Page 1

Technical

Publication

Part Number 2300164-100

Revision 7

GE Medical Systems

Vivid™ 3 Pro/Vivid™ 3 Service Manual

Copyright© 2006 by GE Medical Systems

Page 2

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

IMPORTANT PRECAUTIONS

• THIS SERVICE MANUAL IS AVAILABLE IN ENGLISH ONLY.

• IF A CUSTOMER’S SERVICE PROVIDER REQUIRES A LANGUAGE OTHER THAN

ENGLISH, IT IS THE CUSTOMER’S RESPONSIBILITY TO PROVIDE

TRANSLATION SERVICES.

WARNING

AVERTISSEMENT

• DO NOT ATTEMPT TO SERVICE THE EQUIPMENT UNLESS THIS SERVICE

MANUAL HAS BEEN CONSULTED AND IS UNDERSTOOD.

• FAILURE TO HEED THIS WARNING MAY RESULT IN INJURY TO THE SERVICE

PROVIDER, OPERATOR OR PATIENT FROM ELECTRIC SHOCK, MECHANICAL

OR OTHER HAZARDS.

• CE MANUEL DE MAINTENANCE N’EST DISPONIBLE QU’EN ANGLAIS.

• SI LE TECHNICIEN DU CLIENT A BESOIN DE CE MANUEL DANS UNE AUTRE

LANGUE QUE L’ANGLAIS, C’EST AU CLIENT QU’IL INCOMBE DE LE FAIRE

TRADUIRE.

• NE PAS TENTER D’INTERVENTION SUR LES ÉQUIPEMENTS TANT QUE LE

MANUEL SERVICE N’A PAS ÉTÉ CONSULTÉ ET COMPRIS.

• LE NON-RESPECT DE CET AVERTISSEMENT PEUT ENTRAÎNER CHEZ LE

TECHNICIEN, L’OPÉRATEUR OU LE PATIENT DES BLESSURES DUES À DES

DANGERS ÉLECTRIQUES, MÉCANIQUES OU AUTRES.

WARNUNG

• DIESES KUNDENDIENST-HANDBUCH EXISTIERT NUR IN ENGLISCHER

SPRACHE.

• FALLS EIN FREMDER KUNDENDIENST EINE ANDERE SPRACHE BENÖTIGT, IST

ES AUFGABE DES KUNDEN FÜR EINE ENTSPRECHENDE ÜBERSETZUNG ZU

SORGEN.

• VERSUCHEN SIE NICHT, DAS GERÄT ZU REPARIEREN, BEVOR DIESES

KUNDENDIENST-HANDBUCH NICHT ZU RATE GEZOGEN UND VERSTANDEN

WURDE.

• WIRD DIESE WARNUNG NICHT BEACHTET, SO KANN ES ZU VERLETZUNGEN

DES KUNDENDIENSTTECHNIKERS, DES BEDIENERS ODER DES PATIENTEN

DURCH ELEKTRISCHE SCHLÄGE, MECHANISCHE ODER SONSTIGE

GEFAHREN KOMMEN.

i

Page 3

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• ESTE MANUAL DE SERVICIO SÓLO EXISTE EN INGLÉS.

• SI ALGÚN PROVEEDOR DE SERVICIOS AJENO A GEMS SOLICITA UN IDIOMA

QUE NO SEA EL INGLÉS, ES RESPONSABILIDAD DEL CLIENTE OFRECER UN

SERVICIO DE TRADUCCIÓN.

• NO SE DEBERÁ DAR SERVICIO TÉCNICO AL EQUIPO, SIN HABER

AV I S O

CONSULTADO Y COMPRENDIDO ESTE MANUAL DE SERVICIO.

• LA NO OBSERVANCIA DEL PRESENTE AVISO PUEDE DAR LUGAR A QUE EL

PROVEEDOR DE SERVICIOS, EL OPERADOR O EL PACIENTE SUFRAN

LESIONES PROVOCADAS POR CAUSAS ELÉCTRICAS, MECÁNICAS O DE OTRA

NATURALEZA.

• ESTE MANUAL DE ASSISTÊNCIA TÉCNICA SÓ SE ENCONTRA DISPONÍVEL EM

INGLÊS.

• SE QUALQUER OUTRO SERVIÇO DE ASSISTÊNCIA TÉCNICA, QUE NÃO A

GEMS, SOLICITAR ESTES MANUAIS NOUTRO IDIOMA, É DA

RESPONSABILIDADE DO CLIENTE FORNECER OS SERVIÇOS DE TRADUÇÃO.

ATENÇÃO

• NÃO TENTE REPARAR O EQUIPAMENTO SEM TER CONSULTADO E

COMPREENDIDO ESTE MANUAL DE ASSISTÊNCIA TÉCNICA.

• O NÃO CUMPRIMENTO DESTE AVISO PODE POR EM PERIGO A SEGURANÇA

DO TÉCNICO, OPERADOR OU PACIENTE DEVIDO A‘ CHOQUES ELÉTRICOS,

MECÂNICOS OU OUTROS.

AVVERTENZA

• IL PRESENTE MANUALE DI MANUTENZIONE È DISPONIBILE SOLTANTO IN

INGLESE.

• SE UN ADDETTO ALLA MANUTENZIONE ESTERNO ALLA GEMS RICHIEDE IL

MANUALE IN UNA LINGUA DIVERSA, IL CLIENTE È TENUTO A PROVVEDERE

DIRETTAMENTE ALLA TRADUZIONE.

• SI PROCEDA ALLA MANUTENZIONE DELL’APPARECCHIATURA SOLO DOPO

AVER CONSULTATO IL PRESENTE MANUALE ED AVERNE COMPRESO IL

CONTENUTO.

• NON TENERE CONTO DELLA PRESENTE AVVERTENZA POTREBBE FAR

COMPIERE OPERAZIONI DA CUI DERIVINO LESIONI ALL’ADDETTO ALLA

MANUTENZIONE, ALL’UTILIZZATORE ED AL PAZIENTE PER FOLGORAZIONE

ELETTRICA, PER URTI MECCANICI OD ALTRI RISCHI.

ii

Page 4

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

iii

Page 5

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

DAMAGE IN TRANSPORTATION

All packages should be closely examined at time of delivery. If damage is apparent write “Damage In

Shipment” on ALL copies of the freight or express bill BEFORE delivery is accepted or “signed for” by

a GE representative or hospital receiving agent. Whether noted or concealed, damage MUST be

reported to the carrier immediately upon discovery, or in any event, within 14 days after receipt, and the

contents and containers held for inspection by the carrier. A transportation company will not pay a claim

for damage if an inspection is not requested within this 14 day period.

CERTIFIED ELECTRICAL CONTRACTOR STATEMENT - FOR USA ONLY

All electrical Installations that are preliminary to positioning of the equipment at the site prepared for the

equipment shall be performed by licensed electrical contractors. Other connections between pieces of

electrical equipment, calibrations and testing shall be performed by qualified GE Medical Systems

personnel. In performing all electrical work on these products, GE will use its own specially trained field

engineers. All of GE’s electrical work on these products will comply with the requirements of the

applicable electrical codes.

The purchaser of GE equipment shall only utilize qualified personnel (i.e., GE’s field engineers,

personnel of third-party service companies with equivalent training, or licensed electricians) to perform

electrical servicing on the equipment.

OMISSIONS & ERRORS

If there are any omissions, errors or suggestions for improving this documentation, please contact the

GE Medical Systems Global Documentation Group with specific information listing the system type,

manual title, part number, revision number, page number and suggestion details. Mail the information

to: Service Documentation, 4855 W. Electric Ave (EA-53), Milwaukee, WI 53219, USA.

GE Medical Systems employees should use the iTrak System to report all documentation errors or

omissions.

iv

Page 6

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

LEGAL NOTES

The contents of this publication may not be copied or duplicated in any form, in whole or in part, without

prior written permission of GE Medical Systems.

GE Medical Systems may revise this publication from time to time without written notice.

TRADEMARKS

All products and their name brands are trademarks of their respective holders.

COPYRIGHTS

All Material Copyright© 2006 by General Electric Inc. All Rights Reserved

v

Page 7

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Revision History

Revision Date Reason for change

0 2002 Initial Release

1 April 2002 Second Release

2 November 2002 Third Release

3 September 2003 Fourth Release

4 December 2003 New Breakthrough

5 March 2004 Hardware Modifications; Corrections

6 July 2005 Updated System Labels;

added Waste Electrical and Electronic Equipment (WEEE) Disposal warning

7 February 2006 Software Upgrade

List of Effected Pages

Pages Revision Pages Revision Pages Revision

Title Page N/A

Important Precautions

pages i to iv

Legal / Rev History/LOEP

pages v to vi

Table of Contents

pages vii to xxii

Chapter 1 - Introduction

pages 1-1 to 1-28

vi

7

7

7

7

Chapter 2 - Pre-Installation

pages 2-1 to 2.12

Chapter 3 - Installation

pages 3-1 to 3-78

Chapter 4 - Functional Checks

pages 4-1 to 4-34

Chapter 5 - Theory

pages 5-1 to 5-52

Chapter 6 - Service Adjustments

pages 6-1 to 6-18

Chapter 7 - Diagnostics/

7

7

7

Chapter 10 - Periodic Maintenance

7

7 Back Cover N/A

Troubleshooting

pages 7-1 to 7-130

Chapter 8 - Replacement

Procedures

pages 8-1 to 8-190

Chapter 9 - Replacement Parts

pages 9-1 to 9-38

pages 10-1 to 10-32

7

7

7

7

Page 8

GE MEDICAL SYSTEMS DIRECTION 2300164-100, REVISION 7 VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

Table of Contents

CHAPTER 1

Introduction

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose of Chapter 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Purpose of Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

Typical Users of the Basic Service Manual . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Vivid™ 3 Models Covered in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

System History - Hardware and Software Versions . . . . . . . . . . . . . . . . . . . 1 - 5

Purpose of Operator Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Important Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Human Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Mechanical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Dangerous Procedure Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Product Labels and Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Product Label Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Label Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Vivid™ 3 External Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

EMC, EMI, and ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

Electrostatic Discharge (ESD) Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 25

Standards Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 26

Lockout/Tagout Requirements (For USA Only) . . . . . . . . . . . . . . . . . . . . . . 1 - 26

Customer Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 27

Contact Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 27

Table of Contents vii

Page 9

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 2

Pre-Installation

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Purpose of Chapter 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Console Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Unit Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Cooling Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Lighting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Time and Manpower Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

EMI Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Probe Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Facility Needs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Purchaser Responsibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Mandatory Site Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

Site Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 8

Networking Pre-Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Connectivity Installation Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

viii

Page 10

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 3

Installation

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Purpose of Chapter 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Installation Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Average Installation Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Installation Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Receiving and Unpacking the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Unpacking the Wooden Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Unpacking the Cardboard Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Unpacking and Removing the Unit from the Cardboard Shipping Carton . 3 - 9

Preparing for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Confirming Customer Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Verifying the Shipping Crate Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Component Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

System Voltage Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

Video Formats Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Ensuring Protection from EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 21

