Page 1

Title page

ISO9001:2000

GE Consumer & Industrial

Multilin

MM200

Motor Management System

COMMUNICATIONS GUIDE

MM200 revision: 1.0x

Manual P/N: 1601-9033-A1

GE publication code: GEK-113402

Copyright © 2007 GE Multilin

GE Multilin

215 Anderson Avenue, Markham, Ontario

Canada L6E 1B3

Tel: (905) 294-6222 Fax: (905) 201-2098

Internet: http://www.GEmultilin.com

*1601-9033-A1*

E83849

LISTED

IND.CONT. EQ.

52TL

T

E

S

I

R

E

G

D

E

R

G

E

GE Multilin's Quality

Management System is

registered to ISO9001:2000

QMI # 005094

N

I

M

L

I

U

T

L

Page 2

© 2007 GE Multilin Incorporated. All rights reserved.

GE Multilin MM200 Motor Management System Communications Guide for revision 1.0x.

MM200 Motor Management System, EnerVista, EnerVista Launchpad, EnerVista MM200

Setup, and FlexLogic are registered trademarks of GE Multilin Inc.

The contents of this manual are the property of GE Multilin Inc. This documentation is

furnished on license and may not be reproduced in whole or in part without the permission

of GE Multilin. The content of this manual is for informational use only and is subject to

change without notice.

Part number: 1601-9033-A1 (December 2007)

Page 3

Table of Contents

Communications interfaces ........................................................................................1

RS485 interface (Modbus RTU) ....................................................................................2

Modbus Protocol ..............................................................................................................................................2

Electrical Interface .........................................................................................................................................2

Data Frame Format and Data Rate ....................................................................................................... 2

Data Packet Format ......................................................................................................................................2

Error Checking .................................................................................................................................................. 3

CRC-16 Algorithm ........................................................................................................................................... 3

Timing ...................................................................................................................................................................4

MM200 supported functions ..................................................................................................................... 4

Modbus Functions ..........................................................................................................................................4

Function Code 03H ........................................................................................................................................4

Function Code 04H ........................................................................................................................................5

Function Code 05H ........................................................................................................................................6

Function Code 06H ........................................................................................................................................7

Function Code 07H ........................................................................................................................................7

Function Code 08H ........................................................................................................................................8

Function Code 10H ........................................................................................................................................9

Performing Commands Using Function Code 10H .......................................................................10

Using the User Definable Memory Map .............................................................................................10

Error Responses ............................................................................................................................................11

Modbus memory map ............................................................................................................................... 11

Format codes ................................................................................................................................................. 20

Fieldbus interface 28

Profibus protocol (DP V0) .......................................................................................................................... 28

Profibus Output Data .................................................................................................................................... 8

Profibus DP-Diagnostics ............................................................................................................................28

Profibus Input Data ......................................................................................................................................29

DeviceNet protocol ...................................................................................................................................... 32

DeviceNet Communications ....................................................................................................................32

Identity Object (Class Code 01H) ...........................................................................................................33

Message Router (Class Code 02H) ........................................................................................................33

DeviceNet Object (Class Code 03H) ......................................................................................................33

DeviceNet Connection Object (Class Code 05H) ............................................................................34

I/O Data Polled Object (Class Code 64H) ............................................................................................35

DeviceNet Motor Data - Poll, Explicit Object (Class Code A0H) ...............................................36

DeviceNet - Explicit Motor Analog Data Object, Class Code B0H, Services ......................37

DeviceNet - Explicit Motor Object, Class Code B1H ......................................................................39

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE i

Page 4

ii MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 5

GE Consumer & Industrial

NOT

NOT

Multilin

MM200 Motor Management System

Communications Guide

Communications Guide

Communications interfaces

The MM200 has two communications interfaces:

• RS485

•Fieldbus

NOTE:

NOTE:

Setpoint changes related to RS485, DeviceNet, and Profibus, require a power cycle to be

activated.

E

External power must be present on the Fieldbus port at power-up, in order to correctly

initialize.

E

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 1

Page 6

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

NOT

RS485 interface (Modbus RTU)

The RS485 interface is a serial two-wire port intended for use as a Modbus RTU slave. The

RS485 port has the following characteristics.

• Address: 1 to 254

• Baud rate: 9600 to 115200 bps

• Supported Modbus function codes: 3, 4, 5, 6, 7, 8, 16

Modbus Protocol

The MM200 implements a subset of the Modicon Modbus RTU serial communication

standard. The Modbus protocol is hardware-independent. That is, the physical layer can be

any of a variety of standard hardware configurations. This includes RS232, RS422, RS485,

fibre optics, etc. Modbus is a single master / multiple slave type of protocol suitable for a

multi-drop configuration as provided by RS485 hardware. The MM200 Modbus

implementation employs two-wire RS485 hardware. Using RS485, up to 32 MM200s can be

daisy-chained together on a single communication channel.

The MM200 is always a Modbus slave. It can not be programmed as a Modbus master.

Computers or PLCs are commonly programmed as masters.

Both monitoring and control are possible using read and write register commands. Other

commands are supported to provide additional functions.

Electrical Interface The hardware or electrical interface in the MM200 is two-wire RS485. In a two-wire link,

data is transmitted and received over the same two wires. Although RS485 two wire

communication is bi-directional, the data is never transmitted and received at the same

time. This means that the data flow is half duplex.

RS485 lines should be connected in a daisy chain configuration with terminating networks

installed at each end of the link (i.e. at the master end and at the slave farthest from the

master). The terminating network should consist of a 120 W resistor in series with a 1 nF

ceramic capacitor when used with Belden 9841 RS485 wire. Shielded wire should always

be used to minimize noise. The shield should be connected to all of the MM200s as well as

the master, then grounded at one location only. This keeps the ground potential at the

same level for all of the devices on the serial link.

NOTE:

Data Frame Format

and Data Rate

Polarity is important in RS485 communications. The '+' (positive) terminals of every device

must be connected together.

E

One data frame of an asynchronous transmission to or from a MM200 typically consists of

1 start bit, 8 data bits, and 1 stop bit. This produces a 10 bit data frame. This is important

for transmission through modems at high bit rates (11 bit data frames are not supported

by Hayes modems at bit rates of greater than 300 bps).

Modbus protocol can be implemented at any standard communication speed. The MM200

supports operation at 9600, 19200, 38400, 57600, and 115200 baud.

Data Packet Format A complete request/response sequence consists of the following bytes (transmitted as

separate data frames):

Master Request Transmission:

SLAVE ADDRESS: 1 byte

FUNCTION CODE: 1 byte

DATA: variable number of bytes depending on FUNCTION CODE

2 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 7

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

CRC: 2 bytes

Slave Response Transmission:

SLAVE ADDRESS: 1 byte

FUNCTION CODE: 1 byte

DATA: variable number of bytes depending on FUNCTION CODE

CRC: 2 bytes

SLAVE ADDRESS: This is the first byte of every transmission. This byte represents the userassigned address of the slave device that is to receive the message sent by the master.

Each slave device must be assigned a unique address and only the addressed slave will

respond to a transmission that starts with its address. In a master request transmission the

SLAVE ADDRESS represents the address of the slave to which the request is being sent. In a

slave response transmission the SLAVE ADDRESS represents the address of the slave that

is sending the response.

FUNCTION CODE: This is the second byte of every transmission. Modbus defines function

codes of 1 to 127.

DATA: This will be a variable number of bytes depending on the FUNCTION CODE. This may

be Actual Values, Setpoints, or addresses sent by the master to the slave or by the slave to

the master.

CRC: This is a two byte error checking code.

Error Checking The RTU version of Modbus includes a two byte CRC-16 (16 bit cyclic redundancy check)

with every transmission. The CRC-16 algorithm essentially treats the entire data stream

(data bits only; start, stop and parity ignored) as one continuous binary number. This

number is first shifted left 16 bits and then divided by a characteristic polynomial

(11000000000000101B). The 16 bit remainder of the division is appended to the end of the

transmission, MSByte first. The resulting message including CRC, when divided by the

same polynomial at the receiver will give a zero remainder if no transmission errors have

occurred.

If a MM200 Modbus slave device receives a transmission in which an error is indicated by

the CRC-16 calculation, the slave device will not respond to the transmission. A CRC-16

error indicates than one or more bytes of the transmission were received incorrectly and

thus the entire transmission should be ignored in order to avoid the MM200 performing

any incorrect operation.

The CRC-16 calculation is an industry standard method used for error detection. An

algorithm is included here to assist programmers in situations where no standard CRC-16

calculation routines are available.

CRC-16 Algorithm Once the following algorithm is complete, the working register “A” will contain the CRC

value to be transmitted. Note that this algorithm requires the characteristic polynomial to

be reverse bit ordered. The MSBit of the characteristic polynomial is dropped since it does

not affect the value of the remainder. The following symbols are used in the algorithm:

—>: data transfer

A: 16 bit working register

AL: low order byte of A

AH: high order byte of A

CRC: 16 bit CRC-16 value

i, j: loop counters

(+): logical exclusive or operator

Di: i-th data byte (i = 0 to N-1)

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 3

Page 8

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

G: 16 bit characteristic polynomial = 1010000000000001 with MSbit dropped and bit order

reversed

shr(x): shift right (the LSbit of the low order byte of x shifts into a carry flag, a '0' is shifted

into the MSbit of the high order byte of x, all other bits shift right one location

The algorithm is:

1. FFFF hex —> A

2. 0 —> i

3. 0 —> j

4. Di (+) AL —> AL

5. j+1 —> j

6. shr(A)

7. is there a carry? No: go to 8. Yes: G (+) A —> A

8. is j = 8? No: go to 5. Yes: go to 9.

9. i+1 —> i

10. is i = N? No: go to 3. Yes: go to 11.

11. A —> CRC

Timing Data packet synchronization is maintained by timing constraints. The receiving device

must measure the time between the reception of characters. If 3.5 character times elapse

without a new character or completion of the packet, then the communication link must

be reset (i.e. all slaves start listening for a new transmission from the master). Thus at 9600

baud a delay of greater than 3.5 x 1 / 9600 x 10 x = x 3.65 x ms will cause the

communication link to be reset.

MM200 supported

functions

The following functions are supported by the MM200:

• FUNCTION CODE 03 - Read Setpoints and Actual Values

• FUNCTION CODE 04 - Read Setpoints and Actual Values

• FUNCTION CODE 05 - Execute Operation

• FUNCTION CODE 06 - Store Single Setpoint

• FUNCTION CODE 07 - Read Device Status

• FUNCTION CODE 08 - Loopback Test

• FUNCTION CODE 10 - Store Multiple Setpoints

Modbus Functions

Function Code 03H Modbus implementation: Read Holding Registers

MM200 implementation: Read Setpoints

For the MM200 implementation of Modbus, this function code can be used to read any

setpoints (“holding registers”). Holding registers are 16 bit (two byte) values transmitted

high order byte first . Thus all MM200 Setpoints are sent as two bytes. The maximum

number of registers that can be read in one transmission is 125.

The slave response to this function code is the slave address, function code, a count of the

number of data bytes to follow, the data itself and the CRC. Each data item is sent as a two

byte number with the high order byte sent first.

