GE Consumer & Industrial

g

Multilin

G650

Generator Protection & Control

System

Instruction manual

GEK-113285A

Firmware version: 3.74

GE Multilin

215 Anderson Avenue

L6E 1B3 Markham, ON -CANADA

T (905) 294 6222 F (905) 294 8512

E gemultilin@ge.com

EnerVista 650 Setup version: 3.76

Copyright © 2008 GE Multilin

GE Multilin

Avda. Pinoa, 10

48170 Zamudio SPAIN

T +34 94 485 88 00 F +34 94 485 88 45

E gemultilin.euro@ge.com

Internet: www.GEMultilin.com

TABLE OF CONTENTS

1. GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.1 CAUTIONS AND WARNINGS ........................................................................... 1-1

1.1.2 INSPECTION CHECKLIST................................................................................ 1-4

1.1.3 SAFETY INSTRUCTIONS ................................................................................. 1-6

1.2 OVERVIEW

1.2.1 INTRODUCTION TO 650 FAMILY OF RELAYS ............................................... 1-7

1.2.2 HARDWARE ARCHITECTURE......................................................................... 1-7

1.2.3 SOFTWARE ARCHITECTURE.......................................................................... 1-9

1.2.4 COMMUNICATIONS ARCHITECTURE ............................................................ 1-9

1.3 ENERVISTA 650 SETUP SOFTWARE

1.3.1 SYSTEM REQUIREMENTS ............................................................................ 1-11

1.3.2 INSTALLATION................................................................................................ 1-11

1.3.3 CONNECTING ENERVISTA 650 SETUP WITH G650.................................... 1-15

1.4 650 HARDWARE

1.4.1 MOUNTING & WIRING.................................................................................... 1-17

1.4.2 650 COMMUNICATIONS................................................................................. 1-17

1.4.3 FACEPLATE DISPLAY....................................................................................1-18

1.4.4 MAINTENANCE ...............................................................................................1-18

2. PRODUCT DESCRIPTION 2.1 OVERVIEW

2.1.1 G650 OVERVIEW.............................................................................................. 2-1

2.2 SUMMARY

2.2.1 ANSI DEVICE NUMBERS AND FUNCTIONS................................................... 2-3

2.2.2 OTHER DEVICE FUNCTIONS .......................................................................... 2-4

2.3 ORDERING CODE

2.4 TECHNICAL SPECIFICATIONS

2.4.1 PROTECTION ELEMENTS ............................................................................... 2-7

2.4.2 CONTROL........................................................................................................ 2-17

2.4.3 MONITORING.................................................................................................. 2-22

2.4.4 USER-PROGRAMMABLE ELEMENTS...........................................................2-24

2.4.5 METERING ...................................................................................................... 2-25

2.4.6 INPUTS............................................................................................................ 2-26

2.4.7 REAL TIME CLOCK......................................................................................... 2-28

2.4.8 OUTPUTS........................................................................................................ 2-28

2.4.9 CONTROL POWER SUPPLY.......................................................................... 2-29

2.4.10 COMMUNICATIONS........................................................................................2-29

2.4.11 OPTIC FEATURES..........................................................................................2-31

2.4.12 ENVIRONMENTAL CHARACTERISTICS .......................................................2-32

2.4.13 PACKAGING AND WEIGHT............................................................................ 2-32

2.4.14 TYPE TESTS ................................................................................................... 2-32

2.4.15 APPROVALS ...................................................................................................2-32

2.5 EXTERNAL CONNECTIONS

3. HARDWARE 3.1 MODULE DESCRIPTION

3.2 POWER SUPPLY

3.3 MECHANICAL DESCRIPTION

3.3.1 MOUNTING........................................................................................................ 3-3

3.3.2 REAR DESCRIPTION........................................................................................3-6

3.4 WIRING

3.4.1 EXTERNAL CONNECTIONS............................................................................. 3-9

3.4.2 DIGITAL INPUTS WITH TRIP CIRCUIT SUPERVISION ..................................3-9

3.4.3 CABLE/FIBER ETHERNET BOARD................................................................ 3-10

GEK-113285A G650 Generator Protection & Control System 1

TABLE OF CONTENTS

3.5 TRANSCEIVER OPTICAL POWER BUDGET VERSUS LINK LENGTH

4. HUMAN INTERFACES.

SETTINGS & ACTUAL

VALUES

4.1 ENERVISTA 650 SETUP SOFTWARE INTERFACE

4.1.1 INTRODUCTION ................................................................................................4-1

4.1.2 ENERVISTA 650 SETUP SOFTWARE OVERVIEW..........................................4-1

4.1.3 MAIN SCREEN...................................................................................................4-3

4.1.4 COMMUNICATION MENU .................................................................................4-4

4.1.5 FILE MANAGEMENT .........................................................................................4-6

4.1.6 ENERVISTA 650 SETUP MENU STRUCTURE...............................................4-10

4.1.7 FILE MENU OVERVIEW ..................................................................................4-11

4.1.8 SETPOINT MENU OVERVIEW........................................................................4-15

4.1.9 ACTUAL VALUES MENU OVERVIEW.............................................................4-23

4.1.10 OPERATIONS MENU OVERVIEW ..................................................................4-26

4.1.11 COMMUNICATION MENU OVERVIEW...........................................................4-27

4.1.12 SECURITY MENU OVERVIEW........................................................................4-30

4.1.13 VIEW MENU OVERVIEW.................................................................................4-30

4.1.14 HELP MENU OVERVIEW ................................................................................4-30

4.2 HUMAN MACHINE INTERFACE (HMI)

4.2.1 DISPLAY...........................................................................................................4-31

4.2.2 FRONT LED INDICATORS ..............................................................................4-32

4.2.3 PUSHBUTTONS...............................................................................................4-32

4.2.4 FRONT PORT AND COVER SEALING SYSTEM............................................4-33

4.2.5 TEXT MENUS...................................................................................................4-34

4.2.6 GRAPHIC DISPLAY .........................................................................................4-52

4.3 WEB SERVER

4.3.1 HOME ...............................................................................................................4-61

4.3.2 SNAPSHOT EVENTS.......................................................................................4-62

4.3.3 CONTROL EVENTS.........................................................................................4-63

4.3.4 ALARMS ...........................................................................................................4-64

4.3.5 OSCILLOGRAPHY...........................................................................................4-65

4.3.6 FAULT REPORT ..............................................................................................4-66

4.3.7 DATA LOGGER................................................................................................4-67

4.3.8 METERING.......................................................................................................4-68

5. SETTINGS 5.1 OVERVIEW

5.1.1 SETTING MAIN MENU.......................................................................................5-1

5.2 PRODUCT SETUP

5.2.1 COMMUNICATION SETTINGS..........................................................................5-3

5.2.2 MODBUS USER MAP ........................................................................................5-6

5.2.3 FAULT REPORT ................................................................................................5-7

5.2.4 OSCILLOGRAPHY.............................................................................................5-9

5.2.5 DATA LOGGER................................................................................................5-12

5.2.6 DEMAND .........................................................................................................5-14

5.3 SYSTEM SETUP

5.3.1 GENERAL SETTINGS......................................................................................5-20

5.3.2 FLEX CURVES.................................................................................................5-20

5.3.3 BREAKER.........................................................................................................5-23

5.3.4 SWITCHGEAR .................................................................................................5-25

5.4 PROTECTION ELEMENTS

5.4.1 CHANGE OF SETTING TABLES IN G650 ELEMENTS ..................................5-26

5.4.2 INVERSE TIME CURVES CHARACTERISTICS..............................................5-30

5.4.3 PHASE CURRENT ...........................................................................................5-40

5.4.4 NEUTRAL CURRENT ......................................................................................5-46

5.4.5 GROUND CURRENT .......................................................................................5-52

5.4.6 RESTRICTED GROUND FAULT (ONLY FOR ENHANCED MODELS) ..........5-56

5.4.7 SENSITIVE GROUND CURRENT (ONLY FOR ENHANCED MODELS) ........5-59

5.4.8 NEGATIVE SEQUENCE CURRENT................................................................5-60

5.4.9 VOLTAGE ELEMENTS ....................................................................................5-63

5.4.10 POWER ............................................................................................................5-71

