Page 1

K

-

4

-

7

-

000 A

December 2001

Programmable Contr ol Product s

GE Fanuc Automat ion

IC697VAL348

8-Channel, 16-bit Digital-to-Analog Converter Board

User’s Ma nual

GF

2059 51

00043

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in this

equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

GFL-002

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardwar e or software, nor to provide for every possible contingency in

connection with installation, ope ration, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to change s subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Master Genius PROMACRO Series Six

CIMPLICITY Helpmate PowerMotion Series Three

CIMPLICITY 90–ADS Logicmaster PowerTRAC VersaMax

CIMSTAR Modelmaster Series 90 VersaPro

Field Control Motion Mate Series Five VuMaster

GEnet ProLoop Series One Workmaster

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved

Page 3

Chapter 1 Introduction, Description, and Specifications .........................................1-1

Reference Material and Other GE Fanuc Manuals...................................................1-1

General Description .................................................................................................1-2

Functional Description.............................................................................................1-3

Functional Description.............................................................................................1-3

Safety Summary.......................................................................................................1-4

Chapter 2 Configuration and Installation..................................................................2-1

Physical Installation.................................................................................................2-2

Configuration...........................................................................................................2-3

Before Applying Power: Checklist ..........................................................................2-4

Board Address Selection Switches...........................................................................2-5

Address Modifier Response Selection.....................................................................2-7

Digital Code Selection.............................................................................................2-8

Program Controlled and External Start Convert Mode............................................2-9

Connector Descriptions..........................................................................................2-10

DAC Zero Offset and Gain Calibration .................................................................2-15

Contents

Chapter 3 Programming..............................................................................................3-1

Introduction to Programming the Digital-to-Analog Converter Board.................... 3-2

Digital-to-Analog Converter Board Programming Options.....................................3-3

Delayed DAC Update Mode.................................................................................... 3-6

Test Mode Programming..........................................................................................3-7

Program Example (Delayed DAC Update Mode)....................................................3-8

Chapter 4 Theory of Operation..................................................................................4-1

Operational Overview..............................................................................................4-2

Immediate DAC Update Mode ................................................................................4-3

Delayed DAC Update Mode.................................................................................... 4-4

VMEbus Interface Description.................................................................................4-6

Chapter 5

Maintenance................................................................................................5-1

GFK-2059 iii

Page 4

Chapter

Introduction, Description, and Specifications

1

This manual describes installation and operation of the IC697VAL348 8-Channel, 16-Bit Digitalto-Analog Converter (DAC) Board.

Reference Material and Other GE Fanuc Manuals

For a detailed explanation of the VMEbus and its characteristics, “The VMEbus Specification” is

available from:

VITA

VMEbus International Trade Association

7825 East Gelding Dr., No. 104

Scottsdale, AZ 85260

(480) 951-8866

FAX: (480) 951-0720

Internet: www.vita.com

The following Application and Configuration Guides are available from GE Fanuc to assist in the

selection, specification, and implementation of systems based upon GE Fanuc’s products:

Analog I/O Products (Built-in-Test)

Configuration Guide (catalog number

GFK-2084)

Provides assistance in configuring analog I/O

subsystems based on GE Fanuc’s analog I/O

products, including common designs, which offer a

wide variety of solutions.

GFK-2059 1-1

Page 5

1

General Description

The primary features of the Digital-to-Analog Converter Board are as follows:

16-Bit resolution

Buffered voltage output (±10 V @ 5 mA)

Double-buffered data latches

Eight channels

Eight 16-Bit DACs (one per channel)

Front panel Fail LED

High reliability DIN type output connector

Multiplexed programmable outputs

Jumper-selectable synchronized update control

Double Eurocard form factor

Selectable external update control input pro vides single update strobe for all

DAC outputs

Fast settling: 10 µs maximum to ±0.0003 percent of FSR

1-2 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 6

Functional Description

The Digital-to-Analog Converter Board delivers ±10 V outputs with positive true offset binary

input coding or two's complement coding. The Digital-to-Analog Converter Board features doublebuffered data latches, buffered voltage outputs, and selectable external or internal update control

strobes. A front panel Fail LED is provided for quick fault location.

1

GFK-2059 Chapter 1 Introduction, Description, and Specifications 1-3

Page 7

1

Safety Summary

The following general safety precautions must be observed during all phases of this

operation, service, and repair of this product. Failure to comply with these precautions or

with specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of this product. GE Fanuc assumes no liability for the

customer’s failure to comply with these requirements.

Ground the System

To minimize shock hazard, the chassis and system cabinet must be connected to an electrical

ground. A three-conductor AC power cable should be used. The power cable must either be

plugged into an approved three-contact electrical outlet or used with a three-contact to two-contact

adapter with the grounding wire (green) firmly connected to an electrical ground (safety ground) at

the power outlet.

Warning

Do Not Operate in an Explosive Atmosphere

Do not operate the system in the presence of flammable gases or fumes. Operation of any electrical

system in such an environment constitutes a definite safety hazard.

Keep Away from Live Circuits

Operating personnel must not remove product covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace components with

power cable connected. Under certain conditions, dangerous voltages may exist even with the

power cable removed. To avoid injuries, always disconnect power and discharge circuits before

touching them.

Do Not Service or Adjust Alone

Do not attempt internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

Do Not Substitute Parts or Modify System

Because of the danger of introducing additional hazards, do not install substitute parts or perform

any unauthorized modification to the product. Return the product to GE Fanuc for service and

repair to ensure that safety features are maintained.

