Page 1

g

GE Power Management

MM2

MOTOR MANAGER 2

Instruction Manual

MM2 Firmware Revision: 4.0x

MM2 Software Revision: 4.0X or newer

Manual P/N: 1601-0056-DN (GEK-106294)

Copyright © 2001 GE Power Management

®

Units must be powered up at least once per year to avoid deterioration

of electrolytic capacitors and subsequent relay failure.

NOTE

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet:

KWWSZZZ*(LQGXVWULDOFRPSP

R

E

D

G

E

R

I

E

S

T

Manufactured under an

ISO9001 Registered system.

Page 2

Page 3

These instructions do not purport to cover all details or variations in equipment nor provide for every possible contingency to be met in connection with installation, operation, or

maintenance. Should further information be desired or should particular problems arise

which are not covered sufficiently for the purchaser’s purpose, the matter should be

referred to the General Electric Company .

To the extent required the products described herein meet applicable ANSI, IEEE, and

NEMA standards; but no such assurance is given with respect to local codes and ordinances because they vary greatly.

Page 4

Page 5

TABLE OF CONTENTS

1. INTRODUCTION

2. INSTALLATION

1.1 OVERVIEW

1.1.1 DESCRIPTION..............................................................................1-1

1.1.2 FEATURES ...................................................................................1-1

1.2 ORDERING

1.2.1 ORDER CODES ...........................................................................1-2

1.2.2 ACCESSORIES ............................................................................1-3

1.2.3 SPECIAL ORDER.........................................................................1-3

1.3 SPECIFICATIONS

1.3.1 MM2 SPECIFICATIONS ...............................................................1-4

2.1 MOUNTING

2.1.1 DESCRIPTION..............................................................................2-1

2.2 INPUTS AND OUTPUTS

2.2.1 PHASE CT INPUTS......................................................................2-5

2.2.2 GROUND FAULT CT INPUT ........................................................2-5

2.2.3 SUPPLY VOLTAGE......................................................................2-5

2.2.4 GROUND SURGE ........................................................................2-5

2.2.5 EXTERNAL CONNECTIONS........................................................2-5

2.2.6 THERMISTOR INPUT...................................................................2-6

2.2.7 ANALOG INPUT ...........................................................................2-6

2.2.8 AUX 2 COIL ..................................................................................2-6

2.2.9 OUTPUT RELAYS ........................................................................2-6

2.2.10 SWITCH INPUTS..........................................................................2-6

2.2.11 PROGRAMMABLE SWITCH INPUTS..........................................2-6

2.2.12 SERIAL COMMUNICATION PORT..............................................2-7

2.2.13 STOP ............................................................................................2-7

2.2.14 START A / START B.....................................................................2-8

2.2.15 LOCAL ISOLATOR N/O................................................................2-8

2.2.16 CONTACTOR STATUS................................................................2-8

2.2.17 SWITCH COMMON......................................................................2-8

2.2.18 DIELECTRIC STRENGTH TESTING ...........................................2-8

3. HARDWARE

GE Power Management

3.1 FACEPLATE FUNCTIONS

3.1.1 DESCRIPTION..............................................................................3-1

3.1.2 MESSAGE DISPLAY ....................................................................3-1

3.1.3 INDICATOR LEDs.........................................................................3-2

3.2 KEYPAD

3.2.1 SETPOINTS KEY..........................................................................3-3

3.2.2 ACTUAL VALUES KEY.................................................................3-3

3.2.3 STORE KEY..................................................................................3-4

3.2.4 STOP KEY ....................................................................................3-4

3.2.5 RESET KEY .................................. ................................................3-4

3.2.6 START A KEY...............................................................................3-4

3.2.7 START B KEY...............................................................................3-5

3.2.8 MESSAGE UP/DOWN KEYS .......................................................3-5

3.2.9 MESSAGE LEFT/RIGHT KEYS....................................................3-5

3.2.10 VALUE UP/DOWN KEYS .............................................................3-5

3.3 THEORY OF OPERATION

3.3.1 HARDWARE DESCRIPTION........................................................3-6

MM2 Motor Manager 2 i

Page 6

TABLE OF CONTENTS

4. SETPOINTS

4.1 OVERVIEW

4.1.1 DESCRIPTION............................................................................. 4-1

4.1.2 ABBREVIATIONS ........................................................................ 4-1

4.2 S1 CONFIGURATION

4.2.1 DESCRIPTION............................................................................. 4-3

4.2.2 COMMUNICATIONS.................................................................... 4-3

4.2.3 MOTOR IDENTIFICATION ............................. ...... ...... ..... ...... ...... 4-3

4.2.4 STARTER.....................................................................................4-4

4.2.5 CT / VT INPUTS........................................................................... 4-5

4.2.6 THERMISTOR.............................................................................. 4-6

4.2.7 FAULT MODE .............................................................................. 4-6

4.2.8 STATISTICS.................................................................................4-7

4.2.9 PROGRAMMABLE MESSAGE.................................................... 4-7

4.2.10 PREFERENCES .......................................................................... 4-7

4.3 S2 PROTECTION

4.3.1 DESCRIPTION............................................................................. 4-8

4.3.2 STANDARD OVERLOAD CURVES............................................. 4-8

NEMA COMPATIBLE OVERLOAD CURVES

4.3.3

4.3.4 MOTOR PROTECTION – THERMAL ........................................ 4-12

4.3.5 MOTOR PROTECTION – GROUND FAULT............................. 4-13

4.3.6 MOTOR PROTECTION – OPTIONS......................................... 4-15

4.3.7 LOAD PROTECTION................................................................. 4-17

4.3.8 UNDER/OVERVOLTAGE PROTECTION.................................. 4-19

...........................4-10

4.4 S3 PROCESS

4.4.1 DESCRIPTION........................................................................... 4-20

4.4.2 PROGRAMMABLE INPUTS ...................................................... 4-20

4.4.3 INTERLOCK NAMES................................................................. 4-25

4.4.4 STOP CONFIGURATION .......................................................... 4-25

4.4.5 ANALOG INPUT......................................................................... 4-26

5. ACTUAL VALUES

4.5 S4 CONTROL

4.5.1 DESCRIPTION........................................................................... 4-28

4.5.2 UNDERVOLTAGE AUTORESTART.......................................... 4-28

4.5.3 AUX RELAY 1/2 CONFIG .......................................................... 4-29

4.6 S5 MONITORING

4.6.1 DESCRIPTION........................................................................... 4-32

4.6.2 PLANT CONDITION................................................................... 4-32

4.6.3 PRESET COUNTERS AND TIMERS......................................... 4-33

4.7 S6 FACTORY DATA

4.7.1 DESCRIPTION........................................................................... 4-34

4.7.2 PRODUCT FIRMWARE ............................................................. 4-34

4.7.3 PRODUCT MODEL IDENTIFICATION ...................................... 4-34

4.7.4 FACTORY SERVICE DATA.......................................................4-34

5.1 OVERVIEW

5.1.1 DESCRIPTION............................................................................. 5-1

5.1.2 DEFAULT MESSAGE SELECTION.............................................5-1

5.1.3 ABBREVIATIONS ........................................................................ 5-2

5.2 A1 DATA

5.2.1 DESCRIPTION............................................................................. 5-3

5.2.2 MOTOR DATA ................................ ..... ...... .................................. 5-3

ii MM2 Motor Manager 2

GE Power Management

Page 7

TABLE OF CONTENTS

5.2.3 PROCESS DATA..........................................................................5-4

5.2.4 PROGRAMMABLE MESSAGE.....................................................5-4

5.3 A2 STATUS

5.3.1 DESCRIPTION..............................................................................5-5

5.3.2 TRIP DATA ...................................................................................5-5

5.3.3 ALARM DATA ...............................................................................5-6

5.3.4 MOTOR STATUS..................................... ...... ...............................5-8

5.4 A3 INPUTS

5.4.1 DESCRIPTION..............................................................................5-9

5.4.2 INPUT CONTACTS STATUS .................................................... ...5-9

5.5 A4 STATISTICS

5.5.1 DESCRIPTION............................................................................5-11

5.5.2 TIMERS.......................................................................................5-11

5.5.3 COUNTERS ................................................................................5-11

6. COMMUNICATIONS

6.1 MM2 MODBUS PROTOCOL

6.1.1 OVERVIEW...................................................................................6-1

6.1.2 ELECTRICAL INTERFACE...........................................................6-1

6.1.3 DATA FRAME FORMAT AND DATA RATE.................................6-1

6.1.4 DATA PACKET FORMAT.......................................................... ...6-2

6.1.5 ERROR CHECKING .....................................................................6-2

6.1.6 CRC-16 ALGORITHM...................................................................6-3

6.1.7 TIMING..........................................................................................6-4

6.1.8 MM2 SUPPORTED FUNCTIONS.................................................6-4

6.2 MODBUS FUNCTIONS

6.2.1 FUNCTION CODE 01H.................................................................6-5

6.2.2 FUNCTION CODE 03H.................................................................6-6

6.2.3 FUNCTION CODE 04H.................................................................6-7

6.2.4 FUNCTION CODE 05H.................................................................6-8

6.2.5 FUNCTION CODE 06H.................................................................6-9

6.2.6 FUNCTION CODE 07H...............................................................6-10

6.2.7 FUNCTION CODE 08H...............................................................6-11

6.2.8 FUNCTION CODE 10H...............................................................6-12

6.3 ERROR RESPONSES

6.3.1 DESCRIPTION............................................................................6-13

6.4 APPLICATIONS

6.4.1 PERFORMING COMMANDS USING FUNCTION CODE 10H...6-14

6.4.2 STORING COMM ADDRESS USING THE BROADCAST

COMMAND.................................................................................6-15

6.4.3 USING THE USER DEFINABLE MEMORY MAP.......................6-16

6.4.4 USER DEFINABLE MEMORY MAP DEFAULT VALUES...........6-17

GE Power Management

6.5 MEMORY MAP

