Page 1

g

GE Power Management

469

MOTOR MANAGEMENT RELAY

Instruction Manual

469 Firmwar e Revision: 30E281.000

469PC Software Revision: 2.8x

Manual P/N: 1601-0057-D9 (GEK-106289A)

Copyright © 2001 GE Power Management

SR469 STATUS MOTOR STATUS OUTPUT RELAYS

SR469 IN SERVICE STOPPED R1 TRIP

SETPOINT ACCESS

COMPUTER RS232

COMPUTER RS485

AUXILIARY RS485

LOCKOUT

RESET

RESET

POSSIBLE

MESSAGE

NEXT

STARTING R2 AUXILIARY

RUNNING R3 AUXILIARY

OVERLOAD PICKUP

UNBALANCE PICKUP

GROUND PICKUP

HOT RTD

LOSS OF LOAD

R4 ALARM

R5 BLOCK START

R6 SERVICE

®

PROGRAM PORT

GE Power Management

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 294-8512

Internet: http://www.GEindustrial.com/pm

SETPOINT

MESSAGE

ACTUAL

ESCAPE

VALUE

ENTER

469 Motor Management Relay®

7 89

5

4

12 3

.

0

6

HELP

806766A5.CDR

R

E

D

G

E

R

I

E

S

T

Manufactured under an

ISO9001 Registered system.

Page 2

Page 3

g

g

g

WARNING

These instructions do not purport to cover all details or variations in equipment nor

provide for every possible contin

ency to be met in connection with installation,

operation, or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchaser’s purpose, the

matter should be referred to the General Electric Company.

To the extent required the products described herein meet applicable ANSI, IEEE,

and NEMA standards; but no such assurance is

ordinances because they vary

reatly.

