Page 1

GE Oil & Gas

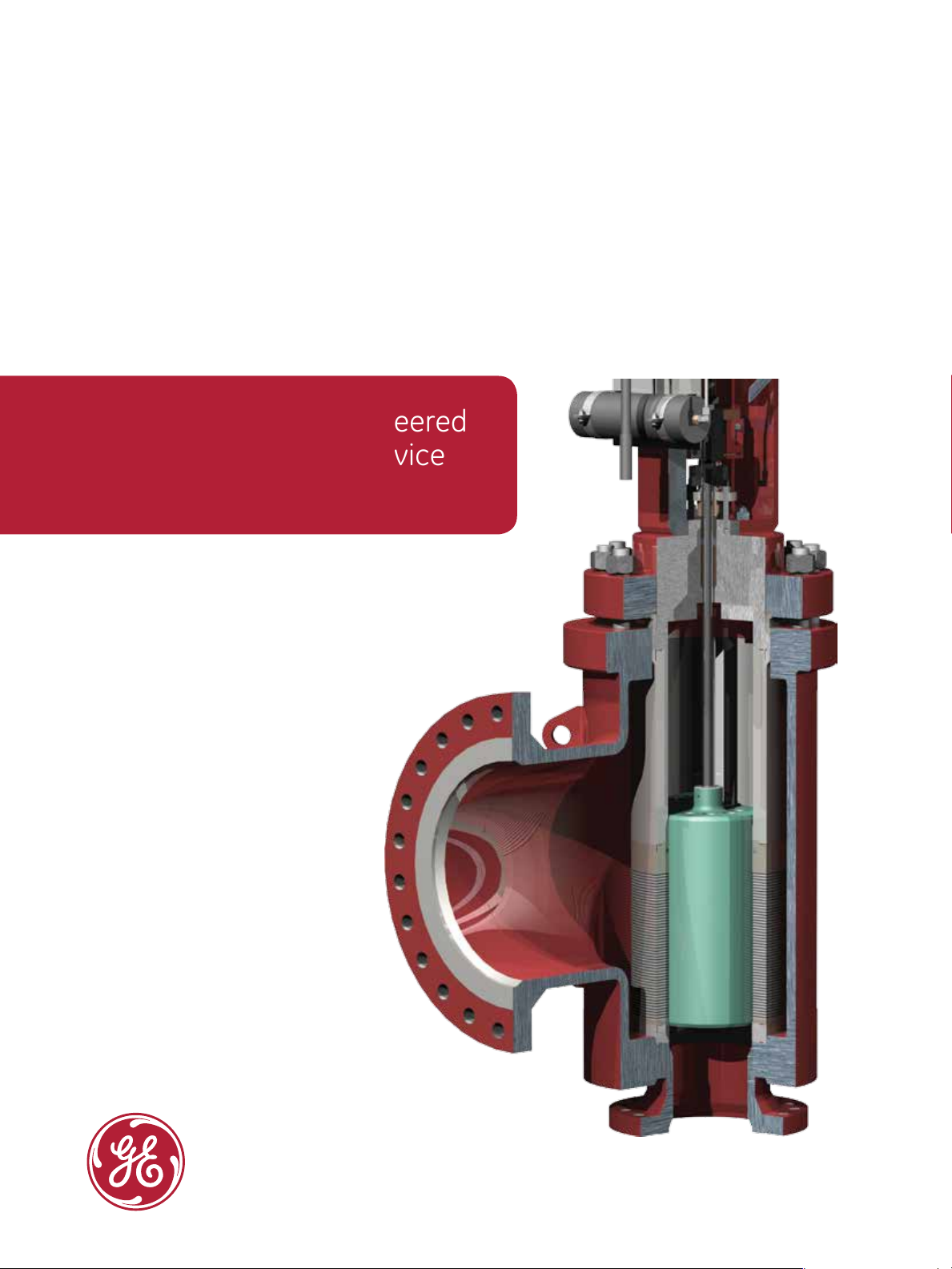

Masoneilan* Products

V-LOG* Energy Management Trim

Integrated smart engineered

solutions for severe service

applications

• Scalable trim design

• Operational stability

• Precision control

Page 2

V-LOG* Trim Technology

GE Oil & Gas offers a broad portfolio of Masoneilan* products

consisting of general service and severe service control

valves, actuators, pressure regulators, and valve-mounted

smart instrumentation and accessories – all supported by

an integrated network of sales offices. The breadth of our

offerings enables us to help customers meet the demanding

requirements of process control applications.

