Page 1

GE Energy

Masoneilan* Products

ValVue* FF (Rev B)

Maintenance Manual

ValVue-FF is a software tool to

configure, calibrate, and operate

FOUNDATION Fieldbus

pneumatic control valve

positioners.

Page 2

Warranty

Items sold by GE Energy are warranted to be free from defects in materials and workmanship for a

period one (1) year from first use or eighteen (18) months from delivery provided said items are used

according to GE recommended usages. GE reserves the right to discontinue manufacture of any

product or change product materials, design or specifications without notice.

Software is warranted for ninety (90) days from delivery.

This instruction manual applies to the following instruments and approved software: FVP110

Positioner and ValVue

The FVP110 positioners are warranted for use only with interface software approved by GE Energy.

Consult factory locations for approved software listing.

About this Guide

This instruction manual applies to the following instruments and approved software:

❑ ValVueFF

The information in this manual is subject to change without prior notice.

The information contained in this manual, in whole or part, shall not be transcribed or copied without

GE Energy’s written permission.

In no case does this manual guarantee the merchantability of the positioner or the software or its

adaptability to a specific client needs.

*

software.

❑ with Firmware version 3

❑ with ValVueFF software 2.32 or greater

❑ with ValVue version 2.4 or greater

*

Digital

Copyright

GE Energy reserves the right to discontinue manufacture of any product or change product materials,

design or specifications without notice.

Please report any errors or questions about the information in this manual to your local supplier or

visit www.dressermasoneilan.com.

All software is the intellectual property of GE Energy.

The complete design and manufacture is the intellectual property of GE Energy.

*

Masoneilan

contained herein is believed to be accurate at the time of publication and is subject to change without

notice.

Copyright 2012 by GE Energy. All rights reserved.

P/N 720003262-888-0000 Rev B

, FVP*, SVI*, and ValVue

*

are registered trademarks of GE Energy. All information

Page 3

ValVueFF Software Interface to FVP

Contents

ValVueFF Software Interface to FVP Safety Information ...............................................................1

Safety Symbols ..........................................................................................................................1

Product Safety ...........................................................................................................................2

Introduction to ValVueFF and FVP ................................................................................................5

Overview ....................................................................................................................................5

ValVueFF Specifications............................................................................................................5

Installation of Hardware and Software ...........................................................................................7

Getting Started With ValVueFF..................................................................................................7

General Installation and Setup Procedure .................................................................................9

Wiring Requirements ...............................................................................................................10

Installing NIFB Software and Hardware...................................................................................10

NI-FBUS Software..............................................................................................................11

ValVueFF Administration .............................................................................................................17

Overview ..................................................................................................................................17

Administration ....................................................................................................................17

Installation Sequence.........................................................................................................17

Installing ValVueFF..................................................................................................................18

Launching the Application..................................................................................................18

Removing a Previous Version of ValVueFF.......................................................................18

Installing ValVueFF............................................................................................................21

Trial Period.........................................................................................................................26

Registration..............................................................................................................................27

Previous Versions ..............................................................................................................27

Registering ValVueFF Software.........................................................................................27

Setting User Accounts, System Administration, Passwords, and Privilege Levels............31

Using ValVueFF ...........................................................................................................................35

Overview ..................................................................................................................................35

Integrated Valve Interface (IVI) ..........................................................................................35

Menu Bar .................................................................................................................................36

Icon Toolbar .............................................................................................................................39

Tool Tips Feature...............................................................................................................39

Positioner Faceplate ................................................................................................................41

Active Faceplate................................................................................................................43

Companion Device Display Frame.....................................................................................44

Status Frame......................................................................................................................45

Selected Device Frame......................................................................................................45

Device Selection ................................................................................................................47

Using ValVueFF Menu Selections ...........................................................................................48

i

Page 4

GE Energy

ValVueFF Software Interface to FVP

Setup Menu..............................................................................................................................49

Setup Wizard .....................................................................................................................49

Configuration Services.......................................................................................................55

Calibration Services ...........................................................................................................56

Device Tag/Address...........................................................................................................57

View Menu ...............................................................................................................................58

View Trend.........................................................................................................................58

PID Controller ....................................................................................................................59

Device Operation State......................................................................................................61

Tools Menu ..............................................................................................................................62

Diagnostic Services ...........................................................................................................62

Query Device .....................................................................................................................63

Rescan Devices .................................................................................................................64

Help Menu................................................................................................................................ 65

About..................................................................................................................................65

Registration Info.................................................................................................................65

Offline Use of ValVueFF ..........................................................................................................66

Setup Wizard Procedure ..............................................................................................................67

Step 1: Welcome...................................................................................................................... 68

Step 2: Actuator Wizard...........................................................................................................69

Step 3: Tuning Wizard .............................................................................................................70

Step 4: Travel Calibration Wizard ............................................................................................72

Step 5: Position Control Limits Wizard.....................................................................................75

Step 6: Finish Setup Wizard ....................................................................................................77

Configuration Services .................................................................................................................79

Configuration............................................................................................................................ 79

General Page...........................................................................................................................80

Device Info .........................................................................................................................80

Block Tag Info ....................................................................................................................81

Others Installed..................................................................................................................81

Position Tab.............................................................................................................................82

Servo Parameters Frame...................................................................................................82

Position Limits Frame ........................................................................................................84

Limit Switch Threshold.......................................................................................................85

Fault Control ......................................................................................................................85

Actuator Page ..........................................................................................................................87

Diagnostic Parameters.......................................................................................................88

Model and Serial Number ..................................................................................................88

AO Block Tab...........................................................................................................................89

Limits..................................................................................................................................89

AO Block Options...............................................................................................................90

PID Block .................................................................................................................................92

PID Control and Status Option...........................................................................................94

ii

Page 5

Options.....................................................................................................................................96

Characterization Frame......................................................................................................96

Custom Characterization Dialog Box .................................................................................99

Pressure Frame ...............................................................................................................103

Others Frame ...................................................................................................................103

Calibration Services ...................................................................................................................105

Overview ................................................................................................................................105

Range Tab .............................................................................................................................105

Find Range Result ...........................................................................................................106

Auto Stop Limits...............................................................................................................106

Manual Stop Limits...........................................................................................................107

Open Stop Adjustment.....................................................................................................108

Tuning Tab.............................................................................................................................109

Auto Tune.........................................................................................................................111

Search Stops and Auto Tune In One Step.......................................................................112

Manual Parameter Adjustment.........................................................................................112

Travel Calibration Tab............................................................................................................112

Calibrating ........................................................................................................................113

Advanced Tab........................................................................................................................115

Advanced Servo Tuning Buttons......................................................................................115

Advanced Servo Tuning Parameters ...............................................................................116

Advanced (Double Acting) Tuning Parameters................................................................117

PID Block and Trending Services ..............................................................................................119

Overview ................................................................................................................................119

PID Status Frame ..................................................................................................................120

States and Modes ............................................................................................................120

Simulation Function..........................................................................................................121

Others - Tuning Parameters ..................................................................................................122

PID Output and Valve Position ..............................................................................................123

Trending Overview.................................................................................................................123

Zooming ...........................................................................................................................124

Customizing the Trend.....................................................................................................124

Viewing Valve Dynamic Responses.................................................................................125

Saving and Opening Trend Files......................................................................................126

Saving a Configuration ...............................................................................................................127

Overview ................................................................................................................................127

Open File ...............................................................................................................................127

Save to File ............................................................................................................................128

Downloading to the FVP ........................................................................................................129

Download Firmware ...............................................................................................................131

Copying a Configuration to a New Positioner ........................................................................132

Diagnostic Services ...................................................................................................................135

General ..................................................................................................................................135

Self Check..............................................................................................................................136

iii

Page 6

GE Energy

ValVueFF Software Interface to FVP

Performing a Self Test ...........................................................................................................136

