Page 1

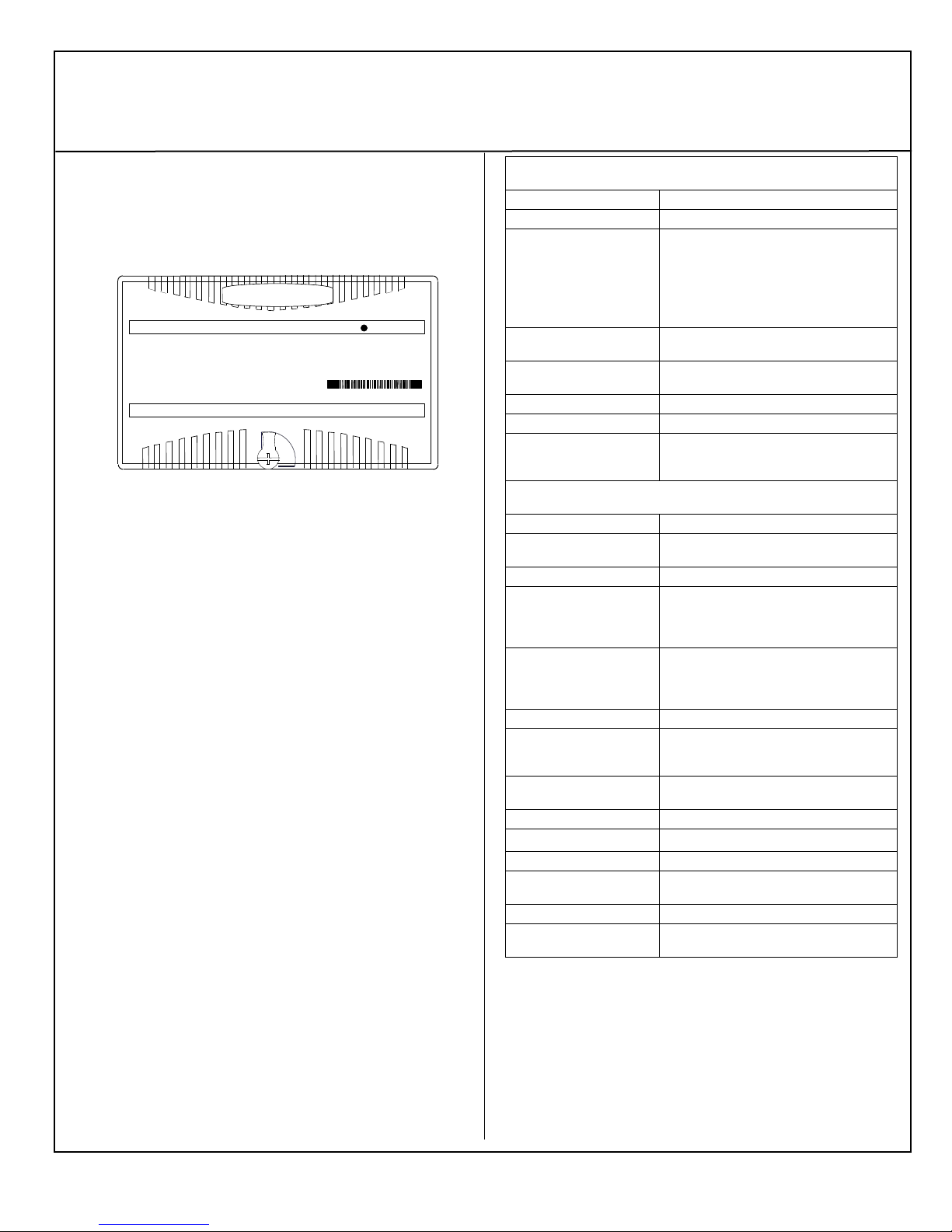

VersaMax* Analog Input, 16-Bit Thermocouple Module

1

1234567 831

ANALOG INPUT 16BIT

THERMOCOUPLE 7CH

OK

Module Characteristics

Channels

Seven thermocouple or millivolt inputs

Module ID

FFFF9804

Isolation:

User input to logic

(optical) and to frame

ground

Group to group

Channel to channel

250VAC continuous; 1500VAC for 1 minute

Not applicable

None

LED indicators

OK LED: Green indicates backplane power is

present. Amber indicates module fault.

Backplane current consumption

5V output: 125mA maximum. 3.3V output: 125mA

maximum.