2 G650 Generator Protection & Control System GEK-113285A

TABLE OF CONTENTS

5.5 CONTROL ELEMENTS

5.5.1 SETTING GROUP ........................................................................................... 5-77

5.5.2 UNDERFREQUENCY ELEMENT (81U).......................................................... 5-78

5.5.3 OVERFREQUENCY ELEMENT (81O) ............................................................5-78

5.5.4 SYNCHRONISM CHECK ELEMENT - SYNCHROCHECK (25) ..................... 5-79

5.5.5 BREAKER FAILURE ELEMENT (50BF) (ENHANCED MODELS ONLY) ....... 5-88

5.5.6 VT FUSE FAILURE ELEMENT (VTFF) (ENHANCED MODELS ONLY)......... 5-91

5.5.7 PULSE COUNTERS ........................................................................................ 5-92

5.5.8 ANALOG COMPARATORS............................................................................. 5-94

5.5.9 FREQUENCY RATE OF CHANGE.................................................................. 5-95

5.5.10 LOSS OF MAINS (78V) (FOR ENHANCED MODELS)..................................5-97

5.5.11 LOSS OF EXCITATION (40)...........................................................................5-99

5.5.12 ACCIDENTAL ENERGIZATION (50/27)........................................................ 5-101

5.6 INPUTS/OUTPUTS

5.6.1 INPUT/OUTPUT PLACEMENT......................................................................5-103

5.6.2 CONTROL SETTINGS FOR INPUTS/OUTPUTS.......................................... 5-104

5.6.3 INPUTS.......................................................................................................... 5-106

5.6.4 OUTPUTS...................................................................................................... 5-108

5.6.5 CIRCUIT SUPERVISION AND CONTACT SEAL-IN CIRCUITS ................... 5-110

5.6.6 ANALOG BOARDS SPECIFIC SETTINGS ................................................... 5-120

5.6.7 VIRTUAL INPUTS.......................................................................................... 5-120

5.6.8 VIRTUAL OUTPUTS...................................................................................... 5-121

5.7 TESTING

5.7.1 FORCE IO–INPUT TESTING ........................................................................ 5-122

5.7.2 FORCE IO–OUTPUT TESTING .................................................................... 5-122

5.8 RELAY CONFIGURATION

5.8.1 OUTPUTS...................................................................................................... 5-123

5.8.2 LEDS..............................................................................................................5-125

5.8.3 OPERATIONS................................................................................................5-126

5.8.4 PROTECTION ELEMENTS ........................................................................... 5-130

5.8.5 OSCILLOGRAPHY ........................................................................................ 5-132

5.8.6 CONTROL EVENTS ...................................................................................... 5-133

5.8.7 SWITCHGEAR .............................................................................................. 5-135

5.8.8 HMI (HUMAN-MACHINE INTERFACE).........................................................5-137

5.9 LOGIC CONFIGURATION (PLC EDITOR)

5.9.1 INTRODUCTION............................................................................................5-141

5.9.2 THEORY OF OPERATION............................................................................ 5-142

5.9.3 MAIN MENU................................................................................................... 5-145

5.9.4 CONFIGURATION GENERATION ................................................................5-146

5.9.5 GENERATION OF LIBRARIES ..................................................................... 5-147

5.9.6 EXAMPLE OF APPLICATION ....................................................................... 5-148

6. ACTUAL VALUES 6.1 FRONT PANEL

6.1.1 LEDS..................................................................................................................6-1

6.2 STATUS

6.2.1 OPERATION BITS .............................................................................................6-2

6.2.2 BREAKER.......................................................................................................... 6-2

6.2.3 PROTECTION.................................................................................................... 6-3

6.2.4 CONTROL ELEMENTS ................................................................................... 6-12

6.2.5 PROTECTION SUMMARY .............................................................................. 6-19

6.2.6 SNAPSHOT EVENTS SUMMARY...................................................................6-22

6.2.7 MODBUS USER MAP......................................................................................6-24

6.2.8 SWITCHGEAR STATUS..................................................................................6-24

6.2.9 CALIBRATION ................................................................................................. 6-25

6.2.10 FLEX CURVES ................................................................................................6-27

6.2.11 SYSTEM INFO................................................................................................. 6-27

6.2.12 RECORD STATUS .......................................................................................... 6-27

6.3 METERING

6.3.1 PRIMARY VALUES..........................................................................................6-32

6.3.2 SECONDARY VALUES ................................................................................... 6-36

6.3.3 PHASOR DIAGRAM ........................................................................................ 6-38

GEK-113285A G650 Generator Protection & Control System 3

TABLE OF CONTENTS

6.3.4 FREQUENCY ...................................................................................................6-38

6.4 INPUTS / OUTPUTS

6.4.1 CONTACT INPUTS ..........................................................................................6-39

6.4.2 CONTACT OUTPUT STATUS..........................................................................6-40

6.4.3 CONTACT OUTPUT OPERATES....................................................................6-40

6.4.4 CONTACT OUTPUT RESETS .........................................................................6-41

6.4.5 I/O BOARD STATUS ........................................................................................6-42

6.4.6 VIRTUAL INPUTS ............................................................................................6-42

6.4.7 VIRTUAL OUTPUTS ........................................................................................6-42

6.4.8 ANALOG INPUTS.............................................................................................6-43

6.5 RECORDS

6.5.1 EVENT RECORDER ........................................................................................6-44

6.5.2 WAVEFORM CAPTURE ..................................................................................6-46

6.5.3 FAULT REPORT ..............................................................................................6-47

6.5.4 DATA LOGGER................................................................................................6-48

7. SECURITY 7.1 ADDING USERS

7.1.1 USER RIGHTS ...................................................................................................7-1

7.2 CHANGING PASSWORDS

7.3 ENABLING SECURITY

7.4 LOGING INTO ENERVISTA 650 SETUP

8. BOOTCODE AND

FIRMWARE UPGRADE

8.1 INTRODUCTION

8.1.1 COMMUNICATION PARAMETERS...................................................................8-2

8.2 BOOT CODE UPGRADE

8.3 FIRMWARE VERSION UPGRADE

8.3.1 FIRMWARE UPGRADE .....................................................................................8-9

8.3.2 BOOT CODE UPGRADE (*).............................................................................8-11

8.3.3 FIRMWARE UPGRADE (*)...............................................................................8-12

9. COMMISSIONING 9.1 VISUAL INSPECTION

9.2 GENERAL CONSIDERATIONS ON THE POWER SUPPLY NETWORK

9.3 ISOLATION TESTS

9.4 INDICATORS

9.5 POWER SUPPLY TESTING

9.6 COMMUNICATIONS

9.7 VERIFICATION OF MEASUREMENT

9.7.1 VOLTAGES ........................................................................................................9-7

9.7.2 PHASE CURRENTS...........................................................................................9-7

9.7.3 ACTIVE, REACTIVE POWER, AND COSJ METERING....................................9-8

9.7.4 FREQUENCY .....................................................................................................9-8

9.8 INPUTS AND OUTPUTS

9.8.1 DIGITAL INPUTS................................................................................................9-9

9.8.2 CONTACT OUTPUTS ......................................................................................9-10

9.8.3 CIRCUIT CONTINUITY SUPERVISION INPUTS ............................................9-10

9.8.4 LATCHING CIRCUITS......................................................................................9-10

4 G650 Generator Protection & Control System GEK-113285A

TABLE OF CONTENTS

9.9 CONNECTIONS FOR TESTING PROTECTION ELEMENTS

9.10 INSTANTANEOUS OVERCURRENT (50PH, 50N, 50G Y 50SG)

9.11 TIME OVERCURRENT (51PH, 51PL, 51N, 51G)

9.12 DIRECTIONAL ELEMENTS (67N, 67G)

9.12.1 67N ELEMENT................................................................................................. 9-14

9.12.2 67G ELEMENT ................................................................................................ 9-15

9.13 UNDERVOLTAGE ELEMENTS (27P, 27X)

9.13.1 27P ELEMENT................................................................................................. 9-16

9.13.2 27X ELEMENT................................................................................................. 9-16

9.14 OVERVOLTAGE ELEMENTS (59P, 59X, 59NH)

9.14.1 59P ELEMENT................................................................................................. 9-17

9.14.2 59X ELEMENT................................................................................................. 9-17

9.14.3 59NH ELEMENT..............................................................................................9-18

9.14.4 47 ELEMENT - NEG SEQ OV ......................................................................... 9-19

9.15 FREQUENCY ELEMENTS (81O/81U)

10. APPLICATION EXAMPLES 10.1 EXAMPLE 1: COMMUNICATION & PROTECTION SETTINGS

PROCEDURE

10.1.1 DESCRIPTION OF THE EXERCISE ...............................................................10-1

10.1.2 PROCEDURE TO COMMUNICATE WITH THE RELAY................................. 10-1

10.1.3 PROCEDURE TO SET THE PROTECTION FUNCTION ................................ 10-3

10.1.4 TEST ................................................................................................................ 10-4