Self Test Explanation .......................................................................................................137

Signature Tab ........................................................................................................................138

Signature Selection Frame ....................................................................................................139

Signature Measurement...................................................................................................140

Signature Graphs.............................................................................................................142

Signature Notes ...............................................................................................................147

Signature Setting Frame........................................................................................................149

Standard Actuator Signature............................................................................................149

Extended Actuator Signature ...........................................................................................151

High Resolution Actuator Signature.................................................................................152

Step Response Test ........................................................................................................153

Positioner Signature.........................................................................................................162

Query and Reporting Services ...................................................................................................165

Query Services ......................................................................................................................165

Query Device General Tab ..............................................................................................165

Query Device Block Parameters Tab...............................................................................166

Reporting Services.................................................................................................................168

Configuration Report........................................................................................................168

Using Report Generation .................................................................................................169

Communication Error Log ................................................................................................170

Failsafe Handling .......................................................................................................................173

Introduction ............................................................................................................................ 173

Failsafe Active Latched....................................................................................................173

Failsafe Clear Latched .....................................................................................................174

Failsafe Clear Non-Latch .................................................................................................174

Exiting Failsafe.................................................................................................................174

Launching from Yokagawa and Emerson ..................................................................................193

Launching from Yokagawa PRM ...........................................................................................193

Emerson Delta V Snap-On ....................................................................................................198

Configuring DI to TB ..................................................................................................................201

Installing the Interface Board .....................................................................................................203

Installing the Interface Board .................................................................................................203

Installing the NI-FBUS Software ......................................................................................203

Installing the PCMCIA Card .............................................................................................204

Install the USB-8486 ........................................................................................................204

Replacing an FVP Configuration ...............................................................................................205

Replacing an FVP Configuration............................................................................................205

Error Messages .........................................................................................................................207

Auto Tune Results ................................................................................................................. 207

Online Diagnostics.................................................................................................................208

Block Error ............................................................................................................................. 209

iv

Page 7

Foundation Fieldbus ..................................................................................................................211

Overview ................................................................................................................................211

Reference Model Process......................................................................................................212

P& I D....................................................................................................................................212

Function Block Links ..............................................................................................................213

Device Operational States and Block Modes.........................................................................215

Block Modes.....................................................................................................................216

Multiple Modes and States..............................................................................................217

Examples of IVI Operational States .................................................................................218

Transferring to Manual State............................................................................................219

RCas Mode ......................................................................................................................221

Changing Target Operational State .................................................................................222

Changing to Auto from OOS ............................................................................................222

Fieldbus Resources and References .........................................................................................223

Information .............................................................................................................................224

Fieldbus Foundation.........................................................................................................224

National Instruments ........................................................................................................225

v

Page 8

ValVueFF Software Interface to FVP

This page intentionally left blank.

Page 9

ValVueFF Software Interface to FVP

Figures

1 ValVueFF Reference Model Fieldbus Segment..................................................................8

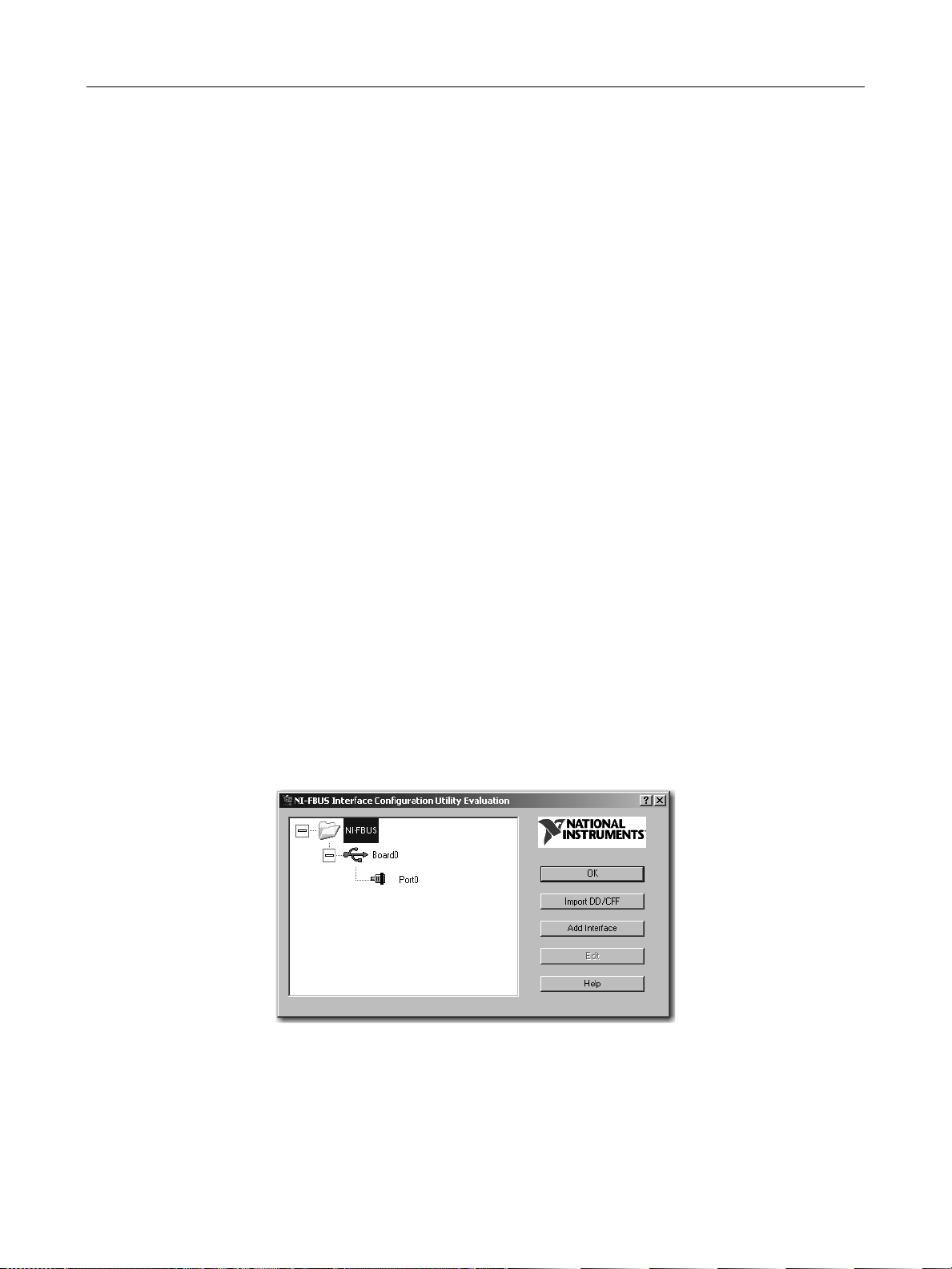

2 Interface Configuration Utility............................................................................................12

