Page 1

GE

Intelligent Platforms

Programmable Control Products

VersaPoint* I/O System

Profibus-DP NIU

User’s Manual, GFK-1911B

March 2010

Page 2

GFL-002

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment,

a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to

understanding and operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Intelligent Platforms assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Intelligent Platforms makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

* indicates a trademark of GE Intelligent Platforms, Inc. and/or its affiliates. All other

trademarks are the property of their respective owners.

©Copyright 2010 GE Intelligent Platforms, Inc.

All Rights Reserved

Page 3

Contact Information

If you purchased this product through an Authorized Channel Partner, please contact the seller

directly.

General Contact Information

Online technical support and

1H2Hhttp://www.ge-ip.com/support

GlobalCare

Additional information 3Hhttp://www.ge-ip.com/

Solution Provider 4Hsolutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this guide, please

contact us by telephone or email, or on the web at

5Hwww.ge-ip.com/support

Americas

Online Technical Support 6H7Hwww.ge-ip.com/support

Phone 1-800-433-2682

International Americas Direct Dial 1-780-420-2010 (if toll free 800 option is unavailable)

Technical Support Email 8H9Hsupport.ip@ge.com

Customer Care Email 10H11Hcustomercare.ip@ge.com

Primary language of support English

Europe, the Middle East, and Africa

Online Technical Support 12H13Hwww.ge-ip.com/support

Phone +800-1-433-2682

EMEA Direct Dial +352-26-722-780 (if toll free 800 option is unavailable or if

dialing from a mobile telephone)

Technical Support Email 14H15Hsupport.emea.ip@ge.com

Customer Care Email 16H17Hcustomercare.emea.ip@ge.com

Primary languages of support English, French, German, Italian, Czech, Spanish

Asia Pacific

Online Technical Support 18H19Hwww.ge-ip.com/support

+86-400-820-8208 Phone

+86-21-3217-4826 (India, Indonesia, and Pakistan)

Technical Support Email

20H21Hsupport.cn.ip@ge.com (China)

22H23Hsupport.jp.ip@ge.com (Japan)

24H25Hsupport.in.ip@ge.com (remaining Asia customers)

26H27Hcustomercare.apo.ip@ge.com Customer Care Email

28Hcustomercare.cn.ip@ge.com (China)

Page 4

Page 5

Contents

Chapter 1 Introduction ........................................................................................... 1-1

Features ............................................................................................................................ 1-2

Advantages ....................................................................................................................... 1-2

I/O Station Capacity.................................................................................................. 1-2

What’s In This Manual....................................................................................................... 1-3

Other Documents You’ll Need........................................................................................... 1-4

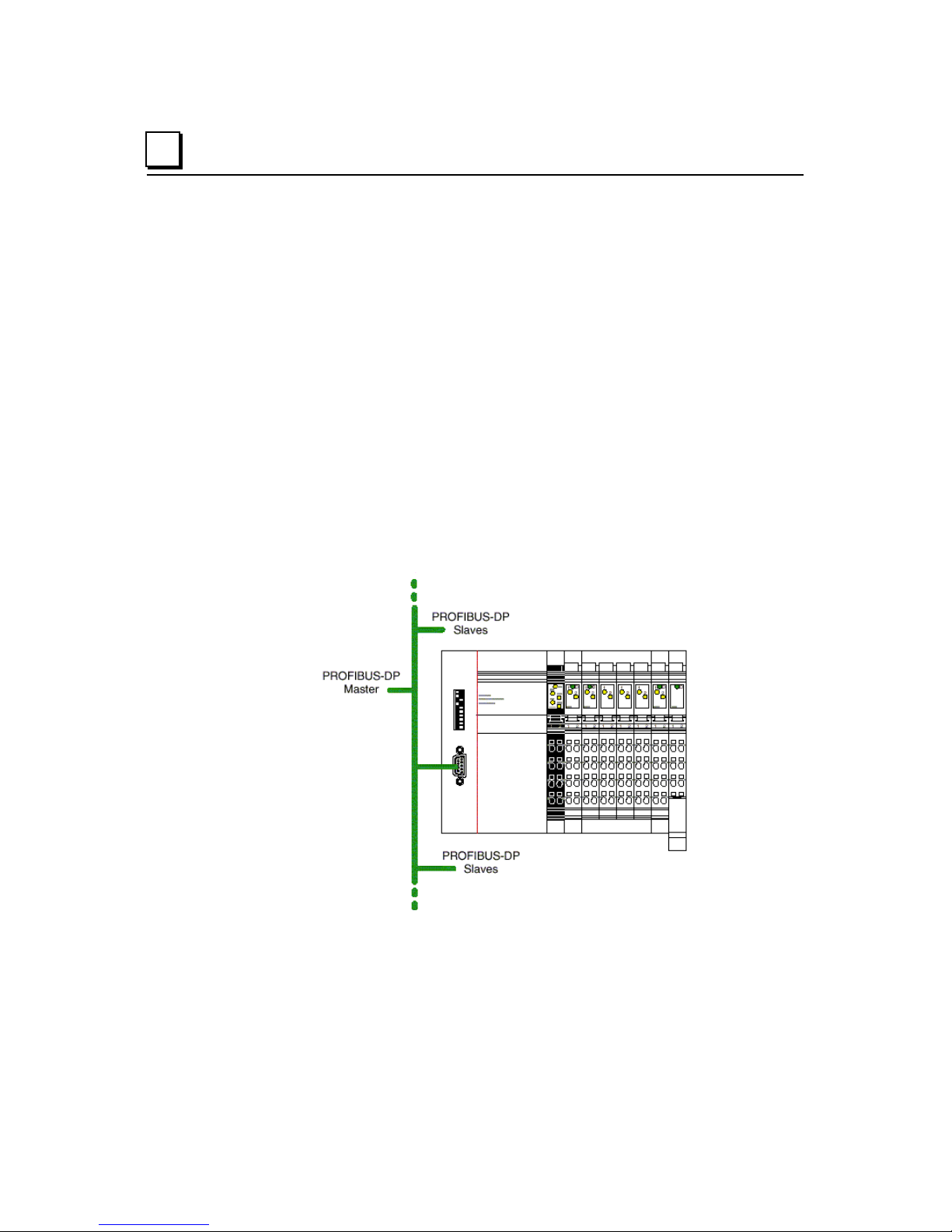

Example Plant ...................................................................................................................1-5

Chapter 2 The Profibus NIU.................................................................................... 2-1

The Profibus System ......................................................................................................... 2-2

Typical Profibus-DP VersaPoint I/O Station ............................................................. 2-2

Structure of a VersaPoint I/O Station .......................................................................2-3

The Profibus-DP Network Interface Unit ........................................................................... 2-4

Features ................................................................................................................... 2-4

Comparison of Features ........................................................................................... 2-5

Items Used with the NIU........................................................................................... 2-6

Ordering Information................................................................................................. 2-6

Connectors on the NIU...................................................................................................... 2-7

Profibus Connector ................................................................................................... 2-7

Power Connector...................................................................................................... 2-8

NIU Power ................................................................................................................2-8

DIP Switches on the NIU................................................................................................... 2-9

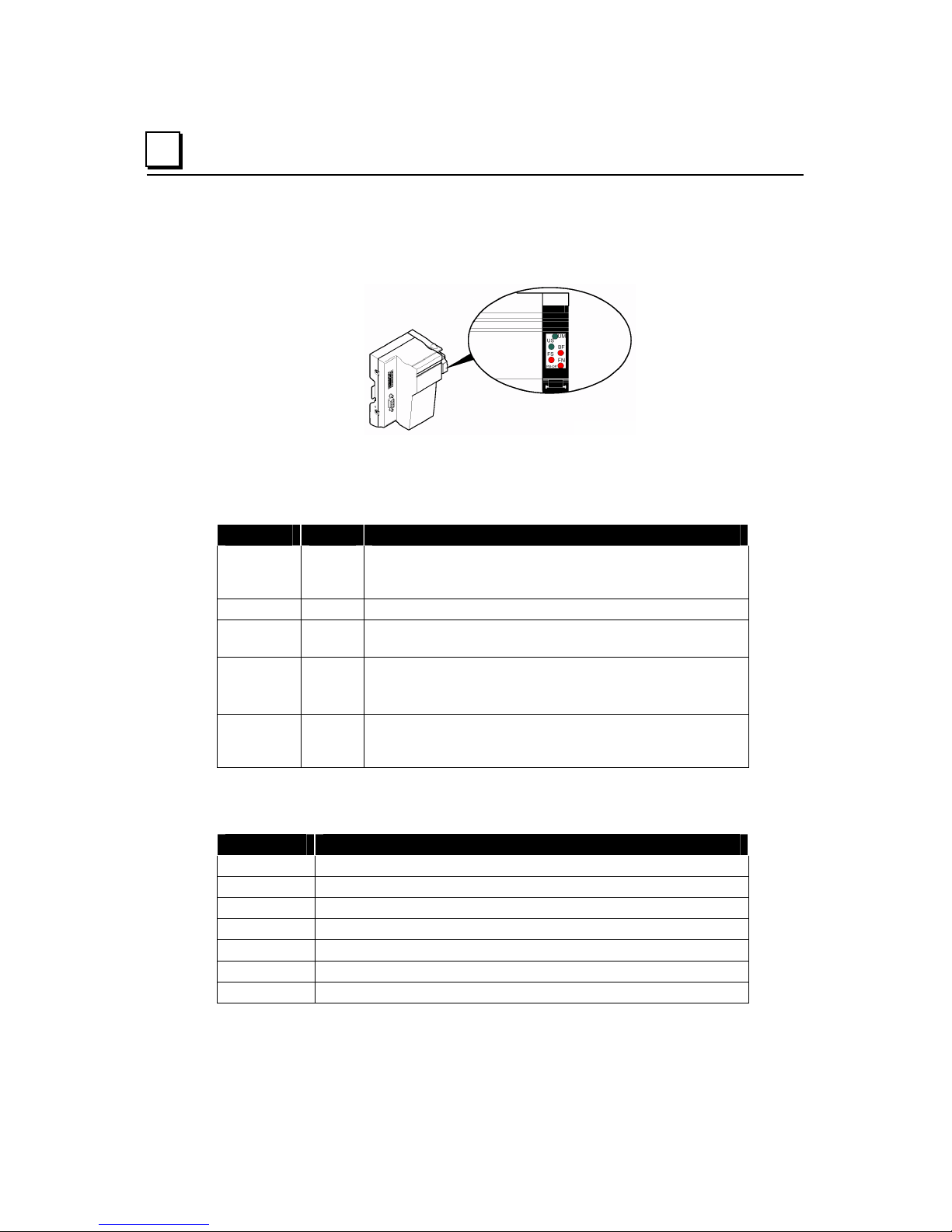

LEDS on the NIU............................................................................................................. 2-10

DPV1 Communications for Profibus NIU

IC220PBI002 ................................................................................................................... 2-11

NIU Specifications ........................................................................................................... 2-12

Chapter 3 VersaPoint Modules............................................................................... 3-1

Modules in a VersaPoint Station ....................................................................................... 3-2

Input/Output Modules ............................................................................................... 3-3

Terminal Points......................................................................................................... 3-3

Power Losses for I/O Modules ................................................................................. 3-4

Analog Modules ........................................................................................................ 3-5

Power Terminal Modules .......................................................................................... 3-6

Segment Terminal Modules ..................................................................................... 3-7

Parts of a VersaPoint Module ........................................................................................... 3-8

The Electronics Base ........................................................................................................ 3-9

Diagnostic and Status Indicators ............................................................................ 3-10

Module Color Coding.............................................................................................. 3-10

Status LEDs and I/O Points.................................................................................... 3-11

GFK-1911B v

Page 6

Contents

Connectors .............................................................................................................3-12

Module Dimensions......................................................................................................... 3-14

Chapter 4 Installation.............................................................................................. 4-1

Parts of a VersaPoint I/O Station ...................................................................................... 4-2

End Plate .................................................................................................................. 4-2

End Clamps .............................................................................................................. 4-2

Planning Module Sequence in the I/O

Station ............................................................................................................................... 4-3

Locations for Analog Modules .................................................................................. 4-3

Power for the Station......................................................................................................... 4-4

Electrical isolation ..................................................................................................... 4-5

Dangerous voltage! .................................................................................................. 4-5

Setting the NIU Switches .................................................................................................. 4-6

Keying Connectors and Modules ...................................................................................... 4-7

