Page 1

GE Healthcare

MicroCal™ iTC

Operating Instructions

Original Instructions

200

System

Page 2

Page 3

Table of Contents

1 Introduction .............................................................................. 5

1.1 Important user information ................................................................................. 6

1.2 Regulatory information .........................................................................................7

1.3 Instrument ................................................................................................................ 10

1.4 Control software .................................................................................................... 13

2 Safety instructions................................................................. 15

2.1 Safety precautions ............................................................................................... 15

2.2 Labels .......................................................................................................................... 21

2.3 Recycling procedures .......................................................................................... 25

3 Installation .............................................................................. 27

3.1 Site requirements .................................................................................................. 27

3.2 Transport ...................................................................................................................29

3.3 Unpacking ................................................................................................................. 29

3.4 Set up .......................................................................................................................... 29

3.5 Validation ..................................................................................................................37

3.6 Configuring a MicroCal iTC

Table of Contents

controller for networking .................... 38

200

4 Operation ................................................................................ 39

4.1 Procedure before a run ...................................................................................... 39

4.2 Basics of performing a run ............................................................................... 39

4.3 Loading the syringe ............................................................................................. 39

4.4 Loading the cell ...................................................................................................... 40

4.5 Experimental design ............................................................................................ 42

4.6 Advanced experimental design ...................................................................... 43

4.7 Instrument controls .............................................................................................. 44

4.8 Real time plot .......................................................................................................... 46

4.9 Set up .......................................................................................................................... 46

4.10 Procedures after a run ........................................................................................ 47

5 Maintenance ........................................................................... 49

5.1 Cell cleaning ............................................................................................................ 49

5.2 Removing injection syringe .............................................................................. 49

5.3 Inserting a new syringe ...................................................................................... 50

5.4 Syringe cleaning .................................................................................................... 51

5.5 Removing pipette .................................................................................................. 52

5.6 Changing pipette tips .......................................................................................... 53

5.7 Pipette calibration ................................................................................................. 54

5.8 Y-axis calibration check ..................................................................................... 54

5.9 Replacement of fuses ......................................................................................... 56

MicroCal iTC

Operating Instructions 28-9639-77 AA 3

200

Page 4

Table of Contents

6 Troubleshooting..................................................................... 57

6.1 How to get help ......................................................................................................57

7 Reference information.......................................................... 59

7.1 Instrument specifications .................................................................................. 59

7.2 Ordering information ...........................................................................................60

4 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 5

1 Introduction

Purpose of the Operating

Instructions

The Operating Instructions provide you with the instructions needed to handle the

MicroCal iTC

Prerequisites

In order to operate the MicroCal iTC

following prerequisites must be met:

• You should have a general understanding of the use of a personal computer.

running Microsoft™ Windows™ in the version provided with your product .

• You should be acquainted with the use of general laboratory equipment and with

handling of biological materials.

in a safe way.

200

Introduction 1

safely and according to the intended purpose the

200

• You must read the Safety Instructions in Chapter 2 of these Operating Instructions.

• The system should be installed according to the instructions in Chapter 3 of these

• You should understand the concepts of titration Calorimetry.

• You must read and understand these Operating Instructions.

In this chapter

This chapter contains important user information and a general description of the

MicroCal iTC

Operating Instructions.

and its intended use.

200

MicroCal iTC

Operating Instructions 28-9639-77 AA 5

200

Page 6

1 Introduction

1.1 Important user information

1.1 Important user information

Read this before using the

MicroCal iTC

200

All users must read the Safety Instructions in Chapter 2 of these Operating Instructions

before installing, using or maintaining the system.

Intended use

Safety notices

Do not operate the MicroCal iTC

documentation. If you do, you may be exposed to hazards that can lead to personal

injury and you may cause damage to the equipment.

The MicroCal iTC

molecular interaction studies in research applications.

The MicroCal iTC

clinical procedures or for diagnostic purposes.

These Operating Instructions contain WARNINGS, CAUTIONS and NOTICES concerning

the use of the product, with meanings as defined below.

is an Isothermal Titration Calorimeter system designed for bio-

200

system is intended for research use only and shall not be used in any

200

WARNING

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury. It is important not to proceed until all

stated conditions are met and clearly understood.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury. It is important not to proceed until all

stated conditions are met and clearly understood.

in any other way than described in the user

200

NOTICE

NOTICE indicates instructions that must be followed to avoid damage to

the product or other equipment.

6 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 7

Notes and tips

Note: A Note is used to indicate information that is important for trouble-free and

optimal use of the product.

Tip: A tip contains useful information that can improve or optimize your procedures.

Typographical conventions

Software texts and commands are identified by bold italic text. A colon is used to

separate menu levels (e.g. File:Open refers to the Open option in the File menu).

1.2 Regulatory information

This section lists the directives and standards that are fulfilled by MicroCal iTC

Manufacturing information

Introduction 1

Regulatory information 1.2

.

200

CE conformity

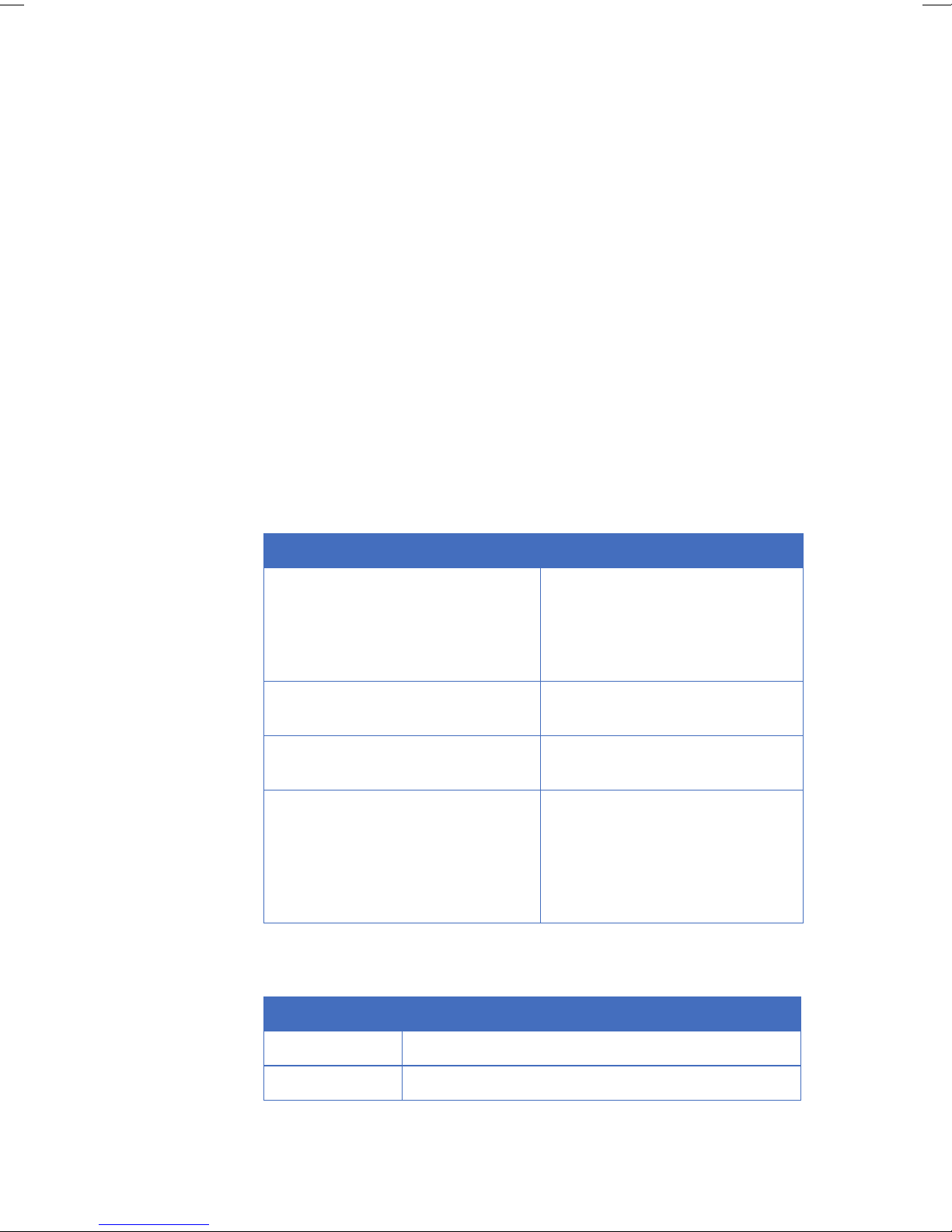

Requirement Content

Name and address of manufacturer GE Healthcare

MicroCal Products Group

22 Industrial Drive East

Northampton, Massachusetts

01060 USA

Place and date of declaration Northampton, Massachusetts,

USA, Jan. 2010

Identity of person authorized to sign

Declaration of Conformity

Date of manufacture and serial

number

See EC Declaration of Conformity in

system documentation kit.

The serial number contains the

code for the year of the

manufacture of the instrument.

(the serial number takes the form

of) xx.yy.zzz where

yy = year of manufacture.

