Page 1

Consumer Home Services Training

TECHNICAL SERVICE GUIDE

TMNF 20 Cubic Foot

GE Refrigerators

MODEL SERIES:

GTRS0

GTRC0

GTRL0

MTRL0

PUB #01-2010

Page 2

Page 3

– 1 –

!

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injur y and proper ty

damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

Page 4

– 2 –

20

TOP MOUNT GE™

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL

All

parts of this

rent are grounded.

or

washers

for service, they must be

properly

appliance capable

If

used to complete a path to ground are r

fastened.

grounding wires, scr

GROUNDING DE

returned

of conducting

to their original position and

VICES

electrical

ews, straps,

ELECTRICAL

T

emperature

Defrost Control (w/no door openings)

Overtemperature

Electrical Rating:

Maximum

Maximum Ground Path Resistance .............................................

NO LOAD

Control Position 5/5 and Ambient of 70°F to 90°F

Fresh Food, °F

Frozen Food, °F

Run

Time, % @ 70°F

Run

Time, % @ 90°F

SPECIFICATIONS

Control (P

Current

osition FF/FZ)

Thermostat

115V AC

Leakage

...................................................

.............................

..............................................................

60 Hz

.....................................................

..................................................................

PERFORMANCE

............................................................................................ 34

............................................................................................. -3

.................................................................................. 20

.................................................................................. 40

AIR FLOW

EVAPORATOR

COLD

MIXED AIR

AIR RE

EVAPORATOR

AIR

TURN TO

FREEZE R

FRESH

FOOD

.105”

T

echnical Data

IMPORTANT SAFETY NOTICE

This

cur-

clips, nuts

emoved

information is intended for use by individuals

adequate backgrounds

experience. Any

in personal injury and pr

seller cannot be responsible for the

tion, nor can it

10hrs @ 35 min

37/0°F

63-57°F

11.6 Amp

0.75

0.14 Ohms

to 40

to 3F

to 40

to 70

REFRIGERATION SY

Compressor

Minimum Compressor Capacity

Minimum Equalized Pr

mA

@ 70°F

PSIG

@ 90°F

PSIG

REFRIGERANT

20

TMNF

TO

CABINET

WIRING

ORANGE

REV. 0

of electrical, electronic

attempt

assume

...........................................................................................

.................................................................................................

.................................................................................................

CHARGE

models

................................................................................

to repair a

operty damage.

any

liability

STEM

essure

(R134a)

.............................................. 22 inches Hg

major

interpretation

in

238C4518P001

possessing

and mechanical

appliance may result

The

manufacturer or

connection

of

with its

BLACK

GREEN/YELLOW

COMPRESSOR

OUND

GR

this

700

4.00

informa-

use.

BTU/hr

40 to 45

48 to 60

ounces

Page 5

– 3 –

Page 6

– 4 –

20

TOP MOUNT GE™

ELECTRONIC

DISCONNECT POWER CORD BEFORE SERVICING

IMPORTANT - RECONNECT ALL

All

parts of this

rent are grounded.

or

washers

for service, they must be

properly

appliance capable

If

grounding wires, scr

used to complete a path to ground are r

fastened.

GROUNDING DE

returned

of conducting

to their original position and

ELECTRICAL

T

emperature

Defrost Control (w/no door openings)

Thermistor kilo-ohm r

.............................................................................................................

.............................................................................................................

Overtemperature

Defrost Thermistor

Electrical Rating:

Maximum Current Leakage

Maximum Ground Path Resistance .............................................

NO LOAD

Control Position 5/5 and Ambient of 70°F to 90°F

Fresh Food, °F

Frozen Food, °F

Run

Time, % @ 70°F

Run

Time, % @ 90°F

SPECIFICATIONS

Control (P

osition FF/FZ)

esistance

Thermostat

.............................................................................................

115V AC

...................................................

.............................

............................................. @0°F

..............................................................

60 Hz

.....................................................

..................................................................

PERFORMANCE

............................................................................................ 34

............................................................................................. -3

.................................................................................. 15

.................................................................................. 30

VICES

electrical

ews, straps,

@37°F

@77°F

AIR FLOW

EVAPORATOR

COLD

MIXED AIR

AIR RE

EVAPORATOR

AIR

TURN TO

FREEZE R

FRESH

FOOD

.105”

T

echnical Data

IMPORTANT SAFETY NOTICE

This

cur-

clips, nuts

emoved

information is intended for use by individuals

adequate backgrounds

experience. Any

in personal injury and pr

seller cannot be responsible for the

tion, nor can it

96hrs @ 35 min

37/0°F

..........

42.7

..........

14.3

.............

5.0

69-59°F

34°F

11.6 Amp

0.75 mA

0.14 Ohms

to 40

to 3F

to 40

to 60

REFRIGERATION SY

Compressor 20 - 22 Models

Minimum Compressor Capacity

Minimum Equalized Pr

@ 70°F

PSIG

@ 90°F

PSIG

REFRIGERANT

20 models

TO

CABINET

WIRING

ORANGE

of electrical, electronic

attempt

assume

................................................................................................

.................................................................................................

CHARGE

................................................................................................

to repair a

operty damage.

any

liability

STEM

..........................................................

essure

(R134a)

major

interpretation

in

.............................................. 22 inches Hg

238C4518P002

possessing

and mechanical

appliance may result

The

manufacturer or

of

connection

this

with its

BLACK

GREEN/YELLOW

COMPRESSOR

OUND

GR

informa-

use.

803

BTU/hr

40 to 45

48 to 60

4.0

ounces

Page 7

– 5 –

MODEL NOMENCLATURE

Model series GTRS0, GTRC0, GTRL0, MTRL0 20-cubic foot refrigerators,

Page 8

– 6 –

F -

Flat

L - Left door swing

WW - White

on

white

T =Top Freezer

G = GE

M = Moffat

Configuration

Exterior

C=Color

F=High Gloss

L=Laminate

S=Stainless S teel

Volume

0 = 20 ft

Model Year

Z=201 0

Engineering Nomenclature

A=Initial Design

B=1stRevisio n

C=2nd Revision

D=3rd Revision

Etc.

Door Type / Special

Characters

L=Left Door Swing

R= Right Door Swing

K= Conv ersion Kit Mod el

<SPACE>

P T S C 0 L H Z A R W W

Interior/Shelves

Brand/Product

Depth/Power

C=Custom Style

H=Energy Star

L=Clean Steel

R=Canadá

S=Standard Depth

TM

F= Superior Wire Shelves

G=Standar d Glass Shelves

H=Upgrade Glass Shelves

I=Deluxe Glass Shelves

J=Spill Proof Glass/2 Split/1 FW

K=Spill-Proo f Glass Shelves 4-Split L=

Spill-Proo f/Slid e-Out GlassShelves

M=Spill-Proof/Slide-Out G lass & Quic k

Space Shalves

Icemaker/Exterior

A=Not Ice Maker Ready

B= Ice Maker Ready

C= Factory Ice Maker

D=Filter Ready/Ice Maker

E=6 Month Filter/Ice Mak er

F=1 Year Filter/Ice Maker*

(*Profi le CS has Ext Dips / Crush ed

/Cub ed/Wate r/ 6 Month Filter)