6.5.1 DESCRIPTION............................................................................6-19

6.5.2 MEMORY MAP TABLE...............................................................6-20

6.6 DATA FORMATS

6.6.1 DATA FORMATS TABLE..................................... ..... ...... ..... .......6-41

MM2 Motor Manager 2 iii

Page 8

TABLE OF CONTENTS

7. TESTING

8. MM2PC® SOFTWARE

7.1 INJECTION TESTING

7.1.1 PRIMARY INJECTION TESTING ................................................ 7-1

7.1.2 SECONDARY INJECTION TESTING.......................................... 7-1

7.2 FUNCTIONAL TESTS

7.2.1 PHASE CURRENT FUNCTIONS................................................. 7-3

7.2.2 UNBALANCE EXAMPLES .................................... ...... ..... ...... ...... 7-4

7.2.3 GROU ND FAULT CURRENT FUNCTIONS ................................7-5

7.2.4 INPUT FUNCTIONS.............................................. ...... ..... ...... ...... 7-5

7.2.5 THERMISTOR INPUT TESTS ..................................................... 7-6

7.2.6 POWER FAIL TEST.....................................................................7-6

8.1 OVERVIEW

8.1.1 DESCRIPTION............................................................................. 8-1

8.1.2 HARDWARE & SOFTWARE REQUIREMENTS.......................... 8-1

8.1.3 CHECKING IF INSTALLATION/UPGRADE IS REQUIRED ........ 8-2

8.2 INSTALLING MM2PC

8.2.1 SOFTWARE INSTALLATION/UPGRADE .................................... 8-3

®

8.3 CONFIGURATION

8.3.1 CONFIGURING MM2PC®............................................................ 8-4

8.3.2 MM2PC

8.4 USING MM2PC

8.4.1 SAVING SETPOINTS TO A FILE ................................................ 8-7

8.4.2 MM2 FIRMWARE UPGRADES.................................................... 8-8

8.4.3 LOADING SETPOINT FILES ....................................................... 8-9

8.4.4 ENTERING SETPOINTS ........................................................... 8-10

8.4.5 VIEWING ACTUAL VALUES ..................................................... 8-11

®

PROGRAM MENUS..................................................... 8-6

®

9. STARTER TYPES

8.5 CHASSIS MOUNT UNITS

8.5.1 DESCRIPTION........................................................................... 8-13

8.5.2 SETTING THE BAUD RATE AND PARITY ...............................8-13

9.1 FV NON-REVERSING STARTER

9.1.1 DESCRIPTION............................................................................. 9-1

9.1.2 MM2 SEQUENCES...................................................................... 9-1

9.2 FV REVERSING STARTER

9.2.1 DESCRIPTION............................................................................. 9-3

9.2.2 MM2 SEQUENCES...................................................................... 9-4

9.2.3 NOTES......................................................................................... 9-4

9.3 TWO SPEED STARTER

9.3.1 DESCRIPTION............................................................................. 9-6

9.3.2 MM2 SEQUENCES...................................................................... 9-7

9.4 SLIP RING STARTER

9.4.1 DESCRIPTION........................................................................... 9-11

9.4.2 MM2 SEQUENCES.................................................................... 9-12

9.5 PRIMARY RESISTANCE STARTER

9.5.1 DESCRIPTION........................................................................... 9-14

9.5.2 MM2 SEQUENCE ...................................................................... 9-15

iv MM2 Motor Manager 2

GE Power Management

Page 9

TABLE OF CONTENTS

9.6 INVERTER STARTER

9.6.1 DESCRIPTION............................................................................9-17

9.6.2 MM2 SEQUENCES.....................................................................9-18

9.7 AUTOTRANSFORMER OPEN TRANSITION STARTER

9.7.1 DESCRIPTION............................................................................9-20

9.7.2 MM2 SEQUENCES.....................................................................9-21

9.8 AUTOTRANSFORMER CLOSED TRANSITION STARTER

9.8.1 DESCRIPTION............................................................................9-24

9.8.2 MM2 SEQUENCES.....................................................................9-25

9.9 PART WINDING STARTER

9.9.1 DESCRIPTION............................................................................9-28

9.9.2 MM2 SEQUENCE.......................................................................9-28

9.10 WYE-DELTA OPEN TRANSITION STARTER

9.10.1 DESCRIPTION............................................................................9-29

9.10.2 MM2 SEQUENCES.....................................................................9-30

9.11 WYE-DELTA CLOSED TRANSITION STARTER

9.11.1 DESCRIPTION............................................................................9-32

9.11.2 MM2 SEQUENCE.......................................................................9-33

9.12 DUTY/STANDBY STARTER

9.12.1 DESCRIPTION............................................................................9-35

9.12.2 MM2 SEQUENCES.....................................................................9-35

9.12.3 NOTES........................................................................................9-36

10.CONTROL WIRE

APPLICATIONS

A. MM2 COMMISSIONING

9.13 SOFT STARTER

9.13.1 DESCRIPTION............................................................................9-38

9.13.2 MM2 SEQUENCE.......................................................................9-38

10.1 TWO WIRE CONTROL

10.1.1 DESCRIPTION......................................... ...................................10-1

10.1.2 CONTROL OPERATION ............................................................10-1

10.2 HAND/OFF/AUTO CONFIGURATION

10.2.1 2-WIRE HAND / 2-WIRE AUTO..................................................10-3

10.2.2 CONTROL OPERATION ............................................................10-3

10.2.3 3-WIRE HAND / 2-WIRE AUTO..................................................10-5

10.2.4 CONTROL OPERATION ............................................................10-5

10.2.5 3 WIRE HAND / 3 WIRE AUTO..................................................10-7

10.2.6 CONTROL OPERATION ............................................................10-7

10.3 HAND/AUTO CONFIGURATION

10.3.1 3-WIRE HAND / 2-WIRE AUTO..................................................10-9

A.1 COMMISIONING SUMMARY

A.1.1 DESCRIPTION......................... ....................................................A-1

B. MM2 FAQ

GE Power Management

B.1 MM2 FAQ

B.1.1 QUESTIONS AND ANSWERS....................................................B-1

MM2 Motor Manager 2 v

Page 10

TABLE OF CONTENTS

C. DO’S AND DONT’S

D. ASYMMETRICAL

CURRENT

E. CT ISOLATION

F. FIGURES AND TABLES

G. MISCELLANEOUS

C.1 DO’S AND DONT’S

C.1.1 CHECKLIST.................................................................................C-1

D.1 ASYMMETRICAL CURRENT

D.1.1 OVERVIEW..................................................................................D-1

E.1 CT ISOLATION

E.1.1 MM2 CT WITHSTAND .................................................................E-1

E.1.2 CT SIZE AND SATURATION.......................................................E-1

F.1 LISTS

F.1.1 LIST OF FIGURES.......................................................................F-1

F.1.2 LIST OF TABLES......................................................................... F-2

G.1 EU DECLARATION OF CONFORMITY

0.1 GE POWER MANAGEMENT WARRANTY

vi MM2 Motor Manager 2

GE Power Management

Page 11

1 INTRODUCTION 1.1 OVERVIEW

1 INTRODUCTION

The MM2 combines control functions normally found in a low voltage motor control center (MCC)

with motor protection. This compact, microprocessor-based device provides sophisticated control

and protective relaying at significant cost savings over an MCC design using discrete devices.

Standard features in every MM2 simplify maintenance and plan t expans ion. One MM2 is requi red for

every starter unit in the MCC. The contactor can be energized and de-energized using the MM2’s

direct-wired inputs, or via the serial port. Full Voltage Non-reversing, Full Voltage Reversing, Two

Speed, Autotransformer, Inverter, Wye-Delta, Slip Ring, and Part Winding type starters may be completely controlled by the MM2 using the two contactor outputs.

Motor protection is included for the most common causes of failure to prevent costly shutdowns and

rewinds. These include 3 phase overload, stalled rotor, ground fault and loss of phase.

A two wire RS485 Modbus protocol communications port i s pro vid ed for high -spee d communicati ons

with a complete line-up of MCCs. Any MM2 may be interrogated on demand, to determine both

Actual and Setpoint operating parameters. Fast response time to a request for alarm or trip status

makes real time control of a complete process possible. Statistical recording of running hours and

number of starts and trips assists with predictive maintenance scheduling.

The MM2 has been developed with economy in mind. The customer is able to choose from different

options to achieve maximum benefit from the relay when integrated into the process environment.

1.1 OVERVIEW 1.1.1 DESCRIPTION

1.1.2 FEATURES

1

The basic MM2 comes with 3 phase overload protection (49/51), single phase, 4 control inputs

(Start, Stop, Local Isolator, Contactor A status) plus 2 programmable inputs. Depending upon which

option is ordered, the following addit ional features are available:

•20×2 alphanumeric display (Option PD)

• 8 additional programmable inputs (Option 1)

• 2 additional electromechanical relays: Aux Relay 1 and Aux Relay 2 (Option 1)

• 4 to 20 mA process analog input (Option 1)

• programmable undervoltage restart of motors following an undervoltage condition (Option 1)

• diagnostics which includes pretrip data and historical statistics (Option 1)

• 2nd contactor control (wye/delta, two speed, reversing, etc.) which i n cludes all timers, relays and

control inputs (Option 2)

• ground fault trips (50G/51G) (Optio n 2)

• stalled rotor protection (48) (Opt ion 2)

• single voltage input which allows the MM2 to calculate and display kW and kWh (Option 2)

• undercurrent/underpower protection (37) (Option 2)

• thermistor (49) input which accepts PTC and NTC thermistor types (Option 2)

• overvoltage (59) and undervoltage (27) protection (Option 2)

GE Power Management

MM2 Motor Manager 2 1-1

Page 12

1.2 ORDERING 1 INTRODUCTION

1.2 ORDERING 1.2.1 ORDER CODES

1

NOTE

This instruction manual describes the features of a MM2 with all options incl uded.

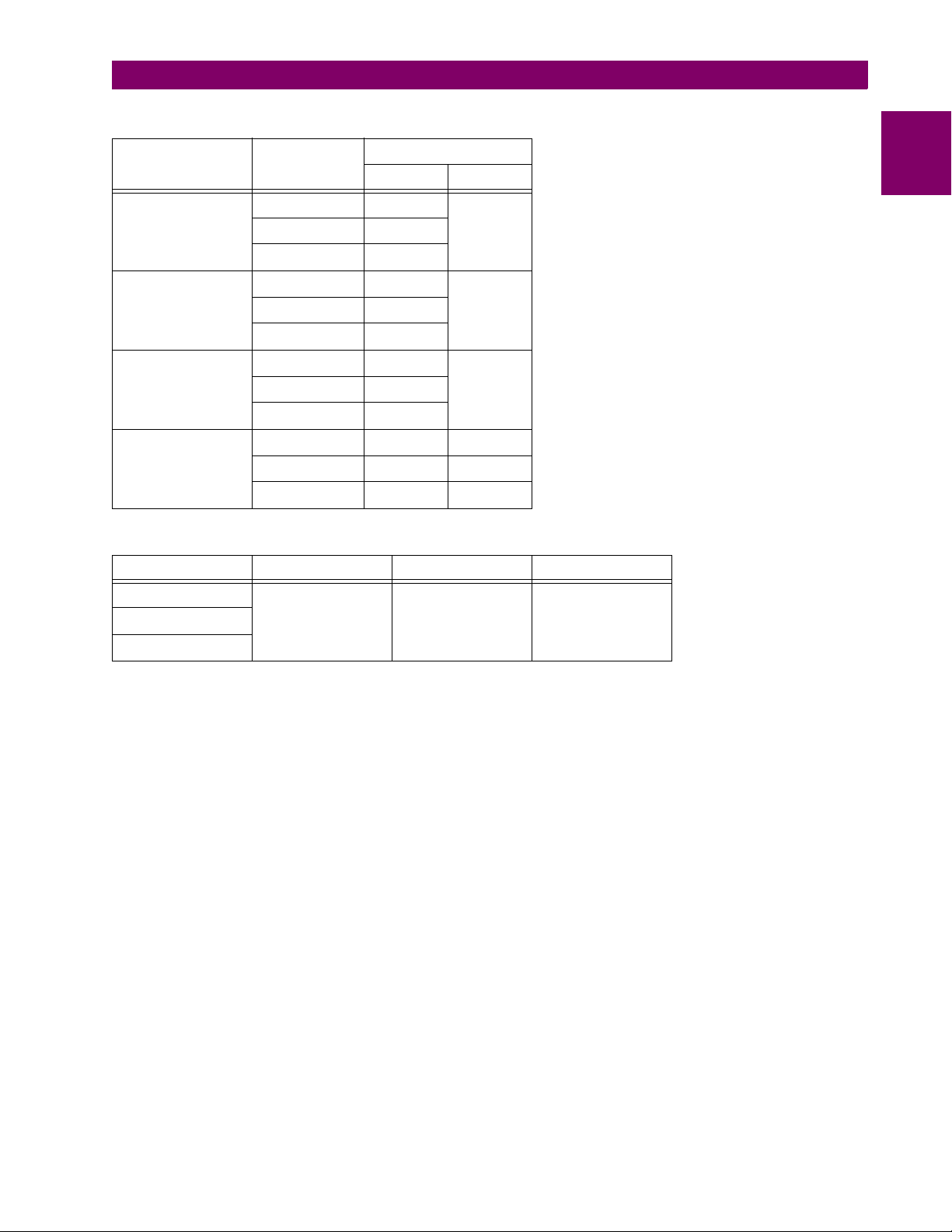

Table 1–1: SELECTION GUIDE

g g g g

PD | | | Panel Mount with Display (only available with both options)

C | | | Chassis Mount (Black Box)

1 | | Option 1: Process control, 10 process inputs, undervoltage

autorestart, diagnostics

2 | | Option 1: Enhanced protection, power (kW), thermistor, 2nd

contactor control, 2 process inputs

120 120 V AC Control Voltage

240 240 V AC Control Voltage

Base Unit

Mounting

Option 1

Option 2

Power

MM2

MM2 | | | | Product Family

All models contain three phase overload protection (49/51), single phase, 4 control inputs

(start, stop, local isolator, contactor A status), plus two programmable inputs and one output

NOTE

relay. The control voltage can be changed in the field.

a) MOUNTING

Chassis Mount: “Black box” version of the MM2 mounted inside the MCC starter.

Panel Mount with Display: Mounted on a panel with a 20 × 2 display, LEDs, and keypad. This fea-

ture is only available with both options

b) OPTION 1

Process Control and Process Inputs: Incl udes 10 programmable switch inputs, 2 extra electrome-

chanical relays (Aux1 and Aux2), and a 4 to 20 mA input.

Undervoltage Auto-Restart: Programmable under voltage restart following undervoltage condition.

Diagnostics: Alarms, pretrip data, and historical statistics about the motor or drive performance.

c) OPTION 2

2nd Contactor Control: Includes all timers, contactor A and B relays, and 2 programmable switch

inputs for two-contactor starter types such as wye/delta, two-speed, and reversing.

