GE Masoneilan 469 Series, Masoneilan 496-857, Masoneilan 496-858, Masoneilan 496- Series 58, Masoneilan 496- Series 57 Instruction Manual

Page 1

Masoneilan*

496 Series

Position Transmitter and Limit Switch

ATEX Instruction Manual (Rev.B)

BHGE Data Classification: Public

Page 2

THESE INSTRUCTIONS PROVIDE THE CUSTOMER/OPERATOR WITH IMPORTANT PROJECT-SPECIFIC

REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION

AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY,

BHGE (BAKER HUGHES, A GE COMPANY AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT

ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND

REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

THESE INSTRUCTIONS ASSUME THAT OPERATORS ALREADY HAVE A GENERAL UNDERSTANDING OF

THE REQUIREMENTS FOR SAFE OPERATION OF MECHANICAL AND ELECTRICAL EQUIPMENT IN

POTENTIALLY HAZARDOUS ENVIRONMENTS. THEREFORE, THESE INSTRUCTIONS SHOULD BE

INTERPRETED AND APPLIED IN CONJUNCTION WITH THE SAFETY RULES AND REGULATIONS

APPLICABLE AT THE SITE AND THE PARTICULAR REQUIREMENTS FOR OPERATION OF OTHER

EQUIPMENT AT THE SITE.

THESE INSTRUCTIONS DO NOT PURPORT TO COVER ALL DETAILS OR VARIATIONS IN EQUIPMENT

NOR TO PROVIDE FOR EVERY POSSIBLE CONTINGENCY TO BE MET IN CONNECTION WITH

INSTALLATION, OPERATION OR MAINTENANCE. SHOULD FURTHER INFORMATION BE DESIRED OR

SHOULD PARTICULAR PROBLEMS ARISE WHICH ARE NOT COVERED SUFFICIENTLY FOR THE

CUSTOMER/OPERATOR'S PURPOSES THE MATTER SHOULD BE REFERRED TO BHGE.

THE RIGHTS, OBLIGATIONS AND LIABILITIES OF BHGE AND THE CUSTOMER/OPERATOR ARE

STRICTLY LIMITED TO THOSE EXPRESSLY PROVIDED IN THE CONTRACT RELATING TO THE SUPPLY OF

THE EQUIPMENT. NO ADDITIONAL REPRESENTATIONS OR WARRANTIES BY BHGE REGARDING THE

EQUIPMENT OR ITS USE ARE GIVEN OR IMPLIED BY THE ISSUE OF THESE INSTRUCTIONS.

THESE INSTRUCTIONS ARE FURNISHED TO THE CUSTOMER/OPERATOR SOLELY TO ASSIST IN THE

INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED.

THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT THE WRITTEN

APPROVAL OF BHGE.

2 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 3

Conversion Table

All the USCS values are converted to

metric values using the following conversion factors:

Metric values using

the following

conversion factors:

Conversion Factor

Metric Unit

in. 25.4 mm lb.

0.4535924

kg in

2

6.4516

cm

2

ft3/min

0.02831685

m3/min

gal/min

3.785412

L/min

lb/hr

0.4535924

kg/hr

psig

0.06894757

barg

ft lb

1.3558181

Nm °F

5/9 (°F-32)

°C

Note: Multiply USCS value with conversion factor to get metric value.

NOTICE!

For valve configurations not listed in this

manual, please contact your local MARC or

BHGE sales office for assistance.

© 2018 Baker Hughes, a GE company. All rights reserved. Masoneilan 496 Series Position Transmitter ATEX Instruction Manual | 3

Page 4

Contents

1. Instrument Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2. Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3. Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4. ATEX Intrinsic Safety Marking and Electrical Safety Parameters . . . . . . . . . . . . . . . . . . . . .8

5. ATEX Flameproof Marking and Electrical Safety Parameters. . . . . . . . . . . . . . . . . . . . . . . 10

6. Position Transmitter 496-8../. Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7. Electrical Connection, Installation and Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10. Special Conditions of Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11. Special Conditions of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Annex I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Annex II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Annex III. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 5

Warning

BEFORE installing, using or carrying out any

maintenance tasks associated with this instrument,

READ THE INSTRUCTIONS CAREFULLY.

These instruments comply with the essential

safety requirements of the European Directive

ATEX 94/9/CE. It is certified to be used in Gas or Dust

explosive atmospheres, groups IIA, IIB, IIC and IIIC:

• Category II 1GD – zones 0, 1, 2, 20, 21 and 22

for the protection mode “ia”

• Category II 2GD – zones 1, 2, 21 and 22 for the

protection mode “d” and “tb”

They also comply with the essential safety

requirements of the European Directive EMC

2004/108/EC as amended, for use within an industrial

environment.

Products certified as explosion proof equipment

MUST BE:

a) Installed, put into service, used and maintained

in compliance with European and/or national

and local regulations and in accordance with

the recommendations contained in the relevant

standards concerning potentially explosive

atmospheres.

b) Used only in situations those comply with the

certification conditions shown in this document

and after verification of their compatibility with the

zone of intended use and the permitted maximum

ambient temperature.

c) Installed, put into service and maintained by qualified

and competent professionals who have undergone

suitable training for instrumentation used in areas

with potentially explosive atmosphere. Such trainings

are not supported by BHGE.

It is the end user’s responsibility to:

• Verify material compatibility with the application

• Ensure proper use of fall protection when working

at heights, per Safe Site Work Practices

• Ensure use of proper Personal Protective

Equipment

• Take the appropriate actions to ensure that site

personnel who are performing installation,

commissioning and maintenance have been

trained in proper site procedures for working

with and around equipment, per Safe Site Work

Practices

BHGE reserves the right to discontinue manufacture

of any product or change product materials, design,

or specifications without notice.

Under certain operating conditions, the use of

damaged instruments could cause a degradation of

the performances of the system which may lead to

personal injury or death.

Use only BHGE’s Masoneilan replacement parts to

ensure that the products comply with the essential

safety requirements of the European Directives

mentioned above.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 5

Page 6

Protection

55. Weatherproof

57. Explosionproof and dust and

water tight

58. Intrinsically safe and dust and

water tight

Additional Function

for a Transmitter Only

1. One mechanical switch single

pole double throw

2. Two mechanical switches

single pole double throw

4. One proximity switch

5. Two proximity switches

6. One mechanical switch double

pole double throw

7. Two mechanical switches

double pole double throw

1. Instrument Operation

1.1 The 496-.58 and 496-.57 position

limit switch

Allow switching 1 or 2 electrical circuits. This function is

provided by 1 or 2 micro- switch(es) or 1 or 2 proximity

switch(es).