iven with respect to local codes and

Page 4

Page 5

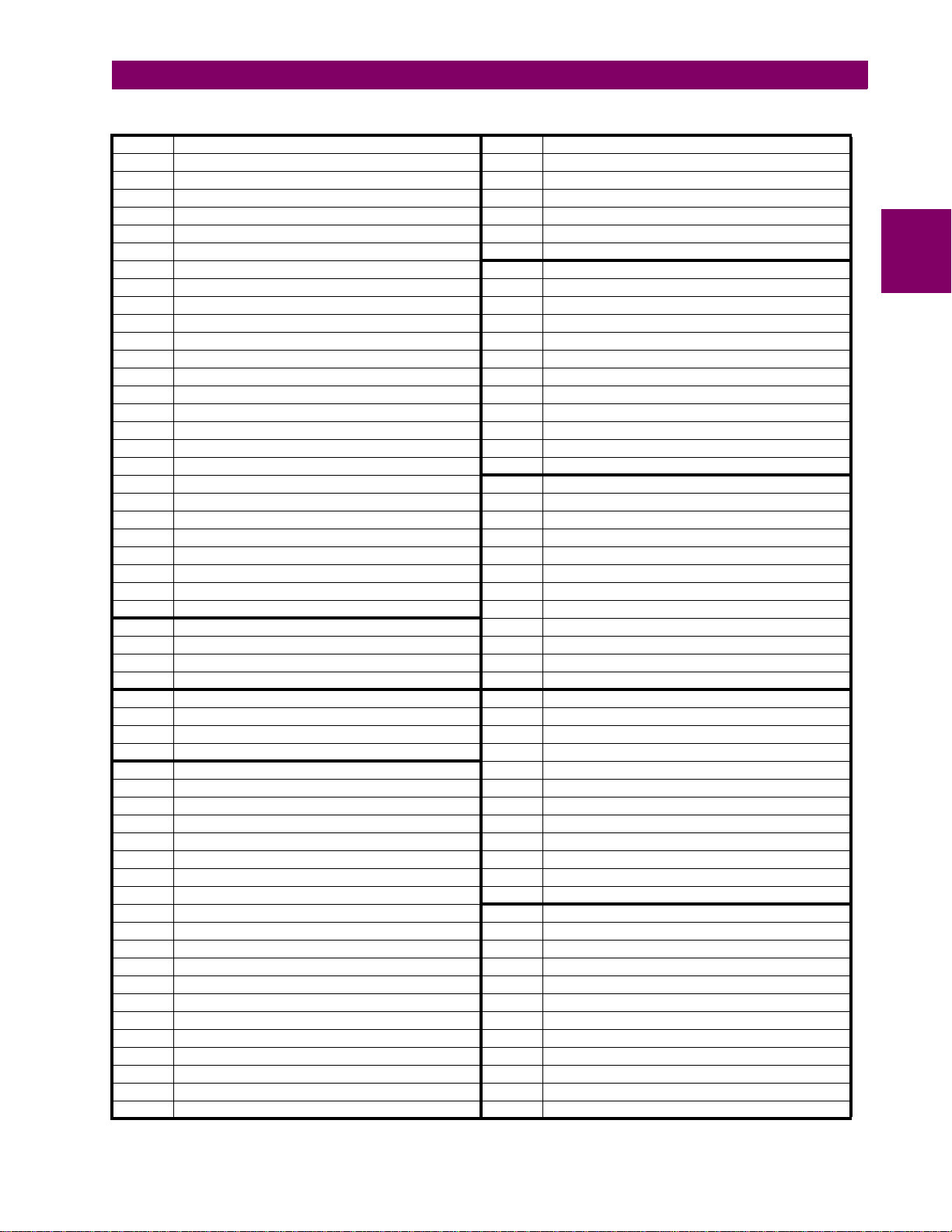

TABLE OF CONTENTS

1. INTRODUCTION

2. INSTALLATION

1.1 OVERVIEW

1.1.1 DESCRIPTION..........................................................................................1-1

1.1.2 ORDER INFORMATION............................................................................1-4

1.1.3 OTHER ACCESSORIES...........................................................................1-4

1.2 SPECIFICATIONS

1.2.1 469 SPECIFICATIONS..............................................................................1-5

2.1 MECHANICAL

2.1.1 DESCRIPTION..........................................................................................2-1

2.1.2 PRODUCT IDENTIFICATION.................................................................... 2-2

2.1.3 INSTALLATION.........................................................................................2-3

2.1.4 UNIT WITHDRAWAL AND INSERTION.................................................... 2-4

2.1.5 TERMINAL LOCATIONS...................... ............... ............................. .........2-6

2.2 ELECTRICAL

2.2.1 TYPICAL WIRING DIAGRAM....................................................................2-8

2.2.2 TYPICAL WIRING...................................................................................... 2-9

2.2.3 CONTROL POWER............................................. ............... .............. .........2-9

2.2.4 PHASE CURRENT INPUTS......... .............................................. .............2-10

2.2.5 GROUND CURRENT INPUT.................................................. .................2-10

2.2.6 DIFFERENTIAL CURRENT INPUTS....................................................... 2-12

2.2.7 VOLTAGE INPUTS............................. ............................. ............... .........2-13

2.2.8 D IG ITAL INPUTS...................................................... .. ............................. 2-13

2.2.9 ANALOG INPUTS................ .............................. ............................. .........2-14

2.2.10 ANALOG OUTPUTS................................................................................2-14

2.2.11 RTD SENSOR CONNECTIONS..............................................................2-15

a DESCRIPTION........................................................................................2-15

b REDUCED RTD LEAD NUMBER APPLICATION...................................2-16

c TWO WIRE RTD LEAD COMPENSATION............................................. 2-17

d GROUNDING OF RTDs.......................................................................... 2-17

2.2.12 OUTPUT RELAYS................................ .............................. .............. ....... 2-18

2.2.13 DRAWOUT INDICATOR.......................................................................... 2-19

2.2.14 RS485 COMMUNICATIONS PORTS...................................................... 2-20

2.2.15 TYPICAL 2 SPEED MOTOR WIRING.....................................................2-21

2.2.16 DIELECTRIC STRENGTH TESTING...................................................... 2-22

3. OPERATION

3.1 OVERVIEW

3.1.1 469 FACEPLATE....................................................................................... 3-1

3.1.2 DISPLAY....................................................................................................3-2

3.1.3 LED INDICATORS.....................................................................................3-2

a 469 STATUS LED INDICATORS............................................................... 3-2

b MOTOR STATUS LED INDICATORS....................................................... 3-3

c OUTPUT RELAY LED INDICATORS.................... .................................... 3-3

3.1.4 RS232 PROGRAM PORT.........................................................................3-3

3.1.5 KEYPAD....................................................................................................3-4

3.1.6 ENTERING ALPHANUMERIC TEXT.........................................................3-4

3.1.7 ENTERING +/– SIGNS..............................................................................3-4

3.2 SETPOINT ENTRY

3.2.1 PROCEDURE............................................................................................ 3-5

GE Power Management 469 Motor Management Relay

i

Page 6

TABLE OF CONTENTS

4. SETPOINT

PROGRAMMING

4.1 OVERVIEW

4.1.1 TRIPS/ALARMS/BLOCKS DEFINED........................................................4-1

a TRIPS ........................................................................................................4-1

b ALARMS....................................................................................................4-1

c BLOCK START........................................... ............... .............. .................. 4-1

4.1.2 REL AY ASSIGNMENT PRACT IC ES... ..................... .. .. .............................4-2

4.1.3 SETPOINT MESSAGE MAP .....................................................................4-3

4.2 S1 469 SETUP

4.2.1 PASSCODE............................................................................................... 4-4

a FUNCTION ................................................................................................4-4

b ENABLING PASSCODE PROTECTION...................................... .............4-4

4.2.2 PREFERENCES.................................................... ....................................4-5

4.2.3 SERIAL PORTS.........................................................................................4-6

4.2.4 REAL TIME CLOCK.......................................................................... .........4-6

4.2.5 DEFAULT MESSAGES............................................................................. 4-7

a ADDING DEFAULT MESSAGES..............................................................4-7

b REMOVING DEFAULT MESSAGES............................. ............................4-7

4.2.6 MESSAGE SCRATCHPAD.......................................................................4-8

4.2.7 CLEAR DATA ............................................................................................4-9

4.2.8 INSTALLATION.......................................................................................4-10

4.3 S2 SYSTEM SETUP

4.3.1 CURRENT SENSING ........................................................ ......................4-11

a FUNCTION ..............................................................................................4-11

b EXAMPLES.......................... ......................................................... ...........4-12

4.3.2 VOLTAGE SENSING............................................... .............. ............... ...4-12

4.3.3 POWER SYSTEM....................................... ............................. ............... .4-13

4.3.4 SERIAL COMMUNICATION CONTROL .................................................4-13

4.3.5 REDUCED VOLTAGE............................................................................. 4-14

4.4 S3 DIGITAL INPUTS

4.4.1 DESCRIPTION ........................................................................................4-16

4.4.2 ACCESS SWITCH........... .............. ............................................. .............4-16

4.4.3 TEST SWITCH.........................................................................................4-16

4.4.4 EMERGENCY RESTAR T ......... .. .............................................................4-16

4.4.5 REMOTE RESET........................................ ............... .............. ................4-16

4.4.6 STARTER STATUS.................................... ............... .............. ................4-17

4.4.7 ASSIGNABLE DIGITAL INPUTS.............................................................4-17

4.4.8 DIGITAL INPUT FUNCTION: REMOTE ALARM.....................................4-18

4.4.9 DIGITAL INPUT FUNCTION: REMOTE TRIP.........................................4-18

4.4.10 DIGITAL INPUT FUNCTION: SPEED SWITCH TRIP .............................4-19

4.4.11 DIGITAL INPUT FUNCTION: LOAD SHED TRIP....................................4-19

4.4.12 DIGITAL INPUT FUNCTION: PRESSURE SWITCH ALARM................. 4-19

4.4.13 DIGITAL INPUT FUNCTION: PRESSURE SWITCH TRIP.....................4-20

4.4.14 DIGITAL INPUT FUNCTION: VIBRATION SWITCH ALARM..................4-20

4.4.15 DIGITAL INPUT FUNCTION: VIBRATION SWITCH TRIP...................... 4-20

4.4.16 DIGITAL INPUT FUNCTION: DIGITAL COUNTER.................................4-21

a FUNCTION ..............................................................................................4-21

b EXAMPLE................................................................................................4-21

4.4.17 DIGITAL INPUT FUNCTION: TACHOMETER........................................4-22

a FUNCTION ..............................................................................................4-22

b EXAMPLE................................................................................................4-22

4.4.18 DIGITAL INPUT FUNCTION: GENERAL SWITCH A-D.......................... 4-23

4.4.19 DIGITAL INPUT FUNCTION: CAPTURE TRACE...................................4-23

4.4.20 DIGITAL INPUT FUNCTION: SIMULATE PRE-FAULT ..........................4-23

4.4.21 DIGITAL INPUT FUNCTION: SIMULATE FAULT ..................................4-23

4.4.22 DIGITAL INPUT FUNCTION: SIMULATE PRE-FAULT…FAULT ...........4-23

4.5 S4 OUTPUT RELAYS

4.5.1 DESCRIPTION ........................................................................................4-24

ii

469 Motor Management Relay

GE Power Management

Page 7

TABLE OF CONTENTS

4.5.2 RELAY RESET MODE ........................................................................... 4-24

a RESETTING THE 469.............................................................................4-24

b EXAMPLE................................................................................................4-24

4.5.3 FORCE OUTPUT RELAY ....................................................................... 4-25

4.6 S5 THERMAL MODEL

4.6.1 MOTOR THERMAL LIMITS................ ............... ............................. .........4-26

4.6.2 469 THERMAL MODEL ..........................................................................4-28

4.6.3 OVERLOAD CURVE SETUP .................................................................4-29

a FUNCTION ..............................................................................................4-31

b CUSTOM OVERLOAD CURVE........................... ....................................4-31

c VOLTAGE DEPENDENT OVERLOAD CURVE...................................... 4-35

4.6.4 UNBALANCE BIAS..................................................................................4-42

4.6.5 MOTOR COOLING..................... ............................................ .................4-43

4.6.6 HOT/COLD CURVE RATIO..................................................................... 4-44

4.6.7 RTD BIAS............................................... ............... ............... .............. ..... 4-44

4.7 S6 CURRENT ELEMENTS

4.7.1 SH ORT CIRCUIT................................. .. ................... .. ................... .. ........ 4-46

4.7.2 O VERLOAD ALARM... .. ........................................ ..................... .............. 4-47

4.7.3 MECHANICAL JAM.......................... ............... ............................. ...........4-47

4.7.4 UNDERCURRENT.................... ............................... ................................4-48

a FUNCTION ...................................................... ........................................4-48

b EXAMPLE.................. ............... .............. ............... ............... .............. ..... 4-48

4.7.5 CURRENT UNBALANCE .............................................. ..........................4-49

a FUNCTION .................................................................... ..........................4-49

b EXAMPLE.................. ............... .............. ................................................. 4-49

4.7.6 GROUND FAULT............................................... ............................... ....... 4-50

4.7.7 PHASE DIFFERENTIAL........ .............................. ............................. ....... 4-52

4.8 S7 MOTOR STARTING

4.8.1 ACCELERATION TIMER.........................................................................4-53

4.8.2 START INHIBIT.......................................................................................4-54

a FUNCTION ..............................................................................................4-54

b EXAMPLE................................................................................................4-54

4.8.3 JOGGING BLOCK...................................................................................4-55

a FUNCTION ..............................................................................................4-55

b STARTS / HOUR..................................................................................... 4-55

c TIME BETWEEN STARTS ......................................................................4-55

4.8.4 RESTART BLOCK................................ .............................. .............. ....... 4-56

4.9 S8 RTD TEMPERATURE

4.9.1 RTD TYPES................................ .............. ............... ............... .............. ...4-57

4.9.2 RTDS 1 TO 6...........................................................................................4-58

4.9.3 RTDS 7 TO 10.........................................................................................4-59

4.9.4 RTD 11..................................................................... ............... .................4-60

4.9.5 RTD 12..................................................................... ............... .................4-61

4.9.6 OPEN RTD SENSOR.............................................................................. 4-62

4.9.7 RTD SHORT/LOW TEMP........................................................... .............4-62

4.10 S9 VOLTAGE ELEMENTS

4.10.1 UNDERVOLTAGE................................................................................... 4-63

4.10.2 OVERVOLTAGE......................................................................................4-64

4.10.3 PHASE REVERSAL...... .............. .............. ............... ........................... ..... 4-64

4.10.4 FREQUENCY ...................... ....................................................................4-65

4.11 S10 POWER ELEMENTS

4.11.1 POWER MEASUREMENT CONVENTIONS...........................................4-66

4.11.2 POWER FACTOR.................................................................................... 4-67

4.11.3 REACTIVE PO WER... .. ......................................................... .. ................ 4-6 8

4.11.4 UNDERPOWER.......................................................................................4-69

a FUNCTION ..............................................................................................4-69

b EXAMPLE ................................................................................................ 4-69

GE Power Management 469 Motor Management Relay

iii

Page 8

TABLE OF CONTENTS

4.11.5 REVERSE POWER.................................................................................4-70

4.11.6 TORQUE SETUP......................... ............... ............... .............. ............... .4-71

4.11.7 OVERTORQUE SETUP ............ ............... ............................. .................. 4-71

4.12 S11 MONITORING

4.12.1 TRIP COUNTER...................................................................................... 4-72

4.12.2 STARTER FAILURE........ .............. .............................. ............................4-72

4.12.3 CURRENT, KW, KVAR, KVA DEMAND..................................................4-74

4.12.4 PULSE OUTPUT .....................................................................................4-76

4.13 S12 ANALOG I/O

4.13.1 ANALOG OUTPUTS 1 TO 4....................................................................4-77

c ANALOG OUTPUT TABLE ......................................................................4-78

4.13.2 ANALOG INPUTS 1-4..............................................................................4-79

a FUNCTION ..............................................................................................4-80

b EXAMPLE 1........ ............... ............... .............. ............... ............... ...........4-80

c EXAMPLE 2............................................ ............... .............. ............... .....4-80

4.13.3 ANALOG IN DIFF 1-2..............................................................................4-81

4.13.4 ANALOG IN DIFF 3-4..............................................................................4-82

4.14 S13 469 TESTING

4.14.1 SIMULATION MODE...............................................................................4-83

4.14.2 PRE-FAULT SETUP................................................................................4-84

4.14.3 FAULT SETUP............. .............. ............... ............... .............. .................. 4-85

4.14.4 TEST OUTPUT RELAYS......................................................................... 4-86

4.14.5 TEST ANALOG OUTPUT ........................................................................4-86

4.14.6 COMM PORT MONITOR.........................................................................4-87

4.14.7 MULTILIN USE ONLY ............................................................................. 4-87

4.15 S14 TWO-SPEED MOTOR

4.15.1 DESCRIPTION ........................................................................................4-88

4.15.2 SPEED2 O/L SETUP..................... ............... ............... ............... .............4-88

4.15.3 SPEED2 UNDERCURRENT ...................................................................4-90

4.15.4 SPEED2 ACCELERATION......................................................................4-91

5. ACTUAL VALUES

5.1 OVERVIEW

5.1.1 ACTUAL VALUES MESSAGES ................................................................5-1

5.2 A1 STATUS

5.2.1 MOTOR STATUS ........................................................ ............... ...............5-2

5.2.2 LAST TRIP DATA...................................................................................... 5-3

5.2.3 ALARM STATUS .......................................................................................5-5

5.2.4 START BLOCKS................... .. ......................................................... .. ........5-7

5.2.5 DIGITAL INPUTS.......................................................................................5-8

5.2.6 REAL TIME CLOCK.......................................................................... .........5-8

5.3 A2 METERING DATA

5.3.1 CURRENT METERING .................... ............................... ..........................5-9

5.3.2 TEMPERATURE...................................................................................... 5-10

5.3.3 VOLTAGE METERING.................................................. ..........................5-11

5.3.4 SPEED........................................................................... ..........................5-11

5.3.5 POWER METERING ............... ............................................ ....................5-12

5.3.6 TORQUE ALARM MESSAGE.................. .......................................... .....5-12

5.3.7 DEMAND METERING .............................................................................5-13

5.3.8 ANALOG INPUTS.................... .............................. ............................. .....5-14

5.3.9 PHASORS .......................................... ............................. ........................5-15

5.4 A3 LEARNED DATA

5.4.1 MOTOR STARTING ............ ............... ............................. ........................5-17

5.4.2 AVERAGE MOTOR LOAD .................................... .............. ............... .....5-17

iv

469 Motor Management Relay

GE Power Management

Page 9

TABLE OF CONTENTS

5.4.3 RTD MAXIMUMS..................................................................................... 5-18

5.4.4 ANALOG IN MIN/MAX................................ .............................. ...............5-19

5.5 A4 MAINTENANCE

5.5.1 TRIP COUNTERS.................................................................................... 5-20

5.5.2 GENERAL COUNTERS...........................................................................5-22

5.5.3 TIMERS...................................................................................................5-22

5.6 A5 EVENT RECORDER

5.6.1 EVENT01 TO EVENT40..........................................................................5-23

5.7 A6 PRODUCT INFO

5.7.1 469 MODEL INFO.................................................................................... 5-26

5.7.2 C ALIBRATION INFO .. ............................................................................. 5-26

5.8 DIAGNOSTICS

5.8.1 DIAGNOSTIC MESSAGES FOR OPERATORS..................................... 5-27

a EXAMPLE................................................................................................5-27

5.8.2 FLASH MESSAGES....................... ............... .............. ............... .............5-28

6. COMMUNICATIONS

6.1 MODBUS COMMUNICATIONS

6.1.1 ELECTRICAL INTERFACE................................. ......................................6-1

6.1.2 MODBUS RTU PROTOCOL......................................................................6-1

6.1.3 DATA FRAME FORMAT AND DATA RATE..............................................6-1

6.1.4 DATA PACKET FORMAT.......................................... ............... ............... ..6-2

6.1.5 CRC-16 ALGORITHM................................................................................ 6-3

6.1.6 TIMING ......................................................................................................6-3

6.2 SUPPORTED MODBUS FUNCTIONS

6.2.1 OVERVIEW................................................................................................6-4

6.2.2 FUNCTION CODES 01/02: READ RELAY COIL / DIGITAL INPUT STATUS

6-4

a FUNCTION 01 ...........................................................................................6-4

b FUNCTION 02 ...........................................................................................6-4

c MESSAGE FORMAT AND EXAMPLE, FUNCTION 01.............................6-5

d MESSAGE FORMAT AND EXAMPLE, FUNCTION 02.............................6-6

6.2.3 FUNCTION CODES 03/04: READ SETPOINTS/ACTUAL VALUES.........6-8

6.2.4 FUNCTION CODE 05: EXECUTE OPERATION....................................... 6-9

6.2.5 FUNCTION CODE 06: STORE SINGLE SETPOINT.............................. 6-10

6.2.6 FUNCTION CODE 07: READ DEVICE STATUS.................................... 6-11

6.2.7 FUNCTION CODE 08: LOOPBACK TEST ..............................................6-12

6.2.8 FUNCTION CODE 16: STORE MULTIPLE SETPOINTS........................6-13

6.2.9 FUNCTION CODE 16: PERFORMING COMMANDS.............................6-14

6.3 ERROR RESPONSES

6.3.1 DESCRIPTION........................................................................................6-15

6.4 MEMORY MAP

6.4.1 MEMORY MAP INFORMATION............................ ............... .............. ..... 6-16

6.4.2 USER DEFINABLE MEMORY MAP AREA.............................................6-16

6.4.3 EVENT RECORDER ................................... . .................... . .................... . . 6-17

6.4.4 WAVEFORM CAPTURE..........................................................................6-17

6.4.5 469 MEMORY MAP................................................................................. 6-18

6.4.6 469 MEMORY MAP FORMAT CO DES ................................................... 6-61

7. TESTING

7.1 OVERVIEW

7.1.1 TEST SETUP............................................................................................. 7-1

GE Power Management 469 Motor Management Relay

v

Page 10

TABLE OF CONTENTS

7.2 HARDWARE FUNCTIONAL TESTING

7.2.1 PHASE CURRENT ACCURACY TEST......................... ............................7-2

7.2.2 VOLTAGE INPUT ACCURACY TEST................................... ....................7-2

7.2.3 GROUND (1A/5A) AND DIFFERENTIAL ACCURACY TEST ................... 7-3

a 5 A INPUT...................... .............. .............................. .............. ............... ... 7-3

b 1 A INPUT...................... .............. .............................. .............. ............... ... 7-3

7.2.4 GE POWER MANAGEMENT 50:0.025 GROUND ACCURACY TEST..... 7-4

7.2.5 RTD ACCURACY TEST ....................... .............................................. .......7-4

7.2.6 DIGITAL INPUTS AND TRIP COIL SUPERVISION ..................................7-6

7.2.7 ANALOG INPUTS AND OUTPUTS...........................................................7-6

a 4-20 mA .....................................................................................................7-6

b 0-1 mA .......................................................................................................7-7

