Page 1

Installatio

30" Electric

I structio s

BEFORE YOU BEGIN

Read these instructions carefully and completely.

.IMPORTANT- Savetheseinstructionsfor

local inspector's use.

, IMPORTANT - Observe all governing

codes and ordinances.

, Note to Installer - Be sure to leave these

instructions with the consumer.

. ATTENTION INSTALLER: Allelectricdrop-inranges must be hardwired (directwired)intoan

approved junctionbox.A plugand receptacleisNOT permittedon these products.

Drop-ln Ranges

, Note to Consumer - Keep these instructions for

future reference.

, Skill level - Installation of this appliance requires a

qualified installer or electrician.

, Proper installation is the responsibility of the installer.

, Product failure due to improper installation is NOT

covered under the warranty.

FOR YOUR SAFETY

A WARNING Beforebeginningthe installation,switchpower offatthe servicepanel and lockthe

servicedisconnectingmeans to prevent power from beingswitchedon accidentally.When the service

disconnectingmeans cannot be locked,securelyfastena prominent warninc device,such as a tag,tothe service

panel.

A WARNING The information in this manual must be followed to m,nimize the risk of fire, electric shock

or to prevent property damage, personal injury or loss of life.

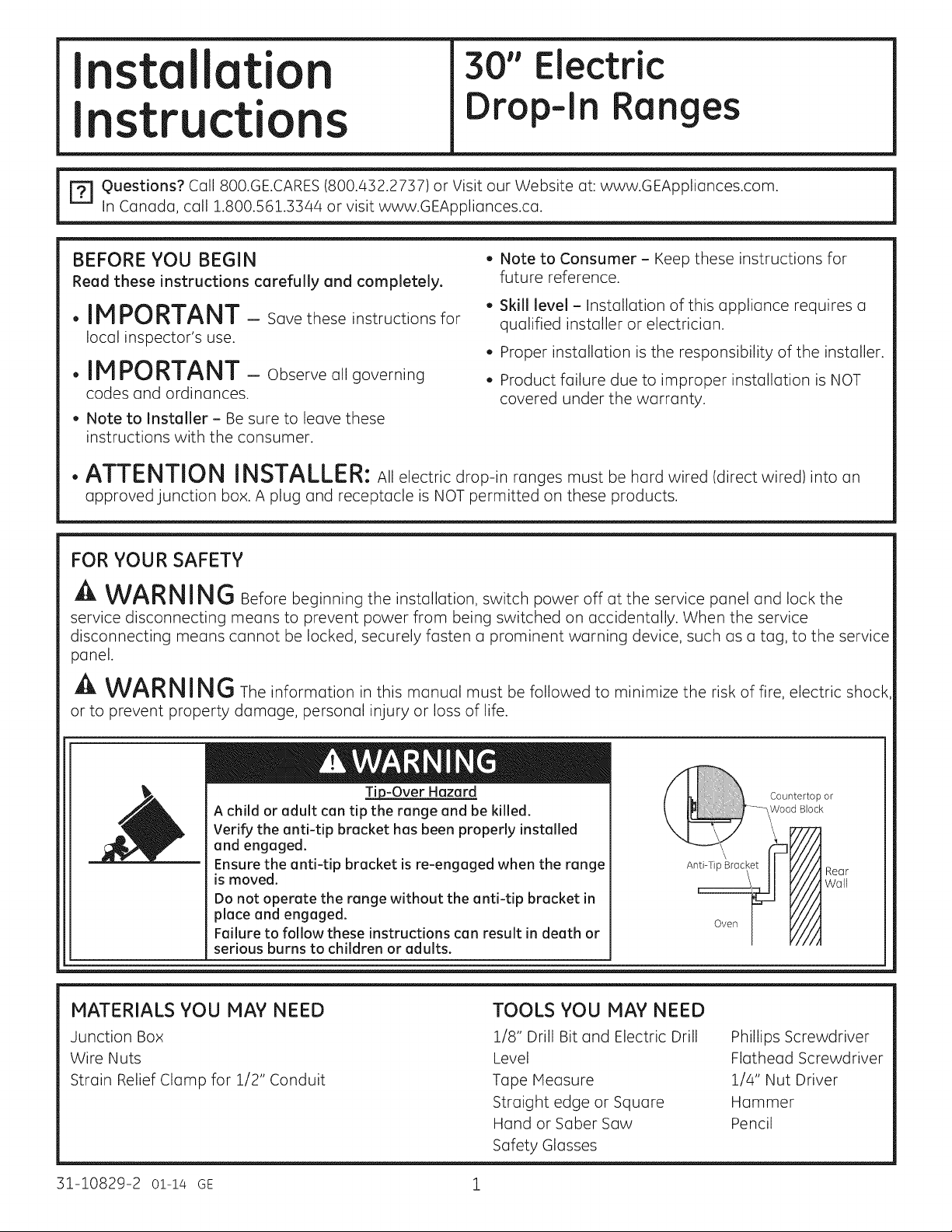

A child or adult can tip the range and be killed.

Verify the anti-tip bracket has been properly installed

and engaged.

Ensure the anti-tip bracket is re-engaged when the range

is moved.

Do not operate the range without the anti-tip bracket in

place and engaged.

Failure to follow these instructions can result in death or

serious burns to children or adults.

MATERIALS YOU MAY NEED

Junction Box

Wire Nuts

Strain Relief Clamp for 1/2" Conduit

T_p-Over Hazard

Oven

TOOLS YOU MAY NEED

1/8" Drill Bit and Electric Drill

Level

Tape Measure

Straightedge or Square

Hand or Sober Saw

SafetyGlasses

Countertop or

Wood Block

7/// Rear

////Wall

II/!

Y/#

Phillips Screwdriver

Flathead Screwdriver

1/4" Nut Driver

Hammer

Pencil

31-i0829-2 o1-14 GE 1

Page 2

Installation Instructions

REMOVE PACKAGING MATERIALS

Failure to remove packaging materials could result in damage to the appliance. Remove all packing parts from

oven, racks, and heating elements. Remove protective film and labels on the outer door and control panel.

Also remove plastic on trims and panel and all tape around the oven. Open oven door and remove literature

pack and oven racks. Removethe bottom trim from the side of the oven. It will be installed at the end of the

installation process.The trim is wrapped separately in a plastic bag which will also contain the 4 screws to

secure the bottom trim and the 2 shoulder screws used to secure the product to the cabinet.

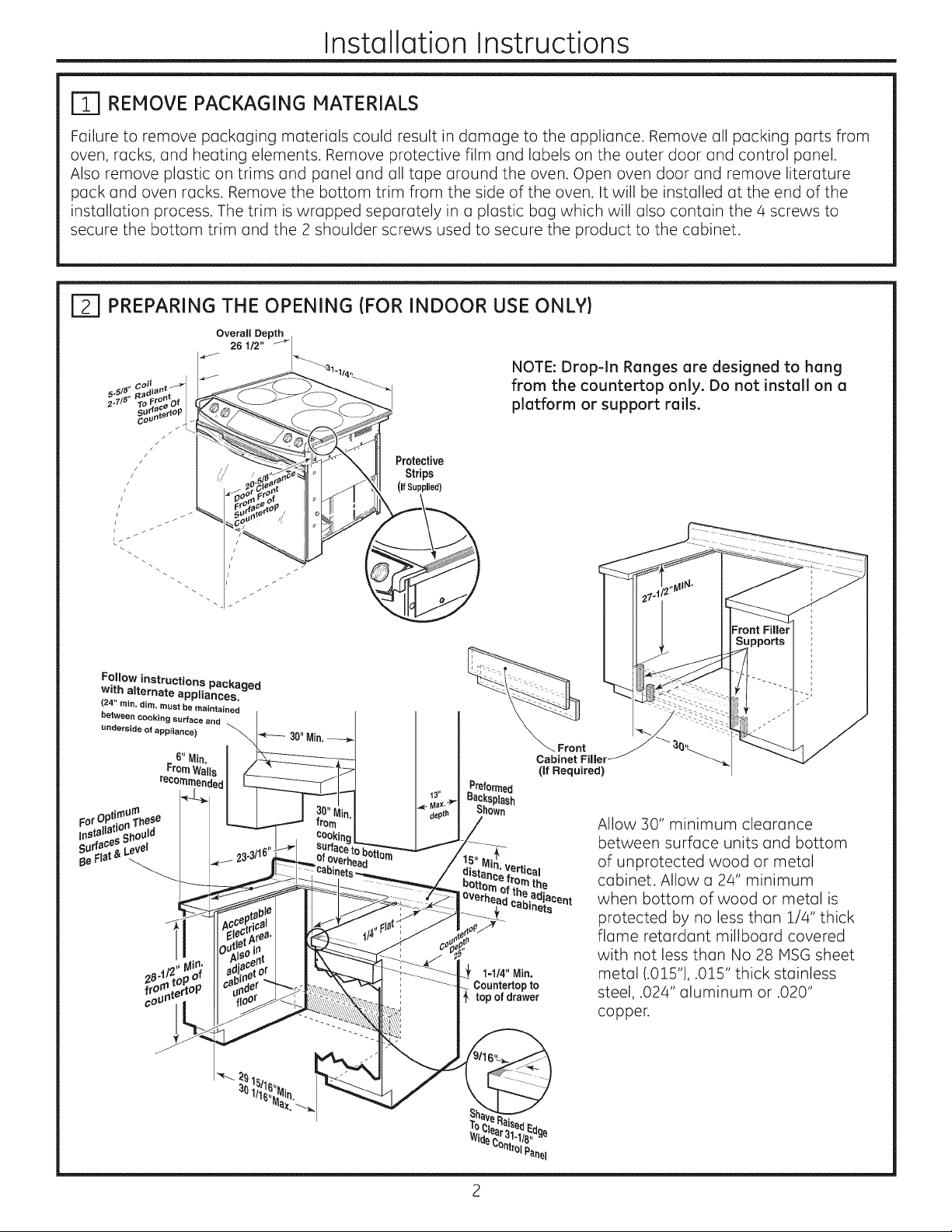

E_ PREPARING THE OPENING (FOR INDOOR USE ONLY)

NOTE: Drop-In Ranges are designed to hang

from the countertop only. Do not install on a

platform or support rails.

Protective

Strips

(if Supplied)

Fellew instructJens packaged

with alternate appliances.

(24" rain, dim, must be maintained

between COoking surface and

underside of appliance)

6"

ertical

' 1=1/4"Min,

Ceuntertepte

topef drawer

Front

(If Required)

the

Allow 30" minimum clearance

between surface units and bottom

of unprotected wood or metal

cabinet. Allow a 24" minimum

when bottom of wood or metal is

protected by no less than 1/4" thick

flame retardant millboard covered

with not less than No 28 P1SGsheet

metal (.015"), .015" thick stainless

steel, .024" aluminum or .020"

copper.