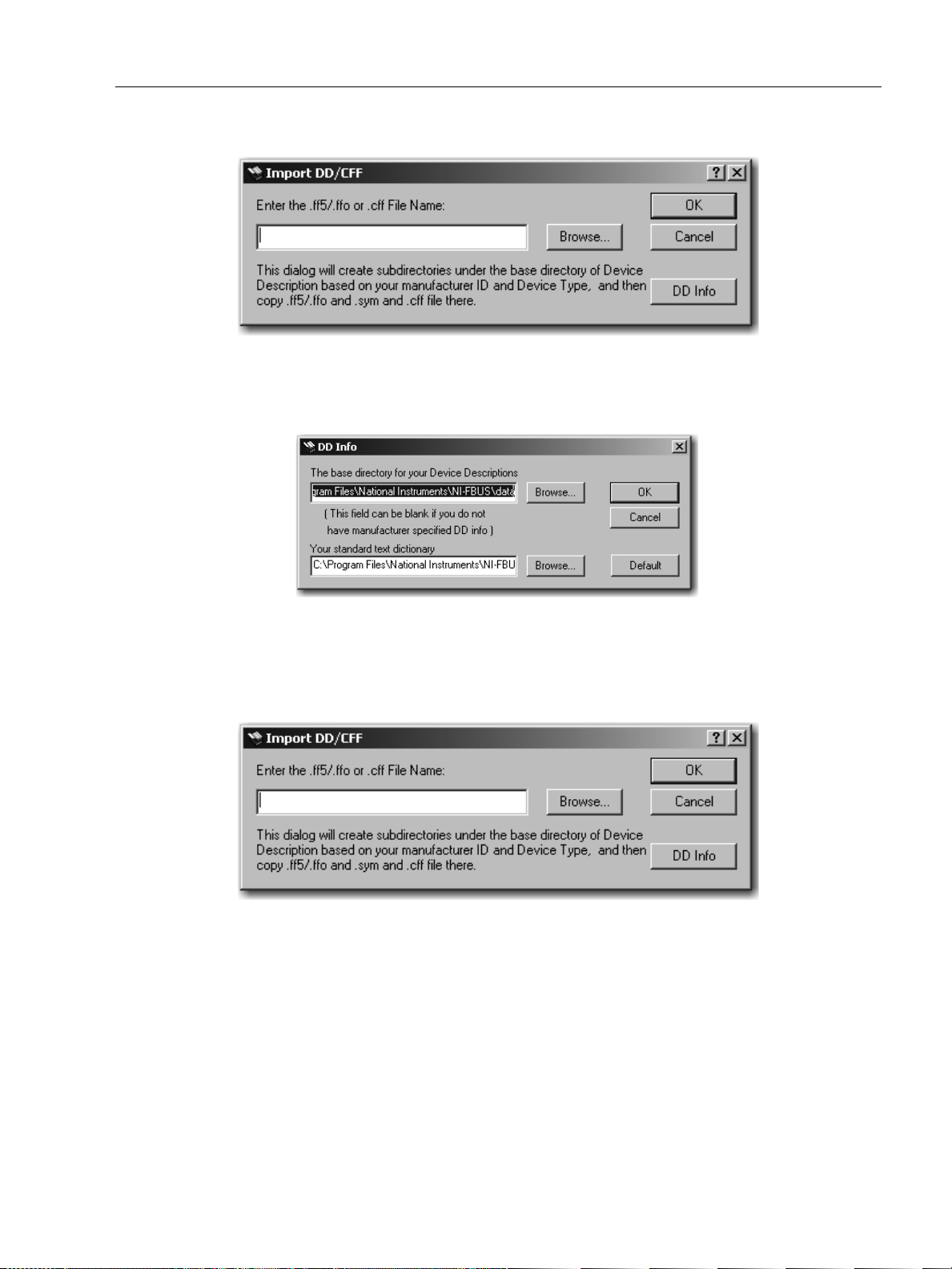

3 Import DD_CFF Browse Dialog ........................................................................................13

4 DD Info Dialog...................................................................................................................13

5 Import DD_CFF Browse Dialog ........................................................................................13

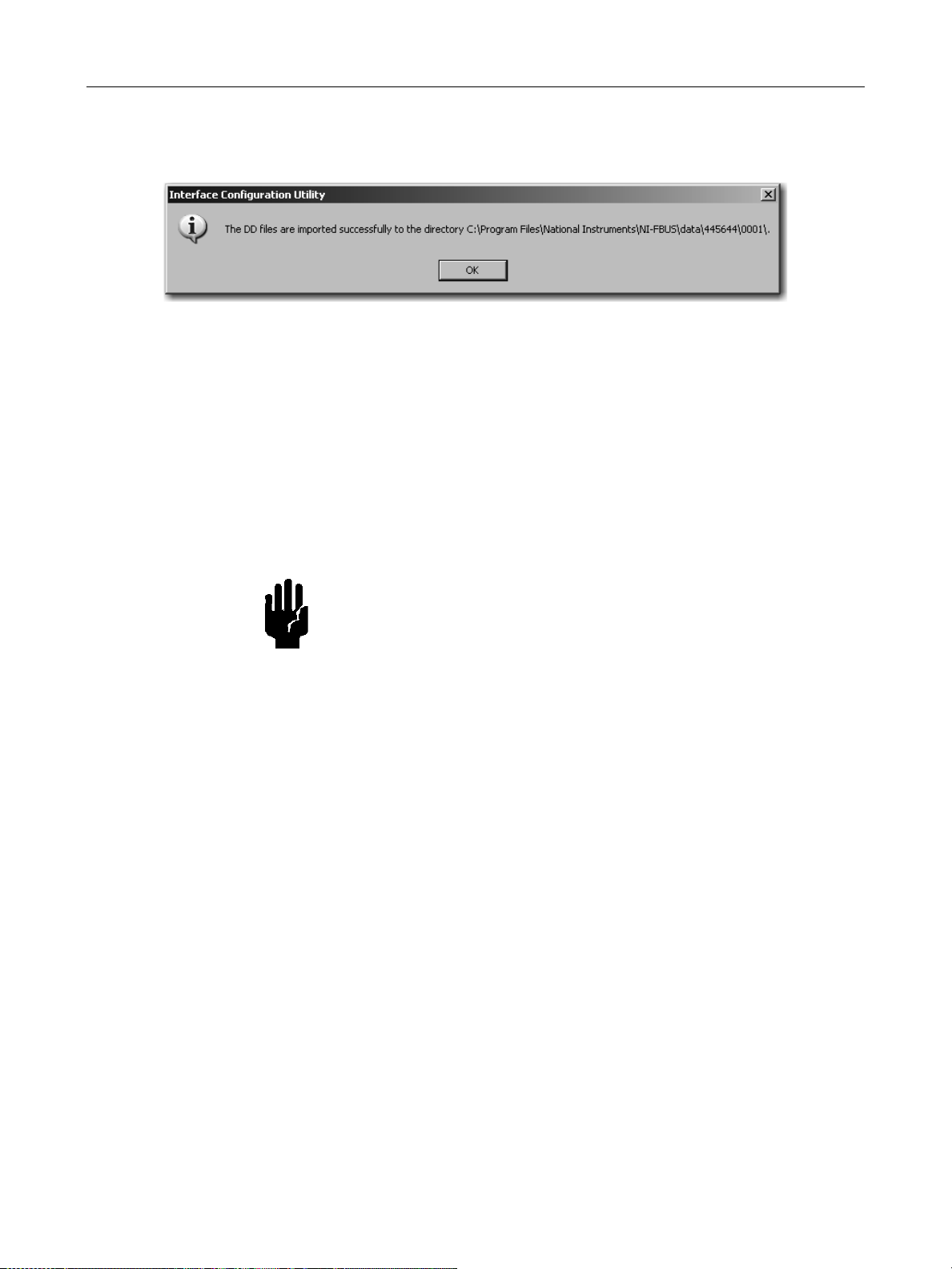

6 Interface Configuration Utility Success Dialog..................................................................14

7 CD Browser Window.........................................................................................................18

8 Software Selection Window ..............................................................................................19

9 NIFB Version Requirement Reminder ..............................................................................19

10 Shut Down Message.........................................................................................................19

11 Select Maintenance Level Dialog Box ..............................................................................20

12 Maintenance Complete Dialog Box...................................................................................20

13 CD Browser Window.........................................................................................................21

14 Software Selection Window ..............................................................................................21

15 NIFB Version Requirement Reminder ..............................................................................22

16 Shut Down Message.........................................................................................................22

17 Welcome to ValVueFF......................................................................................................22

18 License Agreement ...........................................................................................................23

