Page 1

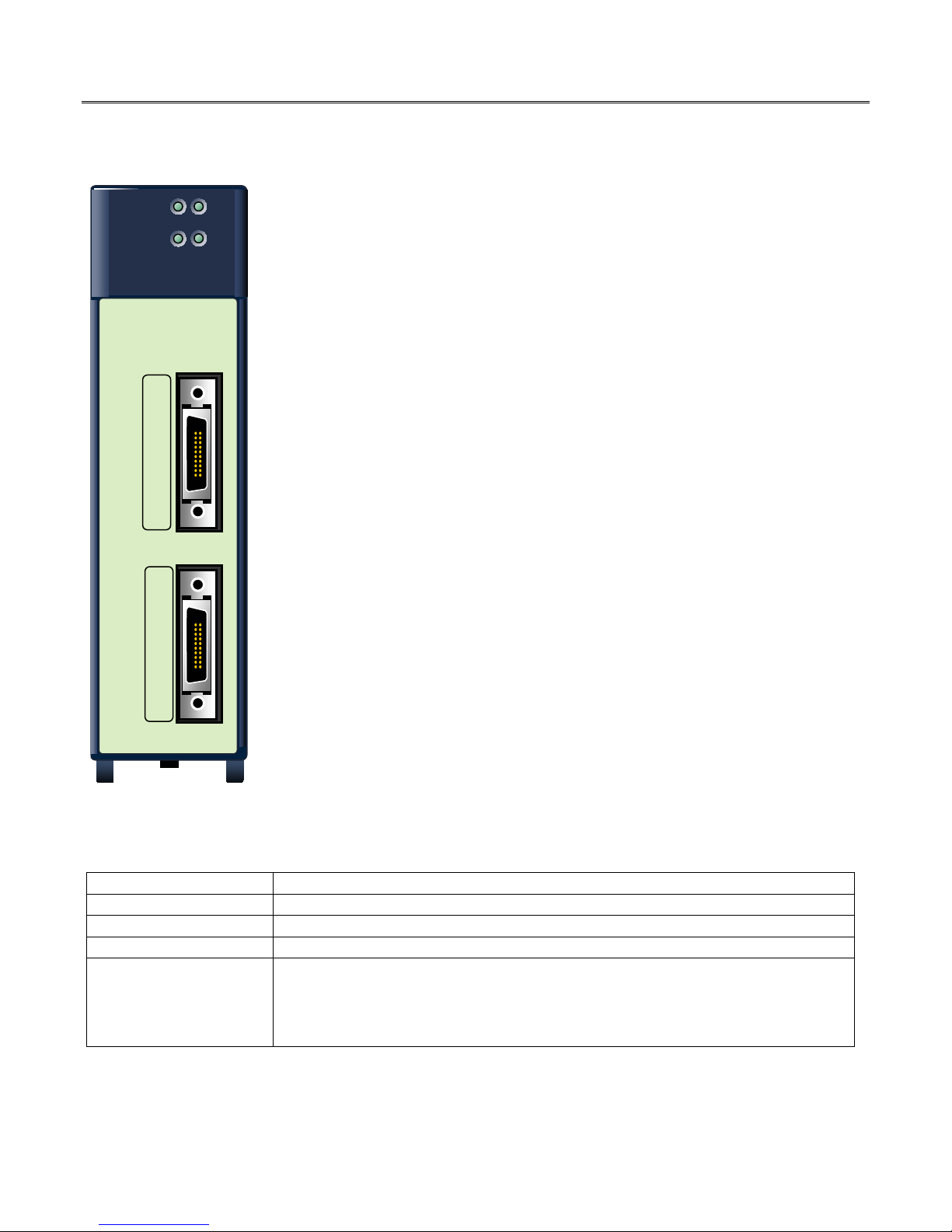

PACSystems* RX3i

RUN

PSM001

GRID 2

GRID 1

FLT

GRID 1

2

CAL

CAL

Module Offset: -2

Module Gain: 4000H

Module Offset: -2

Module Gain: 4000H

IC694PSM001

Replacement PSM module

IC694ACC200

Replacement Terminal Assembly

IC694CBL200

One replacement 2m (6.56 ft.) interface cable

two grounding lug nuts

GFK-2748C Power Sync and Measurement System

May 2014 IC694PSM001-AB and IC694ACC200-A

The PACSystems Power Sync and Measurement (PSM) system monitors two independent

three-phase power grids. It incorporates advanced digital signal processor (DSP) technology

to continuously pr ocess three voltage inputs and four current inputs for each grid.

Measurements include RMS voltages, RMS currents, RMS power, frequency, and phase

relationship between the phase voltages of both grids.

The PSM module performs calculations on each captured waveform, with the DSP

processing the data in less than two-thirds of a power line cycle. The PSM module can be

used with wye or delta type three-phase power systems or with single-phase power systems.

The PSM system can be used for applications such as:

Electrical power consumption monitoring and reporting

Fault monitoring

Generator control features for generator to power grid synchronization

Demand penalty cost reduction/load shedding

The PSM system consi st s of:

PSM module – A standard IC694 module that mounts in an RX3i rack. The PSM

module provides the DSP capability.

Terminal Assembly – A panel-mounted unit that provides the interface between the

PSM module and the input transformers.