Installing Modules on the DIN Rail .................................................................................... 4-8

Removing Modules................................................................................................... 4-9

Replacing a Module .................................................................................................. 4-9

Connecting Unshielded Cables....................................................................................... 4-10

Connecting Shielded Cables........................................................................................... 4-11

Connecting Shielded Cables to the Shielded Terminal Strip ................................. 4-11

Repositioning the Shield Clamp .............................................................................4-12

Grounding........................................................................................................................ 4-13

Grounding the NIU and Power Modules................................................................. 4-13

Required Additional Grounding .............................................................................. 4-13

Installing the Profibus Cable ........................................................................................... 4-14

Profibus Cable Specifications................................................................................. 4-14

The Profibus Cable Connector ............................................................................... 4-15

Shielding the Profibus Cable .................................................................................. 4-15

Bus Termination ..................................................................................................... 4-16

Connecting Power at the NIU.......................................................................................... 4-17

Providing the 24V Segment Supply (US ) at the NIU ............................................. 4-17

Fusing for Short Circuit Protection ......................................................................... 4-17

Replacing Power and Segment Terminal

Fuses............................................................................................................................... 4-18

Connecting Sensors and Actuators................................................................................. 4-19

Connecting Discrete Devices .................................................................................4-19

Connections for Discrete Input Modules ................................................................ 4-19

Connections for Discrete Output Modules.............................................................. 4-19

Connecting 2-Wire Discrete Sensors and Actuators .............................................. 4-20

Connecting 3-Wire Discrete Sensors and Actuators .............................................. 4-20

Connecting 4-Wire Discrete Sensors and Actuators .............................................. 4-21

vi VersaPoint™ I/O System Profibus-DP NIU User’s Manual– August 2005 GFK-1911B

Page 7

Contents

Connecting Analog Devices ...................................................................................4-22

Connecting Field Devices to an Analog Input Module ........................................... 4-22

Connecting a Thermocouple Analog Input Module ................................................ 4-22

Connecting Field Devices to an Analog Output Module......................................... 4-23

Danger of creating ground loops! ........................................................................... 4-23

Connection of actuators for Signal Cables Longer than 10 Meters (32.8

Ft) ........................................................................................................................... 4-23

Module Labeling .............................................................................................................. 4-24

Chapter 5 Power for the Station............................................................................. 5-1

Supply of the Profibus-DP Network

Interface Unit .....................................................................................................................5-2

The Logic Circuit: UL................................................................................................. 5-3

The Analog Circuit: U

The Main Circuit: UM................................................................................................. 5-4

Segment Circuit: US.................................................................................................. 5-5

Electrical Isolation ............................................................................................................. 5-8

Electrical Isolation: Profibus ..................................................................................... 5-8

Electrical Isolation: I/O.............................................................................................. 5-8

Electrical Isolation: Discrete Modules....................................................................... 5-9

Electrical isolation: Analog module......................................................................... 5-10

Electrical isolation: Other ........................................................................................ 5-11

VersaPoint Power Consumption Example ...................................................................... 5-12

........................................................................................... 5-3

ANA

Chapter 6 Diagnostics ............................................................................................ 6-1

Local Diagnostics .............................................................................................................. 6-2

LEDS on the Network Interface Unit ........................................................................ 6-2

Possible LED combinations...................................................................................... 6-3

Determining the Error Cause and Remedy from the NIU LEDs ............................... 6-4

Power and Segment Module LEDs ........................................................................ 6-10

I/O Module LEDs ....................................................................................................6-11

Local Diagnostics Example .................................................................................... 6-12

Example Station for Error Identification.................................................................. 6-12

Diagnostics on the Profibus Master ................................................................................ 6-14

Profibus Standard Diagnostics ............................................................................... 6-14

Profibus – Device-Specific Diagnostics (For NIU Model IC670PBI002) ................ 6-17

Profibus – Device-Specific Diagnostics (For NIU Model IC670PBI001) ................ 6-18

Module Diagnostics, NIU Model IC670PBI002 ...................................................... 6-19

Chapter 7 Configuration ......................................................................................... 7-1

Powerup Autoconfiguration of the NIU.............................................................................. 7-2

Configuration of the Profibus Master ................................................................................ 7-3

The GSD File............................................................................................................ 7-3

GFK-1911B Contents vii

Page 8

Contents

Configuring the Profibus Master ............................................................................... 7-3

Configuring Profibus Parameters for the Profibus Master CPU ............................... 7-5

Network Settings for the Profibus Master................................................................. 7-6

Adding the Profibus NIU to the

IC693CPU366 Master Configuration ................................................................................ 7-8

Configuring the Modules in the I/O Station ....................................................................... 7-9

Configuring Module Data Areas ............................................................................. 7-10

Byte Rotation for 16-Point Discrete Modules ......................................................... 7-12

Byte Rotation for 32-Point Discrete Modules ......................................................... 7-12

Configuring DP-V1 Settings for the Profibus NIU................................................... 7-13

Dynamic Configuration .................................................................................................... 7-16

Indexes ................................................................................................................... 7-16

Index 6: Activation/deactivation of terminals and slots Access: Read and write................ 7-16

Index 7: Read back active/inactive terminals and slots .................................................. 7-17

Index 8: Read/write ID Access: Read and write ............................................................ 7-17

Accessing the Indexes via Process Data ...............................................................7-17

Specify an ID .......................................................................................................... 7-20

Chapter 8 Communications.................................................................................... 8-1

Types of Acyclic Communication ...................................................................................... 8-2

Acyclic Communication Via the Class 1 Master ....................................................... 8-2

Acyclic Communication Via the Class 2 Master ....................................................... 8-2

PCP Communication Basics ............................................................................................. 8-3

Device Parameter Data ............................................................................................8-3

Acyclic Communication in DP/V1 Mode............................................................................ 8-4

Accessing NIU Data ................................................................................................. 8-5

Accessing Module Data............................................................................................ 8-5

DP/V1 Examples ...................................................................................................... 8-9

PCP Communication Via Process Data

(Class1 Master in DP/V0 Mode)...................................................................................... 8-17

Mechanism for Transmission in the Process Data ................................................. 8-17

Process Data Width of the Virtual C1 “Module” ..................................................... 8-17

Responses.............................................................................................................. 8-21

Examples of Communications using a Virtual C1 Module ..................................... 8-22

Format of the Parameter Telegram................................................................................. 8-29

NIU Parameters...................................................................................................... 8-29

Module Parameters ................................................................................................8-30

Object Dictionary for the Profibus-DP/V1 NIU........................................................ 8-31

Error Codes for DP/V1 and VC1

Communication ............................................................................................................... 8-35

Error Codes for PCP Communication .................................................................... 8-36

Other Error Messages ............................................................................................ 8-36

viii VersaPoint™ I/O System Profibus-DP NIU User’s Manual– August 2005 GFK-1911B

Page 9

Contents

Appendix A Reference Data.......................................................................................A-1

I/O Station Information ......................................................................................................A-2

Ambient Conditions ...........................................................................................................A-3

Mechanical Demands........................................................................................................A-4

Noise Immunity Test .........................................................................................................A-4

Electrical Specifications ....................................................................................................A-5

Cables ...............................................................................................................................A-7

I/O Modules .......................................................................................................................A-7

Air and Creepage Distances .............................................................................................A-8

Test Voltages ....................................................................................................................A-9

Appendix B Glossary .................................................................................................B-1

Appendix C Output Module Derating ........................................................................C-1

Power Loss of the Housing Within the

Operating Temperature Range Depending

on the Ambient Temperature ............................................................................................C-2

Power Loss of the Housing ...............................................................................................C-3

Permissible Operating Temperature Range .....................................................................C-4

Appendix D The NIU GSD File ...................................................................................D-1

GSD File for NIU Version IC220PBI002 ...........................................................................D-2

GSD File for NIU Version IC220PBI001 .........................................................................D-21

GFK-1911B Contents ix

Page 10

Contents

x VersaPoint™ I/O System Profibus-DP NIU User’s Manual– August 2005 GFK-1911B

Page 11

Chapter

1

Introduction

The VersaPoint product family is a modular automation system. With

VersaPoint modules you can easily add one module to the next and build

functional units that meet your automation requirements exactly.

A set of interconnected VersaPoint I/O modules can be selected to suit the

application, and connected as a slave on a Profibus-DP network. The

interface between the network and the modules is a VersaPoint Profibus-DP

Network Interface Unit (NIU).

The NIU is located to the left of the other modules. Together, the NIU and

the modules selected for the application function as an I/O Station. The I/O

Station can include up to 63 I/O modules.

Within the VersaPoint station the bus connection, power supply, and power

distribution for the devices connected to the bus terminal are realized by

connecting modules together on the DIN rail.

Sensors and actuators are easily wired to the VersaPoint I/O modules via

spring-clamp terminals on the modules' removable connectors. These

connectors can be keyed so that they cannot be mixed up. If a module must

be exchanged the wiring does not need to be removed. Just remove the

connector from the terminal.

GFK-1911B 1-

1

Page 12

1

Features

Advantages

Characteristic VersaPoint features are:

– Modules can be easily installed/interconnected without tools.

– Automatic creation of isolated groups, current, data, and safety circuits

– Open, flexible, and modular structure

– Modules of varying point counts can be combined to create a

VersaPoint station that optimizes unit space while minimizing unit cost.

VersaPoint design offers the following advantages:

– Reduced control cabinet space.

– The amount of costly parallel wiring is reduced. Within a station, voltage

and data routing can be carried out without additional wiring.

– The modular structure makes it possible to assemble standard function

blocks in advance. Different parts of the system can be operated

independently of one another. This means that pretests can be carried

out when the system is set up and that the whole system can be

adapted and expanded.

I/O Station Capacity

– Up to 63 devices can be connected to an NIU (Depending on power

consumption. See chapter 5).

– The sum of all input and output data can be up to 184 bytes per station.

1-2 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 13

What’s In This Manual

This manual contains the instructions and reference information needed to

plan and install a VersaPoint I/O Station on a Profibus-DP network.

Chapter 1 is a quick introduction to VersaPoint.

Chapter 2. The Profibus NIU, describes the Profibus Network Interface

Unit module, which connects the VersaPoint I/O Station to the Profibus

network.

Chapter 3. VersaPoint Modules, describes the parts and dimensions of

VersaPoint I/O and power modules.

Chapter 4. Installation, describes basic VersaPoint module installation

and cable connections.

Chapter 5 Power for the Station, explains how power is utilized by the

station and routed among the modules.

Chapter 6. Diagnostics, describes in detail the indications of the NIU and

module LEDs, as well as additional diagnostics features of the VersaPoint

station.

Chapter 7. Configuration, describes the configuration options of the

VersaPoint Profibus NIU.

Chapter 8. Communications, describes the data structures used for

communications with the Profibus NIU.

Appendix A. Reference Data, summarizes the standard data for a

VersaPoint Profibus I/O system..

Appendix B. Glossary explains many of the terms used in this manual.

Appendix C. Output Module Derating, describes how to calculate power

loss and operating temperature limits for I/O modules.

1

GFK-1911B Chapter 1 Introduction 1-3

Page 14

1

Other Documents You’ll Need

These documents are available online at http://www.ge-ip.com/, and on the

Infolink for PLC document library on CDs (catalog number IC690CDR002).

Check the GE website for the most up-to-date document versions

and other important product information.