10.2 EXAMPLE 2: PROCEDURE TO SET AN OPERATION

10.2.1 DESCRIPTION OF THE EXERCISE ...............................................................10-5

10.2.2 PROCEDURE ................................................................................................. 10-5

10.2.3 TEST ................................................................................................................ 10-7

11. FREQUENTLY ASKED

QUESTIONS

11.1 COMMUNICATIONS

11.2 PROTECTION

11.3 CONTROL AND HMI

11.4 RELAY CONFIGURATION

12. G650TROUBLESHOOTING

12.1 SYMPTOMS AND RECOMMENDED ACTIONS

GUIDE

A. LOGIC OPERANDS A.1 LOGIC OPERANDS

B. MODBUS PROTOCOL B.1 ACCESS TO G650 DATA

B.2 MODBUS G650

B.2.1 FUNCTIONS USED ...........................................................................................B-2

B.2.2 PHYSICAL LAYER.............................................................................................B-2

B.2.3 DATA LINK LAYER............................................................................................B-3

B.2.4 GENERIC READING .........................................................................................B-4

B.2.5 GENERIC WRITING ..........................................................................................B-5

B.2.6 FUNCTION CODES ..........................................................................................B-6

B.2.7 EXCEPTIONS AND ERROR RESPONDS ........................................................B-6

GEK-113285A G650 Generator Protection & Control System 5

TABLE OF CONTENTS

B.3 DATA TYPE

B.4 MODBUS APPENDIX

B.4.1 DATA MANAGEMENT ...................................................................................... B-8

B.4.2 WRITING SETTINGS ........................................................................................B-8

B.4.3 SNAPSHOT EVENTS........................................................................................ B-8

B.4.4 OPERATIONS .................................................................................................B-12

B.5 OUTPUT WRITING

B.5.1 CONTROL EVENTS........................................................................................ B-14

B.5.2 EVENT STRUCTURE...................................................................................... B-15

B.6 EVENTS STATUS REQUEST(ALARMS)

B.6.1 CONTROL EVENTS RETRIEVAL FROM THE COMMAND LINE ................. B-17

B.6.2 SERIAL COMUNICATION...............................................................................B-17

B.6.3 ETHERNET COMMUNICATION ..................................................................... B-17

B.6.4 ACKNOWLEDGEMENT OF EVENTS (ALARMS)...........................................B-18

B.6.5 VIRTUAL INPUTS WRITING........................................................................... B-18

B.6.6 USER MAP ......................................................................................................B-18

B.6.7 RETRIEVING OSCILOGRAPHY ..................................................................... B-19

B.6.8 TIME SYNCHRONIZATION ............................................................................ B-19

B.6.9 ENQUEUEING MESSAGES .......................................................................... B-20

B.6.10 TRACES AND TROUBLESHOOTING.............................................................B-20

B.6.11 MODBUS CHECK FUNCTION........................................................................ B-21

B.7 MEMORY MAP

C. DNP 3.0 PROTOCOL FOR

G650

C.1 DNP 3.0 PROTOCOL SETTINGS

C.2 DNP 3.0 DEVICE PROFILE DOCUMENT

C.3 IMPLEMENTATION TABLE

C.4 BINARY INPUT POINTS

C.5 DNP CONFIGURATION EXAMPLES

C.5.1 CONFIGURING DNP USER MAP................................................................... C-11

C.5.2 EXAMPLE OF CUSTOM BINARY INPUT POINTS MAP................................C-13

C.5.3 MULTIPLE DNP 3.0 MASTERS COMMUNICATION WITH G650 .................. C-15

C.6 BINARY OUTPUT AND CONTROL RELAY OUTPUT

C.7 BINARY COUNTERS

C.8 ANALOG INPUTS

D. IEC 60870-5-104 PROTOCOL D.1 INTRODUCTION

D.2 TECHNICAL DESCRIPTION

D.3 BASIC APPLICATION FUNCTIONS

D.4 IEC 104 SETTINGS

D.5 IEC 60870-5-104 POINT LIST

E. FACTORY DEFAULT LOGIC E.1 FACTORY DEFAULT LOGIC

F. FACTORY DEFAULT

CONFIGURATION

F.1 FACTORY DEFAULT SETTINGS

F.2 FACTORY DEFAULT CONFIGURATION

6 G650 Generator Protection & Control System GEK-113285A

TABLE OF CONTENTS

G. MISCELLANEOUS G.1 GE MULTILIN WARRANTY

GEK-113285A G650 Generator Protection & Control System 7

TABLE OF CONTENTS

8 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

1 GETTING STARTED 1.1IMPORTANT PROCEDURES 1.1.1 CAUTIONS AND WARNINGS

To help ensure years of trouble free operation, please read through the following chapter for information to help guide you

through the initial installation procedures of your new relay.

BEFORE ATTEMPTING TO INSTALL OR USE THE RELAY, IT IS IMPERATIVE THAT ALL WARNINGS AND CAUTIONS

IN THIS MANUAL ARE REVIEWED TO HELP PREVENT PERSONAL INJURY, EQUIPMENT DAMAGE, AND/OR

DOWNTIME.

CAUTION: THE OPERATOR OF THIS INSTRUMENT IS ADVISED THAT IF THE EQUIPMENT IS USED IN A MANNER

NOT SPECIFIED IN THIS MANUAL, THE PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED.