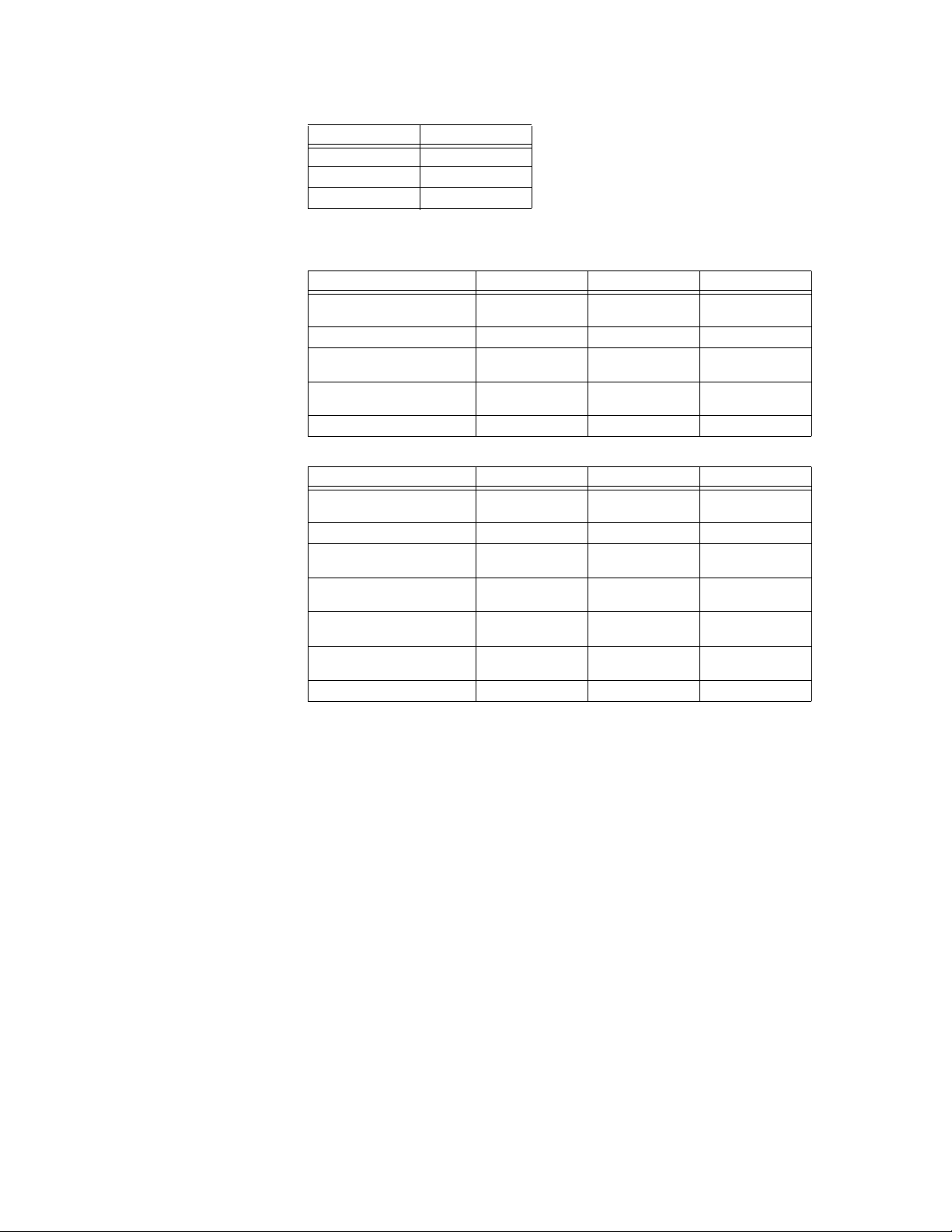

For example, consider a request for slave 17 to respond with 3 registers starting at address

006B. For this example the register data in these addresses is as follows:

4 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 9

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Address Data

006B 022B

006C 0000

006D 0064

The master/slave packets have the following format:

Table 1: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 03H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 03 read registers

DATA STARTING ADDRESS 2 00 6B data starting at

NUMBER OF SETPOINTS 2 00 03 3 registers = 6

CRC 2 76 87 CRC error code

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 03 read registers

BYTE COUNT 1 06 3 registers = 6

DATA 1 (see definition above) 2 02 2B value in address

DATA 2 (see definition above) 2 00 00 value in address

DATA 3 (see definition above) 2 00 64 value in address

CRC 2 54 83 CRC error code

17

006B

bytes total

slave 17

bytes

006B

006C

006D

Function Code 04H Modbus Implementation: Read Input Registers

MM200 implementation: Read Actual Values

For the MM200 implementation of Modbus, this function code can be used to read any

actual values (“input registers”). Input registers are 16 bit (two byte) values transmitted high

order byte first . Thus all MM200 Actual Values are sent as two bytes. The maximum

number of registers that can be read in one transmission is 125.

The slave response to this function code is the slave address, function code, a count of the

data bytes to follow, the data itself and the CRC. Each data item is sent as a two byte

number with the high order byte sent first .

For example, request slave 17 to respond with 1 register starting at address 0008. For this

example the value in this register (0008) is 0000.

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 5

Page 10

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Table 2: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 04H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 04 read registers

DATA STARTING ADDRESS 2 00 08 data starting at

NUMBER OF ACTUAL VALUES 2 00 01 1 register = 2 bytes

CRC 2 B2 98 CRC error code

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 04 read registers

BYTE COUNT 1 02 1 register = 2 bytes

DATA (see definition above) 2 00 00 value in address

CRC 2 78 F3 CRC error code

17

0008

slave 17

0008

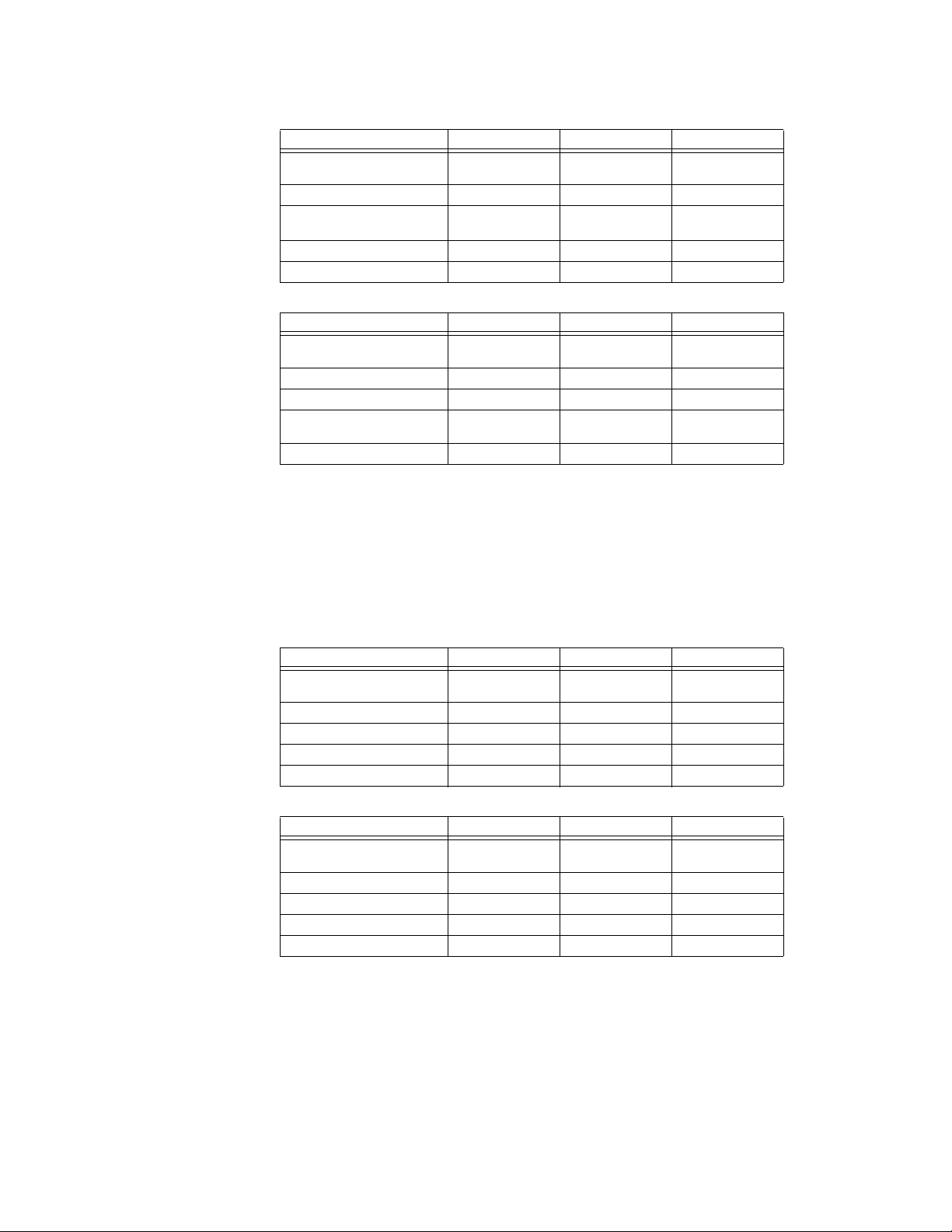

Function Code 05H Modbus Implementation: Force Single Coil

MM200 Implementation: Execute Operation

This function code allows the master to request a MM200 to perform specific command

operations.

For example, to request slave 17 to execute operation code 1 (reset), we have the following

master/slave packet format:

Table 3: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 05H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 05 execute operation

OPERATION CODE 2 00 01 operation code 1

CODE VALUE 2 FF 00 perform function

CRC 2 DF 6A CRC error code

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 05 execute operation

OPERATION CODE 2 00 01 operation code 1

CODE VALUE 2 FF 00 perform function

CRC 2 DF 6A CRC error code

17

slave 17

The commands that can be performed by the MM200 using function code 05 can also be

initiated by using function code 16.