Interface cables – Provide the GRID 1 and GRID 2 connections between the PSM

module and the Terminal Assembly.

PSM System Features

Uses standard, user-supplied current transformers (CTs) and potential transformers

(PTs) as its input devices.

Accurately measures RMS voltage and current, power, power factor, frequency,

energy, and total three-phase 15-minute power demand.

Provides two isolated relays that close when the voltage phase relationships between

the two monitored grids are within the specified ANSI 25 limits provided by the RX3i

host controller. These contacts can be used for general-purpose, lamp duty or pilot

duty loads. Voltage and current ratings for these load types are provided in GFK-2749,

PACSystems RX3i Power Sync and Measurement System User’s Manual.

Provides a cable monitoring function that indicates when the cables linking the PSM

module and Terminal Assembly are correctly installed.

PSM module and Terminal Assembly are easily calibrated by hardware configuration

using the Proficy* Machine Edition (PME) software.

Ordering Information

IC694PSK001 PSM System. Includes a PSM module, a Terminal Assembly and two interface cables

IC694ACC201 PSM replacement parts:

two finger guards

four thumb screws

one relay connector

____________________________

© 2014 General Electric Company. All Rights Reserved.

*

Indicates a trademark of General Electric Company and/or its subsidiaries. All other trademarks are the property of their

respective owners.

Page 2

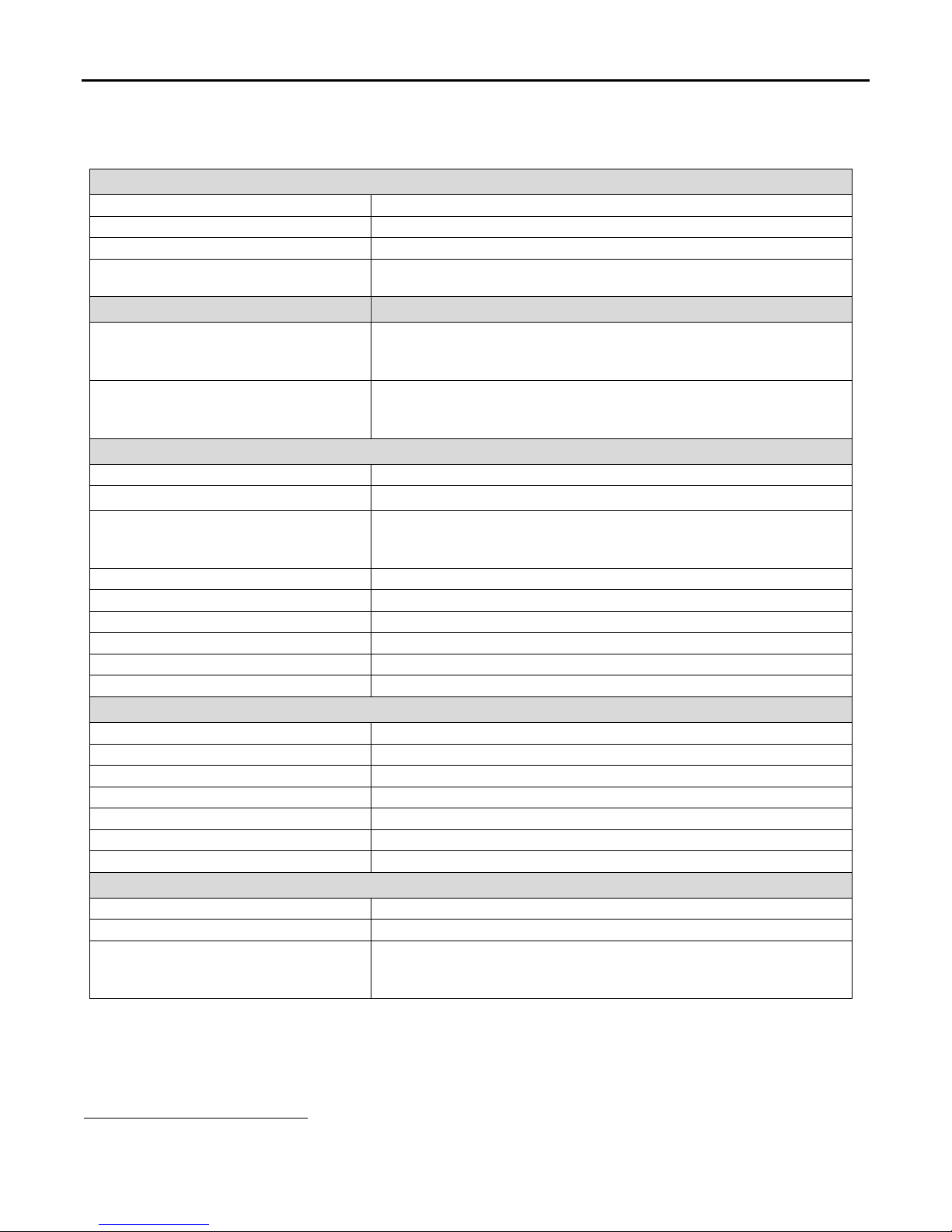

2 RX3i Power Sync and Measurement System

Backplane Power Consumption

400 mA max. at 5 VDC

Total Power Dissipation

2.0 W max.

Isolation from Backplane

1500 VDC

RX3i system

Pilot duty: 125 VAC / 125 VDC maximum at 0.35 amp

5 ms

Frequency

30–70 Hz

Impedance

<5 milliohms

Range

0–5 A RMS (5 A nominal)

Phase difference between grids:

±180O

Voltage

0.2%

kW, kVAR, kVA

0.4%

kWH, kVARH, kVAH

0.4%

Power factor

1%

Phase angle

0.1O

Current

15 Amps continuous maximum

Voltage

690 VAC RMS

Contacts above.