1

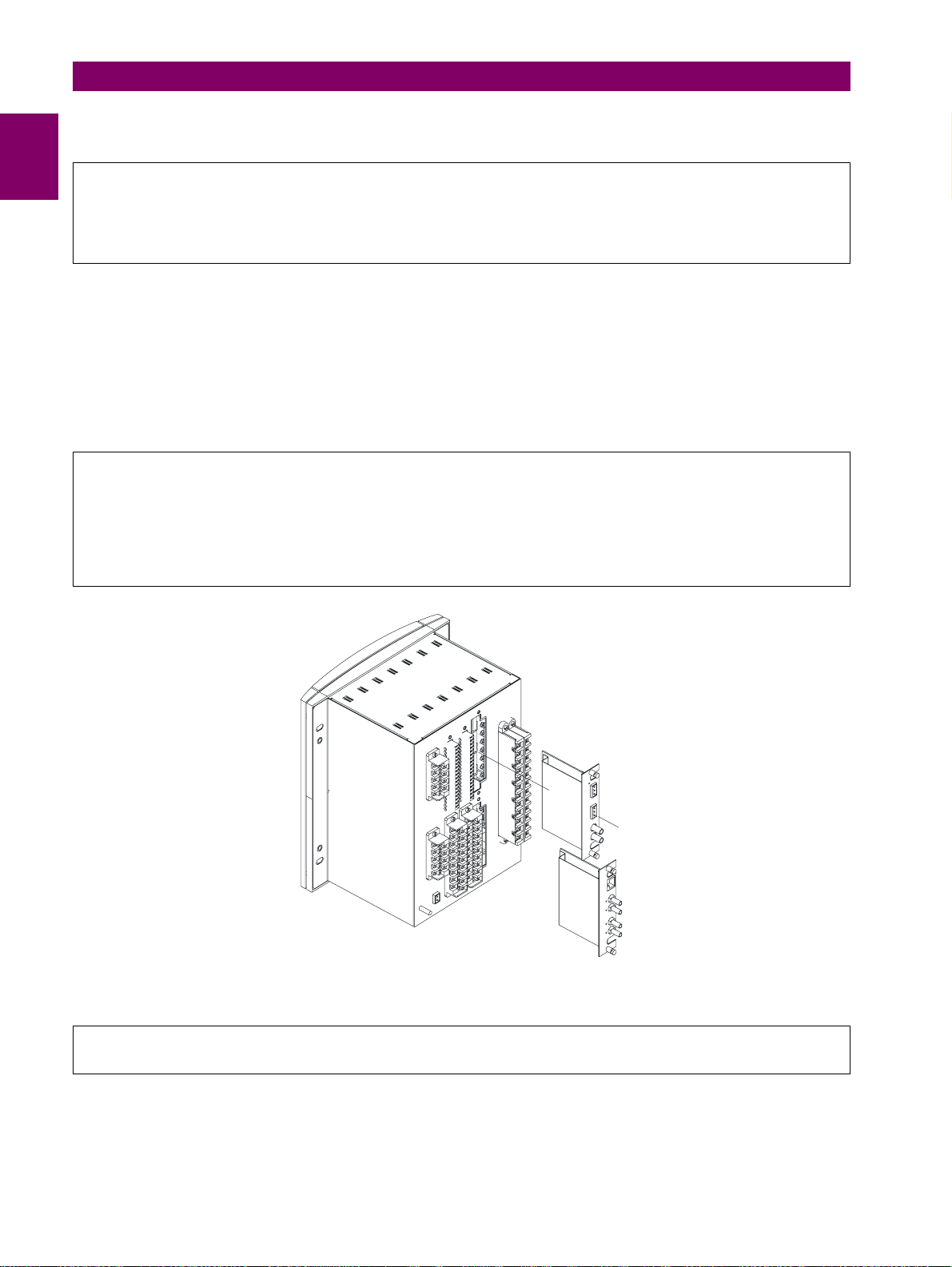

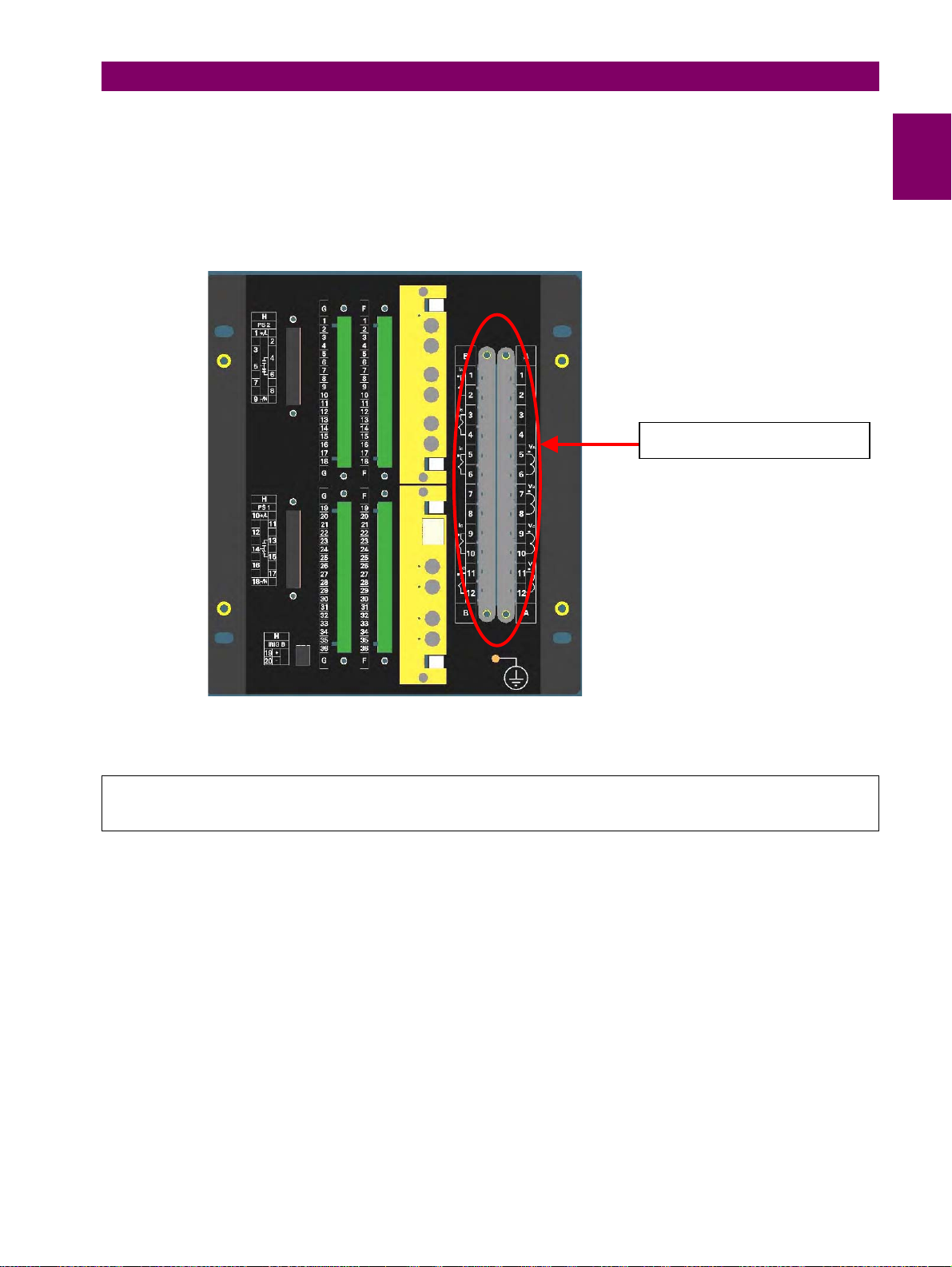

Figure 1–1: FRONT VIEW OF G650 UNITS

GEK-113285A G650 Generator Protection & Control System 1-1

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1.1.1.1 COMMUNICATION BOARDS WITHDRAWAL / INSERTION

WARNING: MODULE WITHDRAWAL AND INSERTION SHALL ONLY BE PERFORMED BY DULY QUALIFIED

SERVICE PERSONNEL. FOR PERSONAL SECURITY PURPOSES, BEFORE ACCOMPLISHING ANY

WITHDRAWAL OR INSERTION OPERATION, THE RELAY MUST BE POWERED OFF AND ALL THE REAR

TERMINALS MUST BE POTENTIAL FREE. THE RELAY MUST BE GROUNDED USING THE REAR GROUNDING

SCREW.

The modular design of the relay allows for the withdrawal and insertion of the communication module.

Figure 1–2: shows the location of communication modules on the rear part of the relay. Qualified personnel must carry out

the insertion or extraction of the communication boards only after interrupting the relay auxiliary voltage and ensuring that

all the rear terminals are potential free.

Communication boards are installed on the rear of the unit, the upper port being reserved for the asynchronous

communications board and CAN, and the lower port for the ETHERNET board in any of its configurations.

Before performing any of these actions, control power must be removed fro m the relay and all the r ear terminals

must be potential free. A grounded antistatic wristband must be used when manipulating the module in order to avoid

electrostatic discharges that may cause damage to the electronic components.

WITHDRAWAL: Loosen the small screws that keep the faceplate in place and extract the module.

INSERTION: Insert the module and press it firmly in the case, until it is completely fixed. After this, bolt the faceplate

screws and replace the control power. Check that the relay is fully operative.

Figure 1–2: MODULE WITHDRAWAL/INSERTION

GE Multilin will not be responsible for any damage of the relay, connected equipment or personnel whenever

these safety rules are not followed.

1-2 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

1.1.1.2 MAGNETIC MODULE TERMINALS

The transformer module for the VTs and CTs is already connected to a female connector screwed to the case. The

current inputs incorporate shorting bars, so that the module can be extracted without the need to short-circuit the

currents externally. It is very important, for safety reasons not to change or switch the terminals for CTs and VTs.

AC Input Terminals

1

GE Multilin

Figure 1–3: REAR VIEW OF G650 UNIT

will not be responsible for any damage of the relay, connected equipment or personnel

whenever these safety rules are not followed.

