GE MILLENIUM GE OSMONICS MILLENIUMTM REVERSE OSMOSIS UNIT, Osmonics Millenium Operation And Maintenance Manual

Page 1

GE OSMONICS

MILLENIUM™ REVERSE OSMOSIS UNIT

Operation

and Maintenance Manual

SUPERCEDES P/N 14693 REV. D

Page 2

Page 3

MILLENIUM REVERSE OSMOSIS UNIT

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Page

CHAPTER ONE: GENERAL INFORMATION 1-1

Section 1.1 The Manual 1-3

1.2 Safety Summary 1-3

1.3 Applications 1-4

1.4 Contraindications 1-4

1.5 Environmental Considerations 1-5

1.6 Theory of Operation 1-6

1.7 Fluid Components 1-7

1.8 Monitors and Controls 1-9

1.9 Optional Equipment 1-11

1.10

1.10.1

1.10.2

1.10.3

1.10.4

1.10.5

1.10.6

Specifications

Inlet Water Requirements

Flow Rates

Electrical Requirements

Dimensions

Membrane Performance Characteristics

Environmental Requirements

1-12

1.11 Disposal 1-13

1.12 Electromagnetic Interference 1-14

1.13 Service Assistance 1-14

1.14 Return Goods Authorization (RGA) 1-15

1.15 Symbols and Abbreviations 1-16

CHAPTER TWO: INSTALLATION GUIDELINES AND INITIAL

2-1

SYSTEM START UP

Section 2.1 Installation Considerations 2-3

2.2 Installation Procedure 2-3

2.3 Product Water Analysis Procedure 2-6

CHAPTER THREE: SYSTEM OPERATION 3-1

Section 3.1 Daily Start-up Procedure 3-3

3.2 Shut Down Procedure 3-3

14693e

A 31 March 2003

A

Page 4

CHAPTER FOUR: ROUTINE MAINTENANCE 4-1

Section 4.1

4.1.1

Routine Maintenance of Millenium™ RO System

Daily / Per Treatment Maintenance

4-3

4-3

4.1.2 Weekly Maintenance 4-4

4.1.3 Monthly Maintenance 4-4

4.1.4 Quarterly Maintenance 4-4

4.1.5 Semi-Annual Maintenance 4-5

4.1.6 Annual Maintenance 4-5

4.2

4.2.1

Specific Maintenance Procedures and Instructions

Motor Lubricant Procedure

4-6

4-6

4.2.2 Leak Repair 4-6

4.2.3 Product Recirculation Check Valve Test 4-9

4.3 Millenium™ Cleaning Indications 4-9

4.3.1 Pre Cleaning Preparation 4-10

4.3.1.1 Pre Cleaning Procedure 4-10

4.3.1.2 Cleaner Recirculation and Dwell Time 4-11

4.3.1.3 Post Cleaning Rinse Procedure 4-12

4.3.2 BIOSAN™ Pre Cleaning Preparation 4-14

4.3.2.1 BIOSAN™ Cleaning Procedure 4-14

4.3.2.2 BIOSAN™ Recirculation and Dwell Time 4-15

4.3.2.3 BIOSAN™ Post Cleaning Rinse Procedure 4-16

4.4 Millenium™ Disinfection Indications 4-17

4.4.1 Formaldehyde Disinfection Preparation 4-17

4.4.1.1 Formaldehyde Pre Disinfection Procedure 4-18

4.4.1.2 Formaldehyde Disinfection and Dwell Time 4-18

4.4.1.3 Formaldehyde Post Disinfection Rinse Procedure 4-19

4.4.2 “RENALIN®” Disinfection Procedure

4-21

(Peracetic Acid and Peroxide-Based Compounds

such as Renalin®, Minncare™, & Peracidin™)

4.4.2.1 “RENALIN®” Pre Disinfection Preparation 4-22

4.4.2.2 “RENALIN®” Disinfection and Dwell Time 4-23

4.4.2.3 “RENALIN®” Post Disinfection Rinse Procedure 4-23

4.5 Product Water Culture 4-25

4.5.1 Product Water Culture Procedure 4-26

4.6 System Storage 4-27

4.6.1 Formaldehyde Storage Procedure 4-27

4.6.2 BIOSAN™ Storage Procedure 4-28

14693e

B 31 March 2003

B

Page 5

CHAPTER FIVE: TROUBLESHOOTING 5-1

Table of Content 5-3

Section 5.1 Unit Fails to Run 5-5

5.2 Unit Runs Intermittently 5-5

5.3 Motor Runs Hot 5-6

5.4 Water Produced While Unit is Off 5-6

5.5 Low Pump Pressure 5-7

5.6 Pressure Gauge Vibrates Erratically 5-7

5.7 Excess Product Pressure (too high) 5-7

5.8 Product Flow Too Low 5-8

5.9 Product Flow Too High 5-8

5.10 Leaks 5-9

5.11 Low Percent Rejection 5-9

5.12 TDS Value High 5-10

5.13 RO Fails to Draw Disinfectant 5-11

5.14 RO Pump Leaks 5-11

5.15 TDS Value Fluctuates 5-11

CHAPTER SIX: DRAWINGS 6-1

CHAPTER SEVEN: SPARE PARTS LIST 7-1

14693e

C 31 March 2003

C

Page 6

This page intentionally left blank

14693e

D 31 March 2003

D

Page 7

Millenium™ RO System by GE Osmonics

M

Millenium RO System

CHAPTER ONE:

GENERAL INFORMATION

14693e – 31 Mar 03 1 - 1 General Information

Page 8

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e – 31 Mar 03 1 - 2 General Information

Page 9

Millenium™ RO System by GE Osmonics

M

1.1 The Manual

This manual has been prepared to provide the operator with information and instructions

regarding the installation, use, maintenance and troubleshooting of the GE Osmonics

Millenium™ Reverse Osmosis System.

CAUTION:

When used as a medical device, Federal law restricts this device to sale by or on the

order of a physician. Per CFR 801.109 (b)(1).

The manual has been written in narrative form supplemented with schematics and

drawings for clarification. The operator can perform most procedures mentioned in this

manual. Any exceptions will be clearly identified by a qualifying statement.

1.2 Safety Summary

Words in BOLD CAPITAL letters are used to identify labels on the device and key

safety or qualifying statements. A list of all symbols and abbreviations is located at the

end of this chapter. See Technote 120 for a glossary of relevant terms.

This safety summary does not contain all of the safety statements in the manual. Other

safety statements are included within the manual text and are enhanced and defined as

follows:

NOTE:

Statements that provide further clarification.

CAUTION:

Statements identifying conditions or practices that could result in equipment or

other property damage.

WARNING:

Statements identifying conditions or practices that could result in personal injury or

loss of life.

READ THIS MANUAL:

Prior to operating or servicing this device, this manual must be read and understood.

Keep this and other associated manuals for future reference and for new operators or

qualified service personnel. A note sheet is provided at the end of each chapter for

operators to make notations that may be valuable to other users.

USE PROPER POWER CONNECTIONS:

Use proper wiring and connection methods to satisfy hospital electrical codes.

DO NOT REMOVE COVERS OR PANELS:

To avoid electrical shock hazard, do not remove covers or panels when power is supplied

to the device. Do not operate the device when covers or panels are removed.

14693e – 31 Mar 03 1 - 3 General Information

Page 10

Millenium™ RO System by GE Osmonics

M

SHOCK HAZARD:

Connect this device to a proper ground connection in accordance with the National

Electrical Code. DO NOT under any circumstances remove the ground wire or ground

prong from any power plug. DO NOT use an extension cord with this equipment. Keep

the surface under the RO(s) free of water.

DEVICE LABELING:

Do not under any circumstances; remove any Caution, Warning or any other descriptive

labels from the devices until the conditions warranting the label are eliminated.

DO NOT OPERATE IN A FLAMMABLE ATMOSPHERE:

To avoid fire or explosion, do not operate this device in an explosive environment or near

flammable anesthetics.

1.3 Applications

The Millenium™ Reverse Osmosis (RO) System is designed to purify water by forcing

water through a semi-permeable RO membrane. Water purified by reverse osmosis has

had approximately 95% of the dissolved ions and approximately 99% of most other

contaminants removed. The quality of the purified water, referred to as product water or

permeate, depends on the quality of the feed water and normally is equal to or exceeds

AAMI standards. Such water is suitable for hemodialysis applications.

1.4 Contraindications

WARNING:

GE Osmonics systems are not designed, sold, or intended for use in producing

water for injection

Furthermore, GE Osmonics systems are not intended to be used outside of the device

specifications and limitations, as outlined in this manual and other related materials.

14693e – 31 Mar 03 1 - 4 General Information

Page 11

Millenium™ RO System by GE Osmonics

M

1.5 Environmental Considerations

Prior to the installation of the Millenium™ RO System, it will be necessary to provide

utilities and create an environment suitable for the trouble free operation of the RO

system and its accessories.

POWER:

The Millenium™ operates on 115 VAC single-phase power. Histories of power

failure, power surges, and low line voltages should be noted and reported to the

manufacturer or their agent as they may create adverse conditions for the operation

of equipment.

WATER:

Reverse osmosis systems require a reliable water source. The Millenium™ RO

needs a minimum of 30-PSI pressure at a minimum flow of 2 gallons per minute. It

is important that water is flowing at the design flow rate when testing water

pressure rather than reading static pressure.

DRAIN:

A drain outlet is required by the RO system. The drain must have a minimum

capacity of 2 gallons per RO per minute of continuous flow for as long as and as

often as the RO is operating.

TEMPERATURE:

The Millenium™ RO is normally connected to a cold water supply. The

performance specifications of the RO are based on 77°F (25°C) feed temperature.

Each degree Fahrenheit the feed water temperature falls, the RO product flow

decreases approximately 1.5%, and each degree Celsius drop, the product flow is

reduced by 3% (See Technote 113 for the “Temperature Correction Factors” chart).

