GE Top-Mount No-Frost Use and Care Manual

Use and Care & Installation Guide

Refrigerator

GE Appliances

Top-Mount No-Frost

English Version...................................2

Version française...........................21

Versión en español ......................43

Safety Instructions.....................2, 3

Operating Instructions, Tips

Automatic Icemaker ......................................7

Icemaker Accessory Kit ................................7

Shelves .........................................................4, 5

Storage Drawers.............................................6

Temperature Controls ...................................3

Water Filter Accessory..................................7

Care and Cleaning

Behind Refrigerator ........................................8

Cleaning, Outside and Inside .......................8

Drawer and Cover Removal.........................9

Light Bulb Replacement ...............................9

Under Refrigerator .........................................8

Problem Solver .......................19, 20

Normal Operating Sounds.........................19

Preparation

Clearances.....................................................10

Dimensions....................................................10

Rollers and Leveling Legs ..........................10

Vacation and Moving..................................10

Water Supply to Icemaker.........................10

Installation ..................................11–18

Earthing ..........................................................11

Electrical Requirements .............................11

Fitting a Different Plug................................12

Great Britain and Ireland ............................12

Mains Lead Replacement .....................3, 12

Reversing the Door Swing .................13–16

Water Line Installation ........................17, 18

Model and Serial Numbers ..........................2

HELP US HELP YOU…

Read this guide carefully. Write down the model and serial numbers.

It is intended to help you operate and maintain your new refrigerator

properly. Keep it handy for answers to your questions.

If you received a damaged refrigerator…

Immediately contact the dealer (or builder) that sold you

the refrigerator.

Save time and money . Befor e you r equest service…

Check the Problem Solver. It lists minor operating problems that you

can correct yourself.

You’ll see them on a label on the left side of the fresh food

compartment.

Model Number

Serial Number

Use these model and serial numbers in any correspondence or service

calls concerning your refrigerator.

WARNING—When using this appliance,

always exercise basic safety precautions,

including the following:

• Use this appliance only for its intended purpose

as described in this Use and Care Guide.

• This refrigerator must be properly installed

in accordance with the Installation Instructions

before it is used. See the grounding instructions in

the Installation section.

• Never unplug your refrigerator by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet.

• Repair or replace immediately all electric service

cords that have become frayed or otherwise

damaged. Do not use a cord that shows cracks or

abrasion damage along its length or at either the plug

or appliance end.

• When moving your refrigerator away from the

wall, be careful not to roll over or damage the

power cord.

• Do not allow children to climb, stand or hang on

the shelves in the refrigerator. They could damage

the refrigerator and seriously injure themselves.

• If your old refrigerator is still around the

house but not in use, be sure to remove

the doors. This will reduce the possibility

of danger to children.

• After your refrigerator is in operation, do

not touch the cold surfaces in the frozen food

storage compartment, particularly when hands

are damp or wet. Skin may adhere to these

extremely cold surfaces.

• If your refrigerator has an automatic icemaker,

avoid contact with the moving parts of the ejector

mechanism, or with the heating element that

releases the cubes. Do not place fingers or hands on

the automatic icemaking mechanism while the

refrigerator is plugged in.

• Don’t refreeze frozen foods which have thawed

completely. Food safety experts say:

‘‘…You may safely refreeze frozen foods that have

thawed if they still contain ice crystals or if they are

still cold—below 40°F (4°C).

‘‘…Thawed ground meats, poultry or fish that have

any off-odor or off-color should not be refrozen and

should not be eaten. Thawed ice cream should be

discarded. If the odor or color of any food is poor or

questionable, get rid of it. The food may be dangerous

to eat.

‘‘…Even partial thawing and refreezing reduces

the eating quality of foods, particularly fruits,

vegetables and prepared foods. The eating quality of

red meats is affected less than that of many other

foods. Use refrozen foods as soon as possible to save

as much of their eating quality as you can.’’

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions before using this appliance.

2

• Unplug your refrigerator before cleaning

and making repairs. NOTE: We strongly

recommend that any servicing be performed

by a qualified individual.

• Before replacing a burned-out light bulb, the

refrigerator should be unplugged in order to avoid

contact with a live wire filament. (A burned-out

light bulb may break when being replaced.)

NOTE: Turning control to “ ” position does

not remove power to the light circuit.

• Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

Mains lead replacement

If the mains lead on your refrigerator needs replacing

at any time, it must be replaced by a special lead which

is obtainable from your local dealer. A charge will be

made for the replacement of the mains lead if you have

damaged the lead.

SAVE THESE

INSTRUCTIONS

TEMPERATURE CONTROLS

After changing the controls, allow 24 hours for the refrigerator to reach the temperature you set.

Fresh Food Frozen Food

The fresh food control dial has nine settings plus “ .” “1”is the

warmest. “9” is the coldest. At first, set the dial at “5.” After using

the refrigerator, adjust the dial if necessary.

Insert a coin into the slot in the middle of the dial to turn the dial.

Allow 24 hours for the refrigerator to get cold.

NOTE: Turning the dial to “ ” stops cooling in both

compartments—fresh food and frozen food storage—but does not

shut off power to the refrigerator.

At first, set the dial at “3”. The frozen

food control moves a damper to change

the amount of cold air that moves from the

frozen food compartment to the fresh food

compartment.

1

7

9

3

5

Cold air

Frozen food

compartment

Fresh food

compartment

Cold air

5 (coldest setting)

1 (warmest

setting)

Anti-Condensation Switch Ambient Room Temperature Limits

If moisture develops on the ceiling of

the fresh food compartment, turn the

anti-condensation switch to the ON

position. Moisture is likely to appear

when the air is humid—in the summer,

in the early morning hours or in non-air

conditioned rooms. Move to the OFF

position in less humid conditions.

No Defrosting

It is not necessary to defrost the frozen food or fresh food

compartment. Although your refrigerator is designed and equipped to

defrost itself automatically, some frost on packages is normal.

This refrigerator is designed to operate in ambient temperatures

specified by its Temperature Class which is marked on the rating plate.

Temperature Symbol Ambient Temperature

Class

Maximum Minimum

ExtendedTemperate SN 32°C 10°C

Temperate N 32°C 16°C

Subtropical ST 38°C 18°C

Tropical T 43°C 18°C

NOTE: Internal temperature may be affected by such factors as the

location of the refrigerator, ambient temperature and frequency of

door openings. Adjust temperature controls as required to compensate

for these factors.

ON

Important Safety Information Temperature Controls

3

4

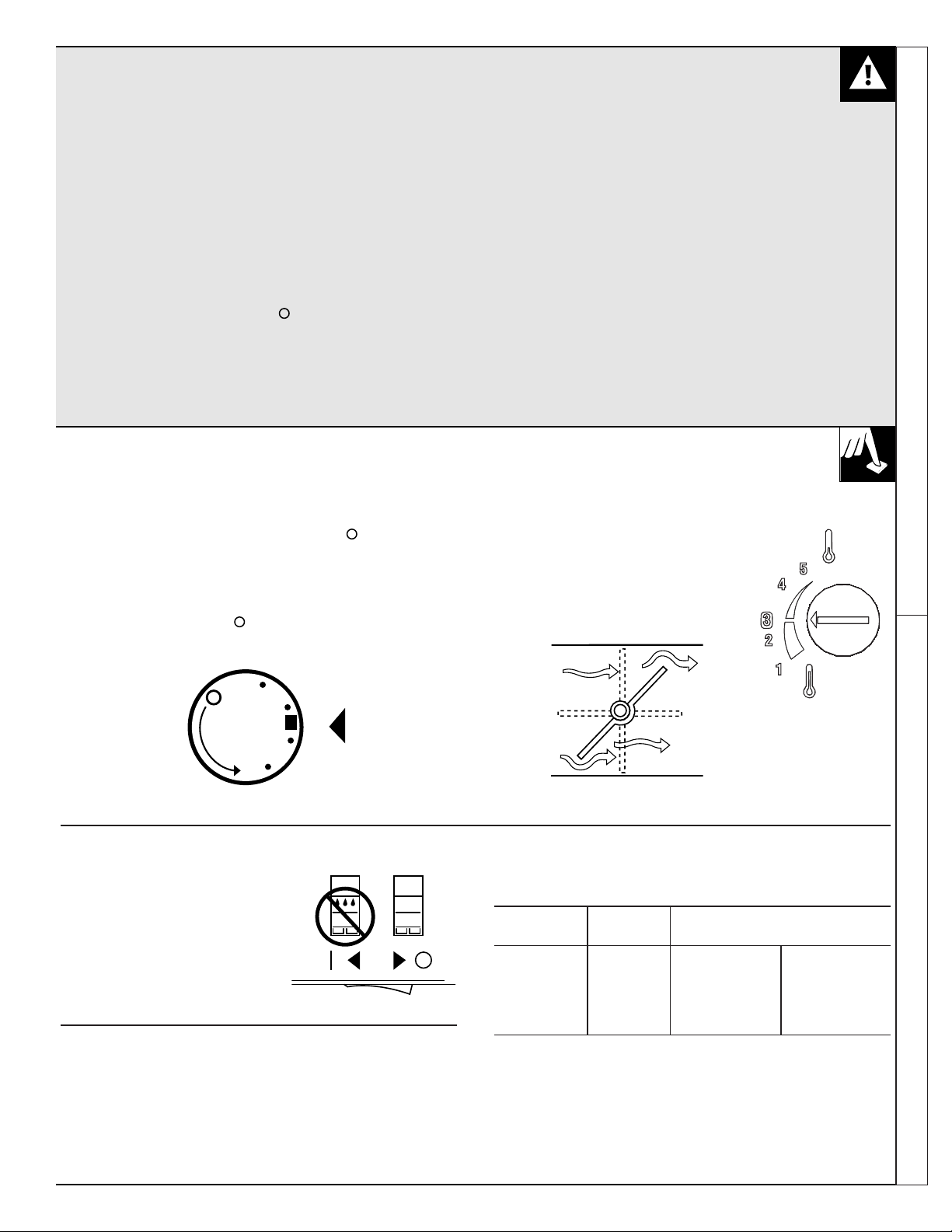

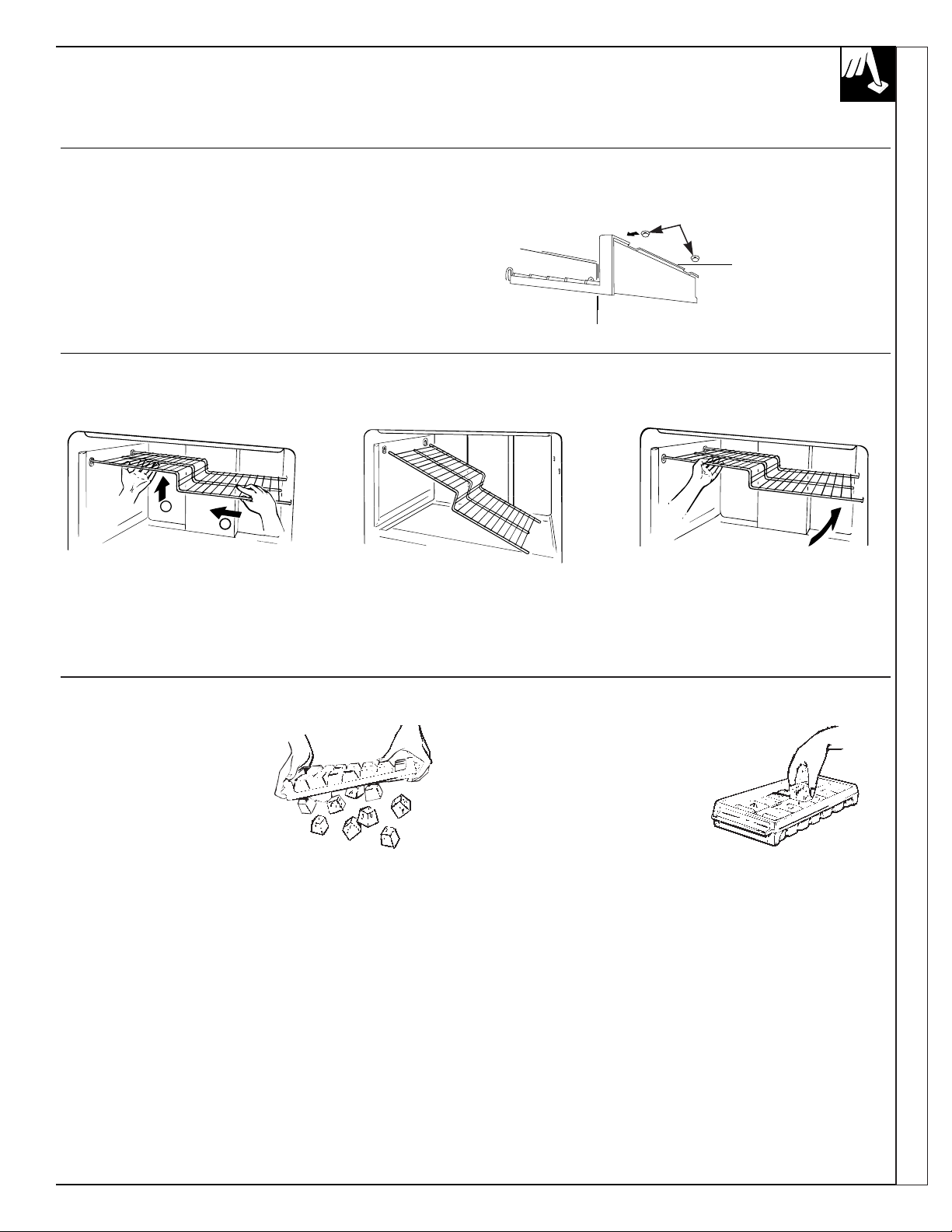

Half-Width Shelves (on some models)

One end of the shelf rests on

a molded side-wall support;

a bracket on the other end

hooks into a track on the rear

cabinet wall.

