Page 1

GE Oil & Gas

GE Data Classification: Public

Masoneilan* Valves

ValVue* ESD

Instruction Manual

Digital communications

software designed

exclusively for SVI* II ESD

Page 2

About this Guide

This instruction manual applies to the following instruments and approved software:

SVI II ESD

with Firmware version

with ValVue ESD version 1.0 or greater

with a handheld communicator with DD published for SVI II ESD

The information in this manual is subject to change without prior notice.

The information contained in this manual, in whole or part, shall not be transcribed or copied without GE Oil & Gas’s written

permission.

In no case does this manual guarantee the merchantability of the PST Controller or the software or its adaptability to a spe-

cific client needs.

Please report any errors or questions about the information in this manual to your local supplier or visit

www.ge-energy.com/valves.

DISCLAIMER

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION AND MAINTENANCE PROCEDURES. SINCE

OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES AND

AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND

REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF THE REQUIREMENTS

FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT IN POTENTIALLY HAZARDOUS ENVIRONMENTS.

THEREFORE, THESE INSTRUCTIONS SHOULD BE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES

AND REGULATIONS APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT NOR TO PROVIDE FOR

EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE.

SHOULD FURTHER INFORMATION BE DESIRED OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED

SUFFICIENTLY FOR THE CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE STRICTLY LIMITED TO THOSE

EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE

INSTRUCTIONS.

THESE INSTRUCTIONS CONTAIN PROPRIETARY INFORMATION OF GE, AND ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT

DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART NOR SHALL ITS CONTENTS BE DISCLOSED TO ANY THIRD PARTY WITHOUT THE WRITTEN APPROVAL OF GE.

Copyright

All software is the intellectual property of GE Oil & Gas.

The complete design and manufacture is the intellectual property of GE Oil & Gas.

*

Masoneilan

accurate at the time of publication and is subject to change without notice.

Copyright 2014 by GE Oil & Gas. All rights reserved.

PN 720002-392 Rev. G

, SVI*, and ValVue* are registered trademarks of GE Oil & Gas. All information contained herein is believed to be

Page 3

Document Changes

Version/ Date Changes

C/02-2011

D/3-2013

E/9-2013

F/02-2014

G/8-2014

Added to section on DO switches configuration.

Updated Registration section updated to GE logo software

Removed references to double-acting

Fixed issues from S. Leledy.

Changed the Simplified Switch diagram in Configure I/O section.

Added Cautions about Position Low and Upper Limits.

Added text about the 4-20 retransmit galvanic isolation.

Updated the Simplified Switch diagram in Configure I/O section

and updated the text.

Updated Configure tab to add Air Loss Trip and Trip Level fields.

Update software install section to reflect 1.10.0 version.

Page 4

Contents

About This Manual..................................................................................................................................................................... 19

Documentation Conventions ...............................................................................................................................................20

ValVue ESD Overview...............................................................................................................................................................21

System Requirements.............................................................................................................................................................. 21

Hardware ..............................................................................................................................................................................21

Software ................................................................................................................................................................................22

Install ValVue ESD and PRM Plug-In..................................................................................................................................23

Installing ValVue ESD Software...................................................................................................................................23

Installing the Yokogawa PRM Plug-In ......................................................................................................................27

Registering ValVue ESD...........................................................................................................................................................39

Entering Software Keys ..................................................................................................................................................43

Licensing........................................................................................................................................................................................45

Activating the License .....................................................................................................................................................47

Main Window............................................................................................................................................................................... 49

Connected Devices Icons.......................................................................................................................................................50

Plant Schedule ............................................................................................................................................................................51

Editing Plant Schedule.............................................................................................................................................................52

Editing Plant Schedule for a Selected Device.......................................................................................................54

Export to Excel .................................................................................................................................................................... 56

Connected Devices Help ........................................................................................................................................................56

Connected Devices Tools Menu..........................................................................................................................................57

Configuring ValVue ESD Options ........................................................................................................................................58

Launching Set Options.................................................................................................................................................... 58

Set Options Screen............................................................................................................................................................58

Multiplexor Setup and Operation ....................................................................................................................................... 62

Selecting Mux Setup.........................................................................................................................................................62

Configuring the Multiplexor ..........................................................................................................................................64

Mux Reset..............................................................................................................................................................................65

Scan Option..........................................................................................................................................................................66

Troubleshooting ValVue ESD Used with Mux .......................................................................................................67

Configuring Burst Mode..................................................................................................................................................68

Launching a Device ..................................................................................................................................................................69

Offline Mode.........................................................................................................................................................................70

Selecting an Offline Device ...........................................................................................................................................71

Selecting a Connected Device.....................................................................................................................................74

Device Information ...........................................................................................................................................................75

Find by Tag ...........................................................................................................................................................................75

Re-Scan.................................................................................................................................................................................. 76

Right Clicking on Device Name ...........................................................................................................................................77

Launching ValVue ESD....................................................................................................................................................77

Launching Historical View.............................................................................................................................................78

View latest PST....................................................................................................................................................................80

Overview ........................................................................................................................................................................................81

4 | =GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Page 5

Working in ESDVue ................................................................................................................................................................... 82

Toolbar ................................................................................................................................................................................... 82

Modes of Operation ......................................................................................................................................................... 82

Device Trip............................................................................................................................................................................ 83

Change Mode...................................................................................................................................................................... 83

Exit............................................................................................................................................................................................ 84

ESDVue Help ................................................................................................................................................................................ 84

Help Menu.............................................................................................................................................................................84

ESDVue Screens ......................................................................................................................................................................... 85

Monitor Screen ................................................................................................................................................................... 85

Trend Screen ....................................................................................................................................................................... 86

Configure Screen............................................................................................................................................................... 87

Calibrate Screen ................................................................................................................................................................88

Diagnostics Screen........................................................................................................................................................... 89

PST............................................................................................................................................................................................ 90

Status Screen...................................................................................................................................................................... 91

Check ......................................................................................................................................................................................92

What You Can Do on the Monitor Screen ...................................................................................................................... 93

PST Controller Characteristics............................................................................................................................................. 94

Pressure, Pressure1 and Pressure2.......................................................................................................................... 94

Position Indicator .............................................................................................................................................................. 94

Signal ...................................................................................................................................................................................... 94

Position................................................................................................................................................................................... 95

Setpoint.................................................................................................................................................................................. 95

Changing the Setpoint ............................................................................................................................................................ 96

Entering Setpoint Value.................................................................................................................................................. 97

Status on the Monitor Screen .............................................................................................................................................. 98

Tag Information.......................................................................................................................................................................... 99

PST/ESD Information................................................................................................................................................................ 99

ESD Types................................................................................................................................................................................... 100

Monitor Context Menu ......................................................................................................................................................... 101

Reports ........................................................................................................................................................................................ 103

How to Create Reports ................................................................................................................................................ 103

Creating Report Template Files ............................................................................................................................... 103

Report Setup..................................................................................................................................................................... 108

(Generate) Report........................................................................................................................................................... 108

View All Parameters .............................................................................................................................................................. 110

Device .................................................................................................................................................................................. 111

All ........................................................................................................................................................................................... 112

PST Config.......................................................................................................................................................................... 113

PST DATA ............................................................................................................................................................................ 114

Calibrate ............................................................................................................................................................................. 115

Config................................................................................................................................................................................... 116

Dynamic.............................................................................................................................................................................. 117

What you can do on the Trend Screen ........................................................................................................................ 119

© 2014 General Electric Company. All rights reserved.