Completing the Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Connecting the Footswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Connecting Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Connecting Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 28

Connecting the ECG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

Connecting the Unit to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 31

Switching the System ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

Adjusting the Display Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

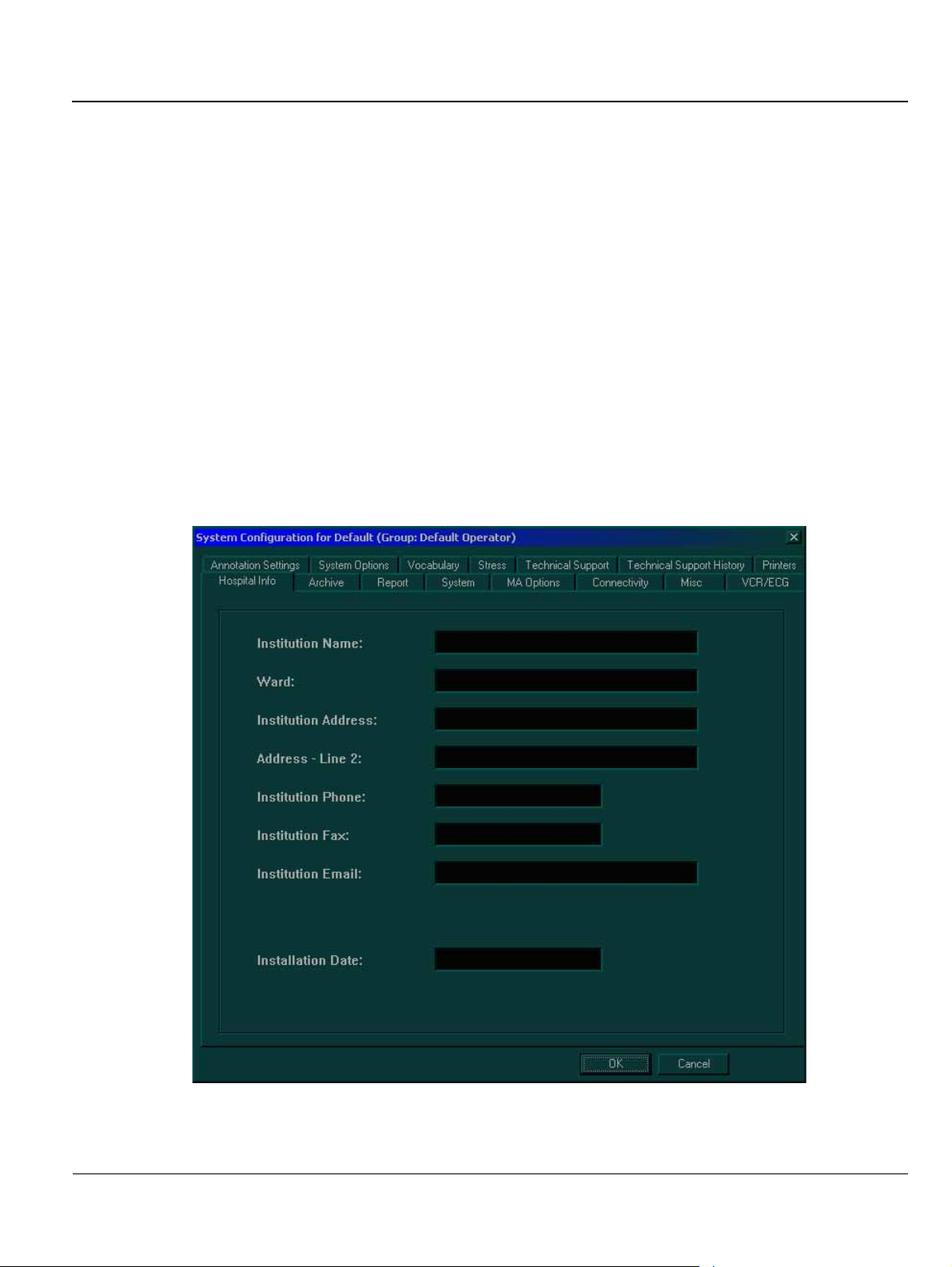

Hospital Info Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

System Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 36

Connectivity Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 37

Archive Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 37

Annotation Settings Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 39

System Options Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 41

Printers Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 43

ix

Page 11

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

VCR/ECG Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 45

Technical Support Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 47

Technical Support History Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 49

Connectivity Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 50

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 50

Physical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 50

Setting Up for Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 52

Setting Up the Network Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 55

Setting Up for Communication with a Prosolv Workstation . . . . . . . . . . . . . 3 - 57

Connecting Directly to EchoPAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 63

Storing and Transporting the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 68

Disconnecting the Unit when Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 68

Preparing the Unit for Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 68

Safety Precautions for Moving the Vivid™ 3 Unit . . . . . . . . . . . . . . . . . . . . 3 - 69

Wooden Shipping Crate and Packaging Materials . . . . . . . . . . . . . . . . . . . . 3 - 69

Cardboard Shipping Carton and Packaging Materials . . . . . . . . . . . . . . . . . 3 - 70

Packing the Unit into the Wooden Shipping Crate . . . . . . . . . . . . . . . . . . . . 3 - 71

Assembling the Wooden Shipping Crate . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 72

Packing the Unit in the Cardboard Shipping Carton . . . . . . . . . . . . . . . . . . 3 - 74

Assembling the Cardboard Shipping Carton . . . . . . . . . . . . . . . . . . . . . . . . 3 - 75

Completing the Installation Paperwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 76

System Installation Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 76

Product Locator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 76

User Manual(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 77

x

Page 12

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 4

Functional Checks

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Purpose of Chapter 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Power ON/OFF and Boot-up Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Diagnostic Power Supply Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Functional Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Basic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Mechanical Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Back End Processor Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

Image Testing: 2D/M/CFM/Doppler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

3S Probe Image Quality Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

7S Probe Image Quality Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 18

C358 Curved Probe Image Quality Tests . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

739L Probe Image Quality Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 21

Probe 10S Image Quality Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 25

2D (Pencil) Probe Image Quality Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 25

System Turnover Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 26

Software Configuration Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 26

Site Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 33

xi

Page 13

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 5

Components and Function (Theory)

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Purpose of Chapter 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Front End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Front Board Assembly (FB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 16

MUX Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 18

Beamformer Board (BF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 19

Radio Frequency Interface (RFI) Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 20

Front End Controller Board (FEC) (RFT) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 23

RF and Tissue Processor Board (RFT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 24

Image Port Board (IMP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 25

Back Plane Board (Motherboard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 25

Back End Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 26

Central Processing Unit (CPU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 31

Keyboard Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 34

Multifunction I/O Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

Frame Grabber (RFI systems only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

PC2IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

Plug and Scan Card and Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

Network Onboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

SCSI Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

Floppy Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 36

Hard Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 36

Magneto-Optical Drive (MOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

CD Read Write (CDRW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

ECG Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 37

Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 38

PC-VIC Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

External Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

xii

Page 14

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 41

Vivid™ 3 Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 42

Electrical Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 42

AC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 43

AC Distribution Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 45

Front End DC Power Distribution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 47

Front End Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 49

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 49

Location in the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 49

Common Service Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 50

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 50

iLinq Interactive Platform Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 50

Global Service User Interface (GSUI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 51

xiii

Page 15

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 6

Service Adjustments

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Purpose of Chapter 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Input AC Voltage Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Secondary Voltage Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

AC Input Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Front End Voltages and Signal Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

RFI LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Image Port (IMP) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Front End Controller (FEC) LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

RF and Tissue Processor (RFT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Beamformer (BF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Channels Multiplexer (MUX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Front Board Assembly (FB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Back End Power Supply Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

VIC Video Signal Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Video Format Confirmation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Monitor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Vivid™ 3 Samsung 15" and 17" Monitor Operation . . . . . . . . . . . . . . . . . . . 6 - 9

Image Quality Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

Image Quality Calibration for the Vivid™ 3 15" and 17" Samsung Monitors 6 - 12

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

Accessing the Calibration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 14

Monitor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 16

Beamformer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

Video Grabbing Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 17

xiv

Page 16

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 7

Diagnostics/Troubleshooting

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Purpose of Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Diagnostic Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Diagnostic Procedure Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Accessing the Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 3

Performing Front End (FE) Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 5

Accessing the Front End Diagnostic Options . . . . . . . . . . . . . . . . . . . . . . . 7 - 6

Radio Frequency Interface (RFI) Diagnostic Tests (for RFI Configuration) 7 - 11

Image Port (IMP) Diagnostic Tests (for RFT Configuration) . . . . . . . . . . . . 7 - 13

VME Bus (VME) Diagnostic Tests (for RFT Configuration) . . . . . . . . . . . . 7 - 15

RFT Diagnostic Tests (for RFT Configuration) . . . . . . . . . . . . . . . . . . . . . . 7 - 17

Front End Controller (FEC) Diagnostic Tests (for RFT Configuration) . . . . 7 - 19

Beamformer (BF) Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 21

Front Board Assembly (FB) Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . 7 - 25

MUX Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 47

H/W Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 66

Current Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 67

Performing Back End Diagnostics on the System . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 68

Accessing the Back End Diagnostic Options . . . . . . . . . . . . . . . . . . . . . . . 7 - 68

Audio (Doppler Sound Driver) Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . 7 - 70

ECG/Phono Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 71

External Keyboard Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 73

Keyboard Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 76

Media Driver Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 77

Computer Diagnostic Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 79

UPS Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 82

Checking the Network Adaptors from Windows Device Manager . . . . . . . 7 - 83

Common Service Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 84

iLinq Interactive Platform Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 84

Global Service User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 84

Error Logs Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 88

Diagnostics Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 96

Image Quality Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 109

xv

Page 17

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Calibration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 109

Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 110

Utilities Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 111

Replacement Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 125

PM Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 125

Automatic Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 126

Adding Comments to the Daily Logger Report . . . . . . . . . . . . . . . . . . . . . . . 7 - 126

Saving the Logger Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 127

Sending the Logger Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 127

xvi

Page 18

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 8

Replacement Procedures

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Purpose of Chapter 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

Cover Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Overview of Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 2

Side Covers Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 4

Front Cover and Air Filter Replacement Procedures . . . . . . . . . . . . . . . . . 8 - 5

Rear Cover Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 7

Connector Panels Cover Replacement Procedures . . . . . . . . . . . . . . . . . . 8 - 8

Top Cover (Lower Section) Replacement Procedures . . . . . . . . . . . . . . . . 8 - 9

Gas Spring Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 8 - 13

Bottom Keyboard Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . 8 - 14

Speaker Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 16

Control Console Bottom Cover (Upper Section) Replacement Procedure . 8 - 17

Control Console Top Cover Replacement Procedure (Upper Section) . . . 8 - 20

Right and Left Probe Holders Replacement Procedure . . . . . . . . . . . . . . . 8 - 23

Front Handle Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 24

Rear Handle Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 25

Control Console Components Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 27

Vivid™ 3 Monitor 15" Replacement Procedure (Samsung; P/N 2336022-2) 8 - 27

Vivid™ 3 17" Monitor Replacement - Procedure 1 . . . . . . . . . . . . . . . . . . . 8 - 30

Vivid™ 3 17" Monitor Replacement - Procedure 2 . . . . . . . . . . . . . . . . . . . 8 - 34