In climates where the winter water temperature drops significantly below 77°F it

may be necessary to temper (heat) the water.

WARNING:

The temperature of the tempered water should be monitored closely with a

thermometer as high temperatures can damage the RO membranes and possibly

harm the patient. Refer to the inlet water requirements (Section 1.10.1) for the

maximum operating temperature for the Millenium™ RO.

CAUTION:

It is necessary to keep the RO from freezing to prevent serious damage to the RO

unit.

NOISE:

The RO unit does not generate significant noise levels. Hard walls may reflect

noise and will make the RO seem louder.

14693e – 31 Mar 03 1 - 5 General Information

Page 12

Millenium™ RO System by GE Osmonics

M

WATER PURITY:

Plumbing materials can significantly contribute to the contamination of the water.

Metallic pipes (with the exception of 316 stainless steel) must be eliminated once

the purification process has begun. Schedule 40 or 80 PVC pipes, polypropylene,

PVDF, and other FDA recommended materials are suitable for most grades of

purified water. Care must also be exercised in the choice of a thread sealant.

Teflon tape is suitable for all threaded connections in this system.

WARNING:

Ordinary pipe dope must be avoided since it may leach objectionable and

potentially dangerous impurities into the water.

1.6 Theory of Operation

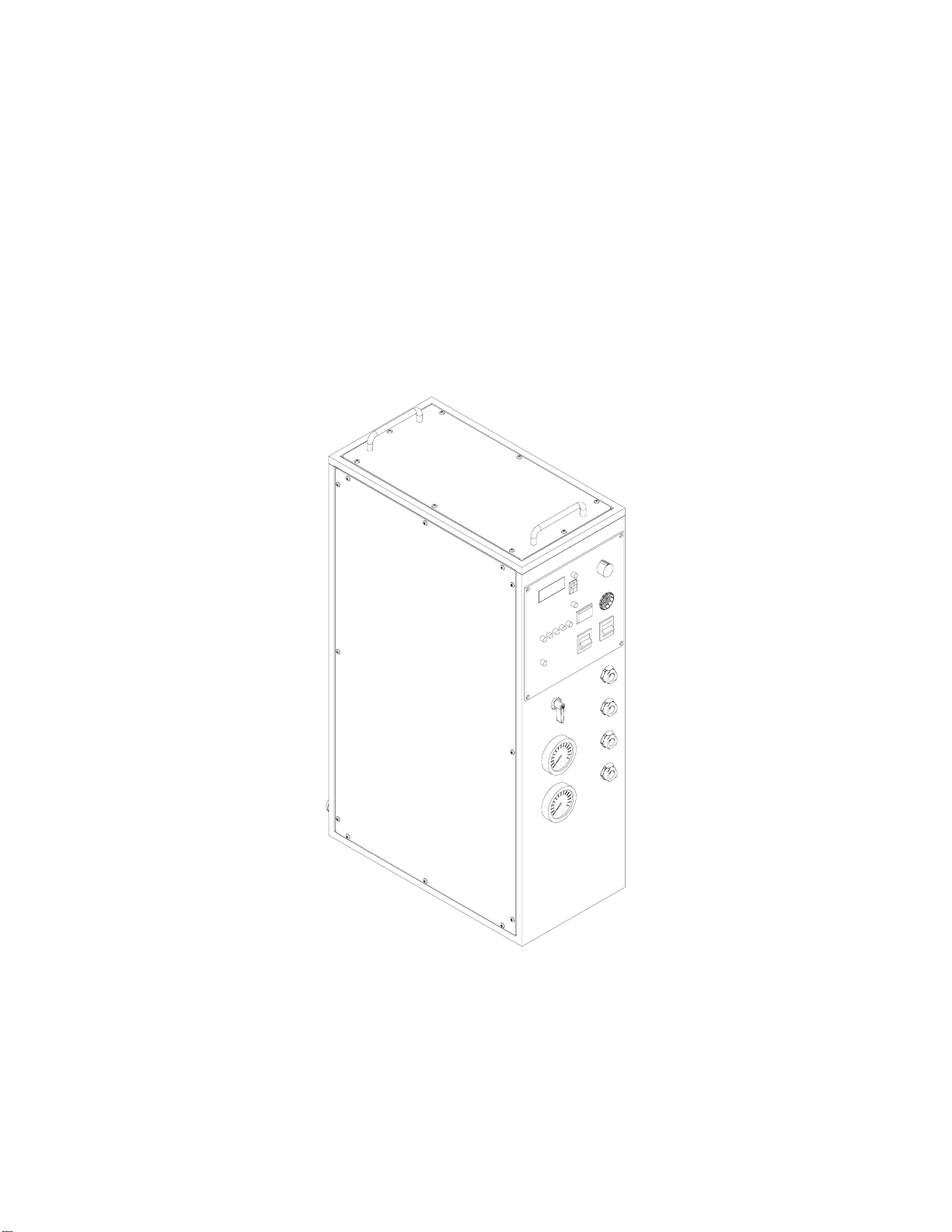

The Millenium™ Portable Reverse Osmosis system (RO) is a fully cabinetized unit that

purifies a given feed water (by way of reverse osmosis) for use in hemodialysis

applications. The Millenium™ RO possesses monitoring for pressure, product water

quality and membrane performance (percent rejection). The RO pump provides the

pressure required to push water through the RO membranes. The fluid controls provide a

means of managing flow rates and pressures. The following paragraphs detail the

function of these fluid control components, which are used within the RO.

14693e – 31 Mar 03 1 - 6 General Information

Page 13

Millenium™ RO System by GE Osmonics

M

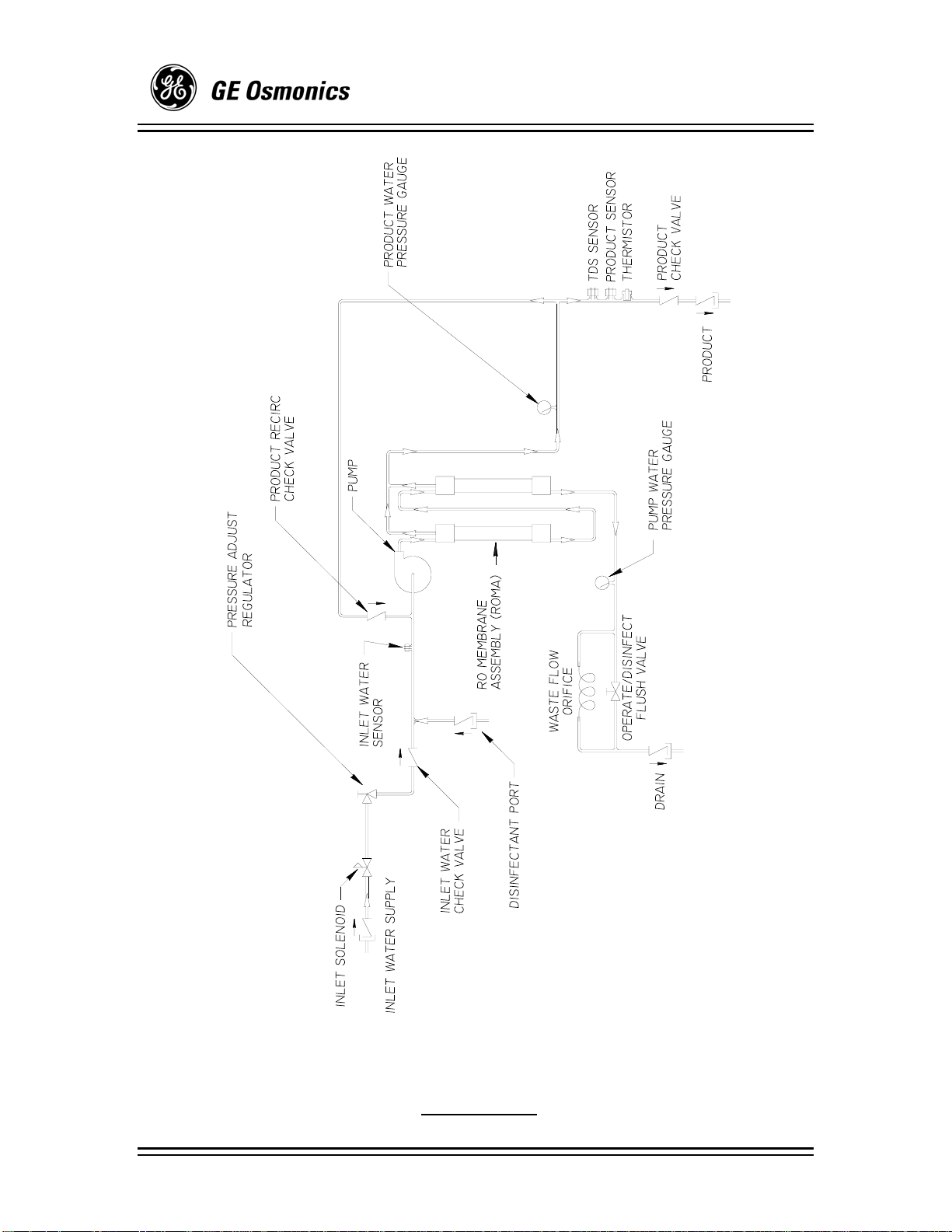

1.7 Fluid Components

Inlet Solenoid:

Located inside the Millenium™ RO at the inlet, and serves to shut off the water

supply to the system, until it is actuated when the Inlet water valve switch is placed

in the ON position.

Pressure Adjust Regulator:

Used to adjust the product pressure. The pressure is displayed on the product

pressure gauge, on the front of the RO.

Inlet Water Check Valve:

Prevents back-flow of disinfectants or cleaning agents.

Inlet Water Sensor:

Monitors the quality of the inlet water. Inlet quality is compared to the outlet

(product) water quality and is displayed as "percent rejection" on the front panel.