To remove, lift the shelf up at

front, then off the support and

out of the track.

To replace, select desired shelf

height. With shelf front raised

slightly, hook the bracket’s top

lug into the track, then lower

the shelf onto the support.

NOTE: The shelf to the right of the track is

designed to hook into the right-hand slot; the

shelf to the left is designed to hook into the

left-hand slot.

FRESH FOOD COMPARTMENT SHELVES

Shelf supports at various levels allow you to custom-space shelves

2

Lift up

and out

1

Tilt up

Full-Width Shelves (on some models)

Some models have a steel wire sliding shelf, a stationary tempered

glass shelf or two steel wire stationary shelves. These shelves can be

moved to another place in the fresh food compartment.

The full-width sliding shelf has

stop-locks. When placed correctly on the

shelf supports, the shelf will stop before

coming completely out of the refrigerator

and will not tilt when you place food on it or

remove food from it.

To remove a fullwidth shelf.

Lift the rear of the shelf

and pull forward.

To remove a fullwidth shelf when the fresh food

compartment door cannot be

opened fully… lift the rear of the

shelf, pull forward and down, tilt the

shelf and take it out.

5

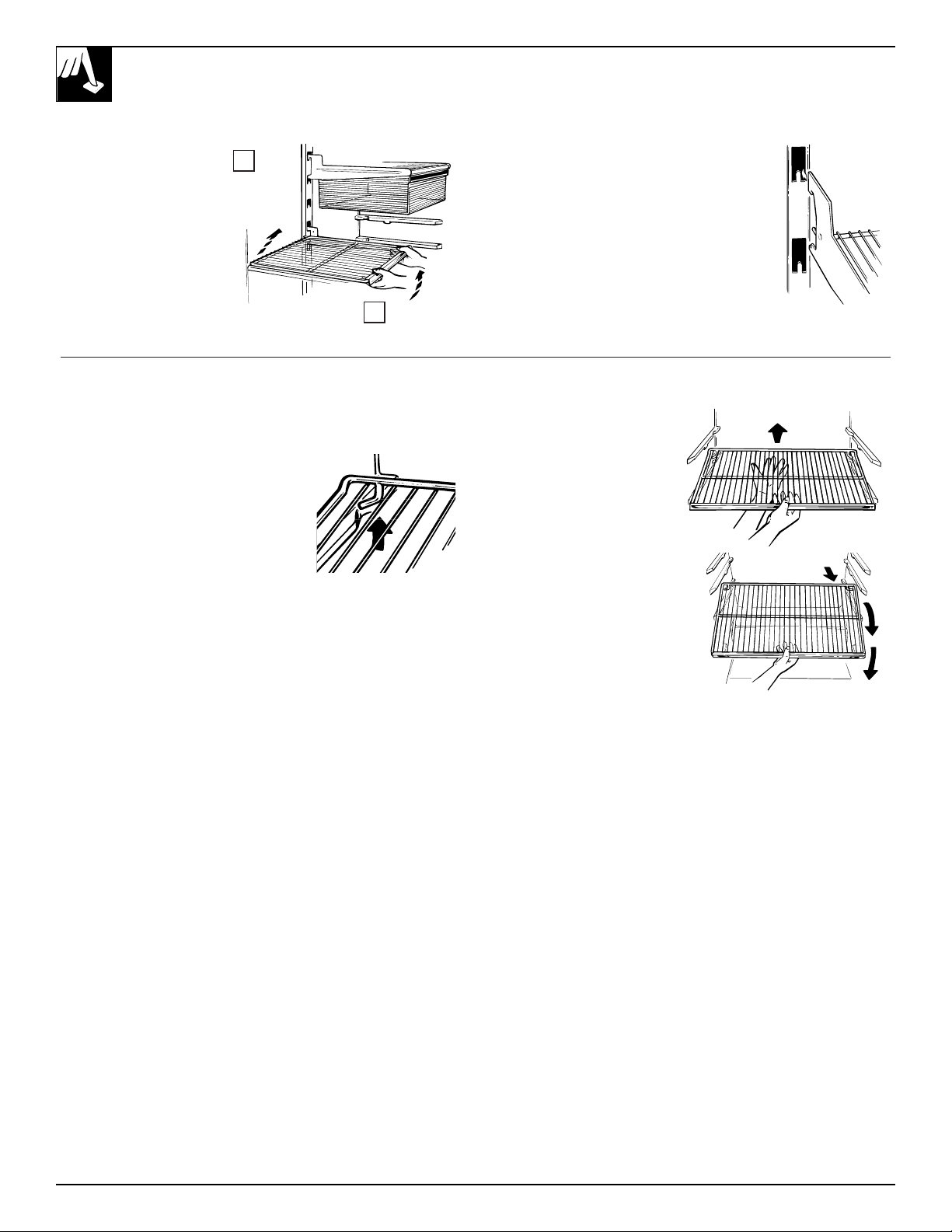

FROZEN FOOD STORAGE COMPARTMENT SHELVES

(on some models)

Some models have an ice-tray shelf and some have a full-width step shelf.

Ice Tray Shelf

To remove the ice tray shelf: Lift the left side of the shelf off its

supports, then pull the shelf to the left to free it of the plug supports.

Pull the shelf to the right to free the pins from the holes in the

cabinet wall.

Step Shelf

To remove the step shelf:

1. Lift left side of shelf slightly.

2. Move shelf to the left to free its right ends

from holes in the cabinet wall.

3. Lower right side of shelf, move shelf to the

right and take it out.

To replace the step shelf:

1. With shelf tilted as shown, fit left ends of

shelf into holes in cabinet wall.

2. Lift left side of shelf slightly, swing shelf

up, fit right ends of shelf into holes in

cabinet wall, and lower shelf into place.

1

2

Plug supports

Ice Trays (on some models)

Ice trays are designed to release

ice cubes easily. Hold tray upsidedown over a container and twist

both ends to release cubes.

For only one or two ice cubes,

leave the tray right-side up, twist

both ends slightly and remove

desired number of cubes. Wash ice

trays and storage bin in lukewarm

water only. Do not put them in an

automatic dishwasher.

Shelves

6

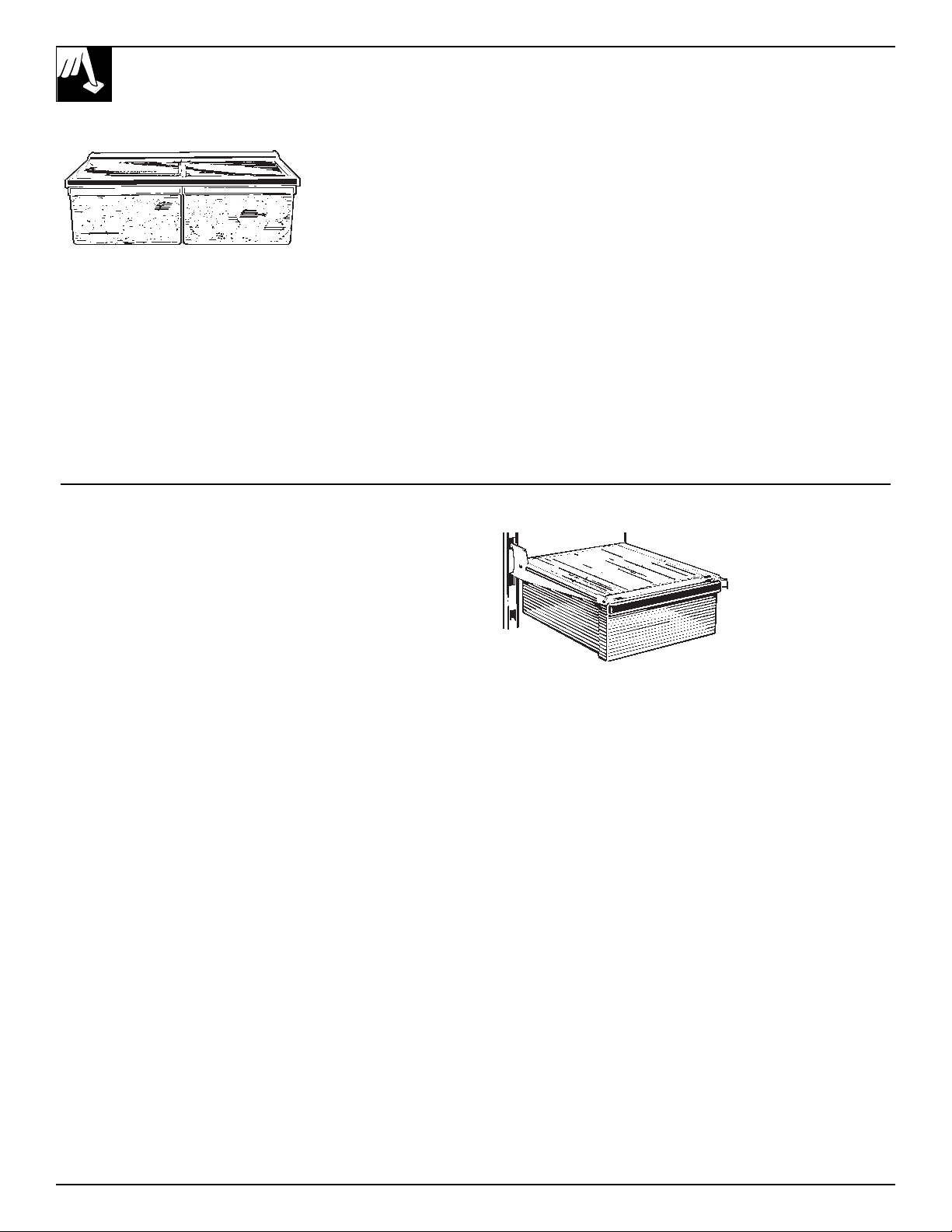

STORAGE DRAWERS

Fruit & Vegetable Drawers

The storage drawers at the bottom of the fresh

food compartment are designed to provide

high humidity levels required by most

vegetables and lower humidity levels

required for most fruits.

When replacing the drawers, always push

them all the way in.

Storage time will depend upon the type of

food and its condition when placed in the

drawers.

Excess water which may accumulate in the

bottom of the drawers should be emptied and

the drawers wiped dry.

High Humidity Drawer

(on some models)

This refrigerated drawer is designed to keep

unwrapped foods fresh by retaining the

natural moisture content of foods such as:

• Artichokes • Cherries • Peas, green

• Asparagus • Corn • Plums

• Beets,

• Currants • Radishes

•

topped

• Greens, • Rhubarb

• Blueberries •

leafy

• Spinach

• Carrots • Lettuce • Tomatoes,

• Celery • Parsley •

ripe

As in any refrigerated storage area, it is

recommended that foods with strong odors

be stored wrapped––foods such as:

• Broccoli • Cabbage • Parsnips

• Brussels • Cauliflower • Turnips

•

Sprouts

•

Green Onions

Low Humidity Drawer

(on some models)

This refrigerated drawer is designed to

provide lower humidity storage for items

such as:

• Apples • Oranges • Squash,

• Apricots • Peaches •

summer

• Grapes • Pears • Strawberries

• Mushrooms • Raspberries • Tangerines

• Nectarines

Snacks Drawer (on some models)

The slide-out Snacks Drawer can be removed and taken to the sink

or food preparation area. You may also relocate it and the shelf to

which it attaches within the fresh food compartment to suit your

storage needs.

