Page 1

GE Voluson E10

Ultrasound Training Manual

Page 2

GE Voluson E10 Training Manual

i

Table of Contents

Table of Contents ................................................................................... i

Module 1 Introduction .......................................................................... 1

Other Course Offerings ........................................................................1

Voluson E10 ................................................................................................... 2

Module 2 System Hardware and Theory .............................................. 3

Signal Flow ..............................................................................................3

System Block Diagram ................................................................................... 4

System Front End Components .............................................................5

Voluson E10 Front End Processor (FEP) .................................................5

RTF - Probe Control Board ......................................................................6

RSE - Pencil Probe Board (optional) ........................................................6

RFM - (RF-Interface & Beamformer) FE Mainboard ...............................6

RFM Board - Interface FPGA.......................................................................... 6

RFM Board - Processing FPGA ....................................................................... 6

RSX - (Beamformer Receiver/Transmitter) Extension Board ..................6

Front End Block Diagram ............................................................................... 7

System Backend Components...............................................................7

Back End Processor (BEP) ........................................................................7

Back End Block Diagram ................................................................................ 8

PC-Motherboard .....................................................................................8

Hard Disk Drive (HDD) .............................................................................9

Distribution of partitions at 500 Gbyte HDD ................................................. 9

Graphic Card ......................................................................................... 10

RTV - Video Management Board .......................................................... 10

External I/O Connection Panel ............................................................. 10

Patient I/O Module .............................................................................. 11

User Console ........................................................................................ 11

Control Panel ........................................................................................ 12

Control Console Positioning ........................................................................ 12

Video Monitor ...................................................................................... 13

Audio .................................................................................................... 13

Power Distribution Components......................................................... 14

Main Power Supply (RSP) ..................................................................... 14

Power Supply Block Diagram ...................................................................... 15

RTB - Distribution Board Bottom ......................................................... 16

Normal Power ON / Shut Down Sequence .......................................... 16

Power On / Boot Up: ................................................................................... 16

Normal Boot-up Process ............................................................................. 17

Boot screen ................................................................................................. 17

Normal Power Off / Shutdown .................................................................... 18

Temperature Control ........................................................................... 18

Module 3 Operating Modes ................................................................ 20

© 2017 Conquest Imaging

Page 3

GE Voluson E10 Training Manual

ii

B-Mode ............................................................................................. 20

Harmonic Imaging .............................................................................. 20

M-Mode ............................................................................................ 21

Color Flow Doppler Mode .................................................................. 21

Power Doppler ................................................................................... 22

Pulsed (PW) Doppler .......................................................................... 22

Continuous Wave (CW) Doppler ......................................................... 22

Other Modes ..................................................................................... 23

Module 4 Network Configuration ....................................................... 24

DICOM ............................................................................................... 24

Prepare for Network Configuration .................................................... 24

GE Dataflows ..................................................................................... 24

TCP/IP Configuration .......................................................................... 25

Device Setup ...................................................................................... 31

DICOM Configuration ........................................................................... 32

Controls ...................................................................................................... 32

Adding a Service ......................................................................................... 34

Services ................................................................................................ 34

STORE / STORE3D Screen ........................................................................... 36

MPPS .......................................................................................................... 37

ST.COMMIT ................................................................................................. 37

STR.REPORT ................................................................................................ 38

QUERY RETRIEVE ........................................................................................ 38

WORKLIST ................................................................................................... 38

REPORT ....................................................................................................... 39

Module 5 Preventive Maintenance .................................................... 40

System Backup ................................................................................... 40

Backup/Restore Database, Presets and Images................................... 40

Backup - SYSTEM CONFIGURATION ............................................................ 40

Save Small Backup (Scan Settings) ....................................................... 41

Load Backups ........................................................................................ 42

Load Small Backup (Scan Settings) ............................................................. 42

Backup Full System Configuration (Full Backup) .................................. 44

External USB-Devices ......................................................................... 46

Disconnection of External USB-Devices ............................................... 47

Connect USB and Network Drives .............................................................. 47

Cleaning the Air Filters ....................................................................... 48

Cleaning the Trackball ........................................................................ 48

Motherboard Battery ......................................................................... 48

Module 6 General Safety Precautions ................................................ 49

Electrical Safety .................................................................................... 49

Electromagnetic Interference .............................................................. 50

Electrostatic Discharge ESD Precautions .............................................. 50

Fire Safety............................................................................................. 51

General Cautions .................................................................................. 51

© 2017 Conquest Imaging

Page 4

GE Voluson E10 Training Manual

iii

Module 7 Troubleshooting ................................................................. 52

Normal Power On/Boot Sequence ...................................................... 52

Connect AC (mains) Power to the Vivid E9/Logiq E9 ........................... 52

Turn System ON ................................................................................... 53

Sleep Mode .......................................................................................... 53

Troubleshooting Log/Image Capture................................................... 54

Shortcuts List ........................................................................................ 55

System Does Not Boot-up .................................................................. 56

Monitor Troubleshooting ................................................................... 57

Load Default Monitor Settings ............................................................. 57

Monitor Test ........................................................................................ 58

Trouble Shooting Operator Panel Issues ............................................. 59

No Audio .............................................................................................. 59

No Video on LCD Display ...................................................................... 59

Wrong Key Activated on the Touch Panel ........................................... 59

Touch Panel Not Responding ............................................................... 60

Probe Recognition ................................................................................ 60

Module 8 Parts Replacement ............................................................. 61

System Layout ................................................................................... 61

System Power Down .......................................................................... 62

Panel Removal ................................................................................... 62

Foot Rest .............................................................................................. 62

Front Panel ........................................................................................... 63

Front Panel Screw Locations ....................................................................... 63

Side Panel ............................................................................................. 64

Back Panel ............................................................................................ 64

Boards and Modules .......................................................................... 64

Power Supply ....................................................................................... 65

Front End .............................................................................................. 65

Back End ............................................................................................... 65

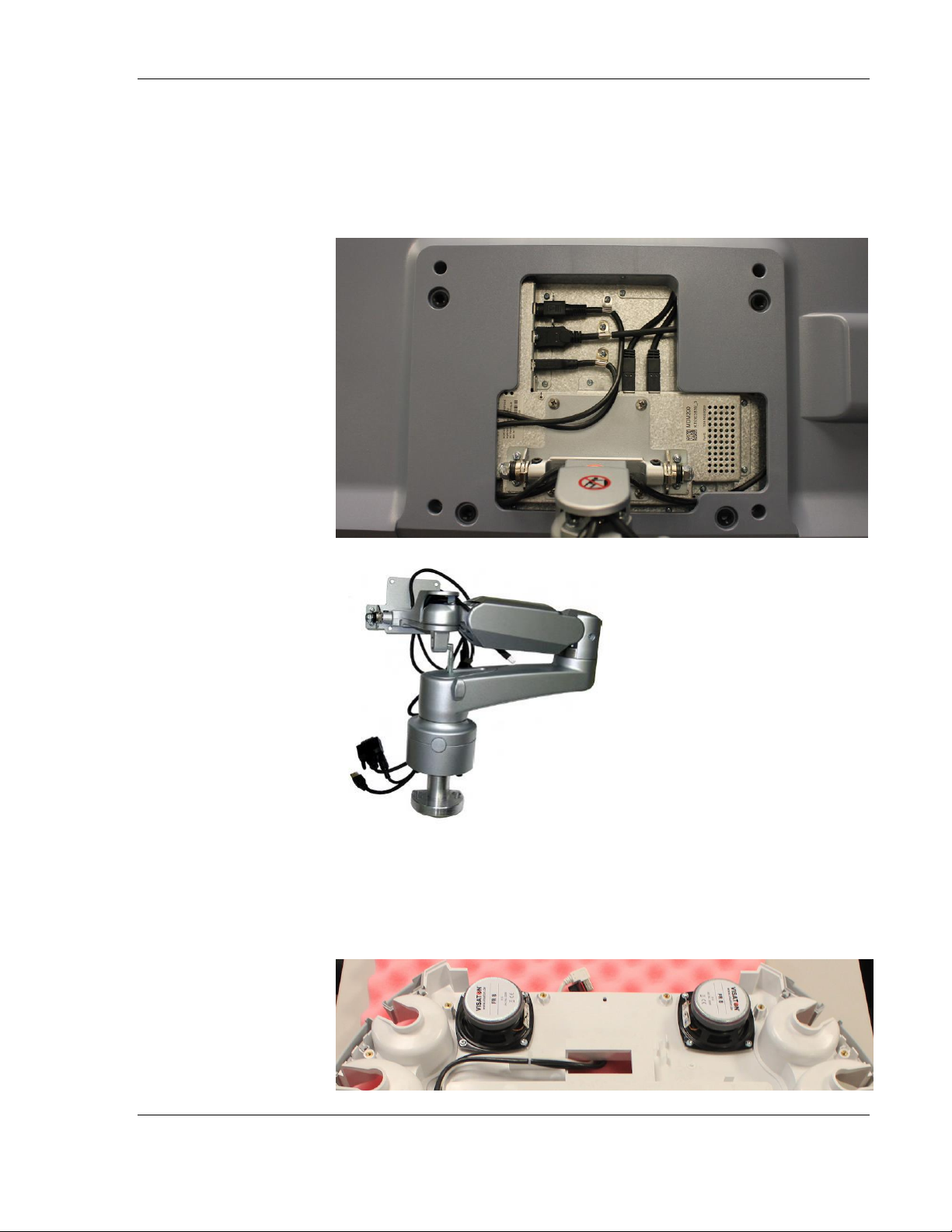

Monitor and Arm Replacement ........................................................... 65

Module 9 System Adjustments ........................................................... 66

Control Console Positioning ............................................................... 66

Control Console Rotation ..................................................................... 66

Control Console Height Adjustment .................................................... 66

Video Monitor ...................................................................................... 66

Glossary ............................................................................................... 67

Acronyms ............................................................................................ 70

Appendix 1 Network Configuration Worksheets ................................ 73

Checklist for Configuring Ultrasound System Network Parameters .... 73

Print Device Information ...................................................................... 74

HIS/RIS Server Information .................................................................. 75

DICOM Devices to Connect to System: ................................................ 76

© 2017 Conquest Imaging

Page 5

GE Voluson E10 Training Manual

iv

Other Needed Information: ................................................................. 76

© 2017 Conquest Imaging

Page 6

GE Voluson E10 Training Manual

1

Module 1 Introduction

This manual is specific to the GE Voluson E10 systems field service

training presented by the Conquest Imaging training department.

After completing the training, you will:

Understand overall system operation.

Identify the parts, boards and modules.

Understand the role of each component in the system.

Be able to perform standard maintenance procedures.

Have the knowledge to troubleshoot common problems.

Be able to safely access and replace boards and modules.

Understand of some of the differences in configuration for

different system versions.

Other Course Offerings

This course is one of many ultrasound training courses offered by

Conquest Imaging.