Enhanced Protection: Includes ground faul t, stalled rotor, and undercurrent protection.

Power (kW): Includes a single VT input allowing for calculation of kW and kWhrs, as well as under-

power alarm.

Thermistor: Includes a thermistor i nput with alarm or trip sett ings for NTC and P TC type ther mistors.

1-2 MM2 Motor Manager 2

GE Power Management

Page 13

1 INTRODUCTION 1.2 ORDERING

1.2.2 ACCESSORIES

MM2PC

RS-232/485: RS232 to RS485 converter box designed for harsh industrial envi ronments

5A Phase CT: 50,75,100,150,200,250,300,350,400,500,600,750,1000

1A Phase CT: 50,75,100,150,200,250,300,350,400,500,600,750,1000

50:0.025 Ground CT: For sensitive ground detection on high resistance grounded systems

Collar: For reduced depth mounting

MOD601 – 240 V AC Switch Inputs: Allows use of external 240 VAC supply to power swi tch in puts .

MOD602 – 24 to 48 V DC Switch Inputs: Allows use of external 24 to 48 V DC supply to power

switch inputs.

MOD603 – ESD Relay: Converts AUX Relay 2 into an Emergency Shutdown Relay.

MOD605 – Removable Rear Terminals: Allows terminals 13 to 58 to be unplugged from the MM2.

MOD610 – Conformal: Provides protect ion in harsh environments.

MOD613 – 240 VAC VT Input: Allows 240 V AC to be applied to the VT input.

MOD614 – 7200 VT Primary Setting: VT PRIMARY setpoint up to 7200 V and Variable Overload

Curve setting.

®

Software: Software package to aid in setting up MM2 operating parameters (free)

1.2.3 SPECIAL ORDER

1

MOD615 – 7200 VT Primary Setting: VT PRIMARY setpoint up to 7200 V and Backspin Timer.

GE Power Management

MM2 Motor Manager 2 1-3

Page 14

1.3 SPECIFICATIONS 1 INTRODUCTION

1.3 SPECIFICATIONS 1.3.1 MM2 SPECIFICATIONS

1

NOTE

Design and specifications are subject to change without notice.

PHASE CURRENT INPUTS

CONVERSION: true RMS, sample time 1.67ms

RANGE: 0.1 to 8 ×

FULL SCALE: 8 ×

ACCURACY: ±2% of

PHASE CT PRIMARY AMPS

PHASE CT PRIMARY AMPS

PHASE CT PRIMARY AMPS

setpoint

setpoint

setpoint or ±2% of reading, whichever is greater

GROUND FAULT CURRENT INPUT

CONVERSION: true RMS, sample time 1.67 ms

RANGE: 0.1 to 1.0 ×

0.5 to 15.0 A (for 50:0.025 CT)

FULL SCALE: 1.5 ×

15 A (for 50:0.025 CT)

ACCURACY: for 5A CT: ±2% of full scale (5A CT)

for 50:0.025 CT: ±0.10 A (0.0 to 3.99 A)

G/F CT PRIMARY AMPS

G/F CT PRIMARY AMPS

±0.20 A (4.00 to 15.00 A)

setpoint (for 5 A secondary CT)

setpoint (for 5 A secondary CT)

VOLTAGE INPUT / POWER READING

CONVERSION: true RMS, sample time 1.67ms

VOLTAGE FULL SCALE: 1.5 × VT Primary

VOLTAGE ACCURACY: ±2% of VT Primary or ±2% of reading, whichever is greater

POWER ACCURACY: ±5% of nominal or ±5% of reading, whichever is greater

INPUT VOLTAGE: Nominal: 120 V AC or 110 V AC

Maximum: 150 V AC

VT BURDEN: 0.01 VA

OVERLOAD CURVES

TRIP TIME ACCURACY: ±200 ms up to 10 seconds

±2% of trip time over 10 seconds

DETECTION LEVEL: ± 1% of primary CT amps

GROUND FAULT TRIP TIME

ACCURACY: –0 ms / +50 ms, 0.0 = less than 50 ms

ACCELERATION TIME

RANGE: 0.5 to 125 seconds or OFF

ACCURACY: ±0.5 seconds

SINGLE PHASE

RANGE: greater than 30% U/B

ACCURACY: ± 2 percentage points

TRIP DELAY: 5 seconds ± 1 second

1-4 MM2 Motor Manager 2

GE Power Management

Page 15

1 INTRODUCTION 1.3 SPECIFICATIONS

–

IMI

CALCULATION METHOD: if

≥

I

I

:

AV

<

I

if

AV

where

I

= current in a phase with maximum deviation from

M

I

=

FLC

UB%

FLC

I

:

UB%

FLC

I

= average phase current

AV

MOTOR FULL LOAD CURRENT

=

=

AV

----------------------

i

AV

–

IMI

AV

----------------------

i

AV

×

100%

×

100%

setpoint

I

AV

THERMAL COOLING TIMES

RANGE: 5 to 1080 min when motor is stopped;

50% of motor stopped value when motor is running.

ACCURACY: ± 1 minute

UNDERCURRENT

RANGE: 10 to 100% × motor FLC or OFF

DELAY RANGE: 1 to 60 seconds

ACCURACY: ±1 second

STALLED ROTOR

RANGE: 1.15 to 4.50 × FLC or OFF

DELAY RANGE: 0.5 to 5 seconds

ACCURACY: ±0.5 second

1

THERMISTOR INPUTS

SENSOR TYPES: positive temperature coefficient PTC;

negative temperature coefficient NTC;

DELAY: 1 second

ACCURACY: ±5% or 100 Ω (whichever is greater)

R

=100 to 30000

HOT

R

=100 to 30000

HOT

Ω

Ω

ANALOG INPUT

RANGE: 4 to 20 mA

ACCURACY: ±1% of full scale

ALARM: programmable 4 to 20 mA

TRIP: programmable 4 to 20 mA

COMMUNICATIONS

TYPE: RS485 2 wire, half duplex

BAUD RATE: 1200 to 19200 baud

PROTOCOL: Modbus RTU

FUNCTIONS: Read/write setpoints, Read coil status, Read actual values, Read device status,

Execute commands, Loopback Test

GE Power Management

MM2 Motor Manager 2 1-5

Page 16

1.3 SPECIFICATIONS 1 INTRODUCTION

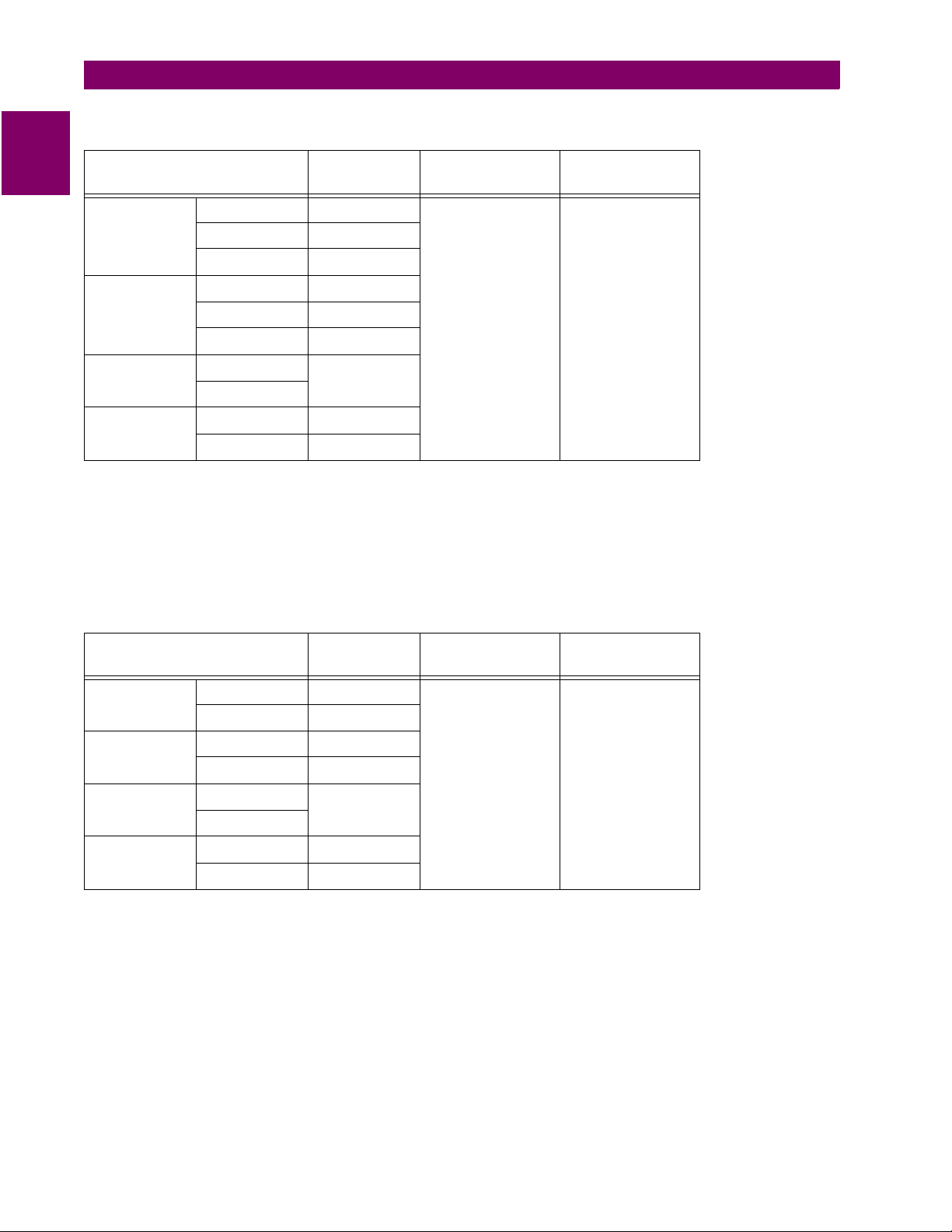

MM2 CONTACTOR A & B AND AUX 2 OUTPUT RELAY CONTACTS

1

VOLTAGE BREAK MAKE/CARRY

30 V DC 10 A

RESISTIVE

INDUCTIVE

(L/R = 7 ms)

RESISTIVE

INDUCTIVE

(PF = 0.4)

CONFIGURATION: CONTACTOR A AND B: Form A

CONTACT MATERIAL: Silver Alloy (AgCdO)

MAX. OPERATING VOLTAGE: 280 V AC, 250 V DC

MAXIMUM PERMISSIBLE LOAD: 5 V DC, 100 mA

125 V DC 0.5 A

250 V DC 0.3 A

30 V DC 5 A

125 V DC 0.25 A

250 V DC 0.15 A

120 V AC

10 A

240 V AC

120 V AC 10 A

225 V AC 8 A

AUX RELAY 2: Form C

MM2 AUX 1 OUTPUT RELAY CONTACTS

CONTINUOUS

10 A 30 A

MAKE/CARRY

0.2 seconds

VOLTAGE BREAK MAKE/CARRY

CONTINUOUS

RESISTIVE

INDUCTIVE

(L/R = 7 ms)

RESISTIVE

INDUCTIVE

(PF = 0.4)

CONFIGURATION: Dual Form C

CONTACT MATERIAL: Silver Alloy (AgCdO)

MAX. OPERATING VOLTAGE: 280 V AC, 125 V DC

30 V DC 5 A

125 V DC 0.25 A

30 V DC 2.5 A

125 V DC 0.1 A

5 A 15 A

120 V AC

5 A

240 V AC

120 V AC 5 A

225 V AC 3 A

UNDERVOLTAGE – SUPPLY VOLTAGE

UNDERVOLTAGE: 65% of nominal (120 V AC or 240 V AC);

Immediate restart for maximum dip time of 0.1 to 0.5 seconds or OFF;

Delayed restart for maximum dip time of 0.1 to 10.0 seconds or UNLIMITED time

DELAY RESTART RANGE: 0.2 to 300 seconds

DELAY RESTART ACCURACY: ±0.2 seconds

MAKE/CARRY

0.2 seconds

1-6 MM2 Motor Manager 2

GE Power Management

Page 17

1 INTRODUCTION 1.3 SPECIFICATIONS

CT BURDEN

CT INPUT CURRENT BURDEN

VA OHMS

1 A 0.009

1 A PHASE CT

5 A PHASE CT

5 A GROUND CT

50:0.025

GROUND CT

20 A 3.5

5 A 0.04

100 A 16

5 A 0.04

100 A 17

0.025 A 0.07 116

0.1 A 1.19 119

0.5 A 30.5 122

0.015 A 0.2

0.00225 A 0.9

0.00225 A 1.1

CT WITHSTAND (1 A / 5 A PHASE CTs; 5 A GROUND CT)