19 Choose Destination Dialog Box ........................................................................................23

20 Ready to Install Dialog Box...............................................................................................24

21 Setup Status Dialog Box ...................................................................................................24

22 Installation Complete ........................................................................................................25

23 Use National Instrument Tool Dialog ................................................................................25

24 Registration Dialog............................................................................................................26

25 Trial Logon Dialog.............................................................................................................26

26 Registration Dialog............................................................................................................27

27 Logon Dialog.....................................................................................................................28

28 Software Key Dialog Box ..................................................................................................28

29 Registration Form .............................................................................................................29

30 Software Key Dialog Box ..................................................................................................30

31 Admin Logon Dialog Box ..................................................................................................31

32 Adding Users in VFAdmin Dialog Box ..............................................................................32

33 ValVueFF Integrated Valve Interface (IVI)........................................................................36

34 Tool Tips Message............................................................................................................39

35 Status Bar Message..........................................................................................................39

36 IVI Positioner Faceplate Frame - Functions Turned Off ...................................................41

37 IVI Positioner Faceplate Frame - Functions On................................................................42

38 IVI Faceplate in Normal State ...........................................................................................43

39 Companion Device............................................................................................................44

40 Status Frame ....................................................................................................................45

41 Positioner Faceplate with =% Characteristic ....................................................................45

vii

Page 10

GE Energy

ValVueFF Software Interface to FVP

42 Device Selection Dialog Box.............................................................................................47

43 Device Selection Popup for Tag/Address .........................................................................48

44 Device Selection with Popup Menu ..................................................................................48

45 Setup Wizard ....................................................................................................................49

46 Actuator Wizard ................................................................................................................50

47 Tuning Wizard...................................................................................................................51

48 Travel Calibration Wizard .................................................................................................52

49 Position Control Limits Wizard..........................................................................................53

50 Setup Wizard Finished......................................................................................................54

51 Configuration Dialog Box ..................................................................................................55

52 Calibration Dialog Box ......................................................................................................56

53 Tag/Address Dialog ..........................................................................................................57

54 Trend Dialog .....................................................................................................................58

55 PID Process Controller Dialog Box...................................................................................59

56 Change PID Tuning Parameters Dialog Box ....................................................................60

57 Device Operation Dialog Box............................................................................................61

58 Diagnostic Services DIalog Box........................................................................................62

59 Device Query Dialog Box..................................................................................................63

60 Rescan Message Box.......................................................................................................64

61 Link Selection ...................................................................................................................64

62 Link Selection ...................................................................................................................65

63 About ValVueFF Message Box.........................................................................................65

64 Setup Wizard Dialog Box..................................................................................................68

65 Actuator Wizard Dialog Box..............................................................................................69

66 Tuning Wizard Dialog Box ................................................................................................70

67 Tuning Results Dialog Box ...............................................................................................71

68 Tuning Wizard Message Boxes ........................................................................................71

69 Tuning Wizard Error Message Boxes ...............................................................................72

70 Travel Calibration Wizard .................................................................................................73

71 Position Control Limits Wizard..........................................................................................75

72 Finish Setup Dialog Box ...................................................................................................77

73 General Tab - Configuration Dialog Box...........................................................................79

74 Position Tab - Configuration Dialog Box...........................................................................82

75 Advanced Servo Tuning Parameters................................................................................83

76 Alarms...............................................................................................................................86

77 Actuator Tab-Configuration Dialog Box ............................................................................87

78 AO Block Tab-Configuration Dialog Box...........................................................................89

79 Analog Output Block Options Dialog Box .........................................................................90

80 PID Block Tab-Configuration Dialog Box..........................................................................92

81 PID Control and Status Options........................................................................................94

82 Options Tab-Configuration Dialog Box .............................................................................96

83 Custom Characterization Dialog Box................................................................................99

84 Display Showing Non-Linear Characteristic ...................................................................100

85 Custom Linearization Dialog Box....................................................................................101

86 Rotation Angle ................................................................................................................102

87 Calibration Dialog Box - Range Tab ...............................................................................106

viii

Page 11

88 Stroke Valve Message Box.............................................................................................106

89 Progress Dialog Box .......................................................................................................107

90 Manual Stops Progress Bar ............................................................................................107

91 Auto Tune Warning Dialog Box.......................................................................................111

92 Auto Tune Progress Dialog Box......................................................................................111

93 Increment the Closed Position - 0% Calibration .............................................................113

94 Non-linearity Travel Correction .......................................................................................114

95 Calibration Dialog Box - Advanced Tab ..........................................................................115

96 PID Process Controller Dialog Box .................................................................................119

97 Change PID Tuning Parameters Dialog..........................................................................122

98 PID Output Slider ............................................................................................................123

99 Trend Screen with Pressure Loop ..................................................................................123

100 Trend Selection...............................................................................................................124

101 Trend Scope Setup.........................................................................................................124

102 Sampling Interval ............................................................................................................125

103 Change Set Point in Trend..............................................................................................125

104 Saving a Trend................................................................................................................126

105 Select a Trend File Name ...............................................................................................126

106 Configuration Toolbar Icons............................................................................................127

107 Open Configuration File Dialog Box................................................................................128

108 Download Select Dialog Box...........................................................................................129

109 Download Confirm Process ............................................................................................130

110 Device Tag is Not Unique ...............................................................................................130

111 Downloading Firmware ...................................................................................................131

112 Activate Firmware Dialog ................................................................................................131

113 Confirm Tag or Address Change ....................................................................................132

114 Configuration Download Progress ..................................................................................133

115 General Tab - Diagnostic Dialog Box..............................................................................135

116 Self Check Dialog Box ....................................................................................................136

117 Signature Tab - Diagnostic Dialog Box...........................................................................138

118 Positioner SIgnature Graph ............................................................................................139

119 Selecting Signatures Dialog Box.....................................................................................140

120 Signature Measurement..................................................................................................141

121 Signature Graphs............................................................................................................142

122 Signature Graphs Right Click Menu................................................................................143

123 Clear Existing Graphs.....................................................................................................144

124 Scale Settings.................................................................................................................146

125 Signature Summary Dialog Box......................................................................................146

126 Signature Notes ..............................................................................................................148

127 Standard Actuator SIgnature Graph ...............................................................................149

128 Standard Actuator Signature Settings Dialog Box ..........................................................150

129 Extended Signature Dialog Box......................................................................................151

130 Step Response Setting Dialog Box.................................................................................153

131 Step Response Test Graph ............................................................................................155

132 Step Response Notice ....................................................................................................156

133 Step Response Setup - Normal ......................................................................................156

ix

Page 12

GE Energy

ValVueFF Software Interface to FVP

134 Test Graph Result - Normal............................................................................................157

135 Result Analysis - Normal ................................................................................................157

136 Step Response Setup - Cyclical .....................................................................................158

137 Test Graph Result - Cyclical ...........................................................................................158

138 Result Analysis - Cyclical................................................................................................159

139 Step Response Setup - Cyclical with Deadband ............................................................159

140 Test Graph Result - Cyclical with Deadband ..................................................................160

141 Result Analysis - Cyclical with Deadband.......................................................................160

142 Step Response Setup - Resolution.................................................................................161

143 Test Graph Result - Resolution ......................................................................................161

144 Result Analysis - Resolution ...........................................................................................162

145 Position Signature Setting Dialog Box ............................................................................163

146 Query Device Dialog Box - General Tab Pulldown List ..................................................165

147 Reply List Populated.......................................................................................................166

148 Query Device Dialog Box - Block Parameters ................................................................166

149 Parameter Pull Down List ...............................................................................................167

150 Parameter Attribute Dialog Box ......................................................................................167

151 Report Format Dialog Box ..............................................................................................168

152 Configuration Report in a Browser..................................................................................168

153 Open Device Configuration File......................................................................................169