The following are some of our current course offerings:

Basic Ultrasound

DICOM Standards and Networks

© 2017 Conquest Imaging

Page 7

GE Voluson E10 Training Manual

2

You can use this margin

for taking notes.

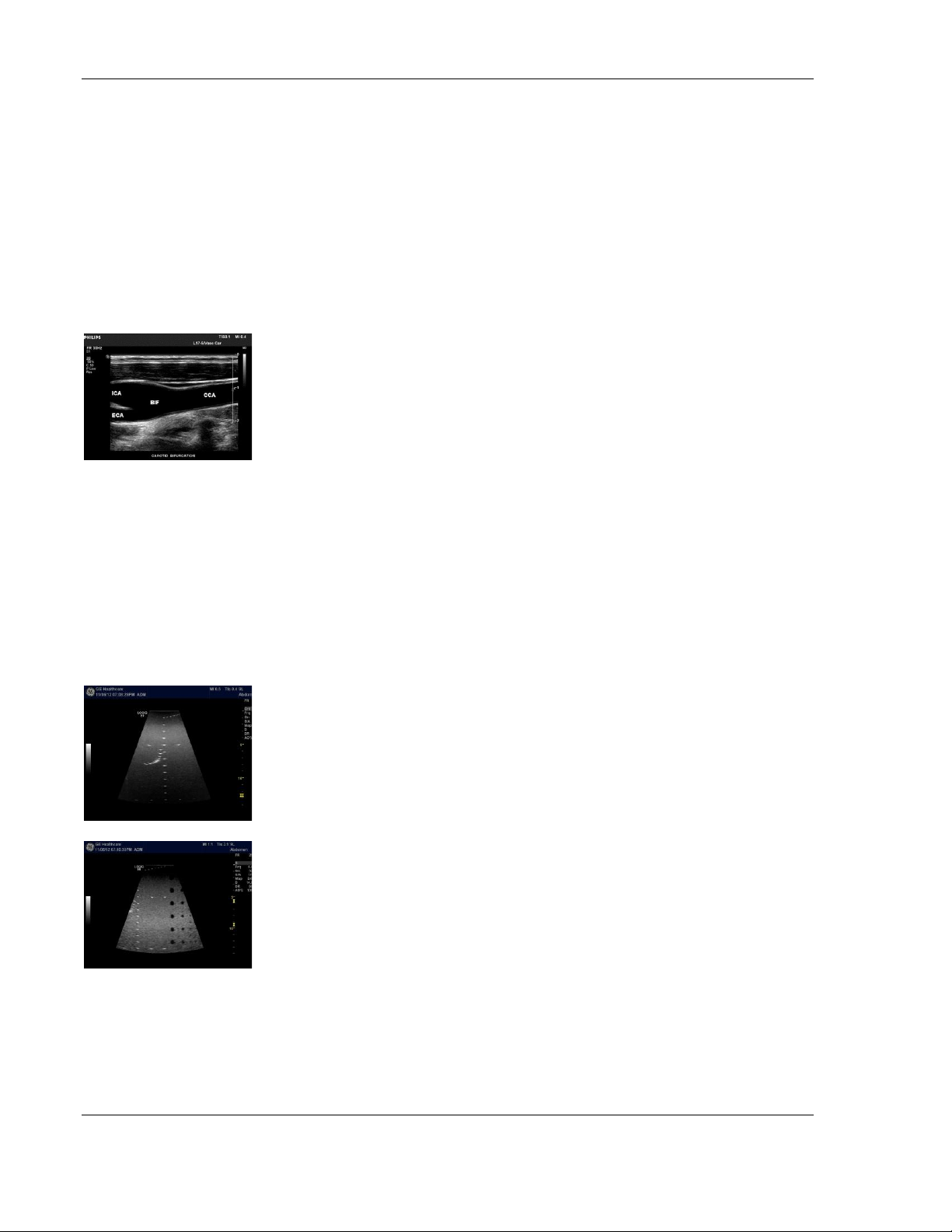

Voluson E10

The Voluson E10 is most

often used for womens

health-OB/GYN

applications.

Preventive Maintenance

Probe Care and Handling

NFPA 99 Electrical Safety

Crash Course

OEM Platforms

To see the full descriptions and the scheduling of these courses,

please visit our training department website:

http://conquestimaging.com/education/

© 2017 Conquest Imaging

Page 8

GE Voluson E10 Training Manual

3

Module 2 System Hardware and Theory

The goal of the System Hardware and Theory Module is to provide

you with a solid grounding on the purpose of the GE Voluson E10

system’s different components and how they function together

within the system.

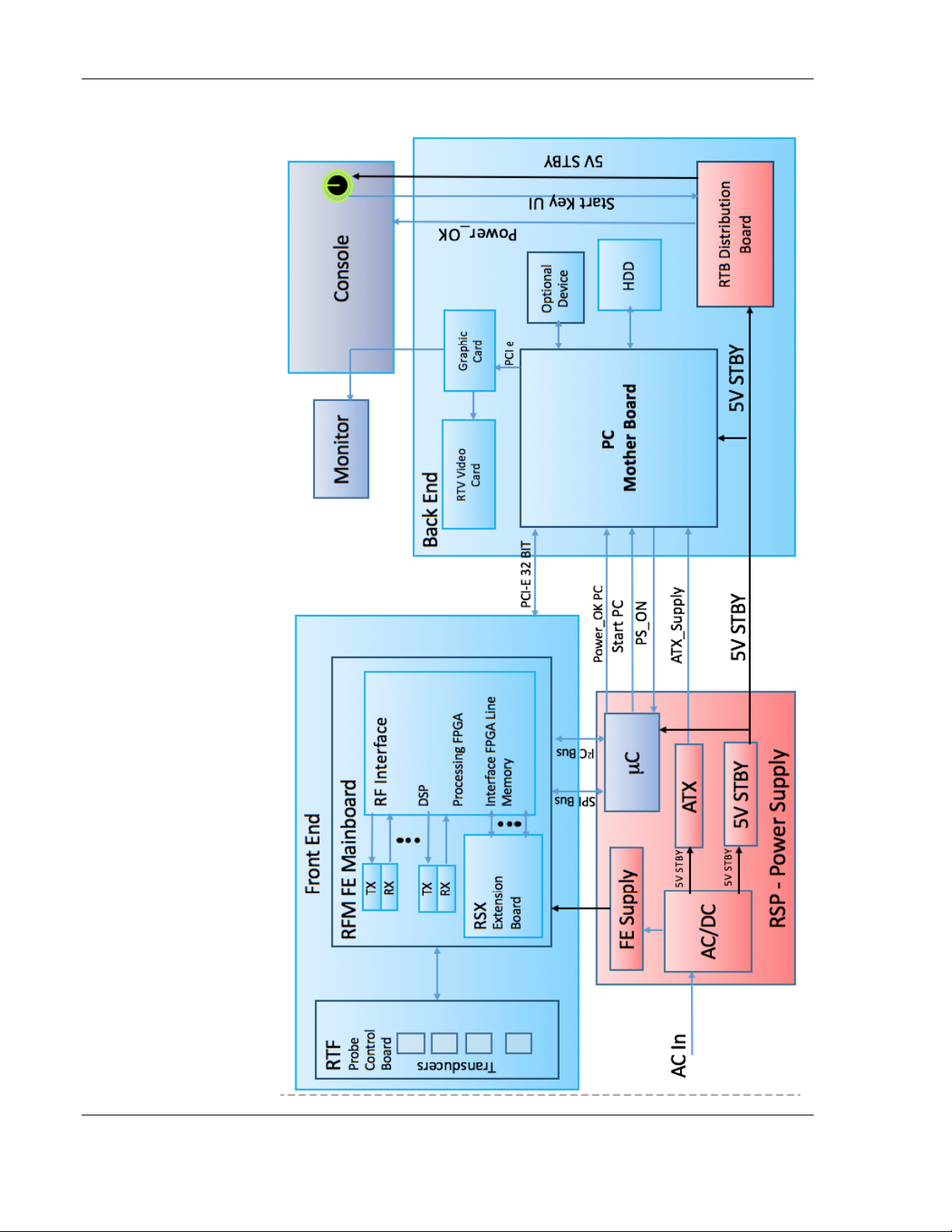

The three major functional blocks in all ultrasound systems are:

Front End – Includes transducer analog signal processing

functions.

Back End – Includes user interface and system communication

with DICOM systems.

Power Systems – Generates, regulates and supplies the required

voltages to the various parts of the system.

Signal Flow

System configurations (GE dataflows) are stored on a hard drive

inside the BEP, and all the necessary software is loaded from the hard

drive on power up of the system.

The transmit bursts are routed from the RF interface to the relays

where the ultrasound probes are connected. The signals are

transmitted by the probes as ultrasound into the body. The input

signals travel from the probe connector panel to the Front End

Processor (FEP), then to the Back End Processor (BEP) for digital signal

processing(DSP) and finally, the results are displayed on the monitor.

© 2017 Conquest Imaging

Page 9

GE Voluson E10 Training Manual

4

System Block

Diagram

© 2017 Conquest Imaging

Page 10

GE Voluson E10 Training Manual

5

System Front End Components

This section covers system frontend topics for the GE Voluson E10.

Front End is a general term for the parts of the ultrasound system

that receive the reflections from acoustic energy that have been

transmitted into the body and perform the various signal processing

functions on them needed to produce an ultrasound image. The

following are some of the components and functions that are found

in a typical ultrasound system front end:

Transducers – Transmit focused acoustic energy and receive the

resultant reflections.

High voltage switches – Used for multiplexing (connects a

particular transducer element to a particular transmitter/receiver

pair)

High voltage transmitters – Transmit analog data from the

transducers.

Time Gain Control Amp (TGC) – A variable gain amplifier (VGA) is

used to compensate for image variations due to tissue depth.

Analog to Digital converter and noise filtering.

Digital Beamformers – Upconverts signals which increases

sample rates. The signals are stored in memory, apodized and

summed.

Beamformed Digital Signal Processing – The digital beamformed

signals received are processed into visual and audio outputs the

process of which depends on if the transducer is B-mode (2D),

Doppler, PWD or CWD.

The front end manages the input from the transducers, performs

Analog to Digital conversion, Digital to Analog conversion along with

many other signal processing functions.