GEK-113285A G650 Generator Protection & Control System 1-3

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1.1.2 INSPECTION CHECKLIST

Unwrap the relay and inspect the relay for physical damage.

Verify that the model on the label on the side of the relay matches the model ordered.

Figure 1–4: IDENTIFICATION LABEL (A4454P30)

Please ensure that you received the following items with your relay:

• Mounting screws for fixing the relay to a cabinet

• CD containing EnerVista 650 Setup software

• Wiring diagram

• Certificate of Compliance

1-4 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.1 IMPORTANT PROCEDURES

For product information, instruction manual updates, and the latest software updates, please visit the GE Multilin Home

Page www.geindustrial.com/multilin

Note: If there is any physical damage detected on the relay, or any of the contents listed are missing, please

contact GE Multilin immediately at:

.

EUROPE, MIDDLE EAST AND AFRICA:

GE MULTILIN

Av. Pi noa, 10

48170 Zamudio, Vizcaya (SPAIN)

Tel.: (34) 94-485 88 54, Fax: (34) 94-485 88 38

E-mail: multilin.tech.euro@ge.com

AMERICA, ASIA AND AUSTRALIA:

GE MULTILIN

215, Anderson Avenue

L6E 1B3 Markham, ON (CANADA)

Tel.: +1 905 294 6222, Fax: +1 905 201 2098

E-mail: multilin.tech@ge.com

1

The information provided herein is not intended to cover all the details of the variations of the equipment, nor does

it take into account the circumstances that may be present in your installation, operating or maintenance

activities.

Should you wish to receive additional information, or for any particular problem that cannot be solved by referring

to the information contained herein, please contact GENERAL ELECTRIC MULTILIN.

GEK-113285A G650 Generator Protection & Control System 1-5

1.1 IMPORTANT PROCEDURES 1 GETTING STARTED

1.1.3 SAFETY INSTRUCTIONS

The G650 ground screw shown in Figure 1–5: must be correctly grounded.

Figure 1–5: LOCATION OF GROUNDING SCREW

Before communicating with a G650 unit through the front serial port, please ensure that the computer is grounded.

In case of using a laptop, it is recommended not to have it connected to its power supply. In many cases it might not be

correctly grounded either due to the power supply or to the connector cables used.

This is required not only for personal protection, bu t also to avoid a potential voltage difference between the

relay’s serial port and the computer’s port, which could produce permanent damage to the computer or the relay.

GE Multilin will not be responsible for any damage to the relay or connected equipment whenever this elemental

safety rule is not followed.

1-6 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.2 OVERVIEW

1.2OVERVIEW 1.2.1 INTRODUCTION TO 650 FAMILY OF RELAYS

Historically, substation protection, control and metering functions were performed with electromechanical equipment. This

first generation of equipment was gradually replaced by analog electronic equipment (called static devices), most of which

emulated the single-function approach of their electromechanical precursors. Both of these technologies required

expensive cabling and auxiliary equipment to produce functioning systems.

Recently, digital electronic equipment has begun to provide protection, control and metering functions. Initially, this

equipment was either single function or had very limited multi-function capability, and did not significantly reduce the

cabling and auxiliary equipment required. However, recent digital relays have become quite multi-functional, reducing

cabling and auxiliaries significantly. These devices also transfer data to central control facilities and Human Machine

Interfaces using electronic communications. The functions performed by these products have become so broad that many

users prefer the term IED (Intelligent Electronic Device).

It is obvious to station designers that the amount of cabling and auxiliary equipment installed in stations can be even further

reduced, to 20% to 70% of the levels common in 1990, to achieve large cost reductions. This requires placing even more

functions within the IEDs.

Users of power equipment are also interested in reducing cost by improving power quality and personnel productivity, and

as always, in increasing system reliability and efficiency. These objectives are realized through software which is used to

perform functions at both the station and supervisory levels. The use of these systems is growing rapidly.

High speed communications are required to meet the data transfer rates required by modern automatic control and

monitoring systems. In the near future, very high speed communications will be required to perform protection signalling.

IEDs with capabilities outlined above will also provided significantly more power system data than is presently available,

enhance operations and maintenance, and permit the use of adaptive system configuration for protection and control

systems. This new generation of equipment must also be easily incorporated into automation systems, at both the station

and enterprise levels.

1

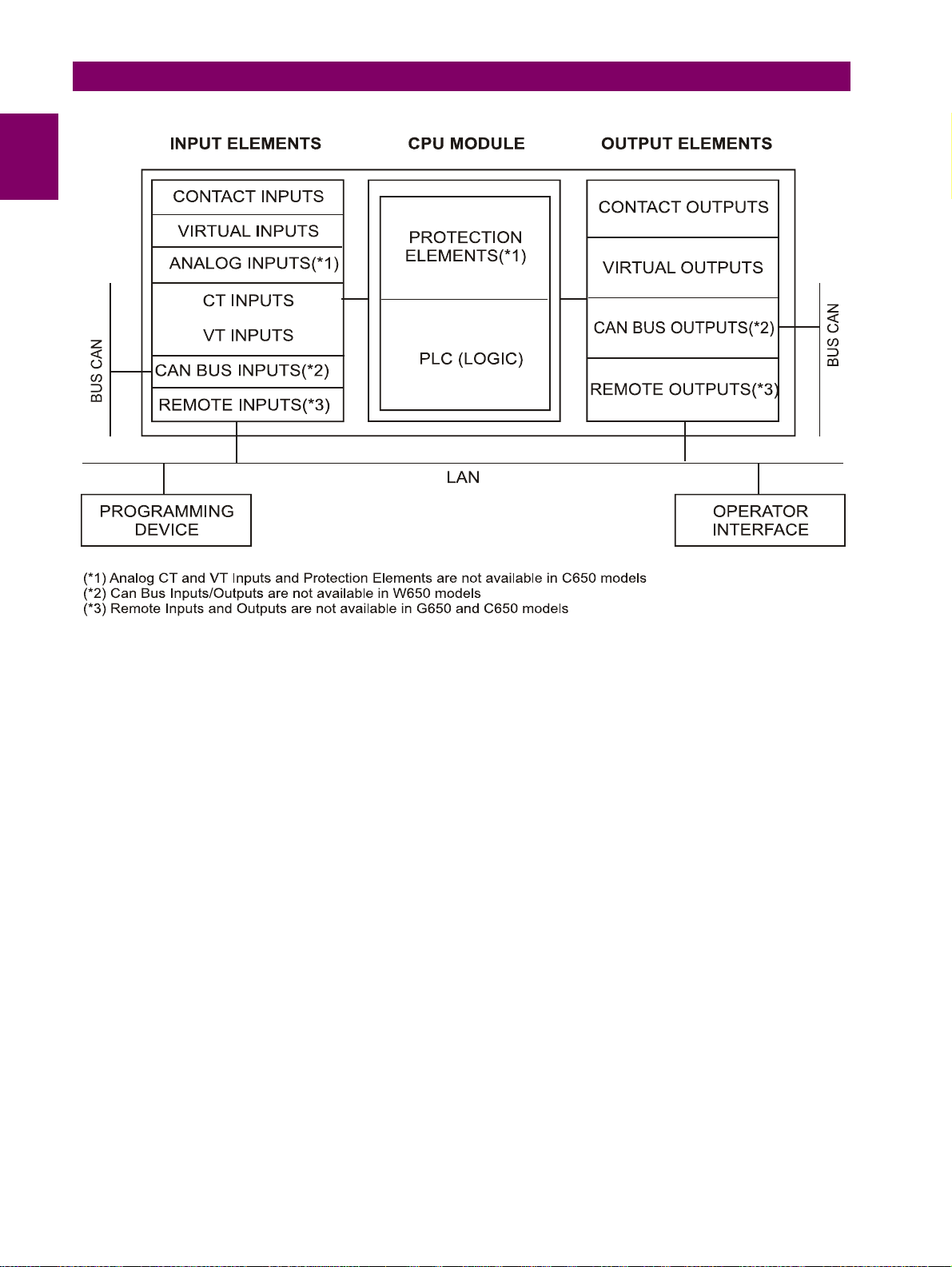

1.2.2 HARDWARE ARCHITECTURE

650 family of relays has been designed to meet the goals described above that are appearing nowadays in the environment

of new substations.