Keyboard Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 37

Keypad Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 38

Keycaps (External Keyboard) Replacement Procedure . . . . . . . . . . . . . . . 8 - 39

Rotary Knob (External Keyboard) Replacement Procedure . . . . . . . . . . . . 8 - 40

Trackball Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 42

Speaker Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 43

Front End Parts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

Front End Boards Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 8 - 44

TR4 Boards Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 46

DC Power Supply Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

TX Power Supply Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 8 - 48

Front End Crate Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 50

Fan Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 52

xvii

Page 19

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Back End Parts Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 54

Back End Processor Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . 8 - 58

BEP1 Cover Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 64

BEP2 Cover and Octopus Card Holder Replacement Procedure . . . . . . . . 8 - 66

Plug & Scan Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . 8 - 69

Plug & Scan Battery Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . 8 - 70

VGA AGP Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 72

SCSI Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 73

PC2IP Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 75

Frame Grabber Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . . 8 - 76

Keyboard Control Board Replacement Procedure . . . . . . . . . . . . . . . . . . . . 8 - 77

CDRW Drive Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 78

MO Drive Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 80

ECG Module Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 82

PC-VIC Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 87

BEP2 Power Supply Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . 8 - 90

Hard Disk Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 96

Lower Section Components Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 99

AC Distribution Box Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . 8 - 99

AC Input Box Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 101

Keyboard or Monitor Cable Replacement Procedure . . . . . . . . . . . . . . . . . 8 - 102

AC, BEP or FE Cable Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . 8 - 103

Gas Spring Cable Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 104

Up/Down Handle Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 106

Gas Spring Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 111

Front Wheel Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 114

Rear Wheel Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 119

Software Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 121

Software Installation/Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 121

Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 123

B/W Video Printer Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 123

Mitsubishi VCR Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 128

Sony VCR Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 136

JVC VCR Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 141

Panasonic VCR Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 151

Sony UP 2950 MD & 2800P Color Video Printer Replacement Procedure . 8 - 156

Sony UP-21MD Color Video Printer Replacement Procedure . . . . . . . . . . . 8 - 167

xviii

Page 20

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

HP 6540/3 USB Deskjet Color Printer Replacement Procedure for

Vivid™ 3 BT03 Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 175

xix

Page 21

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 9

Renewal Parts

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

Purpose of Chapter 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

List of Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 2

Renewal Parts Lists and Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

Mechanical Hardware Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 3

AC System Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 9

Front End Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 11

Back End Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 15

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 21

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 33

Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 34

Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 35

Cabling Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 36

xx

Page 22

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

CHAPTER 10

Periodic Maintenance

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Purpose of Chapter 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

Why Perform Periodic Maintenance Procedures? . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Keeping Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Quality Assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 2

Periodic Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 3

How Often Should PM Procedures be Performed? . . . . . . . . . . . . . . . . . . 10 - 3

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

Special Tools, Supplies and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

System Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 7

Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 8

Input Power Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 9

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 10

Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 12

Diagnostic Checks (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 13

Probe Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 14

Probe Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 14

Probe Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 14

Basic Probe Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 15

Probe Cleaning and Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 15

Returning and Shipping of Defective Probes . . . . . . . . . . . . . . . . . . . . . . . 10 - 16

Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 17

Safety Test Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 17

GEMS Current Leakage Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 18

Outlet Test Wiring Arrangement - USA & Canada . . . . . . . . . . . . . . . . . . . 10 - 19

Grounding Continuity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 19

Chassis Current Leakage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 21

Isolated Patient Lead (Source) Leakage – Lead-to-Ground . . . . . . . . . . . . 10 - 23

Isolated Patient Lead (Source) Leakage – Lead-to-Lead . . . . . . . . . . . . . . 10 - 24

Isolated Patient Lead (Sink) Leakage - Isolation Test . . . . . . . . . . . . . . . . 10 - 24

xxi

Page 23

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Probe Current Leakage Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 26

Excessive Current Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 29

Possible Causes of Excessive Current Leakage . . . . . . . . . . . . . . . . . . . . . 10 - 29

PM and Safety Inspection Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 30

xxii

Page 24

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Chapter 1 Introduction

Section 1-1 Overview

1-1-1 Purpose of Chapter 1

This chapter describes important issues related to safely servicing the Vivid™ 3 scanner. The service

provider must read and understand all the information presented here before installing or servicing a

unit.

Table 1-1 Contents in Chapter 1

Section Description Page Number

1-1

1-2

1-4

1-3

1-5

1-6

Overview

Important Conventions

Product Labels and Icons

Safety Considerations

EMC, EMI, and ESD

Customer Assistance

1-1-2 Purpose of Service Manual

This manual provides installation and service information for the Vivid™ 3 ultrasound unit, and contains

the following chapters:

• Chapter 1 - Introduction:

Contains a content summary and warnings.

• Chapter 2 - Pre-Installation

Contains pre-installation requirements for the Vivid™ 3 ultrasound unit.

• Chapter 3 - Installation

Contains installation procedures and an installation checklist.

• Chapter 4 - Functional Checks

Contains functional checks that are recommended as part of the installation procedure, or as

required during servicing and periodic maintenance.

1-1

1-6

1-11

1-8

1-25

1-27

• Chapter 5 - Components and Function (Theory)

Contains block diagrams and functional explanations of the electronic circuits.

• Chapter 6 - Service Adjustments

Contains instructions for performing service adjustments to the Vivid™ 3 ultrasound unit.

• Chapter 7 - Diagnostics/Troubleshooting

Provides instructions for setting up and running diagnostic, troubleshooting and other related

routines for the Vivid™ 3 ultrasound unit.

Chapter 1 - Introduction 1-1

Page 25

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Chapter 8 - Replacement Procedures

Provides disassembly and reassembly procedures for all Field Replaceable Units (FRUs).

• Chapter 9 - Renewal Parts

Contains a complete list of field replaceable parts for the Vivid™ 3 ultrasound unit.

• Chapter 10 - Periodic Maintenance

Provides periodic maintenance procedures for the Vivid™ 3 ultrasound unit.

1-1-3 Typical Users of the Basic Service Manual

This manual is intended for the following categories of users:

• GE service personnel (installation, maintenance, etc.).

• Hospital service personnel.

• Contractors (some parts of Chapter 2 - Pre-Installation).

1-2 Section 1-1 - Overview

Page 26

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

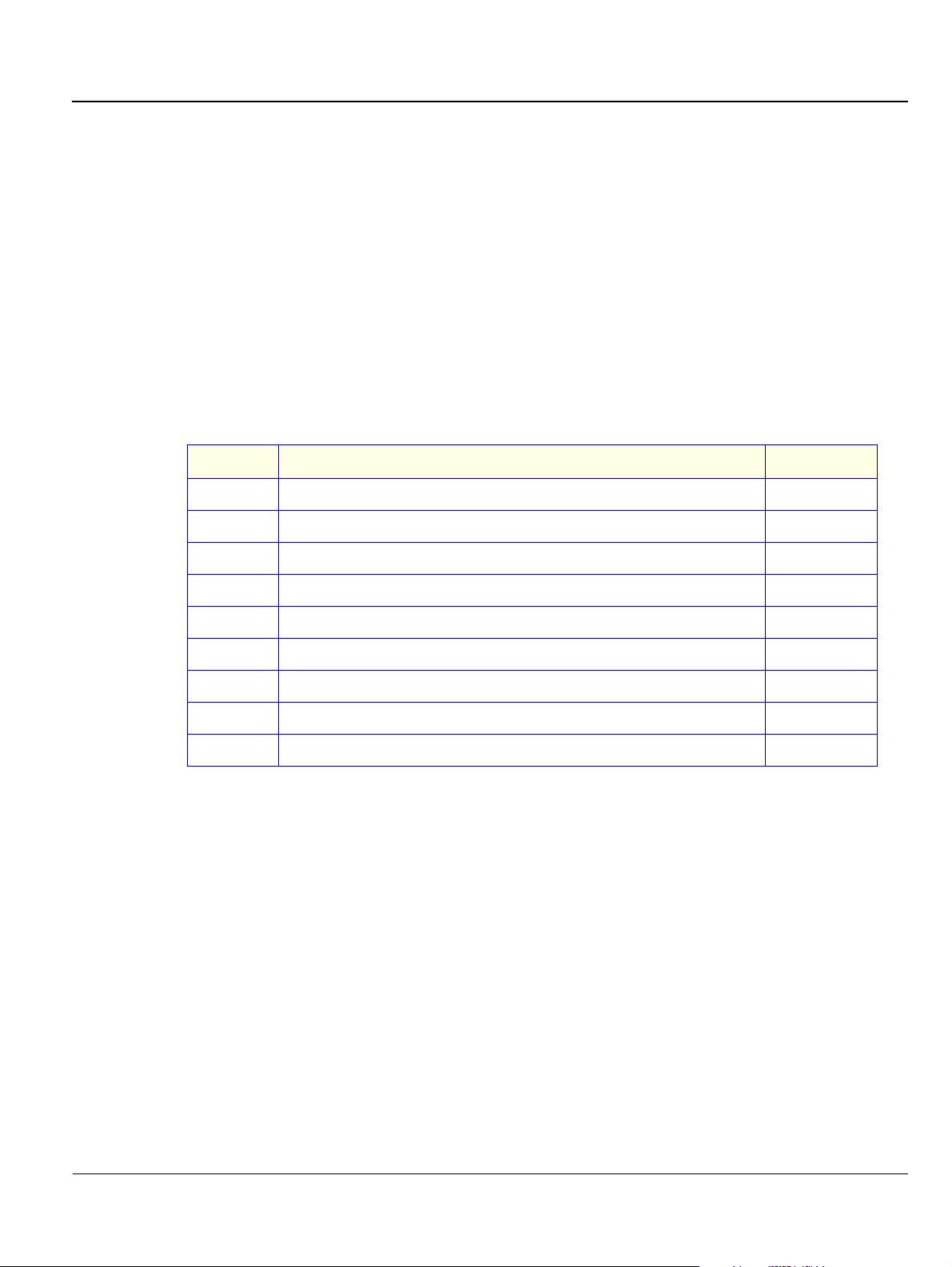

1-1-4 Vivid™ 3 Models Covered in this Manual

The Vivid™ 3 models documented in this manual are shown in Tab le 1 -2 and Ta bl e 1- 3 below.

NOTE: The difference between the two types of Vivid™ 3 BTO3 models are as follows:

On RFI models (supported by software version 3.2, and above), Image Port, RFT, and FEC functionality

are all incorporated into one board - the RFI board.

For RFT models (supported by software versions below 3.2), the Image Port, RFT, and FEC boards are

all separate components.