7.2.8 OUTPUT RELAYS....................... ............... ............... .............. ..................7-8

7.3 ADDITIONAL FUNCTIONAL TESTING

7.3.1 OVERLOAD CURVE TEST.......................................................................7-9

7.3.2 POWER MEASUREMENT TEST............................................................7-10

7.3.3 UNBALANCE TEST.................................................................................7-11

7.3.4 VOLTAGE PHASE REVERSAL TEST ....................................................7-12

7.3.5 SHORT CIRCUIT TEST...........................................................................7-13

8. 469 PC SOFTWARE

A. APPENDIX A

8.1 INSTALLATION/UPGRADE

8.1.1 DESCRIPTION ..........................................................................................8-1

8.1.2 HARDWARE & SOFTWARE REQUIREMENTS.......................................8-1

8.1.3 CHECKING IF INSTALLATION/UPGRADE IS REQUIRED......................8-2

8.1.4 INSTALLING/UPGRADING 469PC ...........................................................8-3

8.2 CONFIGURATION

8.2.1 STARTUP & COMMUNICATIONS CONFIGURATION............................. 8-4

8.3 USING 469PC

8.3.1 SAVING SETPOINTS TO A FILE..... .............. ............................ .............. .8-5

8.3.2 469 FIRMWARE UPGRADES ................................................................... 8-6

8.3.3 LOADING SETPOINTS FROM A FILE.................. .............. ......................8-7

8.3.4 ENTERING SETPOINTS...........................................................................8-8

8.3.5 UPGRADING SETPOINT FILES TO NEW REVISION..............................8-9

8.3.6 PRINTING SETPOINTS & ACTUAL VALUES.........................................8-10

a SETPOINTS.............................................................................................8-10

b ACTUAL VALUES....................................... ............... .............. ............... .8-10

8.3.7 TRENDING.................... .............. ........................................................... .8-11

8.3.8 WAVEFORM CAPTURE..........................................................................8-13

8.3.9 PHASORS ...............................................................................................8-15

8.3.10 EVENT RECORDING..............................................................................8-16

8.3.11 TROUBLESHOOTING.............................................................................8-17

A.1 COMMISSIONING

A.1.1 COMMISSIONING SUMMARY..................................................................A-1

B. APPENDIX B

vi

B.1 TWO-PHASE CT CONFIGURATION

B.1.1 DESCRIPTION ..........................................................................................B-1

469 Motor Management Relay

GE Power Management

Page 11

TABLE OF CONTENTS

C. APPENDIX C

D. APPENDIX D

E. APPENDIX E

F. APPENDIX F

G. WARRANTY

C.1 SELECTION OF COOL TIME CONSTANTS

C.1.1 DESCRIPTION ..........................................................................................C-1

C.1.2 EXAMPLE..................................................................................................C-1

D.1 CURRENT TRANSFORMERS

D.1.1 GROUND FAULT CTS FOR 50:0.025 A ............... ................. ................. ..D-1

D.1.2 GROUND FAULT CTS FOR 5 A SECONDARY CT...... ................. ...........D-2

D.1.3 PHASE CTS.... ............... ............................................ .............................. ..D-3

E.1 FIGURES AND TABLES

E.1.1 LIST OF FIGURES................... .............. .............................. .............. .......E-1

E.1.2 LIST OF TABLES.......................................................................................E-3

F.1 EU DECLARATION OF CONFORMITY

G.1 WARRANTY INFORMATION

G.1.1 WARRANTY ..............................................................................................G-1

GE Power Management 469 Motor Management Relay

vii

Page 12

Page 13

1 INTRODUCTION 1.1 OVERVIEW

1 INTRODUCTION 1.1 OVERVIEW 1.1.1 DESCRIPTION

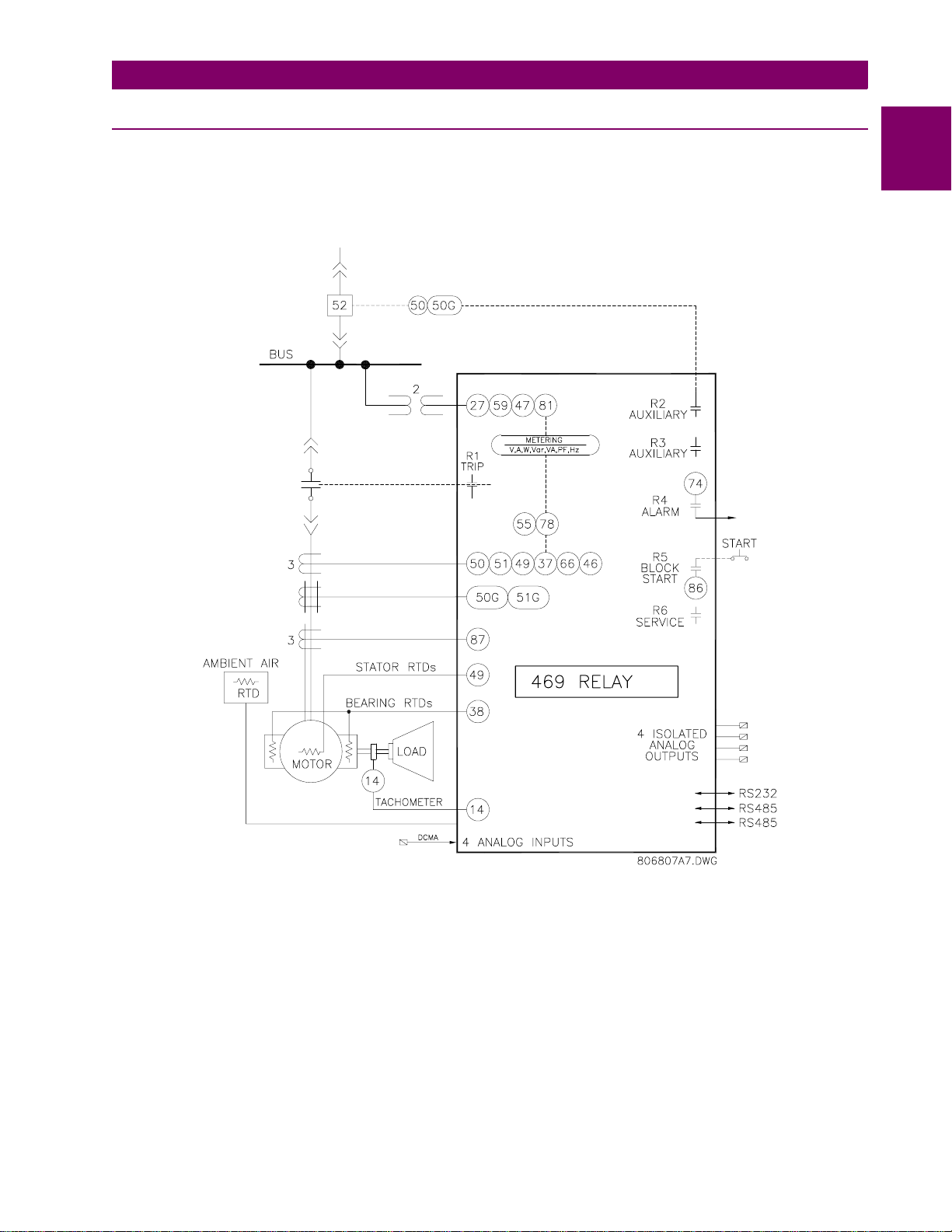

The 469 Motor Managemen t Relay is a micropro cessor ba sed rela y design ed for the prote ction and m anagement of medium and large hor sepower motors and driven equipment. Th e 469 is equipped with six output

relays for trips, alar ms, and start blocks. Motor protection, fault diagnosti cs, power metering, and RTU functions are integrated into one ec onomical drawout package. The single-line diagram below illus trates the 469

functionality using ANSI (American National Standards Institute) device numbers.

1

Figure 1–1: SINGLE LINE DIAGRAM

Typical applications include:

• Pumps • Fans • Compressors

•Mills •Shredders •Extruders

• Debarkers • Refiners • Cranes

• Conveyors • Chillers • Crushers

•Blowers

GE Power Management 469 Motor Management Relay 1-1

Page 14

1.1 OVERVIEW 1 INTRODUCTION

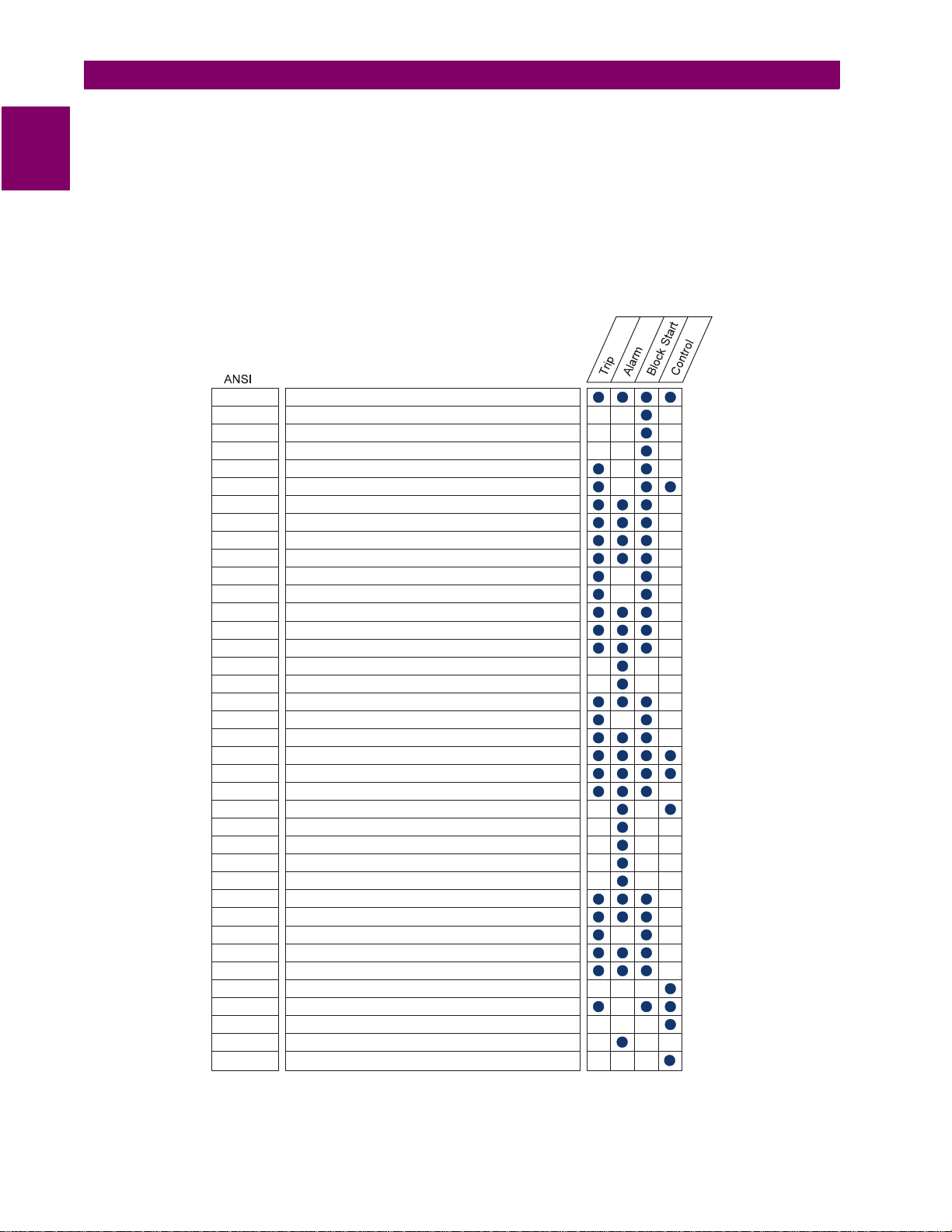

Some of the protection highlig hts are detailed here; a complete list is shown below. Four assignable digital

inputs may be configured for a number of different features including tachometer or generic trip and alarm with

1

a programmable name . The thermal model inc orporates unbalance bia sing, RTD feedback, and exponent ial

cooling. In addition to the 15 standard overload curves, there is a custom curve feature and a curve specifically

designed for the starting of high inertia loads, when the acceleration time exceeds the safe stall time. A second

overload curve is pr ovided for two-speed motors. Ground fau lts or earth leakage as low as 0.25 A may be

detected using the GE Power Management 50:0.025 Ground CT. CT inputs for phase differential protection are

also provided. The 12 RTD inputs provided may be individually field programmed for different RTD types. Voltage transformer inputs allow for numerous protec tion features based on vo ltage and power quantities. F our

4 to 20 mA analog inputs ma y be used for tripping and alarm ing on any transducer input such as vibration,

pressure, flow, etc.