Masoneilan* valve solutions, which include leading designs

such as the LincolnLog* liquid letdown control valve, range

from regulators to customized solutions, including the patented

V-LOG* labyrinth trim technology. We offer custom-tailored

solutions configured for control performance, shut-off reliability

and life-cycle cost- effectiveness. Leading product technology

coupled with application expertise are the keys to our ability to

meet customers’ specifications.

Cost-Effective Engineered Solutions

We offer leading microprocessor-based field instrumentation

technology. Award-winning HART communicating SVI* and

FVP* digital positioners help improve your asset’s effectiveness,

resulting in higher returns on investment. By using patented

tuning algorithms that optimize valve control performance, our

digital positioners deliver improved process yields and lower

maintenance cost.

Innovative V-LOG* Design

Our valve design innovation is at the foundation of our

extensive portfolio of field-proven severe service products

configured for the most challenging applications. GE Oil & Gas’

Masoneilan* products have long been benchmarks for severe

service innovation in industries such as power generation,

oil and gas production and liquefied natural gas (LNG).

These industries present many of the toughest control valve

applications, particularly those involving large mass flow rate

and high differential pressure such as compressor anti-surge,

high pressure vents and turbine bypass.

Severe service applications present technical challenges

associated with the high energy of the flow stream. V-LOG*

Energy Management trim meets these challenges, including

the energy-related issues of noise and vibration, and stringent

demands for control performance.

Benefiting from a very scalable trim design architecture,

V-LOG* trim offers a customized solution for a broad set of

severe compressible fluid and liquid applications. Each V-LOG*

trim solution is designed to meet customer requirements

including tight shutoff, fast opening speeds, operational

stability, and precision control over a wide range of operating

conditions.

Flexibility is built into each of GE Oil & Gas’ digital

instrumentation offerings. SVI* II AP and FVP* valve positioners

mount on any control valve actuator and interface effectively

with HART and Foundation Fieldbus distributed control

schemes, respectively (since SVI* is only Hart and FVP* is only

FF).

You can further increase flexibility and functionality with GE’s

smart instrument companion software such as ValVue*, a tool

that monitors real-time device status. In addition, ValvKeep*

valve database management and AMS Snap-on™ asset

management software provide a comprehensive view into

valve asset maintenance history and performance trends.

These software support tools, in conjunction with the advanced

diagnostic capabilities of smart devices, help significantly

reduce operating costs.

V-LOG* Trim Stack

2 | GE Oil & Gas

Page 3

Energy Management Principles

3-Dimensional Tortuous Path Flow

The three-dimensional tortuous path design of GE Oil & Gas’

Masoneilan V-LOG* trim controls pressure reduction through the

management of process fluid energy. This is accomplished by

directing the fluid through discrete flow channels which alternate

across two adjacent planes to create a labyrinth effect. These

flow channels contain multiple stages defined by 90 degree turns

with intermediate contractions and expansions in the flow path.

Staged Pressure Drop

The labyrinth flow path of the V-LOG* trim subjects the gas to a

high level of friction as it is redirected through each turn in the

flow path. V-LOG* trim’s patented flow contractions produce

predictable and repeatable flow resistance that differentiates its

design and performance from competing products. The V-LOG*

trim’s design offers a unique flow path shape which maximizes

valve efficiency and performance versus more traditional

tortuous path trim technologies.

The enhanced flow geometry of the V-LOG* trim creates a series

of kinetic energy losses followed by partial energy recoveries at

each stage. The staged reduction of the fluid pressure makes the

gradual letdown process highly effective for noise attenuation.