1-4 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 8

Chapter

2

Configuration and Installation

This chapter contains configur ation and installation instructions for the Digital-to-Analog

Converter Board, and is divided into the following sections:

Physical Installation

Configuration

Before Apply Power: Checklist

Board Address Selection Switches

Address Modifier Response Selection

Digital Code Selection

Program Controlled and External Start Convert Mode

Connector Descriptions

Analog Output Accuracy

DAC Zero Offset and Gain Calibration

Caution

Some of the components assembled on GE Fanuc’s products may be

sensitive to electrostatic discharge and damage may occur on boards that are

subjected to a high energy electrostatic field. Unused boards should be

stored in the same protective boxes in which they were shipped. When the

board is to be placed on a bench for configuring, etc., it is suggested that

conductive material be inserted under the board to provide a conductive

shunt.

Upon receipt, any precautions found in the shipping container should be observed. All items should

be carefully unpacked and thoroughly inspected for damage that might have occurred during

shipment. The board(s) should be checked for broken components, damaged circuit board(s), heat

damage, and other visible contamination. All claims arising from shipping damage should be filed

with the carrier and a complet e report sent to GE Fanuc together with a request for advice about the

disposition of the damaged item(s).

GFK-2059 2-1

Page 9

2

Physical Installation

To install the board, de-energize the equipment and insert the board into an appropriate slot of the

chassis while ensuring that the board is properly aligned and oriented in the supporting card guides.

Slide the board smoothly forward against the mating connector until firmly seated. Review

“Configuration” on page 2-3 and “Before Applying Power: Checklist” on page 2-4 before operating

the board.

Caution

Do not install or remove boards while power is applied.

2-2 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 10

,

Configuration

This section of the manual describes the Digital-to-Analog Converter Board set-up procedure and

jumper configuration. The board select base address and board jumper configuration is factory

preset and shown in Table 2-1 below. The base address selection switches (S1 and S2) are factory

configured at XXXX0060 HEX.

Table 2-1: Digital-to-Analog Converter Board Factory Preset Configuration

Jumper Function Preset Condition

NOT

USED A07 A06 A05

2

S1

S2

JC

JA, JB

Base address selection switches

(A07, A06, A05)

Base address selection switches

(A15 to A08)

Determines address modifier

response of the board. Installed

jumper indicates response to short

nonprivileged I/O access.

Determines the digital code written

to the DAC. JB installed gives

two’s complement binary coding.

JA installed gives offset binary

coding.

A15

ON, CLOSED =0

OPEN = 1

OFF

NOT

A08

ON

OFF

JC

INSTALLED

JA

JB

Installation of this jumper enables

the program controlled start

JD

JE

GFK-2059 Chapter 2 Configuration and Installation 2-3

convert mode as detailed in

“Program Control Update Mode”

on page 4-4.

Installation of this jumper enables

the external start convert mode as

detailed in “External Trigger

Update Mode” on page 4-4.

Jumper JD must also be installed

to enable this mode.

JD

INSTALLED

JE

INSTALLED

NOT

NOT

Page 11

2

Before Applying Power: Checklist

Before installing the board in a VMEbus system go through the following checklist to verify that

the board is ready for the intended operation:

1. Have the chapters on Theory and Programming of the DAC board, Chapters 3 and 4, been

read and applied to system requirements?

2. Review Table 2-1 on page 2-3 to verify the factory installed jumpers and board address

switches are set to what is desired.

To change DAC board switches (S1 and S2) refer to “Board Address Selection Switches”

on page 2-5.

To change address modifier response jumper (JB) refer to “Address Modifier Response

Selection” on page 2-7.

3. To change the DAC digital code selection refer to “Digital Code Selection” on page 2-8.

4. To use either the program controlled start convert mode or the external start convert mode

refer to “Program Controlled and External Start Convert Mode” on page 2-9.

5. Has the cable, with proper mating connector, been connected to the analog output

connector (P3)? Refer to “Connector Descriptions” on page 2-10.

Digital-to-Analog Converter Board Installation

After steps 1 through 5 have been reviewed, the DAC board may be installed in a VMEbus system.

(Do not install or remove the board with power ON). The DAC board may generally be installed in

any slot position, except slot "one" which is usually reserved for the master processing unit.

2-4 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 12

B

Board Address Selection Switches

There are two address select DIP switches on-board the Digital-to-Analog Converter Board. Each

individual switch corresponds to an address bit, or is not used. If the switch is ON the

corresponding address bit is compared to a logic "zero". All corresponding address bits must

compare with the switch positions during a Write/Read of the DAC board. Each switch corresponds

to the address bits as shown in Figure 2-1 be low. For the board switch locations are shown in

Figure 2-2 on page 2-6.

Example: For the Digital-to-Analog Converter Board to respond to a base address of

(FXFFBC40

) the S1 and S2 switches would be set accordingly.

16

Figure 2-1. Address Selection Switches

C

16

2

16

0011

A08 A09 A10 A11 A12 A13 A14 A15

*

0000

2

1101

2

A05 A06 A07

4321

0010

2

NOT

USED

X

READ THIS DIRECTION

2

OFF, OPEN = 1

S2

ON, CLOSED = 087654321

OFF

S1

ON

READ THIS DIRECTION

04

16

*No switches on-board to represent bits A00 through A04. These bits are understood to

be "zeros".