51 Overload

86 Overload Lockout

66 Starts/Hour & Time Between Starts

Restart Block (Anti-Backspin Timer)

50 Short Circuit & Short Circuit Backup

Mechanical Jam

32

37

46 Current Unbalance

50G/51G Ground Fault & Ground Fault Backup

87 Differential

49 Stator RTD

38 Bearing RTD

27/59 Undervoltage/Overvoltage

47 Phase Reversal

81 Frequency

55/78 Power Factor

14 Speed Switch & Tachometer Trip

19 Reduced Voltage Start

48

Reverse Power

Undercurrent/Underpower

Acceleration

Other RTD & Ambient RTD

Open RTD Alarm

Short/Low RTD

Reactive Power

Analog Input

Demand Alarm: A kW kvar kVA

SR469 Self-Test, Service

Trip Coil Supervision

Welded Contactor

Breaker Failure

Remote Switch

Load Shed Switch

Pressure Switch

Vibration Switch

Incomplete Sequence (Reduced Voltage Start)

Remote Start/Stop

Over Torque

Forced Relay Operation

PROCTLA5.CDR

Figure 1–2: PROTECTION FEATURES

1-2 469 Motor Management Relay GE Power Management

Page 15

1 INTRODUCTION 1.1 OVERVIEW

Fault diagnostics are provided through pretrip data, event record, trace memory, and statistics. Prior to issuing

a trip, the 469 takes a snapshot of the measured parame ters and stores them with the cause of the trip. This

pre-trip data may be viewed using the key before the trip i s reset, or by accessing the

LAST TRIP DATA

actual values. The 469 event recorder stores up to 40 time and date stamped events including

NEXT

A1 STATUS /

the pre-trip data. Each time a trip occurs, the 469 stores a trace of 8 cycles pre-trip and 8 cycles post-trip for all

measured AC quantities . Trip counters record the number of occurrenc es of each type of trip. Minimum an d

maximum values for RTDs and analog inputs are also recorded. These features enable the operator to pinpoint

a problem quickly and with certainty.

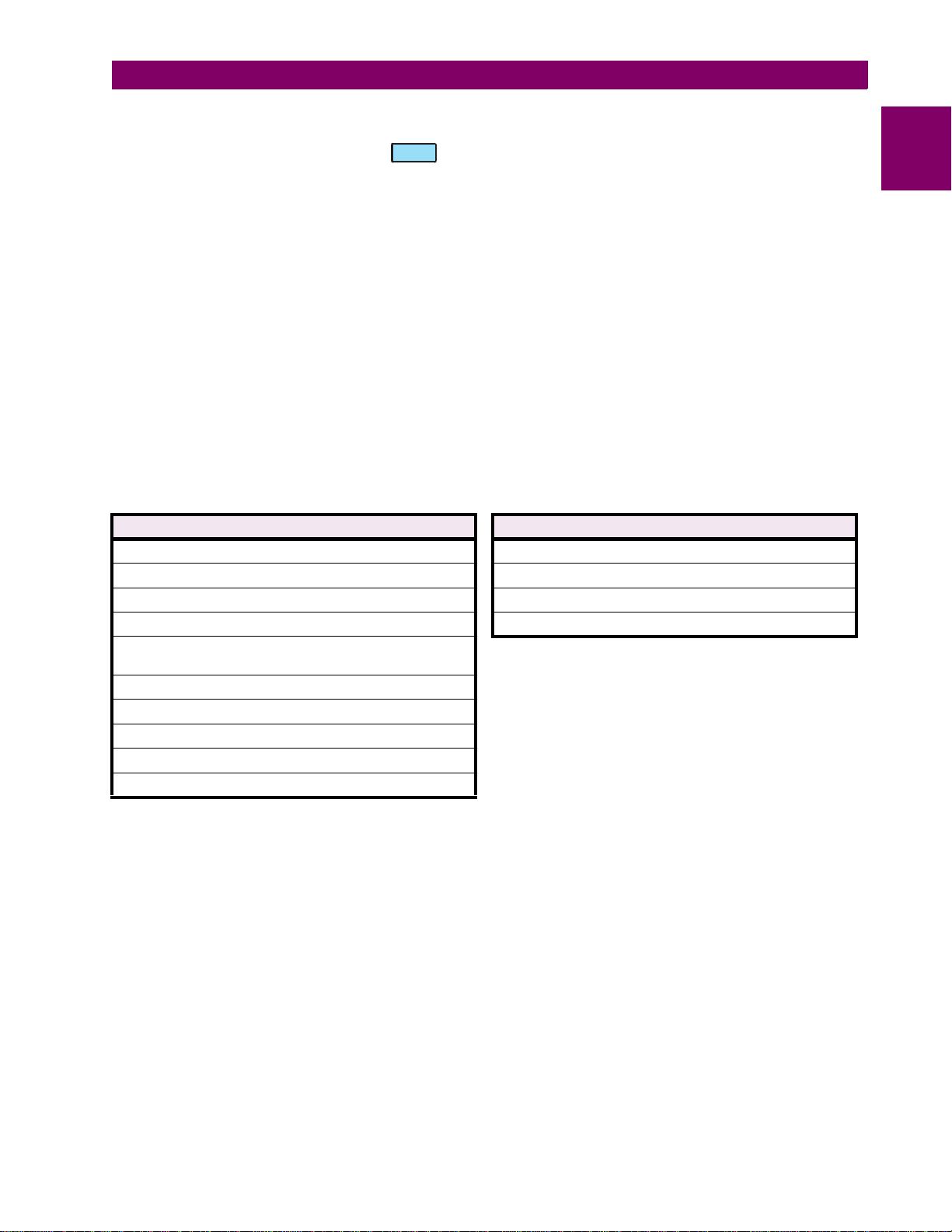

Power metering is buil t into the 469 as a s tandard feature. The ta ble below outline s the metered param eters

available either through the front panel or communications ports.

The 469 is equipped with 3 fully functional and independent communications ports. The front panel RS232 port

may be used for 469 setpoint program ming , loca l interro gation or control , and upgradi ng of 469 fir mware. Th e

Computer RS485 port m ay be connecte d to a PLC, DCS , or PC based u ser interfac e program. The A uxiliary

RS485 port may be used for redundancy or simultaneous interrogat ion and/or control from a second PLC,

DCS, or PC software.

There are also four 4 to 20 mA or 0 to 1 mA (as specified with order) transducer outputs that may be assi gne d

to any measured parameter. The range of these outputs is scalable.

Additional features are outlined in the table below.

Table 1–1: METERING AND ADDITIONAL FEATURES

METERING ADDITIONAL FEATURES

Voltage Drawout case (for ease of maintenance/testing)

Current and amps demand Reduced voltage starting control for single transition

Real power, kW demand, kW power consumption Trip coil supervision

Apparent power and kVA demand Flash memory for easy firmware upda tes

Reactive power, kvar demand, kvar consumption/

generation

Frequency

Power Factor

RTD

Speed in RPM with a key phasor input

User-programmable analog inputs

1

GE Power Management 469 Motor Management Relay 1-3

Page 16

1.1 OVERVIEW 1 INTRODUCTION

1.1.2 ORDER INFORMATION

1

All 469 features are standard; there are no options. The phase CT secondaries, control power, and analog output range must be specified at the time of order. The 469 differential CT inputs are field programmable for CTs

with 1 A or 5 A secondaries. There are two gr ound CT inputs, one for the GE Power Manageme nt 50:0.025

core balance CT and one for a ground CT with a 1 A or 5 A secondary, also field programmable. The VT inputs

will accommodate VTs in either a delta or wye configuration. The output relays are always non-failsafe with the

exception of the serv ice relay. The 469PC software is p rovided with each unit. A metal dem o case may be

ordered for demonstration or testing purposes.

469

469 Basic unit

Additional access ories are listed in the following section.

• 469PC

DEMO:

•

SR 19-1 PANEL:

•

SR 19-2 PANEL:

•

SCI MODULE:

•

Phase CT:

•

HGF3, HGF5, HGF8:

•

Software:

***

P1

P5

LO

HI

A1

A20

Provided free with each relay

Metal Carry Case in which 469 unit may be mounted

Single cutout 19" panel

Dual cutout 19" panel

RS232 to RS485 converter box designed for harsh industrial environments

50, 75, 100, 150, 200, 250, 300, 350, 400, 500, 600, 750, 1000

For sensitive ground detection on high resistance grounded systems.

1A phase CT secondaries

5A phase CT secondaries

DC: 25-60 V; AC: 20-48 V @ 48-62 Hz

DC: 90-300 V; AC: 70-265 V @ 48-62 Hz

0-1 mA analog outputs

4-20 mA analog outputs

Figure 1–3: 469 ORDER CODES

1.1.3 OTHER ACCESSORIES

• 469

• 469

•

1" Collar:

3" Collar:

Optional Mounting Kit:

For shallow switchgear, reduces the depth of the relay by 1 #3/8"

For shallow switchgear, reduces the depth of the relay by 3"

Additional mounting support 1819-0030

1-4 469 Motor Management Relay GE Power Management

Page 17

1 INTRODUCTION 1.2 SPECIFICATIONS

1.2 SPECIFICATIONS 1.2.1 469 SPECIFICATIONS

POWER SUPPLY

Options: LO / HI (must be specified with order)

Range: LO: DC: 20 to 60 V DC

AC: 20 to 48 V AC at 48 to 62 Hz

HI: DC: 90 to 300 V DC

AC: 70 to 265 V AC at 48 to 62 Hz

Power: 45 VA (max), 25 VA typical

Proper operation time without supply voltage: 30 ms

PHASE CURRENT INPUTS

CT Primary: 1 to 5000 A

CT Secondary: 1 A or 5 A (must be specified with order)

Burden: Less than 0.2 VA at rated load

Conversion Range: 0.05 to 20 × CT

Accuracy: at < 2 x CT: ± 0.5% of 2 × CT

at ≥ 2 x CT: ± 1% of 20 × CT

CT Withstand: 1 second @ 80 × rated current

2 seconds @ 40 × rated current

continuous @ 3 × rated current

GROUND CURRENT INPUTS

CT Primary: 1 to 5000 A

CT Secondary: 1 A or 5 A (setpoint)

Burden: < 0.2 VA at rated load for 1 A or 5 A

< 0.25 VA for 50:0.025 @ 25 A

Conversion Range: 0.02 to 1 × CT primary Amps

Accuracy: ± 0.5% of 1 × CT for 5 A

± 0.5% of 5 × CT for 1 A

± 0.125 A for 50:0.025

CT Withstand: 1 second @ 80 × rated current

2 seconds @ 40 × rated current

continuous @ 3 × rated current

DIFFERENTIAL PHASE CURRENT INPUTS

CT Primary: 1 to 5000A

CT Secondary: 1 A or 5 A (setpoint)

Burden: Less than 0.2 VA at rated load

Conversion Range: 0.02 to 1 × CT

Accuracy: ±0.5% of 1 × CT for 5 A

±0.5% of 5 × CT for 1 A

CT Withstand: 1 second @ 80 × rated current

2 seconds @ 40 × rated current

continuous @ 3 × rated current

VOLTAGE INPUTS

VT Ratio: 1.00 to 150.00:1 in steps of 0.01

VT Secondary: 273 V AC (full scale)

Conversion Range: 0.05 to 1.00 × full scale

Accuracy: ±0.5% of full scale

Max. Continuous:280 V AC

Burden: > 500 kΩ

DIGITAL INPUTS

Inputs: 9 opto-isolated inputs

External Switch: dry contact < 800 Ω, or

open collector NPN transistor from sensor; 6 mA sinking from internal 4 KΩ pullup at 24 V DC with Vce < 4 V DC

469 Sensor Supply: +24 V DC at 20 mA max.

RTD INPUTS

RTDs: 3 wire type:100Ω Platinum (DIN.43760)

100 Ω Nickel

120 Ω Nickel

10 Ω Copper

RTD Sensing Current: 5mA

Isolation: 36 Vpk

(isolated with analog inputs and outputs)

Range: –50 to +250°C

Accuracy: ±2°C

Lead Resistance:25 Ω Max per lead for Pt and Ni type

3 Ω Max per lead for Cu type

No Sensor: >1000 Ω

Short/Low Alarm: < –50°C

TRIP COIL SUPERVISION

Applicable Voltage: 20 to 300 V DC / V AC

Trickle Current: 2 to 5 mA

ANALOG CURRENT INPUTS

Current Inputs: 0 to 1 mA, 0 to 20mA or 4 to 20 mA

(setpoint)

Input Impedance: 226 Ω ±10%

Conversion Range: 0 to 21 mA

Accuracy: ±1% of full scale

Type: passive

Analog Input Supply: +24 V DC at 100 mA max.