7

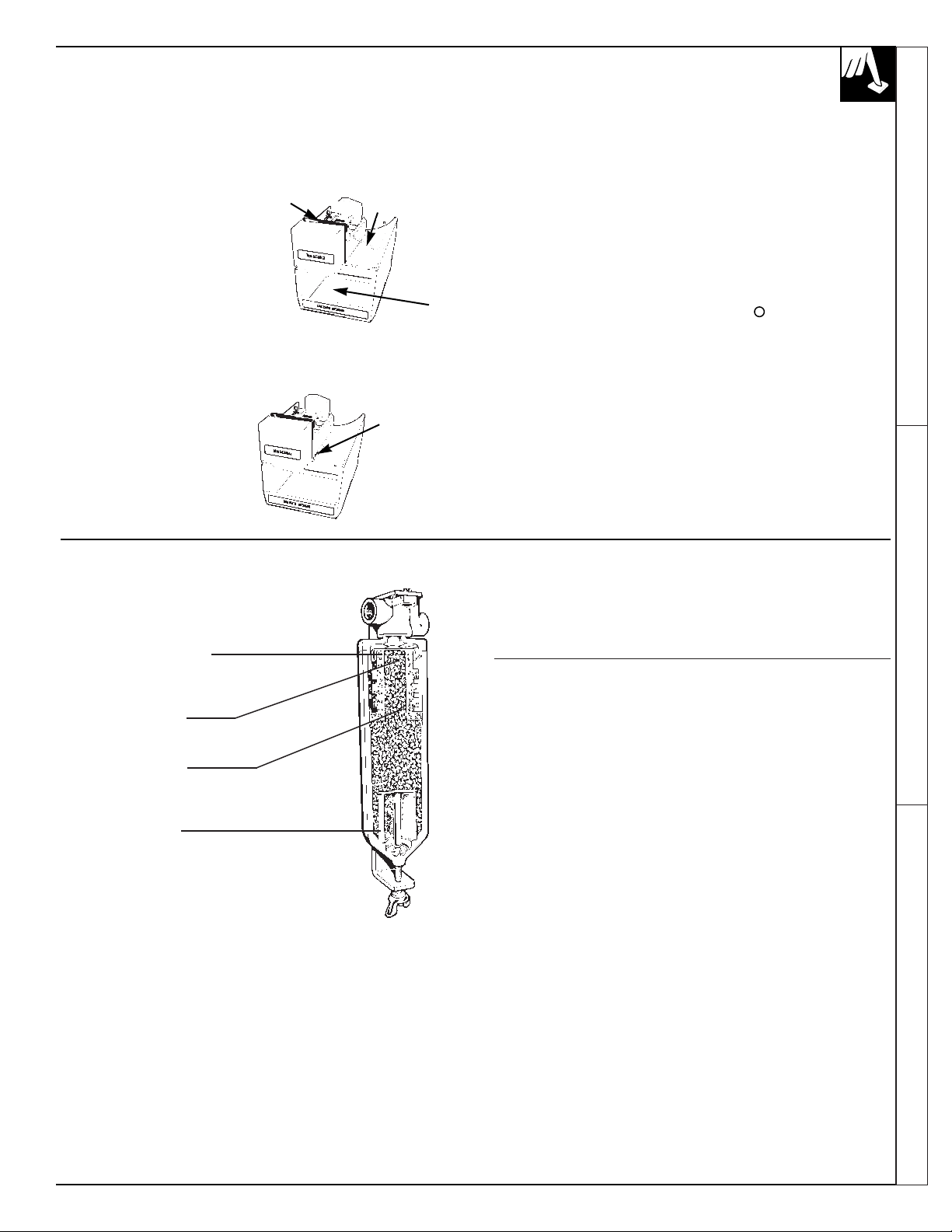

Your icemaker will produce eight cubes per cycle—approximately

100 cubes in a 24-hour period, depending on frozen food storage

compartment temperature, room temperature, number of door

openings and other use conditions.

If your refrigerator is

operated before the water

connection is made to the

icemaker, keep the feeler arm

in the STOP (up) position.

When the refrigerator is first

installed, allow about 24 hours

for the frozen food storage

compartment to cool down to

icemaking temperatures.

Throw away the first few batches

of ice. This flushes away impurities

in the water line.

When the refrigerator has

been connected to the water

supply, move the feeler arm

to the ON (down) position.

Icemaking will continue until the feeler arm is pushed up to the STOP

(up) position by the ice cubes in the storage bin. For maximum ice

storage, level the stored cubes with your hand occasionally. Be sure

nothing interferes with the swing of the feeler arm.

The icemaker ejects cubes in groups of eight and it is normal for

several cubes to be joined together.

Move the icemaker feeler arm to the STOP (up) position when:

• Home water supply is to be off for several hours.

• Ice storage bin is to be removed for a period of time.

• Going away on vacation, at which time you should also turn off the

valve in the water supply line to your refrigerator.

• Turning the temperature control dial to the “ ” position.

If ice is not used frequently, old ice cubes will become cloudy and

taste stale. Empty the ice storage bin periodically and wash it in

lukewarm water. Be sure to allow the storage bin to dry before

replacing it—otherwise ice cubes may stick to other parts of

the icemaker.

If this is your first icemaker, you’ll hear occasional sounds that may

be unfamiliar. They are normal icemaking sounds and are not a cause

for concern.

AUTOMATIC ICEMAKER

(on some models)

Icemaker

Ice

storage bin

Feeler arm in

STOP (up) position

Feeler arm in

ON (down)

position

Water Filter Accessory Water Supply Kit

Your ice cubes can only be as fresh-tasting

as the water that produces them. That’s why

it’s a good idea to purify your water with a

water filter.

REMOVES SEDIMENT

Rigid, porous graded density depth

cellulose fiber cartridge catches dirt,

rust particles, sand and silt.

REMOVES ODORS

Activated charcoal granules

remove musty, stale odors.

IMPROVES TASTE

Activated charcoal granules

remove oily, medicinal, plastic

and metallic tastes.

REDUCES SCALE

Special crystals reduce hard

scale deposit formation.

The water filter is an option at extra cost and is

available from your local distributor. It has

complete installation instructions and installs in

minutes on 1/4

² O.D. copper water line.

A kit containing copper tubing, shutoff valve, fittings and instructions

needed to connect the icemaker to your cold water line is available at

extra cost. Contact your local distributor and order the appropriate kit

depending on how much copper tubing you need.

Icemaker Accessory Kit

If your refrigerator did not come already equipped with an automatic

icemaker, an Icemaker Accessory Kit is available at extra cost from

your local distributor. Check the back of the refrigerator for the

specific icemaker kit needed for your model.

Storage Drawers Automatic Icemaker Accessories

CARE AND CLEANING

Cleaning—Outside

The door handles and trim (on some models) can be cleaned with a

cloth dampened with a solution of mild liquid dishwashing detergent

and water. Dry with a soft cloth. Don’t use wax on the door handles

or trim.

Keep the finish clean. Wipe with a clean cloth lightly dampened with

kitchen appliance wax or mild liquid dishwashing detergent. Dry and

polish with a clean, soft cloth.

Do not wipe the refrigerator with a soiled dishwashing cloth or wet

towel. These may leave a residue that can erode the paint. Do not use

scouring pads, powdered cleaners, bleach or cleaners containing

bleach because these products can scratch and weaken the paint finish.

Protect the paint finish. The outside of the refrigerator has a high

quality, baked-on paint finish. With proper care, it will stay newlooking and rust-free for years. Apply kitchen/appliance wax when

the refrigerator is new and then at least twice a year.

8

Cleaning—Inside

Clean the inside of the fresh food and frozen food storage

compartments at least once a year. Unplug refrigerator before

cleaning. If this is not practical, wring excess moisture out of sponge

or cloth when cleaning around switches, lights or controls. Apply an

appliance wax/polish to the inside surface between the doors.

Use warm water and baking soda solution—about a tablespoon

(15 ml) of baking soda to a quart (1 l) of water. This both cleans and

neutralizes odors. Rinse thoroughly with water and wipe dry.

Other parts of the refrigerator—including door gaskets, vegetable

drawers, ice trays and all plastic parts—can be cleaned the same way.

After cleaning the door gaskets, apply a thin layer of petroleum jelly

to the door gaskets at the hinge side. This helps keep the gaskets from

sticking and bending out of shape. Do not use cleansing powders or

other abrasive cleaners.

To help prevent odors, leave an open box of baking soda in the rear of

the refrigerator, on the top shelf. Change the box every three months.

An open box of baking soda in the frozen food storage compartment

will absorb stale frozen food storage compartment odors.

Do not wash any of your refrigerator’s plastic parts in your

automatic dishwasher.

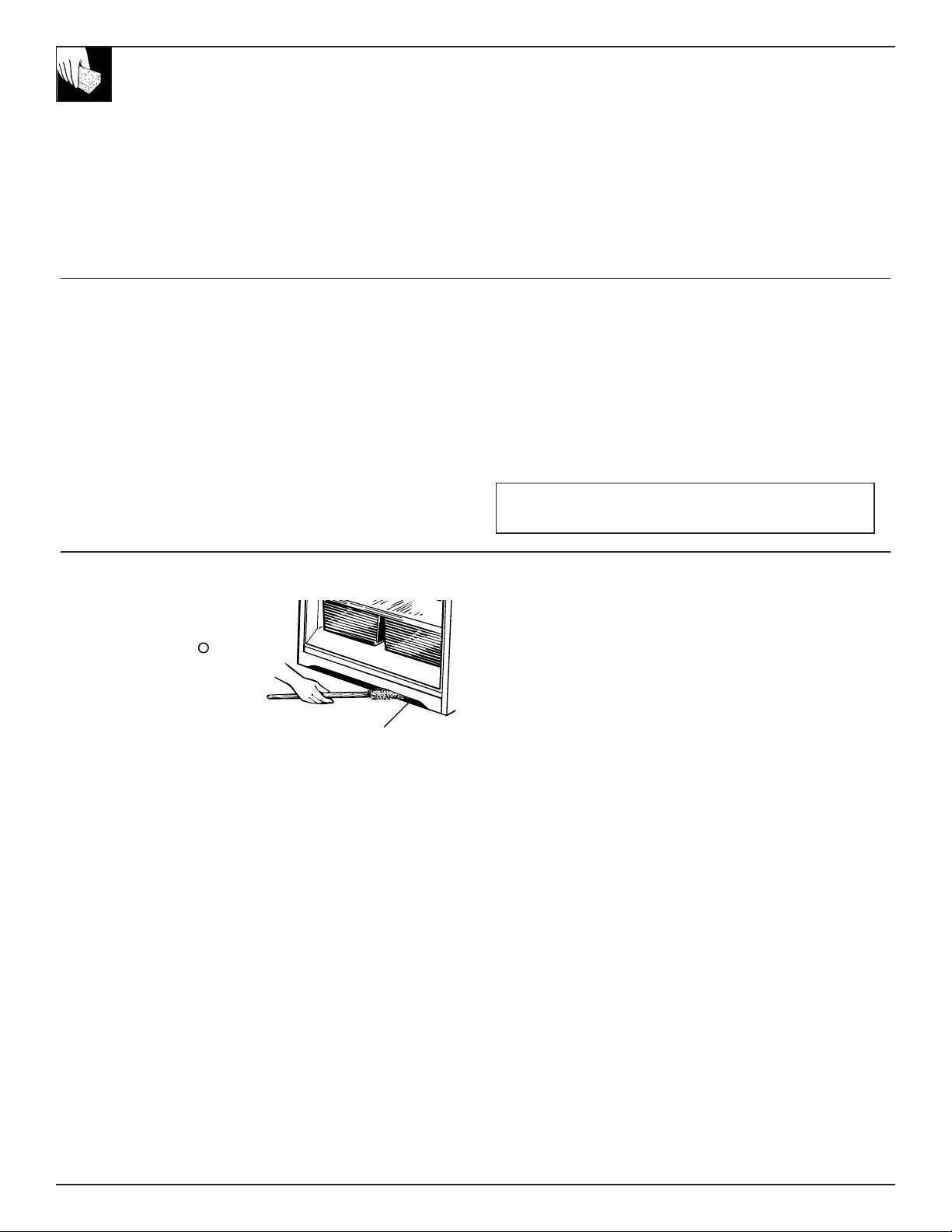

Under Refrigerator Behind Refrigerator

For most efficient operation, you

need to keep the area under the

refrigerator clean. Turn the

temperature control to “ .” Sweep

away or vacuum dust that is readily

accessible on the condenser coils,

then turn the control back on.

For best results, use a brush

specially designed for this purpose,

available from your local distributor.

This easy cleaning operation should

be done at least once a year.

Care should be taken in moving your refrigerator away from the wall.

All types of floor coverings can be damaged, particularly cushioned

coverings and those with embossed surfaces.

Turn the leveling legs at each front corner of the refrigerator counterclockwise until the rollers support the refrigerator; then pull the

refrigerator straight out and return it to position by pushing it straight

in. Moving your refrigerator in a side direction may result in damage

to your floor covering or refrigerator.

After rolling the refrigerator back into place, turn the legs clockwise

until the legs again bear the weight of the refrigerator. Refer to the

Rollers and Leveling Legs section.