High-Pressure Pump:

Provides up to a 200 PSI boost of the inlet water to the Reverse Osmosis Membrane

Assembly (ROMA). The RO pump pressure is displayed on a 0 to 300 PSI gauge

mounted outside the RO, above the product pressure gauge. The pressure is factory

set at 190 PSI.

Reverse Osmosis Membrane Assemblies (ROMAs):

Two are included in the Millenium™ RO. A ROMA is an assembly that includes

the membrane housing, end caps, fittings, and a membrane. Depending on the

model, thin film membrane ROs can either provide up to 500 or 750 gallons per day

of product water, depending on membrane type, condition, and water temperature.

Waste Flow:

The Waste Flow is controlled by a length of 1/8" tubing. The length of the tube is

factory determined to correctly govern the wastewater flow to drain.

Operate/Flush Valve:

The Operate/Flush Valve on the front panel is used to flush the membrane surface

of rejected contaminants, and to accelerate the rinse out of cleaners or disinfectants

from the RO. Some pump noise (chattering) is normal in the flush position. The RO

is in "flush" from the full open (flush) to just before the fully closed (operate)

position.

CAUTION:

Excessive “chattering” may be eliminated by slowly moving the valve from the full

flush position towards “OPERATE”.

14693e – 31 Mar 03 1 - 7 General Information

Page 14

Millenium™ RO System by GE Osmonics

M

Product Water Pressure:

Product Water Pressure is read on a 0 to 100 PSI gauge on the front panel. Product

pressures will register only when the product is back pressured (product hose

removed from fitting or connected to dialysis unit).

Product Recirculation Check Valve:

Prevents over-pressuring of the product supply. When the product pressure exceeds

the set point of the pressure regulator, the product recirculation check valve opens.

Excess product water is then recirculated back to the inlet water flow.

Product Water Sensor:

The Product Water Sensor is used in conjunction with the inlet water sensor by the

percent-rejection circuitry to calculate the membrane rejection rate. The rate of

rejection is displayed from 70% - 99% in a 5 LED array on the front panel.

Product Check Valve:

The Product Check Valve is used to prevent anything from flowing backward into

the product side of the RO membranes.

CAUTION:

Back-flow pressure into the product line can cause damage to the membranes.

Total Dissolved Solids (TDS) Sensor:

Samples the product water quality via the sensor probe, and the final quality of the

product water is indicated on a digital display on the front panel as TDS in mg/L

and ppm. The monitor is temperature compensated to adjust the display value to

changing water temperature.

Disinfect Inlet Port:

The Disinfect Inlet Port is a quick-disconnect valve that allows access to the inlet

water side of the pump. The port is used when cleaners or disinfectants are

introduced to the RO. The valve can also be used to obtain feed water samples for

testing feed water for chlorine/chloramine, pH and hardness levels.

WARNING:

Water from this port is NOT RO product water and should not be used for dialysis

solutions.

Disinfect Switch:

The Disinfect Switch is used to introduce disinfectants and cleaners into the RO.

For safety, this switch must be held continuously to operate.

CAUTION:

When drawing disinfectants or cleaning solutions, do not allow the RO to draw air.

This may cause irreparable damage to the RO pump.

14693e – 31 Mar 03 1 - 8 General Information

Page 15

Millenium™ RO System by GE Osmonics

M

1.8 Monitors and Controls

Inlet Water Valve Switch:

The Inlet Water Valve Switch is mounted on the control panel. The switch is used

to energize a solenoid, pressurizing the system with feed water.

RO Pump Power Switch:

The RO Pump Power Switch is mounted on the control panel. The switch is used to

energize the RO pump/motor. The inlet water switch must be ON for the

pump/motor to operate.

Disinfect Switch:

The Disinfect Switch is mounted on the front panel. This switch is used to

introduce disinfectant or cleaning agents into the RO through the disinfect port.

Pressure Adjust Regulator:

The Pressure Adjust Regulator inside the RO is used to set the maximum product

pressure needed to supply a dialysis machine. Adjusting this regulator will also

result in small adjustments in the pump pressure.

Product Pressure Gauge:

The Product Pressure Gauge reads the product pressure from 0 to 100 PSI. Product

pressure will read zero when the product line is not connected to a dialysis unit and

the product hose is connected to the product fitting and the valve is open.

Pump Pressure Gauge:

The Pump Pressure Gauge reads the pump pressure from 0 to 300 PSI. It is used

for monitoring during operation and when adjusting the pump pressure, and is

located on the front of the RO.

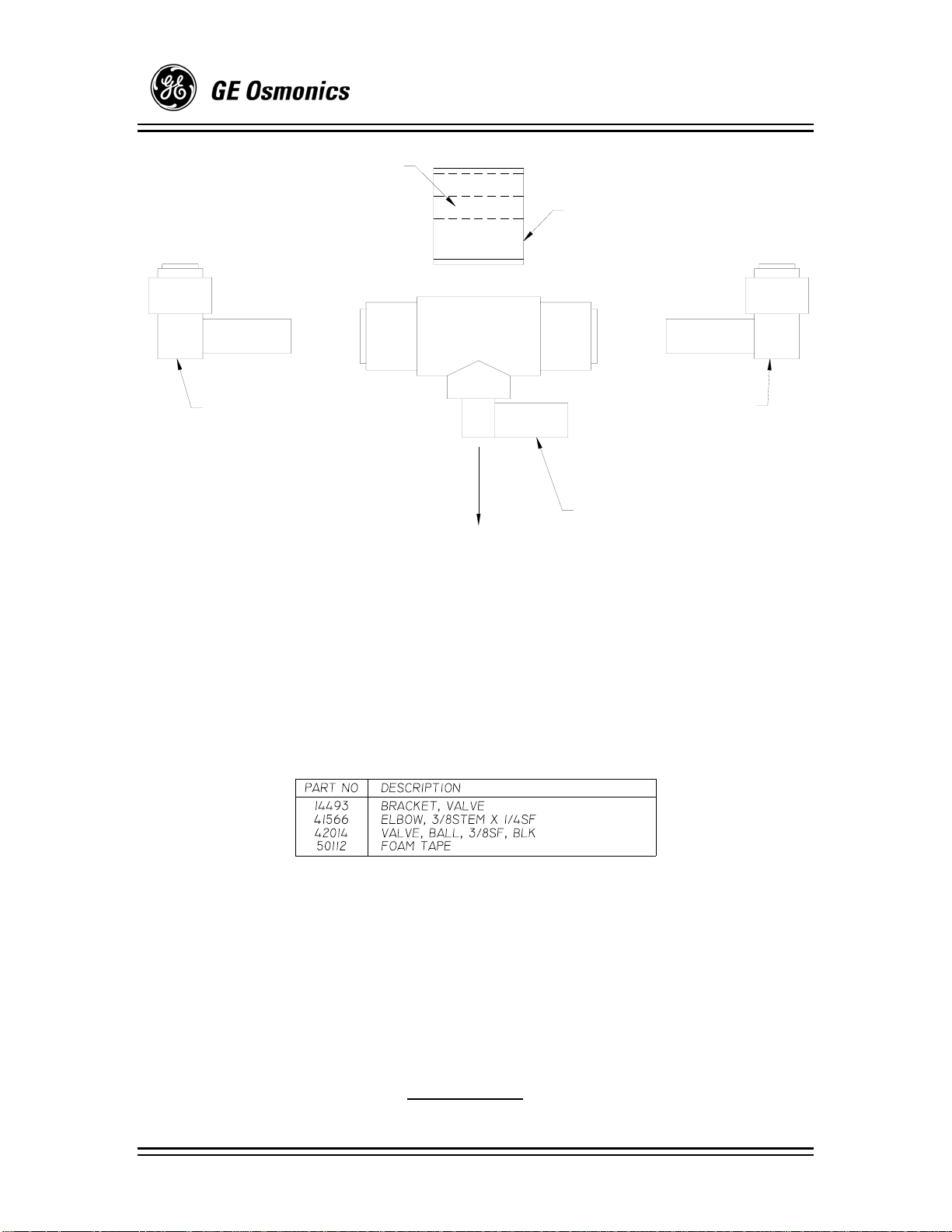

Operate/Flush Valve:

The Operate/Flush Valve is a 1/4-turn ball valve. When in the operate mode, the

valve is in the closed position. When the valve is turned at any point towards flush,

the valve is open. The closer to the flush point, the more the valve is open. When in

flush, the valve bypasses the waste flow tube.

Disinfect Port:

The Disinfect Port is a quick-disconnection port for the introduction of disinfectant

or cleaning agents. The port has a check valve that closes when there is no hose

connected to the fitting.

Feed Port:

The Feed Port is a quick-disconnection port for the introduction of feed water to the

RO. The port has a check valve that closes when there is no hose connected to the

fitting.

14693e – 31 Mar 03 1 - 9 General Information

Page 16

Millenium™ RO System by GE Osmonics

M

Product Port:

The Product Port is a quick-disconnection port for the output of purified product

water. The port has a check valve that closes when there is no hose connected to

the fitting.

Waste Port:

The Waste Port is a quick-disconnection port for the output of concentrate or waste

to the drain. The port has a check valve that closes when there is no hose connected

to the fitting.

Percent Rejection Display:

The Percent Rejection Display is a 5 LED array that indicates how the RO

membranes are performing. The lights correspond to 99%, 95%, 90%, 85%, and

>70% rejection. The 99% light, when illuminated, indicates a need to evaluate the

RO system performance. RO units do not normally perform in excess of 99%;

verify this reading with an independent meter and take corrective action if

indicated. Some RO membranes will achieve this level of performance under

optimum conditions.

Product Water Total Dissolved Solids (TDS):

The Product Water Total Dissolved Solids (TDS) digital display indicates product

water purity in mg/L (ppm). It is temperature compensated to adjust the value of the

display with changing water temperature for better accuracy.

Less Than 0.5 mg/L Check System Lamp:

The Less Than 0.5 mg/L Check System lamp illuminates when the TDS reading is

0.5 mg/L or less. This indicates a need to evaluate the RO system performance.