1.2 The 496-857 and 496-857/. and

496-858 or 496-858/. position

transmitter

The 496 Series instrument is a non-contact optoelectronic positioner transmitter which provides a

4-20mA analog output signal proportional to the valve

position. This device can be mounted both on rotary

and reciprocating valves through a system of gears

and (for reciprocating valves only) a linkage.

The displacement of the stem or shaft is transmitted to

the opto-electronic sensor by 2 gears.

The opto-electronic sensor has the same function than

a standard potentiometer and its output voltage is

proportional to the rotation of its axis.

An electronic circuit amplifies this voltage to a 4-20 mA

signal proportional to the angle of rotation.

This equipment has many advantages:

• non electrical noise typical of potentiometer

with cursor

• frictionless

• unlimited life

• non sensitive to vibration and electrical noise

• very low operating torque: 0.02 N.m

Optionally 496-857/. or 496-858/. apparatus can also be

used as a limit switch to switch 1 or several electrical

circuits. 1 or 2 micro- switch(es) or 1 or 2 proximity

switch(es) are provided for this supplementary function.

2. Numbering System

496 - _ _ _ / _

6 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Type

1. One mechanical switch single

pole double throw

2. Two mechanical switches

single pole double throw

4. One proximity switch

5. Two proximity switches

6. One mechanical switch double

pole double throw

7. Two mechanical switches

double pole double throw

8. Optoelectronic position

transmitter

Page 7

3. Technical Specification

Internal components for limit switch and position transmitter are mounted inside an IP66/IP67 enclosure.

Performances of position transmitter type 496-857 or 496-857/. and 496-858 or 496-858/.

• Output signal: 4-20 mA (2 wires)

• Acceptable span on the command axle: from 25° to 90° for rotary or reciprocating valves

• Rotation: clockwise or counter clockwise

• Linearity: ≤ ± 0.5% for a rotary angle of 25° to 90° (typically ± 0.3% for a rotary angle ≥ 60°)

• Hysteresis: ≤ 0.1%

• Dead band: ≤ 0.1%

• Repeatability: ≤ 0.1%

• Total drift in temperature: 0.02 %/°C or 200 ppm/°C (zero and span range)

• Operating temperature range: -40°C to +80°C

Electrical characteristics and temperature range of the position transmitter with micro-switch(es) or proximity

switch(es) are given in the following sections.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 7

Page 8

4. ATEX Intrinsic Safety Marking and Electrical

Safety Parameters

4.1 Marking

The marking is on the serial plate stamped on the 496

cover (rep 14).

• Name and address of the manufacturer:

Dresser Produits Industriels S.A.S.

14110 CONDE SUR NOIREAU - FRANCE

• Type designation:

– 496-858 for transmitter,

– 496-858/• for transmitter with additional

function(s)

– 496-•58 for position switches

the “•” can take the values 1, 2, 4, 5.

• Basic and complementary marking:

– Transmitter alone or with mechanical switch(es)

(additional function):

II 1 GD

Ex ia IIC T.* Ga Tamb = -..°C à +..°C *

Ex ia IIIC T..°C* Da

– Transmitter alone or with proximity switch(es)

(additional function):

II 1G* or II 2G*

Ex ia IIC T.* Ga Tamb = -..°C à +..°C *

– Position mechanical switch(es):

II 1 GD

Ex ia IIC T.* Ga Tamb = -..°C à +..°C *

Ex ia IIIC T..°C* Da

– Position proximity switch(es) (additional function):

II 1G*, II 2G*

Ex ia IIC T.* Ga Tamb = -..°C à +..°C *

* Ambient temperatures ranges and surface

temperatures for the temperature classifications T6, T5

and T4 are given in ANNEX I with:

– Tables 1, 2 and 3 for the transmitter alone, the

mechanical switch(es) alone and the proximity

switch(es) alone.

– Tables 4 and 5 for the transmitter with mechanical

switch(es) and for the transmitter with proximity

switch(es).

• Serial number

• Year of manufacturing

• Number of notified body ••••

• EC-Type examination certificate number

Warning:

AVERTISSEMENT : DANGER POTENTIEL DE CHARGES

ELECTROSTATIQUES – VOIR INSTRUCTIONS

WARNING: POTENTIAL DANGER OF ELECTROSTATIC

CHARGES. SEE INSTRUCTIONS

4.2 Electrical safety parameters

4.2.1 Type 496-.58

4.2.1.1 Option with 1 or 2 Micro-Switch(es)

• Type identification is: 496-158 and 496-258.

• Mechanical switch(es): type BZ-2R72-A2,

manufacturer: HONEYWELL

• They are supplied by a certified power source for

explosible atmospheres group IIC with the maximal

characteristics:

– Constant power supply: Ui= 30V, Ii = 0.5A, Ci = 0F

and Li = 0H

– Alternative power supply: Ui= 90V, Ii = 1.4A, Ci = 0F

and Li = 0H

• The wiring connection is done directly on mechanical

switch(es).

4.2.1.2 Option with 1 or 2 Proximity Switch(es)

• Type identification is: 496-458 and 496-558.

• These detectors from PEPPERL & FUCHS are

defined as:

– II 1G Ex ia IIC T6 Ga

– II 2G Ex ia IIC T6 Gb

• EC type examination certificate:

– PTB 00 ATEX 2048 X (II1G, II2G)

PTB 00 ATEX 2049 X (II1G, II2G)

8 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 9

4. ATEX Intrinsic Safety Marking and Electrical

Variation

Ui Ii Ci

(V) (A) (nF)

Li Pi

(μH) (W)

With

Microswitch

DC Source

30 0.5 0 0 -

AC Source

Peak Value

90

1.4

0

0

-

With Proximity Switch

16 0.052

120 200

0.169

Safety Parameters (Contd)

• They are supplied by a certified power source

* for explosible atmospheres with the maximal

characteristics:

Ui = 16V ; Ii = 0.052A ; Pi = 0.169W.

* The power source (Control circuit) must be one

manufactured by Pepperl & Fuchs below:

WE 77/EX 1 or WE 77/EX 2

• The wiring connection is done on one or two terminal

connector type:

MK 3 ; 2.5mm2 ; 380 volts ; manufacturer:

WEIDMULLER or equivalent product.

4.2.1.3 Maximum Input Characteristics

4.2.2.2 Type 496-858/. :

The additional functions of position transmitters are

identical to type 496-•58

Maximum input characteristics at terminal block of

additional function:

Variation

Ui Ii Ci

(V) (A) (nF)

Li Pi

(μH) (W)

With

Microswitch

DC Source

30 0.5 0 0 –

AC Source

Peak Value

90

1.4

0

0

-

With Proximity Switch

16 0.052

120 200

0.169

4.2.2 Types 496-858 and 496-858/. :

4.2.2.1 Type 496-8:

The position transmitter is connected to a linear tension

source of a certified type for use in group IIC hazardous

locations and its output circuit must be intrinsically safe

approved per EN 60079-11.

