GE PSGN, PSFA, ULGC, PSGV Installation Guide

g

GEH-5820C

GE

INSTRUCTIONS

Lighting Solutions

Powr•Spot® Floodlight

READ THOROUGHLY BEFORE INSTALLING

WARNING

Risk of electric shock

• Turn power o before servicing

– see instructions

GENERAL

This luminaire is designed for outdoor lighting service, and should not be used in

areas of limited ventilation, or in high ambient temperature enclosures. Best results will

be obtained if installed and maintained according to the following recommendations.

UNPACKING

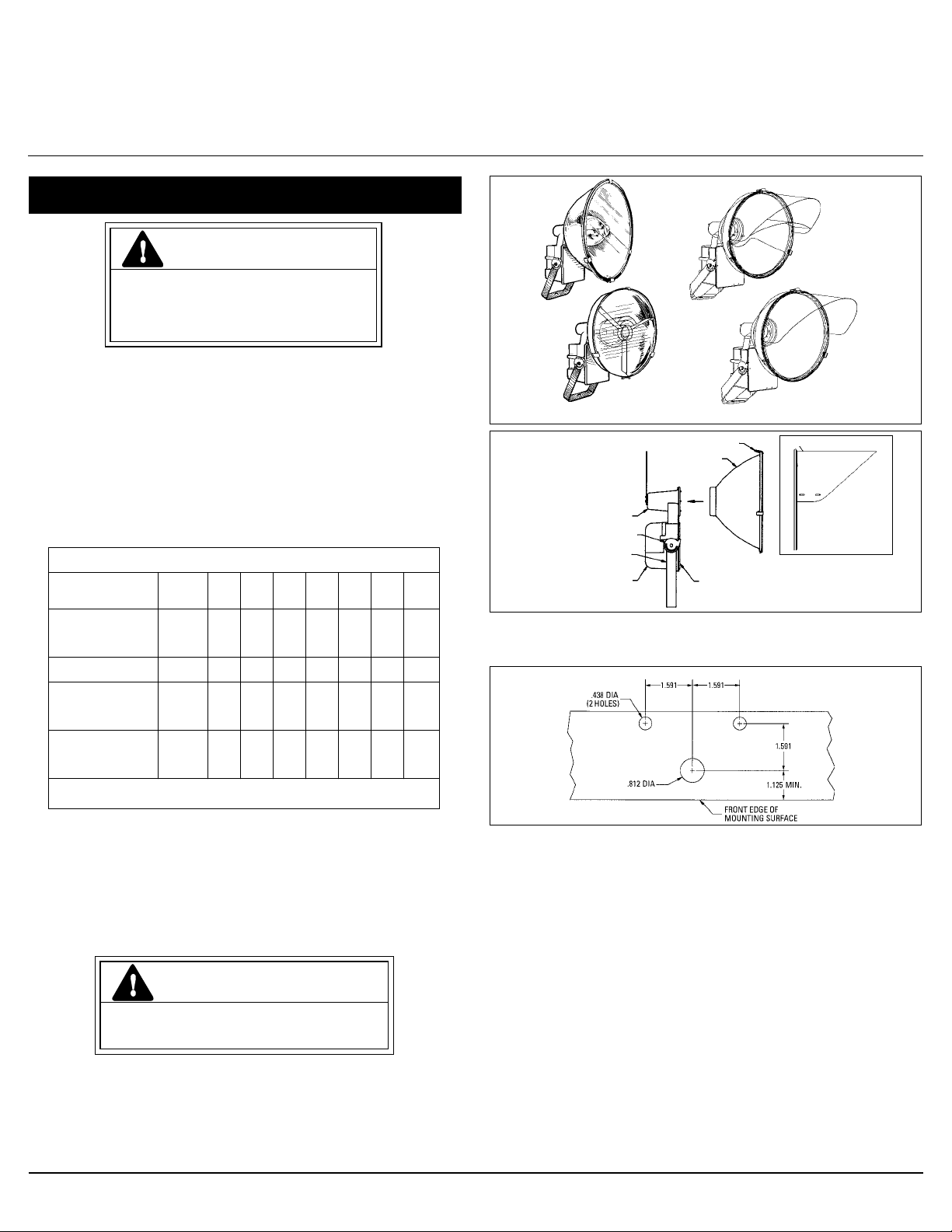

The system consists of three components; ballast, optical reector (with and

without a heavy-duty optical cover) and glass lens. If luminaire is ordered with a

PSFA (See Figure 1A) prex glass lens is shipped in same carton as optical reector.

With a ULGC (See Figure 1B), PSGN (See Figure 1C), or PSGV (See Figure 1D), glass

lens will be in a third carton with glare control device in place. Component catalog

numbers for each of assemblies are shown in Table 1. Included in table are NEMA

beam descriptions for each reector catalog number. This is VERY IMPORTANT when

more than one light distribution is to be used.