RO units do not normally have this low product TDS. Verify this reading with an

independent meter and take corrective action if indicated. RO membranes may

achieve this level of performance under optimum conditions (good feed water).

Alarm Set:

The Alarm Set switch allows the operator to set the TDS levels at which the alarm

will sound. The alarm should be set at twice the initial TDS reading. If the set

point is exceeded, an audible alarm will sound.

Alarm Mute:

The Alarm Mute switch will mute the audible alarm for 30 - 45 seconds. A red

indicator lamp is displayed on the switch when the mute switch has been pressed.

14693e – 31 Mar 03 1 - 10 General Information

Page 17

Millenium™ RO System by GE Osmonics

M

1.9 Optional Equipment

GE Osmonics offers a number of optional items to adapt the equipment to meet specific

needs. Options are available to improve portability, and to improve the quality of the

feedwater to the RO. Frequently requested options are briefly described in the following

paragraphs. If more information is needed, or if other options are desired, please consult

the factory.

Pretreatment Cart holds the Millenium™ RO and feedwater treatment equipment. The

cart has a bracket that provides for the attachment of prefilter cartridge housings. The

cart will hold any combination of two or three of the following tank sizes, .25 c.f., .47

c.f., or .60 c.f..

Carbon Filter Tanks remove chlorine/chloramine from the feed water, preventing

damage to the RO membrane and injury to patients. The filter incorporates a bed of

granular activated carbon. Three sizes of carbon tanks come in semi-automatic control

valve and exchange head styles.

WARNING:

Carbon is not regenerated and must be replaced when exhausted.

WARNING:

A suitable carbon filter should always be present as pretreatment for the RO unit in

order to prevent chlorine/chloramine damage to the thin film RO membrane and

harm to the patient. Osmonics strongly recommends the use of two carbon tanks,

used in a series configuration.

Softeners remove calcium, magnesium, and other scale producing contaminants from the

feed water. Their removal prevents the build-up of scale on the membrane surface. A

control valve drives the regeneration of the softener, and will remove the hardness ions

with a brine solution and rinse the ion exchange bed afterwards. The control valve is

normally governed by a semi-automatic time clock. There are three sizes of softener

tanks available.

Dealkalizers are used to lower the pH of alkaline feed water. Water with pH levels

above 8.5 with chloramines present can reduce the performance of the carbon filters and

thin-film membranes. A control valve drives the regeneration rinsing of the dealkalizer.

The control valve is normally governed by a semi-automatic time clock. There are three

sizes of dealkalizer tanks available.

14693e – 31 Mar 03 1 - 11 General Information

Page 18

Millenium™ RO System by GE Osmonics

M

1.10 Specifications:

1.10.1 Input Water Requirements

Minimum Maximum

Input flow Rate 2.0 GPM N/A

Temperature (water) 1.7°C (35°F) 32°C (90°F)

NOTE:

Operating at lower temperatures may make it impossible for the Millenium™ to

produce adequate permeate for the dialysis machine.

pH (operating) 4.0 11.0

TF Membranes

pH w/chloramines present (operating) 4.0 8.5

TF Membranes

pH (cleaning) 2.0 11.0

TF Membranes

Pressure, dynamic 30 PSI 100 PSI

1.10.2 Flow Rates

Product Flow based on the following conditions:

New Membranes

Operating Pressure: 190 PSI

Product Pressure: 1 PSI

Feed Water Temperature: 77°F (25°C)

GPM LPM GPD LPD

.34 1.31 500 1892.5

.52 1.97 750 2839.1

Membrane flux may vary ±15%

Waste Flow: .84 GPM (3.2 LPM) (

±10%)

1.10.3 Electrical Requirements

Motor 1/3 HP

Voltage 115 VAC / 230 VAC

Hertz 60 / 50

Amps 8 / 5

Phase single

14693e – 31 Mar 03 1 - 12 General Information

Page 19

Millenium™ RO System by GE Osmonics

M

1.10.4 Dimensions

Vertical Cabinet Horizontal Cabinet

Height 25 ½ inches 8 inches

Depth 15 inches 15 inches

Width 8 inches 25½ inches

Weight – Operating – 55 lbs.

1.10.5 Membrane Performance Characteristics

Salt rejection (TF Membranes): 95% minimum at initial testing at factory.

Test Solution: Inlet water 1000 PPM NaCl

Conductivity: 2000 micro mhos-cm

Operating Pressure: 190 PSI, ±10 PSI

Product Back pressure: 0 PSI

1.10.6 Environmental Requirement

Minimum Maximum

Ambient Temperature 4°C (39°F) 32°C (90°F)

Storage Temperature 2°C (36°F) 32°C (90°F)

Altitude N/A 10,000 feet

CAUTION:

This equipment must not be allowed to freeze. Irreparable harm to various

components, including RO membranes may result.

NOTE:

The user/operator should recognize that moisture can be caused by condensation

and is not necessarily an equipment leak. This equipment will function in the

presence of condensation.

1.11 Disposal

Disposal of this product or parts must be carried out according with local disposal codes.

14693e – 31 Mar 03 1 - 13 General Information

Page 20

Millenium™ RO System by GE Osmonics

M

1.12 Electromagnetic Interference

This equipment can generate, uses and can radiate radio frequency energy and, if not

installed and used in accordance with these instructions, may cause harmful interference

to other devices in the vicinity. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference with

other devices, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving device

• Increase the separation between the equipment

• Connect the equipment into an outlet on a circuit different from that to

which the other device(s) is connected

• Consult the field service technician or manufacturer for help.

1.13 Service Assistance

If service assistance is required, please take the following steps:

Consult the “Troubleshooting” section of this manual (Chapter Five). If the problem

cannot be identified and corrected by any of the procedures found in that section, then...

Contact your Facility Equipment Technician. If the technician is unable to help then…

Call GE Osmonics Technical Service Department at (800) 633-3080 or (206) 395-2200.

Technicians are available for all calls between 7:00 a.m. and 4:30 p.m. PST, Monday

through Friday. Technicians are also available at other times for emergency calls only.

Product consultants will be on hand to discuss the problem with you and endeavor to

rectify it over the phone. If the problem appears to be of a more serious nature, you will

be given instructions regarding the action to be taken. Prior to making the phone call,

you must be prepared to answer two questions:

1. What RO do you have, i.e. Millenium™

2. What is the serial number of your RO? (Label, found on back of RO.)

RO SERIAL NUMBER: ______________________

14693e – 31 Mar 03 1 - 14 General Information

Page 21

Millenium™ RO System by GE Osmonics

M

1.14 Return Goods Authorization (RGA) Procedure

If you wish to return goods for, warranty evaluation and/or credit please have your

original sales order, invoice and device serial number available when you call GE

Osmonics. Call GE Osmonics at (800)-633-3080 and request Technical Service. A GE

Osmonics Technical Service representative will provide instructions and a return

authorization number, which needs to be clearly written on the outside of the box used to

ship your materials. All equipment must be shipped to GE Osmonics with the freight

prepaid by the customer. Call our Customer Service Center with any questions or issues

concerning freight claims and a representative will discuss your situation.

All materials to be returned must be rendered into a non-hazardous condition prior to

shipping.

14693e – 31 Mar 03 1 - 15 General Information

Page 22

Millenium™ RO System by GE Osmonics

M

1.15 Symbols and Abbreviations

“RENALIN®” Refers to Peracetic Acid and Peroxide-based Compounds, such as

Renalin®, Minncare™, Peracidin™ (20% peroxide, 4% Peracetic

Acid)

ASTM American Society for Testing and Materials

AAMI Association for the Advancement of Medical Instrumentation

CA Cellulose Acetate

C Celsius

CSA Canadian Standards Association

cc Cubic Centimeters

cf Cubic Foot (feet)

cfu/ml. Colony Forming Units per milliliter

cm Centimeters

DI Deionization

F Fahrenheit

FDA Food and Drug Administration

Ft Foot (feet)

GPD Gallons Per Day

GPM Gallons Per Minute

GHT Garden Hose Thread

gr Grains

GAC Granular Activated Carbon

HZ Hertz

HP Horse Power

lbs. Pounds

LED Light Emitting Diode

LPD Liters Per Day

LPM Liters Per Minute

m. Meter

mg/L. Milligrams Per Liter

ml. Milliliters

14693e – 31 Mar 03 1 - 16 General Information

Page 23

MNPT Male National Pipe Thread

MSDS Material Safety Data Sheet

Megohm/cm Million Ohms/Centimeter

mw Molecular Weight

NaCl Sodium Chloride

N/A Not Applicable

NPT National Pipe Thread

NSF National Sanitation Foundation

PA Polyamide

P/N Part Number

ppm Parts Per Million

psi Pounds Per Square Inch

PVC Polyvinyl Chloride

Millenium™ RO System by GE Osmonics

M

QD Quick Disconnect

RO Reverse Osmosis

ROMA Reverse Osmosis Membrane Assembly

TB Terminal Barrier Strip (Main): “TB1” (Example: “TB1-9” refers

to the terminal marked number 9 on the Main Terminal Barrier

Strip)

TF Thin Film

TDS Total Dissolved Solids

UL Underwriters Laboratory

VAC Volts Alternating Current

WFI Water for Injection

WT Weight

~ Volts Alternating Current

14693e – 31 Mar 03 1 - 17 General Information

Page 24

NOTES:

Millenium™ RO System by GE Osmonics

M

14693e – 31 Mar 03 1 - 18 General Information

Page 25

Millenium™ RO System by GE Osmonics

M

Millenium RO System

CHAPTER 2:

INSTALLATION GUIDELINES AND INITIAL SYSTEM START-UP

14693e - 31 Mar 03 2 - 1 Installation Guidelines and Instructions

Page 26

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e - 31 Mar 03 2 - 2 Installation Guidelines and Instructions

Page 27

Millenium™ RO System by GE Osmonics

M

2.1 Installation Considerations

1. Select a location for the Millenium™ near the required utilities and dialysis

equipment.