Maximum input characteristics at terminal block:

Ui (V) Ii (A)

Ci (nF)

Li (μH)

Pi (W)

28

0.11

36 0 0.77

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 9

Page 10

Type

Min Max

Voltage Voltage

496-157 or

496-257 or

496-657 or

496-757

-

220V

(direct current) or

250V (alternative

current)

496-457 or

496-557

Pepperl

and Fuchs

-

16V

(direct current)

496-457 or

496-557

Télémécanique

-

58V

(direct current)

496-857/.

9.0V

(direct current)

36V

(direct current)

5. ATEX Flameproof Marking and Electrical Safety

Parameters

5.1 Marking

The marking is on the serial plate stamped on the 496

cover (rep 14).

• Name and address of the manufacturer

Dresser Produits Industriels S.A.S.

14110 CONDE SUR NOIREAU – FRANCE

• Type designation:

– 496-857 for a position transmitter

– 496-857/• for a position transmitter with

additional function(s), for a transmitter

– 496-•57 for a position limit switch

The • can be replaced by 1, 2, 4, 5, 6 and 7.

• the specific marking:

II 2 GD

• the complementary marking:

– Ex d IIC T6 Gb Ta –55°C, +75°C (*)

Ex tb IIIC T85°C Db IP66/IP67

– Ex d IIC T5 Gb Ta –55°C, +85°C (*)

Ex tb IIIC T100°C Db IP66/IP67

• Serial number

• Year of manufacturing

• Number of notified body ••••

• EC-Type examination certificate number

Warning:

AVERTISSEMENT : NE PAS OUVRIR SOUS TENSION

WARNING : DO NOT OPEN WHEN ENERGIZED

• T cable : (**)

(*) temperature range can be reduced without

exceeding above values depending upon the type

of component mounted inside the enclosure.

(**) Mandatory mention when the ambient

temperature is higher than 70°C.

T ambient T cable

70°C

75°C

75°C

80°C

80°C

85°C

85°C

90°C

5.2 Electrical safety parameter

• Maximum dispersed power = 5W

• Voltage supply allowable:

Warning:

AVERTISSEMENT : DANGER POTENTIEL DE CHARGES

ELECTROSTATIQUES – VOIR INSTRUCTIONS

WARNING: POTENTIAL DANGER OF ELECTROSTATIC

CHARGES. SEE INSTRUCTIONS

10 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 11

6. Position Transmitter 496-8../. Electrical data

• Power supply:

Voltage Supply U (V)

Mini

Maxi

Flameproof

9.0V

36V

Intrinsic Safety

9.0V

28V

• Lightning protection (in standard) : 1500W 10/1000µs

• Output current 4-20mA (two wires)

Zc

• Zero range adjustment : ±0.5mA

U

• Span range adjustment : ±2.5mA

• Protected against polarity inversion

Supply Voltage (V) – 9.0 (V

)

• Maximum load

Zc

(Ω)

=

This means for 20mA:

Imaxi (A

)

Zc = 950 Ohm max with for an intrinsically safe loop

and

Zc = 1350 Ohm for Flameproof.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 11

Page 12

Plug

Manufacturer

Certification

ATEX

Certificate

IECEx

Certificate

REDAPT

Ex d IIC

Ex tb IIIC

SIRA 99

ATEX

1115U

IECEx SIR

05.0042U

Others plugs if apparatus certified ATEX or IECEx

(type Cooper CAPRI CODEC).

Adaptor or Reducer

Manufacturer

Certification

ATEX

Certificate

IECEx

Certificate

REDAPT

Ex d IIC

Ex tb IIIC

SIRA 99

ATEX

1115U

IECEx SIR

05.0042U

Other adaptors or reducers if apparatus certified

ATEX or IECEx (Cooper CAPRI CODEC).

7. Electrical Connection, Installation and Start-up

• Comply with current national and local regulations for electrical installation work.

• Must be installed and put into service in conformance with EN 60079-14 and/or national and local

regulations applicable for explosible atmospheres.

• Before carrying out any work on the device, power off the instrument or make sure that the local

conditions in the potentially explosive atmosphere permit – the safe opening of the cover.

• Connect the wires to the instrument terminals, taking care of complying with polarities and maximum

voltage allowed.

• Before power up or after doing any work on the device always check the cover (12) is fully screwed,

O-ring (10) is free of any damage and security screw (9) is well locked.

Note: Before installation, check that the device is undamaged. In the event of damage, inform the manufacturer

whose address is shown on the serial plate.

7.1 Conduit entry in flameproof application

The connections can be done with different variations

taking into account approved manufacturer and

requested approvals:

• A cable entry of a certified type Ex d IIC / Ex tb IIIC

can be mounted directly on the single ¾" NPT (ANSI/

ASME B1.20.1) housing conduit connection.

• For an adaptor or reducer need, these component

are allowed:

• For multiple cable entries (3 maximum), the adaptor

Y237 “Masoneilan” can be used for ATEX application

only.

– If one Y237 input is not used, the conduit will be

closed by the followed plugs:

– If two Y237 inputs are not used, the Y237 must be

suppressed.

• The cable entry with or without its adaptor/reducer

and the Y237 with its cable entry must be installed in

conformance with Annex III.

12 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 13

7. Electrical Connection, Installation and Start-up (Contd)

7.2 Electrical connection for type

496-.57 or 496-.58

• The electrical cables are connected either directly

on to the micro switch(es) or to the proximity switch

terminal block.

• Connect the device to the earth using the earth

connections provided inside and outside the housing

of the device.

• Basic rule for wiring:

– Must be used in addition to local regulation for

electrical installation

– Connector slot approval:

– Insulation must be free of any damage along the

wires inside the housing

– Tightening must be sufficient to bring constant

contact in time without being excessive to cut or

damage connection.

7.3 Electrical connection for type

496-857 or 496-857/. and 496-858

or 496-858/.

Connect the electrical cables to the position transmitter

terminal block located on the printed circuit board.

Respect the polarities + and – and the maximum

voltage allowed.

When a position transmitter is provided with an

additional function, the electrical cables are connected

either directly on to the micro switch(es) or to the

proximity switch terminal block.

Connect the device to the earth using the earth

connections provided inside the housing and on the

outside of the device.