154 Communication Error Message Box ...............................................................................170

155 Drop Down Menu............................................................................................................170

156 Error Log.........................................................................................................................171

157 Active Latched ................................................................................................................173

158 Clear Latch .....................................................................................................................174

159 Clear Non-Latch..............................................................................................................174

160 Failsafe Step 1 and 2......................................................................................................176

161 Resetting Failsafe Parameters .......................................................................................177

162 Clear (Latched) Failsafe Status ......................................................................................178

163 Confirm Change to OOS to Clear Failsafe .....................................................................178

164 PRM - Login Dialog.........................................................................................................193

165 PRM Main Screen...........................................................................................................194

166 PRM Main Screen Populated .........................................................................................195

167 PLUG-IN Selection .........................................................................................................195

168 PRM Main Screen Valve Selected..................................................................................196

169 PRM Plug In ValVueFF Main Screen .............................................................................197

170 AMS Suite Intelligent Device Manger Window ...............................................................198

171 Searching Dialog ............................................................................................................198

172 Reading Parameters Dialog............................................................................................199

173 FVP for PRM Main Screen .............................................................................................199

174 Heat Exchanger ..............................................................................................................211

175 Piping and Instrumentation Diagram ..............................................................................212

176 Temperature Cascade Block Diagram............................................................................213

177 Level Loop Block Diagram..............................................................................................214

178 ValVueFF Connected as a Visitor Device.......................................................................214

179 Device Operation State Dialog Box ................................................................................215

x

Page 13

180 Out of Service at Startup.................................................................................................218

181 Manual State...................................................................................................................220

182 Normal State ...................................................................................................................220

183 Out of Service State Change Warning Message Box.....................................................222

xi

Page 14

ValVueFF Software Interface to FVP

This page intentionally left blank.

Page 15

ValVueFF Software Interface to FVP

Tables

1 ValVueFF Version 2.32 Specifications............................................................................... 5

2 Two Configurations of the NIFB Interface Card............................................................... 11

3 Network Parameters for Reference Model....................................................................... 15

4 User Privilege Level Descriptions .................................................................................... 33

5 ValVueFF Menu Selections ............................................................................................. 36

6 Toolbar Icons ................................................................................................................... 39

7 IVI Faceplate Parameters ................................................................................................ 46

8 Block Modes ................................................................................................................... 47

9 Characteristic Choice....................................................................................................... 97

10 Servo Tuning Parameter Ranges .................................................................................. 112

11 Advanced Servo Tuning Parameters ............................................................................. 116

12 Failsafe Case One ......................................................................................................... 175

13 Failsafe Case Three....................................................................................................... 175

14 Failsafe Case Two ......................................................................................................... 179

15 Failsafe Case Four......................................................................................................... 179

16 Auto Tune Results ......................................................................................................... 207

17 Error Messages.............................................................................................................. 208

18 Error Bit Strings.............................................................................................................. 209

19 Mode Operation ............................................................................................................. 218

xiii

Page 16

ValVueFF Software Interface to FVP

This page intentionally left blank.

Page 17

ValVueFF Software Interface to FVP

WARNING

CAUTION

NOTE

Safety Information

This section provides safety information including safety symbols that are used on the

FVP110 and the safety symbol definition.

Safety Symbols

Instructions contain WARNINGS, CAUTIONS labels and Notes, where necessary, to alert

you to safety related or other important information. Read the instructions carefully before

installing and maintaining your instrument. Total compliance with all WARNING, and

CAUTION notices is required for safe operation.

Indicates a potentially hazardous situation, which if not avoided could result in serious injury.

1

Indicates a potentially hazardous situation, which if not avoided could result in property or data damage.

Indicates important facts and conditions.

1

Page 18

GE Energy

Product Safety

This software is intended for use with Masoneilan FVP positioners only.

For positioners intended for use with industrial compressed air: Ensure that an adequate

pressure relief provision is installed when the application of system supply pressure could

cause peripheral equipment to malfunction. Installation must be in accordance with local

and national compressed air and instrumentation codes.

General installation, maintenance or replacement

❑ Products must be installed in compliance with all local and national codes and

standards by qualified personnel using safe site work practices. Personal

Protective Equipment (PPE) must be used per safe site work practices.

❑ Ensure proper use of fall protection when working at heights, per safe site work

practices. Use appropriate safety equipment and practices to prevent the dropping

of tools or equipment during installation.

Intrinsically Safe Installation

ValVueFF Software Interface to FVP

Products certified for use in intrinsically safe installations MUST BE:

❑ Installed, put into service, used and maintained in compliance with national and

local regulations and in accordance with the recommendations contained in the

relevant standards concerning those environments.

❑ Used only in situations that comply with the certification conditions shown in this

document and after verification of their compatibility with the zone of intended use

and the permitted maximum ambient temperature.

❑ Installed, put into service and maintained by qualified and competent professionals

who have undergone suitable training for instrumentation used in such areas.

WARNING Before using these products with fluids/compressed gases

other than air or for non-industrial applications, consult GE.

This product is not intended for use in life support systems.

WARNING Do not use damaged instruments.

WARNING Installation in poorly ventilated confined areas, with any

potential of gases other than oxygen being present, can lead

to a risk of personnel asphyxiation.

2

Page 19

Product Safety

Use only genuine replacement parts which are provided by the manufacturer, to

guarantee that the products comply with the essential safety requirements of the

European Directives.

Changes to specifications, structure, and components used may not lead to the revision

of this manual unless such changes affect the function and performance of the product.

This product is not intended for use in safety shutdown systems. Substitution of parts

and components can lead to unsafe operation or compromise performance.

ValVueFF Software Interface to

3

Page 20

ValVueFF Software Interface to FVP

This page intentionally left blank.

Page 21

Introduction to ValVueFF and FVP

Overview

ValVueFF is a software tool that enables you to configure, calibrate, and operate

FOUNDATION Fieldbus pneumatic control valve positioners with internal process control

and limit switches. ValVueFF is compatible with Masoneilan Model FVP110 by and Model

YVP110 by Yokogawa Electric Corporation. It fully supports FOUNDATION Fieldbus

specifications.