External power supply

None

Thermal derating

None

Diagnostics

Open Thermocouple, over/under range, and

high/low alarm, thermistor fault (reported as

internal fault).

Input Characteristics

Thermocouple types

J, K, T, S, R, none (used for mV inputs)

Spans (+/–)

19.5mV, 39mV, 78.125mV, 156.25mV, 312.5mV,

625mV

Converter resolution

15 bits + sign

Cold junction compensation

If used, reference junction temperature is

measured at thermocouple termination using a

precision thermistor, or supplied by system, or by

fixed configuration value.

Cold junction temperature error

+/–0.25 degree Celsius (local measurement). To

reduce temperature transients, thermocouple

terminations should not be installed in the same

cabinet as heat dissipation assemblies.

Conformity error

+/–0.3 degree Celsius, +/–0.5 degree Fahrenheit.

Accuracy, at 25° C

on voltage measurement:

on temp. measurement:

+/–0.2%

+/- 3 degrees Celsius.

Temperature sensitivity

(0° to 60°C)

+/–0.004% of reading, +/–1.5µV per ° Celsius

referred to input

Normal mode rejection

60dB, at 50/60 Hz, 100% span

Common mode rejection

120 dB at 50/60Hz, 100 ohm imbalance

Common mode voltage

3 VDC maximum

Maximum voltage between

channels

50V

Normal mode voltage

5 VDC maximum

Scan time

60 Hz: approximately 60 milliseconds per point

50 Hz: approximately 70 milliseconds per point.

IC200ALG630

October 2016 GFK-1700L

Product Description

The IC200ALG630 Analog Input Thermocouple Module is an intelligent

module that accepts seven independent thermocouple or millivolt inputs.

The module receives power from the backplane power supply. No

external power source is required.

Each input channel can be configured to report millivolts ranges as

1/100 of millivolts, or thermocouple inputs as linearized temperature in

tenths of degrees Celsius or Fahrenheit, with or without cold junction

compensation.

The module automatically performs A/D calibration at powerup.

Automatic calibration is then repeated periodically to compensate for

changes in the ambient temperature. New calibration values are filtered

into the current calibration values.

Host Interface

The Analog Input Thermocouple Module uses the following data types:

7 words of analog input data.

7 optional words of analog output data.

The module exchanges data in the same manner as other types of I/O

modules: it provides all its input data when requested.

Diagnostics

The Analog Input Thermocouple Module performs diagnostics and

provides the following information.

Alarm faults are reported if the processed value for a channel

exceeds its configured alarm limit.

Over/underrange faults are reported if the millivolt value for an

input exceeds the limits of its span.

Open circuit is checked every time a thermocouple input is read

(unless Open TC checking is disabled). If the circuit is open, a fault

is reported and the input defaults to the configured channel default.

Thermistor fault will be reported as Internal fault in the I/O Fault

table.

A thermistor fault occurs if the calculated temperature value from the

thermistor is less than -10 °C or greater than +75 °C.

LED Indicators

The green OK LED is on when backplane power is present to the

module. If this LED is amber, it indicates a module fault.

Preinstallation Check

Carefully inspect all shipping containers for damage. If any equipment

is damaged, notify the delivery service immediately. Save the

damaged shipping container for inspection by the delivery service.

After unpacking the equipment, record all serial numbers. Save the

shipping containers and packing material in case it is necessary to

transport or ship any part of the system.