6 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 11

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

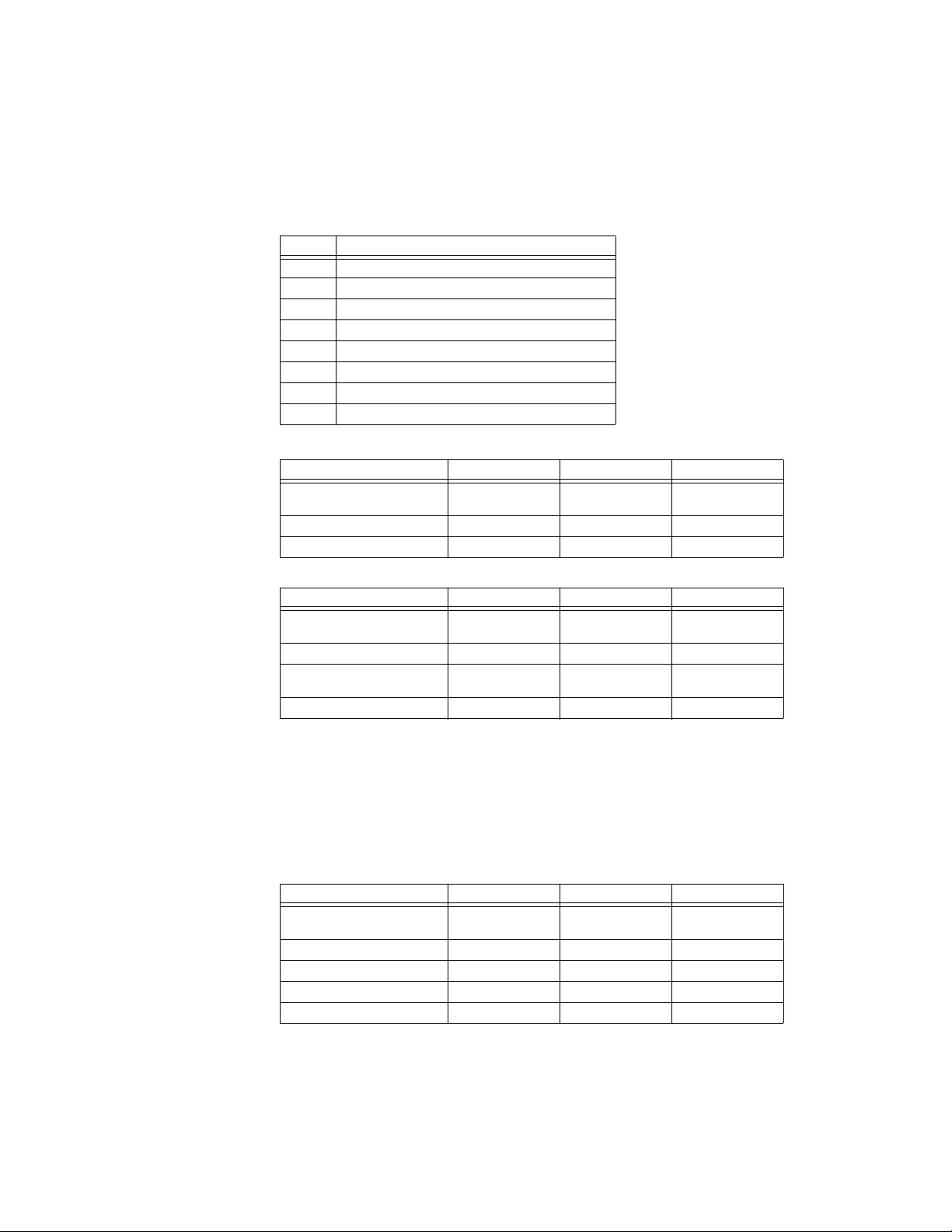

Operation Code Description

1Reset

2Lockout Reset

3Stop

4Start A

5Start B

96 Clear Last Trip Data Prompt

99 Clear Counters

113 Reset Motor Information

114 Auto Mode

115 Manual Mode

116 Manual Inhibit

117 Manual Restore

Function Code 06H Modbus Implementation: Preset Single Register

MM200 Implementation: Store Single Setpoint

This command allows the master to store a single setpoint into the memory of a MM200

The slave response to this function code is to echo the entire master transmission.

For example, request slave 17 to store the value 2 in setpoint address 04 5C. After the

transmission in this example is complete, setpoints address 04 5C will contain the value

01F4. The master/slave packet format is shown below:

Table 4: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 06H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 06 store single

DATA STARTING ADDRESS 2 04 5C setpoint address

DATA 2 00 02 data for setpoint

CRC 2 CB B9 CRC error code

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 06 store single

DATA STARTING ADDRESS 2 04 5C setpoint address

DATA 2 00 02 data stored in

CRC 2 CB B9 CRC error code

Function Code 07H Modbus Implementation: Read Exception Status

MM200 Implementation: Read Device Status

17

setpoint

04 5C

address 04 5C

slave 17

setpoint

04 5C

setpoint address

04 5C

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 7

Page 12

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

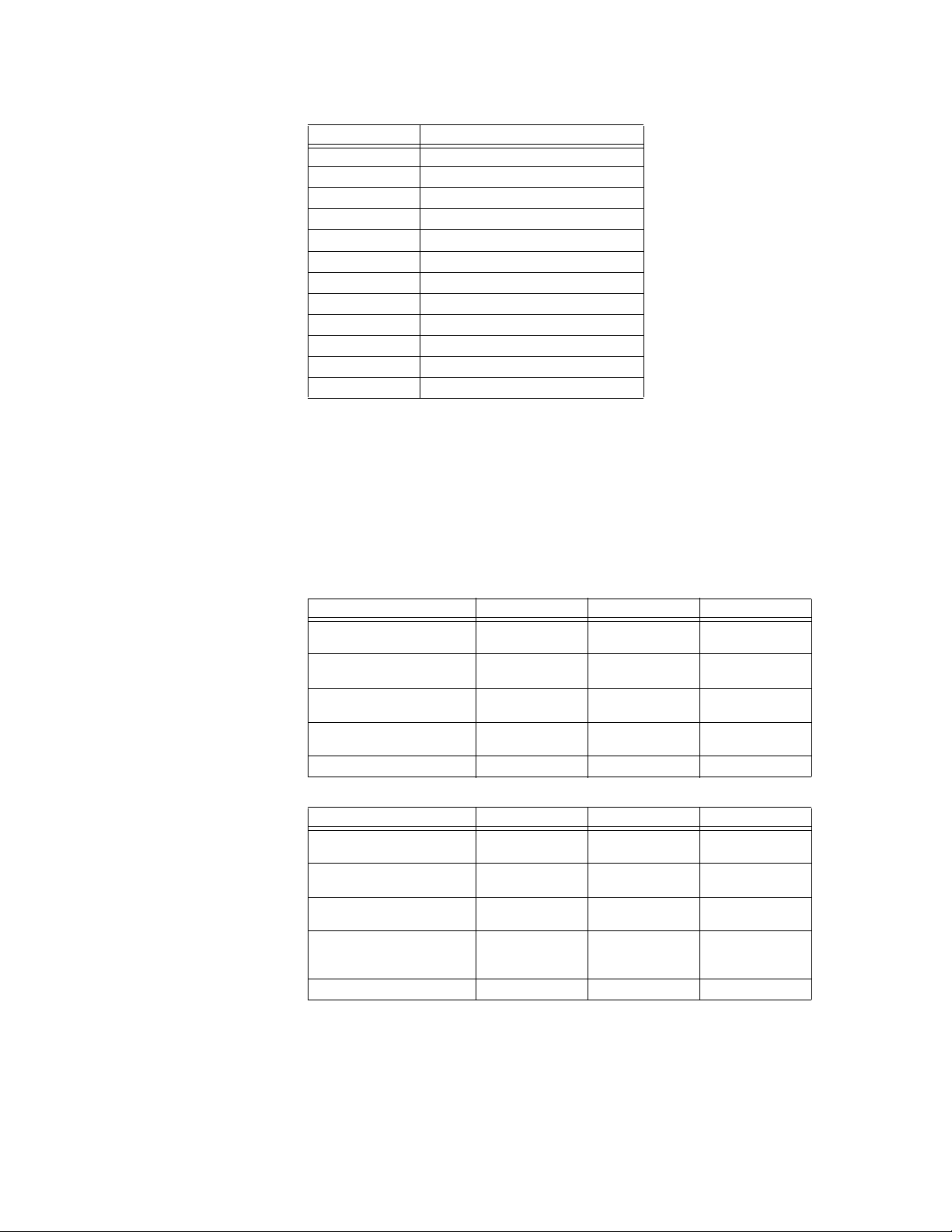

This is a function used to quickly read the status of a selected device. A short message

length allows for rapid reading of status. The status byte returned will have individual bits

set to 1 or 0 depending on the status of the slave device. For this example, consider the

following MM200 general status byte:

The master/slave packets have the following format:

Table 5: Function code 7 bitmask

Bit Function

0Alarm

1Trip

2 Internal fault

3Auto

4 Contactor A

5 Contactor B

6 Contact output 3

7 Drive available (communications control)

Table 6: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 07H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 07 read device status

CRC 2 4C 22 CRC error code

17

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 07 read device status

DEVICE STATUS (see

definition above)

CRC 2 22 28 CRC error code

1 2C status = 00101100

Function Code 08H Modbus Implementation: Loopback

Test MM200 Implementation: Loopback Test

This function is used to test the integrity of the communication link. The MM200 will echo

the request.

For example, consider a loopback test from slave 17:

Table 7: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 08H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 08 loopback test

DIAG CODE 2 00 00 must be 00 00

DATA 2 00 00 must be 00 00

CRC 2 E0 0B CRC error code

slave 17

(in binary)

17

8 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 13

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 08 loopback test

DIAG CODE 2 00 00 must be 00 00

DATA 2 00 00 must be 00 00

CRC 2 E0 0B CRC error code

slave 17

Function Code 10H Modbus Implementation: Preset Multiple Registers

MM200 Implementation: Store Multiple Setpoints

This function code allows multiple Setpoints to be stored into the MM200 memory. Modbus

“registers” are 16-bit (two byte) values transmitted high order byte first. Thus all MM200

setpoints are sent as two bytes. The maximum number of Setpoints that can be stored in

one transmission is dependent on the slave device. Modbus allows up to a maximum of 60

holding registers to be stored. The MM200 response to this function code is to echo the

slave address, function code, starting address, the number of Setpoints stored, and the

CRC.

For example, consider a request for slave 17 to store the value 00 02 to setpoint address

04 5C and the value 01 F4 to setpoint address 04 5D. After the transmission in this example

is complete, MM200 slave 17 will have the following setpoints information stored:

Address Data

04 5C 00 02

04 5D 01 F4

The master/slave packets have the following format:

Table 8: MASTER/SLAVE PACKET FORMAT FOR FUNCTION CODE 10H

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

FUNCTION CODE 1 10 store setpoints

DATA STARTING ADDRESS 2 04 5C setpoint address

NUMBER OF SETPOINTS 2 00 02 2 setpoints = 4

BYTE COUNT 1 04 4 bytes of data

DATA 1 2 00 02 data for setpoint

DATA 2 2 01 F4 data for setpoint

CRC 2 31 11 CRC error code

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

FUNCTION CODE 1 10 store setpoints

DATA STARTING ADDRESS 2 04 5C setpoint address

NUMBER OF SETPOINTS 2 00 02 2 setpoints

CRC 2 82 7A CRC error code

17

04 5C

bytes total

address 04 5C

address 04 5D

slave 17

04 5C

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 9

Page 14

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Performing

Commands Using

Function Code 10H

Commands can be performed using function code 16 as well as function code 5. When

using FUNCTION CODE 16, the Command Function register must be written with a value of

5. The Command Operation register must be written with a valid command operation

number. The Command Data registers must be written with valid data; this is dependent

upon the command operation.

For example, consider a request for slave 17 to perform command operation 1 (RESET): The

master/slave packets have the following format:

Table 9: MASTER/SLAVE PACKET FORMAT FOR PERFORMING COMMANDS

MASTER TRANSMISSION BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message for slave

17

FUNCTION CODE 1 10 store multiple

setpoints

DATA STARTING ADDRESS 2 00 80 setpoint address

00 80

NUMBER OF SETPOINTS 2 00 02 2 setpoints = 4

bytes total

BYTE COUNT 1 04 4 bytes of data

DATA 1 2 00 05 data for address

00 80

DATA 2 2 00 01 data for address

00 81

CRC 2 7E CE CRC error code

Using the User

Definable Memory

Map

SLAVE RESPONSE BYTES EXAMPLE DESCRIPTION

SLAVE ADDRESS 1 11 message from

slave 17

FUNCTION CODE 1 10 store multiple

setpoints

DATA STARTING ADDRESS 2 00 80 setpoint address

00 80

NUMBER OF SETPOINTS 2 00 02 2 setpoints

CRC 2 42 B0 CRC error code

The MM200 contains a User Definable area in the memory map. This area allows remapping of the addresses of any Actual Values or Setpoints registers. The User Definable

area has two sections:

1. A Register Index area (memory map addresses 020BH-0287H) that contains 125

Actual Values or Setpoints register addresses.