Response Time: ≤ 100 ms

COMMUNICATIONS PORTS

RS232 Port: 1, Front Panel, non-isolated

RS485 Ports: 2, Isolated together @ 36 V

Baud Rates: RS485: 300, 1200, 2400, 4800, 9600,

19200

RS232: 9600

Parity: None, Odd, Even

Protocol: Modbus® RTU / half duplex

pk

1

GE Power Management 469 Motor Management Relay 1-5

Page 18

1.2 SPECIFICATIONS 1 INTRODUCTION

ANALOG CURRENT OUTPUT

Type: Active

1

Range: 4 to 20 mA, 0 to 1 mA

(must be specified with order)

Accuracy: ±1% of full scale

4 to 20 mA maximu m load: 1200 Ω

0 to 1 mA maximum load: 10 kΩ

Isolation: 36 Vpk

(Isolated with RTDs and Analog Inputs)

4 Assignable Outputs:

phase A current

phase B current

phase C current

3 phase average current

ground current

phase AN (AB) voltage

phase BN (BC) voltage

phase CN (CA) voltage

3 phase average voltage

hottest stator RTD

hottest bearing RTD

hottest other RTD

RTD # 1 to 12

Power factor

3 phase Real power (kW)

3 phase Apparent power (kVA)

3 phase Reactive power (kvar)

Thermal Capacity Used

Relay Lockout Time

Current Demand

kvar Demand

kW Demand

kVA Demand

Motor Load

Torque

OVERLOAD / STALL PROTECTION /

THERMAL MODEL

Overload Curves:15 Standard Overload Curves, Custom

Curve, Voltage Dependent Custom

Curve for high inertia starting (all curves

time out against average phase current)

Curve Biasing: Phase Unbalance

Hot/Cold Curve Ratio

Stator RTD

Running Cool rate

Stopped Cool Rate

Line Voltage

Overload Pickup: 1.01 to 1.25 (for service factor)

Pickup Accuracy: as per Phase Current Inputs

Timing Accuracy: ±100 ms or ±2% of total time

Elements: Trip and Alarm

OUTPUT RELAYS

Configuration: 6 Electromechanical Form C

Contact Material: silver alloy

Operate Time: 10 ms

Max ratings for 100000 operations:

VOLTAGE MAKE/CARRY BREAK MAX.

DC

RESISTIVE

DC

INDUCTIVE

L/R=40ms

AC

RESISTIVE

AC

INDUCTIVE

P.F.=0.4

CONTINUOUS

30 V 10 A 30 A 10A 300 W

125 V 10 A 30 A 0.5 A 62.5 W

250 V 10 A 30 A 0.3 A 75 W

30 V 10 A 30 A 5A 150 W

125 V 10 A 30 A 0.25 A 31.3 W

250 V 10 A 30 A 0.15 A 37.5 W

120 V 10 A 30 A 10 A 2770 VA

250 V 10 A 30 A 10 A 2770 VA

120 V 10 A 30 A 4 A 480 VA

250 V 10 A 30 A 3 A 750 VA

0.2s

LOAD

TERMINALS

Low Voltage (A, B, C, D terminals): 12 AWG max.

High Voltage (E, F, G, H terminals): #8 ring lug, 10 AWG

wire standard

PHASE SHORT CIRCUIT

Pickup Level: 4.0 to 20.0 × CT primary in steps of 0.1

of any one phase

Time Delay: 0 to 1000 ms in steps of 10

Pickup Accuracy: as per Phase Current Inputs

Timing Accuracy: +50 ms

Elements: Trip

MECHANICAL JAM

Pickup Level: 1.01 to 3.00 × FLA in steps of 0.01 of any

one phase, blocked on start

Time Delay: 1 to 30 s in steps of 1

Pickup Accuracy: as per Phase Current Inputs

Timing Accuracy: ±0.5 s or ±0.5% of total time

Elements: Trip

UNDERCURRENT

Pickup Level: 0.10 to 0.95 × CT primary in steps of

0.01 of any one phase

Time Delay: 1 to 60 s in steps of 1

Block From Start: 0 to 15000 s in steps of 1

Pickup Accuracy: as per Phase Current Inputs

Timing Accuracy: ±0.5 s or ±0.5% of total time

Elements: Trip and Alarm

1-6 469 Motor Management Relay GE Power Management

Page 19

1 INTRODUCTION 1.2 SPECIFICATIONS

CURRENT UNBALANCE

Unbalance: I2/I1 if I

I

2/I1

Range: 0 to 100% UB in steps of 1

Pickup Level: 4 to 40% UB in steps of 1

Time Delay: 1 to 60 s in steps of 1

Pickup Accuracy: ±2%

Timing Accuracy: ±0.5 s or ± 0.5% of total time

Elements: Trip and Alarm

× I

avg

avg

> FLA

/FLA if I

avg

< FLA

GROUND INSTANTANEOUS

Pickup Level: 0.1 to 1.0 × CT primary in steps of 0.01

Time Delay: 0 to 1000 ms in steps of 10

Pickup Accuracy: as per Ground Current Input

Timing Accuracy: +50 ms

Elements: Trip and Alarm

PHASE DIFFERENTIAL INSTANTANEOUS

Pickup Level: 0.05 to 1.0 × CT primar y i n st eps of 0.01

of any one phase

Time Delay: 0 to 1000 ms in steps of 10

Pickup Accuracy: as per Phase Differential Current Inputs

Timing Accuracy: +50 ms

Elements: Trip

ACCELERATION TIMER

Pickup: transition of no phase current to > over-

load pickup

Dropout: when current falls below overload pickup

Time Delay: 1.0 to 250.0 s in steps of 0.1

Timing Accuracy: ±100 ms or ± 0.5% of total time

Elements: Trip

JOGGING BLOCK

Starts/Hour: 1 to 5 in steps of 1

Time Between Starts: 1 to 500 min.

Timing Accuracy: ±0.5 s or ± 0.5% of total time

Elements: Block

RESTART BLOCK

Time Delay: 1 to 50000 s in steps of 1

Timing Accuracy: ±0.5 s or ± 0.5% of total time

Elements: Block

RTD

Pickup: 1 to 250°C i n steps of 1

Pickup Hysteresis:2°C

Time Delay: 3 s

Elements: Trip and Alarm

UNDERVOLTAGE

Pickup Level:

Motor Starting: 0.60 to 0.99 × Rated in steps of 0.01

Motor Running:0.60 to 0.99 × Rated in steps of 0.01

of any one phase

Time Delay: 0.1 to 60.0 s in steps of 0.1

Pickup Accuracy: as per Voltage Inputs

Timing Accuracy: <100 ms or ±0.5% of total time

Elements: Trip and Alarm

OVERVOLTAGE

Pickup Level: 1.01 to 1.10 × Rated in steps of 0.01 of

any one phase

Time Delay: 0.1 to 60.0 s in steps of 0.1

Pickup Accuracy: as per Voltage Inputs

Timing Accuracy: ±100 ms or ±0.5% of total time

Elements: Trip and Alarm

VOLTAGE PHASE REVERSAL

Configuration: ABC or ACB phase rotation

Timing Accuracy: 500 to 700 ms

Elements: Trip

FREQUENCY

Required Voltage:> 30% of full scale in Phase A

Overfrequency Pickup: 25.01 to 70.00 in steps of 0.01

Underfrequency Pickup: 20.00 to 60.00 in steps of 0.01

Accuracy: ±0.02 Hz

Time Delay: 0.1 to 60.0 s in steps of 0.1

Timing Accuracy: <100 ms or ±0.5% of total time

Elements: Trip and Alarm

REDUCED VOLTAGE START

Transition Level: 25 to 300% FLA in steps of 1

Transition Time: 1 to 250 s in steps of 1

Transition Control: Current, Timer, Current and Timer

REMOTE SWITCH

Configurable: Assignable to Digital Inputs1 to 4

Timing Accuracy: 100 ms max.

Elements: Trip and Alarm

SPEED SWITCH

Configurable: Assignable to Digital Inputs1 to 4

Time Delay: 1.0 to 250.0 s in steps of 0.1

Timing Accuracy: 100 ms max.

Elements: Trip

LOAD SHED

Configurable: Assignable to Digital Inputs1 to 4

Timing Accuracy: 100 ms max.

Elements: Trip

1

GE Power Management 469 Motor Management Relay 1-7

Page 20

1.2 SPECIFICATIONS 1 INTRODUCTION

PRESSURE SWITCH

Configurable: Assignable to Digital Inputs1 to 4

1

Time Delay: 0.1 to 100.0 s in steps of 0.1

Block From S tart: 0 to 5000 s in steps of 1

Timing Accuracy: ±100 ms or ±0.5% of total time

Elements: Trip and Alarm

VIBRATION SWITCH

Configurable: Assignable to Digital Inputs1 to 4

Time Delay: 0.1 to 100.0 s in steps of 0.1

Timing Accuracy: ±100 ms or ±0.5% of total time

Elements: Trip and Alarm

DIGITAL COUNTER

Configurable: Assignable to Digital Inputs1 to 4

Counting Frequency: ≤ 50 times a second

Range: 0 to 1 000 000 000

Elements: Alarm

TACHOMETER

Configurable: Assignable to Digital Inputs1 to 4

RPM Measurement: 100 to 7200 RPM

Duty Cycle of Pulse: > 10%

Elements: Trip and Alarm

GENERAL PURPOSE SWITCH

Configurable: Assignable Digital Inputs1 to 4

Time Delay: 0.1 to 5000.0 s in steps of 0.1

Block From S tart: 0 to 5000 s in steps of 1

Timing Accuracy: ±100 ms or ±0.5% of total time

Elements: Trip and Alarm

POWER FACTOR

Range: 0.01 lead or lag to 1.00

Pickup Level: 0.99 to 0.05 in steps of 0.01, Lead & Lag

Time Delay: 0.2 to 30.0 s in steps of 0.1

Block From S tart: 0 to 5000 s in steps of 1

Pickup Accuracy: ±0. 02

Timing Accuracy: ±100 ms or ±0.5% of total time

Elements: Trip and Alarm

3 PHASE REAL POWER

Range: 0 to ±99999 kW

Underpower Pickup: 1 to 25000 kW in steps of 1

Time Delay: 1 to 30 s in steps of 1

Block From Start: 0 to 15000 s in steps of 1

Pickup Accuracy:

±1% of × 2 × CT × VT × VT

±1.5% of × 20 × CT × VT × VT

3

3

full scale

full scale

at I

avg

at I

< 2 × CT

> 2 × CT

avg

Timing Accuracy: ±0.5 s or ±0.5% of total time

Elements: Trip and Alarm

3 PHASE APPARENT POWER

Range: 0 to 65535 kVA

Accuracy:

±1% of × 2 × CT × VT × VT

±1.5% of × 20 × CT × VT × VT

3

3

full scale

full scale

@ I

avg

@ I

< 2 × CT

> 2 × CT

avg

3 PHASE REACTIVE POWER

Range: 0 to ±99999 kvar

Pickup Level: ±1 to 25000 kvar in steps of 1

Time Delay: 0.2 to 30.0 s in steps of 0.1

Block From Start: 0 to 5000 s in steps of 1

Pickup Accuracy:

±1% of × 2 × CT × VT × VT

±1.5% of × 20 × CT × VT × VT

3

3

full scale

full scale

@ I

avg

@ I

< 2 × CT

> 2 × CT

avg

Timing Accuracy: ±100ms or ± 0.5% of total time

Elements: Trip and Alarm

OVER TORQUE

Pickup Level: 1.0 to 999999.9 Nm/ft·lb in steps of 0.1;

torque unit is selectable under torque

setup

Time Delay: 0.2 to 30.0 s in steps of 0.1

Pickup Accuracy: ±2.0%

Time Accuracy: ±100 ms or 0.5% of total time

Elements: Alarm (INDUCTION MOTORS ONLY)

METERED REAL POWER CONSUMPTION

Description: Continuous total of real power

consumption.

Range: 0 to 2000000.000 MW·hours.

Timing Accuracy: ±0.5%

Update Rate: 5 seconds

METERED REACTIVE POWER CONSUMPTION

Description: Continuous total of reactive power

consumption.

Range: 0 to 2000000.000 Mvar·hours

Timing Accuracy: ±0.5%

1-8 469 Motor Management Relay GE Power Management

Page 21

1 INTRODUCTION 1.2 SPECIFICATIONS

FUSE

Hi-Volt:

Current Rating: 2 A

Type: 5 × 20mm Slo-Blo Littelfuse

High Breaking Capacity

Model#: 215002

Lo-Volt:

Current Rating:3.15 A

Type: 5 × 20mm Slo-Blo Littelfuse

High Breaking Capacity

Model#: 2153.15

External fuse must be used if the supply voltage exceeds 250 V.

NOTE

DEMAND

Metered Values: Max imum Phase Current

3 Phase Real Power

3 Phase Apparent Power

3 Phase Reactive Power

Measurement Type: Rollin g Demand

Demand Interval: 5 to 90 minutes in steps of 1

Update Rate: 1 minute

Elements: Alarm

OTHER FEATURES

Pre-Trip Data

Event Recorder

Trace Memory

Starter Failure

Fault Simulation

VT Failure

ENVIRONMENT

Ambient Operating Temperature: –40°C to +60°C

Ambient Storage Temperature: –40°C to +80°C

Humidity: Up to 90%, noncondensing.

