Page 1

4

-

or 8

-

2

-

bit Analog

K

-

4

-

5

-

B

Programmable Contr ol Product s

GE Fanuc Automat ion

IC697VAL3xx Series Isolated

Channel 1

Output Board with Voltage or Curren t Loop Outputs

User’s Ma nual

GF

2057 51

00043

000

May 2002

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

GFL-002

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardwar e or software, nor to provide for every possible contingency in

connection with installation, ope ration, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to change s subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Genius PROMACRO Series Six

CIMPLICITY Helpmate PowerMotion Series Three

CIMPLICITY 90–ADS Logicmaster PowerTRAC VersaMax

CIMSTAR Modelmaster Series 90 VersaPro

Field Control Motion Mate Series Five VuMaster

GEnet ProLoop Series One Workmaster

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved

Page 3

Chapter 1 Introduction, Description, and Specifications .........................................1-1

Reference Material and Other GE Fanuc Manuals...................................................1-1

General Description .................................................................................................1-2

Functional Description.............................................................................................1-3

Safety Summary.......................................................................................................1-5

Chapter 2 Configuration and Installation..................................................................2-1

Physical Installation.................................................................................................2-2

Before Applying Power: Checklist ..........................................................................2-3

Operational Configuration .......................................................................................2-4

Calibration..............................................................................................................2-14

I/O Cable and Front Connector Configuration.......................................................2-17

Contents

Chapter 3 Programming..............................................................................................3-1

Introduction to Controlling the Analog Output Board.............................................3-2

Board Identification Register (BIR).........................................................................3-3

Control/Status Register (CSR)................................................................................. 3-4

Control of Analog Outputs.......................................................................................3-6

Reset Operations......................................................................................................3-8

Chapter 4 Theory of Operation..................................................................................4-1

Internal Functional Organization .............................................................................4-2

VMEbus Interface....................................................................................................4-3

Channel Control Logic............................................................................................. 4-4

Analog Output Channels..........................................................................................4-6

DC/DC Power Converters........................................................................................4-9

Chapter 5 Maintenance................................................................................................5-1

GFK-2057 iii

Page 4

Chapter

Introduction, Description, and Specifications

1

This manual describes the installation and operation of the IC697VAL304, IC697VAL308,

IC697VAL314, IC697VAL318, IC697VAL324, and IC697VAL328 Isolated 8-Channel 12-bit

Analog Output Board with Voltage or Current Loop Outputs.

Reference Material and Other GE Fanuc Manuals

For a detailed explanation of the VMEbus and its characteristics, “The VMEbus Specification” is

available from:

VITA

VMEbus International Trade Association

7825 East Gelding Dr., No. 104

Scottsdale, AZ 85260

(480) 951-8866

FAX: (480) 951-0720

Internet: www.vita.com

The following Application and Configuration Guides are available from GE Fanuc to assist in the

selection, specification, and implementation of systems based upon GE Fanuc’s products:

Analog I/O Products (Built-in-Test)

Configuration Guide (catalog number

GFK-2084)

Connector and I/O Cable Application

Guide (catalog number GFK-2085)

GFK-2057 1-1

Provides assistance in configuring analog I/O

subsystems based on GE Fanuc’s analog I/O

products, including common designs, which offer a

wide variety of solutions.

Describes I/O connections that can be used with

GE Fanuc’s VMEbus products. Includes connector

compatibility information and examples.

Page 5

1

General Description

The Analog Ou tput Board provides eight isolated high quality 12 -bit analog output channels on a

single 6U form factor VMEbus board. Each channel is electrically isolated from all other channels

and from the VMEbus.

Listed below are some features of the Analog Output Board:

• Eight fully isolated analog outputs

• 1,500 Vpk isola tion, channel-to -channel and channel-to-bus

• 12-bit resolution

• Bipolar voltage output ranges selectable as ±2.5, ±5, or ±10 V

• Unipolar voltage output ranges selectable as 0 to 2.5 V, 0 to 5 V, or 0 to 10 V

• 10 mA load capacity for voltage outputs over full ±10 V range

• Available with 4 to 20 mA current loop outputs

• 0.05 percent accuracy for voltage outputs, 0.08 percent for current loop outputs

• Four or eight -channel options

• Optical data coupling provides full galvanic isolation

• Static readback data registers simplify program control

• Front panel access for field connections

• Program-controlled connect/di sco nnect operation of voltage outputs facilitates system