CT INPUT 1 SEC 5 SEC CONTINUOUS

1 A PHASE CT

100 × CT 40 × CT 3 × CT5 A PHASE CT

1

5 A GROUND CT

CT WITHSTAND (50:0.025 A GROUND CT)

CONTINUOUS: 150 mA

MAXIMUM: 12 A for 3 cycles

SUPPLY VOLTAGE

AC NOMINAL: 120 V AC, range 80 to 135 V AC

240 V AC, range 150 to 250 V AC

FREQUENCY: 50/60 Hz

POWER CONSUMPTION: 25 VA (maximum), 7 VA (nominal)

TYPE TESTS

TRANSIENTS: ANSI/IEEE C37.90.1 Oscillatory/Fast Risetime Transients

IEC 801-4 Electrical Fast Transient/Burst Requirements

IMPULSE: IEC 255-5 5 kV Impulse Voltage Test

RFI: 150 MHz, 450 MHz 5 W Handheld Transmitter at 25 cm

ST ATIC: IEC 801-2 Electrostatic Discharge

HI-POT: 1500 V, 1 minute; all inputs > 30 V

GE Power Management

MM2 Motor Manager 2 1-7

Page 18

1.3 SPECIFICATIONS 1 INTRODUCTION

ENVIRONMENT/GENERAL INFORMATION

POLLUTION DEGREE: 2

1

OVERVOLTAGE CATAGORY: 2

INSULATION VOLTAGE: 300 V

OPERATING TEMPERATURE RANGE: 0°C to 60°C

DUST & MOISTURE RATING: NEMA Type 12 and 12K

IP CLASS: IEC 529 - IP53

WEIGHT

MAX WEIGHT: 4 lbs. (1.8 kg)

SHIPPING BOX SI ZE: 8.30” (211 mm) × 5.625” (143 mm) × 5.80” (147 mm)

FUSE TYPE/RATING

0.5 A; 250 V Fast Blow, High breaking capacity

INSTALLATION

WARNING: HAZARD may result if the product is not used for its intended purpose

VENILATION REQUIREMENTS: None

CLEANING REQUIREMENTS:None

CERTIFICATION/COMPLIANCE

CE: IEC 947-1,IEC 1010-1

CSA: Approved File No. LR41286

UL: Recognized File No. E83849

QUALITY ASSURANCE SYSTEM: Registered by QMI to CSA CAN3.Z299.3-1985 & ISO 9001-1994

NOTE

It is recommended that all MM2 relays are powered up at least once per year to avoid

deterioration of electrolytic capacitors in the power supply.

1-8 MM2 Motor Manager 2

GE Power Management

Page 19

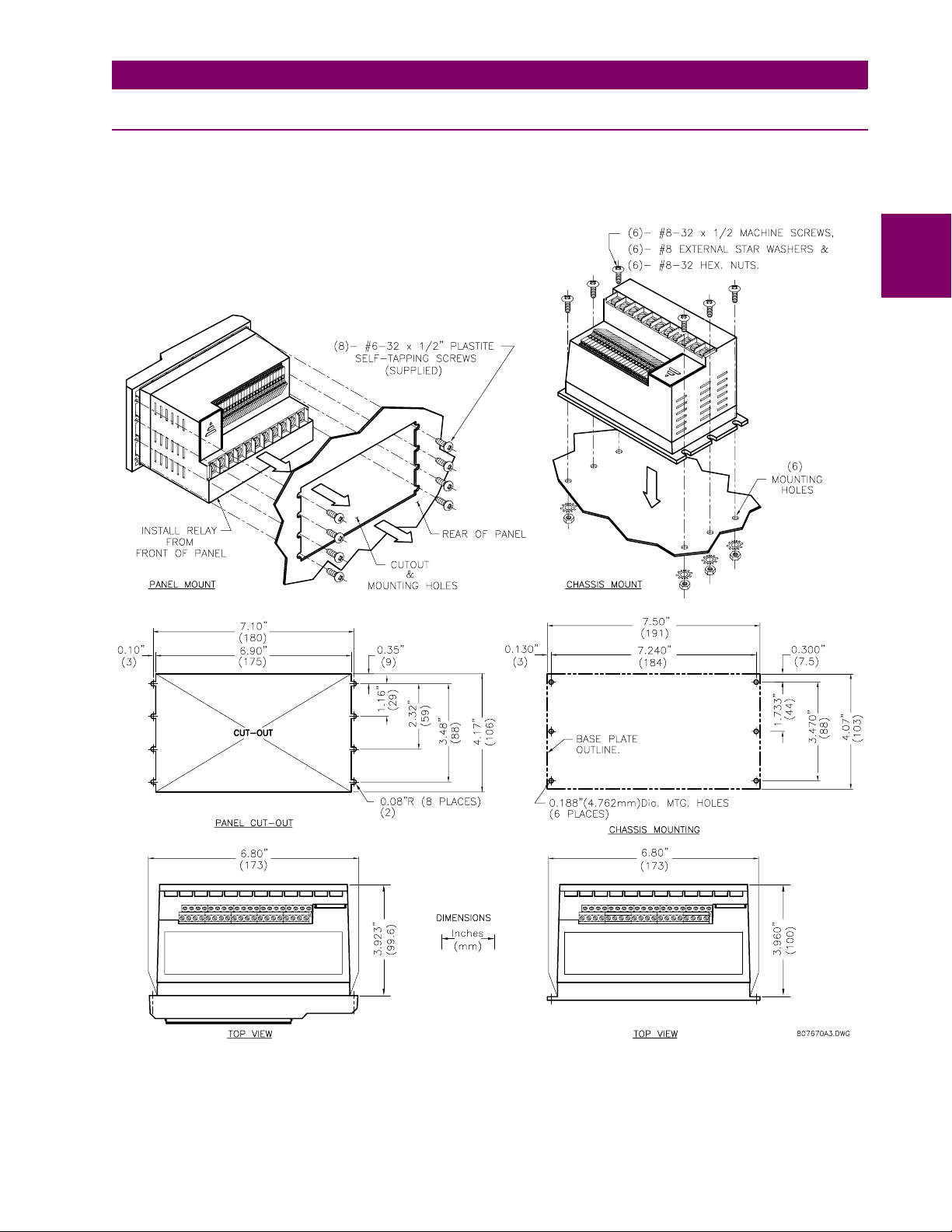

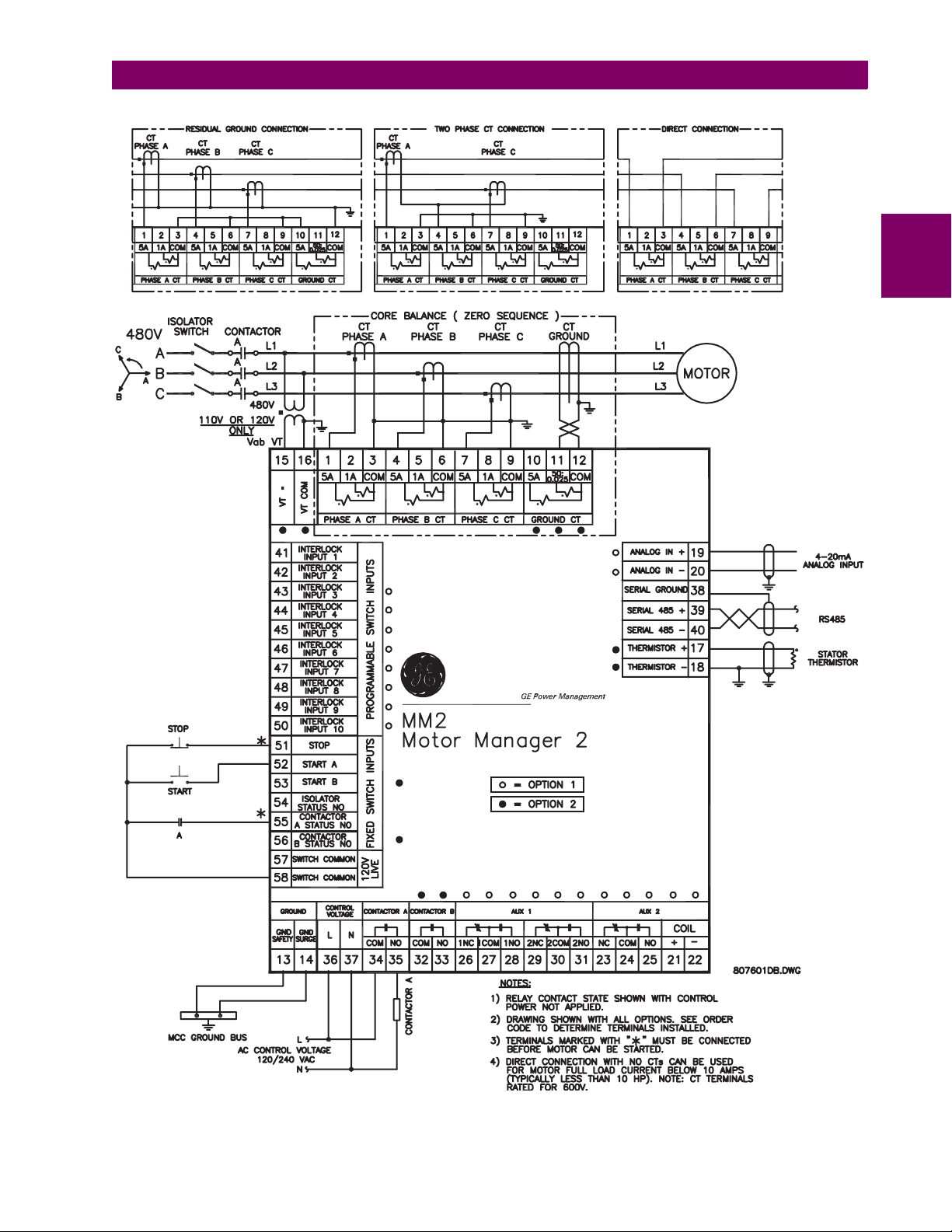

2 INSTALLATION 2.1 MOUNTING

2 INSTALLATION

Cut the panel as shown below to mount the MM2. Use either the #8-32 or #6×½” mounting screws

provided to mount the MM2 to the panel.

