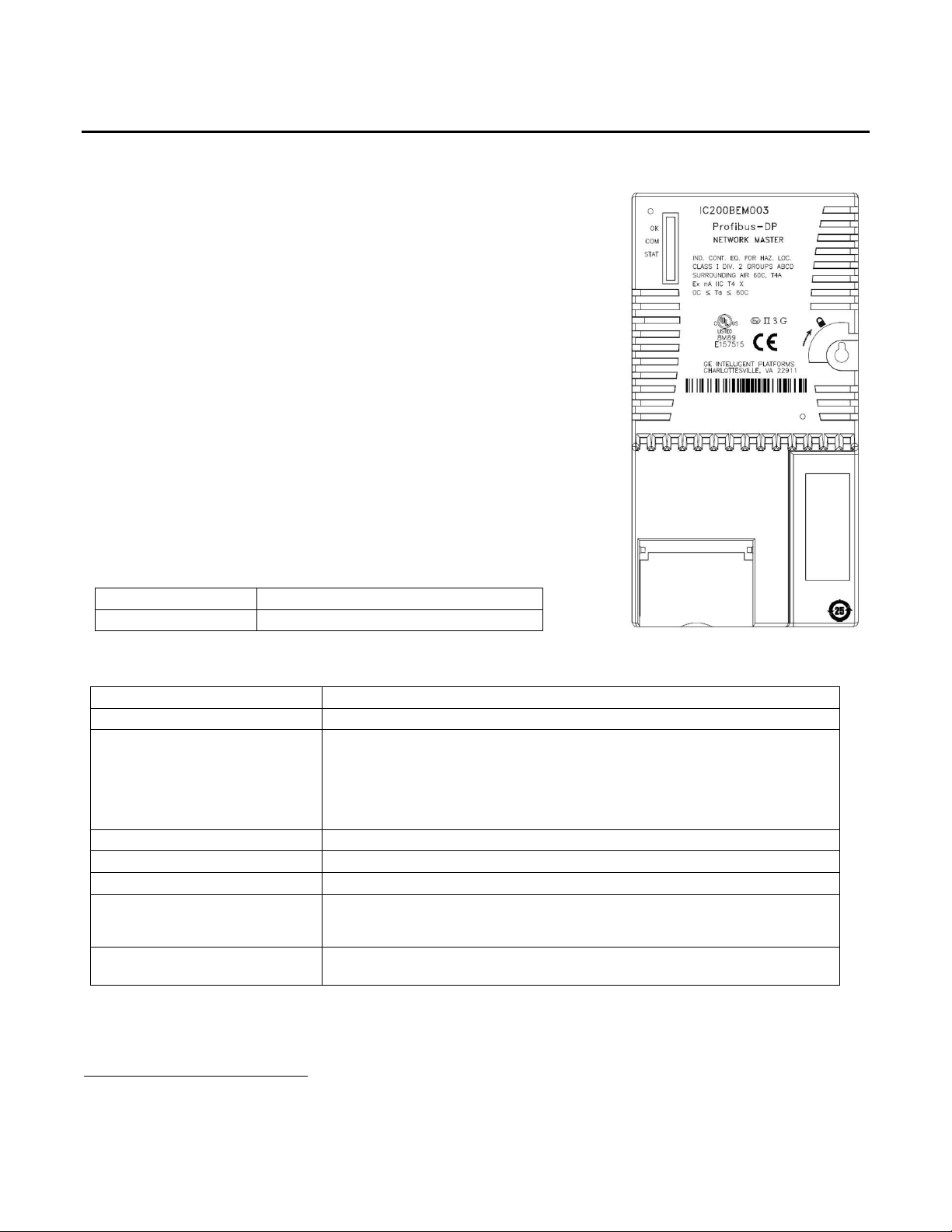

GE VersaMax IC200BEM003, VersaMax IC200CHS006 Quick Start Manual

VersaMax*

The VersaMax* IC200BEM003 PROFIBUS Master Module allows a VersaMax

CPU005, CPUE05 or PROFINET Scanner (PNS) to send and receive data on a

PROFIBUS-DP V1 network.

The PROFIBUS Master module provides the following PROFIBUS

communications features:

Supports all standard data rates

Supports a maximum of 3,584 bytes of input data and 3,584 bytes of output

data with a VersaMax CPU; a maximum of 1440 bytes of input data and 1440

bytes of output data with a PNS.

