Page 1

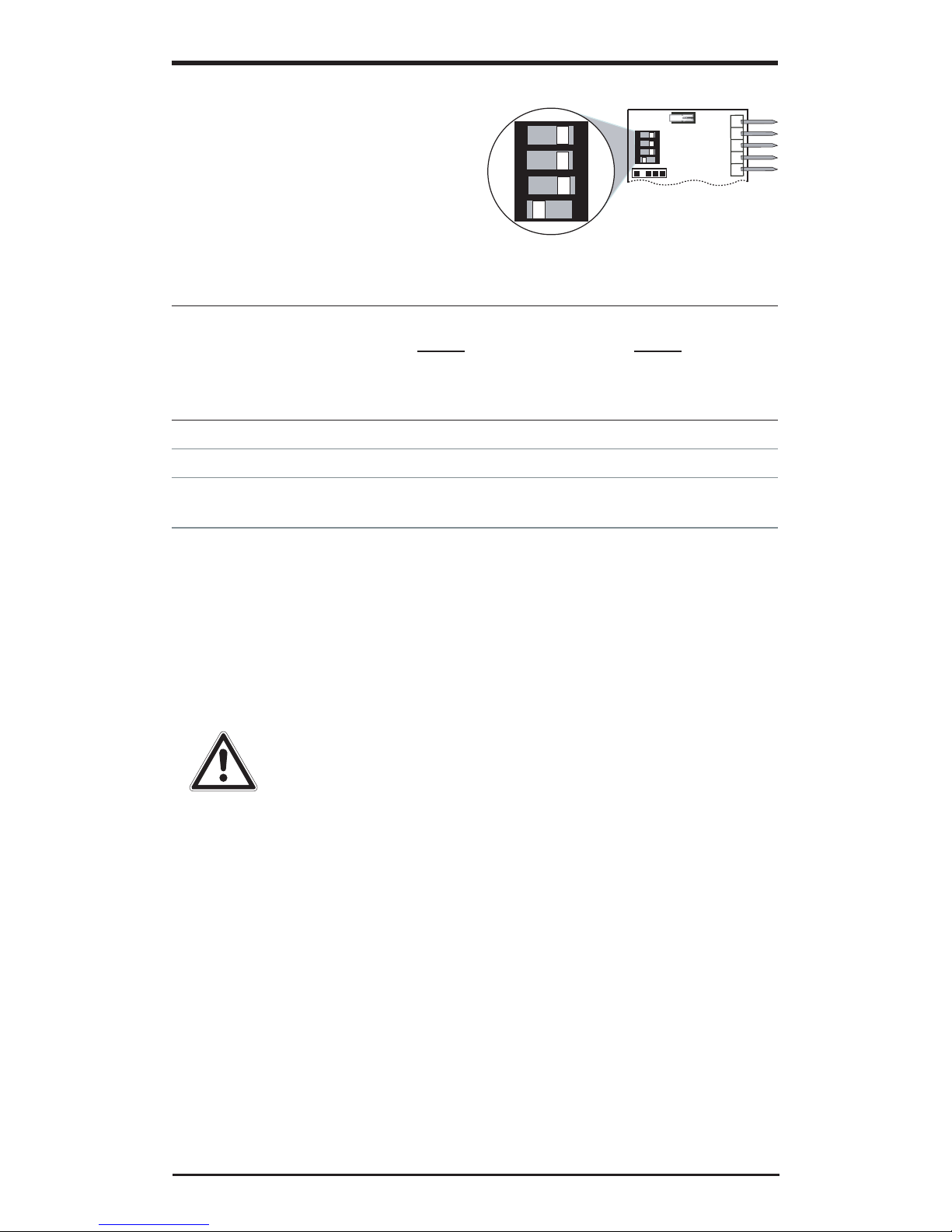

Vector Enhanced Motion Sensor VE700AM

Installation instructions

pages 8-19

Rivelatore di movimento Vector Enhanced

VE700AM

Istruzioni per l’installazione

pagg. 20-33

Capteur de mouvement à vecteur amélioré

VE700AM

Manuel d’installation

pages 34-47

Bewegingsdetector met vector VE700AM

Installatie-handleiding

Pagina’s 48-60

Bewegungsmelder VE700AM mit

Vektorauswertung

Installationsanweisungen

Seiten 61-74

GE

Security

EN

IT

FR

NL

DE

Page 2

Page 3

- 1 -

Click!

A

B

A

B

A

B

A

B

C

C

D

D

D

D

C

C

DIN 7996

(3.5 mm x 35 mm)

123456789101112

A

A

BB

C

C

D

D

Page 4

- 2 -

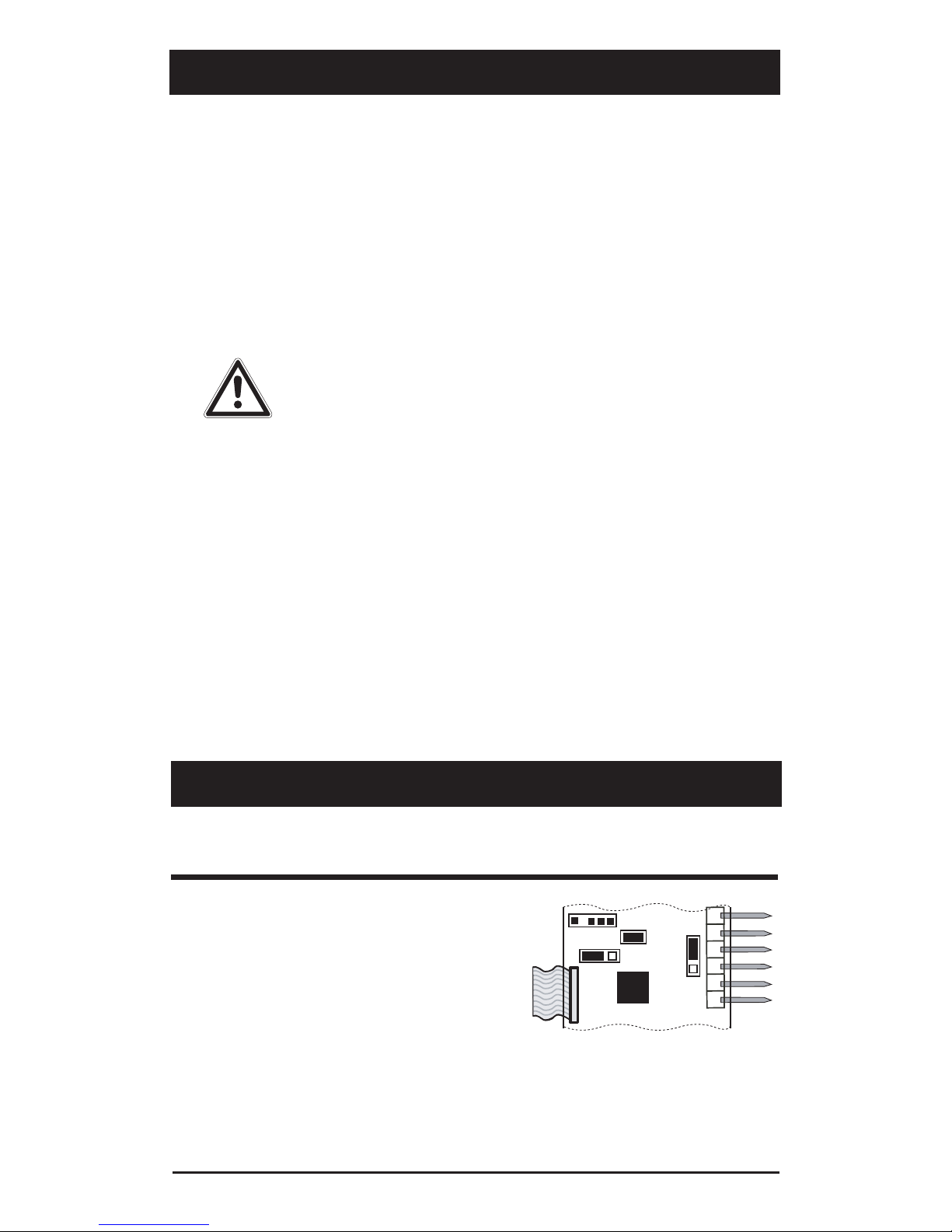

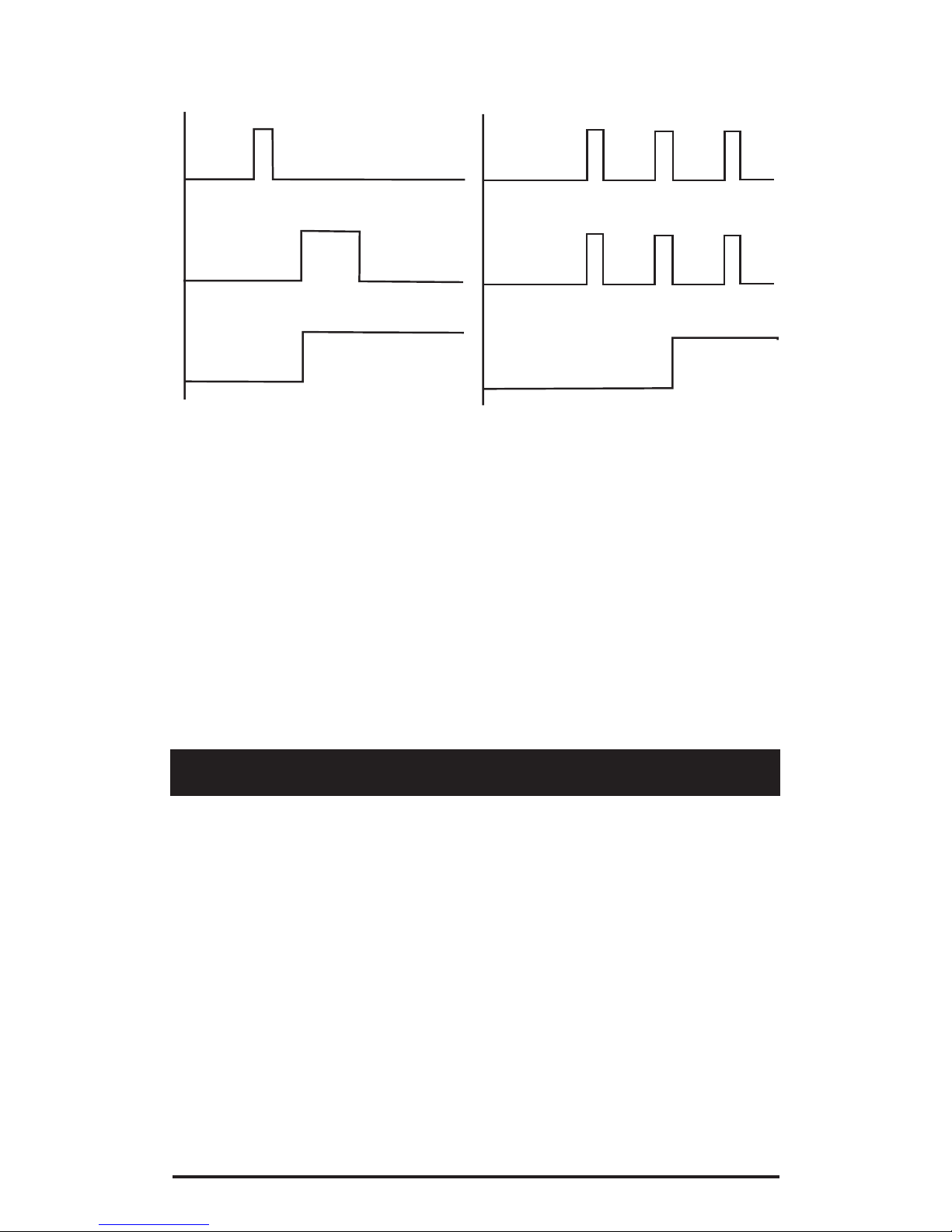

VE735AM

VE736AM

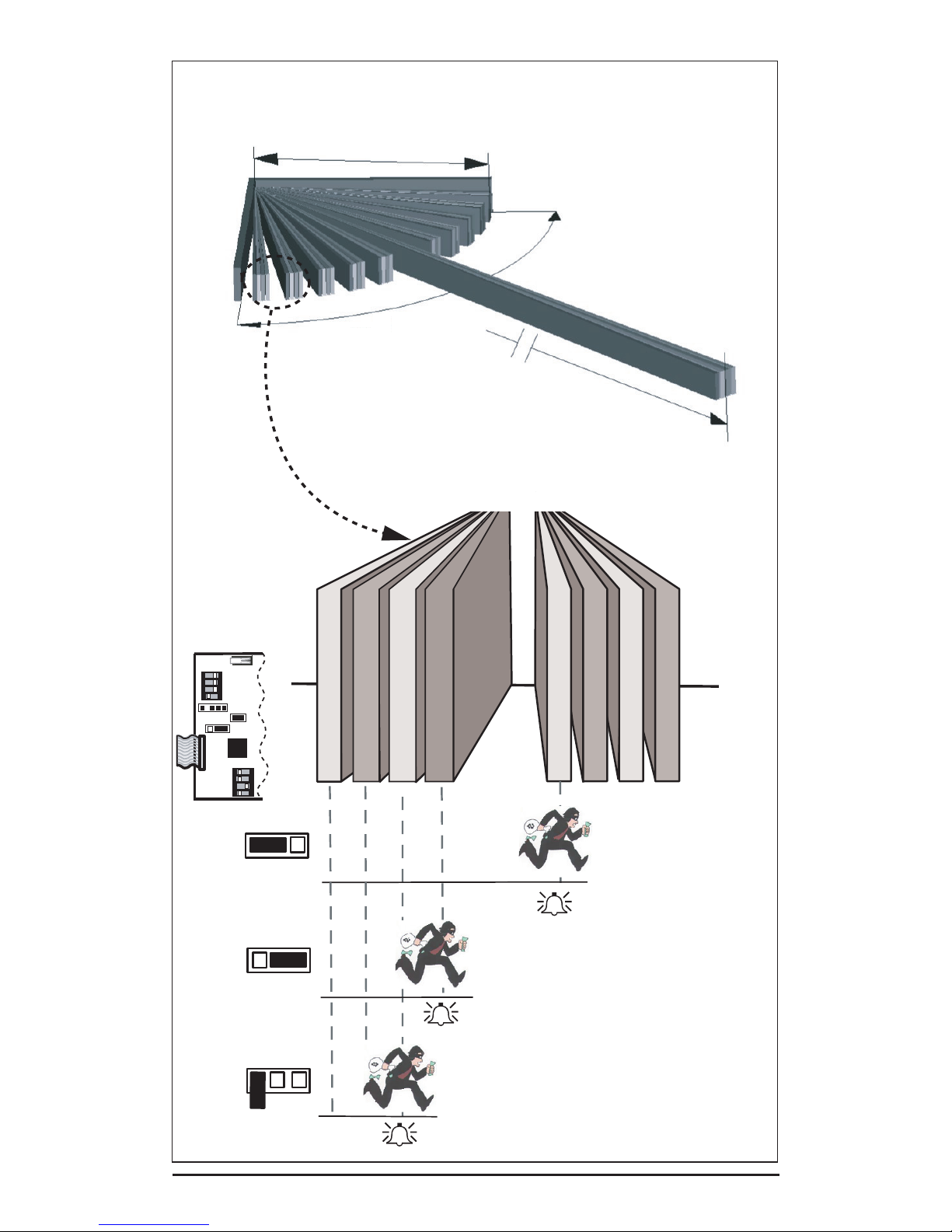

Single device:

Multiple devices:

