GE

Measurement & Control

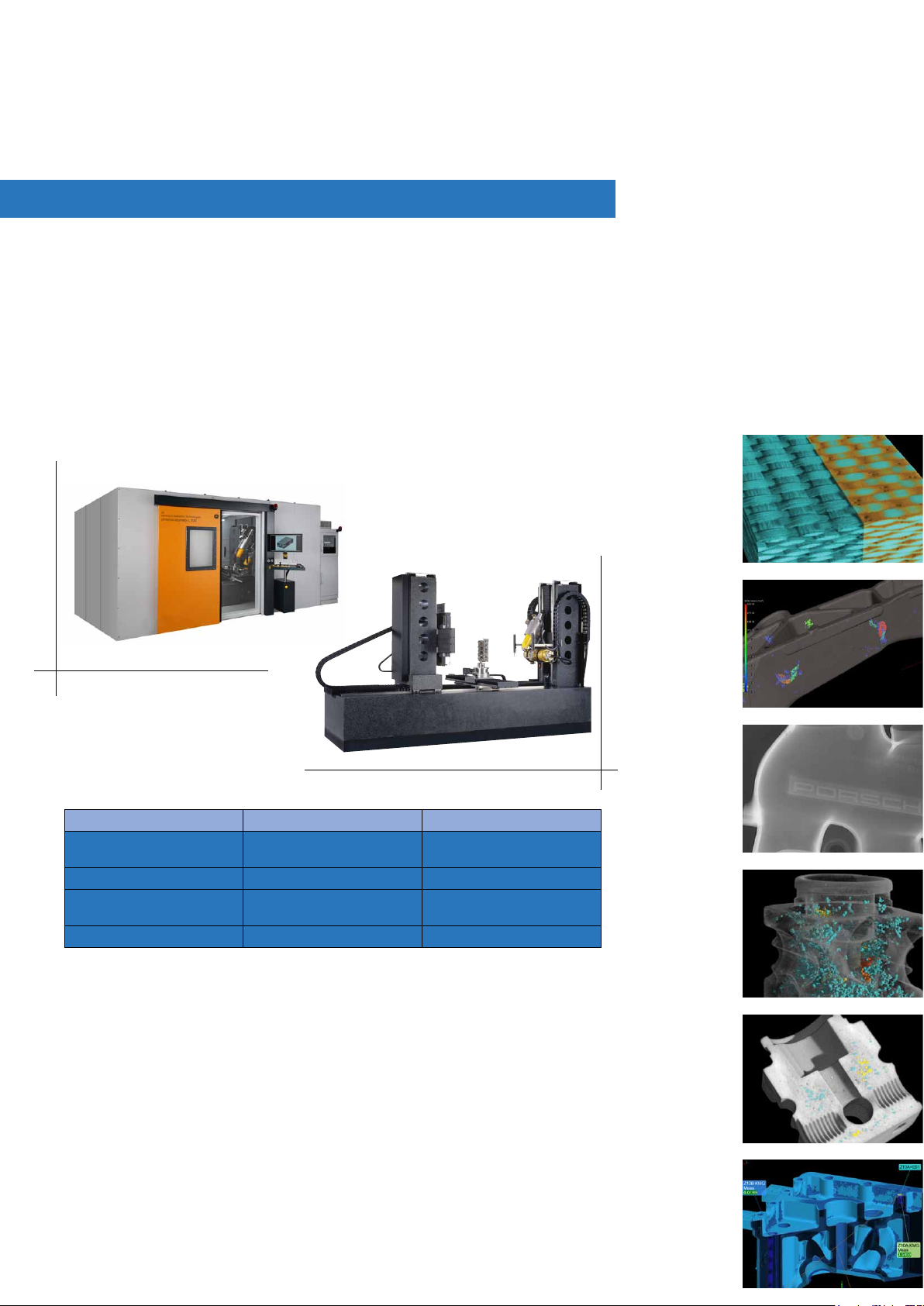

phoenix v|tome|x L – versatile and exible CT system

The phoenix v|tome|x L 240/300 and L 450 are versatile high resolution microfocus systems for

3D and 2D Computed Tomography and 2D non-destructive X-ray inspection. With their granitebased 8-axes manipulation they are handling even large samples with highest precision. Both

systems are the optimal solution for void and flaw detection and 3D metrology (e.g. first article

inspection) of castings. Furthermore, phoenix|x-rays high resolution X-ray technology with many

extras like an optionally second X-ray tube allows to adapt the v|tome|x L to any kind of industrial and scientific CT application. A variety of effective software tools minimises physical effects

like ring-artefacts or beam-hardenings for highest CT quality.