testing

1-2 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 6

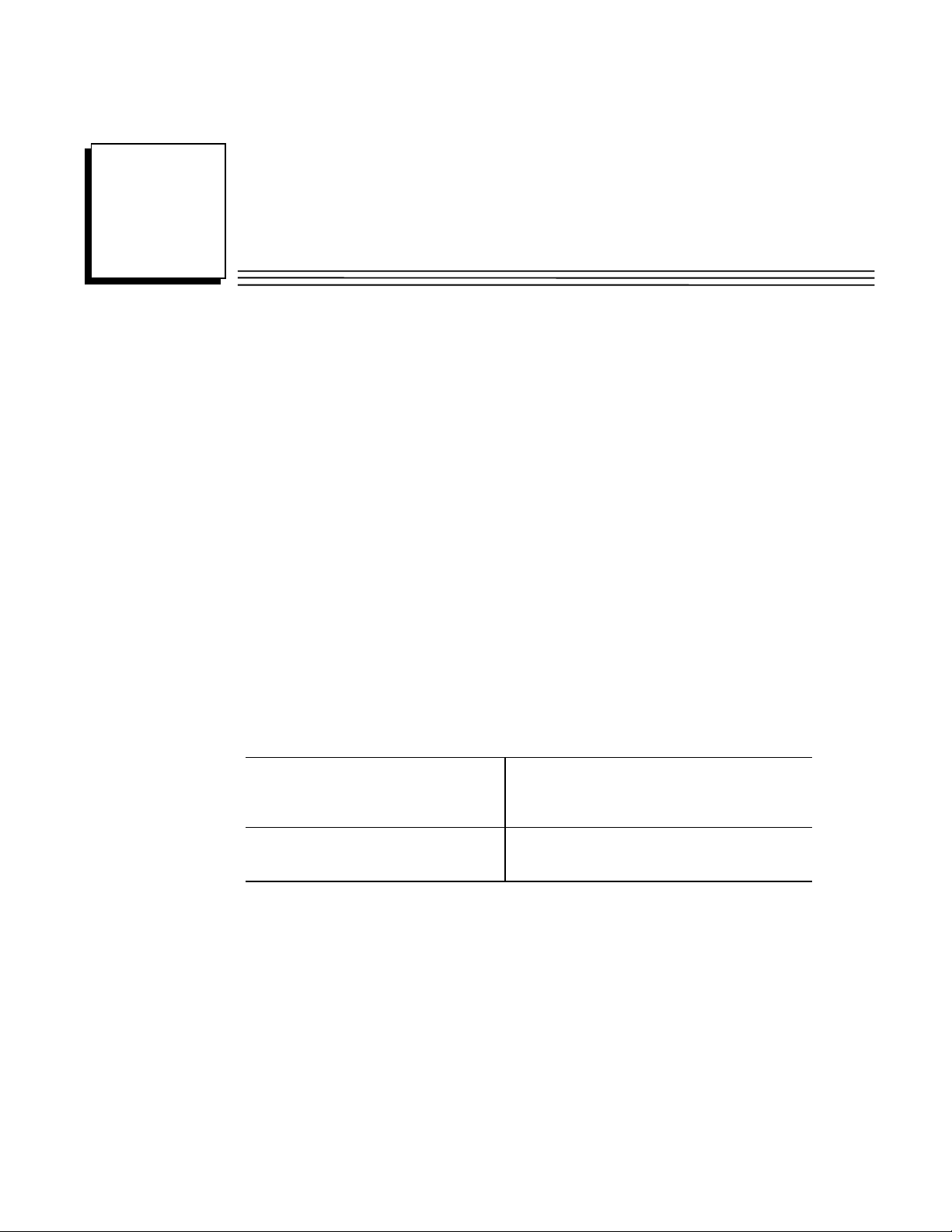

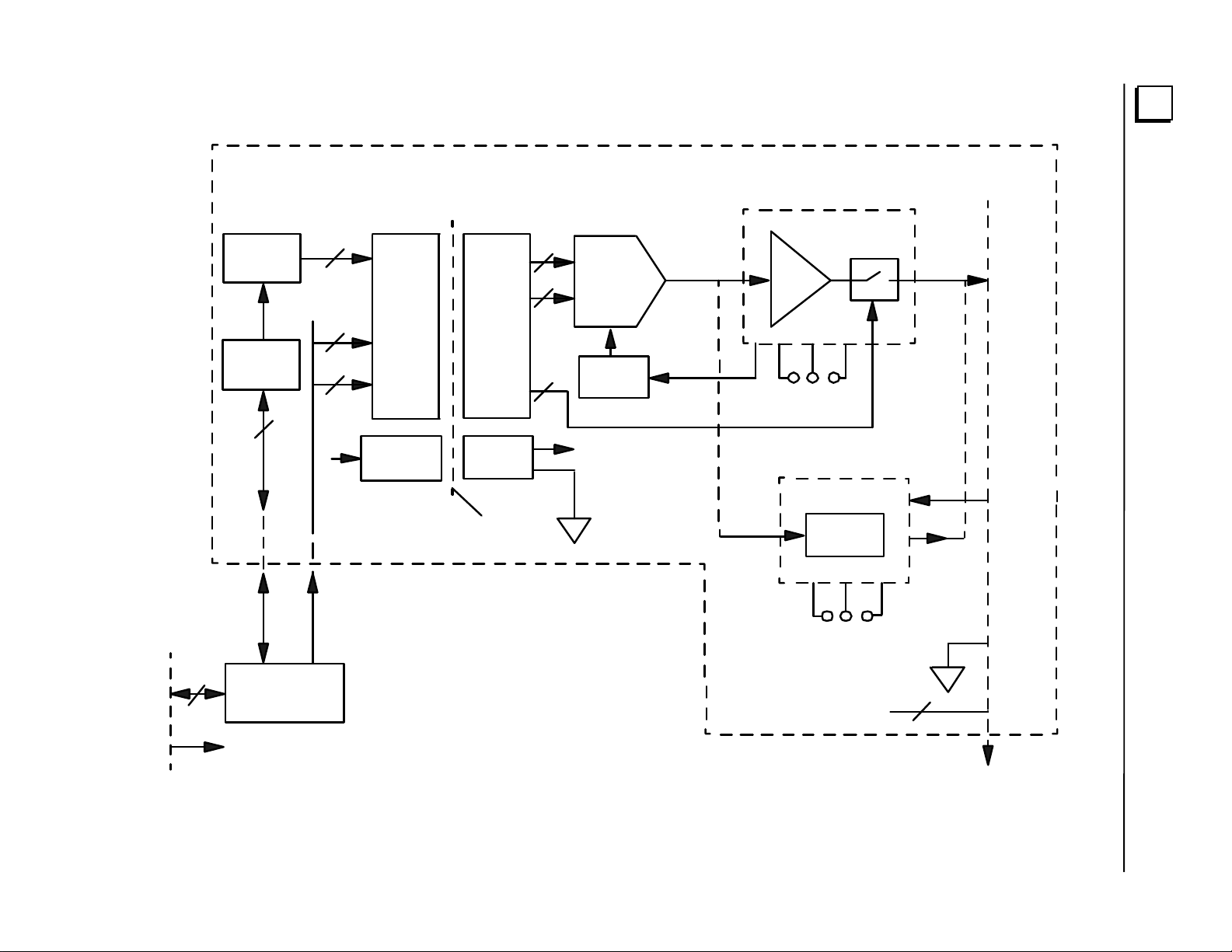

Functional Description

The Analog Output Board internal organization is illustrated in the functional b lock diagram shown

in Figure 1-1 on page 1-4. The board will operate with sustained isolation voltages as high as 1,500

Vpk. Bipolar output voltage ranges are selectable as ±2.5 V, ±5 V, or ±10 V. Unipolar output

voltage ranges are selectable as 0 to 2.5 V, 0 to 5 V, or 0 to 10 V, and full 10 mA loading is

supported throughout these ranges. Four or 8-channel configurations are available.

Voltage outputs may be disconnected under program control during system testing, and are

disconnected automatically during reset. Current-mode outputs support applications that require

standard 4 to 20 mA analog current loops. Compliance of the current mode outputs is 9 V if the

loop supply originate s on the board, or 27 V with an external loop power supply. A front panel

LED (Fail) is provided. The LED is illuminated during power up or system reset and can be turned

OFF under user software control.

1

GFK-2057 Chapter 1 Introduction, Description, and Specifications 1-3

Page 7

or Current Loop Outputs User’s Manual

1

1-4 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

OUTPUT CHANNEL 00 (1 OF 8 IDENTICAL CHANNELS)

4-CHANNEL

PTOISOLATOR

O

SHIFT

REGISTER

DATA

1

2

LATCH

1

+5V

DC-TO-DC

– May 2002

CONV

1

2

1

ISOLATED

12-BIT

SERIAL

D/A

VREF

±15 V

RANGE

(VOLTAGE OUTPUT MODULE)

BUFFER

RA NGE

2.5, 5,10 V

(CURRENT OUTPUT MODULE)

OUTPUT

00

VOLTAGE

OR

CURRENT

Figure 1-1: Analog Output Board Functional Block Diagram

E-EXT 00

INTE RNA L

DA TA BUS

VMEb us

P

1

VMEbu s

ATIB

MP

CO

INTE RFACE

CHANNEL

CONTROL

ITY

IL

ISOLATION

BARRIER

ISOLATED

GROUND00

V/I CONV

INT EXT

LOOPSUPPLY

ISOLATED

GROUND-B0

(N/ C)

ISOLAT ED

GROUN D

PLANE

COMM 00

GUARD

+5 V

TO CHANNEL S

01TO 07

Page 8

Safety Summary

The following general safety precautions must be observed during all phases of this

operation, service, and repair of this product. Failure to comply with these precautions or

with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of this product. GE Fanuc assumes no liability for the

customer’s failure to comply with these requirements.

Ground the System

To minimize shock hazard, the chassis and system cabinet must be connected to an electrical

ground. A three-conductor AC power cable should be used. The power cable must either be

plugged into an approved three-contact electrical outlet or used with a three-contact to two-contact

adapter with the grounding wire (green) firmly connected to an electrical ground (safety ground) at

the power outlet.

Do Not Operate in an Explosive Atmosphere

1

Do not operate the system in the presence of flammable gases or fumes. Operation of any electrical

system in such an environment constitutes a definite safety hazard.

Keep Away from Live Circuits

Operating personnel must not remove product covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace components with

power cable connected. Under certain conditions, dangerous voltages may exist even with the

power cable removed. To avoid injuries, always disconnect power and discharge circuits before

touching them.

Do Not Service or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

Do Not Substitute Parts or Modify System

Because of the danger of introducing additional hazards, do not install substitute parts or perform

any unauthorized modification to the product. Return the product to GE Fanuc for service and

repair to ensure that safety features are maintained.

GFK-2057 Chapter 1 Introduction, Description, and Specifications 1-5

Page 9

Chapter

2

Configuration and Installation

This chapter provides configuration and installation instructions for the Relay Board, and is divided

into the following sections:

Ph ysical Installation

Before App lying Power: Checklist

Operational Configuration

Calibration

I/O Cable and Front Connector Configuration

Caution

Some of the components assembled on GE Fanuc products can be sensitive

to electrostatic discharge and damage can occur on boards that are

subjected to a high-energy electrostatic field. When the board is placed on a

bench for configuring, etc., it is suggested that conductive material be placed

under the board to provide a conductive shunt. Unused boards should be

stored in the same protective boxes in which they were shipped.

Upon receipt, any precautions found in the shipping container should be observed. All items should

be carefully unpacked and thoroughly inspected for damage that might have occurred during

shipment. The board(s) should be checked for broken components, damaged printed circuit

board(s), heat damage, and other visible contamination. All claims arising from shipping damage

should be filed with the carrier and a complete report sent to GE Fanuc together with a request for

advice concerning the disposition of the damaged item(s).

GFK-2057 2-1

Page 10

2

Physical Installation

De-energize the equipment and insert the board into an appropriate slot of the chassis. While

ensuring that the board is properly aligned and oriented in the supporting board guides, slide the

board smoothly forward against the mating connector until firmly seated.

Caution

Do not install or remove board while power is applied.

2-2 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 11

Before Applying Power: Checklist

Before installing the board in a VMEbus system, check the following items to ensure that t he board

is ready for the intended application.

• Have the sections pertaining to and programming and theory, chapters 3 and 4, been

reviewed and applied to system requirements?

• Review “Operational Configuration” on page 2-4 and Table 2-1 on page 2-5 to verify that

all factory-installed jumpers are in place. To change the board address or address modifier

response, refer to “Operational Configuration” on page 2-4.

• Have the I/O cables, with the proper mating connectors, been connected to the

input/output connectors? Refer to “I/O Cable and Front Connector Configuration” on page

2-16 for connector descriptions

• Calibration has been performed at the factory. If recalibration is required, refer to

“Calibration” on page 2-13.

2

After the checklist above has been completed, the b oard can be installed in a VMEbus syste m. This

board may be installed in any slot position, except slot-one which is usually reserved for the system

controller.

Caution

Do not install or remove this board with power applied.

GFK-2057 Chapter 2 Configuration and Installation 2-3

Page 12

2

Operational Configuration

Control of the Analog Output Board address and I/O access mode are determined by field

replaceable, onboard jumpers. This section describes the use of these jumpers, and their effects onboard performance. The Analog Output Board jumpers are summarized in Table 2-1 on page 2-5.

The locations and functions of all Analog Output Board jumpers are shown in Figure 2-1 on page

2-6. The function of the output range selec t jumpers are option dependent and will be d iscussed in

detail in “Bipolar Voltage Outputs (Optional)” on page 2-7, “Unipolar Voltage Outputs” on page 28, and “Current Loop Output (Optional)” on page 2-9.

