GE PSB48YPHSV, PSB48YSHSS, PSB42YPHSV, PSB42YSHSS Use & Care Guide

GEAppliances.com

Safety Instructions

Operating Instructions

Automatic Icemaker ................10

Care and Cleaning .............12, 13

ClimateKeeper

with Dual Evaporators ...............6

Drawers and Baskets ................9

Ice and Water Dispenser ....... 10, 11

Refrigerator Doors ..................8

Replacing the Light Bulbs ...........14

Shelves and Bins ....................7

Temperature Controls ...............5

Water Filter .........................6

Installation Instructions

Anti-Tip Brackets ...................34

Dimensions, Clearances ............17

Door, Grille Panels ..............36–38

Installation Space ..................17

Leveling ...........................35

Built-In Side by Side

™

Panel Dimensions ..............21–30

Water Line .....................33, 34

Water Supply ......................39

............2–4

Owner’s Manual and

Installation Instructions

Model 42, 48

GE Profile Côte à Côte

Réfrigérateurs

Manuel d’utilisation

et d’installation

La section française commence à la page 49

GE Profile

Troubleshooting Tips ......42–44

Normal Operating Sounds ..........41

Consumer Support

Consumer Support ........Back Cover

Performance Data Sheet ...........46

Warranty ..........................45

Write the model and serial numbers

here:

Model # _________________________

Serial # __________________________

Find these numbers on a label inside

the refrigerator compartment at the

top on the right side.

Refrigerators

225D2637P001 49-60558-2 09-14 GE

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY

GE Appliances Website

For more information on your refrigerator’s operation, visit www.GEAppliances.com or

call 800.GECARES (800.432.2737). In Canada visit GEAppliances.ca or call 800.561.3344.

REFRIGERATOR SAFETY INFORMATION

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others. All safety

messages will follow the safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”. These words are defined as:

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

DANGER

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

CAUTION

IMPORTANT SAFETY INSTRUCTIONS

WARNING

This refrigerator must be properly installed and located in

accordance with the Installation Instructions before it is used.

Replace all parts and panels before operating.

Do not store or use gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

Because of potential safety hazards under certain conditions, we

strongly recommend against the use of an extension cord. However,

if you must use an extension cord, it is absolutely necessary that it

be a UL-listed (in the United States) or a CSA certified (in Canada),

3-wire grounding type appliance extension cord having a grounding

type plug and outlet and that the electrical rating of the cord be 15

amperes (minimum) and 120 volts.

To reduce the risk of fire, explosion, electric shock, or injury when using your

refrigerator, follow these basic safety precautions:

To prevent suffocation and entrapment hazards to children, remove

the fresh food and freezer doors from any refrigerator before

disposing of it or discontinuing its use.

Do not allow children to climb, stand or hang on the door handles

or the shelves in the refrigerator. They could seriously injure

themselves.

Unplug the refrigerator :

• To disconnect power to the refrigerator. It cannot be turned off by

any setting on the control panel.

• To clean, replace a burned out light bulb, or make repairs.

Note: Repairs must be performed by a qualified Service Professional.

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

To reduce the risk of injury when using your refrigerator, follow these basic

precautions.

In refrigerators with automatic ice makers, avoid contact with the

moving parts of the ejector mechanism, or with the heating element

that releases the cubes. Do not place fingers or hands on the

automatic ice making mechanism while the refrigerator is plugged

in.

Do not clean glass shelves or covers with warm water when they

are cold. Glass shelves and covers may break if exposed to sudden

temperature changes or impact, such as bumping or dropping.

Tempered glass is designed to shatter into many small pieces if it

breaks.

2

Keep fingers out of the “pinch point” areas; clearances between the

doors and between the doors and cabinet are necessarily small. Be

careful closing doors when children are in the area.

Do not touch the cold surfaces in the freezer compartment when

hands are damp or wet, skin may stick to these extremely cold

surfaces.

Do not refreeze frozen foods which have thawed completely.

GEAppliances.com

SAFETY (CONT.)

INSTALLATION

WARNING

Explosion Hazard.

Keep flammable materials and vapors, such as gasoline, away from refrigerator. Failure to do so can

result in fire, explosion, or death.

WARNING

Tip Over Hazard.

This refrigerator is top heavy and must be handled with care. Failure to do so can result in the unit

tipping over and result in death or serious injury. Reference Installation Instructions for correct anti-tip

bracket installation.

CONNECTING ELECTRICITY

WARNING

Plug into a grounded 3-prong outlet

Do not remove the ground prong

Do not use an adapter

Electrical Shock Hazard.

Failure to follow these instructions can result in

death, fire, or electrical shock.

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped with a 3-prong

(grounding) plug which mates with a standard 3-prong

(grounding) wall outlet to minimize the possibility of electric

shock hazard from this appliance.

Have the wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly grounded.

Where a standard 2-prong wall outlet is encountered, it is

your personal responsibility and obligation to have it replaced

with a properly grounded 3-prong wall outlet. Do not use an

adapter.

The refrigerator should always be plugged into its own

individual electrical outlet which has a voltage rating that

matches the rating plate.

A 115 Volt AC, 60 Hz, 15- or 20-amp fused, grounded

electrical supply is required. This provides the best

performance and also prevents overloading house wiring

circuits which could cause a fire hazard from overheated

wires.

Never unplug your refrigerator by pulling on the power cord.

Always grip plug firmly and pull straight out from the outlet.

Repair or replace immediately all power cords that have

become frayed or otherwise damaged. Do not use a cord

that shows cracks or abrasion damage along its length or at

either end.

When moving the refrigerator away from the wall, be careful

not to roll over or damage the power cord.

DO NOT USE AN ADAPTER PLUG OR EXTENSION CORD

(Adapter plugs not permitted in Canada)

Do not use an adapter plug to connect the refrigerator to a 2-prong outlet.

Do not use an extension cord with this appliance.

3

IMPORTANT SAFETY INFORMATION.

READ ALL INSTRUCTIONS BEFORE USING.

SAFETY (CONT.)

PROPER DISPOSAL OF YOUR OLD REFRIGERATOR

WARNING

Remove fresh-food and freezer doors from the refrigerator, prior to disposal. Failure to do so can result

in child entrapment which can lead to death or brain damage.

IMPORTANT:

Suffocation and child entrapment hazard.

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous even if they will sit for “just a few

days.” If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

Before You Throw Away Your Old Refrigerator

or Freezer:

Take off the fresh food and freezer doors.

Leave the shelves in place so that children may not

easily climb inside.

Refrigerants

All refrigeration products contain refrigerants,

which under federal law must be removed prior

to product disposal. If you are getting rid of an old

refrigeration product, check with the company

handling the disposal about what to do.

READ AND FOLLOW THIS SAFETY INFORMATION CAREFULLY.

SAVE THESE INSTRUCTIONS

4

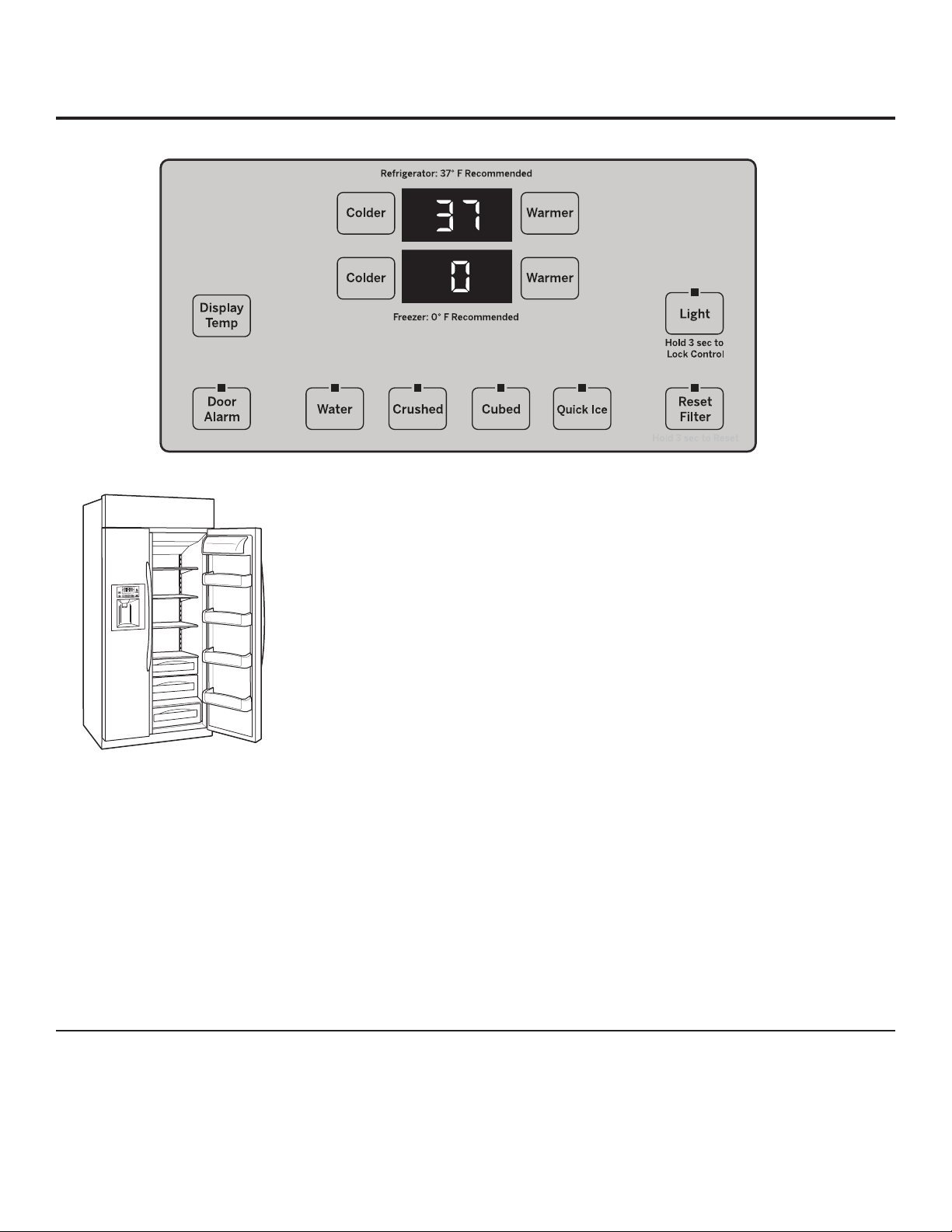

About the temperature controls. GEAppliances.com

The temperature controls are preset in the factory at 37°F for

the refrigerator compartment and 0°F for the freezer compartment.

Allow 24 hours for the temperature to stabilize to the preset

recommended settings.

The temperature controls can display both the SET temperature

as well as the actual temperature in the refrigerator and freezer.

The actual temperature may vary slightly from the SET temperature

based on usage and operating environment.

NOTE: The refrigerator is shipped with protective film covering

the temperature controls. If this film was not removed during

installation, remove it now.

To change the temperature, press and release

the WARMER or COLDER button. SET will illuminate in the

display, as well as the set temperature. To change the

temperature, tap either the WARMER or COLDER button

(while SET is illuminated) until the desired temperature

is displayed. Refrigerator temperatures can be adjusted

between 34°F and 47°F and

the freezer temperatures can be adjusted

between –6°F and +8°F.

Performance Air Flow System

Once the desired temperature has been set,

the temperature display will clear after 10 seconds.

To display the temperature, the DISPLAY TEMP button

may be tapped.

Several adjustments may be required. Each time you

adjust controls, allow 24 hours for the refrigerator to

reach the temperature you have set.

The Performance Air-Flow System is designed to

maximize temperature control in the refrigerator

and freezer compartments. This unique special feature

consists of the Air Tower along the back

wall of the refrigerator and the freezer. Placing food

in front of the louvers on these components will not

affect performance.

5

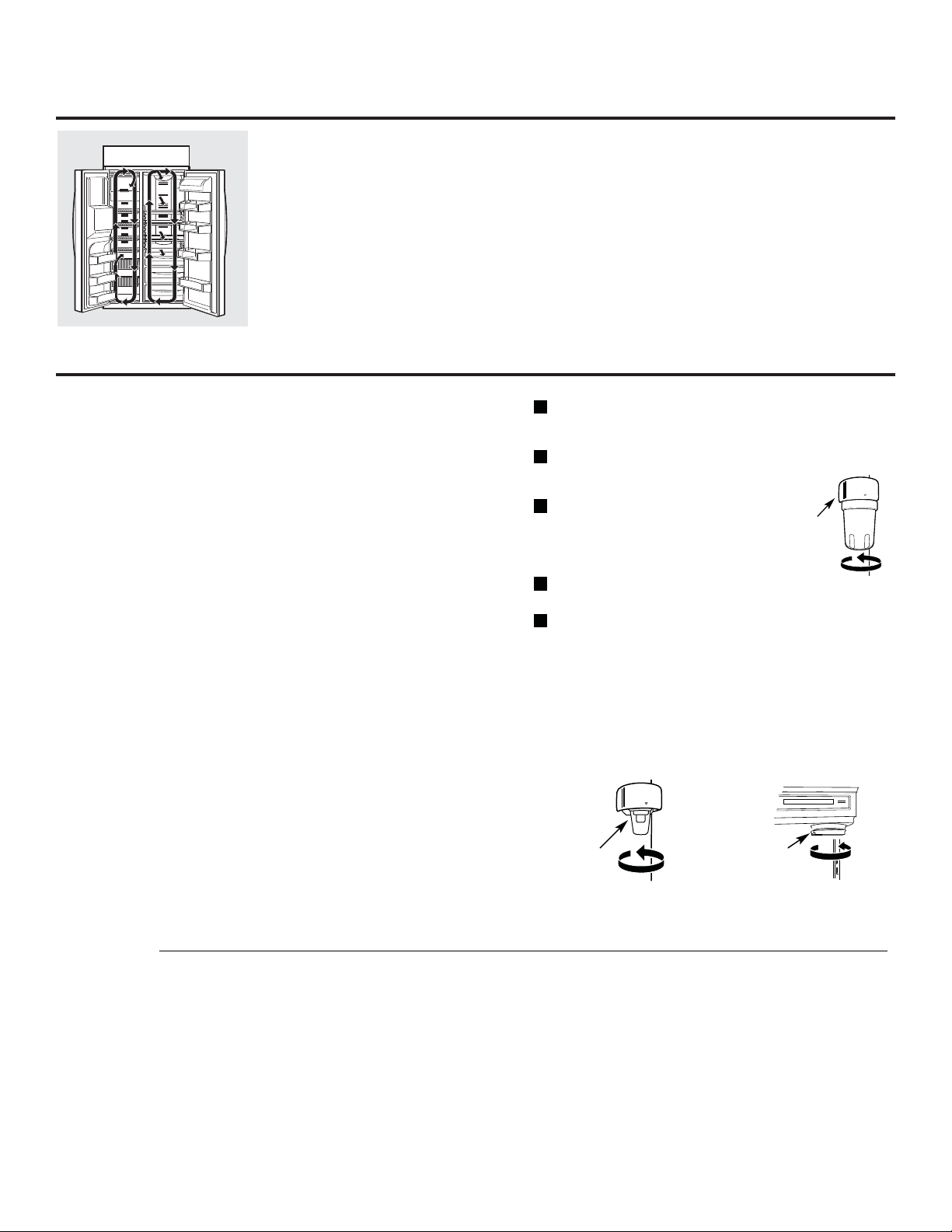

About ClimateKeeper® with dual evaporators.

How it Works

The ClimateKeeper with dual evaporators system

IHDWXUHVWZRHYDSRUDWRUV³RQHIRU

the refrigerator and one for the freezer.

This provides two separate cooling systems, and

separates the airflow between the fresh food and

freezer compartments during normal cooling

operations.

The separate airflow system minimizes

the mixing of air between the two compartments,

which reduces fresh food odor transfer to improve

the taste of ice.

The ClimateKeeper system also reduces

the number of defrosting cycles in the freezer

evaporator, thereby reducing freezer burn.

About the water filter.