Base Reector Catalog Numbers and NEMA Beam Spreads*

Optical Assembly MH MH MH HPS HPS HPS

Cat. No. REFL. 1500 1000 400 1000 750 400 REFL.

XX= GP or HD DIA. NEMA NEMA NEMA NEMA NEMA NEMA ”ID’’

PSFBBxx0 20" 3X3 3X3 3X3 — 3X3 3X3 B0

PSFBCxx0 20" 4X4 4X4 3X3 — 4X4 4X4 C0

PSFBDxx0 20" 5X5 5X5 5X5 — 5X5 5X5 D0

PSFBExx0 20" 6X6 6X6 6X6 5X5 5X5 6X6 E0

PSFBAxx2 22" 2X2 2X2 1X1 — — 1X1 A2

PSFBBxx2 22" 3X3 3X3 2X2 — — 2X2 B2

ULGCBxx0 20" 3X3 3X3 — — — — B0

ULGCCxx0 20" 4X4 4X4 — — — — C0

ULGCDxx0 20" 5X5 5X5 — — — — D0

ULGCExx0 20" 6X6 6X6 — — — — E0

*PSGNBxx0 20" 3X3 3X3 — — — — B0

*PSGNCxx0 20" 4X4 4X4 — — — — C0

*PSGNDxx0 20" 5X5 5X5 — — — — D0

*PSGNExx0 20" 6X6 6X6 — — — — E0

* Glare control optics may dier from base reector

NEMA Beam spreads.

Bill of lading lists component catalog numbers in addition to complete system

catalog number. Component catalog number is a prominent feature of label on

carton and is conspicuously displayed on outside of each component. Each optical

reector has label displaying a reector "ID" which consists of fth (5) and eighth (8)

alpha/numeric character from its component catalog number: xxxx"A"xx"N". This

can be seen from ground.

Check to see that you have received the correct material undamaged in transit.

INSTALLATION

TABLE 1

CAUTION

Unit will fall if not installed properly

• Follow installation instructions

A. CROSSARM SPACING:

These dimensions should preclude physical interference between oodlights

– when visors or other external accessories are used the vertical spacing will be

greater – contact factory.

HORIZONTAL spacing between oodlights 30"

VERTICAL spacing 36" without Top Visor

VERTICAL spacing 52" with Top Visor

PSFA

FIGURE 1A

ULGC/ULGN/ULGV

All 20" Reector ID's

FIGURE 1B

PSGN

All 20" Reector ID's

FIGURE 1C

FIGURE 2

DRAIN HOLE

KNOCK-OUT

REPOSITIONING STOP

TRUNNION BRACKET

DRAIN HOLE

KNOCK-OUTS

BALLAST

B. MOUNTING:

Floodlight is provided with either a straight or angled trunnion bracket for

mounting on at surfaces. Trunnion brackets have a clearance hole for a 3/4-

TOP LENS GLASS CLIP

REFLECTOR

GP

REFLECTOR

WITH LENS

COVER

PSGV

All 20" Reector ID's

FIGURE 1D

VISOR WITH

GLARE SHIELD & LENS

FIGURE 3

inch

bolt (Tighten to 80-90 Ft. Lbs.). Angled trunnion has a slot for a 3/8-inch

bolt for anti-rotate feature. Hole pattern required for 180 degrees of rotational

freedom of angled trunnion is shown in gure 3. Note that clearance hole for

3/4-inch bolt needs to be at least 1.125-inches from edge of at mounting surface

(See gure 3).

Special mounting adapters are available for other applications.

CAUTION: Drain holes are provided for normal below-horizontal aiming. Drain

hole knockouts are provided for above-horizontal aiming. Two drain hole

knockouts are on back of casting and one is on back of socket housing. (See

Figure 2) Open these three holes if the unit is to be aimed above horizontal. It

is not necessary to close normal holes hidden below cover.

C. WIRING:

Make all electrical connections in accordance with the National Electrical Code

and any applicable local code requirements.

Verify that supply voltage is correct by comparing it to nameplate.

1. Remove cover (four screws).

NOTE: Cable strain relief and seal are provided by the casting V-notch, the rubber

bushing, and the cover.

9/16-inch O.D. three-conductor AWG #14 cable is recommended.

2. Insert cable through the rubber bushing and make electrical connections.

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be met in connection with installation, operation or maintenance.

Should further information be desired or should particular problems arise which are not covered suciently for the purchaser’s purposes, the matter should be referred to GE Lighting Solutions.

Connect ground lead to the green lead, green ground screw on housing or terminal

block provided.