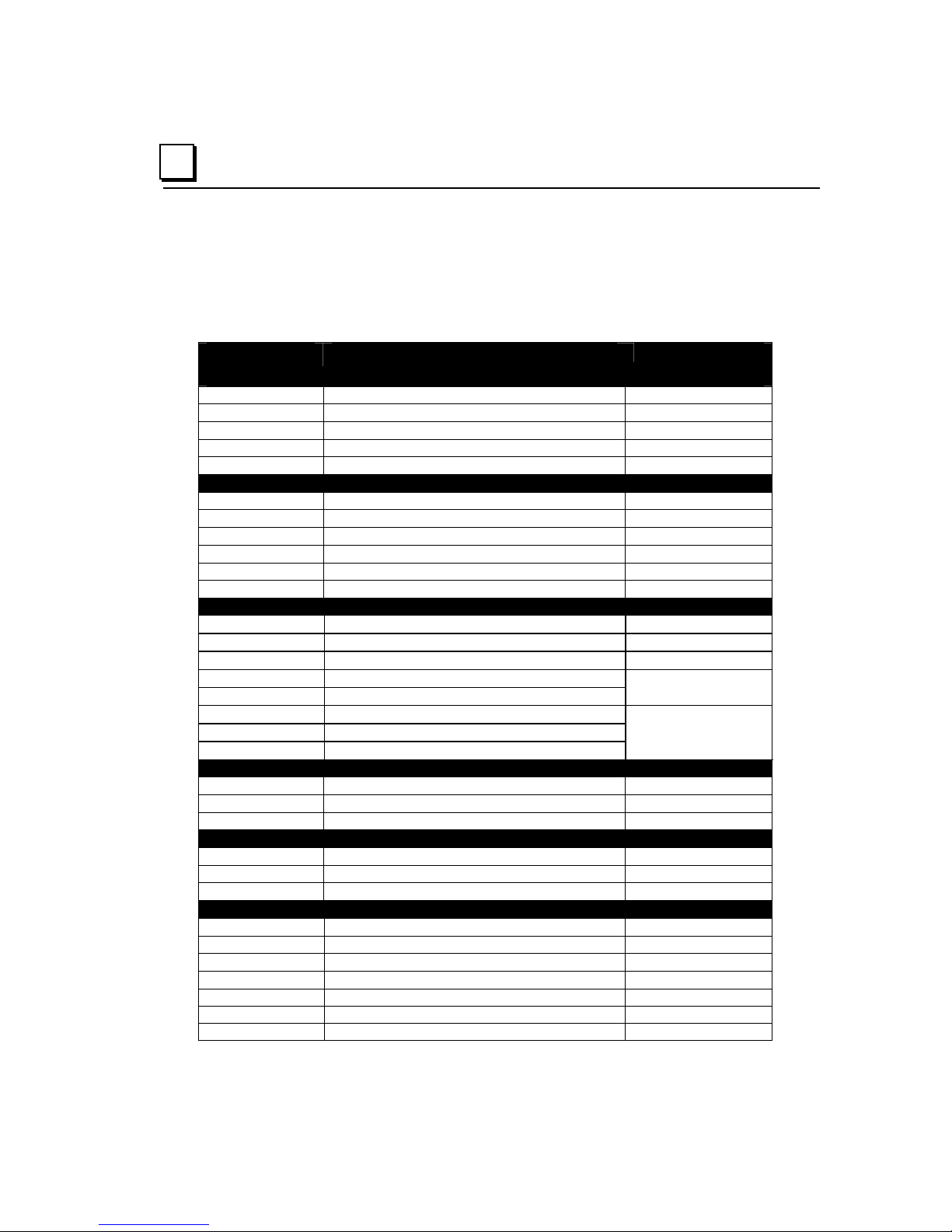

Module Number Module Description Document Number

Discrete Input Modules

IC220MDL641 Input 24VDC Positive Logic 2 Points GFK-1901

IC220MDL642 Input 24VDC Positive Logic 4 Points GFK-1902

IC220MDL643 Input 24VDC Positive Logic 8 Points GFK-2000

IC220MDL644 Input 24VDC Positive Logic 16 Points GFK-2001

IC220MDL661 Input 24VDC Negative Logic 2 Points GFK-2002

Discrete Output Modules

IC220MDL721 Output 24VDC Positive Logic 2.0A 2 Points GFK-1903

IC220MDL751 Output 24VDC Positive Logic 0.5A 2 Ppoints GFK-2003

IC220MDL752 Output 24VDC Positive Logic 0.5A 4 Points GFK-1904

IC220MDL753 Output 24VDC Positive Logic 0.5A 8 Points GFK-2004

IC220MDL754 Output 24VDC Positive Logic 0.5A 16 Points GFK-1913

IC220MDL761 Output 24VDC Positive Logic 0.5A 2 Points GFK-2005

Special Function Modules

IC220BEM232 RS-232 Communications Module GFK-2394

IC220BEM485 RS-485/422 Communications Module GFK-2395

IC220MDD840 High-speed Counter 1 In/1 Out 24VDC GFK-2052

IC220MDD841 Absolute Encoder Module

IC220MDD842 Incremental Encoder Module

IC220STR001 Motor Starter Direct, 1.5KW/400VAC

IC220STR002 Motor Starter Direct, 3.7KW/400VAC

IC220STR003 Motor Starter Reversing

Analog Input Modules

IC220ALG220 Analog In 15 Bit Voltage/Current 2 Channels GFK-1906

IC220ALG620 Analog In 16 Bit RTD 2 Channels GFK-2013

IC220ALG630 Analog In 16 Bit Thermocouple 2 Channels GFK-2012

Analog Output Modules

IC220ALG320 Analog Out 16 Bit Voltage/Current 1 Channel GFK-1907

IC220ALG321 Analog Out 13 Bit Voltage 1 Channel GFK-1908

IC220ALG322 Analog Out 13 Bit Voltage 2 Channels GFK-2011

Power and Segment Terminals

IC220PWR001 Power Terminal 24VDC GFK-1909

IC220PWR002 Power Terminal Fused 24VDC GFK-2006

IC220PWR003 Power Terminal Fused with Diag. 24VDC GFK-2007

IC220PWR011 Segment Terminal 24VDC GFK-1910

IC220PWR012 Segment Terminal Fused 24VDC GFK-2008

IC220PWR013 Segment Terminal Fused W/Diag 24vdc GFK-2009

IC220PWR014 Segment Terminal Elec Fused 24vdc GFK-2010

GFK-2125

GFK-2134

1-4 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 15

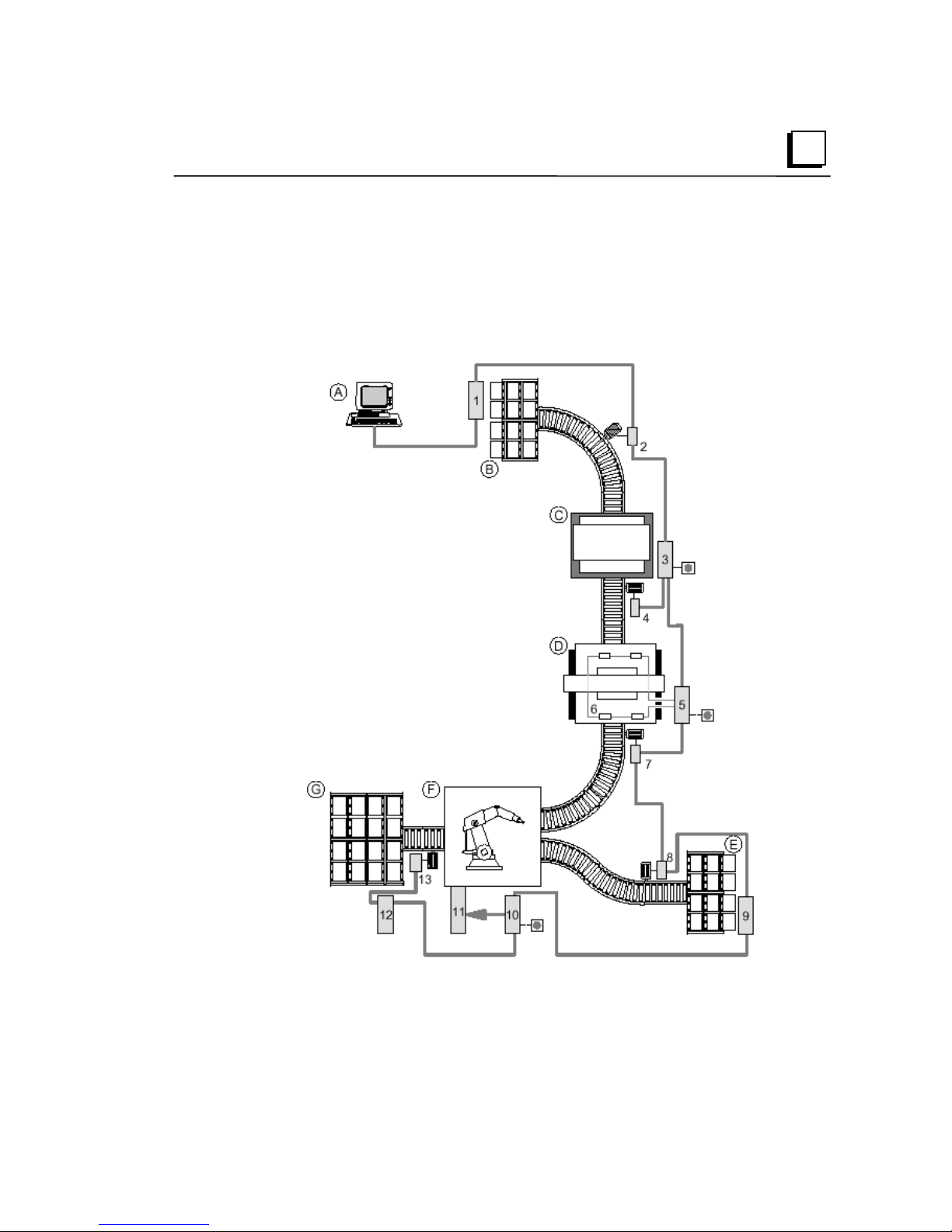

Example Plant

The following example provides an illustration of how the VersaPoint I/O

System may be applied. This example highlights the distributed nature of

the VersaPoint product line as well as its ability to fit a variety of difficult

applications within a single system.

1

GFK-1911B Chapter 1 Introduction 1-5

Page 16

1

Key:

A Plant control

B Material removal area 1

C Press

D Punching device

E Material removal area 2

F Welding robot

G Material area 3

1, 3, 5, 6, 9, 10, 12 VersaPoint™ stations

2, 4, 7, 8,13 Motor starter

11 Robot controller

Emergency stop switch

This example is a schematic diagram of a plant which is controlled by a host

computer.

VersaPoint station 1 modules control the removal of material from area 1.

The motor starter (2) is directly connected to the remote bus. This controls a

conveyor belt motor.

VersaPoint station 3 controls the press. As this machine must be

particularly well protected, an emergency stop switch has been integrated.

VersaPoint station 5 controls the punching device. Station 6 is connected to

station 5, and its modules monitor the status of the press. An emergency

stop switch has also been provided here.

Two motor starters are connected at points (7) and (8). They control

conveyor belt motors.

VersaPoint station 9 controls the removal of material from area 2.

A robot control system (11) is connected to the communications bus using

VersaPoint station 10. An emergency stop switch has also been connected

here.

VersaPoint station 12 controls the storage of material in area 3.

Motor starter 13 is directly connected to the remote bus and controls the

conveyor belt motor.

1-6 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 17

Chapter

2

The Profibus NIU

This section describes the Profibus Network Interface Unit module IC220PBI002.

▪ The Profibus System

▪ Typical Profibus-DP VersaPoint I/O Station

▪ Structure of a VersaPoint I/O Station

▪ The Profibus-DP Network Interface Unit

▪ Features

▪ Items Used with the NIU

▪ Ordering Information

▪ Connectors on the NIU

▪ Profibus Connector

▪ Power Connector

▪ DIP Switches on the NIU

▪ LEDs on the NIU

▪ Diagnostics

▪ NIU Specifications

GFK-1911B 2-1

Page 18

2

The Profibus System

Profibus is a serial bus system for data transmission between control systems and

distributed input and output modules, to which sensors and actuators are

connected.

Profibus has a star tree structure. In the Profibus topology the single bus devices

can be differentiated by means of their addressing. The communication profiles

determine how the devices transmit their data via the bus.

Profibus DP is normally a single master system. It is designed for easy

transmission of input and output data and specifically designed for communication

between automation systems and the distributed I/O devices.

Typical Profibus-DP VersaPoint I/O Station

A set of interconnected VersaPoint I/O modules can be selected to suit the

application, and connected as a slave on a Profibus-DP network. The interface

between the network and the modules is a VersaPoint Profibus-DP Network

Interface Unit (NIU) module.

The intelligent wiring method used in the VersaPoint modules allows I/O stations

to be constructed easily and quickly. Normally, it is only necessary for the power

supply units integrated in the Profibus NIU to be supplied with 24VDC on the input

side. They generate the operating voltage required for the NIU itself and for the

connected VersaPoint I/O modules.