Masoneilan Valves ValVue ESD Instruction Manual =| 5

Page 6

Trend Graph Features .......................................................................................................................................................... 120

Changing the Graph View .......................................................................................................................................... 120

Capture to Clipboard .................................................................................................................................................... 120

Trend Context Menu...................................................................................................................................................... 121

What You Can Do on the Configure Screen ............................................................................................................... 123

Changing Tag Information ................................................................................................................................................. 124

Button Lock................................................................................................................................................................................ 125

Fault Settings............................................................................................................................................................................ 125

Fault Settings Options .................................................................................................................................................. 125

PST Allow Options................................................................................................................................................................... 128

Language ................................................................................................................................................................................... 128

Pressure Units .......................................................................................................................................................................... 129

Air Action ................................................................................................................................................................................... 129

Configure I/O............................................................................................................................................................................. 129

Accessing Configure I/O.............................................................................................................................................. 129

Setup Wizard............................................................................................................................................................................. 133

Setup Wizard Selections.............................................................................................................................................. 134

What you can do on the Calibrate Screen.................................................................................................................. 151

Find Stops................................................................................................................................................................................... 152

Advanced Parameters.......................................................................................................................................................... 155

Auto Tune ................................................................................................................................................................................... 157

Auto Tune Diagnostic Graph ............................................................................................................................................. 162

Diagnostic Graph Color Legend .............................................................................................................................. 163

Set Graph Scale............................................................................................................................................................... 163

Select Additional Calibration Curve ....................................................................................................................... 165

Show Computed Calibration Results..................................................................................................................... 170

Save to File......................................................................................................................................................................... 171

Export to Excel ................................................................................................................................................................. 173

Calibrate Context Menu....................................................................................................................................................... 175

Run Find Stops................................................................................................................................................................. 177

Manual Find Stops ......................................................................................................................................................... 180

Applying Calibration Changes .......................................................................................................................................... 183

What you can do on the Diagnostics Screen ............................................................................................................ 185

Step Diagnostics ..................................................................................................................................................................... 186

Running a Step Test ...................................................................................................................................................... 186

Step Diagnostics Graph............................................................................................................................................... 191

Show Computed Step Results .................................................................................................................................. 199

Save to File......................................................................................................................................................................... 201

Export to Excel ................................................................................................................................................................. 203

Extended Signature Diagnostics ..................................................................................................................................... 205

Extended Signature Diagnostics Graph Features........................................................................................... 209

Show Computed Extended Signature Results .................................................................................................. 217

Save to File................................................................................................................................................................................. 219

Export to Excel.......................................................................................................................................................................... 221

6 | =GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Page 7

Load Data................................................................................................................................................................................... 223

Loading Data from a Database............................................................................................................................... 223

Load Data from a File on Diagnostics Screen .................................................................................................. 226

What you can do on the PST Screen............................................................................................................................. 231

PST Setup Guidelines ............................................................................................................................................................ 232

1. Set PST Start Trigger ................................................................................................................................................ 233

2. Run Extended Signature ........................................................................................................................................ 234

3. Determine Friction, Breakout, PST Minimum Pressure From Extended Signature ..................... 235

4. Set PST Parameters.................................................................................................................................................. 237

PST Schedule ............................................................................................................................................................................ 238

Changing Interval of Days.......................................................................................................................................... 238

Changing New PST Schedule.................................................................................................................................... 239

PST Configuration................................................................................................................................................................... 242

Partial Stroke Test Settings........................................................................................................................................ 242

PST Travel........................................................................................................................................................................... 243

Minimum Pressure......................................................................................................................................................... 244

Maximum Time................................................................................................................................................................ 244

PST Speed .......................................................................................................................................................................... 244

Dwell Time ......................................................................................................................................................................... 245

Friction Low Limit ........................................................................................................................................................... 245

Friction High Limit.......................................................................................................................................................... 245

Breakout Limit.................................................................................................................................................................. 246

Droop Limit........................................................................................................................................................................ 246

Freeze DO........................................................................................................................................................................... 246

Freeze AO........................................................................................................................................................................... 246

Enable Schedule ............................................................................................................................................................. 246

Set.......................................................................................................................................................................................... 247

PST Diagnostics....................................................................................................................................................................... 247

Diagnostics Area............................................................................................................................................................. 247

Perform PST ...................................................................................................................................................................... 249

PST Diagnostic Graph................................................................................................................................................... 253

Perform TBT............................................................................................................................................................................... 264

Load Diagnostic Data........................................................................................................................................................... 266

Load Data from Database ......................................................................................................................................... 267

Load from File .................................................................................................................................................................. 273

Historical View ......................................................................................................................................................................... 276

Changing the Historical View Start and End Dates........................................................................................ 277

Displaying Historical View Diagnostic Graphs.......................................................................................................... 281

Diagnostic Graph Color Legend .............................................................................................................................. 282

PST Context Menu .................................................................................................................................................................. 283

What you can do on the Status Screen ....................................................................................................................... 285

Active Faults.............................................................................................................................................................................. 287

General........................................................................................................................................................................................ 288

Critical..........................................................................................................................

................................................................ 289

Instrumentation ...................................................................................................................................................................... 290

Actuator ...................................................................................................................................................................................... 291

© 2014 General Electric Company. All rights reserved.

Masoneilan Valves ValVue ESD Instruction Manual =| 7

Page 8

Pneumatics................................................................................................................................................................................ 292

Electronics.................................................................................................................................................................................. 293

Clear Current Faults............................................................................................................................................................... 294

Clear All Faults.......................................................................................................................................................................... 296

Clear Individual Fault.................................................................................................................................................... 298

Set Fail High/Low.................................................................................................................................................................... 300

Status Fault Code List................................................................................................................................................... 300

Fault Matrix................................................................................................................................................................................ 301

Status Context Menu............................................................................................................................................................. 325

What you can do on the Check Screen........................................................................................................................ 327

Information Displayed on the Check Screen ............................................................................................................. 328

Send Command....................................................................................................................................................................... 329

List of Available HART Commands ......................................................................................................................... 331

Check Context Menu............................................................................................................................................................. 333

Overview ..................................................................................................................................................................................... 335

Methods to Set Up the SVI II ESD..................................................................................................................................... 335

Steps to Set Up SVI II ESD.................................................................................................................................................... 335

Configuration Parameters.......................................................................................................................................... 336

Calibration Steps............................................................................................................................................................. 336

Run Find Stops................................................................................................................................................................. 336

Manual Find Stops ......................................................................................................................................................... 339

Run Auto Tune.................................................................................................................................................................. 341

