Page 1

GE Oil & Gas

496 Series

Masoneilan* Rotary Electric Switch

Instruction Manual

GE Data Classification : Public

Page 2

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC REFERENCE

INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION AND MAINTENANCE PROCEDURES.

SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY, GE (GENERAL ELECTRIC COMPANY AND ITS SUBSIDIARIES

AND AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND

REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF THE REQUIREMENTS

FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT IN POTENTIALLY HAZARDOUS ENVIRONMENTS.

THEREFORE, THESE INSTRUCTIONS SHOULD BE INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY

RULES AND REGULATIONS APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER

EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT NOR TO PROVIDE FOR

EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH INSTALLATION, OPERATION OR MAINTENANCE.

SHOULD FURTHER INFORMATION BE DESIRED OR SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED

SUFFICIENTLY FOR THE CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO GE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF GE AND THE CUSTOMER/OPERATOR ARE STRICTLY LIMITED TO

THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF THE EQUIPMENT. NO ADDITIONAL

REPRESENTATIONS OR WARRANTIES BY GE REGARDING THE EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE

ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE INSTALLATION,

TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE

REPRODUCED IN WHOLE OR IN PART TO ANY THIRD PARTY WITHOUT THE WRITTEN APPROVAL OF GE.

b | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Page 3

Contents

Safety Information .........................................................1

1. Introduction ............................................................2

2. Operation ..............................................................2

3. Installation .............................................................2

4. Adjustments ............................................................2

5. Mounting Arrangements .................................................4

A. 35002 Series Camflex II

30000 Series Varimax ....................................................................................4

B. 36002 Series Control Ball II

37002 Series MiniTork II

39002 Series High Performance Butterfly .................................................................6

C. 37/38 Diaphragm Actuators ..............................................................................7

D. 87/88 Spring Diaphragm Actuators .......................................................................8

Masoneilan 496 Series Rotary Electric Switch Instructions Manual | c© 2015 General Electric Company. All rights reserved.