Altitude: Up to 2000 m

Pollution Degree: 2

It is recommended that the 469 be powered up

at least once per year to prevent deterioration

NOTE

of electrolytic capacitors in the power supply.

PRODUCTION TESTS

Thermal Cycling: Operational test at ambient, reducing to

–40°C and then increasing to 60°C

Dielectric Strength: 2.0 kV for 1 minute from relays, CTs,

VTs, power supply to Safety Ground

DO NOT CONNECT FILTER GROUND TO

SAFETY GROUND DURING TEST!

WARNING

TYPE TESTS

Dielectric Strength: Per IEC 255-5 and ANSI/IEEE C37.90

2.0 kV for 1 minute from relays, CTs,

VTs, power supply to Safety Ground

DO NOT CONNECT FILTER GROUND TO

SAFETY GROUND DURING TEST

WARNING

Insulation Resistance: IEC255-5 500 V DC, from relays,

CTs, VTs, power supply to Safety

Ground

DO NOT CONNECT FILTER GROUND TO

SAFETY GROUND DURING TEST

WARNING

Transients: ANSI C37.90.1 Oscillatory (2.5kV/1MHz)

ANSI C37.90.1 Fast Rise (5kV/10ns)

Ontario Hydro A-28M-82

IEC255-4 Impulse/High Frequency Dis-

turbance, Class III Level

Impulse Test: IEC 255-5 0.5 Joule 5 kV

RFI: 50 MHz/15 W Transmitter

EMI: C37.90.2 Electromagnetic Interference

@150 MHz and 450 MHz, 10 V/m

Static: IEC 80 1-2 Static Discharge

Humidity: 95% non-condensing

Temperature: –40°C to +60°C ambient

Environment: IEC 68-2-38 Temperature/Humidity

Cycle

Vibration: Sinusoidal Vibration 8.0 g for 72 hrs.

PACKAGING

Shipping Box: 12” × 11” × 10” (W × H × D)

30.5cm × 27.9cm × 25.4cm

Shipping Weight: 17 lbs Max / 7.7 kg

1

BATTERY BACKUP

Used only when no control power to relay.

Life expectancy is ≥ 10 ye ars wi th n o co ntro l po wer to relay

CASE

Fully drawout (automatic CT shorts)

Seal provision

Dust tight door

Panel or 19" rack mount

IP Class: IP20-X

CERTIFICATION

ISO: Manufactured under an ISO9001 registered system.

UL: UL approved

CSA: CSA approved

CE: Conforms to EN 55011/CISPR 11, EN 50082-2

Conforms to IEC 947-1,1010-1

GE Power Management 469 Motor Management Relay 1-9

Page 22

Page 23

2 INSTALLATION 2.1 MECHANICAL

2 INSTALLATION 2.1 MECHANICAL 2.1.1 DESCRIPTION

The 469 is packaged in the standard GE Power Management SR series arrangement, which consists of a drawout unit and a co mpanion fixed case. The case provides mechanical protection to the unit and is used to

make permanent con nections to al l external e quipment. The only electric al components mounted in the case

are those required to c onnect the unit to the external wiring. Connections in th e case are fitted with mechanisms required to al low the sa fe r em ov al of th e rel ay uni t fr om an ene rg ized panel (for example, automatic CT

shorting). The unit is mechanically held in the case by pins on the locking handle that cannot be fully lowered to

the locked position unt il the elec trical con nections ar e complete ly mated. A ny 469 can b e install ed in any 46 9

case, except for c ustom man ufactured un its that a re clearl y identifie d as suc h on both case and unit, and are

equipped with an index pin keying mechanism to prevent incorrect pairings.

No special ventilatio n requirements need to be observed duri ng the installation of the unit. The 469 c an be

cleaned with a damp cloth.

2

Figure 2–1: DIMENSIONS

To prevent unauthorized re moval of th e drawou t unit, a wire lead seal ca n be ins talled in the s lot provi ded on

the handle. With this seal in place, the drawout unit cannot be removed. A passcode or setpoint access jumper

can be used to prevent entry of setpoints but allow monitoring of actual values. If access to the front panel controls must be restricted, a separate seal can be installed on the cover to prevent it from being opened.

Hazard may result if the product is not used for its intended purpose.

WARNING

Figure 2–2: SEAL ON DRAWOUT UNIT

GE Power Management 469 Motor Management Relay 2-1

Page 24

2.1 MECHANICAL 2 INSTALLATION

2.1.2 PRODUCT IDENTIFICATION

Each 469 unit and c ase are e qui ppe d wi th a p er man ent lab el . T his l abe l i s ins tal led on t he l eft s i de (when facing the front of the relay) of both unit and case. The case label details which units can be installed.

2

The case label details the following info r mation:

• MODEL NUMBER

• MANUFACTURE DATE

• SPECIAL NOTES

The unit label details the following information:

• MODEL NUMBER

•TYPE

• SERIAL NUMBER

• MANUFACTURE DATE

• PHASE CURRENT INPUTS

• SPECIAL NOTES

• OVERVOLTAGE CATEGORY

• INSULATION VOLTAGE

• POLLUTION DEGREE

• CONTROL POWER

• OUTPUT CONTACT RATING

Figure 2–3: CASE AND UNIT IDENTIFICATION LABELS

2-2 469 Motor Management Relay GE Power Management

Page 25

2 INSTALLATION 2.1 MECHANICAL

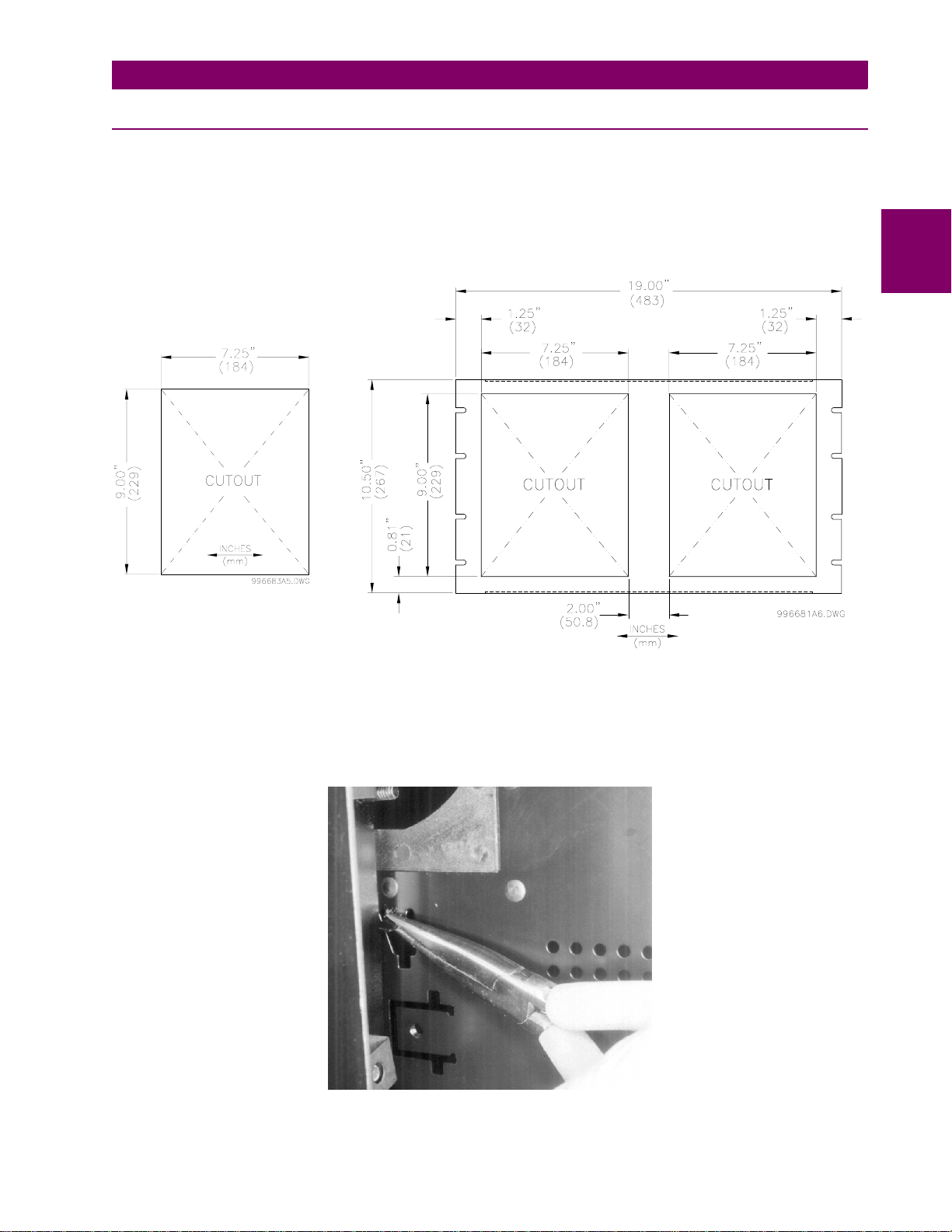

2.1.3 INSTALLATION

The 469 case, alone or adj acen t to anothe r SR ser ies u nit, ca n be instal led in the p anel of a stand ard 19-i nch

rack (see the diagr am below for panel cutout d imensions). Provision must b e made when mounting for the

front door to swing open without interference to, or from, adjacent equipment. Normally the 469 unit is mounted

in its case when shipped fr om the fa ctory, and should be removed befo re mou nting the case in the supp ortin g

panel. Unit withdrawal is described in the next section.

Double Cutout Panel

Single Cutout Panel

2

Figure 2–4: SINGLE AND DOUBLE 469 CUTOUT PANELS

After the mounting hole in the panel has been prepared, slide the 469 case into the panel from the front. Applying firm pressure on the front to ensur e the front be zel fits snugl y against the fr ont of the panel , bend out the

pair of retaining tabs (to a horizontal po sition) from each side of the case as shown below. The case is no w

securely mounte d, read y for panel wiring. If additional sup port i s de si red, the SR optional mounting kit may b e

ordered.

Figure 2–5: BEND UP MOUNTING TABS

GE Power Management 469 Motor Management Relay 2-3

Page 26

2.1 MECHANICAL 2 INSTALLATION

2.1.4 UNIT WITHDRAWAL AND INSERTION

TURN OFF CONTROL POWER BEFORE DRAWING OUT OR RE-INSERTING THE RELAY TO

PREVENT MALOPERATION!

CAUTION

2

CAUTION

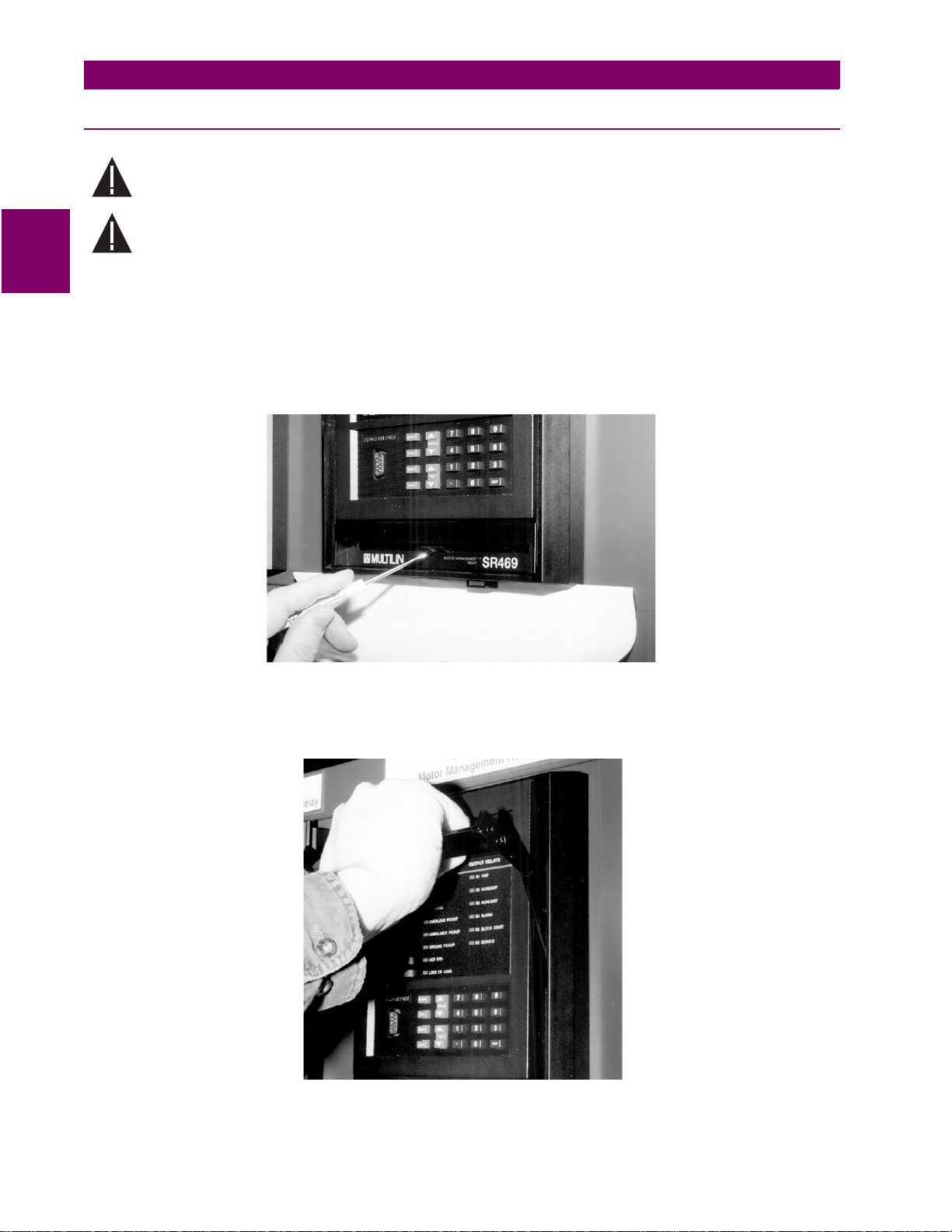

To remove the unit from the case:

1. Open the cover by grasping the center of the right side and then pulli ng the cover, which will rotate about

2. Release the locking latch, located below the locking handle, by pressing upward on the latch with the tip of

If an attempt is made to install a unit into a non-matching case, the mechanica l key will prevent full insertion of the unit. Do not apply strong force in the following step or damage may

result.

the hinges on the left.

a screwdriver.