8 | =GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Page 9

List of Figures

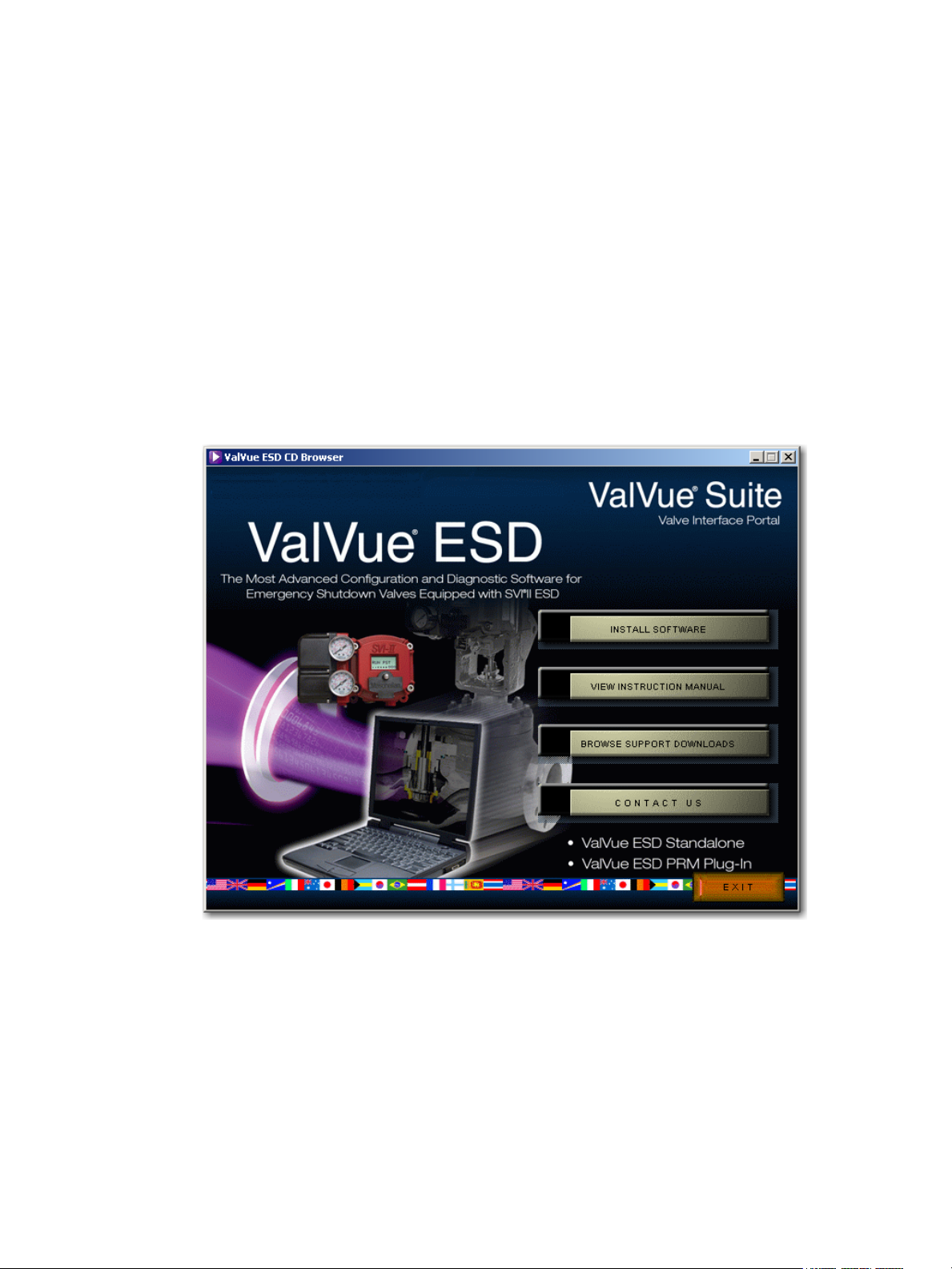

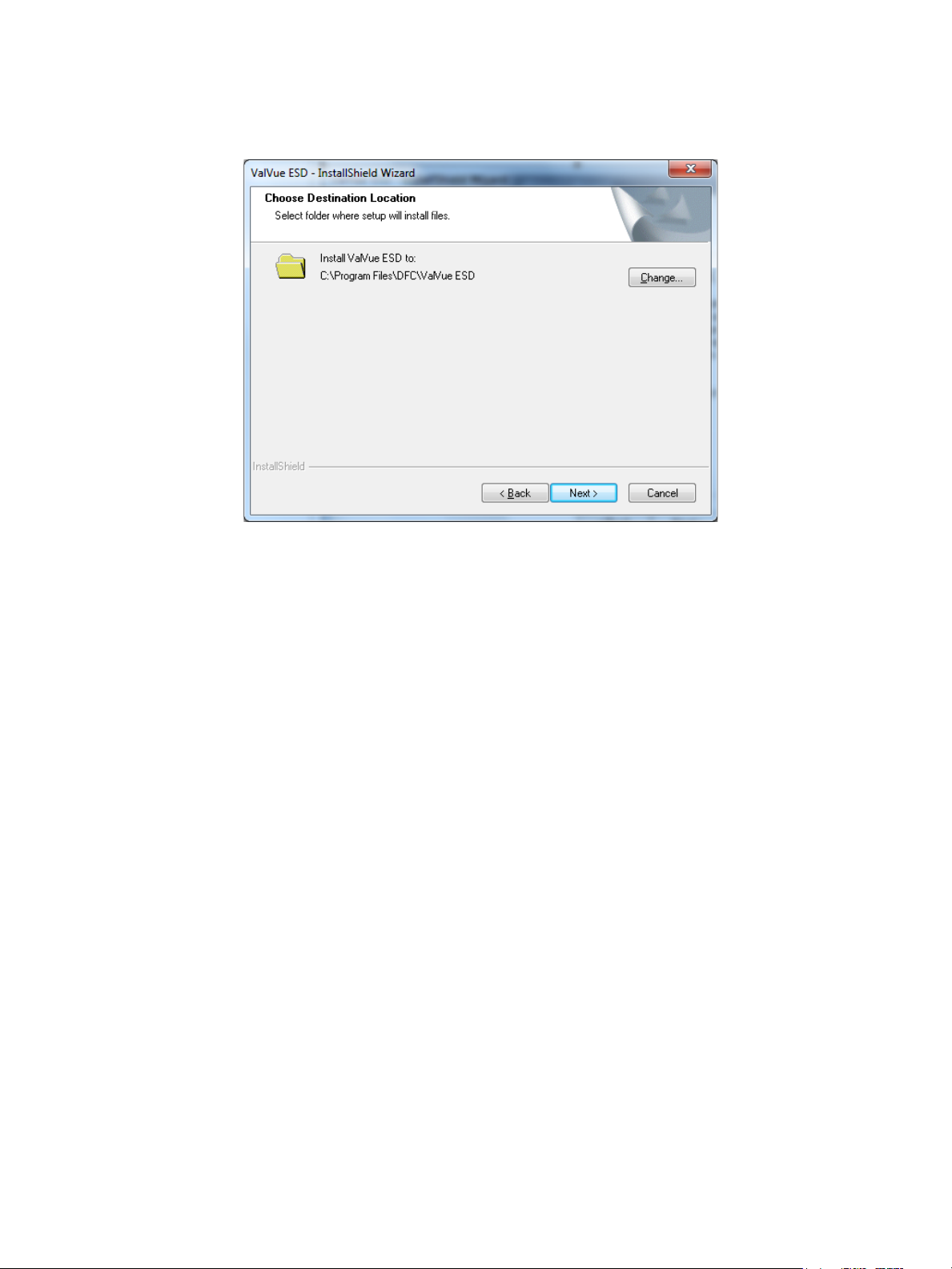

1 ValVue ESD CD Browser ............................................................................................................................................... 23

2 Software Choice............................................................................................................................................................... 24

3 Install Shield Wizard....................................................................................................................................................... 24

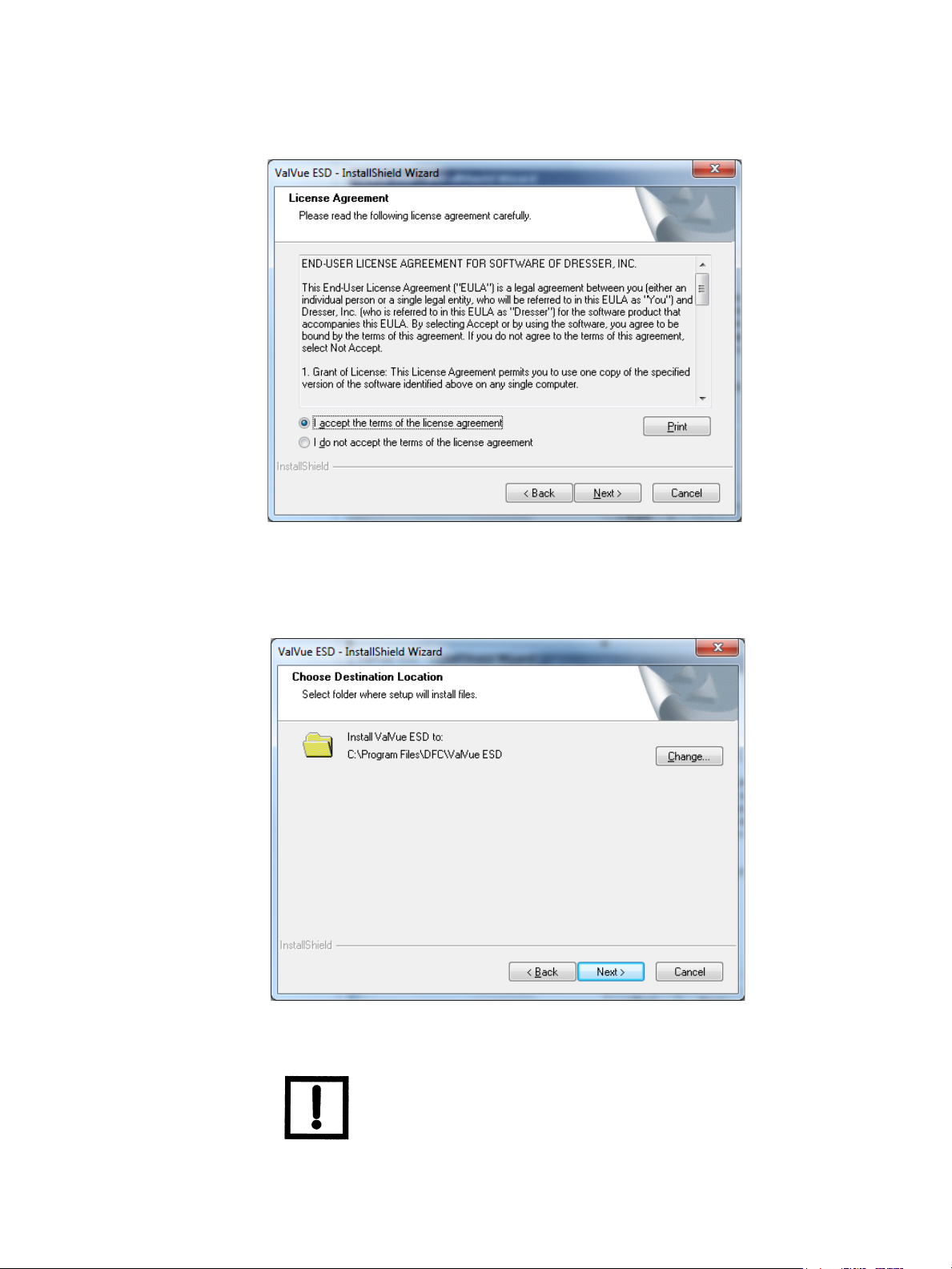

4 License Agreement......................................................................................................................................................... 25