Water filter cartridge

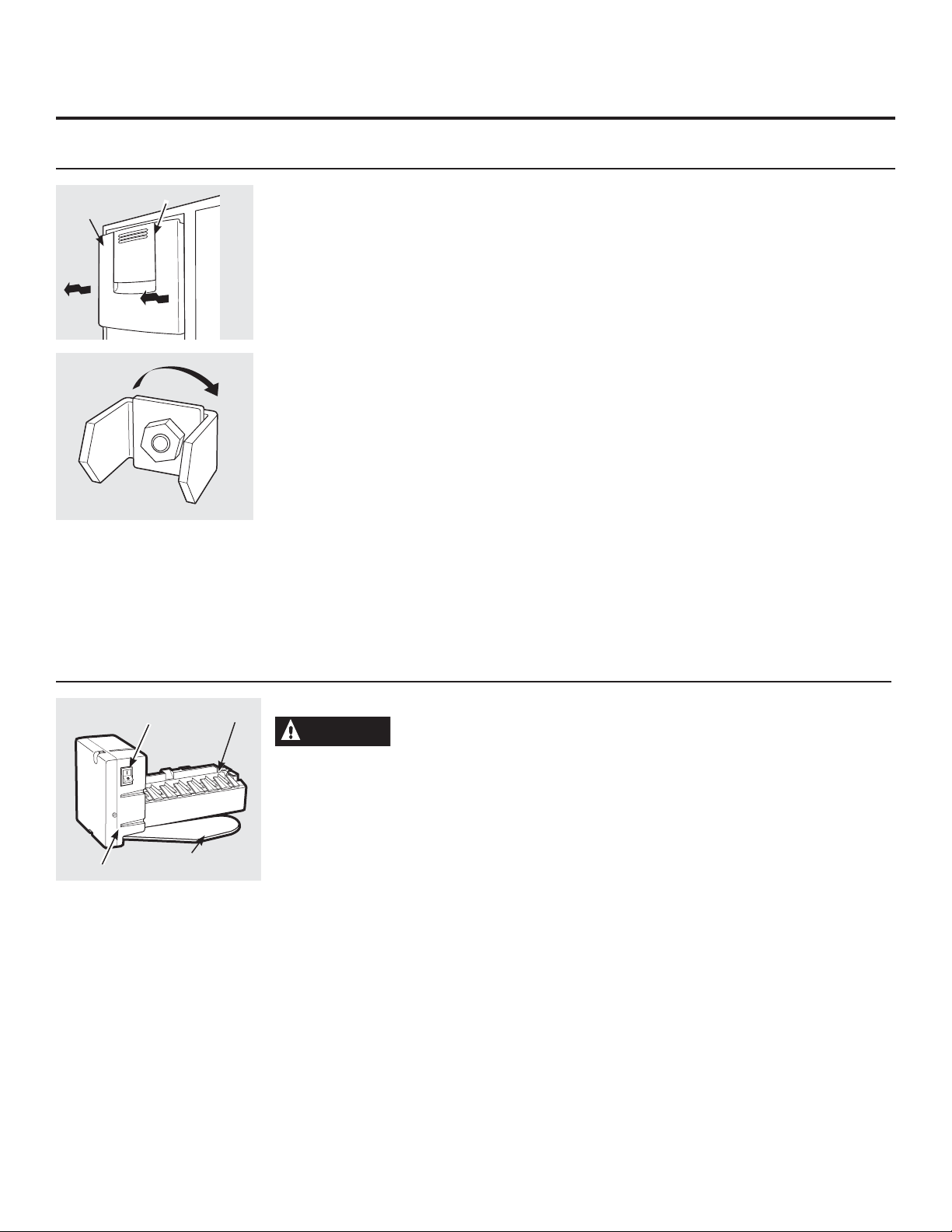

The water filter cartridge is located in the back upper right corner of

the refrigerator compartment.

When to replace the filter on models

with a replacement indicator light

There is a replacement indicator light for the water filter cartridge

on the dispenser. This light will turn orange to

tell you that you need to replace the filter soon.

The filter cartridge should be replaced when the replacement

indicator light turns red or if the flow of water to the dispenser or

icemaker decreases.

When to replace the filter on models

without a replacement indicator light

The filter cartridge should be replaced every six months

or earlier if the flow of water to the dispenser or

icemaker decreases.

Removing the filter cartridge

If you are replacing the cartridge, first remove the old one

by slowly turning it to the left. Do not pull down on the cartridge. A

small amount of water may drip down.

CAUTION: To reduce the risk associated with property damage due

to water leakage, read and follow instructions before installation

and use of this system. Installation and use MUST comply with all

state and local plumbing codes.

Installing the filter cartridge

Fill the replacement cartridge with water from the tap

1

to allow for better flow from the dispenser immediately

after installation.

Line up the arrow on the cartridge and the cartridge holder. Place

2

the top of the new cartridge up inside the holder.

Do not push it up into the holder.

Slowly turn it to the right until the filter

3

cartridge stops. DO NOT OVERTIGHTEN.

As you turn the cartridge, it will

automatically raise itself into position.

The cartridge will move about a ½ turn.

Run water from the dispenser for 1-1/2 gallons (about three

4

minutes) to clear the system and prevent sputtering.

Press and hold the RESET WATER FILTER pad (on some models) on

5

the dispenser for three seconds.

NOTE: A newly installed water filter cartridge may cause water

to spurt from the dispenser.

Cartridge

Holder

Filter bypass plug

ou must use the filter bypass plug when a replacement filter

Y

cartridge is not available. The dispenser and the icemaker will not

operate without the filter or filter bypass plug.

Filter Bypass

Plug

Filter Bypass

Plug

SmartWater

To use the filter bypass plug on Water by Culligan

you must first remove the filter adaptor from the cartridge holder by

turning it to the left.

Water by Culligan

™

models,

)RUWKHPD[LPXPEHQH¿WWR\RXU¿OWUDWLRQV\VWHP*(UHFRPPHQGVWKHXVHRI*(EUDQGHG¿OWHUVRQO\8VLQJ*(EUDQGHG¿OWHUVLQ*(

and Hotpoint

®

UHIULJHUDWRUVSURYLGHVRSWLPDOSHUIRUPDQFHDQGUHOLDELOLW\*(¿OWHUVPHHWULJRURXVLQGXVWU\16)VWDQGDUGVIRUVDIHW\

DQGTXDOLW\WKDWDUHLPSRUWDQWIRUSURGXFWVWKDWDUH¿OWHULQJ\RXUZDWHU*(KDVQRWTXDOL¿HGQRQ*(EUDQGHG¿OWHUVIRUXVHLQ*(

DQG+RWSRLQWUHIULJHUDWRUVDQGWKHUHLVQRDVVXUDQFHWKDWQRQ*(EUDQGHG¿OWHUVPHHW*(·VVWDQGDUGVIRUTXDOLW\SHUIRUPDQFHDQG

reliability.

,I\RXKDYHTXHVWLRQVRUWRRUGHUDGGLWLRQDO¿OWHUFDUWULGJHVYLVLWRXUZHEVLWHDWZZZJHZDWHU¿OWHUVFRPRUFDOO*(3DUWVDQG

Accessories, 800.626.2002.

Customers in Canada should consult the yellow pages for the nearest Camco Service Center.

6

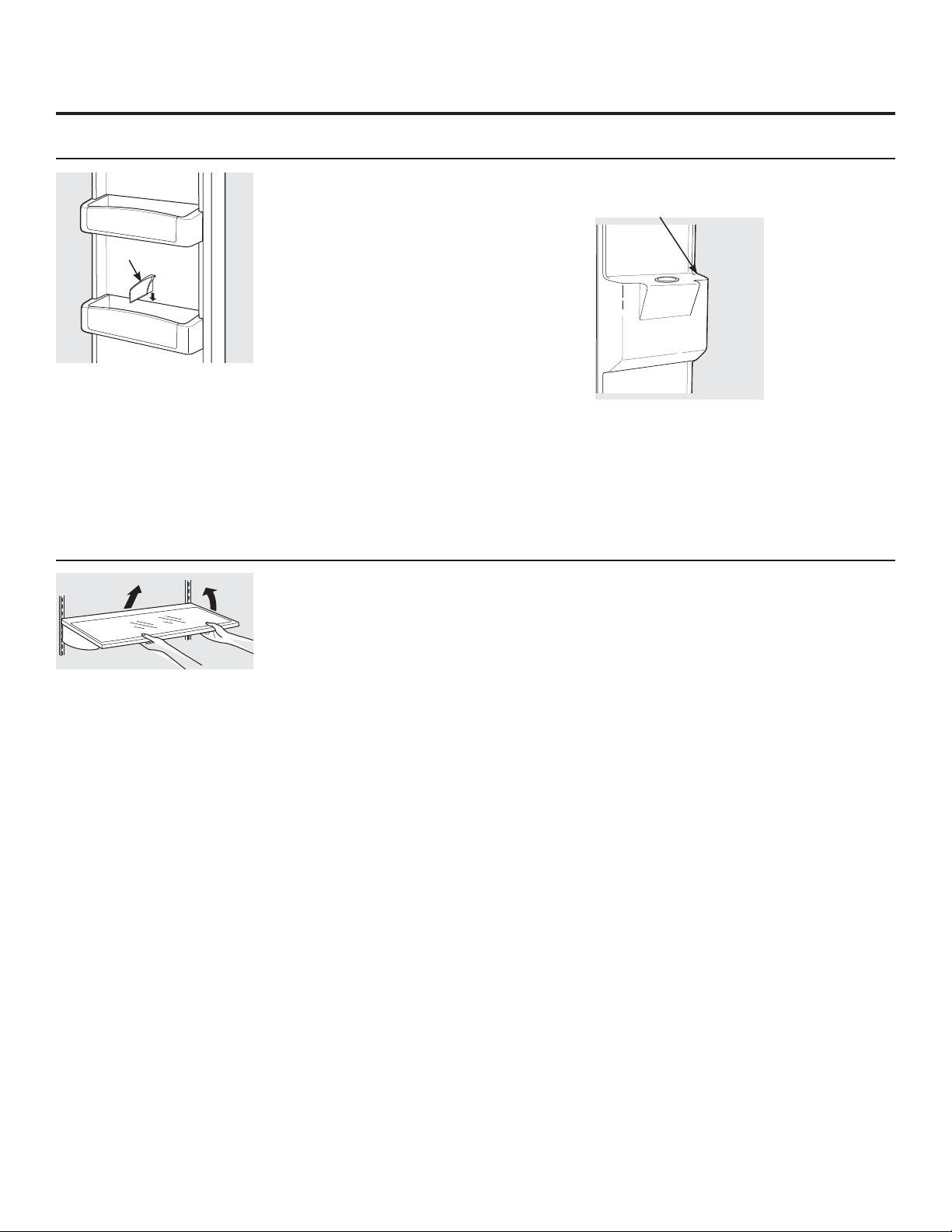

About the shelves and bins. GEAppliances.com

Not all features are on all models.

Refrigerator Door Bins and Freezer Door Bins

Do not block

NOTE: Make sure

that items do not

block or fall into the

ice chute.

Snugger

All door bins, except for the deep gallon

door bin and freezer bins, are adjustable

and can be moved up and down to meet your

storage needs. The deep gallon door

bin and the freezer bins can be removed

for cleaning.

To remove any bin: Lift the bin up and pull

it toward you.

Refrigerator bins

To replace or relocate: Engage the back side

of the bin in the molded supports on the door.

Then push down on the front of the bin.

Bin will lock in place.

The snugger helps prevent tipping, spilling

or sliding of small items stored on the door shelf.

Place a finger on either side of the snugger near

the rear and move it back

and forth to fit your needs.

Spillproof Shelves and Freezer Shelves

The special edges are designed to help prevent

spills from dripping to lower shelves.

To remove shelves:

Tilt shelf up at front, then lift it up and out of

tracks on rear wall of refrigerator.

To replace shelves:

Select desired shelf height. With shelf front

raised slightly, engage top lugs in tracks at rear

of cabinet. Then lower front of shelf until it locks

into position.

Make sure you push the shelves all the way

back in before you close the door.

Top freezer bin

7

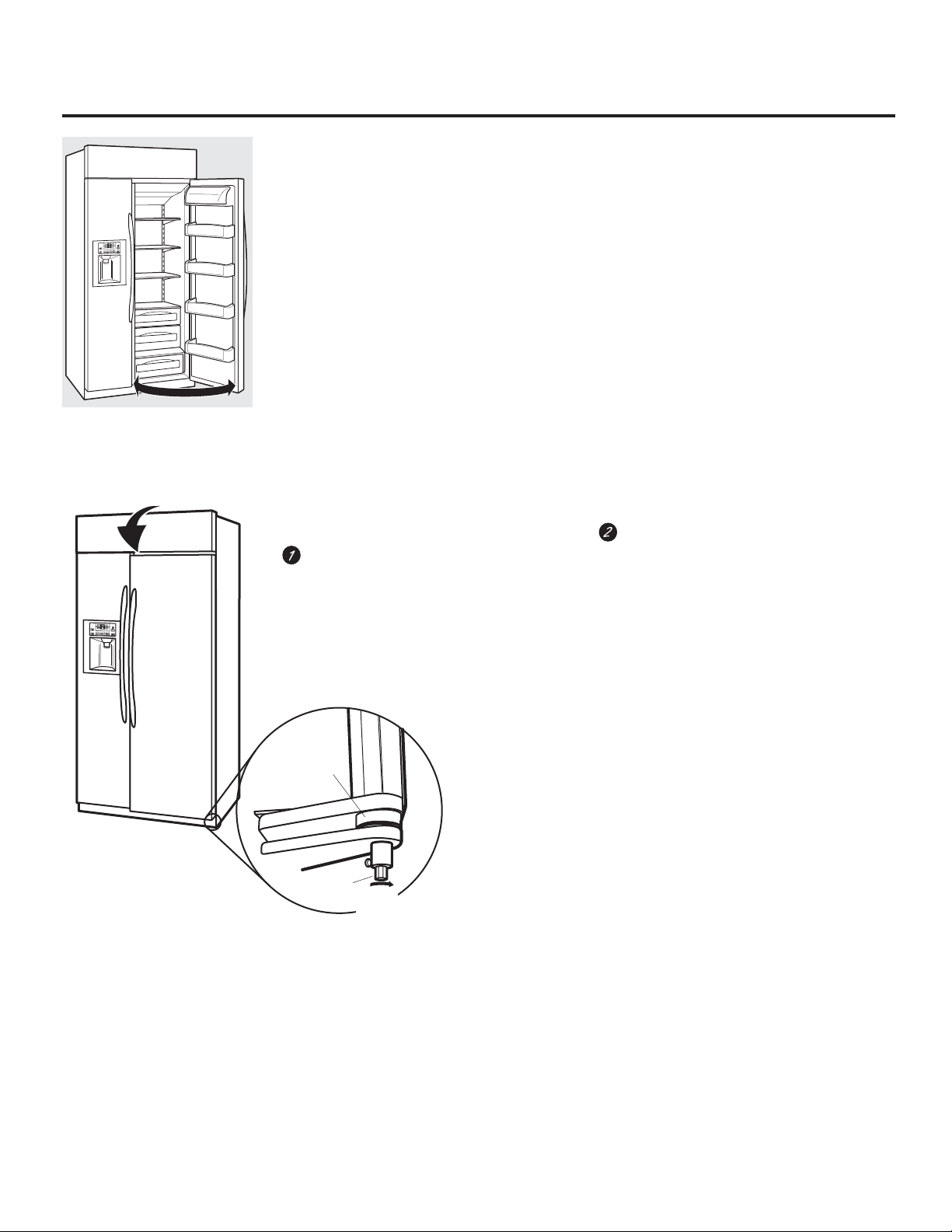

About the refrigerator doors.

Refrigerator Doors

When the door is at 90° open,

it will automatically close.

Beyond this stop the door will stay open.

The refrigerator doors may feel different than

the ones you are used to. The secure door

opening/closing feature makes sure the doors

close all the way and are securely sealed.

When opening and closing the door,

you will notice a stop position. When

the door is at the 90° stop position,

it will automatically close.