2-4 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 13

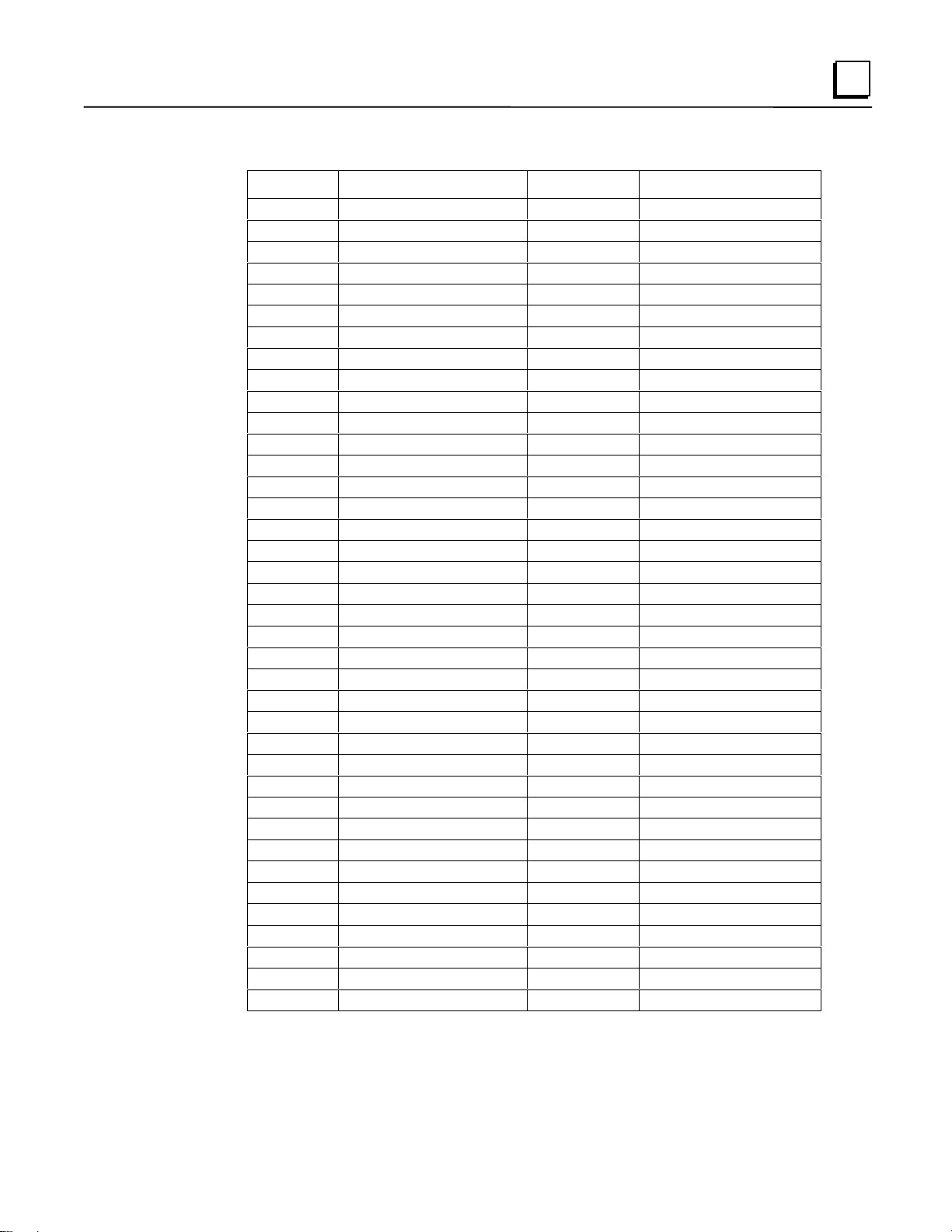

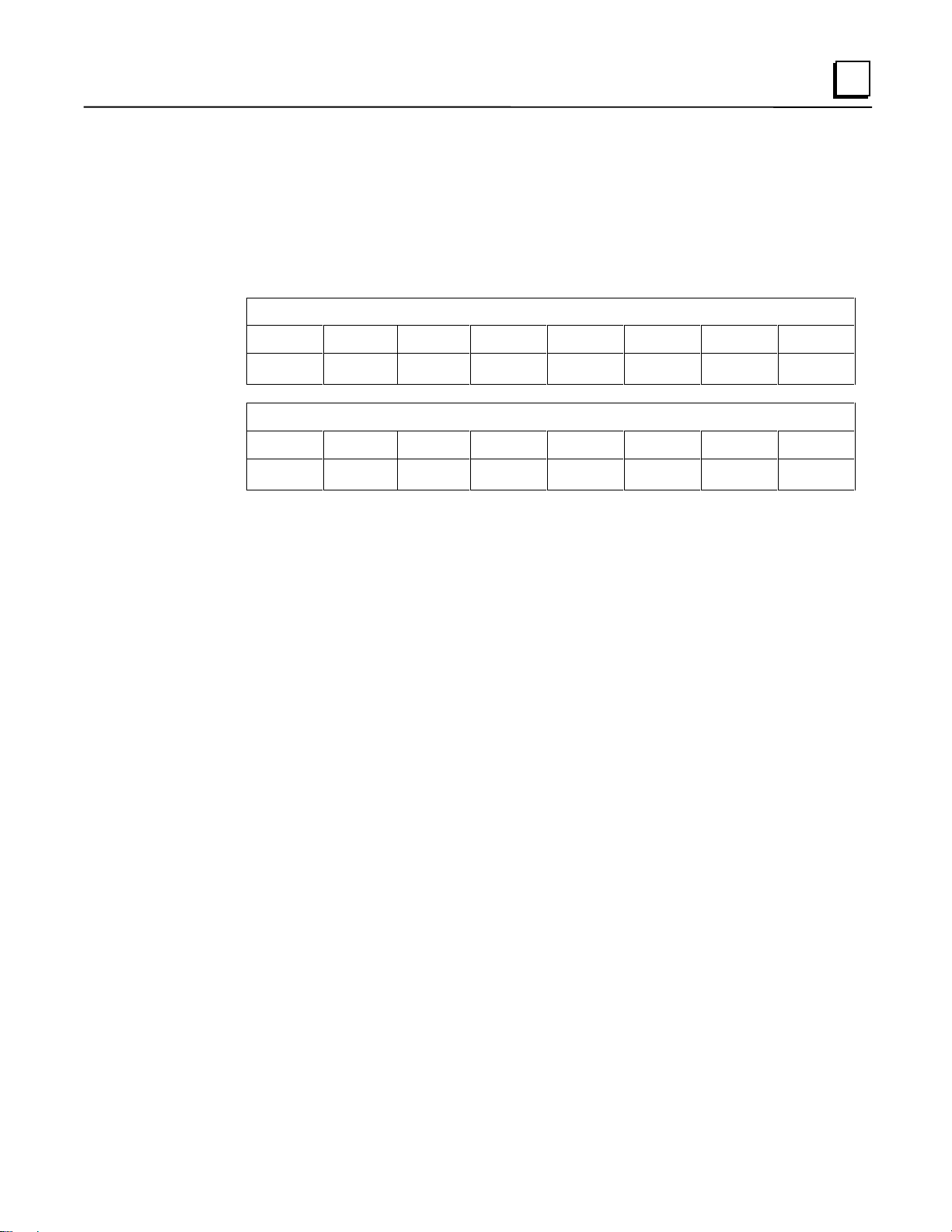

Table 2-1: Analog Output Board Jumper Configuration and Functions

Jumper ID Function Configurable Factory Configuration

E11-1, 2 Supervisory Only Yes Omitted

E11-3, 4 NonprivilegedO nly Yes Installed

E11-5, 6 Short I/O Yes Installed

E12-1, 2 Memory Address Bit A5= 0 Yes Installed

E12-3, 4 Memory Address Bit A6= 0 Yes Installed

E12-5, 6 Memory Address Bit A7= 0 Yes Installed

E9-1, 2 Memory Address Bit A8=0 Yes Installed

E9-3, 4 Memory Address Bit A9=0 Yes Installed

E9-5, 6 Memory Address Bit A10=0 Yes Installed

E9-7, 8 Memory Address Bit A11=0 Yes Installed

E9-9, 10 Memory Address Bit A12=0 Yes Installed

E9-11, 12 Memory Address Bit A13= 0 Yes Installed

E9-13, 14 Memory Address Bit A14= 0 Yes Installed

E9-15, 16 Memory Address Bit A15= 0 Yes Installed

E10-1, 2 Memory Address Bit A16= 0 Yes Installed

E10-3, 4 Memory Address Bit A17= 0 Yes Installed

E10-5, 6 Memory Address Bit A18= 0 Yes Installed

E10-7, 8 Memory Address Bit A19= 0 Yes Installed

E10-9, 10 Memory Address Bit A20= 0 Yes Installed

E10-11, 12 Memory Address Bit A21=0 Yes Installed

E10-13, 14 Memory Address Bit A22=0 Yes Installed

E10-15, 16 Memory Address Bit A23=0 Yes Installed

E1-1, 2 Channel 0 Output Range Sel Yes Installed

E1-2, 3 Channel 0 Output Range Sel Yes Omitted

E2-1, 2 Channel 1 Output Range Sel Yes Installed

E2-2, 3 Channel 1 Output Range Sel Yes Omitted

E3-1, 2 Channel 2 Output Range Sel Yes Installed

E3-2, 3 Channel 2 Output Range Sel Yes Omitted

E4-1, 2 Channel 3 Output Range Sel Yes Installed

E4-2, 3 Channel 3 Output Range Sel Yes Omitted

E5-1, 2 Channel 4 Output Range Sel Yes *Installed

E5-2, 3 Channel 4 Output Range Sel Yes Omitted

E6-1, 2 Channel 5 Output Range Sel Yes *Installed

E6-2, 3 Channel 5 Output Range Sel Yes Omitted

E7-1, 2 Channel 6 Output Range Sel Yes *Installed

E7-2, 3 Channel 6 Output Range Sel Yes Omitted

E8-1, 2 Channel 7 Output Range Sel Yes *Installed

E8-2, 3 Channel 7 Output Range Sel Yes Omitted

2

* Omitted for 4-Channel Op tions

GFK-2057 Chapter 2 Configuration and Installation 2-5

Page 14

2

U16

U16

Figure 2-1: Location of User-Configurable Jumpers and Potentiometers

6

1

R

U12

U10

1

D

U8

2

2

2

3

3

3

C

A

B

U15

8

E

4

1

R

7

E

2

1

R

6

E

0

1

R

5

E

8

R

4

E

6

R

3

E

U10*

U8*

U15*

*

*

*

1

1

1

C

B

A

P1

0

1

E

9

E

2

2

2

3

3

3

C

B

A

2

1

E

1

1

E

1

1

1

C

B

A

U14

4

R

2

E

2

R

1

E

*

*

P2

2

2

2

3

3

3

C

B

A

– May 2002

P3

2

2

2

A

B

C

* Potentiometers are located in this position on the current output

board only.