GFK-2059 Chapter 2 Configuration and Installation 2-5

16

Page 13

2

CODE SELECTION

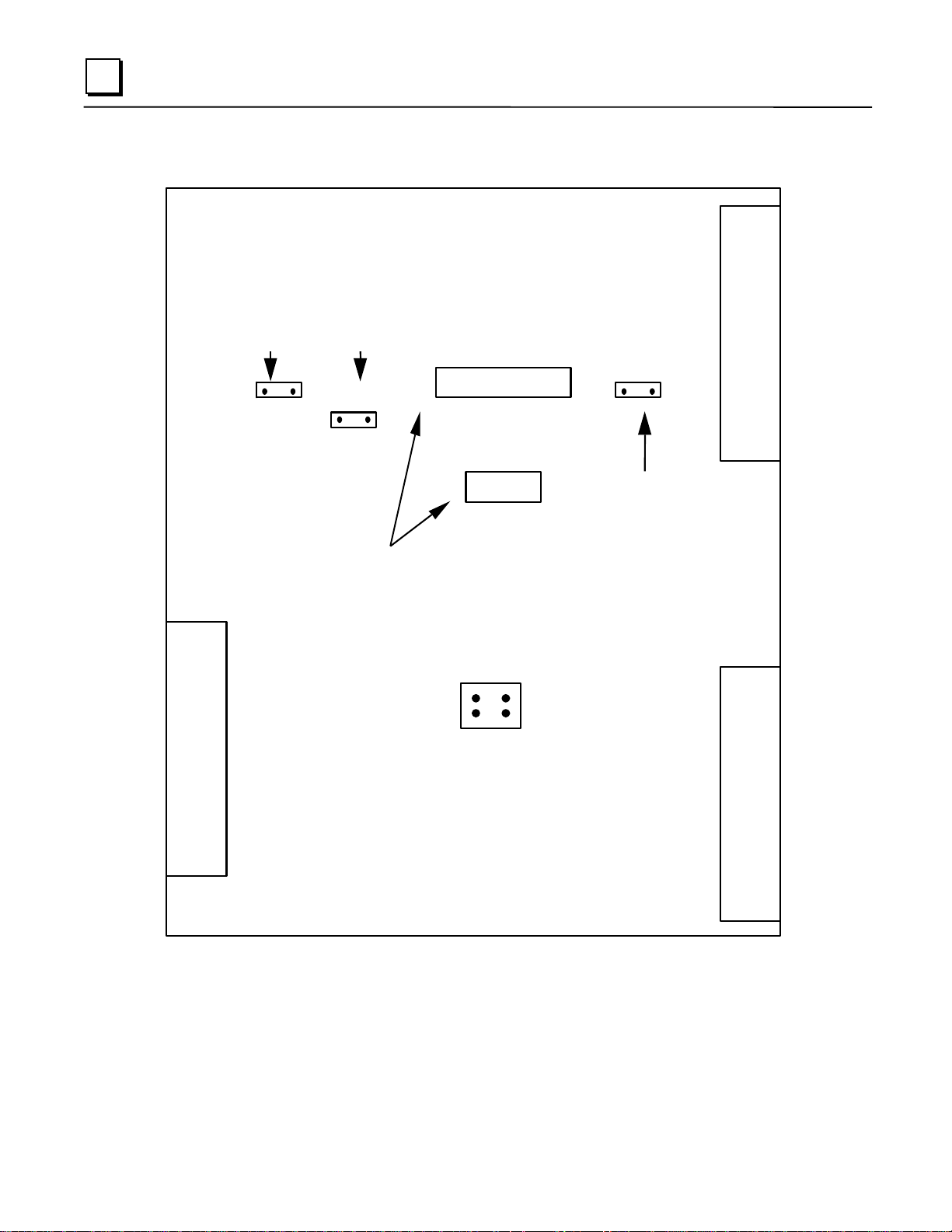

Figure 2-2: Jumper and Switch Locations on the Digital-to-Analog

Converter Board

MODE JUMPER

DAC UPDATE

JD

EXTERNAL

JE

TRIGGER JUMPER

S2

P1

JC

S1

P3

SWITCHES

BOARD BASE

ADDRESS SELECTION

JA

JUMPER

DAC BINARY

JB

ADDRESS MODIFIER

JUMPER

P2

COMPONENT SIDE SHOWN

2-6 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 14

Address Modifier Response Selection

The DAC board is memory mapped in the short I/O address space as described in Chapter 3. The

DAC board will respond to either of the two address modi fier codes that may be issued to the DAC

board by a CPU board during a Write or Read cycle. The DAC board is factory set to respond to

supervisory short I/O access. To select short nonprivileged I/O access, and install the jumper at

jumper location (JC).