2.1 MOUNTING 2.1.1 DESCRIPTION

2

GE Power Management

Figure 2–1: MM2 MOUNTING INSTRUCTIONS

MM2 Motor Manager 2 2-1

Page 20

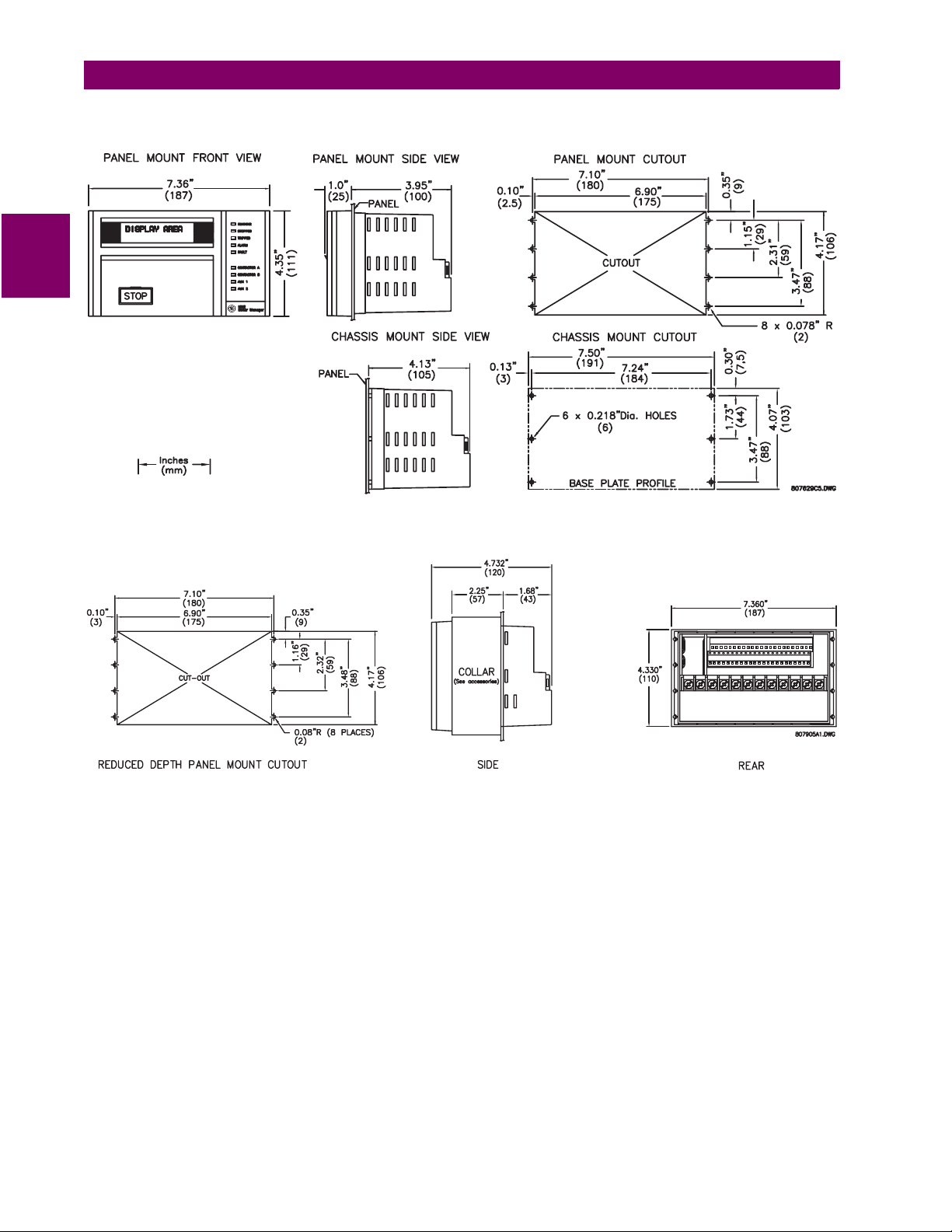

2.1 MOUNTING 2 INSTALLATION

The dimensions for the standard MM2 and the MM2 with reduced mounting collar are shown below:

2

Figure 2–2: MM2 DIMENSIONS

Figure 2–3: MM2 WITH DEPTH REDUCTION COLLAR DIMENSIONS

2-2 MM2 Motor Manager 2

GE Power Management

Page 21

2 INSTALLATION 2.1 MOUNTING

2

GE Power Management

Figure 2–4: TYPICAL WIRING DIAGRAM

MM2 Motor Manager 2 2-3

Page 22

2

2.1 MOUNTING 2 INSTALLATION

52

480 VOLT BUS480 VOLT BUS

FUSEFUSE

CONTCONTACTACTOROR

PHASE PTPHASE PT

PHASE CTPHASE CT

GROUND CTGROUND CT

THERMISTOR

MOTOR

WINDINGWINDING

THERMISTTHERMISTOROR

LOAD

CONTACTOR ACONTACTOR A

(FOR(FORWARD/WYE)ARD/WYE)

CONTACTOR BCONTACTOR B

(REVERSE/DEL(REVERSE/DELTA)

51 49 37

51G

MOTOR

49

MANAGER 2MANAGER 2

46

AUXAUX

1

RELARELAY

AUXAUX

2

RELARELAY

CONTROLCONTROL

INPUTSINPUTS

4-20mA4-20mA

INPUTINPUT

RS485 REMOTERS485 REMOTE

COMMUNICACOMMUNICATIONTION

1200-19K2 BAUD1200-19K2 BAUD

PROCESSPROCESS

PLC ORPLC

OR

TRANSDUCERTRANSDUCER

Figure 2–5: MM2 FUNCTIONAL BLOCK DIAGRAM

2-4 MM2 Motor Manager 2

GE Power Management

Page 23

2 INSTALLATION 2.2 INPUTS AND OUTPUTS

2.2 INPUTS AND OUTPUTS 2.2.1 PHASE CT INPUTS

Both 5 A and 1 A current transformer secondaries are accommodated by the MM2. Each phase current input to the MM2 has 3 terminals: 5 A input, 1 A input, and the common input. For example, if th e

phase CTs are 200:5, connect phase 1, 2, and 3 CT secondaries to terminals 1/3, 4/6, and 7/9,

respectively. For motor full-load currents up to 10 A, the phase conductors can be direct connected

to the MM2 with no phase CTs required providing that the voltage at the CT terminals does not

exceed 600 V RMS.

CTs should be selected to be capable of supplying the required current to the total secondary load

which includes the MM2 relay burden of 0.1 VA at rated secondary current and the connection wiring

burden. The CT must not saturate under maximum current conditions which can be up to 8 times

motor full load during starting.

2.2.2 GROUND FAULT CT INPUT

The ground CT has a 5 A input, a 50:0.025 input, and a common input. The 5 A input on the ground

CT is used for 5 A secondary CTs or for residual connection of phase CTs. Residual ground fault protection provides a sensitivity of 5% of motor Phase CT Primary. The 50:0.025 core balance (zerosequence) CT input can be used for improved sensitivity when measuring the ground fault current.

2

Care must be taken when turning ON the Ground Fault Trip feature. If the interrupting

device (contactor or circ uit breaker ) is not ra ted to break gro und f ault c urr ent (l ow r esist ance

NOTE

Supply voltage of 120/240 V AC, 50 or 60 Hz, is required to power t he MM2. T he label on the back o f

the unit will specify the voltage which has been internally set inside the MM2. To change the voltage

setting, open the sliding door on the back of the MM2 and locate the supply voltage selector slide

switch. The selector slide switc h has a label af fixed to show t he 120/240 VAC positions. Set the slide

switch to the desired voltage.

This is an additional ground terminal provided for dissipating transient signals and surges. This must

be connected by a thick wire or braid to the system gro und for reliable operation.

Signal wiring is to box terminals that can accommodate wire as large as 12 gauge. CT connections

are made using #8 screw ring terminals that can accept wire as large as 8 gauge. Consult Figure 2–

4: TYPICAL WIRING DIAGRAM on page 2–3. Other features can be wired as required.

or solidly grounded systems), the feature should be disabled. The 50:025 input is only recommended to be used on resistance grounded systems. Where the system is solidly

grounded or high levels of current are to be detected use the 5 A ground input.

2.2.3 SUPPLY VOLTAGE

2.2.4 GROUND SURGE

2.2.5 EXTERNAL CONNECTIONS

GE Power Management

MM2 Motor Manager 2 2-5

Page 24

2.2 INPUTS AND OUTPUTS 2 INSTALLATION

2.2.6 THERMISTOR INPUT

Either a Positive Temperature Coefficient (PTC) or Negative Temperature Coefficient (NTC) thermistor may be directly connected to the MM2. By specifying the hot and cold thermistor resistance,

the MM2 automatically determines the thermistor type as NTC or PTC. Use thermistors with hot and

cold resistance values in the range 100 to 30000Ω. If no thermistor is connected, the thermistor

alarm and trip detection must be set to DISABLE in the S1: CONFIGURATION \ THERMISTOR page.

2

2.2.7 ANALOG INPUT

The analog input accepts an input from a standard 4 to 20 mA source. This input can be used for

process control monitoring to provide status and/or alarm and tripping signals related to the level of

the input signal. The analog input messages (S3: PROCESS \ ANALOG INPUT) can be programmed to

show a user defined name and units.

2.2.8 AUX 2 COIL

The AUX Relay 2 can be internally energized by the MM2 or externally energized by applying a 24

V DC signal to these terminals. Correct polarity is requir ed (Terminal 21 = +24 V DC, Terminal 22 = 0

V DC).

2.2.9 OUTPUT RELAYS

There are up to 4 output relays on t he MM2. Contact s witching ra ting fo r the output r elays as well can

be found in Section 1.3: SPECIFICATIONS on page 1–4.

• Contactor A Relay (34/35): non-reversing, forward, low speed, etc.

• Contactor B Relay (32/33): reversing, high speed, etc.

• AUX Relay 1 (26/27/28, 29/30/31): field programmable

• AUX Relay 2 (23/24/25): field programmable or hard-wired 24 V DC coil

2.2.10 SWITCH INPUTS

SWITCH INPUT COMMON TERMINALS 57 AND 58 ARE LIVE 120 VAC.

CAUTION

All switch inputs are opto-isolated and operate at a voltage of 120 V AC. The switch will read closed

when 120 VAC is applied to the switch terminal. This 120 V AC can be supplied from the switch common terminals (57, 58) or from an external source providing that the source is in phase with the supply voltage of the MM2.

2.2.11 PROGRAMMABLE SWITCH INPUTS

These 10 inputs can be programmed to one of a number of differ ent funct ions. Some of th e availabl e

functions are: Setpoint Access, Lockout Reset, Plant Interlock, Auto Start, Remote Permissive, and

Test. See the S3: PROCESS \ PROGRAMMABLE INPUTS page for complete list of available functions.

2-6 MM2 Motor Manager 2

GE Power Management

Page 25

2 INSTALLATION 2.2 INPUTS AND OUTPUTS

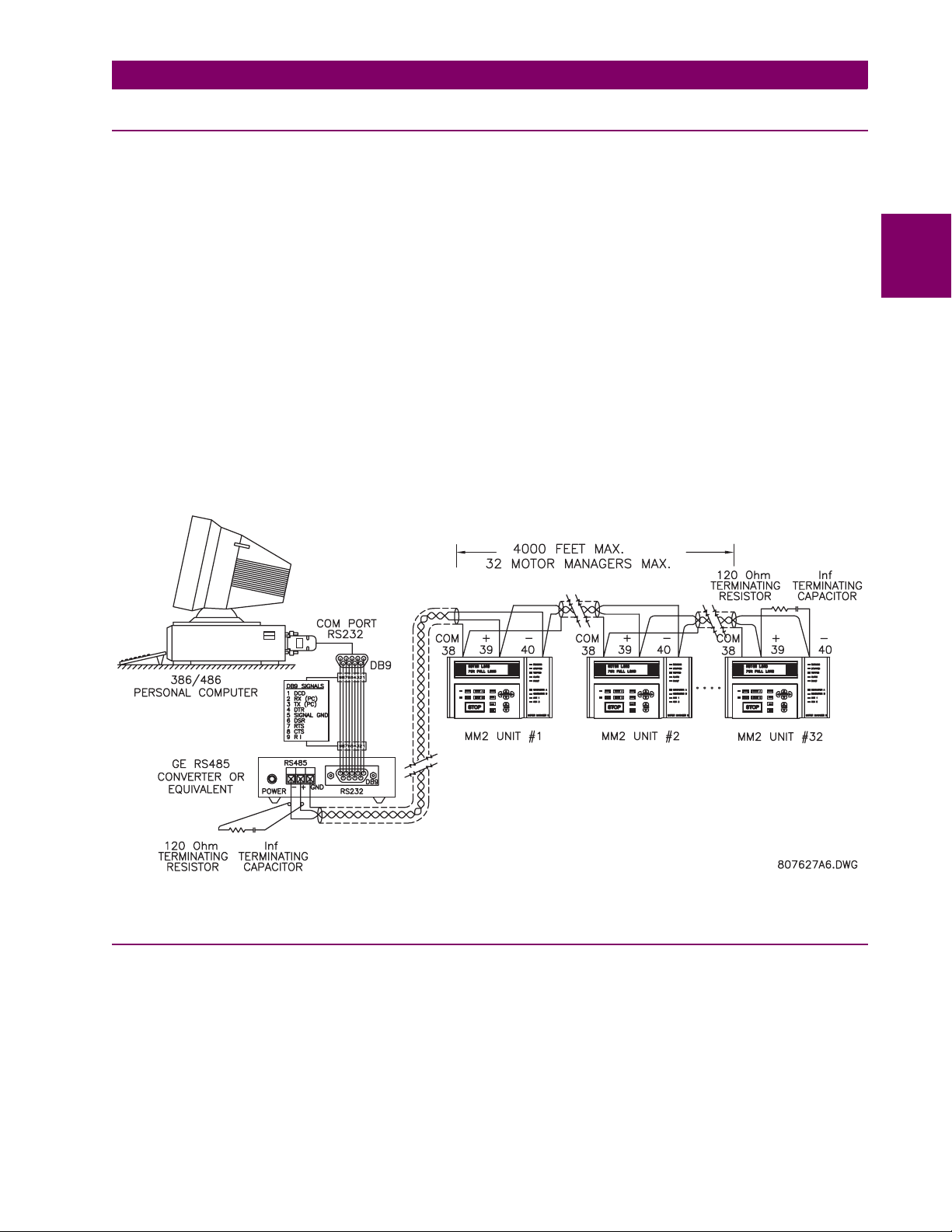

2.2.12 SERIAL COMMUNICA TION PORT

A serial port provides communication capabilities to the MM2. Multiple MM2s can be connected

together with a 24 AWG stranded, shielded twisted pair with a characteristic impedance of 120

such as Belden 9841 or equivalent. The total length of communications wiring should not exceed

4000 feet. Care should be used when routing the communications wiring to keep away from high

power AC lines and other sources of electrical noise.