2-6 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

Page 15

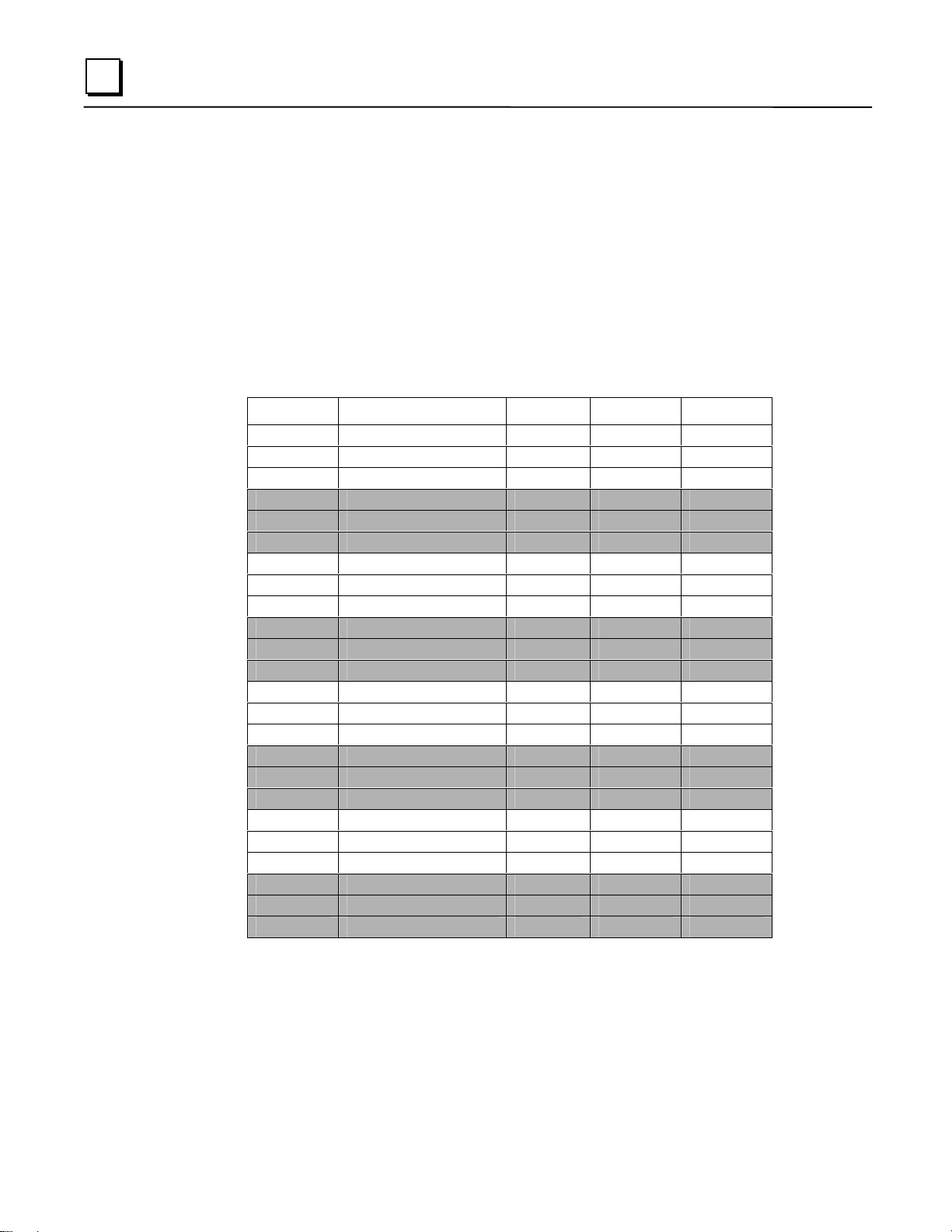

Bipolar Voltage Outputs (Optional)

The following table applies to IC697VAL304 and IC697VAL308 only.

The Analog Output Board provides Bipola r Voltage Outputs for four or eight channels. The

channel can be configured by user-installed jumpers for ±2.5 V, ±5 V, or ±10 V. Table 2-2 below

describes the jumper functions for this mode, along with the designators for the adjustment

potentiometers (POT) associated with each channel.

Table 2-2: Bipolar Voltage Jumper Functions

Channel* Output Range Jumper Voltage Gain Adj Zero Adj

0 E1-1,2 ±2.5 V R2 U1 POT

0 E1-2,3 ±5 V R2 U1 POT

0 E1-OPEN ±10 V R2 U1 POT

1 E2-1,2 ±2.5 V R4 U14 POT

1 E2-2,3 ±5 V R4 U14 POT

1 E2-OPEN ±10 V R4 U14 POT

2 E3-1,2 ±2.5 V R6 U15 POT

2 E3-2,3 ±5 V R6 U15 POT

2 E3-OPEN ±10 V R6 U15 POT

3 E4-1,2 ±2.5 V R8 U16 POT

3 E4-2,3 ±5 V R8 U16 POT

3 E4-OPEN ±10 V R8 U16 POT

4 E5-1,2 ±2.5 V R10 U6 POT

4 E5-2,3 ±5 V R10 U6 POT

4 E5-OPEN ±10 V R10 U6 POT

5 E6-1,2 ±2.5 V R12 U8 POT

5 E6-2,3 ±5 V R12 U8 POT

5 E6-OPEN ±10 V R12 U8 POT

6 E7-1,2 ±2.5 V R14 U10 POT

6 E7-2,3 ±5.0 V R14 U10 POT

6 E7-OPEN ±10 V R14 U10 POT

7 E8-1,2 ±2.5 V R16 U12 POT

7 E8-2,3 ±5 V R16 U12 POT

7 E8-OPEN ±10 V R16 U12 POT

* Channels 0 through 3, the IC697VAL304 option of the Analog Output Board

Channels 0 through 7, the IC697VAL308 option of the Analog Output Board

2

Note

GFK-2057 Chapter 2 Configuration and Installation 2-7

Page 16

2

Unipolar Voltage Outputs (Optional)

The following table applies to IC697VAL324 and IC697VAL328 only.

The Analog Output Board provides Unipolar Voltage outputs for four or eight channels. The

channel can be configured by way of user-installed jumpers for 0 to 2.5 V, 0 to 5 V, or 0 to 10 V.

Table 2-3 below describes the jumper functions for this mode, along with the associated gain and

zero adjustment designator for each channel.

Table 2-3: Unipolar Voltage Jumper Functions

Channel* Output Range Jumper Voltage Gain Adj Zero Adj

0 E1-1,2 0 to 2.5 V R2 U1 POT

0 E1-2,3 0 to 5 V R2 U1 POT

0 E1-OPEN 0 to 10 V R2 U1 POT

1 E2-1,2 0 to 2.5 V R4 U14 POT

1 E2-2,3 0 to 5 V R4 U14 POT

1 E2-OPEN 0 to 10 V R4 U14 POT

2 E3-1,2 0 to 2.5 V R6 U15 POT

2 E3-2,3 0 to 5 V R6 U15 POT

2 E3-OPEN 0 to 10 V R6 U15 POT

3 E4-1,2 0 to 2.5 V R8 U16 POT

3 E4-2,3 0 to 5 V R8 U16 POT

3 E4-OPEN 0 to 10 V R8 U16 POT

4 E5-1,2 0 to 2.5 V R10 U6 POT

4 E5-2,3 0 to 5 V R10 U6 POT

4 E5-OPEN 0 to 10 V R10 U6 POT

5 E6-1,2 0 to 2.5 V R12 U8 POT

5 E6-2,3 0 to 5 V R12 U8 POT

5 E6-OPEN 0 to 10 V R12 U8 POT

6 E7-1,2 0 to 2.5 V R14 U10 POT

6 E7-2,3 0 to 5 V R14 U10 POT

6 E7-OPEN 0 to 10 V R14 U10 POT

7 E8-1,2 0 to 2.5 V R16 U12 POT

7 E8-2,3 0 to 5 V R16 U12 POT

7 E8-OPEN 0 to 10 V R16 U12 POT

* Channels 0 Through 3, the IC697VAL324 option of the Analog Output Board

Channels 0 Through 7, the IC697VAL328 option of the Analog Output Board

Note

2-8 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 17

Current Loop Output (Optional)

The following table applies to IC697VAL314 and IC697VAL318 only.

The Analog Output Board provides Current Loop Outputs for four or eight channels. A 15 V loop

power supply is provided on the board, or a maximum of 30 V can be supplied with an external

loop power supply. A jumper is provided fo r each channel to configure the internal or external

power supply as shown in Table 2-4 below.