Fluid Velocity Control

Each stage of the V-LOG* trim is designed with an expansion

in flow area, which is essential for managing fluid velocity that

would otherwise increase as the pressure is reduced across each

stage. The expanding area can compensate for the volumetric

expansion of the gas, reducing any increase in the kinetic energy

as the pressure is reduced.

Trim velocity control is important for maintaining low

aerodynamic noise levels within the valve body and trim. High

velocity trim exit flow will yield high magnitude sound waves,

which lead to valve body vibration in high-pressure letdown

applications.

Exit Flow Jet Spacing

By design, the process fluid is precisely separated into discrete

flow jets upon exiting the V-LOG* trim channels. The proper sizing

and spacing of these channels prevents the exiting flow jets from

reconverging, thus producing lower amplitude sound waves with

higher peak frequencies. These lower sound pressure and higher

frequency waves result in lower acoustical coincidence with

the surrounding system and downstream piping. This reduces

both the overall noise level and vibration effect of the throttling

process.

The V-LOG* Trim’s Labyrinth

Flow Path

Overall System Noise Reduction

As a gas experiences a large reduction in pressure, its volume

expands. This phenomenon will yield a higher downstream

velocity if the piping is configured without considering this

volumetric expansion. Our angle body valve designs feature

expanded outlet areas to accommodate this expansion and

minimize the overall system noise level. (we consider both Outlet

Mach Number and the Outlet Expansion Ratio for system noise

calculation, per the IEC International Noise Prediction Standard

[IEC-60534-8-3]).

GE’s Masoneilan V-LOG* Energy Management Trim for Severe Service Applications | 3

Page 4

V-LOG* Trim

Features & Benefits

Laser Cut Technology

The V-LOG* trim’s disks are laser cut, resulting in the tight

tolerances and smooth surfaces which are required for throttling

control. Precision trim-part cutting supports throttling area integrity

that is necessary for fine control resolution and accuracy.

Prior to being secured through vacuum-tight brazing, the V-LOG*

trim’s disks are stacked together and aligned using precision

tooling. Each disk is designed with maximum surface area to

promote a secure bond between disks during the brazing process.

Customized Flow Characterization

The laser manufacturing process gives each disk in the V-LOG*

trim the necessary geometry to provide desired control. In addition,

the V-LOG* trim’s stack can be configured with tiered capacities in

each disk to produce specific flow characteristic across the entire

range of travel. For example, the stack design may be configured

with a highly resistant flow path (up to 40 stages) at low lift and

then progressively less resistant flow paths as the valve opens

to its full capacity. Some designs may also combine V-LOG*

trim’s stacked disk technology with drilled-hole or ported-cage

technology.

Laser Cut V-LOG* Trim Disks

These combination trim configurations offer rangeability with

excellent control. This is especially important for applications

requiring the control valve to throttle during plant startup and at

full load production.

Tight Shutoff

The full line of GE’s Masoneilan* V-LOG* trim products achieve

tight shutoff through seating-surface geometry and material

selection. Shutoff performance consistent with ANSI/FCI Class

IV and Class V leakage, as well as MSS-SP-61, is available. Tight

shutoff performance is critical for preventing product loss,

especially in applications that vent to atmosphere or burn off

in a flare stack. Long-lasting tight shutoff is essential in turbine

bypass and compressor surge applications to help protect critical

equipment. To promote overall long-term trim integrity, V-LOG*

trim technology takes full advantage of hardened materials such

as stellite and tungsten carbide.

Characterized V-LOG* Trim & Ported Cage Design

49000 Series with V-LOG* Trim Stack

4 | GE Oil & Gas

Page 5

Features

Benefits

• 3-D Tortuous Path

• Patented Flow Contractions

• Multiple Stages

• Exit Flow Jet Spacing

• Expanded Outlet

• Laser Cut Disk

• Precision Alignment

• Flow Channel Characterization

• Trim Technology Combinations

• GE’s Masoneilan* SVI* II AP Valve Positioner Sensitivity

and Accuracy

Efficient scalable solution for high pressure drop

applications. Trim technology can be packaged in a

variety of valve sizes and designs to offer the cost

benefit of standardization and the reduced downtime

associated with easy retrofit.