Clean the condenser coils

at least once a year.

9

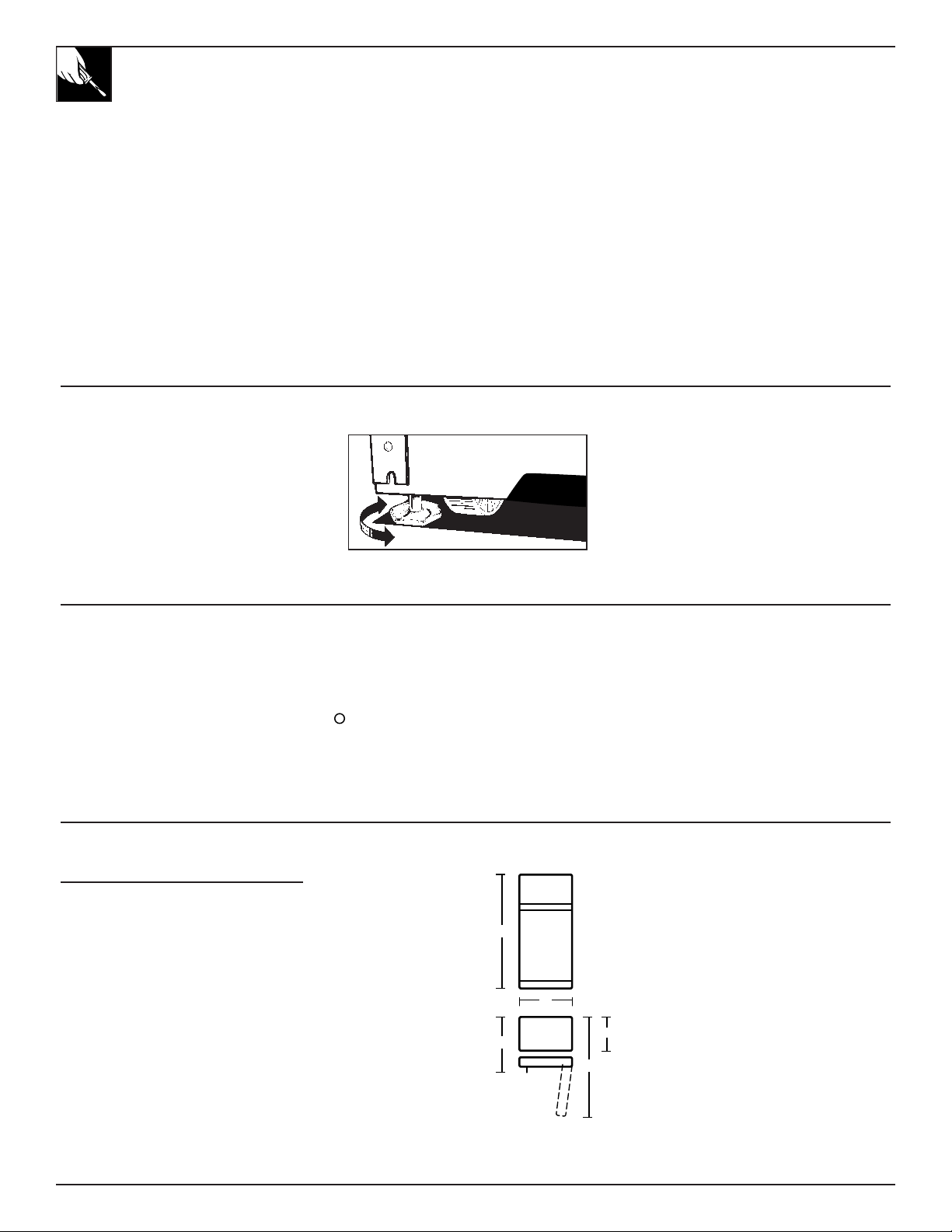

Drawer and Cover Removal

Drawers at the bottom of the fresh food compartment will stop

before coming all the way out of the refrigerator, to help prevent

contents from spilling onto the floor. These drawers can be removed

easily by lifting the sides up slightly while pulling the drawers past

the ‘‘stop’’ location.

Full-Width Drawer with Plastic Cover

(on some models)

To remove the cover, lift it off

its supports, pull it forward,

tilt it and take it out.

Twin Drawers with Glass Cover (on some models)

To remove the glass cover:

1. Remove the drawers.

2. Reach in, push the front of glass cover

up and, at the same time, pull it forward

as far as it will come.

Tilt it and take it out. Avoid cleaning the

cold glass cover with hot water because the

extreme temperature difference may cause

it to break.

3. Remove the drawer frame. (Always remove the glass cover before

you take out the drawer frame.)

Lift the frame off the supports at each side and back, pull it forward,

tilt it and take it out.

To replace the glass cover:

1. Lower the frame until it rests on the supports at each side and back.

2. Replace the glass cover, pushing its rear edge firmly into the rear

frame channel and gently lowering the front into place.

3. Replace the drawers.

Light Bulb Replacement (on some models)

A light bulb and socket are located at the top of the fresh food

compartment opposite the temperature control panel.

To replace the bulb, first unplug the refrigerator from its electrical

outlet. Put your hand under the light shield and release the hook at

the bulb end of the shield. (The light shield is on some models.)

Squeeze to

release the hook

Care and Cleaning

PREPARA TION

Clearances Water Supply to Icemaker (on some models)

Allow the following clearances for ease of installation, proper air

circulation and plumbing and electrical connections:

Sides..........................................................................19 mm

Top.............................................................................25 mm

Back...........................................................................25 mm

If your refrigerator has an icemaker, or if you plan to add an

icemaker later, the icemaker will have to be connected to a cold

drinking water line.

A water supply kit containing copper tubing, shutoff valve, fittings

and instructions is available at extra cost from your local distributor.

There should be sufficient tubing from the cold water supply to the

icemaker inlet to allow moving the refrigerator out from the wall

several feet (approximately 244 cm of 1/4

² copper tubing in three

25 cm diameter coils).

Do not use kits with plastic tubing since there is water pressure in the

supply line at all times.

Maximum permissible inlet water pressure—8.3 bars.

Minimum permissible inlet water pressure—1.4 bars.

Installation of icemaker must be made by a qualified service technician.

10

When You Go on Vacation When You Move

For shorter vacations, remove perishable foods and leave controls at

regular settings. However, if room temperature is expected to drop below

16°C, follow the same instructions as for extended vacations.

For extended vacations or absences, shut off the power to the

refrigerator, move the fresh food control to the “ ” position, and

clean the interior with a baking soda solution of 15 ml of baking soda

to 1 liter of water. Wipe dry. To prevent odors, leave an open box of

baking soda in the refrigerator. Leave doors open.

Move icemaker feeler arm to STOP (up) position and be sure to shut

off water supply to the refrigerator.

Disconnect power cord from wall outlet, remove all food, and clean

and dry the interior.

Secure all loose items such as grille, shelves, storage drawers and ice

trays by taping them securely in place to prevent damage, and raise

leveling legs.

Be sure refrigerator stays in

upright position during actual moving and

in van. Refrigerator must be secured in van to prevent movement.

Protect outside of refrigerator with blanket.

Rollers and Leveling Legs

Leveling legs near each front corner of the

refrigerator are adjustable. They firmly

position the refrigerator and prevent it from

moving when the doors are opened.

Leveling

legs should be set so the front of the

refrigerator is raised just enough that the doors

close easily when opened about halfway.

Turn the leveling legs clockwise to raise the

refrigerator, counterclockwise to lower it.

Rollers next to the leveling legs allow you to

move the refrigerator away from the wall for

cleaning.

Turn the legs counterclockwise until the weight

of the refrigerator is transferred from them to

the rollers. After rolling the refrigerator back

into place, turn the legs clockwise until the legs

again bear the weight of the refrigerator.

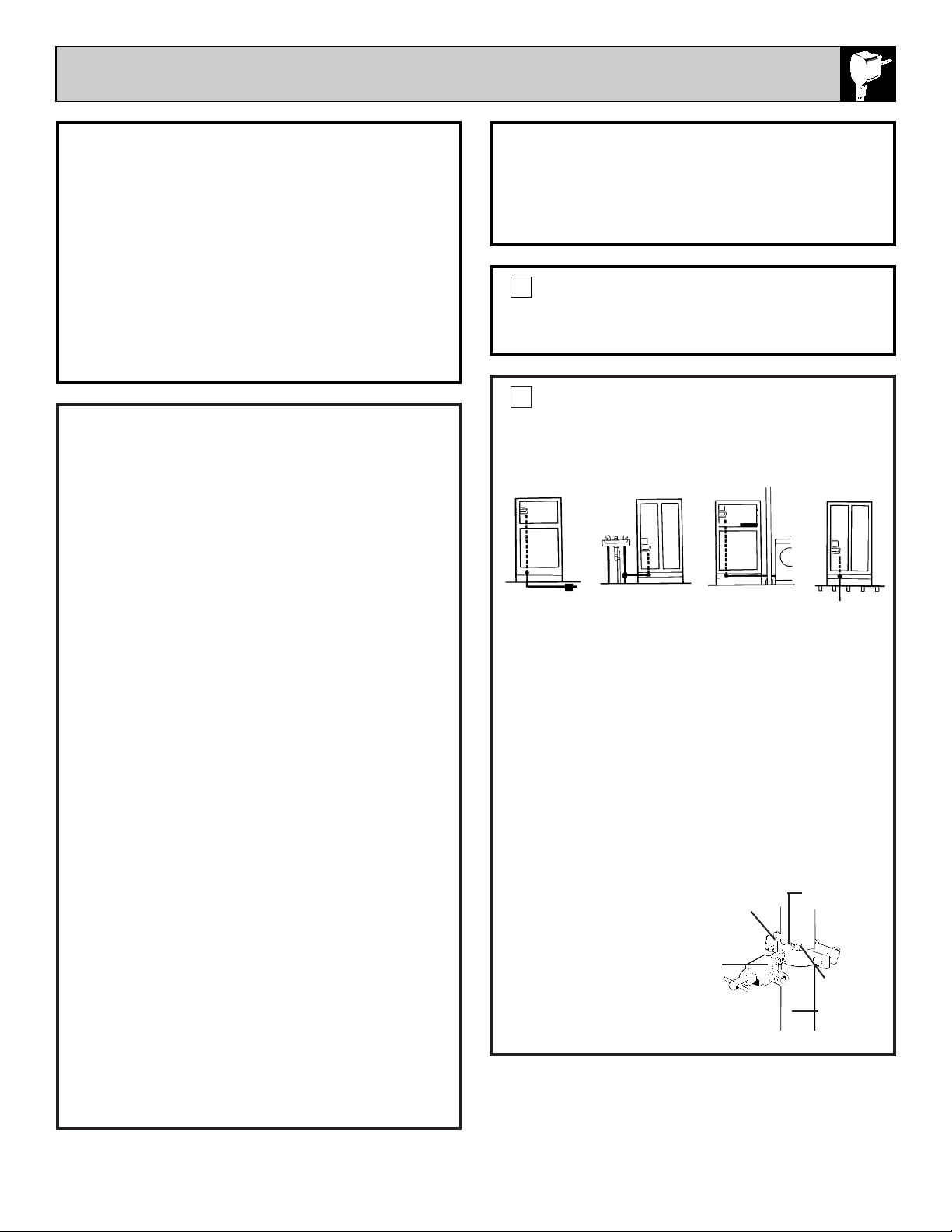

Dimensions

Model 14 16

A* 155 cm 163 cm

B 71 cm 71 cm

C** 75 cm 75 cm

D 138 cm 138 cm

E 62 cm 62 cm

* Height does not include hinge—Add 22 mm for hinge.

** Depth includes handle.

A

B

C

D

E

11

Preparation Installation

INSTALLA TION REQUIREMENTS

IMPORTANT…Please Read Carefully

How to Connect Electricity

For personal safety, this appliance must be

properly earthed.

The power cord of this appliance

is equipped with an earthing plug

which mates with a standard

earthed wall outlet to minimize

the possibility of electric shock

hazard from this appliance.

Have the wall outlet and circuit

checked by a qualified electrician

to make sure the outlet is properly

earthed.

Where an unearthed wall outlet is encountered, it is your personal

responsibility and obligation to have it replaced with a properly

earthed wall outlet.

If the product plug does not fit your outlet, the product should be fitted

with a new plug.

IMPORTANT: The refitting of electric plugs and cables should

be done by a qualified technician or service agent. In some

countries the refitting of electric plugs and cables is only

permitted when the work is completed by a qualified technician.

If the power supply cord becomes damaged, it must be replaced by a

qualified service agent in order to avoid a safety hazard.

Insure proper

earthing exists

before using.

Earthing plug

Electrical Requirements

The refrigerator should always be plugged into its own individual

electrical outlet. This is recommended for best performance and to

prevent overloading house wiring circuits, which could cause a fire

hazard from overheated wires. Please refer to the rating plate on the

refrigerator for the correct voltage, wattage and frequency.