Table 2-4: Current Loop Output Jumper Functions

Channel* Jumper Loop Supply Gain Adj Zero Adj

0 E1-1,2 Internal R2 U1 POT

0 E1-2,3 External R2 U1 POT

1 E2-1,2 Internal R4 U14 POT

1 E2-2,3 External R4 U14 POT

2 E3-1,2 Internal R6 U15 POT

2 E3-2,3 External R6 U15 POT

3 E4-1,2 Internal R8 U16 POT

3 E4-2,3 External R8 U16 POT

4 E5-1,2 Internal R10 U6 POT

4 E5-2,3 External R10 U6 POT

5 E6-1,2 Internal R12 U8 POT

5 E6-2,3 External R12 U8 POT

6 E7-1,2 Internal R14 U10 POT

6 E7-2,3 External R14 U10 POT

7 E8-1,2 Internal R16 U12 POT

7 E8-2,3 External R16 U12 POT

* Channels 0 Through 3, the IC697VAL314 option of the Analog Output Board

Channels 0 Through 7, the IC697VAL318 option of the Analog Output Board

2

Note

GFK-2057 Chapter 2 Configuration and Installation 2-9

Page 18

2

Figure 2-2: Typical External Voltage Connection

OUTPUT

MODULE

P3

+15V

OUT

AGND

VLOOP

321

EXTERNAL

OUT

COMM

-

VEXT

+

LOAD

EXTERNAL

VOLTAGE

SOURCE

30 VOLTS MAX

2-10 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 19

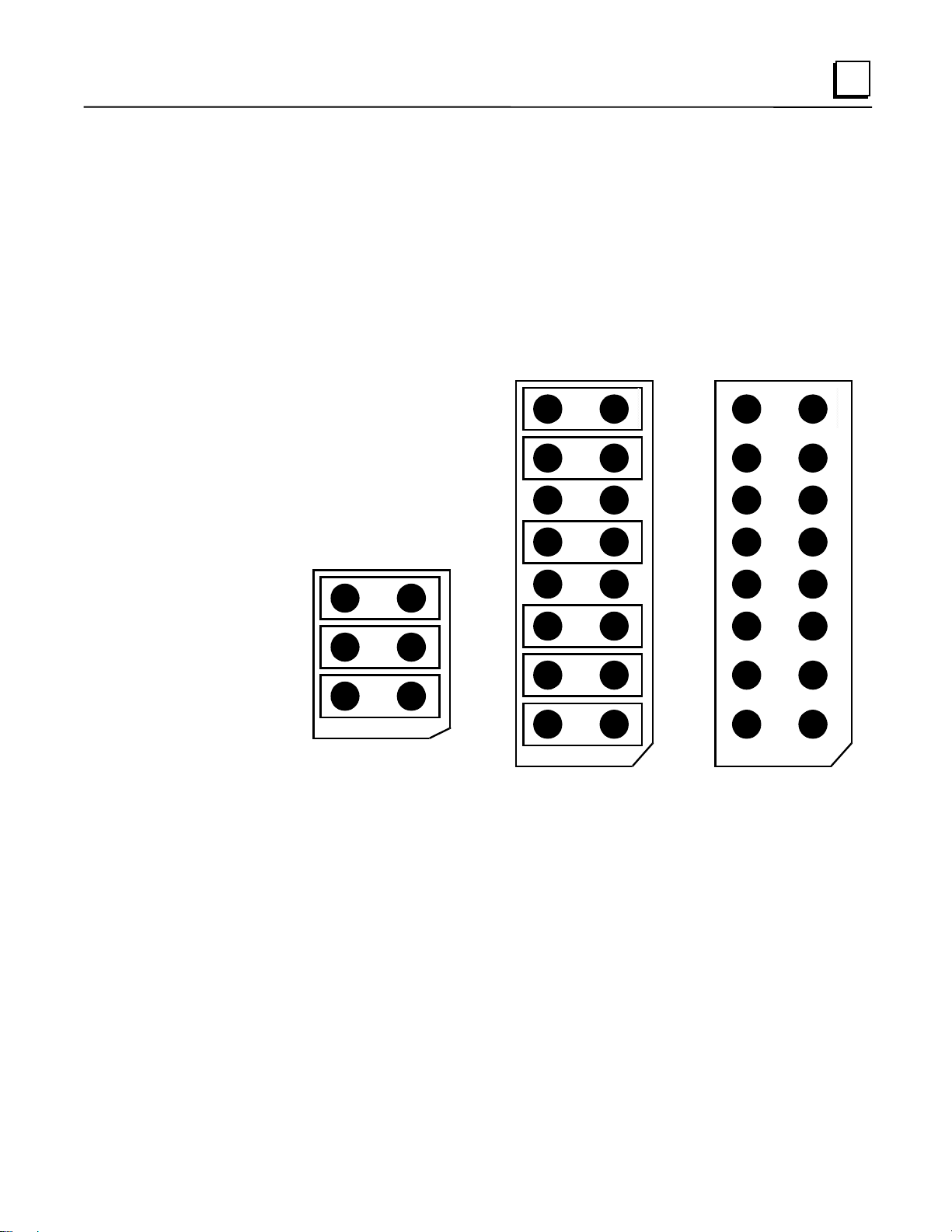

Address Modifiers

The Analog Output Board is factory configured to respond to short nonprivileged access as shown

in Figure 2-3 below and Figure 2-4 on page 2-12. The configuration can be changed by installing

jumpers at the appropriate locations in the header as shown in Figure 2-3 below and Figure 2-4 on

page 2-12.

2

Figure 2-3: Address Modifier Jumper Configurations (a)

E11

E11

Short

I/O

Short

I/O

NP

NP

Supervisory

1

Jumper Configuration for Standard

Supervisory Access

Supervisory

1

Jumper Configuration for Shor t

Addressing with Supervisory or

Nonprivileged Access

Short

I/O

NP

Supervisory

1

Jumper Configuration for Standard

Addressing with Supervisory or

E11

GFK-2057 Chapter 2 Configuration and Installation 2-11

Nonprivileged Access

Page 20

2

Figure 2-4: Address Modifier Jumper Configurations (b)

E11

E11

Short

I/O

Short

I/O

NP

NP

Supervisory

1

Jumper Configuration for Shor t

Supervisory Access

Supervisory

1

Jumper Configuration for Standard

Nonprivileged Access

E11

Short

I/O

NP

Supervisory

1

Jumper Configuration for Shor t

Nonprivileged Access

2-12 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 21

Address Selection

The Analog Output Board is designed with banks of Address Select Jumpers that specify the base

address of the board. The Address Selection Jumpers are shown in Figure 2-5 below. The Analog

Output Board is factory configured to respond to $0000 short nonprivileged access. An installed

jumper causes the board to compare to a low address line, an omitted jumper causes the board to

compare to a high address line.

2

Figure 2-5: Base Address Select Jumpers

E12

A15

A14

A13

A12

A11

E9

A23

A22

A21

A20

A19

E10

A07

A10

A18

A06

A09

A17

A05

A08

The example shown is for a I/O base address of $2800h (Short I/O Access) or FF2800 (Standard

I/O Access)

A16

GFK-2057 Chapter 2 Configuration and Installation 2-13

Page 22

2

Calibration

Before delivery from the factory, the Analog Output Board is fully calibrated. Should recalibration

be required, refer to “Equipment Required” and “Analog Outputs Calibration Procedure” below,

“Bipolar Voltage Output Cali bration” and “Unipolar Voltage Output Calibration” on page 2-14,

and “Current Output Calibration” on page 2-15 and perform the indicated calibration procedures in

the order shown. Location of all adjustments are shown in Figure 2-1 on page 2-6. As delivered

from the factory, all calibration adjustments are sealed against accidental movement. The seals are

easily broken for recalibration, however, all adjustments should be resealed with a suitable fastcuring sealing compound after recalibration has been completed.

Note:

The bipolar and unipolar voltage modules (option dependent) will be

calibrated at full scale value for the MINimum range. If the user configures

the board for any OTHER range, calibration will be required.

Equipment Required

Digital Mutimeter:

Chassis:

Extender Card:

Resistors:

Voltage Measurements: ±10 VDC range; 5 or more digits; ±0.005 percent

of reading accuracy; 10W minimum input resistance.

Current Measurements: 0 -100 mADC range; 5 or more digits; ±0.005

percent of reading accuracy; 100 maximum input resistance.

VMEbus 6U backplane or equivalent, with J1 and J2 connectors, 680x0

series controller, +5 ±0.2 VDC, 8 Amp (reserved current) power supply.

One slot allocated for testing the Analog Output Board.

VMEbus 6U extender card.

250Ω ±5%, 1/4 watt (current outputs only)

Analog Outputs Calibration Procedure

1. Refer to “Operational Configuration” on page 2-4 and configure the Analog Output Board

for the output configuration that is required for the application. For calibration of current

outputs, configure the outputs for operation with the internal loop supply.

2. Install the Analog Output Board on an extender card in the VMEbus chassis. Make

provisions for connecting the DMM to each analog output channel, with the (+) common

lead at the output pin (OUT*) and the (-) lead at the common pin (COMM*). The channel

output pins are defined in the table in Figure 2-6 on page 2-16.

3. Apply power to the board. Write the value A000 (HEX) to the CSR, this will enable all

outputs and extinguish the fail LED (refer to Table 3-1 on page 3-2 for the locations of all

registers). All data transfers will be D16.