Page 4

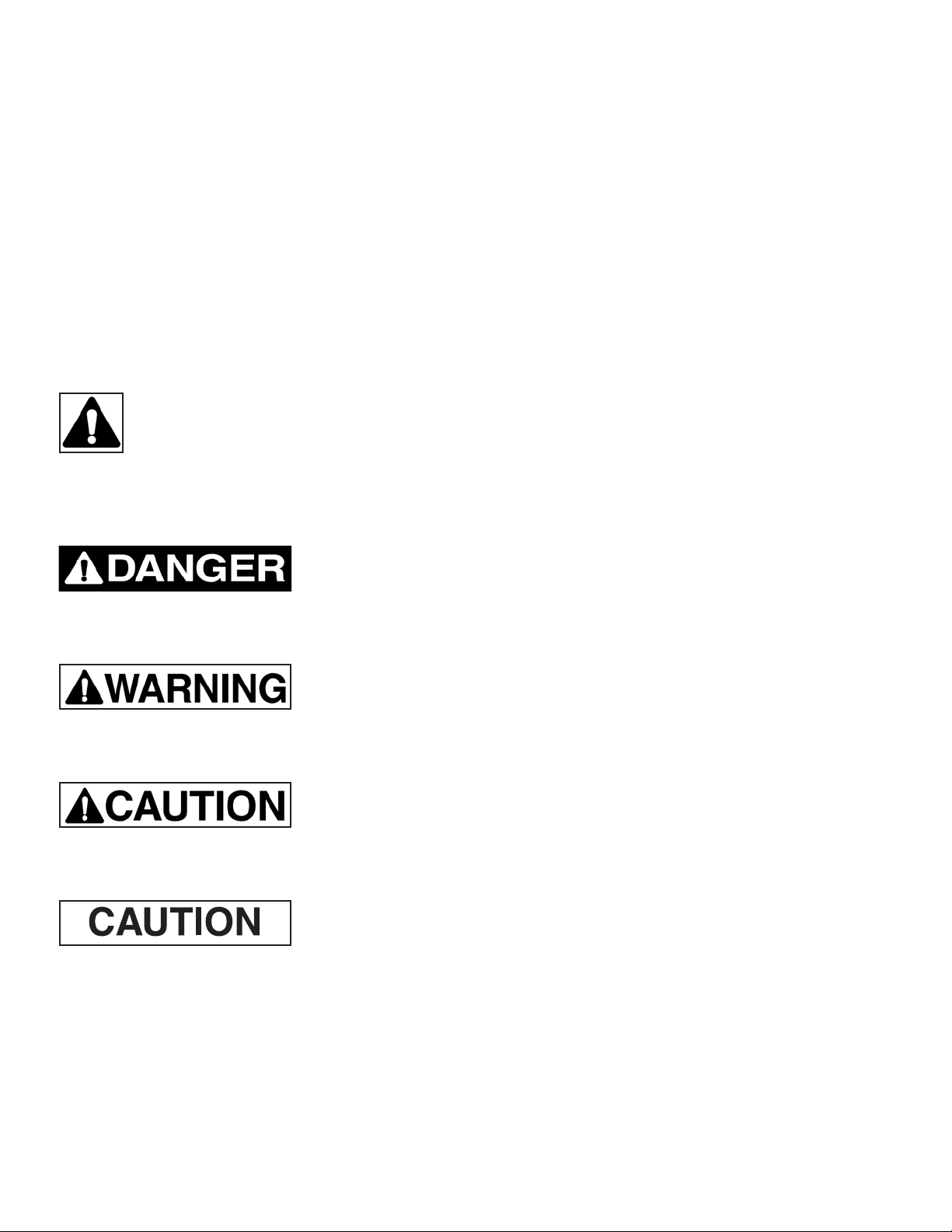

Safety Information

Important - Please Read Before Installation

Masoneilan model 496 Series Rotary Electric Switch

instructions contain DANGER, WARNING, and CAUTION

labels, where necessary, to alert you to safety related or other

important information. Read the instructions carefully before

installing and maintaining your control valve. DANGER and

WARNING hazards are related to personal injury. CAUTION

hazards involve equipment or property damage. Operation of

damaged equipment can, under certain operational conditions,

result in degraded process system performance that can

lead to injury or death. Total compliance with all DANGER,

WARNING, and CAUTION notices is required for safe operation.

This is the safety alert symbol. It alerts you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

About this Manual

• The information in this manual is subject to change without

prior notice.

• The information contained in this manual, in whole or part,

shall not be transcribed or copied without Masoneilan’s

written permission.

• Please report any errors or questions about the

information in this manual to your local supplier.

• These instructions are written specifically for the

496 Series Rotary Electric Switch, and do not apply for

other valves outside of this product line.

Warranty

Items sold by GE are warranted to be free from defects in

materials and workmanship for a period of one year from

the date of shipment provided said items are used according

to GE recommended usages. GE reserves the right to

discontinue manufacture of any product or change product

materials, design or specifications without notice.

This instruction manual applies to the Masoneilan

496 Series Rotary Electric Switch.

The rotary electric switch MUST BE:

• Installed, put into service and maintained by qualified and

competent professionals who have undergone suitable

training.

Indicates a potentially hazardous situation which, if not

avoided, could result in serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury.

When used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, could

result in property damage.

Note: Indicates important facts and conditions.

• Under certain operating conditions, the use of damaged

equipment could cause a degradation of the performance of

the system which may lead to personal injury or death.

• Changes to specifications, structure, and components

used may not lead to the revision of this manual unless

such changes affect the function and performance of the

product.

• All surrounding pipe lines must be thoroughly flushed

to ensure all entrained debris has been removed from the

system.

1 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Page 5

1. Introduction

3. Installation

Series 496 rotary switches are used for electrically indicating

one or two predetermined positions in the stroke of a control

valve. They may be connected to audible alarms or signal

lights for warning of valve or system malfunction. These

switches may also be used to actuate solenoids, relays and

other electrical devices.