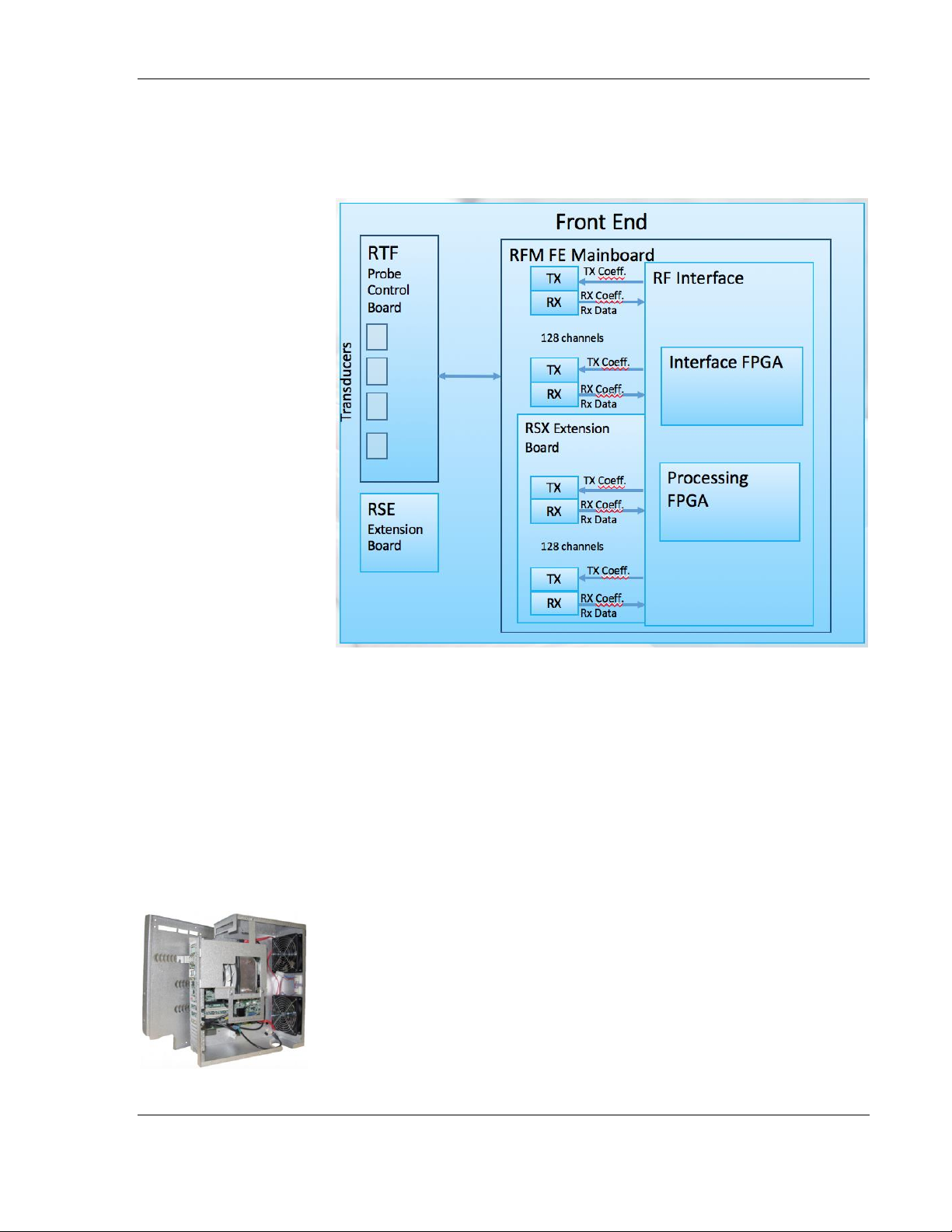

Voluson E10 Front End Processor (FEP)

In the Voluson E10 systems the front end beamforming electronics

are comprised of the following boards:

© 2017 Conquest Imaging

Page 11

GE Voluson E10 Training Manual

6

To extend to 192 or 256

channels, the RSX(Beamformer

Receiver/Transmitter)

Extension board is

required.

RTF - Probe Control Board

The probe control board (RTF) recognizes different probe types and

switches between the Probe Connectors (3 DLP-Connectors, 1 CWConnector) as required. The board contains:

One optional CW-Probe Connector

Three 408 pin Probe-Connectors

One 408pin Dummy-Probe Connector

Probe Select Relays

Probe Recognition

RSE - Pencil Probe Board (optional)

CW scanning is optional on the Voluson E10. This adapter board is for

the connection of CW pencil probes is required for CW-Option.

RFM - (RF-Interface & Beamformer) FE Mainboard

The FrontEnd Mainboard supports Tx/Rx for 128 channels only.

RFM Board - Interface FPGA

The interface FPGA on the RFM board provides the following

functions:

DMA logic

Beamformer Interface

RTF Control Interface

RTF FPGA Control Interface

RFM Board - Processing FPGA

The processing FPGA on the RFM board provides the following

functions:

Ultrasound Data Pre-Processing

System Control

Motor Control

RSX - (Beamformer Receiver/Transmitter) Extension Board

Subset (for RFM) that is required to extend to 192 or 256 channels. All

© 2017 Conquest Imaging

Page 12

GE Voluson E10 Training Manual

7

Front End Block

Diagram

components of RSX board are also present on RFM - (RF-Interface &

Beamformer) FE Mainboard.

System Backend Components

This section describes the System Back End topics for the GE Voluson

E10. The back end includes system blocks/components on the user

interface side that perform functions such as master controller, signal

processing, image memory, video layout, peripherals and user

interface.

Back End Processor (BEP)

The Back End Processor (BEP) unit receives the data from the FEP

electronics, stores it in memory, performs scan conversion to the

pixel domain, and drives the system’s monitors.

Contains the HDD that holds the Base Image (Windows 7) and

Application Software (System Specific). The BEP software also

processes the Color Flow, Doppler, M-Mode data and the 3D/4D data.

© 2017 Conquest Imaging

Page 13

GE Voluson E10 Training Manual

8

Back End Block

Diagram

PC-Motherboard

The major tasks of the motherboard are system control and image

processing/rendering for 2D/3D/4D. It also provides control for the

DVD drive and User Interface (UI) via USB connections. There are four

motherboard configurations for the Voluson E10:

ADVANTECH Micro-ATX + RTT/RTH6x

ADVANTECH Micro-ATX + RTH50

KONTRON Flex-ATX + RTT/RTH6x

KONTRON Flex-ATX + RTH50

Built in or external Components:

© 2017 Conquest Imaging

Page 14

GE Voluson E10 Training Manual

9

Distribution of

partitions at 500

Gbyte HDD

On Board VGA and Graphic Card

LAN

USB 2.0

USB 3.0

Sound

CPU: 3.1 GHz at 4 cores

Hard Disk Drive (HDD)

The 500GB Hard Disk is the main storage device of the Voluson ESeries ultrasound system. The Voluson E-Series Hard disk drive (HDD)

is divided into four different partitions:

C: System partition:

Operating System (Windows 7) including all Windows settings

(IP-address, Network Name, etc.)

US-Application Software (UISAPP)

Global Service Platform Software

Software Options

D: User partition:

User Presets (Backup) database

Images (Archive), Patient-ID´s and Reports database

Service and System settings databases

R: Rescue partition:

Factory Images of the C: Partition for System recovery after

HDD (Windows) crash.

Printer Drivers

LINUX partition: (not visible in Windows)

Linux operating system for rescue functionality.

© 2017 Conquest Imaging

Page 15

GE Voluson E10 Training Manual

10

Graphic Card

The graphic Card supplies the RTV (Video manager) board with DVI

Video. It offers dynamic contrast enhancement and color stretch

video processing.

RTV - Video Management Board

Distributes DVI-D-information coming from the Graphic Card to the

DVI-D (digital) and DVI-I (integrated) connectors. It also converts DVID-inputs to S-Video output(s). Displays external playback video and

adds overlay graphics to it.

DVI-D output for the System Main Monitor

DVI-I output for external device (only RGB signals used)

S-Video output (2 channels)

S-Video input for external devices

USB connector for board configuration

External I/O Connection Panel

The GES30 external I/O connection Panel is found at the rear of the

system and includes VGA, USB, Network and S-Video cables to the

Voluson E-Series system.

HDMI OUT Connector for external monitor

VGA OUT Connector for external monitor

USB 3.0 port

USB 2.0 port

S-Video OUT S-Video OUT connector

Network DICOM input/output, twisted pair RJ-45 10/100

megabit/s

© 2017 Conquest Imaging

Page 16

GE Voluson E10 Training Manual

11

Inputs for the patient I/O

are not meant for patient

monitoring they are

meant for correlation with

patient scans only.

Patient I/O Module

The Patient I/O module allows ECG inputs to be used in conjunction

with patient studies. The scanned image that is displayed is

synchronized with the ECG and PCG traces. In Doppler or M-Mode,

the traces are synchronized to that particular mode’s sweep. The AUX

input is capable of handling external ECG signals from other

diagnostic ECG devices.

User Console

The Voluson E-Series control console or User Interface(UI) consists of

the following electronic sub-assemblies and/or functional

components:

Display/Touch screen module:

WXGA display - 1280 x 800 pixels

Integrated USB to converter with USB2.0 High Speed

Interface

Projected capacitive touch screen

Console module

Seven port USB 2.0 Hub controller:

Contols (Encoder/Joycoder) with integrated rotary/push/flip

function

USB Trackball (2”) with dedicated buttons to emulate

standard three button mouse

USB standard alphanumeric keyboard

USB extended keyboard with controller

LED Indicators with wide range dimming

LED to illuminate probe port connectors

DC/DC Converter:

Converts 12VDC input voltage to 5VDC and 3.3VDC output voltages

for UI components.