The 650 is a digital-based device containing a central processing unit (CPU) that handles multiple types of input and output

signals. The 650 family can communicate over a local area network (LAN) with an operator interface, a programming

device, or another 650 or UR device.

The CPU module contains firmware that provides protection elements in the form of logic algorithms, as well as

programming logic gates, timers, and latches for control features. It incorporates two internal processors, one for generic

use and a second one dedicated for communications.

Input Elements accept a variety of analog or digital signals from the field. The 650 isolates and converts these signals into

logic signals used by the relay.

Output Elements convert and isolate the logic signals generated by the relay into digital signals that can be used to control

field devices.

GEK-113285A G650 Generator Protection & Control System 1-7

1.2 OVERVIEW 1 GETTING STARTED

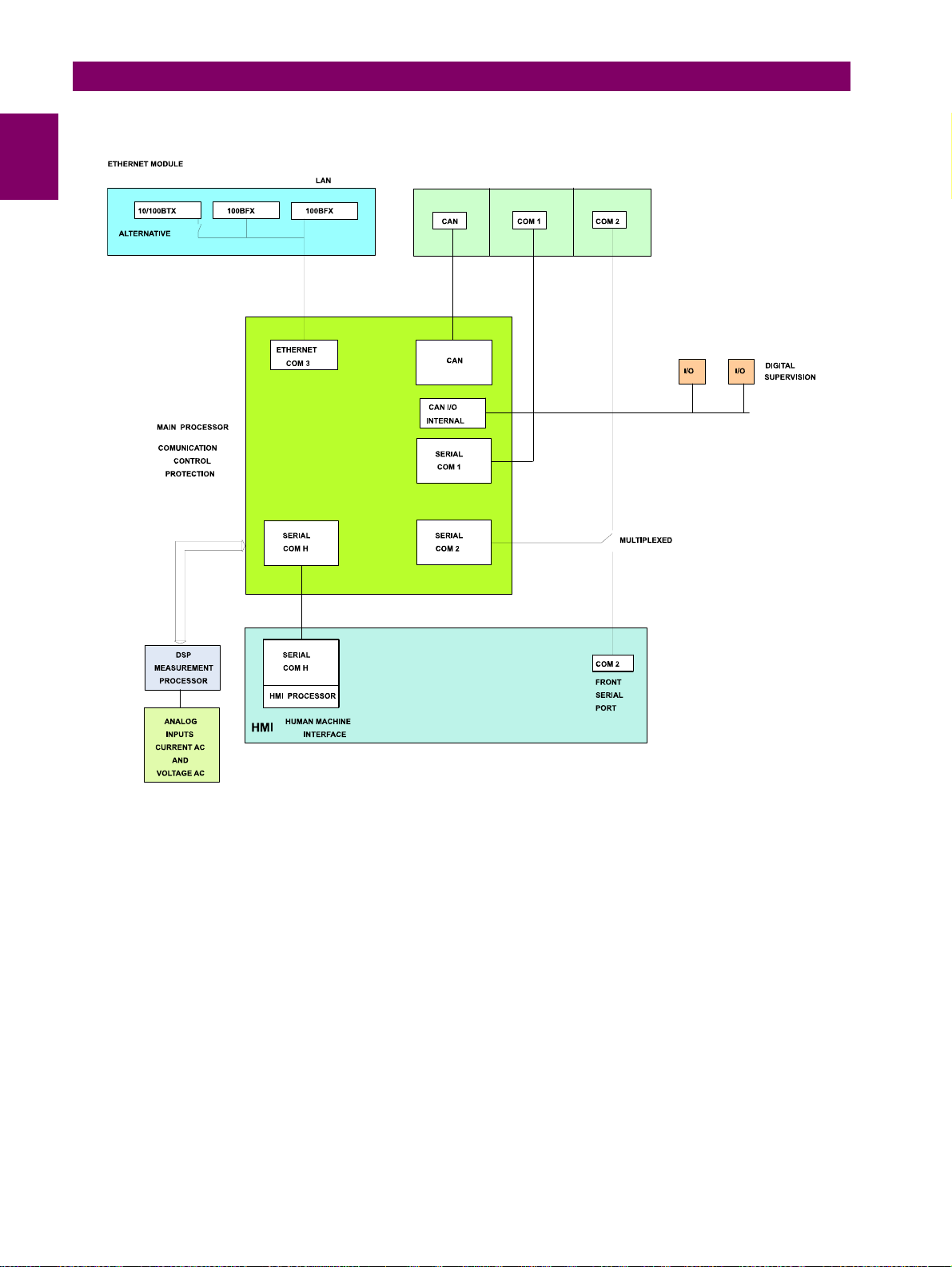

Figure 1–6: 650 CONCEPT BLOCK DIAGRAM

Contact Inputs/Outputs are signals associated to the physical input/output contacts in the relay

CT and VT inputs are signals coming from the inputs of current and voltage transformers, used for monitoring the power

system signals. Not available for C650 models.

CAN Bus Inputs/Outputs: are signals associated to physical input/output contacts from independent modules connected

to the 650 unit via a CAN Bus. Not available for W650 models.

PLC: Programmable Logic Controller. Control module that enables the unit configuration (assignment of inputs/outputs)

and the implementation of logic circuits.

Protection Elements: Relay protection elements, for example: Overcurrent, overvoltage, etc. Not available for C650

models.

Remote inputs and outputs provide a means of sharing digital point state information between remote devices using IEC

61850 GSSE and GOOSE messages.Remote I/O are not available for G650 models. Not available for G650 and C650

models.

Analog Inputs are signals associated with transducers.

1-8 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.2 OVERVIEW

1.2.3 SOFTWARE ARCHITECTURE

The firmware (software embedded in the relay) has been designed using object oriented programming techniques (OOP).

These techniques are based on the use of objects and classes, and provide the software architecture with the same

characteristics as the hardware architecture, i.e., modularity, scalability and flexibility.

1.2.4 COMMUNICATIONS ARCHITECTURE

The main processor performs protection, control, and communication functions, incorporating two internal processors, one

for generic use and a second one dedicated for communications.

A dedicated serial port is used for communication between the main processor and the human-machine interface. The

serial connection provides great immunity against electromagnetic disturbances, thus increasing system safety.

All G650 units incorporate an RS232 serial port on the front of the relay. There is also a possibility to incorporate up to two

additional communication modules on the rear.

One of the modules provides asynchronous serial communications, using different physical media (RS485, plastic or glass

fiber optic) depending on the selected model. The module incorporates two identical ports, COM1 and COM2. The COM2

port is multiplexed with the front port. Additionally, this module may incorporate a port for CAN BUS communications, used

for the connection to the Remote CAN BUS I/O module. This feature allows increasing up to 100% the I/O capability, when

the maximum number of I/Os available inside the relay is not enough for a specific application.

Available options are:

Table 1–1: REAR SERIAL COMMUNICATIONS BOARD 1

BOARD CODE FUNCTIONALITY

F Without additional communication ports

A Two RS485 ports

P Two Plastic F.O. ports

G Two Glass F.O. ports

X Two RS485 ports and a CAN port for remote CAN Bus Inputs/Outputs

Y Two Plastic F.O. ports and a CAN port for remote CAN Bus Inputs/Outputs (fiber)

Z Two Glass F.O. ports and a CAN port for remote CAN Bus Inputs/Outputs (fiber)

C CAN port for remote CAN Bus I/O (cable)

M RS485 CAN port for remote CAN bus I/O (cable)

1

The other module provides Ethernet communications (COM3 port), using 10/100BaseTX (self-negotiable speed) or

100BaseFX connectors, depending on the selected model. The most complete models include a double redundant

100BaseFX fiber optic port. Redundancy is provided at the physical level; the unit incorporates internally duplicated and

independent controllers for extended system reliability and accessibility.

Available Options are:

Table 1–2: REAR ETHERNET COMMUNICATIONS BOARD 2

BOARD CODE FUNCTIONALITY

B One 10/100BaseTX port (self-negotiable speed)

C One 10/100BaseTX port and one 100BaseFX port.