2. A Register area (memory map addresses 020BH-0287H) that contains the data at the

addresses in the Register Index.

Register data that is separated in the rest of the memory map may be re-mapped to

adjacent register addresses in the User Definable Registers area. This is accomplished by

writing to register addresses in the User Definable Register Index area. This allows for

improved throughput of data and can eliminate the need for multiple read command

sequences. The User Definable Register Index is stored as a setpoint and therefore it is

“remembered” even when the power is removed.

For example, if the values of MOTOR LOAD (register address 014FH; modbus address

30336) and DRIVE STATUS (register address 0135H; modbus address 30310) are required to

be read from a MM200, their addresses may be re-mapped as follows:

1. Write 30336 to address 020BH (40524) (User Definable Register Index 0000) using

function code 06 or 16.

10 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 15

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

2. Write 30310 to address 020CH (40525) (User Definable Register Index 0001) using

function code 06 or 16.

The MM200PC software can be used to write these locations to the User Definable Register

Index using the Setpoints > Modbus Memory Map > User Map screen.

It is now possible to read these two data registers with one read, at addresses 020BH,

020CH. Address 020BH will contain MOTOR LOAD. Address 020CH will contain DRIVE

STATUS.

Error Responses When a MM200 detects an error other than a CRC error, a response will be sent to the

master. The MSBit of the FUNCTION CODE byte will be set to 1 (i.e. the function code sent

from the slave will be equal to the function code sent from the master plus 128). The

following byte will be an exception code indicating the type of error that occurred.

Transmissions received from the master with CRC errors will be ignored by the MM200.

The slave response to an error (other than CRC error) will be:

SLAVE ADDRESS: 1 byte

FUNCTION CODE: 1 byte (with MSbit set to 1)

EXCEPTION CODE: 1 byte

CRC: 2 bytes

The MM200 implements the following exception response codes:

01 - ILLEGAL FUNCTION

The function code transmitted is not one of the functions supported by the MM200.

02 - ILLEGAL DATA ADDRESS

The address referenced in the data field transmitted by the master is not an allowable

address for the MM200.

03 - ILLEGAL DATA VALUE

The value referenced in the data field transmitted by the master is not within range for the

selected data address.

Modbus memory map

Modbus Hex Description Min Max Step Units Format Default Size in

ACTUAL VALUES

PRODUCT INFORMATION

30001 0000 Product Device Code --- --- --- --- F22 N/A 1

30002 0001 Hardware Revision --- --- --- --- F15 N/A 1

30003 0002 Firmware Version --- --- --- --- F3 N/A 1

30004 0003 Reserved --- --- --- --- --- --- 1

30005 0004 Modification Number --- --- --- --- F1 N/A 1

30006 0005 Boot Version --- --- --- --- F3 N/A 1

30007 0006 Reserved --- --- --- --- --- --- 1

30008 0007 Serial Number --- --- --- --- F22 N/A 6

30014 000D Order Code --- --- --- --- F22 N/A 16

30036 0023 Reserved --- --- --- --- --- --- 1

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 11

Words

Page 16

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Modbus Hex Description Min Max Step Units Format Default Size in

30037 0024 Build Date --- --- --- --- F22 N/A 6

30043 002A Build Time --- --- --- --- F22 N/A 4

30047 002E Original Calibration Date --- --- --- --- F18 N/A 2

30049 0030 Last Calibration Date --- --- --- --- F18 N/A 2

30051 0032 Reserved --- --- --- --- --- --- 6

▼▼▼ ▼▼ ▼▼▼▼ ▼

30185 00B8 Reserved 1

LAST TRIP DATA

30186 00B9 Cause of Last Trip --- --- --- --- FC134 N/A 1

30187 00BA Reserved --- --- --- --- --- --- 2

30189 00BC Reserved --- --- --- --- --- --- 2

30191 00BE Reserved --- --- --- --- --- --- 1

30192 00BF Pre Trip Ia --- --- --- A F10 N/A 2

30194 00C1 Pre Trip Ib --- --- --- A F10 N/A 2

30196 00C3 Pre Trip Ic --- --- --- A F10 N/A 2

30198 00C5 Reserved --- --- --- --- --- --- 1

30199 00C6 Reserved --- --- --- --- --- --- 1

30200 00C7 Reserved --- --- --- --- --- --- 1

30201 00C8 Pre Trip Motor Load --- --- --- % F1 N/A 1

30202 00C9 Pre Trip Current Unbalance --- --- --- % F1 N/A 1

30203 00CA Pre Trip Ig --- --- --- A F10 N/A 2

30205 00CC Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30229 00E4 Reserved --- --- --- --- --- --- 1

TRIP COUNTERS

30230 00E5 Total Number of Trips --- --- --- --- F1 N/A 1

30231 00E6 Reserved --- --- --- --- --- --- 1

30232 00E7 Overload Trips --- --- --- --- F1 N/A 1

30233 00E8 Mechanical Jam Trips --- --- --- --- F1 N/A 1

30234 00E9 Undercurrent Trips --- --- --- --- F1 N/A 1

30235 00EA Current Unbalance Trips --- --- --- --- F1 N/A 1

30236 00EB Ground Fault Trips --- --- --- --- F1 N/A 1

30237 00EC Motor Acceleration Trips --- --- --- --- F1 N/A 1

30238 00ED Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30256 00FF Reserved --- --- --- --- --- --- 1

GENERAL TIMERS

30257 0100 Number of Motor Starts --- --- --- --- F1 N/A 1

30258 0101 Reserved --- --- --- --- --- --- 1

30259 0102 Motor Running Hours --- --- --- hrs F9 N/A 2

30261 0104 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30269 010C Reserved --- --- --- --- --- --- 1

START BLOCKS

30270 010D Overload Lockout --- --- --- --- F1 N/A 1

30271 010E Reserved --- --- --- --- --- --- 1

Words

12 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 17

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Modbus Hex Description Min Max Step Units Format Default Size in

30272 010F Reserved --- --- --- --- --- --- 1

30273 0110 Restart Block --- --- --- s F1 N/A 1

30274 0111 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30282 0119 Reserved --- --- --- --- --- --- 1

CONTACT/VIRTUAL INPUTS/OUTPUTS STATUS

30283 011A Reserved --- --- --- --- --- --- 2

30285 011C Contact Input 7-1 (Bit Field) --- --- --- --- FC167 N/A 2

30287 011E Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30297 0128 Reserved --- --- --- --- --- --- 1

30298 0129 Contact Output 3-1 (Bit Field) --- --- --- --- FC167 N/A 2

30300 012B Reserved --- --- --- --- --- --- 1

30301 012C Reserved --- --- --- --- --- --- 1

SECURITY

30302 012D Current Security Access Level --- --- --- --- F1 N/A 1

30303 012E Reserved --- --- --- --- --- --- 1

30304 012F Reserved --- --- --- --- --- --- 1

STATUS - MOTOR

30305 0130 Motor Status --- --- --- --- FC129 N/A 1

30306 0131 Extended Status --- --- --- --- FC178 N/A 1

30307 0132 Thermal Cap Used --- --- --- % F1 N/A 1

30308 0133 Time to Overload Trip --- --- --- s F20 N/A 2

30310 0135 Drive Status --- --- --- --- FC143 N/A 1

30311 0136 Reserved --- --- --- --- --- --- 1

30312 0137 Command Status --- --- --- --- FC128 N/A 1

30313 0138 Reserved --- --- --- --- --- --- 1

30314 0139 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30327 0146 Reserved 1

CURRENT METERING

30328 0147 Ia --- --- --- A F10 N/A 2

30330 0149 Ib --- --- --- A F10 N/A 2

30332 014B Ic --- --- --- A F10 N/A 2

30334 014D Iavg --- --- --- A F10 N/A 2

30336 014F Motor Load --- --- --- % F1 N/A 1

30337 0150 Current Unbalance --- --- --- %Ub F1 N/A 1

30338 0151 Ig --- --- --- A F10 N/A 2

30340 0153 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30434 01B1 Reserved --- --- --- --- --- --- 1

TEMPERATURE METERING

30435 01B2 Thermistor --- --- --- ohms F1 N/A 1

30436 01B3 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30466 01D1 Reserved 1

Words

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 13

Page 18

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Modbus Hex Description Min Max Step Units Format Default Size in

MOTOR STARTING LEARNED DATA

30467 01D2 Learned Acceleration Time --- --- --- s F2 N/A 1

30468 01D3 Learned Starting Current --- --- --- A F10 N/A 2

30470 01D5 Learned Starting Capacity --- --- --- % F1 N/A 1

30471 01D6 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30504 01F7 Reserved --- --- --- --- --- --- 1

LED STATUS FOR GRAPHICAL AND BASIC CONTROL PANEL

30505 01F8 LED Status --- --- --- --- FC144 N/A 2

30507 01FA Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30523 020A Reserved --- --- --- --- --- --- 1

USER MAP VALUES

30524 020B User Map Value 1 --- --- --- --- F1 N/A 1

30525 020C User Map Value 2 --- --- --- --- F1 N/A 1

30526 020D User Map Value 3 --- --- --- --- F1 N/A 1

30527 020E User Map Value 4 --- --- --- --- F1 N/A 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30645 0284 User Map Value 122 --- --- --- --- F1 N/A 1

30646 0285 User Map Value 123 --- --- --- --- F1 N/A 1

30647 0286 User Map Value 124 --- --- --- --- F1 N/A 1

30648 0287 User Map Value 125 --- --- --- --- F1 N/A 1

30649 0288 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

30656 028F Reserved --- --- --- --- --- --- 1

SELF TEST

30657 0290 Internal Fault Cause --- --- --- --- FC188 N/A 2

30659 0292 Reserved --- --- --- --- --- --- 2

▼▼▼ ▼▼ ▼▼▼▼ ▼

30951 03B6 Reserved 1

STATUS BUFFER

30952 03B7 Reserved --- --- --- --- --- --- 2

30954 03B9 Reserved --- --- --- --- --- --- 2

30956 03BB Alarm Status 2 --- --- --- --- FC180 N/A 2

30958 03BD Alarm Status 1 --- --- --- --- FC179 N/A 2

30960 03BF Reserved --- --- --- --- --- --- 2

30962 03C1 Reserved --- --- --- --- --- --- 2

30964 03C3 Trip Status 2 --- --- --- --- FC184 N/A 2

30966 03C5 Trip Status 1 --- --- --- --- FC183 N/A 2

30968 03C7 Reserved --- --- --- --- --- --- 2

▼▼▼ ▼▼ ▼▼▼▼ ▼

30978 03D1 Reserved --- --- --- --- --- --- 2

30980 03D3 Ctrl Element Status 2 --- --- --- --- FC192 N/A 2

30982 03D5 Ctrl Element Status 1 --- --- --- --- FC191 N/A 2

30984 03D7 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

Words

14 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 19

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Modbus Hex Description Min Max Step Units Format Default Size in