• Basic rule for wiring:

– Must be used in addition to local regulation for

electrical installation

– Connector slot approval:

– Insulation must be free of any damage along the

wires inside the housing

– Tightening must be sufficient to bring constant

contact in time without being excessive to cut or

damage connection.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 13

Page 14

7. Electrical Connection, Installation and Start-up (Contd)

7.4 Installation and start-up

7.4.1 Installation

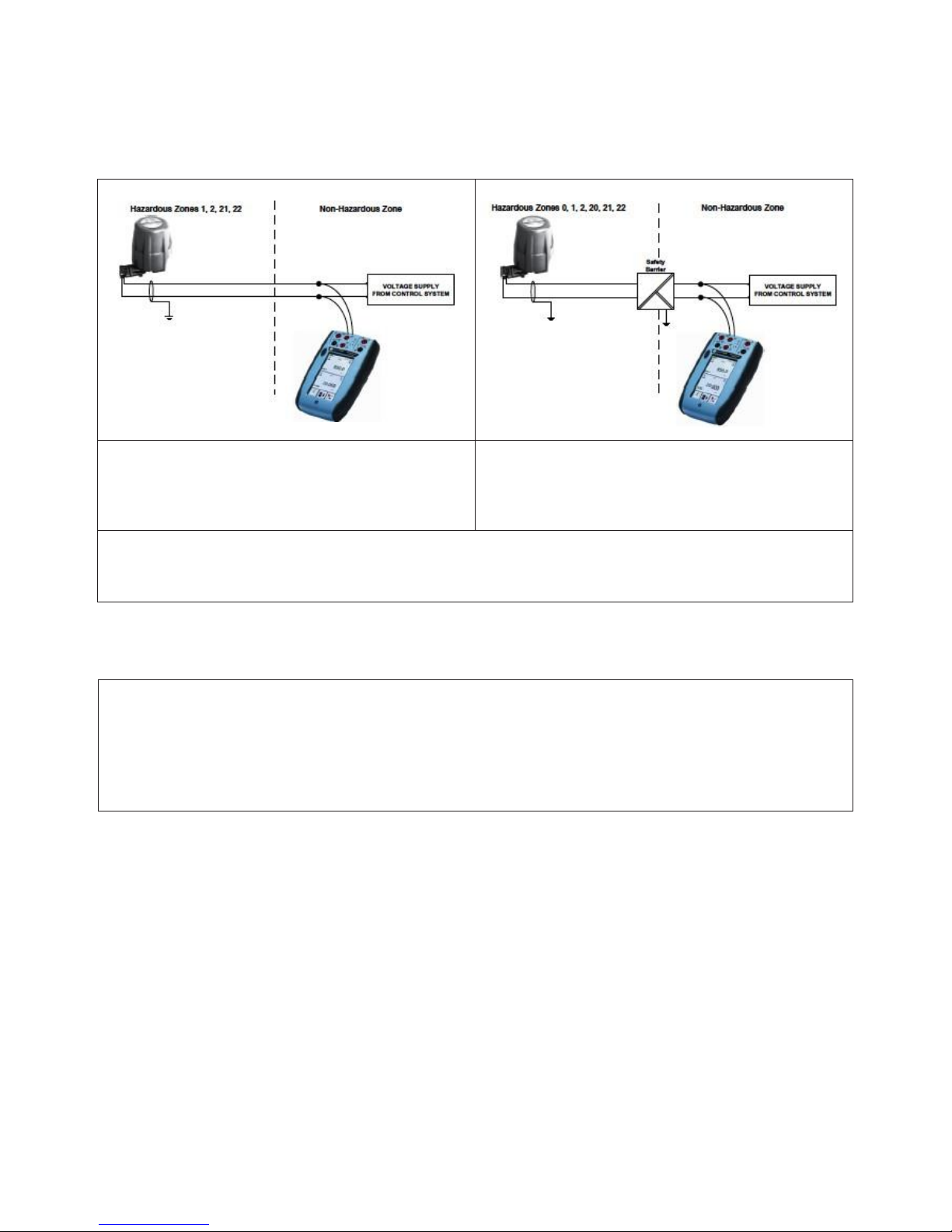

Flameproof instrument may be installed in gas and

dust explosive atmosphere of groups IIA, IIB, IIC and

IIIC for the zones 1, 2, 21 and 22 with “d” and “tb”

protection mode.

Intrinsically safe instrument may be installed in gas

and dust explosive atmosphere of groups IIA, IIB,

IIC and IIIC for zones 0, 1, 2, 20, 21 and 22 with “ia”

protection mode.

Nota:

It is under the user responsibility to check the installation against Intrinsic safety rules taking into account

entity parameters of all devices in the loop in addition of temporary one like measurement devices.

7.4.2 Start-up

– Before power up or after doing any work on the device always check the cover (12) is fully screwed,

O-ring (10) is free of any damage and security screw (9) is well locked.

– Check that the cable gland is certified for the intended use and that the electrical data are suitable for

the operating zone.

Before start up, proceed, if required, with instrument calibration as per §8 and/or ensure that all the safety

instructions in the preceding paragraphs have been strictly followed.

14 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 15

8. Calibration

Before power up the device to proceed with calibration

carefully read the following safety warnings.

– Comply with current national and local

regulations for electrical installation work.

– Must be installed and put into service in

conformance with EN 60079-14 and / or

national and local regulations applicable for

explosible atmospheres.

– Before carrying out any work on the device,

power off the instrument or make sure

that the local conditions in the potentially

explosive atmosphere permit- the safe

opening of the cover.

– Connect the wires to the instrument’s

terminals, taking care of complying with

polarities and maximum voltage allowed.

– Before power up or after doing any work on

the device always check the cover (12) is fully

screwed, O-ring (10) is free of any damage

and security screw (9) is well locked.

8.1 Calibration of rotary limit switch

496-.57 and 496-.58 equipped with

micro switch(es)

• The concave portion of the lever (5) must be strictly

concentric to the cam (13) when the micro-switch is

actuated.

• This is an important caution to make sure the lever is

properly depressed when not actuated.

• If not, loosen the screws (3 & 17) and slightly move

the lever upwards or downwards. Tighten the screws.

• Slightly loosen the cam locking screw (1) using a

3/32” socket hex head wrench.

• Move the plug stem to the position required to

actuate the switch.

• It is important to note that the cam operating the

right hand micro-switch must actuate the lever (5) at

the end of the counterclockwise rotation. (See detail

figure below).

• This makes sure the screw (2) has free the lever (5)

when the valve is throttling. The remaining concave

portion only ensures micro-switch actuation in case

of over travel. Conversely, the cam operating the left

hand micro-switch must actuate the lever (5) at the

end of the clockwise rotation. (See front view below).

• To meet the above requirement when only one

micro-switch is provided (type 496-158) it may

be necessary to change the location of the

micro-switch.