Directive Title

2006/42/EC Machinery Directive (MD)

2006/95/EC Low Voltage Directive (LVD)

MicroCal iTC

Operating Instructions 28-9639-77 AA 7

200

Page 8

1 Introduction

1.2 Regulatory information

Directive Title

2004/108/EC ElectroMagnetic Compatibility (EMC) Directive

International standards

Standard Description Notes

CE marking

EN 61010-1,

IEC 61010-1,

CAN/CSA-C22.2

Safety requirements for electrical

equipment for measurement,

control and laboratory use

no. 61010-1

EN 61326-1

(CISPR Group 1,

Class A)

EN-ISO 12100-1,

12100-2

EMC emissions and immunity

requirements for measurement,

control and laboratory use

Safety of machinery – Basic

concepts, general principles and

Harmonized with

2004/108/EC

Harmonized with

2006/42/EC

design

EN-ISO 14121-1,

14121-2

Safety of machinery – Principles of

risk assessment

Harmonized with

2006/42/EC

The CE marking and the corresponding Declaration of Conformity is valid for the

instrument when it is:

• used as a stand-alone unit, or

• connected to other CE-marked instruments, or

• connected to other products recommended or described in the user

documentation, and

• used in the same state as it was delivered from GE Healthcare, except for

alterations described in the user documentation or explicitly authorized by GE

Healthcare.

8 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 9

Regulatory compliance of

connected equipment

Any equipment connected to the MicroCal iTC

of EN 61010-1/IEC61010-1 or relevant harmonized standards. Within the European

Union, connected equipment must be CE-marked.

Introduction 1

Regulatory information 1.2

should meet the safety requirements

200

MicroCal iTC

Operating Instructions 28-9639-77 AA 9

200

Page 10

1 Introduction

1.3 Instrument

1.3 Instrument

The MicroCal iTC

heat evolved or absorbed in liquid samples as a result of mixing precise amounts of

reactants. A spinning syringe is utilized for injecting and mixing of reactants. Spin rates

are user selectable; the usual range is 500 to 1000 rpm. The normal temperature

operating range is 2°C to 80°C. Wetted cell surfaces are Hastalloy, which are resistant

to most solutions, however, strong acids should be avoided.

Sample and reference cells are accessible for filling and cleaning through the top of the

unit. The sample cell is on the left as one faces the front of the unit. A pair of identical

coin shaped cells is enclosed within two shields; the inner shield is referred to as the

jacket. Access stems travel from the top exterior of the instrument to the cells. Both the

coin shaped cells and the access stems are completely filled with liquid during

operation. This requires approximately 280 µL per cell even though the working volume

of the cell is only 200 µL.

(Isothermal Titration Calorimeter, 200 µL cell) unit directly measures

200

Figure 1-1. Principle drawing of ITC.

Part Description Part Description

1Pipette 5Sample cell (with syringe)

2 Plunger screw (dark blue) 6 Adiabatic jackets

3 Stirring motor 7 Reference cell

4 Syringe (light blue) 8 Outer shield

10 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 11

Introduction 1

Instrument 1.3

2

3

4

5

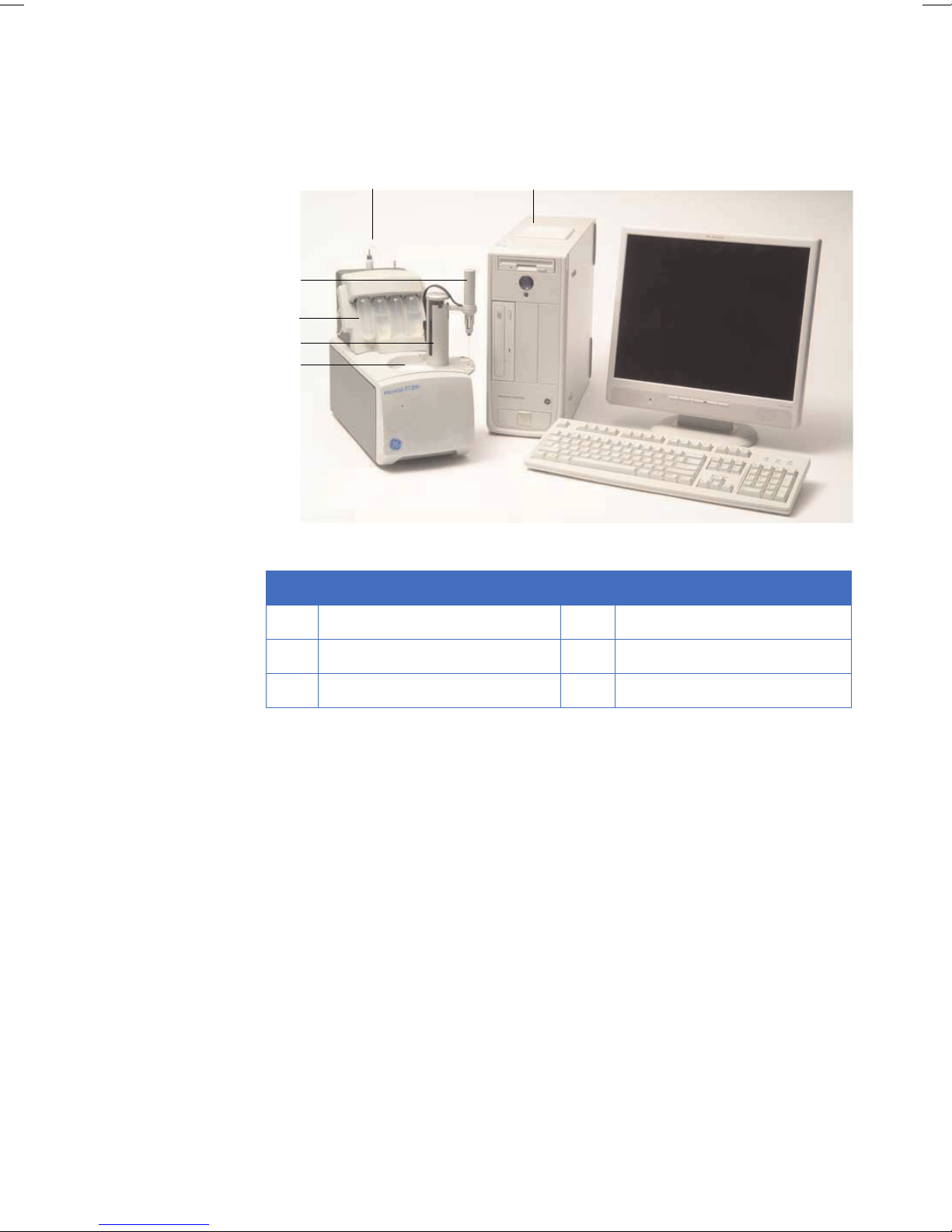

6

Figure 1-2. MicroCal iTC

complete system.

200

1

Part Description Part Description

1 Controller 4 Washing module

2 MicroCal iTC

200

5Tower

3 Pipette 6 Cell Unit

Temperature differences between the reference cell and the sample cell are measured,

calibrated to power units and displayed to the user as well as saved to disk. The data

channel is referred to as the DP signal, or the differential power between the reference

cell and the sample cell. This signal is sometimes thought of as the "feedback" power

used to maintain temperature equilibrium. Calibration of this signal is obtained

electrically by administering a known quantity of power through a resistive heater

element located on the cell.

In a typical experiment, the syringe containing a ligand is titrated (injected) into the cell

containing a solution of macromolecule. An injection which results in the evolution of

heat (exothermic) within the sample cell causes a negative change in the DP power,

since the heat evolved chemically provides heat that the DP feedback is no longer

required to provide.

The opposite is true for endothermic reactions. Since the DP has units of power, the time

integral of the peak yields a measurement of thermal energy, dH. This heat is released

or absorbed in direct proportion to the amount of binding that occurs. When the

macromolecule in the cell becomes saturated with added ligand, the heat signal

diminishes until only the background heat of dilution is observed.

MicroCal iTC

Operating Instructions 28-9639-77 AA 11

200

Page 12

1 Introduction

1.3 Instrument

With the MicroCal iTC

system the entire experiment takes place under computer

200

control. The user inputs the experimental parameters (temperature, number of

injections, injection volumes) and the computer carries out the experiment.

<DoNotTranslate_GE_Color>Origin™ software is then used to analyze the ITC data

using fitting models to calculate reaction stoichiometry (n), binding constant (K

),

A

enthalpy (ΔH) and entropy (ΔS).