31377 0560 Reserved --- --- --- --- --- --- 1

COMMUNICATION

31378 0561 Serial Status --- --- --- --- FC112 N/A 1

31379 0562 Reserved --- --- --- --- --- --- 1

31380 0563 Profibus Status --- --- --- --- FC112 N/A 1

31381 0564 DeviceNet Status --- --- --- --- FC112 N/A 1

31382 0565 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

32272 08DF Reserved 1

SETPOINTS

COMMANDS

40001 0000 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40128 007F Reserved 1

40129 0080 Command address 0 65535 0 --- F1 0 1

40130 0081 Command Function 0 65535 0 --- F1 0 1

40131 0082 Command Data 1 0 65535 0 --- F1 0 1

40132 0083 Command Data 2 0 65535 0 --- F1 0 1

40133 0084 Command Data 3 0 65535 0 --- F1 0 1

40134 0085 Command Data 4 0 65535 0 --- F1 0 1

40135 0086 Command Data 5 0 65535 0 --- F1 0 1

40136 0087 Command Data 6 0 65535 0 --- F1 0 1

40137 0088 Command Data 7 0 65535 0 --- F1 0 1

40138 0089 Command Data 8 0 65535 0 --- F1 0 1

40139 008A Command Data 9 0 65535 0 --- F1 0 1

40140 008B Command Data 10 0 65535 0 --- F1 0 1

40141 008C Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40171 00AA Reserved 1

COMMUNICATION SETTINGS

40172 00AB Slave Address 1 254 1 --- F1 254 1

40173 00AC RS485 Baud Rate 0 4 1 --- FC101 4 1

40174 00AD Reserved --- --- --- --- --- --- 1

40175 00AE Reserved --- --- --- --- --- --- 1

40176 00AF Reserved --- --- --- --- --- --- 1

40177 00B0 Reserved --- --- --- --- --- --- 1

40178 00B1 DeviceNet MAC ID 0 63 1 --- F1 63 1

40179 00B2 DeviceNet Baud Rate 0 2 1 --- FC156 0 1

40180 00B3 Reserved --- --- --- --- --- --- 1

40181 00B4 Reserved --- --- --- --- --- --- 2

▼▼▼ ▼▼ ▼▼▼▼ ▼

40191 00BE Reserved --- --- --- --- --- --- 1

40192 00BF Profibus address 1 125 1 --- F1 125 1

40193 00C0 Profibus Baud Rate 1 2018 1 --- FC155 2018 1

Words

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 15

Page 20

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Modbus Hex Description Min Max Step Units Format Default Size in

40194 00C1 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40265 0108 Reserved --- --- --- --- --- --- 1

CURRENT SENSING

40266 0109 Phase CT Type 0 3 1 --- FC105 0 1

40267 010A CT Primary 5 1000 1 A F1 5 1

40268 010B Reserved --- --- --- --- --- --- 1

40269 010C High Speed CT Primary 5 1000 1 A F1 5 1

40270 010D Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40283 011A Reserved --- --- --- --- --- --- 1

MOTOR DATA SETUP

40284 011B Reserved --- --- --- --- --- --- 1

40285 011C Motor Name 0 10 0 --- F22 3 10

40295 0126 Starter Type 0 3 1 --- FC139 0 1

40296 0127 Reserved --- --- --- --- --- --- 1

40297 0128 Reserved --- --- --- --- --- --- 1

40298 0129 Motor FLA 5 10001 1 A F2* 10001 1

40299 012A High Speed FLA 5 10001 1 A F2* 10001 1

40300 012B Motor Nameplate Voltage 100 690 1 V F1 690 1

40301 012C Reserved --- --- --- --- --- --- 1

40302 012D Reserved --- --- --- --- --- --- 1

40303 012E Transfer T ime 0 125 1 s F1 1 1

40304 012F High Speed Start Block 0 1 1 --- FC126 1 1

40305 0130 Reserved --- --- --- --- --- --- 1

40306 0131 Reserved --- --- --- --- --- --- 1

40307 0132 Pre-contactor Time 0 60 1 s F1 0 1

40308 0133 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40516 0203 Reserved --- --- --- --- --- --- 1

COMMUNICATION SETUP

40517 0204 Comms OK Evaluation 0 64 1 --- FC131 1 1

40518 0205 Reserved --- --- --- --- --- --- 1

40519 0206 Comm Failure Trip 5 30 5 s F1* 30 1

40520 0207 Comm Failure Alarm 5 30 5 s F1* 30 1

OPEN CONTROL CIRCUIT

40521 0208 Open Ctrl Circuit Trip 0 1 1 --- FC126 0 1

40522 0209 Reserved --- --- --- --- --- --- 1

40523 020A Reserved --- --- --- --- --- --- 1

USER MAP ADDRESSES

40524 020B User Map Address 1 30001 43763 1 --- F1 30001 1

40525 020C User Map Address 2 30001 43763 1 --- F1 30001 1

40526 020D User Map Address 3 30001 43763 1 --- F1 30001 1

40527 020E User Map Address 4 30001 43763 1 --- F1 30001 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40645 0284 User Map Address 122 30001 43763 1 --- F1 30001 1

Words

16 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 21

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Modbus Hex Description Min Max Step Units Format Default Size in

40646 0285 User Map Address 123 30001 43763 1 --- F1 30001 1

40647 0286 User Map Address 124 30001 43763 1 --- F1 30001 1

40648 0287 User Map Address 125 30001 43763 1 --- F1 30001 1

40649 0288 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40701 02BC Reserved --- --- --- --- --- --- 1

THERMAL MODEL SETUP

40702 02BD Overload Pickup Level 101 125 1 x FLA F3 101 1

40704 02BF Cool Time Constant Running 1 1000 1 min F1 15 1

40705 02C0 Cool Time Constant Stopped 1 1000 1 min F1 30 1

40706 02C1 Hot/Cold Safe Stall Ratio 1 100 1 % F1 75 1

40707 02C2 Reserved --- --- --- --- --- --- 1

40708 02C3 Standard Overload Curve 1 15 1 --- F1 4 1

40709 02C4 Reserved --- --- --- --- --- --- 1

40710 02C5 Reserved --- --- --- --- --- --- 1

40711 02C6 Reserved --- --- --- --- --- --- 1

40712 02C7 Reserved --- --- --- --- --- --- 1

40713 02C8 Minimize Reset Time --- 1 --- --- FC126 0 1

40714 02C9 Overload Reset Mode 0 1 --- --- FC160 1 1

40715 02CA Reserved --- --- --- --- --- --- 1

40716 02CB Reserved --- --- --- --- --- --- 1

40717 02CC Reserved --- --- --- --- --- --- 1

40718 02CD Reserved --- --- --- --- --- --- 1

MECHANICAL JAM

40719 02CE Mechanical Jam Level 101 451 1 x FLA F3* 451 1

40720 02CF Mechanical Jam Delay 1 300 1 s F2 1 1

40721 02D0 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40824 0337 Reserved --- --- --- --- --- --- 1

THERMISTOR (CPU)

40825 0338 Cold Resistance 1 300 1 k ohms F2 1 1

40826 0339 Hot Resistance 1 300 1 k ohms F2 50 1

40827 033A Thermistor Alarm 0 1 1 --- FC126 0 1

40828 033B Thermistor Trip 0 1 1 --- FC126 0 1

40829 033C Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40833 0340 Reserved --- --- --- --- --- --- 1

UNDERCURRENT (REQUIRED=IO_A)

40834 0341 Undercurrent Alarm Level 1 101 1 %FLA F1* 101 1

40835 0342 Undercurrent Alarm Delay 1 60 1 s F1 1 1

40836 0343 Undercurrent Trip Level 1 101 1 %FLA F1* 101 1

40837 0344 Undercurrent Trip Delay 1 60 1 s F1 1 1

40838 0345 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40850 0351 Reserved --- --- --- --- --- --- 1

Words

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 17

Page 22

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Modbus Hex Description Min Max Step Units Format Default Size in

ACCELERATION

40851 0352 Acceleration Alarm Timer 5 2501 1 s F2* 2501 1

40852 0353 Acceleration Trip Timer 5 2501 1 s F2* 2501 1

40853 0354 Reserved --- --- --- --- --- --- 1

40854 0355 Reserved --- --- --- --- --- --- 1

40855 0356 Reserved --- --- --- --- --- --- 1

40856 0357 Reserved --- --- --- --- --- --- 1

CURRENT UNBALANCE (REQUIRED=IO_A)

40857 0358 Current Unbalance Alarm Level 4 41 1 % F1* 15 1

40858 0359 Current Unbalance Alarm

Delay

40859 035A Current Unbalance Trip Level 4 41 1 % F1* 30 1

40860 035B Current Unbalance Trip Delay 1 60 1 s F1 1 1

40861 035C Reserved --- --- --- --- --- --- 1

40862 035D Reserved --- --- --- --- --- --- 1

40863 035E Reserved --- --- --- --- --- --- 1

40864 035F Reserved --- --- --- --- --- --- 1

GROUND FAULT

40865 0360 Reserved --- --- --- --- --- --- 1

40866 0361 CBCT Ground Alarm Level 5 151 1 A F2* 151 1

40867 0362 Ground Alarm Delay On Start 0 60 1 s F1 10 1

40868 0363 Reserved --- --- --- --- --- --- 1

40869 0364 CBCT Ground Trip Level 5 151 1 A F2* 151 1

40870 0365 Ground Trip Delay On Start 0 100 1 s F2 0 1

40871 0366 Ground Alarm Delay On Run 0 60 1 s F1 10 1

40872 0367 Ground Trip Delay On Run 0 50 1 s F2 0 1

40873 0368 Reserved --- --- --- --- --- --- 1

40874 0369 Reserved --- --- --- --- --- --- 1

LOAD INCREASE

40875 036A Load Increase Alarm Level 50 151 1 %FLA F1* 151 1

40876 036B Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

40911 038E Reserved --- --- --- --- --- --- 1

MAINTENANCE

40912 038F Drive Greasing Interval 100 50100 100 hrs F1* 50100 1

40913 0390 Contactor Inspection Interval 100 65000 100 ops F1* 65000 1

40914 0391 Max Motor Stopped T ime 10 10010 10 hrs F1* 10010 1

40915 0392 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41039 040E Reserved 1

CALIBRATION

41040 040F Calibration Date 0 203360302 1 --- F18 0 2

41042 0411 Calibration T ime 0 389757795 1 --- F19 0 2

41044 0413 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41105 0450 Reserved 1

160 1s F11 1

Words

18 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 23

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Modbus Hex Description Min Max Step Units Format Default Size in

SECURITY

41106 0451 Passcode Level 1 11111 55556 1 --- F1* 11111 1

41107 0452 Passcode Level 2 11111 55556 1 --- F1* 22222 1

41108 0453 Reserved --- --- --- --- --- --- 1

41109 0454 Access Switch Level 1 3 1 --- F1 1 1

41110 0455 Comms Security 0 1 1 --- FC126 0 1

41111 0456 MCC Setpoint Access 0 1 1 --- FC126 1 1

41112 0457 Passcode Entry 0 55555 1 --- F1 0 1

41113 0458 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41372 055B Reserved --- --- --- --- --- --- 1