Supports a maximum of 125 PROFIBUS-DP slaves, with a maximum of 244

bytes of input data and 244 bytes of output data for each slave

Supports Sync and Freeze modes

Supports DP-V1 Read, Write and Alarm messages

Has PROFIBUS-compliant module and network status LEDs

This module must be located in a VersaMax Communications Carrier.

The PROFIBUS module receives its firmware upgrades indirectly from the

head end CPU or PNS using the WinLoader software utility. WinLoader is

supplied with any updates to the PROFIBUS module software.

Ordering Information

IC200BEM003

VersaMax PROFIBUS Master Module

IC200CHS006

VersaMax Communications Carrier

PROFIBUS support

PROFIBUS-DP V1

Power Consumption

450mA at +5V

I/O Data

With a CPU

A maximum of 3584 bytes of input data and 3584 bytes of output data

With a PNS

A maximum of 1440 bytes of input data and 1440 bytes of output data

With either CPU or PNS head end, a maximum of 244 bytes of input data and 244

bytes of output data for each slave.

PROFIBUS network addresses

0 to 125, software-configurable

Maximum no. of slave devices

125

Network data rate

9.6K up to 12 Mbaud (bit/sec)

Status information

Slave Status Bit Array Table

Firmware Module Revision

Slave Diagnostic Address

Module isolation

Network to Frame ground: 250VAC continuous, 1500VAC for 1 min

Profibus network to backplane: 1500VAC minimum

IC200BEM003

GFK-2739 PROFIBUS Master Module

April 2012

Specifications

For product standards, general operating specifications, and installation requirements, refer to the VersaMax I/O Modules

Manual, GFK-1504.

*

indicates a trademark of GE Intelligent Platforms, Inc. and/or its affiliates. All other trademarks are the property

of their respective owners.

2 PROFIBUS Master Module

GFK-2739

Installation in Hazardous Areas

The following information is for products bearing the UL marking for Hazardous Locations or ATEX marking for

explosive atmospheres:

EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 HAZARDOUS LOCATIONS IS

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS LOCATIONS ONLY

Equipment labeled with II 3 G is suitable for use in Group 2 Category 3 environments.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE REPLACING

OR WIRING MODULES; AND

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

WARNING - EXPLOSION HAZARD - USB PORT IS ONLY FOR USE IN NONHAZARDOUS LOCATIONS, DO NOT

USE UNLESS AREA IS KNOWN TO BE NON-HAZARDOUS.

ATEX Marking

II 3 G Ex nA IIC T4 X 0°C<Ta<60°C

Diagnostic Status Arrays

The starting addresses of these arrays are set in the hardware configuration. For information on using memory mapped

COMMREQs, refer to “Diagnostics” in VersaMax PROFIBUS Master User’s Manual, GFK-2740.

Slave Status Bit Array. This 128*-bit array contains a bit for each slave. If communication with a slave has no errors, the

bit corresponding to the slave (determined by its network address) is set. If the communication has errors or is not

occurring for any reason, the bit is cleared. The Master also maintains its own status in the bit corresponding to its network

address.

Slave Diagnostics ID Array. If diagnostics are pending, the first word of this two-word array contains the station address

of the first slave that has diagnostics. The diagnostics can be read using the Get Device Diagnostics COMMREQ

(command 4). This clears the word and the master then places the next pending diagnostic address into the Slave

Diagnostics word. If this word is zero there are no pending diagnostics. The second word of this array is reserved and set

to 0.

DPV1 Alarm Status Array. The 32-bit DPV1 Alarm Status array is used at the beginning of a scan to receive the station

address of a slave that has sent a DPV1 Alarm message. If another slave has sent a DPV1 alarm message, it is ignored

until the first one has been serviced, and will then appear in a subsequent scan.

Slave Configured Bits. This 128-bit array indicates which slaves on the PROFIBUS network are configured. Each slave

has a corresponding bit in this array. A slave's configuration status address equals Start Address + Station Address of the

slave.

Slave Diagnostic Bits. This 128-bit array indicates which slaves on the PROFIBUS network have diagnostic data

available. The diagnostics can be read using the Get Device Diagnostics COMMREQ (command 4).

Each slave has a corresponding bit in this array. A slave's diagnostic status address equals Start Address + Station

Address of the slave.

PROFIBUS Master Module LEDs

On initial powerup with no configuration stored, the LED display should be as shown on page 3. For details on the Master

module’s LED operation, refer to the VersaMax PROFIBUS Master User’s Manual, GFK-2740.

Loading...

Loading...