123

ALARM

TAMPER

EOL

Panel

Dual Loop Zone

J3

Page 5

- 3 -

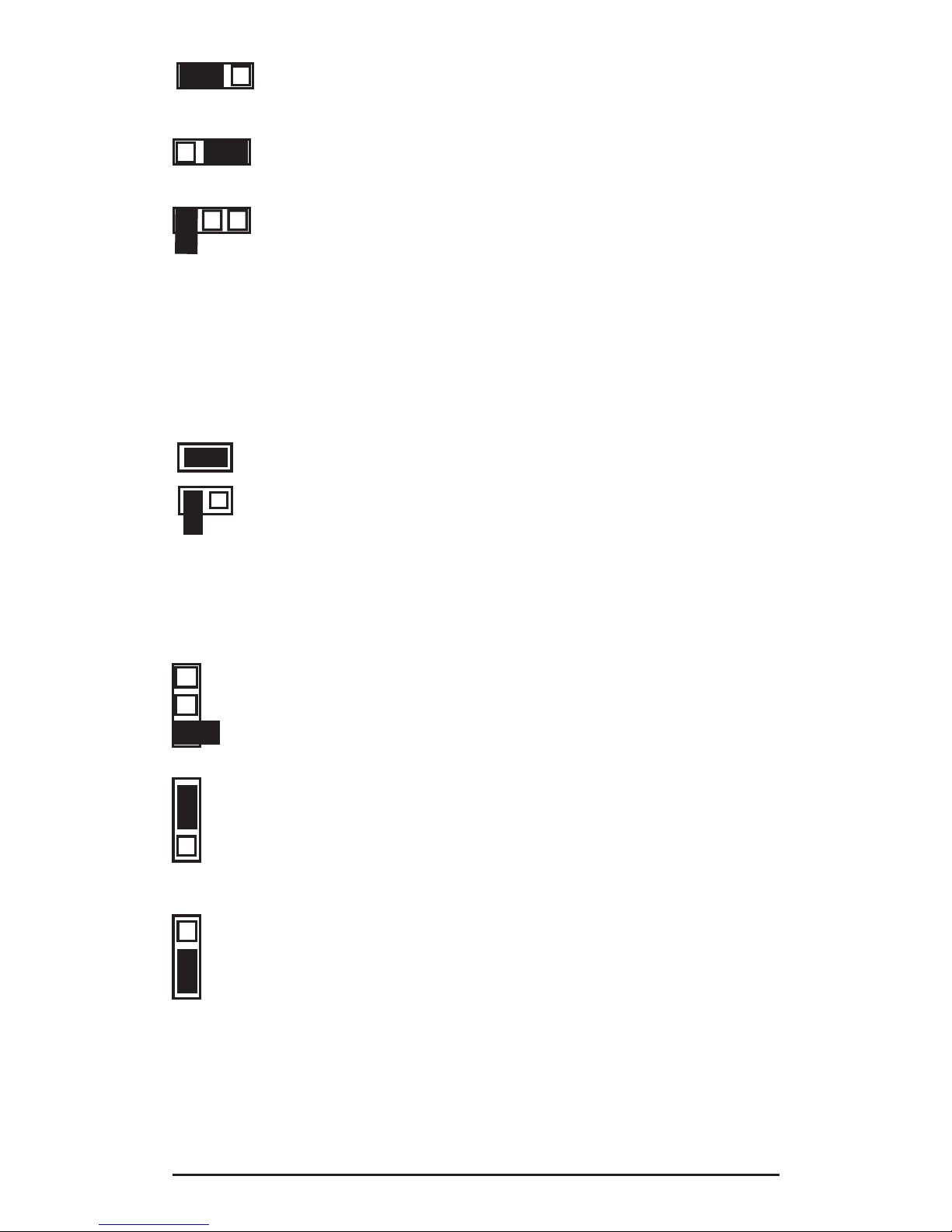

(ex-factory)

COM port

CON

J1

J2

J3

12 34

ON

1234567891011 12

12 34

ON

AM DIP switches

PIR DIP switches

Page 6

VE700AM

J1

20 m (65.6 ft)

60 m (197 ft)

J1

J2

12 34

ON

12 34

ON

J1

J1

86˚

- 4 -

Medium sensitivity

(ex-factory)

Low sensitivity

High sensitivity

Page 7

- 5 -

a

LeftRight

12 34

ON

12 34

ON

Day Night

Chime

Alarm

----

A

B

A

B

Day Night

Chime

Alarm

----

A

B

Alarm

Alarm

VE700AM

12 34

ON

VE700AM

On

Off

(ex-factory)

J2

3 sec.

3 sec.

J2

J1

J2

12 34

ON

12 34

ON

Page 8

1.8-3.0 m

(5.9-9.8 ft.)

VE700AM

- 6 -

B

A

c

b

Page 9

- 7 -

d

e

f

g

h

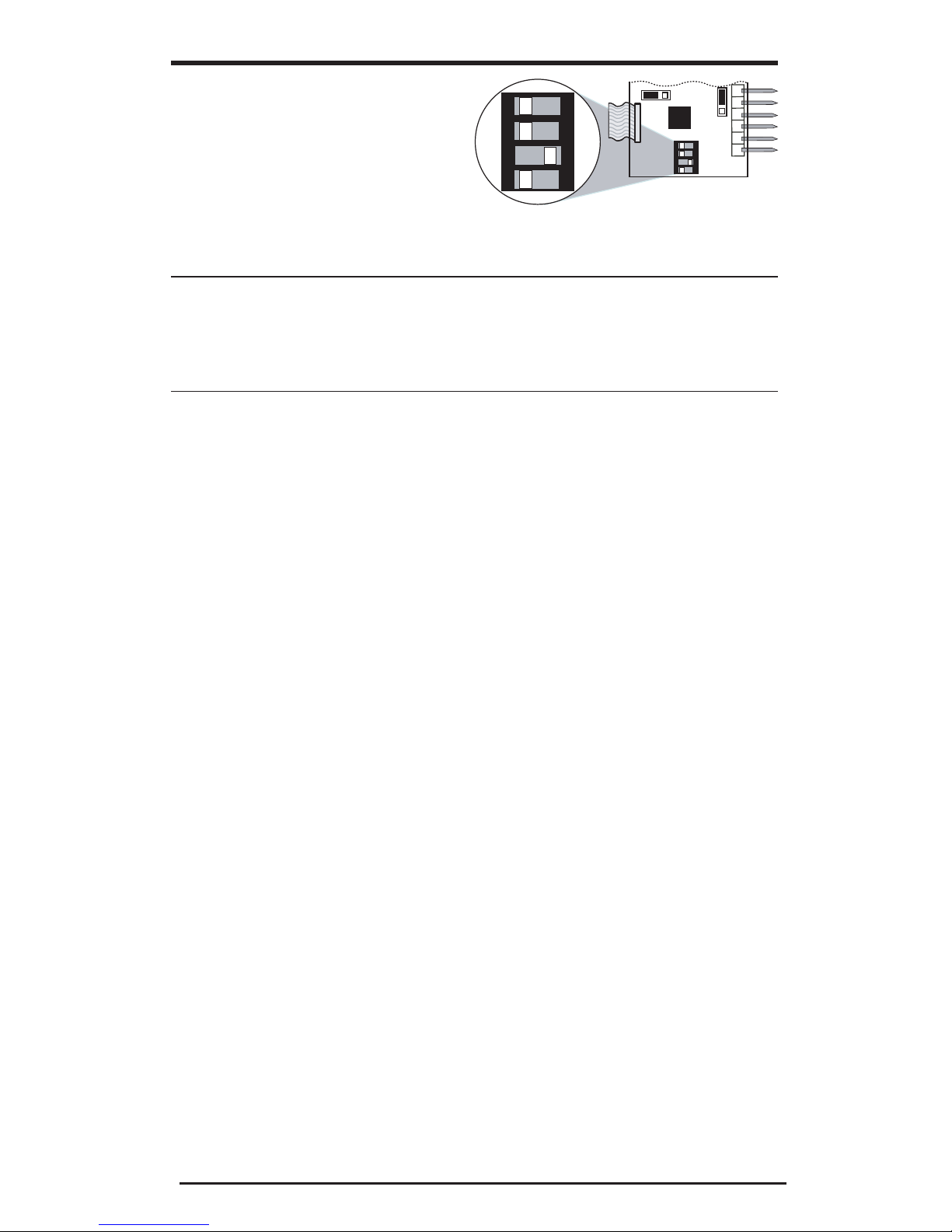

Control

panel

i

12

1

23

4

5

67

8

9

10

11

SB01

20 m (65.6 ft)

60 m (197 ft)

2.3 m (7.5 ft)

1

2

3

4

5

6

7

8

9

10

11

12

1

23

4

5

67

8

9

10

11

ST400

Page 10

- 8 -

EN

Installation Instructions

1. Introduction .............................................................................................. 8

2. Installation guidelines ............................................................................... 8

3. Mounting the detector .............................................................................. 9

4. Setting the detector ................................................................................. 9

5. Testing the anti-masking ........................................................................ 13

6. Aligning the beam and walk testing the detector ................................... 13

7. Identifying detector status by the LEDs ............................................... 15

8. General information ............................................................................... 16

9. Remote and self-testing the detector .................................................... 17

10. Glossary .............................................................................................. 18

11. Technical specifications ....................................................................... 18

1. Introduction

The VE735AM/VE736AM are PIR/AM motion sensors. They have a patented

verified PIR technology, multi-channel anti-masking. They were tested and

certified to TS50131-1 / TS50131-2-2 for security grade 3, environmental

class 2, by the Dutch testing and certification body Telefication B.V.

2. Installation guidelines

The technology in this detector resists false alarm hazards. Nevertheless

avoid potential causes of instability, such as:

Direct sunlight on the detector.

Heat sources within a field of view.

Strong draughts onto the detector.

Large animals in a field of view.

Objects within 50 cm (20 in.) of the anti-masking (AM) detector.

Obscuring the detector’s field of view with large objects, such as

furniture.

Installing two detectors facing each other and less than 50 cm apart.

Page 11

- 9 -

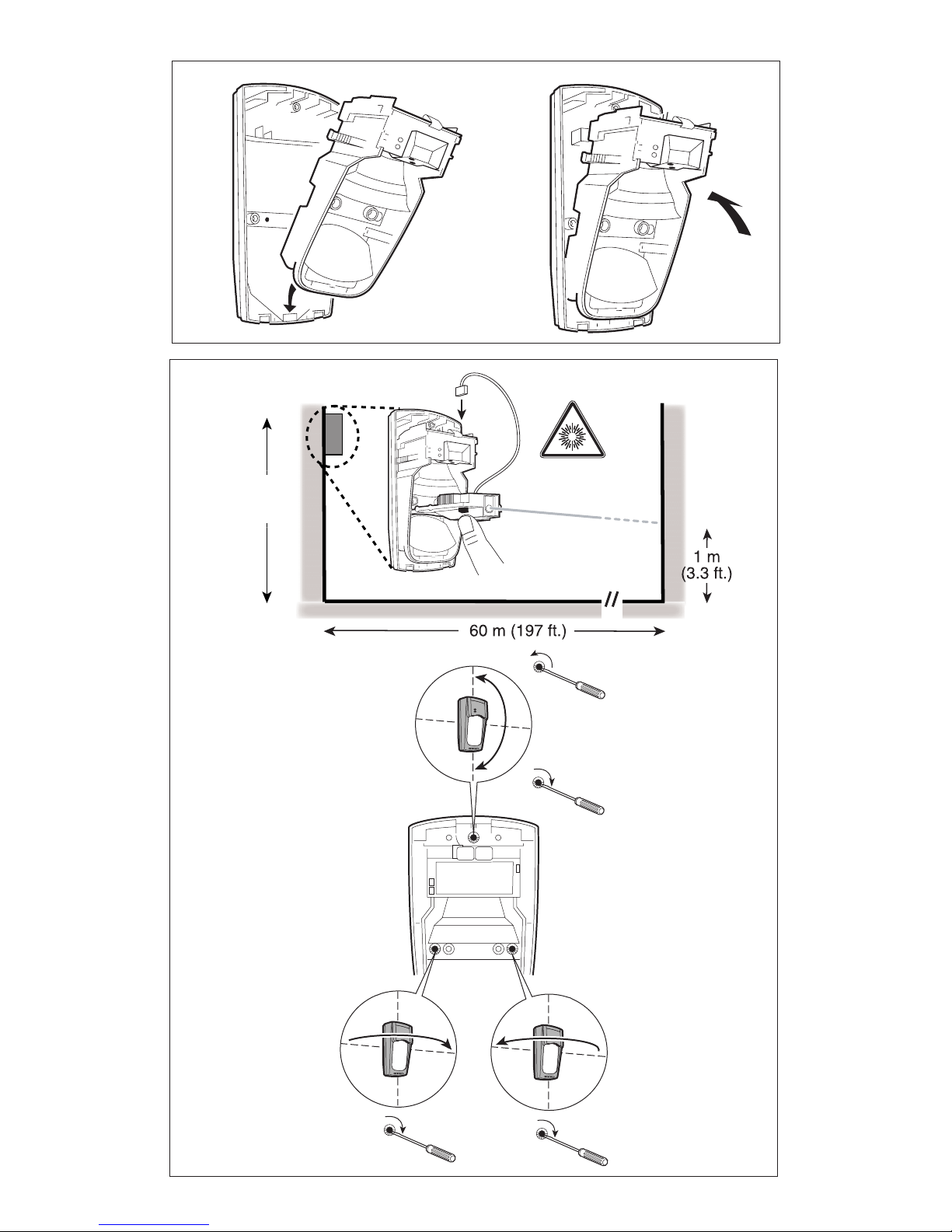

3. Mounting the detector

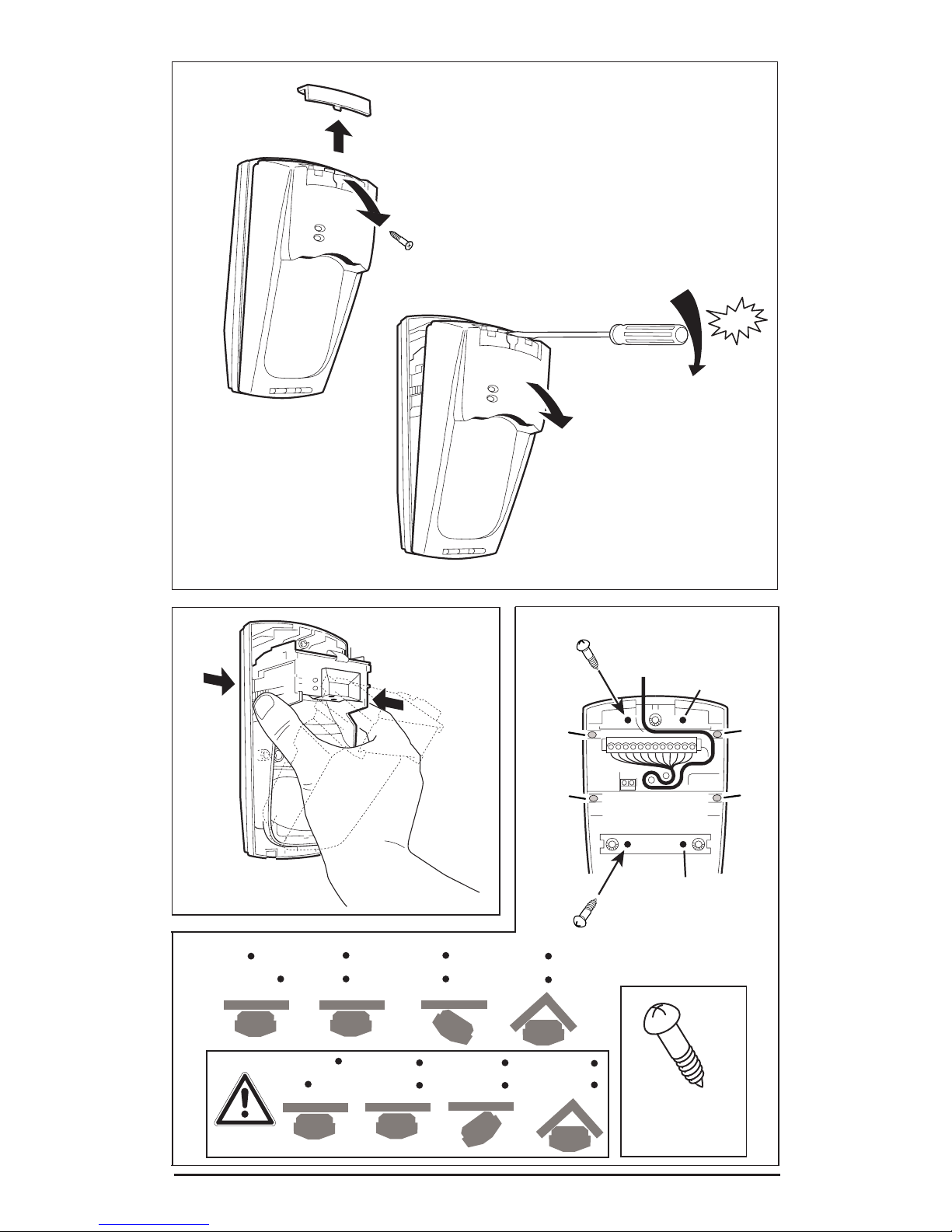

1. Lift off the custom insert and remove the enclosed screw (fig. ,

steps 1 and 2).

