occasionally be necessary to clean the outside of

the refractor to maintain light levels. Frequency of cleaning

will depend on ambient dirt level and minimum light level

which is acceptable to the user. The refractor should be

washed in a solution of warm water and any mild,

nonabrasive household detergent, rinsed with clean water

and wiped dry. Should the optical assembly become dirty on

the inside, wipe the reflector and clean the refractor in the

above manner.

Route incoming supply conductors through clips

provided and maintain half inch minimum spacing

from ballast and reflector.

NOTE: Connect ground lead to ground (gnd) screw

on the back plate.

Do not remove insulated connectors from wires not

needed for required voltage connection.

IF SINGLE VOLTAGE:

All single voltage ballasts are pre-wired such that user

need only connect the supply conductors.

IF MULTIVOLT: (120/208/240/277 volts)

Connect the ballast lead with the insulated terminal to

the desired voltage terminal as indicated on the ballast

terminal nameplate.

IF MULTIWATT:

Multiwatt ballasts are available in various combinations of

wattage. See wiring instructions on wiring tag inside the

luminaire.

To complete installation refer to MOUNTING.

The light output of a luminaire is dependent on the age

of the lamp. In applications where the light level is critical,

it may be desirable to replace lamps before they burn out.

The lamp manufacturer can provide data showing how the

lamp light output decreases with use.

Page 3

GE

g

W1LR, W1SR, W1LG, W1SG, W25C (optique à écran)

Lighting Solutions

À LIRE TOTALEMENT AVANT D'INSTALLER

DANGER

Risque d'électrocution

• Mettre hors tension avant

d'intervenir - Suivez les instructions

GEH-5794

INSTRUCTIONS

Luminaires Wallighter

175 et 250 à écran

A. MONTAGE

ATTENTION

DANGER

Risque d'incendie

Risque de chute en cas de mauvais

montage - Suivre les instructions

• Utilisez le câble d'alimentation

spécifié sur la plaque d'identification

Montage sur boîte de raccordement électrique : Le luminaire peut

être monté sur une boîte de raccordement électrique adéquate à

GÉNÉRALITÉS

Ce luminaire est conçu pour les applications d'éclairage en

extérieur, et ne doit pas être utilisé dans des zones à ventilation

limitée, ou dans des lieux fermés à température élevée. Pour une

performance optimale, il doit être installé et entretenu en suivant les

recommendations suivantes.

surface en saillie (forme octogonale de 3'’ ou 4'’, ou rectangulaire de

2'’x4'’ ). Sa plaque arrière peut être fixée à cette boîte de

raccordement avec deux vis (non fournies) de dimension approximative 10-24'’’. Une autre méthode de montage de la plaque arrière sur

une boîte de raccordement en saillie est de la positionner puis de la

fixer avec deux boulons de 3/8'’ (non fournis) au travers des trous

repoussés dans le panneau arrière (voir figure 2). Câblez l'appareil

(voir le section CÂBLAGE). Rattachez le boîtier avant/réflecteur sur

DÉBALLAGE

Ce luminaire a été soigneusement emballé de sorte qu'aucune

pièce ne devrait avoir été endommagée pendant le transport.

Effectuez une inspection pour le confirmer.

INSTALLATION

Le réfracteur doit être déposé pour accéder aux deux écrous (un

la plaque arrière. Pour les modèles W25C à douille sur le boîtier avant,

rebranchez l'assemblage de bornier enfichable au remontage.

Figure 1

327mm

(12.875 in)

.688 in (17mm) DIA

BOUCHON D

POUR ASSEMBLAGE

É

FONÇABLE

de chaque côté du réflecteur) qui attachent le boîtier avant à la

plaque arrière. La dépose du boîtier avant permet de procéder au

montage et au câblage.

367mm

(14.438 in)

NOTE : Sur les modèles marqués W25C ayant la douille

montée sur le boîtier avant, l'assemblage de bornier

enfichable situé sur le centre haut du panneau arrière doit

être débranché avant de pouvoir déposer le boîtier avant.

Un joint statique est fourni avec l'appareil pour son montage sur

une boîte de raccordement électrique, et doit être installé entre la

partie postérieure de la plaque arrière et la surface de montage. S'il y a

Figure 2

73mm

(2.875 in)

besoin de plus d'étanchéité, colmatez l'arrière du boîtier avec de

l'enduit générique sans durcissement (non fourni) sur son sommet et

en bas sur les côtés.

Ces instructions n'ont pas pour destination de couvrir tous les détails ou variantes de l'équipement, ni de répondre à toutes les éventualités que vous pourriez rencontrer pendant l'installation,

le fonctionnement ou l'entretien. Si vous souhaitez des informations complémentaires, ou si vous rencontrez un problème particulier qui ne soit pas adressé de votre point de vue d'acheteur,

le sujet doit être remonté jusqu'à la société GE Lighting Solutions

2 PERÇAGES Ø 11mm (.437")

4 PERÇAGES Ø 5mm (.188")

À UTILISER POUR MONTAGE SUR

BOÎTE OCTOGONALE 83mm (3.250")

4 PERÇAGES

Ø 9mm (.356")

111mm

(4.375 in)

203mm

(8.000 in)

4 PERÇAGES Ø 5mm (.188")

À UTILISER POUR MONTAGE SUR

BOÎTE OCTOGONALE 102mm (4")

35mm (1.375 in) MAX

16mm (.625 in) MIN

161mm

(6.344 in)

4mm

(.150 in)

22mm (.875 in) DIA

102mm

(4.000 in)

2 PERÇAGES Ø 5mm (.188")

À UTILISER POUR MONTAGE SUR

BOÎTE GEM

Page 4

Tube protecteur d'alimentation :

Note : Certains modèles peuvent ne pas permettre ce

montage ou nécessiter du câblage spécial haute

température. Reportez-vous aux étiquettes sur la

plaque arrière pour les instructions.