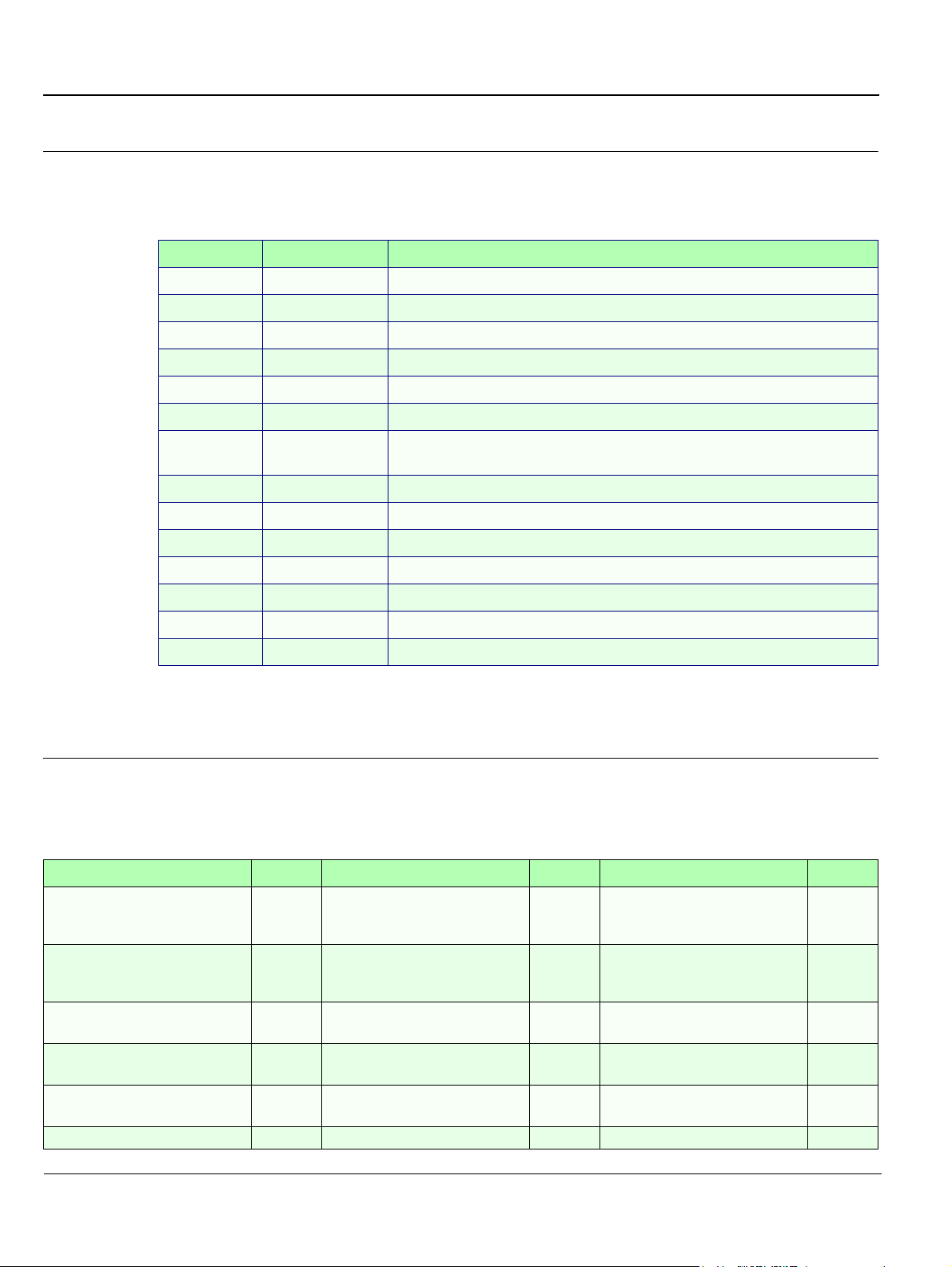

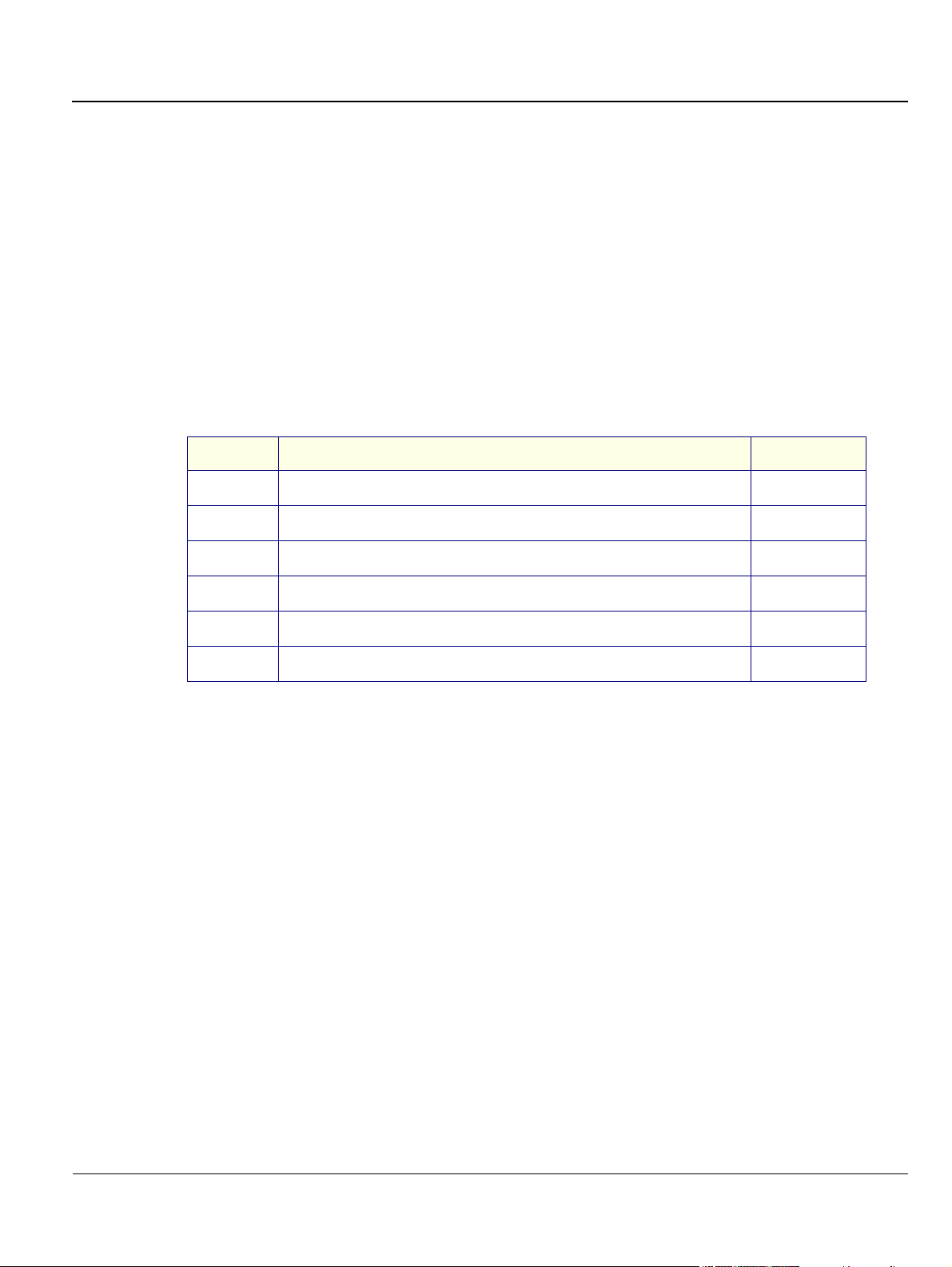

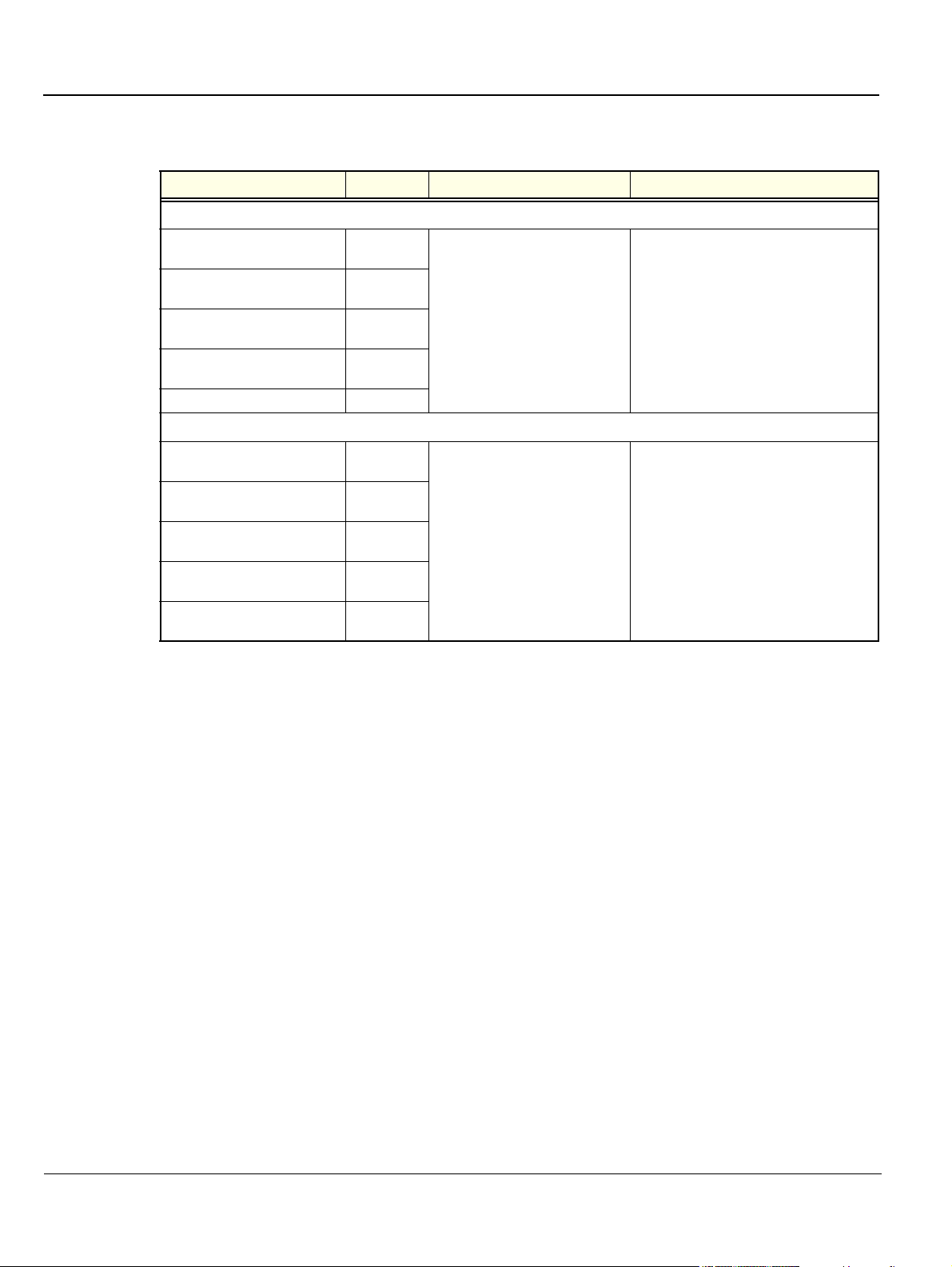

Table 1-2 Vivid™ 3 - BT03 - RFI Models

Model Cat No. Description Comments

BASE Vivid 3 Console

Vivid 3 BT03

console, 220-240V AC, RFI

Vivid 3 BT03

console, 100V AC, RFI

Vivid 3 BT03

console, 110-120V AC, RFI

Vivid 3 BT03

console, 220-230V AC / NTSC, RFI

Vivid 3 BT03 console, NTRL, RFI H45521JB

H45011GD

H45011GE

H45011GF

H45011GG

An advanced version of the newer

generation of the Vivid™ 3 BT03

Ultrasound Scanning System.