2. Using a screwdriver, carefully prise open the detector (fig.

, steps 3

and 4).

3. Remove the interior part (fig.

).

4. Fix the base to the wall between 1.8 m and 3.0 m (5.9-9.8 ft.) from the

floor. For flat-mounting use a minimum of two screws (DIN 7998), at

least one in position A and one in position B. For corner-mounting use

screws in positions C or D (fig.

).

CAUTION! Not all screw positions have pry-off tamper. Non

pry-off positions are shown in the Warning box in figure

.

5. Wire the detector (figs. and ).

6. Select the desired jumper and DIP switch settings (Section 4).

7. Replace the interior part (fig. b).

8. Align the detector, as shown (figs. c and

j) and see

Aligning the

beam and walk testing the detector

(section 6).

9. Remove the blinders and add the stickers, if required (see figs. d and

e for an example).

10. Insert the insect-protection caps (fig. f, step 1).

11. Close the cover (fig. f, step 2).

12. Insert the screw (if required) and replace the custom insert (fig. f,

step 3).

4. Setting the detector

The detector must be restarted (re-powered) after changing the settings or

detection pattern.

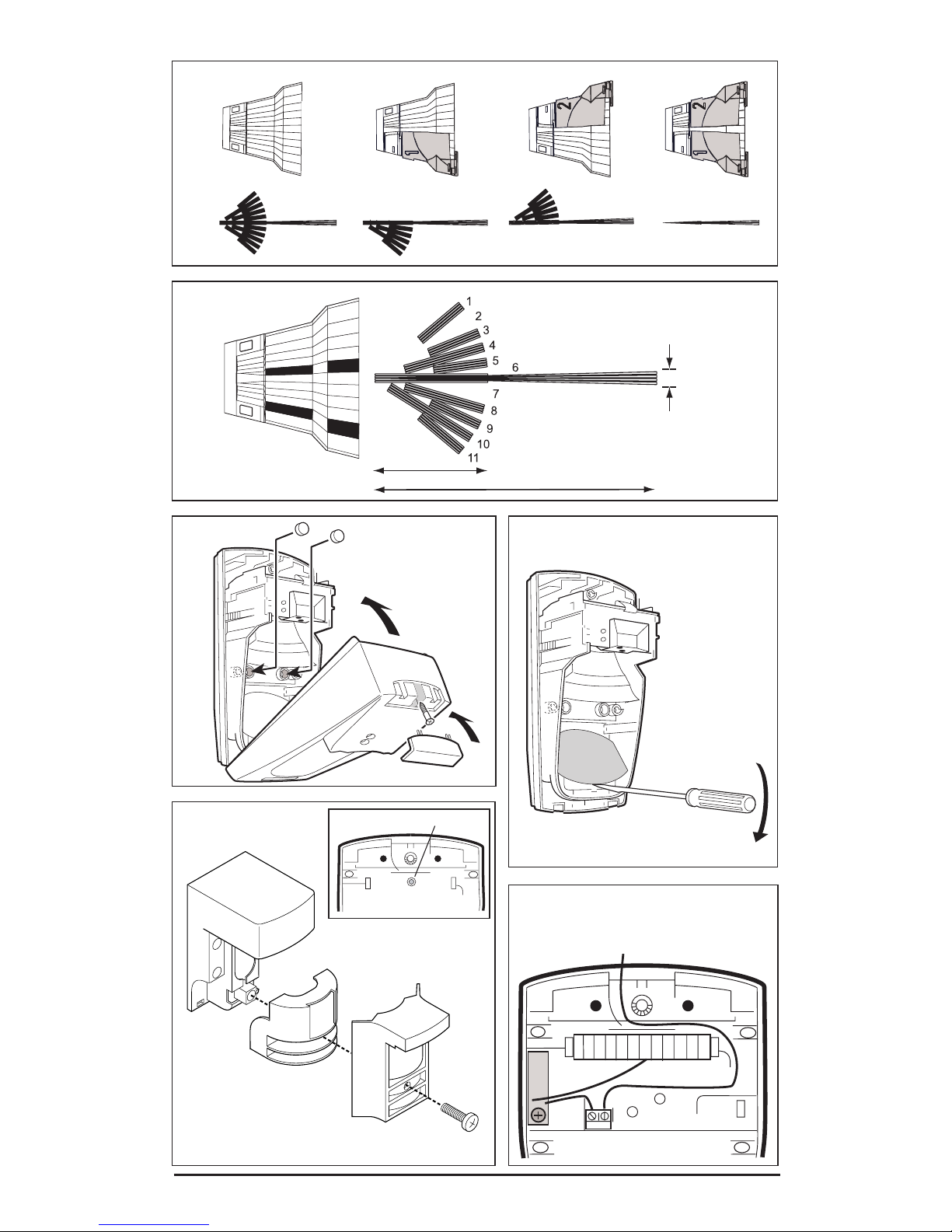

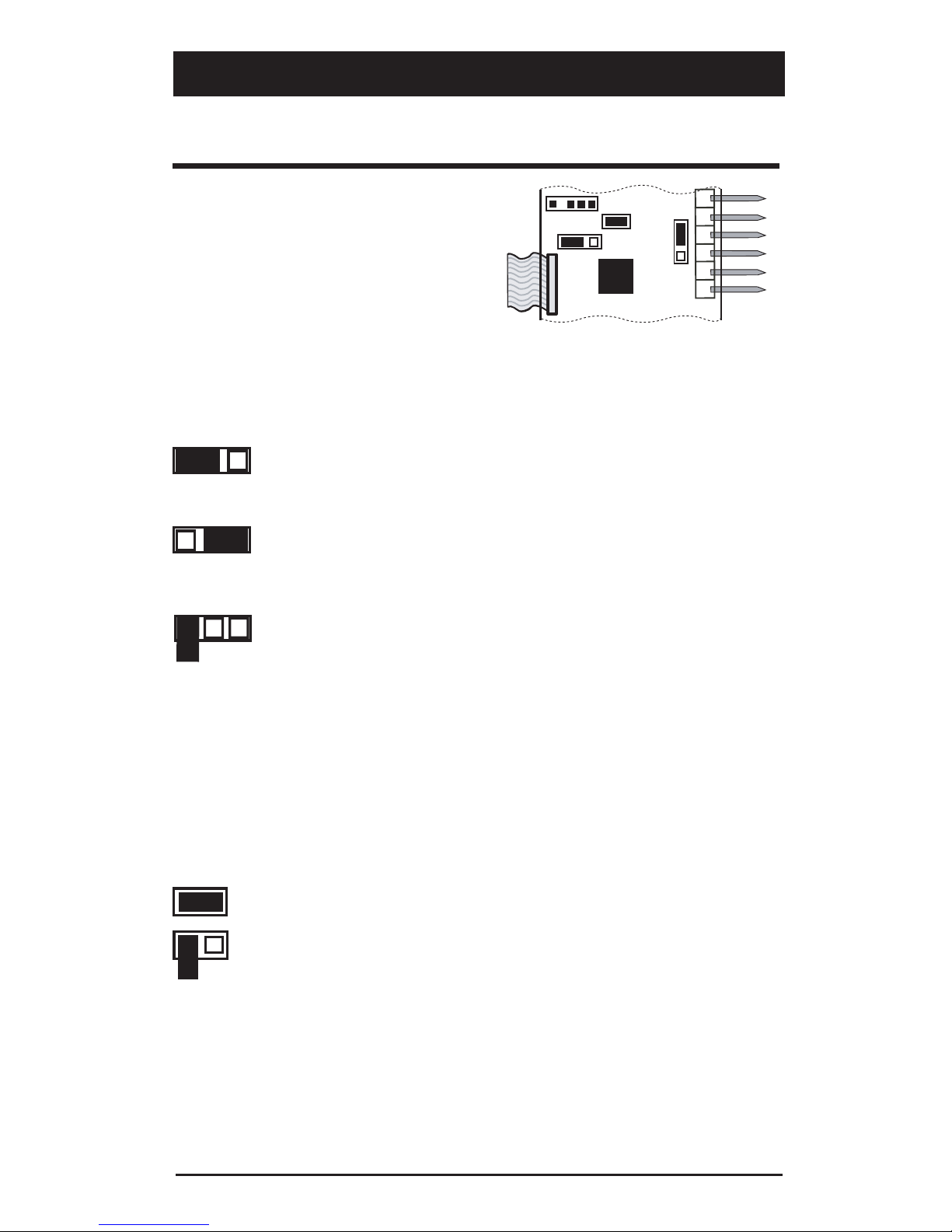

Jumpers (fig. )

J1 : PIR sensitivity

It changes the distance-to-alarm delay (the speed of the decision

algorithm); the higher the sensitivity, the faster the sensor will react

(fig.

). There are three different PIR sensitivities.

J1

J2

J3

5 6 7 8 9 10

Page 12

- 10 -

Low sensitivity

: Use where there is a risk of false alarms. Do

not use in long-range applications (>20 m (65.6 ft.)) or singlecurtain applications.

Medium sensitivity:

Most situations (ex-factory).

High sensitivity:

Use for high-risk situations. Recommended

for use in corridors.

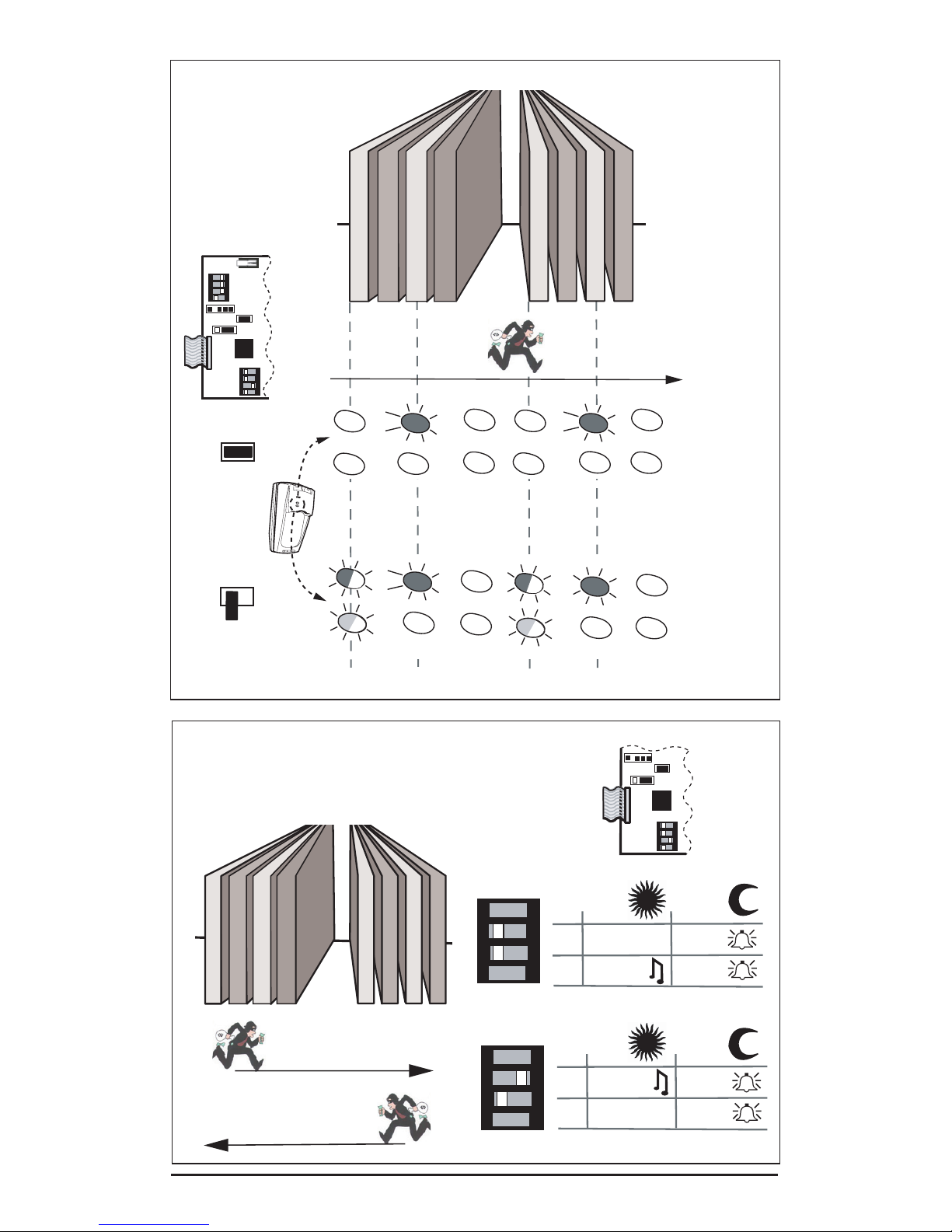

J2 : Curtain Location Mode (CLM)

It allows you to identify where the edges of the curtains are precisely

located. When an intruder enters a curtain, the red and yellow LEDs flash

alternatively (fig.

). J2 is also used for long-range alignment (see section

6).

Off

On.

See Section 6B.