D One 10/100BaseTX port and redundant 100BaseFX ports

E Redundant 10/100BaseTX ports

For options C and D it is required to select the active physical media, by means of an internal selector inside the module.

The factory configuration for this selection is the 10/100BaseTX port.

Finally, internal communication with input and output modules is performed via an internal CAN bus, independent from the

one used for remote CAN BUS I/Os. This fact provides increased communication speed, as well as the possibility of

acknowledgement of modules, abnormalities, etc. As this is a serial port supporting a communications protocol, it provides

extraordinary immunity against external or internal disturbances.

GEK-113285A G650 Generator Protection & Control System 1-9

1.2 OVERVIEW 1 GETTING STARTED

Figure 1–7: COMMUNICATIONS ARCHITECTURE (B6816F1)

1-10 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

1.3ENERVISTA 650 SETUP SOFTWARE 1.3.1 SYSTEM REQUIREMENTS

The EnerVista 650 Setup software interface is the preferred method to edit settings and view actual values because the PC

monitor can display more information in a simple comprehensible format.

The following minimum requirements must be met for the EnerVista 650 Setup software to properly operate on a PC:

• Pentium® class or higher processor (Pentium® II 300 MHz or higher recommended)

• Windows® NT 4.0 (Service Pack 3 or higher), Windows® 2000, Windows® XP

• Internet Explorer® 5.0 or higher

• 64 MB of RAM (128 MB recommended)

• 40 MB of available space on system drive and 40 MB of available space on installation drive

• RS232C serial and/or Ethernet port for communications to the relay

1.3.2 INSTALLATION

After ensuring the minimum requirements for using EnerVista 650 Setup are met (see previous section), use the following

procedure to install the EnerVista 650 Setup from the GE EnerVista CD.

1. Insert the GE EnerVista CD into your CD-ROM drive.

2. Click the Install Now button and follow the installation instructions to install the no-charge EnerVista software.

3. When installation is complete, start the EnerVista Launchpad application.

4. Click the IED Setup section of the Launch Pad window.

1

Figure 1–8: LAUNCHPAD WINDOW

GEK-113285A G650 Generator Protection & Control System 1-11

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

5. In the EnerVista Launch Pad window, click the Add Product button and select the “G650 Generator Protection &

Control System” relay from the Install Software window as shown below. Select the “Web” option to ensure the most

recent software release, or select “CD” if you do not have a web connection, then click the Add Now button to list

software items for the G650.

Figure 1–9: ADD PRODUCT WINDOW

6. If “Web” option is selected, choose the G650 software program and release notes (if desired) from the list and click the

Download Now button to obtain the installation program.

Figure 1–10: WEB UPGRADE WINDOW

1-12 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

7. EnerVista Launchpad will obtain the installation program from the Web or CD. Once the download is complete, double-

click the installation program to install the EnerVista 650 Setup software.

8. Select the complete path, including the new directory name, where the EnerVista 650 Setup will be installed.

9. Click on Next to begin the installation. The files will be installed in the directory indicated and the installation program

will automatically create icons and add EnerVista 650 Setup to the Windows start menu.

10. Follow the on-screen instructions to install the EnerVista 650 Setup software. When the Welcome window appears,

click on Next to continue with the installation procedure.

1

Figure 1–11: ENERVISTA 650 SETUP INSTALLATION

11. When the Choose Destination Location window appears, and if the software is not to be located in the default

directory, click Change… and type in the complete path name including the new directory name and click Next to

continue with the installation procedure.

Figure 1–12: ENERVISTA 650 SETUP INSTALLATION CONT.

GEK-113285A G650 Generator Protection & Control System 1-13

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

12. The default program group where the application will be added to is shown in the Selected Progra m Folder window.

Click Next to begin the installation process, and all the necessary program files will be copied into the chosen directory.

Figure 1–13: SELECT PROGRAM FOLDER

13. To finish with the installation process, select the desired language for startup.

Figure 1–14: LANGUAGE WINDOW

1-14 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.3 ENERVISTA 650 SETUP SOFTWARE

14. Click Finish to end the installation. The G650 device will be added to the list of installed IEDs in the EnerVista

Launchpad window, as shown below.

1

Figure 1–15: ENERVISTA LAUNCHPAD

1.3.3 CONNECTING ENERVISTA 650 SETUP WITH G650

This section is intended as a quick start guide to using the EnerVista 650 Setup software. Please refer to section 4.1 in this

manual for more information about the EnerVista 650 Setup software interface.

a) CONFIGURING AN ETHERNET CONNECTION

Before starting, verify that the Ethernet network cable is properly connected to the Ethernet port on the back of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista CD or online

from http://www.GEindustrial.com/multilin (see previous section for installation instructions).

2. Go to “Communication>Computer” and enter the following data referring to communications:

3. Select Control Type as MODBUS TCP/IP from the drop-down list. This option will display a number of interface

parameters that must be entered for proper Ethernet communications.

4. Enter the relay IP address (from “Setpoint>Product Setup >Communication Settings>Network>IP ADDRESS”) in

the IP Address field in MODBUS TCP/IP SETUP.

5. Enter the relay ModBus address (from “Setpoint>Product Setup >Communication Settings>ModBus

Protocol>ModBus Address COM1/COM2 setting”) in the Unit Identifier (Slave Address) field.

6. Enter the ModBus port address (from “Setpoint>Product Setup >Communication Settings>ModBus

Protocol>ModBus Port Number” setting) in the ModBus Port field.

7. The Device has now been configured for Ethernet communications. Proceed to press the ON button to begin

communicating.

GEK-113285A G650 Generator Protection & Control System 1-15

1.3 ENERVISTA 650 SETUP SOFTWARE 1 GETTING STARTED

b) CONFIGURING AN RS232 CONNECTION

Before starting, verify that the RS232 serial cable is properly connected to the RS232 port on the front panel of the relay.

1. Install and start the latest version of the EnerVista 650 Setup software (available from the GE EnerVista CD or online

from http://www.GEindustrial.com/multilin (see previous section for installation instructions).

2. Go to “Communication>Computer” and enter the following data referred to communications:

3. Select Control Type as No Control Type from the drop-down list. This option will display a number of interface

parameters that must be entered for proper serial communications.

4. Enter the relay Slave Address (“Setpoint>Product Setup >Communication Settings>ModBus Protocol” menu) in

the Slave Address field. The default value is 254.

5. Enter the physical communications parameters (Baudrate and parity settings) from the “Setpoint>Product Setup

>Communication Settings>Serial Ports” menu, in their respective fields. Default values are 19200 for baudrate and

none for parity.

6. The Device has now been configured for RS232 communications. Proceed to press the ON button to begin

communicating.

1-16 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.4 650 HARDWARE

1.4650 HARDWARE 1.4.1 MOUNTING & WIRING

Please refer to Chapter 3. Hardware for detailed mounting and wiring instructions.