© 2017 Conquest Imaging

Page 17

GE Voluson E10 Training Manual

12

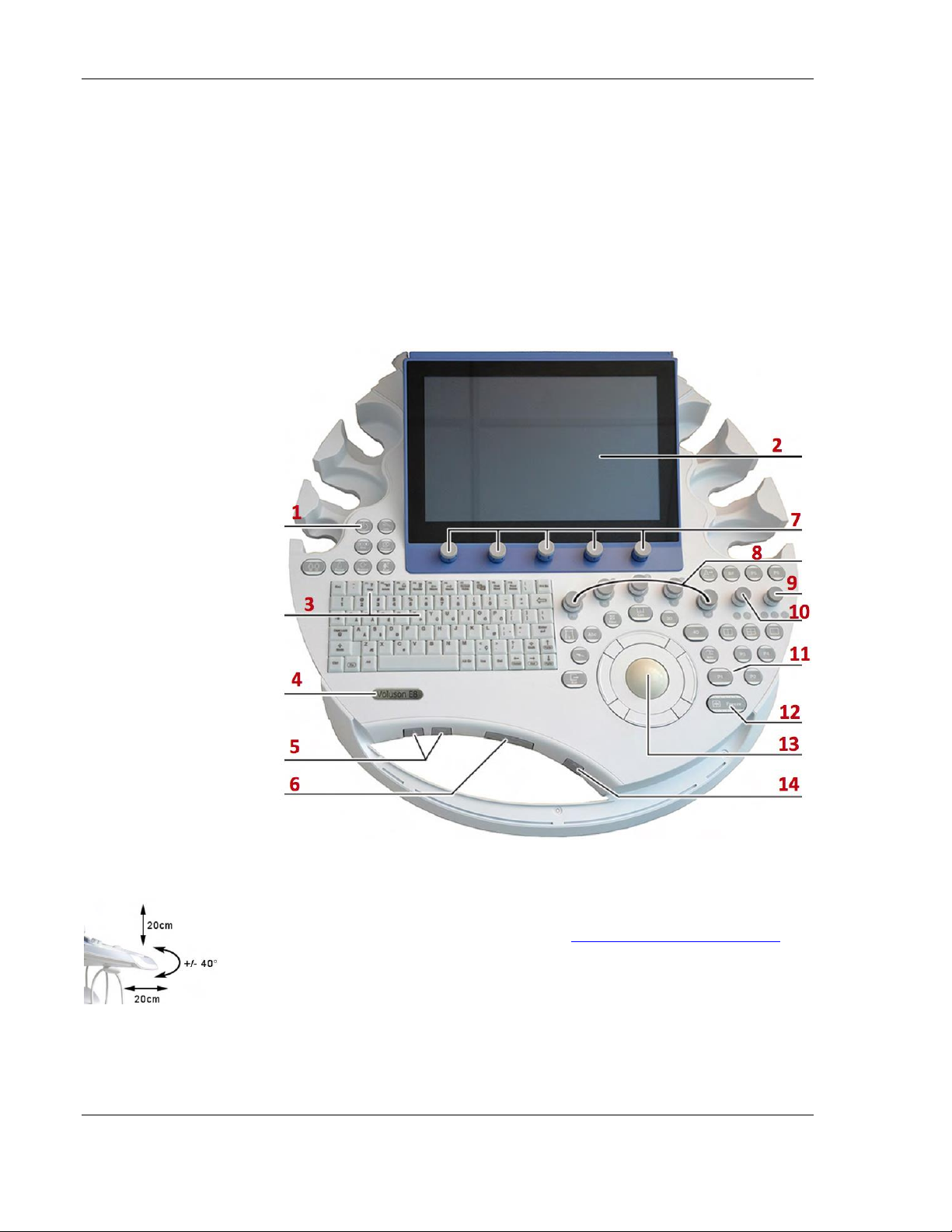

1.Power button

ON/OFF/Standby

2. Touch Panel screen

3. Alphanumeric keyboard

and F1 key (to invoke

EUM)

4. Logo

5.Height adjustment

control.

6. Console rotation button

7. Touch Panel

rotary/push/flip controls

8. Five mode keys on/off

(push), Gain (rotate) X,Y,Z

rotary controls in 3D/4D

Volume Mode

9. Focus Depth (flip), BImage Angle (rotate),

Focus Zones (push)

10. Zoom Box on/off

(push), Zoom Size (rotate),

B-Image Depth (flip)

11. P-keys

12. Freeze / Run key

13. Trackball and Trackball

keys

14. Lamp on/off

Control Panel

The control panel is the main user interface, receives user inputs,

communicates with the system host CPU via Universal Serial Bus

(USB) ports and displays various outputs via the touch panel.

It includes the On/Off switch, controls used to manipulate picture

quality, and controls used to measure and analyze, an alphanumeric

keyboard and ergonomic controls.

Control Console Positioning

For ergonomic considerations the control console can be rotated,

translated and adjusted in height. See Control Console Positioning in

the Adjustments module of this manual.

Height adjustment: 20 cm (7.9 inch)

Translation adjustment: 20 cm (7.9 inch)

Rotation adjustment: +/- 40°

© 2017 Conquest Imaging

Page 18

GE Voluson E10 Training Manual

13

The monitor and it’s

housing are sold as

separate FRUs.

Video Monitor

The Voluson E-Series system video monitor displays the ultrasound

images on a 23” color LCD.

Audio

Audio is provided by two 8 Ohm speakers located in the user console

on either side of the touch panel.

© 2017 Conquest Imaging

Page 19

GE Voluson E10 Training Manual

14

The audio system is used for:

Audio Doppler operation

Audio playback of recorded scan sessions

Audio error notification.

The audio signal is passed to the speakers from either the RTH50

board or the RTT board depending on the version of the system.

Power Distribution Components

The power distribution components in Voluson E10 systems are

described in this section.

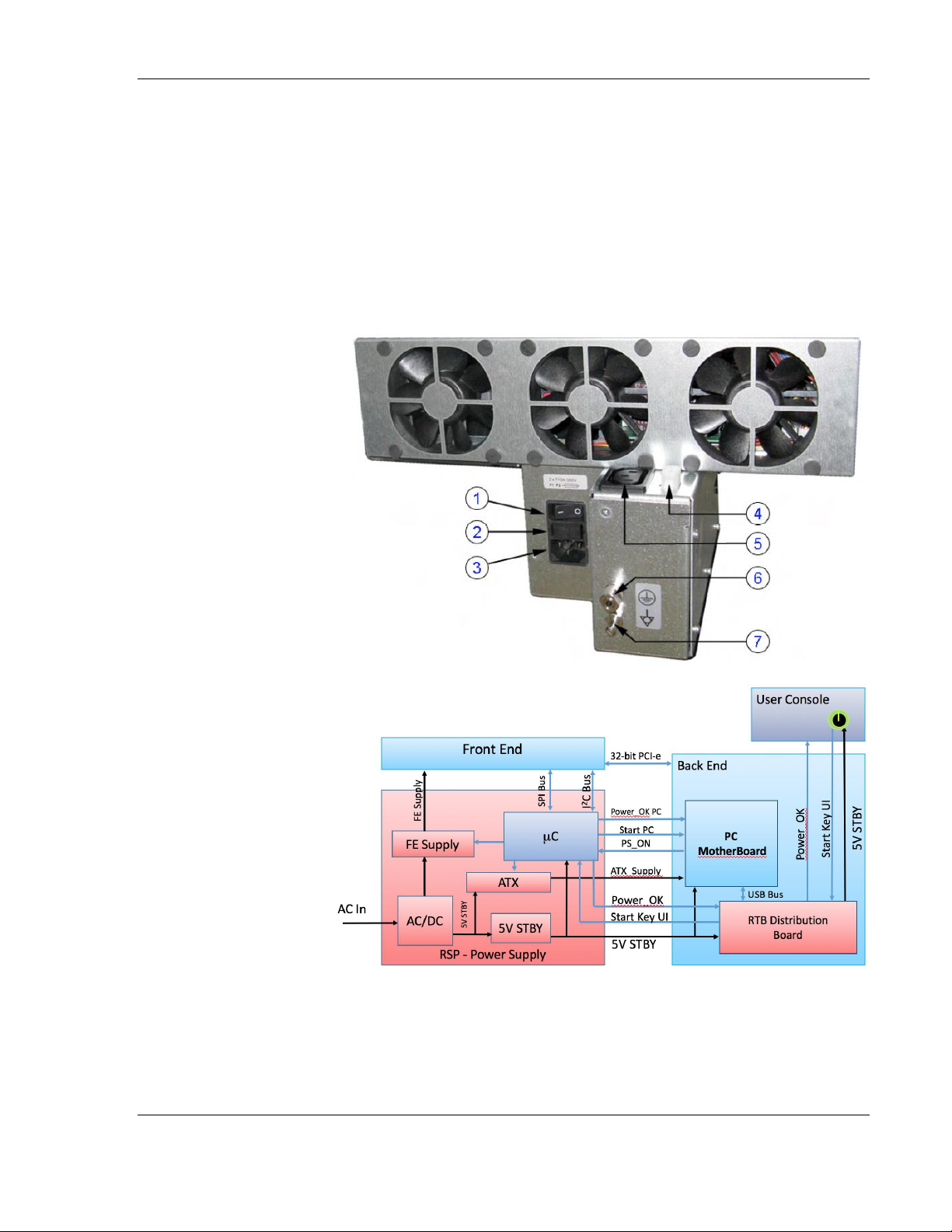

Main Power Supply (RSP)

The AC Power's main tasks are to supply the various internal

subsystems with AC power and to galvanically isolate the system from

the on site Mains Power System. To reduce inrush current, an inrush

current limiter is implemented. From the input voltage from the

Power Supply (RSP) the AC/DC converter generates all system supply

voltages, which include the:

Front End voltages

Standby voltages

ATX motherboard supply

Tx voltages

© 2017 Conquest Imaging

Page 20

GE Voluson E10 Training Manual

15

1 Circuit Breaker

2 Fuses (2x T10A H/250V)

3 connector for Main

Power Cable

4 Lift system (12VDC)

5 Auxiliary Output

6 Protective Earth

connection

7 Equipotential

connection

Power Supply

Block Diagram

In addition, the AC/DC device contains the digital motor amplifier.

Input Voltage Range: 100 - 240VAC; 50/60Hz

Auxiliary Output Voltage nominal 115VAC

All DC-supply voltages for built-in peripherals are also generated in

the RSP- Power Supply Module.

© 2017 Conquest Imaging

Page 21

GE Voluson E10 Training Manual

16

Note After turning off a

system, wait at least 10

seconds before turning it

on again. The system may

not be able to boot if

power is recycled too

quickly.

1. Circuit Breaker

2. Fuses

3. Outlet Plug

RTB - Distribution Board Bottom

The following are the functions of the Distribution Board Bottom

(RTB):

USB2.0 Interface, Board is connected to PC via a USB cable.

5 port USB2.0 Hub for connecting peripherals (e.g., optional ECG)

Feed through DC-Power and Signals for the console (12V_ATX,

5V_ATX, 5VSB, PWR_On, Start_Key, Loud speaker)

Multiplexer and Amplifier for PC-Sound, Doppler Audio and

VCR/DVD-Recorder)

Normal Power ON / Shut Down Sequence

Power On / Boot Up:

1. Connect the main power cable to the back of the system.

2. If not already done, screw on the pull-out protection of the mains

power cable with the two screws.

3. Connect the main power cable to a hospital grade power outlet

with the proper rated voltage. Never use an adapter that would

defeat the safety ground.

4. Switch ON the circuit breaker at the rear of the system.

When AC power is applied to the system, the ON/OFF standby button

on the control console is amber, indicating that the system is in

standby mode.

© 2017 Conquest Imaging

Page 22

GE Voluson E10 Training Manual

17

Note The mains outlet for

the system peripheral

auxiliary equipment are

commonly switched with

the ON/OFF standby

button. The power switch

of any attached printer(s)

must be in ON position

before starting the

system. Some auxiliary

equipment may switch

itself to standby mode and

must therefore be

switched on separately.