G=Intern al Water Dispenser/ Filter

Ready/ Ice Maker

H=Intern al Water Dispenser/ 6

Month Filter / Ice Maker

I=Inter nal Water Dispenser/ 1 Year

Filter / Ice Maker

AA - Almond on almond

R - Right door swing

Exterior Color /Special

BB=Black / Black

BB - Black on black

BS=Stainless / Black Case,

CC - Bisque on Bisque

Handles

CC=Bisqu e / Bisqu e

WH - White on black

CS = Clean Steel / Black Case,

AD - Almond on Black

Handles

LB = Clean steel/Black Handles

SS=Stainless / Stainless

Appea rance Handl

Features

Page 9

– 7 –

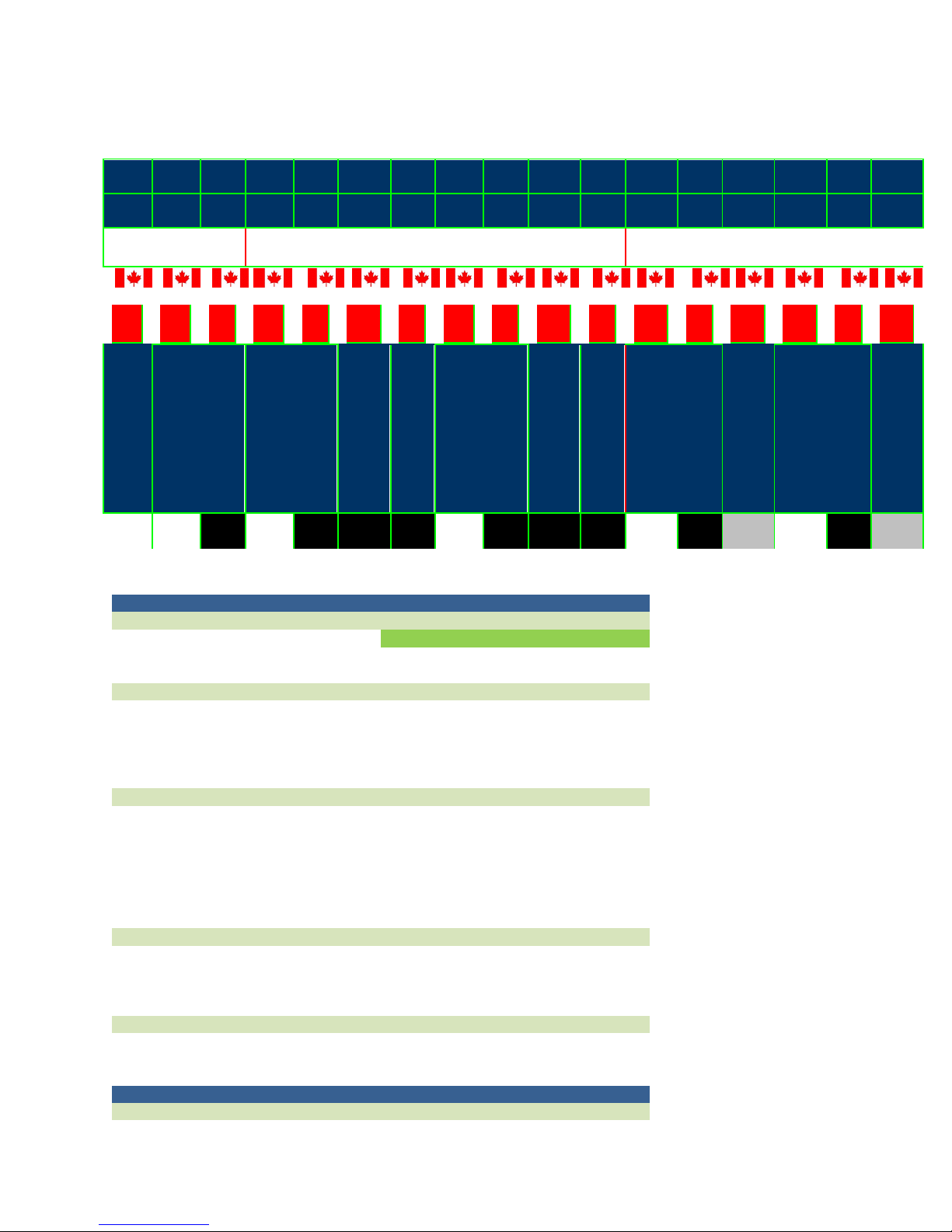

SERIAL NUMBERS

The serial numbers for General Electric refrigerators consists of two letters, followed by six

numerals. The two prefix letters of the serial number indicate the month and year the product was

manufactured. The year of manufacture does not correspond with the model year of the model

number.

JAN

FEB

MAR

APR

MAY

JUN

JUL

AUG

SEP

OCT

NOV

DEC

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

AA

AD

AF

AG

AH

AL

AM

AR

AS

AS

AT

AV

AZ

AA

AD

AF

AG

AH

AL

AM

AR

AS

Refrigerators using a number four (4) as the first digit of the serial number are designated as

Celaya production.

AZ

DZ

DA

DD

DF

DG

DH

DL

DM

DR

DS

DS

DT

DV

DZ

DA

DD

DF

DG

DH

DL

DM

DR

DS

FZ

FA

FD

FF

FG

FH

FL

FM

FR

FD

FD

FT

FV

FZ

FA

FD

FF

FG

FH

FL

FM

FR

FD

GZ

GA

GD

GF

GG

GH

GL

GM

GR

GS

GS

GT

GV

GZ

GA

GD

GF

GG

GH

GL

GM

GR

GS

HZ

HA

HD

HF

HG

HH

HL

HM

HR

HS

HS

HT

HV

HZ

HA

HD

HF

HG

HH

HL

HM

HR

HS

LZ

LA

LD

LF

LG

LH

LL

LM

LR

LS

LS

LT

LV

LZ

LA

LD

LF

LG

LH

LL

LM

LR

LS

MZ

MA

MD

MF

MG

MH

ML

MM

MR

MS

MS

MT

MV

MZ

MA

MD

MF

MG

MH

ML

MM

MR

MS

RZ

RA

RD

RF

RG

RH

RL

RM

RR

RS

RS

RT

RV

RZ

RA

RD

RF

RG

RH

RL

RM

RR

RS

SZ

SA

SD

SF

SG

SH

SL

SM

SR

SS

SS

ST

SV

SZ

SA

SD

SF

SG

SH

SL

SM

SR

SS

TZ

TA

TD

TF

TG

TH

TL

TM

TR

TS

TS

TT

TV

TZ

TA

TD

TF

TG

TH

TL

TM

TR

TS

VZ

VA

VD

VF

VG

VH

VL

VM

VR

VS

VS

VT

VV

VZ

VA

VD

VF

VG

VH

VL

VM

VR

VS

ZZ

ZA

ZD

ZF

ZG

ZH

ZL

ZM

ZR

ZS

ZS

ZT

ZV

ZZ

ZA

ZD

ZF

ZG

ZH

ZL

ZM

ZR

ZS

Page 10

– 8 –

MODELS:

0 0 0

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

0 0 4000 0 0 0 1000 0 5200 800 6000 1300 200 1500

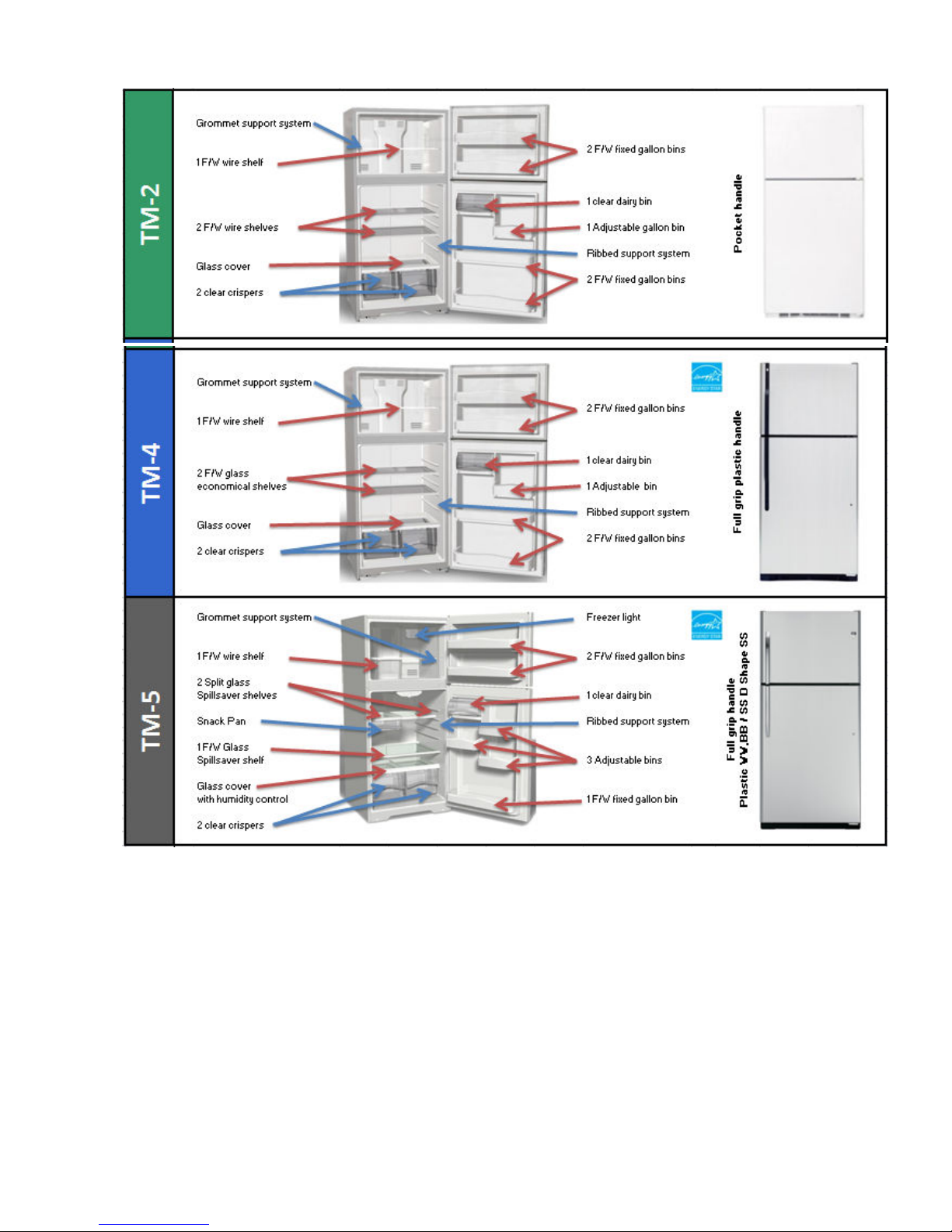

TM 2 T M 4 T M 5

WW WW BB WW BB LB BS WW BB LB BS WW BB SS WW BB SS

C

MTRC0FAZAR

C

C

GTRC0GAZAR

C

C

GTRC0HBZAR

C

C

GTRL0HBZAR

GTRS0HBZAR

C

C

GTRC0HBZAL

C

C

GTRL0HBZAL

GTRS0HBZAL

C

C

GTRC0KBZAR

C

GTRS0KBZAR

C C

C

GTRC0KBZAL

PRODUCT

General Information

Brand GE

Configuration Top Freezer

Total (cubic feet) 20.0

Controls

Type Knob, Electro-mechanical and Knob, electronic

Location Upfront

Features Temp (1-9)

Sensors No

Graphics GE

GE Smartwater

Filter No

Lighting 1-40W

Protective Lamp Covers Clear

Internal Dispenser No

Door Hinge Hinge Right. Reversible

Door Stops Yes

Leveling System 2 Point Front Adj.