Figure 2–6: PRESS LATCH TO DISENGAGE HANDLE

3. While holding the latch raised, grasp the locking handle in the center and pull firmly, rotating the handle up

from the bottom of the unit until movement ceases.

Figure 2–7: ROTATE HANDLE TO STOP POSITION

2-4 469 Motor Management Relay GE Power Management

Page 27

2 INSTALLATION 2.1 MECHANICAL

4. Once the handle is released from the locking mechan ism, the unit ca n freely slide ou t of the case whe n

pulled by the handle. It may sometimes be necessary to adjust the handle position slightly to free the unit.

2

Figure 2–8: SLIDE UNIT OUT OF CASE

To insert the unit into the case:

1. Raise the locking handle to the highest position.

2. Hold the unit immediately in front of the case and align the rolling guide pins (near the hinges of the locking

handle) to the guide slots on either side of the case.

3. Slide the unit into the case until the guide pi ns on th e unit have engaged the guid e slots on either si de of

the case.

4. Grasp the locking handle fr om the ce nter and pre ss down firm ly, rotating the handle from the ra ised posi-

tion toward the bottom of the unit.

5. When the unit is fully inserted, the latch will be heard to click, locking the handle in the final position.

No special ventilation requirements need to be observed during the installation of the unit.

The unit does not require cleaning.