GFK-2748C

Specifications

PSM Module Power Requirements

Maximum number of PSM modules per

Sync Relay Contacts

Two isolated relay outputs General purpose: 125 VAC / 125 VDC maximum at 1 amp

Switching speeds

Turn-on time

Turn-off time

Measurement Specifications

Three voltage inputs per grid

Impedance:

Range

Low range

High range

Four current inputs per grid

Frequency 30–70 Hz

Measurement Accuracy 1

No restrictions, as long as the power supply has sufficient capacity

Lamp duty: 125 VAC / 125 VDC maximum at 1 amp

20 ms

All voltage data is scaled in 0.1 VAC units.

>1 MΩ

45–150 VAC RMS (120 VAC nominal)

120–690 VAC RMS (600 VAC CAT IV; 690 VAC CAT III)

All current data is scaled in 0.001 Amp units.

Current 0.2%

Frequency 0.01 Hz

Terminal Assembly Input Terminal Ratings

Sync Relay contacts 150 VAC/VDC at 1 Amp Resistive, maximum

Note: Actual contact ratings depend on load type. Refer to Sync Relay

1

In the presence of severe conducted RF interference (IEC 61000-4-6, 10 volts) accuracy could be degraded by ±2% of full

scale.

Page 3

RX3i Power Sync and Measurement System 3

%I

80 bits

%Q

32 bits

%AI

64 words

A complete data exchange between the PSM and RX3i occurs during each controller scan.

Refer to GFK-2749, the section s, System Operation and PSM Status Flags.

ANSI 25 – Generator and Public Grid Synchronization

ANSI 27 – Under-voltage Protection

ANSI 32 – Reverse Power Protection

ANSI 47 –Voltage Phase Sequence Protection

ANSI 59 – Over-voltage Protection

ANSI 60 – Voltage (Current) Imbalance Protection

ANSI 81U – Under-frequency Protection

ANSI 81O – Over-frequency Protection

Four-wire three phase wye systems: 3 PTs and 3 CTs plus Neutral CT (optional)

Three-wire single phase systems: 120/240 (2 PTs and 2 CTs)

GFK-2748C

RX3i CPU Memory Requirement for Automatic Data Exchange

%AQ 2 words

Data Exchange Time Between RX3i CPU and PSM

Minimum scan time is 3.5 ms per PSM module in the backplane. Minimum data update rate is one power line period.

ANSI Protective Functions

ANSI 50 – Instantaneous Over-current Protection

Power Measurement Configurations

Three-wire three phase delta systems: 2 PTs and 2 CTs

Three independent single phase systems: 1 PT and 1 CT for each phase

Operating Environment

Enclosure mounting Required. PSM module and Terminal Assembly must be installed in a

NEMA/UL Type 1 enclosure or an IP20 rating providing at least a pollution

degree 2 environment.

When this system is installed in an area designated as Class 1 Zone 2 in

Europe, compliance with the ATEX Directive requires an enclosure with a

minimum rating of IP54.

For product standards, general operating sepcifications, and installation requirements, refer to GFK-2749, PACSystems RX3i

Power Sync and Measurement System User’s Manual.

Installation in Hazardous Locations

The following information is for products bearing the UL marking for Hazardous Areas, or ATEX marking for explosive

atmospheres:

Class 1 Division 2 Groups ABCD

• This equipment shall be installed in an ultimate enclosure suitable for the environment that is only accessible with the

use of a tool.

• Suitable for use in Class I, Division 2, Groups A, B, C and D Hazardous Locations, or nonhazardous locations only.

EXPLOSION HAZARD - Substitution of components may impair suitability for class I, division 2.

Page 4

4 RX3i Power Sync and Measurement System

GFK-2748C

When in hazardous locations, turn off power before replacing or wiring modules; and

DO NOT connect or disconnect equipment unless power has been switched off or the area is known

to be nonhazardous.

ATEX Zone 2

This product must be mounted in an enclosure certified in accordance with EN60079-15 for use in Zone 2, Group IIC and rated

IP54. The enclosure shall only be able to be opened with the use of a tool .

Quick Reference Guide

HIGH VOLTAGE; HIGH CURRENT

DO NOT TOUCH the connectors or wiring after powering up the PSM system. Hazardous voltages

exist, and death or injury may result.

The Terminal Assembly frame ground connection must always be installed and must be installed

before any other wiring is attached.

To reduce risk of electric shock or damage to the attached CTs, always open or disconnect all

voltage circuits and apply the shorting bar connections to the current inputs before installing or

servicing the connections to the Terminal Assembly.

Never disconnect the GRID 1 or GRID 2 field wiring while power is present. Personal injury or

equipment damage may result. Finger guards must be installed on the Terminal Assembly before

energizing the field wiring.