5 Choose Destination Location..................................................................................................................................... 25

6 Ready to Install ................................................................................................................................................................. 26

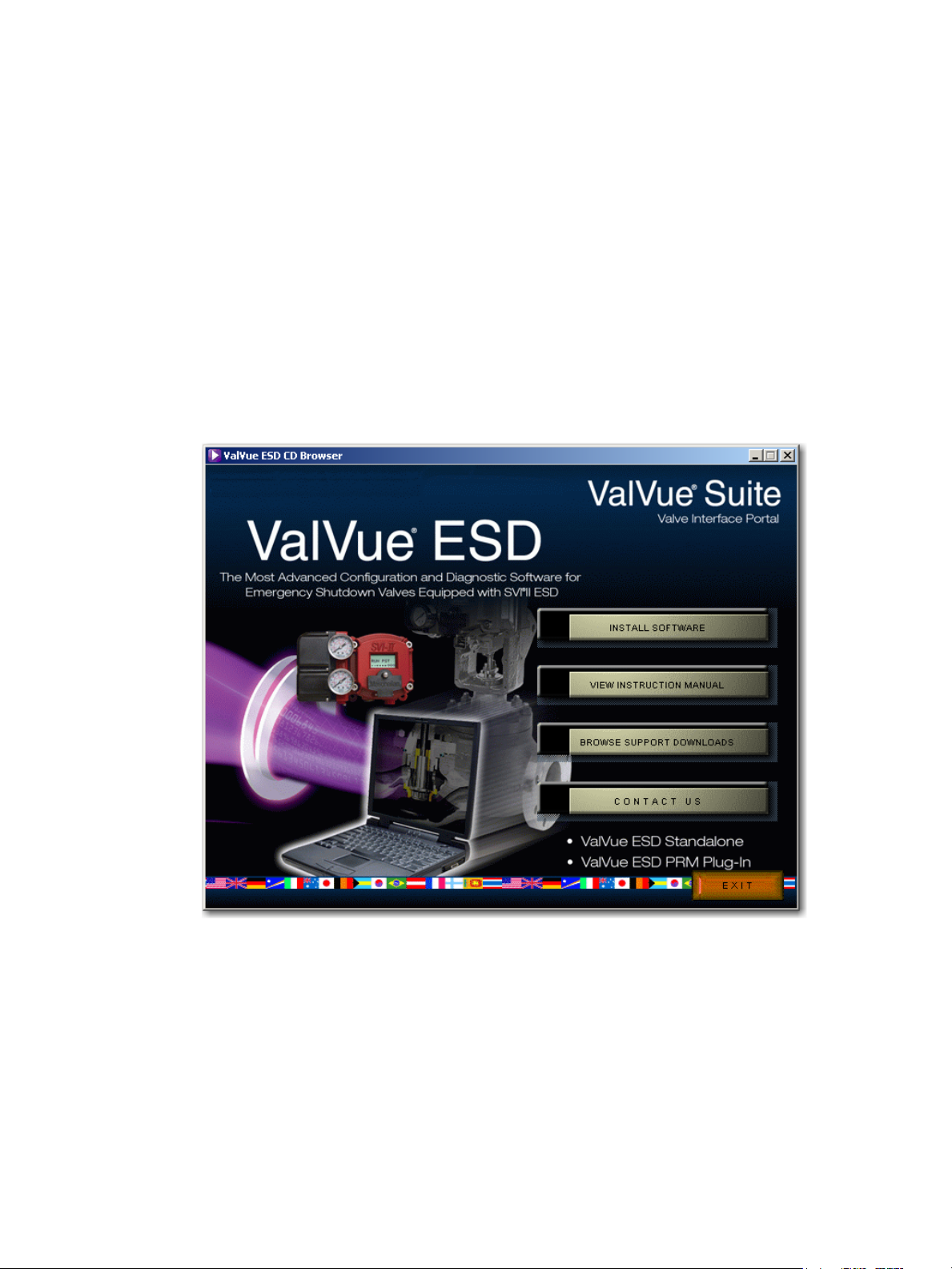

7 ValVue ESD CD Browser ............................................................................................................................................... 27

8 Software Choice............................................................................................................................................................... 28

9 PRM Plug-In Main Screen.............................................................................................................................................28

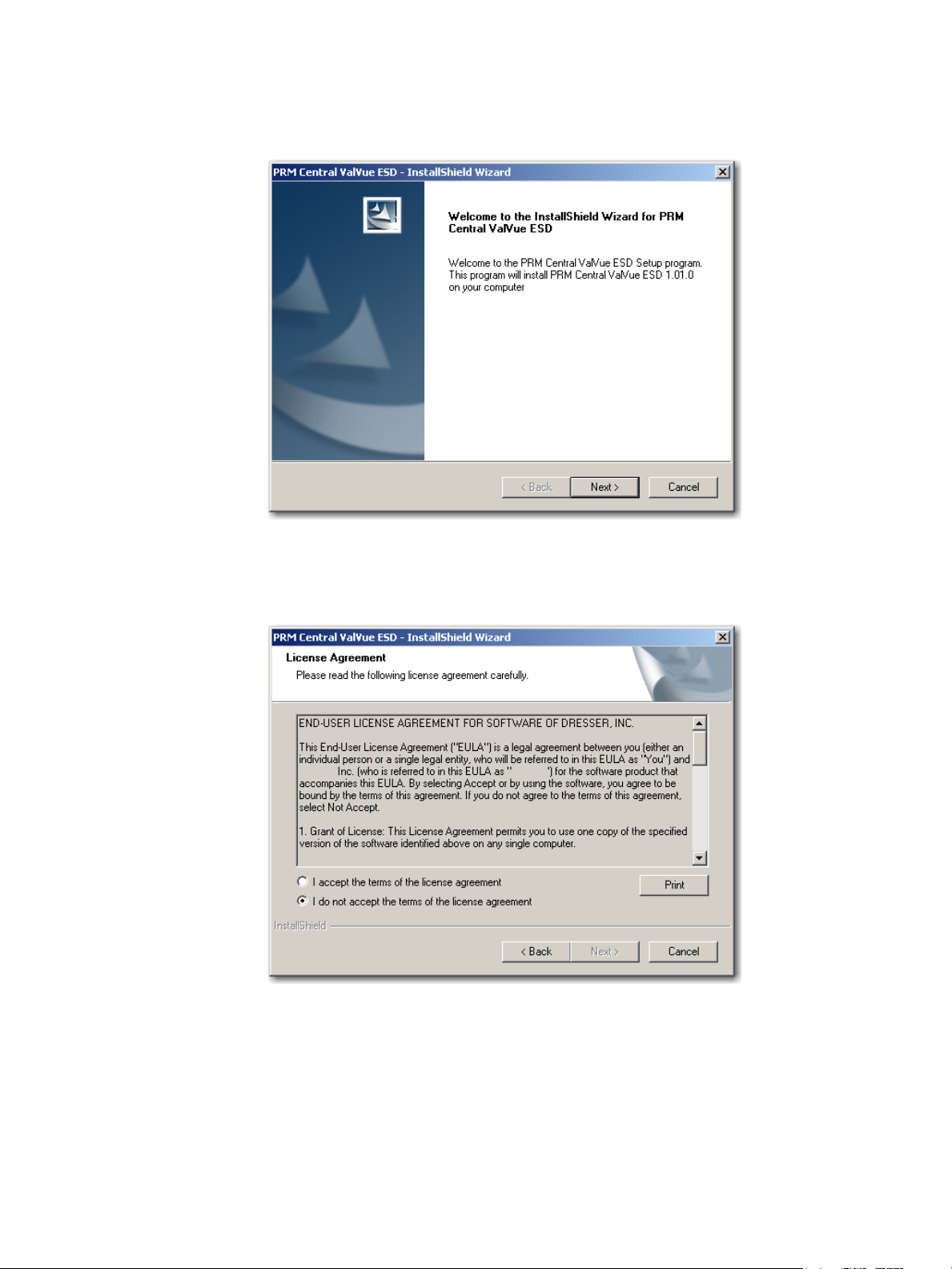

10 Install Shield Central Server........................................................................................................................................29