Correct polarity is essential for the communications port to operate. Terminal 39 ("+") of every MM2

in a serial communication link must be connected together. Similarly, Terminal 40 ("–") of every MM2

must also be connected together. The shield wire must be connected to Terminal 38 (485 SERIAL

GROUND) on every unit in the link to provide a common ground potential for all units. Each relay

should be "daisy chained" to the next one. Avoid star or stub connected configurations if possible to

avoid potential communication problems.

A terminating resistor and capacitor network is required to prevent communication errors. Only the

last MM2 and the master computer driver should have the terminating network to ensure proper

matching. Using terminating resistors and capacitors on all the MM2s would load down the communication network while omitting them at the ends could cause reflections resulting in communication

errors.

Ω

2

Figure 2–6: RS485 TERMINATION

2.2.13 STOP

If this terminal is de-energized, both contactor A and contactor B output relays will open causing the

contactor coils to de-energize. The stop input must be energized before the MM2 will process any

start commands.

GE Power Management

MM2 Motor Manager 2 2-7

Page 26

2.2 INPUTS AND OUTPUTS 2 INSTALLATION

2.2.14 START A / START B

When the start input terminals are energized, the corresponding contactor output relay will be energized provided all other valid start conditions are met. If any trip occurs, both contactor outputs will

be de-energized. Start A input is used for all types of contactors, that is: Full Voltage Non-reversing,

Reversing, Two Speed (low speed), Wye Delta Open Trans iti on, Inver ter, Slip Ring, Autotransformer,

Part Winding or Wye Delta Closed Transition. Start B input is used for Reversing and Two Speed

2

(high speed) contactor control. Start inputs are usually momentary unless Two Wire control is

selected. Start A and B commands may also be initiated via the seri al link.

2.2.15 LOCAL ISOLATOR N/O

The local isolator NO auxi liar y c ontacts are used to pr event motor star ts i n t he event of t he Local Iso lator being in the “open” position. To prevent starts, the MM2 produces a trip when the Local Isolator

input is open. A Local Isolator Trip is automatically reset when the Local Isolator is re-closed. The

Local Isolator input can be enabled or disabled as required. The factory default is disabled.

2.2.16 CONTACTOR STATUS

The MM2 must know the state of the contactor at all times in order to detect discr epancies in contac tor close/open commands and also to display the state of the contactor. There are two contactor status inputs on the MM2, one for contactor A, the other for contactor B.

Auxiliary contacts mechanically linked to the contactor itself are used to feed back to the contactor

status inputs. No status change following a "start" command indicates an open contactor control circuit and no status change following "stop" command indicates a welded contactor. Appropriate messages and alarms are displayed for these conditions and the status can be read via the serial port.

If the motor contactor is externally energized, the MM2 will seal in the output relay and display an

“EXTERNAL START” message. If the motor contactor is externally de-energized, the MM2 will drop

out the output relay and display an “EXTERNAL STOP” message.

2.2.17 SWITCH COMMON

These two terminals serve as the common for all switches. The MM2 switch inputs operate at 120

VAC which is supplied from these terminals.

2.2.18 DIELECTRIC STRENGTH TESTING

It may be required to test a complete MCC with MM2s installed for dielectric strength. This is also

known as "flash" or "hi-pot" testing. The MM2 is rated for 1500 V AC for 1 minute or 1800 VAC for 1

second isolation between switch inputs, relay outputs, VT voltage input, supply voltage inputs and

ground terminal 13.

When performing dielectric test s, the connect ion to t he sur ge ground t erminal (14) must b e removed .

A filter network is used on the AC input to filter out RF and EMI noise. The filter capacitors and transient absorbers could be damaged by the high voltages relative to surge ground on the AC input.

Under no circumstances should any inputs other than switches, relays, supply voltage, VT input, and CT inputs be dielectric tested.

WARNING

2-8 MM2 Motor Manager 2

GE Power Management

Page 27

3 HARDWARE 3.1 FACEPLATE FUNCTIONS

3 HARDWARE

3.1 FACEPLATE FUNCTIONS 3.1.1 DESCRIPTION

Once the MM2 has been wired and powered on, it is ready to be programmed for a specific application. Local programming is done using the front panel keypad and the 40 character alphanumeric

display. Remote programming via the serial port is also possible using the MM2PC

®

software.

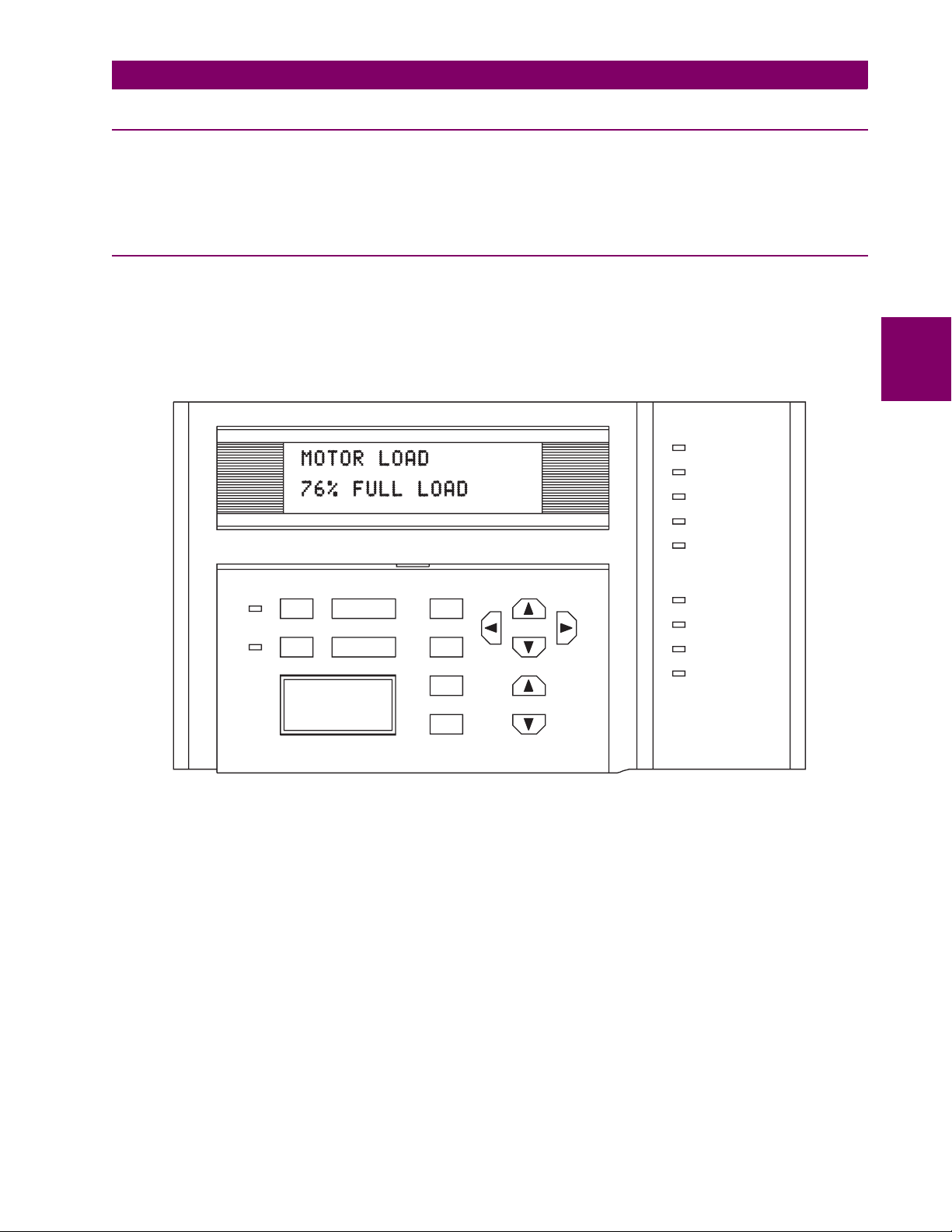

3.1.2 MESSAGE DISPLAY

A 40 character display is used to communicate all information about the syste m to the user. Trip and

alarm messages will automatically override the currently-displayed message. If no key is pressed for

2 minutes, a user-selected default messaging sequence will be displayed. If the motor is currently

stopped, the Motor Status message will be the default message. Once the motor is started, the first

user-selected message will appear.

RUNNING

STOPPED

TRIPPED

ALARM

FAULT

3

START AAUTO

MANUAL START B

STOP

SETPOINT

MESSAGE

ACTUAL

RESET

VALUE

STORE

Figure 3–1: FRONT PANEL

CONTACTOR A

CONTACTOR B

AUX 1

AUX 2

807230A1.CDR

GE Power Management

MM2 Motor Manager 2 3-1

Page 28

3.1 FACEPLATE FUNCTIONS 3 HARDWARE

3.1.3 INDICATOR LEDs

• RUNNING: Whenever contactor A and/or B relays are closed and the contactor status inputs

acknowledge the correct state, the RUNNING indicator will be on. Current flow does not affect

the indicator, only contactor status.

• STOPPED: If both contactors A and B are in the OFF state, the STOPPED indicator will be on.

• TRIPPED: If a trip condition causes the A or B contactor relays to de-energize, this indicator will

be on. As long as this indicator is on, the motor cannot be started. It is cleared using the reset

key, lockout reset facility or serial port reset, dependent on the type of trip.

• ALARM: If an alarm condition is present this indicator will be on. Use the A2: ALARM DATA actual

3

values to view current alarm status.

• FAULT: If an internal fault within the MM2 is detected by self-checking, this indicator will be on.

The MM2 must be replaced or repaired.

• CONTACTOR A: If the Contactor A Relay is energized, this indicator will be on.

• CONTACTOR B: If the Contactor B Relay is energized, this indicator will be on.

• AUX 1: If Auxiliary Relay # 1 is on, this indicator will be on.

• AUX 2: If Auxiliary Relay # 2 is on, this indicator will be on.

• AUTO: If the MM2 is in Auto control mode or the Hard-Wired Auto mode, this indicator will be on.

In Auto mode the Start A / Start B switch inputs and START A / START B keypad keys are nonoperational but serial port st art commands are operati onal. In the Hardwir ed Auto Mode, the Auto

Start A and Auto Start B switch inputs are functional in conjunction with the Auto Permissive

switch input. Serial, faceplate and remote starts are disabled. STOP commands from any location are always operational.

• MANUAL: If the MM2 is in Manual control mode, this indicator will be on. In Manual mode the

Start A / Start B switch inputs, AUTO START A / AUTO START B switch inputs and START A /

START B keypad keys are operational but serial port start commands are ignored. All stop commands are operational.

3-2 MM2 Motor Manager 2

GE Power Management

Page 29

3 HARDWARE 3.2 KEYPAD

3.2 KEYPAD 3.2.1 SETPOINTS KEY

FUNCTION: The SETPOINT key allows the user to examine and alter all trip, alarm, and other MM2

setpoints. There are 6 pages of Setpoints:

• Page 1: Configuration

• Page 2: Protection

• Page 3: Process

• Page 4: Control

• Page 5: Monitoring

• Page 6: Factory Data

EFFECT: Pressing this key will cause the display to show the beginni ng of the next page of setpoints

data. If Actual Values data was on the disp lay bef ore pressing th e SETPOINT k ey, setpoints page S1

will be shown:

]] SETPOINTS

]] S1: CONFIGURATION

USE: This key can be pressed at any time to view MM2 setpoints. To scroll through the setpoint

pages, press the SETPOINT key. To go from section to section within a page, press the MESSAGE

UP and MESSAGE DOWN keys. To go from line to line within a section, press the MESSAGE LEFT

and MESSAGE RIGHT keys.

To alter a setpoint, the VALUE UP and VALUE DOWN keys can be used. All setpoints can be incremented or decremented to pre-determined limits. When the desired value is reached, the STORE

key must be used to save the n ew set point. If an a lt ered set poin t is n ot s tored, the previous val ue will

still be in effect. All control and protection features continue to operate while setpoints data is displayed.