Basic switches (4) in the unit are single pole, double throw

snap acting and are individually adjusted by cams (13) on

the rotating shaft (11). Vernier adjustment is made by means

of locking type set screws (Nylock) (2) in the cams and these

screws actuate the switches by contacting the switch spring

levers. The spring levers provide overtravel protection and

allow maintained contact when required. The Series 496

is available with either one or two switches, each with an

adjustable cam to actuate it.

The housing and cover are made of anodized aluminum and

are explosion proof. In addition, O-ring seals

(7 and 10) in the cover and rotary shaft, make the

switch waterproof.

Series 496 switches may be mounted on the 35002

Series Camflex, 30000 Series Varimax, 36002 Series Control

Ball and 37002 Series MiniTork Butterfly valves. Also, the

addition of a standard back lever and linkage permits its use

with the 10000 and 21000 Series and linear motion valves.

For complete parts list for the Series 496 switch refer to Parts

Supplement FS7000.

Only two couplings are used to connect the switch shaft (11)

to the valve; a strip type coupling (Ref. 9, Figure 3) for rotating

shaft valves and a back lever (Ref. 9, Figure 6)

for linear motion valves. Each is fastened to the switch shaft

(11) with a spring washer and cap screw. Refer to Figures 3

through 7 for mounting details.

Microswitches are rated at 10, 15 or 20 amps at 115 or 230

volts dc. Check the rating printed on each switch. Each

microswitch has three terminals. The lower one is common,

the middle terminal is for normally open circuit; the top

terminal is for normally closed circuit. Pass wiring through the

3/4" NPT port in the bottom of the case.

4. Adjustments

The Series 496 switch is normally mounted and adjusted on

a control valve at the factory. To adjust the instrument in the

field, proceed as follows:

A. The concave part of the levers (5) should be exactly

concentric with the cams (13) with the switch actuated.

This is an important step to assure that once the lever is

depressed, it stays depressed during overtravel (if any).

If not, loosen screws (3 and 17) and slide the levers up or

down slightly. Tighten screws (3).

B. Unscrew slightly the cam locking screws (1) using a 3/32"

Allen wrench.

2. Operation

The motion of the control valve turns by means of a back lever

(or coupling) the switch shaft (11). Cams (13), fastened to the

shaft by screws (1), actuate microswitches (4) by pushing levers

(5). Each switch may be wired to either open or close the circuit

when the lever is depressed.

C. Actuate the valve to the desired position (usually the full

opened or full closed position).

D. It is important to note that the cam operating the right-

hand switch should make contact with lever (5) only at

the end of a counterclockwise rotation.

This assures that when the valve is throttling, the screw

(2) is completely free of the lever. The concave part of the

lever is only to maintain contact during

over-travel (if any). Similarly, the cam operating

the left-hand switch should make contact with

lever (5) only at the end of a clockwise rotation. If there

is only one switch (Model 496-1) it may be necessary to

reverse the position of the switch from left to right or vice

versa depending on the rotation and stroke position.

E. Turn the cam (13) on the shaft until the switch is a

voltmeter.) Lock the cam (13) with screw (1).

F. Make a fine adjustment with screw (2) using a

1/16" Allen wrench. The screw (2) must extend out from

the cam far enough to assure sufficient depression of

lever (5).

Masoneilan 496 Series Rotary Electric Switch Instructions Manual | 2© 2015 General Electric Company. All rights reserved.

Page 6

1

/

16

3

9

/

16

2

9

/

16

1

8 Mounting

17

/

Holes

64 D A

15

/

16

3

5

/

16

13

/

16

2

Cover

Removal

Clearance

11

/

16

2

3

/

5

8

15

/

16

3

/

2

4

3

/

NPT

4

Figure 1

Figure 1

Dimensions

Dimensions

Ref.

No.

13

17

18

Description

1

2

6

11

8

3

7

4

9 10 12 13

14

15

16

5

Figure 2

Cutaway Views

Contact Points

Ref.