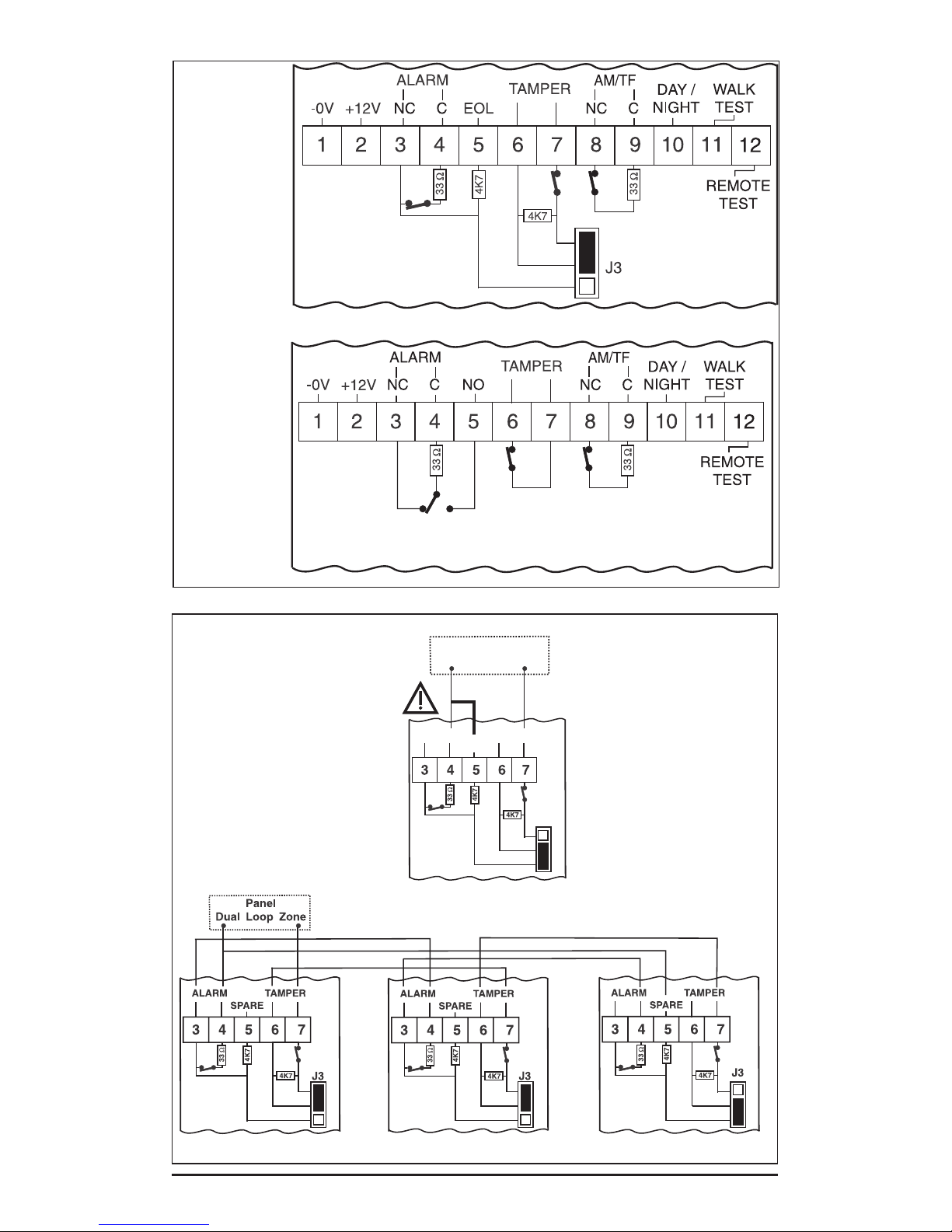

J3 : Dual loop (only available on VE735AM)

It is used to set the alarm and tamper relay. It allows you to connect the

detector to any control panel.

EOL Loop (4K7)

Terminals 4 and 5 of the alarm output must be used when

connecting to the control panel.

Isolated Alarm and Tamper Loop (ex-factory)

Tamper is isolated from the alarm relay. The EOL resistor in

the tamper circuit is short-circuited.

Terminals 3 and 4 of the alarm output must be used when

connecting to the control panel.

Dual Loop

Tamper and alarm loop can be monitored over two wires.

In a normal situation (no alarm) the Dual Loop impedance is

4K7. For a detector alarm, the alarm relay contact opens and

the impedance of the Dual Loop increases to 9K4, indicating

an alarm. When the detector housing is opened, the tamper

circuit opens and the Dual Loop is interrupted, indicating a

tamper alarm (fig.

).

Page 13

- 11 -

PIR DIP switches (fig. )

Table 1: PIR DIP switches

Function DIP switch On DIP switch Off

4. LEDs LEDs On LEDs Off

3. Chime direction Left-to-right Right-to-left

2. Chime Chime On Chime off

1. Polarity Active High Active Low

DIP switch 1: Polarity of control voltage (CV)

On: “Active High” provides the standard GE Security logic with “Active

High” logic to enable Walk Test and Day/Night inputs.

Off: “Active Low” provides “Active Low” logic to enable Walk Test and Day/

Night inputs.

DIP switch 2: Chime (fig. )

The detector can distinguish the direction of the intruder during daytime.

Disable this option by setting the detector to Chime Off. When the chime

is On, the detector will trigger an alarm when the intruder moves right-to-left

or left-to-right across the curtains.

Note: If the Day/Night terminal is not used and the chime is On, the

chime will be On both during arm and disarm (Day/Night) mode.

DIP switch 3: Chime direction (fig. )

On: Alarm when an intruder walks from left-to-right.

Off: Alarm when an intruder walks from right-to-left.

(Stand with your back to the detector to determine left and right directions.)

DIP switch 4: LEDs

On: Enables both LEDs on the detector at all times.

Off: Puts both LEDs under the control of the Walk Test and Day/Night

input.

(ex-factory)

J1

J3

12 34

ON

7 8 9 1 0 11 12

12 34

ON

Page 14

- 12 -

AM DIP switches (fig. )

Table 2: AM DIP switches

Function DIP switch On DIP switch Off

4. How to signal

AM or TF output

Relay Relay

AM Alarm AM Alarm

AM

-

TF -

-

3. Reset AM or TF After walk test Authorised reset

2. AM sensitivity High Standard

1. When to signal Day mode only Day/Night mode

AM or TF output

AM DIP switch settings:

1. When to signal AM (anti-masking) or TF (technical fault)

output

On: Signals AM or TF only when the system is in Day mode. EN 50131-2-2

compliant.

Off: Always signal AM or TF.

CAUTION! To prevent AM alarms during Night mode, the

following DIP switch settings are recommended:

4: Off

3: Off

2: Off

1: On

AM alarms are now only signaled to the control panel during

Day mode by the AM relay. The LEDs are controlled by Day/

Night and Walk Test inputs. Resetting the AM alarm can only

be done in walk test mode.

Never show the detector state to the intruder via the LEDs.

2. AM sensitivity

On: Selects a higher level of AM sensitivity. AM relay reacts within 6

seconds.

Off: Selects the standard AM sensitivity. AM relay reacts within 12

seconds.

(ex-factory)

1 2 3 4 5

12 34

ON

12 34

ON

Page 15

- 13 -

3. Resetting the AM/TF output

The VE700AM will only reset an AM alarm if it has ensured that the cause of

the AM alarm has been removed. If the AM circuitry cannot return to its

original reference levels, then either the detector is still masked or has

possibly been damaged. The owner should then visually check that the

detector is still fully functional.

On: After a 40-second inhibit period, resets the AM or TF status when a PIR

alarm is generated.

Off: Resets the AM or TF status after a PIR alarm, when the system is set

into Day and Walk Test status. The yellow LED will blink quickly. When

the system is in Night status, the yellow LED will turn off and the

system is reset.

4. How to signal AM or TF output

On: Signals AM on

both

the AM and Alarm relays.

Signals TF on the AM relay only.

Off: Signals AM and TF on the AM relay.

5. Testing the anti-masking

AM start-up sequence: When the VE700AM is powered, the AM circuitry will

wait until the cover of the detector is properly mounted.

As soon as the cover is mounted, the AM circuitry will monitor the housing

and the surrounding area and store the received signal levels as reference

levels. This procedure takes 75 seconds. During this period, the surrounding

area should remain clear from movement and objects temporarily placed

within 50 cm of the detector.

To test the anti-masking ensure that the PIR DIP switch 4 is set to On (LED

On) and then hold your hand approximately 10 cm (4 in.) in front of the

detector for 12 seconds (when using standard sensitivity) or for 6 seconds

(when using high sensitivity). The yellow LED will light accordingly.

6. Aligning the beam and walk testing the

detector

A. Using VE710 alignment tool (fig. c)

1. Insert the VE710 in the sub-frame with the On/Off switch facing the

floor.

2. Connect it to the COM port.

3. Turn on the VE710.

Page 16

- 14 -

WARNING! Do not look into the laser beam.

The output power is less than 1 mW. Consequently the

VE710 laser is classified by IEC60825-1 as a Class 2

laser. The eye’s blinking reflex is fast enough to prevent

any permanent damage to the eye.

4. The laser spot indicates the product alignment (Fig. c A). If this spot

on the wall veers from the centre of the desired detection area 1 m

(3.3 ft.) from the ground, then loosen the base fixation screws (Fig.

) and use the three adjustment screws in the base to realign it to the

centre, as shown in Fig. c B. When the spot is correctly realigned,

retighten the base fixation screws.

5. Remove the alignment tool and replace the cover.

6. Carry out the walk test. Make sure that the red LED is On after the

walk test.

B. Without the alignment tool (fig. j, back cover)

1. Insert the mirror blinders in order to ensure that the detector is in

single-curtain mode.

2. Put J2 to On and wait until both LEDs are Off.

3. Walk in front of the detector across the field of view at normal speed

(without pausing) and at the maximum possible range. When you enter

the beam, both LEDs will start to blink simultaneously.

After crossing the beam, if:

1. The red LED is On (fig.

j A), the alignment is OK.

2. The red and yellow LEDs are blinking simultaneously then the

field of view is obstructed and is insufficient to verify an alarm.

There are two options:

If the blinking started near the end of the detection area, you need

to align the beam to the left (fig.

j B).

If the blinking started near the start of the detection area, you need

to align the beam to the right (fig.

j C).

Loosen the base fixation screws (fig.

) and use the three adjustment

screws in the base to realign the beam to the centre, as shown in fig.

c B. When the beam is correctly realigned, retighten the base fixation

screws.

4. If the LEDs do not blink, the curtain is outside of the detection range

(fig.

j D) . Walk across the beam at a shorter distance to try to

detect it.

5. Redo the walk test to confirm that the detector is correctly aligned.

6. Put J2 to Off.

Note 1: If the CLM is On, the alarm output is activated.

Note 2: It is recommended to place the cover on the detector during the

CLM walk test.

Page 17

- 15 -

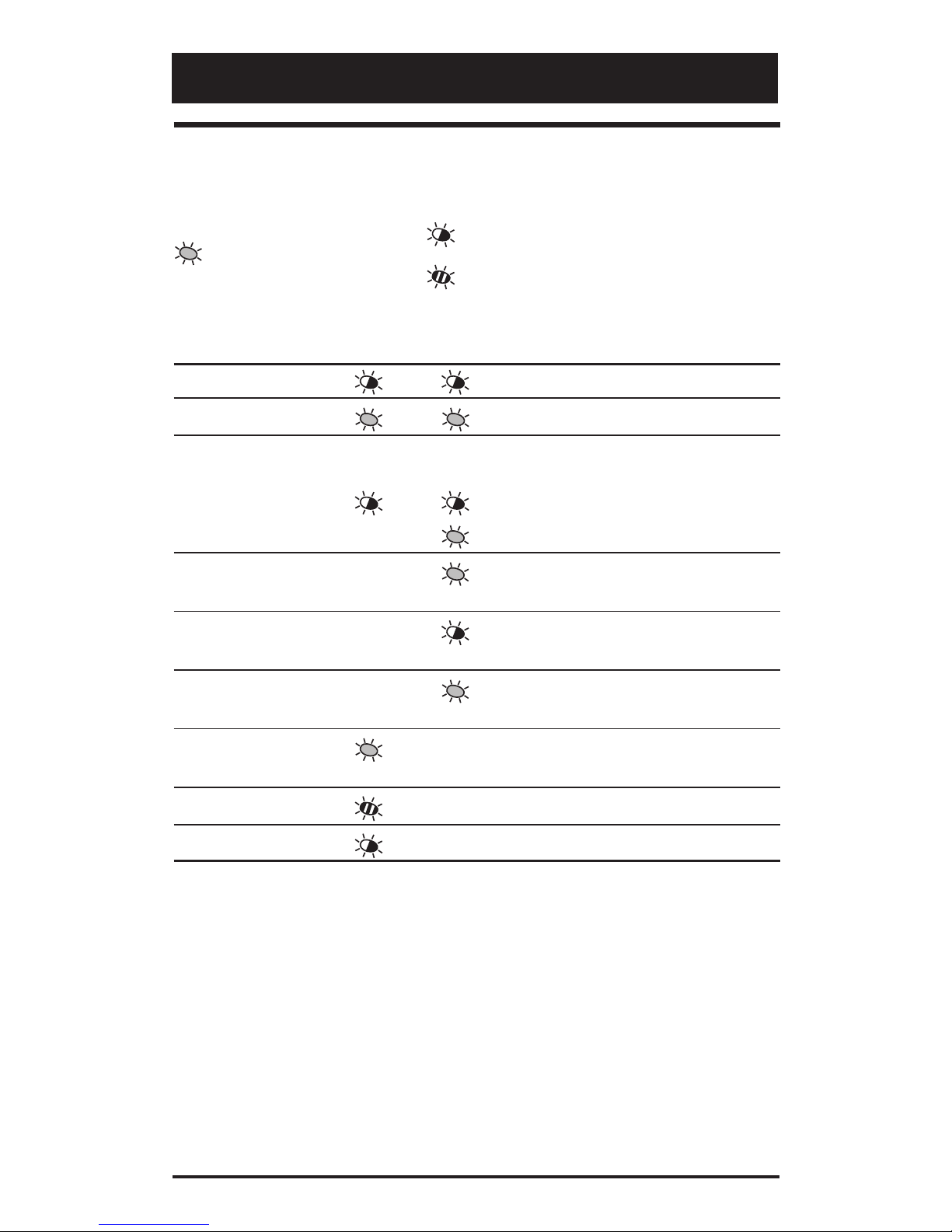

7. Identifying detector status by the LEDs

A) LED indication

Table 3: LED indication

= Continuously On = Normal blinking (1 Hz)

= Fast blinking (4 Hz)

Detector Yellow Red To reset

status LED LED

Power On Automatically after 70 sec.

High/Low voltage Apply correct voltage.

CLM

Someone enters

the curtains

PIR intruder alarm - - - Automatically after 3 sec.

PIR intruder alarm - - -

Automatically after 3 sec.

Latched PIR - - - Switch to Day mode.

alarm: 1st to alarm

Latched PIR - - -

Switch to Day mode.

alarm: 2nd to alarm

AM alarm

- - - See table 2, DIP switch 2

(page 12).

After AM reset - - - Switch to Night mode.

Technical fault - - - Do a successful walk test.

Page 18

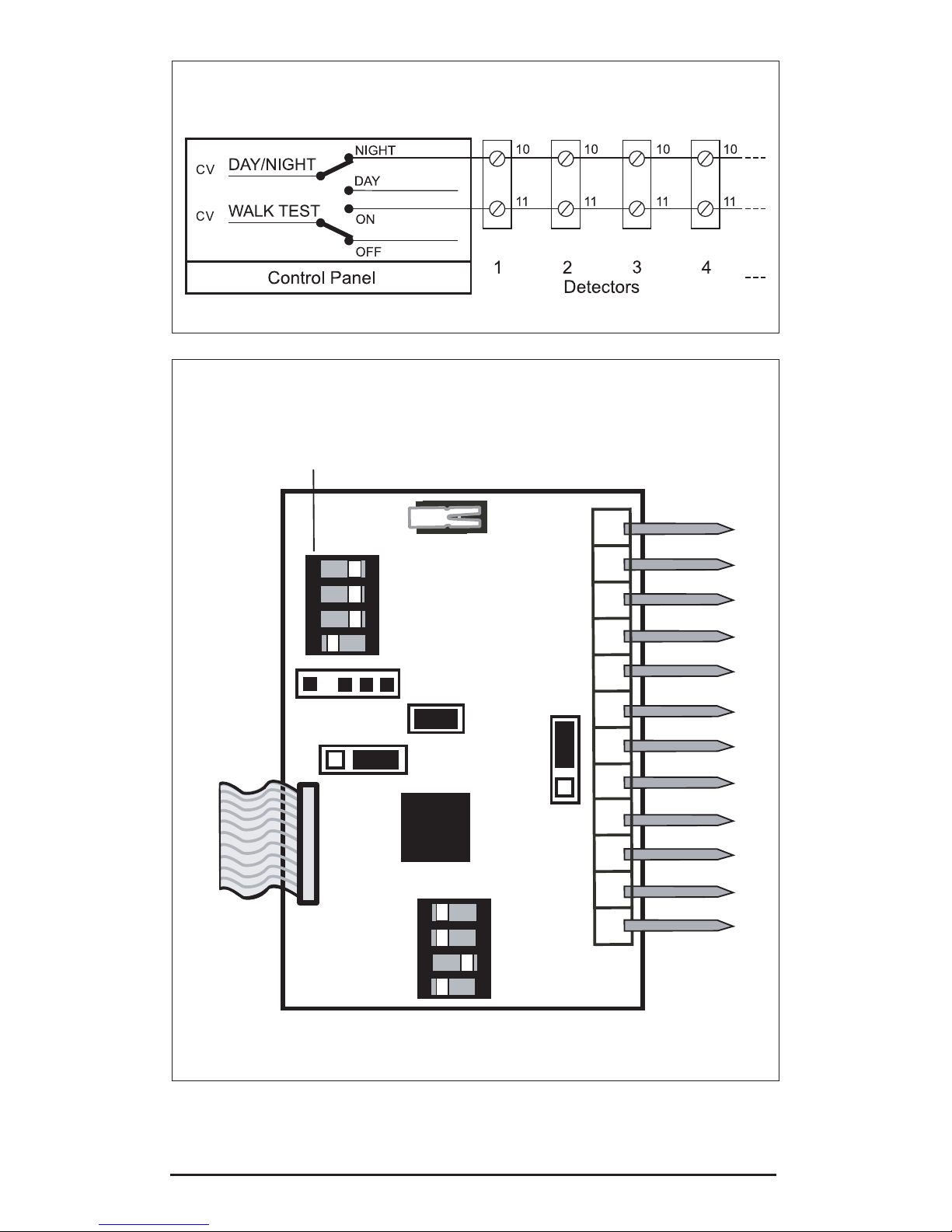

8. General information

Note: First set the appropriate active polarity of the Control Voltage

(CV) using the PIR DIP switch 1. The detector is in Night mode when

the appropriate control voltage is applied to terminal 10 and in Day mode

when the control voltage is disconnected.