4. Allow a minimum warm-up interval of ten minutes before proceeding.

2-14 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 23

5. See the following sections for bipolar voltage outputs, unipolar voltage outputs, or current

outputs. The locations of output modules and adjustment potentiometers are illustrated in

Figure 2-1 on page 2-6.

Bipolar Voltage Output Calibration

1. Connect the DMM to the channel 00 output pins, with the (+) lead connected to the output

pin and the (-) lead connected to the common pin.

2. Write the value $0800 to the channel 00 output data register. Adjust the ZERO

potentiometer on the channel 00 output module for a DMM indication that conforms to the

MIDSCALE value contained in Table 2-5 below for the assigned output range.

3. Write the value $0FFF to the c han nel 00 output data register. Adjust the Channel-00 gain

potentiometer for a DMM indication that conforms to the POSITIVE FULL SCALE value

contained in Table 2-5 below for the assigned output range.

4. Write the value $0000 to the channel 00 output data register. If the DMM indication does

not conform to the NEGATIVE FULL SCALE value co ntained in Table 2-5 below for the

assigned output range, repeat steps 2, 3, and 4 until the measurements for all three steps

are correct.

2

5. Repeat steps 1 through 4 for the remaining active output channels.

6. Bipolar calibration is completed. Remove power. Remove all test connections.

Table 2-5: Bipolar Voltage Output Calibration Values

Output Range

(VDC)

±2.5 0.0000 ±0.0006 +2.4988 ±0.0006 -2.5000 ±0.008

±5 0.0000 ±0.0010 +4.9975 ±0.0010 -5.0000 ±0.011

±10 0.0000 ±0.0002 +9.9951 ±0.0020 -10.0000 ±0.018

Midscale

Output Value (VDC)

Unipolar Voltage Output Calibration

1. Connect the DMM to the channel 00 output pins, with the (+) lead connected to the output

pin and the (-) lead connected to the common pin.

2. Write the value $0000 to the channel 00 output data register. Adjust the channel 00 gain

potentiometer for a DMM indication that conforms to the ZERO value contained in Table

2-6 on page 2-15 for the assigned output range.

3. Write the value $0FFF to the channel 00 output data register. If the DMM indication does

not conform to the POSITIVE FULL SCALE value contained in Table 2-6 on page 2-15

for the assigned output range, repeat steps 2, 3, and 4 until the measurements for all three

steps are correct.

Positive Full

Scale

Negative Full

Scale

4. Repeat steps 1 through 3 for the remaining active output channels.

5. Unipolar calibration is completed. Remove power. Remove all test connections.

GFK-2057 Chapter 2 Configuration and Installation 2-15

Page 24

2

Table 2-6: Unipolar Voltage Output Calibration Values

Output Range

(VDC)

0 to +2.5 0.0000 ±0.0006 +2.4988 ±0.0015

0 to +5 0.0000 ±0.0010 +4.9975 ±0.0020

0 to +10 0.0000 ±0.0020 +9.9951 ±0.0040

Zero Positive Full Scale

Current Output Calibration

1. Connect the DMM to the channel 00 output pins (see the table in Figure 2-6 on page 2-

16), with the (+) lead connected to the output pin through a series resistance of 250, and

the (-) lead connected to the common pin. Leave the external loop supply pins (VEXT)

disconnected.

2. Write the value $0000 to the channel 00 output data register. Adjust the ZERO

potentiometer on the channel 00 output module for a DMM indication that conforms to the

ZERO SCALE value contained in Table 2-7 below for the assigned output range.

3. Write the value $0FFF to the c han nel 00 output data register. Adjust the cha nnel 00 gain

potentiometer for a DMM indication that conforms to the FULL SCALE value contained

in Table 2-7 below for the assigned output range.

4. Repeat steps 1 through 4 for the remaining active output channels.

5. Calibration is completed. Remove power, remove all test connections.

Output Value (VDC)

Table 2-7: Current Output Calibration Values

Output Range

(mADC)

4 to 20 4.000 ±0.004 +20.000 ±0.008

Output Value (mADC)

Zero Positive Full Scale

2-16 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 25

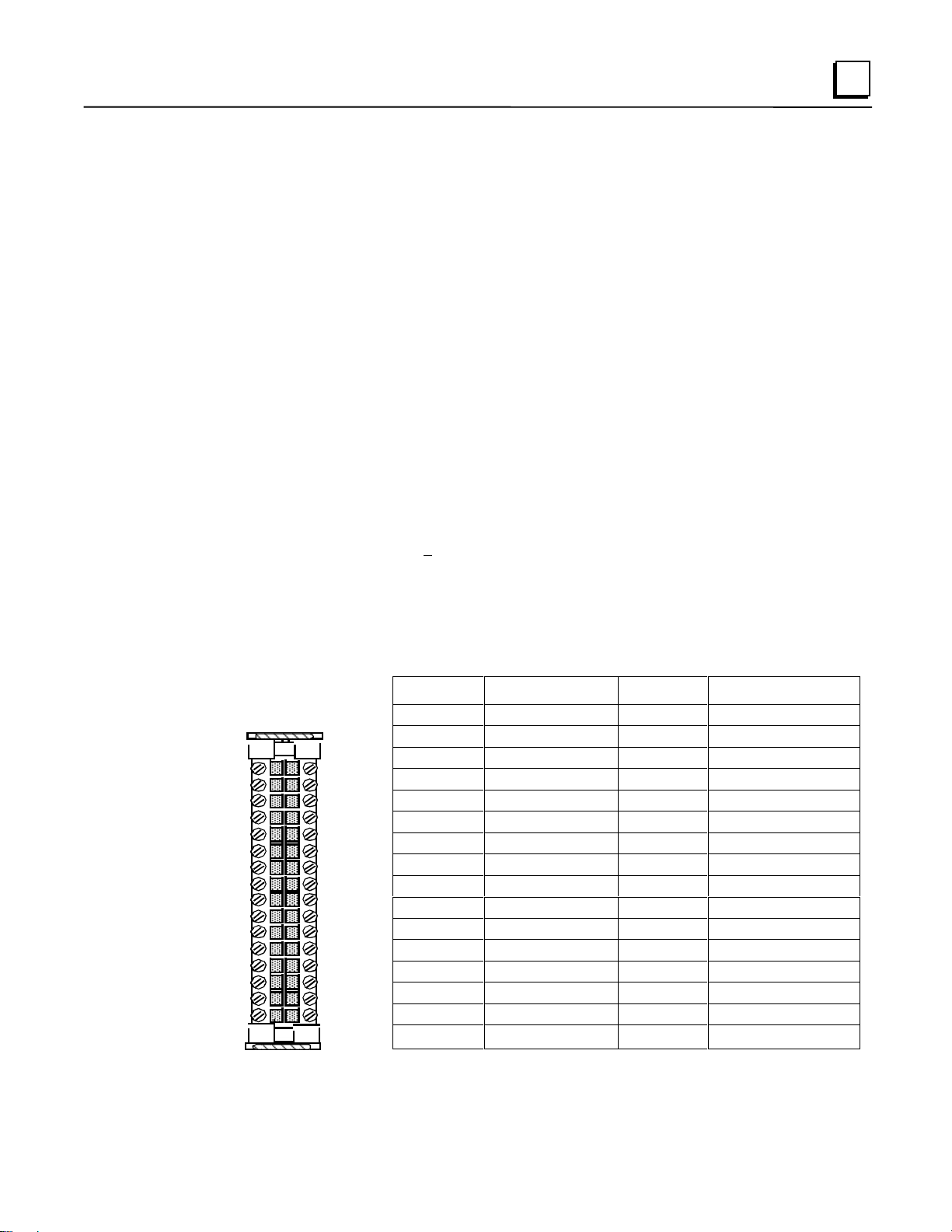

I/O Cable and Front Connector Configuration

The front input connector (P3) on the Analog Output Board is a standard 41612 DIN form E screw

terminal connector. The P3 connector pin layout is shown in Figure 2-6 below. The pin

assignments for P3 are also shown below. The connector is supplied with integral latches. To

remove the connector, depress both latches simultaneously while gently pulling connector from

socket. Install connector by aligning keying and pressing the connector into place.

32-Pin DIN Connector: Connector Specification

• Wire should be 14-22 AWG

• Insulation stripping length: .315” ±.20”/8mm ±0.5mm

• The binding screw terminals are best suited for a .138” x.20”/3.5mm x 0.5mm common

flat-blade screwdriver.

2

• Recommended screw tightening torque: 5 . 22 lb./in. /0.6mN

• Contact resistance: <

Due to chassis vibration, GE Fanuc recommends periodic checks of screw

torque.

Front View (Cable Side) of

P3 Connector

PIN No.

A32

A2

C2

C32

10 mΩ

Note

Figure 2-6: P3 Connector Pin Layout and P3 Pin Assignments

P3 Pin No. Signal P3 Pin No. Signal

A32 *VEXT 7 C32 N/C

A30 OUT 7 C30 COMM 7

A28 *VEXT 6 C28 N/C

A26 OUT 6 C26 COMM 6

A24 *VEXT 5 C24 N/C

A22 OUT 5 C22 COMM 5

A20 *VEXT 4 C20 N/C

A18 OUT 4 C18 COMM 4

A16 *VEXT 3 C16 N/C

A14 OUT 3 C14 COMM 3

A12 *VEXT 2 C12 N/C

A10 OUT 2 C10 COMM 2

A8 *VEXT 1 C8 N/C

A6 OUT 1 C6 COMM 1

A4 *VEXT 0 C4 N/C

A2 OUT 0 C2 COMM 0

* VEXT pins have no effect on voltage outputs.