Door Alignment

If doors are uneven, adjust the refrigerator door.

Using a 7/32” socket wrench, turn the door

adjusting screw clockwise to raise the

door, counterclockwise to lower

the door. (A nylon plug, imbedded in the

threads of the pin, prevents the pin from

turning unless a wrench is used.)

The resistance you feel at the stop

position will be reduced as the door

is loaded with food.

After one or two turns of the wrench, open

and close the refrigerator door

and check the alignment at the top

of the doors.

Bushing

Door Hinge

Case Hinge

7/32" Wrench

Raise

Clockwise

8

About the drawers and baskets. GEAppliances.com

Not all features are on all models.

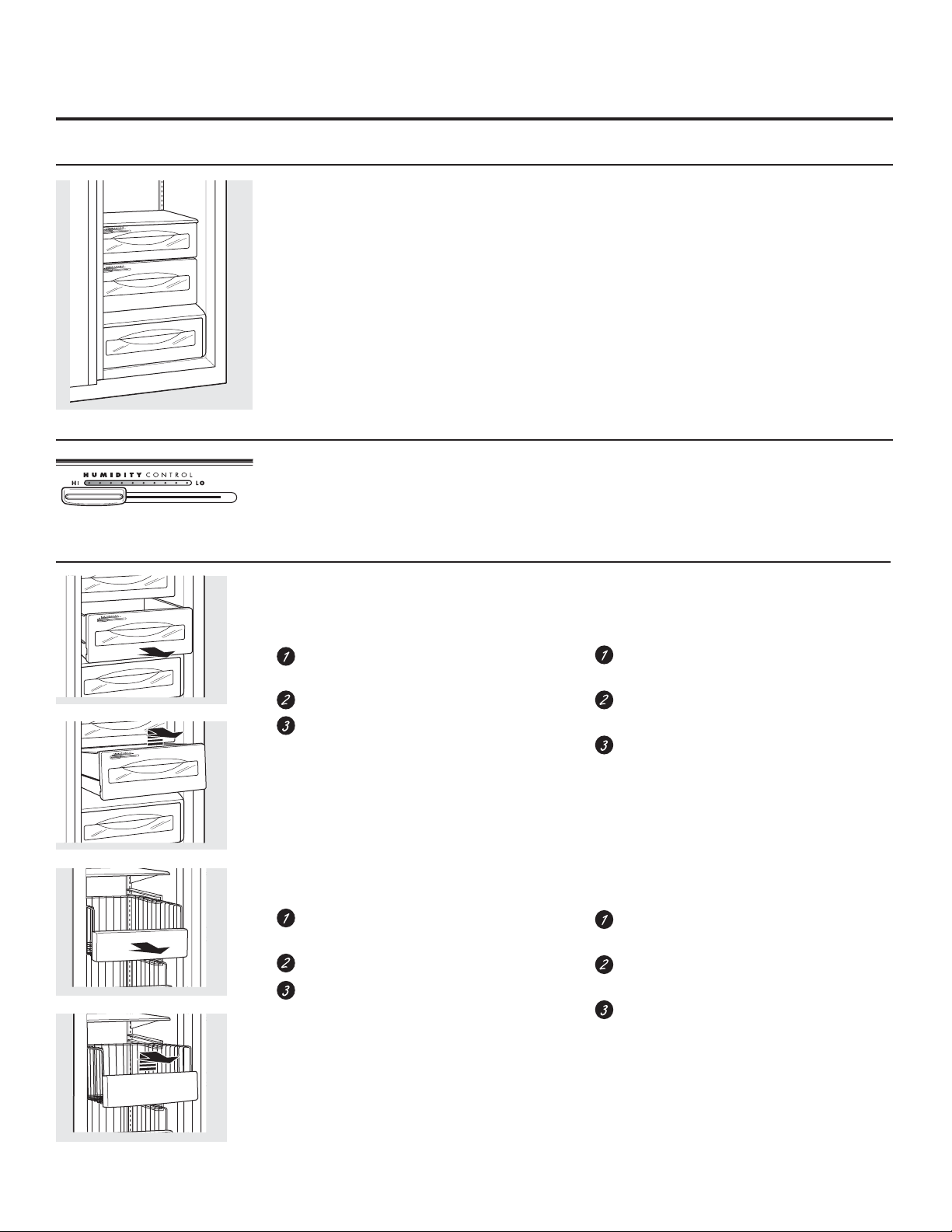

Fruit and Vegetable Drawers

Excess water that may accumulate in the

bottom of the drawers should be wiped dry.

Adjustable Humidity Drawers

Slide the control all the way to the HI setting to

provide high humidity recommended for most

vegetables.

Slide the control all the way to the LO

setting to provide lower humidity levels

recommended for most fruits.

How to Remove and Replace the Drawers and Freezer Baskets

To remove fresh food drawers:

Pull the desired drawer out to the

stop position.

Lift up slightly on the front of the drawer.

Pull the drawer slightly forward and

out of the refrigerator.

To remove freezer baskets:

Pull the desired basket out to the

stop position.

Lift up slightly on the front of the basket.

Pull the basket slightly forward and

out of the freezer.

To replace fresh food drawers:

Tip the back rollers of the drawer behind the

rollers in the track.

Lower the front of the drawer into normal

position.

Slide the drawer to the back of the

refrigerator.

To replace freezer baskets:

Place the back corners in the rail

with the basket tilted up.

Lower the basket down to the normal

position.

Slide the basket to the back of the freezer.

9

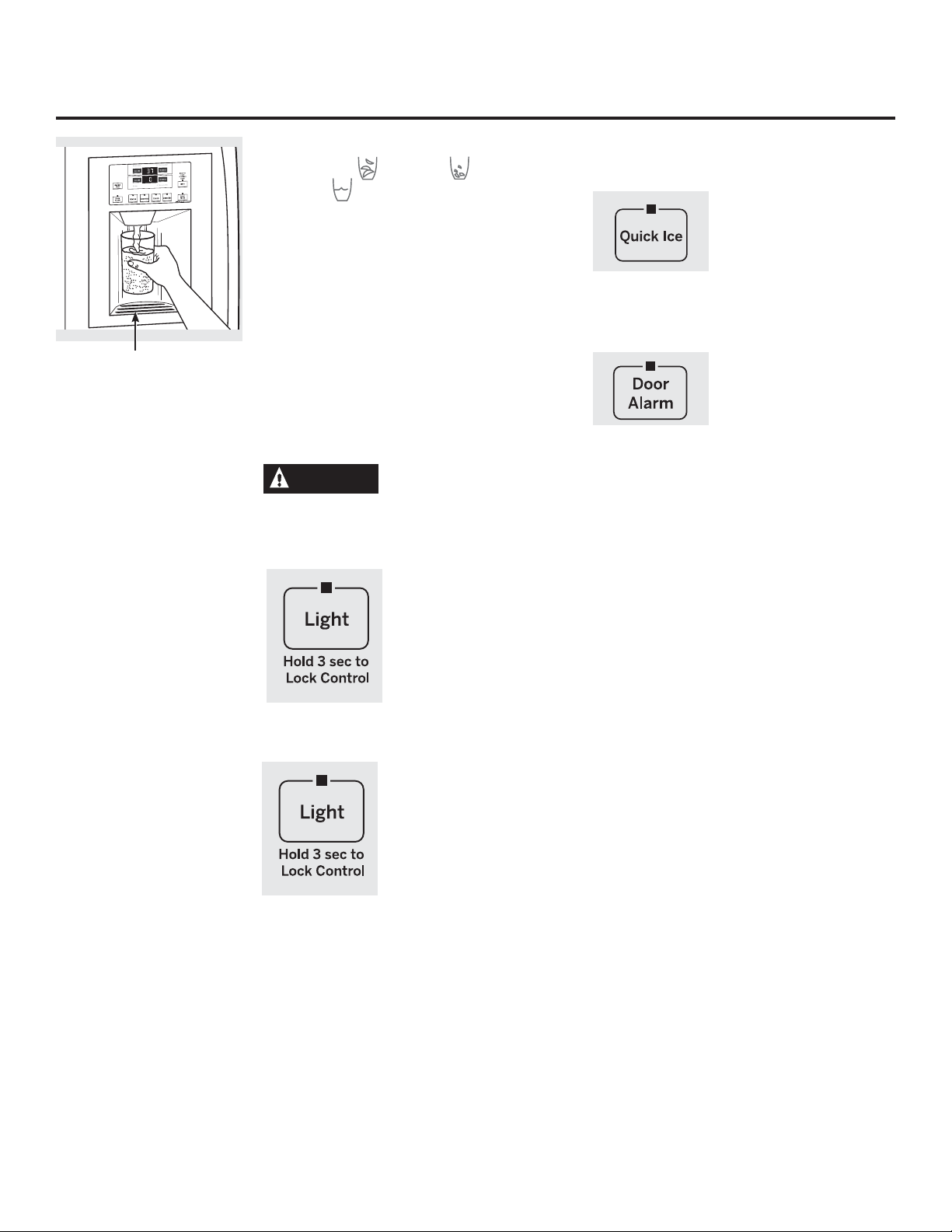

About the ice and water dispenser and automatic icemaker.

A newly installed refrigerator may take 12 to 24 hours to begin making ice.

Ice Storage

Bin

Access Door

Rotate

Drive

Mechanism

Ice Storage Bin

To remove:

Lift up the access door to reach the

icemaker. Set the icemaker power switch

to the O (off) position. With the access door

closed, support the storage bin at

the bottom while slightly lifting. Pull bin

straight out.

To replace:

Slide the bin back until the tab on

the bin locks into the slot on the shelf.

If the bin does not go all the way back,

remove it and rotate the drive mechanism 1/4

turn. Then push the bin back again.

Important facts about your

ice and water dispenser

Do not add ice from trays or bags to the

storage bin. It may not crush or dispense well.

Avoid overfilling glass with ice and use of

narrow or extra-tall glasses. Backed-up ice

can jam the chute or cause the door in the

chute to freeze shut. If ice is blocking the

chute, poke it through with a wooden spoon.

Beverages and foods should not be

quick-chilled in the ice storage bin.

Cans, bottles or food packages in the storage

bin may cause the icemaker

or auger to jam.

To keep dispensed ice from missing

the glass, put the glass close to, but not

touching, the dispenser opening.

Some crushed ice may be dispensed

even though you selected CUBED. This

happens occasionally when a few cubes

accidentally get directed to the crusher.

After crushed ice is dispensed, some water

may drip from the chute.

The first glass of water dispensed may

be warmer than the following ones.

This is normal.

Green Power

Light

Power

Switch

Feeler Arm

Ice maker

Automatic Icemaker

CAUTION

moving parts of the ejector mechanism, or with

the heating element (located on the bottom of

the ice maker) that releases the cubes. Do not

place fingers or hands on the automatic ice

making mechanism while the refrigerator is

plugged in.

A newly-installed refrigerator may take 12–24

hours to begin making ice.

The icemaker will produce seven cubes per

F\FOH³DSSUR[LPDWHO\F\FOHVRUPRUHLQ

a 24-hour period, depending on freezer

compartment temperature, room temperature,

number of door openings

and other use conditions.

If the refrigerator is operated before the water

connection is made to the icemaker, set the

power switch to O (off).

When the refrigerator has been connected to

the water supply, set the power switch to I (on).

The green light will come on.

Avoid contact with the

Throw away the first full bucket of ice.

Be sure nothing interferes with the sweep of the

feeler arm.

When the bin fills to the level of the feeler arm,

the icemaker will stop producing ice.

It is normal for several cubes to be joined

together.

If ice is not used frequently, old ice cubes will

become cloudy, taste stale and shrink.

After the icemaker has been turned on again,

there will be a delay of about 45 minutes before

the icemaker resumes operations.

NOTE: In homes with lower-than-average water

pressure, you may hear the icemaker water

valve cycle on several times when making one

batch of ice. Recommended water pressure is

60 psi.

10

About the ice and water dispenser. GEAppliances.com

To Use the Dispenser

Spill Shelf

Select CUBED , CRUSHED

or WATER .

Press the glass gently against the middle of the

dispenser pad.

The spill shelf is not self-draining. To reduce

water spotting, the shelf and its grille should be

cleaned regularly.

If no water is dispensed when the

refrigerator is first installed, there may

be air in the water line system. Press the

dispenser arm for at least two minutes to

remove trapped air from the water line

and to fill the water system. To flush out

impurities in the water line, throw away the

first six glassfuls of water.

CAUTION

other objects into the ice crusher discharge

opening.

Never put fingers or any

Locking the Dispenser

Press the LIGHT button

for 3 seconds to lock the

dispenser and control

panel. To unlock, press and

hold the button again for 3

seconds.

Quick Ice

Door Alarm

When you need ice in a

hurry, press this button to

speed up ice production.

This will increase ice

production for the following

48 hours or until you

press the button again.

To turn the Door

Alarm on, press the

DOOR ALARM button

once. The ACTIVE light will

come on. To turn it off,

press it again. When the

DOOR ALARM is active, the

ACTIVE light will flash if you

open the door and beep

if you keep the door open

for more than 2 minutes.

The light goes out and the

beeping stops when you

close the door.

Dispenser Light

This button turns the light on

the dispenser on and off. The

light also comes on when the

dispenser pad is pressed. If

this light burns out, it should

be replaced with a 6 watt

12V maximum bulb.

11

Care and cleaning of the refrigerator.

Cleaning the Outside

Dispenser drip area.

The spill shelf and the area beneath it should

be cleaned periodically with a mild liquid dish

detergent.

Dispenser pad. Before cleaning, lock the

dispenser by pressing the LOCK/LIGHT

button for 3 seconds to prevent activating the

dispenser. Clean with warm water and a mild

liquid dish detergent. Rinse thoroughly and wipe

dry. Unlock the dispenser by pressing the LOCK/

LIGHT button for 3 seconds.

Door handles. Clean with a cloth dampened

with soapy water. Dry with a soft cloth.

Do not wipe the refrigerator with a soiled dish

cloth or wet towel. These may leave a residue

that can damage the finish. Do not use scouring

pads, powdered cleaners, bleach or cleaners

containing bleach because these products can

scratch and damage the finish.

Cleaning the Inside

Turn off power at the circuit breaker or fuse

box before cleaning. If this is not practical,

wring excess moisture out of sponge or cloth

when cleaning around switches, lights or

controls.

8VHZDUPZDWHUDQGEDNLQJVRGDVROXWLRQ³

about a tablespoon (15 ml) of baking soda

to a quart (1 liter) of water. This both cleans and

neutralizes odors. Thoroughly rinse and wipe

dry.

The stainless steel doors and door handles

(on some models) can be cleaned with a

commercially available stainless steel cleaner.

Cleaners with oxalic acid such as Bar Keepers

Friend Soft Cleanser™ will remove rust, tarnish

and small blemishes. Use only a liquid cleanser

free of grit and rub in the direction of the brush

lines with a damp soft sponge. Do not use

appliance wax or polish on the stainless steel.

Other parts of the refrigerator, including door

gaskets, snack pan and vegetable drawers, ice

storage bin and all plastic parts, can be cleaned

the same way.

Do not wash the tray or any plastic refrigerator

parts in the dishwasher.

CAUTION

or covers with warm water when they are

cold. Glass shelves and covers may break

if exposed to sudden temperature changes

or impact, such as bumping or dropping.

Tempered glass is designed to shatter into

many small pieces if it breaks.

Do not clean glass shelves

12

GEAppliances.com

Preparing for Vacation

For long vacations or absences, remove

food and unplug the refrigerator. Clean

the interior with a baking soda solution of one

tablespoon (15 ml) of baking soda to one quart

(1 liter) of water. Leave the doors open.

Set the icemaker power switch to the O (off)

position and shut off the water supply to

the refrigerator.

Preparing to Move

Secure all loose items such as shelves and

drawers by taping them securely in place

to prevent damage.

WARNING

of this refrigerator, and to reduce the risk of

personal injury or damage to the product,

A MINIMUM OF 4 PEOPLE ARE REQUIRED

TO BRING THE UNIT INTO THE HOME AND

2 PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

Be sure the refrigerator stays in an upright

position during moving.