Page 2

VersaMax* Analog Input, 16-Bit Thermocouple Module

2

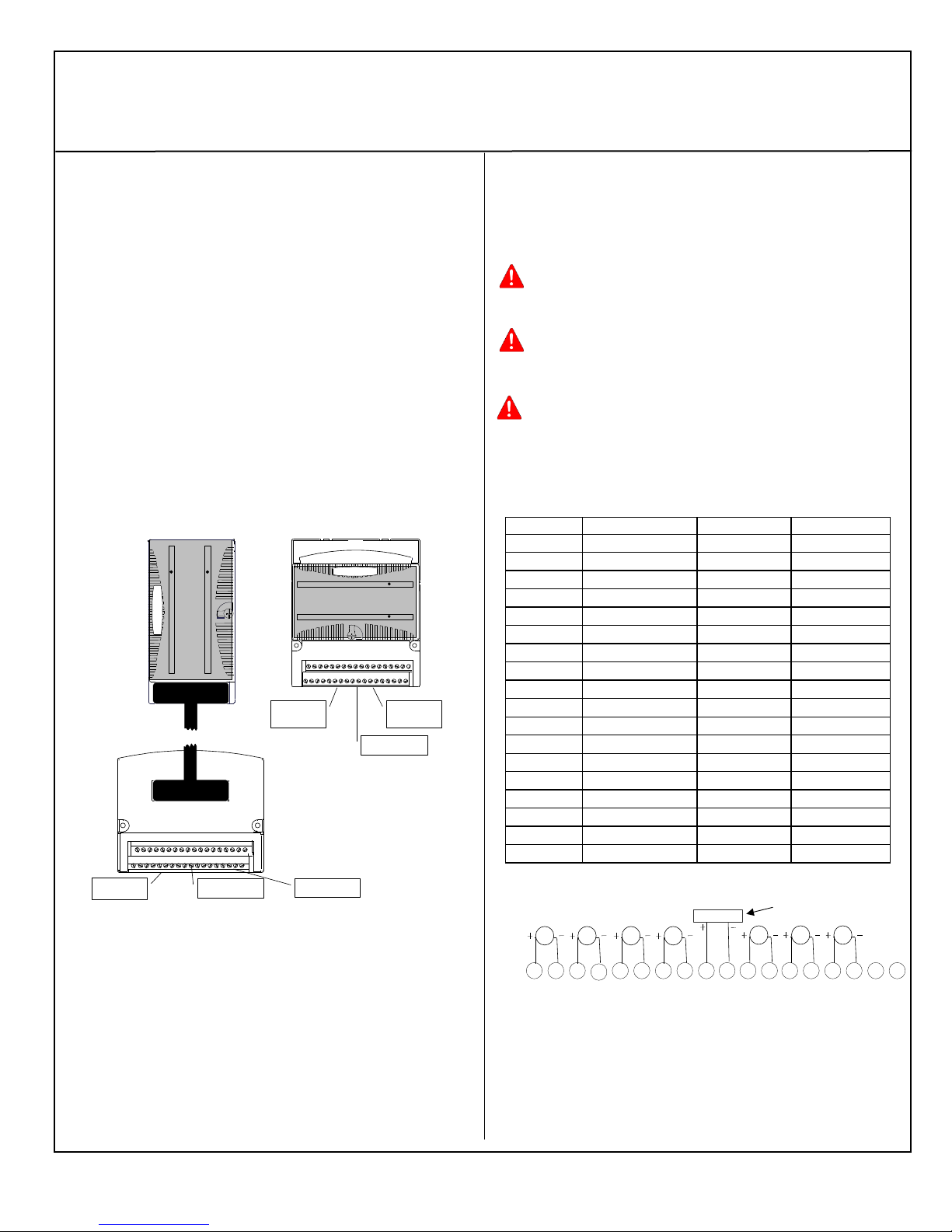

Thermocouple

or Millivolt

Inputs

Thermocouple

or Millivolt

Inputs

Install Optional

Thermistors Here

Thermocouple

Inputs

Thermocouple

Inputs

Built-In Thermistors

Located Here

CHS014

Number

Connection

Number

Connection

A1

Channel 1 (+)

B1

No connection

A2

Channel 1 (-)

B2

Shield

A3

Channel 2 (+)

B3

No connection

A4

Channel 2 (-)

B4

Shield

A5

Channel 3 (+)

B5

No connection

A6

Channel 3 (-)

B6

Shield

A7

Channel 4 (+)

B7

No connection

A8

Channel 4 (-)

B8

Shield

A9

(Thermistor (+))

B9

No connection

A10

(Thermistor (-))

B10

Shield

A11

Channel 5 (+)

B11

No connection

A12

Channel 5 (-)

B12

Shield

A13

Channel 6 (+)

B13

No connection

A14

Channel 6 (-)

B14

Shield

A15

Channel 7 (+)

B15

No connection

A16

Channel 7 (-)

B16

No connection

A17

No connection

B17

No connection

A18

No connection

B18

No connection

1234567891112131415161718

10

AI 1

AI 2

AI 3

AI 5

AI 6

AI 7

Thermistor

AI 4

A

Note: only for thermocouple carrier

IC200ALG630

October 2016 GFK-1700L

Installation Instructions

The preferred installation technique is to mount the Thermocouple

Module on a Connector-style I/O Carrier and connect thermocouples to

an Interposing Thermocouple Carrier as shown below. The Interposing

Thermocouple-style I/O Carrier provides both box-style wiring terminals

and a built-in thermistor for Local Cold Junction Compensation. It

connects to the Connector-Style Carrier via a cable as shown. This

allows the thermocouple connections to be located away from the I/O

modules in the system. Each TC terminal on the Interposing

Thermocouple Carrier accommodates one solid or stranded AWG #14

(avg. 2.1mm2 cross section) to AWG #22 (avg. 0.36mm2 cross section)

wire, or two wires up to AWG #18 (avg. 0.86mm2 cross section).