CONTACT INPUT ASSIGNMENT

41373 055C Reserved --- --- --- --- --- --- 1

41374 055D Lockout Reset 0 57344 0 --- FC142 0 1

41375 055E Access Switch 0 57344 0 --- FC142 0 1

41376 055F Field Permissive 0 57344 0 --- FC142 0 1

41377 0560 Comms Permissive 0 57344 0 --- FC142 0 1

41378 0561 Forward Limit 0 57344 0 --- FC142 0 1

41379 0562 Reverse Limit 0 57344 0 --- FC142 0 1

41380 0563 Remote Reset 0 57344 0 --- FC142 0 1

41381 0564 MCC Permissive 0 57344 0 --- FC142 0 1

41382 0565 Hard Wired Start A 0 57344 0 --- FC142 0 1

41383 0566 Hard Wired Start B 0 57344 0 --- FC142 0 1

41384 0567 Hard Wired Stop 0 57344 0 --- FC142 0 1

41385 0568 Hard Wired Permissive 0 57344 0 --- FC142 0 1

41386 0569 Field Start A 0 57344 0 --- FC142 0 1

41387 056A Field Start B 0 57344 0 --- FC142 0 1

41388 056B Field Stop 0 57344 0 --- FC142 0 1

41389 056C Contactor Status A 0 57344 0 --- FC142 0 1

41390 056D Contactor Status B 0 57344 0 --- FC142 0 1

41391 056E Auto/Manual Switch 0 57344 0 --- FC142 0 1

41392 056F Reserved --- --- --- --- --- --- 1

41393 0570 Test Switch 0 57344 0 --- FC142 0 1

41394 0571 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41475 05C2 Reserved --- --- --- --- --- --- 1

LEDs

41476 05C3 Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41495 05D6 USER1 LED Assignment 0 57344 1 --- FC142 0 1

41496 05D7 USER1 LED Color 0 3 1 --- FC157 1 1

41497 05D8 USER2 LED Assignment 0 57344 1 --- FC142 0 1

41498 05D9 USER2 LED Color 0 3 1 --- FC157 1 1

41499 05DA Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41514 05E9 Reserved --- --- --- --- --- --- 1

Words

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 19

Page 24

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Modbus Hex Description Min Max Step Units Format Default Size in

CONTACT OUTPUTS

41515 05EA Contact Output 1 0 57344 0 --- FC142 0 1

41516 05EB Contact Output 2 0 57344 0 --- FC142 0 1

41517 05EC Contact Output 3 0 57344 0 --- FC142 0 1

41518 05ED Reserved --- --- --- --- --- --- 1

▼▼▼ ▼▼ ▼▼▼▼ ▼

41571 0622 Reserved --- --- --- --- --- --- 1

AUTO / MANUAL CONTROL

41572 0623 Comms Start Ctrl 0 1 1 --- FC126 0 1

41573 0624 Comms Stop Mode 0 1 1 --- FC172 0 1

41574 0625 Hard Wired Start Ctrl 0 1 1 --- FC126 0 1

41575 0626 Hard Wired Stop Mode 0 1 1 --- FC172 0 1

41576 0627 Hard Wired Stop Actn 0 1 1 --- FC174 0 1

41577 0628 Hard Wired 2W/3W 0 1 1 --- FC173 1 1

41578 0629 Field Start Ctrl 0 1 1 --- FC126 0 1

41579 062A Field Stop Mode 0 1 1 --- FC172 0 1

41580 062B Field Stop Action 0 1 1 --- FC174 0 1

41581 062C Field 2W/3W 0 1 1 --- FC173 1 1

41582 062D MCC Start Ctrl 0 1 1 --- FC126 0 1

41583 062E MCC Stop Mode 0 1 1 --- FC172 0 1

41584 062F MCC Stop Action 0 1 1 --- FC174 0 1

41585 0630 Test Auto Mode 0 2 1 --- FC175 1 1

41586 0631 Test Manual Mode 0 2 1 --- FC175 0 1

41587 0632 External Stop Action 0 1 1 --- FC174 0 1

41588 0633 Auto/Manual Key 0 1 1 --- FC126 0 1

Words

Format codes

Code Type Definition

F1 16 bits UNSIGNED VALUE

Example: 1234 stored as 1234

F2 16 bits UNSIGNED VALUE, 1 DECIMAL PLACE

Example: 123.4 stored as 1234

F3 16 bits UNSIGNED VALUE, 2 DECIMAL PLACES

Example: 12.34 stored as 1234

F9 32 bits UNSIGNED LONG VALUE

1st 16 bits High Order Word of Long Value

2nd 16 bits Low Order Word of Long Value

Example: 123456 stored as 123456

i.e. 1st word: 0001 hex, 2nd word: E240 hex

F10 32 bits UNSIGNED LONG VALUE, 1 DECIMAL PLACE

1st 16 bits UNSIGNED LONG VALUE, 1 DECIMAL PLACE

2nd 16 bits Low Order Word of Long Value

Example: 12345.6 stored as 123456

i.e. 1st word: 0001 hex, 2nd word: E240 hex

20 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 25

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Code Type Definition

F13 32 bits 2’s COMPLEMENT SIGNED LONG VALUE, 1 DECIMAL PLACE

1st 16 bits High Order Word of Long Value

2nd 16 bits Low Order Word of Long Value

Example: -12345.6 stored as -123456

i.e. 1st word: FFFE hex, 2nd word: 1DC0 hex

F15 16 bits HARDWARE REVISION

0Prototype

1A

2B

3C

4D

5E

6F

7G

8H

9I

10 J

11 K

12 L

13 M

14 N

15 O

16 P

17 Q

18 R

19 S

20 T

21 U

22 V

23 W

24 X

25 Y

26 Z

F17 32 bits UNSIGNED LONG VALUE, 3 DECIMAL PLACES

1st 16 bits High Order Word of Long Value

2nd 16 bits Low Order Word of Long Value

Example: 123456 stored as 123456

i.e. 1st word: 0001 hex, 2nd word: E240 hex

F20 32 bits 2’s COMPLEMENT SIGNED LONG VALUE

1st 16 bits High Order Word of Long Value

2nd 16 bits Low Order Word of Long Value

Note: -1 means “Never”