Minimum system noise and vibration results in longer

product life, lower life-cycle maintenance costs and

reduced risk of critical equipment downtime.

Trim integrity yields high control resolution and

unequaled control accuracy for optimum process

efficiency.

Exceptional digital positioner control performance offers

higher yield of “on-spec” product for maximized return

on investment.

High rangeability satisfies varying process demands.

The “two-valves-in-one” approach reduces life-cycle

maintenance costs.

• ValVue* OVD (Online Valve Diagnostics)

• Maximum Brazing Surface

• Seating Geometry and Materials

• Hardened Trim Materials

• SVI* II AP Valve Positioner Diagnostics

Performance reliability of integrated, smart-engineered

control solutions results in faster startups and

accelerated “time to revenue.”

Trim integrity and reliability minimizes maintenance and

overall life-cycle costs.

Diagnostic information enables preventive maintenance

and provides substantial life-cycle cost savings due to

less process downtime.

Reliable tight shutoff minimizes loss of revenuegenerating process fluid (steam, natural gas, etc.).

.

GE’s Masoneilan V-LOG* Energy Management Trim for Severe Service Applications | 5

Page 6

Typical V-LOG* Trim Applications

Liquified Natural Gas

V-LOG* trim technology can be applied throughout

the entire Liquefied Natural Gas (LNG) process. From

the gas production and receiving stage through the

compression and processing stages, V-LOG* trim

technology can help keep the plant running in a

stable and continuous mode of operation. In addition,

fast and precise control with actuator stroke speeds

measured in milliseconds makes V-LOG* trim suitable

for compressor surge control. With expanded outlets,

extension bonnets and energy management trim,

V-LOG* trim technology often is a solution for the

high-fluid-energy applications in LNG liquefaction and

re-gasification processes.

Vent-to-Flare

As an LNG train comes online, it is essential to achieve

a stable and controllable gas flow before the gas is

passed into the separators, strippers, compressors,

and other critical process equipment. The gas flow

is passed through a vent-to-flare valve until the unit

reaches the desired level of capacity.

72000 Series Severe Service Control Valve

GE’s Masoneilan* 72000 series is available with single

or double stage Lo-dB* trim, as well as V-LOG* trim

for higher-pressure drop applications. These valves

are available with a number of different instrument

packages to meet various specifications, including a

fast stroke of one second or less, or precise control

with resolution to 1/10,000th of an inch.

Reliable gas venting in less

than one second

Class V and MSS-SP-61 tight

shutoff

Lo-dB* and V-LOG* trims

reduce the pressure drop

across multiple stages

Protects costly downstream

equipment and reduces downtime

Grows revenue by preventing loss

of process flow

Reduces noise through staged

pressure reduction and minimizes

velocity

6 | GE Oil & Gas

Page 7

Compressor Recycle & Anti-Surge

To achieve maximum efficiency, compressors are challenged

to operate as close as possible to their surge limits. The risk

of control loop instability is magnified with reduced surge

operating margins.

The technology offered with the low vibration V-LOG* trim,

combined with the precision control and fast response of

the SVI* II AP valve positioner, offer the security needed for

this critical service application. Coupling this technology with

ValVue* OVD (Online Valve Diagnostics) for real-time asset

management helps to protect your system.

Class V and MSS-SP-61 tight

shutoff

Fast response, less than one

second

SVI* II AP precision positioning,

and quick response (1-3

seconds) through complete

range of travel during recycle

operation

Increases efficiency

by reducing leakage

to latter stages of the

compressor system

Prevents the compressor

from going into a surge,

which prevents down

time and increases

production

Increases profitability by

reducing wasted process

energy

GE Oil & Gas’ Masoneilan* 49000 Series and 72000 Series

control valves are available with several features that help

meet the demands of these severe service applications.