3.2.2 ACTUAL VALUES KEY

FUNCTION: The ACTUAL key allows the user to examine all of the actual motor operating parame-

ters. There are 4 pages of ACTUAL VALUES data:

3

• Page 1: Data

• Page 2: Status

• Page 3: Inputs

• Page 4: Statistics

EFFECT: Pressing this key will cause the display to show the beginning of the next page of Actual

Values data. If setpoints data was on th e displ ay befor e pressin g t he ACTUAL key, page A1 of Actual

Values will be shown:

]] ACTUAL VALUES

]] A1: DATA

GE Power Management

MM2 Motor Manager 2 3-3

Page 30

3.2 KEYPAD 3 HARDWARE

USE: This key can be pressed at any time to view MM2 actual values. To scroll through the actual

values pages, press the ACTUAL key. To go from section to section within a page, press the MESSAGE UP and MESSAGE DOWN keys. To go from line to line within a section, press the MESSAGE

LEFT and MESSAGE RIGHT keys.

The VALUE UP and VALUE DOWN keys have no effect when actual values data is displayed.

3.2.3 STORE KEY

FUNCTION: The STORE key allows the user to store new setpoints into th e MM2 internal memory.

EFFECT: When this key is pressed the currently displayed Setpoint will be stored in non-volatile

memory and will immediately come into effect. When a Setpoint is stored, the following flash mes-

3

sage will appear on the display:

NEW SETPOINT

STORED

USE: The STORE key can be used only in SETPOINTS mode to store new setpoints, or in ACTUAL

VALUES mode to select a new default message.

3.2.4 STOP KEY

FUNCTION: The STOP key will allow the user to stop the motor from the face plate of the MM2.

EFFECT: Pressing this key will cause the Contactor A and Contactor B output relays to de-energize

therefore dropping out the motor contactor.

USE: The STOP key is used to stop the motor.

3.2.5 RESET KEY

FUNCTION: The RESET key allows the user to reset MM2 trips.

EFFECT: Pressing this key will reset a tri pped stat e on the MM2. A message i ndicati ng that a r eset i s

not possible will be displayed if the condition causing the trip is still present.

USE: The RESET key can be used to reset all trip conditions from the faceplate of the MM2. A

Ground Fault, Stalled Rotor and Overload Trip can be assigned to the LOCKOUT RESET feature on

one of the programmable switch inputs for adde d safety. The factory default allows the resetting of all

trips using the front panel reset key.

3.2.6 START A KEY

FUNCTION: The START A key can be used to start the motor.

EFFECT: Pressing this key will cause the programmed start sequence to begi n.

USE: The START A key is used to sta rt the motor from the faceplate of the MM2. Start A can also be

initiated from the start switch inputs at the back of the MM2 or from the serial port.

3-4 MM2 Motor Manager 2

GE Power Management

Page 31

3 HARDWARE 3.2 KEYPAD

3.2.7 START B KEY

FUNCTION: The START B key can be used to start the motor.

EFFECT: Pressing this key will cause the programmed start sequence to begi n.

USE: This START B key is used to start a reversing or two speed motor from the faceplate of the

MM2. Start B can also be initiated from the start switch input at the back of the MM2 or from the

serial port.

3.2.8 MESSAGE UP/DOWN KEYS

FUNCTION: The MESSAGE UP and MESSAGE DOWN keys allow the user to move to the next or

previous section of the currently selected page.

EFFECT: Pressing the MESSAGE DOWN key will cause the display to move to the next section of

the current page. Pressing the MESSAGE UP key will cause the display to move to th e previous section of the current page. Note: If either key is held for more than 1 second, the next or previous sections will be selected at a fas t rate. When the c urrent display is a t a page heading, t he MESSAGE UP

key has no effect. When the curr ent displ ay is at t he end of the page, the MESSAGE DOWN key has

no effect.

USE: These keys are used to move through the sections of the currently selected page.

3.2.9 MESSAGE LEFT/RIGHT KEYS

FUNCTION: The MESSAGE LEFT and MESSAGE RIGHT keys allow the user to scan the next or

previous line of the currently selected section.

EFFECT: Pressing the MESSAGE RIGHT key displays the next line of the current section. Pressing

the MESSAGE LEFT key displays the previous line of the current section. If either key is held for

more than 1 second, the next or previous line will be selected at a faster rate. If the display shows a

section heading, the MESSAGE LEFT key has no effect. If the MESSAGE RIGHT key has no effect,

the display is showing the last line of a section.

USE: These keys are used to move through the lines of the currently selected sect ion.

3

3.2.10 VALUE UP/DOWN KEYS

FUNCTION: The VALUE UP and VALUE DOWN keys allow the user to change setpoint values prior

to pressing the STORE key.

EFFECT: Pressing the VALUE UP key will increment the currently displayed setpoint value. Pressing

the VALUE DOWN key will decrement the currently displayed setpoint value. If the display shows an

Actual Value these keys will have no effect

USE: These keys can be used any time to change the value displayed in the setpoint messages.

GE Power Management

MM2 Motor Manager 2 3-5

Page 32

3.3 THEORY OF OPERATION 3 HARDWARE

3.3 THEORY OF OPERATION 3.3.1 HARDWARE DESCRIPTION

A 16 bit 68HC16 microc ontroller IC performs program execution and control logic for the MM2. Refer

to the block diagram for a complete overview of the MM2 circuitry. It has an 8 or 16 bit bus width

which can be selected dynamically with each external memory fetch allowing a mix of 8 and 16 bit

devices. Internal clock rate is 16 Mhz. Instructions are stored in two 128K×8 bit flash memory, data

is stored in an 32K×8 RAM while Setpoints and accumulated data are stored in a 8K×8 EEPROM.

An intelligent display module with its own microprocessor, memory and command set is accessed

through a buffer on the data bus. The display, a 4×4 keypad and the front panel LEDs are multiplexed through the same buffer.

External switch inputs ar e driven with 120 VAC whi ch triggers an optocoupler for isolation. All control

3

logic based on the state of these inputs determines operation of up to 4 output relays which are also

driven from a latch under program control. Like the inputs, the relay outputs are driven from an isolated power supply and optocoupler to prevent switch ing transient energy from affecting the CPU.

A 10 bit successive approximation A/D on the 68HC16 CPU with 8 channels is used to measure all

analog signals. Separate AC inp uts for phase 1 , phase 2, phase 3, and g round f ault sig nals are sampled at a 1.67 ms rate, squared and summed. RMS current is then determined by deriving the

square root of the sampled waveform over several cycles. The sampling time is set to measure an

integral number of cycles to reduce the affects of noise and harmonics. Thermistor, analog input, VT

voltage, control supply voltage and internal reference voltage are also monitored. An external precision 5V DC reference is used as the input reference for the A/D converter.

When power to the unit is removed, a small 8-bit processor (68HC705) will continue to operate for a

period of at least 1 hour. This processor is powered from a large backup capacitor. The 68HC705

accurately measures the time that the MM2 has been without control power. When power is reapplied the main processor will read the time off from the small processor and then very accurately

calculate the thermal capaci ty value. This time off value is also used for the undervoltage restart feature.

Serial communications at up to 19200 baud is implemented with UART circuitry internal to the

68HC16 microcomputer. All necessary timing and control is performed inside the chip. An external

transceiver chip converts the digital data to an RS485 interface. Direction, receive data and transmit

data are on the input side with a two wire twisted pair driver on the output.

AC control voltage to power the MM2 can be selected as 120 or 240 V AC using a switch and dual

wound primary transformer. A filter is incorporated between the incoming supply and transformer primary to prevent transients from affecting the circuitry.

Separate, isolated secondary supplies are used for CPU power, I/O and communication drivers.

Optocoupling and transformer coupling are used between isolated circuits to prevent transients from

upsetting program execution. The 68HC705 is used to provide separate watchdog timer and power

fail monitoring control to ensure that the main CPU starts and operates under any input voltage conditions. Should normal program execution fail, the 68HC705 reset s the main CPU.

3-6 MM2 Motor Manager 2

GE Power Management

Page 33

3 HARDWARE 3.3 THEORY OF OPERATION

3

GE Power Management

Figure 3–2: BLOCK DIAGRAM

MM2 Motor Manager 2 3-7

Page 34

3

3.3 THEORY OF OPERATION 3 HARDWARE

3-8 MM2 Motor Manager 2

GE Power Management

Page 35

4 SETPOINTS 4.1 OVERVIEW

4 SETPOINTS

4.1 OVERVIEW 4.1.1 DESCRIPTION

By pressing the SETPOINT key, any of the motor trip/alarm Setpoints may be viewed or altered. Setpoints data is divi ded into si x pages. I nformati on a bout the conf ig urati on of t he mot or as wel l as othe r

connected devices is entered in page one, S1: CONFIGURATION. Information for programming the

protection features is located in page two, S2: PROTECTION. Information describing the process

control functions is described in page three, S3: PROCESS. Information for programming the cont rol

functions in the MM2 is contained in page four, S4: CONTROL. Information to aid with plant maintenance is contained in page five, S5: MONITORING. Information about the internal configuration of

the MM2 as well as the software version is contained in page, S6: FACTORY DATA.

To scroll through the Setpoint pages, press the SETPOINT key. When this key is pressed for the first

time the following message will appear on the display:

]] SETPOINTS

]] S1: CONFIGURATION

This is the first page of Setpoints. The MESSAGE RIGHT, MESSAGE LEFT, MESSAGE UP and

MESSAGE DOWN keys may be used to view all of the setpoints data.

The Setpoint values themselves are changed by pressing the VALUE UP or VALUE DOWN keys

until the desired value is reached. When a Setpoint is adjusted to its proper value the STORE key

must be pressed in order to store the Setpoint into the MM2 non-volatile memory. Once the STORE

key is pressed the flash mess age shown below will appear on the displa y and the new Setpo int value

will be permanently saved.

4

NEW SETPOINT

STORED

Setpoints may be changed while the motor is running; however it is not recommended to change important protection parameters without first stopping the motor.

WARNING

Setpoints will remain stored indefinitely in the MM2 internal non-volatile memory even when control

power to the unit is removed. Protection parameters are based on the entered data. This data must

be complete and accurate for the given system for reliable protection and operation of the motor.

All Setpoint messages shown contain the factory defaul t settings.

NOTE

4.1.2 ABBREVIATIONS

The following abbreviations are used in the messages in the setpoints pages.

• A, AMPS: Amperes

• AUX: Auxilia ry

• CBCT: Core Balance Current Transformer

• COM, COMMS: Communication

• CT: Current Transformer

• FLC: Full Load Current

• FV: Full Voltage

• G/F: Ground Fault

GE Power Management

MM2 Motor Manager 2 4-1

Page 36

4.1 OVERVIEW 4 SETPOINTS

• GND: Ground

•Hz: Hertz

• KOHMS: kiloOhms

• MAX: Maximum

• MIN: Minim um

• SEC, s: Seconds

• UV: Undervoltage

• VT: Voltage Transformer

4

]] SETPOINTS

]] S1: CONFIGURATION

] COMMUNICATION

]

] MOTOR

] IDENTIFICATION

] STARTER

]

] CT/VT INPUTS

]

] THERMISTOR

]

] FAULT MODE

]

] STATISTICS

]

] PROGRAMMABLE

] MESSAGES

]] SETPOINTS

]] S2: PROTECTION

] MOTOR PROTECTION

] THERMAL

] MOTOR PROTECTION

] GROUND FAULT

] MOTOR PROTECTION

] OPTIONS

] LOAD PROTECTION

]

] UNDER/OVERVOLTAGE

] PROTECTION

]] SETPOINTS

]] S3: PROCESS

] PROGRAMMABLE

] INPUTS

] PROCESS INTERLOCK

] NAMES

] STOP CONFIGURATION

]

] ANALOG INPUT

]

]] SETPOINTS

]] S4: CONTROL

] UNDERVOLTAGE

] AUTO RESTART

] AUX RELAY 1 CONFIG

]

] AUX RELAY 2 CONFIG

]

] PREFERENCES

]

]] SETPOINTS

]] S5: MONITORING

] PLANT CONDITION

]

] PRESET COUNTERS

] AND TIMERS

Figure 4–1: SETPOINTS MESSAGES

4-2 MM2 Motor Manager 2

]] SETPOINTS

]] S6: FACTORY DATA

] PRODUCT FIRMWARE

] IDENTIFICATION

] PRODUCT MODEL

] IDENTIFICATION

] FACTORY SEVICE

] DATA

GE Power Management

Page 37

4 SETPOINTS 4.2 S1 CONFIGURATION

4.2 S1 CONFIGURATION 4.2.1 DESCRIPTION

This page is used to enter all information about the configuration of the MM2 and the motor being

protected by the MM2. Setpoints Page 1 is divided into eight sections, COMMUNICATIONS,

MOTOR IDENTIFICATION, STARTER, CT / VT INPUTS, THERMISTOR, FAULT MODE, STATISTICS, PROGRAMMABLE MESSAGE and PREFERENCES.