However, it is also possible to mount the Thermocouple Module on one

of the terminal-style carriers (box-style, spring-style, or barrier-style) and

provide Local Cold Junction Compensation by using a kit that includes

the correct type of thermistor, as described in the I/O Modules User

Manual. Both methods are shown below. The thermistor kit must be

installed on the A9 and A10 terminals of the carrier.

If the module will only be used to measure millivolt inputs, not

thermocouple inputs, it can be mounted on any type of I/O Carrier. The

thermistor terminals A9 and A10 cannot be used as millivolt input

terminals.

Installation in Hazardous Locations

EQUIPMENT LABELED WITH REFERENCE TO CLASS I,

GROUPS A, B, C & D, DIV. 2 HAZARDOUS LOCATIONS IS

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C,

D OR NON-HAZARDOUS LOCATIONS ONLY

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS

LOCATIONS, TURN OFF POWER BEFORE REPLACING OR

WIRING MODULES; AND

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR

THE AREA IS KNOWN TO BE NONHAZARDOUS.

Field Wiring Terminals

The terminal assignments shown below are the same for all carriers.

Wiring Connections for Carriers with Two Rows of Terminals:

Page 3

VersaMax* Analog Input, 16-Bit Thermocouple Module

3

12345

6

789111210A131415161718

AI 1

AI 2

AI 3

AI 5

AI 6

AI 7

Thermistor

AI 4

Note: only for thermocouple carrier

Revision letters:

KF

Firmware version:

1.25

Firmware

upgrades:

44A750342-G05. Available as a free

download at http://ge-ip.com/support.

Revision

Date

Description

IC200ALG630-KF

Oct 2016

EU RoHS compliant module per

directive 2011/65/EU dated 8-June-

2011. No changes to features,

performance or compatibility.

IC200ALG630-JF

Jan 2012

Label change. No changes to

features, performance or

compatibility.

IC200ALG630-HF

Apr 2011

Firmware release 1.25. Resolves

component obsolescence issue. No

change to features, performance or

compatibility.

IC200ALG630-HE

Feb 2011

Labeling change. No changes to

compatibility, functionality or

performance.

IC200ALG630-GE

IC200ALG630-FE

Sept 2010

Firmware release 1.24. Resolved

fault reporting issue in Remote/Local

IO configuration.

IC200ALG630-GD

Aug 2009

Changed manufacturing location. No

changes to compatibility, functionality

or performance.

IC200ALG630-FD

BXIOAI7-FD

Oct 2008

Updated Power Supply OK signal

circuitry.

IC200ALG630-ED

BXIOAI7-ED

Sept 2007

Firmware release 1.20. Improved I/O

scanning.

IC200ALG630-EC

BXIOAI7-EC

Apr 2005

Plastic change on locking

mechanism

IC200ALG630-DC

BXIOAI7-DC

Feb 2005

Configurable for 50Hz line frequency

IC200ALG630-DB

BXIOAI7-DB

Apr 2004

Changed to V0 plastic for module

housing.

IC200ALG630-CB

BXIOAI7-CB

Jan 2004

ATEX approval for Group 2 Category

3 applications.

IC200ALG630-BB

BXIOAI7-BB

Nov 2002

Improved reporting of Open Input

error at higher temperatures.

IC200ALG630-AB

BXIOAI7-AB

June 2001

Firmware version 1.01. Enhanced

Open Circuit reporting

IC200ALG630-AA

BXIOAI7-AA

July 1999

Initial product release

IC200ALG630

October 2016 GFK-1700L

Wiring Connections for Carriers with Three Rows of Terminals:

Cable Shield Connections

Shielded twisted pair cable is recommended for the analog channel

connections. If possible, the cable should be grounded at the source

device. If that is not possible, the cable shield must be grounded at the

I/O module. This can be done using an Auxiliary I/O Terminal strip.

If the module is installed on a Terminal-style I/O Carrier, shield

connections can be made on an Auxiliary I/O Terminal that is attached

to the I/O carrier.