Enables a larger variety of probes

and larger application use.

The BT03 is backward compatible to its

parallel product, the BT02 Pro and Expert

and its predecessor BT01 Pro and Expert.

Contact your local distributor for more

information about upgrades and backward

compatibility. BT00 hardware cannot be

upgraded to this level.

PRO Console

Vivid 3 BT03 PRO console, 220-240V AC, RFI H45011G

Vivid 3 BT03 PRO console, 100V AC, RFI H45011GA

Vivid 3 BT03 PRO console, 110-120V AC, RFI H45011GB

Vivid 3 BT03 PRO console, 220V-230V AC

/ NTSC, RFI

Vivid 3 BT03 PRO console, NTRL, RFI H45521JA

H45011GC

New generation of the Vivid™ 3

Ultrasound Scanning System,

continuation of the product line of

Vivid™ 3 BT01 & BT02. For global

universal use.

The Pro is backward compatible to its

predecessor, the BT01 & BT02.

Contact your local distributor for more

information about upgrades and backward

compatibility. BT00 hardware cannot be

upgraded to this level

Chapter 1 - Introduction 1-3

Page 27

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

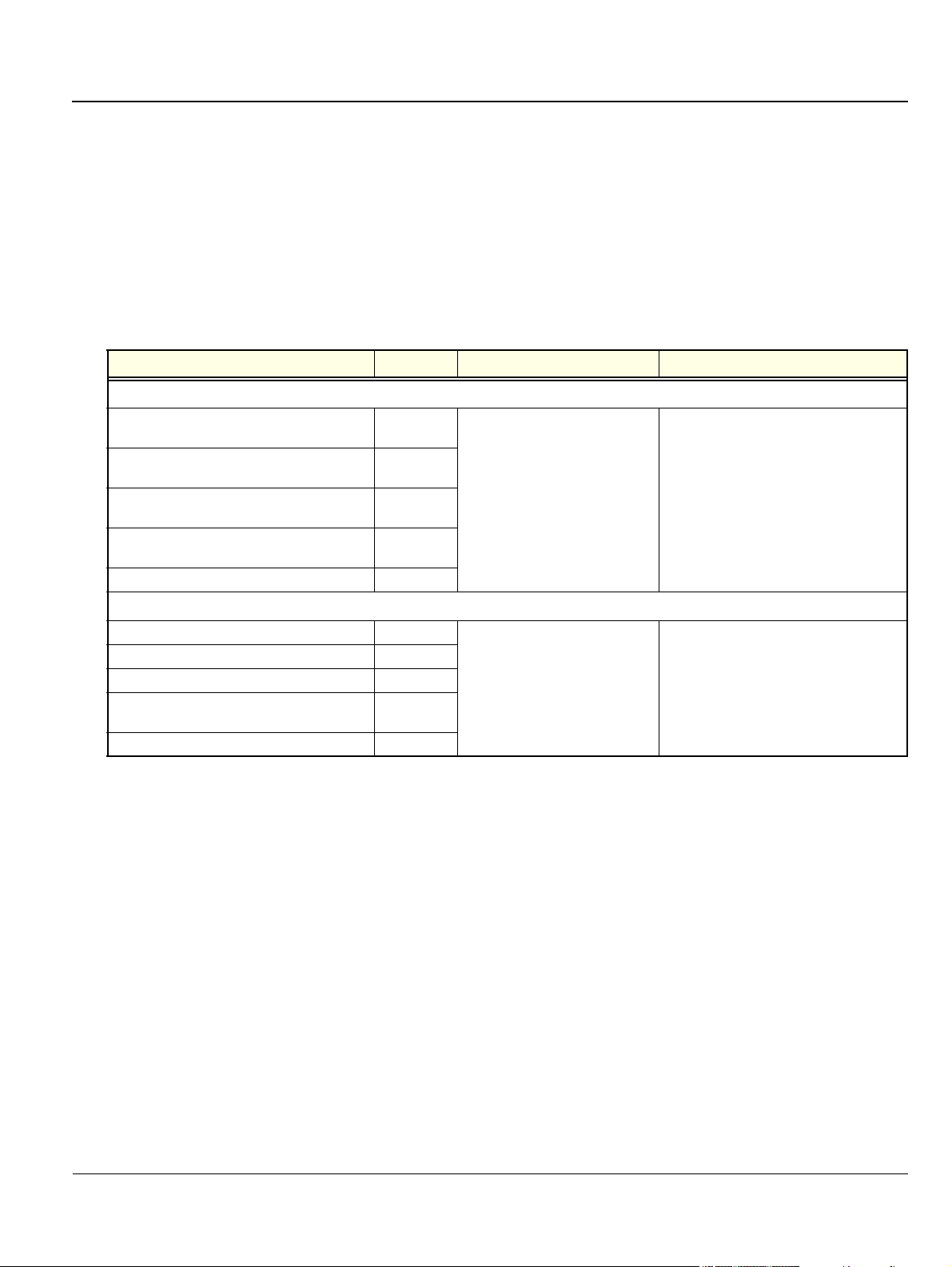

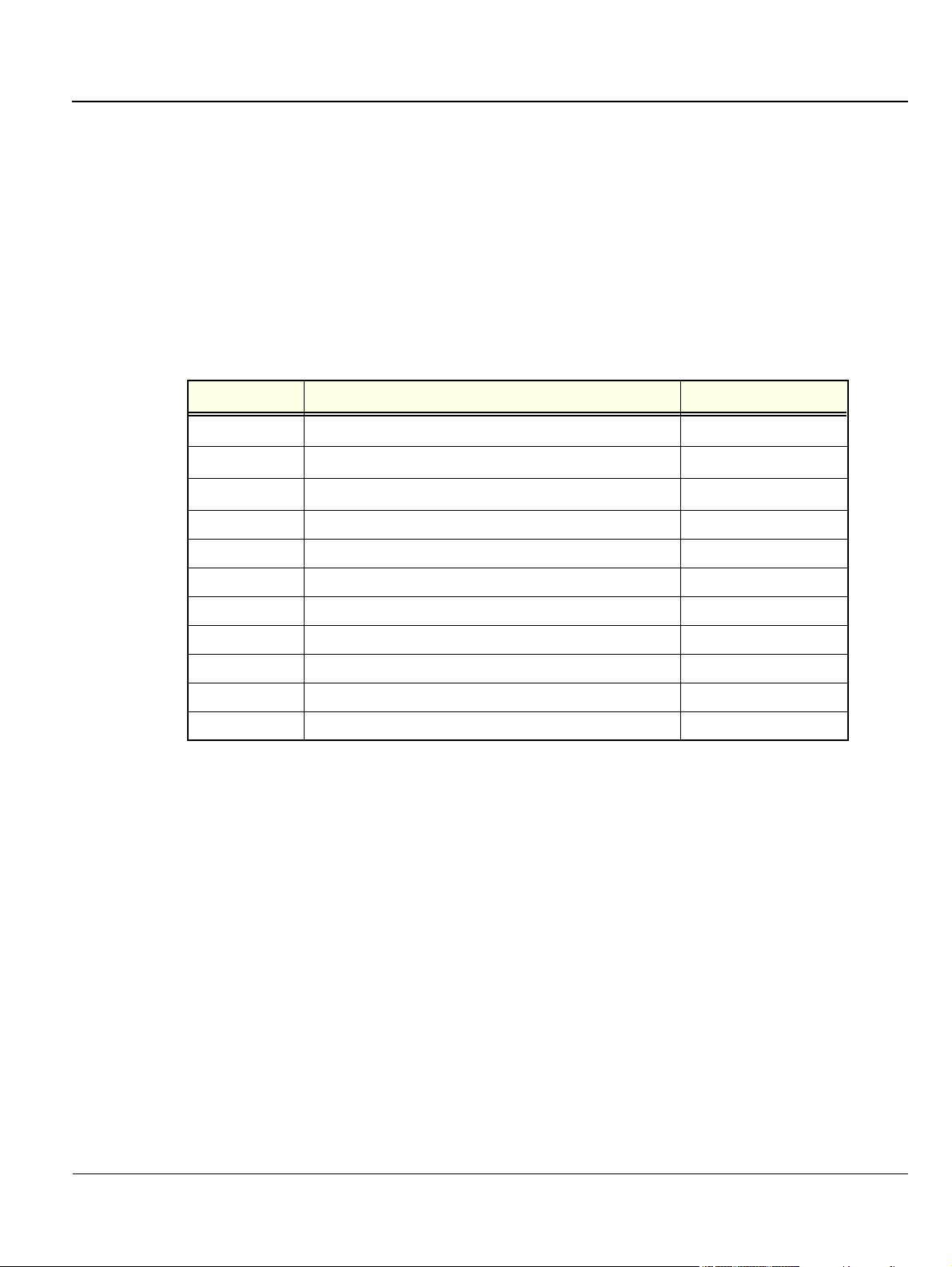

Table 1-3 Vivid™ 3 - BT03 - RFT Models

Model Cat No. Description Comments

BASE Vivid 3 Console

Vivid 3 BT03

console, 220-240V AC

Vivid 3 BT03

console, 100V AC

Vivid 3 BT03

console, 110-120V AC

Vivid 3 BT03

console, 220-230V AC / NTSC

Vivid 3 BT03 console, NTRL H45521EW

PRO Console

Vivid 3 BT03 PRO console,

220-240V AC

Vivid 3 BT03 PRO console,

100V AC

Vivid 3 BT03 PRO console,

110-120V AC

Vivid 3 BT03 PRO console,

220V-230V AC / NTSC

Vivid 3 BT03 PRO console,

NTRL

H45011ES

H45011ET

H45011EU

H45011EV

H45011FD

H45011FE

H45011FF

H45011FG

H45521FH

An advanced version of the newer

generation of the Vivid™ 3 BT03

Ultrasound Scanning System.

Enables a larger variety of probes

and larger application use.

New generation of the Vivid™ 3

Ultrasound Scanning System,

continuation of the product line of

Vivid™ 3 BT01 & BT02. For global

universal use.

The BT03 is backward compatible to its

parallel product, the BT02 Pro and Expert

and its predecessor BT01 Pro and Expert.

Contact your local distributor for more

information about upgrades and backward

compatibility. BT00 hardware cannot be

upgraded to this level.

The Pro is backward compatible to its

predecessor, the BT01 & BT02.