CAUTION

GE Power Management 469 Motor Management Relay 2-5

Page 28

2

2.1 MECHANICAL 2 INSTALLATION

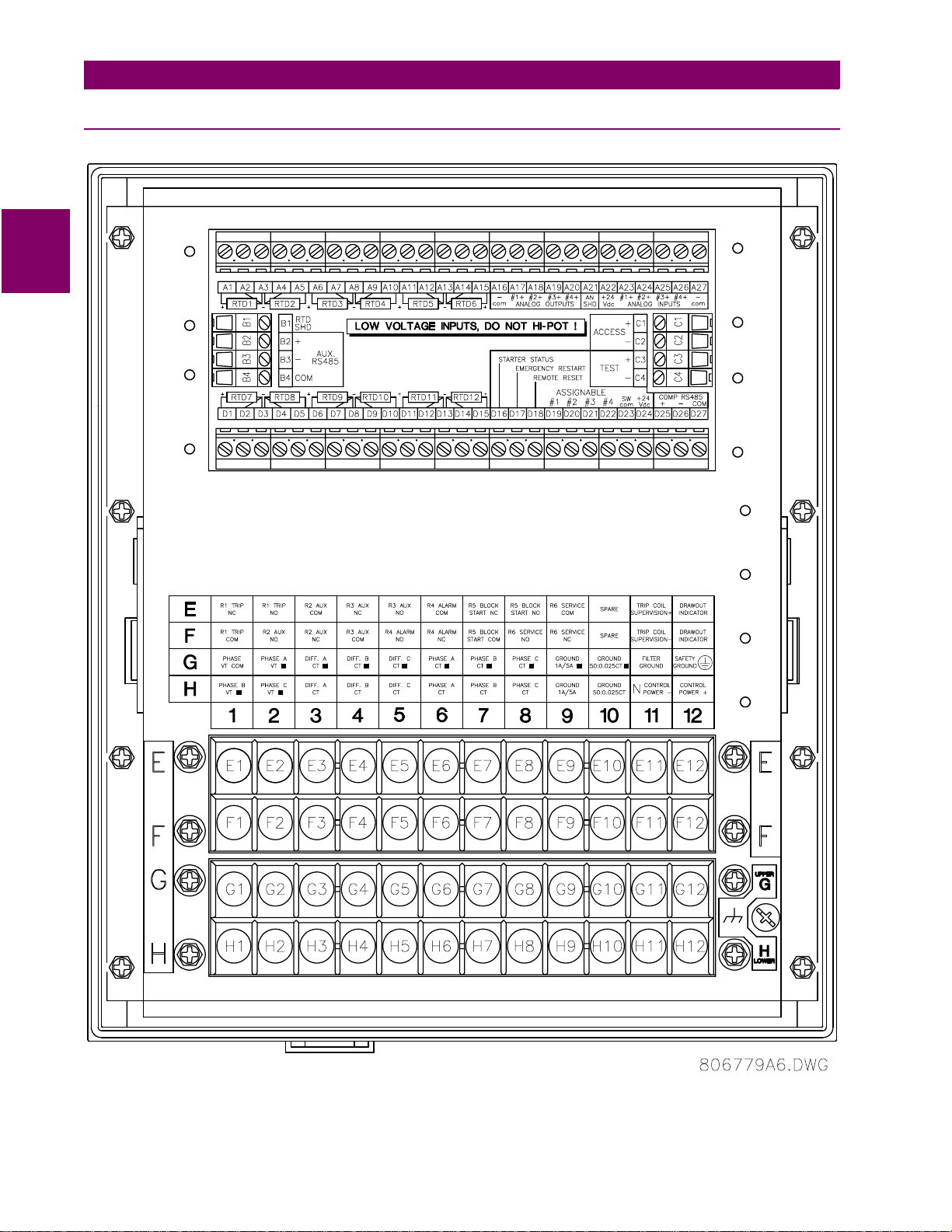

2.1.5 TERMINAL LOCATIONS

Figure 2–9: TERMINAL LAYOUT

2-6 469 Motor Management Relay GE Power Management

Page 29

2 INSTALLATION 2.1 MECHANICAL

T able 2–1: 469 TERMINAL LIST

A01 RTD #1 HOT D21 ASSIGNABLE SW. 03

A02 RTD #1 COMPE NSATION D22 ASSIGNABLE SW. 04

A03 RTD RETURN D23 SWITCH COMMON

A04 RTD #2 COMPENSATION D24 SWITCH +24 V DC

A05 RTD #2 HOT D25 COMPUTER RS485 +

A06 RTD #3 HOT D26 COMPUTER RS485 –

A07 RTD #3 COMPENSATION D27 COMPUTER RS485 COMMON

A08 RTD RETURN E01 R1 TRIP NC

A09 RTD #4 COMPE NSATION E02 R1 TRIP NO

A10 RTD #4 HOT E03 R2 AUXILIARY COMMON

A11 RTD #5 HOT E04 R3 AUXILIARY NC

A12 RTD #5 COMPE NSATION E05 R3 AUXILIARY NO

A13 RTD RETURN E06 R4 ALARM COMMON

A14 RTD #6 COMPENSATION E07 R5 BLOCK START NC

A15 RTD #6 HOT E08 R5 BLOCK START NO

A16 A NALO G OUT COMMON – E09 R6 SERVICE COMMON

A17 ANALOG OUT 1 + E10 not used

A18 ANALOG OUT 2 + E11 COIL SUPERVISION +

A19 ANALOG OUT 3 + E12 469 DRAWOUT INDICATOR

A20 ANALOG OUT 4 + F01 R1 TRIP COMMON

A21 ANALOG SHIELD F02 R2 AUXILIARY NO

A22 ANALOG INPUT 24 V DC POWER SUPPLY + F03 R2 AUXILIARY NC

A23 ANALOG INPUT 1 + F04 R3 AUXILIARY COMMON

A24 ANALOG INPUT 2 + F05 R4 ALARM NO

A25 ANALOG INPUT 3 + F06 R4 ALARM NC

A26 ANALOG INPUT 4 + F07 R5 BLOCK START COMMON

A27 A NALOG INPUT COMMON – F08 R6 SERVICE NO

B01 RTD SHIELD F09 R6 SERVICE NC

B02 AUXILIARY RS485 + F10 not used

B03 AUXILIARY RS485 – F11 COIL SUPERVISION –

B04 A UXILIARY RS485 COMMON F12 469 DRAWOUT INDICATOR

C01 ACCESS + G01 PHASE VT NEUTRAL

C02 ACCESS – G02 PHASE A VT

C03 469 UNDER TEST + G03 DIFFERENTIAL A CT

C04 469 UNDER TEST – G04 DIFFERENTIAL B CT

D01 RTD #7 HOT G05 DIFFERENTIAL C CT

D02 RTD #7 COMPENSATION G06 PHASE A CT

D03 RTD RETURN G0 7 PHASE B CT

D04 RTD #8 COMPENSATION G08 PHASE C CT

D05 RTD #8 HOT G09 1A/5A GROUND CT

D06 RTD #9 HOT G10 50:0.025 GROUND CT

D07 RTD #9 COMPENSATION G11 FILTER GROUND

D08 RTD RETURN G1 2 SAFETY GROUND

D09 RTD #10 COMPENSATION H01 PHASE B VT

D10 RTD #10 HOT H02 PHASE C VT

D11 RTD #11 HOT H03 DIFFEREN TIAL A CT

D12 RTD #11 COMPENSATION H04 DIFFERENTIAL B CT

D13 RTD RETURN H05 DIFFERENTIAL C CT

D14 RTD #12 COMPENSATION H06 PHASE A CT

D15 RTD #12 HOT H07 PHASE B CT

D16 STARTER STATUS H08 PHASE C CT

D17 EMERGENCY RESTART H09 1A/5A GROUND CT

D18 REM OT E RESET H10 50:0.025 GROUND CT

D19 ASSIGNABLE SW. 01 H11 CONTROL POWER –

D20 ASSIGNABLE SW. 02 H12 CONTROL POWER +

•

•

•

•

•

•

•

•

•

•

•

2

GE Power Management 469 Motor Management Relay 2-7

Page 30

2.2 ELECTRICAL 2 INSTALLATION

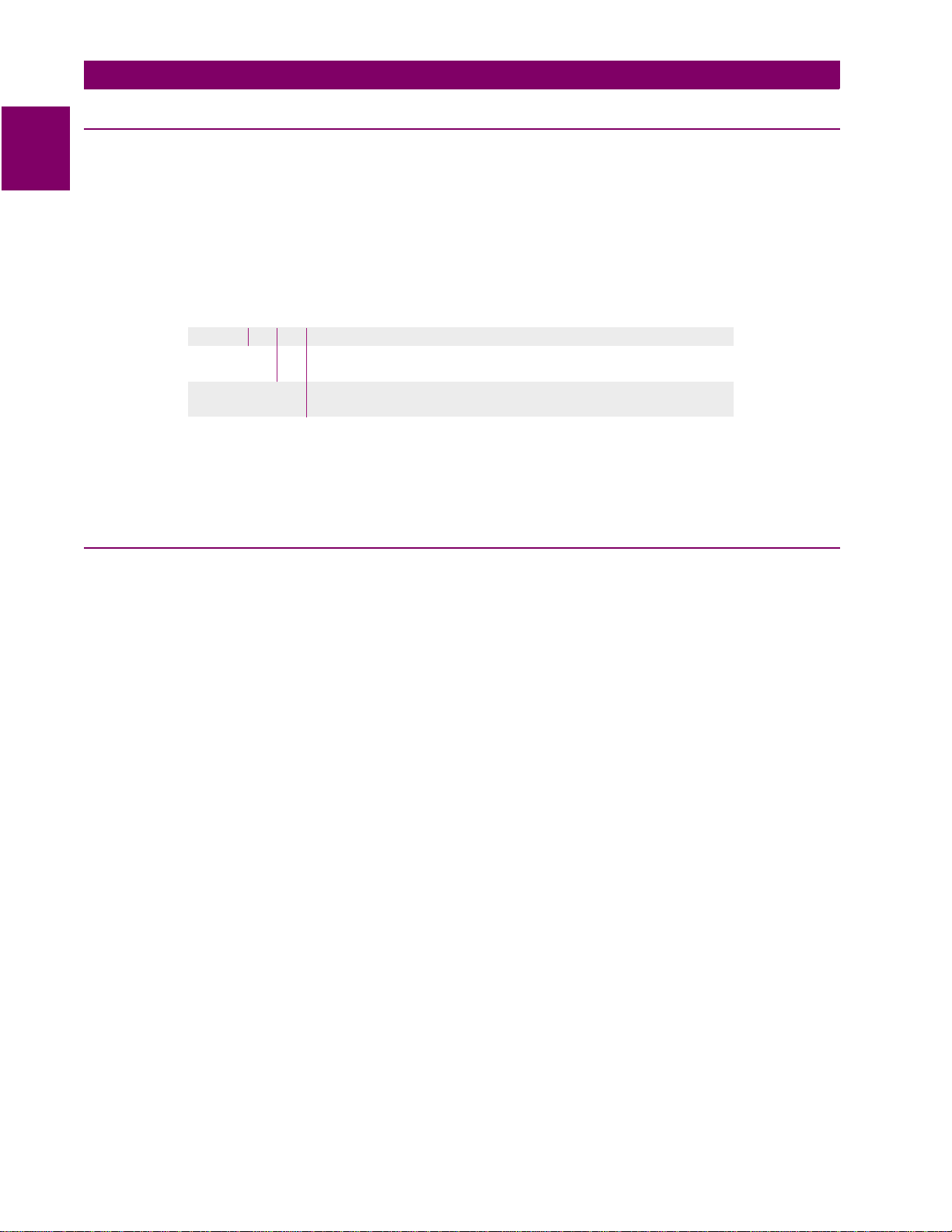

2.2 ELECTRICAL 2.2.1 TYPICAL WIRING DIAGRAM

2

Figure 2–10: TYPICAL WIRING DIAGRAM

2-8 469 Motor Management Relay GE Power Management

Page 31

2 INSTALLATION 2.2 ELECTRICAL

2.2.2 TYPICAL WIRING

A broad range of 469 applications are available. Although it is not possible to present typical connections for all

possible schemes, this section will cover the inte rconnections of instrument tr ansformer inputs, other inp uts,

outputs, communicat ions, and grounding. See Figure 2–9: TERMINAL LAYOUT on page 2–6 and Table 2–1:

469 TERMINAL LIST on page 2–7 for terminal arrangement.

2.2.3 CONTROL POWER

The

does not match, damage to the unit may occur!

CAUTION

The order code from th e te r min al la bel on th e s id e o f th e d ra wout uni t s pe cif ie s the nom in al co ntr ol v olt age as

one of the following:

LO: 20 to 60 V DC

20 to 48 V AC

Ensure applied control voltage and rated voltag e on drawout case termina l label match . For example, the HI

power supply will work with any DC voltage from 90 to 300 V, or AC voltage from 70 to 265 V. The internal fuse

may blow if the applied voltage exceeds this range.

control power must match the installed switching power supply. If the applied voltage

469

HI: 90 to 300 V DC

70 to 265 V AC

2

Figure 2–11: CONTROL POWER CONNECTION

Extensive filtering a nd transient protecti on are built into the 469 to ensure proper oper ation in h arsh indus trial

environments. Transient energ y must be conducted back to the source through the f ilter ground terminal. A

separate safety ground terminal is provided for hi-pot testing.

All grounds MUST be hooked up for normal operation regardless of control power supply

type.

WARNING

GE Power Management 469 Motor Management Relay 2-9

Page 32

2.2 ELECTRICAL 2 INSTALLATION

2.2.4 PHASE CURRENT INPUTS

The 469 has three chan nel s fo r phas e c urr ent i npu ts , each wi th a n is ol ati ng tran sf or mer. There are no inter nal

ground connections on the current inputs. If the unit is withdrawn , each phase CT ci rcuit is shorted by automatic mechanisms on the 469 cas e. The phas e CTs should be chosen so the FLA is no less than 50% of th e

rated phase CT prim ary. Ideally, the phase CT primary should be chos en such that the FLA is 100% of the

phase CT primary or slightly less, nev er more. This will ensure maximum ac curacy for the cu rrent measure-

2

ments. The maximum phase CT primar y cu rren t is 5000 A.

The 469 correctly mea sures up to 20 times the phas e current nominal rating. Sin ce the conversion range is

large, 1 A or 5 A CT secondaries must be specified at the time of order to ensure the appro priate interpos ing

CT is installed in the unit. The chosen CTs must be capable of drivi ng the 469 p hase CT burd en (see Sec tion

1.2: SPECIFICATIONS on page 1–5 for ratings).

Ver ify that th e

nections of the connected CTs. Unmatched CTs may result in equipment damage or inade-

CAUTION

See Appendix B.1: TWO-PHASE CT CONFIGURATION on page B–1 for 2-phase CT information.

The 469 has a dual primary isolating transformer for ground CT connection. There are no internal ground connections on the gr ound current inputs. The ground CT c ircuits are shorted by automatic mech anisms on the

469 case if the uni t i s wit hdr awn . The 1 A / 5 A tap is used either for ze ro -seq uen ce /co re ba lan ce ap pl ic ati ons

or residual ground con nections where the summation of the three phase current CTs is passed through the

ground current input (s ee the figure below). The ma ximum ground CT pr imary current is 5000 A for the 1 A /

5 A tap. Alternatively, the 50:0.025 ground CT inpu t has been d esigned f or sensiti ve ground cu rrent de tection

on high resistance grounded systems wher e the GE Power Mana gement 50:0.025 core b alance CT is to be

used. For example, in mining applications where earth leakage current must be measured for personnel safety,

primary ground cu rren t as low as 0 .25 A may be detected with the GE Power Mana gem ent 50:0 .025 CT . Only

one ground CT input tap should be used on a given unit.

quate protection. Polarity of the phase CTs is critical for Negative Sequence Unbalance

calculation, power measurement, and residual ground current detection (if used).

nominal phase current of 1 A or 5 A matches the secondary rating and con-

469

2.2.5 GROUND CURRENT INPUT

Figure 2–12: RESIDUAL GROUND CT CONNECTION

2-10 469 Motor Management Relay GE Power Management

Page 33

2 INSTALLATION 2.2 ELECTRICAL

The 469 measures up to 5 A secondary current if the 1 A / 5 A tap is used. Since the conversion range is relatively small, the 1 A or 5 A option is field programmable. Proper selection of this setpoint ensures proper reading of primary gr ound c urr ent. T he 1 A / 5 A gr ou nd CT c ho sen m us t b e c ap abl e of driv in g t he 469 ground CT

burden (see Section 1.2: SPECIFICATIONS on page 1–5). The 469 measures up to 2 5 A of primary groun d

current if this tap is used in conjunction with the GE Power Management core balance CT.

The zero-sequence connection is recommended. Unequal saturation of CTs, size and location

of motor, resistance of power system and motor core saturation density, etc., may cause false

NOTE

NOTE

The exact placement of a zero-sequence CT to detect only ground fault current is shown below. If the core balance CT is placed ov er s hie ld ed c ab le, ca pac it iv e c ou pli ng of p has e c urr ent in to th e c ab le shield during motor

starts may be detected as ground current unless the shield wire is also passed through the CT window.

Twisted pair cabling on the zero-sequence CT is recommended.

readings in the residually connected GF circuit.

Only one ground input should be wired – the other input should be unconnected.

2

SHIELDED CABLE

Figure 2–13: CORE BALANCE GROUND CT INSTALLATION

UNSHIELDED CABLE

GE Power Management 469 Motor Management Relay 2-11

Page 34

2.2 ELECTRICAL 2 INSTALLATION

2.2.6 DIFFERENTIAL CURRENT INPUTS

The 469 has three channe ls for differential current inputs, each with an is olating transformer. There are no

internal ground co nnection s on the current i nputs. Ea ch differenti al CT circ uit is sho rted by aut omatic m echanisms on the 469 case if the unit is withdrawn. The maximum differential CT primary current is 5000 A.

The 469 measures up to 5 A secondary current for the differential CT inputs. Since the conversion range is relatively small, the 1 A or 5 A option is field programmable. Proper selection of this setpoint ensures proper read-

2

ing of primary phas e differential curren t. The 1 A / 5 A differential CT chosen must b e capable of drivin g the

469 differential CT burden (see Section 1.2: SPECIFICATIONS on page 1–5 for ratings).

The differential CT s may be core balance as shown in the first figure below. Alternatively , the summation of two

CTs per phase into the d ifferentia l i npu t wi ll p rovi de a l arge r zo ne of p r otec tion. If the summation of two CTs is

used, observation of CT polarity is important. The summation m ethod may also be implemented usin g the

phase CTs as shown below. They will have to have the same CT ratio.

Figure 2–14: CORE BALANCE METHOD

WITHOUT PHASE CTs WITH PHASE CTs

Figure 2–15: SUMMATION METHOD

2-12 469 Motor Management Relay GE Power Management

Page 35

2 INSTALLATION 2.2 ELECTRICAL

2.2.7 VOLTAGE INPUTS

The 469 has three chan nels for AC voltage inputs , each with an isolating transf ormer. There are no internal

fuses or ground connec tions on the volta ge inputs. The maximum V T ratio is 150.00:1. T he two VT connections are open delta (s ee Figure 2–10: TYPICAL W IRING DIAGRAM on page 2–8) or wye (see below). T he

voltage channels are connected in wye internally, which means that the jumper shown on the delta-source connection of the TYPICAL WIRING DIAGRAM, between the phase B input and the 469 neutral terminal, must be

installed for open delta VTs.

Polarity of the VTs is critical for correct power measurement and voltage phase reversal operation.

A 1 A fuse is typically used to protect the inputs.

2

Figure 2–16: WYE VOLTAGE TRANSFORMER CONNECTION

2.2.8 DIGITAL INPUTS

There are 9 digital inputs designed for dry contact connections only. Two of the digital inputs (Access and Test)

have their own comm on termi nal; th e bal ance of th e d igital i nputs share o ne com mon te rmin al (see Fig ure 2–

10: TYPICAL WIRING DIAGRAM on page 2–8).

In addition, the + 24 V DC swi tc h s up ply is br ou ght out for c on tro l powe r of an inductive or capacitive pr oximity

probe. The NPN transistor output could be taken to one of the assignable digital inputs configured as a counter

or tachometer. Refer to Section 1.2: SPECIFICATIONS on page 1–5 for maximum current draw from the

+24 V DC switch supply.

DO NOT INJECT VOLTAGES TO DIGITAL INPUTS. DRY CONTACT CONNECTIONS ONLY.

CAUTION

GE Power Management 469 Motor Management Relay 2-13

Page 36

2.2 ELECTRICAL 2 INSTALLATION

2.2.9 ANALOG INPUTS

The 469 provides terminals for four 0 to 1mA, 0 to 20mA, or 4 to 20mA current input signals (field programmable). This current sig nal can be used to monitor exter nal quantities such as v ibration, pressure, or flow. T he

four inputs share one common return. Polarity of these inputs must be observed for proper operation The analog input circuitry is is olated as a group with the analog output circuitry and the RTD circuitry. Only one ground

reference should be u sed for the three c ircuits. Transorbs limit th is isolation to ±36 V with respec t to the 469

2

safety ground.

In addition, the +24 V DC analo g input supply is brought o ut for control power of loop power ed transducers.

Refer to Section 1.2: SPECIFICATIONS on page 1–5 for maximum current draw from this supply.

Figure 2–17: LOOP POWERED TRANSDUCER CONNECTION

2.2.10 ANALOG OUTPUTS

The 469 provides 4 analog outp ut channels whi ch may be ordered to prov ide a full-sc ale range of e ither 0 to

1 mA (into a maximum 10 kΩ impedance) or 4 to 20 mA (into a maximum 1200Ω impedance). Each cha nnel

can be configured to provide full-scale output sensitivity for any range of any measured parameter.

As shown in Figure 2–10: TYPICAL WIRING DIAGRAM on page 2–8, these outputs share one common

return. Polarity of thes e outputs must be obs erved for proper o peration. Shie lded cable should b e used, with

only one end of the shield grounded, to minimize noise effects.

The analog output circuitry is isolated as a group with the Analog Input circuitry and the RTD circuitry. Only one