WARNING: HOW TO AVOID ACCIDENTS TO CHILDREN.

WHEN DISCARDING AN OLD REFRIGERATOR OR

FREEZER BE CERTAIN TO MAKE THE LOCK UNUSABLE.

IF POSSIBLE, REMOVE THE DOORS AND DISCARD

SEPARATELY. DO NOT ATTEMPT TO STAND ON TOP OF

YOUR APPLIANCE. IT IS NOT DESIGNED FOR SUCH USE

AND YOU COULD INJURE YOURSELF OR DAMAGE THE

APPLIANCE BY SUCH ABUSE. CHILDREN SHOULD NOT

BE ALLOWED TO PLAY WITH THE APPLIANCE OR

TAMPER WITH THE CONTROLS.

INSTALLA TION INSTRUCTIONS

FOR GREA T BRITAIN AND IRELAND ONLY

12

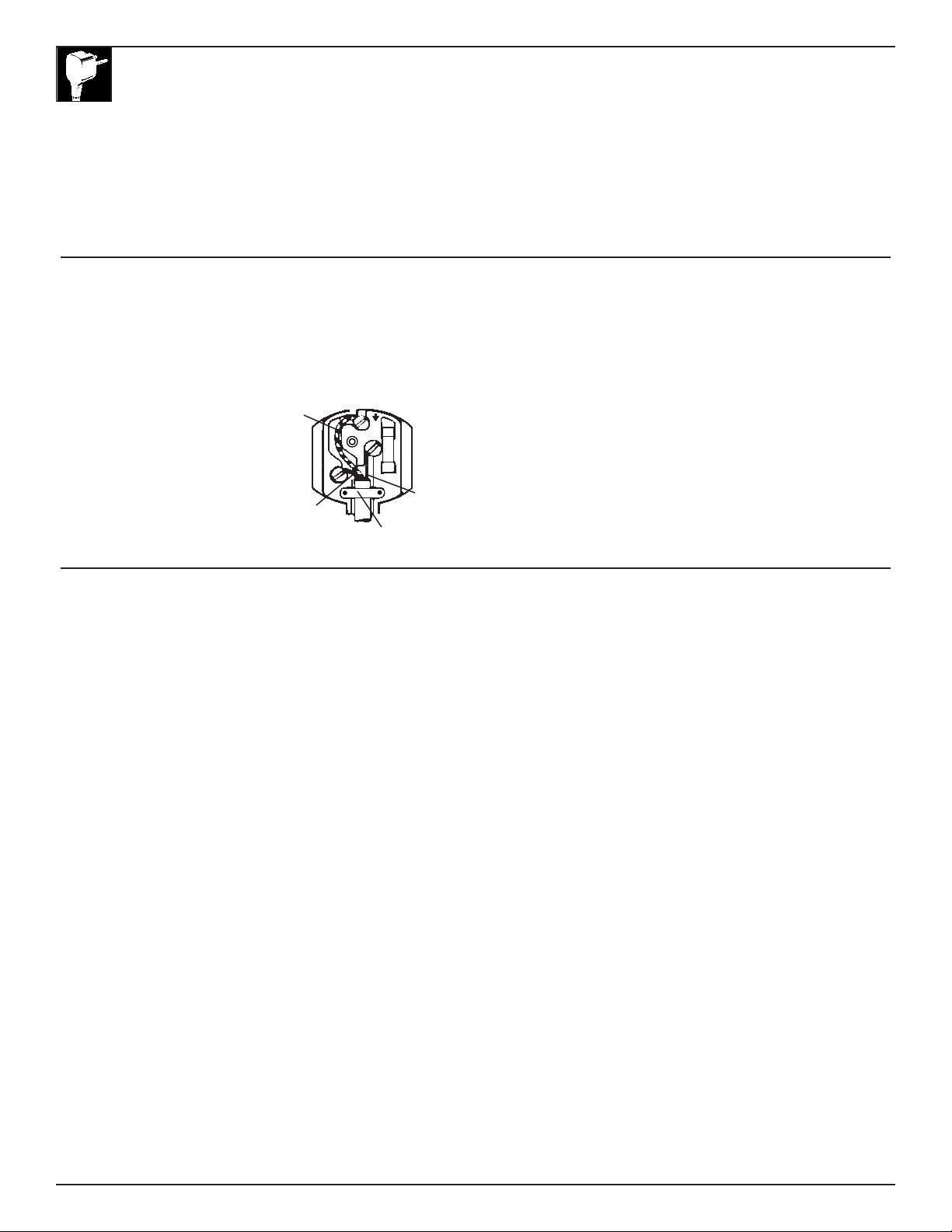

IMPORTANT: Fitting a Different Plug

The wires in the mains lead are coloured in accordance with the

following code: Green and Yellow-Earth; Blue-Neutral; Brown-Live.

If you fit your own plug the colours of these wires may not correspond

with the identifying marks on the plug terminals. This is what you

have to do:

1. Connect the green and yellow

(earth) wire to the terminal

in the plug marked ‘E’ with

the symbol or coloured green

or green and yellow.

2. Connect the blue (Neutral) wire

to the terminal in the plug

marked ‘N’ or coloured black.

3. Connect the brown (Live) wire to

the terminal marked ‘L’ or

coloured red.

With alternative plug, a 15A fuse must be fitted either in the plug or

adapter or in the main fuse box. In the event of replacing a fuse in the

plug supplied, a 13A ASTA-approved fuse to BS1362 must be fitted.

If the plug is the moulded-on type, the fuse cover must be refitted

when changing the fuse. In the event of losing the fuse cover, the plug

must not be used until a replacement fuse cover has been obtained and

fitted. A new fuse cover can be obtained from your nearest service

centre or local electricity board. The colour of the correct replacement

fuse cover is that of the coloured marks or insert in the base of the

plug.

E

13 AMP

L

N

Mains Lead Replacement

If the mains lead on this appliance needs replacing at any time, it must be replaced by a

special lead which is obtainable from your nearest service centre. A charge will be made for

the replacement of the mains lead if you have damaged it.

Green

Yellow

Blue

Brown

Cord grip

Electrical Requirements

We recommend that this appliance be connected to the mains supply via a suitable switched

socket in a readily accessible position. All appliances come complete with a fitted plug. The

plug on your refrigerator has a 13A fuse. If the plug does not fit your sockets, a new plug can

be fitted. Cut off the old plug and throw it away. Do not insert it into a socket elsewhere in

the house as this could cause a shock.

WARNING: THIS APPLIANCE MUST BE EARTHED.

13

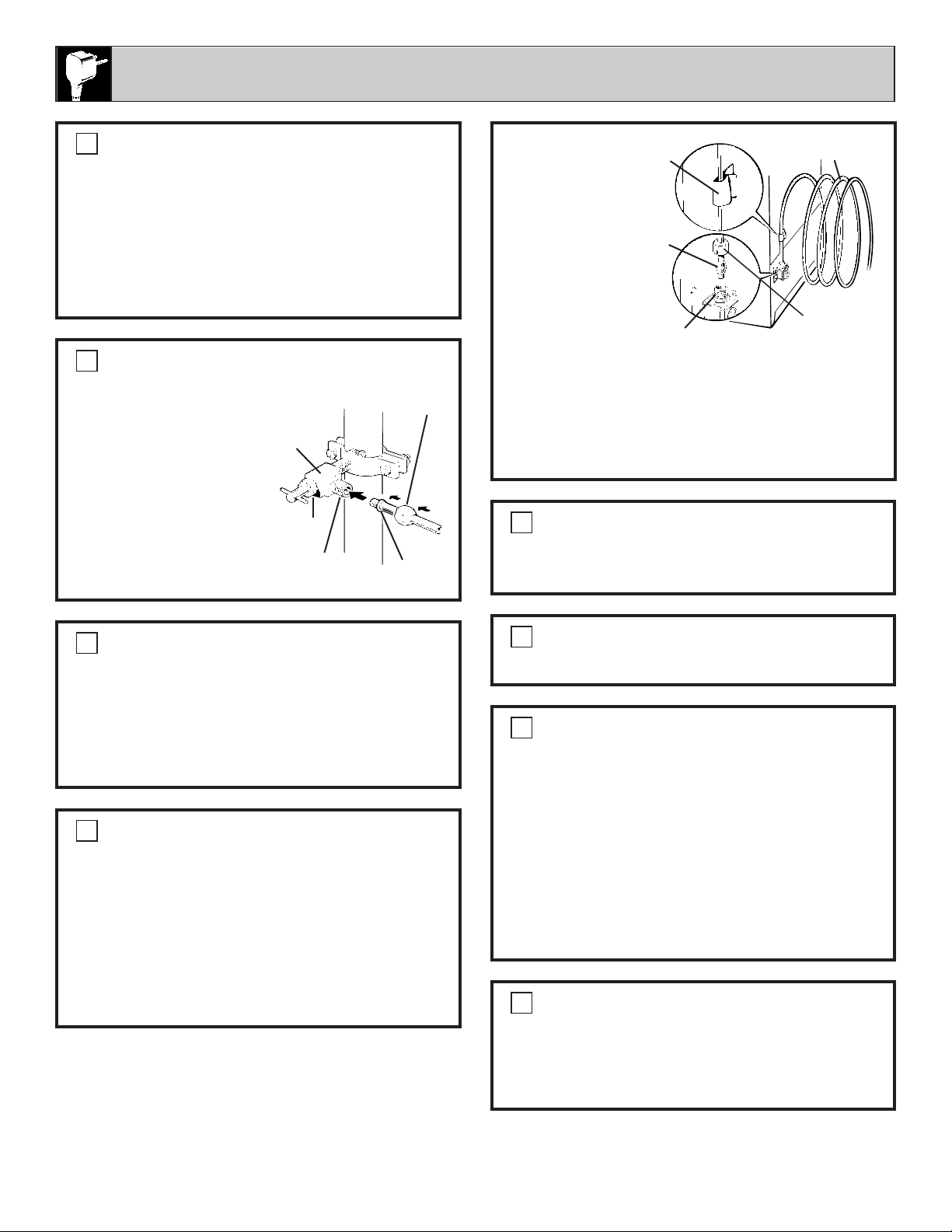

REVERSING THE DOOR SWING

BEFORE YOU BEGIN

• Read these instructions all the way through

before starting.

• Unplug the refrigerator from its electrical

outlet.

• Empty all door shelves, including the dairy

compartment.

• Provide a non-scratching work surface for

the doors.

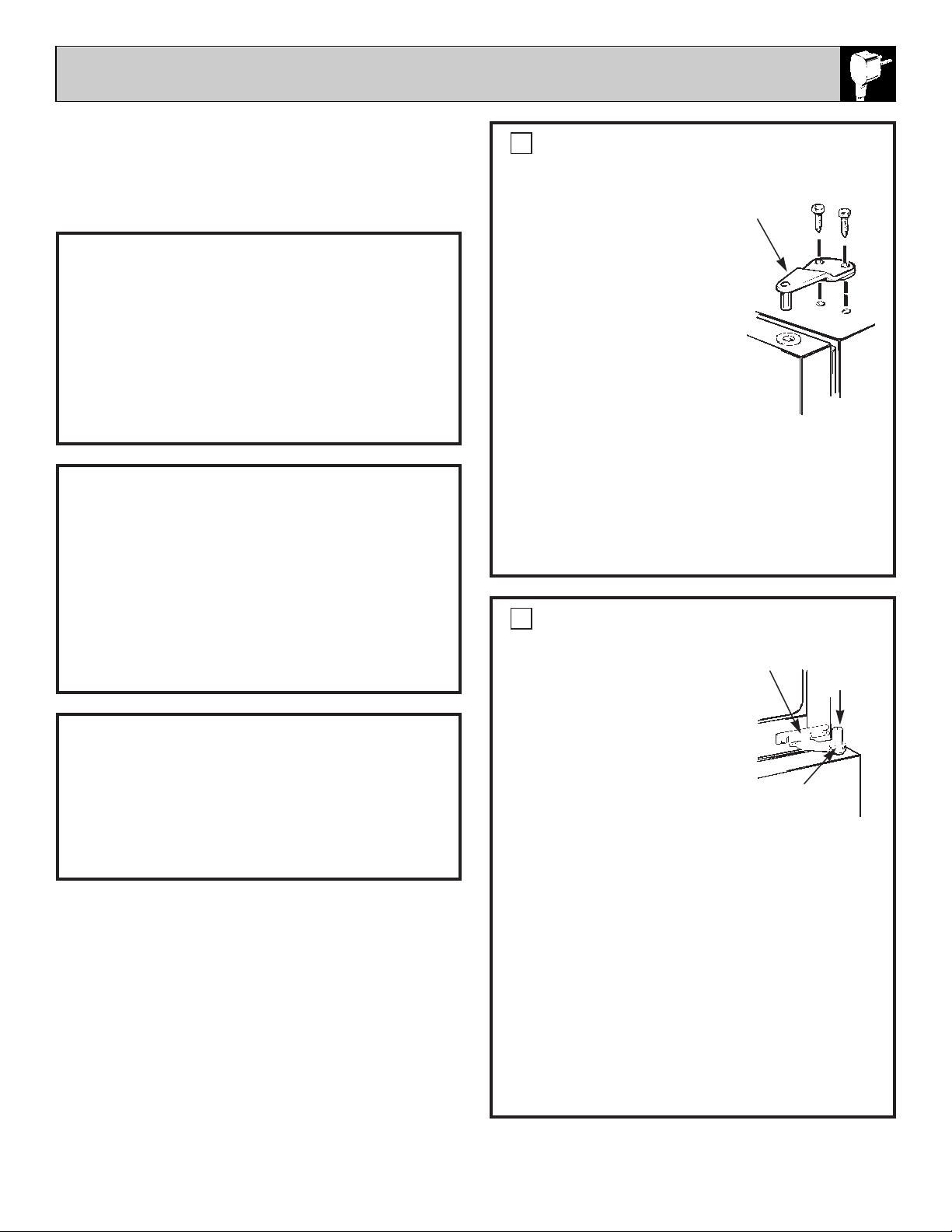

REMOVE THE FROZEN FOOD STORAGE

COMPARTMENT DOOR.