If the module is installed on a Compact Terminal-style I/O Carrier, shield

connections can be made on an Auxiliary I/O Terminal that is mounted

near the I/O carrier.

If the module is installed on a Connector-style I/O Carrier, the cable

shield can be connected directly to an Interposing Terminal. A shielded

interposing cable (shielded cables are available separately) must be

used between the Connector-style I/O Carrier and the Interposing

Terminal. An Auxiliary I/O Terminal Strip can also be added to the

Interposing Terminal if additional shield connections are required.

Product Revision History

Product Version Information

Compatibility

Firmware version 1.25 is compatible with all hardware versions of the

ALG630.

This module is compatible with:

PLC CPU Firmware version 1.20 or later.

Ethernet NIU EBI001 all versions.

Genius NIU GBI001 Firmware version 1.10 or later*

Profibus NIU PBI001 Firmware version 1.10 or later*

DeviceNet NIU DBI001 Firmware version 1.10 or later. The

DeviceNet NIU does not support software configuration. Therefore,

analog modules used with a DeviceNet NIU must be

autoconfigured and use only their default configuration settings.

* For GBI001, NIU version 2.0 or above is required to perform software

configuration. For PBI001, NIU version 2.01 or above is required to

perform software configuration.

Restrictions and Open Issues

Additional faults may be logged when a new configuration

containing parameter changes such as the Alarm High limit or

Alarm Low limit in the hardware configuration of an analog module

is stored followed by a Clear All operation. The additional faults are

logged against the previous configuration. This issue is observed

when Machine Edition is connected to Versamax CPUs

(IC200CPU001, IC200CPU002, IC200CPU005 and IC200CPUE05)

and does not occur with Versamax NIUs (IC200GBI001,

IC200EBI001, IC200PBI001, and IC200DBI001).

When more than 20 faults are sent to a GBC70 within a single

Genius scan, under rare conditions one fault or fault contact may

not be reported by the GBC70. This has been observed when

simultaneous open wire condition occurs in all eight channels of

IC200ALG240 module or if several I/O modules in a GNIU rack

generate multiple faults simultaneously. This issue has only been

observed when the GBC70 was in a rack with an RX7i CPU.

Page 4

VersaMax* Analog Input, 16-Bit Thermocouple Module

4

Parameter

Default

Choices

Analog Input Data Length

7

1 to 7

Analog Input Data

Reference

user selectable

Analog Output Data

Length

0

0 to 7

Analog Output Data

Reference

user selectable

Line Frequency

60 Hz

50 Hz, 60 Hz

Suppress Open

Thermocouple

No

Yes, No

Channel Active

Active

Inactive (off), Active (on)

Engineering Units

1/10

degrees C

Millivolts, 1/10 degrees C, 1/10 degrees F

Thermocouple Type

J

None, J, K, T, S, R

Range

625

19.53, 39.06, 78.125, 156.25, 312.5, 625.

R J Type

Local

Local, Remote, Fixed, None

Alarm Low

–2000

–32,768 to +32,767

Alarm High

8000

–32,768 to +32,767

Reference Junction Value

250

–32,768 to +32,767

Correction Factor 0 –32,768 to +32,767

Channel Default Input 0 +32,767

Cold Junction Default

250

+32,767

TC Type

Low mV

Limit

High mV

Limit

Low

Temperature

Limit (C)

High

Temperature

Limit (C)

J

–8.0960

57.9420

–210.00

1000.00

K

–5.8910

54.8069

–200.00

1370.00

T

–5.6030

20.2520

–200.00

390.00

S

–0.1940

18.5040

–40.00

1750.00

R

–0.1880

20.8780

–40.00

1750.00

IC200ALG630

October 2016 GFK-1700L

When 45 or more faults are sent to a GBC70 within a single Genius

scan, a few faults or fault contacts may not be reported by the

GBC70. This is most likely to be caused by the sudden loss of

numerous blocks at each bus controller in the system. The

resulting PLC diagnostics and diagnostic contacts may be

incorrect.

Operational Notes

If hot insertion of a module is done improperly, the operation of

other modules on the same backplane may be disrupted. See

Installing a Module on a Carrier in the VersaMax Modules Manual,

GFK-1504.

Clarification of Default/Hold Last State configurations:

If there is an error on a specific input channel, the modules will

always report the Channel Default value from the Input Parameters

tab of the module configuration.