F22 16 bits TWO 8-BIT CHARACTERS PACKED INTO 16-BIT UNSIGNED

MSB First Character

LSB Second Character

Example: String ‘AB’ stored as 4142 hex

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 21

Page 26

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Code Type Definition

FC101 16 bits RS 485 Baud Rate

0 9600 baud

1 19200 baud

2 38400 baud

3 57600 baud

4 115200 baud

FC105 16 bits CT Type

0None

1 1 A Secondary

2 5 A Secondary

3 Direct Connect

FC107 16 bits Supply Frequency

060

150

FC112 16 bits Communication Status

0Error

1OK

FC126 16 bits Disabled / Enabled Selection

0Disabled

1 Enabled

FC128 16 bits Command Status

0Manual

1Auto

2 Manual Inhibit

3 Auto/ Manual

4Hardwired Auto

5None

FC129 16 bits Quick Status Status

Bit 0 Alarm

Bit 1 Trip

Bit 2 Self Test Fault

Bit 3 Auto

Bit 4 Contactor A

Bit 5 Contactor B

Bit 6 Contact Output 3

Bit 7 Drive Available

FC131 16 bits Comm Fail Mode

1 Serial

2Reserved

4 Serial & FieldBus

8Reserved

16 FieldBus

32 Reserved

64 All

FC134 16 bits Cause of Event

0No Event/Trip To Date

1 Control Power Lost

22 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 27

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Code Type Definition

2 Control Power Applied

3 Date or Time Set

4Reset

5Lockout Reset

0x8002 Any Trip

0x8042 Thermal O/L Trip

0x8082 Ground Fault Trip

0x80C2 Acceleration Trip

0x8202 Mechanical Jam Trip

0x8242 UnderCurrent Trip

0x8282 Unbalance Trip

0x8442 Comm Fail Trip

0x8742 Hard Wired Trip

0x8782 Field Trip

0x87C2 MCC Trip

0x8842 Emergency Stop

0x8902 Thermistor Trip

0xA002 Any Alarm

0xA042 Thermal Level Alarm

0xA082 Ground Fault Alarm

0xA0C2 Acceleration Alarm

0xA242 UnderCurrent Alarm

0xA282 Unbalance Alarm

0xA842 External Stop Alarm

0xA8C2 Open Ctrl Cct Alarm

0xA902 Thermistor Alarm

0xAB02 Load Increase Alarm

0XAB42 Drive Greasing Alarm

0xAB82 Contactor Inspect Alarm

0xABC2 Max Stopped Alarm

0xAC82 Comm Fail Alarm

0xC002 Any Stop

0xC082 AutoMode

0xC0C2 Manual Mode

0xC102 Auto/Manual Mode Input

0xC182 Contactor A

0xC1C2 Contactor B

0xC202 Forward Limit

0xC302 Level 1 Access

0xC342 Level 2 Access

0xC382 Level 3 Access

0xC3C2 Comms Ctrl Active

0xC402 Hard Wired Ctrl Active

0xC442 Field Ctrl Active

0xC482 MCC Ctrl Active

0xC742 HW Stop

0xC782 Field Stop

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 23

Page 28

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Code Type Definition

0xC7C2 MCC Stop

0xC802 Access Switch Closed

0xC842 Test Switch Closed

0xC882 Hard Wired Start A

0xC8C2 Hard Wired Start B

0xC902 Start A

0xC942 Start B

0xC982 Field Start A

0xC9C2 Field Start B

0xCA02 Contactor A Status

0xCA42 Contactor B Status

0xCA82 Remote Reset Closed

0xCAC2 Lockout Reset Closed

0xCB42 Pre-Contactor

0xCB82 MCC Start A

0xCBC2 MCC Start B

FC139 16 bits Starter Type

0None

1 FV Nonreversing

2FV Reversing

3Two Speed

FC142 16 bits Contact Input/Contact Output Element Assignment

0x0000 OFF

0x0001 ON

0x0040 Contact Inputs

0x8000 Trip

0xA000 Alarm

0xC000 Control

FC143 16 bits Drive Status

0 Drive Unavailable

1 Available Auto

2 Available Manual

3 Available

4 Running

FC144 32 bits LED Status

Bit 0 Running Red

Bit 1 Running Green

Bit 2 Stopped Red

Bit 3 Stopped Green

Bit 4 Tripped Red

Bit 5 Tripped Green

Bit 6 Alarm Red

Bit 7 Alarm Green

Bit 8 Auto Red

Bit 9 Auto Green

Bit 10 Manual Red

Bit 11 Manual Green

24 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 29

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Code Type Definition

Bit 12 Comms OK Red

Bit 13 Comms OK Green

Bit 14 USER1 Red

Bit 15 USER1 Green

Bit 16 USER2 Red

Bit 17 USER2 Green

Bit 20 50% Red

Bit 21 50% Green

Bit 22 80% Red

Bit 23 80% Green

Bit 24 100% Red

Bit 25 100% Green

FC155 16 bits Profibus Baud Rate

0x0001 9600

0x0002 19200

0x0004 31250

0x0008 45450

0x0010 93750

0x0020 187500

0x0040 500000

0x0080 1500000

FC156 16 bits DeviceNet Baud Rate

0 125 kbps

1 250 kbps

2 500 kbps

FC157 16 bits LED Colour

0None

1Red

2 Green

3Orange

FC160 16 bits Auto/Manual Mode

0Auto

1Manual

FC167 32 bits Contact Input/Output Status

Bit 0 Input/Output 1

Bit 1 Input/Output 2

Bit 2 Input/Output 3

Bit 3 Input/Output 4

Bit 4 Input/Output 5

Bit 5 Input/Output 6

Bit 6 Input/Output 7

FC172 16 bits Auto/Manual Control Stop Mode

0 Always Enabled

1Follow Ctrl Mode

FC173 16 bits Wire Selection

02W

13W

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 25

Page 30

RS485 INTERFACE (MODBUS RTU) COMMUNICATIONS GUIDE

Code Type Definition

FC174 16 bits Source Stop Action

0Stop

1Trip

FC175 16 bits Test Auto/Manual Mode

0ON

1OFF

2 Unaffected

FC178 16 bits Motor Status

Bit 0 Lockout

Bit 1 Non-Lockout Trip

Bit 4 Running

Bit 5 Precontactor

Bit 6 Starting

Bit 8 Inhibit

Bit 9 Stopped

Bit 10 Self Test Fault

Bit 11 Alarm

Bit 12 Forward

Bit 13 Reverse

Bit 14 Low Speed

Bit 15 High Speed

FC179 32 bits Alarm Status 1

Bit 0 Any Alarm

Bit 1 Thermal Level Alarm

Bit 2 Ground Fault Alarm

Bit 3 Acceleration Alarm

Bit 9 UnderCurrent Alarm

Bit 10 Unbalance Alarm

FC180 32 bits Alarm Status 2

Bit 0 Aux U/V Alarm

Bit 1 External Stop Alarm

Bit 3 Open Ctrl Cct Alarm

Bit 4 Thermistor Alarm

Bit 6 External Start A Alarm

Bit 7 External Start B Alarm

Bit 8 Welded Contactor

Bit 12 Load Increase Alarm

Bit 13 Drive Greasing Alarm

Bit 14 Contactor Inspect Alarm

Bit 15 Max Stopped Alarm

Bit 18 Comm Fail Alarm

FC183 32 bits Trip Status 1

Bit 0 Any Trip

Bit 1 Thermal O/L Trip

Bit 2 Ground Fault Trip

Bit 3 Acceleration Trip

Bit 8 Mechanical Jam Trip

26 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 31

COMMUNICATIONS GUIDE RS485 INTERFACE (MODBUS RTU)

Code Type Definition

Bit 9 UnderCurrent Trip

Bit 10 Unbalance Trip

Bit 29 Hard Wired Trip

Bit 30 Field Trip

Bit 31 MCC Trip

FC184 32 bits Trip Status 2

Bit 1 Emergency Stop

Bit 3 OpenControl Circuit

Bit 4 Thermistor Trip

FC191 32 bits Ctrl Element Status 1

Bit 0 Any Stop

Bit 1 Thermal Inhibit

Bit 2 AutoMode

Bit 3 Manual Mode

Bit 4 AutoManualMode

Bit 8 Forward Limit

Bit 9 Reverse Limit

Bit 15 Comms Ctrl Active

Bit 16 Hard Wired Ctrl Active

Bit 17 Field Ctrl Active

Bit 18 MCC Ctrl Active

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 27

Page 32

FIELDBUS INTERFACE COMMUNICATIONS GUIDE

Fieldbus interface

The fieldbus interface is configurable as either Profibus DPV0 or DeviceNet. Both Fieldbus

interfaces support control and status – refer to the specific data map below for details.

Note that external power, 5 to 24 VDC, is required for this interface to operate. (Ensure that

switches 7 and 8 of the DIPswitch on the communication card, are ON.)

Profibus protocol (DP V0)

To enable the Profibus physical interface, ensure that switches 3 and 4 of the DIP switch on

the communications card (on the CPU) are on. The external connections through the

Fieldbus interface are as follows.

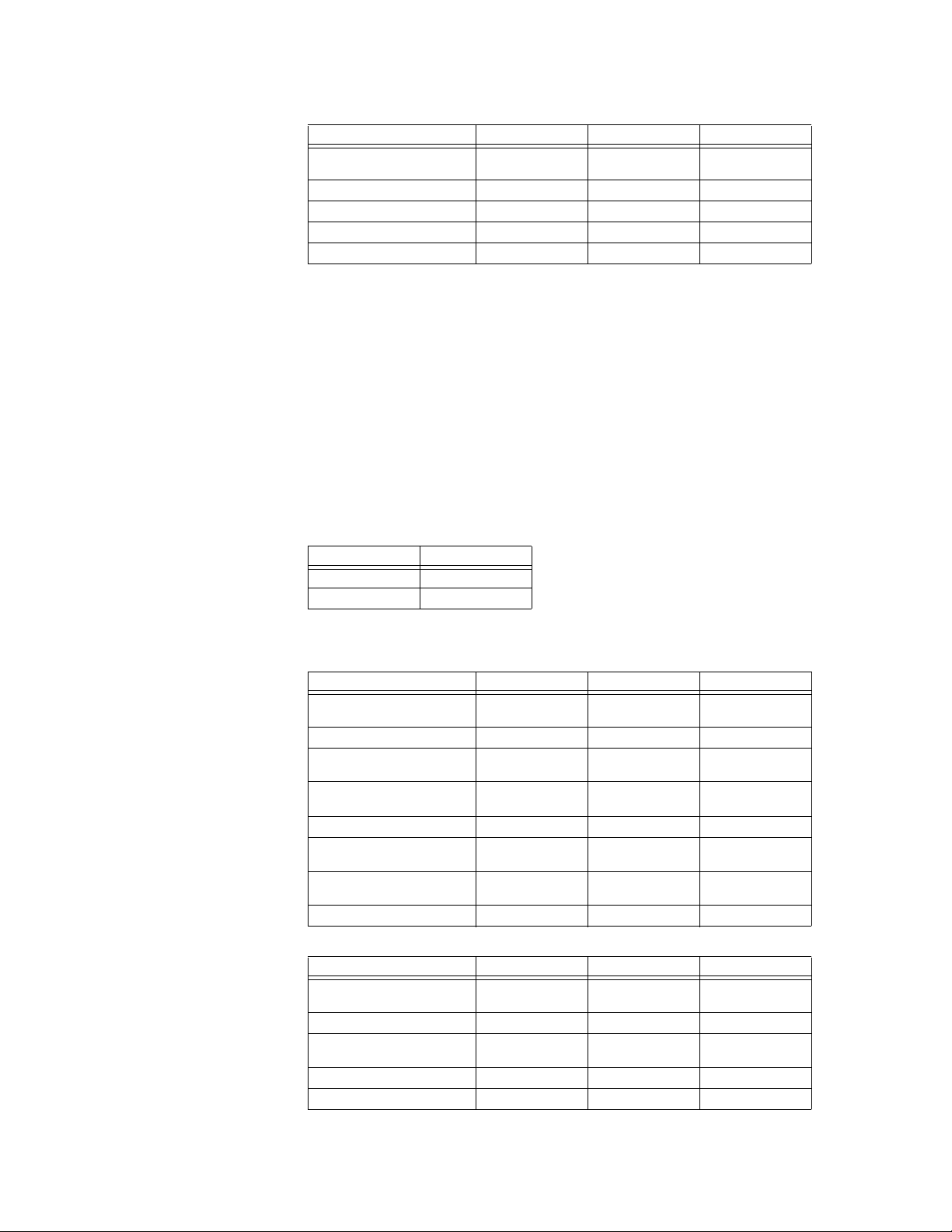

Table 10: Fieldbus interface external connections (Profibus)

Pin Connection (external device)

V– Pin 5

L Pin 8, line A (negative TX/RX)

CCommon drain

H Pin 3, line B (positive TX/RX)

V+ Pin 6

Profibus Output Data

The Modbus status (MS) and network status (NS) LEDs indicate the status of the Fieldbus

interface.

Table 11: Profibus LED indications

LED Color Description

MS Green Processor OK

Off Processor FAIL

NS Green Communications to master OK

Red Communications to master FAIL

When used for Profibus, the fieldbus port has the following characteristics.

• Baud rate: 9600, 19200, 31250, 45450, 93750, 187500, 500000, and 1.5M bps

• Address: 1 to 125

• Vendor ID: 3005 (hex)

• Data table size: inputs = 240 bytes, outputs = 240 bytes

Bit Description

0Reset

1Lockout Reset

2Stop

3Start A

4Start B

Commands are actioned on rising edge (0 to 1 transition).

Profibus DP-

MM200 supports bot slave mandatory and slave specific diagnostic data.

Diagnostics

28 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 33

COMMUNICATIONS GUIDE FIELDBUS INTERFACE

Table 12: System Standard Diagnostics Bytes 1 through 6

Byte Description

0 Station Status 1

1 Station Status 2

2 Station Status 3

3 Diagnostic Master Address

4 Identification Number (High Byte)

5 Identification Number (Low Byte)

The extended diagnosis for the relay is composed of 49 bytes (bytes 7 to 55) and contains

diagnostic information according to the following table, with bit descriptions listed in the

following pages.

Address (By Bytes) Description Format

6 No. of Extended Diagnostic Bytes Unsigned

7-10 Reserved

11-14 Trip Status 2 FC184

15-18 Trip Status 1 FC183

19-22 Reserved

23-26 Alarm Status 2 FC180

27-30 Alarm Status 1 FC179

31-46 Reserved

47-50 Ctrl Element Status 2 FC192

51-54 Ctrl Element Status 1 FC191

Profibus Input Data

Category Address (By Bytes) Description Format

Status-Motor 0 Motor Status FC129

2 Extended Status FC178

4 Thermal Cap Used F1

6 Time to Overload Trip F20

10 Overload Lockout F1

12 Reserved NA

14 Reserved NA

16 Reserved F1

18 Reserved NA

20 Reserved NA

22 Reserved NA

24 Reserved NA

26 Reserved NA

Learned 28 Learned Acceleration Time F2

30 Learned Starting Current F10

34 Learned Starting Capacity F1

Counters 36 Number of Motor Starts F1

38 Reserved NA

40 Motor Running Hours F9

44 Reserved NA

46 Reserved NA

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 29

Page 34

FIELDBUS INTERFACE COMMUNICATIONS GUIDE

Category Address (By Bytes) Description Format

48 Reserved NA

50 Reserved NA

52 Reserved NA

54 Reserved NA

56 Reserved NA

58 Reserved NA

Current Metering 60 Ia F10

64 Ib F10

68 Ic F10

72 Reserved NA

74 Reserved NA

76 Reserved NA

78 Iavg F10

82 Igrd F10

86 Motor Load F1

88 I Unb F1

90 Reserved NA

92 Reserved NA

94 Reserved NA

96 Reserved NA

98 Reserved NA

100 Reserved NA

102 Reserved NA

104 Reserved NA

106 Reserved NA

108 Reserved NA

110 Reserved NA

112 Reserved NA

114 Reserved NA

116 Reserved F3

118 Reserved NA

120 Reserved NA

122 Reserved NA

126 Reserved NA

128 Reserved NA

132 Reserved NA

134 Reserved NA

138 Reserved NA

140 Reserved NA

142 Reserved NA

146 Reserved NA

148 Reserved NA

150 Reserved NA

152 Reserved NA

154 Reserved NA

156 Reserved NA

158 Reserved NA

30 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 35

COMMUNICATIONS GUIDE FIELDBUS INTERFACE

Category Address (By Bytes) Description Format

160 Reserved NA

162 Reserved NA

164 Reserved NA

166 Reserved NA

168 Reserved NA

170 Reserved NA

172 Reserved NA

174 Reserved NA

176 Reserved NA

178 Reserved NA

Last Trip Data 180 Cause of Last Trip FC134

182 Reserved NA

186 Reserved NA

190 Pre Trip Ia F10

194 Pre Trip Ib F10

198 Pre Trip Ic F10

202 Pre Trip Motor Load F1

204 Pre Trip Current Unbalance F1

206 Pre Trip Igrd F10

210 Reserved NA

212 Reserved NA

214 Reserved NA

216 Reserved NA

218 Reserved NA

220 Reserved NA

222 Reserved NA

224 Reserved NA

226 Reserved NA

228 Reserved NA

232 Reserved NA

236 Reserved NA

238 Reserved NA

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 31

Page 36

FIELDBUS INTERFACE COMMUNICATIONS GUIDE

DeviceNet protocol

To enable the DeviceNet physical interface, ensure that switches 1 and 2 of the DIP switch

communications card (on the CPU) are on. The external connections through the fieldbus

interface are as follows.