IF SINGLE VOLTAGE:

All single voltage ballasts are pre-wired such that user need only connect the

supply conductors.

IF MULTIVOLT: (120/208/240/277 volts)

Connect the ballast lead with the insulated terminal to the desired voltage terminal

as indicated on the ballast terminal nameplate.

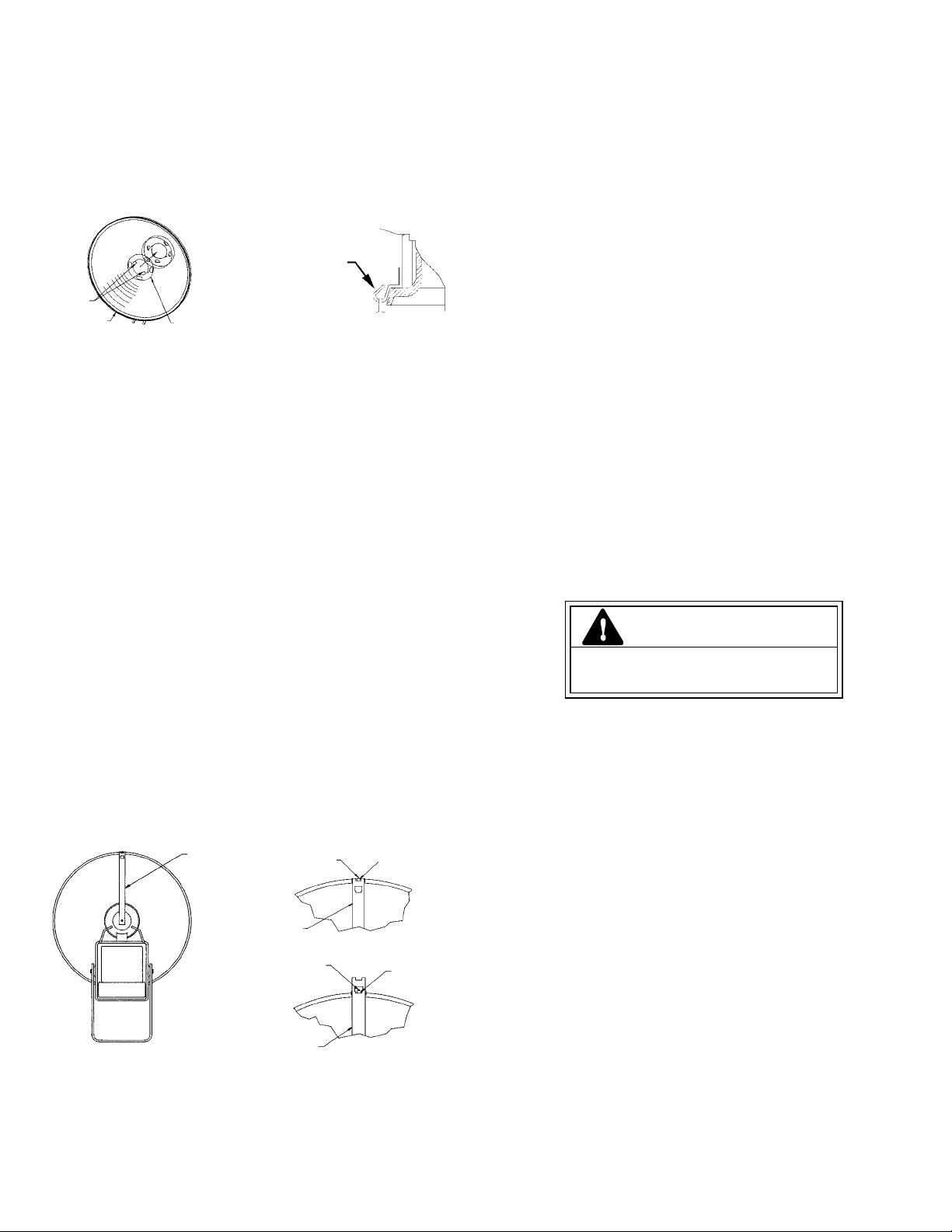

D. FINAL ASSEMBLY:

BEND HINGE TO

RETAIN DOOR GLASS

(WHEN REQ’D)

TABS

REFLECTOR

FIGURE 4A

SHIELD INSERT

FIGURE 4B

With optical open, align keyhole slots in optical assembly with mounting bolts on

ballast housing. Rotate optical clockwise 15 degrees, and tighten bolts.

CAUTION: Close hinge bracket around glass door hinge clip with pliers.

See Fig. 4B

AIMING PREPARATION

It is very important to know NEMA light distribution for each reector if more than

one light distribution is to be used. Each light distribution is assigned an aiming point

on site or a horizontal and vertical aiming vector with respect to pole or structure

on which it is located. Each light distribution may be assigned a specic location on

each pole or structure.