12 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 13

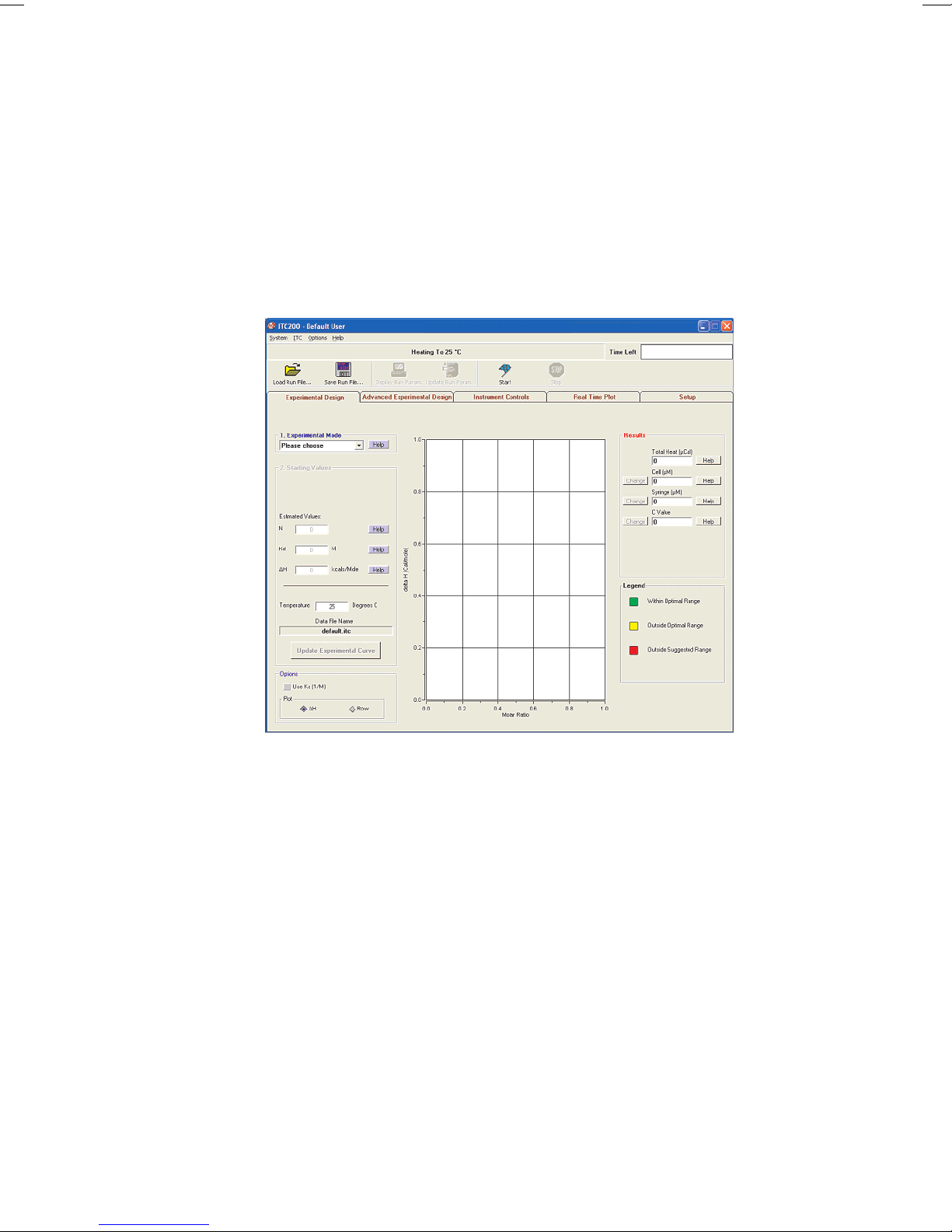

1.4 Control software

In order for the system to initialize properly, all components must be powered up in the

correct order. First, boot up the computer and log in to Windows. Once Windows has

started, power the MicroCal iTC

several seconds, open the MicroCal iTC

copy of <DoNotTranslate_GE_Color>Origin will open automatically, as well as the

MicroCal iTC

control software.

200

Introduction 1

Control software 1.4

by operating the switch at the rear of the unit. After

200

software. If the option is selected, a real-time

200

MicroCal iTC

Figure 1-3. Instrument control software.

When the instrument first boots up, the line just below the menus reads "System

Initialization - Please Wait", which is the current status of the instrument. After a few

seconds, the system will begin heating or cooling to the preset temperature. If the

instrument is not attached or not turned on, the program will open into Demo Mode, in

which the user can see and manipulate the program, but it will not attempt to control

the MicroCal iTC

. To the right of the status bar, the Time Left box, during a run, will

200

show the time left until the end of the run.

When the software is first started, the Experimental Design tab is selected; this

contains the simple run controls. Experimental Mode can be Highest Quality, Minimum

Protein, or High Speed. The expected n, K

, and ΔH and the desired run temperature will

D

allow the software to calculate the recommended concentrations for the cell and

syringe, and set the run parameters. The Advanced Experimental Design tab contains

more direct controls for the more advanced user. This tab should be very familiar to

users of the VP line of instruments. The Instrument Controls tab allows the user to

name the output files, choose post-run analysis options, and start and stop the run. The

Real Time Plot tab shows the data currently being generated. The Setup tab contains

various options and preferences.

Operating Instructions 28-9639-77 AA 13

200

Page 14

1 Introduction

1.4 Control software

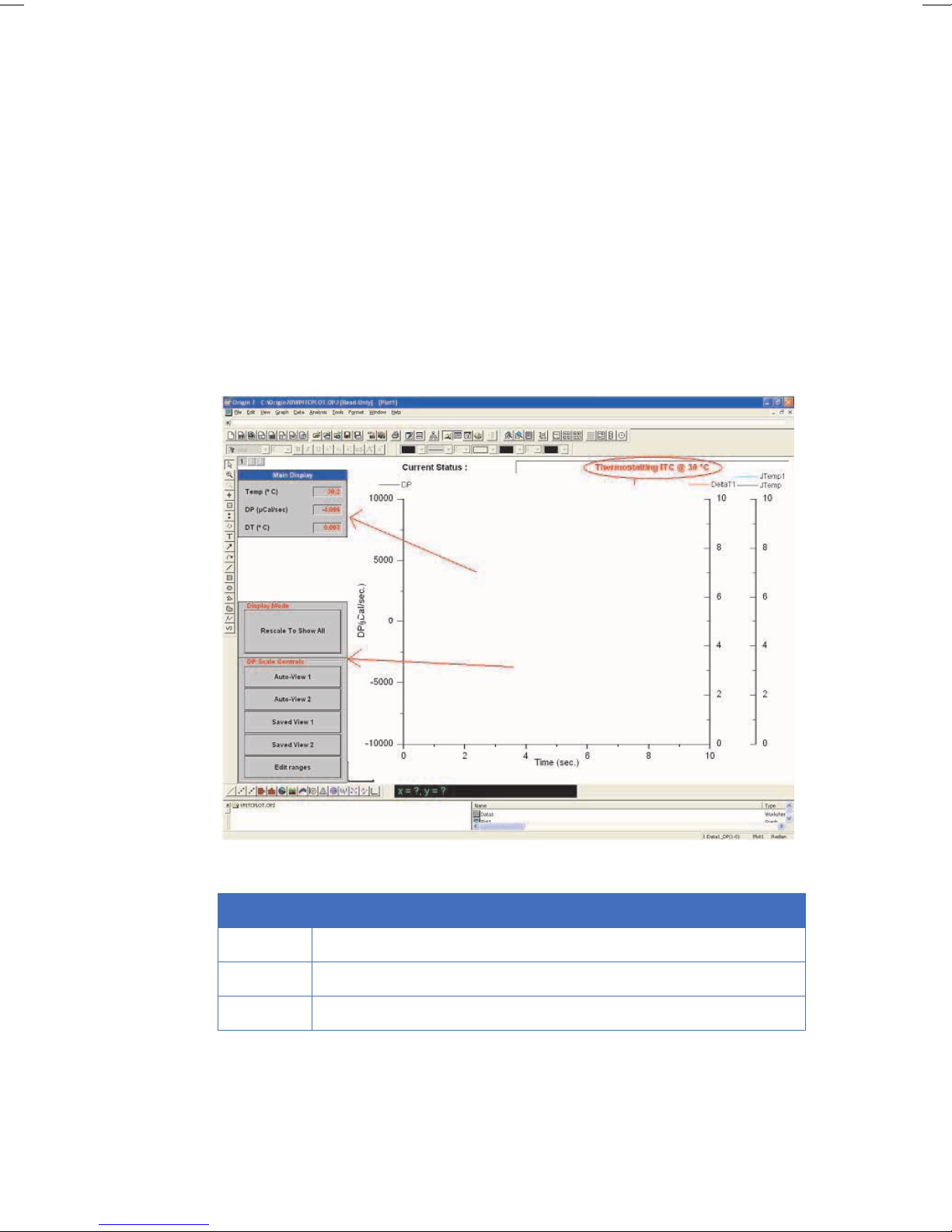

Origin software

Origin Real-Time Display

This section describes the functionality of the optional copy of

<DoNotTranslate_GE_Color>Origin for real-time display. When the software is opened,

it will open the <DoNotTranslate_GE_Color>Origin™ project window VPITCPLOT.OPJ for

real time data display. This project of <DoNotTranslate_GE_Color>Origin is dedicated to

data display only, and should not be used for data analysis. Users should open a

separate copy of <DoNotTranslate_GE_Color>Origin for MicroCal iTC

analysis. Pictured below is the main <DoNotTranslate_GE_Color>Origin window for

MicroCal iTC

data display.

200

to perform data

200

1

2

3

Figure 1-4. <DoNotTranslate_GE_Color>Origin Real-Time display.