Contact your local distributor for more

information about upgrades and backward

compatibility. BT00 hardware cannot be

upgraded to this level

NOTE: Vivid™ 3 systems with Serial No 5000 and above, have the RFI system hardware configuration. All

systems with a serial number prior to this (i.e. 4999 and below) are configured with RFT hardware.

1-4 Section 1-1 - Overview

Page 28

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

1-1-5 System History - Hardware and Software Versions

The newest generation of the Vivid™ 3 (BT03) ultrasound unit is based on its predecessor, the

Vivid™ 3 (BT01 and BT02) ultrasound unit, and is therefore backward compatible. The Vivid™ 3

ultrasound unit enables advanced features in a compact and user friendly tool.

Note: Vivid™ 3 (BT00) cannot be upgraded to the Vivid™ 3 Pro 03 as was the case for Pro 02.

The Vivid™ 3 Pro and Vivid™ 3 are the same generation of products, but differ in their functionality,

enabling customers to receive some of the advanced Vivid™ 3 features. With minor software and hardware

modifications, the Vivid™ 3 Pro can be upgraded to the Vivid™ 3 - refer to Ta bl e 1 -4 .

Table 1-4 Vivid™ 3 Upgrade Options Available

Part No. Upgrade Comments

H45011BA BT00 to BT00 Pro upgrade

H45011BP BT00 to BT00 Pro upgrade for P509 probe

H45011BC Platform upgrade from Vivid™ 3 BT01 "Pro" to "Expert"

H45011DL BT00 to Pro-02 upgrade

H45011DM BT00 Pro to Pro-02 upgrade

H45011DR BT01 Pro to Pro-02 upgrade

H45011DS BT01 Expert to Expert -02 upgrade

H45011FB BT01/BT02 Pro to BT03 Upgrade New

H45011FC BT01/BT02 Expert to BT03 Upgrade New

H45011BN 3rd Probe Connector for Vivid 3 system field upgrade New

H45011MK 17 " Monitor field upgrade New

1-1-6 Purpose of Operator Manual(s)

The Operator Manual(s) should be fully read and understood before operating the Vivid™ 3 system, and also

kept near the unit for quick reference.

Chapter 1 - Introduction 1-5

Page 29

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Section 1-2 Important Conventions

1-2-1 Conventions Used in this Manual

1-2-1-1 Model Designations

This manual covers the Vivid™ 3 ultrasound units listed in Table 1-2 on page 1-3 and Table 1-3 on

page 1-4.

1-2-1-2 Icons

Pictures, or icons, are used wherever they will reinforce the printed message. The icons, labels and

conventions used on the product and in the service information are described in this chapter.

1-2-1-3 Safety Precaution Messages

Various levels of safety precautions are found on the equipment and throughout this service manual.

Different levels of severity are identified by one of the following icons which precede precautionary

statements in the text.

DANGER: Indicates the presence of a hazard that will cause severe personal injury or death if the

instructions are ignored.

WARNING: Indicates the presence of a hazard that can cause severe personal injury and property

damage if the instructions are ignored.

CAUTION: Indicates the presence of a hazard that can cause property damage but has absolutely no

personal injury risk.

Note: Notes are used to provide important information about an item or a procedure. Be sure to read

the notes as the information they contain can often save you time or effort.

1-6 Section 1-2 - Important Conventions

Page 30

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

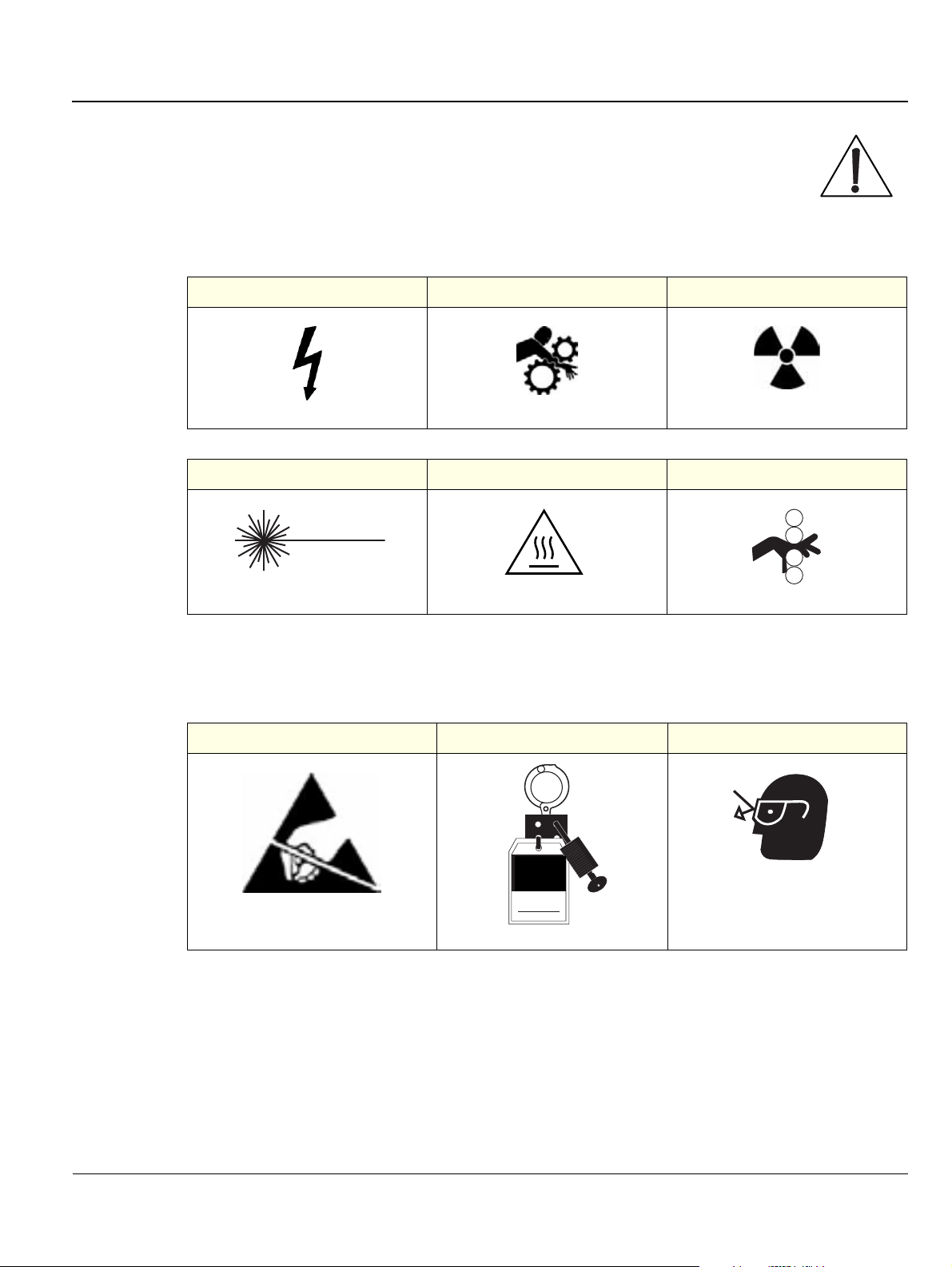

1-2-1-4 Standard Hazard Icons

Important information will always be preceded by the exclamation point contained within

a triangle, as seen throughout this chapter. In addition to text, several different graphical

icons (symbols) may be used to make you aware of specific types of hazards that could

cause harm.

Table 1-5 Standard Hazard Icons

ELECTRICAL MECHANICAL RADIATION

LASER HEAT PINCH

LASER

LASER

LIGHT

LIGHT

Other hazard icons make you aware of specific procedures that should be followed.

Table 1-6 Standard Icons Indicating a Special Procedure Be Used

AVOID STATIC ELECTRICITY TAG AND LOCK OUT WEAR EYE PROTECTION

TAG

TAG

&

&

LOCKOUT

LOCKOUT

Date

Signed

EYE

EYE

PROTECTION

PROTECTION

Chapter 1 - Introduction 1-7

Page 31

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Section 1-3 Safety Considerations

1-3-1 Introduction

The following safety precautions must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with these precautions or with specific warnings elsewhere in this

manual, violates safety standards of design, manufacture and intended use of the equipment.

1-3-2 Human Safety

Operating personnel must not remove the system covers.

Servicing should be performed by authorized personnel only.

Only personnel who have participated in Vivid™ 3 Training are authorized to service the equipment.

1-3-3 Mechanical Safety

DANGER: WHEN THE UNIT IS RAISED FOR A REPAIR OR MOVED ALONG ANY INCLINE,

USE EXTREME CAUTION SINCE IT MAY BECOME UNSTABLE AND TIP OVER.

DANGER: ULTRASOUND PROBES ARE HIGHLY SENSITIVE MEDICAL INSTRUMENTS

THAT CAN EASILY BE DAMAGED BY IMPROPER HANDLING. USE CARE WHEN

HANDLING AND PROTECT FROM DAMAGE WHEN NOT IN USE. DO NOT USE A

DAMAGED OR DEFECTIVE PROBE. FAILURE TO FOLLOW THESE PRECAUTIONS CAN

RESULT IN SERIOUS INJURY AND EQUIPMENT DAMAGE.

DANGER: NEVER USE A PROBE THAT HAS BEEN SUBJECTED TO MECHANICAL

SHOCK OR IMPACT. EVEN IF THE PROBE APPEARS TO BE UNBROKEN, IT MAY IN

FACT BE DAMAGED.

CAUTION: Always lower and center the Operator I/O Panel before moving the scanner.

CAUTION: The Vivid™ 3 weighs 160 kg (353 lbs.)or more, depending on installed peripherals,

when ready for use. Care must be used when moving it or replacing its parts. Failure to follow

the precautions listed could result in injury, uncontrolled motion and costly damage.

ALWAYS:

Be sure the pathway is clear.

Use slow, careful motions.

Use two people when moving the system on inclines or lifting more than 16 kg (35 lbs).:

WARNING: Always lock the control console in its parking (locked) position after moving the

system. Failure to do so could result in personal injury or equipment damage.

1-8 Section 1-3 - Safety Considerations

Page 32

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

WARNING: Equipment damage could result if special care is not taken when transporting the

system in a vehicle.

ALWAYS:

• Secure the system in an upright position and lock the wheels (brake).

• DO NOT use the control console as an anchor point.

• Place the probes in their carrying case.

• Eject any disks from the MOD (if installed).

• Ensure that the system is well prepared and packed in its original packaging before

transporting. Special care must be taken to correctly position the packing material

supporting the monitor. For further information, refer to Chapter 3 - Installation.

CAUTION: Keep the heat venting holes on the monitor unobstructed to avoid overheating of the

monitor.

1-3-4 Electrical Safety

To minimize shock hazard, the equipment chassis must be connected to an electrical Ground. The

system is equipped with a three-conductor AC power cable. This must be plugged into an approved

electrical outlet with safety grounding.

The power outlet used for this equipment should not be shared with other types of equipment. Both the

system power cable and the power connector must meet international electrical standards.