• Rotate the cam (13) until the micro-switch is

actuated. Lock the cam (13) tightening the screw (1).

• Fine tune adjustment with screw (2). Use a 1/16”

socket hex head wrench. The screw (2) must come

out the cam enough to properly depress the lever (5).

• Strictly follow safety instructions under §7.4 before

putting into service.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 15

Page 16

8. Calibration (Contd)

1 6 9 10 11 12 8

13

A

8

2

13

3

4

3

17

7

15

5

14

18

5

16

B

Parts List

Rep.

Designation

Rep.

Designation

Rep. Designation

1

Adjusting screw

8

Snap ring

2

Adjusting screw

9

Safety screw

16

Insulating

3

Screw (1 micro switch)

10 (1)

Oring

17

Screw (second micro switch)

4

Micro switch

11

Axis 18

Washer

5

Lever

12

Cover

19 (2)

Spacer (Not shown)

6

Housing

13

Cam A

Contact point for the left micro switch

7 (1)

O ring

14

Serial plate

B

Contact point for the right micro switch

(1) Recommended spare parts

(2) Only for 496-2 model

16 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 17

8. Calibration (Contd)

Rep.

Designation

Rep.

Designation

33

Arm

34

Proximity switch

8.2 Calibration of rotary limit switch

496-.57 and 496-.58 equipped with

proximity switch(es)

8.2.1 Type 496-4

• Actuate the valve to the desired triggering position

and check the sense of rotation when the arm leaves

the proximity sensor.

• The figure below shows the location of the proximity

sensor and of the arm when triggering as a function

of the sense of rotation.

• Slowly move the arm towards the proximity sensor

until it triggers. Triggering occurs when the arm

overlaps approximately 1/3 of the proximity switch.

• Strictly follow safety instructions under §7.4 before

putting into service.

34 34

33

8.2.2 Type 496-5

During adjustment make sure that the proximity

switch with the red spot is triggered by the arm with

the red spot.

• Adjustment of the first proximity switch

– The first switch is adjusted at the beginning of

the stroke.

– Check what will be the sense of rotation when the

valve is actuated. Figure (b, c) below shows the

proximity sensor and the arm assigned to the first

triggering point for a given the sense of rotation.

– Slowly move the arm towards the proximity switch

until it triggers.

• Adjustment of the second proximity switch

– The second switch is adjusted at the end of the

actuator stroke.

– Immobilize the first arm previously adjusted and

slowly move the second arm towards the second

proximity sensor until it triggers.

– Make sure the first proximity switch is still

correctly adjusted.

• Strictly follow safety instructions under §7.4 before

putting into service.

a

A

B

b

B

c

Rep.

Designation

Rep.

Designation

A

Red spot

B

First triggering point

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 17

Page 18

8. Calibration (Contd)

8.2.3 Air-gap adjustment

Air-gap between the proximity switch and the arm is

factory adjusted. If new adjustment is required proceed

as follows:

• Loosen the proximity sensor nut (37A), located on the

front of the bracket (36).

• Unscrew a few turns the locknut (37B) located on the

back of the bracket.

• Position the arm above the proximity sensor and

push the shaft end (11) towards the outside of the

housing so as to eliminate the longitudinal play.

• Hold in position the proximity sensor and screw the

nut (37A). Adjust air gap to 0,3 mm using a shim

• Tighten the lock nut (37B).

6 9 10 11 12 8 30 37A

8

31

32

33

3

36

7

15

25

14

3

24

34 37B 19

Parts List

Rep.

Designation

Rep.

Designation

Rep.

Designation

3

Screw

12

Cover

31

Snap ring

6

Housing

14

Serial plate

32

Washer

7 (1)

O-ring

33

Arm 8 Snap ring

19

Spacer

34

Proximity sensor

9

Safety screw

24

Terminal block

35 (2)

Spacer (Not shown)

10 (1)

O-ring

25

Terminal block

36

Sensor bracket

11

Axis

30

Spacer

37

Nut

(1) Recommended spare parts (2) Only for 496-4 model

18 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 19

8. Calibration (Contd)

Masoneilan

8.3 Calibration of position transmitter

496-858 or 496-858/

• Action

The action sense of the valve (open or closed valve,

compared to the 4 - 20 mA of the loop signal),

determines the position of the connector 3 points

of the optoelectronic sensor on one of the two

connectors of electronic circuit A or B.

The operation rule is: for a clockwise rotation of

the pinion of the control shaft (view cover side),

the output current increases (4→20 mA) when the

connector of the optoelectronic sensor is connected

in A and decreases when connected in B.

A B

C

Z S

-

PN:

+

• Linkage adjustment

When mounted on reciprocating valves, adjust the

turnbuckle to get the instrument lever perpendicular

to the plug stem at mid-travel.

• Position transmitter adjustment

– Position the connector 3 points on connector A

or B in function of the chosen action.

– Preset mid travel the zero adjustment (Z)

if necessary *.

– Preset mid travel the span adjustment (S) if

necessary **.

– Configure the switch C (see annex II) on the

rotation angle of the control axle.

– Position the valve to the origin of travel that should

correspond to the minimum of the signal (4 mA).

– Install a milliamp meter in series in the loop and

power up the instrument.

– Rotate the primary pinion on the control axle to

get an output signal around 4 mA

– Fine tune-up of the 4 mA signal with the zero

potentiometer (Z).

– Full stroke the valve to the rated travel and

adjust the output signal to 20 mA with the span

potentiometer (S).

– Check the zero and span calibration compared

to the valve stroke. Repeat the zero and span

calibration operations if necessary.

* In case of problem of Zero adjustment due to

the physical limits of the potentiometer, turn

of 5 turns in the reverse direction that desired

and turn the primary pinion to obtain an output

current nearest to 4 mA.

** In case of problem of span adjustment due to

the physical limits of the potentiometer, turn of

5 turns in the reverse direction that desired and

configure the switch C (see annex II) for a higher

or lower angle than that basis.

• Adjustment of micro-switch(es) or proximity

switch(es)

Refer to paragraph §8.1 or §8.2 to adjust microswitches or proximity switch(es).

• Strictly follow safety instructions under §7.4 before

putting into service.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 19

Page 20

8. Calibration (Contd)

9 10 11 8 12 23 111 44 110

7

8 220

221

44

6

114

46

222

114

14

F

View F

Vue

108

106

105

101 102 103 104

38 42

107

Parts List

Rep. Designation Rep. Designation Rep. Designation

6

housing

38

spacer

106

Grower washer

7

O-ring

42

electronic card

107

stirrup

8

circlips

44

washer

108

washer

9

CHC screw

46

card support

110

screw

10

O-ring

101

ground screw (inside)

111

spring washer

11

shaft

102

Grower washer

114

CHC screw

12

cover

103

stirrup

220

detector set

14

serial plate

104

washer

221

detector support

23

pinion

105

ground screw (outside)

222

screw

20 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 21

9. Maintenance

– Before carrying out any work on the device,

power off the instrument or make sure

the local conditions are free of potentially

explosive atmosphere for safe opening of

the cover.