2. The RO unit requires 115 VAC power for operation and consumes 8 amps of

current (the 230 VAC model consumes 5 amps).

3. The RO unit requires nominally 2 GPM water at 30 PSI. Warmer feed water (up

to 25°) will produce more permeate, and will consume more water. The water

may also require some pretreatment to ensure maximum performance and

suitability. GE Osmonics recommends that feed water be chlorine/chloramine

free and solids above 5 microns in size be filtered out.

4. A drain with a minimum capacity of 2 GPM is required for the RO unit.

5. Back flow prevention may be required in accordance with local codes.

6. Special connections may be needed to connect to water supply. Connections vary

with different facilities.

2.2 Installation Procedures:

CAUTION:

If a carbon tank is present on the RO system, the carbon tank must be completely

rinsed of all carbon fines and ash before connecting to the RO unit. Otherwise,

irreparable damage to the TF membrane will result (refer to Carbon Manual).

WARNING:

The Millenium™ RO is stored with 1 wt.% sodium metabisulfite from the factory.

Follow all Material Safety Data Sheet (MSDS) guidelines that are included with the

RO.

NOTE:

For initial start-up, the large removable panel must be removed to allow access to

the pump and regulator for adjustments as well as to remove shipping materials.

The panel is held on with twelve stainless steel screws. Use caution any time a

panel is removed from the Millenium™.

1. Connect the Millenium™ RO inlet tubing GHT (garden hose thread) connector to

the inlet cold water supply, and the QD (quick-disconnect) end to the “Feed”

connection on the front panel.

2. Connect the waste water line to the waste QD connection on the front of the RO,

and to the drain in accordance with the local plumbing code. Making this

connection allows the waste flow by opening a check valve; disconnecting closes

it.

3. Connect the product line QD connector to the product fitting on the front panel.

Connecting together the male and female fittings (hose to RO) opens a check

14693e - 31 Mar 03 2 - 3 Installation Guidelines and Instructions

Page 28

Millenium™ RO System by GE Osmonics

M

valve allowing product flow. When the hose is disconnected, the product flow is

stopped.

4. Make sure that the inlet water valve switch and the RO pump power switch are in

the OFF position. Plug the power cord into a 115 VAC (230 VAC) grounded

outlet. Do not use an extension cord or an adapter.

5. Turn the water supply to the RO on.

6. Turn the operate/flush valve to the flush position.

7. Turn the inlet water valve switch on. Water will start to fill the RO. Allow the

RO to rinse to drain for five minutes after water begins to flow from the drain

line. The pump pressure gauge should indicate some pressure.

8. Turn the RO pump power switch on.

NOTE:

The operate/flush valve may need to be rotated part way towards the operate

position if the pump makes excessive noise.

9. Slowly turn the operate/flush valve to the operate position. Pump pressure should

not exceed 200 PSI. If 200 PSI is exceeded, adjust pump pressure on pump head

located inside the cabinet. See instructions in Figure 1 below:

FFiigguurree 11

14693e - 31 Mar 03 2 - 4 Installation Guidelines and Instructions

Page 29

Millenium™ RO System by GE Osmonics

M

10. Let the RO run for an additional 15 minutes or until the percent rejection and

TDS values have stabilized.

WARNING:

Ensure that TDS and membrane performance (% rejection) are normal for the

regions water quality. Consult your facility physician. An AAMI analysis and

bacteria test of the product water must be obtained and interpreted before using the

RO unit for hemodialysis treatment (refer to the Product Water Analysis procedure

and the Product Water Culture Procedure).

11. Set the product water TDS alarm limit switch as prescribed by the physician. The

switch is normally set to twice the initial TDS reading (or “next higher” setting) at

start-up.

WARNING:

The TDS alarm limit should not be moved from this setting unless instructed by a

physician.

12. After a minimum of 3 hours run time, disinfect and rinse the RO unit with an

approved disinfectant before using for hemodialysis treatment (refer to the

Formaldehyde and ‘RENALIN®’-type disinfection procedures in chapter four).

CAUTION:

New RO units with thin film membranes must be rinsed to drain with normal

pressures for a minimum of three (3) hours before exposure to disinfectants.

WARNING:

After disinfection, the product water must be verified free of residual disinfectant.

13. The RO product may be used in conjunction with hemodialysis treatment

equipment only after obtaining test results which validate compliance with

excepted standards.

• AAMI Product Water Panel

• Microbiological Culture (colony count) results

• Endotoxin (pyrogen) level testing (if applicable)

14. The Millenium™ RO is now ready for use.

14693e - 31 Mar 03 2 - 5 Installation Guidelines and Instructions

Page 30

Millenium™ RO System by GE Osmonics

M

2.3 Product Water Analysis Procedure:

In order to ensure that the RO is performing at or above AAMI (Association for the

Advancement of Medical Instrumentation) Standards, it is necessary to perform an

AAMI Water Quality Analysis test. For new units, the RO must be operated (rinsed to

drain) for at least two hours before taking a sample, to ensure that the membranes are free

of preservative or other contaminants which would invalidate the test.

WARNING:

There are many documented clinical risks in using less than AAMI Standard

product water (refer to Technote 103, "AAMI Hemodialysis Water Quality

Standards").

NOTE:

Follow the procedures recommended by your water quality-testing laboratory if

they vary from the following steps.

Materials Required: Produce water sampling kit, sterile gauze, tape, and container (such

as a small bucket).

1. Ensure that all pre-RO devices are operating correctly and are performance

verified by the appropriate testing.

2. Connect the RO unit to the required utilities (feed water, drain, power).

3. Operate the RO unit with product and waste flows to drain for at least 15 minutes

after the product water quality has stabilized before drawing the water sample.

4. Hold the product line over the container and run product water for 60 seconds.

5. Aseptically remove the lid from the sample bottle and rinse the bottle twice with

RO product water.

6. Fill the bottle completely with RO product water and cap it immediately.

7. Fill out the laboratory requisition form. Ensure the requisition form has, at a

minimum, information to identify the facility or location of the RO, the serial

number or facility equipment number to ensure which RO was tested and name,

phone number and address of whom to contact.

8. Place the bottle and the completed requisition in the pre-addressed mailer and

mail it directly to the laboratory.

NOTE:

Total chlorine must be measured on-site. Tests for Chlorine/Chloramine (total

chlorine) are not typically reported on the AAMI Analysis. Chlorine and

chloramine dissipate from the water sample over time and reported results will be

inaccurate.

NOTES:

14693e - 31 Mar 03 2 - 6 Installation Guidelines and Instructions

Page 31

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e - 31 Mar 03 2 - 7 Installation Guidelines and Instructions

Page 32

Millenium™ RO System by GE Osmonics

M

Millenium RO System

CHAPTER 3:

SYSTEM OPERATION

14693e - 31 Mar 03 3 - 11 System Operation

Page 33

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e - 31 Mar 03 3 - 22 System Operation

Page 34

Millenium™ RO System by GE Osmonics

M

3.1 Daily Start-up

WARNING:

Verification of the absence of all sanitizers, cleaners, disinfectants and

chlorine/chloramines must be performed before RO product water is used for any

patient related uses.

1. Connect the RO unit to the required utilities (feed water, drain, and power).

2. Ensure that all the valves in the water supply line to the RO are open.

3. Ensure that all pre-RO devices have been flushed and tested and are operating

within their specifications.

4. Ensure that the product rinse line is connected to the RO, with the other end in a

drain.

5. Move the inlet water valve switch to the open position. When water flows to

drain, the RO pump power switch can be moved to the on position.

6. The "Percent Rejection" monitor should indicate 95% rejection within 2 minutes

of start-up. It is normal for rejection to drop off until membranes have rinsed up

to optimum quality.

7. The TDS monitor should stabilize within 2 minutes of start-up. The TDS during

this time may be higher than the alarm set point. The audible alarm may be

muted at this time by pressing the alarm mute switch. The alarm mute switch will

silence the audible alarm for 30 - 45 seconds each time the switch is used.

WARNING:

When the RO is used for dialysis service, a test for disinfectant residual MUST be

performed.

8. Record data on a daily log sheet.

WARNING:

Any data that does not meet minimum standards set at your facility must be

reported to the medical director. The RO should not be placed in service until

readings are acceptable.

9. The Millenium™ RO is now ready for connection to the dialysis machine.

3.2 Shut Down Procedure

1. Turn off the RO pump power switch.

2. Turn off the inlet water valve switch.

3. Turn off the inlet water supply.

14693e - 31 Mar 03 3 - 33 System Operation

Page 35

Millenium™ RO System by GE Osmonics

M

4. Briefly turn on the inlet water valve switch. This will release pressure from the

feed water hose. When the pressure is released, turn the switch off.

NOTE:

If the Millenium™ RO is to be stored for more than 24 hours (RO not being

operated), the RO should be stored in an approved disinfectant or storage solution

(Not ‘RENALIN®’ or other type oxidizing products). Refer to the disinfection or

storage procedure in this manual.

5. Disconnect from the utilities and store the RO.

14693e - 31 Mar 03 3 - 44 System Operation

Page 36

NOTES:

Millenium™ RO System by GE Osmonics

M

14693e - 31 Mar 03 3 - 55 System Operation

Page 37

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e - 31 Mar 03 3 - 66 System Operation

Page 38

Millenium™ RO System by GE Osmonics

M

Millenium RO System

CHAPTER FOUR:

ROUTINE MAINTENANCE

14693e - 31 Mar 03 4- 1 Routine Maintenance

Page 39

Millenium™ RO System by GE Osmonics

M

This page intentionally left blank.