No. Description

1iTC cell status

2iTC numeric display

3 Buttons for iTC data display

The ITC cell status, the MicroCal iTC

data tools (as indicated above) have been added for user convenience in viewing

iTC

200

data generated by the MicroCal iTC

14 MicroCal iTC

numeric display and the buttons for MicroCal

200

. For a more thorough description of these real-

200

Operating Instructions 28-9639-77 AA

200

Page 15

Introduction 1

Control software 1.4

time tools in <DoNotTranslate_GE_Color>Origin, refer to the MicroCal iTC

Experimental and Data Analysis Tutorial Guide.

200

MicroCal iTC

Operating Instructions 28-9639-77 AA 15

200

Page 16

1 Introduction

1.4 Control software

16 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 17

2 Safety instructions

The points below are intended to enhance your safety awareness and to draw your

attention to risks which only you, the operator, can prevent . While GE Healthcare works

to ensure that the instrument is designed and tested to be as safe as possible, proper

handling is also critical. The operators should be responsible people trained in basic

laboratory protocol, and they should be familiar with the possible hazards before

operating this instrument. All instrument modifications should be performed only by

personnel trained by GE Healthcare. Equipment damage, personal injury or even death

may result if this equipment is operated, altered or maintained by untrained personnel

or in an irresponsible or improper manner.

2.1 Safety precautions

Safety instructions 2

Safety precautions 2.1

Introduction

Before installing, operating of maintaining the system, you must be aware of the

hazards described in the user documentation. Follow the instructions provided to avoid

personal injury or damage to the equipment.

The safety precautions in this section are grouped into the following categories:

• General precautions

• Flammable liquids

• Personal protection

• Installing and moving the instrument

•System operation

•Maintenance

MicroCal iTC

Operating Instructions 28-9639-77 AA 15

200

Page 18

2 Safety instructions

2.1 Safety precautions

General precautions

WARNING!

Provide proper electrical power to the instrument. This should be 100 –

240 Volt, 50/60 Hertz alternating current, with a Ground Fault Circuit

Interrupter (GFCI). Some power strips, such as the one provided by GE

Healthcare with your instrument, contain a GFCI. All power plugs and

cords should be 3-prong, grounded cables or outlets.

WARNING!

In case of fire, unplug instrument.

WARNING!

Do not operate the MicroCal iTC

the MicroCal iTC

and/or Auto-MicroCal iTC

200

in any other way than described in

200

manuals.

200

WARNING!

Make sure the rear power connector is always accessible.

WARNING!

Use caution when using solutions near the instrument. If any liquid is

spilled on or around the instrument, unplug the instrument immediately

and wipe it up. If there is any possibility that liquid may have leaked into

the instrument case, contact GE Healthcare immediately. Do not plug

the instrument into any electrical outlet until the problem is resolved.

WARNING!

This instrument is not designed to the Medical Devices Directive 93/42/

EEC and should not be used for medical purposes and/or in the

diagnosis of patients.

NOTICE

The MicroCal iTC

cells are constructed out of Hastelloy. Strong acids

200

should be avoided.

16 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 19

Using flammable liquids

WARNING!

A fume hood or similar ventilation system shall be installed when

flammable or noxious substances are used.

WARNING!

Fire Hazard. Before starting the system make sure that there is no

leakage.

Personal protection

WARNING!

Always use protective glasses and other personal protective equipment

appropriate with the current application, to ensure personal safety

during operation.

Safety instructions 2

Safety precautions 2.1

WARNING!

The operator should always follow proper laboratory procedures in

handling and disposing of volatile or hazardous solutions.

WARNING!

This instrument is used for a wide variety of experiments that can utilize

potentially hazardous materials. Use of these could cause exposure to

biological, chemical and radiation hazards depending on the user’s

experiments. Users should educate themselves about the samples they

are using to avoid these hazards.

MicroCal iTC

Operating Instructions 28-9639-77 AA 17

200

Page 20

2 Safety instructions

2.1 Safety precautions

Installing and moving the

instrument

WARNING!

Power cord. Only use power cords delivered or approved by GE

Healthcare.

WARNING!

Do not block the ventilation inlets or outlets on the system.

WARNING!

The Washing Module may only be powered by the power supply

provided with the Unit.

WARNING!

Installing the controller. The controller should be installed and used

according to the instructions provided by the documentation included

in the shipment.

WARNING!

Replace fuses ONLY with 4.00 Amp 250 Volt Time Delay Fuses. Several

spare fuses are provided with the original shipment.

WARNING!

Access to power switch and power cord. Do not block the rear and side

panel of the instrument. The Power switch must always be easy to

access. The power cord must always be easy to disconnect.

NOTICE

Disconnect power. To prevent equipment damage, always disconnect

power from the MicroCal iTC

and washing module system before an

200

instrument module is removed or installed or a cable is connected or

disconnected.

System operation

WARNING!

All solutions in the cells must be cooled down below 40ºC before

removal. Any higher temperature may cause the syringe to break, and

will increase the dangers of most hazardous solutions.

18 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 21

Safety instructions 2

Safety precautions 2.1

WARNING!

Do not place containers of liquid on top of the instrument, except those

designed for the washing module. Spilled liquid is a fire and electrical

hazard.

CAUTION

Waste tubes and containers shall be secured and sealed to prevent

accidental spillage.

NOTICE

Never allow liquid in the cells to freeze. The expansion of the liquid can

distort the cells and rupture the most critical sensor, causing irreparable

damage.

NOTICE

Intermittent operation of the Washing Module is required so that the

Washing Module valves are on for a maximum of 20 minutes, then off for

30 minutes. Software limits the valve on period to 10 minutes before an

experiment, so this does not affect normal operation of the instrument.

Maintenance

NOTICE

The MicroCal iTC

instrument should always be moved in its normal

200

operating orientation. Other orientations will subject delicate sensors

inside the instrument to stress.

WARNING!

Replace fuses ONLY with same type fuses. Several spare fuses are

provided with the original shipment and the power receptacle is labeled

with the correct type.

WARNING!

Repairs, alterations or modifications must only be carried out by a GE

Healthcare specialist , or with explicit directions from a GE Healthcare

technician. Removal or modification of any cover or component could

result in an unsafe or easily damaged instrument. The GE Healthcare

service department will be happy to answer any questions and provide

parts and service when necessary.

WARNING!

Only spare parts that are approved or supplied by GE Healthcare may

be used for maintaining or servicing the system.

MicroCal iTC

Operating Instructions 28-9639-77 AA 19

200

Page 22

2 Safety instructions

2.1 Safety precautions

WARNING!

Disconnect power. Always disconnect power from the instrument before

replacing any component on the instrument, unless stated otherwise in

the user documentation.

WARNING!

Hazardous chemicals during run. When using hazardous chemicals,

flush the entire system tubing with distilled water, before service and

maintenance.

WARNING!

Hazardous chemicals during maintenance. When using hazardous

chemicals for cleaning, wash the system with a neutral solution in the

last phase or step.

WARNING!

Decontaminate the equipment before decommissioning to ensure the

removal of all hazardous residues.

equipment.

WARNING!

CONTRAD® 70 (Decon 90) is corrosive and therefore dangerous to

health. When using hazardous chemicals, avoid spillage and wear

protective glasses, gloves, and other suitable personal protective

20 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 23

2.2 Labels

Labels on the instrument

The illustration below shows an example of the identification labels attached to the rear

of the MicroCal iTC

instrument.

200

Safety instructions 2

Labels 2.2

Figure 2-1. Back panel of instrument.

Labels on the USB hub

The illustration below shows an example of the label on the back of the USB hub.

Figure 2-2. USB hub label.

MicroCal iTC

Operating Instructions 28-9639-77 AA 21

200

Page 24

2 Safety instructions

2.2 Labels

Labels on the Washing Module

The illustration below shows an example of the identification labels attached to the rear

of the Washing Module.

Figure 2-3. Labels on Washing Module.

22 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 25

Symbols used in safety labels

Labels concerning hazardous

substances

Safety instructions 2

Labels 2.2

The system complies with the requirements for

electromagnetic compliance (EMC) in Australia and New

Zeeland.

Warning! Read the user manual before using the system. Do

not open any covers or replace parts unless specifically

stated in the user manual.

The system complies with applicable European directives.

Emergency procedures

In an emergency situation, do as follows to stop the run:

Step Action

1 Disconnect the equipment from the power outlet .

Power failure

MicroCal iTC

• The run is interrupted immediately, in an undefined state.

This symbol indicates that the waste of electrical and

electronic equipment must not be disposed as unsorted

municipal waste and must be collected separately. Please

contact and authorized of the manufacturer for information

concerning the decommissioning of equipment.

This symbol indicates that the product contains hazardous

materials in excess of the limits established by the Chinese

standard SJ/T11363-2006. Requirements for Concentration

Limits for certain Hazardous Substances in Electronics.

200

• The data collected up to the time of the power failure is saved.

MicroCal iTC

Operating Instructions 28-9639-77 AA 23

200

Page 26

2 Safety instructions

2.2 Labels

Controller

• The controller shuts down, in an undefined state.

•The MicroCal iTC

run is interrupted immediately, in an undefined state.

200

Washing module

• The washing module shuts down immediately, in an undefined state.