2

GFK-2059 Chapter 2 Configuration and Installation 2-7

Page 15

2

Digital Code Selection

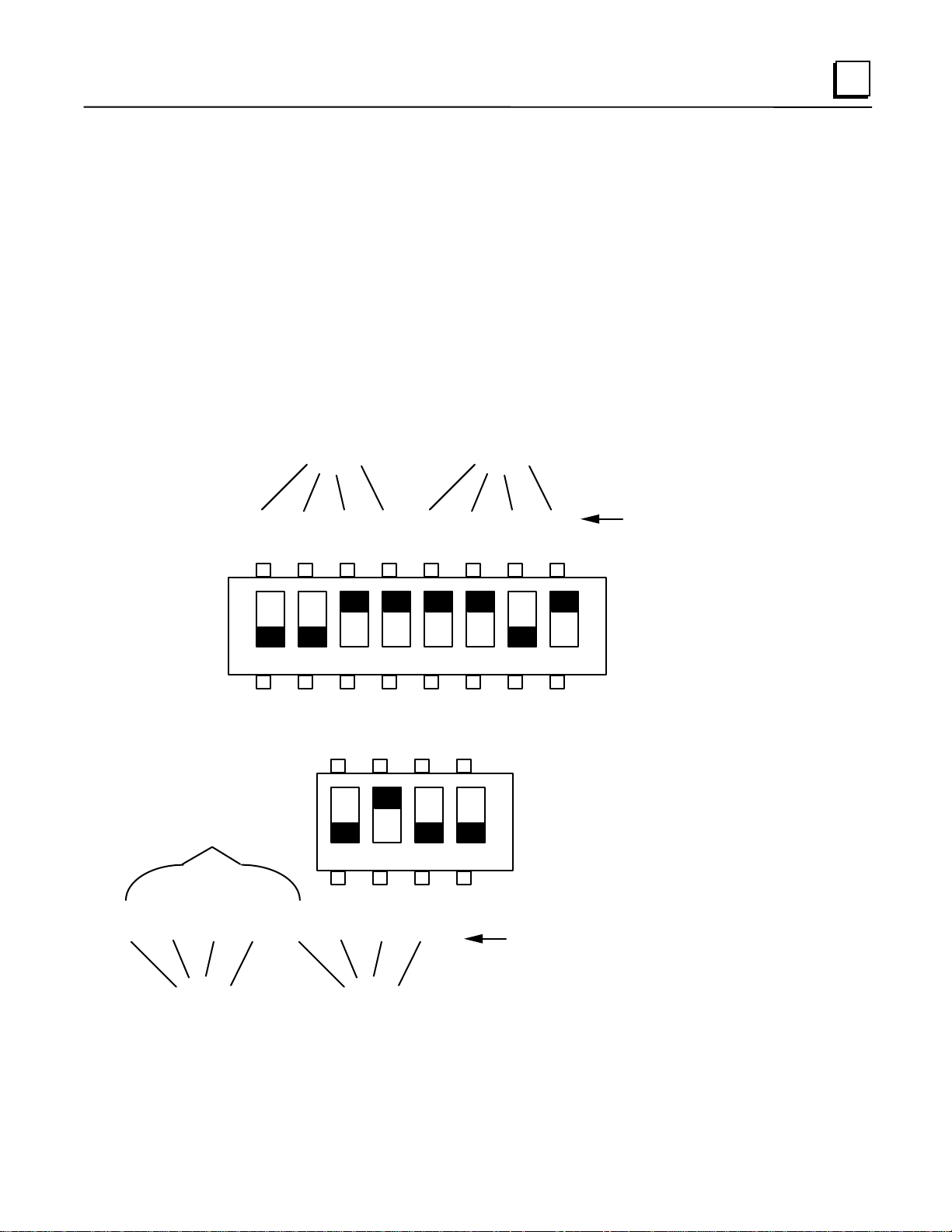

The DAC board is factory configured for offset binary coding. To change the DAC input coding to

two’s complement binary, remove jumper JA and install jumper JB (see Figure 2-3 below).

Figure 2-3: Digital Code Selection

JA

JB

(TWO’S COMPLEMENT CODE)(OFFSET BINARY)

2-8 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 16

Program Controlled and External Start Convert Mode

The PROGRAM CONTROLLED START CONVERT MODE is enabled by inserting jumper JD.

This mode is detailed in “Program Control Update Mode” on page 4-4 and “Delayed DAC Update

Mode” on page 3-6. With no jumper installed at JD, the board operates in the IMMEDIATE DAC

UPDATE MODE as described in “Immediate DAC Update Mode” on page 4-3 and “Immediate

DAC Update Mode” on page 3-3.

Installing jumper JE enables the EXTERNAL START CONVERT MODE. Jumper JD must also

be installed (refer to “External Trigger Update Mode” on page 4-4). The external trigger is buffered

in through the P2 connector pin A25 with an associated digital ground wire at pin A26. The

locations of jumpers JD and JE are shown in Figure 2-2 on page 2-6.

2

GFK-2059 Chapter 2 Configuration and Installation 2-9

Page 17

2

Connector Descriptions

Two 96-pin DIN type connectors, P1 and P2, connect the DAC board to the VMEbus backplane.

The primary connector, P1, contains the address d a ta and control lines and all additional signals

necessary to control data transfer and other bus functions. See Figure 2-4 on page 2-11 and Table

2-2 on page 2-12 for the P2 connector signal assignments.

The P3 connector is a Panduit 32-pin male connector type, number 120-332-033A. The matching

Panduit connector for the input cable is a female connector type, number 120-332-435E. This

connector handles the 16 analog outputs, each with an associated analog ground wire. See Figure 25 on page 2-13 and Table 2-3 on page 2-14 for P3 connector assignment.

2-10 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 18

PC BOARD

2

Figure 2-4: P2 Connector – Pin Assignments

ROW

C B A

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

PIN 10

PIN 11

PIN 12

PIN 13

PIN 14

PIN 15

PIN 16

PIN 17

PIN 18

PIN 19

PIN 20

PIN 21

PIN 22

PIN 23

PIN 24

PIN 25

PIN 26

PIN 27

PIN 28

PIN 29

PIN 30

PIN 31

PIN 32

REAR VIEW

GFK-2059 Chapter 2 Configuration and Installation 2-11

Page 19

2

Table 2-2: P2 Connector

Pin Number

1 ANA COM +5V

2 ANA COM GND

3 ANA COM

4 ANA COM

5 ANA COM

6 ANA COM

7 AINTESTBS

8 ANA COM

9

10 ANA COM

11

12 ANA COM GND

13 +5V

14 ANA COM

15 GND SEN

16 ANA COM

17

18 ANA COM

19

20 ANA COM

21

22 ANA COM GND

23 ANA COM

24 ANA COM

25 EXTSCL

26 GND

27

28

29

30

31 GND

32 +5V

Row A

Signal Mnemonic

Row B

Signal Mnemonic

Row C

Signal Mnemonic

2-12 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 20

"PC Board"

2

Figure 2-5: P3 Connector – Pin Assignments

ROW

A C*

PIN 16

PIN 15

PIN 14

PIN 13

PIN 12

PIN 11

PIN 10

PIN 9

PIN 8

PIN 7

PIN 6

PIN 5

PIN 4

PIN 3

PIN 2

FRONT VIEW

OF "P3"

CONNECTOR

PIN 1

*Row C pins are all analog common

GFK-2059 Chapter 2 Configuration and Installation 2-13

Page 21

2

Table 2-3: P3 Connector

Pin Number

1 ANA COM ANA COM

2 AN00 ANA COM

3 AN01 ANA COM

4 AN02 ANA COM

5 AN03 ANA COM

6 AN04 ANA COM

7 AN05 ANA COM

8 AN06

9 AN07

10

11

12

13

14

15

16

Row A

Signal Mnemonic

Row B

Signal Mnemonic

Row C

Signal Mnemonic

2-14 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 22

DAC Zero Offset and Gain Calibration

Note

This procedure assumes that the offset binary coding jumper (JA) is

selected.