11 PRM Central Server License Agreement............................................................................................................... 29

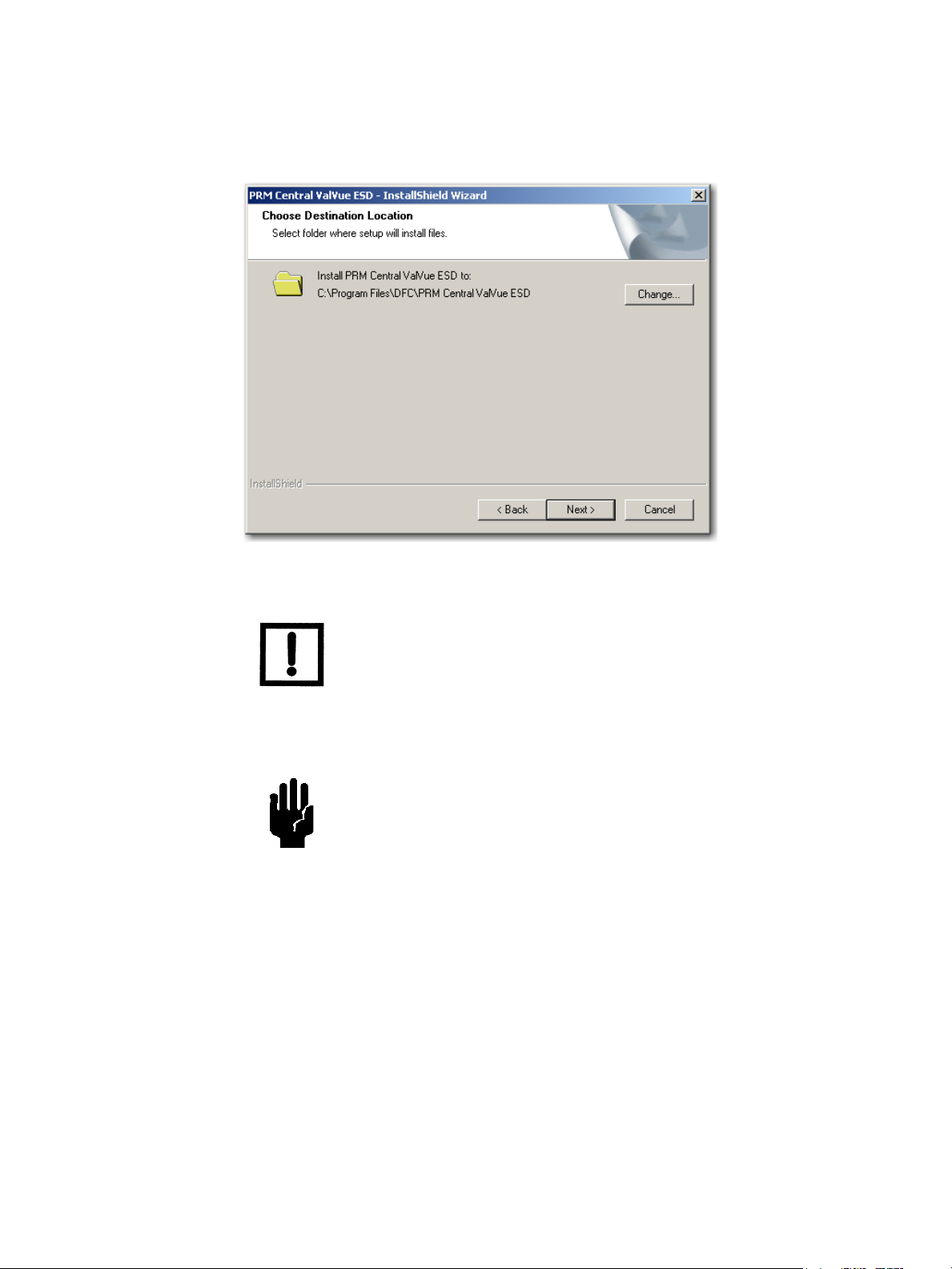

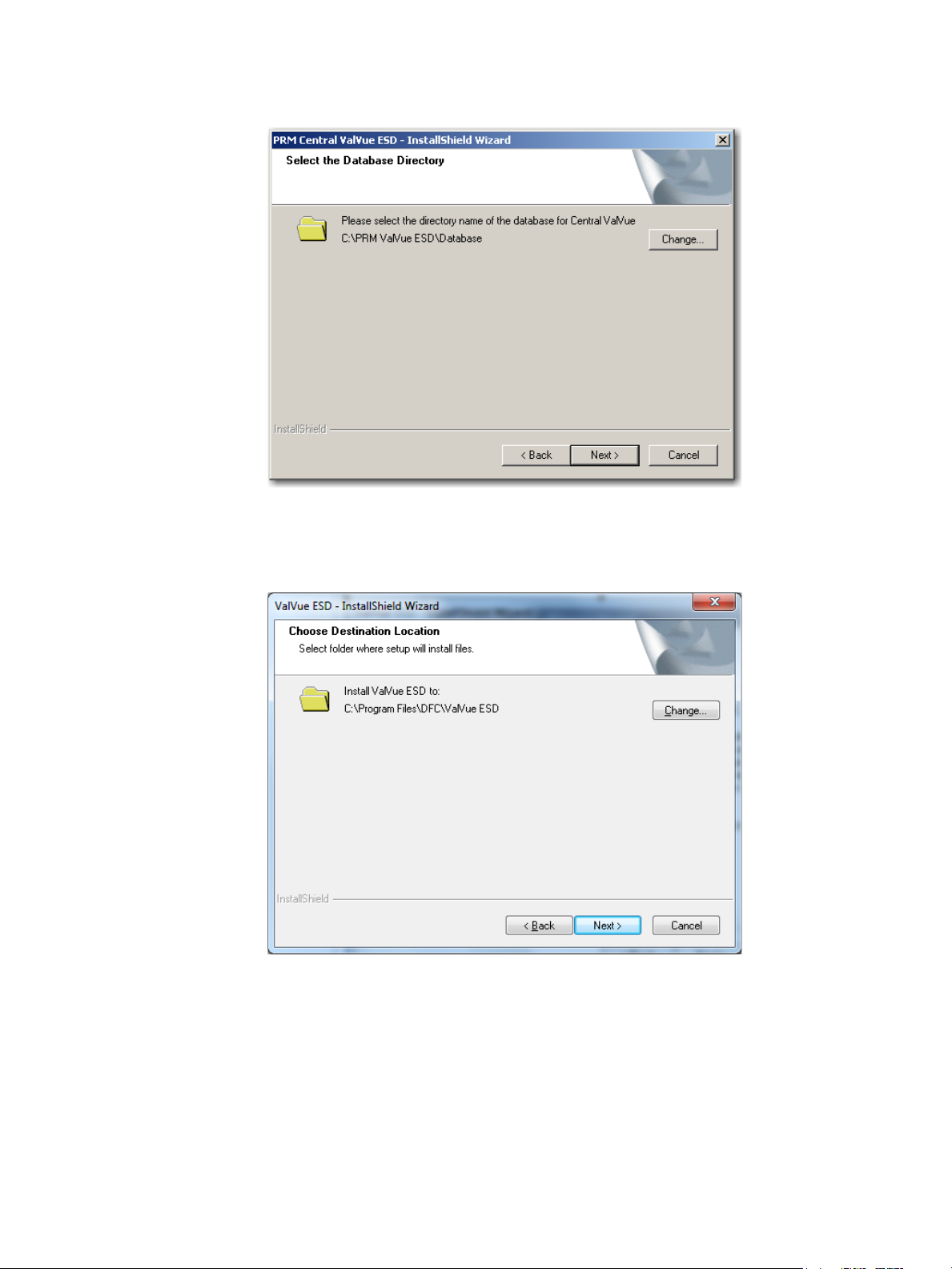

12 PRM Central Server Destination Folder ................................................................................................................. 30

13 PRM Central Server Database Directory Destination Folder....................................................................... 31

14 Ready to Install ................................................................................................................................................................. 31