Des bouchons défonçables sont disponibles pour permettre le

montage de la plaque arrière sur des surfaces verticales avec deux

boulons de 3/8 po (non fournis). Le tube protecteur d'alimentation

est positionné sur les supports de chaque côté de la plaque arrière, et

fixé avec les colliers et vis fournis (voir figure 2). Le tube peut aussi

être fixé au mur d'un côté ou de l'autre du luminaire avec des brides

pour tuyau (non fournies). Faites les raccordements (voir la section

CÂBLAGE). Repoussez les surfaces de passage de chaque côté du

boîtier avant en utilisant des pinces, en les tordant vers l'intérieur.

Rattachez le boîtier avant et réflecteur sur la plaque arrière. Pour le

modèle W25C qui a la douille montée sur le boîtier avant, il faut

rebrancher le bloc bornier d'alimentation amovible au remontage.

Mettez l'ampoule en place (voir la section INSTALLATION

D'AMPOULE) et remontez le réfracteur ou l'assemblage optique à

écran.

NOTE : Ne mettez pas une pression excessive du joint sur les

lentilles acryliques car elles pourraient alors se fissurer

autour des trous de vissage.

B. CÂBLAGE

Établissez toutes les liaisons électriques en conformité avec

la norme NEC ou vos réglementations locales en vigueur.

Vérifiez que la tension secteur disponible est compatible avec

celle de l’appareil indiquée sur sa plaque d’identification.

Le câblage par le client arrive soit par le trou central de la

plaque arrière, soit par les passages pour tube protecteur

d'alimentation sur les côtés du boîtier avant. Dans les deux

cas un accès facile à la zone de câblage (voir figure 2) est

fourni pour les connexions électriques.

Faites passer les fils d'arrivée d'alimentation dans les passe-

fils fournis et gardez au moins un écartement de 13 mm par

rapport au ballast et au réflecteur.

NOTE : Connectez l'arrivée de masse sur la vis de terre

(marquée <<gnd>>) de la plaque arrière.

N'enlevez pas les bornes isolantes des fils non nécessaires

pour la connexion de tension requise.

MONO-TENSION

Tous les ballasts pour les modèles mono-tension sont précâblés de

sorte que l’usager n’ait qu’à relier les fils conducteurs

d’alimentation.

MULTI-TENSION – (120/208/240/277 volts)

Connectez la sortie du ballast ayant la borne isolée sur la borne de tension

voulue comme indiqué sur la plaque d’identification sur le ballast.

MULTI-PUISSANCE

Des ballasts sont disponibles pour diverses combinaisons de

puissances. Reportez-vous aux instructions de câblage sur

l'étiquette de câblage située à l'intérieur du luminaire.

Pour terminer l'installation reportez-vous à MONTAGE.

INSTALLATION D'AMPOULE

ATTENTION

Risque de brûlure

• Laissez le bloc d’ampoule refroidir

avant d’y toucher

DANGER

Risque de brûlure

• Ne pas toucher si en marche

N’utilisez que le type d’ampoules spécifié sur la plaque

d’identification. Suivez les recommandations et restrictions des

fabricants d’ampoules, en particulier pour le type de ballast, la position

d’utilisation, etc.

Serrage d’ampoule- modèle à culot Mogul : l’ampoule doit être

mise en place de façon sûre, par un serrage NEMA-EEI spécifié au

couple de 35 pouces-livres, qui s’effectue le plus aisément par un

serrage manuel ferme. Le vissage doit être suffisant pour

complètement abaisser et charger le contact central de la douille.

Serrage d’ampoule- modèle à culot moyen : L’ampoule doit être

vissée en douceur assez loin pour enfoncer le contact central de sa

douille.

ENTRETIEN ET NETTOYAGE

Il faudra à l’occasion nettoyer le réfracteur pour maintenir son

apparence et le niveau d’éclairage. La fréquence de nettoyage

dépendra de la densité de poussière ambiante et du niveau minimum

d’éclairage désiré. Le réfracteur et le boîtier seront lavés avec une

solution d’eau chaude et de détergent ménager léger, puis rincés à

l’eau claire et séchés par essuyage. Si l’ensemble optique interne

devenait sale, nettoyez le réflecteur et l’intérieur du réfracteur de la

même façon. Remplacez le joint statique s’il est endommagé.

La puissance lumineuse générée par le luminaire est également

dépendante de l’âge de son ampoule. Pour les applications où le

niveau lumineux est critique, il peut être souhaitable de remplacer les

ampoules avant qu’elles ne grillent. Le fabricant d'ampoules peut

fournir des données sur la baisse de luminosité en fonction du

vieillissement.

g

GE Lighting Solutions • 1-888-MY-GE-LED • www.gelightingsolutions.com

16943533----888

GE Lighting Solutions is a subsidiary of the General Electric Company. Evolve and other trademarks belong to GE Lighting Solutions. The GE brand and logo are trademarks of the General Electric Company.

© 2011 GE Lighting Solutions. Information provided is subject to change without notice. All values are design or typical values when measured under laboratory conditions.

35-201578-4A (7/00)

Loading...

Loading...