1. Remove power from the Digital-to-Analog Converter Board.

2. Remove any cable connected to the P3 connector.

3. Remove the Digital-to-Analo g Converter Board from the chassis assembly and install a

VMEbus Extender board in its place.

4. Install the Digital-to-Analog Converter Board onto the VMEbus Extender board.

5. Apply power to the module and allow 15 minutes for Temperature Stabilization before

making any measurements.

6. Using the IMMEDIATE UPDATE MODE write digital code 4100 HEX to the CSR

location XXXX0070. This HEX code is the Control Word for output to the Digital-to-

Analog Converter Board’s P3 connector.

2

7. Write 8000 HEX to each of the eight DAC channels at addresses XXXX0060 through

XXXX006E.

8. Using a 6-digit multimeter, monitor each DAC output at the P3 connector. Connect the

negative lead to connector P3 pin C2. Adjust each DAC's offset potentiometer for a

voltage of 0.0000 ±60 µ V. Refer to Table 2-4 below and Figure 2-6 on page 2-16 for the

Potentiometer Location and P3 connector pin for each channel.

Table 2-4. Digital-to-Analog Converter Board Calibration Table

Channel Offest Pot Gain Pot P3 Connector

1 R23 R21 A2

2 R19 R17 A3

3 R31 R29 A4

4 R27 R25 A5

5 R3 R1 A6

6 R7 R5 A7

7 R15 R13 A8

8 R11 R9 A9

9. Repeat Step 7 using digital code FFFF HEX.

10. Using the multimeter, monitor each DAC output at t he P3 connector. Connect the negative

lead to connector P3 pin C2. Adjust each DAC's gain potentiometer for a voltage of

9.99969 ±60 µV. Refer to Table 2-4 above and Figure 2-6 on page 2-16 for the

Potentiometer Location and P3 connector pin for each channel.

11. Remove extender and re-install board into the chassis. Calibration completed.

GFK-2059 Chapter 2 Configuration and Installation 2-15

Page 23

2

Figure 2-6: Calibration Adjustment Locations

P1

16

R29

R17 R25

P3

R11 R19 R27

R1 R9

1

R3

R21

R13

R5

P2

R15 R23 R31

R7

COMPONENT SIDE

2-16 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 24

Chapter

3

Programming

This chapter co ntains programming instructions for the Digital-to-Analog Converte r Board, and is

divided into the following sections:

Introduction to Programming the Digital-to-Analo g Converter Board

Digital-to-Analog Converter Board Progra mming Optio ns

Delayed DAC Update Mode

Test Mode Programming

Program Example (Delayed DAC Update Mode)

GFK-2059 3-1

Page 25

3

Introduction to Programming the Digital-to-Analog Converter Board

The Digital-to-Analog Converter Board is memory mapped in the short I/O address space. The

board occupies 16 successive word locations in the VME short I/O address space of 65,535 bytes.

Only the first nine word locations are actually used by the board. The short I/O space is located

from XXXX0000 HEX to XXXXFFFF HEX. The address bits A31 to A16 are CPU dependent.

Each Read cycle may be either a word or byte transfer. The board base address may be selected by

DIP switches as shown in “Board Address Selection Switches” on page 2-5. Tables 3-1 and 3-2

below represent the DAC address map assuming the factory set base address of XXXX0060 HEX.

Table 3-1:Control and Status Register

Control and Status Register (CSR) (Read/Write) Address $XXXX0070

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

Control and Status Register (CSR) (Read/Write) Address $XXXX0070

D07 D06 D05 D04 D03 D02 D01 D00

Control and Status Bits

Not Used

Table 3-2: DAC Channels Address Map

DAC Channels (0 to 7) Address (Write Only)

Address D15 (MSB) D00 (LSB)

XXXX0060 DAC OUT 0

XXXX0062 DAC OUT 1

XXXX0064 DAC OUT 2

XXXX0066 DAC OUT 3

XXXX0068 DAC OUT 4

XXXX006A DAC OUT 5

XXXX006C DAC OUT 6

XXXX006E DAC OUT 7

Note

Jumper JC determines whether the board operates in Short Supervisory I/O

Access or Short NonPrivileged I/O Access. With the jumper installed Short

NonPrivileged I/O Access is selected.

Tables 3-1 and 3-2 above shows addressing information for 16-bit word transfers. Data may be

transferred to the DACs in 8-bit format. When using byte format, the low byte is always transferred

first then the high byte next. For example, assuming a board base address of XXXX0000 HEX, a

low byte transfer (D7 to D0) to Channel 0 is written to address XXXX0001 HEX. The high byte of

data (D15 to D8) is then written to address XXXX0000 HEX.

3-2 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 26

Digital-to-Analog Converter Board Programming Options

There are two types of registers that must be written to for prop er operation of the DAC board. One

is the CSR, and the other is the DAC. The order in which they are written to may differ depending

on the method used to start a conversion.

Immediate DAC Update Mode

The IMMEDIATE DAC UPDATE MODE is described in “Program Control Update Mode” on

page 4-4 and the board is configured for this mode when received from the factory. Once this has

been set up, a 16-bit word can be written to any DAC channel where it will begin immediate analog

conversion. When byte transfer (8-bit) is used to load the DAC channel, conversion begi ns

immediately upon the loading of the high byte (D15 to D8).

All eight DAC channels can be initiated to a value, as described in the preceding paragraph, before

they are connected to the external circuitry. After powering up the board, load the DAC channels

with the initial 16-bit word (or two 8-bit bytes) required (positive true offset binary or binary two's

complement coding, Table 3-3 below). A control word can then be written to the CSR to enable the

DAC outputs to the P3 connecto r . The CSR bit description for this mode of operation is detailed in

Table 3-4 on page 3-4 and Table 3-5 on page 3-5.