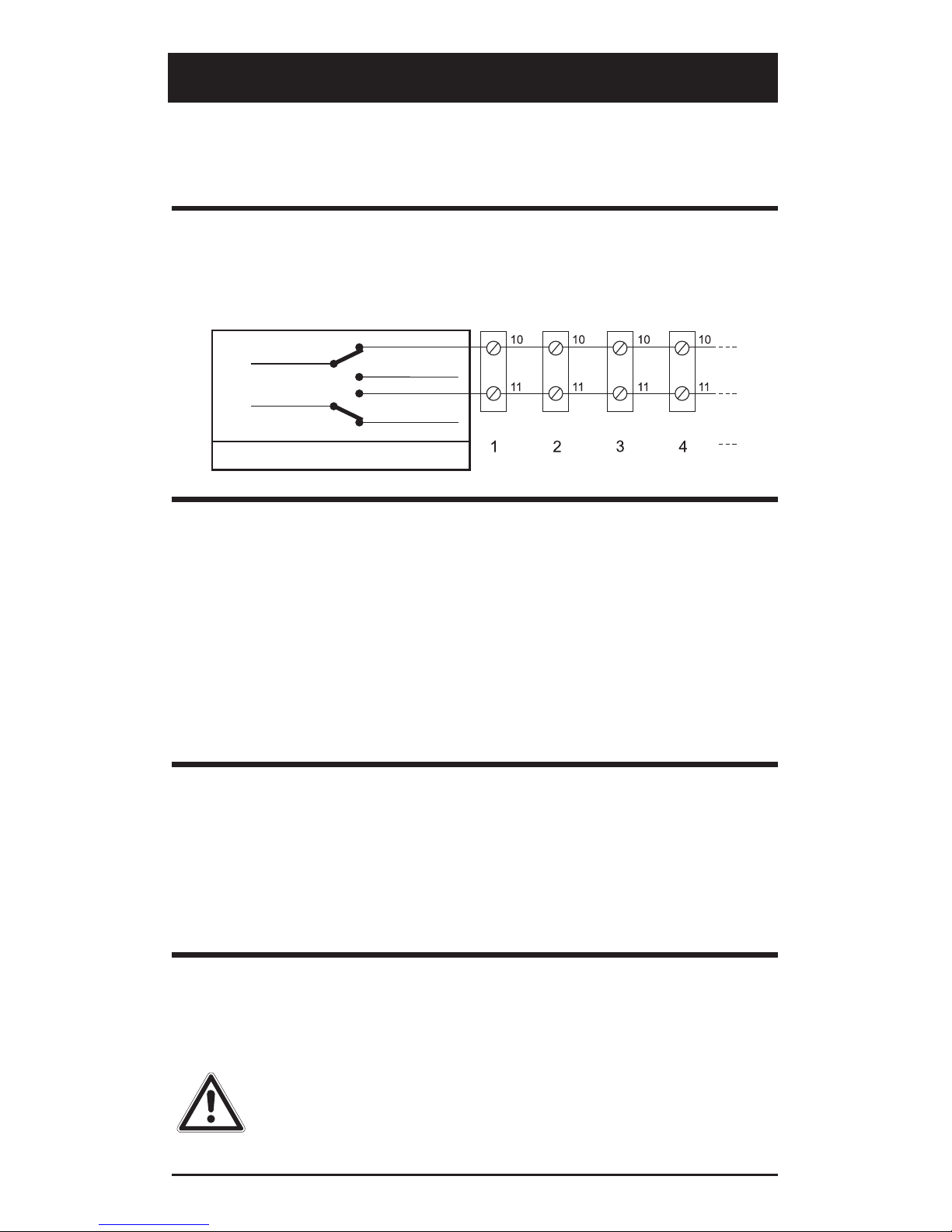

A) Latching

When using multiple detectors in a single loop, wire for Day/Night and Walk

Test inputs, as shown below (repeated in figure

).

B) Remotely enabling/disabling the walk test LED (fig.

)

Put the detector in Day mode and enable the walk test status. The

detector’s LED will turn on as the alarm relay opens and turn off when the

relay closes. The walk test can now be carried out.

To enable the walk test LED without a remote CV input, set DIP switch 4 to

the On position. After the walk test, set DIP switch 4 to the Off position.

It is recommend that the detector is regularly walk tested and the

communication with the control panel checked.

C) Setting the alarm memory (fig. )

In Day mode a blinking LED indicates which of the detector(s) have caused

the alarm during Night mode.

Switching back into Night mode will clear the memory and turn the LED off.

Enabling the walk test will not clear the alarm memory. Disabling the walk

test will cause the indication of memorised alarms to re-appear.

D) Selecting the coverage pattern (fig. e)

The coverage pattern can be changed to fit specific requirements by using

the mirror stickers (enclosed), as shown. It is recommended to blind unused

curtains that are looking at objects located very close to the detector.

CAUTION! Removing the stickers can damage the mirror

surface!

- 16 -

Detectors

Day/Night

Walk test

Night

Day

Off

On

Control panel

CV

CV

Page 19

E) Blocking the curtains (fig. d)

The mirror blinders are fitted ex-factory on the mirror. To remove a blinder,

first remove the interior part of the detector. Then lift the lower part of the

blinder and wiggle the upper part to loosen it. When long-range detection

is not required (>20 m (>65.6 ft.)), remove the long-range mirror (fig.

g).

F) Pry-off and cover tamper

The detector has both pry-off and cover tamper (EN 50131-2-2 compliant).

A. It is important to use the screw indicated

in figure in order to

ensure pry-off tamper.

B. For corner-mount applications, use the ST400 for pry-off tamper (fig.

i). However, see the caution listed in section 3, step 4.

G) SB01 swivel-mount bracket (optional)

When it is not possible to mount the detector on a wall, use the SB01 to

mount it on the ceiling (fig.

h).

9. Remote and self-testing the detector

Technical fault: There are two causes for technical faults.

A: It is caused by continuously monitoring the pyro and the AM circuit

reference levels.

B: It is caused by the Self Test and the Remote Test.

Remote test: This test allows the VE700AM to be tested from the control

panel. Use terminal 12 to activate it. The VE700AM will activate the Alarm

relay if the test result is positive and the AM relay if the test result is

negative.

Self test: The VE700AM monitors the PIR and AM circuits continuously. A

defect is reported as a technical fault.

- 17 -

Page 20

- 18 -

Remote test: Self test:

Technical fault:

A: A technical fault detected by continuous monitoring can be reset in two

ways.

1. Authorised reset. Set the system to Day and Walk Test status and

then carry out a walk test. At the next PIR alarm the system resets if

all reference levels are within the specified limits.

2. Auto reset. After a 40-second inhibit period, it automatically resets

after a successful walk test if all reference levels are within the

specified limits.

B: A technical fault detected by a Self Test or a Remote Test can only be

reset by another Self Test or a Remote Test if the test is successful.

10. Glossary

Alarm memory: A storage medium located on the detector that can record

signals generated by the detector.

Anti-masking (AM): A feature of the detector that allows it to detect when

someone is trying to mask it (for example, by spraying paint on it). When

masking is detected, a relay is activated.

Curtains: A vertical continuous layer of detection zones. The PIR detector

can only detect motion within the curtains and not in the spaces between

them.

Curtain Location Mode (CLM): A feature of the detector that identifies

precisely the edges of the curtains.

Day mode: The detector is not required to generate an alarm signal or

message when activated by a person walking in front of it.

Masking: Placing a physical barrier (such as paper, metal or sprayed

paints) close to or on the detector which interferes with its capability to

detect an intrusion.

3 sec.

8 hr.

8 hr.

8 hr.

8 hr.

AM relay:

Alarm relay:

Status

Terminal 12:

VE700AM

OK

AM relay:

* Starts 1 hour after installation

VE700AM

not OK

PIR*:

AM*:

VE700AM

not OK

Page 21

- 19 -

Night mode: The detector generates an alarm signal or message when

activated by a person walking in front of it.

Remote test: The control panel monitors the detector’s sensor and

associated on-board signal processing circuitry.

Self test: The detector itself monitors the sensor and associated on-board

signal processing circuitry.

Technical fault (TF): The fault signal or message that is generated on the

AM relay when the detector suffers a fault.

Walk test: An operational test done by the installer to see if the equipment

will generate an alarm.

11. Technical specifications

Input power 9 VDC to15 VDC (12 Vnominal)

Peak-to-peak ripple 2 V (at 12 VDC)

Current consumption:

Normal operation 20 mA

Alarm 24 mA

Maximum 34 mA

Control input voltage Low 0 to1.5 VDC

(terminals 10-11-12) High 3.5 to 15 VDC

Mounting height Min 1.8 m, max 3.0 m

(Min 5.90 ft., max 9.84 ft.)

Target speed range 10 cm/sec to 4 m/sec

(4 in./sec to 13 ft./sec)

Alarm relay Optical relay is immune to magnetic influence

Alarm output 80 mA at 30 VDC max.

Tamper output 80 mA at 30 VDC max.

Trouble output 80 mA at 30 VDC max.

Alarm time 3 sec

Detector start-up time 70 sec

Operating temperature -10°C to +55°C

(14°F to 130°F)

Relative humidity Max. 95%

Dimensions (H x W x D) 175 x 93 x 66 mm

(6.88 x 3.66 x 2.60 in.)

Weight 275 g (9.70 oz.)

Number of curtains 11 at 20 m and 1 at 60 m

(11 at 65.6 ft. and 1 at 197 ft.)

Viewing angle 86° at 20 m and 3° at 60 m

IP/IK rating IP30 IK02

Page 22

Istruzioni per l’installazione

1. Introduzione ............................................................................................ 20

2. Linee guida per l’installazione ................................................................. 20

3. Montaggio del rilevatore ......................................................................... 21

4. Impostazione del rilevatore .................................................................... 22

5. Test dell’antimascheramento ................................................................. 26

6. Allineamento della tenda centrale e test di copertura del rilevatore ..... 26

7. Identificazione dello stato del rilevatore tramite i LED .......................... 28

8. Informazioni generali .............................................................................. 28

9. Test remoto e autotest........................................................................... 30

10. Glossario .............................................................................................. 31

11. Specifiche tecniche .............................................................................. 32

1. Introduzione

VE735AM e VE736AM sono rilevatori di movimento PIR/AM, vale a dire

dotati di tecnologia PIR brevettata e di antimascheramento a canale

multiplo. Sono stati approvati dall’organismo olandese di test e

certificazione Telefication B.V per gli standard TS50131-1 / TS50131-2-2,

grado di sicurezza 3, classe ambientale 2.

2. Linee guida per l’installazione

La tecnologia contenuta nel rilevatore è a prova di falsi allarmi. È tuttavia

opportuno evitare possibili fattori di instabilità, quali:

Esposizione del rilevatore alla luce solare diretta.

Fonti di calore all’interno del campo visivo.

Forti correnti d’aria in prossimità del rilevatore.

Animali di grossa taglia all’interno del campo visivo.

Presenza di oggetti nel raggio di 50 cm dal rilevatore

antimascheramento.

Oscuramento del campo visivo del rilevatore con oggetti di grandi

dimensioni (es. mobilio).

Installazione di due rilevatori l’uno di fronte all’altro a meno di 50 cm

di distanza.

IT

- 20 -

Page 23

- 21 -

3. Montaggio del rilevatore

1. Sollevare la chiusura a incastro e rimuovere la vite (fig. , passi 1

e 2).

2. Aprire il rilevatore facendo leva con un cacciavite (fig.

, passi 3 e

4).

3. Rimuovere la parte interna (fig.

).

4. Fissare la base al muro ad un’altezza dal pavimento compresa tra 1,8

e 3 m. Per il montaggio su superficie piana, utilizzare almeno due viti

(DIN 7998), una nella posizione A e una nella posizione B. Per il

montaggio angolare, utilizzare le viti nelle posizioni C o D (fig.

).

ATTENZIONE: non tutte le posizioni delle viti sono dotate di

protezione antimanomissione e antirimozione. Le posizioni non

dotate di protezione antirimozione sono mostrate nel riquadro

contrassegnato dal simbolo di Attenzione nella figura

.

5. Collegare il rilevatore (fig. e ).

6. Selezionare le impostazioni desiderate dei ponticelli e dei commutatori

DIP switch (sezione 4).

7. Riposizionare la parte interna (fig. b).

8. Allineare il rilevatore come illustrato (fig.

c e j) e consultare la

sezione 6

Allineamento della tenda centrale e test di copertura del

rilevatore

.

9. Rimuovere la schermatura e applicare gli adesivi secondo necessità

(alcuni esempi alle figg. d e e).

10. Inserire i tappi di protezione dagli insetti (fig. f, passo 1).

11. Chiudere il coperchio (fig. f, passo 2).

12. Inserire la vite se necessario e riposizionare la chiusura a incastro

(fig. f, passo 3).

Page 24

4. Impostazione del rilevatore

Riavviare (spegnere e riaccendere) il rilevatore dopo aver modificato le

impostazioni o il campo di rilevazione.

Ponticelli (fig. )

J1 : Sensibilità PIR

Questa impostazione agisce sulle semitende da interessare per ottenere

un allarme; maggiore è la sensibilità, maggiore è la velocità di reazione

del sensore (fig.

). Sono disponibili tre diverse sensibilità PIR.

Sensibilità bassa

: da utilizzare quando vi è il rischio di falsi

allarmi. Non utilizzare in applicazioni a lungo raggio (>20 m) o

a tenda singola.

Sensibilità media:

per la maggior parte delle situazioni

(impostazione di fabbrica).

Sensibilità alta:

per situazioni ad alto rischio. Raccomandata

per l’uso nei corridoi.

J2 : Modalità di posizionamento della tenda centrale

(CLM)

Consente di identificare esattamente la posizione dei margini delle tende

di rilevazione. Quando un intruso attraversa una delle tende, i LED rosso

e giallo lampeggiano alternativamente (fig. ). J2 viene utilizzato anche

per l’allineamento della tenda centrale a lungo raggio (vedere la sezione

6).