24 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 27

2.3 Recycling procedures

The equipment shall be decontaminated before decommissioning and all local

regulations shall be followed with regard to scrapping of the equipment.

Disposal, general instructions

When taking the MicroCal iTC

separated and recycled according to national and local environmental regulations.

Recycling of hazardous

substances

The MicroCal iTC

available from your GE Healthcare representative.

Disposal of electrical

components

Waste of electrical and electronic equipment must not be disposed as unsorted

municipal waste and must be collected separately. Please contact an authorized

representative of GE Healthcare for information concerning the decommissioning of

equipment.

instrument contains hazardous substances. Detailed information is

200

Safety instructions 2

Recycling procedures 2.3

system out of service, the different materials must be

200

MicroCal iTC

Operating Instructions 28-9639-77 AA 25

200

Page 28

2 Safety instructions

2.3 Recycling procedures

26 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 29

3 Installation

NOTICE

It is recommended that the installation of the MicroCal iTC

be performed by GE Healthcare personnel.

Installation 3

Site requirements 3.1

instrument

200

This section provides information about the installation of MicroCal iTC

Figure 3-1. MicroCal iTC

Any equipment connected to the MicroCal iTC

with washing module and control computer..

200

must fulfill applicable standards and

200

local regulations.

200

.

3.1 Site requirements

The MicroCal iTC

70 cm wide). This location should be away from strong drafts, room temperature

fluctuations, intense sunlight, vibrations and strong electrical or magnetic fields (as

may be produced by an NMR, microwave oven, large motors or refrigeration units). In

addition the mains power source (100 to 240 VAC) should be properly grounded and free

from voltage fluctuations, harmonic distortions, power dips and spikes. The AC power

line should be dedicated to the MicroCal iTC

with additional equipment.

MicroCal iTC

Operating Instructions 28-9639-77 AA 27

200

with Controller requires about 1 meter of normal bench space (ca.

200

system and should not share that power

200

Page 30

3 Installation

3.1 Site requirements

Although, the power filtering in the MicroCal iTC

instrument is adequate for most

200

laboratory environments, some disturbances may affect the performance of the

instrument and it may be necessary to have the AC Mains power source evaluated (see

table below) or install a power conditioner. Since power source problems can be

manifested in many different ways, it is not possible to recommend a power conditioner

for all situations. It is recommended that you test a power conditioner, at your location,

before you purchase it. If you believe you are experiencing power source related

problems, please contact a GE Healthcare field engineer.

Table 3-1. Power supply requirements.

AC Mains Requirements

Specification Requirement

Voltage Regulation 100 to 240 VAC, stable to ± 3%

Frequency Stability 0.5% Maximum Deviation

Power Line Noise < 3% Common Mode or Differential Mode at any

Frequency

Harmonic Content < 5% Total Harmonic Distortion to 1500 Hz, < 3% For

any Single Frequency

Ground Noise < 1 VAC Peak-To-Peak, < 2 VAC Ground to Neutral

Peak-To-Peak at any Frequency

Ground Quality < 25 Ohm

It is emphasized that room temperature fluctuations (i.e. maximum 2.5 ºC) due to the

cycling on/off of heating and cooling systems, strong air currents, sunlight directly on

the instrument and through space electromagnetic waves may cause subtle

performance problems.

Table 3-2. Environmental operating requirements.

Environmental (Operating) requirements

Temperature 10 to 28ºC, constant to 2.5ºC

Humidity 0 to 70% Relative Humidity, non-condensing

Atmospheric Pressure 700 hPa to 1060 hPa

28 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 31

3.2 Transport

Before moving the system:

• Disconnect all cables and tubing connected to peripheral components and liquid

containers.

• Remove all items from the top of the system.

• Grasp the system under the two sides.

3.3 Unpacking

The MicroCal iTC

with great care.

Installation 3

NOTICE

Lift the MicroCal iTC

front panel cover as a lifting handle.

is delivered in protective packing material and shall be unpacked

200

instrument in the upright position. Do not use the

200

Transport 3.2

3.4 Set up

Check the equipment for damage before starting assembly and installation.

Document any damage and contact your local GE Healthcare representative.

Arrange the components on the desktop similar to the picture of the system (see Figure

3-1). The computer may be on either side depending on convenience. Do not place the

wash station into position yet. Follow the instructions below for assembly.

NOTICE

Before connecting the hardware, make sure the controller PC is off.

MicroCal iTC

Operating Instructions 28-9639-77 AA 29

200

Page 32

3 Installation

3.4 Set up

1 Remove the top and front panel.

2 Remove the three screws and washers on the top of the instrument used to mount

the injection tower.

1

5

2

6

7

3

8

9

4

Figure 3-2. MicroCal iTC

with washing module.

200

Part Description

1 Cell cleaning adaptor

2 Washing module

3 Solution tubes (Waste, Water, Methanol, Buffer)

4Cell port

5 Fill port adaptor

6Pipette

7Pipette tower

8 Syringe washing and drying station

9 Tube holder

30 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 33

Installation 3

Set up 3.4

3 Attach the tower with the washers and screws. Do not seat the screws but leave

them just slightly loose enough to slide the injector around for alignment in step 5.

4 Carefully insert the pipette into the lock ring. Ensure that the pipette is fully seated

and the black cable is parallel with the arm before tightening the screw (below).

5 Very carefully insert the pipette into the cell. You may need to move the injector a

small amount to achieve this, and avoid bending the syringe.

6 Align the pipette in the center of the port such that the pipette slides in/out of the

cell easily and the spaces on both sides of the pipette are even. This alignment is

critical to achieve acceptable noise levels. Hold the injection tower down firmly

with one hand while tightening the screws with the other.

7 Plug the pipette connector to the back of the injector tower riser and tighten the

lock screws with a 0.05 inch hex driver (1.3mm).

8 Lift the black locking clip on the front of the instrument on the interconnection

board behind the faceplate. Insert the ribbon cable from the injection mechanism

until it seats.

9 Alternately push the locking clip down to hold the cable in place.

10 Snap the two cover plates back into place.

Washing module installation

USB connector types

The MicroCal iTC

with different connector types. You have been supplied with two cables that have Type

A and Type B connector ends.

An additional cable has been supplied that has Type A and Type B (mini) connector ends.

Table 3-3. Cable connectors.

Connector Description

cell and Washing Module connect to the host PC through USB ports

200

Type A

Type B (mini)

MicroCal iTC

Operating Instructions 28-9639-77 AA 31

200

Type B

Page 34

3 Installation

3.4 Set up

1 Identify the only cable with the USB type B (mini) cable end. Connect the type B

(mini) cable end to the USB hub (see Fig 3-4). Connect the USB type A end of that

cable to the labeled Controller PC USB port.

A

Figure 3-3. Controller connector to PC (A).

2 Connect the USB type A ends of two USB cables to the hub as shown in Figure 3-5.

Figure 3-4. USB connectors.

3 Connect the USB type B ends to the USB 1 and USB 2 connectors on the rear of the

MicroCal iTC

4 Place the Washing Module on top of the MicroCal iTC

instrument (Fig 3-6).

200

200

cell.

5 Connect the USB type A end from the Washing Module to the hub (Fig 3-6).

32 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 35

Installation 3

Set up 3.4

6 Connect the green grounding strap wire between the Washing Module and the

MicroCal iTC

1

200

cell.

Figure 3-5. Washing Module and MicroCal iTC

Note: 1 in Figure 3-5 is the power cord grommet.

MicroCal iTC

Operating Instructions 28-9639-77 AA 33

200

200

cell.

Page 36

3 Installation

3.4 Set up

Electrical connections

MicroCal iTC

200

cell

Connect the power cord to the IEC 320 inlet power receptacle (see Figure 3-6 below) on

the back of the cell. Connect the power plug only to a main power supply receptacle

with a 3-wire protective Earth ground and a Ground Fault Circuit Interrupter (GFCI).

WARNING

To enhance safety always plug the instrument into a Ground Fault

Circuit Interrupter (GFCI) device.

1

2

3

4

Figure 3-6. MicroCal iTC

Part Description Part Description

1Fan 4Power fuses

2 & 6 USB connectors 5 IEC 320 inlet power receptacle

3 Mains power switch 7 µP activity indicator

Washing module

Connect the power cord from the power supply to the power receptacle (see Figure 3-7)

on the rear of the Washing module (see Figure 3-6, Power). Connect the power supply

view of back plate.

200

5

6

7

34 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 37

Installation 3

Set up 3.4

only to a main power supply receptacle with a 3-wire protective Earth ground and a

Ground Fault Circuit Interrupter (GFCI).

WARNING

To enhance safety always plug the instrument into a Ground Fault

Circuit Interrupter (GFCI) device.

Figure 3-7. Washing module power supply unit

MicroCal iTC

Operating Instructions 28-9639-77 AA 35

200

Page 38

3 Installation

3.4 Set up

Fluid connections

Figure 3-8. Washing Module pipette wash station connections.

Attach Washing Module Tubing

• C1 to syringe fill port (Figure 3-8),

• C2 to needle wash port (Figure 3-8),

• C3 to top of cleaning device (Figure 3-9),

• C4 to side of cleaning device (Figure 3-9),

•C5 to waste (Figure 3-9).

Figure 3-9. Cell tool connections.