2

Page 3

Installation Instructions

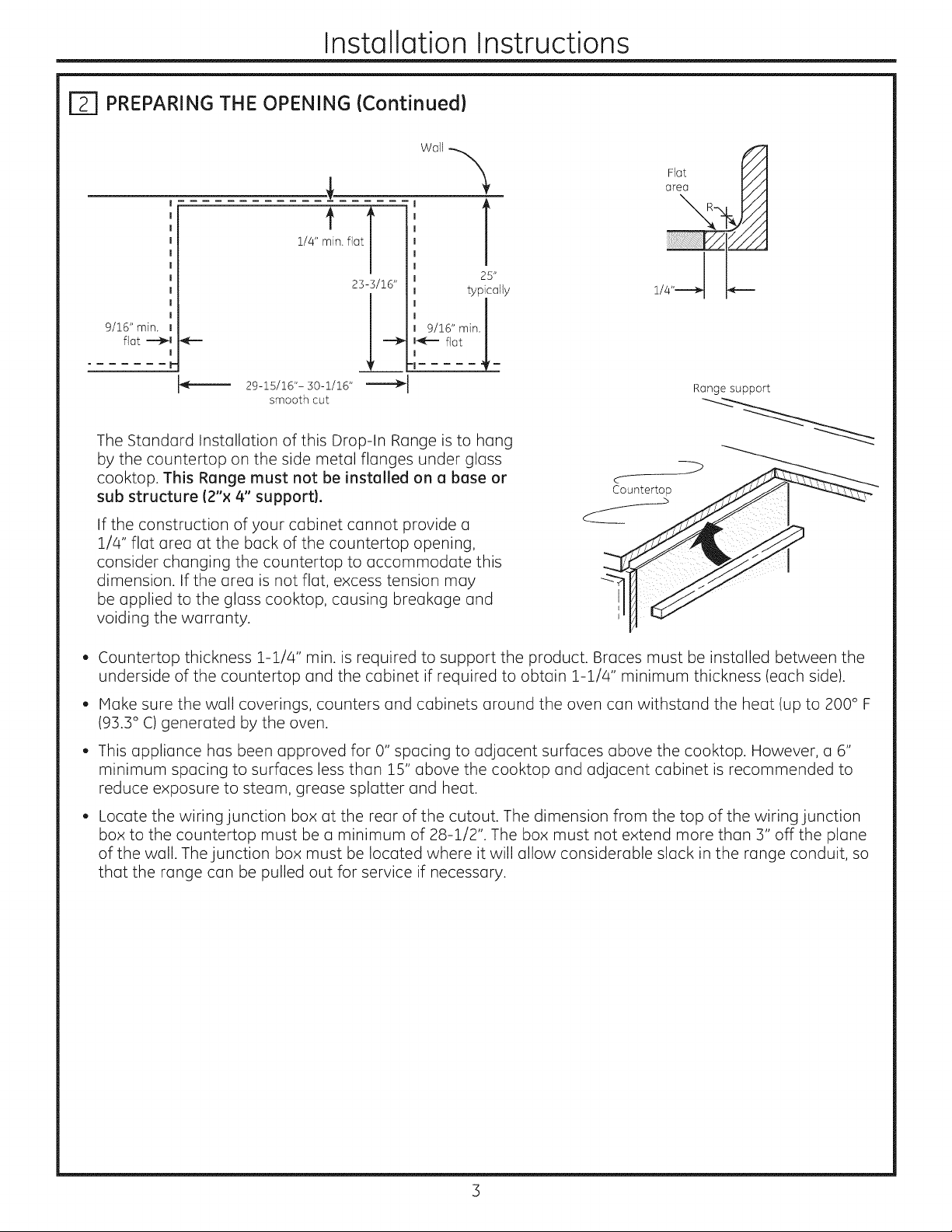

El PREPARING THE OPENING (Continuedl

1/4" min. flat

Flat

area R _'/'A

23-3/16"

9/16" min.

fiat _

I

P

29-15/16"- 30-1/16"

smooth cut

The Standard Installation of this Drop-In Range is to hang

by the countertop on the side metal flanges under glass

cooktop. This Range must not be installed on a base or

sub structure 12"× 4" support).

If the construction of your cabinet cannot provide a

1/4" flat area at the back of the countertop opening,

consider changing the countertop to accommodate this

dimension. If the area is not flat, excess tension may

be applied to the glass cooktop, causing breakage and

voiding the warranty.

Countertop thickness 1-1/4" min. is required to support the product. Braces must be installed between the

underside of the countertop and the cabinet if required to obtain 1-1/4" minimum thickness (each side).

Hake sure the wall coverings, counters and cabinets around the oven can withstand the heat (up to 200 ° F

(93.3° C)generated by the oven.

1-

9/16" min. ]

X:a:_!

25"

typically

Range support

(-

Countertop

Thisappliance has been approved for 0" spacing to adjacent surfaces above the cooktop. However, a 6"

minimum spacing to surfaces less than 15" above the cooktop and adjacent cabinet is recommended to

reduce exposure to steam, grease splatter and heat.

Locate the wiring junction box at the rear of the cutout. The dimension from the top of the wiring junction

box to the countertop must be a minimum of 28-1/2". The box must not extend more than 3" off the plane

of the wall. The junction box must be located where it will allow considerable slack in the range conduit, so

that the range can be pulled out for service if necessary.

3

Page 4

Installation Instructions

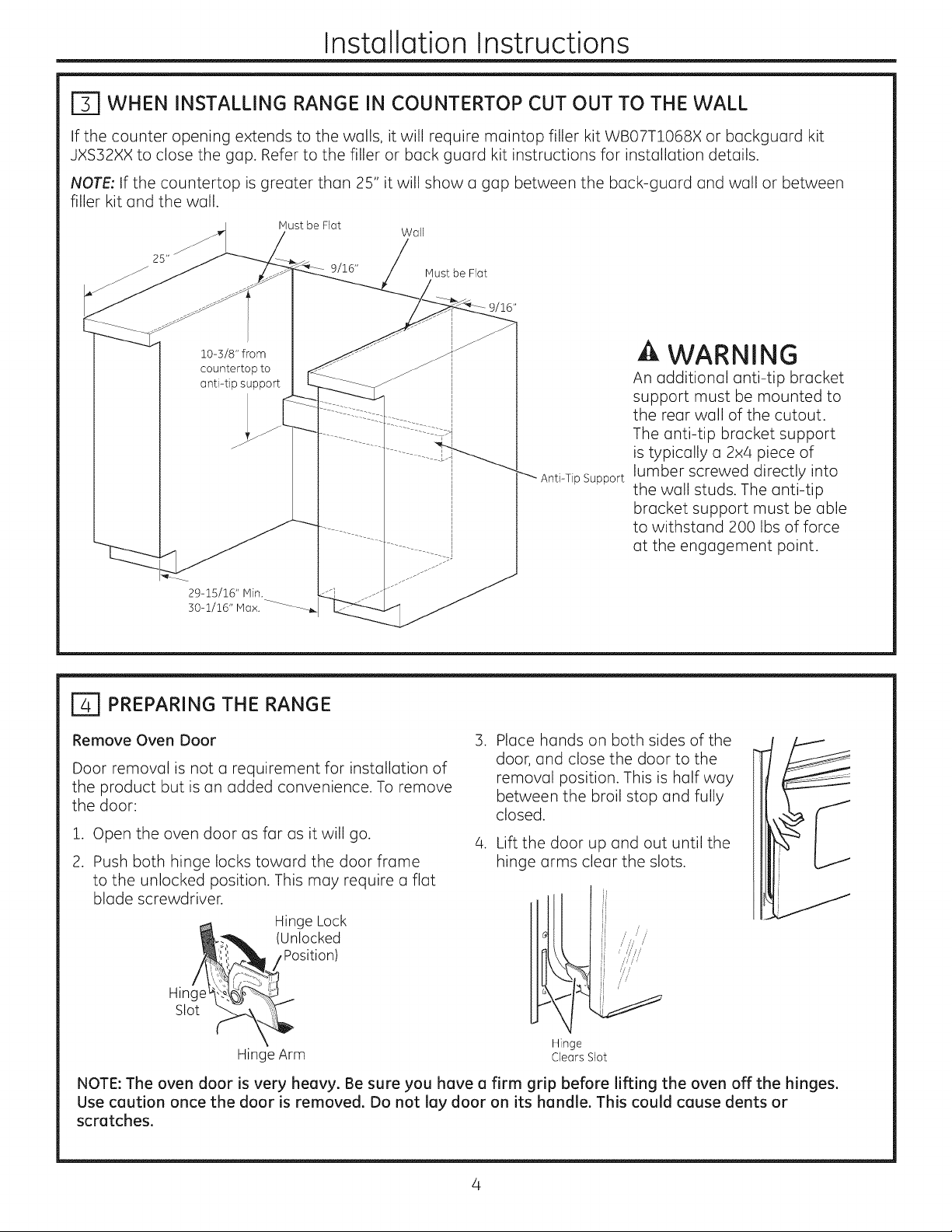

E_ WHEN INSTALLING RANGE IN COUNTERTOP CUT OUT TO THE WALL

If the counter opening extends to the walls, it will require maintop filler kit WB07T1068X or backguard kit

JXS32XX to close the gap. Refer to the filler or back guard kit instructions for installation details.

NOTE: If the countertop is greater than 25" it will show a gap between the back-guard and wall or between

filler kit and the wall.

Must be Flat

Wall

10-3/8" from

countertop to

anti-tip support

F_ PREPARING THE RANGE

9/16"

Must be Flat

"_ Anti-Tip Support

A WARNING

An additional anti-tip bracket

support must be mounted to

the rear wall of the cutout.

The anti-tip bracket support

is typically a 2x4 piece of

lumber screwed directly into

the wall studs. The anti-tip

bracket support must be able

to withstand 200 Ibs of force

at the engagement point.

Remove Oven Door

Door removal is not a requirement for installation of

the product but is an added convenience. To remove

the door:

.

Open the oven door as far as it will go.

2.

Push both hinge locks toward the door frame

.

Place hands on both sides of the

door, and close the door to the

removal position. This is half way

between the broil stop and fully

closed.

it.

Lift the door up and out until the

hinge arms clear the slots.

to the unlocked position. This may require a flat

blade screwdriver.

Hinge Lock

//'/

//

/

Hin(

Slot

(Unlocked

/Position)

Hinge Arm Clears Slot

Hinge

NOTE: The oven door is very heavy. Be sure you have a firm grip before lifting the oven off the hinges.

Use caution once the door is removed. Do not lay door on its handle. This could cause dents or

scratches.

Page 5

Installation Instructions

ELECTRICAL REQUIREMENTS

WARNING Electric Shock Hazard

. This appliance must be properly grounded.

o Do not use an extension cord.

Before installing range, switch power off at the service panel and lock the service disconnecting means

to prevent power from being switched on accidentally. When the disconnection means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

Failure to follow these instructions may result in serious injury or death.

A WARNING Fire Hazard

Improper connection of aluminum house wiring to copper leads can result in an electrical or fire hazard. If

residence leads are aluminum, use only connectors designed for joining copper to aluminum and follow the

manufacturer's recommended procedure closely. Failure to do so may result in serious injury or death.

We recommend you have the electrical wiring and hookup of the appliance connected by a qualified

electrician. After installation, have the electrician show you how to disconnect power from the appliance.

You must use a single-phase, 120/208 VAC or 120/240 VAC, 60 Hertz electrical system.

Effective January 1, 1996, the National Electrical Code requires that new construction (not existing) utilize a

four-conductor connection to an electric oven. When installing an electric oven in new construction, a mobile

home, recreational vehicle or area where local codes prohibit grounding through the neutral conductor, refer

to the section on four-conductor branch circuit connections.

Checkwith your local utilities for electrical codes which apply in your area. Failure to wire your oven according

to governing code could result in a hazardous condition. Ifthere are no local codes, your oven must be wired

and fused to meet the National Electrical Code,NFPANo. 70-latest edition, available from the National Fire

Protection Association.

Rating plate is located on oven front frame and is visible when oven door is open.

This appliance must supplied be with the proper voltage and frequency, and connected to an individual,

properly grounded, 40 amp (minimum) branch circuit protected by a circuit breaker or time-delay fuse.

DO NOT shorten the flexible conduit. The conduit strain relief clamp must be securely attached to the junction

box and the flexible conduit must securely attached to the clamp. If the flexible conduit will not fit within the

clamp, do not install the oven until a clamp of the proper size is obtained.