2-2 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 19

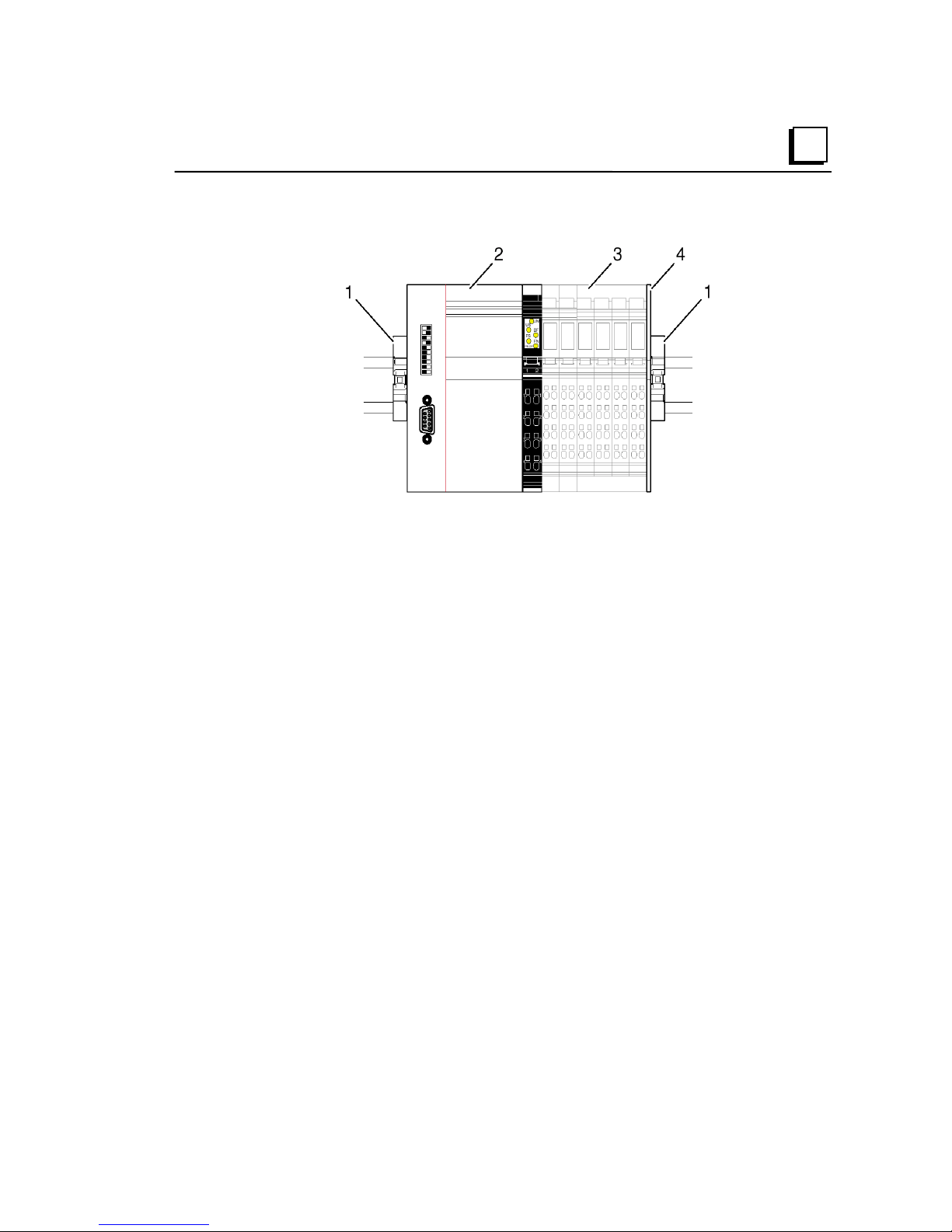

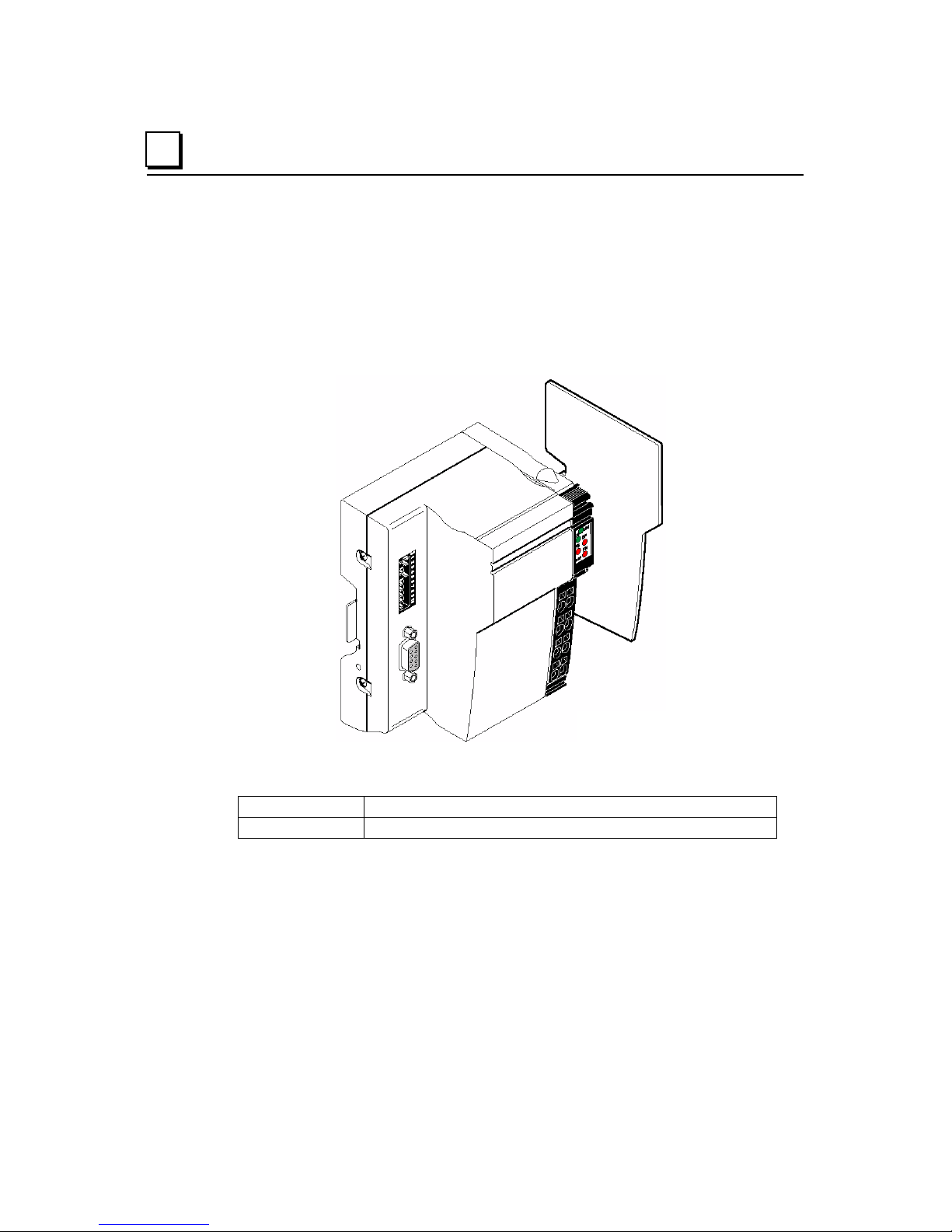

Structure of a VersaPoint I/O Station

2

A VersaPoint station with a Profibus NIU consists of:

– (1) End clamps (part number IC220ACC313, supplied with the NIU)

– (2) Profibus-DP Network Interface Unit

– (3) Modules appropriate to the application

– (4) End plate (supplied with the NIU)

GFK-1911B Chapter 2 The Profibus NIU 2-3

Page 20

2

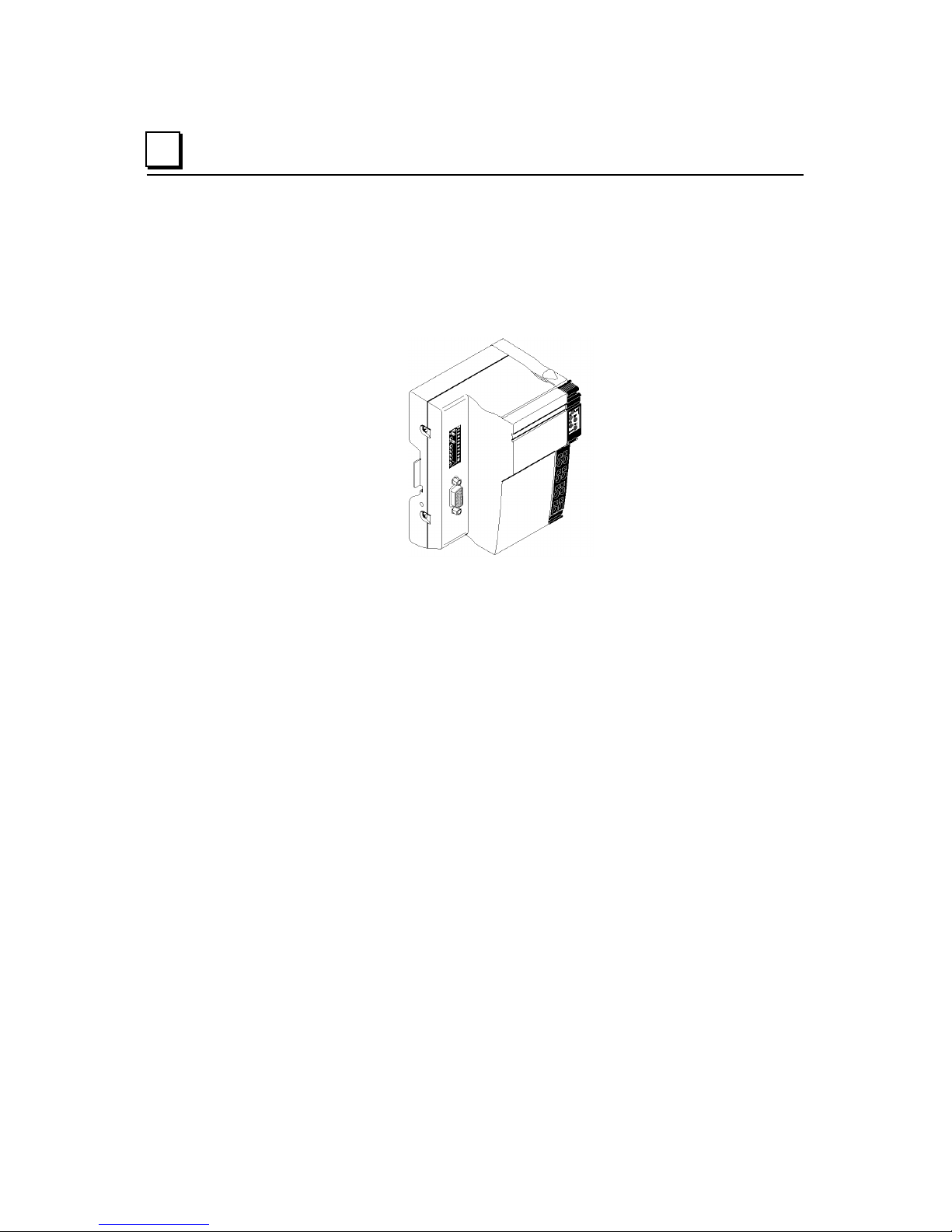

The Profibus-DP Network Interface Unit

The VersaPoint ™ Profibus-DP Network Interface Unit (NIU), IC220PBI002, is the

link between Profibus-DP and the VersaPoint station. This module is an enhanced

version of the earlier Profibus-DP Network Interface Unit module IC220PBI001,

which it replaces. Differences between the two versions are explained below.

Features

The Profibus-DP Network Interface Unit has the following properties:

– A maximum of 63 VersaPoint I/O modules can be connected to Profibus DP

by simply plugging them in side by side next to the NIU. The NIU and the

VersaPoint modules create a station. Check chapter 5 to verify power

consumption.

– The sum of all input and output data can be up to 176 bytes per station for

module IC220PBI002 with its DIP switch 8 in the ON position. The maximum

is 184 bytes per station with DIP switch 8 in the OFF position. The maximum

for module IC220PBI001 is 184 bytes.

– The NIU can be used at a baud rate of 9.6 kbps for Profibus DP with a

maximum total expansion of 1200m (3937ft) or at baud rate of 12mbps with a

maximum of 100m (328 ft). The NIU automatically adjusts to the speed

specified by the Profibus master.

– Model IC220PBI002 also provides:

– DP/V1for Class 1 and Class 2 masters.

– Acyclic communications with modules such as RS-232 modules in the

process data channel.

– Fail-safe values

– Acknowledgement of I/O errors from the user program.

– Adaptation of the high byte/low byte format in 16-channel input and output

modules.