Due to the weight and size

If the temperature can drop below freezing,

have a qualified servicer drain the water supply

system to prevent serious property damage

due to flooding.

13

Replacing the light bulbs.

Setting the controls to OFF does not remove power to the light circuit.

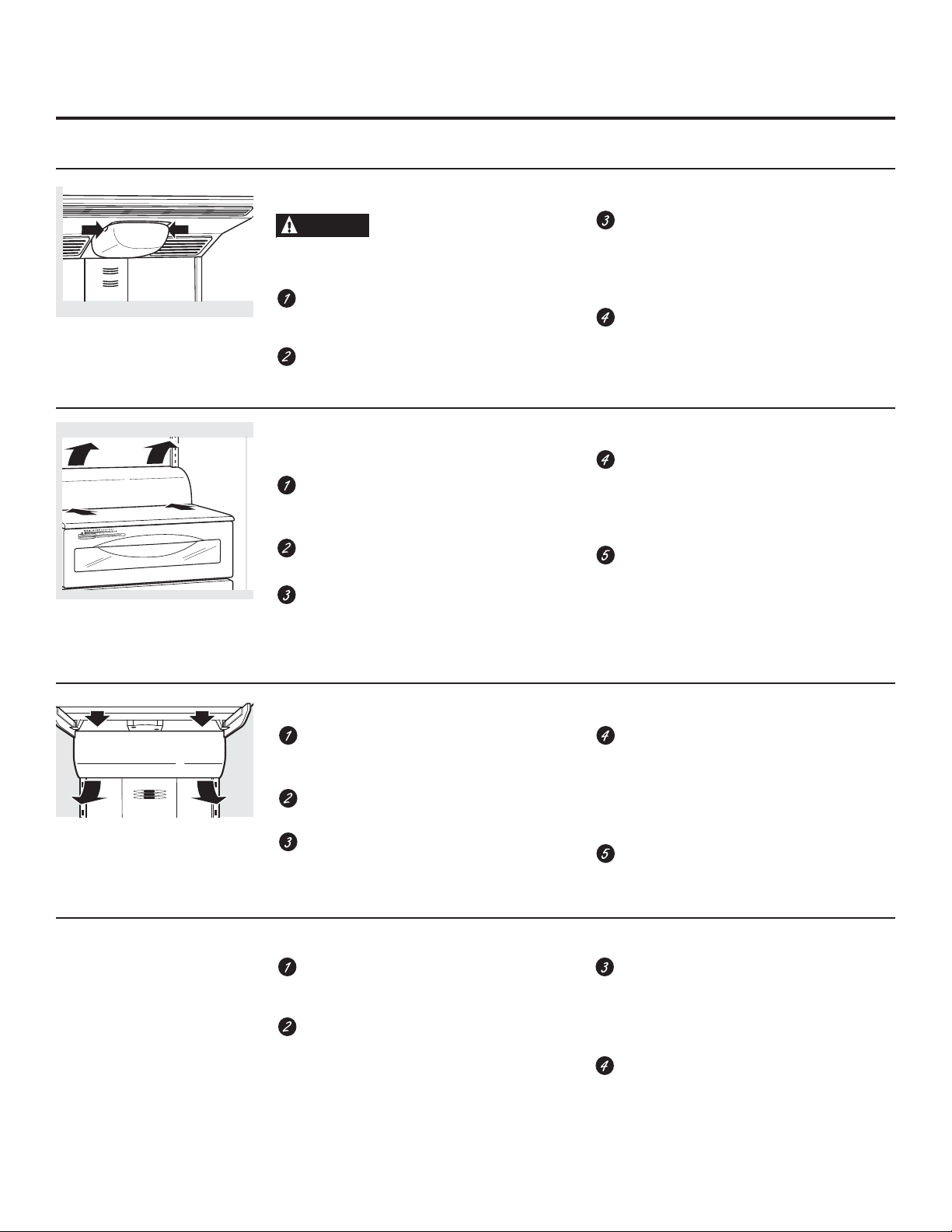

5HIULJHUDWRU&RPSDUWPHQW³8SSHU/LJKW

(appearance may vary)

CAUTION

Burned out bulbs may break when being

replaced.

Raise the grille panel, set the master power

switch to the O (off) position and allow

lamps to cool.

To remove the light shield, press on the

sides of the shield and pull down.

5HIULJHUDWRU&RPSDUWPHQW³/RZHU/LJKW

This light is located above the top drawer.

Raise the grille panel, set the master power

switch to the O (off) position

and allow lamps to cool.

Remove items from the shelf above

the light shield. Remove the shelf.

Use both hands to grasp each end

of the light shield. Press in on the bottom of

the shield with your thumbs while rotating

the cover up and out.

Light bulbs may be hot.

Replace the bulbs with appliance bulbs of

the same or lower wattage. Replace the

shield by engaging the bottom tab into the

slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Replace the bulb with an appliance bulb of

the same or lower wattage. Replace the

shield by engaging the bottom tab into the

slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Freezer Compartment

Raise the grille panel, set the master power

switch to the O (off) position and allow

lamps to cool.

Remove the items from the shelf just below

the light shield. Remove the shelf.

To remove the light shield, press down on

the top of the shield and pull the tabs out of

the slots. Tilt the shield forward and out.

Dispenser

Raise the grille panel, set the master power

switch to the O (off) position

and allow lamps to cool.

The bulb is located in the dispenser under

the control panel. Remove

the two screws from the light shield.

Slide the light shield toward the dispenser

to disengage the tabs, then remove the

light shield. Remove the light bulb by

turning it counterclockwise.

Replace the bulb with an appliance

bulb of the same or lower wattage,

and reinstall the light shield. Replace

the shield by engaging the bottom tab into

the slot and applying light forward pressure

until the shield snaps in place.

Set the master power switch to the I (on)

position and close the grille panel.

Replace the bulb with a bulb

of the same size and wattage. Replace

the light shield by sliding the tabs into

the slots in the front of the dispenser.

Replace the two screws.

Set the master power switch to the I (on)

position and close the grille panel.

14

Installation

Built-In Side-By-Side

Refrigerators

Instructions

If you have questions, call 800.GE.CARES (800.432.2737) or visit our website at: GEAppliances.com

In Canada, call 1.800.561.3344 or visit our website at: www.geappliances.ca

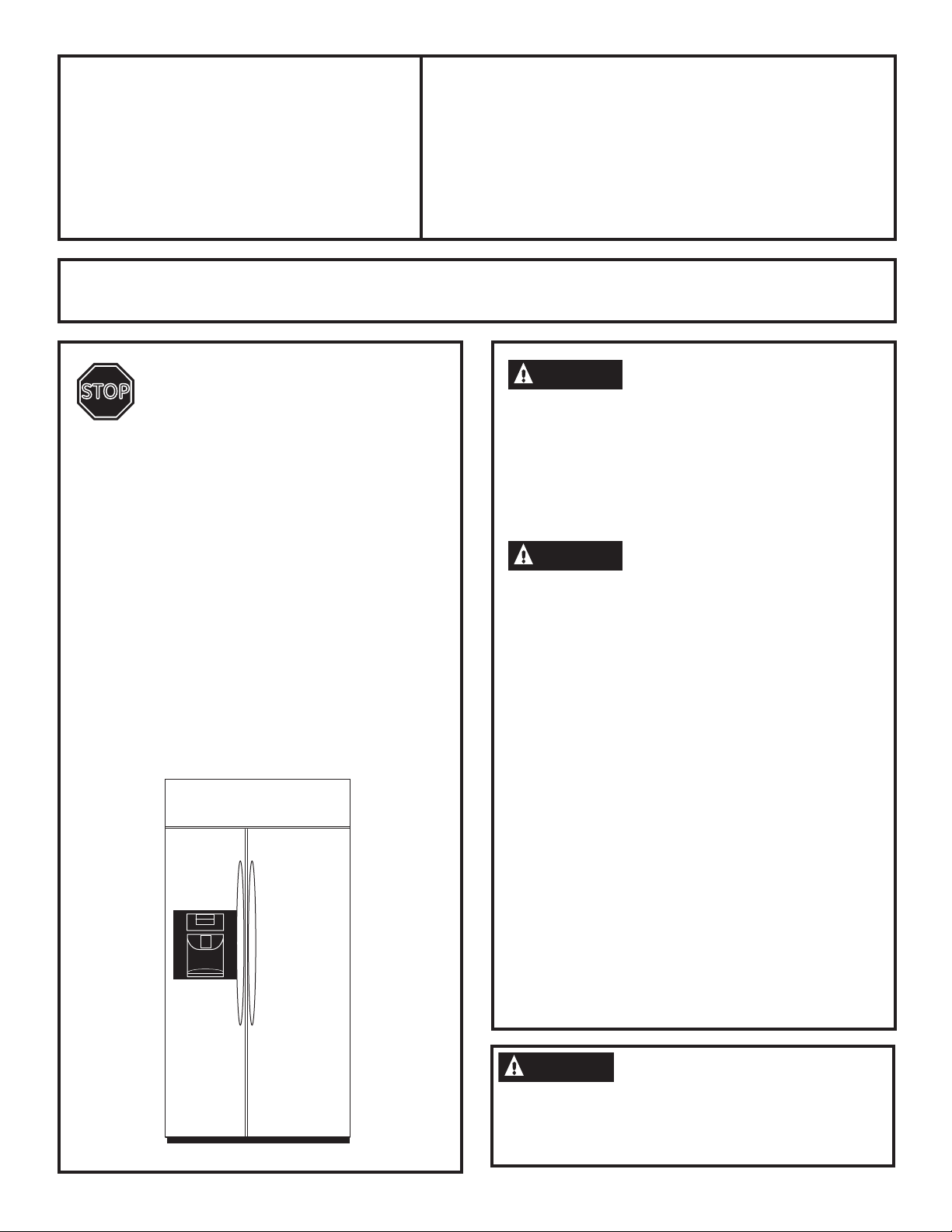

BEFORE YOU BEGIN

STOP

•

IMPORTANT ³ Observe all governing

codes and ordinances.

•

Note to Installer – Be sure to leave these

LQVWUXFWLRQVIRUWKHFRQVXPHU·VDQGORFDO

LQVSHFWRU·VXVH

•

Note to Consumer – Keep these instructions

ZLWK\RXU2ZQHU·V0DQXDOIRUIXWXUHUHIHUHQFH

•

Skill Level – Installation of this refrigerator

requires basic mechanical, carpentry and

plumbing skills. Proper installation is the

responsibility of the installer. Product failure

due to improper installation is not covered

under the GE Appliance Warranty.

See warranty information.

•

Completion Time – 90 minutes (new installations

require more time than replacement installations).

Read these instructions completely

and carefully.

PSB42YS, PSB42YG, PSB48YS, PSB48YG

WARNING

Due to the weight and size of this refrigerator,

and to reduce the risk of personal injury or

damage to the product, A MINIMUM OF 4 PEOPLE

ARE REQUIRED TO BRING THE UNIT INTO THE

HOME AND 2 PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

WARNING

• These refrigerators are top-heavy and must

be secured to prevent the possibility of tipping

forward. Anti-Tip protection is required.

See Step 4 on page 34 for details.

• Use this appliance only for its intended purpose.

• Immediately repair or replace electric power

supply cords that become frayed or damaged.

• Set the Master Power switch to the O (OFF)

position before cleaning or making repairs.

• Repairs should be made by a qualified service

technician.

For GE Profile

call 1.800.432.2737.

For GE Profile service in Canada,

call 1.800.561.3344.

For GE Profile Parts and Accessories,

call 1.800.626.2002.

GEAppliances.com (in Canada, geappliances.ca)

™

local service in your area,

READ CAREFULLY.

KEEP THESE INSTRUCTIONS.

WARNING

To reduce the risk associated with choking, do

not allow children under 3 years of age to have

access to small parts during the installation of this

product.

15

Installation Instructions

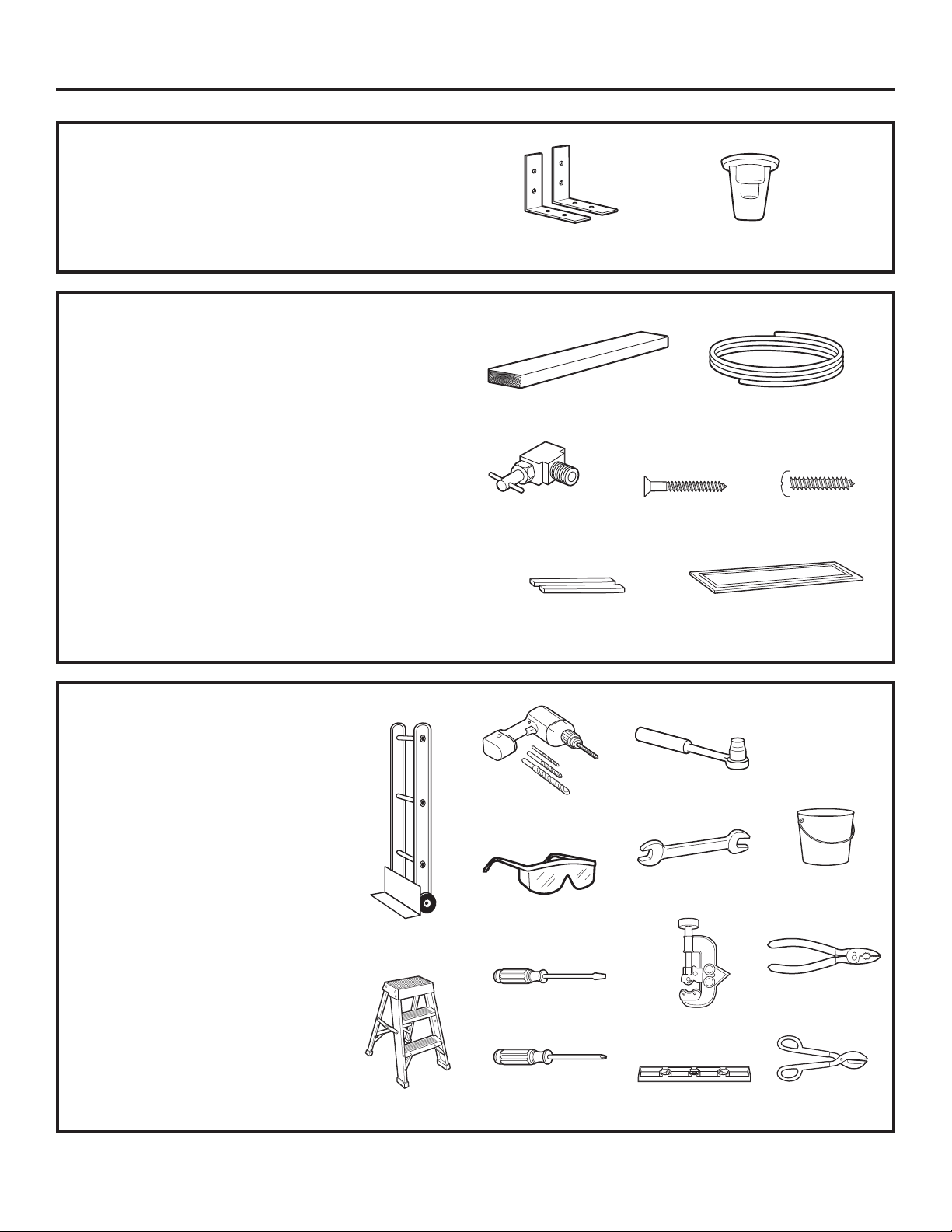

HARDWARE SUPPLIED

• Water filter bypass plug

• Anti-Tip brackets

MATERIALS REQUIRED

• 36” long, 2” x 4” wood block for Anti-Tip bracket

installation

• #12 or #14 wood screws for Anti-Tip bracket

• Screws to secure refrigerator to cabinets

• 1/4” O.D. copper water line tubing or GE

SmartConnect

• Water shutoff valve

• Custom panels for doors and grille panel

(if installing custom panels)

• Special 3M Dual Lock adhesive strips for

1/4” side panels (if installing side panels)