The3 power leads supplied with this appliance are suitable for connection to heavier gauge household

wiring. The insulation of these B leads is rated for temperatures much higher than the temperature rating of

the household wiring. The current-carrying capacity of the conductor isgoverned by the wire gauge and the

temperature rating of the insulation around the wire.

5

Page 6

Installation Instructions

T

MAKE ELECTRICAL CONNECTIONS

Place the unit on a platform or table even with the cutout opening. The platform must support 200 Ibs. (91 kg).

Connect the flexible conduit to the electrical junction box as follows:

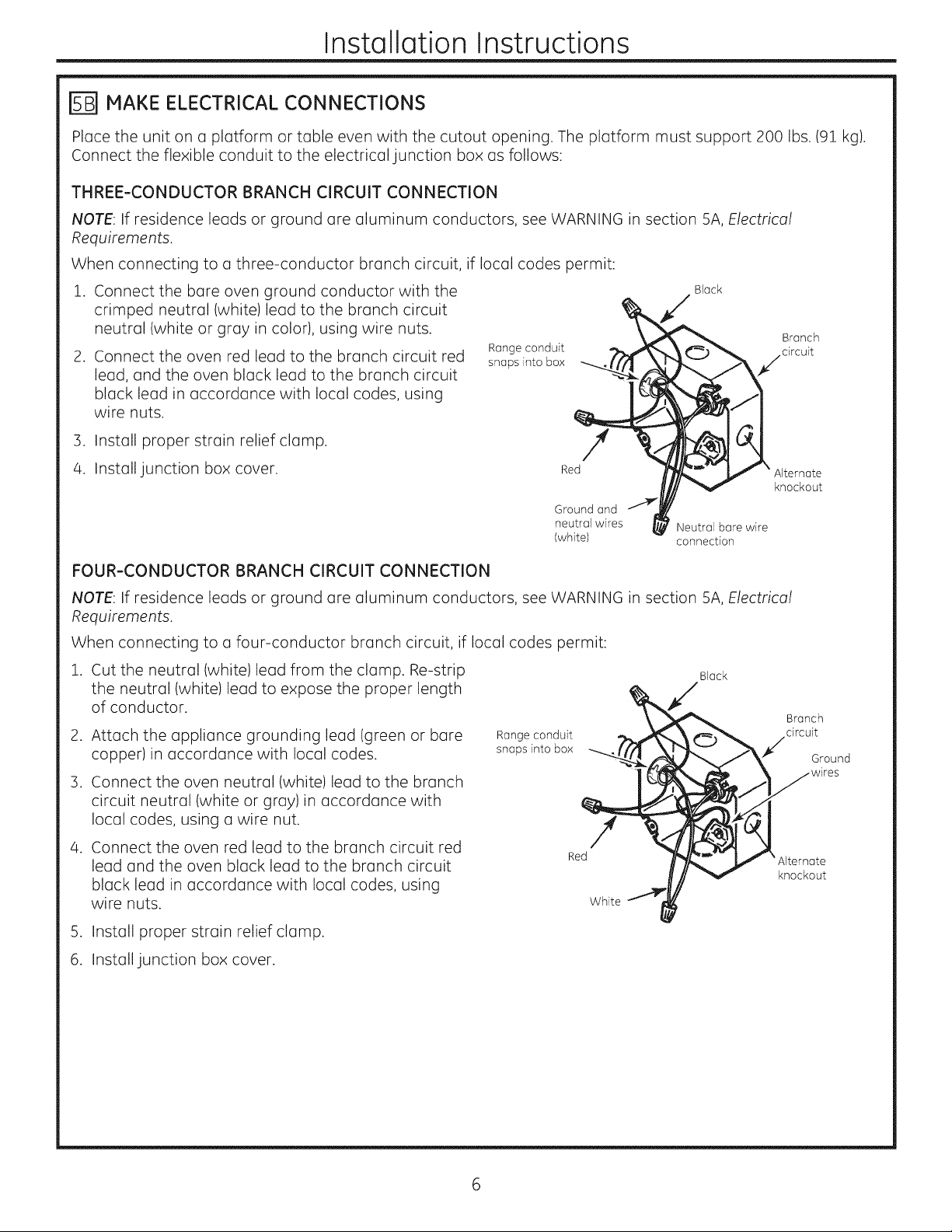

THREE-CONDUCTOR BRANCH CIRCUIT CONNECTION

NOTE: If residence leads or ground are aluminum conductors, see WARNING in section 5A, Electrical

Requirements.

When connecting to a three-conductor branch circuit, if local codes permit:

1. Connect the bare oven ground conductor with the

crimped neutral (white)lead to the branch circuit

neutral (white or gray in color), using wire nuts.

2. Connect the oven red lead to the branch circuit red

lead, and the oven black lead to the branch circuit

black lead in accordance with local codes, using

wire nuts.

Range conduit

snaps into box

Black

Branch

/circuit

3. Install proper strain relief clamp. /

4. Install junction box cover. Red

FOUR-CONDUCTOR BRANCH CIRCUIT CONNECTION

NOTE: If residence leads or ground are aluminum conductors, see WARNING in section 5A, Electrical

Requirements.

When connecting to a four-conductor branch circuit, if local codes permit:

1. Cut the neutral (white) lead from the clamp. Re-strip Black

the neutral (white)lead to expose the proper length

of conductor.

2. Attach the appliance grounding lead (green or bare

copper) in accordance with local codes.

3. Connect the oven neutral (white) lead to the branch

circuit neutral (white or gray)in accordance with

local codes, using a wire nut.

4. Connect the oven red lead to the branch circuit red

lead and the oven black lead to the branch circuit

black lead in accordance with local codes, using

wire nuts.

;;:'pg;i:t°on1:'L_._. >Lo'%,../

/

Ground and

neutral wires Neutral bare wire

(white) connection

1

Red i f_."'- _\ Alternate

_ knockout

White

Alternate

knockout

h

5. Install proper strain relief clamp.

6. Install junction box cover.

Page 7

Installation Instructions

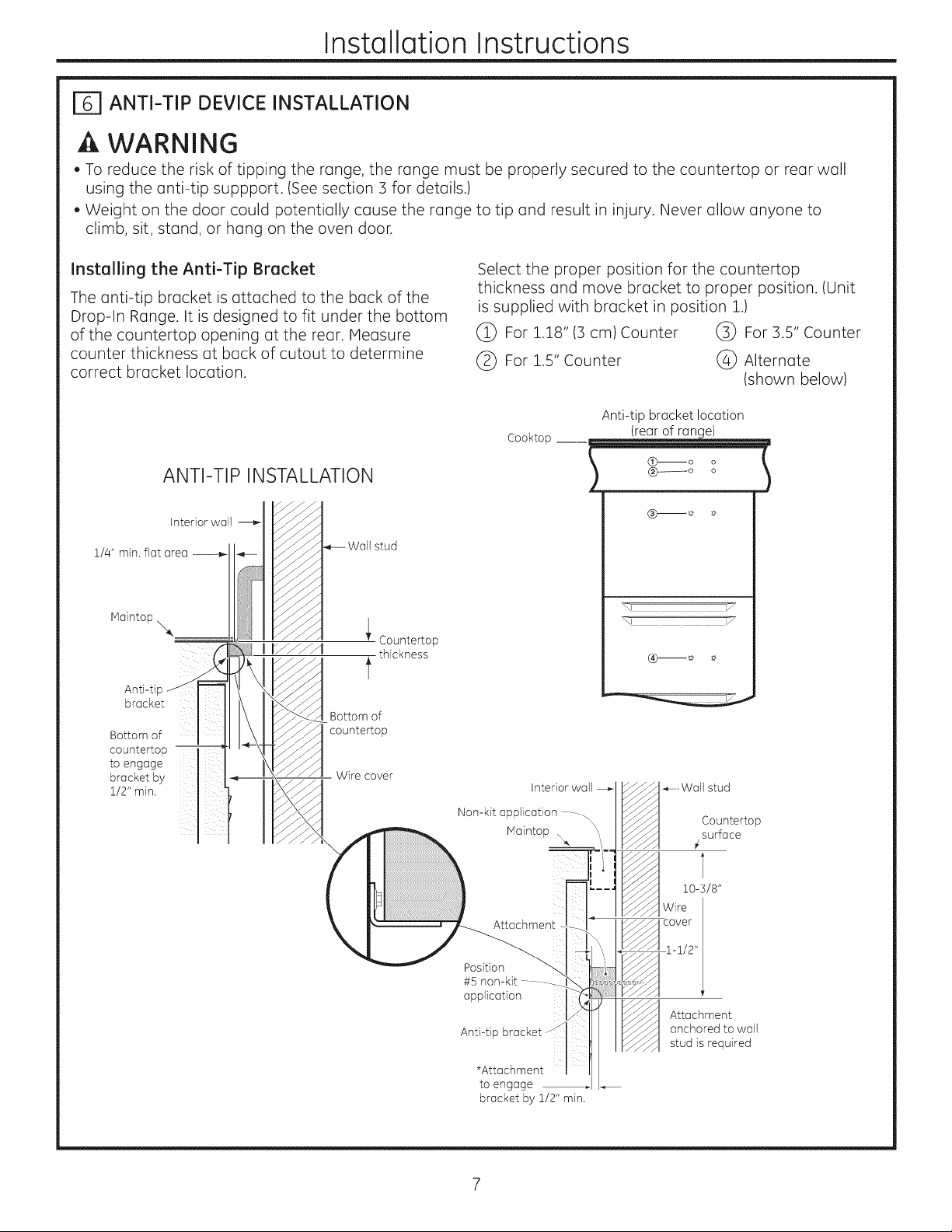

F_ ANTI-TIP DEVICE INSTALLATION

WARNING

. To reduce the risk of tipping the range, the range must be properly secured to the countertop or rear wall

using the anti-tip suppport. (See section 3 for details.)

. Weight on the door could potentially cause the range to tip and result in injury. Never allow anyone to

climb, sit, stand, or hang on the oven door.

Installing the Anti-Tip Bracket

The anti-tip bracket is attached to the back of the

Drop-In Range. It is designed to fit under the bottom

of the countertop opening at the rear. Measure

counter thickness at back of cutout to determine

correct bracket location.

ANTI-TIP INSTALLATION

Interiorwall ---_

1/4" min.flat area

Maintop _,

i Countertop

thickness

t

Anti-ti

bracket

Bottom of

countertop

to engage

bracket by

1/2" min.

Bottom of

countertop

Wire cover

Select the proper position for the countertop

thickness and move bracket to proper position. (Unit

is supplied with bracket in position 1.)

(_ For 1.18" (3 cm) Counter (_) For 3.5" Counter

(_ For 1.5" Counter (_) Alternate

(shown below)

Anti-tip bracket location

Cooktop

Interior wall

(rear of range)

........Wallstud

Non-kit application - -\

Maintop \ ',

Attachment

Position

#5

application

Anti-tip bracket

*Attachment

to engage

bracket by 1/2" min.