User Supplied Equipment

The user must supply the following components depending upon the application. This equipment includes:

5 Amp current transformers

Potential transformers for all installations

1 Amp fuses for each of the voltage leads connected to the Terminal Assembly.

1 Amp fuse for the common or return line for the voltage lead on the Terminal Assembly.

A CT shorting block for each current transformer (CT) connection used on the Terminal Assembly when used with

external CTs.

Installation

Enclosures

The Terminal Assembly and PSM module are considered open equipment (having live electrical parts that may be accessible

to users) and must be installed in a protective enclosure or incorporated into other assemblies manufactured to provide safety.

As a minimum, the enclosure or assembl ies shall prov ide a degree of protection against solid object s up to 12 mm (for

example, fingers). For Non Hazardous environments, this equates to a NEMA/UL Type 1 enclosure or an IP20 rating providing

at least a pollution degree 2 environment.

The enclosure must be able to adequately dissipate t he heat generated by all components mounted inside so that no

components overheat. Heat dissipation is also a factor in determining the need for enclosure cooling options such as fans and

air conditioning.

Installing the PSM Module

Page 5

RX3i Power Sync and Measurement System 5

1

GRID 1 Operation: 0 = disabled, 1 = enabled

GRID 1 Voltage Selection: 0 = low voltage range (120VAC), 1 = high voltage range (600VAC)

bit to a value that does not match the physical configuration will result in erroneous power system

3

GRID 1 Grid Operational Mode: 0 = single phase, 1 = three-phase

GRID 1 Connection mode:

• In three-phase mode: 0 = WYE system configuration, 1 = DELTA system configuration

GRID 1 PTA measurement: 0 = GRID 1 PTA not connected, 1 = GRID 1 PTA connected

GRID 1 CTA measurement: 0 = GRID 1 CTA not connected, 1 = GRID 1 CTA connected

GRID 1 PTB measurement: 0 = GRID 1 PTB not connected, 1 = GRID 1 PTB connected

GRID 1 CTB measurement: 0 = GRID 1 CTB not connected, 1 = GRID 1 CTB connected

GRID 1 PTC measurement: 0 = GRID 1 PTC not connected, 1 = GRID 1 PTC connected

GFK-2748C

The PSM module must be installed in a main (CPU) rack in an RX3i system. For system-level installation information, refer to

GFK-2314, PACSystems RX3i System Manual. The IC694PSM001 Module can be hot-swapped in an RX3i backplane.

Installing the Terminal Assembly

The Terminal Assembly must be securely installed on a rigid, conductive, 12 – 14 gauge steel panel using four user supplied

M4 - M5 or #8 - #10 SAE bolts. The Terminal Assembly should be mounted near the host controller rack containing the PSM

module, close enough to accommodate the 2 meter interface cables provided.

For detailed installation and power system connection instructions, refer to GFK-2749, PACSystems RX3i Power Sync and

Measurement Module User's Manual.

Configuration

The PSM module is configured using the Proficy Machine Edition programming software. For compatible versions, refer to

page 12.

Configuration parameters are used to set nominal values for Grid 1 and Grid 2 voltage, current and frequency, and to calibrate

the PSM system for specific Potential Transformer and Current Transformer gains, increasing the accuracy of the measured

values. Configuration parameters are also used to set ANSI device threshold and delay values.

A Mode Control register, consisting of 32 bits in %Q memory, selects operational and measurement modes. This application

must apply initial values to these bits and can change them while the PSM is running.

The application can change a single configuration parameter in run mode by modifying the two-word Parameter Write register

in %AQ memory.

Mode Control Bits

The RX3i CPU sends 32 %Q bits of Mode Control data to the PSM module every sweep. The application logic must apply

initial values to these bits on the first RX3i scan. The application can change these settings during operation to modify

measurement modes in response to changing conditions.

%Q Bit

Offset

If disabled, the PSM module does no measurements for the GRID1 (power grid) inputs.

Note: Both grid control offset bits (Q1 and Q17) must be enabled in order for the PSM module to operate

as a 2-source synchronizer.

2

Caution: The voltage range is determined by the physical connections in the power system. Changing this

measurements. Note: Do not change this value in while in RUN mode.

4

Works with the Grid Operational Mode setting to determine system type.

• In single phase mode: 0 = Three single phases ,1 = Three-wire, single phase (120/240) using

PTA and PTB

5

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

6

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

7

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

8

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

9

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

Function

Page 6

6 RX3i Power Sync and Measurement System

GRID 1 CTC measurement: 0 = GRID 1 CTC not connected, 1 = GRID 1 CTC connected

GRID 1 CTN measurement: 0 = GRID 1 CTN not connected, 1 = GRID 1 CTN connected

12

GRID 1 Waveform Capture: When this bit is transitioned from 0 to 1 by the control logic, the PSM module

captures 128 samples of all seven data variables on GRID 1.

GRID 1 Delta Mode: 0 = B phase is common, 1= C phase is common

set to 1.

14

Reserved

GRID 1 Energy reset: When set, the accumulated energy values for GRID 1 are reset and held

the last reset.

Relay open: Works with bit 32 to control the Sync Relay operation.

For more information, refer to Relay Open/Relay Close Operation in GFK-2749.