1-3-4-1 Probes

All the probes for the Vivid™ 3 ultrasound unit are designed and manufactured to provide trouble-free,

reliable service. To ensure this, correct handling of probes is important and the following points should

be noted:

• Do not drop a probe or strike it against a hard surface, as this may damage the transducer elements,

acoustic lens, or housing.

• Do not use a cracked or damaged probe. In this event, call your field service representative

immediately to obtain a replacement.

• Avoid pulling, pinching or kinking the probe cable, since a damaged cable may compromise the

electrical safety of the probe.

• To avoid the risk of a probe accidentally falling, do not allow the probe cables to become entangled,

or to be caught in the machine’s wheels.

NOTE: For detailed information on handling endocavity probes, refer to the appropriate supplementary

instructions for each probe. In addition, refer to the Vivid™ 3 Pro/Vivid™ 3 Expert User Manual for

detailed probe handling instructions.

Chapter 1 - Introduction 1-9

Page 33

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

1-3-5 Dangerous Procedure Warnings

Warnings, such as the examples below, precede potentially dangerous procedures throughout this

manual. Instructions contained in the warnings must be followed.

DANGEROUS VOLTAGES, CAPABLE OF CAUSING DEATH, ARE PRESENT IN THIS

EQUIPMENT. USE EXTREME CAUTION WHEN HANDLING, TESTING AND ADJUSTING.

EXPLOSION WARNING

DO NOT OPERATE THE EQUIPMENT IN AN EXPLOSIVE ATMOSPHERE.

OPERATION OF ANY ELECTRICAL EQUIPMENT IN SUCH AN ENVIRONMENT CONSTITUTES A

DEFINITE SAFETY HAZARD.

DO NOT SUBSTITUTE PARTS OR MODIFY EQUIPMENT

BECAUSE OF THE DANGER OF INTRODUCING ADDITIONAL HAZARDS, DO NOT INSTALL

SUBSTITUTE PARTS OR PERFORM ANY UNAUTHORIZED MODIFICATION OF THE

EQUIPMENT.

1-10 Section 1-3 - Safety Considerations

Page 34

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

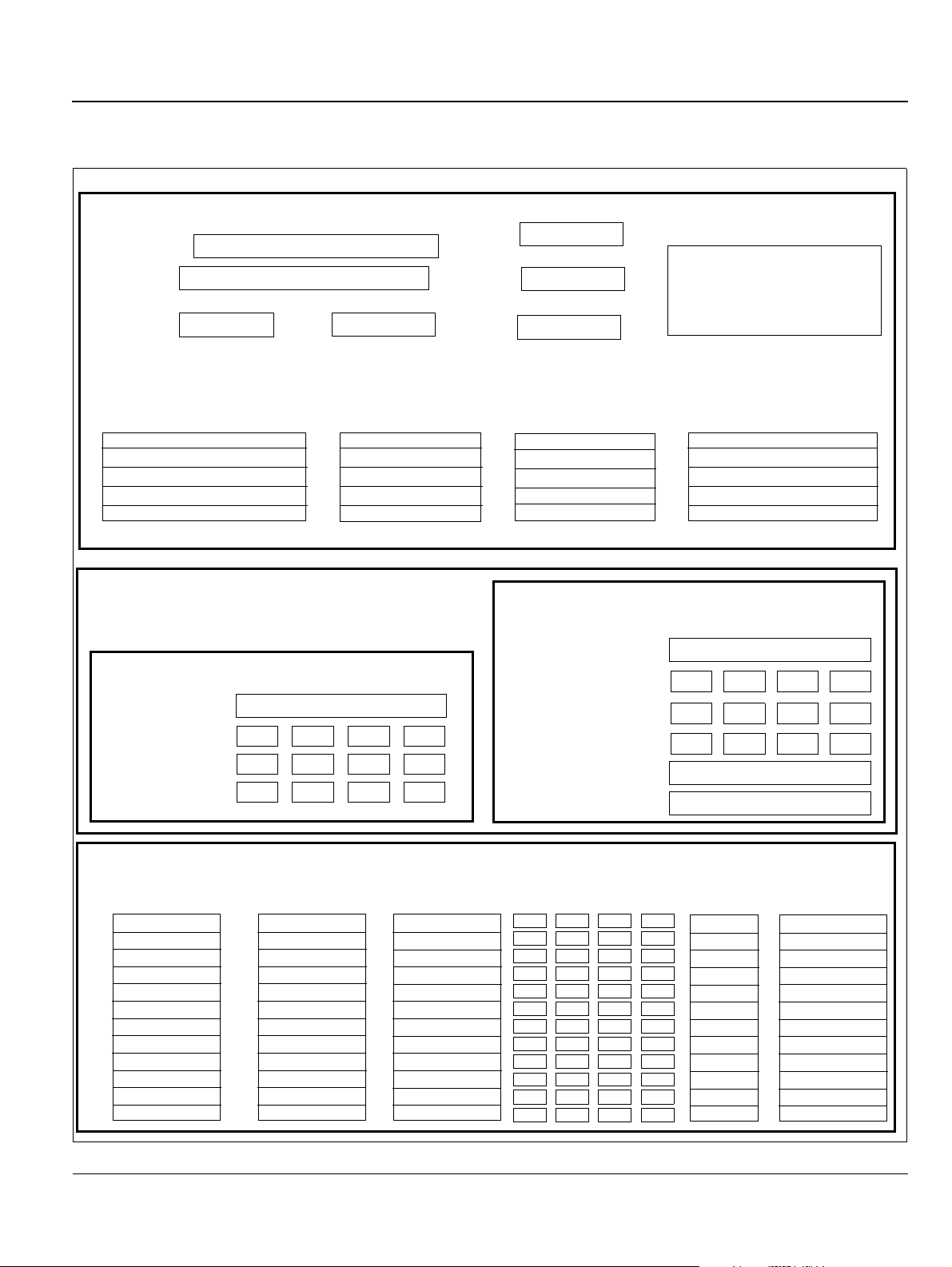

Section 1-4 Product Labels and Icons

The Vivid™ 3 ultrasound unit comes equipped with product labels and icons. These labels and icons

represent pertinent information regarding the operation of the ultrasound unit.

1-4-1 Product Label Locations

The following two diagrams indicate the location of some of the labels and icons found on the Vivid™ 3

ultrasound units. All the labels and icons are described in Table 1-7 on page 1-13.

1

2

3

Figure 1-1 Product Label and Icon Locations (Front)

1 Product Logo

2 Equipment Type CF

3 Parking Label on Brake Pedal

4 Class II Equipment

5 Swivel Brake Label on Brake Pedal

Chapter 1 - Introduction 1-11

4

5

Page 35

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

3

Figure 1-2 Product Label and Icon Locations (Rear)

1 Main Label

2 AC Voltage Rating Label

3 GND Label

1

2

1-12 Section 1-4 - Product Labels and Icons

Page 36

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

1-4-2 Label Descriptions

The following table shows the labels and symbols that may be found on the Vivid™ 3 ultrasound unit,

and provides a description of each label’s purpose and location.

Table 1-7 Product Icons

Label Name Description Location

Product Logo Identifies Vivid™ 3 models. Front of the unit.

Manufacturer’s name and address.

Identification and Rating

Plate

Date of Manufacture.

Model and Serial numbers.

Electrical ratings.

Class I Equipment, in which protection

against electric shock does not rely on basic

insulation only, but which includes an

additional safety precaution in that means

are provided for the connection of the

equipment to the protective earth conductor

in the fixed wiring of the installation - in such

a way that accessible metal parts cannot

become live in the event of a failure of the

basic insulation.

Rear of the unit, near the power inlet.

Rear of the unit and probe

connectors.

Device Listing/Certification

Labels

CAUTION - This machine

weighs...Special care must

be used to avoid..."

Laboratory logos or labels that denote

conformity with industry safety standards,

such as UL or IEC.

CE certification mark. Rear of the unit, on the main label.

Equipment Type BF (man in the box symbol)

IEC 878-02-03 indicates B Type equipment

having even more electrical isolation than

standard Type B equipment because it is

intended for intimate patient contact.

Equipment Type CF IEC 878-02-05

indicates equipment having a floating

applied part that provides a degree of

protection suitable for direct cardiac contact.

This precaution is intended to prevent injury

that may be caused by the weight of the

machine if one person attempts to move it

considerable distances or on an incline.

Rear of the unit.

Probe connectors

PCG connector

or Rear of Console

Front of the unit, ECG connector and

surgical probes.

Used in the Service and User Manual

which should be adjacent to

equipment at all times for quick

reference.

Chapter 1 - Introduction 1-13

Page 37

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Table 1-7 Product Icons (Continued)

Label Name Description Location

"DANGER - Risk of explosion

used in..."

The system is not designed for use with

flammable anesthetic gases.

"CAUTION" The equilateral triangle is

usually used in combination with other

symbols to advise or warn the user.

“ATTENTION - Consult accompanying

documents” is intended to alert the user to

refer to the User Manual or other instructions

when complete information cannot be

provided on the label.

"CAUTION - Dangerous voltage" (the

lightning flash with arrowhead in equilateral

triangle) is used to indicate electric shock

hazards.

"Protective Earth" Indicates the protective

earth (grounding) terminal.

Indicated in the Service Manual.

Rear of the unit.

Rear of the unit.

Rear of the unit.

Rear of the unit.

"Equipotentiality" Indicates the terminal to be

used for connecting equipotential

conductors when interconnecting

(grounding) with other equipment.

Waste Electrical and Electronic Equipment

(WEEE) Disposal

This symbol indicates that the waste of

electrical and electronic equipment must not

be disposed as unsorted municipal waste

and must be collected separately.

Please contact an authorized representative

of the manufacturer for information

concerning the decommissioning of your

equipment.

Peripherals

Rear of the unit.