a. Tape the door shut with

masking tape.

b. Use a 5/16

² hex-head

socket screwdriver to

remove the screws that hold

the top hinge to the cabinet.

c. Lift the hinge (and shim

glued to it) straight up to free

the hinge pin from the socket

in the top of the door and set

it aside, along with its screws.

d. Remove tape, tilt the door

away from the cabinet, and

carefully lift the door to free its bottom socket

from the hinge pin on the center hinge bracket.

e. Set the door on a non-scratching surface with

the outside up.

f. Using a Torxdriver, transfer the two screws

from the opposite side of the cabinet to the screw

holes vacated by the top hinge removal.

1

ONCE YOU BEGIN

• Handle parts carefully to avoid scratching paint.

• Set screws down by their related parts to avoid

using them in the wrong places.

• When reinstalling door hinges, be sure to use

the same number of shims and washers as were

originally used.

• IMPORTANT: Once you begin, do not

move the cabinet until the door-swing reversal

is completed.

REMOVE THE FRESH FOOD DOOR.

a. Tape the door shut

with masking tape.

b. Use a 5/16² hex-head

socket screwdriver and 5/16²

open-end wrench to remove

the two screws holding the

center hinge (and shim glued

to it) to the cabinet. Lift the

center hinge to free its pin

from the socket in the top of

the door, and set hinge and

screws aside.

c. Remove tape, tilt door away from cabinet,

and lift it from the pin in the bottom hinge

bracket. (If the plastic washer sticks to the door

bottom, put it back on the hinge.)

d. Set door outside-up on a non-scratching surface.

e. Using a Torxdriver, transfer the two screws from

the opposite side of the cabinet to the screw holes

vacated by the center hinge removal.

f. Take one of the screws removed in step (b)

and start it in the outermost screw hole on the

opposite side. Do not drive it all the way down—

leave enough space under the screw head for

thickness of shim and bracket.

2

TOOLS REQUIRED

• 5/16² hex-head socket screwdriver

• Putty knife or thin-blade screwdriver

• T20 or T25 Torxdriver • 5/16²

• Phillips screwdriver

open-end wrench

• Masking tape

These instructions are for changing the hinges from

the right side to the left side.

If you ever want to change the hinges back to the right

side, follow these same instructions (merely reverse all

references to left and right).

Top

hinge

Center hinge

bracket

Hinge

pin

Plastic washer

(continued next page)

REVERSING THE DOOR SWING

(continued)

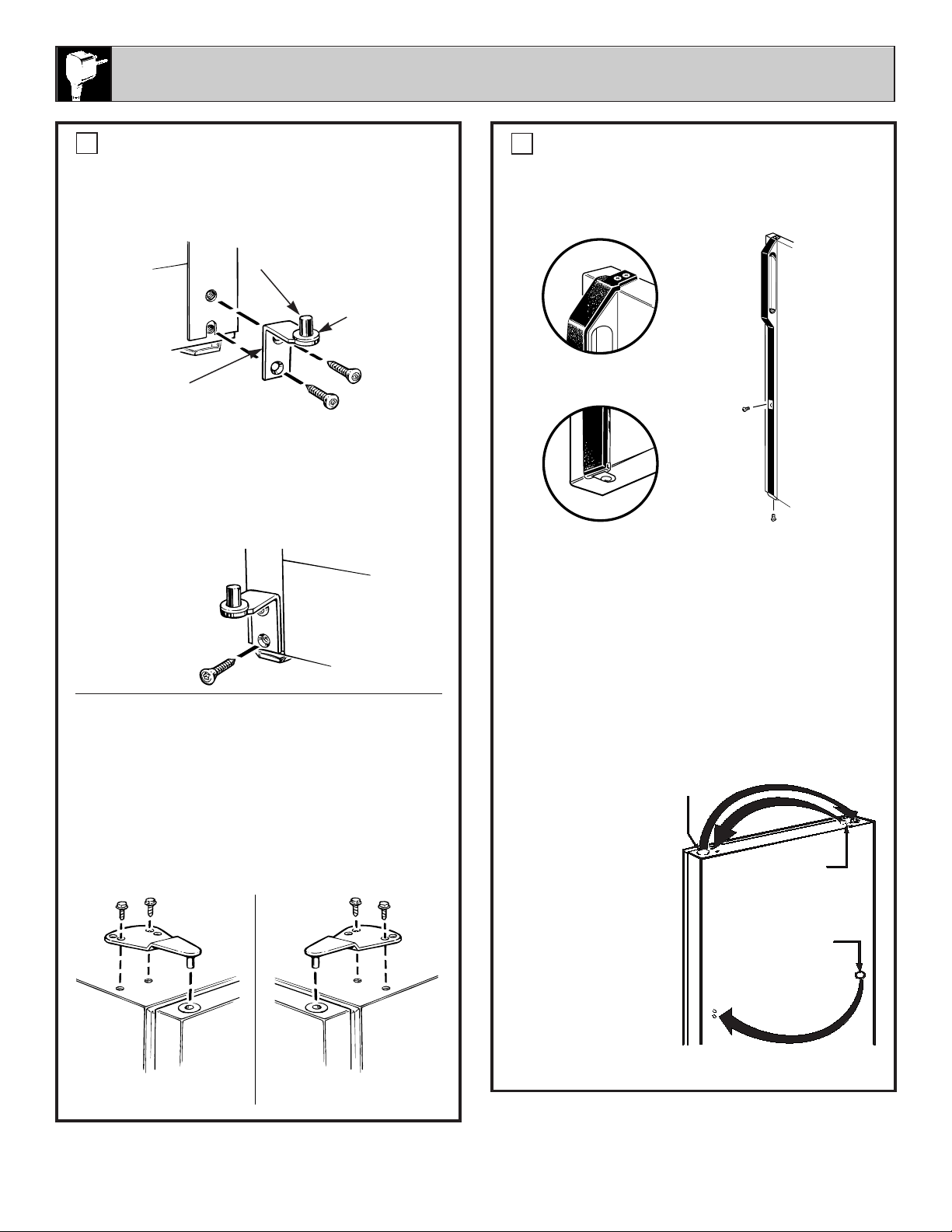

REVERSE CABINET HARDWARE.

1. Transfer the bottom hinge to the left.

a.

Remove the base grille if your refrigerator has

one. Grasp it at the bottom and pull it straight out.

b. Using a Torxdriver, remove the hinge bracket

(and shim glued to it), and plastic washer from

the bottom right side of the cabinet.

c. Reinstall the hinge bracket (and shim glued

to it) and plastic washer on the bottom left side

of the cabinet.

2. Transfer the top hinge to the left.

Reinstall the top hinge (and shim glued to it) on

the left front corner of the cabinet, but do not

tighten the screws at this time.

Some hinges have four holes. Which holes you

use for installing the hinge depends on which

side you install the hinge.

The outer edge of the hinge should be parallel to

the edge of the case for correct installation.

3

REVERSE THE DOOR HANDLES.

(on some models)

1. Transfer the fresh food door handle

to the right.

To remove the handle…

a. Remove the handle plug using a tape-tipped

putty knife under the edge, and remove the

screw underneath.

b. Remove two screws holding the handle to the

top of the door.

c. Remove the handle.

After removing the handle…

a. Remove the screws from the right edge of

the door top and insert them into the handle

screw holes on the opposite side.

b. With tape-tipped

putty knife or thinblade screwdriver,

pry out the plug

button from the

hinge hole on the

left side of the door

and insert it into

the hole on the

opposite side that

was vacated by

removal of the

top hinge.

c. Pull the plug

button from the

front of the door

and transfer it to

the opposite side.

4

Plastic

washer

Hinge

pin

Bottom

hinge

bracket

LEFT SIDE

Plug

button

Plug button

Screws for

handle holes

RIGHT SIDE

TOP

BOTTOM

Installing the hinge

on the left

Installing the hinge

on the right

14

15

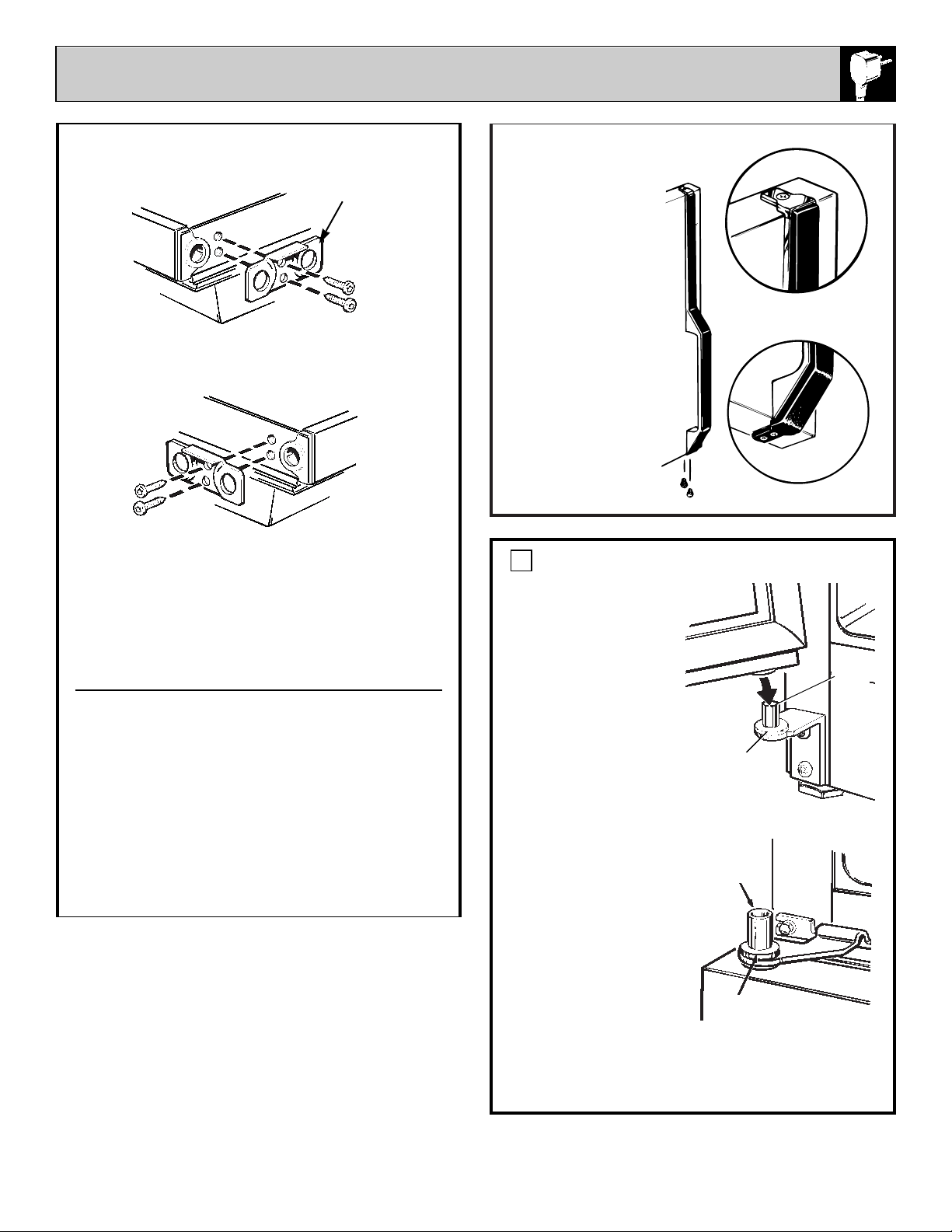

2. Transfer the door stop.

• Move the metal door stop from the right end to

the left end. Use a Torxdriver.