™

refrigerator tubing kits

Anti-Tip Brackets Water Filter Bypass Plug

36” Wood Block 1/4” O.D. Copper Water Line

Water Shutoff

Valve

#12 or #14

Wood Screws

Tubing or GE SmartConnect™

Refrigerator Tubing Kit

Screws

TOOLS REQUIRED

• Tinsnips to cut banding

• Stepladder

• Bucket

• Level

• Appliance dolly

• Tubing cutter

• Flathead screwdriver

• 1/2” open-end wrench

• #2 Phillips screwdriver

• Drill and appropriate bits

• 7/32”, 1/2” sockets

• Safety glasses

• 7/16” open-end wrench

• Pliers

Appliance Dolly

Special 3M Dual Lock

Adhesive Strips

Drill & Bits

Safety Glasses

Flathead

Screwdriver

Sockets

Open-end

Wrenches

Tubing Cutter

Custom Panels

Bucket

Pliers

Stepladder

16

Phillips Head

Screwdriver

Level

Tinsnips

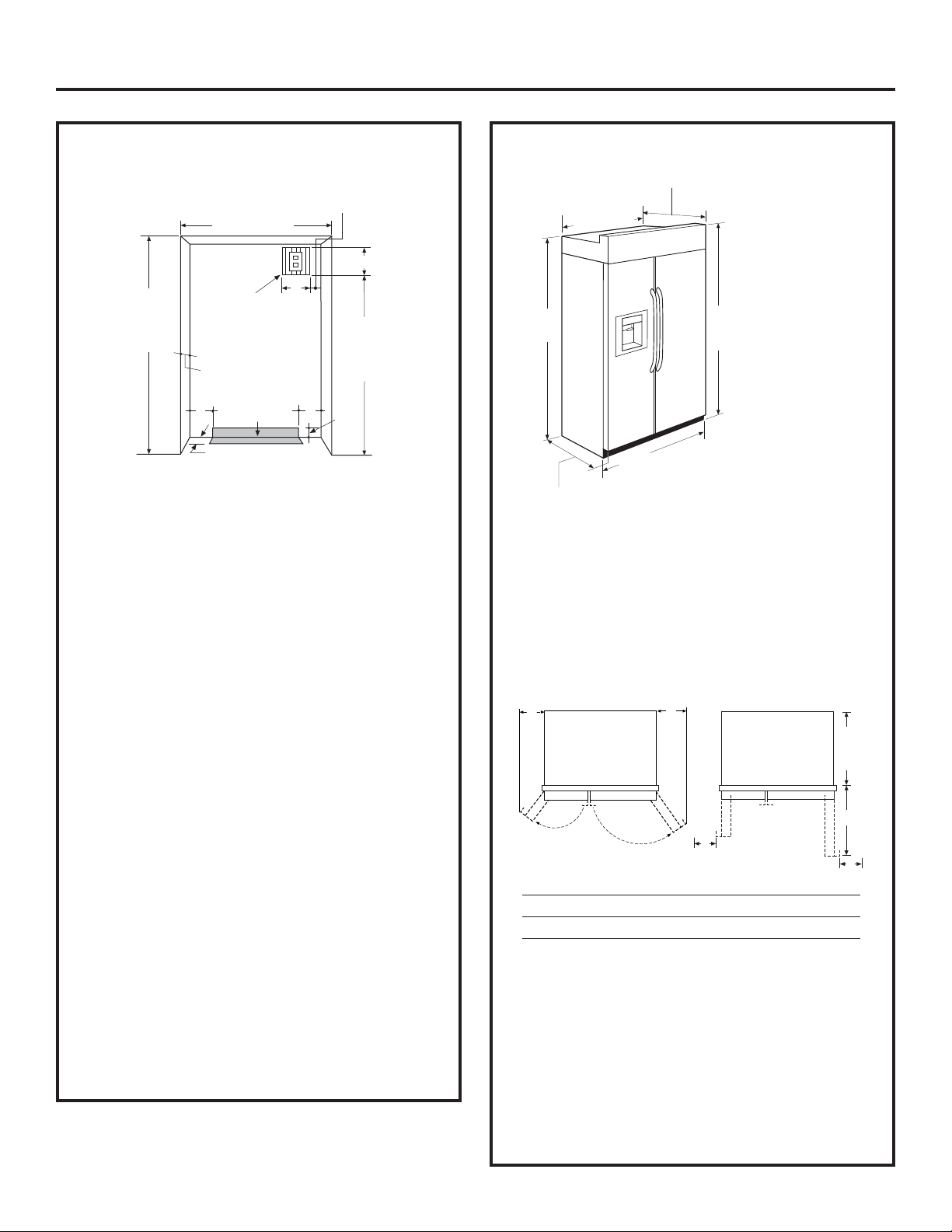

THE INSTALLATION SPACE

Installation Instructions

DIMENSIONS AND CLEARANCES

3"

*Finished Width

7"

84 1/2" max

83 1/2" min

Finished

Opening

Electrical

Area

24"

5"

Water Supply

3 1/2"

7"

74"

From Floor

to Bottom

of Electrical

5"

3 1/2"

*The finished cutout width must be: 41-1/2”

for 42” models and 47-1/2” for 48” models

Water and Electrical Locations

The opening must be prepared with the electrical

and water supply located as shown.

The cutout depth must be 24”

The refrigerator will project forward, slightly

beyond adjacent cabinets, depending on your

installation.

Additional Specifications

• A 120 volt, 60Hz, 15 or 20 amp power supply

is required. An individual properly grounded

branch circuit or circuit breaker is

recommended. Install a properly grounded

3-prong electrical receptacle recessed into

the back wall. Electrical must be located on

rear wall as shown.

Note: GFI (ground fault interrupter) is not

recommended.

• Water line can enter the opening through the

floor or rear wall. The water line installed should

be 1/4” O.D. copper tubing or GE SmartConnect

tubing between the cold water line and water

connection location. The line should be long

enough to extend to the front of the refrigerator.

Installation of an easily accessible shutoff valve

in the water line is required.

*81-3/4"

at Rear

Depth Including

Handles 26-7/8"

25-3/8" Case Depth

**Case Width

*84" From

Floor to

Top Frame

42" Frame-to-Frame for 42" Models

48" Frame-to-Frame for 48" Models

*Shipping height

The front height

may be adjusted

from 83-1/2” to

84-1/2” by adjusting

front and rear

leveling legs a

maximum of 1”.

**The case width must be: 41” for 42”

models and 47” for 48” models

Product Clearances

These refrigerators are equipped with a 2 position

door stop. The factory set 130° door swing can be

adjusted to 90° if clearance to adjacent cabinets

or walls is restricted.

130° Door Swing 90° Door Swing

A

B

23-7/8“

Behind

Frame

C

D

D

Models A B C D

42” 12-3/16” 16” 24” 5”

48” 13-7/16” 18-9/16” 28” 5”

Allow minimum clearances for Freezer door

™

(Dimension A) and Fresh Food door (Dimension B)

for a full 130° door swing and to allow for drawer

removal.

Four inch (4”) minimum clearance is required when

door swing is adjusted to 90°. If the 90° door stop

position is used, drawer access is maintained, but

drawer removal is restricted.

See illustrations, pages 18 and 19, to determine

door swing interaction with adjacent cabinets or

countertops.

17

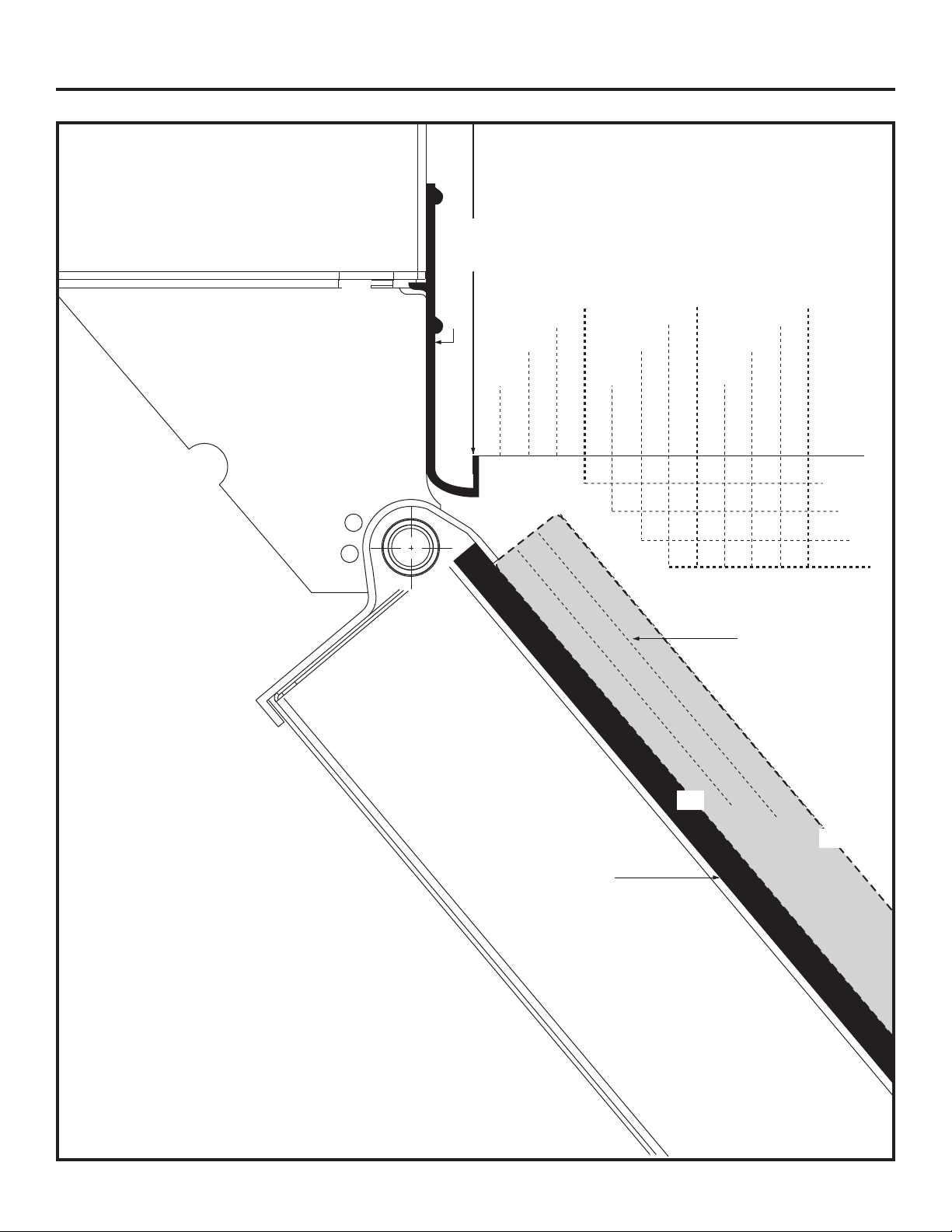

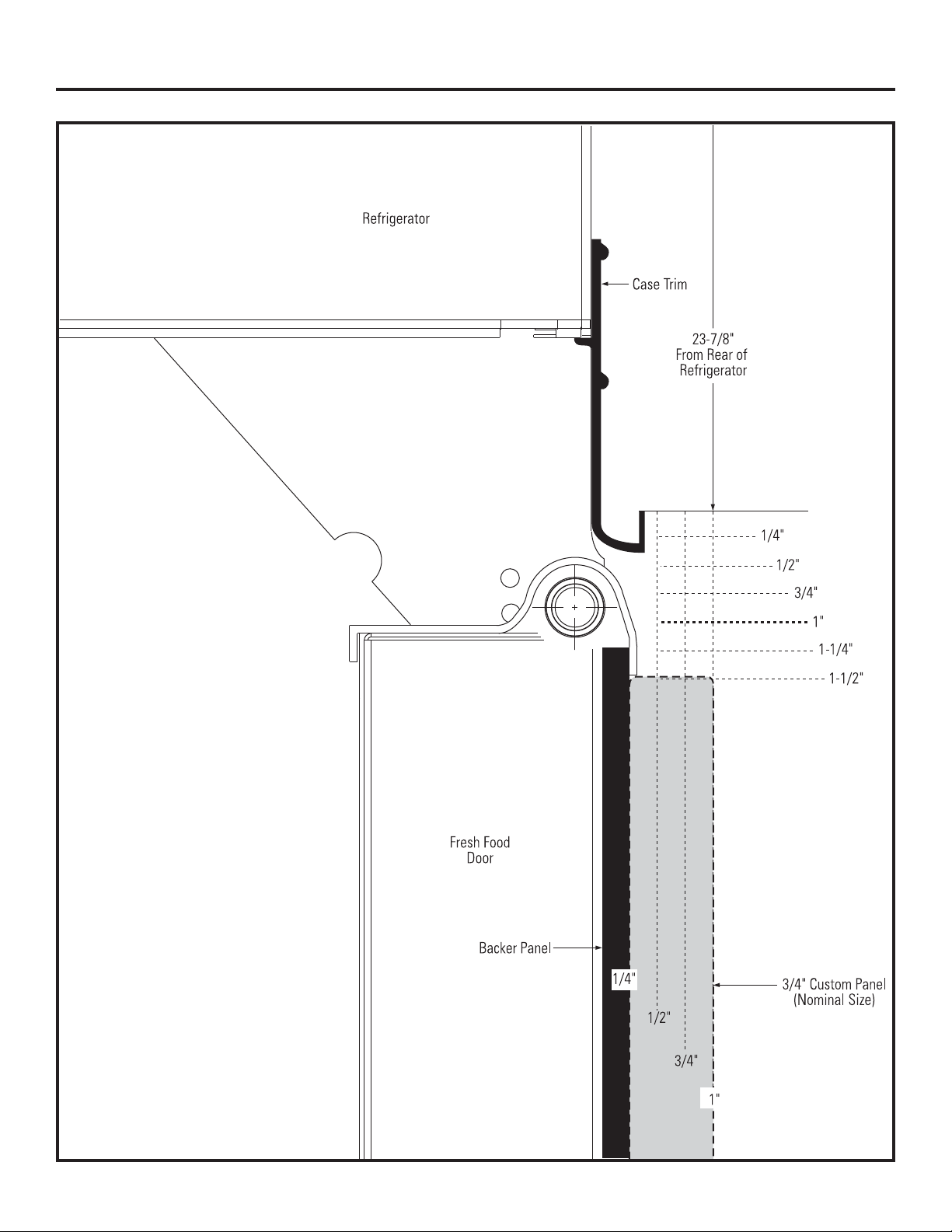

Installation Instructions

Refrigerator

23-7/8" From

Rear of

Refrigerator

Case

Trim

1/4"

1/2"

3/4"

1"

1-1/4"

1-1/2"

1-3/4"

2"

3"

2-3/4"

2-1/2"

2-1/4"

1/4"

1/2"

3/4"

1"

3/4" Custom Panel

(Nominal Size)

Top View

130° Door Swing

(factory setting)

Scale 1:1

Fresh Food

Door

18

Backer Panel

1/4"

1/2"

3/4"

1"

Installation Instructions

Top View

90° Door Swing

(optional setting)