Our compressor anti-surge package offers reliability for not

only LNG plant operation, but all compressor applications.

The V-LOG* Trim manages the fluid energy as pressure is

drastically reduced across as many as 40 stages, while the

valve is fully stroked in as little as a half second.

49000 Series

Severe Service

Control Valve

High turndown characterized

V-LOG* trim

Low noise V-LOG* trim

Reduces initial cost by

allowing single-valve

control over the entire

range of operation

Reduces the pressure

drop across multiple

stages, which lessens

noise, vibration and

maintenance cost

72000 Series

Severe Service

Control Valve

GE’s Masoneilan V-LOG* Energy Management Trim for Severe Service Applications | 7

Page 8

Typical V-LOG* Trim Applications

Gas Production

Oil and gas applications often involve extremely erosive flow streams,

which dictate the proper trim design and material selection. Many

hardened materials, including full tungsten carbide trim in extreme cases,

are used as a rugged barrier on critical surfaces for extended protection

against entrained particles traveling within the flow stream. V-LOG* trim

technology is well suited for the challenges of highly erosive service.

Stellite or equivalent clad guiding for

corrosion and vibration resistance

Inconel clad valve bodies offer long

lasting reliability

Tungsten carbide trim and seat help

protect against wear

Trim integrity extends valve

life and minimizes life-cycle

costs

Wellhead choke applications often are an ideal use for V-LOG* trim

technology. These valves are available as both ANSI or API-rated

designs with enlarged and expanding flow orifices to reduce blockage

caused from loose debris picked up from the inside of the well. When

enhanced with the hardness and ruggedness of tungsten carbide

disks, V-LOG* labyrinth trim yields extended life in these typically highwear applications.

A compact valve package can be a big benefit in offshore production

facilities. V-LOG* trim can be fitted into a lightweight globe or anglestyle body for easy installation. We also offer a range of actuation

options, including a very compact, self-contained, electro-hydraulic

option that is ideal for tight installations between platform decks,

as well as a wide range of packing designs to reduce the release of

fugitive emissions in sour applications.

SE-20 Forged Body Control Valve

Large Flow Path, Tungsten Carbide V-LOG* Trim Disks

8 | GE Oil & Gas

Page 9

49000 Series

with V-LOG* Trim in a

Gas Storage Field

Gas Storage & Well Re-Injection

Gas delivery companies can quickly run out of capacity during

peak seasons due to spikes in demand. To limit the risk of

interrupted supply, gas reserves are typically stockpiled in

underground salt caverns, mines, aquifers, depleted reservoirs

and other natural storage facilities.

Natural gas is compressed for delivery to these storage areas.

This process is regulated by control valves, which must also limit

the formation of hydrates, or fluid icing, that can block small

flow passages. To prevent this icing formation, gas companies

must invest in large and expensive heaters to elevate and

maintain the gas temperature above the hydrate level – unless

they use multi-stage V-LOG* trim technology.

By reducing gas pressure gradually across a smooth and

controlled process, V LOG* trim keeps gas temperature above

the hydrate level without the assistance of additional heaters.

When peak season arrives, these storage reservoirs must

be depleted to return gas to the pipelines for distribution.

The 49000 series with V-LOG* trim is capable of bidirectional

operation, making it well suited for gas injection and

withdrawal. Furthermore, V-LOG* trim can be characterized to

effectively manage both storage and withdrawal operations;

this capability offers savings by limiting the number of valves

and complexity of the control scheme. During the non-peak

season, gas travels through valving with a small pressure

drop and a very large Cv to fill the storage area. As the gas

is later withdrawn from storage, it flows with a high pressure

drop and a low Cv. A Better Fit solution for this application is

a combination trim: V-LOG* trim at low lift and drilled-hole or

ported-cage at high lift. Similar design principles are applied for

wellhead reinjection applications, making the NACE-compliant

49000 Series an ideal fit for performance and control.

T&E Diagram for Methane (Single Stage Valve) T&E Diagram for Methane (Multi-Stage V-LOG* Valve)