2-4 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 21

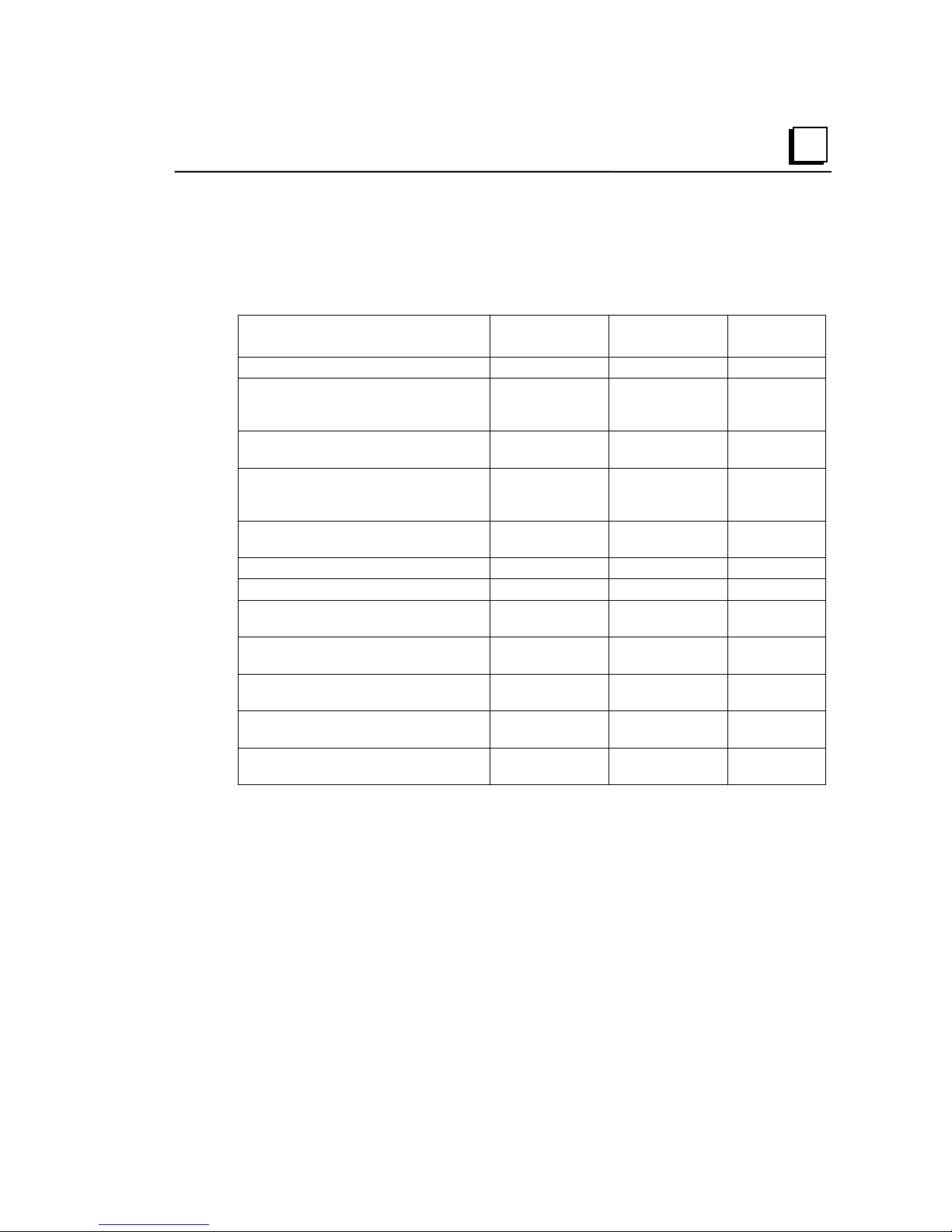

Comparison of Features

The table below compares features of module IC220PBI02 in DP/V1 mode or

DP/V0 mode (as selected with DIP switch 8) with the features of module

IC220PBI001.

2

Feature IC220PBI002 in

DP/V1 mode

PCP module operation x x -

DPV1 Read and DP/V1 Write support

(acyclic communication) Class 1 and

Class 2 masters

Communication with PCP modules

via normal process data (DP/VO)

Byte rotation for 16-point input and

output modules for adaptation to the

control system format

Byte rotation for 32-point input and

output modules

Acknowledgement of bus stops x x -

Acknowledgement of I/O errors x x -

Stop response can be set with DIP

switch

Stop response can be set with

parameter telegram

Assignable station ID firmware rev. B

Failsafe values even without

connection to the PLC

Improved I/O diagnostics during

startup

x - -

x x -

x x -

firmware rev. B

or later

- - x

x x -

or later

firmware rev. B

or later

firmware rev. B

or later

IC220PBO002

in DP/V0 mode

firmware rev. B

or later

- -

- -

- -

IC220PB001

-

GFK-1911B Chapter 2 The Profibus NIU 2-5

Page 22

2

Items Used with the NIU

The Profibus NIU comes with an end plate, the latest GSD file, and one set of end

clamps.

The end plate is installed at the end of the VersaPoint station, after the last

module. It protects the station from electrostatic discharge and the user from

dangerous voltage.

The power connector is ordered separately. See the ordering information below.

Ordering Information

IC220PBI002 Profibus Network Interface Unit (replaces model IC220PBI001)

IC220TBK087 Power connector (quantity 10)

2-6 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 23

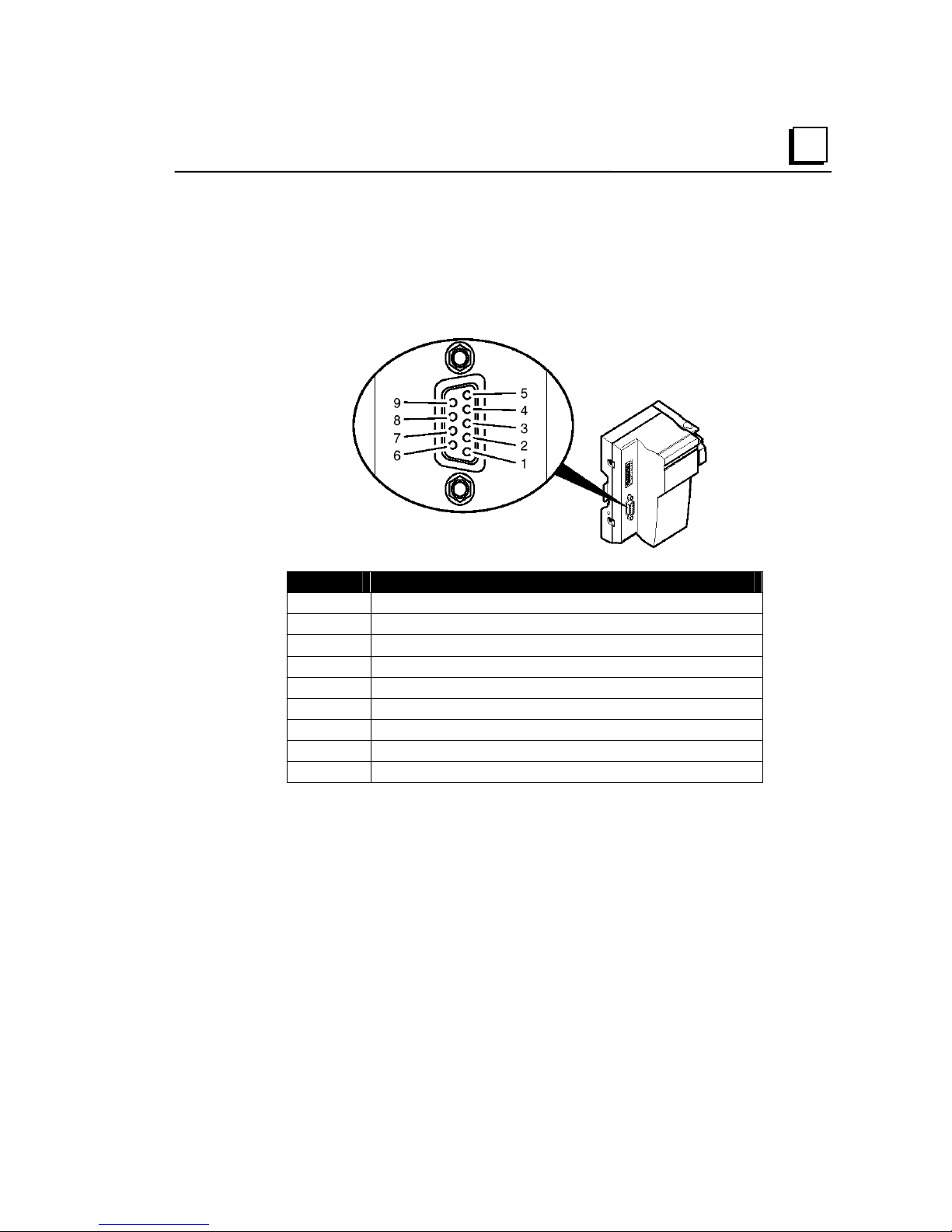

Connectors on the NIU

Profibus Connector

A 9-position, D-SUB connector connects the NIU to the Profibus cable.

2

Pin Assignment

1 Reserved

2 Reserved

3 RxD/TxD-P (+ receive/send data), cable B

4 CNTR-P (control signal for repeater), direction control

5 DGND (reference potential up to 5 V)

6 VP (supply voltage +5 V for terminal resistors)

7 Reserved

8 RxD/TxD-N (– receive/send data), cable A

9 Reserved

Line Terminal Resistors

Since Profibus is a serial bus system in a star-tree structure, the individual

branches must be terminated with a terminal resistor. The NIU does not have an

integrated resistor of this type. Many Profibus connectors are available with an

integrated, switchable resistor. Please contact your GE Intelligent Platforms

dist

ributor to determine availability.

GFK-1911B Chapter 2 The Profibus NIU 2-7

Page 24

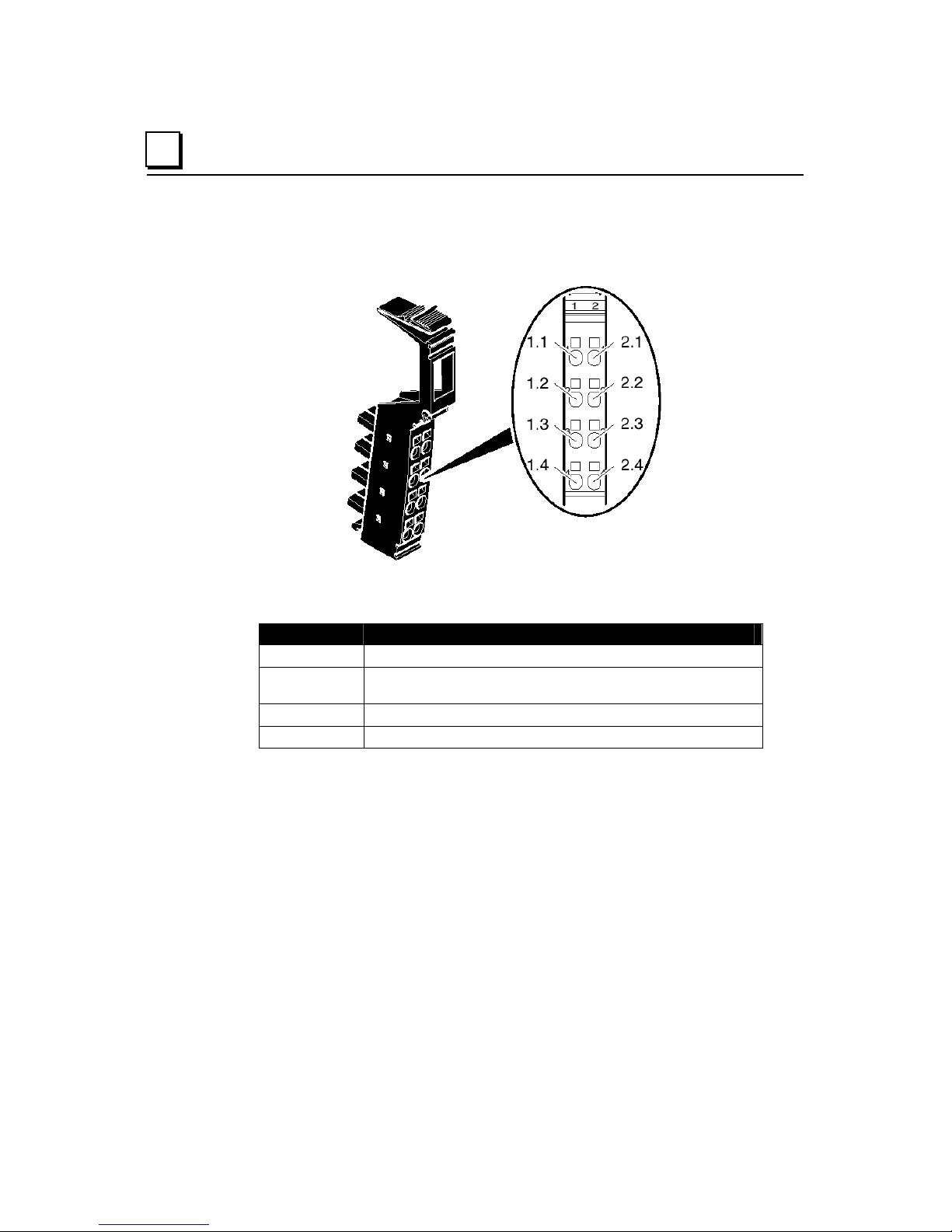

2

Power Connector

A power connector (IC220TBK087), ordered separately, is used to make power

and ground connections to the NIU.