When a Loss of I/O Module fault is logged for a module, the CPU

or NIU will use the Default/Hold Last State setting from the Module

Parameters tab of the module configuration to determine what

value should be reported to the reference tables.

After an Open Circuit fault condition is corrected, the module takes

a few seconds to return to normal operation. During this time, the

module continues reporting the channel default input value. After

the module has recovered from the Open Circuit fault, it returns to

normal inputs and normal operation.

If there is a very large change in an input (for example, an input

quickly goes from 50mV to 400mV), the module may briefly report

an Over-range fault on that circuit even though the circuit is not

actually over its configured upper range limit. This is only

temporary.

When IC200ALG630 or IC200ALG620 modules are present in

GNIU or PNIU rack and a 'Clear all' command is issued from

Machine Edition software, Machine Edition may get disconnected,

displaying timeout error "error 8097 - host disconnect has

occurred". When this error is logged, the Configuration is still

cleared. To avoid this error, the “Request Timeout” value in

“Additional Configuration” in “Target Properties” should be

increased to 30s or more.

When all the channels of IC200ALG630 are set inactive and the

Reference Junction Type parameter is not set to "local", VersaMax

CPUs / NIUs will report a “Loss of IO modules” fault, that points to

the IC200ALG630 itself.

To avoid this fault, either configure at least one thermocouple

channel to active or set reference junction type parameter to

“local”.

Configuration

The default parameters of the Thermocouple Input module can be used

in many applications. The module can be software-configured when it is

installed in a PLC system, or an I/O Station controlled by an NIU that

supports software configuration.

Configurable Features

Channel Active: Each channel can be configured as either active or

inactive. If a channel is inactive, the filtering, scaling, calibration, and

alarm checks are omitted for that channel, and a value of 0 is returned

for the channel. The reference parameter for the analog input data

returns the byte length and is independent of the number of active

channels.

Low Alarm Limit and High Alarm Limit: Each input channel can have

a low alarm limit and a high alarm limit. If an input reaches one of its

limits, the module reports the actual value and sends the appropriate

diagnostic input bit. Alarms do not stop the process or change the value

of the input. Alarm limits can be set anywhere over the dynamic range

of the signal. The range for each is –32,768 to +32,767. The high alarm

limit must be greater than the low alarm limit. If alarm reporting is not

wanted, alarm limits can be set beyond the dynamic range of the signal

so they will never be activated.

Thermocouple Limits: The table below lists millivolt and temperature

limits for applicable thermocouple types.

Page 5

VersaMax* Analog Input, 16-Bit Thermocouple Module

5

IC200ALG630

October 2016 GFK-1700L

Cold Junction Compensation: The Thermocouple module provides

four choices for Cold Junction Compensation.

No Cold Junction Compensation: This is used for millivolt inputs or

if cold junction is maintained at 0 degrees C.

Remote Cold Junction Compensation: With this option, cold

junction is measured externally and provided to the module from

the application, via the module’s analog output (word output) data.

If the module has multiple thermocouples that are configured for

remote compensation, the same compensation value must be used

by each.

Fixed Cold Junction Compensation: This option uses a fixed

compensation value provided by the user in the configuration

parameter, “Reference Junction Value.” The units of this fixed

value are defined in configuration parameter “Engineering Units.”

Local Cold Junction Compensation: The best way to provide local

compensation is with an Interposing Thermocouple Carrier, which

has a built-in thermistor. Using an Interposing Carrier allows the

thermocouple connections to be placed farther away from the I/O

modules in the system, which helps shield thermocouple

connections from module heat.

If Local Cold Junction Compensation is configured and an Interposing

Thermocouple Carrier is not used, a separate thermistor must be

installed directly at the module’s I/O Carrier, using the Thermistor (+)

and Thermistor (–) terminals. The thermistor must be the type specified

in the I/O Modules User’s Manual. Note: If Local Compensation is

selected but an Interposing Thermocouple Carrier or local thermistor is

not used, erroneous temperatures may be reported and a thermistor

error will be reported in the fault table.

Range Selection: The module is configurable for any of six different

millivolt ranges (+/–): 19.5mV, 39mV, 78.125mV, 156.25mV, 312.5mV,

and 625mV. All but the last provide input readings in hundredths of

millivolts. For the 625mV range, inputs are in tenths of millivolts. When

used to read millivolts, the Thermocouple Type configuration parameter

must be set to “none”.

© 1999 - 2016 General Electric Company. All Rights Reserved.

*

Indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

Loading...

Loading...