ValVueFF Specifications

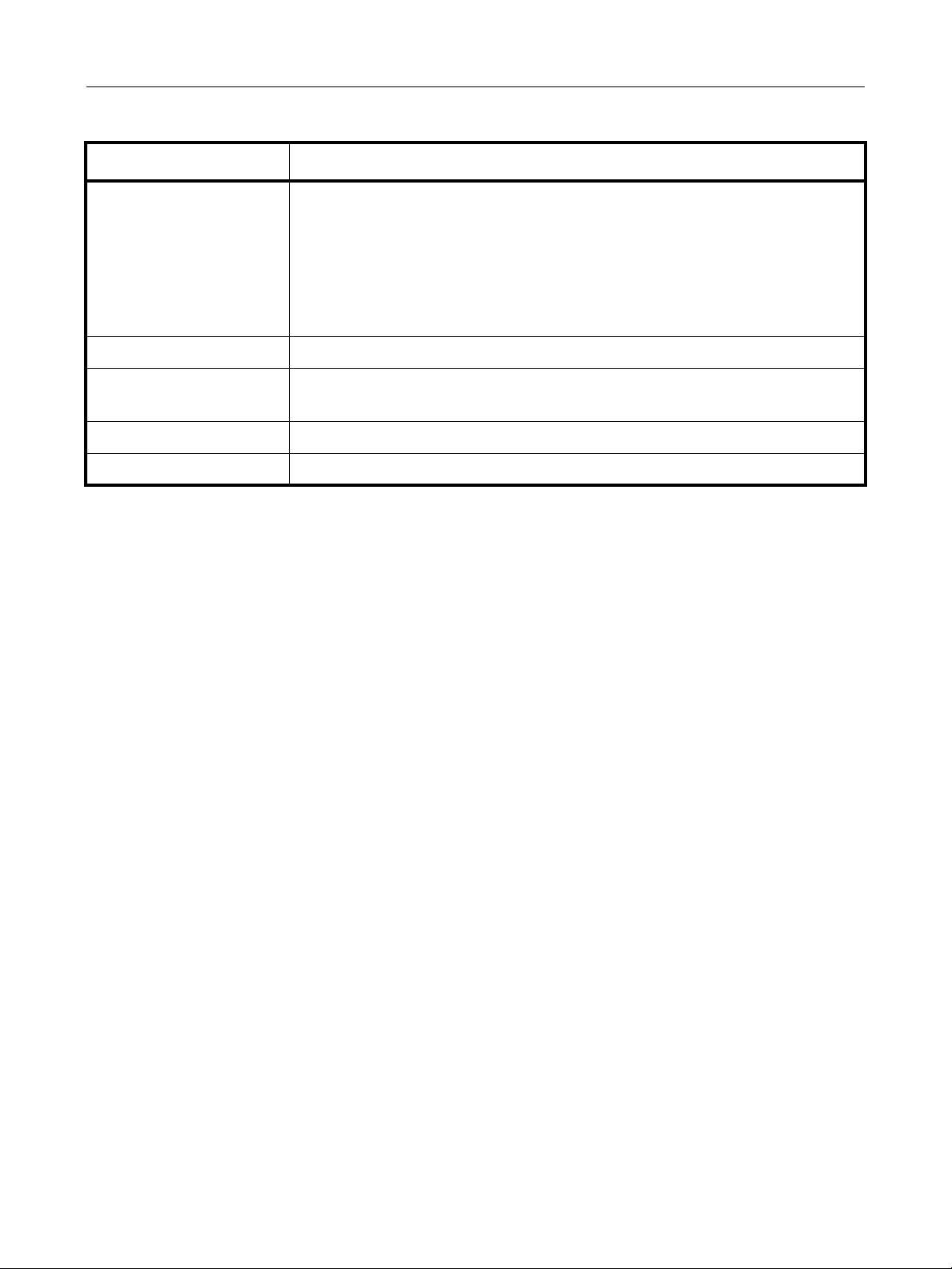

Table 1 ValVueFF Version 2.32 Specifications

2

Dynamic ValVueFF Version 2.32

Compatible OS Windows 2000

Windows XP SP2

Window Server 2003 with Service Pack 1 or Window Server 2003 R2

Interface Cards Supported NI-FBUS ISA bus card

NI-FBUS PCMCIA card

Application Interface

Software

Connection Directly connected to segment.

Positioners Supported Model FVP110 by Masoneilan

NI-FBUS Communication Manager version 4.X.

ftp://ftp.ni.com/support/ind_comm/fieldbus/ni-fbus/ communications_manager

NI-FBUS HSE (High Speed Ethernet) device.

Model YVP110 by Yokogawa Electric Corporation

5

Page 22

GE Energy

ValVueFF Software Interface to FVP

Table 1 ValVueFF Version 2.32 Specifications (Continued)

Dynamic ValVueFF Version 2.32

Blocks Supported Resource Block (RB)

Transducer Block (TB)

Analog Output Block (AO)

Digital Input Block (DI1, DI2)

Control Block (PID)

Output Splitter Block (OS)

Companion Device Model FVP110 or Model YVP110

Configuration Capability Device tag, node address, block tag, TRANSDUCER BLOCK (TB) parameters,

AO and PID

Query Capability All block parameters

Trending Up to 12 hours trending provided.

6

Page 23

Installation of Hardware and Software

Getting Started With ValVueFF

The following tools and software are needed:

❑ ValVueFF software version 2.32 CD-ROM

❑ Windows 2000, Windows Server 2003 or XP operating system

❑ National Instruments AT-FBUS or PCMCIA-FBUS interface card and NI-FBUS

software version 4.X. Earlier versions of NI-FBUS software are NOT compatible with

ValVueFF version 2.32.

❑ Instruction manuals for NI-FBUS interface card and software

❑ Model FVP110 or Model YVP110 positioner installed on a valve

3

❑ Model FVP110 or Model YVP110 Instruction Manual

❑ FOUNDATION Fieldbus power supply and power conditioner, with terminators

❑ Additional fieldbus devices that are installed on the bus segment, optional

❑ Fieldbus Foundation Application Guide AG-140; recommended Fieldbus Foundation

reference

❑ Fieldbus configurator software and instructions

7

Page 24

GE Energy

ValVueFF Software Interface to FVP

Before installing the ValVueFF software, you must install the Foundation Fieldbus

communications hardware and software. To help to reduce the need for digital

communications terminology, refer to an example reference process and Foundation

Fieldbus segment in Figure 1.

Figure 1 ValVueFF Reference Model Fieldbus Segment

CAUTION Improper setup can interfere with process control.

Throughout this instruction manual we use a simplified Fieldbus Reference Model

Process. This is an example of a simple process, not a practical process, that illustrates

many required Foundation Fieldbus elements for a successful installation. “Reference

Model Process” on page 212 contains a description of the model.

8

Page 25

General Installation and Setup

General Installation and Setup Procedure

This manual details the use of ValVueFF software with a Masoneilan FVP valve

positioner. ValVueFF can be used offline but is normally connected to a FVP positioner.

Ensure the following guidelines are adhered to prior to using ValVueFF with a

positioner:

1. Install the positioner on a valve and connect it to an air supply. See the FVP Instruction Manual.

2. Setup and start NIFB Communications Manager software.

3. Install a National Instrument AT-FBUS or PCMCIA-FBUS interface card (NI FBUS Interface) and configure it in the Windows registry. Carefully follow the installation instructions provided with the interface card.

4. Use the NI FBUS Interface Configuration Utility to configure the interface card as a

Visitor. The only exception is when using ValVueFF in a PC for initial setup of a

positioner without a host device; configure the NI FBUS Interface as a Link Master

Device at fixed address 0x10.

Installation of Hardware and

5. Assign the positioner a fieldbus node address and a device tag. Do this while the

device is connected as a single device on a test segment, not while connected to an

operating control segment as this requires a different interface card configuration.

See Configure the NIFB Interface Card Safely for Different Tasks.

6. Configure the entire fieldbus segment with all required function blocks soft-wired and scheduled.

Wiring practices for Foundation Fieldbus differ significantly from 4 to 20 ma instrument

wiring. Refer to the Foundation Fieldbus Application Guide 31.25 kbits/s Wiring and

Installation, AG-140, Revision 1.0 or later. However, some information regarding wiring

of the devices is included.

NOTE Visitor devices cannot start until they are connected to a

running segment with an active LAS that can assign a node

address to the visitor.

9

Page 26

GE Energy

Wiring Requirements

There are cable requirements that must be adhered to for reliable installations. The cable

used must support the digital data signals without reflections, noise, or attenuation. There

are three qualities of cable specified in Fieldbus Foundation AG-140. The type A cable is

used whenever possible and especially for long transmission distances or for segments

with many branches (spurs).

Power Conditioner Use a power conditioner for each segment. The conditioner must

Power Supply The FVP positioner complies with the foundation specification

Terminator Every fieldbus segment requires two, and only two, approved ter-

ValVueFF Software Interface to FVP

be Foundation Fieldbus compliant. The power conditioner functions to isolate the digital signals from the power source.

voltage requirements of 9 to 32 V. The power supply must conform to these requirements with consideration for the current

drawn by all devices powered by the segment. The FVP maximum current consumption is 17 mA.

minators. Terminators are passive circuits that damp signal reflections in the circuit. See AG-140 for the rules for terminator

location. For simple segments having short runs and few spurs

the terminator location can be at each end of the longest cable.