Countertop

surface

10-5/8"

Wire

Attachment

anchored to wall

stud is required

Page 8

Installation Instructions

F_ INSTALL THE RANGE

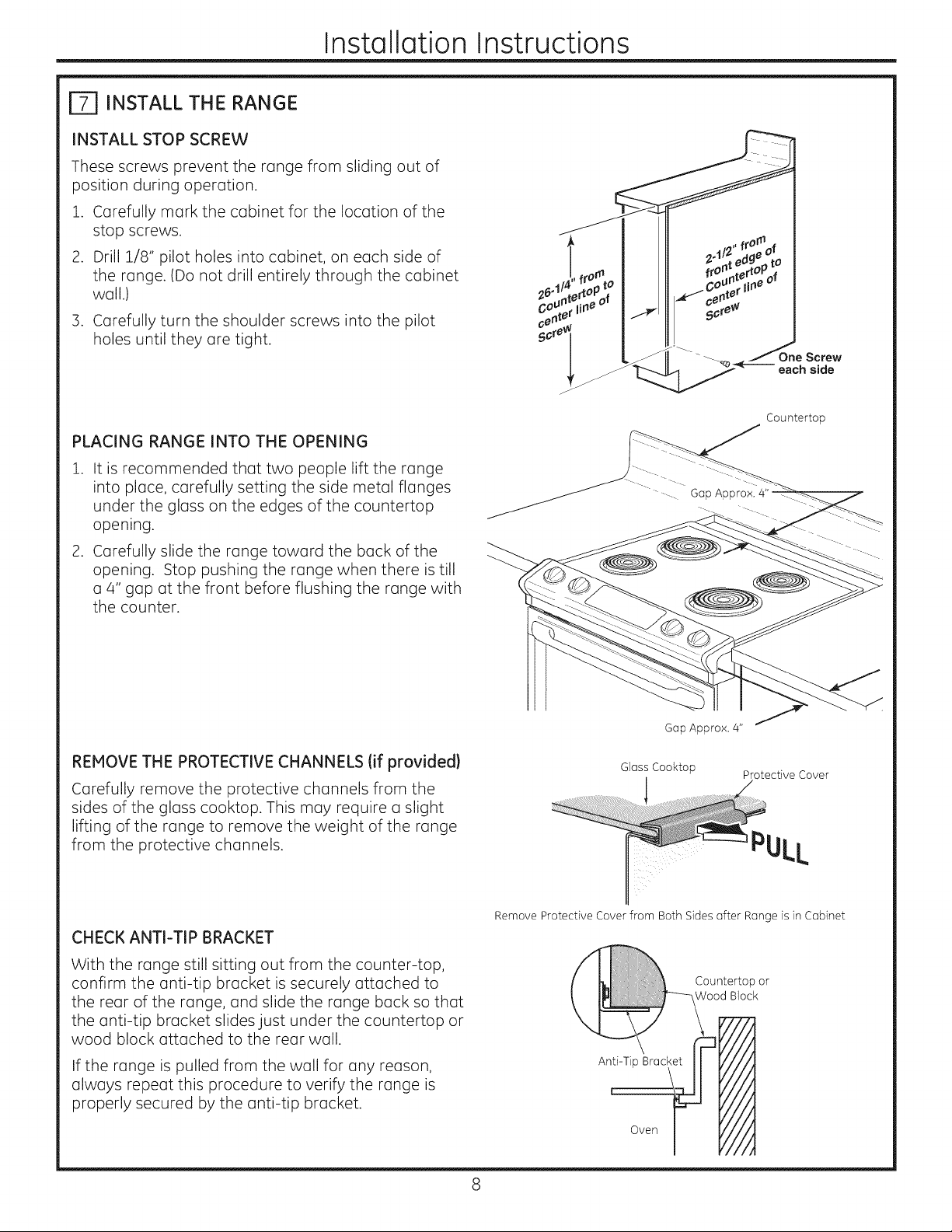

INSTALL STOP SCREW

These screws prevent the range from sliding out of

position during operation.

.

Carefully mark the cabinet for the location of the

stop screws.

.

Drill 1/8" pilot holes into cabinet, on each side of

the range. (Do not drill entirely through the cabinet

wall.)

3. Carefully turn the shoulder screws into the pilot

holes until they are tight.

PLACING RANGE INTO THE OPENING

.

It is recommended that two people lift the range

into place, carefully setting the side metal flanges

under the glass on the edges of the countertop

opening.

.

Carefully slide the range toward the back of the

opening. Stop pushing the range when there is till

a 4" gap at the front before flushing the range with

the counter.

Countertop

REMOVETHE PROTECTIVECHANNELS (if provided}

Carefully remove the protective channels from the

sides of the glass cooktop. This may require a slight

lifting of the range to remove the weight of the range

from the protective channels.

CHECK ANTI=TIP BRACKET

With the range still sitting out from the counter-top,

confirm the anti-tip bracket is securely attached to

the rear of the range, and slide the range back so that

the anti-tip bracket slides just under the countertop or

wood block attached to the rear wall.

If the range is pulled from the wall for any reason,

always repeat this procedure to verify the range is

properly secured by the anti-tip bracket.

Gap Approx. 4"

Glass Cooktop Protective Cover

PULL

Remove Protective Cover from Both Sidesafter Range is in Cabinet

Page 9

Installation Instructions

E_ INSTALL THE RANGE (Continued)

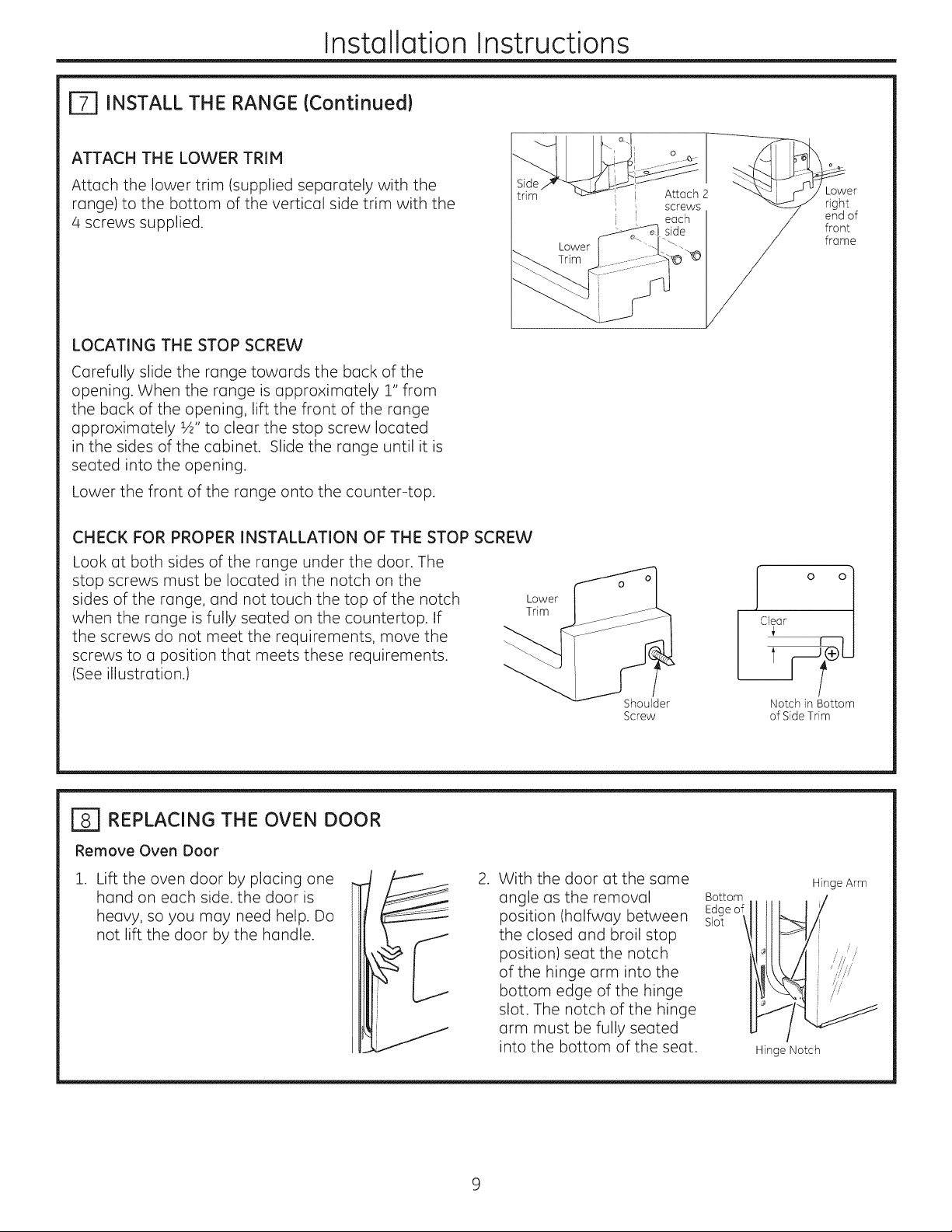

ATTACH THE LOWER TRIM

Attach the lower trim (supplied separately with the

range) to the bottom of the vertical side trim with the

4 screws supplied.

LOCATING THE STOP SCREW

Carefully slide the range towards the back of the

opening. When the range is approximately 1" from

the back of the opening, lift the front of the range

approximately 1W'to clear the stop screw located

in the sides of the cabinet. Slide the range until it is

seated into the opening.

Lower the front of the range onto the counter-top.

CHECK FOR PROPER INSTALLATION OF THE STOP SCREW

Look at both sides of the range under the door. The

stop screws must be located in the notch on the

sides of the range, and not touch the top of the notch

when the range is fully seated on the countertop. If

the screws do not meet the requirements, move the

screws to a position that meets these requirements.

(See illustration.)

Lower

Trim

Lower

Attoch 2

screws

eoch

C,eor o

right

end of

front

frome

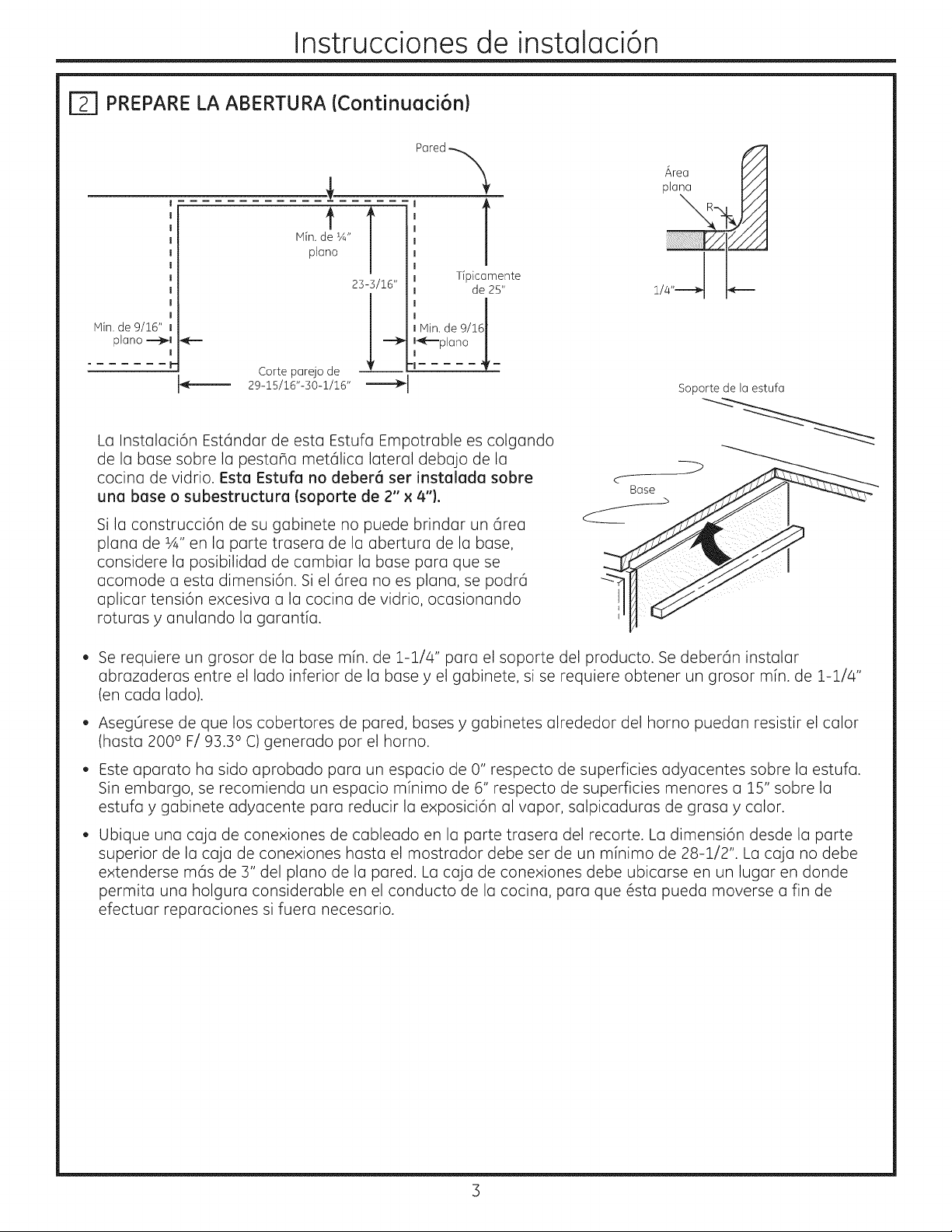

REPLACING THE OVEN DOOR

Remove Oven Door

.