Scale 1:1

19

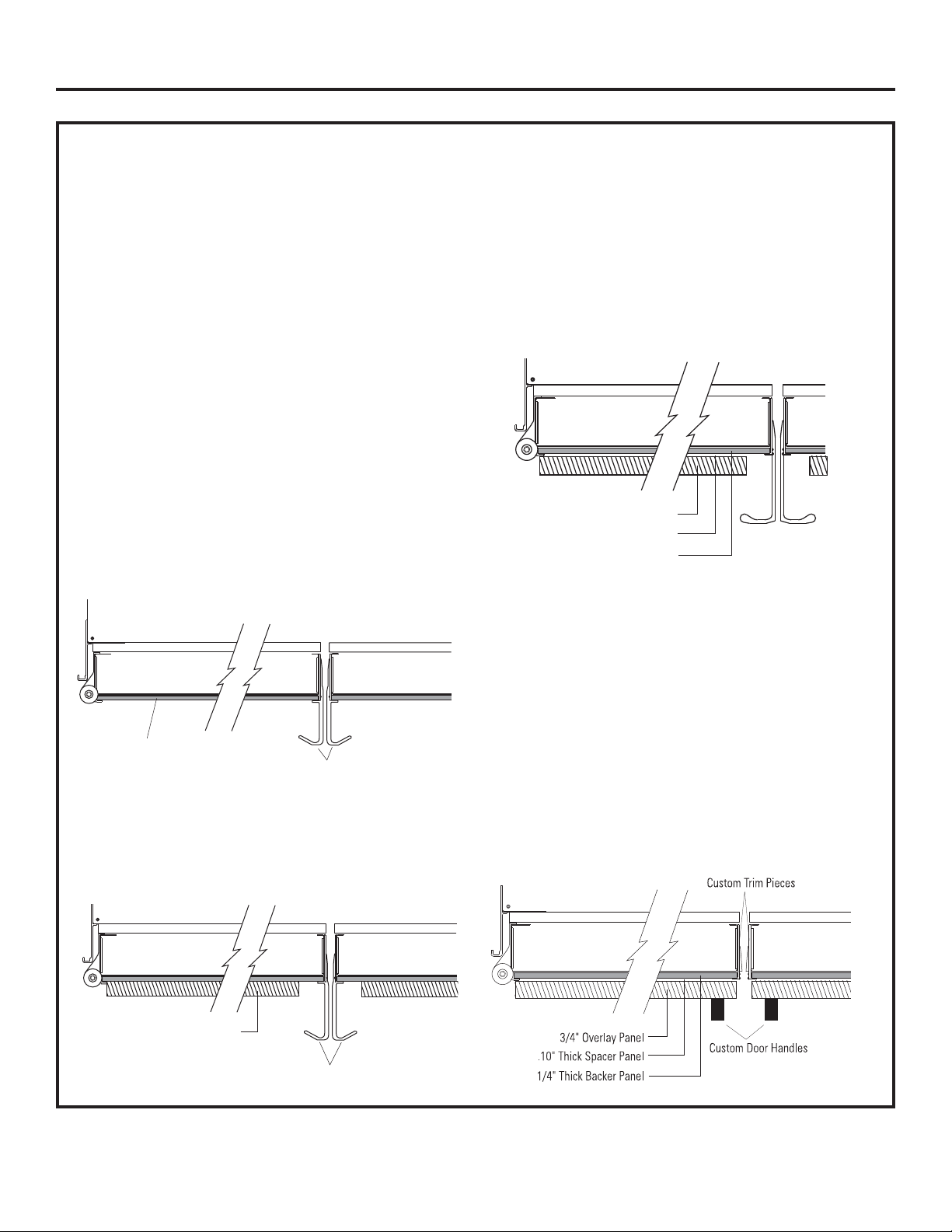

Installation Instructions

CUSTOMIZATION BASICS:

Stainless Steel Wrapped Models

42”ZLGHPRGHO³36%<6

48”ZLGHPRGHO³36%<6

Stainless Steel wrapped refrigerators have wrapped

doors and grille panels, and beveled edges. These

models are shipped ready for installation.

Trimmed Models

42”ZLGHPRGHOV³36%<*

48”ZLGHPRGHOV³36%<*

Trimmed refrigerators are designed to be

customized with decorative panels. Field installed

custom door and grille panels are required. Panels

can be framed or full-width and can use either the

pre-installed handles or custom handles provided

by your cabinet manufacturer.

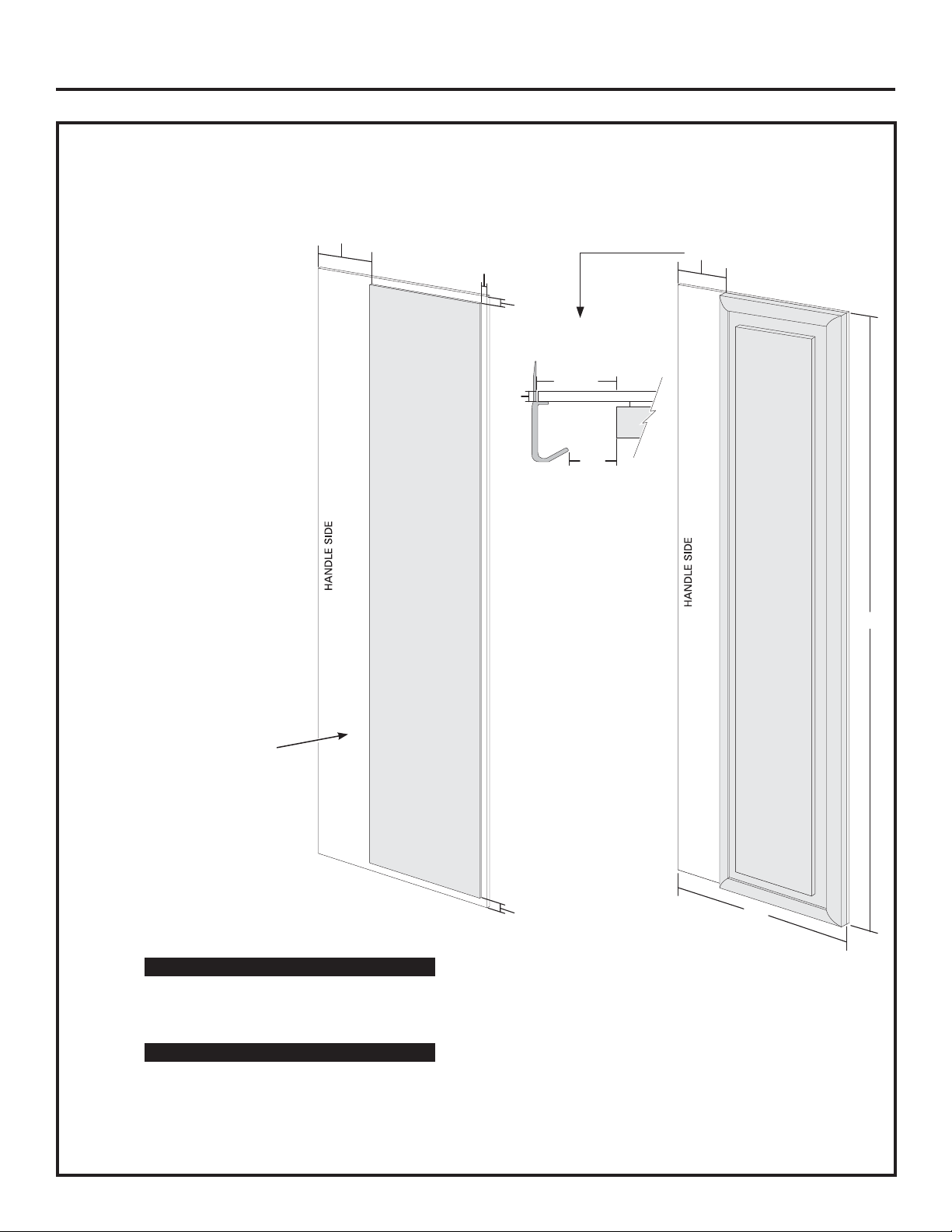

Framed Custom Panels

<RXPD\LQVWDOOFXVWRPSDQHOVIURP\RXUFDELQHW

manufacturer. The decorative panel slides into

the factory installed trim. A 1/4” finished panel

can be used.

Framed Panel

Door Handles

<RXPD\LQVWDOOD” panel attached to a 1/4”

backer panel. If the pre-installed door handles are

used, the backer panel will be exposed by the handle

and therefore must be finished (page 24). Custom

handles can also be used.

Full-Width Overlay Custom Panels

Full-width overlay custom panels are designed

to slide into the factory-installed trim, no kits

required. In this design, you can achieve a nearly

trimless appearance.

A 0.10” spacer panel must be installed between

the finished 1/4” backer panel and 3/4”

appearance panel. If the pre-installed door

handles are used, the backer panel will be

exposed near the handle and therefore

must be finished (page 24).

3/4" Overlay Panel

.10" Thick Spacer Panel

1/4" Thick Backer Panel

Door Handles

The pre-installed handles can accommodate

both framed or overlay panels. Custom handles of

your choice, supplied by your cabinet maker, can

be installed only on 3/4” overlay panels. When

installing custom handles, measure to ensure

the mounting for the handles selected will clear

the dispenser when installed on the freezer door.

Handles need to mount on the upper and lower

wood panels of the freezer door and not

on the dispenser. If a custom handle is used, only

the 3/4” overlay panel must be exposed, and the

custom trim pieces should be installed (page 38).

3/4" Custom Panel

Door Handles

20

Installation Instructions

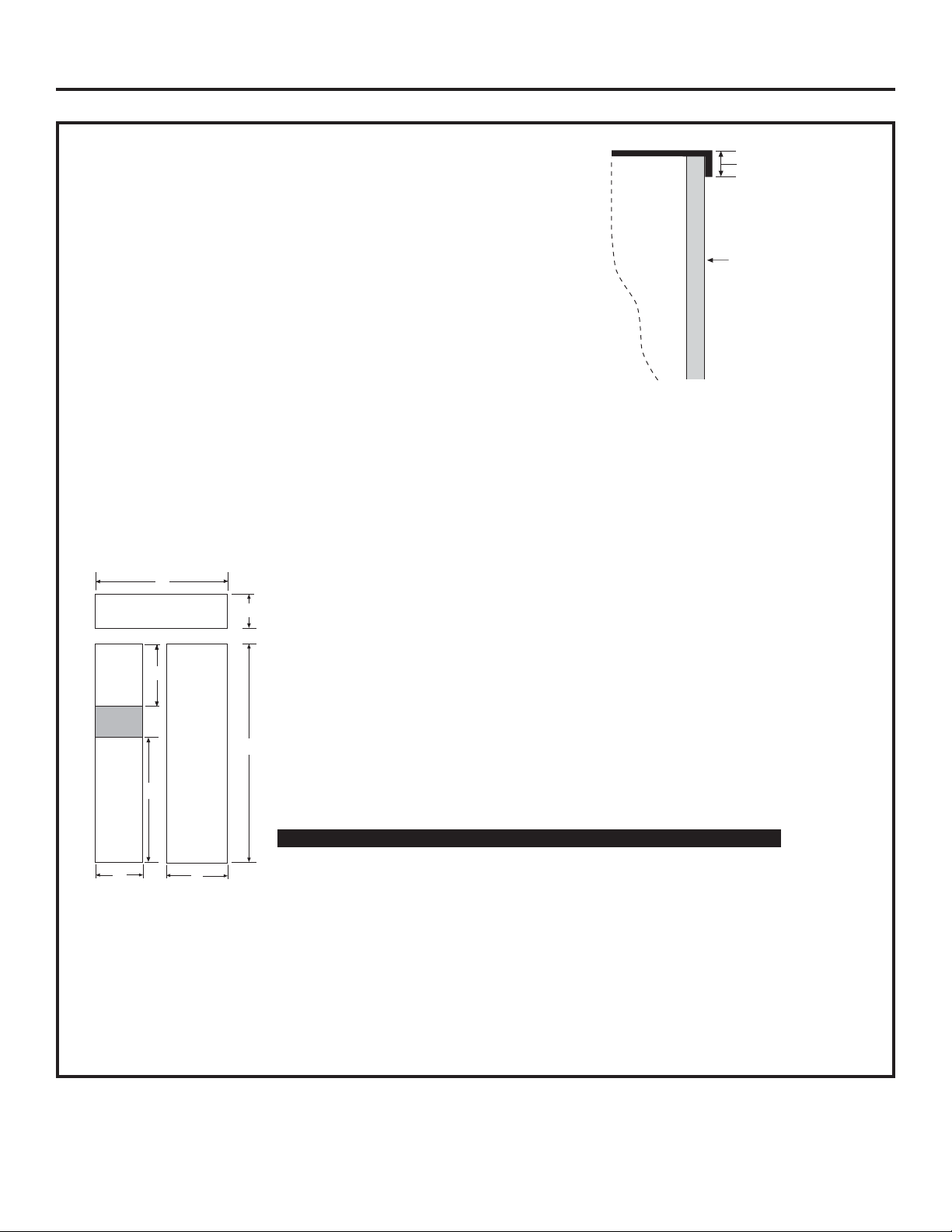

1/4” FRAMED PANEL DIMENSIONS

If you choose to install framed panels, they must be

cut to the dimensions shown. The panels will slide

into the frame on the doors and grille.

A

Grille Panel

B

5/16"

Door

Trim

Reveal

1/4"

Panel

IMPORTANT NOTE: Maximum weight

is 70 pounds for the Fresh Food panel,

45 pounds total for Freezer panels and

15 pounds for the grille panel.

Dispenser

Cutout

Freezer

Panel

G

C

F

Panel

D

Front Panel Dimensions (in inches)

A B C D E F G

42” Models 40-1/8 10-7/8 68 22-1/2 16-1/2 35-1/4 18

48” Models 46-1/8 10-7/8 68 26-1/2 18-1/2 35-1/4 18

Fresh Food

E

IMPORTANT NOTE: Dispenser Trim

The refrigerator is supplied with factory installed dispenser trim.

• If panel is less than 1/4” thick, a noticeable gap will be created

around the dispenser trim. Foam tape may be applied on

the door to improve the fit.

• If panel is more than 1/4” thick, the panel will not fit behind

the trim.