4.2.2 COMMUNICATIONS

P ATH: SETPOINTS t S1: CONFIGURATION t COMMUNICATIONS

COMMUNICATIONS

ADDRESS: OFF

BAUD RATE: 9600

PARITY: NONE

P ATH: SETPOINTS t S1 CONFIGURATION tt MOTOR IDENTIFICATION

MOTOR NAME:

MOTOR

MOTOR RATING

OFF kW

HIGH SPEED MOTOR

RATING: OFF kW

SYSTEM SUPPLY:

480 V

Range: 1 to 255 or OFF, Step: 1

Each MM2 on the same serial communication network must have a

unique address in the range of 1 to 255. Computer software driving the

serial network must be configured to recognize each separate address.

Range: 1200, 2400, 4800, 9600, 19200

Selects the data transfer rate for Modbus serial communications.

Range: NONE, ODD, EVEN

This setpoint determines what type of parity checking is used when communicating to the MM2.

Range: 20 ASCII characters

Enter a motor name that will appear in the actual values message

A1: DATA \ MOTOR DATA \ MOTOR STATUS.

Range: 0.3 kW to 1100 kW or OFF; Step: 0.1 kW

Enter the motor rating (or low speed motor rating for two speed starters)

in kWs on this line. This message is for reference only and does not

affect operation of the MM2.

Range: 0.3 kW to1100 kW or OFF, Step: 0.1 kW

Enter the high speed motor rating (applicable for Two Speed starters

only) in kWs on this line. This message is for reference only and does

not affect operation of the MM2.

Range: 110 V to 600 V; Step: 1 V

Enter system supply voltage on this line. This message is for reference

only and does not affect operation of the MM2.

4

4.2.3 MOTOR IDENTIFICATION

GE Power Management

MM2 Motor Manager 2 4-3

Page 38

4.2 S1 CONFIGURATION 4 SETPOINTS

4.2.4 STARTER

PATH: SETPOINTS t S1: CONFIGURATION

STARTER TYPE:

OFF

CHANGE OVER CURRENT

1.5 xFLC

4

CHANGE OVER TIME:

30 s

TRANSFER TIME:

10 s

HIGH SPEED START

BLOCK: DISABLE

RAMP UP TIME:

5 s

RAMP DOWN TIME:

5 s

STAGE ONE SHORTING

TIME: 5 s

STARTER

ttt

Range: OFF, FV NON-REVERSING, FV REVERSING, WYE DELTA

OPN TRANS, TWO SPEED, INVERTER, SLIP RING,

AUTOTRANS OPN TRANS, PART WINDING, WYE DELTA

CLS TRANS, AUTOTRANS CLS TRANS, DUTY/STANDBY,

SOFT STARTER, WYE DELTA OPN TRANS

Select a type according to the configuration that the MM2 is controlling.

This will determine the control logic used for Contactor A and Contactor

B start and stop sequences. See Chapter 9: STARTER TYPES for a

detailed description of each starter type.

Range: 1.0 to 5.0 x FLC or OFF; Step: 0.1 x FLC

Appears only when STARTER TYPE is WYE DELTA OPN TRNS or WYE DELTA

CLS TRANS. Before CHANGE OVER CURRENT comes into effect on a wye

delta start, a minimum of 25% of the CHANGE OVER TIME must have

expired. After 25% of the time has expired and the average of the three

phase currents has dropped below the CHANGE OVER CURRENT value, the

transition from wye (Contactor A) to delta (Contactor B) will occur. If this

setpoint is OFF, 100% of the CHANGE OVER TIME must expire for the wye to

delta transition to occur.

RANGE: 1 to 100 seconds; Step: 1 second

Appears only if STARTER TYPE is set a s WYE DELTA OPN TRNS or WYE DELTA

CLS TRANS. See CHANGE OVER CURRENT setpoint above for operation.

Range: 1 to 125 seconds; Step: 1 second

Appears only if STARTER TYPE is set as FV REVERSING or TWO SPEED. With

two-speed starters, this delay is required when the motor is switched

from high speed (Contactor B) to low speed (Contactor A). The delay

starts when Contactor B drops out. With a reversing starter, this delay

occurs when switching from forward (Contactor A) to reverse (Contactor

B) and from reverse to forward.

Range: ENABLE, DISABLE

Appears only if STARTER TYPE is TWO SPEED. When disabled, the MM2

allows the motor to be started directly to high speed. When enabled, the

motor must be started in low speed before switching to high speed.

Range: 1 to 125 seconds; Step: 1 second

Appears only if STARTER TYPE is selected as INVERTER. See the descrip-

tion of the Inverter starter type for details on functionality.

Range: 1 to 125 seconds; Step: 1 second

Appears only if STARTER TYPE is selected as INVERTER. See the descrip-

tion of the Inverter starter type for details on functionality.

Range: 1 to 125 seconds; Step: 1 second

Appears only if STARTER TYPE is SLIP RING or PART WINDING. This is the

time delay from the closure of Contac tor A to the closure of Contactor B.

4-4 MM2 Motor Manager 2

GE Power Management

Page 39

4 SETPOINTS 4.2 S1 CONFIGURATION

CONTACTOR SEQUENCE:

1S-2S

CHANGE OVER TIME:

5 s

STARTS PER HOUR:

5

P ATH: SETPOINTS t S1: CONFIGURATION

PHASE CT PRIMARY

AMPS: 100

HIGH SPEED PHASE CT

PRIMARY AMPS: 100

GROUND FAULT CT

INPUT:50:0.025 CBCT

GROUND CT PRIMARY

AMPS: 100

50:0.025 HI-RES

DISPLAY: DISABLE

VT PRIMARY VOLTAGE:

OFF V

Range: 1S-2S, 2S-1S

Appears only if STARTER TYPE is AUTOTRANS OPN TRANS. The 1S-2S value

closes the 1S contactor ahead of the 2S contactor as per some manufacturer wiring practices. The 2S-1S value means that the 2S contactor

will close ahead of the 1S contactor, another common wiring practice.

Range: 1 to 125 seconds; Step: 1 second

Appears only if STARTER TYPE is AUTOTRANS OPN TRANS or AUTOTRANS CLS

TRANS. This is the time delay from the closure of Contactor A until the

opening of Contactor A.

Range: 1 to 40 starts/hour or OFF; Step: 1

Limits the number of starts per hour to prevent over heating of windings.

Range: 5 to 1000 A; Step: 5 A

Enter the phase CT rated primary amps; e.g. if the phase CTs are rated

500:5, enter 500. The CT secondary must be connected to the correct

input, i.e. 1 A or 5 A.

Range: 5 to 1000 A; Step: 5 A

Appears only if STARTER TYPE is TWO SPEED. Enter the high speed CT

rated primary amps. In effect only when Contactor B is energized.

Range: 50:0.025 CBCT, 5 A SEC CBCT, 5 A RESIDUAL

Enter the ground sensing used, either sensitive 50:0.025 core balanced

ground fault CT, 5 A sec. core balanced CT, or 5 A Residual for residual

ground fault current sensing from the 5 A phase CT secondaries.

Range: 5 to 1000 A; Step: 5 A

Appears only if 5A SEC CBCT is selected for the GROUND FAULT CT INPUT.

Enter the GFCT rated primary amps.

Range: Enable, Disable

Increases the displayed resolution to 2 decimal points for the 50:0.025

ground input.

Range: 110 to 600 V or OFF; Step: 1 V

Enables/disables the voltage/power feat ures and sets VT primary volts.

tttt

4.2.5 CT / VT INPUTS

CT/VT INPUTS

4

VT CONNECTION TYPE:

PHASE (A-N)

VT SECONDARY

VOLTAGE: 120V

NOMINAL FREQUENCY:

60 Hz

GE Power Management

Range: PHASE (A-N), LINE (A-B)

Appears only if the VT PRIMARY VOLTAGE setpoint is not set to OFF. Enter

the type of VT connection: PHASE A-N (V

) or LINE A-B (Vab).

an

Range: 110 V, 120 V

Appears only if the VT PRIMARY VOLTAGE setpoint is not set to OFF.

Range: 50 Hz, 60 Hz

MM2 Motor Manager 2 4-5

Page 40

4.2 S1 CONFIGURATION 4 SETPOINTS

4.2.6 THERMISTOR

PATH: SETPOINTS t S1: CONFIGURATION

COLD RESISTANCE:

0.1 kOHMS

HOT RESISTANCE

5.0 kOHMS

THERMISTOR TRIP:

DISABLE

4

THERMISTOR ALARM:

DISABLE

ttttt

THERMISTOR

Range: 0.1 to 30.0 kOHMS; Step: 0.1

For a PTC thermistor, enter the resistance that the thermistor must drop

below before a Thermistor T r ip or Alar m can be cl eared. For a NTC ther mistor, enter the resistance that the thermistor must rise above before a

Thermistor Tri p or Alarm can be cleared.

Range: 0.1 to 30.0 kOhms, STEP: 0.1

For a PTC thermistor, enter the resistance that the thermistor must rise

above before a Thermistor Trip or Alarm will occur. For a NTC thermistor, enter the resistance that the thermistor must drop below before a

Thermistor Tri p or Alarm will occur.

Range: ENABLE, DISABLE

When a thermistor is used, it can be selected for an Alarm or Trip or

both. Choose ENABLE to allow Thermistor Trips to occur .

Range: ENABLE, DISABLE

When a thermistor is used, it can be selected for an Alarm or Trip or

both. Choose ENABLE to allow Thermistor Alarms to occur.

4.2.7 FAULT MODE

PATH: SETPOINTS t S1: CONFIGURATION

INTERNAL FAULT TRIP

ENABLE

Range: ENABLE, DISABLE

An internal fault during self-checking will cause an alarm. Since operation may be erratic depending on the fault condition, it may be desirable

to trip the motor by set ting t his setpoi nt t o ENABLE. The MM2 continues to

run the motor with an internal fault present if set to DISABLE.

SERIAL COMM FAILURE

TRIP: OFF s

Range: 5 to 25 seconds or OFF; Step: 5 seconds

If using serial communications to control a process with several motors

working together, it may be desirable to shut down the motor if communication control is lost. When no activity occurs on the communications

port for 5 to 25 seconds, it will trip if this feature is enabled.

SERIAL COMM FAILURE

ALARM: OFF

CHANGE COMMAND MODE

ON ALARM: DISABLE

Range: 5 to 25 seconds or OFF; Step: 5 seconds

Sets an alarm when the serial communication link is interrupted.

Range: ENABLE, DISABLE

Allows the command mode to automatically switch from AUTO to MANUAL when the SERIAL COMMS FAILURE ALARM is active. If th e motor was

running when the alarm occurred it will be st opped and wil l resta rt b ased

on manual start inputs only. When serial communication is restored the

MM2 will remain in MANUAL command mode.

tttttt

FAULT MODE

4-6 MM2 Motor Manager 2

GE Power Management

Page 41

4 SETPOINTS 4.2 S1 CONFIGURATION

4.2.8 STATISTICS

P ATH: SETPOINTS t S1: CONFIGURATION

CLEAR TIMERS:

DISABLE

Range: ENABLE, DISABLE

Select ENABLE and press STORE to clear the timers on page

A4: STATISTICS \ TIMERS.

CLEAR START/TRIP

COUNTERS: DISABLE

Range: ENABLE, DISABLE

Select ENABLE and press STORE to clear the start and trip counters on

page A4: STATISTICS \ COUNTERS.

CLEAR INTERLOCK

COUNTER: DISABLE

Range: ENABLE, DISABLE

Select ENABLE and press STORE to clear the interlock counter on page

A4: STATISTICS \ COUNTERS.

CLEAR ENERGY USED:

DISABLE

Range: ENABLE, DISABLE

Select ENABLE and press STORE to clear the energy used (kWhrs) on

page A1: DATA \ MOTOR DATA.

P ATH: SETPOINTS t S1: CONFIGURATION

PROGRAMMABLE MESSAGE

SAMPLE TEXT

Range: 40 ASCII characters

Enter a 40 character message using the VALUE UP/DOWN and