Handles

Type GE Face Mounted Plastic

Color Color Matched

Reversible Yes (No kit required)

Defrost Type No Frost (Frost guard)

Air Clearances

Each Side (in.) 1/8

Top (in.) 1

Back (in.) 1

POWER

Electrical Requirements

Volts/Hertz/Amps 120V;60Hz;15A

GTRS0KBZAL

Page 11

– 9 –

Page 12

– 10

SERVICE REVIEW:

REMOVE DOORS:

TOP HINGE WITH 5/16"SOCKET SCREWDRIVER REMOVE TWO NUTS.

REMOVE THE TOP HINGE

Page 13

– 11

REMOVE THE FREEZER DOOR

INTERMEDIATE HINGE:

WITH TORX T-15 HEAD SCREWDRIVER REMOVE THREE SCREWS AND REMOVE

INTERMEDIATE HINGE

Page 14

– 12

REMOVE FRESH FOOD DOOR:

LOWER HINGE:

WITH 5/16"SOCKET SCREWDRIVER REMOVE TWO NUTS.

Page 15

– 13

ROLLERS

ROLLERS AT THE BASE OF THE CABINET ENABLE THE CUSTOMER TO EASILY MOVE

THE REFRIGERATOR. CABINET LEVELING IS DONE BY ADJUSTING THE FRONT

ROLLERS. TO ADJUST THE FRONT ROLLERS, USE A 3/8-IN. SOCKET OR A LARGE FLAT

HEAD SCREWDRIVER TO TURN THE ROLLER ADJUSTMENT SCREWS LOCATED BEHIND

THE BASE GRILLE.

FREEZER COMPARTMENT

Page 16

– 14

LIFT UP THE LEFT SIDE OF THE SHELF AND SLIDE IT LEFT INTO THE CENTER OF THE

SHELF SUPPORTS.

ROTATE THE RIGHT SIDE OF THE SHELF UP AND OUT OF THE SHELF SUPPORTS

ICEMAKER

REMOVE THE ICEMAKER AND WITH THE PHILLIPS HEAD SCREWDRIVER TWO SCREWS

PRESS AND

PULL

COVER EVAPORATOR

Page 17

– 15

REMOVE THE COVER EVAP WITH THE PHILLIPS HEAD SCREWDRIVER FOUR SCREWS

EVAPORATOR FAN MOTOR

DISCONNECT TERMINALS AND CONNECTOR

Page 18

– 16

EVAPORATOR AND HEATER DEFROST

THE DEFROST HEATER IS A SINGLE-TUBE, RADIANT HEATER. IT IS HELD IN PLACE BY 2

TABS ON THE EVAPORATOR (1 ON EACH SIDE) AND BY 2 CERAMIC AND WIRE

SUPPORTS.

THE CERAMIC AND WIRE SUPPORTS PREVENT THE HEATER FROM SAGGING AND

TOUCHING THE METAL DRAIN PAN IF THE GLASS IS BROKEN.

HEATER

DEFROST

DEFROST DRAIN

PROBE

Page 19

– 17

CONTROL BOX

REMOVE THE CONTROL BOX WITH THE PHILLIPS HEAD SCREWDRIVER TWO SCREWS

COMPRESSOR:

DRYER

COMPRESSOR

NO-CLEAN

CONDENSER

CONDENSER FAN

Page 20

– 18

RATING PLATE

The rating plate, located inside the refrigerator

on the upper left-hand side, contains the model

and serial numbers. Additionally, the rating plate

specifies the minimum installation clearances,

electrical voltage, frequency, maximum

amperage rating, and refrigerant charge and

type.

MINI-MANUAL

The mini-manual, located behind the base grille,

is secured to the underside of the cabinet for

shipping with a piece of tape. After referencing

the mini-manual, return it to its original location

for future use.

DOOR REVERSAL

head WITH 5/16"SOCKET SCREWDRIVER are

used to mount the top, center, and bottom

hinges to the cabinet. Mounting holes in the

hinges are not elongated, and the hinges are

not adjustable. When reinstalling the hinges,

tighten screws firmly but avoid overtightening to

prevent stripping.

Note:

• When reversing the door swing, read all

instructions thoroughly before starting.

• When handling parts, use caution to avoid

scratching paint.

• Sort screws to correspond with related parts

and be certain to use the proper screw with

each part.

• Place doors on a protected surface to

prevent damage.

• Once the door reversal procedure has been

initiated, do not move the cabinet until the

procedure is complete.

• Unplug the refrigerator from its electrical outlet.

• Empty all door shelves, including the dairy

compartment.

Mini-Manual Located Under Base Grille

Rating Plate Location

Page 21

Freezer Door

1. Tape freezer door shut with masking tape.

Remove the hinge cover from the freezer

door hinge (some models).

2. Remove 2 (T-20) Torx head screws and the

top hinge.

3. Remove the tape and tilt the door away from

the cabinet. Lift the door off the center hinge

pin and place on a protected surface.

Fresh Food Door

1. Tape the fresh food door shut with masking

tape.

2. Remove the center hinge pin with a 3/4-in.

socket.

3. Remove the tape and tilt the door away from

the cabinet. Lift the door straight up and off

the bottom hinge and place on a protected

surface.

Note: If the washer is not on the bottom hinge,

check to see if it is stuck to the bottom of the

door.

Reversing the Doors

1. Install the top hinge and screws on the

opposite side of the cabinet. Do not tighten

the screws at this time.

2. Remove the base grille by pulling it straight

out from the unit.

Note : If the washer is not on the bottom hinge,

check to see if it is stuck to the bottom of the

door.

3. Using a Torx driver, remove the screws and

bottom hinge from the cabinet and install on

the opposite side of the cabinet.

– 7 –

Top

Hinge

Hinge

Pin

Page 22

4. Cover the blade of a putty knife or small flat

screwdriver (to avoid scratching the paint)

and use the edge to gently pry the colormatched screw cap off the screw heads.

Note: Keep the screws with the center hinge.

These are longer screws and will be used when

installing the center hinge on the opposite side

of the cabinet.

5. Remove 3 Torx head screws and the center

hinge.

6. Remove the mullion cover using the putty

knife or screwdriver. Install the cover on the

opposite side of the cabinet.

7. Install the center hinge with the three long

screws on the opposite side of the cabinet.

Replace the color-matched cap.

8. Move the metal door stop and any associated

screws to the opposite side of the door.

Fresh Food Door Handles

1. Remove the plug button by carefully prying

underneath the edge with a small, flat blade.

Remove the screw that fastens the bottom of

the handle to the door. Remove the lower

part of the long handle (some models).

2. Remove the 2 screws and the handle from

the top of the door.

– 8 –

Long Handle

Short

Screw

Mullion

Cover

Handle

Hole

Pin

Plug

Screw

Cap

Short

Handle

Handle

Plug

Handle

Plug

Page 23

– 9 –

3. After the handle has been removed, move

the small plug buttons to the opposite side of

the door and install in the screw holes.

4. Move the large plug button to the opposite

side of the door and install in the thimble

hole.

5. Move the front door plug button to the

opposite side of the door and install in the

screw hole.

6. Install the handle to the opposite side of the

door with 3 screws.

Note: If equipped with long handle, ensure that

pin in the lower part of the handle is installed in

bottom of the door.

7. Install handle plug.

Plug Button

Long

Handle

Handle

Plug

Small

Plug

Buttons

Button

Short

Handle

Hole

Pin

Handle

Plug

Page 24

Freezer Door Handles

1. Remove the screws and handle from the

freezer door.

2. Move the plug button to the opposite side of

the door and install in the handle screw hole.

3. Install the handle to the opposite side of the

door using the holes closest to the edge of

the door.

Rehanging The Doors

1. Lower the fresh food door onto the bottom

hinge pin.

Note: Ensure that the washer is on bottom

hinge pin.

2. Line up the fresh food door with the center

hinge bracket. Install the hinge pin in the

center hinge bracket and door with a 3/4-in.

socket. Tighten the hinge pin in the center

hinge bracket.

3. Install the freezer door onto the center hinge

pin and upper hinge (screws loose). Support

the door on the handle side and make sure

the door is straight and the gap between the

doors is even across the front. While

holding the door straight, tighten the top

hinge screws.

– 10 –

Hinge

Pin

Center

Hinge

Bracket

Center Hinge

Pin

Page 25

– 11 –

SHELVES and BINS

Note: Not all features are on all models.

Some models have wire shelves that

can be

adjusted in the same manner.

Refrigerator

To

remove:

Tilt the shelf up at the

Lift the shelf up at the back

the shelf

To

replace:

While tilting the shelf up, insert

hook at the back of the shelf in a slot on

the

track.

Lower the front of the shelf

bottom

of the shelf locks

Freezer

To

To

Compartment

remove:

Lift up the left side of the shelf

it left into the

supports.

Rotate the right side of the shelf up and

out of the shelf

replace:

Holding

left end of the shelf into

shelf

supports

desired

level.

Insert the right end of the shelf

shelf

supports

each end of the shelf on

the shelf

Spillproof

Spillproof

help

shelves. To

see

Rearranging

Shelves

shelves have special edges

prevent

spills from

remove

Compartment

front.

out.

center

of

supports.

the shelf

supports.

diagonally,

on

the

at the same

(on some models)

dripping to lower

or

replace

the Shelves

side wall at the

.

and bring

until

into place.

and

the shelf

insert

the center

into

level.