For very short cables both terminators can be located in the

power supply.

Installing NIFB Software and Hardware

ValVueFF software interfaces to the fieldbus segment through the requires PC interface

card. The card is supplied with NI-FBUS installation software. ValVueFF is designed to

operate only with National Instruments NI-FBUS cards. There is an ISA bus card for

desktop computers (ATFBUS) and a PCMCIA card for notebook computers

(PCMCIA-FBUS) and installation differs. There are two NI configuration tools that serve

separate purposes:

❑ NI-FBUS Interface Configuration Utility - This is used to install and set up interface

boards. It provides access to IRQ and memory settings needed for Windows. It

provides tools for importing DDs. It is described in the Getting Started manual

supplied with the NI-FBUS interface card.

❑ NI-FBUS Fieldbus Configuration System -This is the tool for configuring the

Foundation Fieldbus network, including the devices, setting up the control strategy,

and schedule. It is described in the NI-FBUS Configurator User Manual installed in

the program online help. After opening the NI-FBUS Fieldbus Configuration

System. Select Help > Online Help to open the manual in PDF format.

10

Page 27

NI-FBUS Software

NI-FBUS Software

Install the NI-FBUS software before installing the PCI-FBUS hardware. If you do not

have a this software you can obtain a copy at the following URL

ftp://ftp.ni.com/support/ind_comm/fieldbus/ni-fbus/communications_manager

CAUTION If you are reinstalling the NI-FBUS software over an existing

Installing NI-FBUS 4.X Software

1. Log in as an Administrator or as a user having Administrator privileges.

2. Insert the NI-FBUS CD-ROM. If you do not have this CD-ROM you can download it.

3. Select Start > Run.

4. Type the following in the Run dialog box: X:\Setup....where X equals the letter of the

drive where the NI-FBUS CD-ROM was inserted.

Installation of Hardware and

version, write down the board configuration and all port

configuration parameters that have been changed from their

defaults. Reinstallation causes you to lose all board and port

configuration information.

The interactive setup program takes you through the necessary install steps. At the

end of the setup the Add New Board dialog box may appear. If you have not yet

installed this board select Cancel. The board is installed later in the setup. The

installation program copies:

❑ nifb.dll and drvintf.dll into the \system 32 directory.

❑ nifb.sys into the \drivers directory.

❑ information to the WIndows registry.

Installing the Interface Card

Refer to the NI-FBUS Installation and Configuration manual to install and configure

the PCI-FBUS board and complete all installation and configuration tasks. NIFBUS

manuals are accessed using the following path: Programs\National

Instruments\NI-FBUS\Manuals.

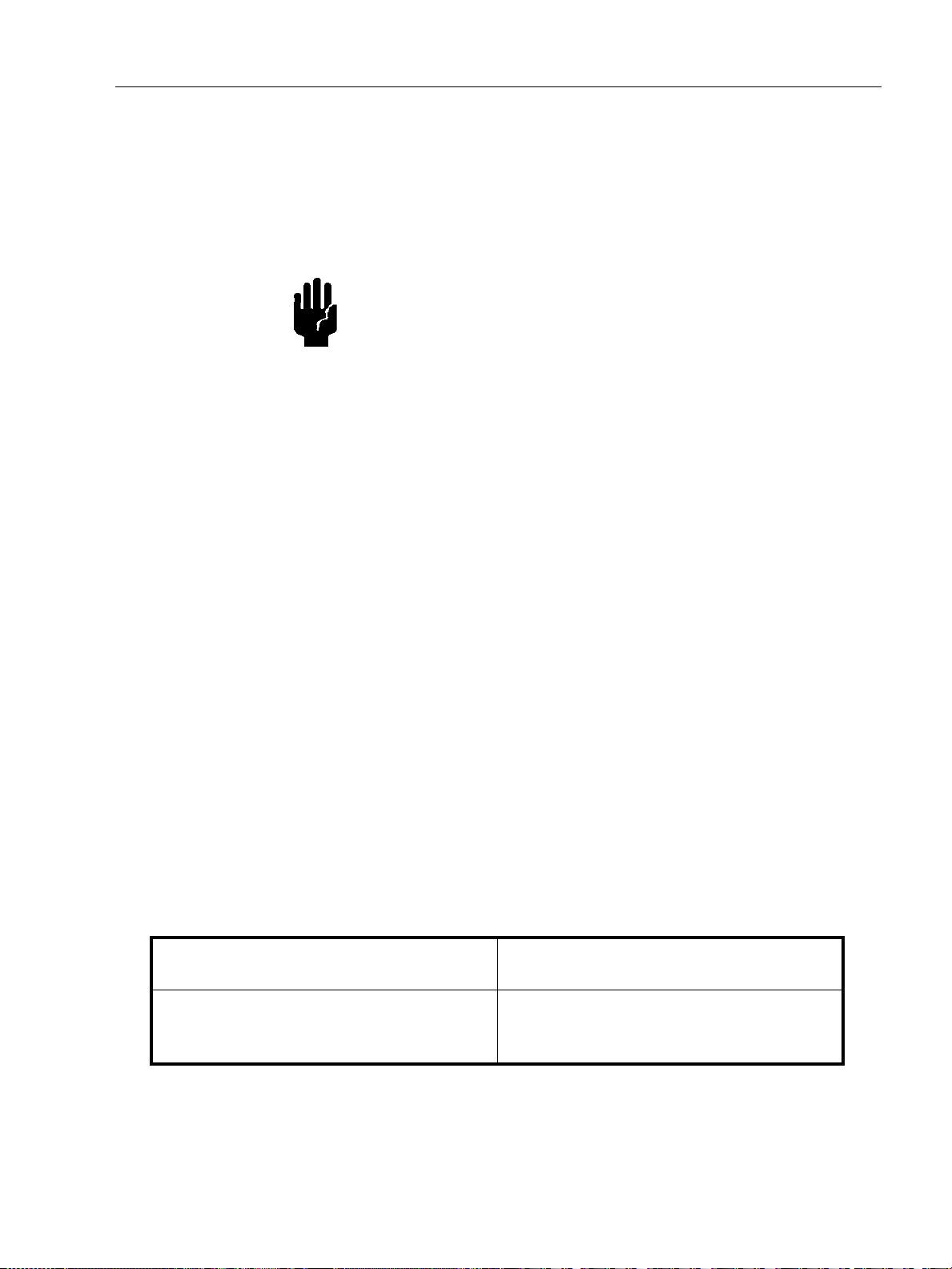

Table 2 Two Configurations of the NIFB Interface Card

To service a positioner in a running Foundation

Fieldbus segment with a host computer.

To configure a positioner, prior to connecting it

to a running segment.

The NIFB Interface card must be configured as

a Visitor device.

The NIFB Interface card must be configured as

a LINK MASTER DEVICE at a FIXED address.

0x10 is recommended

11

Page 28

GE Energy

Configuring the Interface Card

The configuration of a PC for use with ValVueFF varies depending on the immediate task.

If ValVueFF is used to maintain or configure a valve on a working Foundation Fieldbus

segment, the PC running ValVueFF must configured carefully so it does not interfere with

control communication. Two configurations are described in:

❑ “Configuring the Interface Card for Offline Use” on page 12

❑ “Configuring a Device with Third Party Software” on page 14

When an FVP positioner is running on a segment that cannot be disturbed, the interface

card and PC are configured as a BASIC DEVICE at a Visitor address. Open the

configuration utility, NI-FBUS Interface Configuration Utility, and follow the instructions in

the NI manual.

Configuring the Interface Card for Offline Use

The visitor configuration, described previously, does not work if the only devices that are

connected to the segment are a FVP positioner and an NIFB interface card. This is

because there is no Link Master to schedule messages. It is necessary to configure the

interface card as a Link Master. The Interface Name and Device Tag can be any

convenient names. The names are not seen by any other interfaces and are not

important.