– These operations must be done in

conformance with EN 60079-17 and / or

national and local regulations applicable

for explosible atmospheres.

– Before power up or after doing any work

on the device always check the cover (12)

is fully screwed, O-ring (10) is free of any

damage and security screw (9) is well

locked.

• Check that no part of the 496 is damaged.

In the event of damage replace the defective parts

with genuine manufacturer’s replacement part.

• Pay particular attention to the following:

– Check device, mechanical link and general aspect.

– Check the cable gland and the electrical

connections.

– Check the condition of the O-ring (10) of

cover (12) and O-ring (7) of the shaft (11).

– Make sure that shaft (11) is not worn out

or damaged.

– If the shaft (11) must be removed, make sure the

original circlips (8) is put back in place. Check that

neither the housing nor the shaft are damaged.

• Instruments installed in zones 20, 21 and 22 must be

cleaned to prevent any dust build up on the walls.

See instruction §11.1 b&c for safe cleaning.

10. Special Conditions of Work

Based on 94/9/EC directive, a training session must be

followed by person usually recognized to use apparatus

in explosible atmospheres.

This training session is not supported par Dresser

Produits Industriels S.A.S.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 21

Page 22

11. Special Conditions of Use

11.1 For Intrinsic Safety and Flameproof Types 496-.58, 496-858 and 496-858/. and

Types 496- .57, 496-857 and 496-857/.

a. It is under the user responsibility to check once

a year the gasket and in the event of damage to

replace the defective parts with manufacturer’s

replacement parts only.

b. For use in dusty hazardous areas, the user will have

to proceed to a cleaning regularly the different sides

of the enclosure to avoid the deposits of dusts, the

maximum thickness must be <5 mm. This cleaning

will be done using recommendations defined in §c.

For safe operation, this can be done only if the

local conditions around the device are free of

potentially explosive atmosphere.

c. To avoid any spark due to electrostatic discharges, it

is requested to follow the instructions of EN TR50404.

For example, the user will proceed a cleaning of

the device and mainly the plastic label with a wet

rag to. For safe operation, this can be done only if

the local conditions around the device are free of

potentially explosive atmosphere.

d. The user will have to check the temperature

increase on the 496 head coming from the

mechanical part in contact with the 496 housing

or through the process thermal radiation be less or

equal than the temperature classification allowed.

This must be done in conformance with EN 60079-14

and/or national and local regulations applicable for

explosible atmospheres.

e. The final user during the 496 installation on site must

show the protection mode used on the serial plate

removing the tears off tabs or putting a cross in the

dedicated area. This is a requirement only for multi

protection marking. The label here on the right is

shown for example only and not representative to

the 496 label.

22 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 23

11.

Special Conditions of Use (Contd.)

T ambient

T cable

70°C

75°C

75°C

80°C

80°C

85°C

85°C

90°C

11.2 Intrinsically safe apparatus: Types 496-.58, 496-858 and 496-858/.

• The cable entry must have a protection level at least

equal to IP6X according to EN 60529 standards.

• For the 496 housing with aluminum material, the

user will have to determine the use of the device

for group II category 1 (zone 0) against potential

inflammable source causing by sparks in the event

of impact or friction.

• The voltage supply connected on each 496

connectors must be certified for use in group

IIC and the loop intrinsic safety approved. The

entity parameters of the voltage supply must

be compatible with the entity parameters of

the 496 described §4.2.

11.3 Explosion proof apparatus:

Types 496-.57, 496-857

and 496-857/.

• When the ambient temperature is higher than 70°C,

the user will have to choose a cable entry and a

cable compatible with the data of the table below:

• The cable entry must have a degree of protection at

least equal to IP66/67.

• Use only the following greases for the explosionproof gaskets, shaft, cover threads, cable gland and

plug for Y237:

Type

Manufacturer

SI 33

ORAPI

GRAPHENE 702

ORAPI

MOLYKOTE 111 COMPOUND

MOLYKOTE®

MULTILUB

MOLYKOTE®

GRIPCOTT NF

MOLYDAL

• All mechanical parts coupled with the limit switch or

transmitter and likely to generate a spark or a hot

surface will have to be the object, on behalf of the

user, an analysis of the risks in agreement with the

Directive 94/9/CE. The user will have to follow the

conformity module adapted to the zone in which it

will be installed.

• The shaft joint tolerance is lower than one defined by

the standard EN 60079-1. It must be respected with a

maximum radial gap of 0.133mm.

• The length of explosion-proof gaskets is greater than

the one defined in the sheet of EN 60079-1.

• The minimal temperature of the cable is indicated on

the serial plate.

• When the ambient temperature is lower than -20°C,

the user will have to choose a cable entry and a

cable compatible with the ambient temperature

specified on the marking plate.

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 23

Page 24

Annex I

Table 1 Min and Max Ambient Temperatures (°C)

Type 496-858

Ci

Li

1G/2G/1D

1G/2G

1D

nF

µH

MIN

T6

T5

T4

T85°C

T100°C

Transmitter

30 0 -40

70

80

80

70

80

Table 2 Min and Max Ambient Temperatures (°C)

Type 496-158

and 496-258

Ci

Li

1G/2G/1D

1G/2G

1D

nF

µH

MIN

T6

T5

T4

T85°C

T100°C

BZ-2R-72-A2

0 0 -55

80

80

80

70

80

Table 3 Min and Max Ambient Temperatures (°C)

Type 496-458 and 496-558

Ci

Li

1G/2G

1G

2G

1D

nF

µH

MIN

T6

T5

T4

T6

T5

T4

T85°C

T100°C

NJ2-11-N-G

30

50

-25

45

57

81

62

77

81

NJ2-11-SN-G

50

150

-40

45

57

81

62

77

81

NJ2-12GK-N

45

50

-25

51

66

80

NJ2-12GK-SN

50

150

-40

34

46

74

51

66

80

NJ2-12GM-N

30

50

-25

45

57

81

62

77

81

NCB2-12GM35 NO

90

100

-25

45

57

81

62

77

81

NJ3-18-GK-S1N

70

200

-25

34

46

74

51

66

80

NJ4-12GK-N

45

50

-25

51

66

80

NJ4-12GK-SN

70

150

-50

34

46

74

51

66

80

NJ5-18GK-N

70

50

-25

34

46

74

51

66

80

NJ5-18GK-SN

120

200

-40

34

46

74

51

66

80

NJ5-18GM-N

70

50

-25

45

57

81

62

77

81

NJ5-30GK-S1N

100

200

-25

34

46

74

51

66

80

NCB5-18GM40 NO

95

100

-25

45

57

81

62

77

81

24 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 25

Annex I (Contd)