21

Installation Instructions

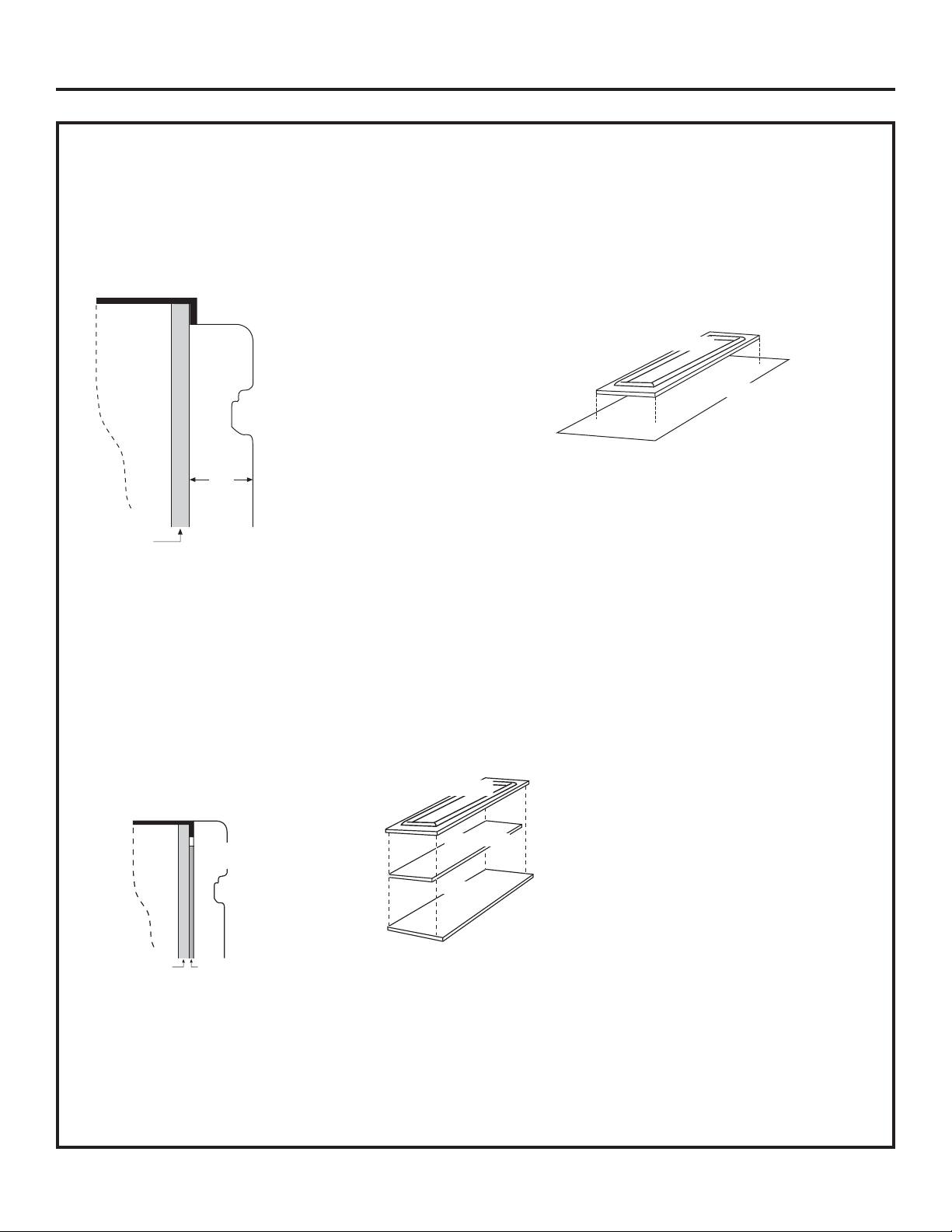

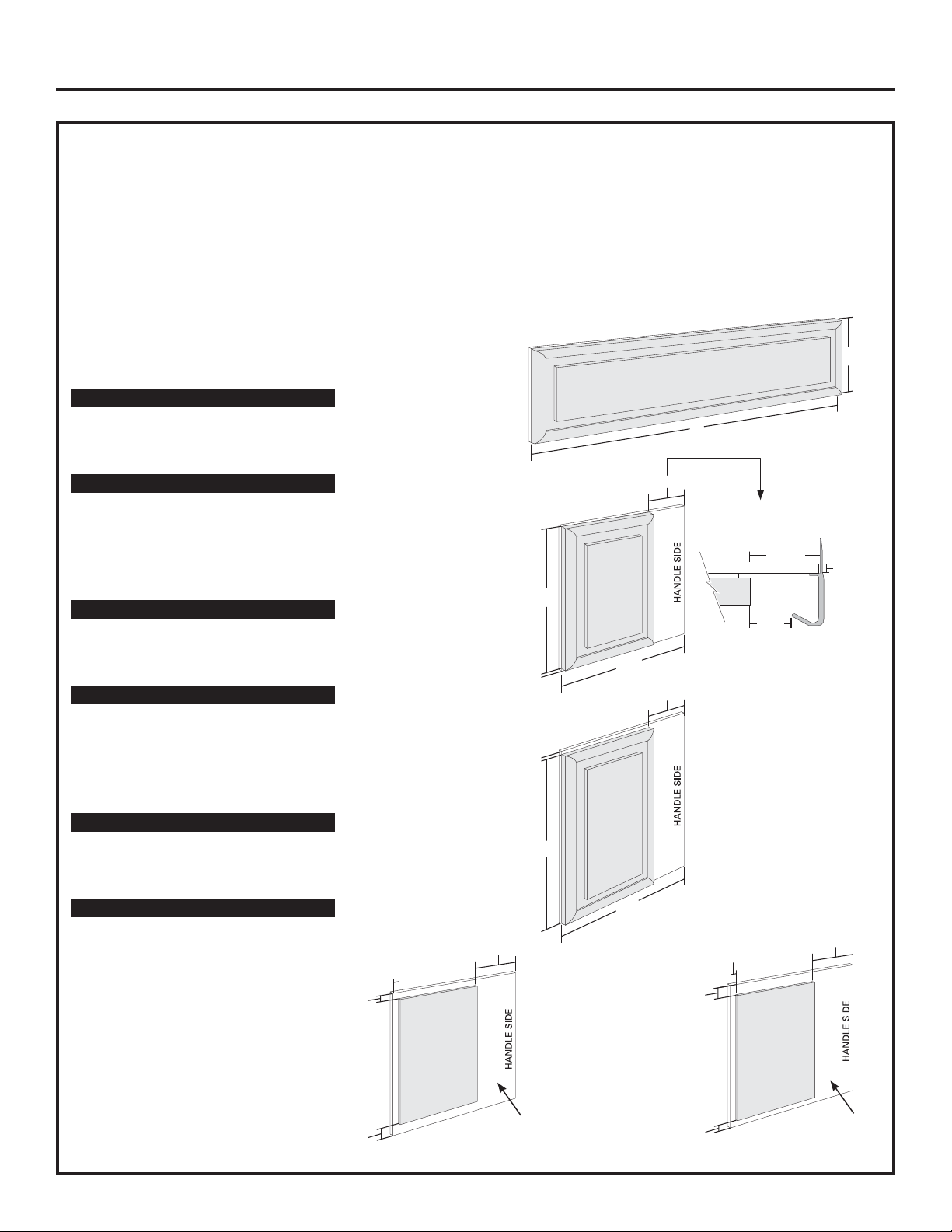

3/4” FRAMED CUSTOM PANEL OPTION

For a more custom appearance, 3/4” framed custom panels

may be installed on trimmed models. The overlay panel is

secured to a 1/4” finished backer panel. The assembled

custom panel then slides into the trim with the same procedure

described on page 37.

Door

3/4"

Custom

Overlay

Panel

3/4"

NOTE: Left-to-right offset is not

equal to top-to-bottom offset.

1/4"

Backer

Panel

.250 + .750 = 1.000 Maximum Total Panel

Thickness

3/4” FULL-WIDTH OVERLAY

CUSTOM PANEL OPTION

This design provides a nearly trimless appearance. The full width overlay

panel covers most of the door trim. In this design, a spacer panel must

be installed between the finished backer and overlay panel.

Overlay Panel

Overlay Panel

Backer Panel

Custom

Overlay

Door

1/4"

Backer

Panel

.250 + .10 + .750 = 1.100 Maximum Total Panel Thickness

Panel

.10 Inch

Spacer

NOTE: Left-to-right offset is not equal

to top-to-bottom offset.

IMPORTANT NOTE: Maximum total weight

is 70 pounds for any assembled Fresh Food

panel, 45 pounds total for the Freezer panels

and 15 pounds for the grille panel.

Spacer Panel

Backer Panel

22

Installation Instructions

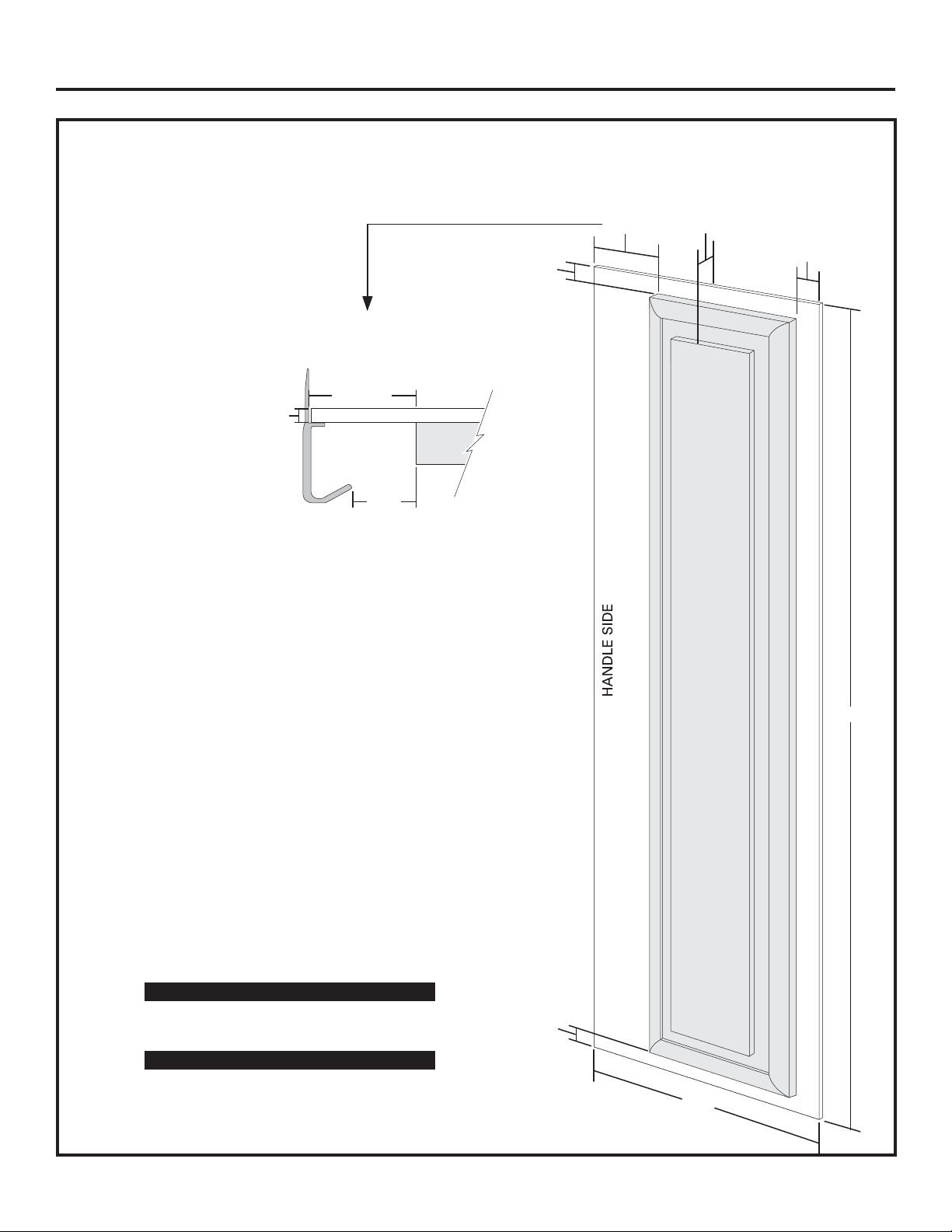

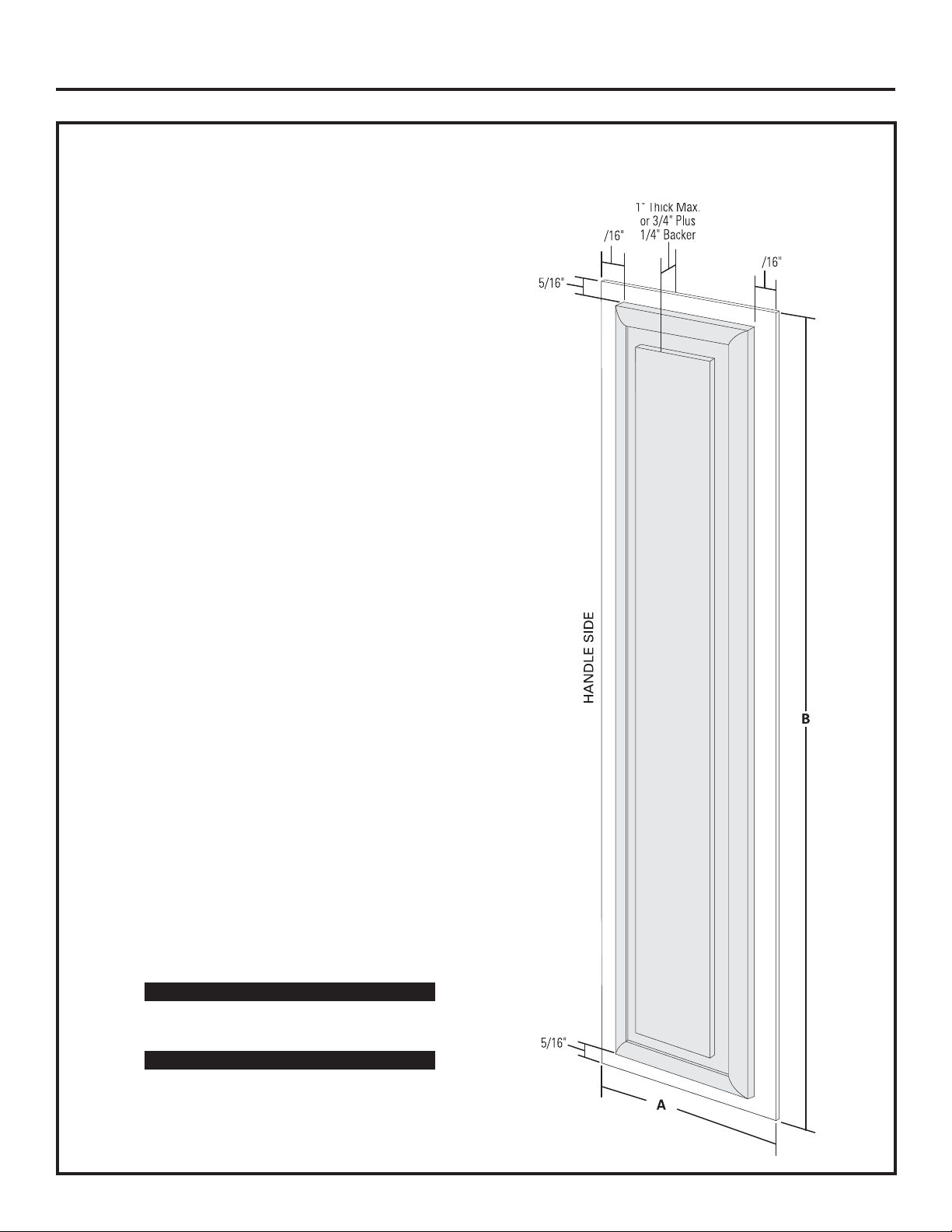

3/4” FRAMED CUSTOM WOOD PANELS WITH PRE-INSTALLED HANDLES

Secured to a 1/4” finished backer panel. This design provides a framed appearance.

1" Thick Max.

or 3/4" Plus

3-1/8"

Fresh Food Panel

5/16"

Required for Optimal

Handle Clearance

3-1/8" Min.

1/4" Max.

2-1/2"

1/4" Backer

3/8"

42” Models A B

1/4” Backer Panel 22-5/16” 67-7/8”

3/4” Overlay Panel 18-13/16” 67-1/4”

48” Models A B

1/4” Backer Panel 26-7/16” 67-7/8”

3/4” Overlay Panel 22-15/16” 67-1/4”

B

5/16"