No.

Description

Ref.

No.

Description

1 Screw 8 Snap Ring 14 Serial Plate

2 Screw 9 Screw 15 Drive Screw

3 Screw 10 O-Ring 16 Insulator

4 Microswitch 11 Shaft 17 Screw

5 Lever 12 Cover 18 Washer

6 Body 13 Cam 19 Spacer (not shown)

7 O-Ring

3 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Page 7

5. Mounting Arrangements

A. 35002 Series Camflex II

30000 Series Varimax

When mounting a Series 496 Switch on a Camflex II or

Varimax valve:

1. Remove shaft cover, or if equipped with a positioner,

remove positioner and mounting plate.

2. Remove bottom cover.

3. Install mounting bracket (3) using two flat head screws

(7).

4. Screw pin (12) to switch lever (10) [Varimax lever (10a)].

5. Remove cap screw (11) [Varimax set screw (11a)] from

switch lever (10) [Varimax lever (10a)] slide switch lever

onto shaft behind the main lever. Position switch lever in

line with main lever. Replace and tighten cap screw (11)

[Varimax set screw (11a)].

6. Mount switch (1) on bracket (3) using cap screws (4) and

hex nuts (8).

7. Place slotted end of the back lever (9) over pin (12) on the

switch lever. Secure with washer (13) and clip (14).

8. For 3" valve and larger slip bottom cover over the linkage

and push in place.

9. Attach the back lever to the switch using lock washer (5)

and cap screw (6).

10. Refer to adjustments (Page 2) to adjust switches.

Figure 3

35002 Series Camflex II

Masoneilan 496 Series Rotary Electric Switch Instructions Manual | 4© 2015 General Electric Company. All rights reserved.

Page 8

Figure 4

35002 Series Camflex II

30000 Series Varimax

Ref.

No.

Description

Ref.

No.

Description

Ref.

No.

Description

1 496 Rotary Switch 7 Flat Head Screw 11 Cap Screw

2 Bottom Cover* 8 Hex Nut 11a Set Screw

3 Mounting Bracket 9 Back Lever 12 Lever Pin

4 Cap Screw 10 Lever 13 Washer

5 Lock Washer 10a Lever 14 Retaining Clip

6 Cap Screw

*Used with 7" Actuator only

5 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Page 9

B. 36002 Series Control Ball II

37002 Series MiniTork II

39002 Series High Performance Butterfly

496 Series Rotary Switch mounted on 36002, 37002 and

39002 valves:

1. Remove shaft cover or if equipped with a positioner

remove positioner and mounting plate.

2. Remove plastic panels for access, bottom front

and side.

3. Remove pivot pin (8) stroke air to open valve to remove

the load from the pin.

4. Replace pin (8) with switch mounting pivot pin.

5. Assemble take off link (6), locknut (9) and turnbuckle (10),

slide assembly over pivot pin (8) and push on retaining

clip (7).

6. Install front cover.

7. Install mounting plate (3) using flat head screws (1).

8. Mount switch (2) to plate (3) using cap screws (5) and nuts

(12).

9. Assemble back lever (14) to the switch using cap screw

(15) and lock washer (16).

10. Assemble clevis (11) to back lever (14) using clevis pin (13)

and retaining clip (7).

11. Replace bottom cover (4).

12. Connect the turnbuckle (10) and clevis (11). Rotate the

turnbuckle to equalize threaded ends and lock the

locknut.

13. Refer to adjustments (Page 2) to adjust switches.

Figure 5

36002 Series Control Ball II, 37002 Series MiniTork II, 39002 Series HPBV

Ref.

No.

1 Flat Head Screw 7 Retaining Clip 12 Hex Nut

2 496 Rotary Switch 8 Pivot Pin 13 Clevis Pin

3 Mounting Plate 9 Hex Jam Nut 14 Back Lever

4 Bottom Cover 10 Turnbuckle 15 Cap Screw

5 Cap Screw 11 Clevis 16 Lock Washer

6 Take Off Link

*Used with 7" Actuator only

Description

Ref.