phoenix v|tome|x L 240/300

phoenix v|tome|x L 240/300 phoenix v|tome|x L 450

Optional X-ray tube combinations unipolar 240 or 300 kV microfocus /

180 kV high-power nanofocus

Max. voxel resolution 1 µm < 2 µm

Max. object size /

3D-CT eld of view

Max. object weight 50 kg 100 kg

Longlife open micro- and nanofocus

X-ray tubes

Unique 300 kV / 500 W unipolar micro-

focus tube for high magnification

Granite based precision manipulation

up to 8 axes

High precision CNC control

High dynamic temperature stabilized

detector technology

High contrast array detector + multi-

line detector or line detector for 2D CT

Ø 800 x H 1300 mm /

Ø 500 x H 600 mm

Virtual detector enlargement

Fully automated click & measure|CT

Reproducible 3D metrology and failure

analysis after short operator training

velo|CT for extreme high speed recon-

struction

Advanced surface extraction for high

precision 3D Metrology (CAD variance

analysis, reverse engineering etc.)

Automatic generation of first-article-in-

spection reports in < 1 hour possible

300 kV microfocus

450 kV macrofocus

Ø 1300 mm, H 2000 mm/

Ø 800 x H 1000 mm

Fiberglass

Cavities in an Aluminum casting

phoenix v|tome|x L 450

Aluminum casting

Cavities in an Aluminum casting

Aluminum casting

AL casting 3D measurements

GE

Measurement & Control

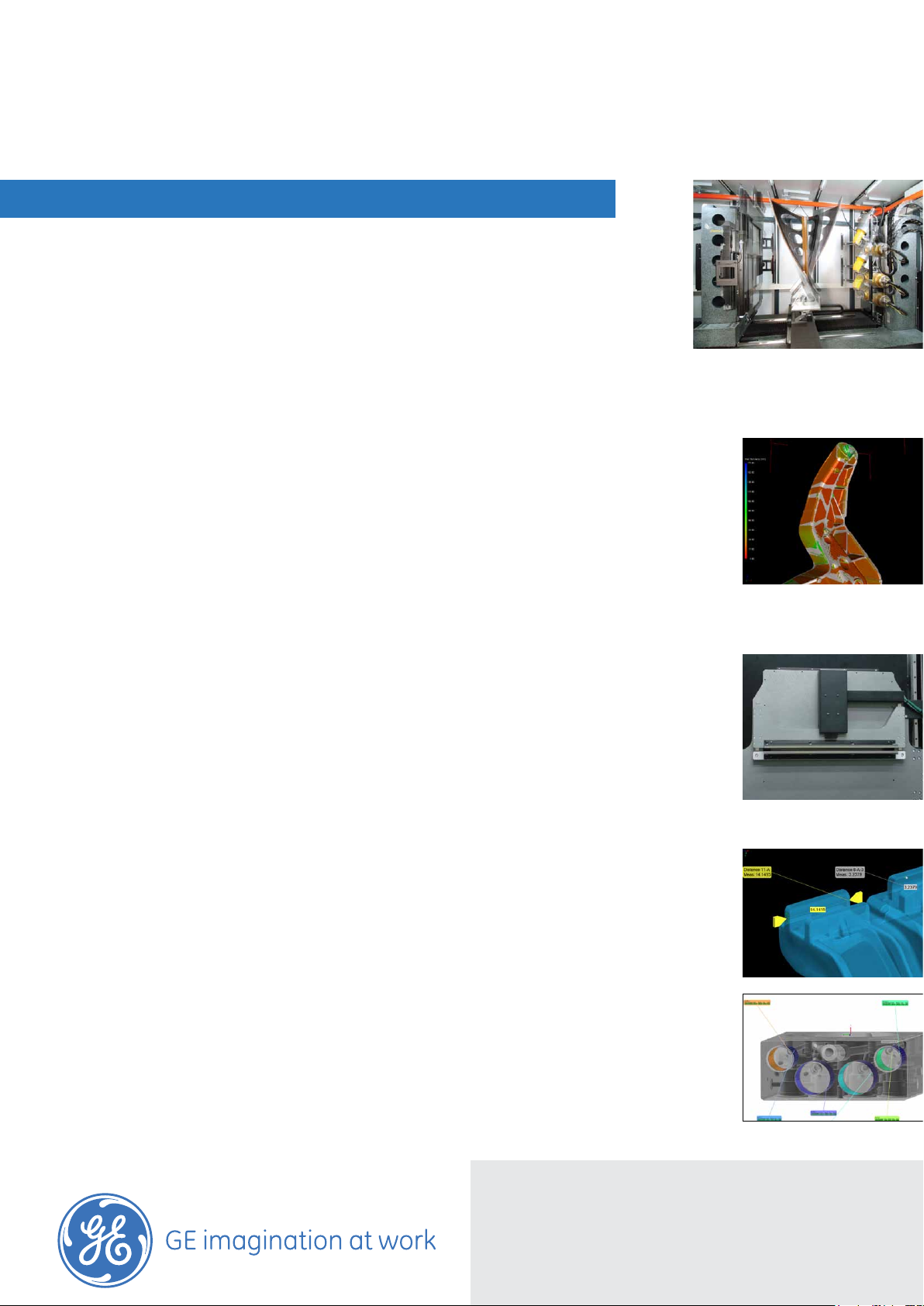

phoenix v|tome|x L – very high precision even for large samples

With its granite-based 8-axis manipulation unit, the phoenix v|tome|x L 450 handles even large

samples (up to 100 kg (220 lbs) in weight, up to 1300 mm in diameter and up to 2000 mm in height)

with highest precision. A supplemental detector axis enlarges the detector width up to 1200 mm.

Additional to its 300 kV / 500 W microfocus X-ray tube, the v|tome|x L 450 may come optionally

equipped with an extra, 450 kV closed minifocus tube for high absorbing samples. All v|tome|x

systems can also be used for 2D inspection with fast and easy switching between 2D and 3D

mode. The wide range of available configurations allows to adapt the v|tome|x L to almost any

kind of application in science, production control and 3D metrology.

Advanced CT software

All v|tome|x CT systems come standard with phoenix|x-rays proprietary CT acquisition and reconstruction software

package datos|x for fast and accurate CT. Due to GPU based reconstruction techniques, CT results are available after just a few minutes. For ease of use and to optimise the quality of high resolution CT data, phoenix|x-ray offers a