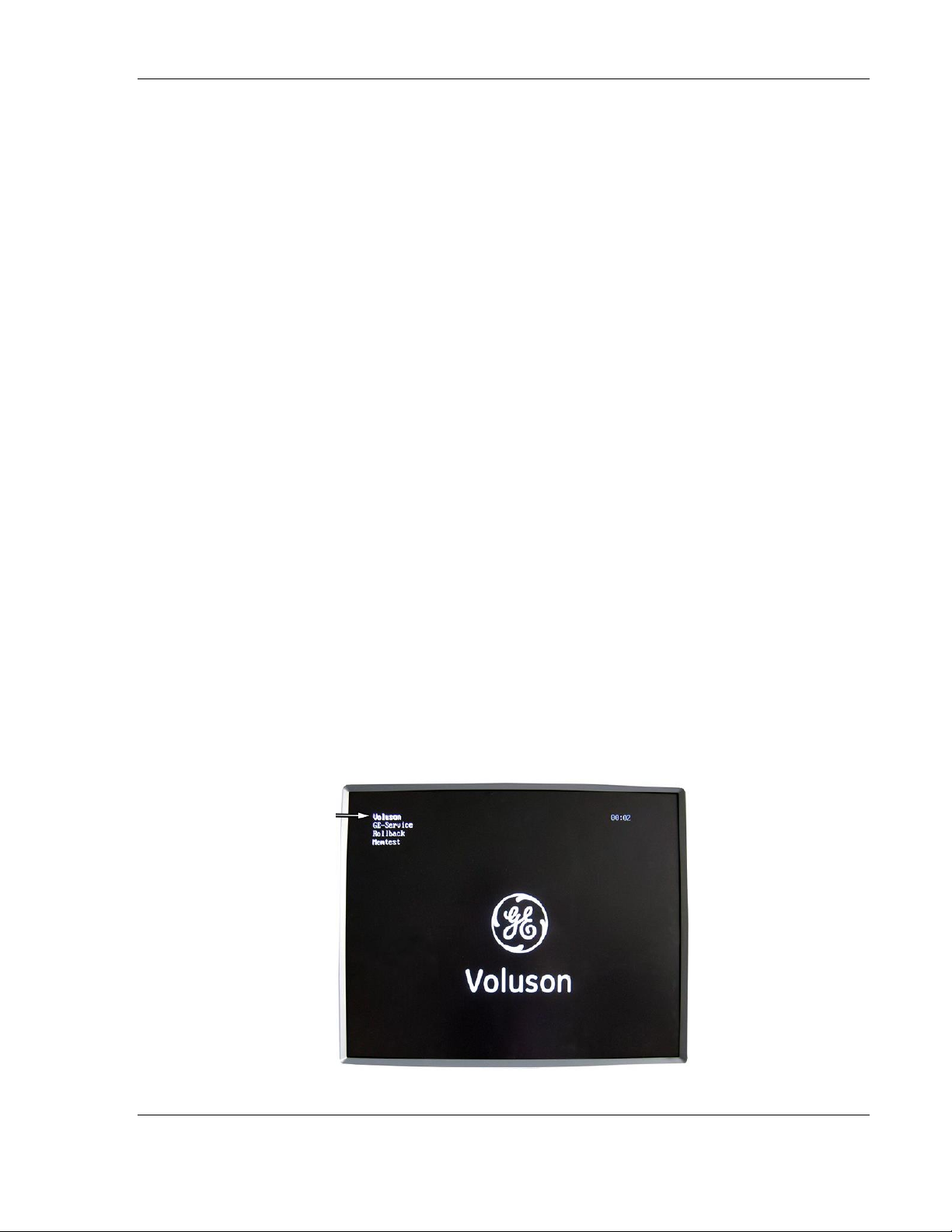

Boot screen

5. Hold down the ON/OFF standby button (see: Figure 3-3 below) on

the control console for ~3 seconds. The system automatically

performs an initialization sequence which takes about two minutes

and includes the following:

Loading the operating system.

Running a quick diagnostic check of the system.

Detecting connected probes.

When the ON/OFF standby button on the control console is pressed,

the system starts and the operating system is loaded which then

leads to activate the application software.

As soon as the software has been loaded, the system enters 2D-Mode

with the probe and application that was used before the system

shutdown.

Normal Boot-up Process

1. Power is distributed to peripherals, control console, monitor,

FrontEnd and BackEnd processor.

2. The BackEnd processor and rest of the system starts with the

sequence listed in following steps:

First the BIOS version is shown on the monitor.

Afterward the “Boot Screen” is displayed. (Voluson is

highlighted).

© 2017 Conquest Imaging

Page 23

GE Voluson E10 Training Manual

18

Note After turning off a

system, wait at least 10

seconds before turning it

on again. The system may

not be able to boot if

power is recycled too

quickly.

A full shutdown is also

performed when pressing

the ON/OFF standby

button on the control

console twice.

3. Back End processor is turned ON and starts to load the software.

4. The start screen is displayed on the monitor.

5. Start-up progress bars indicating software loading procedures, are

displayed on the monitor.

6. The software initiates and sets up the FrontEnd electronics and the

rest of the system (incl. clicking sound of relays on RTF board).

7. The keyboard backlight is lit.

8. As soon as the software has been loaded, the 2D screen is

displayed on the monitor.

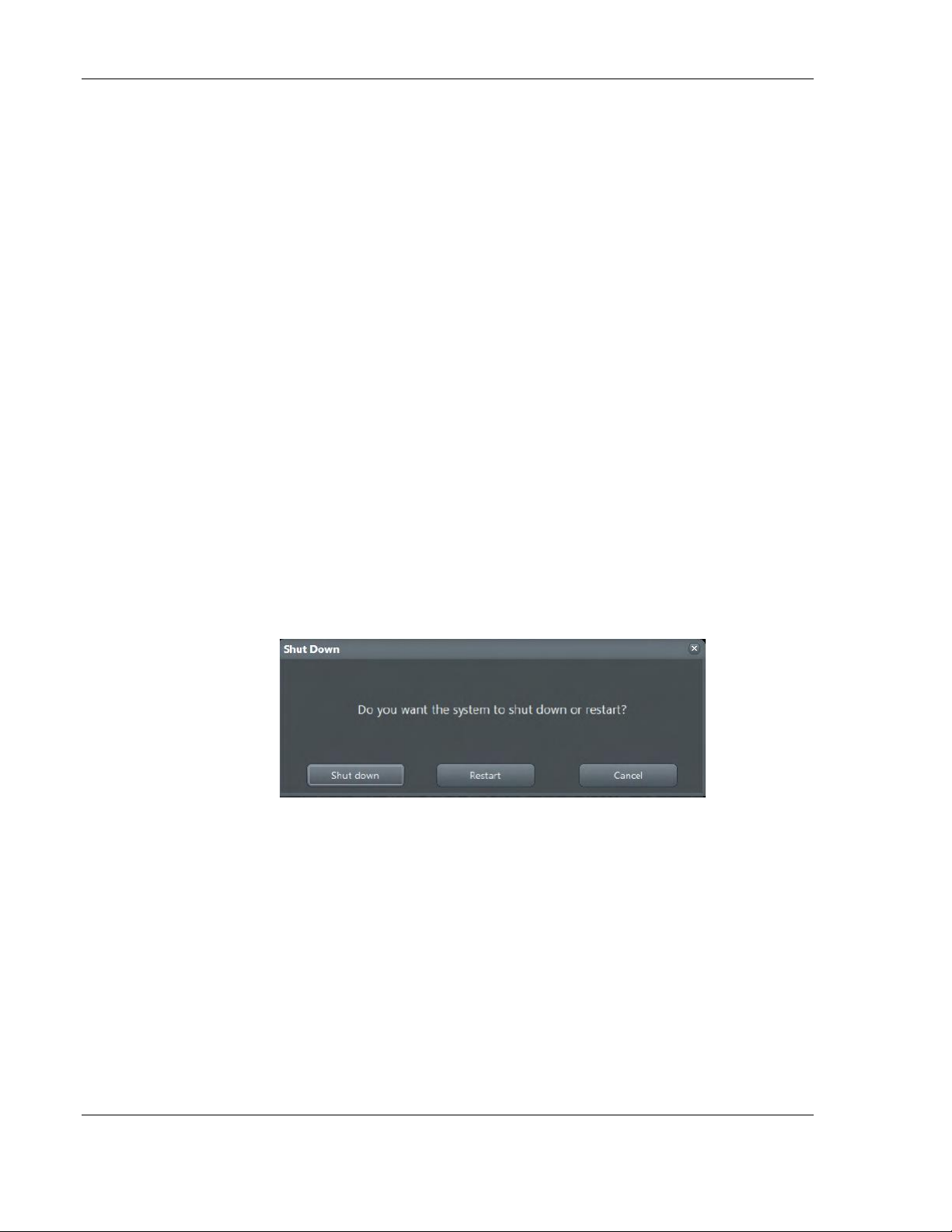

Normal Power Off / Shutdown

To shutdown the system:

1. If not already in read mode, freeze the image.

2. Press the ON/OFF Standby button on the control console. Following

dialog appears:

3. Select Shutdown. The system performs an automatic full shutdown

sequence.

4. Switch OFF the circuit breaker at the rear of the system.

Temperature Control

BTU Info

The main air inlet is through a single filter at the rear of the Voluson

E-Series system:

© 2017 Conquest Imaging

Page 24

GE Voluson E10 Training Manual

19

Air holes in the RSP power supply allow the air to pass through;

the three fans inside the RSP pull in the air and circulate it

through the beamformer.

The two backend fans blow air through the GEB-box (along its

internal components and the PC- Motherboard). The warm air

exits the system through holes in the left side panel (Main Air

Outlet).

© 2017 Conquest Imaging

Page 25

GE Voluson E10 Training Manual

20

Module 3 Operating Modes

The following general operating modes are available on Voluson E10

systems:

B-Mode

B-Mode is a two-dimensional image of the amplitude of the echo

signal. It is used for location and measurement of anatomical

structures and for spatial orientation during operation of other

modes. In B mode, a two-dimensional cross-section of a threedimensional soft tissue structure such as the heart is displayed in real

time.

Ultrasound echoes of different intensities are mapped to different

gray scale or color values in the display. The outline of the 2D (BMode) (B-Mode) cross-section is a sector, depending on the particular

transducer used. B-mode can be used in combination with any other

mode.

Harmonic Imaging

Tissue Harmonic Imaging, acoustic aberrations due to tissue, are

minimized by receiving and processing the second harmonic signal

that is generated within the insonified tissue. Coded Harmonics

enhances near field resolution for improved small parts imaging as

well as far field penetration. It diminishes low frequency amplitude

noise and improves imaging technically difficult patients.

It may be especially beneficial when imaging isoechoic lesions in

shallow-depth anatomy in the breast, liver and hard-to-visualize fetal

anatomy. Coded Harmonics may improve the B-Mode (2D (B-Mode))

image quality without introducing a contrast agent.

© 2017 Conquest Imaging

Page 26

GE Voluson E10 Training Manual

21

M-Mode

In M-mode, soft tissue structure is shown as a scrolling display, with

depth on the Y-axis and time on the X-axis. It is mostly used for

cardiac measurements. M-mode is also known as T-M mode or TimeMotion mode. Ultrasound echoes of different intensities are mapped

to different gray scale values in the display. M-mode displays time

motion information derived from a stationary beam. M-mode is

normally used in conjunction with a 2D (B-Mode) (B-Mode) image for

spatial reference.