36 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 39

Installation 3

Validation 3.5

Insert the vacuum vial and three solvent vials

1 To install the vacuum vial (1 in Figure 3-10) slide the vial up and back, and screw it

into its socket.

2 To install a vial, insert the fill tubing and filter, if applicable, into the vial and slide it

up and back into its slot.

1

2

3

4

Figure 3-10. Solution vials.

Table 3-4. Solution vials

.

Part Description Part Description

1 Vacuum vial (opaque

3 Methanol vial

color)

2 Distilled water vial 4 Buffer vial

Note: If buffer is not desired for some reason, this vial may also be filled with water.

CAUTION

The methanol should be removed and capped when the instrument is

not in use, as methanol is very volatile.

3.5 Validation

After installation it is recommended that a titration of a known system be performed to

test that the instrument has been installed correctly.

MicroCal iTC

Operating Instructions 28-9639-77 AA 37

200

Page 40

3 Installation

3.6 Configuring a MicroCal iTC

controller for networking

200

3.6 Configuring a MicroCal iTC

On a MicroCal iTC

networking and MicroCal iTC

watchdog program must be removed, and once the computer has been configured for

the local domain, two folders must be given special permissions.

Uninstallation:

1Click on the START button on the lower left side of the screen, and then on Control

Panel.

2In the Control Panel window, click on Add or Remove Programs.

3Find InitDTSetup in the program list. Click the Remove button by it. In the next

window, click Yes to confirm the removal.

Special Permissions:

The MicroCal iTC

folders. In order to allow a non-administrator to use this software, read/write privileges

must be set for all users for the MicroCal iTC

folders. The folder properties must allow Read & Execute, List Folder Contents, Read,

and Write, as shown below.

controller, there are several actions that must be performed for the

200

200

so ftwar e and Origi n both need t o be abl e to wri te data into th eir ow n

200

controller for networking

200

control software to work properly. First , the InitDT

and Origin 70 folders, including all sub-

200

Figure 3-11. Configuration dialogs.

38 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 41

4Operation

4.1 Procedure before a run

Note: See Section 1.4 for control software information.

On / Off Instructions

Operation 4

Procedure before a run 4.1

Turning the MicroCal iTC

Once the MicroCal iTC

the cell unit is a power on/off switch, which functions as the master power switch and

must be in the “on” position. It can be turned to “off” when the MicroCal iTC

not be used for long periods of time i.e., weekends, holidays, etc.

NOTICE

The user interface program, iTC200, has to be running for the cell to

function properly even though the power switch is in the “on” position.

Leaving the power on

During frequent “on” periods, the master power may be left as long as the user interface

program, MicroCal iTC

system is does not incur any damage and keeps the MicroCal iTC

Periods of inactivity

GE Healthcare recommends that the MicroCal iTC

master power be turned off, when the system will not be used for extended periods of

time.

cell on

200

cell has been cabled to the PC, it is ready to use. At the rear of

200

cell will

200

, is running. The software automatically ensures that the

200

cell ready.

200

application be closed and the

200

4.2 Basics of performing a run

In order to perform a basic ITC titration experiment, the user must load the sample cell

and the syringe, enter the desired parameters into the control software, and click Start.

The reference cell should be filled with water or buffer, and may be left for several days.

4.3 Loading the syringe

To load the titration syringe, place a micro centrifuge tube containing ~100µL of your

sample in the tube holder. Be sure to push the tube to the bottom of the holder with the

MicroCal iTC

Operating Instructions 28-9639-77 AA 39

200

Page 42

4 Operation

4.4 Loading the cell

lid fitting into the slot provided (see image below). Be careful not to leave any part of the

tube in the path of the syringe needle to prevent damage.

Figure 4-1. Micro centrifuge tube in the tube holder.

Figure 4-2. Fill port adapter threaded into fill port.

Connect the threaded end of the tubing from the Washing Module to the pipette fill port

if necessary (it should still be in place after cleaning and drying of the syringe).

NOTICE

Avoid overtightening the tubing in the pipette fill port. Excessive force will

crack the syringe.

In the Instrument Controls tab, click Syringe Fill. The software will prompt the user to

move the pipette as necessary, and the Washing Module will fill the syringe. See

sections 4.4 to 4.7 for more information.

4.4 Loading the cell

To load the cell do the following:

1 To load the sample cell, gently insert the glass Hamilton syringe into the (left)

sample cell until it touches the bottom.

2 Pull up on the plunger until bubbles are being pulled from the cell, and there is no

more liquid.

3 Remove and empty the syringe. Clean the syringe if necessary.

40 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 43

Operation 4

Loading the cell 4.4

4 Pull approximately 300 µl of sample into the syringe, and tap the syringe glass so

that all air is at the top volume of the syringe. Do not allow air to be put into the

cells.

5 After removing the bubbles, insert the syringe into the cell and gently touch the

bottom of the cell with the tip of the syringe needle.

6 Raise the needle tip about 1 mm off the bottom of the cell, and hold it there until

finished filling. Do not raise the syringe during the filling process.

7 Slowly inject solution into the cell until it spills out the top of the cell stem. Finish the

filling with several small abrupt spurts of solution to dislodge any bubbles in the

cells.

8 Finally, lift the tip of the syringe to the cell port (just below the visible portion of the

cell port) and find the ledge (See Figure 4-3) that is formed where the cell stem

meets the cell port. Place the syringe on the ledge at the top of the metal cell stem

and remove the excess solution. If the reference cell needs ref illing, follow the same

procedure as for the sample cell.

1

Figure 4-3. Schematic representation of the cell (left) and the top of the cell stem (right) where air

bubbles can form if not loaded properly.

2

Part Description

1 Place where bubbles are trapped.

2 Ledge formed where cell stem meets plastic overflow reservoir.

Load the run parameters by clicking the Load Run File button at the top left of the

Advanced Experimental Design tab in the MicroCal iTC

software and select the

200

WATER. inj file. This will populate all the required fields for performing a run. Then click

the Start button on the bar of buttons across the top of the control software.

MicroCal iTC

Operating Instructions 28-9639-77 AA 41

200

Page 44

4 Operation

4.5 Experimental design

Be sure to insert the syringe in to the sample cell before starting the experiment. The

instrument will seek experimental temperature, equilibrate to that temperature, start

the titration syringe stirring, wait until the DP signal is steady, and then start performing

injections. The raw data will appear in the Real Time Plot tab.

Once a run has finished, the syringe and sample cell should be cleaned as soon as

possible.

Procedures after a run

The MicroCal iTC

will keep the system electronics at the normal operating temperature. It is

recommended that the power of the MicroCal iTC

periods of down time, such as holidays and vacations.

After use, clean the sample cell following procedure in Section 4.7 and fill the sample cell

with distilled water. Wash and dry the syringe using procedure in section Section 4.7.

was designed to have its power on for extended periods of time. This

200

cell be turned off during extended

200

4.5 Experimental design

Figure 4-4. Experimental design dialogue box.

42 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 45

Operation 4

Advanced experimental design 4.6

When the software is first started, by default, the Experimental Design tab is selected;

this contains the simple run controls. Experimental Mode can be Highest Quality,

Minimum Protein, or High Speed. Highest Quality uses 20 injections.

These parameters should produce data that is clear and easier to fit. Minimum Protein

uses fewer injections, only 10. The result of these parameters will be the use of the least

amount of sample necessary for a successful titration.

The High Speed mode will do one single longer injection (Single Injection Mode, SIM).

The expected n, Kd, and H and the desired run temperature will allow the software to

calculate the recommended concentrations for the cell and syringe, and set the run

parameters based on mode chosen.

If the user is unsure of the Kd for their system, clicking the Help button causes the

software to prompt for the type of compound in cell and syringe. It will then make a

guess as to the Kd. The user will still be required to choose values for H and n.

Click the Update Experimental Curve button to calculate the results. The simulation

window will update with a rough graph, and the Results column at the right of the

screen will have values for the cell and syringe concentrations. The calculated C value

is listed below; its background is color-coded.

The C-value predicts the shape or sigmoidicity of the curve. Optimal values for C are

between 5 and 500 (green); values between 1 and 5, and 500 and 1000 should work but

may not give the best result (yellow). C values less than 1 or greater than 1000 will

probably not yield usable data (red).

The user may adjust the two experimental concentrations by using the change buttons

beside each concentration box.

Any warnings, such as heats too high for the instrument to measure, will appear in the

status bar near the top of the screen. It is highly recommended that the users look

carefully at the projected curve and make sure that the shape and rough values are

reasonable before proceeding.

A pair of options at the bottom of this tab allows users to work in K

whether to view the simulation plot using raw heat per injection (ΔH) or the heat

normalized to the molar ratio (NΔH).

4.6 Advanced experimental design

This may be used in addition to the Experimental Design tab to modify the suggested

run parameters. It can also be used to save or upload run (*.in) files.

See MicroCal iTC

Experimental and Data Analysis tutorial Guide.

200

or KA, and to choose

D

MicroCal iTC

Operating Instructions 28-9639-77 AA 43

200

Page 46

4 Operation

4.7 Instrument controls

4.7 Instrument controls

Figure 4-5. Instrument control screenshow.