14693e - 31 Mar 03 4- 2 Routine Maintenance

Page 40

Millenium™ RO System by GE Osmonics

M

4.1 Routine Maintenance of Millenium™ RO System

GE Osmonics Millenium™ RO systems have been designed to operate with a minimum

of operator attention. Like all mechanical systems they will operate longer and with less

trouble when operator maintenance is performed regularly. Operator maintenance on a

GE Osmonics reverse osmosis system is limited to maintaining performance logs,

cleaning and disinfection, replacement of damaged or failed parts and periodic

lubrication. The maintenance procedures have been categorized by their frequency of

action and are as follows:

NOTE:

The first part of this section provides the timelines and simple instructions for

maintenance of your RO. The specific instructions and procedures for the more

complex maintenance items are provided in the second part of this section.

WARNING:

Prior to performing any electrical maintenance unplug the RO power cord from the

wall receptacle.

4.1.1 Daily Maintenance

1. Test and record the hardness level of the feed water in the pretreatment log.

2. Observe and record salt level in the brine tank (for systems with water softener

pretreatment).

3. Observe and record the Chlorine/Chloramine concentrations in the pretreatment

log. Follow the instructions included with each test kit.

WARNING:

Take corrective action or contact your local service representative if any optional

pretreatment device fails to provide adequate treatment of feed water before

continuing with the use of the RO unit.

4. If you are using cartridge pre-filters with your Millenium™, observe and record

the pre-filter inlet and outlet pressure gauges on the operation log. The difference

in the pressure values will help measure the condition of the filter cartridge.

When the pressure differential (delta P) increases 8 PSI above the clean, initial

delta P, the cartridges need to be changed (or sooner if the pre-filter core appears

soiled). To change the pre-filter, the water supply must be turned off. The prefilter inlet and outlet gauges should read zero PSI. The pre-filter bowl can now be

removed by rotating it clockwise. Remove the old filter, install the new filter and

re-install the filter bowl.

5. Observe and record the percent rejection and TDS water quality readings in the

operation log.

14693e - 31 Mar 03 4- 3 Routine Maintenance

Page 41

Millenium™ RO System by GE Osmonics

M

4.1.2 Weekly Maintenance

1. Observe, or measure, and record the waste and product flow rates on the operation

log. Allow the water temperature to stabilize before attempting to record the

results. This will help prevent errors due to fluctuating temperature.

2. Observe, or measure, and record the feed water temperature. Systems with

blending valves have thermometers installed in the plumbing. A hand held

thermometer may also be used. The water temperature has a significant effect in

the product flow rate of the RO membrane and on the evaluation of the

membranes’ need to be cleaned.

3. Disinfect the system if needed. Refer to the disinfection procedure in this

chapter.

4.1.3 Monthly Maintenance

1. Take a product water culture to test for bacteria colony forming units count (<200

cfu/ml). Refer to the product water culture procedure in this chapter.

2. Visually inspect the pre-filter core, if you are using cartridge pre-filtration.

CAUTION:

On occasion, the pressure differential between the two pre-filter gauges will not

alter significantly, however, the pre-filter will be soiled. If the core of the pre-filter

is dirty, particulates are breaking through the pre-filter and traveling downstream

and causing damage to the pump and RO membranes. If this is the case, the prefilter will require more frequent replacement on a routine basis.

3. Check the pump pressure settings. The pressure should be 190 PSI ± 10 PSI, and

should not exceed 200PSI.

4. Check the maximum product pressure setting. If it is above the original set point,

reduce the pressure with the regulator inside the cabinet.

5. Perform trend analyses from the log sheets.

4.1.4 Quarterly Maintenance

1. Clean the RO Membranes. Refer to the RO membrane cleaning procedure in this

chapter.

2. Disinfect the RO machine. The RO should be disinfected after cleaning. Refer to

the membrane disinfection procedure in this chapter.

3. Verify the TDS and percent rejection readings with an independent monitoring

device every 3 months.

4. Check the quick-disconnect fittings and hoses. They should seat securely and

fluid should shut off when they are disconnected.

14693e - 31 Mar 03 4- 4 Routine Maintenance

Page 42

Millenium™ RO System by GE Osmonics

M

4.1.5 Semi-annual Maintenance

1. Check and clean the Millenium™ cooling fan and grill.

2. Check the Product Recirculation check valve for proper operation. Refer to the

check valve test instructions in this chapter.

4.1.6 Annual Maintenance

1. An AAMI Water Quality Analysis of the product water should be conducted at

least yearly. (Refer to the Water Quality Analysis Procedure in Chapter two.)

2. Check the monitoring for accuracy.

3. Check the gauges for correct functioning.

4. Check the ball valves for correct operation.

5. Check the tubing and fittings for leaks or wear.

6. Check the switches and lights for correct operation.

7. Check all pre RO devices for correct operation.

8. Lubricate the motor. Refer to the lubricating instructions in this chapter.

14693e - 31 Mar 03 4- 5 Routine Maintenance

Page 43

Millenium™ RO System by GE Osmonics

M

4.2 Specific Maintenance Procedures and Instructions

4.2.1 Motor Lubricant Procedure

1. Remove the plastic plugs at both ends of the motor housing near the motor shaft.

2. Add three drops of SAE 20 wt. non-detergent motor oil into the opening.

3. Replace the plastic plugs.

4. Turn on the motor and run for 10 minutes.

4.2.2 Leak repair

General information

: Any leak from any part of the system should be corrected as soon as

possible. Left unattended, leaks can cause secondary damage necessitating expensive

repairs.

NOTE:

Use FDA/NSF approved silicone sealant on all threaded connections.

Threaded Connections:

1. Prior to performing this maintenance on any threaded fitting, release the pressure

on the piping/tubing system (i.e., turn off the pump, open a drain port, etc.)

2. Remove the connecting tubing.

3. Re-tape the pipe threads with 2 or 3 wraps of Teflon tape. (It is not necessary to

remove the old Teflon tape, although it may be advisable to do so if it is in very

bad shape).

4. Re-insert the threaded fitting into the opening and tighten hand tight. Be careful

to avoid cross threading. Tighten further using a wrench only if necessary, and

only about one-half turn.

5. Re-connect piping, pressurize, and inspect for leaks.

6. If the leak is still present, de-pressurize system again and tighten the fitting

another quarter-turn. Check again for leaks. (Over tightening can crack the

female fitting).

7. If the leak continues, it may be necessary to replace the male threaded fitting

and/or the female threaded fitting.

14693e - 31 Mar 03 4- 6 Routine Maintenance

Page 44

Tubing connections:

Millenium™ RO System by GE Osmonics

M

14693e - 31 Mar 03 4- 7 Routine Maintenance

Page 45

Millenium™ RO System by GE Osmonics

M

1. Prior to performing this maintenance on any tube fitting, release any pressure on

the tubing system (i.e., turn off the pump, open a drain port, etc.).

2. Remove the red locking clip (if applicable).

3. Push the dark gray collar in towards the body of fitting (light gray). This releases

the ‘gripper’ which holds the tubing in place.

4. Hold the gray collar in while gently pulling the tube away from the fitting. It may

be helpful to wiggle the tube side-to-side slightly while pulling.

5. Remove the gripper collar by pulling straight out. Reach into the opening with a

small, blunt (non-scratching) probe and remove the O-ring. (Inspect the collar to

insure that all grippers are intact.)

6. Rinse the O-ring with warm running water to remove any dirt, debris, or crusty

concentrate and set aside to dry on a clean paper towel.

7. Clean the inside of the fitting with a wet cotton swab or paper towel to remove

any dirt or debris. Be sure not to leave any cotton fibers from the swab or towel

inside the fitting.

8. Lubricate the O-ring sparingly with silicone O-ring lubricant and place the O-ring

back inside the fitting.

9. Replace the gripper collar.

10. With a sharp utility knife, cut off approximately ½” to 1” of the tube. Carefully

cut the tube as square (perpendicular to the length) as possible. Inspect remaining

tubing for marks/scratches and replace/repair as necessary.

11. Place the tube in the fitting opening and push firmly until the tube seats fully in

the socket (completely ‘bottomed out’).

12. Pull back on the tubing to seat the grippers, and re-install the locking clip (if

applicable) between the light gray body of the fitting and the dark gray collar (flat

side towards the body).

13. Re-pressurize the system (if applicable) and inspect for leaks.

14. If the leak is not resolved, start over or simply replace the entire tube fitting or

tube.

14693e - 31 Mar 03 4- 8 Routine Maintenance

Page 46

Millenium™ RO System by GE Osmonics

M

4.2.4 Product Recirculation Check Valve Test

With Valve In RO Unit

1. Measure TDS of Product water using a handheld meter. If RO display and TDS

measurement do not match within a small amount, replace check valve. If values

match, check valve is functioning correctly.

2. Measure and record the Product water flow (using a flow meter or graduated

cylinder and stopwatch). After determining flow rate, slowly kink the waste line

being careful to not close off the flow completely. Measure Product water flow

again and compare against previous results. If there is a noticeable increase in

flow, the check valve needs replaced.

3. If none of the above occurs, check valve is functioning correctly. For further

verification, proceed with the following test.

With Valve Removed From RO Unit

1. Apply pressure in opposite direction of flow indicated on check valve. Check

pressure reading (using a gauge) and for seepage. Remove pressure from valve

and cycle it (push in direction of flow several times using care not to scratch or

damage valve). Reapply pressure in opposite direction of flow and recheck

pressure and for seepage. If pressure does not drop and no seepage is found,

valve is functioning correctly.

14693e - 31 Mar 03 4- 9 Routine Maintenance

Page 47

Millenium™ RO System by GE Osmonics

M

4.3 Millenium™ Cleaning Indications

Foulants such as minerals, silt and organic substances may collect on the RO membrane

surface and cause the RO membrane to foul and diminish in its function. Many of these

foulants are prevented by proper selection of pretreatment equipment, while others are

treatable only with more sophisticated designs. Regardless of the foulant, it is essential

to clean the membrane promptly once cleaning is indicated. The longer a foulant is

allowed to remain in contact with the RO membrane, the more difficult it will be to

remove. In severe cases, repeated cleanings may be required.