Table 13: Fieldbus interface external connections (DeviceNet)

Path Connection (external) Wire color

V– Pin 3, CAN_GND Black

L Pin 2, CAN_L Blue

C Pin 5, CAN_SHLD Bare

H Pin 7, CAN_H White

V+ Pin 9, CAN_V Red

The Modbus status (MS) and network status (NS) LEDs indicate the status of the Fieldbus

interface.

Table 14: DeviceNet LED indications

LED LED operation Description

MS Green on, red on, green on Device self-test

Flashing green Device in standby state

Green on Device operational

Flashing red Recoverable fault

Red on Unrecoverable fault

NS Flashing green Online, not connected

Green on Online, connected

Flashing red Connection timeout

Red on Critical link failure

Red and green Network access detected

DeviceNet

Communications

When used for DeviceNet, the fieldbus port has the following characteristics.

• Baud rate: 125, 250, and 500 kbps

• MAC ID: 0 to 63

•Vendor ID: 928

• Product Code: 0x4D39

• Message types: poll, and explicit messaging

The device profile is an extension of the Communications Adapter Device Profile (0xC0). It is

a group 2 only server. The MAC ID and baud rate are programmable through the EnerVista

MM200 Setup software. The MM200 supports the following DeviceNet object classes.

CLASS OBJECT

01H Identify

02H Message Router

03H DeviceNet

05H Connection

64H IO Data

A0H Generic Data - Polling/Explicit

B1H Explicit Control Writes

B0H Analog Data - Explicit

32 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 37

COMMUNICATIONS GUIDE FIELDBUS INTERFACE

The MM200 supports poll and explicit messaging types.

The Poll function will return 38 bytes of status and metering data as described in User

Object Class A0h, Instance 01h, Attribute 01h.

USINT, UINT, UDINT and DINT, stated in this document, stand for the following data types :

USINT = Unsigned integer byte

UINT = Unsigned integer word

UDINT = Unsigned integer double word

DINT = Signed integer double word

Identity Object (Class

Code 01H)

Message Router (Class

Code 02H)

Table 15: Identity Object, Class Code 01h, Services:

CODE SERVICES AVAILABLE TO THIS OBJECT

NAME DESCRIPTION

0x05 Reset Reset the device to power up configuration

0x0E Get_Attribute_Single Returns the contents of the given attribute

Table 16: Identity Object, Class Code 01h, Attributes:

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01h Get Revision of Identity Object UINT 1

Table 17: Identity Object, Class Code 01h, Instance 01h, Attributes:

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01h Get Vendor ID UINT 928

02h Get Device Type UINT 12

03h Get Product Code UINT 0x4D39

04h Get Revision (Major, Minor) 2USINT 1.00

07h Get Product Name SHORTSTRING MM200 MOTOR

MANAGEMENT RELAY

The message router (class code 2) object provides a messaging connection point through

which a client may address a service to any object or instance residing in the physical

device. There is no external visible interface to the message router object.

DeviceNet Object

(Class Code 03H)

Table 18: Identity Object, Class Code 03h, Services:

CODE SERVICES AVAILABLE TO THIS OBJECT

NAME DESCRIPTION

0x0E Get_Attribute_Single Returns the contents of the given attribute

Table 19: Identity Object, Class Code 03h, Attributes:

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01h Get Revision of DeviceNet Object UINT 1

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 33

Page 38

FIELDBUS INTERFACE COMMUNICATIONS GUIDE

Table 20: Identity Object, Class Code 03h, Instance 01h, Attributes:

ATTRIBUTE ACCESS NAME/

DESCRIPTION

01h Get Vendor ID UINT 928 (to be defined)

02h Get Baud Rate USINT 0 = 125 kbps

05h Get Allocation Choice USINT Bit 0: Explicit Messaging

Master/s MAC ID USINT 0 to 63: address; 255 = unallocated

DATA TYPE VALUE

1 = 250 kbps

2 = 500 kbps

Bit 1: polled I/O

Bit 6: acknowledge suppression

DeviceNet Connection

Object (Class Code

05H)

Table 21: Connection Object, Class Code 05h, Services:

CODE SERVICES AVAILABLE TO THIS OBJECT

NAME DESCRIPTION

0x05 Reset Reset the device to power up configuration

0x0E Get_Attribute_Single Returns the contents of the given attribute

0x10 Set_Attribute_Single Sets the contents of the given attribute

Table 22: Connection Object, Class Code 05h, Instance 01h (Explicit Message

Connection):

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01h Get State USINT 0x03

02h Get Instance type USINT 0x00

03h Get Export class trigger USINT 0x83

04h Get Produced connection ID UINT 10xxxxxx011,

xxxxxx - MAC ID

05h Get Consumed connection ID UINT 10xxxxxx100,

xxxxxx - MAC ID

06h Get Initial comm. characteristics USINT 0x21

07h Get Produced connection size UINT 0x00EF

08h Get Consumed connection size UINT 0x00EF

09h Get/Set Expected package rate UINT 0x0000

0Ch Get/Set Watchdog timeout action USINT 0 = transition to

time-out

1 = auto delete

2 = auto reset

3 = deferred delete

0Dh Get Produced path length UINT 0x0000

0Eh Get Produced path USINT [6] <null>

0Fh Get Consumed path length UINT 0x0000

10h Get Consumed path USINT [6] <null>

11h Get Production inhibit timer UINT 0x0000

34 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 39

COMMUNICATIONS GUIDE FIELDBUS INTERFACE

Table 23: Connection Object, Class Code 05h, Instance 04h (Polled Input/Output Connection):

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01h Get State USINT 0x03

02h Get Instance type USINT 0x01

03h Get Export class trigger USINT 0x82

04h Get Produced connection ID UINT MAC ID

05h Get Consumed connection ID UINT MAC ID

06h Get Initial comm. characteristics USINT 0x01

07h Get Produced connection size UINT 0x0026

08h Get Consumed connection size UINT 0x0020

09h Get/Set Expected package rate UINT 0x0000

0Ch Get/Set Watchdog timeout action USINT 0x00

0Dh Get Produced path length UINT 0x0006

0Eh Get Produced path USINT [6] 0x206424013001

0Fh Get Consumed path length UINT 0x0006

10h Get Consumed path USINT [6] 0x206424013002

11h Get Production inhibit timer UINT 0x0000

I/O Data Polled Object

(Class Code 64H)

CODE SERVICES AVAILABLE TO THIS OBJECT

0x0E Get_Attribute_Single Returns the contents of the given attribute

0x10 Set_Attribute_Single Sets the contents of the given attribute

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01H Get Revision of I/O Data Polled Object UINT 1

ATTRIBUTE ACCESS NAME/DESCRIPTION SIZE IN BYTES

01H Get Motor Data (Poll Group) 38

ATTRIBUTE ACCESS NAME/DESCRIPTION SIZE IN BYTES

02H Set Reserved 32

Table 24: I/O Data Polled Object, Class Code 64h, Services:

NAME DESCRIPTION

Table 25: I/O Data Polled Object, Class Code 64h, Attributes:

Table 26: Data Polled Object, Class Code 64h, Instances 01h

Table 27: Data Polled Object, Class Code 64h, Instances 02h

MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE 35

Page 40

FIELDBUS INTERFACE COMMUNICATIONS GUIDE

DATA FORMAT, MOTOR DATA

ITEM DESCRIPTION SIZE IN BYTES FORMAT

Motor status 1 FC129 (low byte only)

Motor load (%) 2 F1

Cause of last trip 2 FC134

Thermal capacity used (%) 2 F1

Average phase current (A) 4 F10

Ground current (A) 4 F10

Reserved 2 NA

Reserved 4 NA

Reserved 2 NA

Contact Input Status 8 BIT per input

Contact Output Status 4 BIT per output

DeviceNet Motor Data

- Poll, Explicit Object

(Class Code A0H)

Table 28: Motor Data Object, Class Code A0h, Services:

CODE SERVICES AVAILABLE TO THIS OBJECT

NAME DESCRIPTION

0x0E Get_Attribute_Single Returns the contents of the given attribute

Table 29: Motor Data Object, Class Code A0h, Attributes:

ATTRIBUTE ACCESS NAME/DESCRIPTION DATA TYPE VALUE

01H Get Revision of Motor Data Object UINT 1

Table 30: Motor Data Object, Class Code A0h, Instance 01h, Attributes, Get Access:

ATTRIBUTE NAME/DESCRIPTION SIZE IN BYTES FORMAT

01H Motor Data (Poll group 1) 38 See below

02H Digital Data 9 See below

03H Summary of Motor Data 7 See below

04H Reserved NA NA

05H Motor status 1 FC129 (low byte only)

06H Motor load (%) 2 F1

07H Cause of last trip 2 FC134

08H Thermal capacity used (%) 2 F1

09H Current metering 8 See below

0AH Reserved 2 NA

0BH Reserved 6 NA

0CH Contact Input Status 8 BIT per input

0DH Contact Output Status 4 BIT per output

0EH Reserved 3 NA

DATA FOR M AT, DIG ITAL DATA

ITEM DESCRIPTION SIZE IN BYTES FORMAT

Motor status 1 FC129 (low byte only)

Contact Input Status 8 BIT per input

36 MM200 MOTOR MANAGEMENT SYSTEM – COMMUNICATIONS GUIDE

Page 41

COMMUNICATIONS GUIDE FIELDBUS INTERFACE

DATA FORMAT, SUMMARY OF MOTOR DATA

ITEM DESCRIPTION SIZE IN BYTES FORMAT

Motor status 1 FC129 (low byte only)

Motor load (%) 2 F1

Cause of last trip 2 FC134

Thermal capacity used (%) 2 F1

DATA FORMAT, MOTOR DATA

ITEM DESCRIPTION SIZE IN BYTES FORMAT

Motor status 1 FC129 (low byte only)

Motor load (%) 2 F1

Cause of last trip 2 FC134

Thermal capacity used (%) 2 F1

Average phase current (A) 4 F10

Ground current (A) 4 F10

Reserved 2 NA

Reserved 4 NA

Reserved 2 NA

Contact Input Status 8 BIT per input

Contact Output Status 4 BIT per output

DeviceNet - Explicit

Motor Analog Data

Object, Class Code

B0H, Services

DATA FORMAT, CURRENT METERING