Pin assignments for this connector are listed below:

Assignment of the NIU terminal points

Terminal Assignment

1.1, 2.1

1.2, 2.2

1.3, 2.3

1.4, 2.4

Segment supply (+24VDC)

Main supply, NIU supply, communications power and

interface supply (+24VDC)

Reference potential

Functional earth ground (FE)

NIU Power

The NIU acts as a power terminal, supplying the logic and module power for some

or all of the of the I/O modules in the station, as well as the sensors and actuators.

Some stations will also use additional power/segment terminals, depending on the

needs of the application. See chapter 5 for additional details.

2-8 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 25

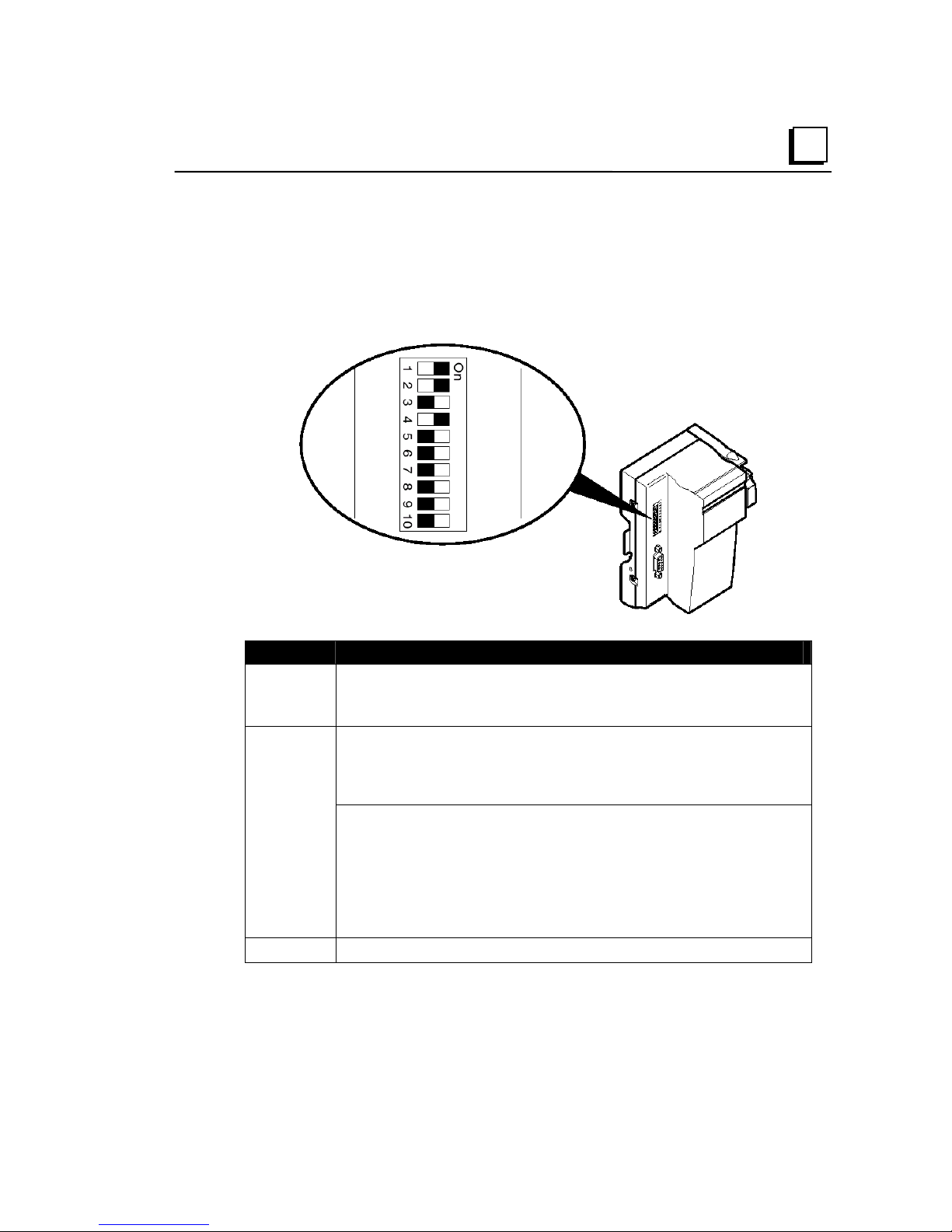

DIP Switches on the NIU

The 10-position DIP switch on the NIU module is used to set the Profibus address.

In addition, switch 8 can be used to select the operating mode of Profibus NIU

IC220PBI002. For model PBI001, the same switch specifies the error response of

the NIU.

2

Switches Meaning

1 to 7 Profibus Address in binary format (= 0 to 127 in decimal format)

0

) and

6

).

8

9 to 10

Switch 1 defines the least significant bit (2

switch 7 defines the most significant bit (2

For Module IC220PBI002: Sets the operating mode. With this switch in

the Off position (the default), this module can directly replace module

version IC220PBI001.

With this switch in the On position, this module operates in DP/V1 mode.

For Module IC220PBI001: Behavior if a data error occurs in the station

(local bus error):

ON = data transmission is stopped after a number of attempts.

OFF = the station constantly attempts to start data transmission.

If DIP switch 8 is in the ON position, a POWER DOWN/POWER UP must

be executed on the NIU so that it will restart. There is no automatic

restart after the error has been removed.

Reserved, both switches must be in the OFF position.

GFK-1911B Chapter 2 The Profibus NIU 2-9

Page 26

2

LEDS on the NIU

The diagnostic LEDs on the NIU indicate the type and location of errors.

The module is functioning correctly if all of the green LEDs are on.

Once errors have been removed, the indicators immediately display the current

status.

NIU LED Color Meaning

UM Green On = supply voltage in the main circuit for the NIU,

communications power and interfaces present. Off = main

circuit supply not present.

US Green On = 24 V segment circuit supply present

BF Red On = No communication on Profibus. Off = no error.

Flashing = PLC stopped, outputs default to safe values.

FS Red Defines the function of the FN LED:

FS ON: FN indicates the type of error.

FS OFF: FN indicates the error number

FN Red Off = no error. If flashing, the number of pulses indicates

the type of error or the error number, depending on

whether FS is on or not

Diagnostics

The NIU provides the following standard Profibus and device-related diagnostics.

Error Type Meaning

1 Parameter error on Profibus (SET_PRM telegram)

2 Configuration error on Profibus (CHK_CFG telegram)

3 Configuration error in the station

4 Error within the station

5 Module error

6 Parameter error on local bus

7 EEPROM error

2-10 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 27

DPV1 Communications for Profibus NIU IC220PBI002

If the DP/V1 communications features of Profibus NIU IC220PBI002 are enabled

by configuration and if DIP switch 8 on the module is set to the On position, the

NIU supports enhanced DP/V1 communications with the master.

DP/V1 expands the cyclic data exchange function according to IEC 61158 to

include acyclic services. This makes it easy to operate even complex devices.

The Profibus NIU prepares the data records, which are sent via DP/V1 from the

master, and provides them to the specified modules in the I/O Station. The NIU

converts data from the modules into DP/V1 telegrams for the Profibus master.

Masters with DP/V1 ability include the PACSystems RX3i Profibus Master Module,

IC695PBM300, and the Series 90-30 CPU model IC693CPU366. Both of these

masters can use three types of COMMREQ (Communications Request) functions

in the application program to communicate with the Profibus NIU:

DPV1 Read Request Performs a DPV1 read request from a slave device

(such as the Profibus NIU).

DPV1 Write Request Performs a DPV1 write request to a slave device.

DPV1 Alarm Request Acknowledges a DPV1 alarm request.

2

GFK-1911B Chapter 2 The Profibus NIU 2-11

Page 28

2

NIU Specifications

General

Housing dimensions

(width x height x depth)

Degree of protection IP 20 according to IEC 60529

Class of protection Class 3 according to VDE 0106, IEC 60536

System Information

Number of devices per station 63, maximum

Sum of all I/O data per station,

maximum

Maximum NIU current for supplying

the I/O module logic

Maximum additional current for

supplying the analog terminals

Profibus-DP Interface Copper cable (RS-485), connected via SUB-D

91mm x 120mm x 71.5mm

(2.874in. x 4.724in. x 2.795in.)

176 bytes for IC220PBI002 in DP/V1 mode.

184 bytes for IC220PBI001, or for PBI002 with

DIP switch 8 set for operation in PBI001 mode

2A at UL

0.5A at U

shield connector; supply electrically isolated,

shielding directly connected with functional earth

ground.

ANA

2-12 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 29

Chapter

3

VersaPoint Modules

This chapter describes the parts and dimensions of VersaPoint modules.

▪ Modules in a VersaPoint Station

▪ Parts of a VersaPoint Module

▪ The Electronics Base

▪ Diagnostics and Status Indicators

▪ Connectors

▪ Module Labeling

▪ Module Dimensions

GFK-1911B 3-1

Page 30

3

Modules in a VersaPoint Station

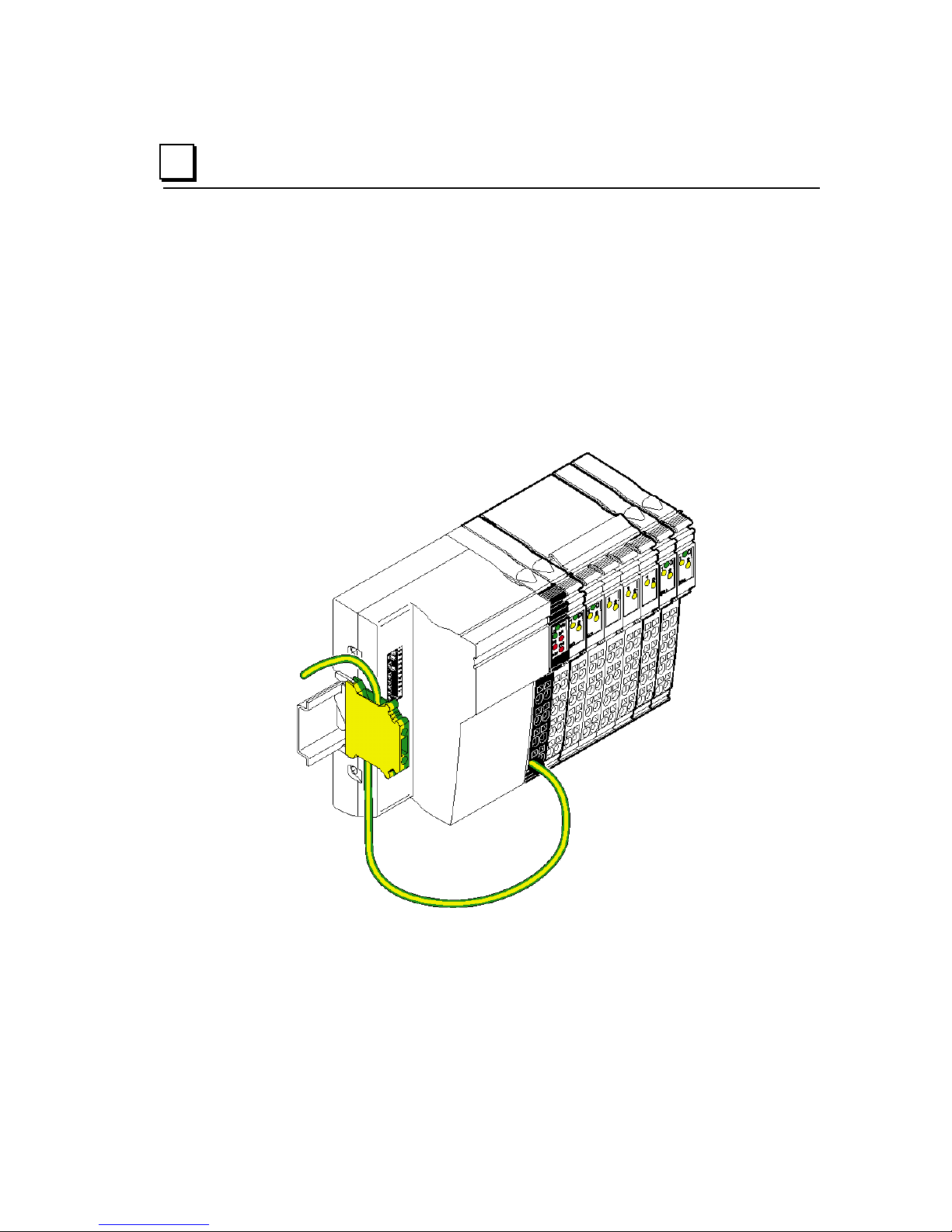

A VersaPoint I/O Station begins with a Network Interface Unit (NIU). The

NIU module is the first module on the DIN rail, at the left end of the I/O

Station. It is shown here with the required grounding to the DIN rail. See

chapter 2 for more information about the Profibus-DP Network Interface

Unit. The NIU performs all the data-handling and communications functions

for the I/O Station.