Color Flow Doppler Mode

Color Doppler is used to detect motion presented as a twodimensional display. There are three applications of this technique:

Color Flow Mode - used to visualize blood flow velocity and

direction.

Power Doppler (Angio) - used to visualize the spatial distribution

of blood.

Tissue Velocity Imaging - The Tissue Color Doppler Imaging is

used for color encoded evaluation of heart movements. Tissue

Velocity Imaging images provide information about tissue motion

direction and velocity.

Blood flow is displayed as a real-time two-dimensional cross-sectional

image. The 2D (B-Mode) (B-Mode) cross-section is presented as a full

color display, with various colors being used to represent blood flow

(velocity, variance, power and/or direction).

To provide spatial orientation, the full color blood flow crosssection is

overlaid on top of the gray scale cross-section of soft tissue structure

(2D (B-Mode) (B-Mode) echo). Blood velocity is the primary

parameter used to determine the display colors, but power and

variance may also be used.

A high pass filter is used to remove the signals from stationary or

slowly moving structures. Tissue motion is discriminated from blood

flow by assuming that blood is moving faster than the surrounding

tissue. Color flow can be used with 2D (B-Mode) (B-Mode) and

Spectral Doppler modes.

© 2017 Conquest Imaging

Page 27

GE Voluson E10 Training Manual

22

CW Doppler is optional on

the Voluson E10 systems.

Power Doppler

Power Doppler is the same as Color Doppler except that it uses the

amplitude of the signal to detect movement. The power in the

remaining signal after wall filtering is then averaged over time to

present a steady state image of blood flow distribution. It is

independent of velocity and direction of flow, so there is no signal

aliasing. It is independent of angle allowing the detection of smaller

velocities than Color Doppler, making it easier to detect indistinct

ischemic areas as well as evaluate tiny low-flow vessels. Power

Doppler can be used in combination with 2D (B-Mode) (B-Mode) and

Spectral Doppler modes as well as with 4D mode.

Pulsed (PW) Doppler

PW Doppler processing is one of two spectral Doppler modes, the

other being CW Doppler. In spectral Doppler, blood flow is presented

as a scrolling display, with flow velocity on the Y-axis and time on the

X-axis. The presence of spectral broadening indicates turbulent flow,

while the absence of spectral broadening indicates laminar flow. PW

Doppler provides real time spectral analysis of pulsed Doppler signals.

PW Doppler can be used alone but is normally used in conjunction

with a 2D (B-Mode) (B-Mode) image with an M-line and sample

volume marker superimposed on the 2-D image indicating the

position of the Doppler sample volume. The sample volume size and

location are specified by the operator. Sample volume can be overlaid

by a flow direction cursor which is aligned, by the operator, with the

direction of flow in the vessel, thus determining the Doppler angle.

This allows the spectral display to be calibrated in flow velocity

(m/sec.) as well as frequency (Hz). PW PW Doppler can be used in

combination with 2D (B-Mode) (B-Mode) and Color Flow modes.

Continuous Wave (CW) Doppler

Continuous Wave Doppler systems use two crystals, one to send and

one to receive the echoes. The transmitter inputs a continuous

sinusoidal wave. The receiver detects the shift. An audible sound is

created and recorded by either an analog recorder or spectral

analyzer. Spectral analysis separates the signal into individual

components and assigns a relative importance.

© 2017 Conquest Imaging

Page 28

GE Voluson E10 Training Manual

23

The benefits of CW Doppler include high sensitivity to low velocities

and detection of high velocities without aliasing. CW Doppler cannot

distinguish between the sending and receiving signals or extraneous

echoes, nor does CW Doppler produce a precise image like Pulsed

Wave Doppler.

Other Modes

4D: The E9 Ultrasound System can be used to acquire multiple,

sequential 2D (B-Mode) (BMode) images which can be combined to

reconstruct a three dimensional image. 4D images are useful in

visualizing three-dimensional structures, and in understanding the

spatial or temporal relationships between the images in the 2D (BMode) (B-Mode) sequence. The 4D image is presented using standard

techniques, such as surface or volume rendering.

© 2017 Conquest Imaging

Page 29

GE Voluson E10 Training Manual

24

Module 4 Network Configuration

The following sections provide some basic biomedical networking

background information along with information and procedures

specific to the GE Voluson E10 ultrasound systems.

DICOM

The Digital Imaging and Communications in Medicine (DICOM) is a

standard that specifies a consistent file structure for biomedical

images and important associated information that must remain

associated with the images such as patient name time, date,

institution etc. The DICOM specification identifies the elements

required to achieve interoperability between medical imaging

computer systems.

DICOM addresses these five general application areas:

Network image management

Network image interpretation management

Network print management

Imaging procedure management

Off-line storage media management

Prepare for Network Configuration

You will need to get the facilities network information from the

system administrator. You can print out the information needed to

configure the system using the Network Configuration Worksheet

appended to the end of this manual.

GE Dataflows

GE refers to communication between its ultrasound systems and

other information providers on the network as “dataflows”. A

dataflow is a set of configured settings.

Communication between the Voluson E-Series ultrasound system and

other information providers on the network takes the form of data

© 2017 Conquest Imaging

Page 30

GE Voluson E10 Training Manual

25

flows. Each dataflow defines the transfer of patient information from

either an input source to the system, or from the system to an output

source. The following are the most common examples:

The local database is used for patient archiving. Images are

stored to internal hard drive.

The local database is used for patient archiving. Afterwards

images are stored to a DVD/CD or external USB device, etc.

A remote database is used for patient archiving. Images are also

stored to a remote archive.

Search in the DICOM Modality Worklist, the patient found is

copied into local database. The patient information and the

examination results are stored to the local database. Images are

stored to a DICOM server and to an image network volume on

the local hard drive.

Patient information can include demographic data and images, as

well as reports and Measurement and Analysis (M&A) data. A

dataflow is a set of pre-configured services. Selecting a dataflow

automatically customizes the ultrasound system to work according to

the services associated with this dataflow.

By utilizing data flows, the Voluson E-Series ultrasound system is

automatically configured to optimally meet the needs of the facility,

while keeping the user interface unchanged. Once a dataflow is

selected, the actual location of the database is entirely transparent to

the user.

TCP/IP Configuration

This section describes how to set up TCP/IP Configuration.

Note The following information for the Voluson E-Series must be

obtained before you can start:

Station name

AE Title

IP address

Port Number.

© 2017 Conquest Imaging

Page 31

GE Voluson E10 Training Manual

26

The IP addresses for the

default gateway and

other routers at the site

for ROUTING

INFORMATION. Only if

necessary (e.g. for

Internet access).

Note This example shows

fictional numbers!

If fixed IP address is

required, ask your

network administrator for

the appropriate settings.

1. Press the Utilities key on the control console.

2. In the “Utilities” menu touch the Setup button to invoke the setup

desktop on the screen.

3. On the right side of the screen select Connectivity and then click

the Device Setup tab.

4. Click the TCP/IP Configuration button, read the message and

confirm with Yes.

5. The "Internet Protocol (TCP/IP) Properties" dialog appears:

The IP and DNS settings can beassigned automatically, if your network

supports this capability.

Type in:

IP address

Subnet mask

Default gateway

DNS server

© 2017 Conquest Imaging

Page 32

GE Voluson E10 Training Manual

27

Note All software drivers

are pre-installed for the

designated Wireless

Network adapter only.

WLAN Setup

The following sections describe WLAN connectivity and setup.

Connecting to the WLAN

To connect and set up the WLAN:

1.Connect the Wireless Network adapter to any accessible USB port.

2. Press the Utilities key on the control console.

3. In the “Utilities” menu touch the Setup button to invoke the setup

desktop on the screen.

4. On the right side of the screen select Connectivity and then click

the Device Setup tab.

5. Click the WLAN Configuration button.

6. The Wireless Network Configuration tool with available Wireless

Networks appears:

7. Check box "Enable Wireless Connection".

© 2017 Conquest Imaging

Page 33

GE Voluson E10 Training Manual

28

Note If the WLAN fails to

connect, review and/or

recreate the Wireless

connection in the Security

tab.

Add WLAN Profile:

8. Highlight the wireless network you want to use and then click

Connect.

Disconnecting from the WLAN

1. Press the Utilities key on the control console.

2. On the right side of the screen select Connectivity and then click

the Device Setup tab.

3. Click the WLAN Configuration button. The Wireless Network

Configuration tool with available Wireless Networks appears.

4. Select the WLAN you are connected to and then click Disconnect.

Adding a WLAN Profile

1. Open the Wireless Network Configuration tool.

2. Select the Security tab and then click Add.

3. Add the following information to the Wireless Network Properties

page:

© 2017 Conquest Imaging

Page 34

GE Voluson E10 Training Manual

29

Network Name (SSID)

Check box "Connect even if Network is not Broadcasting its Name

(SSID)"

Network Authentication (Open, Shared Key, WPA PSK or WPA2

PSK)

Data Encryption

Network Key

Key Index

4. After you have filled in all the required information, click OK.

Refreshing a WLAN Network

1. Open the Wireless Network Configuration tool.

2. Click Refresh.

Setting a WLAN Network as Non-Preferable

When you make a WLAN non-preferable, you disconnect the network

from the system and delete all connection settings from the system.

Afterwards the system WILL NOT try to reconnect to this WLAN

automatically. And if you want to reconnect, you will need to re-add

this WLAN.

1. Press the Utilities key on the control console.

2. On the right side of the screen select Connectivity and then click

the Device Setup tab.

3. Click the WLAN Configuration button; see Figure 3-52 on page 3-59

.

4. The Wireless Network Configuration tool with available Wireless

Networks appear.

5. Highlight the wireless network you want to set as non-preferred.

6. Click Make Non-Preferable and confirm the message box.

Removing a WLAN Profile

1. Press the Utilities key on the control console.

© 2017 Conquest Imaging

Page 35

GE Voluson E10 Training Manual

30

2. On the right side of the screen select Connectivity and then click

the Device Setup tab.

3. Click the WLAN Configuration button; see Figure 3-52 on page 3-59

.

4. The Wireless Network Configuration tool with available Wireless

Networks appear.

5. Select the Security tab and then click Remove.

Customizing an existing WLAN Profile

1. Press the Utilities key on the control console.

2. On the right side of the screen select Connectivity and then click

the Device Setup tab.

3. Click the WLAN Configuration button; see Figure 3-52 on page 3-59

.

4. The Wireless Network Configuration tool with available Wireless

Networks appear.