Disattivata (OFF)

Attivata (ON)

(vedere la sezione 6B)

J3 : Doppio bilanciamento (solo su VE735AM)

Serve per l’impostazione del relè di allarme e antimanomissione e

consente di collegare il rilevatore a qualsiasi centrale.

- 22 -

J1

J2

J3

5 6 7 8 9 10

Page 25

Circuito con resistenza di fine linea singola (4K7)

Per il collegamento alla centrale utilizzare i morsetti 4 e 5

dell’uscita allarme.

Circuito di allarme e antimanomissione isolati

(impostazione di fabbrica)

Il relè di manomissione è isolato dal relè di allarme. Il

resistore di fine linea del circuito antimanomissione è

cortocircuitato.

Per il collegamento del relè di allarme alla centrale utilizzare i

morsetti 3 e 4.

Doppio bilanciamento

I circuiti di allarme e antimanomissione possono essere

monitorati su due fili.

In condizioni normali (nessun allarme) l’impedenza del

circuito è 4K7. Nell’allarme del rilevatore, il contatto del relè

di allarme si apre e l’impedenza del circuito sale a 9K4,

indicando un allarme. Quando il contenitore del rilevatore

viene aperto, il circuito antimanomissione si apre e il circuito

viene interrotto, indicando così un allarme antimanomissione

(fig.

).

Commutatori DIP switch (fig. )

Tabella 1: Commutatori DIP switch PIR

Funzione DIP switch ON DIP switch OFF

4. LED LED accesi LED spenti

3. Direzione controllo Da sinistra a Da destra a sinistra

giorno destra

2. Controllo giorno Controllo giorno attivato Controllo giorno

disattivato

1. Polarità Attiva alta Attiva bassa

Commutatore DIP switch 1: Polarità della tensione di

controllo (CV)

ON: “Attiva alta” fornisce la logica standard GE Security attiva alta che

abilita gli ingressi test di copertura (walk test) e giorno/notte (day/

night).

- 23 -

J1

J3

12 34

ON

7 8 9 1 0 11 12

12 34

ON

(impostazione di fabbrica)

Page 26

OFF: “Attiva bassa” fornisce la logica attiva bassa che abilita gli ingressi

test di copertura e giorno/notte.

Commutatore DIP switch 2: Controllo giorno (fig. )

Il rilevatore è in grado di distinguere la direzione di movimento dell’intruso

durante il giorno. Per disattivare la funzione, impostare il rilevatore su

Controllo giorno disattivato. Quando è attivo il controllo giorno, il

rilevatore è in grado di attivare un allarme se un intruso cammina da

destra verso sinistra o da sinistra verso destra attraverso le tende di

rilevazione.

Nota: se il morsetto giorno/notte non viene usato ed è attivo il

controllo giorno, questo sarà attivo in entrambe le modalità inserimento

e disinserimento (giorno/notte).

Commutatore DIP switch 3: Direzione controllo giorno

(fig. )

ON: l’allarme scatta quando l’intruso procede da sinistra a destra.

OFF: l’allarme scatta quando l’intruso procede da destra a sinistra.

(Per determinare la sinistra e la destra porsi davanti al rilevatore con la

schiena rivolta ad esso.)

Commutatore DIP switch 4: LED

ON: attiva entrambi i LED del rilevatore in qualsiasi momento.

OFF: mette entrambi i LED sotto il controllo degli ingressi test di

copertura (walk test) e giorno/notte (day/night).

Commutatori DIP switch AM (fig. )

Tabella 2: Commutatori DIP switch AM

Funzione DIP switch ON DIP switch OFF

4. Come segnalare

l’uscita AM o TF

Relè Relè

AM Allarme AM Allarme

AM

-

TF -

-

3. Reset AM o TF Dopo test di copertura Reset autorizzato

2. Sensibilità AM Alta Standard

1. Quando segnalare Solo modo giorno Modo giorno/notte

l’uscita AM o TF

(impostazione di fabbrica)

1 2 3 4 5

12 34

ON

12 34

ON

- 24 -

Page 27

Impostazioni dei commutatori DIP switch AM:

1. Quando segnalare l’uscita AM (antimascheramento) o

TF (guasto tecnico)

ON: segnala l’uscita AM o TF solo quando il sistema è nel modo giorno.

Conforme allo standard EN 50131-2-2.

OFF: segnala sempre l’uscita AM o TF.

ATTENZIONE: per prevenire allarmi durante il modo notte, si

consiglia di impostare i commutatori DIP switch nel modo

seguente:

4: OFF

3: OFF

2: OFF

1: ON

Gli allarmi antimascheramento (AM) vengono in questo modo

segnalati alla centrale durante il modo giorno dal relè AM. I

LED sono controllati dagli ingressi giorno/notte e test di

copertura. Il reset degli allarmi AM può essere effettuato solo

nel modo test di copertura.

Evitare che l’intruso possa riconoscere lo stato del rilevatore

tramite i LED.

2. Sensibilità AM

ON: seleziona un elevato livello di sensibilità antimascheramento. Il relè

antimascheramento reagisce entro 6 secondi.

OFF: seleziona la sensibilità antimascheramento standard. Il relè

antimascheramento reagisce entro 12 secondi.

3. Reset dell’uscita AM/TF

Il rilevatore VE700AM consente il reset di un allarme antimascheramento

solo dopo aver accertato che la causa dell’allarme è stata rimossa. Se i

circuiti antimascheramento non possono tornare ai livelli di riferimento

iniziali, significa che il rilevatore è ancora mascherato o è possibile che

sia stato danneggiato. L’utente deve accertarsi tramite ispezione visiva

della corretta funzionalità del rilevatore.

ON: dopo un periodo di inibizione di 40 secondi, resetta lo stato AM o TF

dopo un allarme PIR.

OFF: Resetta lo stato AM o TF dopo un allarme PIR, quando il sistema è

impostato nello stato giorno e l’ingresso test di copertura (walk test) è

attivato. Il LED giallo lampeggerà velocemente. Quando il sistema è

nello stato notte, il LED giallo si spegne e il sistema si resetta.

4. Come segnalare l’uscita AM o TF

ON: segnala AM su

entrambi

i relè AM e allarme e TF solo sul relè AM.

OFF: segnala AM e TF solo sul relè AM.

- 25 -

Page 28

5. Test dell’antimascheramento

Sequenza di avvio AM: all’accensione del VE700AM, i circuiti AM

attenderanno il completamento del montaggio del coperchio del rilevatore.

Non appena il coperchio è montato, i circuiti AM iniziano il monitoraggio

dell’alloggiamento e dell’area circostante, memorizzando i livelli di segnale

ricevuti come livelli di riferimento. Questa procedura richiede 75 secondi.

In questo intervallo di tempo, nell’area circostante non deve esserci

movimento né devono essere temporaneamente posizionati oggetti in un

raggio di 50 cm dal rilevatore.

Per testare l’antimascheramento, verificare che il commutatore DIP

switch PIR 4 sia impostato su ON (LED acceso), quindi tenere la mano a

circa 10 cm di distanza dal rilevatore per 12 secondi (quando si usa una

sensibilità standard) o per 6 secondi (quando si usa una sensibilità

elevata). Il LED giallo si accende come previsto.

6. Allineamento della tenda centrale e test di

copertura del rilevatore

A. Con lo strumento di allineamento VE710 (fig. c)

1. Inserire il VE710 nell’apposito alloggiamento, con l’interruttore On/Off

rivolto verso il pavimento.

2. Collegarlo alla porta COM.

3. Accendere il VE710.

ATTENZIONE: non guardare il raggio laser.

La potenza di uscita è inferiore a 1 mW. Di conseguenza

il laser del VE710 è classificato secondo IEC60825-1

come un laser di Classe 2. Il riflesso di chiusura delle

palpebre è sufficientemente veloce da evitare danni

permanenti all’occhio.

4. Il punto luminoso generato dal laser indica l’allineamento del prodotto

(fig. c A). Se il punto sulla parete si discosta dal centro dell’area di

rilevazione desiderata e da 1 m rispetto al pavimento, allentare le viti

di fissaggio della base (fig.

) e usare le tre viti di regolazione nella

base per riallinearlo al centro, come indicato nella fig. c B. Quando il

punto luminoso è riallineato correttamente, riavvitare le viti di

fissaggio della base.

5. Rimuovere lo strumento di allineamento e riposizionare il coperchio.

6. Eseguire il test di copertura. Assicurarsi che il LED rosso sia acceso

dopo il test di copertura.

- 26 -

Page 29

B. Senza lo strumento di allineamento

(fig. j,

retrocopertina)

1. Inserire gli schermi dello specchio per fare in modo che il rilevatore

sia in modalità di copertura a tenda singola.

2. Portare J2 su ON e attendere che entrambi i LED si spengano.

3. Camminare davanti al rilevatore, attraverso il campo visivo, a

velocità normale (senza fermarsi) e alla distanza massima possibile.

Quando si attraversa il fascio, entrambi i LED iniziano a lampeggiare

simultaneamente.

Dopo aver attraversato il fascio:

1. Se il LED rosso è acceso (fig.

j A), l’allineamento è corretto.

2. Se il LED giallo e quello rosso lampeggiano simultaneamente, il

campo visivo è ostruito e non è sufficiente a verificare un

allarme. Sono disponibili due possibilità:

Se il lampeggiamento è iniziato verso la fine dell’area di

rilevazione, è necessario allineare il fascio a sinistra (fig. j B).

Se il lampeggiamento è iniziato verso l’inizio dell’area di

rilevazione, è necessario allineare il raggio laser a destra (fig. j

C).

Allentare le viti di fissaggio della base (fig. ) e usare le tre viti di

regolazione nella base per riallineare il fascio al centro, come

mostrato nella fig. c B. Quando il fascio è riallineato correttamente,

riavvitare le viti di fissaggio della base.

4. Se i LED non lampeggiano, la tenda è esterna all’area di rilevazione

(fig. j D). Camminare attraverso il fascio a una distanza inferiore

per cercare di rilevarlo.

5. Eseguire nuovamente il test di copertura per verificare il corretto

allineamento del rilevatore.

6. Posizionare J2 su OFF.

Nota 1: se è attiva la modalità di identificazione della posizione della

tenda centrale (CLM), viene attivata l’uscita allarme.

Nota 2: si consiglia di posizionare il coperchio sul rilevatore durante il

test di copertura CLM.

- 27 -

Page 30

7. Identificazione dello stato del rilevatore

tramite i LED

A) Indicatori LED

Tabella 3: Indicatori LED

= Acceso fisso = Lampeggiamento normale (1 Hz)

= Lampeggiamento veloce (4 Hz)

Stato rilevatore LED LED Per il reset

giallo rosso

Accensione Automatico dopo 70 secondi

Tensione alta/bassa Applicare la tensione corretta.

CLM

Qualcuno penetra

nelle tende di rilevazione

Allarme anti intrusione PIR - - - Automatico dopo 3 secondi

Allarme anti intrusione PIR - - - Automatico dopo 3 secondi

Allarme PIR memorizzato:

1° ad attivarsi - - - Commutare su modo giorno.

Allarme PIR memorizzato:

2° ad attivarsi - - - Commutare su modo giorno.

Allarme AM - - - Vedere la tabella 2, commutatore DIP

switch 2 (pagina 24).

Dopo il reset AM - - - Commutare a modo notte.

Guasto tecnico - - - Eseguire con successo un test di

copertura.

8. Informazioni generali

Nota: impostare la corretta polarità attiva della tensione di controllo

(CV) utilizzando il commutatore DIP switch PIR 1. Il rilevatore si trova

nel modo notte quando viene applicata la corretta tensione di controllo

al morsetto 10 e nel modo giorno quando la tensione viene scollegata.

- 28 -

Page 31

A) Collegamenti

Se si utilizzano più rilevatori in un unico circuito, effettuare i collegamenti

per giorno/notte (day/night) e test di copertura (Walk Test) come illustrato

di seguito (e riportato anche nella fig.

).

B) Attivazione/disattivazione remota del LED del test di

copertura (fig. )

Attivare la modalità giorno del rilevatore e lo stato di test di copertura. Il

LED del rilevatore si accenderà all’apertura del relè di allarme e si

spegnerà alla sua chiusura. Ora è possibile effettuare il test di copertura.

Per abilitare il LED del test di copertura senza un ingresso remoto della

tensione di controllo, impostare il commutatore DIP switch 4 su acceso.

Dopo aver effettuato il test di copertura, impostare il commutatore DIP

switch 4 su spento.

Si consiglia di effettuare periodicamente test di copertura e controlli delle

comunicazioni con la centrale.

C) Impostazione della memoria di allarme (fig. )

Nel modo giorno un LED lampeggiante indica il rilevatore che ha

provocato l’allarme durante il modo notte.

Per azzerare la memoria e spegnere il LED, reimpostare il modo notte.

La sola abilitazione del test di copertura non comporta l’azzeramento della

memoria di allarme: disattivando il test di copertura, l’indicazione degli

allarmi memorizzati verrà nuovamente visualizzata.

D) Selezione del campo di copertura (fig. e)

È possibile modificare il campo di copertura per adattarlo a determinate

esigenze utilizzando gli adesivi per gli specchi, come illustrato. È

opportuno schermare le tende non utilizzate rivolte verso oggetti situati in

prossimità del rilevatore.

ATTENZIONE: la rimozione degli adesivi potrebbe

danneggiare la superficie dello specchio.

CV

Giorno/notte

Test copertura

Notte

Centrale

CV

On

Off

Giorno

Rilevatori

- 29 -

Page 32

E) Blocco delle tende (fig. d)

Gli schermi per lo specchio sono montati sullo specchio in fabbrica. Per

rimuovere un oscuratore, rimuovere prima la parte interna del rilevatore.

Quindi sollevare la parte inferiore dell’oscuratore e muovere la parte

superiore per allentarla. Quando la rilevazione a lungo raggio non è

necessaria (>20 m), rimuovere lo specchio a lungo raggio (fig.

g).

F) Protezione antirimozione e antimanomissione

Il rilevatore è dotato di protezione antirimozione e antimanomissione (in

conformità con lo standard EN 50131-2-2).

A. Per fissare correttamente la protezione antirimozione, è importante

utilizzare la vite contrassegnata da

nella figura .

B. Per applicazioni con montaggio ad angolo, usare la protezione

antirimozione e antimanomissione ST400 (fig. i). Tenere presente

l’avvertenza riportata al passo 4 della sezione 3.

Nota: per la conformità al II° livello delle norme CEI 79-2 è obbligatorio

l’utilizzo della protezione antirimozione.

G) Supporto mobile SB01 (opzionale)

Quando non è possibile montare direttamente a parete il rilevatore,

utilizzare il supporto SB01 per montarlo a soffitto (fig. h).Nota: il

supporto mobile SB01 non è certificato IMQ-SISTEMI DI SICUREZZA.

9. Test remoto e autotest

Guasto tecnico: I guasti tecnici possono avere due cause.

A: Il monitoraggio continuo del sensore piroelettrico e i livelli di riferimento

dei circuiti antimascheramento.

B: Il test remoto e l’autotest.

Test remoto: questo test consente di verificare il VE700AM dalla

centrale. Usare il morsetto 12 per attivarlo. Il VE700AM attiva il relè

allarme se il risultato del test è positivo e il relè antimascheramento se il

risultato del test è negativo.

Autotest: il VE700AM effettua il monitoraggio continuo del PIR e dei

circuiti AM. Gli eventuali difetti vengono segnalati come guasti tecnici.

- 30 -

Page 33

3 sec.

8 hr.

8 hr.

8 hr.

8 hr.