Table 5 Min and Max Ambient Temperatures (°C)

Type 496-858/4

and 496-858/5

Ci

Li

1G/2G

1G

2G

1D

nF

µH

MIN

T6

T5

T4

T6

T5

T4

T85°C

T100°C

Transmitter+NJ2-11-N-G

30

50

-25

45

57

80

62

77

80

Transmitter+NJ2-11-SN-G

50

150

-40

45

57

80

62

77

80

Transmitter+NJ2-12GK-N

45

50

-25

51

66

80

Transmitter+NJ2-12GK-SN

50

150

-40

34

46

74

51

66

80

Transmitter+NJ2-12GM-N

30

50

-25

45

57

80

62

77

80

Transmitter+NCB2-12GM35 NO

90

100

-25

45

57

80

62

77

80

Transmitter+NJ3-18-GK-S1N

70

200

-25

34

46

74

51

66

80

Transmitter+NJ4-12GK-N

45

50

-25

51

66

80

Transmitter+NJ4-12GK-SN

70

150

-40

34

46

74

51

66

80

Transmitter+NJ5-18GK-N

70

50

-25

34

46

74

51

66

80

Transmitter+NJ5-18GK-SN

120

200

-40

34

46

74

51

66

80

Transmitter+NJ5-18GM-N

70

50

-25

45

57

80

62

77

80

Transmitter+NJ5-30GK-S1N

100

200

-25

34

46

74

51

66

80

Transmitter+NCB5-18GM40 NO

95

100

-25

45

57

80

62

77

80

Table 4 Min and Max Ambient Temperatures (°C)

Type 496-858/1

and 496-858/2

Ci

Li

1G/2G/1D

1G/2G

1D

nF

µH

MIN

T6

T5

T4

T85°C

T100°C

Transmitter + BZ-2R-72-A2

30 0 -40

70

80

80

70

80

Not Applicable

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual | 25

Page 26

Annex II

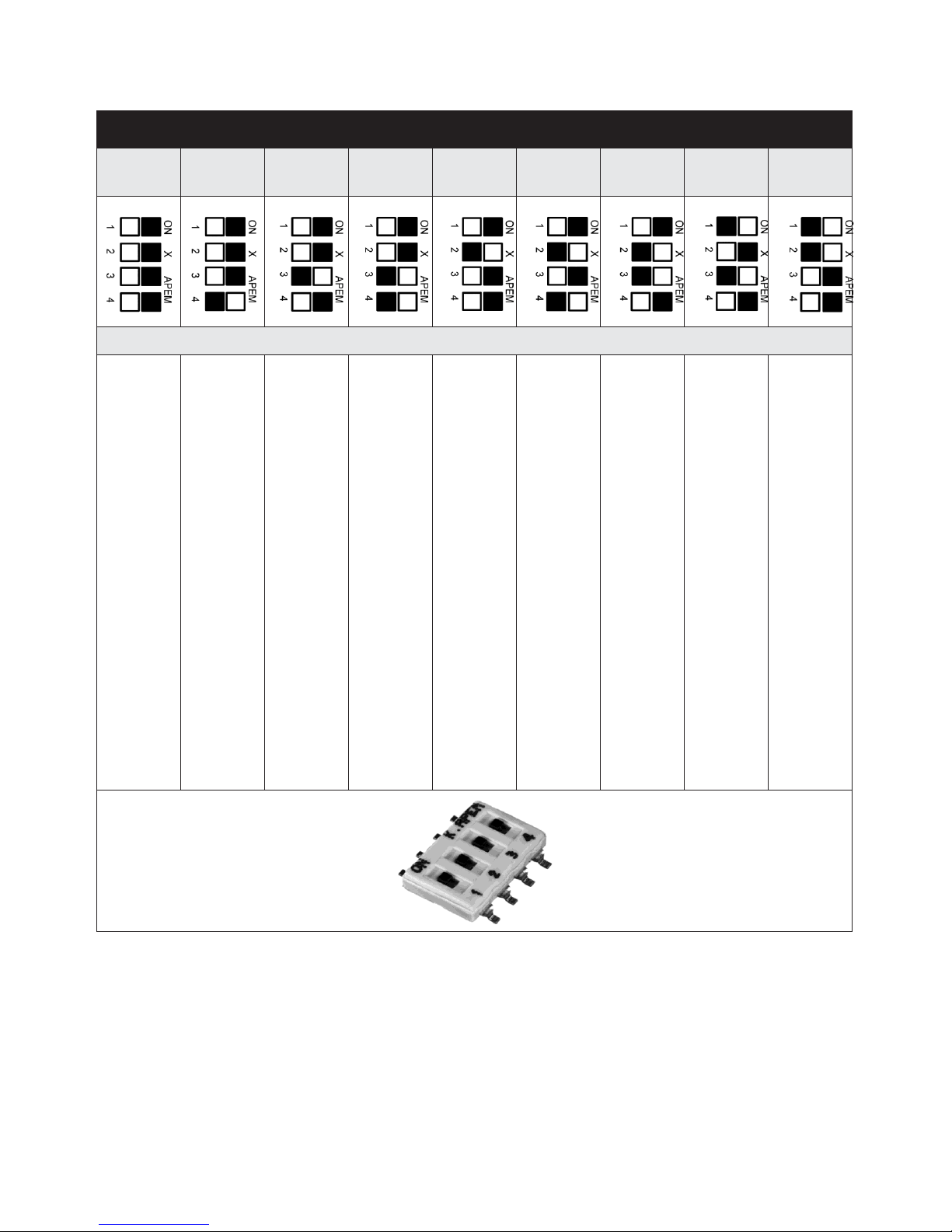

Switch Configuration According to the Rotation Angle of the Control Axle

≤ 24° and

< 30°

≤30° and

< 36°

≤36° and

< 42°

≤42° and

<48°

≤48° and

< 54°

≤54° and

< 62°

≤62° and

<70°

≤70° and

< 80°

≤80° and

≤90°

Concerned Apparatus

• 87/88

strokes

½” to

0,8”

• 37/38

strokes

½” to ¾”

• Sigma F

stroke ¾”

• Varimax

• 67/68

stroke 5”

• Camflex

• Varipak

• 3100

• 87/88

strokes

1” to 2,5”

• 37/38

strokes

1” to 4”

• Sigma F

strokes

1,5” to 2”

• 67/68

stroke 6”

• 67/68

stroke 8:

• Minitork

• Ball

26 | BHGE © 2018 Baker Hughes, a GE company. All rights reserved.