variety of effective software tools, e.g. for automatic geometry calibration, for <360° ROI-CT with maximized magnification, for ring artefact reduction, beam hardening correction, optimization of scans with drift effects as well as for

advanced extraction of surface points for 3D metrology applications. The high precision click & measure|CT funcitionality offers the possiblity for fully automated CT data acquisition, reconstruction and 3D volume evaluation.

Movement of all axes: v|tome|x L 450

at German aerospace centre DLR

Wall-thickness measurement

Extensive flexibility

The v|tome|x L 300 comes with a new unipolar 300 kV / 500 W microfocus source. Due to this unique technique the

system can be used for high magnification applications as well as scans of strongly absorbing samples. Major components of the system, like the X-ray tube and the temperature stabilized detector are proprietary technology of GE

For highest resolution scans, the v|tome|x L 300 can be outfitted with an additional open 180 kV high power nanofocus tube. There are many flat panel and line detector options for v|tome|x L systems. In multiline detector configuration, the reduction of scattered radiation for precise 2D scans for metrology application can be reached without

installation of an additional expensive line detector.

Highest accuracy for 3D metrology

Especially if complex parts with hidden or difficult accessible surfaces have to be measured, CT offers big advantages comparing with conventional tactile or optical coordinate measuring machines (CMMs): high density of measurement points and fast capturing of the complete sample’s geometry. v|tome|x L systems include all essential features for CT with highest accuracy: Minimised focal spot and voxel size, granite based setup in an air-conditioned

walk in cabinet for high mechanical and thermal stability, high power X-ray tube to enable beam filtering as well as

advanced software for optimised CT reconstruction quality and geometrically correct surface extraction.

16 bit multi-line detector in position

Measurements in moulded plastic

GE Sensing & Inspection

Technologies GmbH

phoenix|x-ray

Niels-Bohr-Str. 7

D-31515 Wunstorf | Germany

Tel.: + 49 5031.172-0

Fax: + 49 5031.172-299

phoenix-info@ge.com

Measurement of internal geometry

Further Offices:

phoenix-stuttgart@ge.com

phoenix-muenchen@ge.com

phoenix-france@ge.com

phoenix-asia@ge.com

phoenix-usa@ge.com

www.ge-mcs.com/phoenix

GEIT_31205_e_1213

Loading...

Loading...