3

Table 3-3. DAC Data Format Analog Output versu s Digital Input (±10 V Scale)

Offset Binary Coding

Digital Input Code

(MSB)

D15

0000 0000 0000 0000 -10.000V -Full Scale 1000 0000 0000 0000

0100 0000 0000 0000 -5.000V -1/2 Scale 1100 0000 0000 0000

1000 0000 0000 0000 0.000V Zero 0000 0000 0000 0000

1000 0000 0000 0001

1100 0000 0000 0000 +5.000V +1/2 Scale 0100 0000 0000 0000

1111 1111 1111 1111 9.99969V +Full Scale 0111 1111 1111 1111

The analog output may be calculated by the input code written by the processor to the selected

DAC channel as follows:

(LSB)

D0

Analog Output = -10 V +

Analog Output Voltage Two’s Complement

305µV

+LSB 0000 0000 0000 0001

([(Digital Input Code in decimal) X 20] /65536)

GFK-2059 Chapter 3 Programming 3-3

Page 27

3

Example: The analog output for a digital input of 0A00H would be:

1. 0A00H decimal equivalent is 2560

2. Analog out = -10 V +

((2560) __20__)

65,536

= -9.21875

Table 3-4. Control Register Data Format and Definitions

Control and Status Register

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

Control and Status Register

D07 D06 D05 D04 D03 D02 D01 D00

Not Used

Bit D15: Not used.

Bit D14: A low state turns the Fail LED ON. A high state turns the Fail LED OFF.

At power-up this control bit is low.

Bit D13: A high state enables the selected analog output to pass out the P2 connector

on test bus 2 (AOTESTBS). At power-up this control bit is low.

Bit D12: A high state enables the selected analog output to pass out the P2 connector

on test bus 1 (AINTESTBS). At power-up this control bit is low.

Bit D11

(1)

: When written high, it engages one analog output from the DAC to one of

two test buses. Used in conjunction with D12 and D13 to determine which

test bus is selected. At power-up this control b it is low which disengages

the test buses.

Not

Used

Bit D10: Not used.

Bit D09: Program Control Start Convert. When set to a "one", it generates a signal

that transfers contents of previously loaded DACs to the second rank

register and updates the analog output.

Bit D08: Don’t care

Bits 07 through 00: Not used.

(1) Channel selection for muxing one of the outputs to either test bus is achieved by writing the

CSR data to the data address + 10H. See “T est Mode Programming” on page 3-7 for additional

information.

3-4 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 28

3

Table 3-5: Programming the Control and Status Register for Different Analog Output Variations – Bit

Definitions

Analog Output Over TEST BUS 1 (AINTESTBS)

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

1 0 1 1

Analog Output Over TEST BUS 2 (AINTESTBS)

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

1 1 0 1

Analog Output Over TEST BUS 1 and Over P3 Connector to Field-co nnected

Device (Used for Real-time Fault Detection of DACs)

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

1 1 0 1

Analog Output Over P3 Connector Only

D15 D14 D13 D12 D11 D10 D09 D08

Not

Used

1 0 0 0

Not

Used

Not

Used

Not

Used

Not

Used

0 or 1 0

0 or 1 0

0 or 1 1

0 or 1 1

GFK-2059 Chapter 3 Programming 3-5

Page 29

3

Delayed DAC Update Mode

The DELAYED DAC UPDATE MODE operation is described in “Delayed DAC Update Mode”

on page 4-4. This mode must have previously been enabled by the jumper configuration in

“Program Controlled and External Start Convert Mode” on page 2-9. There are two ways for a

DAC channel to be updated after the 16-bit word is loaded into the DAC's first register. The first

way is under program control when data bit D9 is written high to the CS R. It should be noted that

when setting D9 to initiate t he DAC update that control bits D8, and D11 through D14 should be

set or reset according to where the user wants the converted output to be routed, (refer to Table 3-4

on page 3-4 and Table 3-5 on page 3-5). Also, a previously loaded DAC may be updated by an

external trigger input from another device. A programming example of the DELAYED DAC

UPDATE MODE is detailed in “Program Example (Delayed DAC Update Mode)” on page 3-9.

3-6 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 30

Test Mode Programming

Any of the eight DAC outputs may be selected to pass to an ADC board over test bus 2 to verify

the DAC outputs. If a MUX is present in the analog backplane then any DAC output can be

selected to go to that board for test purposes over test bus 1. Generally the programming sequence

for utilizing one of the two test buses is as follows:

If IMMEDIATE DAC UPDATE MODE is employed, then a Control Word should first be written

to the CSR. This Control Wo rd information includes which test bus the DAC output is to be routed

to, and whether the output is to be isolated or connected to the P3 connector (refer to Table 3-4 on

page 3-4 and Table 3-5 on page 3-5). The DAC to be updated is then loaded with a 16-bit word.

The channel is updated and passes out the selected test bus.

An output may also be updated under program control to route to a specified test bus. The board

must have previously been jumpered to accommodate the DELAYED DAC UPDATE MODE as

shown in “Program Controlled and External Start Convert Mode” on page 2-9. The programming

sequence is as follows:

First, a 16-bit word or two 8-bit bytes are written to the add ress of the DAC channel that is to b e

updated. The data is stored in the DAC Register and will be converted by setting the proper bits in

a Write cycle to the CSR. The CSR must be written to at the same address as that of the DAC

channel that has previously been loaded plus 10 HEX. For example, if the user wanted to convert

Channel no. 2 which was written to address XXXX0062 HEX, then the Control Word would be

written to address XXXX0072 HEX (XXXX0062 and 10 HEX). Data bit D09 when written as

"one" to the CSR initiates the analo g conversion of the previously stored 16-bit word.

3

The test modes can only be used if an ADC board exists in the same GE Fanuc analog (P2)

backplane as the Digital-to-Analog Converter Board.