15 PRM Central Server Dialog .......................................................................................................................................... 32

16 PRM Central Server Dialog II....................................................................................................................................... 32

17 PRM Central Server Dialog III...................................................................................................................................... 32

18 Database Directory Reminder................................................................................................................................... 32

19 ValVue ESD CD Browser ............................................................................................................................................... 33

20 Software Choice............................................................................................................................................................... 34

21 PRM Plug-In Main Screen.............................................................................................................................................34

22 Install Shield PRM Plug-In ............................................................................................................................................ 35

23 PRM Plug-In License Agreement .............................................................................................................................. 35

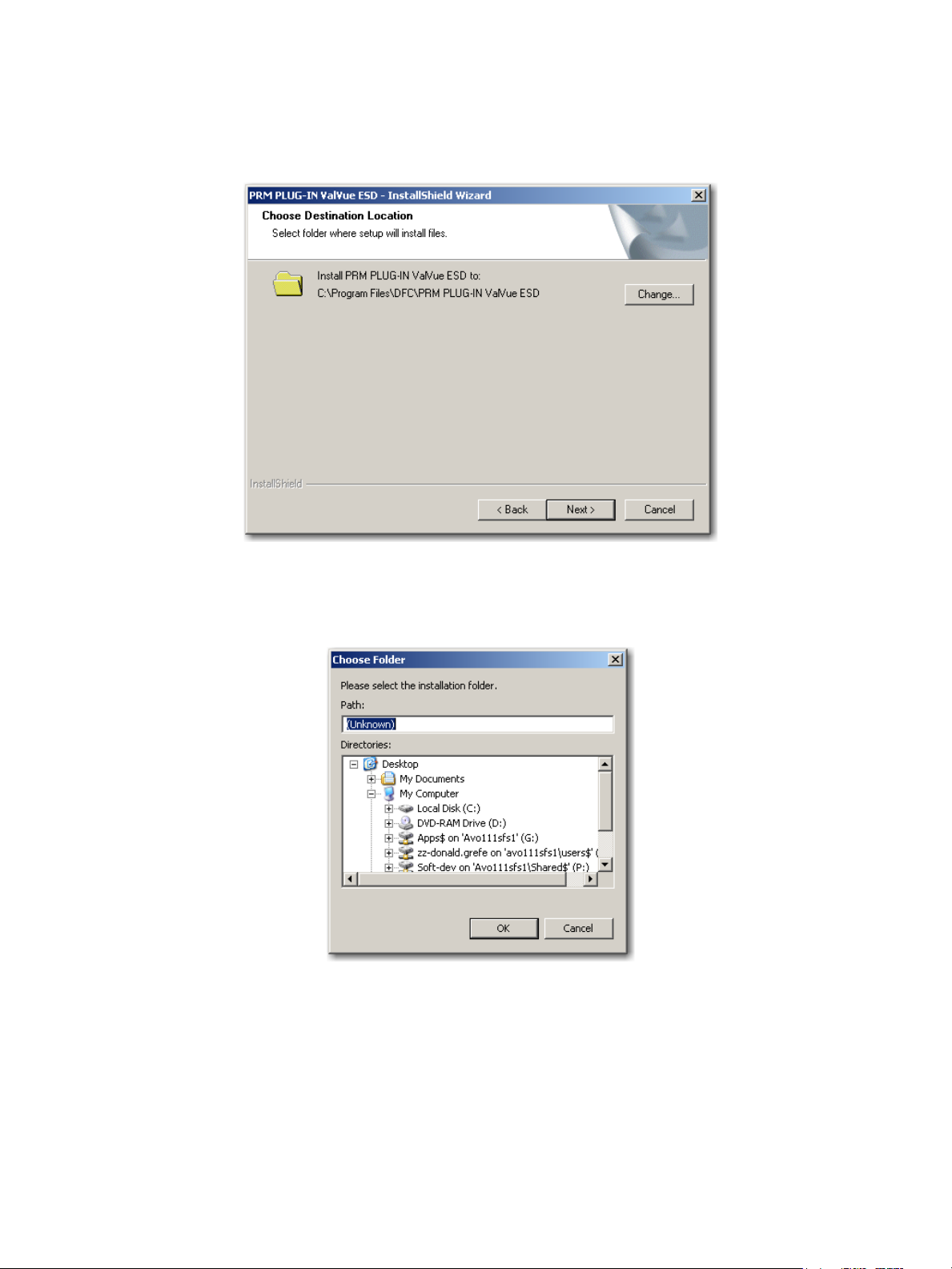

24 PRM Plug-In Destination Folder ................................................................................................................................ 36

25 Choose Folder ................................................................................................................................................................... 36

26 PRM Plug-In Client Database Location Destination Folder.......................................................................... 37

27 Choose Folder ................................................................................................................................................................... 37

28 Ready to Install ................................................................................................................................................................. 38

29 Owner and Product Key Registration Window.................................................................................................. 39

30 Applying Owner and Product Key Information.................................................................................................. 40

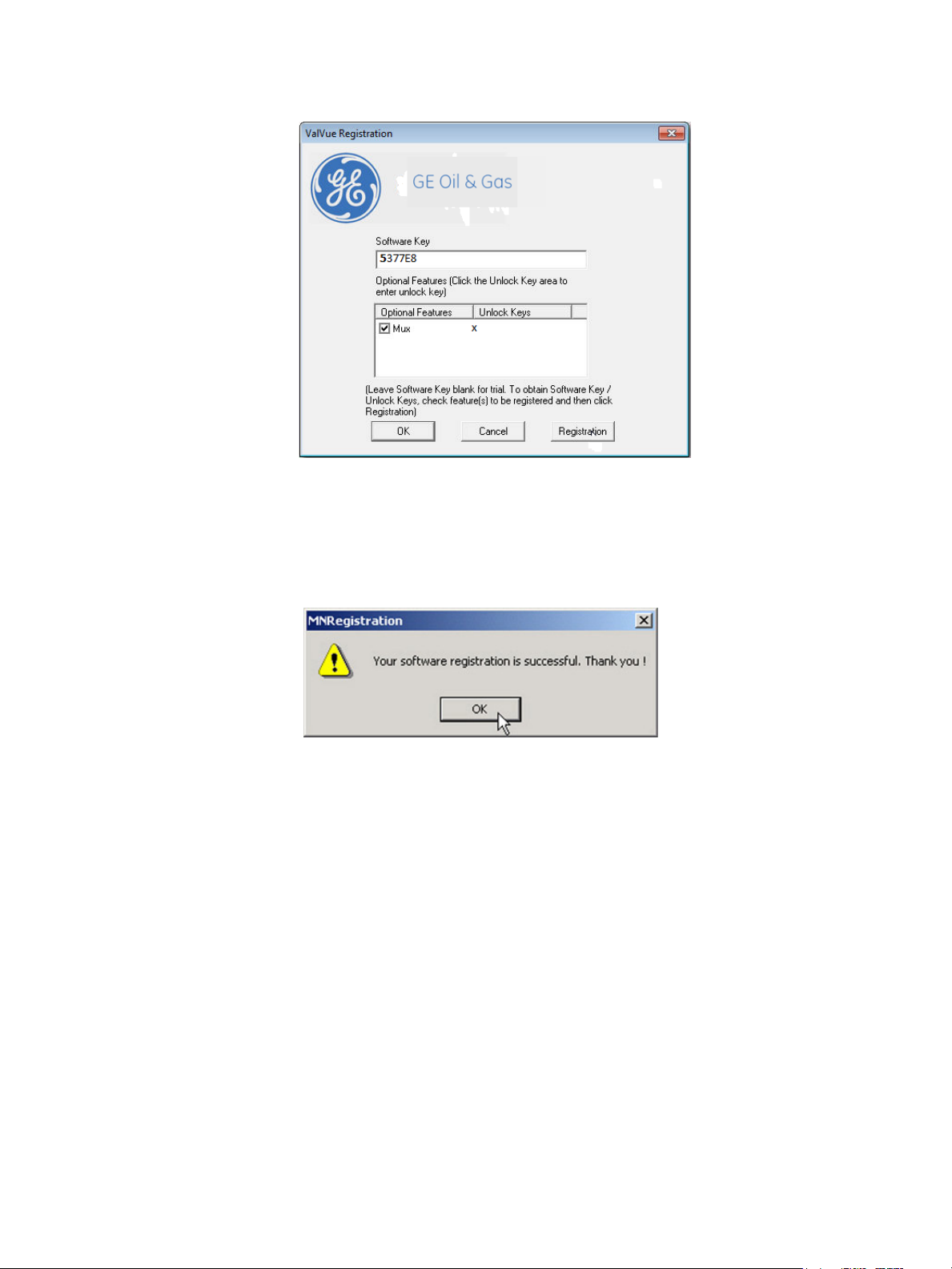

31 Software and Mux Key Window ............................................................................................................................... 40

32 Launching Registration Window..............................................................................................................................41

33 Registration Window...................................................................................................................................................... 41

34 Save Registration Information................................................................................................................................... 42

35 Registration File Saved Dialog................................................................................................................................... 42

36 Registration Email Sent Dialog.................................................................................................................................. 43

37 Entering Software Key................................................................................................................................................... 43

38 Entering Mux Unlock Key ............................................................................................................................................. 44

39 Successful Registration Message ............................................................................................................................ 44

40 Generating License File................................................................................................................................................. 45

41 Saving ESD Licensing Information File .................................................................................................................. 46

42 ESD Licensing Information Email Dialog............................................................................................................... 46

43 Licensing File ..................................................................................................................................................................... 47

© 2014 General Electric Company. All rights reserved.