Stato

Morsetto 12:

Relè di allarme:

VE700AM OK

VE700AM non OK

PIR*:

Relè AM:

Relè AM:

AM*:

- 31 -

Test remoto: Autotest:

* Inizia 1 ora dopo l’installazione

Guasto tecnico:

A: il reset di un guasto tecnico rilevato dal monitoraggio continuo può

essere effettuato in due modi:

1. Reset autorizzato. Impostare il sistema su giorno e test di copertura

ed eseguire il test di copertura. Al successivo allarme PIR, il sistema

effettua il reset se tutti i livelli di riferimento rientrano nei limiti

specificati.

2. Auto reset. Dopo un periodo di inibizione di 40 secondi, viene

effettuato il reset automatico dopo un test di copertura superato se

tutti i livelli di riferimento rientrano nei limiti specificati.

B: il reset di un guasto tecnico rilevato tramite test remoto o autotest può

essere effettuato solo tramite un altro autotest o test remoto se il test

viene superato.

10. Glossario

Antimascheramento (AM): Funzione del rilevatore che consente di

rilevare eventuali tentativi di mascheramento (ad esempio, con vernice a

spruzzo). Quando viene rilevato un tentativo di mascheramento, si attiva

un relè.

Autotest: Il rilevatore stesso controlla il sensore del rilevatore e i circuiti di

elaborazione del segnale.

Guasto tecnico (TF): Messaggio o segnale di guasto generato sul relè

antimascheramento quando si verifica un guasto del rilevatore.

Mascheramento: L’utilizzo di una barriera fisica (carta, metallo o vernice a

spruzzo) nelle vicinanze o a contatto con il rilevatore che compromette la

capacità del dispositivo di rilevare un’intrusione.

Memoria allarme: Supporto di memorizzazione presente nel rilevatore in

grado di registrare i segnali generati dal dispositivo.

Page 34

- 32 -

Modalità di individuazione della posizione della tenda centrale

(CLM): Funzione del rilevatore che identifica con precisione i bordi delle

tende di rilevazione.

Modo giorno: Il rilevatore non genera un messaggio o un segnale di

allarme quando viene attivato dal movimento di una persona davanti ad

esso.

Modo notte: Il rilevatore genera un messaggio o un segnale di allarme

quando viene attivato dal movimento di una persona davanti ad esso.

Tende: Area continua verticale di zone di rilevazione. Il rilevatore PIR è in

grado di rilevare il movimento all’interno delle tende, non negli spazi tra di

esse.

Test di copertura: Test di funzionalità effettuato dall’installatore per

verificare che il sistema genera un allarme.

Test remoto: La centrale controlla il sensore del rilevatore e i circuiti di

elaborazione del segnale.

11. Specifiche tecniche

Corrente d’ingresso 9 -15 V (12 V nominale)

Ondulazione residua picco-picco 2 V (a 12 V )

Consumo di corrente:

Funzionamento normale 20 mA

Allarme 24 mA

Massimo 34 mA

Tensione di ingresso di controllo Bassa da 0 a 1,5 V

(morsetti 10-11-12) Alta da 3,5 a 15 V

Altezza di montaggio Min 1,8 m - max 3,0 m

Gamma velocità bersaglio 10 cm/s - 4 m/s

Relè di allarme Il relè ottico è immune all’influenza magnetica

Uscita allarme 80 mA a 30 V cmax

Uscita antimanomissione 80 mA a 30 V cmax

Uscita guasto 80 mA a 30 V cmax

Tempo di allarme 3 secondi

Tempo di avvio rilevatore 70 secondi

Temperatura di funzionamento Da -10°C a +55°C

. Certificata da +5°C a +40°C

Umidità relativa Max 95%

Dimensioni (A x L x P) 175 x 93 x 66 mm

Peso 275 g

Numero di tende 11 a 20 m + 1 a 60 m

Angolo visivo 86° a 20 m e 3° a 60 m

Page 35

- 33 -

Gradi di protezione IP/IK IP30 IK02

Omologazione IMQ allarme I° e II° Livello solo VE735AM

Omologazione IMQ allarme VE735AM

(Per conformità alle norme CEI 79-2 per II° Livello l’utilizzo della protezione

antirimozione è obbligatorio)

Page 36

- 34 -

Instructions d’installation

1. Introduction ............................................................................................ 34

2. Instructions d’installation ....................................................................... 34

3. Montage du détecteur ............................................................................ 35

4. Réglage du détecteur............................................................................. 36

5. Test de l’anti-masque ............................................................................. 40

6. Alignement du faisceau et test de marche du détecteur ...................... 40

7. Identification de l’état du détecteur via les voyants ............................ 42

8. Informations générales .......................................................................... 42

9. Auto-test et test à distance du détecteur .............................................. 44

10. Glossaire .............................................................................................. 45

11. Spécifications techniques .................................................................... 46

1. Introduction

Les VE735AM/VE736AM sont des détecteurs de mouvements IRP/AM. Ils

présentent la technologie IRP brevetée et la fonction anti-masque multicanaux. Ils ont été testés puis certifiés conformes aux normes TS50131-1

/ TS50131-2-2, au niveau de sécurité 3, classe environnementale 2, par

l’organisme néerlandais d’évaluation de la conformité Telefication B.V.

2. Instructions d’installation

La technologie utilisée dans ces détecteurs est conçue pour résister aux

risques de fausses alarmes. Toutefois, il est conseillé d’éviter les causes

d’instabilité potentielles, telles que :

L’exposition du détecteur à la lumière directe du soleil.

Les sources de chaleur dans le champ de vision.

Les courants d’air puissants sur le détecteur.

La présence de grands animaux dans le champ de vision.

La présence d’objets à moins de 50 cm du détecteur anti-masque (AM).

L’obstruction du champ de vision du détecteur par des objets

volumineux, comme des meubles.

L’installation de deux détecteurs face à face à moins de 50 cm de

distance.

FR

Page 37

- 35 -

3. Montage du détecteur

1. Relevez l’insert personnalisé et retirez la vis qui s’y trouve (figure

, étapes 1 et 2).

2. A l’aide d’un tournevis, ouvrez délicatement le détecteur en faisant

levier (figure

, étapes 3 et 4).

3. Retirez la partie interne (figure

).

4. Fixez la base au mur à une hauteur comprise entre 1,8 m et 3 m du

sol. Pour le montage à plat, utilisez au moins deux vis (DIN 7998), une

en position A et une en position B. Pour le montage en coin, utilisez les

vis en positions C et D (figure

).

ATTENTION ! Tous les emplacements de vis ne disposent pas

d’autoprotection à l’arrachement. Les emplacements sans

autoprotection à l’arrachement dans la boîte d’alarme sont

indiqués à la figure

.

5. Raccordez le détecteur (figures et ).

6. Sélectionnez le cavalier requis et la configuration des commutateurs

DIP (section 4).

7. Replacez la partie interne (figure b)..

8. Alignez le détecteur (comme illustré aux figures c et j) et

reportez-vous à la section

Alignement du faisceau et test de marche

du détecteur

(section 6).

9. Retirez les œillères et placez les autocollants selon les besoins (voir

les figures d et e pour exemple).

10. Insérez les couvercles de protection contre les insectes (figure f,

étape 1).

11. Refermez le couvercle (figure f, étape 2).

12. Insérez la vis (si nécessaire) et replacez l’insert personnalisé (figure

f, étape 3).

Page 38

4. Réglage du détecteur

Il faut redémarrer le détecteur (le remettre sous tension) après avoir

modifié les paramètres ou les schémas de détection.

Cavaliers (figure )

J1 : Sensibilité d’IRP

Le délai de déclenchement de l’alarme (vitesse de l’algorithme de décision)

dépend directement de la sensibilité d’IRP ; plus la sensibilité est élevée,

plus la vitesse de réaction du détecteur est rapide (figure

). Il existe

trois niveaux de sensibilité d’IRP.

Basse sensibilité

: à utiliser dans les zones à risque de

fausses alarmes. N’utilisez pas ce réglage pour les applications à grandes distances (>20 m) ou les applications simple

rideau.

Sensibilité moyenne :

à utiliser dans la plupart des

situations (configuration usine).

Sensibilité haute :

à utiliser dans les situations à haut risque.

Recommandée pour utilisation dans les couloirs.

J2 : Mode de localisation de rideau (MLR)

Ce mode permet de localiser avec précision les extrémités des rideaux.

Lorsqu’un intrus intercepte un rideau, les voyants lumineux rouge et

jaune clignotent alternativement (figure

). Ce mode est également

utilisé pour l’alignement de longue distance (voir la section 6).

Off (Désactivé)

On (Activé).

Reportez-vous à la section 6B.

J3 : Boucle double (disponible uniquement sur

VE735AM)

Elle est utilisée pour régler le relais d’alarme et d’autoprotection. Elle permet

de connecter le détecteur à tout type de centrale.

J1

J2

J3

5 6 7 8 9 10

- 36 -

Page 39

Boucle équilibrée (4K7)

Les bornes 4 et 5 de la sortie d’alarme doivent être utilisées

lors de l’établissement d’une connexion à la centrale.

Boucle AL et AP isolée (configuration usine)

L’autoprotection est isolée du relais d’alarme. La résistance de

boucle équilibrée dans le circuit d’autoprotection est courtcircuitée.

Les bornes 3 et 4 de la sortie d’alarme doivent être utilisées

lors de l’établissement d’une connexion à la centrale.

Boucle double

La boucle AL et AP peut être contrôlée via deux câbles.

Dans une situation normale (pas d’alarme) l’impédance de la

boucle double est de 4K7. Pour une alarme de détecteur, le

contact de relais d’alarme s’ouvre et l’impédance de la boucle

double passe à 9K4, indiquant une alarme. Lorsque le boîtier

du détecteur est ouvert, le circuit d’autoprotection s’ouvre et

la boucle double est interrompue, indiquant une alarme

d’autoprotection (figure

).

Commutateurs DIP IRP (figure )

Tableau 1 : commutateurs DIP IRP

Fonction Commutateur Commutateur

DIP On (Activé) DIP Off (Désactivé)

4. Voyants Voyants allumés Voyants éteints

3. Direction du carillon De gauche à droite De droite à gauche

2. Carillon Carillon activé Carillon désactivé

1. Polarité Activée haut Activée bas

Commutateur DIP 1 : Polarité de tension de contrôle

(CV)

Activé : “Activée haut” (par positif) fournit la logique GE Security

standard avec une sortie active pour activer les entrées test de marche

et jour/nuit.

Désactivé : “Activée bas” fournit une sortie non active pour activer les

entrées test de marche et jour/nuit.

(configuration usine)

J1

J3

12 34

ON

7 8 9 1 0 11 12

12 34

ON

- 37 -

Page 40

Commutateur DIP 2 : Carillon (figure )

Le détecteur distingue la direction de l’intrus pendant la journée. Désactivez

cette option en désactivant le carillon du détecteur. Lorsque le carillon est

activé, le détecteur déclenche l’alarme dès lors qu’un intrus traverse les

rideaux, de droite à gauche ou de gauche à droite.

Remarque : Si la borne jour/nuit n’est pas utilisée mais que le carillon

est activé, celui-ci reste activé quel que soit le mode (armé/désarmé soit

jour/nuit).

Commutateur DIP 3 : Direction du carillon (figure )

Activé : Alarme activée lorsqu’un intrus se déplace de la gauche vers la

droite.

Désactivé : Alarme activée lorsqu’un intrus se déplace de la droite vers la

gauche.

Placez-vous dos au détecteur pour distinguer la gauche et la droite.

Commutateur DIP 4 : Voyants

Activé : Active les deux voyants du détecteur en permanence.

Désactivé : Met les deux voyants sous contrôle des entrées test de

marche et jour/nuit.

Commutateurs DIP AM (figure )

Tableau 2 : commutateurs DIP AM

Fonction Commutateur Commutateur

DIP On (Activé) DIP Off (Désactivé)

4. Signalisation des

sorties AM ou PT

Relais Relais

AM Alarm (Alarme) AM Alarm (Alarme)

AM

-

PT -

-

3. Réinitialisation Après test de marche Réinitialisation

de AM ou PT autorisée

2. Sensibilité High (haute) Standard

d’anti-masque

1. Quand signaler Mode jour Mode jour/nuit

les sorties AM uniquement

ou PT

1 2 3 4 5

12 34

ON

12 34

ON

(configuration usine)

- 38 -

Page 41

Paramètres du commutateur DIP AM :

1. Quand signaler les sorties AM (anti-masque) ou PT

(problème technique)

Activé : Signale les alarmes AM ou PT uniquement quand le système est en

mode jour. Conforme à la norme EN 50131-2-2.

Désactivé : Signale toujours les alarmes AM ou PT.

ATTENTION ! Pour éviter les alarmes AM en mode nuit, il est

recommandé d’appliquer les paramètres du commutateur DIP

suivants :

4: Off (Désactivé)

3: Off (Désactivé)

2: Off (Désactivé)

1: On (Activé)

Les alarmes AM seront dorénavant uniquement signalées à la

centrale en mode jour par le relais AM. Les voyants sont

contrôlés par les entrées jour/nuit et test de marche. La

réinitialisation de l’alarme AM peut être faite uniquement en

mode test de marche.

N’indiquez jamais l’état du détecteur à un intrus via les

voyants.

2. Sensibilité d’anti-masque

Activé : Augmente la sensibilité d’anti-masque. Le relais AM réagit en moins

de 6 secondes.

Désactivé : Sélectionne la sensibilité d’anti-masque standard. Le relais AM

réagit en moins de 12 secondes.

3. Réinitialisation des sorties AM/PT

Le détecteur VE700AM réinitialise une alarme AM une fois qu’il est sûr que

la cause de l’alarme AM a été supprimée. Si le circuit AM ne peut pas

revenir à ses niveaux de référence d’origine, soit le détecteur est toujours

masqué, soit il a été endommagé. Le propriétaire doit alors vérifier

physiquement si le détecteur est toujours fonctionnel.

Activé : Réinitialise l’état AM ou PT après 40 secondes d’inhibition suite au

déclenchement d’une alarme IRP.

Désactivé : Réinitialise l’état AM ou PT suite au déclenchement d’une

alarme IRP, lorsque le système est en mode jour et test de marche. Le

voyant jaune clignote rapidement. Lorsque le système est en état nuit,

le voyant jaune s’éteint et le système se réinitialise.

4. Signalisation de sorties AM ou PT

Activé : Signale les sorties AM

à la fois

sur les relais AM et d’alarme.

Signale les sorties PT sur le relais AM uniquement.

Désactivé : Signale les sorties AM et PT sur le relais AM.

- 39 -

Page 42

5. Test de l’anti-masque

Séquence d’initialisation AM : Lorsque le détecteur VE700AM est alimenté,

le circuit AM attend que le cache du détecteur soit monté de manière

appropriée.

Une fois le cache monté, le circuit AM surveille le boîtier et la zone

environnante et stocke les niveaux des signaux reçus comme niveaux de

référence. Cette procédure prend 75 secondes. Au cours de cette

période, il ne doit y avoir aucun mouvement ou objet dans une zone

environnante de 50 cm autour du détecteur.

Pour tester l’anti-masque, assurez-vous que le commutateur DIP IRP 4

est bien activé (voyant allumé) et maintenez votre main à environ 10 cm

en face du détecteur pendant 12 secondes (si vous utilisez la sensibilité

standard) ou pendant 6 secondes (si vous utilisez la sensibilité haute). Le

voyant jaune s’allume en conséquence.

6. Alignement du faisceau et test de marche du

détecteur

A. Avec l’outil d’alignement VE710 (figure c)

1. Insérez le VE710 dans le sous-cadre avec le commutateur On/Off

(marche/arrêt) orienté vers le bas.

2. Connectez-le au port COM.

3. Allumez le VE710.

AVERTISSEMENT ! Ne regardez pas directement le faisceau

du laser.

La puissance de sortie est inférieure à 1 mW. En

conséquence, le laser du VE710 a été classé comme un laser

de classe 2, conformément à la norme IEC60825-1. et le

réflexe de clignement des yeux est assez rapide pour prévenir

tout dommage irréversible aux yeux.