GE’s Masoneilan V-LOG* Energy Management Trim for Severe Service Applications | 9

Page 10

Typical V-LOG* Trim Applications

Power Generation

Power plants are home to a variety of severe service control

valve applications with high pressure drop ratios that may

result in excessive levels of noise and vibration. Older power

plants were outfitted with available severe service technology,

namely drilled-hole cage valve trim. In many of the most severe

applications, this trim technology only lessened the noise or

vibration problem. Using the latest control valve technology,

V-LOG* trim can help eliminate the problems associated with

the most demanding services in both new and old power plant

designs.

Today, GE’s Masoneilan* Lo-dB* or V-LOG* trim technology

is helping to solve noise and vibration problems in the most

demanding applications.

Vent-to-Atmosphere

Similar to the Vent-to-Flare application, the Vent-toAtmosphere valve must contend with the problems of

high-pressure, high noise and gas expansion. In most

vent applications the process pressure is so extreme that

conventional drilled-hole cage control valves are not suitable.

GE’s cost effective valve and trim solutions for high pressure

steam include:

• 21000 Cast globe or angle control valve to ANSI 2500 with

single or double stage Lo-dB* trim.

• 49000 Cast globe or angle control valve to ANSI 2500 with

single or double stage Lo-dB* and V-LOG* trim.

• SE-20 Forged globe or angle control valve ANSI 4500 with

single or double stage Lo-dB* and V-LOG* trim.

Liquid V-LOG* Trim Technology

Liquid V-LOG* labyrinth trim technology is offered in many

high-turndown, liquid applications where special trim

characterization is required to meet the full range of operating

conditions.

Within a liquid V-LOG* trim stack, each 90-degree turn in flow

direction acts as a step reduction in pressure, simulating the

gradual pressure reduction effect caused by head loss through

a long radius pipe elbow. The gradual pressure reduction

produces less pressure recovery per stage, thus eliminating the

potential for cavitation.

Reduces noise through staged pressure reduction and

minimizes velocity:

• Large valve body gallery minimizes trim exit velocity

• Expanded valve outlet accommodates the volumetric

expansion of steam

• V-LOG* trim reduces the high pressure drop across

multiple stages

GE Oil & Gas’ engineered solution for this application is the

Masoneilan* 72000 Series control valve with V-LOG* trim in

series with a downstream silencer. The 72000 series valve is

a rugged reliable solution that reduces inherent problems,

extends valve life and minimizes costly process downtime.

Soot Blower & Auxiliary Steam

Depending on the power plant design, soot blower and

auxiliary steam process applications can exhibit a wide range

of pressure drops. Because of the wide range of pressure drop

ratios, no one valve or trim design is best suited to serve all

possible variations of soot blower and auxiliary steam process

applications. Depending on the severity of the application,

globe or forged bodies, single stage drilled-hole cages (Lo-dB*

Trim) or V-LOG* trims may be applied.

A comparison between one-step and gradual multistep

pressure reduction solutions is shown in Figures 1 & 2. The

direct pressure reduction scheme (Figure 1) results in a single,

dramatic pressure drop and recovery, which can lead to

cavitation if the initial drop falls below the fluid vapor pressure.

In contrast, the high flow resistance of V-LOG* trim tortuous

path trim creates a multi-step pressure drop profile (similar to

that shown in Figure 2). By managing the energy throughout

the pressure reduction process, V-LOG* trim technology can

address cavitation problems at the source.

Single-Stage Pressure Reduction

Figure 1

10-Stage Pressure Reduction

Figure 2

10 | GE Oil & Gas

Page 11

Boiler Feedwater Start-up and Regulator Valves

Conventional power plants often are designed with feedwater

systems using two separate control valves. The first control

valve is used for startup, as the conditions yield a low amount

of flow with severe pressure drop. This startup condition

exhibits high cavitation risk and requires a very rugged valve

solution. Typically, a second control valve is used to regulate the

feedwater conditions when the plant operates at full capacity.