Rest

the bottom

the shelves,

the

the

to

top

slide

the

of the

the

of

NOTE:

For models with

icemaker, the freezer shelf must

an automatic

be

in

lower position for the ice cube bucket

the

cubes.

the

to

catch

Page 26

– 12 –

Slide-Out Spillproof

The

slide-out spillproof

reach items stored

special edges

spills

from dripping

To remove:

are designed

Remove all items from

Slide the shelf out until it

Lift the front edge of the shelf

central

tabs are above the

Continue pulling

it can be

removed.

Shelf

(on

shelf

allows you

behind others.

to help

to lower

shelves.

shelf.

stops.

front bar.

the shelf

forward

some

The

prevent

until

the

until

models)

to

To

replace:

Place the rear shelf tabs just in

the

central notches

Slide the shelf in until the

are slightly

behind

Lower the shelf into place until it is

horizontal

Make sure

and

doesn’t move freely

and slide the

that the

Make sure you push

in before you close

the

shelf

sits

from

the

shelves all

the door.

on the

front bar.

shelf in.

flat

after

side

front

shelf frame.

central

tabs

reinstallation

to side.

the

way

of

Finger hold

Snugger

Adjustable

Door

Adjustable

refrigerator

To remove:

To

replace or

molded supports

Bin will lock in

Bins on the

bins can easily be

to work

area.

Lift bin

straight

relocate:

Engage the bin in the

of the

door,

place.

carried

up, then

and

from

pull out.

push in.

The snugger

or sliding of small items

shelf. Grip the finger

the

snugger

helps

and

prevent

hold

move it

tipping,

spilling

stored

on the

near the rear of

to fit your

needs.

door

Non-Adjustable

To remove:

pull

To replace:

supports

lock in

Lift the shelf

out.

Engage the shelf in

on the door and

place.

Shelves on the Door

straight up

push

then

the molded

down. It will

Freezer Tilt Out Bin

Push the

To remove:

it

To replace:

the

down. It will lock in

NOTE:

button

Hold the sides of the bin

straight

up, then pull

Engage the ends of the bin in

molded supports

Do not

overload

(on

some models)

as you tilt out the

out.

on the door

place.

the bin.

bin.

and

lift

and push

Page 27

– 13 –

of

To

remove,

position,

position and

slide

lift

the

lift it

the

rack

out to the

rack

up and past the

out.

stop

stop

Shelf Saver Rack

Slide-out beverage rack

soda or

two

wine/water bottles (lengthwise).

(on some

holds

models)

twelve

cans

It can be removed for cleaning.

Fruit and Vegetable Crisper

Excess water that may

bottom

should

of the

be wiped

drawers

dry.

accumulate

or

under the drawers

in

the

Adjustable Humidity Crisper

Slide the

HIGH

recommended

control

setting

all the way to

to

provide

for

most vegetables.

high humidity

(on some models)

the

Slide the

setting

recommended for

control

to

provide

all the way to

lower humidity

most

fruits.

the

LOW

levels

Snack Pan

This pan can be

location

(on some models)

moved

for your

family’s needs.

to the

most useful

Adjustable Temperature

When the pan is

the left side and the lever is set at

air from the

to keep it very

You can move the pan to any

don’t

want the extra cold

placed

freezer

cold.

is

Deli

in the top 6

COLDEST,

forced around

location if you

storage.

Pan

slots

the pan

on

To remove,

position,

position

(on some models)

The

between

When set at

normal refrigerator temperature.

The

storage

slide the pan out to the

lift the pan up and past

and lift it

settings

coldest setting provides

cold

area.

can be

cold,

stop

the

stop

out.

adjusted anywhere

and coldest

the pan will stay at the

the coldest

.

Page 28

– 14 –

Crisper

To Remove:

These drawers can be

lifting up slightly while

past the

Removal

stop

location.

removed

pulling

easily

by

the drawer

When

the

door

cannot be

remove

first. Make sure the drawer

door is fully

front of the

the latch and slide

which the drawer is

door. Remove

the drawer

closed. There

center

the

farthest

slide

rail.

the center

attached,

drawer.

fully

opened,

from

the door

closest

to the

is a latch at the

Push down on

slide rail, to

away from the

Page 29

– 15 –

CABINET CONSTRUCTION

Cabinet

The outer case is made of prepainted steel with

a textured finish. The fresh food and freezer

liners are made of plastic with a smooth finish.

Individual compartments provide separation and

enhanced individual control between the

compartments. The plastic liner provides a

thermal break between the interior of the

refrigerator and freezer compartments and

reduces the transfer of heat from the room into

the fresh food and freezer compartments. The

liner is not removable or replaceable.

Base Grille

The base grille is attached to the cabinet with

two steel spring retainers that clip into elongated

openings in the base channel. To remove the

grille, pull it straight forward.

Doors

The doors are of one-piece construction with

foam insulation. One-piece construction

provides superior thermal performance and

reduces air infiltration. During manufacturing,

the doors are filled with hot foam insulation.

This may cause slight distortion or ripples in the

inner door liner. This is a normal condition and

is the result of the insulating process. This

process requires doors to be equipped with vent

holes that allow air to escape when the door is

filled with foam. A small amount of foam may be

visible around the vent holes.

The inner door panels and outer door panels

cannot be separated and must be replaced as

an assembly.

Vent Holes

GEA01138

GEA01144

GEA01 145

Page 30

– 16 –

Door Gaskets

The fresh food and freezer doors have magnetic

gaskets that create a positive seal to the front of

the steel cabinet. The magnetic door gaskets

are secured to the fresh food and freezer doors

by a barbed edge that locks into a retainer

channel.

1. Starting at any corner, pull the old gasket out

of the retainer channel.

2. Soak the new gasket in warm water to make

it pliable.

3. Push the barbed edge of the gasket into the

retainer channel.

Rollers

Rollers at the base of the cabinet enable the

customer to easily move the refrigerator.

Cabinet leveling is done by adjusting the front

rollers. To adjust the front rollers, use a 3/8-in.

socket or a large flat head screwdriver to turn

the roller adjustment screws located behind the

base grille. The rear rollers are not adjustable.

To remove a front roller assembly from the base

of the cabinet:

1. Tilt the cabinet back and place a

3-in. block under the side of the unit.

2. Remove 3 hex head 1/4-in. screws from the

roller assembly.

3. Loosen the adjustment screw until it

disengages from the assembly and remove

the assembly from the cabinet.

4. Remove the E-ring to remove the

adjustment screw from the base channel.

Note: When reinstalling the roller assembly,

position the nut with the flared thread toward the

rear of the unit.

GEA01150

GEA01147

Page 31

– 17 –

ICEMAKER

Water Valve

A single-coil, 120-VAC valve is secured to the

rear of the cabinet, inside the machine

compartment, on the left-hand side.

GEA01142

GEA01137

Page 32

– 18 –

AIRFLOW

Freezer Compartment

Cold air from the evaporator is forced up against

the top of the freezer and the back of the

evaporator cover. It is then discharged through

slots along the air tower at the rear of the

freezer compartment.

Air is circulated by the evaporator fan

throughout the freezer compartment, where it

picks up heat and moisture. The evaporator fan

then draws the warmer, moisture-laden air

through return louvers in the bottom of the

evaporator cover. The air is then drawn through

the evaporator where heat is removed and

moisture is deposited as frost.

Fresh Food Compartment

Some of the cold air that is being forced against

the top of the freezer and back of the evaporator

cover is diverted through the lower portion of the

freezer air tower and is pushed though the

mullion hole into the fresh food compartment air

channel. The air then exits the air channel in the

front of the fresh food compartment, creating a

curtain of cold air along the front of the shelves.

The fresh food air channel also has a rear

discharge to maintain deli drawer temperatures.

Air circulates throughout the fresh food

compartment, picking up heat and moisture.

The air is then returned to the evaporator

through the return air ducts located at the top

right and left of the fresh food compartment.

Note: These refrigerators do NOT use damper

assemblies to regulate the flow of air to the

fresh food compartment. Airflow is regulated by

a three-speed evaporator fan and a sized air

duct system that provide predictable, consistent

air exchange rates for each level of fan speed.

AIR FLOW

Airflow

COLD AIR

MIXED AIR WARMER AIR

GEA01143

Page 33

– 19 –

Evaporator Fan

The position of the fan blade in relation to the

shroud is critical. Refer to graphic for

specifications.

If the fan shorts, it will damage the main control

board. If the resistor on the main control board

is burnt, you must replace the fan and the board

(see photo).

Evaporator Fan Adjustment

5/16" ±

0.03

1.0" ± 0.05 Target

Blade tip

Motor

GEA01149

Orifice

Air Flow

Airflow

Page 34

– 20 –

EXPLODED VIEWS

Knob, Electro-mechanical

EX

PL

OD

ED

VIE

WS

Page 35

– 21 –

Knob, Electronic

Page 36

– 22 –

structure

Page 37

– 23 –

FREEZER DOOR

FRESHFOOD DOOR

Page 38

– 24 –

HINGE:

Page 39

– 25 –

RACKS SPILLPROOF

Page 40

– 26 –

Condenser Fan

The condenser fan utilizes a DC motor that

operates on a single speed and is mounted in

the machine compartment with the No-Clean

condenser. The fan and fan shroud are

mounted on one end of the condenser, the other

end of the condenser is blocked. When the fan

is operating, air is pulled from the center of the

condenser, drawing air in through the coils. The

air is then exhausted over the compressor and

out the right side of the refrigerator.

Inlet air is available through the left front and left

rear of the machine compartment. A rubber

divider strip underneath the refrigerator divides

the inlet and outlet sides of the machine

compartment.