GFK-2059 Chapter 3 Programming 3-7

Page 31

3

Program Example (Delayed DAC Update Mode)

In the programming example in “Test Mode Programming” on page 3-7, all eight DAC converters

were loaded with a full scale value of FFFH in the IMMEDIATE UPDATE MODE. For illustration

purposes the same result will be obtained by this programming example by using the DELAYED

DAC UPDATE MODE. The DELAYED DAC MODE is jumper-selectable as described in

“Program Controlled and External Start Convert Mode” on page 2-9.

The programming sequence in a flowchart is shown in Figure 3-2 on page 3-12. In the following

program example all eight DAC channels are loaded with new data, and then updated under

program control. Alternatively, if previously enabled, an external trigger input could have initiated

the DAC conversion process.

3-8 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 32

CONTROL

REGISTER

ALL 8 D/A

CHANNEL

END

3

Figure 3-1: DAC Programming Sequence (Immediate DADC Start Convert Mode)

-

INITIALIZATION)

-

LOAD D/A

INITIALIZE

D/A ADDRESS

POINTER

LOAD

HAVE

GFK-2059 Chapter 3 Programming 3-9

BEEN

?

YES

NO

Page 33

3

Table 3-6: Analog Output Control in Immediate DAC Update Mode

Analog Out Pathway Control Word (D15 to D0) Hex Value

P3 Connector 4100

AOTESTBS (TEST BUS 2) 6C00

AINTESTBS (TEST BUS 1) 5C00

AOTESTBS and P3 Connector 6D00

3-10 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 34

(ON-BOARD

INITIALIZE

POINTER

CHANNEL

UPDATED

END

CONTROL

REGISTER

3

Figure 3-2: DAC Programming Sequence (Delayed DAC Update Mode)

POWER-UP

LOAD

BEEN

LOAD D/A

YES

NO

GFK-2059 Chapter 3 Programming 3-11

Page 35

3

Table 3-7: Analog Output Control in Delayed DAC Update Mode

Analog Out Pathway Control Word (D15 to D0) Hex Value

P3 Connector 4300

AOTESTBS (TEST BUS 2) 6E00

AINTESTBS (TEST BUS 1) 5E00

AOTESTBS and P3 Connector 6F00

3-12 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 36

Chapter

4

Theory of Operation

This chapter discusses the operatio n of the Digital-to-Analog Converter Board, and is divided into

the following sections:

Operational Overview

Immediate DAC Update Mode

Delayed DAC Update Mode

VMEbus Interface Description

GFK-2059 4-1

Page 37

4

Operational Overview

The Digital-to-Analog Converter B oard performs digital-to-analog conversion on 16-bit positive

true offset binary or two’s complement coded words, with an analog output range of -10 to +10 V.

This provides for a resolution of 305 µV for each digital input of 1 LSB change. The buffered

output voltage settles to wit hin 1/2 LSB in 10 µs.

The DAC offers a Digital-to-Analog I ntegrated Circuit (IC) per channel. A Control and St atus

Register (CSR) is loaded by the processor and this register controls the functioning of the board.

The processor can read the CSR at any time. The DAC board functional block diagram is shown in

Figure 4-1 on page 4-5. Double-buffered data latches precede each of the eight DACs. The data

latches allow versatility in the way that the DAC analog output may be upd a ted.

There are three methods by which new data can be converted by a DAC.

Each method is enabled/disabled by on-board jumpers and is further controlled by a CSR that must

be loaded by the user (the CSR contents are described in Tables 3-1 and 3-2 on page 3-2, Table 3-4

on page 3-4, and Table 3-5 on page 3-5).

4-2 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 38

Immediate DAC Update Mode

The processor unit sends the 16-bit word to be converted to the first register of the selected DAC. If

that DAC channel has previously been jumpered to, it will automatically pa ss the contents of the

first DAC register into the second register and update the analog output. There is one jumper that

enables/disables all eight DAC channe ls to be in the IMMEDIATE UPDATE MODE as described

above, or in the DELAYED UPDATE MODE. Jumper definition and locations are describ ed in

“Program Controlled and External Start Convert Mode” on page 2-9.

4

GFK-2059 Chapter 4 Theory of Operation 4-3

Page 39

4

Delayed DAC Update Mode

In the DELAYED DAC UPDATE MODE, the processor sends the 16-bit word to be converted to

the first DAC register of the selected DAC. The data is stored there and transferred to the second

DAC register in one of two possible methods, described below.

Program Control Update Mode

One way for the transfer to occur is by writing a "one" to the Control Register bit D09. When the

data is transferred to the second register, digital-to-analog conversion begins and the analog output

settles to within 1/2 LSB in 10 µs. This method of updating the analog output is useful when more

than one DAC channel output is desired to change at a precise time. All eight DAC outputs could

be synchronized to change at certain periodic intervals under software control.

External Trigger Update Mode

The second method to update the second storage register and the DAC output by an external TTL

compatible trigger. This trigger must first have t he external trigger circuitry enabled by installing

an on-board jumper as described in “Program Controlled and External Start Convert Mode” on

page 2-9. The PROGRAM CONTROL UPDATE MODE must also be enabled (refer to “Program

Controlled and External Start Convert Mode” on page 2-9). When the external trigger is received

(active low for a minimum of 150 ns), the value stored in the first DAC register will be transferred

to the second DAC register and begins a conversion. Using this method of updating, all

conversions can be synchronized to an external d evice.