GRID 2 Operation: 0 = disabled, 1 = enabled

operate as a 2-source synchronizer.

GRID 2 Voltage Selection: 0 = low voltage range (120VAC), 1 = high voltage range (600VAC)

Note: Do not change this value in while in RUN mode

19

GRID 2 Grid Operational Mode: 0 = single phase, 1 = three-phase

GRID 2 Connection mode:

21

GRID 2 PTA measurement: 0 = GRID 2 PTA not connected, 1 = GRID 2 PTA connected

22

GRID 2 CTA measurement: 0 = GRID 2 CTA not connected, 1 = GRID 2 CTA connected

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

23

GRID 2 PTB measurement: 0 = GRID 2 PTB not connected, 1 = GRID 2 PTB connected

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

GRID 2 CTB measurement: 0 = GRID 2 CTB not connected, 1 = GRID 2 CTB connected

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

GRID 2 PTC measurement: 0 = GRID 2 PTC not connected, 1 = GRID 2 PTC connected

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

GRID 2 CTC measurement: 0 = GRID 2 CTC not connected, 1 = GRID 2 CTC connected

GRID 2 CTN measurement: 0 = GRID 2 CTN not connected, 1 = GRID 2 CTN connected

GRID 2 Waveform Capture: When this bit is transitioned from 0 to 1 by the control logic, the PSM module

captures 128 samples of all seven data variables on GRID 2.

GRID 2 Delta Mode: 0 = B phase is common, 1= C phase is common

set to 1.

GRID 2 Energy reset: When set, the accumulated energy values for GRID 1 are reset and held at 0 Wh

reset.

GFK-2748C

%Q Bit

Offset

10

11

13

15

16

17

18

Function

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

This bit must be set to 0 if phase B is used as the common connection for the other two voltages (North

American standard). If the phase C is used as the common phase in a Delta connection, this bit must be

at 0 Wh and 0 VARh. When cleared, the GRID 1 energy values represent the accumulated energy since

If disabled, the PSM module does no measurements for the GRID 2 (generator grid) inputs.

Note: Both grid control offset bits (Q1 and Q17) must be enabled in order for the PSM module to

Caution: The voltage range is determined by the physical connections in the power system. Changing

this bit to a value that does not match the physical configuration will result in erroneous power

system measurements.

.

20

24

25

26

27

28

29

30

31

Works with the Grid Operational Mode setting to determine system type.

• In single phase mode: 0 = Three single phases ,1 = Three-wire, single phase (120/240) using

PTA and PTB

• In three-phase mode: 0 = WYE system configuration, 1 = DELTA system configuration

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

The PSM module reconstructs the missing variable. Refer to Reconstructed Variables in GFK-2749.

This bit must be set to 0 if phase B is used as the common connection for the other two voltages (North

American standard). If the phase C is used as the common phase in a Delta connection, this bit must be

Reserved

and 0 VARh. When cleared, the GRID 1 energy values represent the accumulated energy since the last

Page 7

RX3i Power Sync and Measurement System 7

Relay Close: Works with bit 16 to control the Sync Relay operation.

2

1

PSM HeartBeatBit:

Toggled with every scan/sweep

Updated every

scan

ü ü

2

PSM ConnectionOK:

1 = OK

connection failure

A

ü ü

3

PSM PhaseShiftOK:

1 = OK

A

ü

0 = ANSI 25/2 Alarm

ü

5

PSM DeltaFreqOK:

1 = OK

A

ü

ü

0 = Do not close relay

ü

8

PSM New Data

1 = The current PLC sweep is the

previous sweep.

A

ü

ü

9 - 16

Reserved

GFK-2748C

%Q Bit

Offset

32

For more information, refer to Relay Open/Relay Close Operation in GFK-2749.

Function

PSM Status Flags

The PSM returns 80 status flag bits to the RX3i controller. Those 80 bits are grouped into five 16-bit words.

The first status word (%I1 – %I16) contains the overall PSM status flags.

The following two words (%I17 – %I48) contain the individual grid measurement faults. These flags identify

the voltage/current channel experiencing a measurement problem. It can be one or multiple problems

related to:

- Input signal not present, that is, it is indicated as not measured in the corresponding %Q flag bit. If the

signal is not measured, it cannot be reconstructed by the PSM module firmware.

- Input signal is measured but it is clamped due to a higher peak voltage/current value than the

maximum value allowed to be applied to the interface unit

The last two status words (%I49 – %I80) contain the individual grid status flags, including the ANSI alarms.

Alarm

%I Bit

Offset

Definition Value

Status/Alarm

Timing

A, B, AB: Refer to

the section,

Status/Alarm

Timing

Availability

1ø 3ø

0 = PSM to Terminal Assembly

0 = ANSI 25/1 Alarm

4 PSM DeltaVoltOK: 1 = OK

0 = ANSI 25/3 Alarm

6 PSM AllGridAlarmsOK 1 = OK

0 = At least one alarm on either

grid is set

7 PSM RelayCloseOK: 1 = OK

first sweep this power line

cycle data is being delivered

by the PSM to the PLC.