• Move any screws from the left end to the

right end.

When reinstalling the fresh food door handle…

a. Attach the handle to the right side of the door

with screws at the top and under the handle plug.

b. Reinstall the handle plug.

3. Transfer the frozen food storage

compartment door handle to the right.

a. Remove the screw holding the handle to the

top of the door and the two screws holding the

handle to the bottom of the door.

b. Remove the handle.

c. Remove the screw from the right top edge of

the door and insert it into the handle screw hole

on the left side.

d. Transfer the door stop as shown above.

e. Attach the

handle to the

right edge of the

door with screws

at top and bottom,

using bottom

holes vacated by

removal of the

door stop screws.

TOP

BOTTOM

REHANG THE FRESH FOOD DOOR.

a. Lower the bottom

socket of the fresh

food door onto the

pin on the bottom

hinge. Be sure the

plastic washer is in

place on the pin.

b. Insert the pin on

the center hinge into

the socket in the top

of the door. NOTE:

The center hinge must

be turned over as

shown when mounted

on the left side.

c. Tilt the door toward

the cabinet. As the

door is brought into

position, slide the hinge under the head of the

screw which earlier had been partly driven into

the outermost hole. Insert the remaining screw,

then tighten both screws securely.

5

Plastic washer

Plastic washer

Hinge

pin

Hinge

pin

LEFT SIDE

Door stop

RIGHT SIDE

(continued next page)

REVERSING THE DOOR SWING

(continued)

16

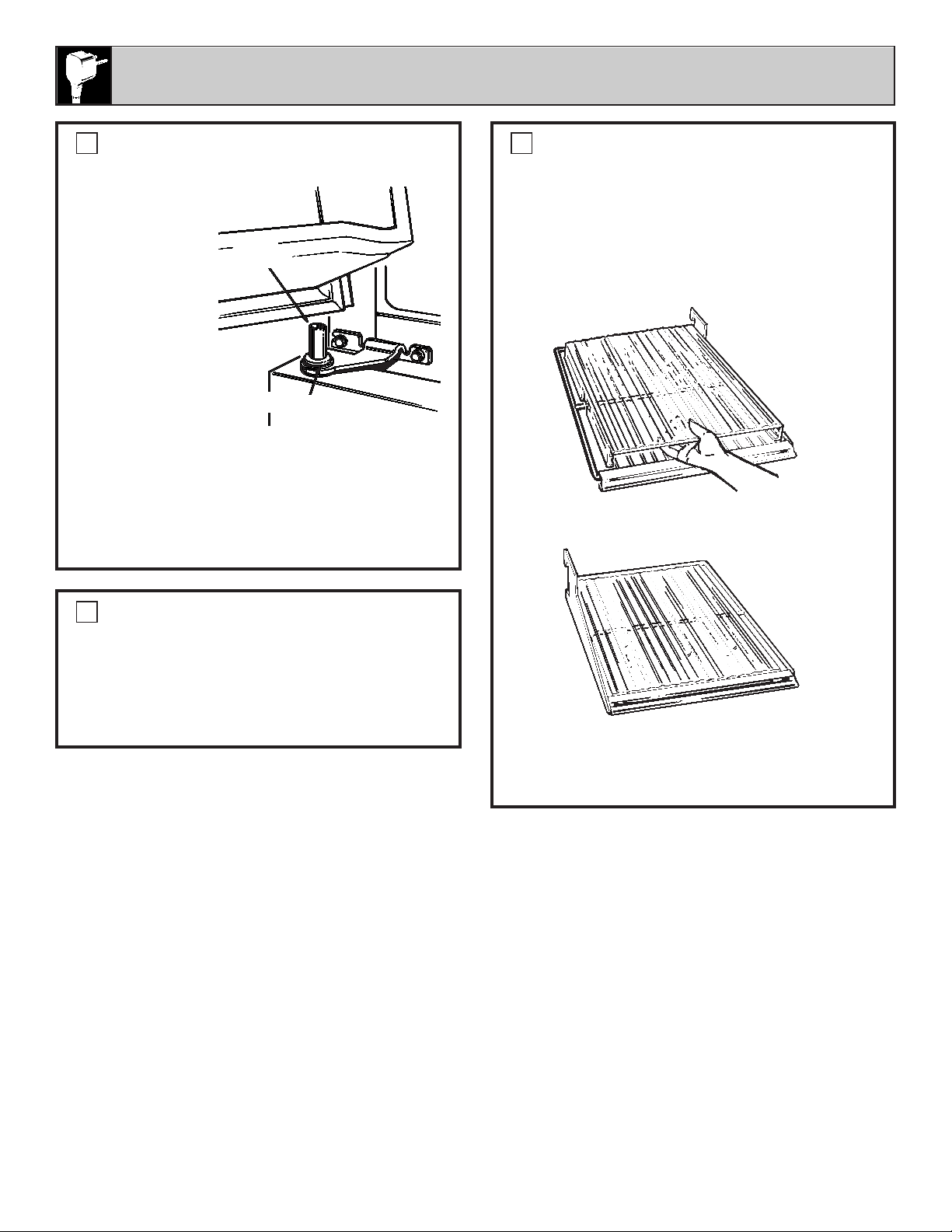

REHANG THE FROZEN FOOD STORAGE

COMPARTMENT DOOR.

a. Lower the

bottom socket of

the frozen food

storage

compartment

door onto the

center hinge pin.

Be sure the

washer is in

place on the pin.

b. Tilt the door

toward the

cabinet, lifting

the top hinge so

the pin fits into the socket on the top of the door.

c. Before tightening the top hinge screws, make

sure the top of the door is level with the cabinet

top and the space between the doors is equal

across the entire front. Do not overtighten these

screws––tighten them until they are just snug,

then turn them in another one-half turn.

6

RELOCATE THE PLASTIC-COVERED

SNACKS DRAWER. (on some models)

For convenient access to the Snacks Drawer

after reversing the door swing, you can move the

drawer to the other side of the cabinet.

1. Slide the drawer out and remove the shelf

to which it was attached.

2. Remove the other half-width shelf.

3. Push the drawer cover forward and up

off the shelf.

4. Put the cover on the other half-width shelf as

shown, flush to the side with the shelf-locking

lugs. Return both shelves to the refrigerator and

slide the Snacks Drawer into its relocated cover.

8

Hinge

pin

Plastic washer

EXAMINE THE DOOR GASKETS.

Check the door gaskets all around, making sure

no gaps are visible between the gaskets and the

cabinet. If a gap shows, try stretching the gasket

away from the door so the magnet in the gasket

will contact the cabinet surface, being careful not

to dislodge the gasket.

7

WATER LINE INSTALLA TION

17

CAUTION:

• If you use your refrigerator before connecting

the water line, make sure the icemaker feeler arm

is kept in the STOP (up) position.

• Do not install the icemaker tubing in areas

where temperatures fall below 32°F (0°C).

•When using any electrical device (such as a

power drill) during installation, be sure the device

is insulated or wired in a manner to prevent the

hazard of electric shock.

• All installations must be in accordance with

local plumbing code requirements.

WARRANTY INFORMATION

This water line installation is not warranted by

the refrigerator or icemaker manufacturer.

Follow these instructions carefully to minimize

the risk of expensive water damage.

SHUT OFF THE MAIN WATER SUPPLY.

Turn on the nearest faucet long enough to clear

the line of water.

1

INSTALL THE SHUTOFF VALVE ON THE

NEAREST FREQUENTLY USED DRINKING

WATER LINE.

a. Choose a location for the valve that is easily

accessible. It is best to connect into the side of

a vertical water pipe. When it is necessary to

connect into a horizontal water pipe, make the

connection to the top or side, rather than at the

bottom, to avoid drawing off any sediment from

the water pipe.

b. Drill a 1/4

² hole in the water pipe, using a

sharp bit. Remove any burrs resulting from

drilling the hole in the pipe. (Do not drill a hole

if the valve is a self-piercing type.)

c. Fasten the shutoff valve to the cold water pipe

with the pipe clamp.

d. Tighten the

clamp screws until the

sealing washer

begins to swell. Do

not overtighten or

you may crush the

copper tubing.

2

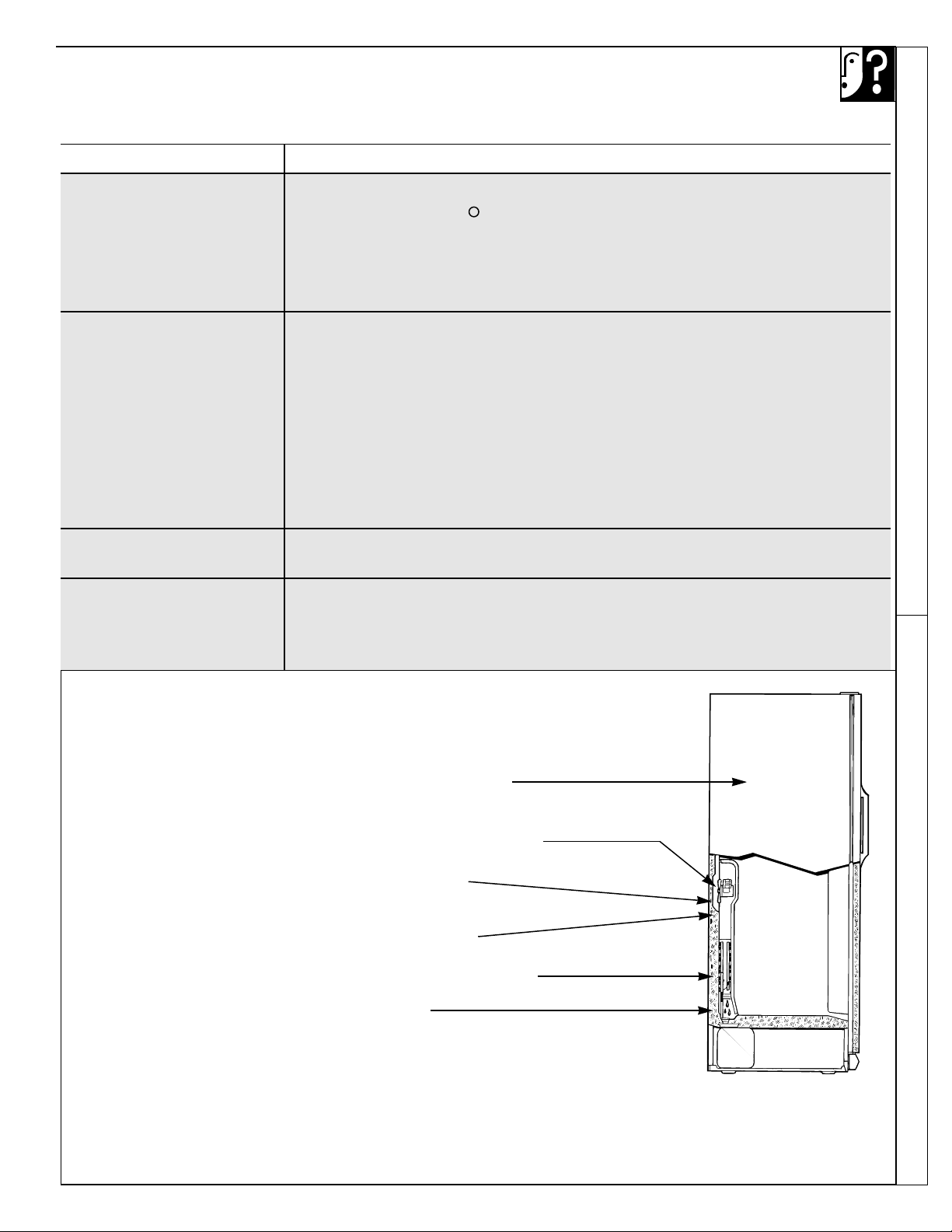

WHAT YOU WILL NEED

• A cold water supply is required for automatic

icemaker operation. The water pressure must be

between 20 and 120 p.s.i. (1.4 and 8.3 bars).

•

Power drill, unless you have a self-piercing valve.

• Copper tubing, 1/4² outer diameter, to

connect the refrigerator to the water supply. Be

sure both ends of the tubing are cut square.

To determine how much copper tubing you need:

measure the distance from the water valve on the

back of the refrigerator to the water supply pipe.

Then add 8 feet (244 cm). Be sure there is

sufficient extra tubing [about 8 feet (244 cm)

coiled into 3 turns of about 10 inches (25 cm)

diameter] to allow the refrigerator to move out

from the wall after installation. Do not use plastic

tubing or plastic fittings because the water supply

line is under pressure at all times. Also, certain

types of plastic tubing may become brittle with

age and crack, resulting in water leakage.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32² at the point of

connection to the COLD WATER LINE. Saddletype shutoff valves are included in many water

supply kits. Before purchasing, make sure a

saddle-type valve complies with your local

plumbing codes.