Lift the oven door by placing one

hand on each side. the door is

heavy, so you may need help. Do

not lift the door by the handle.

Shoulder

Screw

. With the door at the same

angle as the removal

position (halfway between

the closed and broil stop

position) seat the notch

of the hinge arm into the

bottom edge of the hinge

slot. The notch of the hinge

arm must be fully seated

into the bottom of the seat.

Bottom

Edge of

Slot '

Notch in Bottom

of Side Trim

Hinge Arm

i

Hinge Notch

Page 10

Installation Instructions

[_ REPLACING THE OVEN DOOR (Continued)

3. Open the door as far as it will open. Push the

hinge lock up against the front frame of the oven

cavity, to the locked position. Close the door.

Notch of Hinge

Securely Fitted

into Bottom of

Hinge Slot

F_ FINAL CHECKLIST

, Check to make sure the circuit breaker is closed (Reset) or the circuit fuses are replaced.

. Be sure power is in service to the building.

. Check to be sure that all packing materials and tape have been removed. Failure to remove these materials

could result in damage to the appliance once the appliance has been turned on and surface elements have

heated

Hinge in Locked

Position

OPERATION CHECKLIST

. Check to make sure the Clock display is energized. If a series of horizontal red linesappear in the display,

disconnect power immediately. Recheck the range wiring connections. If change is made to connections,

retest again. If no change is required, have building wiring checked for proper connections and voltage. It is

recommended that the clock be changed if the red lines appear.

, Push down and turn any one of the four surface knobs to "HED" setting to observe that the element glows

within 15 seconds. Turn the knob off when glow is detected. If the glow is not detected within the time limit,

recheck the range wiring connections. If change is required, retest again. If no change is required, have

building wiring checked for proper connections and voltage.

10

Page 11

Notes

11

Page 12

12 Printed in the United States

Page 13

I struccio es

de i stol ci°

Cocinas encastra es

de 30"

ANTES DE COMENZAR

Lea estas instrucciones por completo y con

detenimiento.

• IMPORTANTE - Guarde estas

instrucciones para el uso de inspectores locales.

• IMPORTANTE - Cumplaco_todoslos

c6digos y ordenanzas vigentes.

• Noto ol instolador -AsegOrese de dejar estas

instrucciones con el consumidor.

• ATENCI6N INSTALADOR: Todas las cocinas encastrables el6ctricas deben contar con

cableado de conexi6n permanente (cableado directo)dentro de una caja de conexiones aprobada. Enestos

productos NOse permite la conexi6n del tipo "enchufe y recept6culo'.

Nota al consumidor - estas instrucciones para

referencia futura.

Nivel de destreza - La instalaci6n de este aparato

requiere el trabajo de un instalador o electricista

calificados.

®

Elinstalador tiene la responsabilidad de efectuar

una instalaci6n adecuada.

Lagarantia no cubre lasfallas del producto

provocadas pot una instalaci6n incorrecta.

PARA SU SEGURIDAD

A ADVERTENCIA Antes de comenzar la instalaci6n, desconecte la energia del panel de servicio y

bloquee los medios de desconexi6n para evitar el accionamiento de la energia de manera accidental. Cuando los

medios de desconexi6n de servicio no pueden bloquearse, coloque sobre el panel de servicio un dispositivo de

advertencia bien visible, como una etiqueta.

A ADVERTENCIA La informaci6n de este manual debe seguirse al pie de la letra a fin de minimizar e

riesgo de incendios, descargas el6ctricas, o para prevenir daflos a la propiedad, lesiones personales o la muerte.

Riesqn de Vnlcndurns

Un niBn o ndultn pueden vnlcnr In cncinn y mnrir.

Instnle el dispositivo onti-volcoduros (tornillos o soporte)

de ocuerdo con los siguientes instrucciones.

Vuelvo o colocor el soporte onti-volcoduros si In estufn

se mueve de lugor.

Si estns instrucciones no sesiguen, como resultndo se podr6

producir In muerte o quemnduros groves de niBos y odultos.

MATERIALES OUE PUEDE NECESITAR

caja de conexiones

Tapones de alambre

Abrazadera de alivio de tensi6n para conducto de 1/2"

31-i0829-201-14 GE i

HERRAMIENTAS NECESARIAS

Broca de perforadora de 1/8"y perforadora el6ctrical

Destornillador de estrella

Destornillador con punta plana

Llavede tuercas de 1/4"

Punta derecha o cuadrada

Sierra de mano o sierra sable

Nivel

Cinta m6trica

Martillo

L6piz

Gafas de Seguridad

Page 14

Instrucciones de instalaci6n

[_ QUITE LOS MATERIALES DE EMPAQUE

emp(]que del homo, b(]ndej(]s y elementos de c(]lent(]miento. Quite I(] pelfcul(] protector(] y I(]s etiquet(]s de I(]

puert(] exterior y panel de control. Adem6s, quite el pl6stico de los rebordes y panel y tod(] I(] cint(] coloc(]d(]

(]lrededor del homo. Abr(] I(] puert(] del homo y quite el material inform(]tivo y I(]s bandej(]s del homo. Quite

el reborde inferior de I(] p(]rte lateral del homo. Se coloc(]r6 (]1final del proceso de inst(]l(]ci6n. El borde est6

envuelto de form(] (]p(]rte en un(] bols(] pl6stic(] que t(]mbi_n contendr6 4 tornillos p(]r(] (]segur(]r el borde

inferior y los tornill(]s de tope us(]dos par(] (]segur(]r el producto (]1g(]binete.

E_ PREPARE LA ABERTURA (SeLO PARA USO EN EL INTERIOR}

Profundidad total

de 26-i/2"

5-5/8" Bobina

hasta la superficic

frontal de la base

Siga las instrucciones embaladas

con los electrodom_sticos alternativos.

ISe deber6 mantener una dim. mfn.

de 24" entre la superficie de la codna

y el lado inferior del electrodom_stico)'_.

Se recomienda un mfn. Huestra

De 6" desde las Profundidad del Tablero

Para una instalaci6n 6ptima,

estas superficies deber6

ser pianos y estar a nivel

Nfn. de 28 1/2" Mfn. de 1-1/4"

desde la porte desde la base

superior de la mesada a la porte superior

_ y[ del caj6n

Hfn. de 29 15/16"

M6x. de 30

Franjas

de protecci6n

(si se suministran)

m@x de 13" Posterior

Preformado

Distancia vertical mfn. 15"

desde la porte inferior

de los gabinetes adyacentes

dad

de labase

Afeitar borde levantado

para eliminar 31-1/8"

de ancho del panel

NOTA: Las cocinas empotrables son dise_adas

para colgar de la base _nicamente. No instale

sobre una plataforma de rieles con soportes.

Relleno

del gabinete

frontal

(siserequiere)

Deje un espacio minimo de 30"

entre las unidades de la superficie

y la porte inferior del gabinete de

madera o metal sin protecci6n. Deje

un espacio minimo de 24" cuando

la parte inferior de la madera o

metal est@nprotegidas por cart6n

de retardo de incendios de 1/4" de

grosor, cubierto con no menos que

un(] hoj(] de (]cero inoxid(]ble N° 28

IVlGSde 0.15", de (]luminio de 0.24" o

de cobre de .020" de grosor.

2

Page 15

Instrucciones de instalaciOn

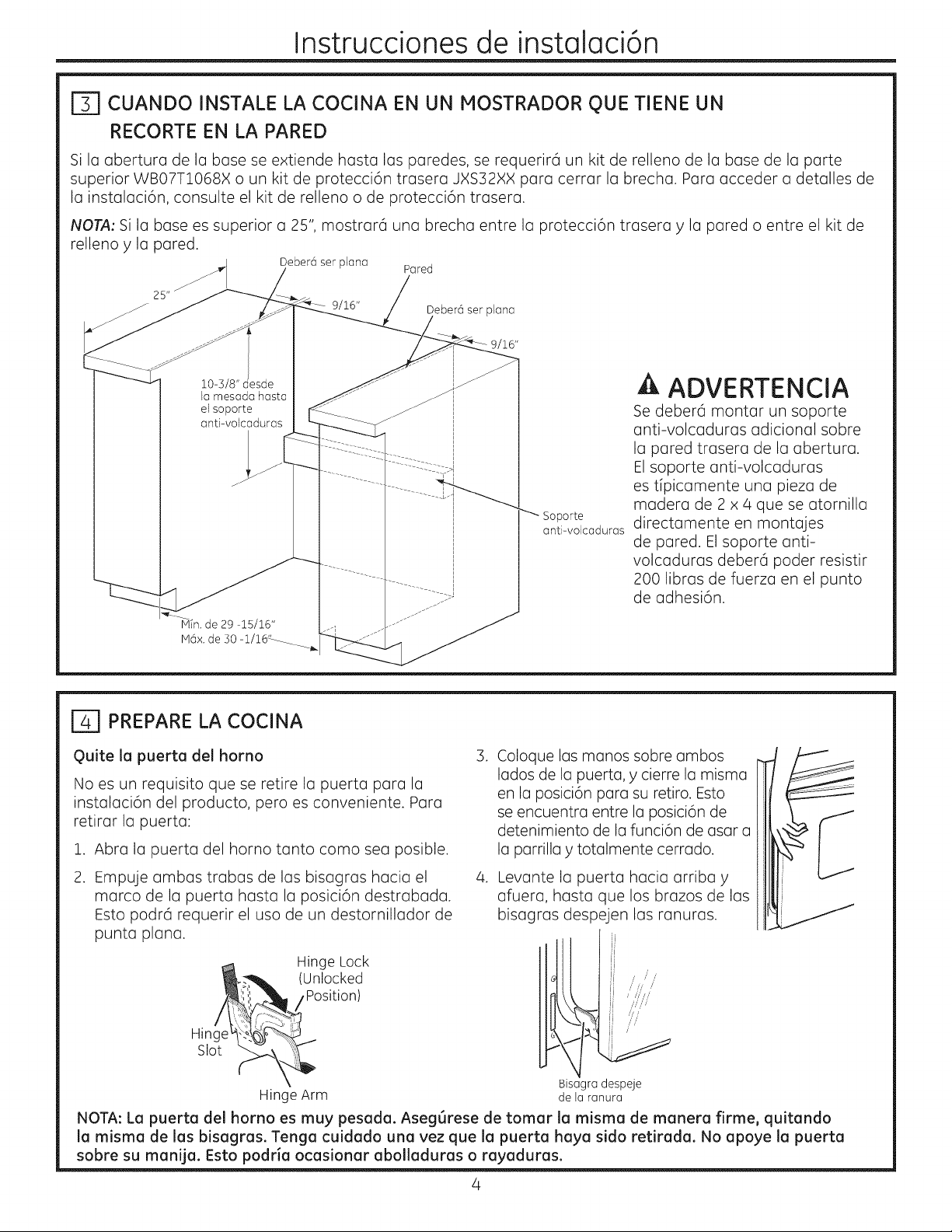

[2] PREPARE LA ABERTURA (Continuaci6nl

Pared %

f

Nin. de 1A"

piano

Min, de 9/16"

piano

La Instalaci6n Est6ndar de esta Estufa Empotrable es colgando

de la base sabre la pesta_a met61ica lateral debajo de la

cocina de vidrio. Esta Estufa no deber6 ser instalada sabre

una base o subestructura (soporte de 2" x 4")o

Si la construcci6n de su gabinete no puede brindar un 6rea

plana de ¼" en la parte trasera de la abertura de la base,

considere la posibilidad de cambiar la base para que se

acomode a esta dimensi6n. Si el @rea no es plana, se podr6

aplicar tensi6n excesiva a la cocina de vidrio, ocasionando

roturas y anulando la garantia.

|

Carte parejo de

29-15/16"-30-1/16"

T

23-3/16"

L

Min. de 9/16 !