NOTE:

Some foulants CANNOT be removed with cleaning and membrane performance

may not be fully restored. Observe the appearance of the cleaning solution before

discarding it. If the solution is heavily soiled, repeat the cleaning procedure with

fresh solution of the same type (high pH or low pH).

Routine cleaning of the RO membranes in conjunction with regular disinfection will keep

bacteria counts at a minimum and the RO membrane performance at its best. Cleaning

removes the silt, organic and mineral deposits that collect on the RO membrane surface

which, if left untreated, encourage bacterial growth and will eventually impair the RO

membranes' ability to perform. Disinfection kills most of the bacteria that may be present

in the system, but it does not remove the deposits on the membrane.

There are a variety of indications for cleaning membranes. The most common is a

reduced product flow rate. Remember that a reduction in inlet water temperature can also

result in a reduced flow rate. Refer to Technote 113 "Temperature Correction Factors" to

determine the reduction in flow that can be attributed to reduced water temperature.

Clean the membranes whenever the temperature compensated flow rate drops by 10%. A

loss in the membrane performance (percent rejection) or increase in TDS of the product

water may also be an indication to clean the membranes. A good preventative

maintenance practice is to clean the membranes on a quarterly basis, and more often if

needed.

CAUTION:

Membranes that have not been cleaned for a long time may actually incur damage

during cleaning as perforations are exposed that were masked by accumulations of

foulant. Regular maintenance cleaning is the best assurance of long membrane

service.

14693e - 31 Mar 03 4- 10 Routine Maintenance

Page 48

Millenium™ RO System by GE Osmonics

M

4.3.1 Pre-Cleaning Preparation

There are two types of cleaners available, a low pH cleaner (Calcium/Iron removal) and a

high pH cleaner (Silt/Organics removal). GE Osmonics provides these cleaners in liquid

form. The low pH cleaner attacks mineral scale deposits such as calcium, magnesium

and iron build-up, and should be used first. The high pH cleaner will remove

accumulated silt and organic matter from the RO membrane.

CAUTION:

The different cleaners must not be mixed together. Introduce the low pH cleaner

first, thoroughly rinse the system, and then use the high pH cleaner.

WARNING:

The solution is a mild irritant to eyes and skin. It is recommended that protective

gloves and eye protection be worn when handling the cleaner. Neither respiratory

protection nor special ventilation are required.

Materials Required:

Liqui-Clean 403™ – (Low pH liquid) - GE Osmonics Part No. 1228653 (1 Gal)

Liqui-Clean 211™ – (High pH liquid) - GE Osmonics Part No. 1228791 (1 Gal)

• high and low pH cleaner

• 2 Gallons pretreated water

• clean wide mouth container with volume of 2 ½ gallon or more

• pH test strips

• product rinse line (clear hose with male QD fitting on one end, open on the other)

• “DO NOT USE” warning labels (not provided by Osmonics)

• cleaning / disinfect log sheets

• most current log sheets for water quality comparison

4.3.1.1 Pre-Cleaning Procedure

Read and understand instructions on cleaner container before beginning procedure.

1. Connect the water inlet line to the water supply, and the waste and product lines

to drain. Turn the RO unit and water supply on.

2. Establish a pre-cleaning % rejection, TDS and pH record on the cleaning disinfect

log sheet.

3. Prepare the cleaning solution by adding the amount of cleaner as specified on the

labeling to two gallons of pretreated or RO product water.

14693e - 31 Mar 03 4- 11 Routine Maintenance

Page 49

Millenium™ RO System by GE Osmonics

M

CAUTION:

Water to be used must be chlorine free or damage to the RO membranes may result.

4. Turn the RO pump power and inlet water valve switches off.

WARNING:

Label machine with appropriate warning signs such as "Do Not Use / Contains

Cleaner" to prevent use of the RO until it is properly rinsed.

5. Connect the disinfect hose quick-disconnect fitting to the disinfect port on the

RO. Place the open end in the cleaning solution.

6. Connect the product rinse line to the product port and place the open end in the

cleaning solution.

7. Place the open end of waste line in the cleaning solution.

4.3.1.2 Cleaner Recirculation and Dwell Time

1. Turn the Operate/Flush valve to the Flush position. The Flush mode will allow the

flow of cleaner only to the rejection side of the RO membrane to flush surface

particulates away. Very little or no product water will be made in flush mode.

2. Push and hold the disinfect switch to operate the RO pump for three minutes.

CAUTION:

Some pump noise (chattering) is normal in the flush position. Excessive pump

noise (chattering) can be damaging to the pump. The RO is in “flush” from the full

open (flush) position to just before the fully closed (operate) position. Adjust it by

partly closing the flush valve to reduce chattering of the pump.

CAUTION:

DO NOT ALLOW PUMP TO RUN DRY. Damage will occur if pump is run dry.

CAUTION:

Check that there is waste flow within 10 seconds. If not, release the button (switch)

and verify that the disinfect-line is connected properly.

CAUTION:

Do not allow air or foam to be drawn into the RO system, as this will damage the

pump.

NOTE:

The cleaners will foam; this is normal. If using a closed container, provide a vent

to the atmosphere to relieve pressure.

3. Let the RO stand dormant with cleaning solution in it for thirty minutes.

4. Remove the waste hose from the cleaning solution and place it in the drain.

5. Using the disinfect switch, turn the RO on and flush approximately 1/2 gallon of

the solution to the drain. This prevents fouling the cleaning solution with the first

14693e - 31 Mar 03 4- 12 Routine Maintenance

Page 50

Millenium™ RO System by GE Osmonics

M

output after the dwell time.

6. Place the waste hose back in the cleaning solution container.

7. Using the disinfect switch, turn the RO on and operate it for five minutes.

8. Remove the product and waste hoses from the cleaning solution tank and place

them in the drain.

4.3.1.3 Post-Cleaning Rinse Procedure

1. Using the disinfect switch, turn the RO on and run cleaning solution to the drain

until the container is empty. This aids in emptying the container of cleaning

solution.

CAUTION:

DO NOT ALLOW THE PUMP TO RUN DRY. As an alternative, the solution

may be poured in the drain.

2. Rinse and drain the cleaning solution tank and the hoses then let them air dry.

3. Disconnect the disinfect hose from the RO.

4. Ensure that the water supply to the RO unit is on. If it is partially closed, rotate

the operate/flush valve to the full flush position.

5. Place the inlet water valve switch in the on position. Let water flow to the drain

for one minute.

6. Rotate the operate/flush valve to the operate position.

7. Set the RO pump power switch in the ON position. Rinse for 20 minutes with the

Operate/Flush valve in the Operate position until the % rejection and TDS

monitors’ displays normalize (e.g. 'usual' % rejection and 'usual' TDS reading).

Refer to your operating log for 'usual' readings and compare to the pre-cleaning

values.

A. During this rinse period, rotate the Operate/Flush valve to the

Flush position briefly and then back to Operate three times to

build-up and release pump pressure. This aids in flushing the

cleaner from the system.

8. Test the product water for post-cleaning pH and compare it to the pre-cleaning pH

level. The values should be the same or very close to the pre-cleaning pH. If it is

not, continue rinsing in the Operate position until equalization of the value occurs.

9. When all of the parameters (% Rejection, TDS, pH) have normalized, operate the

RO for an additional 20 minutes in rinse mode.

10. Repeat the cleaning procedure with the other pH cleaner. GE Osmonics

recommends using a low pH cleaner first, followed by a high pH cleaner after

rinsing thoroughly.

14693e - 31 Mar 03 4- 13 Routine Maintenance

Page 51

Millenium™ RO System by GE Osmonics

M

11. Turn the RO pump and inlet water valve switches OFF. Disconnect the product

rinse line, and drain and store it.

12. Reconnect the product line to its original connection.

13. Remove the “Do Not Use/Contains Cleaner” warning label.

14. The Millenium™ RO system is now ready for use.

14693e - 31 Mar 03 4- 14 Routine Maintenance

Page 52

Millenium™ RO System by GE Osmonics

M

4.3.2 BIOSAN™ Pre-Cleaning Preparation

BIOSAN™ is a liquid cleaner/descaler agent intended for use in removing mineral scale

and organic biofilm and is a short-term storage solution for RO water systems.

CAUTION:

BIOSAN™ is not intended for use in Hemodialysis Machines.

WARNING:

The solution is a mild irritant to eyes and skin. It is recommended that gloves

(latex/vinyl) and eye protection be worn when handling BIOSAN™. Neither

respiratory protection nor special ventilation are required.

Materials Required:

• BIOSAN™ cleaner

• product water

• clean wide mouth container with volume of 2 ½ gallon or more

• pH test strips

• product rinse line (clear hose with male QD fitting on one end, open on the other)

• “DO NOT USE” warning labels (not provided by Osmonics)

• cleaning / disinfect log sheets

• most current log sheets for water quality comparison

4.3.2.1 BIOSAN™ Cleaning Procedure

Read and understand all BIOSAN™ cleaning instructions before beginning

procedure.

1. Connect the water inlet line to the water supply, and the waste and product lines

to drain. Turn the RO unit and water supply on.

2. Establish the pre-cleaning % rejection, pH and TDS readings and record them on

the Cleaning/Disinfect Log Sheet.

3. Prepare the BIOSAN™ solution in accordance with the manufacturers

instructions.

4. Turn the RO pump power and inlet water valve switches off.

WARNING:

Label machine with appropriate warning signs such as "Do Not Use / Contains

BIOSAN™" to prevent use of RO until properly rinsed.

CAUTION:

Water to be used must be chlorine free or damage to the RO membranes may result.

14693e - 31 Mar 03 4- 15 Routine Maintenance

Page 53

Millenium™ RO System by GE Osmonics

M

5. Connect the disinfect line quick-disconnect fitting to the disinfect port on the RO.

Place the other (open) end of the line in the cleaning solution.