• Two 1/4² outer diameter compression nuts

and 2 ferrules (sleeves)—to connect the copper

tubing to the shutoff valve and the refrigerator

water valve.

• If your existing water line has a flared fitting at

the end, you will need an adapter (available at

plumbing supply stores) to connect the water line

to the refrigerator OR—you can cut off the flared

fitting with a tube cutter and then use a

compression fitting.

Typical ways to connect to water supply

Under sink

to cold

water pipe

Through wall to

utility room cold

water pipe

In crawl

space under

house

Through floor

to basement

cold water pipe

Pipe

clamp

Saddle-type

shutoff

valve

Washer

Inlet

end

Vertical

cold water

pipe

(continued next page)

WATER LINE INSTALLA TION

(continued)

18

ROUTE THE COPPER TUBING BETWEEN THE

COLD WATER LINE AND THE REFRIGERATOR.

Route the tubing through a hole drilled in the

floor or wall (behind the refrigerator or adjacent

base cabinet) as close to the wall as possible. Be

sure there is sufficient extra tubing [about 8 feet

(244 cm) coiled into 3 turns of about 10² (25 cm)

diameter] to allow the refrigerator to move out

from the wall after installation.

3

a. Remove the

plastic flexible

cap from the

water valve.

b. Place the

compression

nut and ferrule

(sleeve) onto the

end of the tubing

as shown.

c. Insert the

end of the copper

tubing into the water valve connection as far as

possible. While holding the tubing, tighten the

fitting.

d. Fasten the copper tubing into the clamp

provided to hold it in a vertical position. You may

need to pry open the clamp.

TURN THE WATER ON AT THE

SHUTOFF VALVE.

Tighten any connections that leak.

7

PLUG THE REFRIGERATOR POWER CORD

INTO A GROUNDED ELECTRICAL OUTLET.

8

MOVE THE REFRIGERATOR BACK TO

THE WALL.

Arrange the coil of copper tubing so that it does

not vibrate against the back of the refrigerator or

against the wall.

10

SET THE ICEMAKER FEELER ARM TO THE ON

(DOWN) POSITION.

The icemaker will not begin to operate until it

reaches its operating temperature of 15°F (-9°C).

or below . It will then begin operation automatically

if the icemaker is in the ON (down) position.

NOTE: The icemaker may double-cycle when it

first starts, causing some water spillage from the

icemaker into the ice bucket. This is normal and

should not happen again. The first few batches of

cubes should be thrown away, so that remaining

impurities in the water line will be flushed out.

9

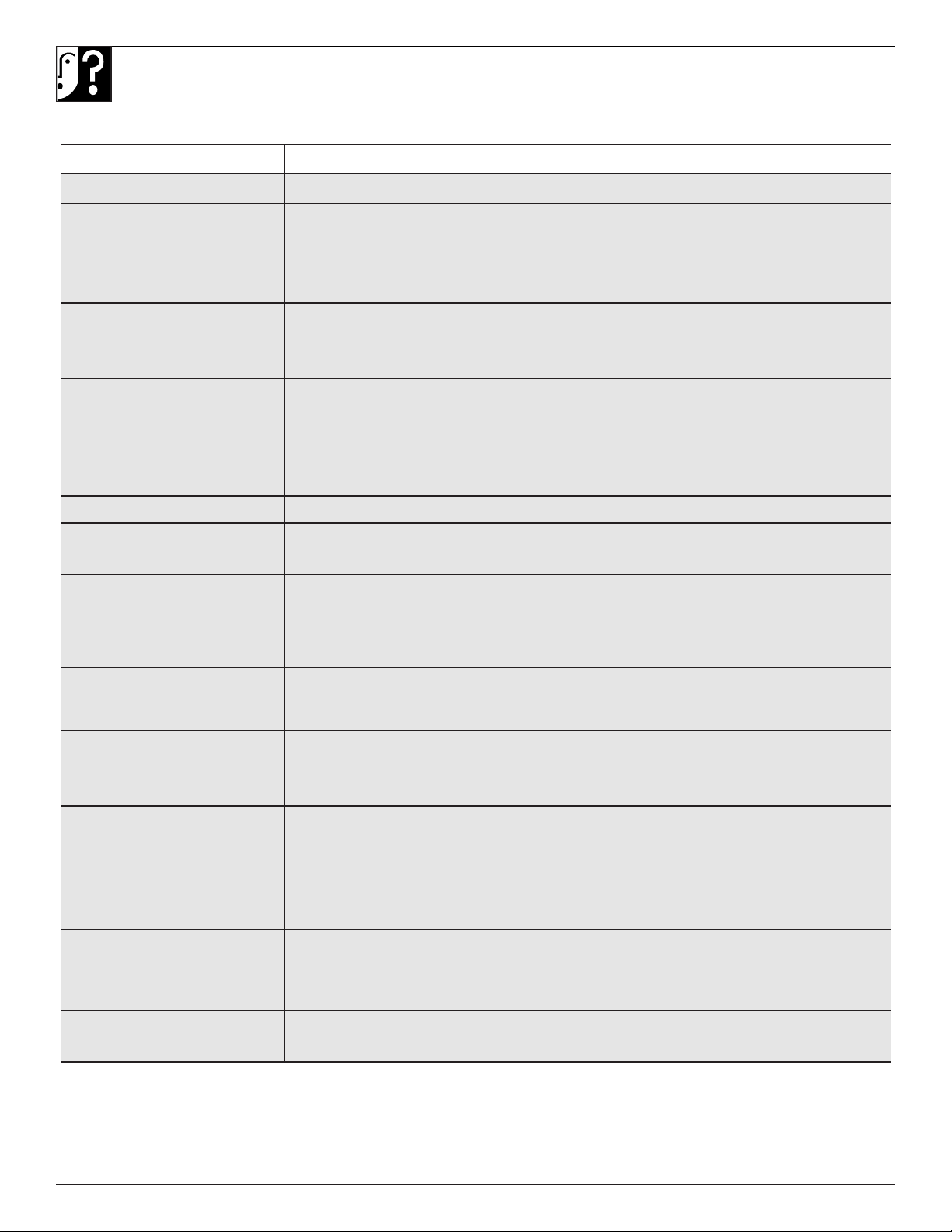

CONNECT THE COPPER TUBING TO THE

SHUTOFF VALVE.

Place the compression

nut and ferrule

(sleeve) onto the

end of the tubing

and connect it to the

shutoff valve. Make

sure the tubing is fully

inserted into the valve.

Tighten the

compression nut

securely.

4

TURN ON THE WATER AND FLUSH OUT

THE TUBING.

a. Turn the main water supply on and flush out

the tubing until the water is clear.

b. Shut the water off at the water valve after

about one quart (1 l) of water has been flushed

through the tubing.

5

CONNECT THE COPPER TUBING TO

THE REFRIGERATOR.

Before making the connection to the

refrigerator, be sure the refrigerator power

cord is not plugged into the wall outlet.

We recommend installing a water filter (available

from your local distributor) if your water supply

has sand or particles that could clog the screen of

the refrigerator’s water valve. Install it in the

water line near the refrigerator.

6

Saddle-type

shutoff

valve

Packing

nut

Outlet

valve

Compression nut

Ferrule

(sleeve)

Ferrule

(sleeve)

1/4² Copper tubing

1/4²

Compression nut

Tubing

clamp

Refrigerator connection

QUESTIONS?

USE THIS PROBLEM SOLVER

PROBLEM POSSIBLE CAUSE

REFRIGERATOR DOES • May be in defrost cycle when motor does not operate for about 30 minutes.

NOT OPERATE

• Fresh food control in “ ” position.

• If interior light is not on, refrigerator may not be plugged in at wall outlet.

• If plug is secure and the refrigerator still fails to operate, plug a lamp or a small

appliance into the same outlet to determine if there is a tripped circuit breaker or

burned-out fuse.

MOTOR OPERATES • Modern refrigerators with more storage space and a larger frozen food storage

FOR LONG PERIODS compartment require more operating time.

• Normal when refrigerator is first delivered to your home—usually requires

24 hours to completely cool down.

• Large amounts of food placed in refrigerator to be cooled or frozen.

• Hot weather—frequent door openings.

• Door left open.

• Temperature controls are set too cold. Refer to Temperature Controls section.

• Grille and condenser need cleaning. Refer to Care and Cleaning section.

MOTOR STARTS AND • Fresh food control starts and stops motor to maintain even temperatures.

STOPS FREQUENTLY

VIBRATION OR RATTLING • If refrigerator vibrates, more than likely it is not resting solidly on the floor.

The front leveling legs need adjusting, or floor is weak or uneven. Refer to

Rollers and Levelling Legs in the Preparation section.

• If dishes vibrate on shelves, try moving them. Slight vibration is normal.

NORMAL OPERATING SOUNDS

These sounds are normal and do not indicate a need for service.

The new high efficiency compressor runs faster and will have a higher pitch hum or

pulsating sound while operating.

Sizzling sound in the frozen food storage compartment during

the defrost cycle, caused by frost thawing and draining.

Defrost timer and refrigerator control click on and off.

The fan circulating air inside the frozen food storage compartment

which keeps the temperatures throughout.

W ater dropping on the defrost heater causing a sizzling,

hissing or popping sound during the defrost cycle.

The flow of refrigerant through the frozen food storage compartment

cooling coils sounds like boiling water or a gurgling noise.

Cracking or popping of cooling coils caused by expansion

and contraction during defrost and refrigeration following defrost.

W ater dripping as it melts from the evaporator

and flows to the drain pan during the defrost cycle.

Icemaker (on some models): The icemaker water valve will buzz when

the icemaker fills with water . If the feeler arm is in the ON (down) position it will buzz

even if it has not yet been hooked up to water . Keeping the feeler arm in the ON (down)

position before it is hooked up to water can damage the icemaker. To prevent this, raise

the feeler arm to the STOP (up) position. This will stop the buzzing.

The sound of cubes dropping into the bin and water running in pipes as icemaker refills.

19

Water Line Installation Problem Solver

(continued next page)

PROBLEM SOLVER

(continued)

20

PROBLEM POSSIBLE CAUSE

FOODS DRY OUT • Foods not covered, wrapped or sealed properly.

FRESH FOOD OR • Temperature controls not set cold enough. Refer to Temperature Controls section.

FROZEN FOOD STORAGE

• Warm weather—frequent door openings.

COMPARTMENT

• Door left open for too long a time.

TEMPERATURE TOO WARM

• Package holding door open or blocking air duct in frozen food storage compartment.

FROST OR ICE CRYSTALS • Door may have been left ajar or package holding door open.

ON FROZEN FOOD

• Too frequent or too long door openings.

• Frost within package is normal.

AUTOMATIC ICEMAKER • Icemaker feeler arm is in STOP (up) position.

DOES NOT WORK

• Water supply turned off or not connected.

(on some models)

• Frozen food storage compartment too warm.

• Piled up cubes in the storage bin may cause icemaker to shut off prematurely.

Remove storage bin from freezer and level cubes by hand.

CUBES TOO SMALL • Water shutoff valve connecting refrigerator to home water line may be clogged.

SLOW ICE CUBE FREEZING • Door may have been left ajar.

• Temperature controls set too warm. Refer to Temperature Controls section.

ICE CUBES HAVE • Ice storage bin needs to be emptied, washed and old cubes need to be discarded.

ODOR/TASTE

• Unsealed packages in fresh food and/or frozen food storage compartments may

be transmitting odor/taste to ice cubes.

• Interior of refrigerator needs cleaning. Refer to Care and Cleaning section.

MOISTURE FORMS ON • Not unusual during periods of high humidity.

CABINET SURFACE

• Move the anti-condensation switch to the ON position.

BETWEEN THE DOORS

MOISTURE COLLECTS • Too frequent or too long door openings.

INSIDE

• In humid weather, air carries moisture into refrigerator when doors are opened.

• Move the anti-condensation switch to the ON position.

REFRIGERATOR HAS ODOR • Foods with strong odors should be tightly covered.

• Check for spoiled food.

• Interior needs cleaning. Refer to Care and Cleaning section.

• Defrost water drainage system needs cleaning.

• Keep open box of baking soda in refrigerator; replace every three months.

HOT AIR FROM BOTTOM • Normal air flow cooling motor. In the refrigeration process, it is normal that heat

OF REFRIGERATOR be expelled in the area under the refrigerator. Some floor coverings will discolor

at these normal and safe operating temperatures. Your floor covering supplier

should be consulted if you object to this discoloration.

FOOD FREEZING IN • Move the food away from the air vent (near the controls).

THE REFRIGERATOR

• Temperature controls set too cold. Refer to Temperature Controls section.

Loading...

Loading...