GFK-2057 Chapter 2 Configuration and Installation 2-17

Page 26

Chapter

3

Programming

This chapter contains programming instructions for the Relay Board , and is divided into the

following sections:

Introduction to Controlling the Analog Output Board

Board Identification Register (BIR)

Contro l/Status Register (CSR)

Control of Analog Outputs

Reset Operatio ns

GFK-2057 3-1

Page 27

3

Introduction to Controlling the Analog Output Board

Communication with the Analog Output Board is established through control, status, data, and

identification registers that are mapped into a 16-word block. On-board configurable address

jumpers permit the communication registers to be located in either the A16 short or the A24

standard I/O data space. Access privilege is jumper-selectable as supervisory, nonprivileged, or

both. All registers are listed in Table 3-1 below and described throughout this section.

Each of the eight analog outputs is controlled through a dedicated 12-bit Output Data Register

(ODR). Data is serialized and transferred to an output D/A converter when the associated ODR

receives a data transfer from the bus. All channels operate independently.

All read/write registers are cleared to ZERO by a system reset or power up operation. The reset

operation places the board in the following state:

Analog Output Level Current and voltage outputs are at lowest level.

Analog Output State All voltage channels are disconnected from the output connectors, no

effect on current option.

Data Coding Offset binary.

Front Panel LED Illuminated.

Table 3-1: Analog Output Board Register Map

Board Address

(Hex)

00 Board ID BIR Read Only Byte/Word/Longword

04 Control and Status CSR Read/Write Byte/Word

06 Reserved ... ...

08 CH 00 Output Data ODR 00 Read/Write Word

0A CH 01 Output Data ODR 01 Read/Write Word

0C CH 02 Output Data ODR 02 Read/Write Word

0E CH 03 Output Data ODR 03 Read/Write Word

10 CH 04 Output Data ODR 04 Read/Write Word

12 CH 05 Output Data ODR 05 Read/Write Word

14 CH 06 Output Data ODR 06 Read/Write Word

16 CH 07 Output Data ODR 07 Read/Write Word

18 to 1E Reserved ... ...

Register

Function

Description Access Size

3-2 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 28

Board Identification Register (BIR)

The Board Identification register contains the board identification code ($46000000) for the Analog

Output Board, and occupies the first two words at the board base address.

Table 3-2: Board ID Register Bit Map

Board ID Register (Offset Address $00) Read-only, Byte

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 09 Bit 08

0 1 0 0 0 1 1 0

Board ID Register (Offset Address $00) Read-only, Byte

Bit 07 Bit 06 Bit 05 Bit 04 Bit 03 Bit 02 Bit 01 Bit 00

0 0 0 0 0 0 0 0

3

GFK-2057 Chapter 3 Programming 3-3

Page 29

3

Control/Status Register (CSR)

Control/Status register functions and the bitmap are summarized in Table 3-3 below. Control

register bits are mapped directly to the readback STATUS register at the same location. All CSR

bits are cleared to zero (LOW) during a power up or reset operation. The CSR provides control and

monitoring of the following board functions:

• Output enabling (voltage outputs)

• Output load cycle status

• Data coding

• Self test LED

Table 3-3: Analog Output Board Control/Status Register (CSR) Bit Map

CSR (Offset Address $04) Read/Write, Byte/Word

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 09 Bit 08

LED Reserved

Bit 07 Bit 06 Bit 05 Bit 04 Bit 03 Bit 02 Bit 01 Bit 00

CH 7

Busy

CH 6

Busy

Output

EN

CSR (Offset Address $04) Read/Write, Byte/Word

CH 5

Busy

Two’s

CMPL

CH 4

Busy

Control/Status Register Bit Definitions

Bit 15: LED – The "FAIL LED" is OFF if Bit 15 is set (logical "1"), or is ON if bit

is cleared (logical "0"). Default = logical "0".

Bit 14: Reserved – This bit is reserved and forced to a logical "0".

Bit 13: Output Enable – Output Enable: All outputs are connected to the output

connectors if Bit 13 is set to a logical "1," or disconnected if Bit 13 is

cleared to a logical zero.

Bit 13 has no effect on current outputs. Default = logical "0."

Note

CH 3

Busy

Reserved

CH 2

Busy

CH 1

Busy

CH 0

Busy

For current output options, the outputs are placed in a minimal current

output state when this bit is cleared to a zero. This bit must be set to a "1" to

allow operation. For the default state, reference “Reset Operations” on page

3-8.

3-4 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 30

3

Bit 12: Two’s Complement – Channel data is processed in 12-bit offset binary if

Bit 12 is cleared (reset default) or in two’s complement format with

extended sign if Bit 12 is set a logical "1".

Bits 11 through 08: Reserved – This bit is reserved and forced to a logical "0".

Bits 07 through 00: CH Busy – The Channel Busy flag is set when the associated channel

Output Data Register receives a data transfer from the bus, and remains set

for approximately 8 msec while the data word is transferred to the output

D/A converte r. A channel register should not be updated from the bus

while the associated busy flag is set.

Note

LOGIC STATE CONVENTION – To avoid ambiguities in references to

logic levels, this document uses the convention that a data bit or control line

is "SET" when it is in the "1", or HIGH state, and is "CLEARED" when

"0" or LOW STATE.

GFK-2057 Chapter 3 Programming 3-5

Page 31

3

Control of Analog Outputs

Output Registers and Data Format

The eight independent analog outputs are controlled through output data registers ODR 00 through

ODR 07. Readback capability is provided, and both D8 (even/odd) and D16 transfers are

supported. It is advisable to update data registers in word format. Data is configured in rightjustified 12-bit offset binary format or two’s complement format, data format is controlled by CSR

Bit 12.

In the offset binary format (reset default), the upper four bits D12 to D15 are ignored during

loading and are returned as zero during readback. In two’s complement format, data is received and

returned in two’s complement with the sign extended through the most significant bit, Bit 15 during

readback.

Table 3-4: Bipolar Output Offset Binary Format Bit Map

Bipolar Output Data Register Read/Write, Byte/Word

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 09 Bit 08

X X X X D11 D10 D09 D08

Bipolar Output Data Register Read/Write, Byte/Word

Bit 07 Bit 06 Bit 05 Bit 04 Bit 03 Bit 02 Bit 01 Bit 00

D07 D06 D05 D04 D03 D02 D01 D00

Table 3-5: Bipolar Output Data Register Bit Map (Two’s Complement)

Bipolar Output Data Register Read/Write, Byte/Word

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 09 Bit 08

X X X X D11 D10 D09 D08

Bipolar Output Data Register Read/Write, Byte/Word

Bit 07 Bit 06 Bit 05 Bit 04 Bit 03 Bit 02 Bit 01 Bit 00

D07 D06 D05 D04 D03 D02 D01 D00

3-6 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 32

Table 3-6: Data Codes for Some Selected Output Voltages

3

Offset

Binary

000 800 -10 V +0 V - FSR

400 C00 -5 V + 2.5 V 1/4 FSR

800 000 +0 V +5 V 1/2 FSR

C00 400 +5 V +7.5 V 3/4 FSR

FFF 7FF +9.9951 V +9.9951 V + FSR - 1 LSB

Two’s

Comp

Scaling and Enabling

Available output ranges are ±2.5 V, ±5 V, or ±10 V for bipolar voltage outputs, 0 to +2.5 V, 0 to

+5 V, or 0 to +10 V for unipolar voltage outputs, and 4 to 20 mA for current outputs. The analog

output range is determined independently for each output channel by on-board jumpers which are

described in Chapter 2. All voltage outputs are disconnected from the output connectors if Bit 13 in

the CSR is cleared, or connected to the output connectors if CSR Bit 13 is set.

If the CSR Bit 12 control bit is cleared, the output data is coded in offset binary. Each output level

is scaled linearly from $0000 for negative full scale or lowest output level, to $0FFF for positive

full scale, or highest output level.

For two's complement coding (CSR Bit 12 set), the output data is scaled from $F800 for negative

full scale to $07FF for positive full scale. Two's complement co ding normally is used only for

bipolar outputs. Various coding examples are summarized in Table 3-6 above.

Bipolar

Output ±10 V

Unipolar Output

0 - 10 V

Scale Factor

Output Load Cycles

Data from an output data register is transferred serially to the output D/A converter during an

internal Output Load Cycle. A data transfer to a data register initiates a load cycle for the

associated output channel. The load cycle is completed in approximately 8 msec, and proceeds

automatically after initiation without further interve ntion from the VMEbus. The level of the

associated analog output channel is updated at the end of the load cycle. For D8 transfers, the load

cycle is initiated by an odd-byte transfer.

Each Channel Busy Flag (Bit 00 through B it 07) is set when the assigned channel output data

register receives a data transfer from the bus, and remains set for approximately 8 msec during the

ensuing output load cycle. Data transfers to an output register should not take place while the

associated busy flag is set. However, any register can be read at any time without affecting board

performance. All output channels are controlled independently, and any output data register can be

updated without affecting the other seven chan nels.

GFK-2057 Chapter 3 Programming 3-7

Page 33

3

Reset Operations

All read/write registers are cleared to ZERO by a system reset operation. The reset operation places

the board in the following state:

Analog Output Level For options "-AB1," current outputs are minimal; For options "-AB0,"

Analog Output State All voltage channels are disconnected from the output connectors.