6. Connect the product rinse line to the product QD port and place the other end of

the line in the cleaning solution.

7. Place the end of the waste line in the cleaning solution.

4.3.2.2 BIOSAN™ Recirculation and Dwell Time

1. Rotate the Operate/Flush valve to the Operate position. This will allow the

BIOSAN™ to pass from the rejection side of the membrane through to the

product side of the membrane for total system exposure to the cleaning solution

once the RO is turned on in disinfect mode (step #2).

2. Push and hold the disinfect switch to operate the RO pump for three minutes.

CAUTION:

Check that there is waste flow within 10 seconds. If not, press the disinfect switch

to turn RO pump off and verify that the disinfect line is connected properly.

CAUTION:

DO NOT ALLOW PUMP TO RUN DRY. Damage will occur if pump is run dry.

CAUTION:

Do not allow air or foam to be drawn up into the RO unit, as this will damage the

pump.

NOTE:

Biosan™ will foam; this is normal. If using a closed container, provide a vent to

the atmosphere to relieve pressure.

3. Turn the Operate/Flush valve to the Flush position and hold the disinfect switch

for an additional 3 minutes. The Flush mode will allow the flow of cleaner only to

the reject side of the RO membrane to flush particles away. Very little or no

product water will be made.

CAUTION:

Some pump noise (chattering) is normal in the flush position. Excessive pump

noise (chattering) can be damaging to the pump. The RO is in “flush” from the full

open (flush) position to just before the fully closed (operate) position. Adjust by

partly closing the flush valve to reduce the chattering of the pump.

4. Allow the BIOSAN™ to dwell in the RO for a minimum of one hour.

14693e - 31 Mar 03 4- 16 Routine Maintenance

Page 54

Millenium™ RO System by GE Osmonics

M

NOTE:

Thin-film RO membranes: The Millenium™ RO unit may be stored in BIOSAN™

for up to two weeks.

5. Remove the waste and product lines from the cleaning solution and place them in

the drain.

4.3.2.3 BIOSAN™ Post-Cleaning Rinse Procedure

1. Using the disinfect switch, turn the RO on and run the cleaning solution to the

drain until the container is empty.

CAUTION:

DO NOT ALLOW THE PUMP TO RUN DRY. As an alternative, the solution

may be poured in the drain.

2. Disconnect the disinfect line from the RO.

3. Ensure that the water supply to the RO system is on. If it is partially closed, rotate

the operate/flush valve to the full flush position.

4. Push the inlet water valve switch to the ON position. Let water flow to the drain

for one minute.

5. Rotate the Operate/Flush valve to the operate position.

6. Set the RO pump power switch in the ON position. Rinse for 20 minutes with the

Operate/Flush valve in the Operate position until the % rejection and TDS

monitor displays normalize (e.g. 'usual' % rejection and 'usual' TDS reading).

Refer to your operating log for 'usual' readings and compare to the pre-cleaning

values.

A. During this rinse period, rotate the Operate/Flush valve to the Flush position

briefly and then back to Operate three times to build-up and release pump

pressure. This aids in flushing the cleaner solution from the system.

7. Test the product water for post cleaning pH and compare it to the pre-cleaning pH

level. The values should be the same or very close. If it is not, continue rinsing

in the Operate position until equalization of the value occurs.

8. When all of the parameters (% Rejection, TDS, pH) have normalized, operate the

RO for an additional 20 minutes in rinse mode.

9. Turn the RO pump and inlet water valve switches OFF. Disconnect the product

rinse line, and drain and store it.

10. Reconnect the product line to its original connections.

11. Remove the 'Do Not Use/Contains BIOSAN™' warning label.

12. The Millenium™ RO System is now ready for use.

14693e - 31 Mar 03 4- 17 Routine Maintenance

Page 55

Millenium™ RO System by GE Osmonics

M

4.4 Millenium™ Disinfection Indications

DETERMINATION OF MICROBIAL CULTURING AND DISINFECTION

FREQUENCY IS THE RESPONSIBILITY OF THE OPERATING FACILITY.

The following is recommended for critical applications where bacteria and endotoxins

are a major concern, such as for Hemodialysis.

Disinfection should occur when bacterial growth is above the limits set by the facility, or

when over 200 CFU/ml (maximum AAMI standard) is detected. Routine disinfection at

lower CFU counts will inhibit colonization of bacteria in the system and the distribution

plumbing.

Rapid re-growth of bacteria following disinfection, or excessively high colony counts

(i.e. TNTC), may indicate a need for more aggressive intervention. Strategies such as

increased frequency of disinfection, longer dwell times, or alternative chemical agents

may be employed.

CAUTION:

Glutaraldehyde and Actril™ are not recommended disinfectants for the

Millenium™.

4.4.1 Formaldehyde Disinfection Preparation

CAUTION:

New replacement thin film membranes must be rinsed to drain with normal

pressures for a minimum of six (6) hours before first exposure to formaldehyde, or

irreversible damage may occur. No mandatory pre-rinse of the membranes is

required for future disinfections.

WARNING:

Always wear rubber gloves, apron and facemask. Use proper ventilation during

disinfection and rinse-out. A face respirator with an organic cartridge to remove

formaldehyde fumes may be worn. DO NOT BREATHE FUMES OR ALLOW

FORMALDEHYDE TO COME IN CONTACT WITH SKIN OR EYES. Refer to

MSDS supplied by manufacturer of the formaldehyde or formalin product.

Materials Required:

• 800 ml. Formaldehyde, 37%

• 2 gallons pre treated or RO water

• clean wide mouth container with volume of 2 ½ gallon or more

• formaldehyde test kit

• product rinse line (clear hose with male QD fitting on one end, open on other)

• “DO NOT USE” warning labels or signs (not provided by Osmonics)

• cleaning / disinfect log sheets

• most current log sheets for water quality comparison

• proper protective body wear

WARNING:

14693e - 31 Mar 03 4- 18 Routine Maintenance

Page 56

Millenium™ RO System by GE Osmonics

M

Label the machine with appropriate warning signs such as "Do Not Use / Contains

Formaldehyde" to prevent use of the RO until it is properly rinsed.

4.4.1.1 Formaldehyde Pre-Disinfection Procedure

1. Turn the Millenium™ RO off.

2. Disconnect the RO system from the dialysis machine.

3. Connect the RO product rinse line to the product port and place the open end in a

drain.

4. Connect the waste line to the RO and run the other end to a drain.

NOTE:

Follow your facility’s procedure for formaldehyde disposal. The drain line may

have to be placed in a container. Verify that the operate/flush valve is in the

OPERATE position.

5. Prepare a 4% solution of formaldehyde (800 ml of 37% formaldehyde to 2 gallons

of pre-treated water. The 2 gallons of solution is adequate for the Millenium™

RO).

CAUTION:

Formaldehyde or Formalin is usually provided in a clinical setting in a 37%

solution. Check the labeling on the packaging to make certain this is the case. If the

solution is other than 37%, the dilution will require adjustment. The end solution

should not exceed 4.2%. Consult the Medical Director or Director of Nursing to

determine the correct solution strength. Osmonics will not be responsible for any

damaged components due to incorrect solution strength.

6. Attach the quick-disconnect end of the disinfect line to the disinfect port of the

RO. Place the open end of the disinfect line in the disinfectant.

4.4.1.2 Formaldehyde Disinfection and Dwell Time

1. Push and hold the disinfect switch to operate the RO pump. Allow the RO to

operate until the disinfectant has been drawn into the machine.

CAUTION:

Check that there is waste flow within 10 seconds. If not, push the switch once and

verify that the disinfect line is submerged in the solution and the QD is connected

correctly. Do not allow air to be drawn into the RO system, as this will damage the

pump.

2. Test for the presence of formaldehyde in the product line (the RO must be

running).

3. Release the disinfect switch.

14693e - 31 Mar 03 4- 19 Routine Maintenance

Page 57

Millenium™ RO System by GE Osmonics

M

4. Momentarily turn the inlet water valve switch on (approximately 5 seconds), then

turn it off again. This allows the water to rinse the disinfectant from the disinfect

line and quick-disconnect connection.

WARNING:

Failure to perform this step creates a potentially dangerous situation

(FORMALDEHYDE SPILLAGE) and prolongs the rinsing out of the disinfectant.

5. Disconnect the disinfect line from the quick-disconnect port.

6. Ensure that the FORMALDEHYDE warning label is clearly visible.

7. Remove the product rinse line and waste line from disinfect tank and RO.

8. Rinse the disinfect line and the disinfect tank with water to remove the

formaldehyde, and store it appropriately.

9. Allow the disinfectant solution in the RO to remain in contact for a minimum of

two hours, or, preferably, overnight.

NOTE:

The RO may be stored for up to one year at this time. If this is the case, a 0.5%

solution may be used instead of 4%.

4.4.1.3 Formaldehyde Post-Disinfection Rinse Procedure

1. Connect the product rinse line, input water and waste lines to the RO.

2. Ensure that the product rinse and waste lines are in the drain.

3. Turn the operate/flush valve to the flush position.

4. Turn on the inlet water valve and allow the system to rinse for 2 minutes.

5. Turn on the RO power switch and run the RO for 10 minutes.

CAUTION:

Some pump noise (chattering) is normal in the flush position. Excessive pump

noise (chattering) can be damaging to the pump. The RO is in “flush” from the full

open (flush) position to just before the fully closed (operate) position. Adjust it by

partly closing the flush valve to reduce the chattering of the pump.

6. Rotate the operate/flush valve to the operate position.

7. Turn RO pump power switch off for 1 minute. Turn the RO pump switch on for

2-3 minutes. This will aid in the rinsing out any trapped formaldehyde in the

Millenium™ RO.

8. Continue to rinse for an additional 5 minutes.

9. Check the product line for residual disinfectant with an appropriate test kit. If the

test is positive, continue to rinse until a negative test is obtained.

10. Disconnect the product rinse line and store it.