The Instrument Controls tab contains the controls for direct operation of the

instrument. At the top of the window, the user can Start the run, using whatever

parameters are currently present in the Experimental Design or Advanced

Experimental Design tabs.

Before clicking this button, it is wise to check that all parameters are correct and that a

valid, unique data file name has been entered. The software will double-check with the

user before allowing any files to be overwritten. The Stop button, which is available only

during a run, will abort the run immediately.

The Thermostat Control section allows for setting of the thermostat temperature,

which will be maintained during the MicroCal iTC

thermostatting the MicroCal iTC

and samples at the run temperature will result in

200

thermostatic (idle) state. Pre-

200

shorter equilibration times. Also, high temperature thermostatting during cell cleaning

can improve the effects of the cleaning. Use the arrow buttons to raise or lower the

temperature or click in the text box and type in a new number. Click Set Jacket Temp to

set the temperature.

44 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 47

Operation 4

Instrument controls 4.7

The Pulse Control section allows for manually administering a DP calibration pulse.

While this is not the most thorough method of checking the y-axis calibration, it is the

quickest method. Pulses may be applied any time the DP signal is equilibrated and the

resulting deflection used as a crude calibration assessment. If Origin for real-time

plotting is enabled, Origin will calculate the error. If this is greater than 1%, please see

Section 5.8 for a more thorough check of the DP calibration.

The Pipette Control panel at the center of this tab provides the controls for loading and

cleaning the syringe. The Open Port button moves the plunger tip to above the fill port

in the side of the syringe. Close Port moves the plunger tip down so that it blocks the fill

port. Purge/Refill pushes the pipette tip all the way down and back up again, dislodging

bubbles on the sides of the syringe. The Pipette Maintenance section provides the

software controls used for changing the pipette tip. Please see Section 5.5 for details on

performing this maintenance.

Insert the cell cleaning apparatus into the sample cell (see pictures below). Be sure to

push down until the device is firmly seated. Attach the syringe connector to the syringe.

Click the Cell and Syringe Wash button in the Instrument Controls tab of the iTC200

software. The software will prompt the user to be sure the cleaning tubing is inserted.

The program will first execute the Cell Buffer Rinse (Short) procedure.

A prompt will appear after the cell wash portion of the sequence is complete. The user

may then load the cell. Click OK to continue and clean the syringe. The program then

executes the Syringe Wash (Short) procedure. The syringe cleaning takes about nine

minutes. Once that has completed, the syringe may be loaded with sample.

Leave the tubing connected to the syringe. Leave the syringe in the wash position or the

rest position. Click Syringe Load.

The plunger will move to the bottom of the syringe to prepare for loading. This must be

performed with the syringe NOT in the titrant to prevent turbulence and gassing of the

sample. The software will prompt the user to move the pipette to the titrant .

Click OK to continue. The pipette tip will move, filling the syringe. After the tip reaches

the open port position, the pump will remove the air bubble, reducing titrant usage. The

port will move to the close position and the vacuum will remove any excess titrant . Once

this has completed, the software will prompt the user to disconnect the syringe tubing,

make sure the cells are filled, and move the pipette into the sample cell.

The cell cleaning device must be inserted into the sample cell until it seats firmly.

Connect the syringe tubing to the vacuum block port at the rear of the Washing Module

to prevent leakage. Click Cell Buffer Rinse (Short). The Washing Module will perform a

short cleaning routine, rinsing the cell with buffer.

The program will rinse the cells with buffer and then with water. It will then empty the

cell, although not all the liquid will be removed. The entire sequence takes a little over a

minute. The user may then remove the excess water and load the cell with sample,

using the Hamilton loading syringe.

The cell cleaning apparatus must be inserted into the sample cell until it seats firmly.

Connect the syringe tubing to the vacuum block port to prevent leakage. Click Cell

Water Rinse (Long). The Washing Module will perform a more thorough cleaning

routine, which takes about 80 seconds. Like the Cell Buffer Rinse (Short), the program

MicroCal iTC

Operating Instructions 28-9639-77 AA 45

200

Page 48

4 Operation

4.8 Real time plot

will rinse the cell, this time with water, using greater quantities. This is especially useful

after a detergent soak, to be sure of removing all of the detergent.

Click the Detergent Soak and Rinse (Long) button and follow the prompts to load ~5%

Contrad70.

The cells will heat to 50°C for half an hour to soak. Once they have cooled, the software

will prompt the user to remove the Contrad70 and insert the cleaning device for rinsing,

and then to connect the pipette connector to its holder. Be sure that the cells have

cooled before removing the Contrad70, as hot liquid may shatter the loading syringe.

This method is used when more vigorous cleaning is required, after a precipitating

sample or if trouble is suspected. It is also a good idea to do this every few weeks, or

every few days for an instrument under heavy use, to prevent problems.

Connect the syringe tubing to the syringe fill port. Click Syringe Wash (Short). The

software will prompt the user to make sure that the tubing is connected.

Click OK. The Washing Module will perform a short washing routine (approximately 8

minutes). It will rinse the syringe first with water and then with methanol. It will then pull

vacuum through the syringe for several minutes to dry it.

Connect the syringe tubing to the syringe fill port. Click Syringe Wash (Long). The

software will prompt the user to make sure that the tubing is connected.

Click OK. The Washing Module will perform a more thorough washing routine

(approximately 8½ minutes). It will rinse the syringe first with water and then with

methanol. It will then pull vacuum through the syringe for several minutes to dry it.

The Dry Syringe function is used when the syringe has been cleaned manually and left

with methanol in it. Attach the syringe connector to the syringe and place the pipette in

the wash position. Click the Dry Syringe button.

The washing module will pull vacuum through the syringe for several minutes to dry it.

4.8 Real time plot

This tab displays the current DP data.

See MicroCal iTC

4.9 Set up

This tab allows for the customizing of data file paths for data storage and setup files. It

is also where the Extended Data Mode button can be found. It is useful to have this box

checked when running test experiments. The additional data it provides will be helpful

for troubleshooting. See MicroCal iTC

Experimental and Data Analysis tutorial Guide.

200

Experimental and Data Analysis tutorial Guide.

200

46 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 49

4.10 Procedures after a run

The MicroCal iTC

will keep the system electronics at the normal operating temperature.

It is recommended that the power of the MicroCal iTC

extended periods of down time, such as holidays and vacations.

After use, clean the sample cell following procedure in Section 4.7 and fill the sample cell

with distilled water. Wash and dry the syringe using procedure in section Section 4.7.

was designed to have its power on for extended periods of time. This

200

NOTICE

For quick start up leave instrument on.

Operation 4

Procedures after a run 4.10

cell be turned off during

200

MicroCal iTC

Operating Instructions 28-9639-77 AA 47

200

Page 50

4 Operation

4.10 Procedures after a run

48 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 51

5 Maintenance

This section provides the user with information on the proper maintenance of the

instrument to ensure proper function.

5.1 Cell cleaning

The MicroCal iTC

stability. These cells must be cleaned routinely to maintain the high performance of the

instrument. Dirty cells will contribute greatly to cell filling problems, accuracy and

repeatability problems and possibly misinterpretation of data. Inadequate cleaning is

the cause of many problems experienced with the MicroCal iTC

The reference cell generally requires no special cleaning; rinsing and refilling every

week or so is suff ic ient . The mildest meth od of cleaning the sample c ell is s imp ly t o rinse

the cell with buffer several times before loading the sample. This should be done

whenever the necessary buffer is available.

uses fixed in place cells in order to provide maximum sensitivity and

200

Maintenance 5

Cell cleaning 5.1

.

200

After every few runs, or after any sample that precipitates, the sample cell should be

cleaned using the Washing Module. Run the appropriate Washing Module sequence

and follow the onscreen prompts as noted below.

1 Cell Buffer Rinse with Syringe

• Similar well behaved samples

2 More Extensive Rinsing with Washing Module

• Dissimilar well behaved samples

3 Aggressive Cleaning

• High temperature soak with cleaning agent (general recommendation of 20%

Contrad70) followed by a thorough rinsing

See Section 4.6 for more detailed information.

5.2 Removing injection syringe

Follow steps below:

1 Clean and dry the syringe before removal.

2 Remove sample tube from loading hole and disconnect the cleaning apparatus.

MicroCal iTC

Operating Instructions 28-9639-77 AA 49

200

Page 52

5 Maintenance

5.3 Inserting a new syringe

3 Insert the syringe storage case into the loading hole.

Figure 5-1. Syringe removal.

4 Slide the pipette to the cleaning position and insert it firmly into the hole.

5 Turn the inner metal syringe holder to the right several full rotations. This will

unscrew the metal nut that holds the syringe in the pipette.

6 Once the nut is loose, move the pipette to the loading hole.

7 Use the manual pipette controls to lower the pipette tip about 0.3 inches. Without

the bottom nut, the syringe will move down with the pipette tip.

8 Pull down on the syringe, gently, until it slides down into the storage case. The soft

grip tweezers may help with this.

9 Move the pipette out of the way, and screw the cap onto the storage case.

10 Remove it from the loading hole.

5.3 Inserting a new syringe

1 Insert the storage case into the loading hole and unscrew the top.

2 Position the pipette over it.

50 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 53

Maintenance 5

Syringe cleaning 5.4

3 Slide the case up until the syringe glass enters the bottom of the pipette.

Figure 5-2. Syringe insertion.