1.4.2 650 COMMUNICATIONS

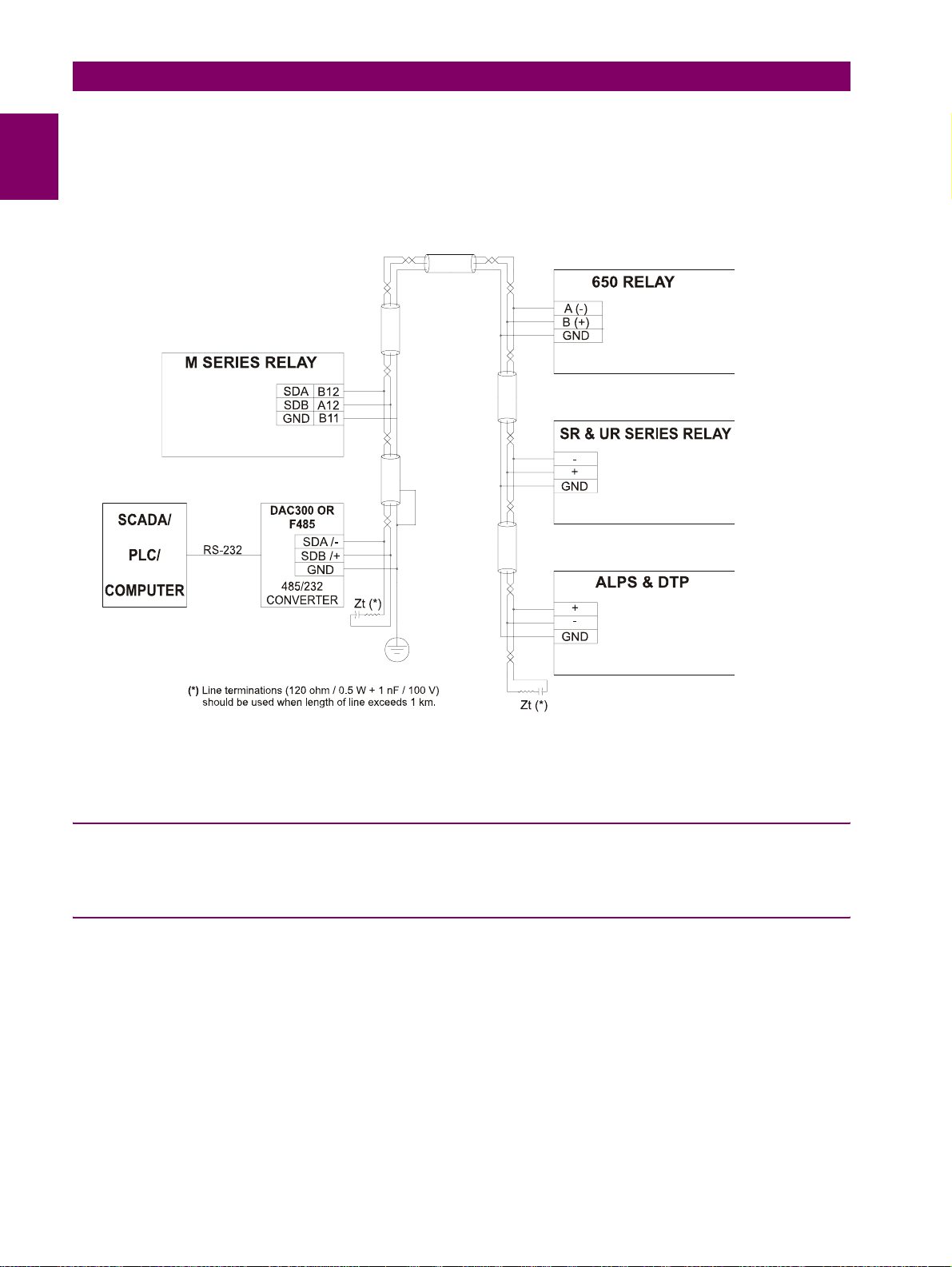

The Enervista 650 Setup software communicates to the relay via the faceplate RS232 port or the rear RS485/Ethernet

ports. To communicate via the faceplate RS232 port, a standard “straight-through” serial cable is used. The DB-9 male end

is connected to the relay and the DB-9 or DB-25 female end is connected to the PC COM1 or COM2 port as described in

Figure 1–16:.

To communicate through the G650 rear RS485 port from a PC RS232 port, the GE Multilin RS232/RS485 converter box is

required. This device (catalog number F485) connects to the computer using a “straight-through” serial cable. A shielded

twisted-pair (20, 22 or 24 AWG according to American standards; 0.25, 0.34 or 0.5 mm2 according to European standards)

connects the F485 converter to the G650 rear communication port.

In order to minimize communication errors that could be caused by external noise, it is recommended to use a shielded

twist pair. In order to avoid loops where external currents could flow, the cable shield must be grounded only at one end.

The converter box (-, +, GND) terminals are connected to the relay (SDA, SDB, GND) terminals respectively. For long

communications cables (longer than 1 km), the RS485 circuit must be terminated in an RC network (i.e. 120 ohm, 1 nF).

This circuit is shown on Figure 1–17: RS485 CONNECTION FOR 650 UNITS, associated to text Zt(*).

1

Figure 1–16: RELAY- PC CONNECTION FOR RS232 FRONT PORT

To minimize errors from noise, the use of shielded twisted pair wire is recommended. For correct operation, polarity must

be respected, although a different polarity will not damage the unit. For instance, the relays must be connected with all

RS485 SDA terminals connected together, and all SDB terminals connected together. This may result confusing

sometimes, as the RS485 standard refers only to terminals named “A” and “B”, although many devices use terminals

named “+” and “-“.

As a general rule, terminals “A” should be connected to terminals “-“, and terminals “B” to “+”. The GND terminal should be

connected to the common wire inside the shield, when provided. Otherwise, it should be connected to the shield. Each

relay should also be daisy chained to the next one in the link. A maximum of 32 relays can be connected in this manner

GEK-113285A G650 Generator Protection & Control System 1-17

1.4 650 HARDWARE 1 GETTING STARTED

without exceeding driver capability. For larger systems, additional serial channels must be added. It is also possible to use

commercially available repeaters to increase the number of relays on a single channel to more than 32. Do not use other

connection configurations different to the recommended.

Lightening strikes and ground surge currents can cause large momentary voltage differences between remote ends of the

communication link. For this reason, surge protection devices are internally provided. To ensure maximum reliability, all

equipment should have similar transient protection devices installed.

Figure 1–17: RS485 CONNECTION FOR 650 UNITS

To communicate through the G650 rear Ethernet port from a PC a crossover cable is required. If the connection is

performed through a hub or a switch, a direct Ethernet cable is required.

1.4.3 FACEPLATE DISPLAY

All messages are displayed on a 20x4 character LCD display. An optional graphic display is also available. Messages are

displayed in different languages according to selected model.

1.4.4 MAINTENANCE

G650 requires a minimum amount of maintenance when it is commissioned into service. G650 is a microprocessor based

relay and its characteristics do not change over time. As such no further functional tests are required. However, it is

recommended that maintenance on the G650 be scheduled with other system maintenance. The maintenance may involve

the following:

In-service maintenance:

1. Visual verification of the analog values integrity such as voltage and current (in comparison to other devices on the

corresponding system).

2. Visual verification of active alarms, relay display messages and LED indications.

3. Visual inspection for any damage, corrosion, dust or loose wires.

1-18 G650 Generator Protection & Control System GEK-113285A

1 GETTING STARTED 1.4 650 HARDWARE

4. Event recorder file download with further event analysis.

Out-of-service maintenance:

1. Check wiring connections for firmness.

2. Analog values (current, voltages, analog inputs) injection test and metering accuracy verification. Calibrated test

equipment is required.

3. Protection elements setpoints verification (analog values injection or visual verification of setting file entries against

relay settings schedule).

4. Contact inputs and outputs verification. This test can be conducted by direct change of state forcing or as part of the

system functional testing.

5. Visual inspection for any damage, corrosion or dust.

6. Event recorder file download with further events analysis.

Unscheduled maintenance such as during a disturbance causing system interruption:

1. View the event recorder and oscillography or fault report for correct operation of inputs, outputs and elements.

If it is concluded that the relay or one of its modules is of concern, contact GE Multilin or one of its representative for prompt

service.

1

GEK-113285A G650 Generator Protection & Control System 1-19

1.4 650 HARDWARE 1 GETTING STARTED

1-20 G650 Generator Protection & Control System GEK-113285A

2 PRODUCT DESCRIPTION 2.1 OVERVIEW

2 PRODUCT DESCRIPTION 2.1OVERVIEW 2.1.1 G650 OVERVIEW

The G650 is a machine generator protection and control device. It may be used to protect and control reciprocating

machines, as well as to operate as a packaged generator sets mains failure detector. Generally speaking the G650

provides distributed generation management capabilities.

The main features of G650 devices include:

• Protection relay with control capabilities for protection of small and medium generators.

• Replacement for legacy devices in the long term based on improved and open protocols in communications as well as

orientation to machine protection system rather than individual protection functions.

• Based on the 650 platform.

• Full graphic capabilities in large display with control functions and PLC programming.

• Protection elements repeated in three groups, used as independent groups or all elements at the same time.

2

Figure 2–1: G650 BLOCK DIAGRAM FOR BASIC FUNCTIONALITY MODELS

GEK-113285A G650 Generator Protection & Control System 2-1

Loading...

Loading...