The rest of the station is made up of a group of I/O modules that can be

selected to exactly fit the needs of the application.

3-2 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 31

Input/Output Modules

Many different types of I/O modules are available. This enables you to build

the station in a modular way so that it meets the application’s requirements.

Example of a digital input module: IC220MDL642

3

Terminal Points

Depending on the module, input/output modules have terminal points to

accommodate 2-, 3-, and 4-wire sensors or actuators. Connections are

made to Terminal Strips, which are ordered separately.

Protection

For output modules, surge voltage protection is provided by a fuse in the

Power Terminal module, or by an external fuse. The value of the fuse must

be such that the maximum load current is not exceeded. For the maximum

permissible load current of an I/O module please refer to the module’s data

sheet.

LEDs

The diagnostic and status indicators on I/O modules provide information on

the status of inputs and outputs.

GFK-1911B Chapter 3 VersaPoint Modules 3-3

Page 32

3

Interfacing to Functional Earth Ground (FE)

There is no interfacing to functional earth ground (FE) in the module, i.e. no

direct connection is made with FE when the module is mounted on a

grounded DIN rail.

Grounding

A module is grounded via the voltage jumper FE when snapping it onto the

previous module. Additional I/O module grounding is not required.

Electrical Isolation

Electrical isolation is not provided by VersaPoint I/O modules. A Power

Terminal module must be used for this purpose.

Voltage Ranges

Low-level signal terminals are available for different voltage ranges. To

utilize different voltage ranges within a station, a new power terminal must

be used for each range.

Power Losses for I/O Modules

Power Loss of the Electronics

The electronics power loss of an I/O module can be calculated following the

formula in the module’s datasheet. The power loss of the module must not

exceed the power loss of the housing.

Power Loss of the Housing

The power loss of the housing indicates the maximum power loss allowed.

The maximum power loss is indicated in the module’s datasheet. This power

loss can be dependent or independent of the ambient temperature. If the

power loss of the housing depends on the ambient temperature, a

permissible operating temperature range can be calculated using the

formula in the module's datasheet.

Permissible Operating Temperature Range

Depending on the power loss of the housing and the power loss of the

electronics at a certain current, the temperature up to which the module can

be operated with this current can be calculated. Please see the module

datasheets for specific information.

See appendix C for example calculations.

3-4 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 33

Analog Modules

Shield

The connectors of analog modules have a special shield connection to

shield the cables.

Configuration

The modules for analog signals operate with a set of default parameters

unless they are reconfigured for the application. Each module’s defaults are

listed in its datasheet.

Diagnostics for Analog Input Modules

3

Analog input modules have overrange recognition in all measuring ranges.

Open circuit diagnostics are also available for some analog input modules. If

extended diagnostics are available for a specific module, they are listed in

the module’s datasheet. Analog error messages include:

▪ Under-range

▪ Open circuit

▪ Measured value invalid

▪ Configuration invalid

▪ Terminal defective

▪ Over-range.

GFK-1911B Chapter 3 VersaPoint Modules 3-5

Page 34

3

Power Terminal Modules

Power Terminal modules can be placed in an I/O Station to provide

additional power, to electrically isolate different circuits, or to create areas

with different voltages (ie: 24VDC versus 120VAC) within a station. Multiple

Power Terminal modules can be used in an I/O station.

A Power Terminal module supplies voltage for both the main circuit and the

segment circuit. See chapter 5 for more details.

Example: 24VDC Power Terminal

The main power circuit should be protected. If a protected Power Terminal

(IC220PWR002 or PWR003) is not used, the 24V supply must be externally

protected.

3-6 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 35

Segment Terminal Modules

Segment Terminal modules can be used to create a segment circuit within

the main circuit. The segment circuit allows the separate supply of power

outputs (e.g., motor contactors), digital actuators, and digital sensors. With a

segment terminal you can also control the segment circuit and switch it on

or off, e.g., using emergency stop loops. Segment Terminal modules can

only be used with 24V power.

3

Segment Terminals do NOT provide electrical isolation. A Power Terminal

module must be used for that purpose.

Segment terminals can only be used with 24V power.

The connection between the main circuit and the segment / auxiliary supply

requires a jumper wire or external switch. Segment terminals have terminal

points for the connection of a jumper or switch. When using a standard

segment terminal, (IC220PWR011), the segment circuit is not protected!

The 24V supply must be externally protected. See "Power Terminals".

Segment terminals with internal fuse protection (IC220PWR012, 013, and

014) are also available.

GFK-1911B Chapter 3 VersaPoint Modules 3-7

Page 36

3

Parts of a VersaPoint Module

A VersaPoint I/O or power module consists of an electronics base and plugin connector.

3-8 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 37

The Electronics Base

The electronics base holds the entire electronics for the VersaPoint module

and the voltage and data routing.

As all the modules are snapped onto the DIN rail, there is a secure interface

between the modules. Voltage and current for station operation are routed

through the jumpers on each module, which are indicated in the following

illustration. This functionality is explained in detail in chapter 5.

3

Built-in snapping mechanisms on the electronics base make it easy to install

on the DIN rail without the use of tools. (Please see the installation

instructions in chapter 4).

GFK-1911B Chapter 3 VersaPoint Modules 3-9

Page 38

3

Diagnostic and Status Indicators

All modules have diagnostic and status indicators for rapid local error

diagnostics.

The diagnostic indicators (red/green) indicate the status of the modules. A

module is operating normally if all its Diagnostic (D) LEDs are solid green.

The status indicators (yellow) display the status of the relevant

inputs/outputs for the connected device. LEDs are described in detail in

chapter 6.

Module Color Coding

The area surrounding each module's LEDs is color-coded to provide an

indication of the module's function. The following table explains this colorcoding.

Color Function

Gray Analog

Blue Digital - DC

Red Special function

Orange Digital mixed

Black Power terminal / segment terminal / NIU

3-10 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 39

Status LEDs and I/O Points

The illustration below shows the relationship between the status LEDs on a

module and the module inputs or outputs.

3

In general, an I/O module's status LEDs appear over their associated

terminals. In cases where two I/O points are terminated in the same column

(for 4 and 16 point modules), the LED's relative position (top or bottom)

indicates the I/O point it is associated with.

For a single-width module with 4 inputs or outputs (middle module in the

illustration above), the LEDs and terminal points are associated as follows:

LED 1 Terminal point 1.1

LED 2 Terminal point 2.1

LED 3 Terminal point 1.4

LED 4 Terminal point 2.4

On the four-slot module, LED 2 on slot 4 is indicated. The LED belongs to

input 14 on terminal point 4/2.1 (slot 4 / terminal point 2.1)

GFK-1911B Chapter 3 VersaPoint Modules 3-11

Page 40

3

Connectors

The connection of the I/O or supply voltages is made by using a connector

that can be plugged on or off the modules.

Connector Types

The following connector types are available:

(1) Standard connector (IC220TBK082, 085, 087)

The standard connector is used for the connection of two signals in 4-wire

format (e.g., digital input/output signals). The standard connector housing is

also used for power and segment terminals and relay terminals, although

the types are NOT interchangeable.

(2 )Shield connector (IC220TBK061)

This connector is used for signals connected using shielded cables (e.g.,

analog I/O signals, high-speed counter inputs, network cable). The FE or

shielding is connected by a shield clamp.

(3) Extended, connector (IC220TBK122, TBK123)

This connector is used for the connection of four signals in 3-wire format

(e.g., digital input/output signals).

Regardless of the width of the electronics base, the connectors are provided

with a standard width. Wider modules may require multiple connectors.

Connector Identification

Connectors have terminal points that are color coded corresponding to their

functions:

Color Terminal point signal

Red +

Blue –

Green Functional earth ground

3-12 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 41

3

Internal Structure of the Connector

A Standard connector (IC220TBK082, 085)

B Connector for power and segment terminals (IC220TBK087)

C Shield connector (IC220TBK061) for analog modules

D Extended connector (IC220TBK122, TBK123)

The dark lines shown on connectors B and D above indicate jumper

connections. These jumpers are internal to the connectors.

The shield connector is jumpered through the shield connection. All other

connectors are jumpered through module point connection.

To avoid a malfunction, only snap a suitable connector on a module that is

appropriate for this connector. Refer to the module-specific data sheet to

select the correct connectors.

A supply connector must not be placed on a module that is to be used

with an extended connector. This will cause a short circuit between

two signal module points (1.4 - 2.4).

Place only supply connectors on supply modules. Do not use the

standard connectors! When the terminal points are jumpered in the

supply connector, power is carried through the jumpering in the

connector and not through the printed circuit board of the module.

GFK-1911B Chapter 3 VersaPoint Modules 3-13

Page 42

3

Module Dimensions

The module dimensions are determined by the dimensions of the electronics

base and the dimensions of the connector.

When a connector is plugged in, each module depth is 71.5mm (2.795 in.).

The height of the module depends on the connector used.

Single Housing Double Housing Wide Housing Depth, All

Connector Dimensions

Key:

A. Standard connector (IC220TBK082, IC220TBK085, IC220TBK087)

B. Shield connector (IC220TBK061)

C. Extended connector (IC220TBK122, IC220TBK123)

The depth of the connector does not influence the overall depth of the

module.

3-14 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 43

Chapter

4

Installation

This chapter describes basic VersaPoint module installation and cable

connections. Please refer to chapter 5 for more information about power

connections for the I/O Station.

▪ Parts of a VersaPoint I/O Station

▪ Planning module sequence in the I/O Station

▪ Power for the station

▪ Setting the NIU switches

▪ Keying

▪ Installing modules on the DIN rail

▪ Removing modules

▪ Connecting unshielded cables

▪ Connecting shielded cables

▪ Grounding

▪ Connecting the Profibus cable at the NIU

▪ Connecting power at the NIU

▪ Replacing power and segment terminal fuses

▪ Connecting sensors and actuators

▪ Module labeling

GFK-1911B 4-

1

Page 44

4

Parts of a VersaPoint I/O Station

A VersaPoint station with a Profibus Network Interface Unit consists of:

– (1) End Clamps (supplied with NIU)

– (2) Profibus NIU

– (3) Modules appropriate to the application

– (4) End Plate (supplied with the NIU)

Mount modules side by side on a 35mm (1.378in.) standard DIN rail. No tools are

required.

Do not set up the station while the power is connected. Before setting up a

VersaPoint station or inserting a module, be sure the entire station is disconnected

from the power. Be sure the entire station is reassembled before switching power

on.

End Plate

The VersaPoint I/O Station must be terminated using the end plate that is supplied

with the Network Interface Unit module. The end plate does not have an electrical

function. It protects the station from ESD pulses and the user from dangerous

voltages.

End Clamps

Install end clamps on both ends of the station to hold it in place on the DIN rail.

End clamps are supplied with the NIU. If additional clamps are required, they are

available as GE

4-2 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Intelligent Platforms part num

ber IC220ACC313.