Masoneilan Valves ValVue ESD Instruction Manual =| 9

Page 10

44 Load Licensing File..........................................................................................................................................................47

45 ValVue ESD Main Window - Connected Devices...............................................................................................49

46 ValVue ESD Main Window with Disconnected Device Icon ......................................................................... 50

47 Plant Schedule Screen...................................................................................................................................................51

48 Accessing Edit Function................................................................................................................................................52

49 Editing Plant Cycle PST..................................................................................................................................................53

50 Applying Edits to the Plant Schedule......................................................................................................................54

51 Changing Plant Schedule Warning ......................................................................................................................... 54

52 Setting PST Schedule for Individual Device .........................................................................................................55

53 Plant Schedule Set for Individual Device ..............................................................................................................55

54 Selecting Export to Excel .............................................................................................................................................. 56

55 Accessing Connected Devices Tools Menu .........................................................................................................57

56 Launching Set Options ..................................................................................................................................................58

57 ValVue ESD Set Options Screen ................................................................................................................................59

58 Context Menu with Mux Functions..........................................................................................................................63

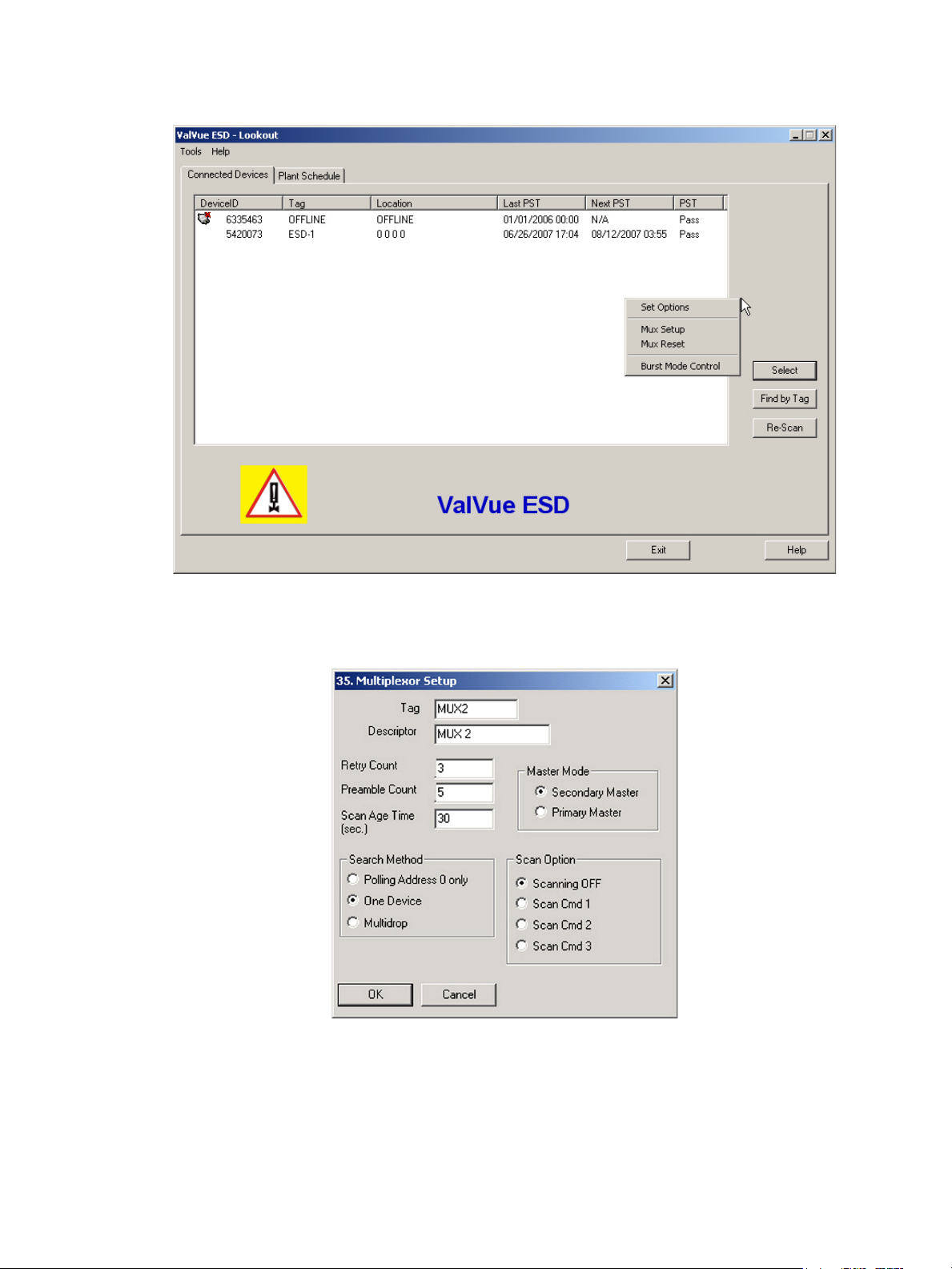

59 Multiplexor Setup.............................................................................................................................................................63

60 Connected Devices .........................................................................................................................................................69

61 Selecting an Offline Device..........................................................................................................................................71

62 Right Clicking Offline Device ....................................................................................................................................... 72

63 File Open Window Launched at ValVue ESD ...................................................................................................... 72

64 Offline dp3 Data File Default Location................................................................................................................... 73

65 Offline Device Displayed at Monitor Screen........................................................................................................73

66 Selecting a Connected Device...................................................................................................................................74

67 Device Information Displayed....................................................................................................................................75

68 Right Clicking on Connected Device .......................................................................................................................77

69 Selecting the Historical View Start Date ............................................................................................................... 79

70 PST Historical View - Friction Displayed................................................................................................................80

71 ESDVue Environment .....................................................................................................................................................81

72 Leaving Normal Mode Warning................................................................................................................................ 83

73 Entering Normal Mode Warning...............................................................................................................................84

74 Monitor Screen..................................................................................................................................................................85

75 Trend Screen......................................................................................................................................................................86

76 Configure Screen ............................................................................................................................................................. 87

77 Calibrate Screen............................................................................................................................................................... 88

78 Diagnostics Screen .........................................................................................................................................................89

79 PST Screen........................................................................................................................................................................... 90

80 Status Screen.....................................................................................................................................................................91

81 Check Screen .....................................................................................................................................................................92

82 Monitor Screen ................................................................................................................................................................. 93

83 Position Indicator Active...............................................................................................................................................96

84 Setpoint Dialog..................................................................................................................................................................97

85 Monitor Screen - Additional Status Available .....................................................................................................98

86 Monitor Screen Context Sensitive Menu ............................................................................................................ 101

87 Report Setup Dialog..................................................................................................................................................... 108

88 Generate Report Dialog............................................................................................................................................. 108

89 Report Sample Using ESDVue Template............................................................................................................ 109

10 | =GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Page 11

90 View All Parameters Window.................................................................................................................................. 110

91 View All Parameters - Device Tab......................................................................................................................... 111

92 View All Parameters - All Tab .................................................................................................................................. 112

93 View All Parameters - PST Config Tab................................................................................................................. 113

94 View All Parameters - PST DATA Tab................................................................................................................... 114