A

23

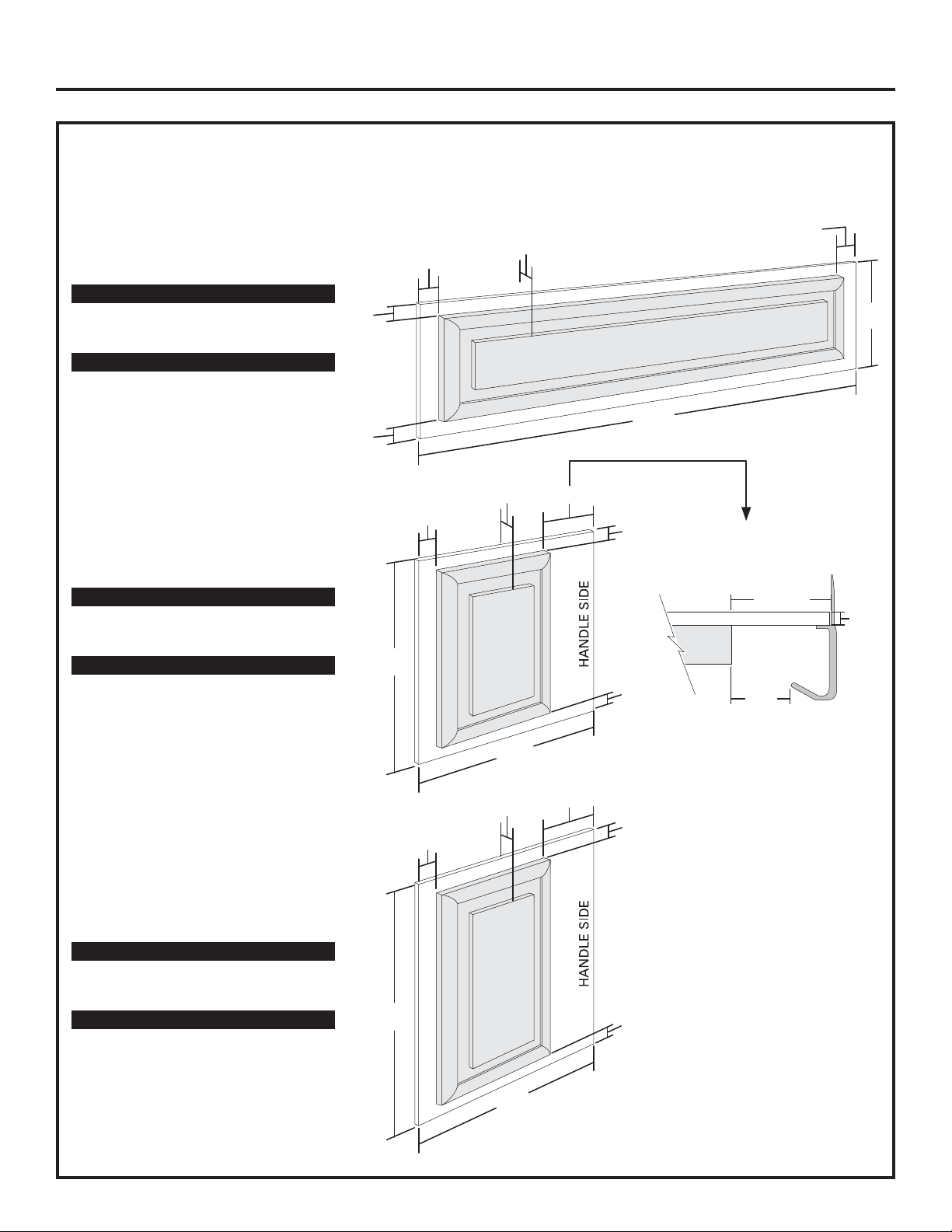

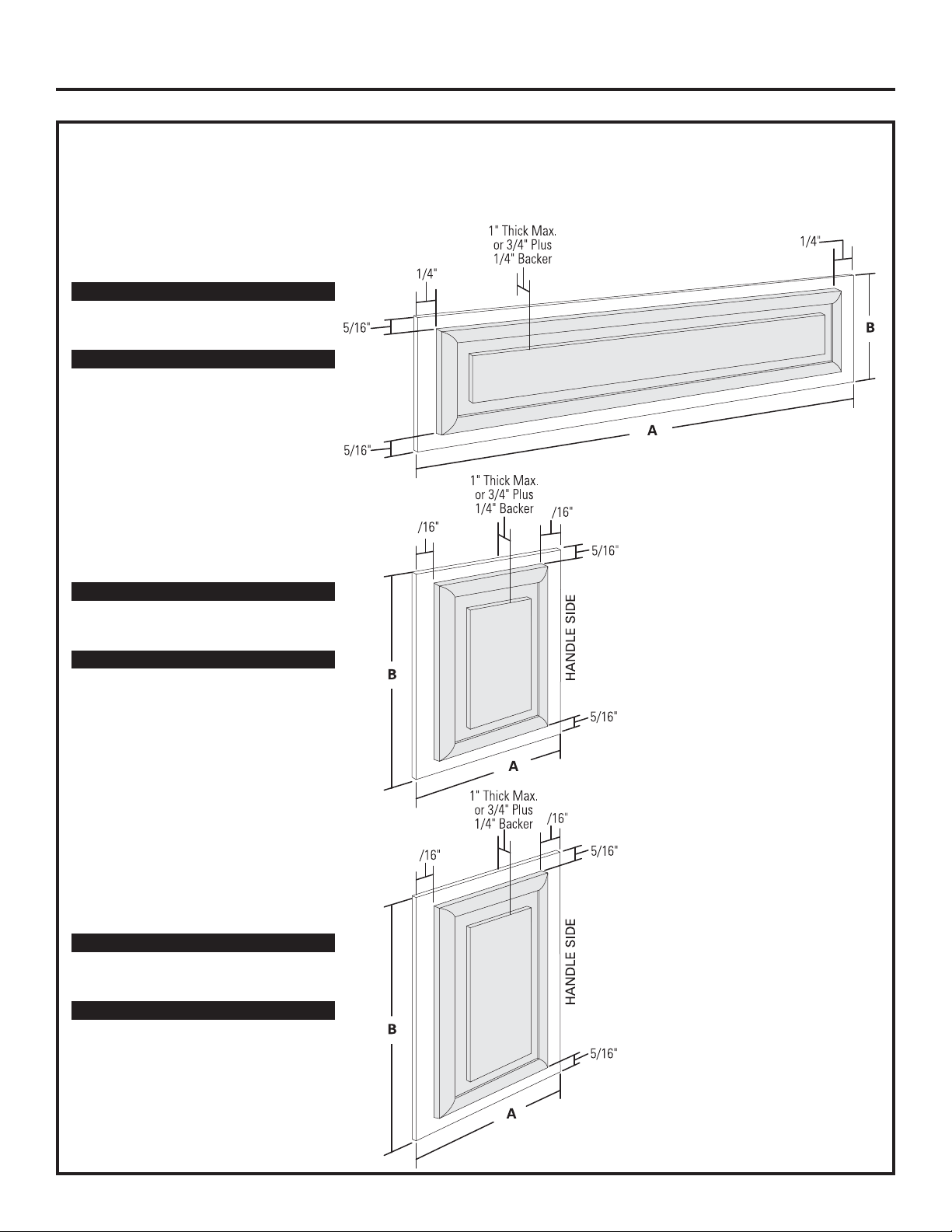

Installation Instructions

3/4” FRAMED CUSTOM WOOD PANELS WITH PRE-INSTALLED HANDLES

Secured to a 1/4” finished backer panel. This design provides a framed appearance.

Grille Panel

42” Models A B

1/4” Backer Panel 39-15/16” 10-3/4”

3/4” Overlay Panel 39-7/16” 10-1/8”

48” Models A B

1/4” Backer Panel 45-15/16” 10-3/4”

3/4” Overlay Panel 45-7/16” 10-1/8”

Upper Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 17-13/16”

3/4” Overlay Panel 12-15/16” 17-3/16”

48” Models A B

1/4” Backer Panel 18-7/16” 17-13/16”

3/4” Overlay Panel 14-15/16” 17-3/16”

5/16"

5/16"

1/4"

3/8"

1" Thick Max.

or 3/4" Plus

1/4" Backer

1" Thick Max.

or 3/4" Plus

1/4" Backer

3-1/8"

5/16"

A

Required for Optimal

1/4"

B

Handle Clearance

3-1/8" Min.

1/4"

Max.

B

5/16"

2-1/2"

Lower Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 35-1/8”

3/4” Overlay Panel 12-15/16” 34-1/2”

48” Models A B

1/4” Backer Panel 18-7/16” 35-1/8”

3/4” Overlay Panel 14-15/16” 34-1/2”

A

1" Thick Max.

or 3/4" Plus

1/4" Backer

3/8"

B

3-1/8"

5/16"

5/16"

A

24

Installation Instructions

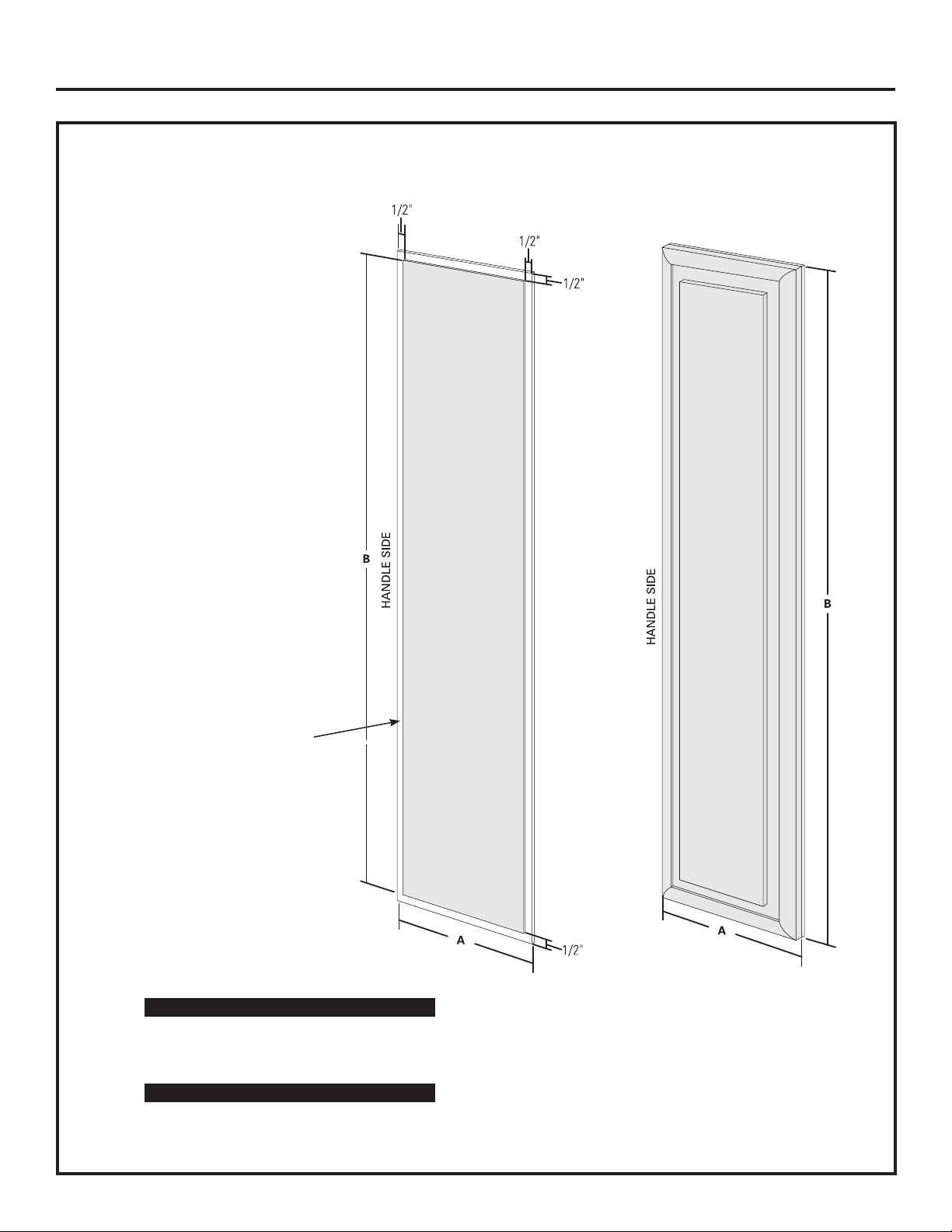

3/4” FULL-WIDTH OVERLAY CUSTOM PANELS WITH PRE-INSTALLED HANDLES

This panel design provides a nearly trimless appearance.

Fresh Food Panel

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2” clearance

on the top, bottom and

hinge side. Allow 3-5/8” on

the handle side. Secure the

panels with glue. Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel.

3-5/8"

Spacer

Panel

1/2"

1/2"

Required for Optimal

Handle Clearance

1/4"

Max.

3-1/8" Min.

3-1/8"

2-1/2"

B

Finished

Backer

Panel

42” Models A B

1/4” Backer Panel 22-5/16” 67-7/8”

0.10” Spacer Panel 18-3/16” 66-7/8”

3/4” Overlay Panel 19-5/16” 68-1/8”

48” Models A B

1/4” Backer Panel 26-7/16” 67-7/8”

0.10” Spacer Panel 22-5/16” 66-7/8”

3/4” Overlay Panel 23-7/16” 68-1/8”

1/2"

A

25

Installation Instructions

3/4” FULL-WIDTH OVERLAY CUSTOM PANELS WITH PRE-INSTALLED HANDLES

This panel design provides a nearly trimless appearance.

Assemble the spacer panel onto the backer panel. Allow 1/2” clearance on all four sides of the grille spacer

panel. Allow 1/2” clearance on the top and hinge side, 15/16” on the bottom and 3-5/8” on the handle side of

the upper freezer door panel. Allow 15/16” on the top, 1/2” clearance on the bottom and hinge side and 3-5/8”

on the handle side of the lower freezer door panel. Secure the panels with glue. Be sure to observe clearances

on all sides.

Secure the appearance panel to the assembled backer/spacer panel. Use glue

and screws. Countersink screws into the backer panel.

Grille Panel

42” Models A B

1/4” Backer Panel 39-15/16” 10-3/4”

0.10” Spacer Panel 38-15/16” 9-3/4”

3/4” Overlay Panel 40-3/16” 11”

A

B

48” Models A B

1/4” Backer Panel 45-15/16” 10-3/4”

0.10” Spacer Panel 44-15/16” 9-3/4”

3/4” Overlay Panel 46-3/16” 11”

Upper Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 17-13/16”

0.10” Spacer Panel 12-5/16” 16-3/8”

3/4” Overlay Panel 13-7/16” 17-5/8”

48” Models A B

1/4” Backer Panel 18-7/16” 17-13/16”

0.10” Spacer Panel 14-5/16” 16-3/8”

3/4” Overlay Panel 15-7/16” 17-5/8”

Lower Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 35-1/8”

0.10” Spacer Panel 12-5/16” 33-11/16”

3/4” Overlay Panel 13-7/16” 34-15/16”

48” Models A B

1/4” Backer Panel 18-7/16” 35-1/8”

0.10” Spacer Panel 14-5/16” 33-11/16”

3/4” Overlay Panel 15-7/16” 34-15/16”

Upper Freezer Panel

Spacer Assembly

3-5/8"

1/2"

5/16"

5/16"

3-1/8"

Required for Optimal

Handle Clearance

3-1/8" Min.

B

2-1/2"

A

3-1/8"

B

A

Lower Freezer Panel

1/4"

Max.

Spacer Assembly

3-5/8"

1/2"

1/2"

15/16"

Spacer

Panel

Backer Panel

26

Finished

15/16"

1/2"

Spacer

Panel

Finished

Backer Panel

Installation Instructions

3/4” FRAMED CUSTOM WOOD PANELS WITH CUSTOM HANDLES

Secured to a 1/4” finished backer panel. This design provides a framed appearance.

Fresh Food Panel

3

3

42” Models A B

1/4” Backer Panel 22-5/16” 67-7/8”

3/4” Overlay Panel 21-15/16” 67-1/4”

48” Models A B

1/4” Backer Panel 26-7/16” 67-7/8”

3/4” Overlay Panel 26-1/16” 67-1/4”

27

Installation Instructions

3/4” FRAMED CUSTOM WOOD PANELS WITH CUSTOM HANDLES

Secured to a 1/4” finished backer panel. This design provides a framed appearance.

Grille Panel

42” Models A B

1/4” Backer Panel 39-15/16” 10-3/4”

3/4” Overlay Panel 39-7/16” 10-1/8”

48” Models A B

1/4” Backer Panel 45-15/16” 10-3/4”

3/4” Overlay Panel 45-7/16” 10-1/8”

Upper Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 17-13/16”

3/4” Overlay Panel 16-1/16” 17-3/16”

48” Models A B

1/4” Backer Panel 18-7/16” 17-13/16”

3/4” Overlay Panel 18-1/16” 17-3/16”

Lower Freezer Panel

42” Models A B

1/4” Backer Panel 16-7/16” 35-1/8”

3/4” Overlay Panel 16-1/16” 34-1/2”

3

3

3

3

48” Models A B

1/4” Backer Panel 18-7/16” 35-1/8”

3/4” Overlay Panel 18-1/16” 34-1/2”

28

Installation Instructions

3/4” FULL-WIDTH OVERLAY CUSTOM PANELS WITH CUSTOM HANDLES

This panel design provides a nearly trimless appearance.

Fresh Food Panel

Assemble the spacer panel

onto the finished backer

panel. Allow 1/2” clearance

on all sides. Secure the

panels with glue. Be sure to

observe clearances shown

on all sides.

Secure the overlay

panel to the assembled

backer/spacer panel.

Use glue and screws.

Countersink screws

into the backer panel.

Finished

Backer

Panel

42” Models A B

1/4” Backer Panel 22-5/16” 67-7/8”

0.10” Spacer Panel 21-13/16” 66-7/8”

3/4” Overlay Panel 22-5/16” 68-1/8”

Spacer

Panel

48” Models A B

1/4” Backer Panel 26-7/16” 67-7/8”

0.10” Spacer Panel 25-13/16” 66-7/8”

3/4” Overlay Panel 26-7/16” 68-1/8”

29

Loading...

Loading...