Page 45

Planning Module Sequence in the I/O Station

The NIU is the first module in the station. The sequence of the other modules

should be planned carefully. Within a main circuit, place the I/O modules with the

highest current consumption (U

) first. For example:

S

▪ Discrete output modules with 8-slot housings

▪ Discrete output modules with 2-slot housings

▪ Discrete input modules with 8-slot housings

▪ Discrete input modules with 2-slot housings

4

▪ Special-function modules

▪ Analog modules

This approach is advantageous in that the high supply current does not flow

through the entire main circuit.

Locations for Analog Modules

High current flowing through voltage jumpers UM and US increases the

temperature of the voltage jumpers and the inside of the module. Note the

following instructions to keep the current flowing through the voltage jumpers of

the analog modules as low as possible:

It is recommended that each analog module have a separate main circuit. If this is

not possible and it is necessary to use analog modules in a main circuit together

with other modules, place the analog modules at the end of the main circuit(to the

right of other modules).

This practice is particularly important for the thermocouple module IC220ALG630.

Internal module heating falsifies the temperature of the internal cold junction.

Therefore, position this module after all of the other modules to minimize the

current flowing through all voltage jumpers.

GFK-1911B Chapter 4 Installation 4-3

Page 46

4

Power for the Station

The Profibus NIU receives power from the Profibus connection. This Profibus

power supplies the NIU, and can also supply the logic and analog power for the

I/O Station. A station may also include one or more Power Terminal and Segment

Terminal modules. Power Terminal modules must be connected to external

power. Segment Terminal modules draw their power from the main supply within

the station, and are not connected to external power.

NIU

Power

Terminal

Segment

Terminal

Please see chapter 5 for more information about station power.

Voltage supplies are connected using unshielded cables as described previously.

4-4 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 47

Electrical isolation

If electrical isolation is required between logic and I/O you must provide the NIU

supply U

If various electrically isolated areas are required within a VersaPoint station,

additional power terminals that draw their current from separate power supplies

must be used.

The correct method of providing and distributing power to the station depends on

the needs of the application. See chapter 5 for detailed information about power

sources and power distribution in the VersaPoint I/O station.

Use power supplies with safe isolation!

Use power supplies that ensure safe isolation between primary and secondary

circuit (according to EN 50178).

For additional voltage supply specifications refer to the data sheets of the NIUs

and power terminals.

Voltage supplies are connected using unshielded cables as described previously.

For the connector assignment of the supply voltage connections please refer to

the module-specific data sheets of NIU, power terminals, and segment terminals.

and the I/O supply US from separate power supplies.

M

4

Dangerous voltage!

When the power terminal is removed, the metal contacts are freely accessible.

With 120V or 230V power terminals, it should be assumed that dangerous voltage

is present. You must disconnect power to the station before removing a terminal!

If these instructions are not followed, there is a danger of damage to health

and danger of a life-threatening injury.

GFK-1911B Chapter 4 Installation 4-5

Page 48

4

Setting the NIU Switches

Configure the hardware using the 10-position DIP switch on the NIU module.

Switches Meaning

1 to 7 Profibus Address in binary format (= 0 to 127 in decimal format)

8

0

Switch 1 defines the least significant bit (2

switch 7 defines the most significant bit (2

For Module IC220PBI002: Sets the operating mode. With this switch in

the Off position, this module can directly replace module version

IC220PBI001.

With this switch in the On position, this module operates in DP/V1 mode.

The On position matches the NIU’s default configuration.

) and

6

).

For Module IC220PBI001: Behavior if a data error occurs in the station

(local bus error):

ON = data transmission is stopped after a number of attempts.

OFF = the station constantly attempts to start data transmission.

If DIP switch 8 is in the ON position, a POWER DOWN/POWER UP must

be executed on the NIU so that it will restart. There is no automatic

restart after the error has been removed.

9 to 10

4-6 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Reserved, both switches must be in the OFF position.

Page 49

Keying Connectors and Modules

You can prevent the mismating of any connector by keying the base and the

connector using module keys (ordered separately, IC220ACC005 quantity 100).

4

A. Plug a coding key into the keyway in the base (1) and turn it away from the

small plate.

B. Use a pair of cutters to cut off the keying tab from the connector.

GFK-1911B Chapter 4 Installation 4-7

Page 50

4

Installing Modules on the DIN Rail

Mount modules side by side on a 35mm (1.378 in.) standard DIN rail.

▪ First, attach the electronics bases to the DIN rail by pushing the base straight-

in towards the rail (1).

Be sure that all featherkeys and keyways on adjacent modules are interlocked

(2). First, align the featherkey of the module with the keyway of the previous

module. Then, attach the new module to the DIN rail by pushing it straight in

toward the rail. Do not twist or pivot the module during installation; that may

damage the modules.

▪ Next, attach the Terminal Strip to the module.

First, place the front latch in the front snap-on mechanism (3).

Then pivot the top of the Terminal Strip towards the module until the back

latch snaps into place (4).

The keyways of a module do not continue on the Terminal Strip. When snapping

on an module, there must be no Terminal Strip on the left-hand side of the

module. If a Terminal Strip is present, remove it before installing the next module.

4-8 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 51

Removing Modules

When removing a module, follow the steps shown below:

▪ If there is a module label present, remove it (A-1, below).

If the module has more than one Terminal Strip, all of the these must be

removed. The following describes how a single-slot module is removed.

4

Lift the Terminal Strip by pressing on the connector latch (A-2).

▪ Remove the Terminal Strip (B).

▪ Remove the left-adjacent and right-adjacent Terminal Strips of the neighboring

modules (C). This prevents the potential routing featherkeys and the

keyway/featherkey connection from being damaged and creates more space

for accessing the module.

▪ Press the release mechanism, and remove the module from the DIN rail by

pulling it straight back (D-2).

▪ To remove the NIU, the left end clamp must be removed first.

Replacing a Module

If you want to replace a module within the VersaPoint station, reverse the removal

procedure above.

GFK-1911B Chapter 4 Installation 4-9

Page 52

4

Connecting Unshielded Cables

Unshielded cables for I/O devices and supply voltages are connected using the

spring-clamp terminals. Signals up to 250VAC/DC and 5A with a conductor crosssection of 0.2mm

2

to 1.5mm2 (AWG24 – 16) can be connected.

For terminal assignments, please consult the appropriate module data sheet.

Follow these steps when wiring:

▪ Strip 8mm (0.3in.) off the cable. Module wiring is normally done without

ferrules. However, it is possible to use ferrules. If using ferrules, make sure

they are properly crimped.

▪ Push a screwdriver into the slot for the appropriate connection (#1 above) so

that you can plug the wire into the spring opening.

▪ Insert the wire (#2 above). Pull the screwdriver out of the opening. The wire is

clamped.

After installation, you should label the wires and Terminal Strips as described later

in this chapter.

4-10 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 53

Connecting Shielded Cables

Observe the following when installing shielding:

▪ Strip the outer cable sheath to the desired length (#1a below). The appropriate

length depends on the connection position of the wires and whether there

should be a large or a small space between the connection point and the

shield connection.

4

▪ Shorten the braided shield to 15mm (0.6 in.) (#1 above).

▪ Fold the braided shield back over the outer sheath. (#2 above)

▪ Remove the protective foil.

▪ Strip 8mm (0.3in.) off the wires. (#2 above)

Connecting Shielded Cables to the Shielded Terminal Strip

▪ Open the shield connector (#3 above).

▪ Check the orientation of the shield clamp in the Shielded Terminal Strip and

change its position if necessary (see below for instructions).

▪ Place the cable with the folded braided shield in the shield connector. (#4

above)

GFK-1911B Chapter 4 Installation 4-11

Page 54

4

▪ Close the shield connector (#5 above).

▪ Fasten the screws for the shield connector using a screwdriver. (#6 above).

Repositioning the Shield Clamp

The shield clamp (2a, below) in the shield connector can be adjusted to

accommodate thin or thick cable. The shield connection is delivered with the

clamp positioned for the connection of thicker cables (#2 below). In that position,

the bend in the clamp faces away from the cable. For thinner cables the bend in

the clamp faces towards the cable (#6 below).

If you need to change the alignment of the shield clamp, proceed as shown below:

▪ Open the shield connector housing (#1).

▪ Remove the clamp (#3), turn the clamp according to the cross-section of the

cable (#4) and then reinsert the clamp. (#5)

4-12 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 55

Grounding

4

All devices in a VersaPoint station must be grounded so that possible signal

interference is shielded and discharged to ground. A wire of at least 1.5mm

AWG) must be used for grounding.

Grounding the NIU and Power Modules

The NIU, power terminals, and segment terminals have an FE spring (metal clip)

on the bottom of the electronics base. These springs create an electric connection

to the DIN rail. VersaPoint I/O modules are automatically grounded via the FE

voltage jumper when they are connected to other modules. The FE voltage jumper

(functional earth ground) runs from the NIU through the entire VersaPoint station.

The function of FE is to discharge interference. It does not provide shock

protection.

Required Additional Grounding

To ensure a reliable ground connection even if the DIN rail is dirty or the metal clip

damaged, GE Intelligent Platforms rec

rail-mounted grounding terminal block, via the FE terminal point.

ommends grounding the NIU to a DIN

2

(16

GFK-1911B Chapter 4 Installation 4-13

Page 56

4

Installing the Profibus Cable

When laying the Profibus cable, note the following:

▪ Do not lay signal and bus cables parallel to power cables or in bundles with

power cables.

▪ Lay Profibus cables and cables with direct voltages > 60V and alternating

voltages > 25V in separate bundles or cable channels.

▪ Always lay signal cables in one channel, following the shortest route.

▪ Avoid extending the Profibus cables with connectors.

▪ Do not lay Profibus cables in bundles with telephone lines and cables leading

to potentially explosive areas.

▪ Avoid branch lines.

Refer to the following cable specifications, connector description, and instructions

for cable shielding and bus termination.

Profibus Cable Specifications

The proper cable for a Profibus network is a shielded twisted pair cable. Profibus

cable is available from Siemens parts distributors and sold as "Profibus Network

Cable". The twisted pair cable consists of a Green and a Red wire. Below are

some of the cable characteristics of Profibus cable.

Profibus Network Cable Siemens part # 6XV1-830

Profibus 9-pin Connector Siemens part # 6ES7972

Impedance 135 to 165 Ohms (3 to 20 MHz)

Capacity < 30 pF per meter

Resistance < 110 Ohms per Kilometer

Wire Gauge > 0.64 mm (0.025 inch)

Conductor Area > 0.34 mm2 (AWG 22)

For data rates up to 500 kbits/second, follow the stub recommendations in the

Profibus technical standard. At 1500 kbits/second the overall drop capacity should

be less than 0.2nF. Maximum length of the stub at 1500 kbits/second is 6.6

meters.

4-14 VersaPoint™ I/O System Profibus-DP NIU User’s Manual – August 2005 GFK-1911B

Page 57

)

)

The Profibus Cable Connector

Most Profibus devices, including the VersaPoint Network Interface Unit, provide

the Profibus standard female 9-pin D subminiature connectors. Cable connectors

are available from Siemens parts distributors as "Profibus 9-pin D connectors".

These connectors provide termination resistors and a switch on the connector to

enable/disable termination.

4

The connectors label the connections for the twisted pair as cable A and cable B.

The following table illustrates the proper assignment of wire to connector to pin to

signal.

Pin Signal

1, 2, 7, 9 Reserved

3 RxD/TxD-P (receive/transmit data +), cable B

4 CNTR-P (control signal for repeater), direction control

5 DGND (reference potential up to 5V)

6 VP (supply voltage +5V for termination resistors)

8 RxD/TxD-N (receive/transmt data -), cable A

Shielding the Profibus Cable

Cable shielding is recommended at higher baud rates. Cable shields must be

attached at each device via the connector shells.

When mounting the NIU in the cabinet, connect the cable shield of the connected

Profibus cable with a shield bus via cable clamps. Use an appropriate shield

clamp for this.

RxD/TxD-P (3)

DGND (5)

VP (6)

RxD/TxD-N (8)

Red (B

Green (A

RxD/TxD-P (3)

DGND (5)

VP (6)

RxD/TxD-N (8)

GFK-1911B Chapter 4 Installation 4-15

Page 58

4

Bus Termination

Termination resistors are needed, as defined in DIN 19245 Part 1 section 3.1.2.5.

Master Slave Slave Slave SlaveSlave