Page 27

Annex

Ill

CABLE GLAND ACCESSORIES MOUNTING

ON

ATEX

and

IECEx

INSTRUMENTS

WITH CABLE

ENTRY

CERTIFIED Ex d IIC , Ex tb IIIC

Taper

threaded joints in conformance

with ANSI ASME

Bl.20.1:

5

threads provided

on

each

part

WITH ADAPTOR or

REDUCER

CERTIFIED Ex d IIC , Ex tb IIIC

Taper threaded joints in conformance

with ANSI ASME

B1.20.1:

5

threads provided

on

each

part

Cemented with •LOCTITE FREINFILET

FORT•

or

equivalent product with similar

efficiency

Y237 ADAPTOR CABLE GLAND ACCESSORIES MOUNTING

ON

ATEX INSTRUMENTS

ONLY

CABLE

ENTRY

ADAPTOR or

REDUCER

HOUSING

CERTIFIED II 2 GO

Ex d IIC

Ex

tb

IIIC

CABLE

ENTRY

CERTIFIED II 2 GO

Ex d IIC

Ex

tb

IIIC

ADAPTOR

or

REDUCER

CERTIFIED II 2 GO

Ex

d IIC

Ex

tb I I

IC

NOTE : A

PLUG

CAN NOT

BE

MOUNTED

ON AN

ADAPTOR

OR REDUCER

PLUG

HOUSING

CERTIFIED II

2

GO

Ex d I

IC

PLUG

CERTIFIED II

2

GO

Ex d I

IC

Ex

tb

IIIC

A:

Taper threaded joints in conformance

with ANSI ASME

Bl.20.1:

S

threads provided

on

each

part

Cemented with •LOCTITE FREINFILET

FORT•

or

equivalent product with similar

efficiency

B :

Taper threaded joints in conformance

Ex

tb IIIC

ONLY ONE PLUG

ALLOWED

B

The

plug

and

the cable

entries

can

be lubricated with

greases

specified in paragraph •special

conditions

of use•

with ANSI ASME

Bl.20.1:

5

threads provided

on

each

part

Cylindrical thread

joints

In conformance with ISO

965-1/3

Effecti

ve threads

engaged

≥ 5

Depth

of

engagement

≥ 8 mm

C:

Taper threaded

joints

in

conformance with ANSI ASME

Bl.20.1:

5

threads provided

on

each

port

Cylindrical thread

joints

in conformance

with

ISO

965-1/3

Effecti

ve threads

engaged

≥ 5

Depth

of

engagement

≥ 8 mm

Cemented with •LOCTITE FREINFILET

FORT•

or

equivalent product with similar

efficiency.

DWG N° 720017989 REV.A

© 2018 Baker Hughes, a GE company. All rights reserved. 496 Series Masoneilan Position Transmitter ATEX Instruction Manual I 27

Page 28

DIRECT SALES OFFICE LOCATIONS

AUSTRALIA

Brisbane

Phone: +61-7-3001-4319

Fax: +61-7-3001-4399

Perth

Phone: +61-8-6595-7018

Fax: +61-8-6595-7299

ITALY

Phone: +39-081-7892-111

Fax: +39-081-7892-208

JAPAN

Tokyo

Phone: +81-03-6871-9008

Fax: +81-03-6890-4620

SOUTH AFRICA

Phone: +27-11-452-1550

Fax: +27-11-452-6542

SOUTH & CENTRAL

AMERICA AND THE CARIBBEAN

Phone: +55-12-2134-1201

Fax: +55-12-2134-1238

Melbourne KOREA

SPAIN

Phone:

+61-3-8807-6002

Phone:

+82-2-2274-0748

Phone:

+34-93-652-6430

Fax:

+61-3-8807-6577

Fax:

+82-2-2274-0794

Fax:

+34-93-652-6444

BELGIUM MALAYSIA UNITED ARAB EMIRATES

Phone:

+32-2-344-0970

Phone:

+60-3-2161-0322

Phone:

+971-4-8991-777

Fax:

+32-2-344-1123

Fax:

+60-3-2163-6312

Fax:

+971-4-8991-778

BRAZIL

Phone: +55-11-2146-3600

Fax: +55-11-2146-3610

CHINA

Phone: +86-10-5738-8888

Fax: +86-10-5918-9707

FRANCE

Courbevoie

Phone: +33-1-4904-9000

Fax: +33-1-4904-9010

GERMANY

Ratingen

Phone: +49-2102-108-0

Fax: +49-2102-108-111

INDIA

Mumbai

Phone: +91-22-8354790

Fax: +91-22-8354791

New Delhi

Phone: +91-11-2-6164175

Fax: +91-11-5-1659635

MEXICO

Phone: +52-55-3640-5060

THE NETHERLANDS

Phone: +0031-15-3808666

RUSSIA

Veliky Novgorod

Phone: +7-8162-55-7898

Fax: +7-8162-55-7921

Moscow

Phone: +7 495-585-1276

Fax: +7 495-585-1279

SAUDI ARABIA

Phone: +966-3-341-0278

Fax: +966-3-341-7624

SINGAPORE

Phone: +65-6861-6100

Fax: +65-6861-7172

UNITED KINGDOM

Wooburn Green

Phone: +44-1628-536300

Fax: +44-1628-536319

UNITED STATES

Jacksonville, Florida

Phone: +1-904-570-3409

Deer Park, Texas

Phone: +1-281-884-1000

Fax: +1-281-884-1010

Houston, Texas

Phone: +1-281-671-1640

Fax: +1-281-671-1735

bhge.com

*Denotes a trademark of Baker Hughes, a GE company LLC.

Other company names and product names used in this document are the

registered trademarks or trademarks of their respective owners.

© 2018 Baker Hughes, a GE company LLC - All rights reserved.

Baker Hughes, a GE company, LLC and its affiliates (“BHGE”) provides this

information on an “as is” basis for general information purposes and believes it

to be accurate as of the date of publication. BHGE does not make any

representation as to the accuracy or completeness of the information and

makes no warranties of any kind, specific, implied or oral, to the fullest extent

permissible by law, including those of merchantability and fitness for a

particular purpose or use. BHGE hereby disclaims any and all liability for any

direct, indirect, consequential or special damages, claims for lost profits, or

third party claims arising from the use of the information, whether a claim is

asserted in contract, tort, or otherwise. The BHGE logo is a trademark of Baker

Hughes, a GE company LLC. GE and the GE monogram are trademarks of the

General Electric Company used under trademark license.

GEA31058B 09/2018

Loading...

Loading...