95 View All Parameters - CAL Tab............................................................................................................................... 115

96 View All Parameters - Config Tab ......................................................................................................................... 116

97 View All Parameters - DYNAMIC Tab ................................................................................................................... 117

98 Trend Screen Displaying All Parameters .......................................................................................................... 119

99 Trend Context Menu.................................................................................................................................................... 121

100 Configure Screen - Setup Mode............................................................................................................................. 124

101 Position Error Band Error Message ...................................................................................................................... 125

102 Position Error Time Error Message ....................................................................................................................... 126

103 Stuck Limit Error Message........................................................................................................................................ 126

104 Linkage Limit Error Message ................................................................................................................................... 126

105 Near Closed Error Message ..................................................................................................................................... 127

106 Supply Limit Low Error Message ........................................................................................................................... 127

107 Supply Limit High Error Message .......................................................................................................................... 127

108 Launching Configure I/O........................................................................................................................................... 129

109 Simplified Switch Installation Drawing: Correct Configuration............................................................... 132

110 Simplified Switch Installation Drawing: Configuration Not Allowed..................................................... 132

111 Starting the Setup Wizard ........................................................................................................................................ 133

112 Setup Wizard Selections Window......................................................................................................................... 134

113 Setup Wizard - Setting Tag and Descriptor...................................................................................................... 135

114 Tag and Descriptor Entered..................................................................................................................................... 136

115 Enabling Set Air Action............................................................................................................................................... 137

116 Air Action Set................................................................................................................................................................... 138

117 Enabling Calibrate Travel.......................................................................................................................................... 139

118 Enabling Autotune........................................................................................................................................................ 140

119 Applying Setup Wizard Changes........................................................................................................................... 141

120 Setup Dialog.................................................................................................................................................................... 141

121 Running Setup Wizard Dialog................................................................................................................................. 142

122 Setup Wizard Progress Dialog................................................................................................................................ 142

123 Setup Wizard Progress Dialog - Running Find Stops .................................................................................. 143

124 Setup Wizard Progress Dialog - Running Autotune ..................................................................................... 143

125 Setup Wizard Autotune Diagnostic Graph ....................................................................................................... 144

126 New PID Values After Setup Wizard Calibration ............................................................................................ 145

127 Setup Wizard Complete............................................................................................................................................. 147

128 Applying Configuration Changes .......................................................................................................................... 148

129 Configure Screen Context Menu ........................................................................................................................... 149

130 Calibrate Screen............................................................................................................................................................ 151

131 Starting Find Stops....................................................................................................................................................... 152

132 Starting Find Stops Dialog........................................................................................................................................ 153

133 Find Stops Dialog.......................................................................................................................................................... 153

134 Find Stops Complete................................................................................................................................................... 154

135 Starting Advanced Parameters ............................................................................................................................. 155

© 2014 General Electric Company. All rights reserved.

Masoneilan Valves ValVue ESD Instruction Manual =| 11

Page 12

136 Advanced Parameters Dialog................................................................................................................................. 156

137 Launching Auto Tune.................................................................................................................................................. 157

138 Auto Tune Dialog........................................................................................................................................................... 158

139 Auto Tune Input Value Dialog ................................................................................................................................. 158

140 Auto Tune Progress Dialog....................................................................................................................................... 159

141 Auto Tune Finished Dialog........................................................................................................................................ 159

142 Auto Tune Diagnostic Graph ................................................................................................................................... 160

143 PID Values - Previous and New .............................................................................................................................. 161

144 Auto Tune Complete Dialog ..................................................................................................................................... 161

145 Auto Tune Diagnostic Graph ................................................................................................................................... 162

146 Selecting Set Graph Scale......................................................................................................................................... 163

147 Set Graph Scale Window........................................................................................................................................... 164

148 Saving Scale Adjustments ........................................................................................................................................ 164

149 Starting Select Additional Curve............................................................................................................................ 165

150 Select Additional Step Curve Dialog..................................................................................................................... 165

151 Selecting Load Data from Database ................................................................................................................... 166

152 Selecting Database File ............................................................................................................................................. 167

153 Selecting Load Data from File................................................................................................................................. 167

154 File Browser ..................................................................................................................................................................... 168

155 Opening File for Additional Curve ......................................................................................................................... 168

156 Selecting Calibration Record ................................................................................................................................... 169

157 Additional Calibration Curve Displayed.............................................................................................................. 169

158 Selecting Show Computed Result......................................................................................................................... 170

159 Auto Tune Calibration Computed Result ........................................................................................................... 170

160 Selecting Save to File .................................................................................................................................................. 171

161 File Browser ..................................................................................................................................................................... 172

162 Selecting a Folder for Saving File .......................................................................................................................... 172

163 Selecting Export to Excel ........................................................................................................................................... 173

164 Diagnostic Graph Data - in Excel .......................................................................................................................... 174

165 Calibrate Screen Context Menu ............................................................................................................................. 175

166 Selecting Run Find Stops........................................................................................................................................... 177

167 Starting Run Find Stops Dialog............................................................................................................................... 178

168 Find Stops Dialog .......................................................................................................................................................... 178

169 Find Stops Complete ................................................................................................................................................... 179

170 Selecting Manual Find Stops ................................................................................................................................... 180

171 Stroke Valve Dialog...................................................................................................................................................... 181

172 Valve Closed Dialog ..................................................................................................................................................... 181

173 Valve Open Dialog........................................................................................................................................................ 182

174 Applying Calibration Changes ................................................................................................................................ 183

175 Applying Calibration Changes ................................................................................................................................ 183

176 Diagnostics Screen ...................................................................................................................................................... 185

177 Start/Stop Error Message.......................................................................................................................................... 186

178 Time/Sample Rate Error Message ........................................................................................................................ 187

179 Step Size Error Message ............................................................................................................................................ 187

180 Executing Perform Step Diagnostics ................................................................................................................... 188

181 Step Diagnostics Warning Dialog ......................................................................................................................... 188

12 | =GE Oil & Gas

© 2014 General Electric Company. All rights reserved.

Page 13

182 Running a Step............................................................................................................................................................... 189

183 Loading Data for a Step ........................................................................................................................................... 189

184 Step Diagnostics Complete - Continue .............................................................................................................. 190

185 Step Diagnostics Graph............................................................................................................................................. 190

186 Selecting Set Graph Scale ........................................................................................................................................ 192

187 Set Graph Scale Window .......................................................................................................................................... 193

188 Saving Scale Adjustments........................................................................................................................................ 193

189 Starting Select Additional Curve............................................................................................................................ 194

190 Select Additional Step Curve Dialog .................................................................................................................... 195

191 Selecting Load Data from Database ................................................................................................................... 195

192 Step Diagnostics Database Browser................................................................................................................... 196

193 Selecting Load Data from File ................................................................................................................................ 196

194 File Browser..................................................................................................................................................................... 197

195 Opening File for Additional Curve ......................................................................................................................... 197

196 Selecting Step Test Record....................................................................................................................................... 198

197 Additional Curve Displayed...................................................................................................................................... 198

198 Selecting Show Computed Result......................................................................................................................... 199

199 Step Diagnostics Computed Result...................................................................................................................... 200

200 Selecting Save To File ................................................................................................................................................. 201

201 File Browser..................................................................................................................................................................... 202

202 Selecting a Folder for Saving File .......................................................................................................................... 202

203 Selecting Export to Excel........................................................................................................................................... 203

204 Diagnostic Graph Data - in Excel .......................................................................................................................... 204

205 Adjusting Extended Diagnostics Parameters.................................................................................................. 205

206 Start and End Positions Error Message .............................................................................................................. 206

207 Speed Level Error Message...................................................................................................................................... 206

208 Executing Perform Ext Sig ........................................................................................................................................ 207

209 EXT Warning.................................................................................................................................................................... 207

210 Extended Signature Progress Dialog................................................................................................................... 208

211 Completing EXT ............................................................................................................................................................. 209

212 Extended Signature Diagnostics Graph............................................................................................................. 210

213 Selecting Set Graph Scale ........................................................................................................................................ 211

214 Set Graph Scale Window .......................................................................................................................................... 211

215 Saving Scale Adjustments........................................................................................................................................ 212

216 Starting Select Additional Curve............................................................................................................................ 212

217 Select Additional Extended Signature Curve Dialog .................................................................................... 213

218 Selecting Load Data from Database ................................................................................................................... 213

219 Database Browser Displaying Extended Signature Data.......................................................................... 214