The rear access cover must be tightly fitted to

prevent air from being exhausted directly out of

the rear of the machine compartment, bypassing

the compressor.

The condenser fan is mounted with screws to a

fan shroud and mounting bracket that is

attached to the condenser. To remove the fan:

1. Remove the rear access cover.

Rear

Condenser Fan Adjustment

2

.

R

Front

Baffle

GEA01152

emove 1 screw

from the

Page 41

– 27 –

condenser fan mounting bracket.

3. Remove 2 screws from the condenser fan

cover.

4. Pull the fan out and disconnect the electrical

connector.

1/2"

Fan

0.375"

Airflow

Air Flow

0.50" ±

0.05

Housing

Motor

Bracket

GEA01 148

Page 42

– 28 –

E

E

DEFROST SYSTEM

Adaptive Defrost

Adaptive Defrost can be described as a defrost

system that adapts to a refrigerator’s

surrounding environment and household usage.

Unlike conventional defrost systems that use

electromechanical timers with a fixed defrost

cycle time, Adaptive Defrost utilizes an

intelligent, electronic control to determine when

the defrost cycle is necessary. In order to

accomplish the correct defrost cycle time, the

main control board monitors the following

refrigerator operations:

• Length of time the refrigerator doors were

open since the last defrost cycle

• Length of time the compressor has run

since the last defrost cycle

• Amount of time the defrost heaters were on

in the last defrost cycle

Adaptive Defrost is divided into 5 separate

cycles. Those operations are:

• Cooling Operation

• Pre-Chill Operation

• Defrost Heater Operation

• Dwell Period

• Post Dwell

Adaptive Defrost (Cooling Operation)

During the cooling operation, the main control

board monitors door opening (fresh food and

freezer doors) and compressor run times. The

board counts the time the doors are open. It

reduces the length between defrosts by 210

seconds (multiplication factor) for each second

that each door is open (if both doors are open,

it reduces it by twice the amount). The

multiplication factor reduces compressor run

time. If the doors are not opened, the

compressor will run up to 60 hours between

When the main control board determines that

defrost is necessary, it will force the

refrigerator into a continuous cool mode (pre-

defrosts. If the doors are opened frequently

and/or for long periods of time, the compressor

run time between defrosts will be reduced to as

little as 8 hours.

Adaptive Defrost (Pre-chill Operation)

F

C˚

R

E

-4˚

E

Z

-7˚

R

15˚ /

A

I

12˚

R

T

-15˚

E

-18˚

M

P

21˚

A

-10˚ / -

R

23˚

T

U

-15˚ / -

26˚

R

E

S

29˚

F˚ /

25˚ /

20˚ /

-9˚

10˚ / -

5˚ /

0˚ /

-5˚ / -

-20˚ / -

PRE-CHILL MODE

08:00

09:00 10:0 0 11:00

12:00

13:00

14:00 15:00 16:00 17:00 18:00

Pre-Chill Defrost

chill). During pre-chill, the freezer temperature

may be driven below the set point. However,

the fresh food temperature will be regulated by

the evaporator fan running at low speed. Prechill will last for 2 hours. These models do not

have a defrost holdoff.

Adaptive Defrost (Defrost Heater

Operation)

After 2 hours of pre-chill operation, the main

control board turns off the compressor,

condenser fan, and evaporator fan.

During defrost operation, the main control board

monitors the evaporator temperature using

evaporator thermistor inputs. Typically, the

evaporator thermistor will sense a temperature

of 65°F within 25 minutes. When the thermistor

senses 65°F, the main control board will

terminate defrost heater operation. Maximum

defrost cycle (heater on) time is 45 minutes

(main control board time out).

The defrost system is protected by a defrost

termination thermostat (switch). The thermostat

opens when the evaporator temperature raises

to 140°F and closes when the evaporator

temperature lowers to 110°F.

Page 43

– 29 –

Adaptive Defrost (Dwell Period)

After defrost heater operation has been

terminated by the main control board, a 5minute dwell period occurs. During this period,

the compressor, condenser fan, and the

evaporator fan remain off. The remaining frost

melting from the evaporator will continue to drip

and drain so that prior to the cooling operation,

the evaporator will be totally clear of any

moisture. After the 5-minute dwell period, the

unit goes into post dwell.

Adaptive Defrost (Post Dwell)

The post dwell period is designed to cool the

evaporator before circulating air within the

refrigerator. This prevents any residual heat on

the evaporator from being distributed in the

freezer. During this period, the compressor is on

and the condenser fan is on, but the evaporator

fan is off. Post dwell will last 15 minutes or until

the evaporator temperature reaches 30°F on

these models.

Normal Operating Characteristics That

Are Different from Previous Models

• Evaporator fan running without compressor

or condenser fan.

• Post Dwell (Adaptive Defrost), compressor,

and condenser fan on with evaporator fan off

after defrost cycle.

• Liner Protection Mode, fan comes on when

the doors are open for 3 minutes.

• Evaporator fan and compressor can run

continuously for 2 hours (Adaptive Defrost).

• Different sound levels can be heard when

the fan changes speed.

• Response time for drastic temperature

change is 2 to 10 minutes. The main control

board will only respond to 8 degrees

(Fahrenheit) of temperature change per

minute as determined by resistance of

sensor.

Abnormal Operating Characteristics

(Incorrect Operation)

• Rapid fan speed changes, fan takes at least

1 minute to change speeds.

• Compressor running without the condenser

fan. The compressor and condenser fan

should always run at the same time.

Liner Protection Mode

The liner protection mode will activate if either of

the doors have been open for 3 minutes. This

mode will start the evaporator fan on high

speed.

This mode is controlled by 2 timers. Timer 1

monitors door-open time. A 3-minute door-open

count begins when the door is opened. If 3

minutes elapse before the door is closed, the

liner protection mode will become active. Once

the door is closed, timer 1 resets and liner

protection mode goes into standby. In standby,

normal fan and damper operations resume and

timer 2 begins a 3-minute door-closed count. If

3 minutes elapse without a door opening, liner

protection mode will completely deactivate. If a

door is opened within the timer 2 door-closed

count, the remaining time in the door-closed

count will be deducted from the timer 1 dooropen count.

Page 44

– 30 –

Defrost Heater

The defrost heater is a single-tube, radiant

heater. It is held in place by 2 tabs on the

evaporator (1 on each side) and by 2 ceramic

and wire supports.

The ceramic and wire supports prevent the

heater from sagging and touching the metal

drain pan if the glass is broken.

Evaporator Thermistor

The evaporator thermistor is mounted on the

upper right side of the evaporator. The defrost

cycle will terminate when the main control board

detects 65°F from the evaporator thermistor.

The main control board must sense 65°F in less

than 45 minutes, or the defrost cycle will time

out. Normal defrost time is 25 minutes or less,

not including the 5-minute dwell or post dwell

periods.

Defrost Overtemperature Thermostat

The defrost overtemperature thermostat

(bimetal switch) is mounted on the evaporator

and provides overtemperature protection during

defrost. This thermostat will open at 140°F and

will close at 110°F.

Note: The main control board will not know if

the heater does not come on due to a broken

heater, open defrost overtemperature

thermostat, or an open wiring harness. The

defrost heater is controlled by maximum time on

the main control board or temperature at the

evaporator thermistor.

Heater Supports

Defrost Drain Probe

Defrost Heater Supports

Defrost Overtemperature Thermostat

Evaporator Thermistor

Page 45

– 31 –

Defrost Probes (on some models)

A defrost drain probe is attached to the

evaporator and extends into the drain opening.

This probe transfers heat to the drain opening

during defrost.

Two additional defrost probes are attached to

the sides of the evaporator. These probes

extend upward between the freezer wall and

evaporator sides to assist the defrosting

process.

Defrost Drain Probe

Evaporator

Page 46

– 32 –

CONTROL SYSTEM

Control Console

The control console, located at the top front of

the fresh food compartment, contains an

encoder (knob version) or a touch panel.

Remove the control console by removing 4 (1/4in.) hex head screws. Use care when

disconnecting the wire connectors from the

encoder or touch panel.

Temperature Encoder

The temperature encoder (knob version)

receives switched DC voltage from the main

control board. There are two possible failure

modes - both are open circuits.

An open circuit from the supply side results in

the refrigerator defaulting to midpoint. The

supply side consists of pins 1 and 2.

An open circuit from the return side results in

inconsistent run mode. The return side consists

of pins 3 and 6.

Failure of the fresh-food-only side results in the

fresh food defaulting to midpoint.

Failure of the freezer side results in the freezer

defaulting to midpoint.

Temperature Touch Panel

The temperature touch panel receives switched

DC voltage from the main control board.

Failure of input results in default to most recent

setting. Input consists of pins 2 to 3.

Failure of output results in erratic control.

Output consists of pin 1.

ADJUST

5

FREE ZER

TEMP

9 IS CO LDE ST

ADJUST RE FRIG ER ATOR

5

TEMP

ADJ UST

RE FRIG ER ATOR TEMP

9 IS

COLDEST

COLDER WA

RME R

ADJ UST

RE FRIG ER ATOR TEMP

9 IS

COLDEST

COLDER WA

RME R

COLDER

COLDER

ADJ UST

WAR MER

ADJ UST

WAR MER

FREE ZER

FREE ZER

9 IS

COLDEST

9 IS

COLDEST

TEMP

TEMP

ACT IVATE LOCK

HOL D

3

SEC S

ACT IVATE LOCK

HOL D

3

SEC S

Page 47

– 33 –

Control Board

127v

Vcc GND

In position 9,

The electronics architecture for top mount 20 ft model consists of 1 electronic board. The control

board reads analog signal from thermistors and convert it to temperature and controls the Compresor

and Defrost heater for Refrigerator operation. It also has 2 door signals to create adaptive defrost. It

communicates to the display board by serial port.

a) Feeding 127VAC control card in the main connector.

b) Measure voltage at the output of voltage regulator on the control card:

The value should be 5 + / - 0.2 VDC at the output of regulator U3 (TP TP Vcc and GND).