Data Coding Offset binary.

Front Panel LED Illuminated.

current outputs are on-line and full-scale voltage outputs are minus full

scale.

3-8 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 34

Chapter

4

Theory of Operation

This chapter describes the internal organization of the Analog Output Board, reviews the general

principles of operation, and is d ivided into the following sections:

Internal Functional Organization

VMEbus Interface

Channel Control Logic

Analog Output Channels

DC/D C Power Converters

GFK-2057 4-1

Page 35

4

Internal Functional Organization

Optical data coupling, serial data transfers, and isolated Digital-to-Analog Converters (DACs) are

used to produce eight galvanically isolated analog output channels. Each channel contains a serial

12-bit DAC which generates a sig nal voltage in response to commands from the VMEbus. The

DAC voltage then drives an output module which is factory configured for a specific voltage or

current output option. Power for each channel is supplied as ±15 VDC by an isolated DC-to-DC

converter. A functional block diagram of the Analog Output Board is shown in Figure 1-1 on page

1-4.

The Analog Output Board consists of the following functional elements, all of which are describ ed

in the following sections:

• VMEbus interface

• Channel control logic

• Isolated analog outputs

• DC/DC power converters

4-2 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 36

VMEbus Interface

Communications with the VMEbus is controlled with a single Electrically Programmable Logic

Device (EPLD), as shown in Figure 4-1 on page 4-4. Data and control registers are distributed

among two channel-control EPLD’s. The control-logic EPLD responds to data transfer requests

from the VMEbus, and directs the flow of data between the bus and the internal data and control

registers. Data Transfer Acknowledge (DTACK*) is generated when a transfer from the bus has

been completed, or when data is ready to be transferred to the bus. Transfers proceed normally if

address pipelining is present, but the board will respond only to the first address in the pipeline

sequence. The VMEbus interface logic will not respond to transfer requests in which the BERR*,

DTACK*, LWORD*, or IACK* control line is asserted.

4

GFK-2057 Chapter 4 Theory of Operation 4-3

Page 37

4

Channel Control Logic

Control of data transfer to the output DAC is partitioned into two identical 4-channel groups, with a

single EPLD assigned to each group. This method of partitioning permits the board to be populated

with only those devices required to support the 4- or 8-channel optional configuration.

As shown in Fi gure 4-1 below , the EPLD which c ontrols channe ls 00 through 0 3 also contains the

Board Identification Register (BIR) and part of the Control/Status register (CSR). This EPLD

detects the presence of one or both of the channel-control EPLD, and adjusts the distribution of the

CSR accordingly.

Figure 4-1: VMEbus Interface and Control

CHANNELS 00-03 CONTROL

ID00-15

XCVR

VMEbus

P1

VMEbus

BUFFERS

CONTROL

LOGIC

(EPLD)

INTERNAL

DATA

INTERNAL

CONTROL

ID00-15

R/W

REG ADDR

R/W

CSR D00-03

D12-15

BIR D00-D31

MUX

CHANNELS 04-07 CONTROL

XCVR

MUX

CHANNEL 00

CONTROL

CHANNEL 01

CHANNEL 02

CHANNEL 03

CSR D04-07

CHANNEL 04

CONTROL

CHANNEL 05

CHANNEL 06

CHANNEL 07

ENABLE OUTPUTS

DTA, CLK, LD

GROUP 1,2

PRESENT

DTA, CLK, LD

TO

OPTICAL

COUPLERS

REG ADDR

4-4 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 38

4

Each channel-control EPLD contains four data registers which receive the channel data words from

the VMEbus, and provides an independent data serializer for each channel. Figure 4-2 on page 4-7

illustrates the movement of data within a single control channel. A data transfer to any 16-bit

channel data register from the bus initiates t he serializing process which moves the data to the

serial output D/A converter. Data in each register is right-justified with 12 significant bits.

Only the 12 significant data bits in each channel are serialized for transfer to the associated D/A

converter. The four digital signals required to produce the transfer are shown in Figure 4-3 on page

4-8. The board selection (BDSEL L) initiates the transfer sequence. The CLOCK line provides the

primary timing, and clocks the information present on the DATA line into the serial D/A converter,

MSB first through LSB last. The output of the converter does not change during the serial transfer.

When the serial transfer has been completed, the LOAD signal performs a parallel transfer of data

to an output latch in the conver ter, and the output voltage responds to the new data.

GFK-2057 Chapter 4 Theory of Operation 4-5

Page 39

4

Analog Output Channels

Isolation

Each output channel is isolated from the VMEbus and from all other channels by an isolated

DC/DC converter and by four optical couplers. The DC/DC converter provides isolated ±15 VDC

power for the channel, and the optical couplers isolate the digital control signals IDTA, ICLK, ILD,

and IENA from EPLD signals DATA, CLOCK, LOAD, and ENAOUT (Figure 4-4 on page 4-9).

Power for the optical couplers is supplied as +5 VDC, and is series regulated from the isolated +15

V rail.

Digital-to-Analog Conversion

A serial Digital-to-Analog Converter (DAC) receives the 12-bit data word from the channel control

EPLD, and produces an output voltage range that is jumper controlled from 0 to 10 V. The D/A

buffer converts this range into the output ranges specified in the output ordering option. Ch annel

span is adjusted in the feedback loop of the D/A buffer.

The voltage reference level is selected as +2.5 V, +5 V, or +10 V by the output module. A current

output module automatically selects a +10 V reference. A voltage output module passes the state of

the module control jumpers directly to the reference, and permits any of the three voltages to be

selected.

4-6 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 40

IDB00-15

RD DTA H

4

Figure 4-2: Analog Output Board Channel Control

CHANNEL CONTROL EPLD

BUS XCVR

16

REG ADDR A1-A4 H

WR DT A H

CLK4 H

CLK8 H

4

12

SEQUENCE

CONTROL

DATA

REGISTER

CHANNEL

MULTIPLEXER

CT RXX 0-3

4

COUNTER

4 CHANNELS

DT AXX H

TO OPTICAL

COUPLERS

CLKXX H

LDXX L

ONE OF

GFK-2057 Chapter 4 Theory of Operation 4-7

Page 41

4

BD SEL L

DATA

Figure 4-3: Analog Output Board Output Timing (Typical Channel)

µ

8.5

SEC MAX

DB 11 (MSB)

CLOCK (2 MHz)

LOAD

Voltage and Current Outputs

All outputs are factory-configured for either unipolar voltage, bipolar voltage, or constant current.

Each module contains an offset potentiometer to permit adjustment of the channel offset error to

zero.

A voltage output module consists of a unity gain buffer and an output switch. The buffer provides

the output drive capability necessary to support 10 mA loads over the maximum output range of

±10 V. The switch provides the on-line/off-line field disconnect feature, and is controlled by the

Output Enable (OUTPUT EN) bit in the Control/Status Register (CSR). The outp ut switch is

located in the feedback loop of the buffer, and consequently does not contribute significantly to the

final output impedance of 0.5Ω. The jumpers connected to the voltage module permit selection of

any of the three available reference voltages.

DB10

DB00 (LSB)

1.0µSEC MIN

The current output module contains a voltage-to-current converter and a pass transistor. The

module is factory-jumpered to provide the specified output current range with a voltage range from

the D/A converter of 0 to +10 V. The pass transistor boosts the current output capability to the

maximum level necessary to support the specified output current range. The jumpers which are

connected to the module are used to select the source of loop power either as the internal isolated

+15 V rail, or as an external supply which can pro vide a loop voltage up to +30 V.

4-8 IC697VAL3xx Series Isolated 4- or 8-Channel 12-bit Analog Output Board with Voltage GFK-2057

or Current Loop Outputs User’s Manual

– May 2002

Page 42

DC/DC Power Converters

Each channel contains a single DC/DC converter (Figure 4-4 below) which derives isolated ±15

VDC power from the VMEbus +5 VDC power bus, and is packaged in a 24-pin dual-in-line

module. The isolated ±15 VDC outputs from the converter supply all power required for the

isolated section of each channel, including the optical isolators, the DAC, and the output module.

4

Figure 4-4: Isolated Output Channel

2.5V

VOLTAGE

REFERENCE

+15V

P3

5V

10V

OUT

COMM

ISO

OUTPUT

MODULE

(OPTIONAL)

IN

OUTPUT ENABLE

BUFFER

12-BIT

SERIAL

D/A CONVERTER

IDTA

IGND

ICLK

ILD

VEXT

AGND

-15V

+15V

(VOLTAGE OPTION ONLY)

IGND

IENA

ISO BARRIER

+15V

+5VDC

IGND

-15V

DGND

DATA

CLOCK

LOAD

ENA OUT

IGND

GFK-2057 Chapter 4 Theory of Operation 4-9

Page 43

Chapter

5

Maintenance

This chapter provides information relative to the care and maintenance of the Analog Output Board

product.

If the product malfunctions, verify the following:

• Software

• System configuration

• Electrical connections

• Jumper or configuration settings

• Boards fully inserted into their proper connector location

• Connector pins are clean and free from contamination

• No components of adjacent boards are disturbed when inserting or removing the board

from the VMEbus card cage

• Quality of cables and I/O connections

User level repairs are not recommended. Contact GE Fanuc for a Return Material Authorization

(RMA) Number. This RMA Number must be obtained prior to any return.

GFK-2057 5-1

Loading...

Loading...