This valve experiences a much higher flow rate, but across a

very moderate pressure drop. This main feedwater regulator

valve does not experience cavitation.

In many of today’s power plants, specifically the combinedcycle plants, engineers often prefer to combine these two

valves into a single control valve to make maintenance easy

and the control scheme simple. Liquid V-LOG* trim technology

is configured to manage and control process fluid energy over

this wide range of operation. This involves characterizing the

trim design to match the characteristic of the feedwater pump’s

operating curve, with the low travel range to include multiple

stages of anti- cavitation stacked disk, while drilled holes on

the high range of travel provide for the large flow capacities

required.

• 49000 Series with quick change trim for

ease of maintenance

• Precision control using GE’s Masoneilan*

SVI* II AP Valve Positioner

• High turndown, characterized trim

- Multi-stage anti-cavitation V-LOG*

trim at low lift for high resistance

- Drilled-hole or ported-cage at full

opening for high capacity

49000 Series

Globe Control Valve

Turbine Bypass Systems

Steam turbine generators create power by passing highpressure steam through a series of stages that propel the

turbine blades at high speeds. At high-pressure-drop ratios,

the turbine design is a very effective model for the multi-stage

pressure letdown process. During startup or upset conditions,

the turbine bypass system is used to divert steam around the

turbine, which maintains stability in the closed loop system.

For high-pressure bypass, the V-LOG* trim follows the same

principles of pressure letdown as the steam turbine, i.e., letdown

across multiple stages of expanding area to reduce damage

resulting from sudden and severe pressure reduction.

The V-LOG* trim is ideal for supercritical and conventional

power applications where there is no reheat section in the

boiler. Both of these applications take steam at very high

pressure down to condenser. Regardless of whether the bypass

system involves desuperheating or not, V-LOG* trim technology

can be integrated into the right valve solution.

GE Oil & Gas’ Masoneilan* 84000 Series SteamForm* steam

conditioning control valve uses patented desuperheating

technology to meet the demands of turbine bypass.

• Expanded outlet to accommodate the

change in steam density and minimize

valve outlet noise

• Low noise V-LOG* trim to reduce the

pressure across stages

• Class IV, Class V, and MSS-SP-61 tight

shutoff

• Fast stoking actuation package to

prevent safety valves from lifting

84000 Series SteamForm*

Steam Conditioning

Control Valve

GE’s Masoneilan V-LOG* Energy Management Trim for Severe Service Applications | 11

Page 12

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth

Phone: +61-8-6595-7018

Fax: +61-8-6595-7299

Melbourne

Phone: +61-3-8807-6002

Fax: +61-3-8807-6577

BELGIUM

Phone: +32-2-344-0970

Fax: +32-2-344-1123

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-5689-3600

Fax: +86-10-5689-3800

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Chiba

Phone: +81-43-297-9222

Fax: +81-43-299-1115

KOREA

Phone: +82-2-2274-0748

Fax: +82-2-2274-0794

MALAYSIA

Phone: +60-3-2161-0322

Fax: +60-3-2163-6312

MEXICO

Phone: +52-55-5640-5060

THE NETHERLANDS

Phone: +0031-15-3808666

Fax: +0031-18-1641438

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

SPAIN

Phone: +34-93-652-6430

Fax: +34-93-652-6444

UNITED ARAB EMIRATES

Phone: +971-4-8991-777

Fax: +971-4-8991-778

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Massachusetts

Phone: +1-508-586-4600

Fax: +1-508-427-8971

Corpus Christi, Texas

Phone: +1-361-881-8182

Fax: +1-361-881-8246

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

* Masoneil an, V-LOG, Lo-d B, LincolnLog , SVI, FVP, ValVue, ValvKee p, and SteamForm a re

register ed trademark s of the General E lectric Com pany.

Other company names and product names used in this document are the registered trademarks

or trademarks of their respective owners.

© 2014 General Ele ctric Compa ny. All rights res erved.

GEA19359A 07/2014

[Formerly Masoneilan BP49000/72000 0611]

Loading...

Loading...