Temperature Verification and start cutting

a) Feeding 127VAC control card in the main connector

b) Turn the potentiometer knob in position 5 (counterclockwise to clockwise).

the flat side of

the stem is at

Page 48

– 34 –

c) placing the temperature sensor in the cold well.

ON

OFF

3

7.02 1.39

1.17 -

1.59

Vcc

P1

d) Measure the temperature and start cutting in this position.

- The card must be cut and start the compressor relay after the temperatures of the table.

Temp

7.02 1.39

1

7.02 1.39

2

4

1.69 -1.67

1.69 -1.67

5

1.69 -1.67

6

7

0.44 -2.33

8

-0.28 -3.06

9

Temp

e) Remove the power supply to the card.

Note: In position 0 must remain off the compressor and defrost relays

Check defrost relay (CTQ).

a) Feeding 127VAC control card in the main connector.

b) Wait for the compressor relay is activated.

c) Force the melting by a short circuit between pins VCC and P1

d) The compressor will stop relay and defrost relay will be activated.

e) Remove the power supply to the card.

Page 49

– 35 –

Thermistors

This main control board uses input from 3 thermistors. These thermistors are located in the fresh

food section, the freezer section, and on the evaporator. The main control board monitors the

thermistors to determine the temperature in these areas of the unit and determines which

components to run and when to run them, based on this information.

Thermistor Values

Control

Setting

Fresh Food

Compartment

Temperature

Degrees

(C)

-40

-30

-20

-10

0

10

20

30

40

50

60

Compartment

Temperature

Temperature Set Point

Degrees

Freezer

-40

-22

104

122

140

(F)

-4

14

32

50

68

86

Fresh Food

Thermistor

Temperature Range

Resistance

in Kilo-ohms

166.8 kΩ

88 kΩ

48.4 kΩ

27.6 kΩ

16.3 kΩ

10 kΩ

6.2 kΩ

4 kΩ

2.6 kΩ

1.8 kΩ

1.2 kΩ

Chart

Freezer Thermistor

Temperature Range

0

1

2

3

4

5

6

7

8

9

Off

44°F

40°F

39°F

38°F

37°F

36°F

35°F

35°F

34°F

Minimum Maximum Minimum Maximum

Off

6°F

4°F

3°F

1°F

0°F

-1°F

-3°F

-4°F

-6°F

43°F

39°F

38°F

37°F

36°F

35°F

34°F

34°F

33°F

45°F

41°F

40°F

39°F

38°F

37°F

36°F

36°F

35°F

1°F

-1°F

-2°F

-4°F

-5°F

-6°F

-8°F

-9°F

-11°F

11°F

9°F

8°F

6°F

5°F

4°F

2°F

1°F

-1°F

Page 50

– 36 –

ELECTRICAL SYSTEM

Door Switches

The door switch (fresh food or freezer) closes when the door is open. When the door switch is

closed, L1 is provided to the compartment light(s). The main control board receives L1 input on

pin 6, J7 when the fresh food door switch is closed (door open). The main control board receives

L1 input on pin 4, J7 when the freezer door switch is closed (door open).

Schematic Knob, Electronic

Page 51

– 37 –

Schematic Knob, Electro-mechanical

Page 52

– 38 –

REFRIGERATION SYSTEM

The major components of the refrigeration

system are a reciprocating-type compressor,

condenser, condenser loop, dryer, and a spinefin evaporator. These components, except for

the condenser loop, are all replaceable

separately.

Compressor

The compressor is a reciprocating type. Refer

to the mini-manual for the BTU/hour rating and

the compressor capacity test specification.

A 1/4-in. O.D. copper process tube is provided

for access to the low-pressure side of the

refrigeration system.

The channel that the compressor is mounted in

must be disengaged from the cabinet to remove

the compressor.

Note:

Capillary tube must be clipped to

compressor suction line near the dryer. If

capillary tube is not clipped to suction line, a

knocking noise may occur during compressor

operation.

Refer to the compressor replacement

instructions included with the replacement

compressor.

No-Clean Condenser

The Condenser is a

condenser made of 3/16-in. O.D. steel tubing.

The outlet of the condenser is connected to a

copper jumper tube that is connected to the inlet

of the condenser loop. The No-Clean

condenser is accessed from the rear of the

cabinet and is designed to be more tolerant of

lint buildup than previous condensers. The

consumer, in normal operating conditions, will

never have to clean the condenser. If

necessary, only an ordinary appliance brush is

used. Air is drawn in from the outside diameter

of the condenser. A condenser fan baffle is

located at the rear to direct airflow through the

condenser. Functionally, the condenser does

the same job as previous models. Air is drawn

into the condenser from the front left and rear

left of the cabinet. Air exits only from the right

side of the cabinet.

No-Clean,

“jelly roll” style

Condenser Loop

The condenser loop, made of 5/32-in. O.D.

copper tubing, is foamed in place behind the

breaker frame and across the mullion. It is not

accessible for replacement. The tubing is

routed from the rear of the machine

compartment forward to the mullion, across the

mullion, across the right side of the freezer

compartment, across the top of the freezer

compartment, down the right side of the freezer,

and back to the rear of the machine

compartment. The outlet of the condenser loop

is connected to the dryer inlet.

Dryer

The dryer is positioned vertically in the center of

the machine compartment. A 1/4-in. O.D.

copper process tube, connected to the inlet of

the dryer, provides access to the high-pressure

side of the refrigeration system. The capillary is

connected to the outlet of the dryer.

Replacement of filter dryer requires additional

refrigerant when installed (0.5 oz).

Note:

The dryer is wrapped in mastic as a

sound reducer and foam tape for shipping

purposes. When replacing the dryer, the mastic

must be reinstalled to reduce sound. It is not

necessary to reinstall the foam tape.

Evaporator

The spine-fin evaporator, made of aluminum

tubing and formed into hairpin spirals, is located

below the evaporator fan housing at the back of

the freezer compartment. The replacement

evaporator is furnished without a heat

exchange.

Evaporator (Soldering Method)

1. Recover the refrigerant.

2. Remove the evaporator cover.

3. Remove the defrost thermostat.

4. Remove the defrost heater.

5. Disconnect the ground wire from the

evaporator and position all wiring to allow for

evaporator removal.

Page 53

– 39 –

6. Remove the 2 screws that hold the

evaporator to the cabinet.

Caution:

• If desoldering the evaporator, heat shield,

, must be used to

prevent damage to freezer liner.

• Protect wiring from heat during

desoldering and resoldering.

• To prevent damage to the capillary tube,

the capillary tube must be desoldered

first.

7. Desolder the capillary tube from the

evaporator.

8. Desolder the suction line. Use a pair of pliers

to hold the evaporator.

9. Remove the evaporator.

10. Using a file, score the capillary tube just above

the old solder and break the solder-covered

section off. This will help prevent the capillary

tube from becoming plugged when

resoldering.

11. Position the new evaporator in the cabinet.

Insert the suction line and capillary tube into

the evaporator.

12. Solder the suction line to the evaporator

using silfos.

13. Solder the capillary tube to the evaporator

using silfos.

Note:

Heat probe assists in defrosting drain.

During assembly, probe must be installed on

evaporator and in drain to prevent drain from

freezing closed.

14. Install a replacement dryer.

15. Evacuate and recharge the system using

currently accepted procedures.

Evaporator (LOKRING Method)

1. Recover the refrigerant.

2. Remove the evaporator cover.

3. Remove the defrost thermostat.

4. Remove the defrost heater.

5. Disconnect the ground wire from the

evaporator and position all wiring to allow for

evaporator removal.

6. Remove the 2 screws that hold the

evaporator to the cabinet.

Caution:

Tubing must be clean and free from

burrs when using LOKRING.

.

7. Replace the evaporator using the LOKRING

method .

• Cut the copper lines of the old evaporator

as close as possible to the aluminum

evaporator tubes.

• Cut the copper lines of the new evaporator

1-1/8 in. from the edge of the aluminum

evaporator tubes.

• Defrost thermostat can be moved from the

horizontal part of the copper line to the

vertical part, just above the bend.

Note:

Heat probe assists in defrosting drain.

During assembly, probe must be installed on

evaporator and in drain to prevent drain from

freezing closed.

8. Install a replacement dryer.

9. Evacuate and recharge the system using

currently accepted procedures.

Refrigerant Charge

The refrigerant used in this model is type

R134a. Refer to the mini-manual or model tag

for the exact refrigerant charge quantity.