5. Select the Security tab and then click Customize.

Figure 3-56 Security - Customize

6. Customize the following information:

- Network Name (SSID)

- Check box "Connect even if Network is not Broadcasting its Name

(SSID)"

- Network Authentication (Open, Shared Key, WPA PSK or WPA2 PSK)

- Data Encryption

- Network Key

- Key Index

7. After you have filled in all the required information, click OK.

© 2017 Conquest Imaging

Page 36

GE Voluson E10 Training Manual

31

Setup Instructions

3-62

Voluson E-Series Service Manual

5539550APB Revision 4

Available WLAN Channels

The available WLAN channels show availability of wireless connect

point that the system can talk to. Each channel supports a finite

number of users and has limited signal strength. This may effect the

ability to connect, the throughput and the connection dropping out.

1. Press the Utilities key on the control console.

2. On the right side of the screen select Connectivity and then click

the Device Setup tab.

3. Click the WLAN Configuration button; see Figure 3-52 on page 3-59

.

4. The Wireless Network Configuration tool with available Wireless

Networks appear.

5. Select the Properties tab.

Figure 3-57 Properties

6. Click Available Channels.

DICOM Device Setup

From the Device Setup screen it is possible to configure:

DICOM

Archive

Network

© 2017 Conquest Imaging

Page 37

GE Voluson E10 Training Manual

32

Controls

DICOM Configuration

The dialog section is where you set up details of all of your DICOM

target nodes (image servers).

AE Title - Enter the AE (Application Entity) Title under which your

DICOM application is known to other DICOM applications (required).

Obtain the correct AE Title from contact your DICOM network

administrator.

Station Name - Enter the name of the hospital or institute.

Retry Count - Number of retries to establish a successful DICOM

© 2017 Conquest Imaging

Page 38

GE Voluson E10 Training Manual

33

connection.

Retry Count Seq. - Retry count for sequential mode (only valid if Send

sequ. is checked). If the end number of Retry Count Seq. is reached

and sending was not successful then the “problem” data set is

marked as “failed” in the spooler and the system continues sending

the next image data

Retry Interval - Retry interval minutes.

Timeout (s) - Define a timeout interval.

Default - Default values of Retry Count, Retry Count Seq., Retry

Interval, Timeout (s) are set.

Test Connection - If a destination from the Destination List is selected

and the Test Connection button is pressed, the connection to the

selected destination is tested. If no destination is selected the button

is disabled.

Ping: Ping the selected destination and check the response.

The result can be OK or Failed

Verify: Send DICOM commands and check the response. The

result can be OK or Failed.

If a serial report destination is selected, the Test Connection button

changes to Send Test Report and the Ping and Verify fields disappear.

A test report is sent to the serial port instead of testing the network

connection.

Sound Notification - Acoustic signal for a successful or unsuccessful

transfer (sending Images, Structured Report Transfer and Report).

Destination List - Contains all available destinations and displays:

Services

Alias

AE Title

IP Address

Port

Color / Size

In the checkboxes next to the destination, mark the currently

© 2017 Conquest Imaging

Page 39

GE Voluson E10 Training Manual

34

The Edit button is disabled

if no destination is

selected.

The Delete button is

disabled if no destination

is selected.

Note: In Edit mode it is

not possible to change the

selected Service.

activated server. If more than one Service is added, then a selection

of one Service can be done with the checkbox.

To check the same Services is not possible for:

Print

MPPS

STR. Report

Query Retrieve

Worklist

When more than one STORE, STORE3D or STORAGE COMMIT service

is activated, images are sent to all selected STORE or STORE3D

destinations and committed with the corresponding STORAGE

COMMIT destinations.

Add - Pressing the Add button opens the Device Setup dialog, where

it is possible to add DICOM destinations. For more information see

'Adding a Service'.

Edit - Selecting a destination from the Destination List and pressing

the Edit button opens the Device Setup dialog, with the information

on the selected destination.

Delete - Selecting a destination from the Destination List and

pressing Delete removes the selected destination. The Delete button

is disabled if no destination is selected.

Save&Exit - When the Save&Exit button is pressed, the DICOM

Configuration dialog is closed and all changes are saved.

Exit - When the Exit button is pressed, the DICOM Configuration

dialog is closed and all changes are discarded.

Adding a Service

Select a Service and enter the destination settings (Alias, AE Title, IP

Address and Port).

Services

The following services are available:

© 2017 Conquest Imaging

Page 40

GE Voluson E10 Training Manual

35

Further information

regarding each service is

provided in the following

sections.

STORE: Send screen images, 2D cine sequences and 3D/4D data

to a DICOM server (e.g., Viewpoint).

STORE3D: Send 3D/4D data only (volumes and cine sequences) to

a different store server (e.g., PC with Software 4D View®

installed) than screen images and 2D cine sequences.

PRINT: Send images stored in printer clipboard to a DICOM

printer.

MPPS: Send images to a DICOM server with transfer information.

ST.COMMIT: Send image with an additional layer of security.

STR.REPORT: Send a structured report.

QUERY RETRIEVE: Query images or other DICOM objects and

Retrieve them from a PACS or other DICOM Modality.

WORKLIST: Retrieve Patient Information (Name, ID, Birth,...)

from an external Worklist server (e.g., HIS - Hospital Information

System / RIS, Viewpoint).

REPORT: Send the Patient report data to a PC via network or

serial port.

Alias - Enter a name for the DICOM node to make it easier to handle

various nodes. Use any name, but do not insert space characters.

AE Title - Enter the AE (Application Entity) Title under which your

DICOM application is known to other DICOM applications (required).

For setting the correct AE Title please contact your DICOM network

administrator.

IP Address - Enter the host name or IP Address of the DICOM node.

Port - Enter the port number of the DICOM node.

© 2017 Conquest Imaging

Page 41

GE Voluson E10 Training Manual

36

STORE / STORE3D

Screen

Note:

2D JPEG Quality is only

active when 2D

Compression is set to

JPEG.

Cine JPEG Quality is only

active when Cine

Compression is set to

JPEG.

Volume Compr. Quality is

only active when Volume

Compr. is set to lossy.

Use for servers that

cannot handle multiple

associations, or do not

sort the images by Image

Number.

If Send sequ. is checked and the Scan Assistant is activated:

The sequentially “send order” of the images (first, second …) is

derived from the check item order as configured in the setup

page (first item, second item …).

If more than one image is available on a check item the send

order is defined by the store date (first stored, second stored

and so on…).

If more than one checklist is available: order as configured in

the setup page.

If more than one checklist group is available: order as

configured in the setup page.

Images stored without check item: send order: date, after the

checklist items.

If the Scan Assistant is deactivated it causes all data to be sent

to this server sequentially. This means that only one transfer is

active to this server at a time. If one transfer fails, all

subsequent transfers are stopped until the failed transfer

succeeds or is removed from the queue.

© 2017 Conquest Imaging

Page 42

GE Voluson E10 Training Manual

37

Use for servers that have

none of the limitations

listed in the above

paragraph.

Caution: A lossy

compression can reduce

image quality which can

lead to a false diagnosis!

MPPS

ST.COMMIT

If Send sequ. is not checked, up to 5 data sets can be

transferred at the same time. This means that transfer is

faster. Images can arrive out of order in this case.

Storage Commit - The Storage Commit drop down list contains all

currently added Storage Commit servers. The selected Storage

Commit server is used for committing the images sent to this store

server.

4D View default - Loads the default settings for 4D View®. The

destination information must be entered manually.

DICOM Station default - Loads the default settings for DICOM

Station. The destination information must be entered manually.

Viewpoint default - Loads the default settings for Viewpoint.

If the volume contains color information, the color part of the

volume is compressed with a setting that is 5 points better

than the selected setting, e.g. Setting Mid: color compression

High, grey compression Mid

If an image / multifram cine is compressed using lossy JPEG

compression, a yellow sign (Jxx; xx = compression factor, e.g.

JH) is added to the image (but not to secondary capture

images).

If a volume is compressed using lossy, a yellow sign (Wxx; xx =

compression factor, e.g. W9) is added when reloading the

image.

The Modality Performed Procedure Step MPPS allows you to select

the Store Server and the SR Server.

Only the images sent to the selected Store Server are added to the

image list of the MPPS completed (or discontinued) message.

Note When the MPPS server is created and selected, MPPS messages

are created when an exam is started or ended.

Add a Storage Commit Server. These servers can then be selected in

the drop down list of the STORE-, STORE3D- and STR.REPORT Service.

© 2017 Conquest Imaging

Page 43

GE Voluson E10 Training Manual

38

STR.REPORT

QUERY RETRIEVE

WORKLIST

(Fields that are available

in the worklist are taken

from the worklist, fields

that are only available in

the data base are taken

from the local data base.)

With the DICOM Structured Report it is possible to send OB, GYN,

Vascular and Cardio data.

Storage Commit The Storage Commit drop down list contains all

currently added Storage Commit servers. The selected Storage

Commit server is used for committing the images sent to this store

server.

Combine OB & GYN If the checkbox is enabled, the system sends the

OB- and GYN - data into one file. If not enabled the files will be sent

individually.

Include Scan Assistant Data Select yes or no (default) from the drop

down menu.

Viewpoint default Loads the default settings for Viewpoint.

Select the Default Appl. from the drop down menu.

The drop down menu contains exam applications available in patient

dialog (Abdomen, OB, GYN, Cardio, Uro, Vascular, Neuro, Small Parts,

Pediatric, Ortho). The selected exam application is used for all exams

that are imported into the local archive from a remote query/retrieve

server.

Private Tags Determines whether the private tags defined for

communication with the Viewpoint - worklist are used when querying

the worklist.

Modality Select either All or ULTRASOUND. No selection is also

possible and defaults to “all”.

Add local data

yes: Locally stored patient data and patient data from the

worklist are merged.

no: Data only contained in the worklist is used to populate the

patient data fields. No locally stored data is used.

ask: A dialog is shown whenever there is data from the worklist

and from the local database available. Depending on the

selection in the dialog, either the action described under yes or

no is executed.

© 2017 Conquest Imaging

Page 44

GE Voluson E10 Training Manual

39

Note Private Tags only

work if the other system

also supports Private

Tags.

REPORT

Note The bit rate (Bits per

second) must be the same

as on the receiving PC

report station.

Viewpoint default Loads the default settings for Viewpoint.

Select one of the following Transfer Modes.

Network: Send the patient report to a PC report station via

DICOM network.

Serial: Send the patient report to a PC report station that is

connected by serial port. The optional “PRY USB-RS232

Connection kit” must be connected to the system.

When this Transfer Mode is selected, different fields are available:

COM Port, Flow control and Bits per second.

© 2017 Conquest Imaging

Page 45

GE Voluson E10 Training Manual

40

To minimize accidental

loss of data, perform

backup of the patient

archive stored on the local

hard drive at least once a

week.

Note It is highly

recommended to Backup

the Full System

Configuration and the

Image Archive at least

once a week.

Backup - SYSTEM

CONFIGURATION

Module 5 Preventive Maintenance

Preventive maintenance procedures are very important in a clinical

setting. Be sure to follow the health care facilities documentation

procedures.

System Backup

System backup is very important. Backup the system anytime you are

in front of it! Your backup is not complete without printouts!