4 Let the case drop and gently push the syringe up through the filling hole and into

the pipette. It will come to a stop with about 4 mm of syringe glass exposed below

the metal.

5 Carefully push up on the glass while spinning the metal syringe holder slowly. Once

the notch in the syringe aligns with the notch in the holder, the syringe will slide up

approximately another 2 mm. Be very careful, as if the syringe is not all the way up,

the needle will catch on the edge of the storage case, likely bending the needle and

making it unusable.

6 Move the pipette to the cleaning hole and turn the inner metal syringe holder to the

left several turns, so that the bottom nut is engaged but not fully tightened.

7 Move the pipette to the loading hole, and insert the fill port adapter. Make sure that

it screws in easily; if it does not, loosen the bottom nut until it does.

8 With the adapter in place, tighten the nut. This ensures that the syringe is lined up

properly within the pipette.

9 Disconnect the adapter.

5.4 Syringe cleaning

If clogging of the syringe is suspected, first refer to the on screen software section for

syringe cleaning to visually see the process.

MicroCal iTC

Operating Instructions 28-9639-77 AA 51

200

Page 54

5 Maintenance

5.5 Removing pipette

If this does not solve the issue, then as a backup method you can use the wire method

explained here. Note this is not the preferred method and it is rare you will need to use

this method.

This must be done very carefully. First, remove the syringe from the pipette.

As always when handling the syringe, be careful not to bend the needle. The wire should

always be inserted through the glass first, both to ensure that the clog is fully removed

from the syringe and to decrease the likelihood of bending the syringe. It may be

difficult to insert the end of the wire from the glass bore into the metal needle; good light

and a magnifying glass will help.

Continue to insert the wire until it emerges from the tip of the needle. Carefully pull the

wire back through the needle and glass bore.

Figure 5-3. Wire in needle.

5.5 Removing pipette

The pipette is held by the arm and connected to the tower by a black cable. First

disconnect the black plastic connector, by removing two screws (see below) and pulling

the connector loose. This requires a 0.050" hex driver. Loosen the screw on the side of

the arm to remove the pipette.

Figure 5-4. Connector cable and the screws that secure it encircled in yellow in picture to the right.

52 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 55

To reinsert the pipette, place the pipette in the socket on the arm and tighten the screw.

Insert the cable into its slot, and tighten the two screws. It is a good idea to re-calibrate

the open fill port position once the pipette has been replaced; see Section 5.7.

5.6 Changing pipette tips

See the instructions above to remove the syringe from the pipette. The pipette should

remain connected to the tower.

1 In the Instrument Controls tab, click the Remove Old Tip button to position the tip.

2 Use the blade of the X-acto knife provided with the instrument to make a diagonal

cut on the side of the white Teflon tip (See Figure 5-5), and use the small-tipped

tweezers to pull the tip off (See Figure 5-5).

3Click the Install New Tip button to position the tip.

4 Use the tip pusher tool, with the new tip in the slot hole-side up, and firmly press

the new tip into place (See Figure 5-6). Rotate the tool to ensure that the tip is f irmly

seated.

Maintenance 5

Changing pipette tips 5.6

5 Remove the tip pusher tool and inspect the tip to be sure it is seated properly.

6 Reinstall the syringe as described above to finish.

12

Figure 5-5. Cutting and removing tip (1,2).

4

3

45

Figure 5-6. Using pusher tool to pipette tip.

MicroCal iTC

Operating Instructions 28-9639-77 AA 53

200

Page 56

5 Maintenance

5.7 Pipette calibration

5.7 Pipette calibration

The pipette may need to be re-calibrated, especially after a new pipette is installed. The

“ITC => Pipette Tools” menu option will open the following popup.

Figure 5-7. Pipette menu.

The Initialize Pipette section will make the software run a routine that checks the

sensors on the pipette and makes sure that the software knows certain constants of the

pipette. The checkbox at the bottom of the section will cause the software to run this

check every time it starts.

The Open Port Calibration section contains the controls for adjusting the position of the

plunger when the fill port is open. Use the distance slider bar and the up and down

buttons to move the plunger tip to just above the fill port in the upper side of the glass

syringe bore. Once the position is correct, click the Calibrate Open Fill Port button to

have the software set the current location as the open fill port location. Click the Open

and Close buttons in the bottom section to check the calibration.

5.8 Y-axis calibration check

It is recommended that the y-axis calibration be checked every few months to ensure

accurate data acquisition. The automatic calibration check routine will send a series of

pulses to the cell heaters, dissipating a known power. The offset in the DP as a result of

this power is analyzed in comparison to the correct DP offset.

Make sure the cells are clean, and fill both cells with degassed, distilled water. Load the

titration syringe with water and insert it into the sample cell. It is recommended that

Origin for real-time data be enabled.

To begin the y-axis calibration check procedure:

54 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 57

Maintenance 5

Y-axis calibration check 5.8

1Select MicroCal iTC

software menu ITC => Start ITC Calibration Run => Y Axis

200

Check. Once the menu has been selected, the Calibration Pulse Setup window will

appear. This window allows the calibration pulses to be modified.

2 Enter individual pulse parameters by first selecting a pulse or multiple pulses, then

enter the desired parameter value into the pulse parameter boxes (Calibration

Power, Pulse Duration and Pulse spacing). Users are encouraged to simply use the

default y-axis calibration parameters.

3 After the run and pulse parameters are entered, click on the Start Run button to

start the run. The ITC will equilibrate in the same manner as it would during a

titration experiment .

If creating customized calibration parameters, users must be aware of the DP range

limits when setting reference power and pulse sizes. The reference power must be high

enough to allow all pulses without hitting saturation, and if a pulse size is too small, it

can show abnormally high error.

After the final equilibration phase has completed, the initial delay will begin and the

pulses will be applied as entered. As each pulse completes, Origin will analyze the pulse

region and determine the deflection of the baseline as well as the energy (area) of the

pulse. The requested power and energy will also be displayed as will a percent error for

both power and energy. The reported error in deflection or energy should be less than

1%. If the error is reported as higher than 1%, please contact GE Healthcare.

For a more rigorous analysis, once the calibration is done and the system is

thermostatting again, open the ITC Calibrations proje ct . Cl ick on t he Y-Axis Calibration

(DP, uCal/sec) button. Origin will ask for the DP check f ile. Select the data file just created

and click Open. The computer will think for a few moments. If any of the pulses are out

of specifications, a pop-up will inform you. It will ask you to save.

Origin will show four graphs. The upper left graph holds the raw data. The lower two

graphs show the energy and power of each pulse. The upper right graph displays the

percent error for the energy and power of each pulse. Right-click at the upper right

portion of the graph and select Go To Window from the menu. Check the sizes of the

errors. If any of the errors is greater than 1%, please contact GE Healthcare.

MicroCal iTC

Operating Instructions 28-9639-77 AA 55

200

Page 58

5 Maintenance

5.9 Replacement of fuses

5.9 Replacement of fuses

WARNING

Always disconnect power supply from the instrument before replacing

fuses.

WARNING

Replace fuses ONLY with same type and of fuse and rating. Several spare

fuses are supplied with the original shipment and the power receptacle

is labeled with the correct type.

The MicroCal iTC

has two fuses, found in the power receptacle at the rear of the

200

instrument, below the power switch and above the plug. If the fuses repeatedly blow,

unplug the instrument and contact your local GE Healthcare representative.

56 MicroCal iTC

Operating Instructions 28-9639-77 AA

200

Page 59

6 Troubleshooting

6.1 How to get help

Please contact us for any instrument or data analysis questions or issues you may have.

For contact/ordering/service inquiries, visit: www.gelifesciences.com/contact, or for

MicroCal-specific information, visit: www.gelifesciences.com/microcal

When e-mailing for technical assistance, if possible, please attach a recent data file(s)

(*.itc, raw ITC data file) that demonstrates the problem. Also, please include all details

that may be relevant to the problem. For instance, where the problem or question

relates to post run data analysis, it is best to attach both the raw data file (*.itc) and the

Origin project file (*.opj) and/or Excel (*.xls) spreadsheet generated during data analysis.

Troubleshooting 6

How to get help 6.1

There are two general categories of troubleshooting for the MicroCal iTC

and its

200

operation. The most extreme category is when a system is not working at all. Problems

that prevent users from operating the instrument require immediate consultation with

a GE Healthcare technician. Customers should not attempt to repair the hardware or

software unless instructed to do so by a MicroCal service representative.

The second, and less extreme general category of a problem is when an MicroCal iTC

200

instrument is functioning, but is not operating within its normal performance

specifications. Large baseline drifting, non-repeatable control peaks (water/water) and/

or an increase in short term noise level are examples of performance problems.

These problems may be corrected by the operator in most cases. For these types of

performance issues it is recommended that customers carry out the following

minimum diagnostic steps prior to requesting service:

Diagnostic steps:

1 Thoroughly clean the cells. Do not assume they are clean; build-up or unexpected

sample residue will cause problems. As a minimum, use the Washing Module to