Page 54

– 40 –

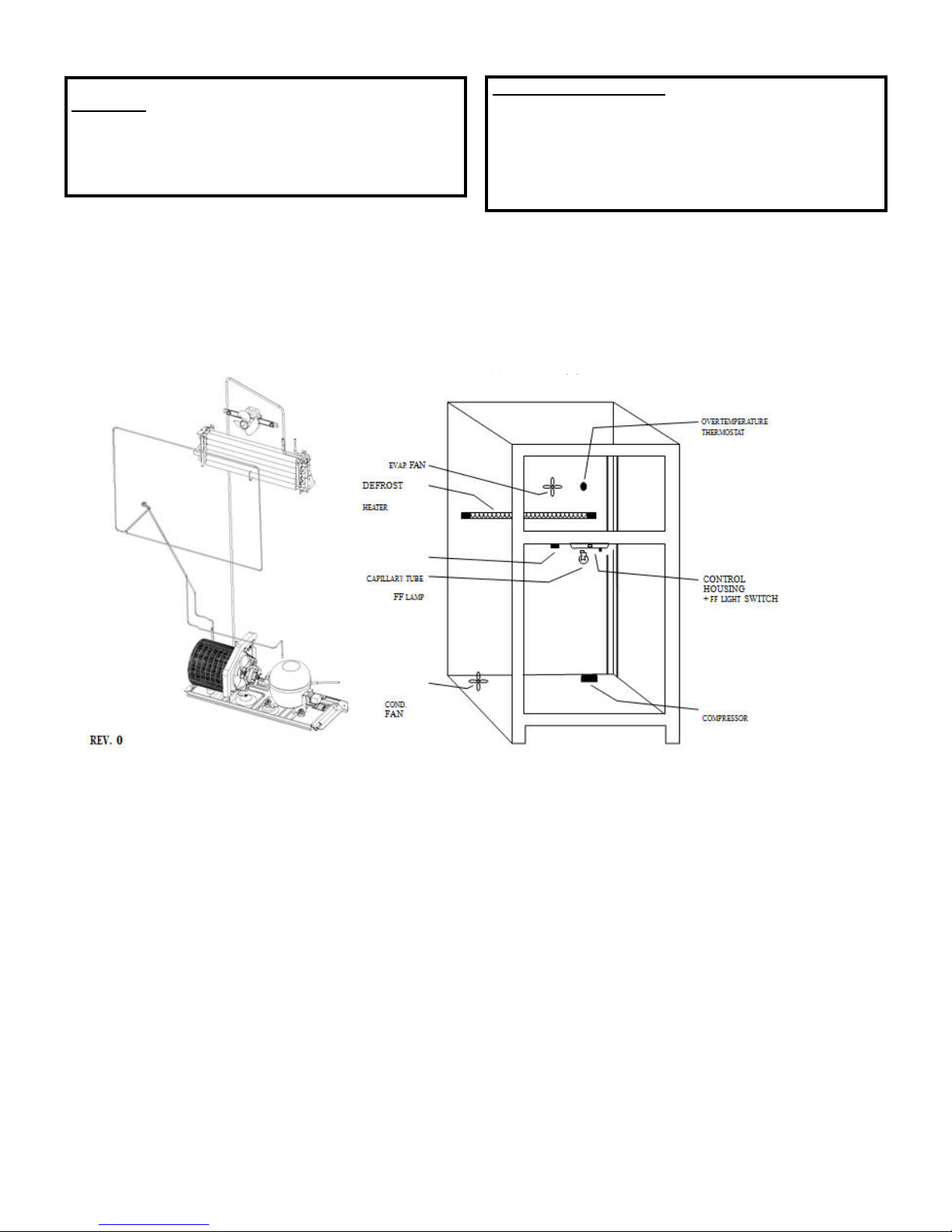

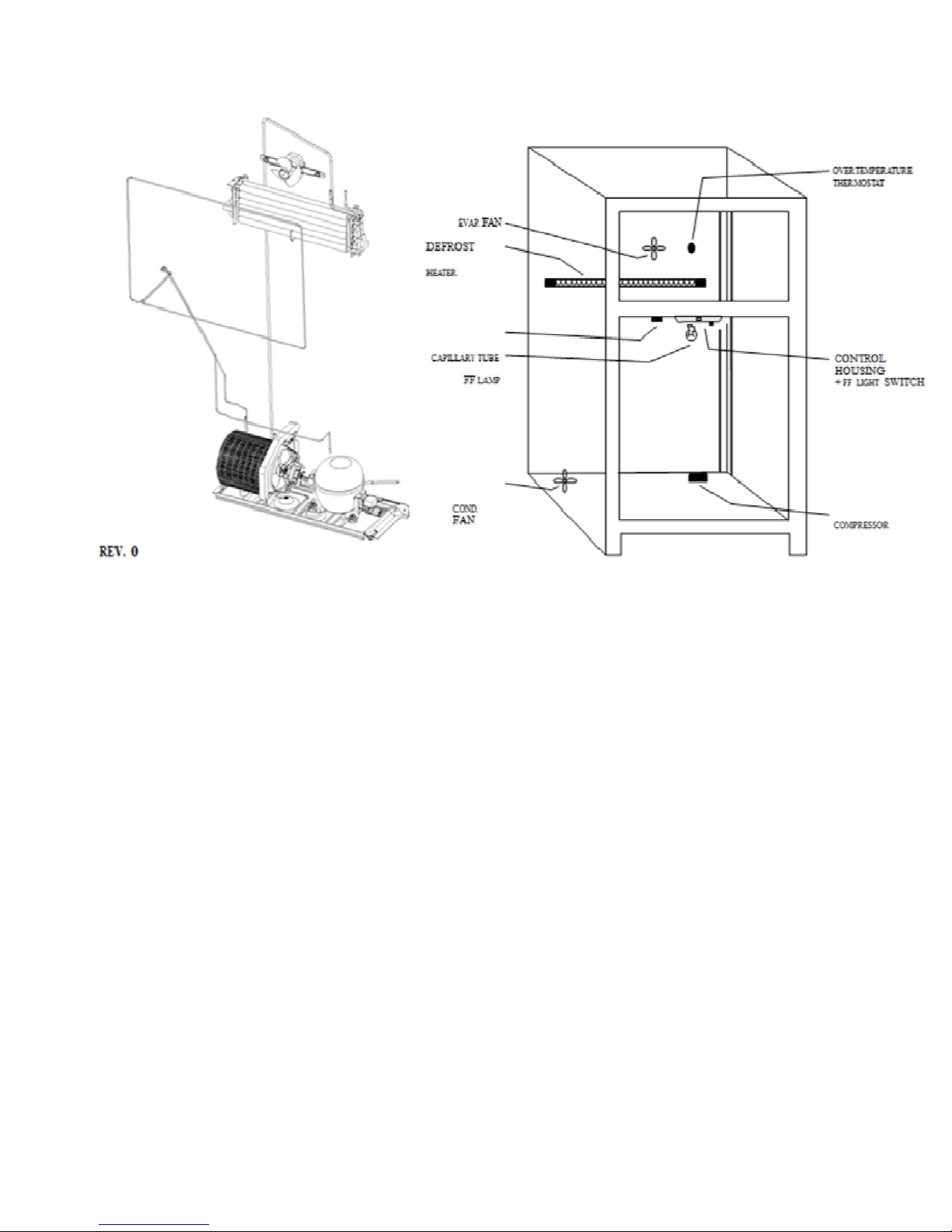

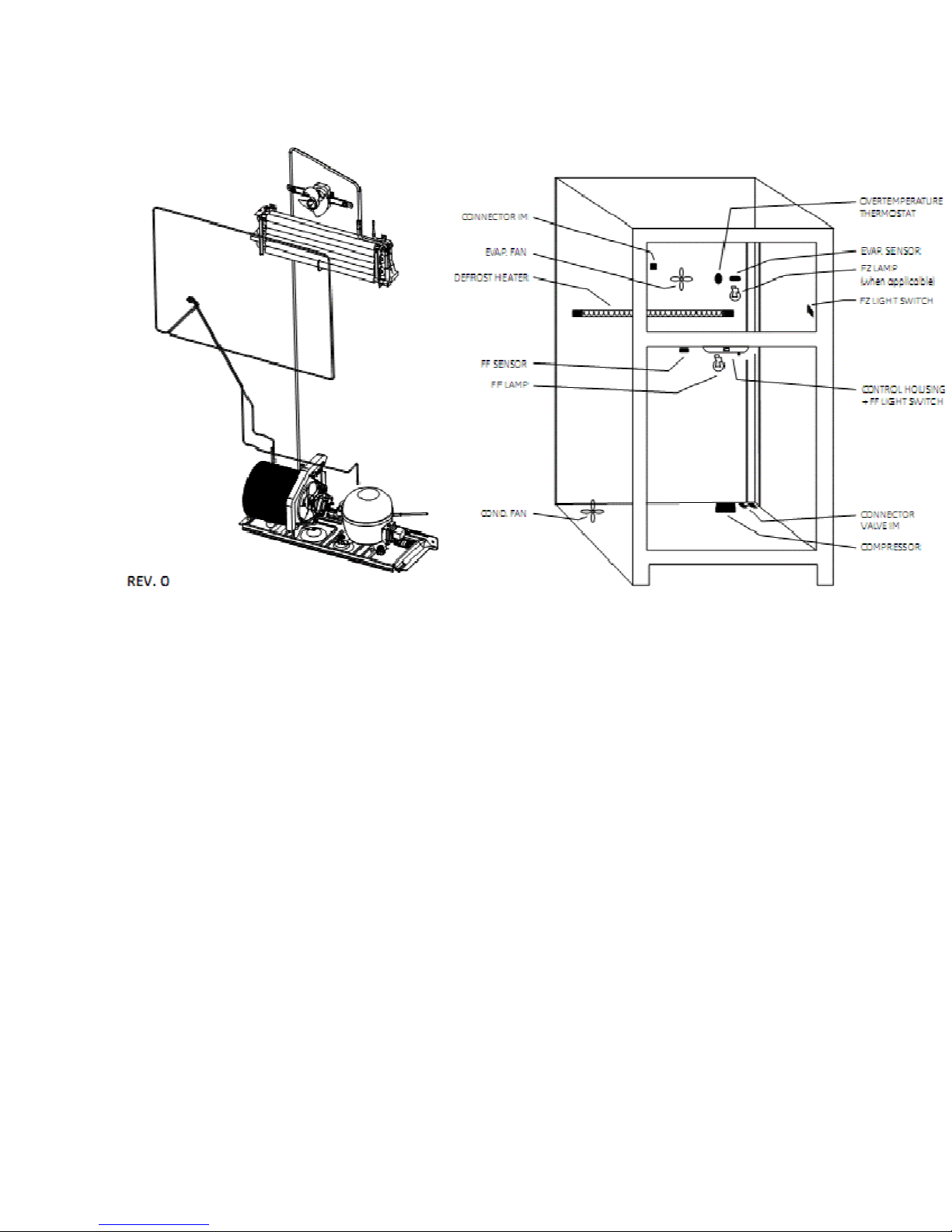

COMPONENT AND CONNECTOR LOCATOR VIEWS

Page 55

– 41 –

Relay and

Overload

(Under Cover)