The Backup/Restore function enables the user to:

Copy/Restore the system configuration. System Configuration

has two options:

1. Small Backup (Scan Settings)

2. Full System Configuration

Copy/Restore the patient archive.

Backup/Restore Database, Presets and Images

To access backup/restore:

1. Press the Utilities key on the control console.

2. In the “Utilities” menu touch the Setup button to invoke the setup

desktop on the screen.

3. On the right side of the screen select Backup and then click the

System Configuration tab.

Settings and/or Full System Configuration can be saved to the

following destinations:

© 2017 Conquest Imaging

Page 46

GE Voluson E10 Training Manual

41

D: partition of internal hard disk

DVD/CD+R/RW

Mapped Network Drive.

Any other drive connected to the system (e.g.; USB-Stick or

external hard disk drive).

Save Small Backup (Scan Settings)

The Image/Scan Settings contain:

Application Settings

2D Factory and 2D User Presets

3D/4D Factory and 3D/4D User Presets

Annotation Presets

Scan Assistant Configuration

Measure Configuration

Biopsy Lines

To create a Small Backup:

Insert a DVD/CD+R/RW into the drive or connect an external USB

device.

Press the Utilities key on the control console.

In the “Utilities” menu touch the Setup button to invoke the

setup desktop on the screen.

On the right side of the screen select Backup and then click the

System Configuration tab.

Click the Save button (1) of the "Small Backup (Scan Settings)"

group.

© 2017 Conquest Imaging

Page 47

GE Voluson E10 Training Manual

42

The loading procedure

overwrites existing

image/scan settings on

the local hard drive.

6. Select the desired media (2) and click the Save button (3).

7. Select the New File... key and enter a file name (without

extension).

8. Click the OK key to start the process. When the saving has been

completed, click OK.

Load Backups

Make sure to insert the correct System DVD. Additionally you can

load the image settings from “D:\usersettings”.

1. Insert a DVD/CD+R/RW into the drive or connect an external USB

device.

2. Press the Utilities key on the control console.

3. In the “Utilities” menu touch the Setup button to invoke the setup

desktop on the screen.

4. On the right side of the screen select Backup and then click the

System Configuration tab.

Load Small Backup (Scan Settings)

5. Click the Load button (1) of the "Small Backup (Scan Settings)"

© 2017 Conquest Imaging

Page 48

GE Voluson E10 Training Manual

43

Note If it is desired to load

settings from media

Internal HDD, click on the

Change folder button,

browse for the folder on

“D:\usersettings” and

then click the Load button.

group:

6. Choose the media (2) and click the Load button (3).

7. Select the appropriate file and click OK.

8. Select the desired loading procedure: Complete Backup or Click the

[+] sign next to “Complete Backup” (1) to open the content tree:

© 2017 Conquest Imaging

Page 49

GE Voluson E10 Training Manual

44

Note To return selected

items from the “Load

Data” field to “Backup

Data” field select the [<<]

button

Note It is recommended to

“Full Backup” system

configuration data before

upgrading the software

and/or image settings

(presets). This ensures

that if settings need to be

reloaded, will be the same

ones the customer was

using prior to service.

3. Click the [+] sign and copy the desired content by clicking the [>>]

button; and so on ....

4. Confirm selection with the Load button (3).

Settings will be loaded and the ultrasound system Application

Software will restart.

Backup Full System Configuration (Full Backup)

A backup of the Full System Configuration contains the following

data:

User Settings (databases and files containing User Programs,

2D/3D/4D Presets, gray curves etc.)

System Settings (general "Setup" settings such as Language,

Time/Date format, Button configuration, Annotation settings,

Biopsy lines, Peripheral data, Video Norm, Archive configuration,

etc.)

Measure Configuration (user specific measure setup settings)

Patient Archive (database containing patient demographic exam

data and measurements) - no images

V830 Settings (Options resp. Permanent Key that is specific for

enabled software options and Demo Key)

Image Transfer Configuration (DICOM configuration e.g., DICOM

servers, AE Title, Station Name, etc.)

Network Configuration (Network settings: IP address, Network

Profiles, e-mail configuration, network printer, network drives,

computer name)

Service Platform (state of the Service Software)

To perform a full backup:

1. Press the Utilities key on the control console.

2. In the “Utilities” menu touch the Setup button to invoke the setup

desktop on the screen.

© 2017 Conquest Imaging

Page 50

GE Voluson E10 Training Manual

45

3. On the right side of the screen select Backup and then click the

System Configuration tab.

4. Click the Save button of the "Full System Configuration" group.

5. Choose the destination (1).

6. Enter the description of the Full Backup (2).

Note Image data will not be backed up! To backup the Image Archive,

refer to Section 4.4.6 on page 4-20 .

7. Click the Next button (3).

8. To start the backup process click Yes.

After copying the data, the Voluson E-Series reboots and the

application starts again.

When the “Full Backup” is saved on a network drive it may be

desirable to move the data (e.g., for backup or maintenance). To map

a network drive see Section 3.13.7 on page 3-70 .

The backups reside in sub folders of the main “fullbackup” -folder

found at the root of the drive. For Example: Backups on the mapped

Network Drive are below path Z:\fullbackup.

© 2017 Conquest Imaging

Page 51

GE Voluson E10 Training Manual

46

The directory structure of the full backup data is as follows:

The sub folders have the names fbX where X is a number (e.g.,

Z:\fullbackup\fb1).

The data resides within a directory structure within these sub folders.

It is possible to move the fbX sub folders, even leaving gaps in the

numeration sequence.

However, NO change MUST be made to the contents of the fbX

folders itself, otherwise the backup data cannot be restored!

If the destination “Other drive“ is selected, the

available drives (e.g., external USB-memory stick)

can be chosen from the pull-down menu.

When the backup is saved to an external USB-device, the system has

to be informed about the removal of the hardware.

This is why every "Full Backup Save" and "Full Backup Delete" dialog

has a Stop USB Devices button.

External USB-Devices

USB sticks should not have any auto install software on it. Always

erase any software from the device first by formatting it on a desktop

PC prior to using it unless you are absolutely certain that the device is

completely blank.

© 2017 Conquest Imaging

Page 52

GE Voluson E10 Training Manual

47

Note When connecting

external USB devices, be

sure to execute Safety

Directions found in the

Voluson E-Series Basic

User Manual.

Note If an external drive

was not recognized

automatically after

connecting it, click Rescan

Drive.

Caution: Unplugging or

ejecting USB devices

without first stopping

them can cause the

system to crash and

possibly result in loss of

important data!!!

Connect USB and

Network Drives

When an external USB-storage device (such as an USB-memory stick

or an external hard disk) is connected to the Voluson E-Series, the

operating system detects the device and automatically installs a

driver. During this process, several dialogs may pop up, starting with

the “Found New Hardware“ dialog box.

The device is then accessible using the drive letter the system

assigned to it.

Disconnection of External USB-Devices

Before an external USB-device such as a memory stick can be

disconnected, the system has to be prepared the removal of the

device!

Before removing any device, you must press the Eject key on the

keyboard.

When you press the Eject key on the keyboard, the following dialog

window will be displayed:

The “Connect USB and Network Drives” window shows all USB and

Network drives that are connected to the system. Use this dialog, to

stop the USB-devices before they are physically disconnected.

To stop the external device, select it and then click the Stop Device

button.

© 2017 Conquest Imaging

Page 53

GE Voluson E10 Training Manual

48

Confirm the "‘Stop Device" dialog with OK and Close the "Connect

USB and Network Drives" window. The device can now be safely

removed.

Cleaning the Air Filters

Clean the system's air filter to ensure that a clogged filter does not

cause the system to overheat and reduce system performance and

reliability. GE recommends the filters be cleaned quarterly.

To remove the air filter reach behind the back handle and lift the filter

upwards. To clean it use a vacumn and replace.

Cleaning the Trackball

The optical trackball of the more

Motherboard Battery

The motherboard battery should be tested as a part of normal

maintenance. A CR2032 lithium coin battery (3V) is recommended by

GE for replacement.

© 2017 Conquest Imaging

Page 54

GE Voluson E10 Training Manual

49

Module 6 General Safety Precautions

This section is not intended to be an all-inclusive safety procedure

guide. It is only brief overview of best practices that applies to all

health care facilities and types of medical equipment. You should be

familiar with the policies and procedures of the facility where you

work AND the safety precautions and procedures described in the

manufacturer’s documentation for a particular OEM.

Electrical Safety

The system is a Class I medical device with Type BF and Type CF

isolated patient-applied parts. Only CF isolated transducers can be

used for invasive (internal) exams.

The following are warnings recommended by the manufacturer:

Grounding prevents shock hazards. The chassis is grounded with

a three wire plug and cable which must be plugged into a

grounded outlet.

Never connect the system using a power strip or extension cord.

The ultrasound system should never be connected to the same

circuit as life-support devices.

All devices that have patient contact: transducers, ECG leads and

pencil probes that are not specifically labeled as defibrillation

proof must be removed from contact with the patient before

defibrillation.

Non-medical peripherals such as printers should not be used

within 1.5 meters (5ft) of a patient unless the device is powered

with an isolated outlet on the back of the system or an isolated

transformer that meets medical safety standards; IEC 60601-1.

Wrist straps should not be worn when working on a system when

the power turned on. The +5 Vdc supply is a very-high current

supply. Use caution when troubleshooting.

© 2017 Conquest Imaging

Page 55

GE Voluson E10 Training Manual

50

Electromagnetic Interference

Electromagnetic Interference (EMI) between wireless electronic

transmitting devices and medical equipment can cause degradation

of the ultrasound image. The system is in compliance with existing

EMI/EMC requirements. However, the use of this system in proximity

of an electromagnetic field can cause degradation of the ultrasound

image at times. Review the environment in which the system is being

used, to identify possible sources of radiated emissions. Sources of

these emissions can be from electrical devices used in the same or

adjacent room. Communication devices that transmit or receive RF

signals; cellular phones, pagers, radio, TV, or microwave transmission

equipment located nearby can cause these emissions. If EMI from an

outside source is causing disturbances, you may need to relocate your

system. Electrosurgical units (ESUs), MRI’s and many other medical

devices introduce radio frequency (RF) electromagnetic fields to the

environment. Because ultrasound imaging frequencies are in the RF

range, ultrasound transducer circuits are also susceptible to RF

interference. For example, the noise generated by an ESU in use can

easily impair or eliminate the ultrasound’s ability to capture an image.

Some measures to reduce the chance of EMI interference include:

Three-meter rule – no powered on cell phones, or pagers within

three meters of the system while in operation.

Locate the system away from other imaging equipment such as

MRI’s that produce strong electromagnetic fields.

Electrostatic Discharge ESD Precautions

Electrostatic discharge (ESD), commonly referred to as a static shock,

is a naturally occurring phenomenon. Electrical charges naturally

build up on individuals and can create static shocks. The human body