0 = Data has not changed from

A

AB

A

2

Alarm availability: A checkmark indicates whether an alarm is available for use in either the 1-Phase (1ø) or the 3-Phase

(3ø) Grid Operational Mode (refer to Mode Control Bits Sent to PSM Module in GFK-2749). All alarms are available in 3-Phase

mode. An absent checkmark indicates that the value of the bit is indeterminate and the bit should be ignored.

Page 8

8 RX3i Power Sync and Measurement System

ü

ü

ü

ü

ü

ü

20

GRID 1 FaultIB:

A

ü

ü

ü

ü

ü

ü

ü

ü

24-32

Reserved

calculated/measured

ü

ü

ü

ü

35

GRID 2 FaultVB_VCB

A

ü

ü

ü

ü

ü

ü

38

GRID 2 FaultIC

A

ü

ü

ü

ü

40 - 48

Reserved

49

GRID 1 ClampedFreq

0 = OK

range (30 - 70 Hz)

A

ü

ü

ü

ü

ü

GRID 1 VoltPhSeqAlarm

1 = ANSI 47 Alarm

ü

GRID 1 UnderVoltAlarm

ü

1 = ANSI 32 Alarm

ü

1 = ANSI 50 Alarm

ü

ü

GFK-2748C

2

Alarm

Status/Alarm

%I Bit

Offset

17 GRID 1 FaultVA 0 = OK

18 GRID 1 FaultIA A

19 GRID 1 FaultVB A

Definition Value

1 = Fault – clamped or not

calculated/measured

A, B, AB: Refer to

the section,

Status/Alarm

Timing

Timing

A

Availability

1ø 3ø

21 GRID 1 FaultVA/VBA;

VB/VAC; VC/VBC

22 GRID 1 FaultIC A

23 GRID 1 FaultIN A

33 GRID 2 FaultVA_VCA 0 = OK

34 GRID 2 FaultIA A

36 GRID 2 FaultIB: A

37 GRID 2 FaultVC: A

39 GRID 2 FaultIN A

A

A

1 = Fault – clamped or not

50 GRID 1 ClampedInput: 0 = OK

51 GRID 1 MixedPolarity 0 = OK

52

53

54 GRID 1 ReversPwrAlarm

55 GRID 1 OverCurrAlarm 0 = OK

1 = Line Frequency outside the

1 = some inputs have signal

clamped

1 = At least one phase PT/CT has

wrong polarity

0 = OK

0 = OK

1 = ANSI 27 Alarm

0 = OK

A

B

B

B

B

B

Page 9

RX3i Power Sync and Measurement System 9

GRID 1 OverVoltAlarm

1 = ANSI 59 Alarm

ü

GRID 1 VIImbalanceAlarm

ü

1 = ANSI 81U Alarm

ü

ü

GRID 1 OverFreqAlarm

1 = ANSI 81O Alarm

ü

ü

ü

range (30 - 70 Hz)

ü ü

clamped

ü ü

wrong polarity

ü

GRID 2 VoltPhSeqAlarm

ü

1 = ANSI 27 Alarm

ü

GRID 2 ReversPwrAlarm

ü

GRID 2 OverCurrAlarm

1 = ANSI 50 Alarm

ü ü

GRID 2 OverVoltAlarm

1 = ANSI 59 Alarm

ü

73

GRID 2 VIImbalanceAlarm

0 = OK

B

ü

GRID 2 UnderFreqAlarm

1 = ANSI 81U Alarm

ü ü

75

GRID 2 OverFreqAlarm

0 = OK

B

ü ü

76 – 80

Reserved

GFK-2748C

2

Alarm

%I Bit

Offset

56

Definition Value

0 = OK

Status/Alarm

Timing

A, B, AB: Refer to

the section,

Status/Alarm

Timing

B

Availability

1ø 3ø

57

58 GRID 1 UnderFreqAlarm 0 = OK

59

60 - 64 Reserved

65 GRID 2 ClampedFreq: 0 = OK

66 GRID 2 ClampedInput: 0 = OK

67 GRID 2 MixedPolarity 0 = OK

68

69 GRID 2 UnderVoltAlarm

70

71

0 = OK

1 = ANSI 60 Alarm

0 = OK

1 = Line Frequency outside the

1 = some inputs have signal

1 = At least one phase PT/CT has

0 = OK

1 = ANSI 47 Alarm

0 = OK

0 = OK

1 = ANSI 32 Alarm

0 = OK

B

B

B

A

A

B

B

B

B

B

72

74

Status/Alarm Timing

Timing A – The PSM buffers an entire power line cycle and takes 11 ms to perform calculations on the waveforms. The new

status bits are available to the application code after the next PLC input data scan.

Total latency = 1-cycle + 11 ms + (0 to PLC scan time)

Update rate = 1-cycle or the PLC scan rate (whichever is longer)

Timing B – The PSM updates this information every 100 ms. The new status bits are available to the application code after

the next PLC input data scan.

0 = OK

1 = ANSI 60 Alarm

0 = OK

1 = ANSI 81O Alarm

B

B

Page 10

10 RX3i Power Sync and Measurement System

RUN

Green

The module is operating correctly and communicating with the RX3i.

Red

The module is operating without backplane communication.

FLT

Green, blinking

During the period when GREEN is ON, Grid 1 can be connected to Grid 2.

Green, steady

Grid 1 and Grid 2 are connected.

Red

The module has detected a fault condition.