Capacitor

Compressor

Dryer

No-Clean Condenser

Condenser Fan

Page 56

– 42 –

Basic refrigeration checks:

Door gasket seal OK?

Door switch - light turning off with NO

Reset electronics by unplugging

refrigerator for 15 seconds then

Is the evaporator fan running? NO

Is the condenser fan running?

Is the airflow in the fresh food

Is the resistance within range?

door closed?

plug back in.

Is the compressor running?

compartment normal?

Verify thermistors are within

proper range. NO

Check sealed system.

Does sealed system check

All OK?

YES

YES

YES

YES

YES

YES

OK?

Fresh Food Warm - Freezer Warm

Repair as

necessary.

Go to Evaporator

Fan Not Running

flowchart.

NO

NO

NO

Go to Condenser Fan

Not Running flowchart.

Go to Compressor Not Running

Look for blockage

at vents or heavy

frost on evaporator

Check wiring

connections. If OK,

replace thermistor.

cover.

flowchart.

Heavy frost

Blockage

Remove blockage from

evaporator cover vent

area.

Go to Heavy Frost

on Evaporator

Cover flowchart.

YES

Unit tests OK.

Run checks again. Look

for usage problem.

Page 57

– 43 –

Check control settings

Food at a setting of 5 and 5 with no door

openings for 12 hours should be:

Fresh food 36 F to 38 F

Freezer -5 F to +5 F

and

temperatures.

Control settings OK?

Basic refrigeration checks:

Door gasket seal OK?

Door switch - light turning off with NO

YES

door closed?

All OK?

YES

Reset electronics

unplugging refrigerator for 15

seconds then plug back in.

by

Is the evaporator fan running? NO

YES

Is the condenser fan running?

Is the airflow in the fresh food

Verify thermistors are within

Is the resistance within range?

YES

compartment

proper range. NO

YES

normal?

YES

Check

sealed

Does sealed system

Unit test OK.

Run checks again. Look for usage

system.

OK?

YES

problem.

check

NO

Freezer Warm - Fresh Food Normal

Adjust settings and allow

NO

24 hours to stabilize.

Repair as

necessary.

Go to Evaporator

Fan Not

Go to Condenser Fan

NO Not Running

NO

connections. If OK,

replace

Running

flowchart.

flowchart.

Check

wiring

thermistor.

Repair sealed

system.

Look for

at vents or heavy

frost on evaporator

blockage

cover

.

Frost

Blockage

Remove

evaporator

Go to

on

Evaporator

Cover

blockage

cover vent

area.

Heavy

Frost

flowchart.

from

Page 58

– 44 –

Fresh Food Warm - Freezer Normal

Check control settings

Food at a setting of 5 and 5 with no door

openings for 12 hours should be:

Fresh food 36 F to 38 F

Freezer -5 F to +5 F

and

temperatures.

Control settings OK?

YES

Basic refrigeration checks:

Door gasket seal OK?

Door switch - light turning off with NO

door closed?

All OK?

YES

Reset electronics by unplugging

refrigerator for 15 seconds then

plug

back in.

Is the evaporator fan running at

correct speed?

YES

Is the airflow in the fresh food

compartment normal?

Verify thermistors

Is the resistance within range?

Check sealed system.

Does sealed system check

YES

are

proper range. NO

YES

OK?

YES

within

Unit test OK.

Run checks again.

usage problem.

Look

for

NO

NO

NO

connections. If OK,

replace thermistor.

NO

Adjust settings and allow

24 hours to stabilize.

Go to Evaporator

Check wiring

Repair sealed

system.

Fan Not

Look for

at vents or heavy

frost on evaporator

Repair as

necessary.

Running

flowchart.

blockage

cover

.

Frost

Blockage

Remove blockage from

evaporator cover vent area.

Go to

Heavy

on

Cover

Frost

Evaporator

flowchart.

Page 59

– 45 –

Fresh Food Too Cold - Freezer Normal

no

YES

Check control

temperatures.

Food at a setting of 5 and 5

door openings for 12

Fresh food 36 F to 38

Freezer -5 F to + 5 F.

Do settings

settings and

with

hours

should

be:

F

require adjustment?

NO

Adjust

allow 24

stabilize.

settings and

hours

to

Advise consumer

refrigeration

requirements.

installation

of

Low

ambient

temperature? Is the

room

temperature above

55

F?

NO

thermistor is

Is

operating at proper

Run checks again.

by

unplugging

seconds.

YES

Verify fresh

proper

resistance within

range?

Is evaporator

speed?

Unit tests

Look for

food

within

range.

YES

YES

OK.

Reset

refrigerator for 15

usage

fan

electronics

problem.

NO

NO

Check

connections.

wiring is

thermistor.

Go to

Evaporator

Fan Not

flowchart.

OK, replace

wiring

If

Running

Page 60

– 46 –

Unplug

Warm freezer thermistor to 70 F.

Connect power and

temperature controls to 5

Does compressor

Check for 120 VAC.

Is 120

thermistor is within

refrigerator.

NO

VAC present?

YES

Verify

freezer

proper

Is

within

Replace main

range.

the resistance

range?

YES

board.

Compressor Not Running

set

and

5.

start?

YES

YES

Adjust

settings and

allow 24 hours to

stabilize.

Direct

test

compressor.

Did compressor

start?

YES

NO

Check wiring to compressor,

Replace

Replace

compressor.

overload,

defective part.

and

relay.

Check wiring

NO connections. If

replace thermistor.

OK,

Page 61

– 47 –

Are interior lights on?

YES

Does unit have

encoder or touch

panel?

Encoder

Is voltage present?

Short in fan motor circuit.

YES

Go to fan flowchart.

Refrigerator Not Responding

NO supply voltage. NO

Check house

120 VAC present?

YES

Check for 120 VAC

120 VAC present?

YES

Repair wiring

connections at 6-pin

connector.

Touch Panel

Unplug (temperature

control).

Does refrigerator

start?

YES

Replace encoder

board.

NO proper range.

House wiring

Repair or replace

Is touch panel lit?

be set to 5 and 5?

thermistor is within

problem.

power cord.

YES

Can touch panel

YES

Verify freezer

Is the resistance

within range?

YES

Replace main

control board.

Check for 12 VDC at

NO voltage, check wiring.

NO

NO

J4-2 to 3. If no

If wiring OK, replace

touch panel.

Membrane, touch

panel, or wiring.

Check wiring

connections. If

wiring is OK, replace

thermistor.

Page 62

– 48 –

Note:

Evaporator Fan Not Running

• When no voltage at main control board, make certain to check for shorted fan motor (less

than 1k ohm between). A shorted fan motor will damage the replacement main board.

Check fan for obstruction.

Find obstruction?

NO

Open door and leave open

for 3 minutes to initiate liner

protection mode.

Does fan begin running?

Unplug refrigerator to reset

Reconnect power. Warm

freezer thermistor to 70 F

and set temperature controls

Did evaporator fan start?

NO

main control board.

to 5 and 5.

YES

YES

YES

Remove

obstruction.

Check thermistors

using thermistor

values or self-

diagnostic test 0-7.

Thermistors pass

Test?

NO

Adjust settings and allow

24 hours to stabilize.

YES

Replace main

Check wiring

connections. If OK,

replace thermistor.

board.

At the fan connector, check 8

NO

to 13 VDC

NO

Check for 13 VDC

NO

Replace main

control board.

YES

YES

Replace

evaporator fan

motor.

Repair wiring between

main control board and

evaporator fan motor.

Page 63

– 49 –

Note:

Condenser Fan Not Running

• Compressor and condensor fan should always operate at the same time.

• When no voltage at main control board,

Check fan for obstruction.

Unplug the refrigerator to

reset main control board.

Warm freezer thermistor

to 70 F. Reconnect

power and set

temperature controls to 5

and 5. Recheck voltage.

Is voltage correct?

Adjust settings and allow

YES

24 hours to stabilize.

NO

At the condenser

fan connector,

check for 13 VDC

.

Is voltage correct

for both?

YES

Replace condenser

fan motor.

NO

.

Check for 13 VDC

Is voltage correct for

both?

YES

Repair wiring between

main control board and

condenser fan motor.

NO

Replace main

control board.

Loading...

Loading...