Each of the DAC outputs may be multiplexed one at a time via the test MUX shown in Figure 4-3

on page 4-8. First, a control word must be written to t he CS R to establish whether the analog output

is to be connected or disconnected from the P3 connector and which one of two test buses the

output is to be routed to. The DAC channel to b e tested has test data written to it in the

IMMEDIATE UPDATE MODE. Address bits A01 through A04 are automatically latched into the

Address Register when the board is written to. The outputs of this Add ress Register select the DAC

channel that has just been upd a ted via the test MUX. Test control infor mation previously latched in

the CSRs passes the DAC output through the analog test switch to the test bus 2. Test bus 2 is

routed via the analog backplane (AMXbus™) to the input of the ADC board where it is available

for analog-to-digital conversion. When the ADC completes its conversion, it se nds an end-ofconvert signal down the P2 backplane to the DAC. This signal removes either of the two test bus

outputs from the analog backplane. Along with the test bus 2 signal being sent to the ADC board

the analog ground (GND SEN) is switched out to the ADC board. This provides an input to the

ADC board, which is similar to a differential si gnal and is called pseudo-differential. Pseudodifferential solves some of the associated common mode error problems with single-ended signals.

The input to the ADC board is referenced to the grou nd of the DAC board instead of the local

ground at the ADC board, effectively canceling out common mode errors associated with different

ground potentials at each of the boards.

4-4 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 40

CH 1

CH 2

CH 3

CH 4

DR SELECT

(

)

(

)

4

Figure 4-1: Digital-to-Analog Converter Board Functional Block Diagram

V

C

L

M

E

b

u

s

O

O

M

G

P

I

A

C

T

I

B

I

L

I

T

Y

PROGRAM

CONTROL UPDATE

16-BIT

DAC

NO. 1

DAC

SEL

16-BIT

DAC

NO. 2

DAC

SEL

16-BIT

DAC

NO. 3

DAC

SEL

16-BIT

DAC

NO. 4

DAC

SEL

DATA BUS

ADDRESS

REGISTER

OPERATION

AND CONTROL

LOGIC

8

CH 1

CH 8

EXTERNAL

UPDATE

16-BIT

DAC

NO. 5

16-BIT

DAC

NO. 6

16-BIT

DAC

NO. 7

16-BIT

DAC

NO. 8

DAC

SEL

ANALOG

OUT

ISOLATION

SWITCHES

DAC

SEL

DAC

SEL

DAC

SEL

CH 5

CH 6

CH 7

CH 8

P3

CH 1

CH 8

CSR

AOUT AD

SELECT AIN

TEST

SELECT A0

TEST

CH 8 CH 1

4

TEST

MODE

SAIT

SA0T

8-CHANNEL

MUX

DUAL

SPDT

SWITCH

A0 TEST

P2

A0IN TEST

A0 TEST

GFK-2059 Chapter 4 Theory of Operation 4-5

Page 41

4

VMEbus Interface Description

The VMEbus interface (Figure 4-4 on page 4-9) contains the necessary logic to interface a DAC

board to the VMEbus. The DAC is memory mapped in the VMEbus short I/O address space.

During a Write cycle to the board, address bits A05 through A15 are compared with the previously

selected board address. DIP switches select the board address. If the address compares, then a

board select signal is issued. This signal along with the control signals received at the board, gate

the data (D0 to D15) to a selected DAC or the CSR on the DAC. Address bits A01 through A03

select one of the eight DAC channels. Data D0 through D15 is latched into the selected DAC

Register. Address bit A04 is used to select the CSR.

The DAC circuitry requires +5 V, +15 V, and -15 V, the +5 V is supplied to the board via the P1

and P2 connectors. An on-board DC-to-DC converter generates the +15 V and -15 V for the analog

circuitry (refer to Figure 4-5 on page 4-11). Thus, the DAC board only needs +5 V from the chassis

power supply.

4-6 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

Page 42

GFK-2059 Chapter 4 Theory of Operation 4-7

REGISTER

A01

A02

A03

A04

ADDRESS

REGISTER

D/A CHANNEL SELECT

3

1

TEST

CLOCK

TEST BUS 1

DA

OUTPUTS

1 TO 8

TEST

MUX

MUX

OUT

1

ANALOG

TEST

SWITCH

TEST

CONTROL

3

TEST BUS 2

GND SEN

P2

Figure 4-2: Test Bus Logic

4

Page 43

4

VMEbus

CONNECTION (P1)

Figure 4-3: VMEbus Interface Logic and Interface Signals

21

A15 to A05

AM5 to AM0

A4 to A01

16

D15 to D0

1

DTACK

5

ADDRESS AND

ADDRESS

MODIFIER

COMPARATOR

TRANSCEIVER

TRANSCEIVER

BOARD

DATA

DATA

BOARD SELECT

1

D/A ADDRESS

D/A CONTROL

TO D/As

16

4

D/A

CHANNEL

4

ADDRESS

AND

CONTROL

REGISTER

INTERNAL DATA BUS

3

7

DTACK

GENERATOR

3

8

P2 CONNECTION

EXTERNAL

DA TRIGGER

4-8 IC697VAL348 8-Channel, 16-bit Digital-to-Analog Converter Board User’s Manual GFK-2059

– December 2001

TEST BUS NO. 1

TEST BUS NO. 2

GND SEN

1

EXTERNAL D/A TRIGGER

TO D/As

Page 44

P1

+15 V

4

Figure 4-4: Digital-to-Analog Converter Board Power

DIG GND

P2

+5 V

GND

GND

+5 V

DC-TO-DC

CONVERTER

+5 V

ANA

CO

GND

-15 V

DC-TO-DC

CONVERTER

+5 V

GND

ANA

CO

+5 V

-15 V

ANA COM

+15 V

GFK-2059 Chapter 4 Theory of Operation 4-9

Page 45

Chapter

5

Maintenance

This chapter provides information relative to the care and maintenance of the Digital-to-Analog

Converter Board.

If the product malfunctions, verify the following:

• Software

• System configuration

• Electrical connections

• Jumper or configuration optio ns

• Boards fully inserted into their proper connector location

• Connector pins are clean and free from contamination

• No components of adjacent boards are disturbed when inserting or removing the board

from the VMEbus card cage

• Quality of cables and I/O connections

User level repairs are not recommended. Contact GE Fanuc for a Return Material Authorization

(RMA) Number. This RMA Number must be obtained prior to any return.

GFK-2059 5-1

Loading...

Loading...