4. Le point du laser indique l’alignement du produit (figure c A). Si ce

point sur le mur dévie du centre de la zone de détection souhaitée

située à 1 mètre du sol, dévissez les vis de fixation de la base (figure

é) et utilisez les trois vis de réglage dans la base pour réaligner le

point au centre de la zone, comme illustré à la figure

c B. Lorsque le

point est correctement aligné, resserrez les vis de fixation de la base.

5. Retirez l’outil d’alignement et remettez le cache en place.

6. Effectuez le test de marche. Assurez-vous que le voyant lumineux

rouge est allumé après le test de marche.

- 40 -

Page 43

B. Sans l’outil d’alignement (fig. j, cache arrière)

1. Insérez les œillères du miroir pour assurer le fonctionnement du

détecteur en mode rideau simple.

2. Placez J2 et patientez jusqu’à l’extinction des voyants lumineux.

3. Déplacez-vous dans le champ de vision du détecteur, à une vitesse

normale (sans pause) et à la distance maximale. Lorsque vous entrez

dans la zone du faisceau, les deux voyants lumineux clignotent

simultanément.

Après avoir traversé le faisceau, si :

1. Le voyant lumineux rouge est allumé (figure

j A), l’alignement

est correct.

2. Les voyants lumineux rouge et jaune clignotent simultanément,

le champ de vision est obstrué et insuffisant pour vérifier

l’alarme. Il existe deux possibilités :

Si le clignotement a commencé près de la fin de la zone de

détection, vous devez aligner le faisceau vers la gauche (figure

j B).

Si le clignotement a commencé près du début de la zone de

détection, vous devez aligner le faisceau vers la droite (figure j

C).

Desserrez les vis de fixation de la base (figure ) et utilisez les

trois vis de réglage dans la base pour réaligner le faisceau au centre,

comme illustré à la figure c B. Lorsque le faisceau est correctement

aligné, resserrez les vis de fixation de la base.

4. Si les voyants ne clignotent pas, le rideau se situe hors de la portée

de détection (figure j D). Déplacez-vous dans le champ du

faisceau sur une distance plus courte pour le détecter.

5. Répétez le test pour confirmer l’alignement correct du détecteur.

6. Enlevez J2.

Remarque 1 : si le MLR est activé, la sortie d’alarme l’est aussi.

Remarque 2 : il est conseillé de remettre le cache sur le détecteur

pendant le test de marche du MLR.

- 41 -

Page 44

7. Identification de l’état du détecteur via les

voyants

A) Indication des voyants

Tableau 3 : Indication du voyant

= Allumage continu = Clignotement normal (1 Hz)

= Clignotement rapide (4 Hz)

Etat du Voyant Voyant Réinitialisation

détecteur jaune rouge

Unité alimentée Automatique après 70 secondes.

Tension haute/basse Utiliser une tension correcte.

MLR

Un intrus intercepte

les rideaux.

Alarme intrusion IRP - - - Automatique après 3 secondes.

Alarme intrusion IRP - - - Automatique après 3 secondes.

Alarme IRP

verrouillée : 1ère alarme - - - Passer en mode jour.

à s’activer

Alarme IRP

verrouillée : 2ème alarme - - - Passer en mode jour.

à s’activer

Alarme AM - - - Voir tableau 2, commutateur DIP 2

(page 38).

Après réinitialisation de l’AM - - - Passer en mode nuit.

Problème technique - - - Réussir un test de marche.

8. Informations générales

Remarque : définissez tout d’abord la polarité active correcte pour la

tension de contrôle (TC) en utilisant le commutateur DIP IRP 1. Le

détecteur est en mode nuit lorsque la tension de contrôle correcte est

appliquée à la borne 10 et en mode jour lorsque la tension de contrôle

est déconnectée.

- 42 -

Page 45

A) Verrouillage

Lorsque vous utilisez plusieurs détecteurs dans une seule boucle, câblez

les entrées jour/nuit et test de marche, comme indiqué ci-après (à la

figure

).

B) Activation/désactivation à distance du voyant du test

de marche (figure

)

Mettez le détecteur en mode jour et activez l’état test de marche. Le

voyant du détecteur s’allume lorsque le relais d’alarme s’ouvre et s’éteint

lorsque le relais se ferme. Vous pouvez maintenant effectuer le test de

marche.

Pour activer le voyant lumineux de test de marche sans une entrée de

tension de contrôle distante, paramétrez le commutateur DIP 4 sur On

(Activé). Après le test de marche, paramétrez le commutateur DIP 4 sur

Off (Désactivé).

Il est conseillé d’effectuer régulièrement des tests de marche du

détecteur et de vérifier la communication avec la centrale.

C) Réglage de la mémoire d’alarme (figure )

En mode jour, un voyant clignotant indique le ou les détecteurs qui ont

déclenché une alarme en mode nuit.

En revenant au mode nuit, la mémoire est effacée et le voyant s’éteint.

L’activation du test de marche n’efface pas la mémoire. La désactivation

du test de marche entraîne la réapparition de l’indication d’alarmes

mémorisées.

D) Sélection de la couverture (figure e)

La couverture peut être modifiée pour répondre à des besoins spécifiques

en utilisant les autocollants de miroir (fournis), comme indiqué. Il est

recommandé de masquer les rideaux non utilisés donnant sur des objets

situés très près du détecteur.

ATTENTION ! Le retrait des autocollants risque

d’endommager la surface des miroirs !

TC

TC

Jour/nuit

Test de marche

Nuit

Jour

Off (Désactivé)

Centrale

Détecteurs

- 43 -

On (Activé)

Page 46

E) Masquage des rideaux (figure d)

Les œillères de rideaux sont installées à la sortie d’usine sur le miroir. Pour

retirer une oeillère, retirez en premier lieu la partie interne du détecteur.

Soulevez ensuite la partie inférieure de l’œillère et recourbez la partie

supérieure pour la détacher. Lorsque la détection de grandes distances

n’est pas requise (>20 m), retirez le miroir de grandes distances

(figure g).

F) AP ouverture et arrachement

Le détecteur dispose d’une AP à l’ouverture et à l’arrachement

(conformément à la norme EN 50131-2-2).

A. Il est important d’utiliser la vis marquée

à la figure pour assurer

l’AP à l’arrachement.

B. Pour les applications utilisant un support en cornière, utilisez le système

ST400 pour la protection contre l’arrachement (figure

i). Consultez

cependant l’avertissement à la section 3, étape 4.

G) Patte de fixation à pivot SB01 (facultatif)

Lorsqu’il n’est pas possible de monter le détecteur sur un mur, utilisez la

patte de fixation à pivot SB01 pour le monter sur le plafond (figure

h).

9. Auto-test et test à distance du détecteur

Problème technique : Les problèmes techniques peuvent avoir deux

causes :

A : Ils sont causés par une surveillance constante du pyro et des niveaux

de référence du circuit AM.

B : Ils sont causés par l’auto-test et le test à distance.

Test à distance : Ce test vous permet de tester le VE700AM depuis la

centrale. Activez-le à partir de la borne 12. Le détecteur VE700AM active le

relais d’alarme si le résultat du test est positif et le relais AM si le résultat

du test est négatif.

Auto-test : Le détecteur VE700AM surveille constamment les circuits IRP

et AM. Une défaillance est reportée de la même manière qu’un problème

technique.

- 44 -

Page 47

3 sec.

8 hr.

8 hr.

8 hr.

8 hr.

Etat

Borne 12 :

Relais d’alarme :

VE700AM

OK

Relais AM :

VE700AM

non OK

PIR (IRP)* :

AM* :

Relais AM :

- 45 -

Test à distance : Auto-test :

* Démarre 1 heure après l’installation

Problème technique :

A : Un problème technique détecté par la surveillance continue peut être

réinitialisé de deux manières :

1. Réinitialisation autorisée. Mettez le système en état jour et test de

marche afin de procéder à un test de marche. Lors de la prochaine

alarme IRP, le système est réinitialisé si tous les niveaux de référence

sont compris dans les limites indiquées.

2. Réinitialisation automatique. Après une période d’inhibition de 40

secondes, il est réinitialisé après un test marche réussi si tous les

niveaux de référence sont compris dans les limites indiquées.

B : Un problème technique détecté par un auto-test ou un test à distance

peut être réinitialisé par un autre auto-test ou un test à distance si le test

est réussi.

10. Glossaire

Anti-masque (AM) : Fonction du détecteur lui permettant de détecter si

quelqu’un essaye de le masquer (par exemple, à l’aide d’une bombe de

peinture). Lorsqu’un masquage est détecté, un relais est activé.

Auto-test : Le détecteur surveille lui-même le capteur et le circuit de

traitement des signaux incorporé correspondant.

Masquage : Fait de placer un obstacle matériel (comme du papier, du

métal ou de la peinture) à proximité ou sur le détecteur pour l’empêcher de

détecter un intrus.

Mémoire alarme : Support de stockage situé sur le détecteur et pouvant

enregistrer les signaux générés par le détecteur.

Page 48

Mode de localisation de rideau (MLR) : Fonction du détecteur permettant

d’identifier précisément les extrémités des rideaux.

Mode jour : Le détecteur ne génère aucun signal ou message d’alarme

lorsqu’il détecte une personne dans son champ de vision.

Mode nuit : Le détecteur génère un signal ou message d’alarme lorsqu’il

détecte une personne dans son champ de vision.

Problème technique (PT) : Signal ou message de défaut généré sur le

relais AM lorsqu’une erreur apparaît sur le détecteur.

Rideaux : Couche continue verticale de zones de détection. Le détecteur

IRP peut détecter le mouvement uniquement dans la zone couverte par les

rideaux et non dans les espaces qui existent entre ces derniers.

Test à distance : La centrale surveille le capteur du détecteur et le circuit

de traitement des signaux incorporé correspondant.

Test de marche : Test opérationnel effectué par l’installateur pour vérifier

que l’équipement peut générer une alarme.

11. Spécifications techniques

Puissance d’entrée 9 à 15 V cc (12 V nominal)

Ondulation crête à crête 2 V (à 12 V cc)

Consommation électrique :

Fonctionnement normal 20 mA

Alarme 24 mA

Maximum 34 mA

Tension d’entrée de contrôle Basse de 0 à 1,5 V cc

(bornes 10-11-12) Elevée de 3,5 à 15 V cc

Hauteur de montage Min 1,8 m ; max 3 m

(min 5,9 pieds, max 9,84 pieds)

Vitesse cible 10 cm/s à 4 m/s

(4 po./s à 13 pieds/s)

Relais d’alarme Le relais optique est indifférent aux forces magnétiques

Sortie d’alarme 80 mA à 30 V cc max.

Sortie autoprotection 80 mA à 30 V cc max.

Sortie défaut 80 mA à 30 V cc max.

Temps d’alarme 3 s

Temps de démarrage du détecteur 70 s

Température de fonctionnement -10 °C à +55 °C

(14 °F à 130 °F)

Humidité relative 95 % max.

Dimensions (H x L x P) 175 x 93 x 66 mm

(6,88 x 3,66 x 2,60 po.)

Poids 275 g

- 46 -

Page 49

Nombre de rideaux 11 à 20 m et 1 à 60 m

(11 à 65,6 pieds et 1 à 197 pieds)

Angle de vue 86° à 20 m et 3° à 60 m

Classe IP/IK IP30 IK02

- 47 -

Page 50

Installatie-instructies

1. Inleiding .................................................................................................. 48

2. Richtlijnen voor de installatie ................................................................. 48

3. De detector monteren ............................................................................ 49

4. De detector instellen .............................................................................. 50

5. De antimaskering testen ........................................................................ 53

6. De straal uitlijnen en de looptest van de detector uitvoeren ................. 54

7. De detectorstatus via de LED’s aflezen ............................................... 55

8. Algemene informatie .............................................................................. 56

9. De detector op afstand of automatisch testen ..................................... 58

10. Woordenlijst ......................................................................................... 59

11. Technische specificaties ...................................................................... 59

1. Inleiding

De VE735AM/VE736AM zijn PIR/AM-bewegingssensors. In de sensors is

gepatenteerde, beproefde PIR-technologie en multikanalige antimaskering

toegepast. Ze zijn getest en gecertificeerd op TS50131-1 / TS50131-2-2

voor beveiligingsniveau 3 en omgevingsklasse 2, door het Nederlandse

test- en certificeringsorgaan Telefication B.V.

2. Richtlijnen voor de installatie

De technologie in deze detector is bestand tegen de gevaren van valse

alarmen. Vermijd niettemin alle mogelijke oorzaken van instabiliteit, zoals:

Rechtstreeks zonlicht op de detector.

Hittebronnen in het kijkveld.

Veel tocht op de detector.

Grote dieren in het kijkveld.

Objecten binnen 50 cm van de AM-detector (anti-maskering).

Het kijkveld van de detector versperren met grote objecten, zoals

meubels.

Twee detectors installeren recht tegenover elkaar en met minder dan

50 cm tussenruimte.

- 48 -

NL

Page 51

3. De detector monteren

1. Til het inzetstuk omhoog en verwijder de aanwezige schroef (fig. ,

stap 1 en 2).

2. Wrik de detector voorzichtig open met een schroevendraaier (fig.

,

stappen 3 en 4).

3. Verwijder het binnengedeelte (fig.

).

4. Monteer de basis tegen de muur tussen 1,8 m en 3,0 m vanaf de

vloer. Gebruik voor vlakke montage minimaal twee schroeven (DIN

7998), ten minste één in positie A en één in positie B. Gebruik voor

hoekmontage schroeven in de positie C of D (fig.

).

LET OP! Niet alle schroefposities hebben een

afneembeveiliging. Niet-afneembare posities worden getoond

in het waarschuwingsvak in figuur

.

5. Sluit de draden van de detector aan (fig. en ).

6. Selecteer de gewenste instellingen voor de jumper en dipswitches

(paragraaf 4).

7. Plaats het binnengedeelte terug (fig.

b).

8. Lijn de detector uit, zoals is weergegeven (fig.

c en j) en zie

De

straal uitlijnen en de looptest van de detector

uitvoeren

(paragraaf 6)).

9. Verwijder de spiegelsegmentafschermingen en breng de stickers aan,

indien nodig (zie fig.

d en e).

10. Plaats de afdekkap tegen insecten (fig.

f , stap 1).

11. Plaats het deksel terug (fig.

f, stap 2).

12. Bevestig de schroef (indien nodig) en plaats het inzetstuk terug (fig.

f, stap 3).

- 49 -

Page 52

4. De detector instellen

De detector moet opnieuw worden gestart nadat de instellingen of het

detectiepatroon zijn gewijzigd.

Jumpers (fig. )

J1 : PIR-gevoeligheid

Hiermee stelt u de afstand-tot-alarm vertraging in (de snelheid van de

beslissingsalgoritme); hoe hoger de gevoeligheid, des te sneller de reactie

van de sensor (fig.

). Er zijn drie verschillende PIR-gevoeligheden.

Lage gevoeligheid

: te gebruiken in situaties met gevaar voor

valse alarmen. Niet gebruiken in langeafstandstoepassingen

(> 20 m) of toepassingen met één gordijn.

Normale gevoeligheid:

De meeste situaties

(fabrieksprogrammering).

Hoge gevoeligheid:

te gebruiken in situaties met verhoogd

risico. Aanbevolen voor gebruik in gangen.

J2 : Gordijnlocatiemodus(CLM)

Hiermee kunt u instellen waar de randen van het gordijn zich precies

bevinden. Wanneer een indringer zich binnen het gordijn begeeft, gaan het

rode en gele lampje afwisselen knipperen (fig.

). J2 wordt ook gebruikt

voor de langeafstandsuitlijning (zie paragraaf 6).

Uit

Aan.

Zie paragraaf 6B.