1-14 Section 1-4 - Product Labels and Icons

Page 38

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

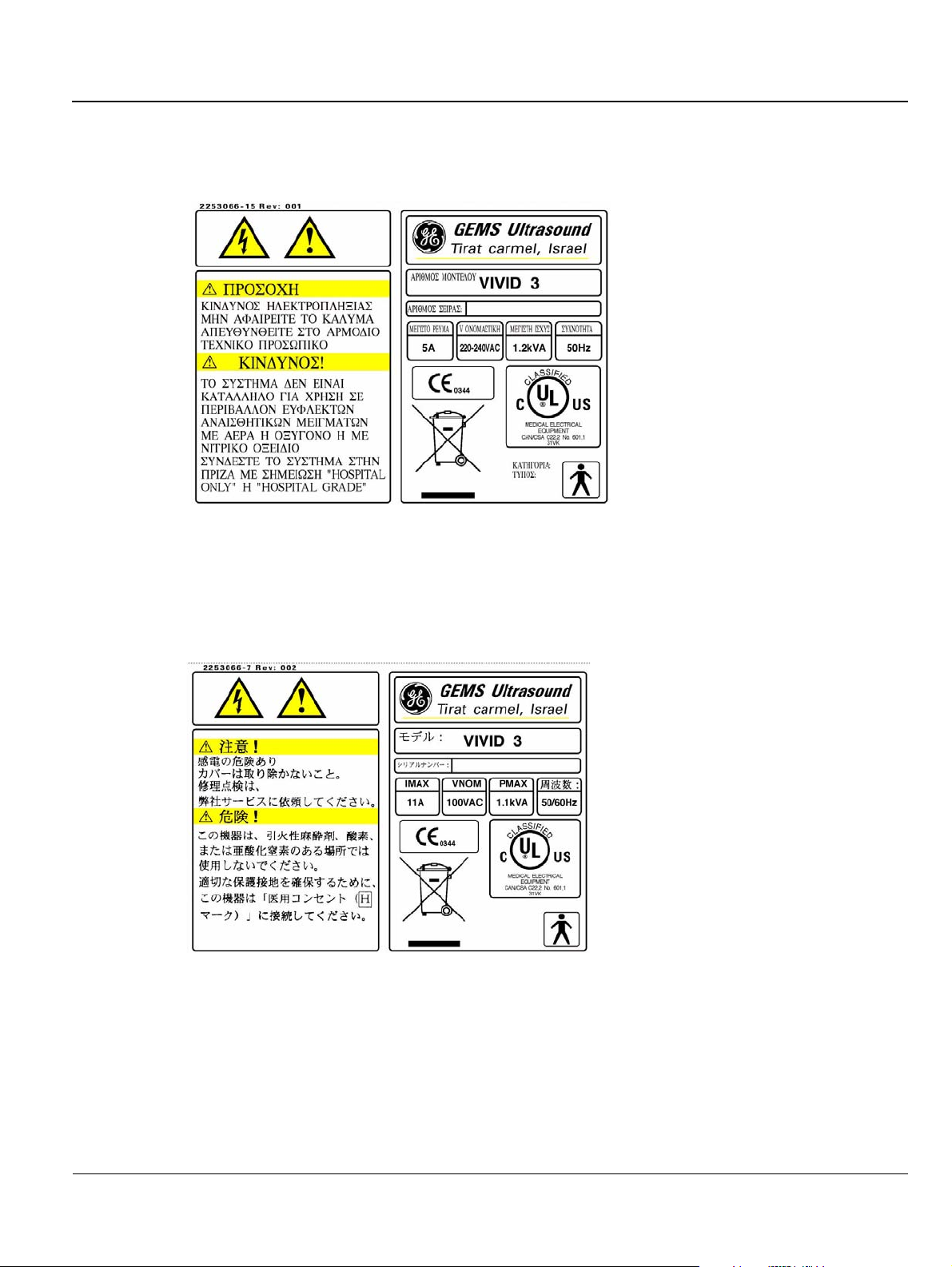

1-4-3 Vivid™ 3 External Labels

In addition to the labels described in the previous section, additional labels may be found on the

Vivid™ 3 ultrasound unit, as described in the following sections:

• Main Label section, on page 1-15.

• Rating Labels section, on page 1-23.

• GND Label section, on page 1-24.

• Parking Label section, on page 1-24.

• Swivel Brake Label section, on page 1-24.

1-4-3-1 Main Label

The main label may be printed in any of the following languages: English, German, French, Spanish,

Portuguese, Italian, Chinese, Danish, Dutch, Finnish, Greek, Japanese, Norwegian, Russian, or

Swedish, as shown in the examples below. Each main label includes a serial number, a voltage rating,

caution warnings, danger warnings and classifications (UL, CE0344 and so on.)

• English: Used for all countries except those in which German, French, Spanish, Portuguese or

Italian are spoken.

Figure 1-3 Main Label (English) 220 -240V

.

Figure 1-4 Main Label (English) USA

Chapter 1 - Introduction 1-15

Page 39

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• German: Used in all German language countries.

Figure 1-5 Main Label (German)

• French: Used in all French language countries.

Figure 1-6 Main Label (French)

1-16 Section 1-4 - Product Labels and Icons

Page 40

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Spanish: Used in all Spanish language countries.

Figure 1-7 Main Label (Spanish)

• Portuguese: Used in all Portuguese language countries.

Figure 1-8 Main Label (Portuguese)

Chapter 1 - Introduction 1-17

Page 41

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Figure 1-9 Main Label (Portuguese) 220 - 240V

• Italian: Used in all Italian language countries.

Figure 1-10 Main Label (Italian)

1-18 Section 1-4 - Product Labels and Icons

Page 42

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Chinese: Used in all Chinese language countries.

Figure 1-11 Main Label (Chinese)

• Danish: Used in all Danish language countries.

Figure 1-12 Main Label (Danish)

Chapter 1 - Introduction 1-19

Page 43

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Dutch: Used in all Dutch language countries.

Figure 1-13 Main Label (Dutch)

• Finnish: Used in all Finnish language countries.

Figure 1-14 Main Label (Finnish)

1-20 Section 1-4 - Product Labels and Icons

Page 44

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Greek: Used in all Greek language countries.

Figure 1-15 Main Label (Greek)

• Japanese: Used in all Japanese language countries.

Figure 1-16 Main Label (Japanese)

Chapter 1 - Introduction 1-21

Page 45

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Norwegian: Used in all Norwegian language countries.

Figure 1-17 Main Label (Norwegian)

• Russian: Used in all Russian language countries.

Figure 1-18 Main Label (Russian)

1-22 Section 1-4 - Product Labels and Icons

Page 46

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

• Swedish: Used in all Swedish language countries.

Figure 1-19 Main Label (Swedish)

1-4-3-2 Rating Labels

Indicates the ultrasound unit’s factory preset input AC voltage as follows:

• AC 100V

• AC 120V

• AC 220-240V

One of the rating labels shown below is located on the rear of the ultrasound unit, as shown in

Figure 1-2 on page 1-12.

Figure 1-20 Rating Labels

Chapter 1 - Introduction 1-23

Page 47

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

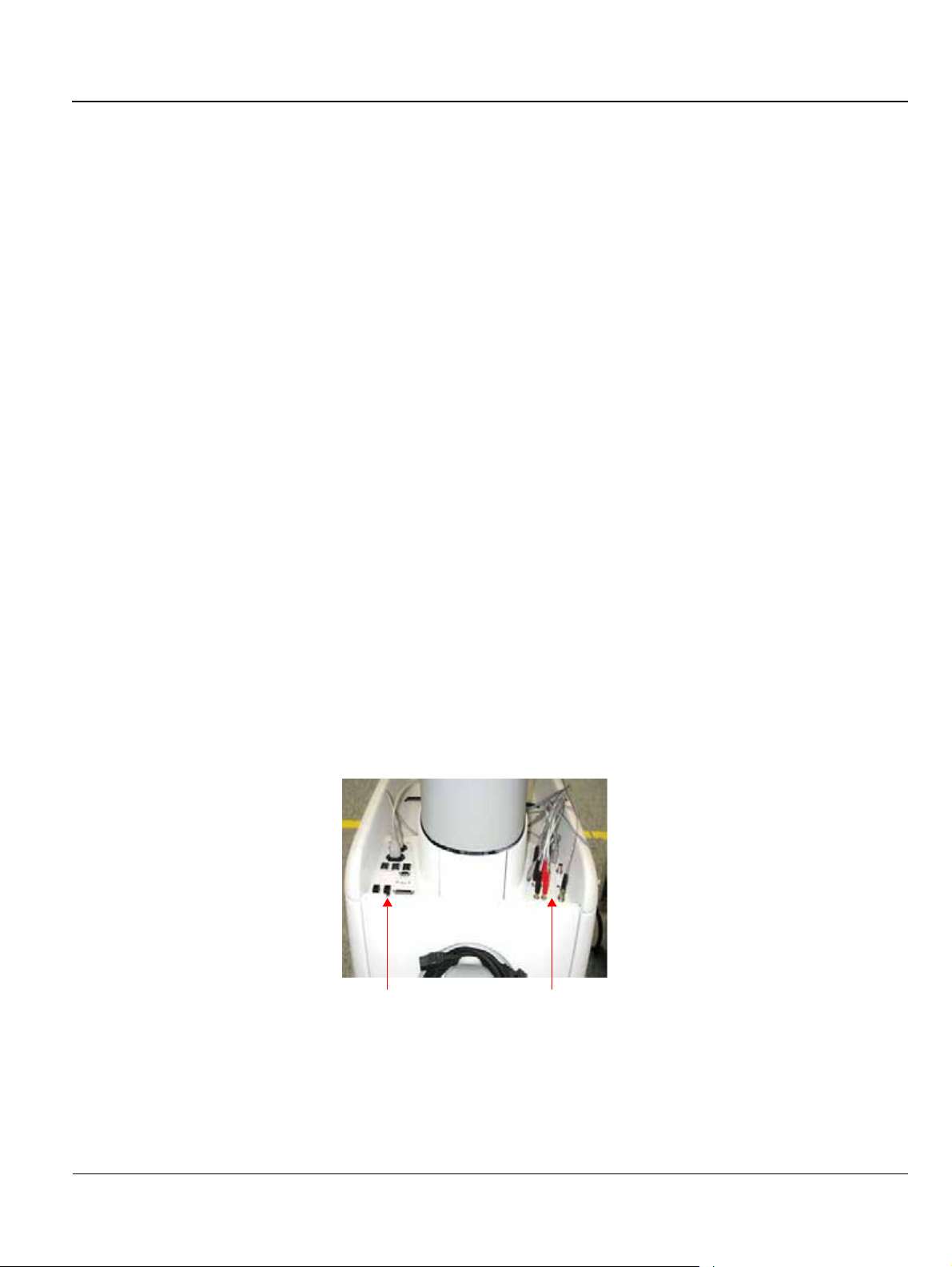

1-4-3-3 GND Label

Indicates the protective earth (grounding) terminal. The GND label shown below is located at the rear

of the unit, as shown in Figure 1-2 on page 1-12.

Figure 1-21 GND Label

1-4-3-4 Parking Label

Indicates the locked pedal position which locks the front castors and prevents the ultrasound unit from

moving. The parking label, shown below, is located on the brake pedal at the front of the unit, as shown

in Figure 1-1 on page 1-11.

Figure 1-22 Parking Label

1-4-3-5 Swivel Brake Label

Indicates the locked swivel position which prevents the front castors from swiveling. The swivel brake

label, shown below, is located on the brake pedal at the front of the unit, as shown in Figure 1-1 on

page 1-11.

Figure 1-23 Swivel Break Label

1-24 Section 1-4 - Product Labels and Icons

Page 48

GE MEDICAL SYSTEMS

IRECTION 2300164-100, REVISION 7VIVID™ 3 PRO/VIVID™ 3 SERVICE MANUAL

D

Section 1-5 EMC, EMI, and ESD

1-5-1 Electromagnetic Compatibility (EMC)

Electromagnetic compatibility describes a level of performance of a device within its electromagnetic

environment. This environment consists of the device itself and its surroundings, including other

equipment, power sources and persons with which the device must interface. Inadequate compatibility

results when a susceptible device fails to perform as intended due to interference from its environment,