No.

Description

Ref.

No.

Masoneilan 496 Series Rotary Electric Switch Instructions Manual | 6© 2015 General Electric Company. All rights reserved.

Description

Page 10

C. 37/38 Diaphragm Actuators

The 496 switch is rigidly mounted on the spring barrel of the

diaphragm actuator by means of a bracket (7) fastened to

the mounting pad with cap screws (8). The back lever (9) is

fastened to the end of the switch shaft with spring washer

(15) and cap screw (17).

The take off linkage must be adjusted before adjusting the

switches. Apply air pressure to the actuator until the actuator

stem has traveled exactly half the rated stroke. Loosen

locknut (5) and turn the turnbuckle (6) until the back lever (9)

is level. Tighten locknut (5) and adjust switches according to

instructions on Page 2.

Figure 6

37/38 Spring Diaphragm Actuator

Ref.

No.

*1 Clamp 7 Mounting Bracket 14 Cap Screw

*2 Clamp 8 Cap Screw 15 Spring Washer

*3 Machine Screw 9 Back Lever 16 Washer

4 Turnbuckle Screw 10 Clevis 17 Cap Screw

5 Locknut 11 Clip 18 Clamp Rod

6 Turnbuckle 12 Pin

*Used with size 9, 11 and 13 actuators only.

7 | GE Oil & Gas © 2015 General Electric Company. All rights reserved.

Description

Ref.

No.

Description

Ref.

No.

Description

Page 11

D. 87/88 Spring Diaphragm Actuators

Series 87/88 Actuators 496 Switch installation

1. Mount bracket (13) to yoke using cap screws (17) and lock

washers (18).

2. Attach the back lever (7) to the switch using cap screw

(11) and spring washer (12).

3. Mount switch on bracket (13) using cap screws (15) and

lock washers (16).

4. Screw locknut (3) onto clamp rod (2) install clamp rod into

split clamp and tighten locknut.

5. Attach clevis (6) to back lever (7) using clevis pin (9)

washer (10) and retaining clip (8).

6. Screw turnbuckle screw (1) onto clamp rod (2) until it lines

up with clevis (6).

7. Apply air pressure to the actuator until the actuator

stem has traveled exactly half the rated stroke.

8. Install and adjust the turnbuckle until the back lever is

horizontal. Tighten locknut.

9. Refer to adjustments (Page 2) to adjust the switches.

Clevis Assembly

Model 88 Actuator

(Air-to-Open)

Figure 7

87/88 Spring Diaphragm Actuator

Ref.

No.

1 Turnbuckle Screw 7 Back Lever 13 Mounting Bracket

2 Clamp Rod 8 Retaining Clip 14 496 Rotary Switch

Description

Ref.

No.

Description

Model 87 Actuator

(Air-to-Close)

Ref.

No.

Description

3 Locknut 9 Clevis Pin 15 Cap Screw

4 Locknut 10 Washer 16 Lock Washer

5 Turnbuckle 11 Cap Screw 17 Cap Screw

6 Clevis 12 Spring Washer 18 Lock Washer

Masoneilan 496 Series Rotary Electric Switch Instructions Manual | 8© 2015 General Electric Company. All rights reserved.

Page 12

DISTRIBUTOR

E.P. & S. - FRANCE

24 bis rue de Picpus

75012 PARIS

Tel: +33 (0)9 83 01 21 01

ventes@fr-eps.com

E.P. & S. - CAMEROON

Immeuble Carré d'Or, Rue Njo-Njo

Bonapriso, DOUALA

Tel: +237 6 52 12 70 95

ventes@fr-eps.com

Visit our web-site:

www.fr-eps.com

* Trademark of the General Electric Company.

Other company names and product names used in this document are

the registered trademarks or trademarks of their respective owners.

© General Electric Company. All rights reserved.

Loading...

Loading...