__Tplan° _r

1

TTpicamente

de 2S"

Area

plana R

Soporte de la estufa

Base

Se requiere un grosor de la base m[n. de 1-1/4" para el soporte del producto. Se deber6n instalar

abrazaderas entre el lado inferior de la base y el gabinete, si se requiere obtener un grosor m[n. de 1-1/4"

(en coda lado).

AsegOrese de que los cobertores de pared, bases y gabinetes alrededor del horno puedan resistir el calor

(basra 2000 F/93.30 C)generado par el horno.

Esteaparato ha sido aprobado para un espacio de 0" respecto de superficies adyacentes sabre la estufa.

Sin embargo, se recomienda un espacio minima de 6" respecto de superficies menores a iS" sabre la

estufa y gabinete adyacente para reducir la exposici6n al vapor, salpicaduras de grasa y calor.

Ubique una caja de conexiones de cableado en la parte trasera del recorte. La dimensi6n desde la parte

superior de la caja de conexiones hasta el mostrador debe set de un minima de 28-1/2". Lacaja no debe

extenderse m6s de Y' del piano de la pared. La caja de conexiones debe ubicarse en un lugar en donde

permita una holgura considerable en el conducto de la cocina, para que 6sta pueda moverse a fin de

efectuar reparaciones sifuera necesario.

3

Page 16

Instrucciones de instalaci6n

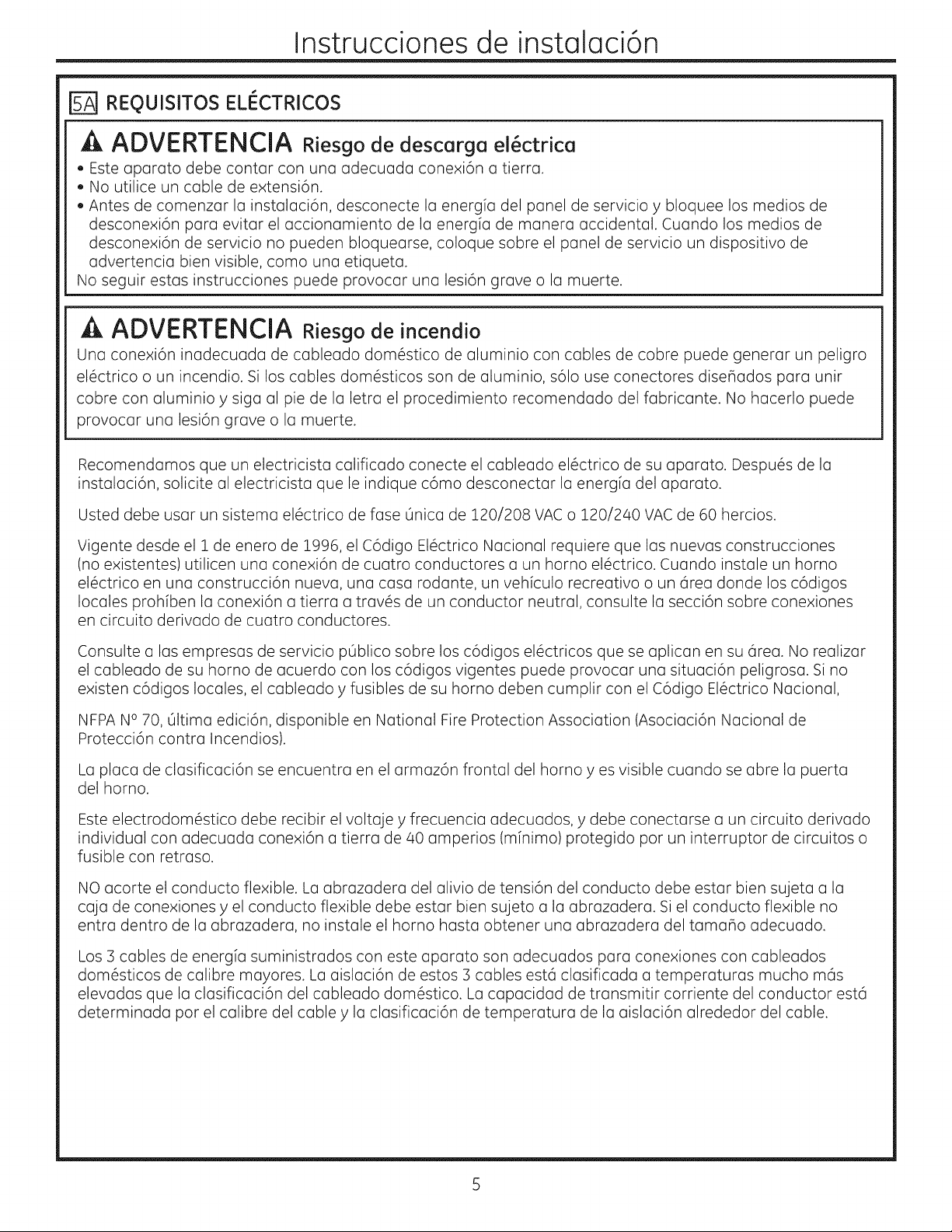

[_ CUANDO INSTALE LA COCINA EN UN MOSTRADOR QUE TIENE UN

RECORTE EN LA PARED

Si la abertura de la base se extiende hasta los paredes, se requerir6 un kit de relleno de la base de la parte

superior WB07T1068X o un kit de protecci6n trasera JXS32XX para cerrar la brecha. Para acceder a detalles de

la instalaci6n, consulte el kit de relleno o de protecci6n trasera.

NOTA: Si la bose es superior a 25", mostrard una brecha entre la protecci6n trasera y la pared o entre el kit de

relleno y la pared.

Deber(_ser piano Pored

10-3/8" desde

Io mesoda basra

el soporte

antPvolcoduros

I_fn. de 29 -15/16"

H6x. de 30 -1/16'<

[_] PREPARE LA COClNA

9/16"

Deber6 ser plana

9/16"

i

Soporte

antFvolcaduras

A ADVERTENCIA

Se deber(] montar un soporte

anti-volcaduras adicional sabre

la pared trasera de la abertura.

El soporte anti-volcaduras

es tipicamente una pieza de

madera de 2 x a,que se atornilla

directamente en montajes

de pared. Elsoporte anti-

volcaduras deber6 poder resistir

200 libras de fuerza en el punto

de adhesi6n.

Quite la puerta del horno

No es un requisito que se retire la puerta para la

instalaci6n del producto, pero es conveniente. Para

retirar la puerta:

1. Abra la puerta del homo tanto coma sea posible.

.

Empuje ambas trabas de las bisagras hacia el

marco de la puerta hasta la posici6n destrabada.

Esto podr6 requerir el usa de un destornillador de

3, Coloque las manos sabre ambos

lados de la puerta, y cierre la misma

en la posici6n para su retiro.Esto

seencuentra entre la posici6nde

detenimiento de la funci6n de asar a

la parrilla y totalmente cerrado.

4. Levante la puerta hacia arriba y

afuera, hasta que los brazos de las

bisagras desp_ en las ranuras.

punta plana.

Hinge Lock

(Unlocked

i_:_ .Position)

,x','¢<_._l/

Bisagra despeje

Hinge Arm

de la ranura

NOTA: La puerta del horno es muy pesada. Aseg6rese de tomar la misma de manera firme, quitando

la misma de las bisagras. Tenga cuidado una vez que la puerta haya sido retirada. No apoye la puerta

sobre su manija. Esto podria ocasionar abolladuras o rayaduras.

/ /

/

Page 17

Instrucciones de instalaci6n

[_ REQUISITOS ELF!CTRICOS

A ADVERTENCIA Riesgode descarga el ctrica

, Este aaparato debe center con unaaaadecuaadaaconexi6n a tierra.

• No utilice un cable de extensi6n.

• Antes de comenzar la instalaaci6n, desconecte la energfa del panel de servicio y bloquee los medios de

desconexi6n para evitar el accionamiento de la energiaade maaneraaaccidental. Cuando los medios de

desconexi6n de servicio no pueden bloqueaarse, coloque sobre el panel de servicio un dispositivo de

aadvertencia bien visible, come una etiquetaa.

No seguir estas instrucciones puede provocar unaalesi6n grave o la muerte.

A ADVERTENCIA Riesgo de incendio

Unaaconexi6n inadecuadaa de cableaado dom_stico de aaluminio con cables de cobre puede generar un peligro

el_ctrico o un incendio. Si los cables dom_sticos son de aaluminio, s61o use conectores diseSados paara unit

cobre con aaluminio y sigaaaalpie de la letra el procedimiento recomendaado del fabricaante. No haacerlo puede

provocar unaalesi6n grave o laamuerte.

Recomendaamos queun electricista caalificaadoconecte el cableaado el6ctrico de su aparaato. Despu6s de laa

instalaci6n, solicite aalelectricista que le indique c6mo desconectaar laaenerg[a del aapaarato.

Usted debe usar un sistema el6ctrico de fase 0nica de 120/208 VACo 120/240 VAC de 60 hercios.

Vigente desde el 1 de enero de 1996, el C6digo EI6ctrico Naacionaalrequiere que laasnuevaasconstrucciones

(no existentes) utilicen unaaconexi6n de cuatro conductores a un homo el6ctrico. Cuando instale un homo

el6ctrico en una construcci6n nueva, unaacase rodante, un vehiculo recreative o un (]re(] donde los c6digos

locales prohiben laaconexi6n aatierraaaatrav6s de un conductor neutral, consulte la secci6n sobre conexiones

en circuito derivaado de cuatro conductores.

Consulte (] los empresas de servicio p6blico sobre los c6digos el6ctricos que se (]plican en su 6re(]. No realizar

el c(]bleado de su homo de (]cuerdo con los c6digos vigentes puede provocar una situ(]ci6n peligros(]. Si no

existen c6digos locales, el cableado y fusibles de su homo deben cumplir con el C6digo El_ctrico Nacion(]l,

NFPA N° 70, 61timaaedici6n, disponible en National Fire Protection Association (Asociaaci6n Nacionaal de

Protecci6n centre Incendios).

L(] placaade claasificaaci6nse encuentra en el (]rmaaz6n frontal del hornoy es visible cuando se abre laapuerto

del homo.

Este electrodom_stico debe recibir el voltaajey frecuenciaa adecuaados, y debe conectarse aaun circuito derivaado

individual con aadecuada conexi6n a tierra de 40 amperios (minimo) protegido per un interrupter de circuitos o

fusible con retraso.