GRID 1

Green

Indicates a voltage signal has been detected on Grid 1.

Red

A frequency out-of-range condition has been detected on Grid 1.

Off

No zero crossing signal of Grid 1 has been detected during the last 250 ms

time period.

GRID 2

Green

Indicates a voltage signal has been detected on Grid 2

GFK-2748C

Update rate = 100 ms or the PLC scan rate (whichever is longer)

Timing AB – AllGridAlarmsOK follows the timing of the alarm that causes it to be cleared or set.

LEDs

LED State Definition

Off The module is not operating.

Off The module has not detected a fault and the grids are not synchronized.

Red A frequency out-of-range condition has been detected on Grid 2.

Off No zero crossing signal of Grid 2 has been detected during the last 250 ms

time period.

Page 11

RX3i Power Sync and Measurement System 11

Grid 1 power system connections to

Grid 2 power system connections to

Sync

Contacts

Interface cables

Load(s)

GFK-2748C

Field Wiring

Wiring to the PSM consists of:

the connection cable between the Terminal Assembly and the PSM

the leads to user-supplied potential and mandatory user-supplied current transformers

Sync relay output connections, and

frame ground connections from the Terminal Assembly to the chassis

No CT shorting bars are provided on the PSM Terminal Assembly; these must be supplied by the user.

Requirements for Terminal Assembly Connections

Terminal Assembly connections above 600 VAC require prepared wire ends, such as tinning of the conductors, or use of

crimpled or soldered forked connectors or ferr ule s.

Terminal connections for COM1, COM2, voltage sensing and current sensing terminals

Terminal torque: 1.81 Nm (16 in-lb)

Wiring size/type: 0.823 mm

Relay output terminal connections

Terminal torque: 0.8 Nm (7 in-lb)

Wiring size/type: 0.205 mm

For additional wiring and connectin information, refer to GFK-2749, PACSystems RX3i Power Sync and Measurement Module

User's Manual.

2

– 5.26 mm2 (18–10 AWG) solid/stranded

2

– 0.410 mm2 (24–21 AWG) solid/stranded

The PSM Terminal Assembly connects to hazardous voltages. Before installing, testing, or

troubleshooting this module, you should refer to the complete instructions in the PACSystems RX3i

Power Sync and Measurement Module User's Manual, GFK-2749. Failure to follow the published

guidelines may result in personal injury, equipment damage, or both.

Note: Although Grid 1 and Grid 2 are interchangeable, you should connect the most stable source to Grid 1. Between a

utility grid and a generator, the utility grid is the best choice for connection to the PSM Grid 1 inputs. This will yield the

most accuracy and the least reading-to-reading fluctuation.

Basic PSM System Connections

user PTs with fuses and CTs with

shorting bars

user PTs with fuses and CTs with

shorting bars

Page 12

12 RX3i Power Sync and Measurement System

Programmer Version

Proficy Machine Edition Logic Developer 7.50 with SIM 2 or newer or

Proficy Machine Edition Logic Developer 7.60 or newer

CPU Firmware Version

IC695NIU001+

GFK-2749 for wiring diagrams.

GFK-2748C

Release History

Version

IC694PSM001-AB 1.01 January 2013 Enhanced operation of sync relay feature as

IC694PSM001-AA 1.00 December 2012 Initial r elease

Firmware

Revision

Date

Comments

described below.

Important Product Information for Release 1.01

New Features and Enhancements

With this release, the PSM accounts for the breaker delay, and the rate of change of the phase shift between the grids, to time

the CloseRelayOK status and ACC200 relay outputs to close the sync relay contacts when the phase shift between the grids is

0⁰.

This release also adds the special case of Breaker Delay = 0. When the ANSI 25 Breaker Delay parameter is set to 0, the

PSM turns off breaker delay calculations and operates in Classic sync relay mode. In Classic mode, the PSM sets the

CloseRelayOK status and the ACC200 relay outputs to On whenever the application requ e st s a sync and the phase shift

between the grids is in the range –Phase Shift Threshold to +Phase Shift Threshold.

Functional Compatibility

Subject Version Required

Requirements

Operational Notes

Wiring

Proficy Machine Edition Logic Developer 7.00 with SIM 12 or newer or

RX3i CPU firmware versions 7.15, 7.16, 7.17, and 7.18.

Note: The PSM module is not compatible with IC695CPE305 and C695CPE310

firmware version 7.30.

CPU firmware version 7.70 or newer support the IC694PSM001 module on these

CPU types:

IC695CPE305

IC695CPE310

IC695CPU315

IC695CPU320

IC695CRU320, including –QP (Quad Redundancy)

Subject Description

COM1 and COM2 of the IC694ACC200 must be connected to functional ground

(Earth ground).

COM1 and COM2 must not be connected to Neutral in a WYE power system.

In certain fault conditions, Neutral can be pulled to the full voltage of any phase. Such

a fault condition can pose a danger to personnel and damage the IC694ACC200. See

Page 13

RX3i Power Sync and Measurement System 13

Breaker Delay

terminal assembly will be turned On.

Delta Power Configurations

there is no Neutral reference.

Nominal Voltage

calculations.

Scaling for PT and CT Ratios

The IC694PSM001 module reports the voltages and currents measured at the

reported power and energy values must both be multiplied by 80 (4 x 20).