Matrix in Table 1 lists component catalog number for each Powr•Spot optical in

terms of reector diameter, lamp rating, NEMA beam and reector “ID’’.

GLARE CONTROL LOUVERS & VISORS

Glare control louver and visor accessories (See Figures 1B, 1C, and 1D) are supplied

pre-assembled to a 20-inch optical glass lens, installed in same manner as a plain

glass lens. If accessories are ordered to retrot an existing 20-inch PSFB optical,

then shield insert must be installed as shown in Figure 4A. Insert may be secured

by bending two tabs through center hole and around back of reector neck. Insert

should be in place on all PSGC optical assemblies (See Table 1).

TARGET AIMING

The following procedure is accomplished after the poles have been erected with

crossarms (or cages) and luminaires assembled:

1. A grid is laid out on the eld as shown on the aiming diagram that is part of

GE supplied information. The origin (x=0, y=0) is positioned at home plate for

baseball/softball or at the center of the eld for football/soccer.

2. A target, such as a pie plate, marked with each xture's XY coordinates is placed

on the eld for all xtures that are indicated by the oodlight blocks in the xture

arrangement and aiming schedule.

3. A person at the oodlight then uses the built in sighting mechanism of the luminaire

to aim each oodlight at the proper target on the ground.

SIGHT BAR

TARGET

SIGHT

TARGET

22 INCH

OPTICAL

CLIP

CLIP

4. Rotate sight bar into position; see Figure 5A.

5. Loosen degree marker/repositioning stop and trunnion clamping bolts.

6. Align the target as shown on Figure 5B.

7. Tighten trunnion clamping bolts (80-90 Ft. Lbs.) Position against the reposition

stop and secure by tightening screw.

DEGREE AIMING

The degree markings on the oodlight mounting lack the necessary precision and

should NOT be used for angle determination. In order to achieve adequate results,

extreme care must used while performing steps described below. The following

procedure is accomplished on the ground before the pole is erected:

1. The pole and crossarms must be braced so that they are both LEVEL (parallel)

with the ground.

2. Each oodlight is attached to the crossarm(s) so that the glass lens is LEVEL

(parallel) with the ground.

3. An inclinometer is positioned on the glass lens perpendicular to the crossarm.

The down angle adjustment that is indicated in the square boxes of the xture

arrangement and aiming schedule is made. The bolts that attach the trunnion to

oodlight housing are tightened.

4. The reposition stop is then aligned against its stop and secured by tightening the

screw.

5. The bolts are then loosened and the oodlight is rotated back to its original

horizontal (level) position in preparation for Left or Right adjustment. Retighten

the bolts.

6. The inclinometer is positioned on the glass lens parallel to the crossarm. The

crossarm attachment bolts are loosened, the Left or Right angle adjustment is

made, and the bolt is retightened.

7. Finally, the trunnion/xture bolts are loosened and the oodlight is rotated to its

nal vertical position (against the reposition stop). Make sure that the stop is not

bent by rapid movement during rotation. Securely tighten all bolts and screws.

MAINTENANCE

Periodic cleaning on outside of glass lens will ensure operation at maximum optical

eciency. Glass and reector (if needed) should be cleaned with soap, glass cleaner

or detergent solutions, rinsed with cold water and wiped dry.

Light output is also dependent on age of lamp. In applications where light levels

are critical, it may be desirable to replace lamps before burn out. Lamp manufacturer

can provide data showing how lamp light output decreases with use.

LAMPS

CAUTION

Risk of burn

• Allow lamp/xture to cool before handling

Use only lamps specified on nameplate. Observe lamp manufacturer's

recommendations and restrictions on lamp operation, particularly ballast type,

burning position, etc.

1. Check trunnion-mounted repositioning stop, ensuring that it is located against

stop and secured to trunnion.

2. Loosen trunnion clamp bolts, rotate luminaire to a convenient relamping position

and tighten bolts.

3. Open glass lens, unlatching top clip last .

4. Replace lamp and close glass lens, latching top rst and checking for proper

gasket sealing. Secure remaining clips.

5. Reposition luminaire and tighten clamp bolts (80-90 Ft. Lbs.) mechanism of the

luminaire to aim each oodlight at the proper target on the ground.

6. Rotate sight bar into position; see Figure 5A.

7. Loosen degree marker/repositioning stop and trunnion clamping bolts.

8. Align the target as shown on Figure 5B.

9. Tighten trunnion clamping bolts (80-90 Ft. Lbs.). Position degree marker against

stop and secure by tightening screw.

FIGURE 5A

SIGHT

FIGURE 5B

20 INCH

OPTICAL

Loading...

Loading...