NO acorte el conducto flexible. Laaabraazadera del aalivio de tensi6n del conducto debe ester bien sujetaa aala

caajaade conexiones y el conducto flexible debe estaarbien sujeto a laaabraazadera. Si el conducto flexible no

entre dentro de laaabraazadera, no instale el homo haasta obtener unaaabrazaderaa del tamaSo aadecuado.

Los 3 cables de energfa suministraados con este aapaaraatoson aadecuaadospar(] conexiones con caableados

dom6sticos de calibre mayores. Laaaislaaci6n de estos 3 cables est6 clasificada a temperaaturaas mucho m6s

elevadas que laaclaasificaaci6ndel cableado dom6stico. La capaacidad de transmitir corriente del conductor est6

determinadaa per el calibre del cable y laaclasificaci6n de temperaturaa de laaaislaaci6n alrededor del cable.

5

Page 18

Instrucciones de instalaci6n

[_ REALICE LAS CONEXIONES ELECTRICAS

Coloque el horno sabre una mesa o plataformu en forma nivelada con la abertura. LG plataforma debe poder

soportar 200 Ibs. (91 kg). Conecte el conducto flexible a la caja de conexiones el_ctrica coma se indica abajo.

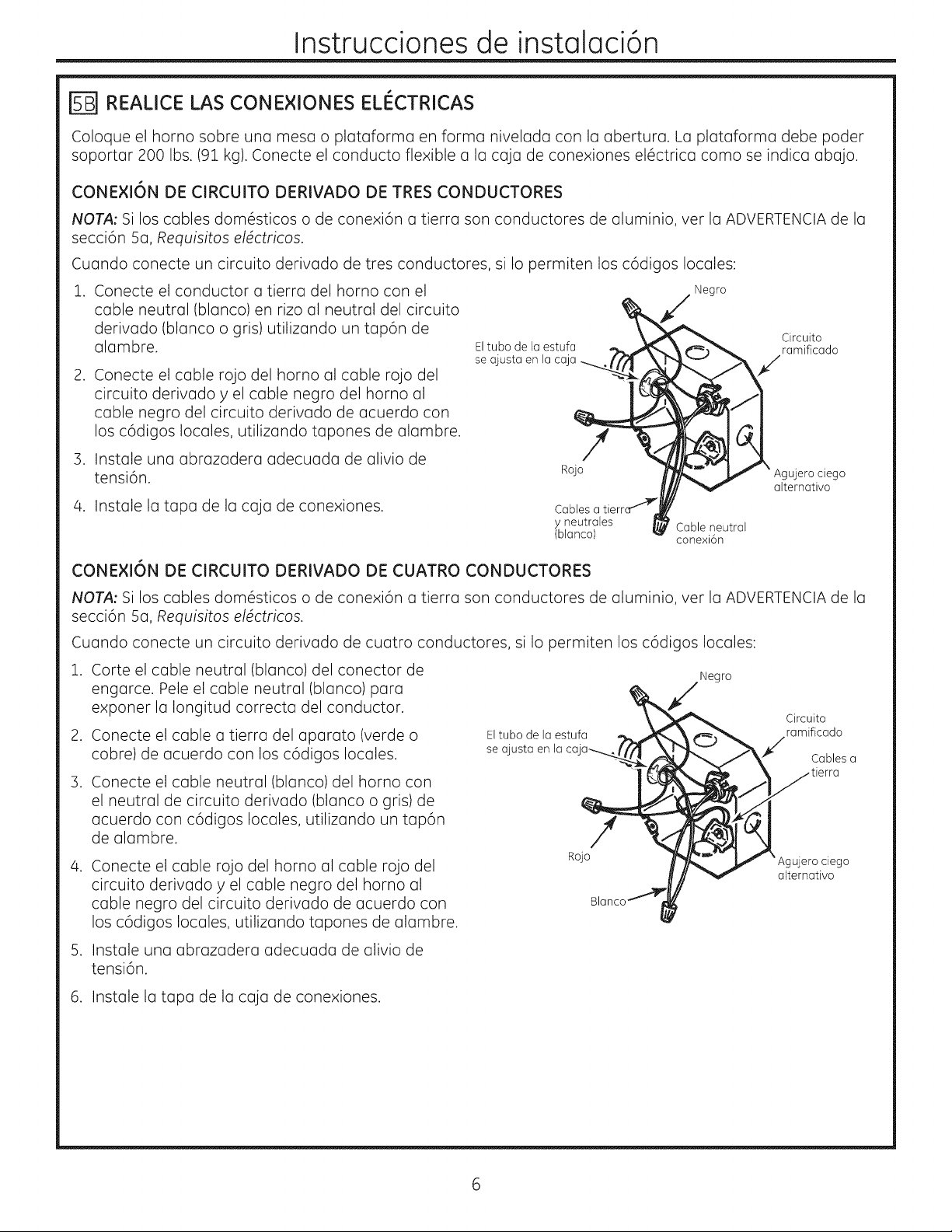

CONEXI6N DE CIRCUITO DERIVADO DE TRES CONDUCTORES

NOTA: Si los cables dom_sticos o de conexi6n a tierra son conductores de aluminio, ver la ADVERTENCIA de la

secci6n 5a, Requisitos eldctricos.

Cuando conecte un circuito derivado de tres conductores, si Io permiten los c6digos locales:

1. Conecte el conductor a tierra del homo con el Negro

cable neutral (blanco)en rizo al neutral del circuito

derivado (blanco o gris) utilizando un tap6n de

alambre, ramificado

2. Conecte el cable rojo del homo al cable rojo del

circuito derivado y el cable negro del homo al

cable negro del circuito derivado de acuerdo con

los c6digos locales, utilizondo tapones de alambre.

3. Instale una abrazadera adecuada de alivio de

tensi6n.

4. Instale la tapa de la caja de conexiones. Cables a

Eltuba de lu estufa

se ajusta en la caja.....

/

Rojo

y neutrales Cable neutral

(blancol conexi6n

Circuito

Agujero ciego

alternativo

CONEXI6N DE CIRCUITO DERIVADO DE CUATRO CONDUCTORES

NOTA: Si los cables dom_sticos o de conexi6n a tierra son conductores de aluminio, ver la ADVERTENCIA de la

secci6n Sa, Requisitos eldctricos.

Cuando conecte un circuito derivado de cuatro conductores, si Io permiten los c6digos locales:

1. Carte el cable neutral (blanco) del conector de

engarce. Pele el cable neutral (blanco) para

exponer la Iongitud correcta del conductor.

2. Conecte elcable a tierra del aparato (verde o

cobre) de acuerdo con los c6digos locales.

3. Conecte el cable neutral (blanco)del homo con

el neutral de circuito derivado (blanco o gris)de

acuerdo con c6digos locales, utilizando un tap6n

de alambre.

/4. Conecte el cable rojo del homo al cable rojo del

circuito derivado y el cable negro del homo al

cable negro del circuito derivado de acuerdo con

los c6digos locales, utilizando tapones de alambre.

Eltuba dela estufa

seajusta en lacaja--...

/

Rojo

Negro

/

Circuito

ramificado

_ CeablaeSa

y "Agujero ciego

alternativo

5. Instale una abrazadera adecuada de alivio de

tensi6n.

6. Instale la tapa de la caja de conexiones.

Page 19

Instrucciones de instalaci6n

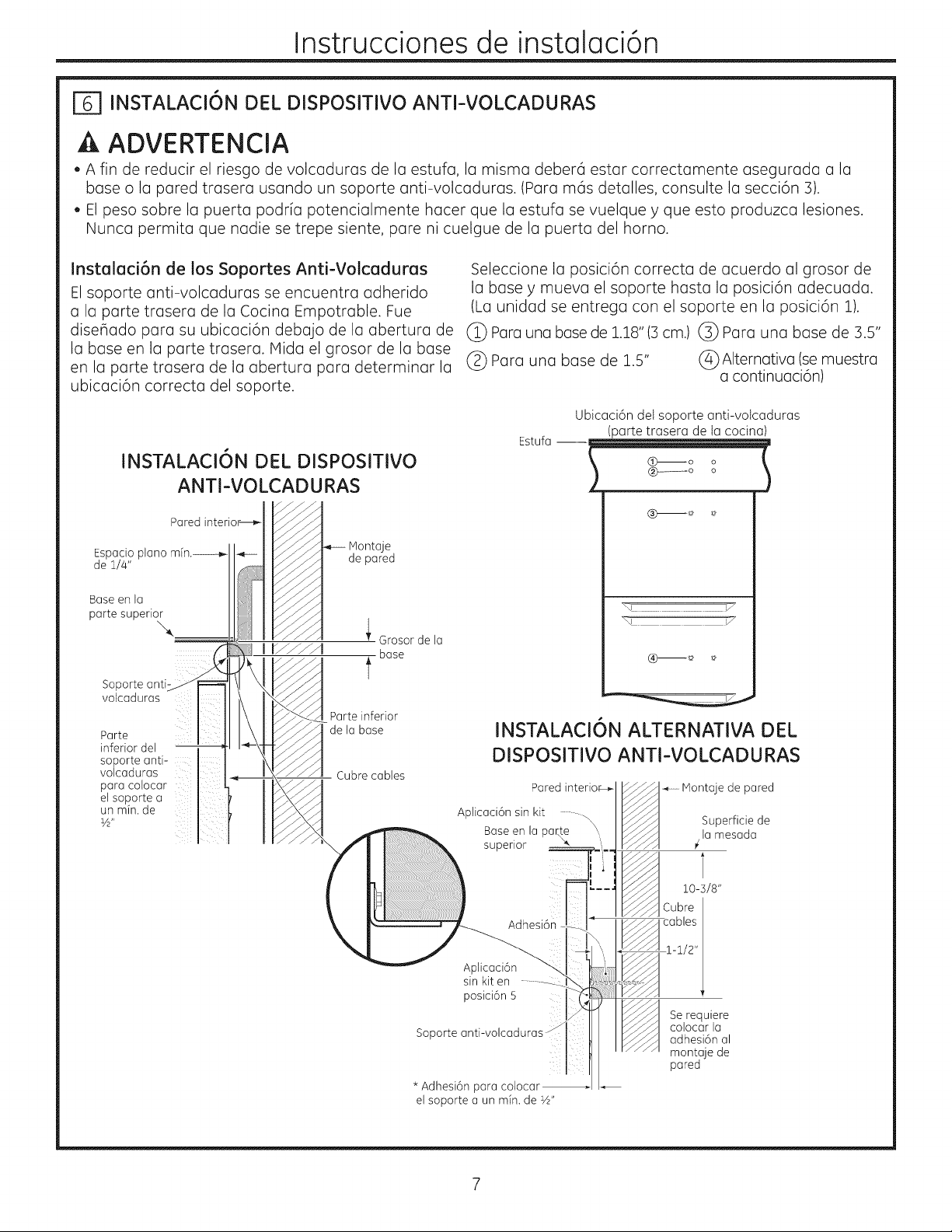

[Z] INSTALACION DEL DISPOSITIVO ANTI-VOLCADURAS

A ADVERTENCIA

• A fin de reducir el riesgo de volcoduros de Io estufo, Io mismo deber5 estor correctomente osegurodo o Io

base o Io pored trosero usondo un soporte onti-volcoduros. (Poro m6s detolles, consulte Io secci6n 3).

• El peso sabre Io puerto podrio potenciolmente hocer que Io estufo se vuelque y que esto produzco lesiones.

Nunco permito que nodie se trepe siente, pare ni cuelgue de la puerto del horno.

Instalaci6n de los Soportes Anti-Volcaduras

El soporte onti-volcoduros se encuentro odherido

o la porte trosera de Io Cocino Empotroble. Fue

dise_odo poro su ubicoci6n debojo de Io oberturo de

Io base en Io porte trosero. Mido el grosor de Io base

en Io porte trosero de Io oberturo poro determinar Io

ubicoci6n correcto del soporte.