ANSI Alarm Delays

Relay Output Options

suit the needs of the application.

Voltage Configuration

GFK-2749 for proper wiring and configuration information.

GFK-2748C

Subject Description

When the ANSI 25 Breaker Delay parameter is set to a non-zero value, the phase

angle difference at which CloseRelayOK (%I offset 7) is set and the IC694ACC200

relay outputs close varies, in direct proportion to the rate of change of the phase

angle of Grid 2 relative to Grid 1. Higher rates of phase angle change and larger

breaker delays require that the PSM assert CloseRelayOK earlier to ensure that the

breaker contacts close within the safe region set by the ANSI 25 Phase Shift

Threshold parameter (Phase_Shift_Thr).

If the PSM does not receive a request to Sync (%Q offset 16=0 and %Q offset 32= 1)

in time for the relay outputs to close within the Phase Shift Threshold limits, it will not

assert CloseRelayOK until the next opportunity.

Breaker Delay = 0

Special Case

When the ANSI 25 Breaker Delay parameter is set to zero, the PSM reverts to classic

sync relay operation. The PhaseShiftOK bit will be set when

–Phase_Shift_Thr < Phase Shift < +Phase_Shift_Thr.

The PSM will not adjust its synchronization timing based on either the interval

between CloseRelayOK being set and the relay contacts actually closing or the rate of

change of the Phase Shift between the two grids. If a request to Sync (%Q offset

16=0 and %Q offset 32=1) is active at any time when the Phase Shift is within

±Phase_Shift_Thr, the CloseRelayOK bit and the relay outputs on the IC694ACC200

Phase-to-Neutral voltages are not reported in Delta power configurat io ns bec au se

Nominal Current

Nominal Voltage refers to the:

Phase-to-Neutral RMS voltage in a WYE power system.

Phase-to-Phase RMS voltage in a Delta power system.

Setting a negative Nominal Current value implies that the IC694ACC200 grid inputs

are connected to a load (drawing power), rather than a power source (producing

power). The power and energy values will be reported as negative numbers. The CTs

must be wired with the correct polarity to achieve the negative power and energy

values. RMS current is necessarily reported as a positive number, due to the RMS

IC694ACC200 terminals. Therefore, the application logic must correct for PT and CT

ratios to reflect the actual power grid voltages, currents, powers and energies.

Example:

Using 480V:120V PTs requires the application logic to multiply the reported voltage

values by 4. Using 100:5 CTs requires the application logic to multiply the reported

current values by 20. Since power and energy combine voltage and current, the

All ANSI alarm delays apply to both setting and clearing the alarms. A delay of 10

seconds means the grid must be in the alarm state for 10 continuous seconds before

the PSM will set the alarm bit; clearing the CloseRelayOK bit and opening the relay

outputs(if the grids were synchronized). Once the alarm is set, the alarm condition

must be eliminated for 10 continuous seconds for the alarm to be cleared.

The isolated, bipolar relay outputs are redundant. Both relay 1 and relay 2 follow the

CloseRelayOK %I offset 7 bit from the PSM. They can be connected in parallel to

increase the reliability of closing, or in series, to increase the reliability of opening, to

The Voltage Selection in the Proficy Machine Edition Hardware Configuration must

match both the physical cable connection to the IC694ACC200 terminal assembly

and the %Q offset 2 (Grid 1) and %Q offset 18 (Grid 2) configuration bits. Refer to

Page 14

14 RX3i Power Sync and Measurement System

Reverse Power Threshold

Power Delay.

VI Imbalance

so the VI Imbalance alarm will not be set.

change configuration parameters in Run Mode.

Power Factor

Although the PSM reports power factor information using three decimal places, the

information is only accurate to two decimal places.

GFK-2748C

Subject Description

The Reverse Power Threshold affects Grid 1 and Grid 2 differently:

For Grid 1, the Reverse Power alarm will be triggered if a circuit’s active power

exceeds the Reverse Power Threshold for a time period longer than Reverse

Power Delay.

For Grid 2, the Reverse Power alarm will be triggered if a circuit’s active power

falls below the Reverse Power Threshold for a time period longer than Reverse

The VI Imbalance Alarm compares voltage phases to voltage phases, and current

phases to current phases within a grid. No comparison is made between grids. If any

voltage varies from the average of all three voltages, or if any current varies from the

average of all three currents (by more than the VI Imbalance Threshold) for longer

than the VI Imbalance Delay, that grid’s VI Imbalance Alarm is set.

Example 1:

VI Imbalance is set to 20%, VA1 = 126V, VB1 = 90V, VC1 = 124V

The difference between VB1 and the average of the three voltages is greater than

20%, so the VI Imbalance alarm will be set.

Example 2:

VI Imbalance is set to 25%, IA2 = 4.2A, IB2 = 3.6A, IC2 = 5.5A

The difference between IC2 and the average of the three currents is less than 25%,

Setting Programmatic

Parameters

Proficy Machine Edition Hardware Configuration parameters are entered as Floating

Point numbers in engineering units. Changing the same parameters programmatically

(using %AQ offset 1 and 2) requires the use of 16-bit Integers which vary from the

Floating Point numbers by factors of 10. Refer to GFK-2749 for details on how to

Loading...

Loading...