ValVueFF Software Interface to FVP

Installing the Device Descriptions with NI-FBUS Interface Configuration Utility

The NI-FBUS Interface Configuration Utility must be used to install the DD for the FVP

and to install the standard dictionary:

1. Select Start > Programs > National Instruments > NI-FBUS > Utilities > Interface

Configuration Utility and the window appears (Figure 2).

Figure 2 Interface Configuration Utility

12

Page 29

NI-FBUS Software

2. Select Import DD/CFF and the browse dialog appears (Figure 3).

3. Click DD Info and the dialog appears (Figure 4).

Installation of Hardware and

Figure 3 Import DD_CFF Browse Dialog

Figure 4 DD Info Dialog

4. Click Browse, navigate to the ValVue installation directory. Default is \\Program Files\DFC\ValVueFF\DD\ and click OK and OK and Figure 5 appears.

Figure 5 Import DD_CFF Browse Dialog

5. Click Browse, navigate to the ValVue installation directory. Default is \\Program

Files\DFC\ValVueFF\DD\FVP until the directory FVP_0001 and FVP_0007

appears. There are three files in the two directories.

6. Select the 0201.ffo file that is under FVP_0001.

7. Select Open.

13

Page 30

GE Energy

ValVueFF Software Interface to FVP

8. Select OK in the Import DD_CFF Browse Dialog and click OK and a dialog appears (Figure 6).

Figure 6 Interface Configuration Utility Success Dialog

9. Click OK.

10. Repeat step 4 through step 9 to import 0306.ffo.

11. Repeat to import DD file in \\Program Files\\....\DD\YVP.

12. Click OK to exit.

After the DDs are installed successfully, they appear in the installation subdirectory of NI-FBUS.

CAUTION The computer and the NIFB interface card with NIFBUS

server software configuration must not conflict with an

operating Foundation Fieldbus segment. Disruption of control

can result. Do not configure the interface as a Link Master.

Configuring a Device with Third Party Software

Fieldbus segments have many devices. Each segment is unique and requires

configuration of the communications and control parameters. Each segment must have a

Link Master that is configured to manage and schedule the communications. The

National Instruments configurator software provides structured access to the parameters.

In this instruction manual screen shots from the National Instruments, Inc. configurator,

NIFBUS Configuration System, version 4.0 are referenced.

Configuring a Valve in an Active Foundation Fieldbus Segment

Because testing a segment can be time consuming it is best to perform the configuration

in a disciplined series of steps. This avoids repeating or repairing configuration steps. You

can refer to the NI-FBUS Configurator User Manual for additional information.

14

Page 31

NI-FBUS Software

Sequencing for Configuration

Use this procedure for sequencing a configuration

1. Set network parameters for Slot time, Max Response Delay, and Inter PDU Delay.

Parameters examples used in the reference model are shown in Table 3. Settings

are different in each Foundation Fieldbus segment.

Table 3 Network Parameters for Reference Model

Installation of Hardware and

Sub Index

1 ST

3 MRD

6 MID

Tag FV

101

Type FVP EJA YTA FVP DLT

Element

Slot Time

Max

Response

Delay

Min Inter PDU

Delay

444 4

12/ST 3 3 3

444 4

FT

102

TT

103

2. Save the as-found configuration.

3. Set node addresses.

4. Assign addresses to the basic devices.

5. Set tag names to unique values.

6. Link function blocks.

LV

201

LT

202

Network Setting Rule Network

Setting

Greatest of each Slot

Time

Greater than 12/ST

Greatest of each Min

Inter PDU Delay

4

3

4

7. Schedule the function blocks.

8. Download the configuration to the devices.

9. Check Clear Devices option in NIFB Configurator download dialog box to remove

bad links.

10. Save a file of the configuration data.

11. Set the devices to their normal states.

Shutting Down ValVueFF

Always close ValVueFF before closing NIFB.

15

Page 32

ValVueFF Software Interface to FVP

This page intentionally left blank.

Page 33

ValVueFF Administration

Overview

This section describes the procedures for installing ValVueFF software. The ValVueFF

installation procedures require a working knowledge of Microsoft Windows, the Masoneilan

FVP positioner, Foundation Fieldbus communications and function block technology. For

additional information about the FVP positioner, see Masoneilan FVP Instruction Manual

(GEA19791_FVP110_IOM).

Administration

ValVueFF Administration, ValVueFF Help, and the FVP Device Instruction Manual are also

installed along with ValVueFF. After successful installation of ValVueFF software, the

System Administrator should:

4

❑ Change the default logon and password.

❑ Set up user accounts through the ValVueFF Administration program.

❑ Secure the ValVueFF CD-ROM in order to provide system security. Anyone with

access to the setup disk could reload the software and thereby get access to FVP

devices.

Installation Sequence

1. Remove existing version of ValVueFF software. ValVue does this for you.

2. Install ValVueFF 2.32 using the instructions in this chapter.

3. Register ValVueFF using the form provided in the software.

17

Page 34

GE Energy

Installing ValVueFF

The following procedure details removing a previous version of ValVueFF and installing

ValVueFF 2.32. Do not install ValVueFF 2.32 until you have installed NI-FBUS 4.X.

Launching the Application

There are several ways to start a ValVueFF 2.32 installation. Depending upon your media

you can use one of the following start options:

1. Select an icon from the CD-ROM.

2. Enter ValVueFF Installer.exe in the Run dialog box.

To install ValVUeFF version 2.32 you must relaunch the application after removing a previous version of ValVueFF.

Removing a Previous Version of ValVueFF

When a previously installed version of ValVueFF is detected by the setup software a

series of messages appear.

ValVueFF Software Interface to FVP

1. Launch the application. The ValVueFF CD Browser window appears (Figure 7).

Figure 7 CD Browser Window

18

Page 35

Removing a Previous Version of

2. Click Install Software and the ValVue FF CD Browser window appears (Figure 8).

ValVueFF Administration

Figure 8 Software Selection Window

3. Click Install Full Edition and the Preparing Setup dialog box appears followed by a

dialog box (Figure 9).

Figure 9 NIFB Version Requirement Reminder

4. Ensure that the fieldbus software is installed, click Yes and the Shut Down message

appears (Figure 10).

Figure 10 Shut Down Message

19

Page 36

GE Energy

ValVueFF Software Interface to FVP

5. Select Yes to continue. The Maintenance dialog box appears (Figure 11).

Figure 11 Select Maintenance Level Dialog Box

6. Select Remove and then Next. A message box appears asking if you want to remove a previous version of ValVueFF.

7. Select Yes. A Setup Status dialog box appears, then a Maintenance Complete dialog box appears (Figure 12).

Figure 12 Maintenance Complete Dialog Box

8. Select Finish.

9. Relaunch ValVueFF to install the application.

20

Page 37

Installing ValVueFF

Installing ValVueFF

1. Launch the application. The ValVueFF CD Browser window appears (Figure 13).

ValVueFF Administration

Figure 13 CD Browser Window

2. Click Install Software and the ValVue FF CD Browser window appears (Figure 13).

Figure 14 Software Selection Window

21

Page 38

GE Energy

ValVueFF Software Interface to FVP

3. Click Install Full Edition and the Preparing Setup dialog box appears followed by a dialog box (Figure 15).

Figure 15 NIFB Version Requirement Reminder

4. Ensure that the fieldbus software is installed, click Yes and the Shut Down message appears (Figure 16).

Figure 16 Shut Down Message

5. Select Yes and the Welcome to ValVueFF dialog box appears (Figure 17).

Figure 17 Welcome to ValVueFF

22

Page 39

Installing ValVueFF

6. Select Next. The License Agreement dialog box appears (Figure 18).

ValVueFF Administration

Figure 18 License Agreement