INSTALAClON DEL DISPOSITIVO

ANTI-VOLCADURAS

Pared interior_

Espacio piano m[n.-----_

de 1/4"

Base en la

porte superior

\

Montaje

de pared

_ Grosor de la

base

t

Soporte ant

volcaduros

Parteinferior

Parte ......

inferior del

soporte anti-

volcaduras

para colocar

el soporte a

un min. de

1/2"

dela base

Cubre cables

Seleccione Io posici6n correcto de ocuerdo al grosor de

Io base y muevo el soporte hosto Io posici6n odecuodo.

(La unidod se entrega con el soporte en Io posici6n 1).

(_) Poro uno bose de 1.18" (3cm.) (_) Poro uno base de 3,5"

(_ Poro uno base de 1,5" (4_Alternotivo (se muestro

o continuoci6n)

Ubicaci6n del soporte anti-volcaduras

Estufa

(parte trasera de la cocina)

\(- u

"__

INSTALACION ALTERNATIVA DEL

DISPOSITIVO ANTI-VOLCADURAS

Pared interior-_

Aplicaci6n sin kit -_

Base en la par_

superior

...........Montaje de pared

Superficie de

la mesado

sin kiten

posici6nS

Soporte anti-volcaduras

* Adhesi6n para colocar

el soporte a un m[n. de VS'

q

6n -

Be requiere

colocar la

adhesi6n al

montaje de

pared

Page 20

Instrucciones de instalaci6n

El INSTALALACI6N DE LA COCINA

INSTALACI6N DEL TORNILLO DE DETENCI6N

Estos tornillos evitan que la cocina se mueva de su

posici6n durante el funcionamiento.

1. Con cuidado, marque en elgabinete la ubicaci6n

de los tornillos de detenci6n.

,

Haga agujeros de prueba de 1/8" en el gabinete,

sobre cada lado de la cocina. (Nohaga el agujero

atravesando la pared del gabinete).

,

Con cuidado, gire los tornillos de tope en los

agujeros de prueba hasta que queden ajustados.

COLOCACI6N DE LA COCINA EN LA ABERTURA

,

Esrecomendable que dos personas levanten la

estufa hasta su ubicaci6n, colocando con cuidado

las pestanas metdlicas laterales debajo del vidrio

sobre los extremos de la abertura de la base.

,

Con cuidado, deslice la cocina hacia la parte

trasera de la abertura. Dejede empujar la cocina

cuando aOn haya un espacio de 4" en elfrente,

antes de colocar la cocina al ras de la base.

cada lado

Base

RETIRELOS CANALES PROTECTORES

(si est6n incluidos)

Con cuidado retire los canales protectores aambos

lados de la estufa de vidrio. Esposible que sea

necesario levantar levemente la cocina, a fin de quitar

el peso de la cocina sobre los canales protectores.

CONTROLE EL SOPORTE ANTI-VOLCADURAS

Con la cocina aOnapoyada en parte afuera de la

punta de la base, confirme que el soporte anti-

volcaduras est@ajustado de forma segura a la parte

trasera de la cocina, y vuelva a deslizar esta Oltima

de modo que el soporte anti-volcaduras se deslice

debajo de la base odel bloque de madera ajustado a

la pared trasera.

Encaso de que la cocina sea empujada de la pared

por alguna raz6n, siempre repita este procedimiento

para verificar que la cocina est@correctamente

asegurada por el soporte anti-volcaduras.

Espacio de 4" aprox.

Estufa de vidrio

Retire la tapa protectora a ambos lados una vez

que la cocina est@en el gabinete,

T,!pa protectora

EMPUJE

Page 21

Instrucciones de instalaci6n

E] INSTALALACi6N DE LA COCINA (Contin6a)

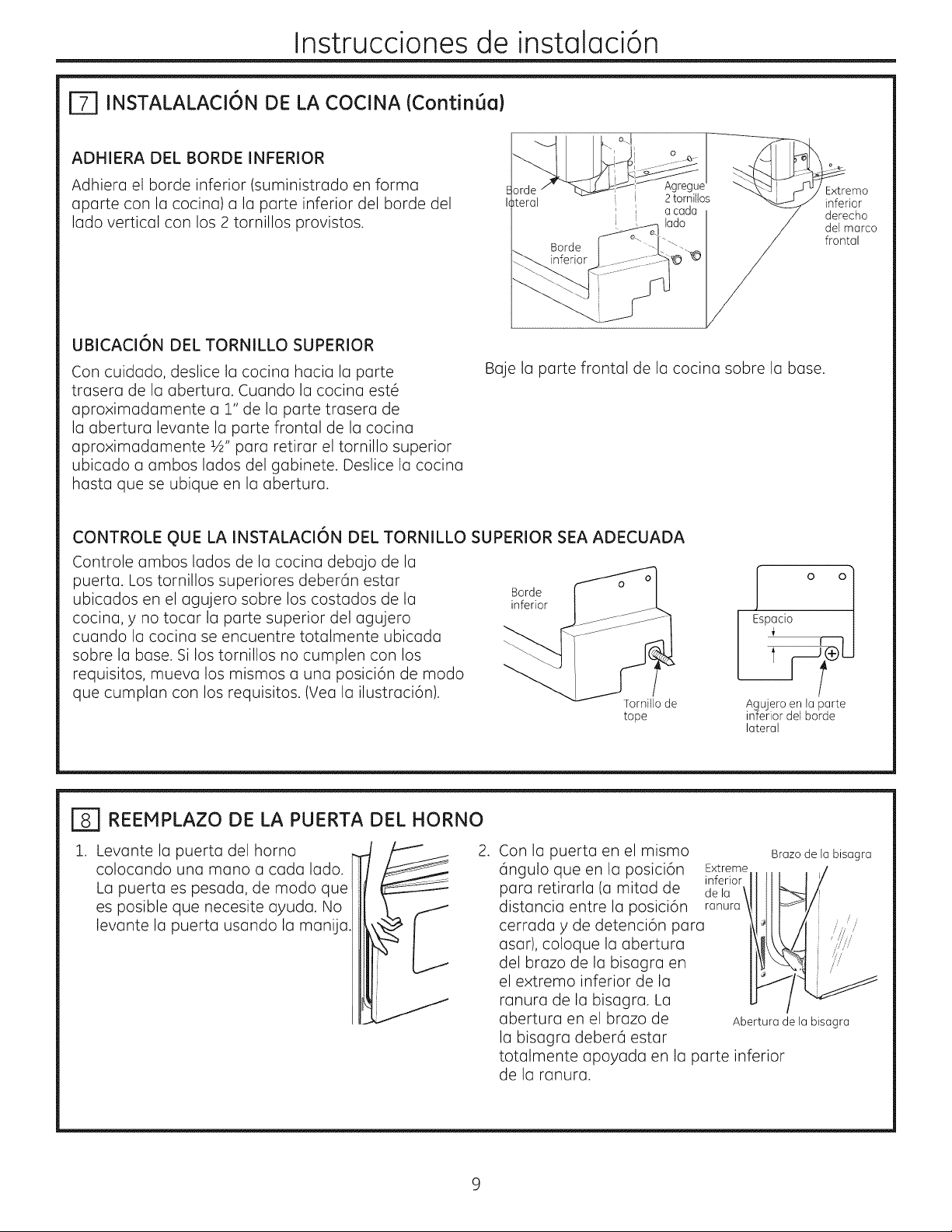

ADHIERA DEL BORDE INFERIOR

Adhiero el borde inferior (suministrado en formo

aparte con la cocina) a la porte inferior del borde del

lado vertical con los 2 tornillos provistos.

UBICACI6N DEL TORNILLO SUPERIOR

Con cuidado, deslice Io cocina hacia la porte

trasera de la abertura. Cuando la cocina est6

aproximadamente a 1" de la porte trusera de

la abertura levante la porte frontal de la cocina

aproximadamente 1_,,pura retirur el tornillo superior

ubicado a ambos lados del gabinete. Deslice la cocina

hasta que se ubique en la abertura.

teral i 2torniltos inferior

I a cada derecho

Borde

Baje la porte frontal de la cocina sobre la bose.

del marco

frontal

CONTROLE QUE LA INSTALACI6N DEL TORNILLO SUPERIOR SEA ADECUADA

Controle ambos lados de la cocina debu]o de la

puerto. Los tornillos superiores deberc_n estar

ubicados en el agujero sobre los costados de Io inferior

cocina, y no tocar la porte superior del agujero

cuando Io cocino se encuentre totalmente ubicada

sobre la bose. Si los tornillos no cumplen con los

requisitos, muevo los mismos a una posici6n de modo

que cumplan con los requisitos. (Vea la ilustraci6n).

Borde

Tornillo de

tope

E] REEMPLAZO DE LA PUERTA DEL HORNO

1. 2.

Levante la puerta del horno

colocando una mano a cada lado.

La puerta es pesada, de modo que

es posible que necesite ayuda. No

levante la puerta usando la manija

Con la puerta en el mismo

6ngulo que en la posici6n Extreme

para retirarla (a mitad de dela \l

distancia entre la posici6n ranura

cerrada y de detenci6n para t\!_l!_

asar), coloque la abertura I,X_/

del brazo de la bisagra en

el extremo inferior de la

ranura de la bisagra. La

abertura en el brazo de Abertura de la bisagra

la bisagra deber6 estar

totalmente apoyada en la parte inferior

de la ranura.

Espacio

Agujero en la parte

inferior del borde

lateral

inferior IIII

i

I°1

Brazo de la bisagra

t

Page 22

Instrucciones de instalaci6n

[_] REEMPLAZO DE LA PUERTA DEL HORNO (ContinUa}

Abro Io puerto del horno tonto como sea posible.

]. bloqueado

Empuje los bloqueos de bisogro contro Io

estructuro frontal de Io covidod del homo, hosto

Io posici6n de bloqueo. Cierre Io puerto.

Aberturade Io

bisograajustoda

en forma sec

en [a porte

inferior de la

ranurade [a

bisogra

E] LISTADO DE CONTROL FINAL

• Verifique que el interruptor de circuitos se encuentre cerrado (RESET)o que los fusibles del circuito se hayan

reemplazado.

Aseg0rese de que haya suministro el6ctrico en el edificio.

Aseg0rese que todos los materiales de empaque y cintas se hayan retirado. Si estos materiales no se retiran

se pueden producir como resultado un daflo sobre el electrodom6stico, una vez que el mismo fue encendido

y las superficies se calientan.

Bisagra en la posici6n

LISTA DE CONTROL DE FUNCIONAMIENTO

AsegOresede que la pantalla del Relojest6 activada. Sien la pantalla aparece una serie de lineas rojas

horizontales, desconecte la energia de inmediato. Vuelva a controlar las conexiones del cableado de la

cocina. Si se efectOa un cambio en los conexiones, vuelva a probar el aparato. Sino se requiere un cambio,

haga controlar el cableado del edificio para verificar las conexiones y voltaje adecuados. Se recomienda

cambiar el reloj si aparecen las lineas rojas.

Empuje y gire cualquiera de las cuatro perilla de la superficie a la configuraci6n "MED" y observe si el

elemento brilla dentro de los 15 segundos. Apague la perilla cuando se detecte el brillo. Si no se detecta el

brillo dentro del tiempo I[mite, vuelva a controlar las conexiones de los cables de la cocina. Si se requiere un

cambio, vuelva a hacer la prueba. Si no se requiere un cambio, solicite que se controlen los conexiones y el

voltaje del cableado de la edificaci6n.

10

Page 23

Not(is

11

Page 24

12 Printed in the United States

Loading...

Loading...