Page 1

Hardware Manual for the

HE500TIU050

HE500TIU100

IC300TIU101

HE500TIU102

HE500TIU103

HE500TIU110

IC300TIU111

HE500TIU112

HE500TIU113

HE500TIU200

IC300TIU201

HE500TIU202

HE500TIU203

And SmartStack Modules

Operator Station

Hardware Manual

06 April 2000 GFK-1819

Page 2

PREFACE 06 Apr 2000 PAGE 3

GFK-1819

Warnings, Cautions, and Notes

as Used in this Publication

Warning

Warning noti ces are used in this publi cat ion to emphasize that

hazardous volt ages, currents, temperatures o r other con ditions that

could cause personal injury exist in this equipment or may be

associated with its use.

In situations wh ere in at t entio n could cause either personal injury

or damage to equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care i s

not taken.

Note

Notes merely call attention to information that is especially signifi c ant to

understanding and operating the equipment.

This document is based on inf ormation available at the time of its publication. Whil e

efforts hav e been made t o be accurate, the information c ontained herein does not

purport to cov er all details or variations in hardware or sof tware, nor to provide f or

every possible cont ingency in connection with installation, oper ation, or maintenance.

Features may be descri bed her ein which are not present in all har dware and sof tware

systems. GE Fanuc Automation assumes no obligation of not ic e to holders of this document wit h

respect to changes subsequently made.

GE Fanuc Automation makes no representations or warranty, expressed, impli ed, or

statutory wit h r espect to, and assumes no responsibilit y for the accuracy, completeness,

sufficiency , or usefulness of the inform ation contained herein. No warranti es of

merchantability or fitness for purpose shall apply.

The following are trademarks of GE Fanuc Automation North America, Inc.

Alarm Ma ster CIMSTAR Helpma te PRO M ACRO Series S ix

CIMPLICITY GEnet Logicmaster Series One Series 90

CIMPLICITY 90 – ADS Genius ModelMaster Series Three VuMaster

CIMPLICITY Power TRAC Genius PowerTRAC ProLoop Series Five Workmaster

The following are trademarks of Horner Elect ric, APG, LLC.

Cscape SmartStack CsCAN

Copyright 2000 GE Fanuc Automation North America, Inc.

All Rights Reserved

Page 3

PAGE 4 06 Apr 2000 PREFACE

GFK-1819

ABOUT PROGRAMMING EXAMPLES

Any example programs and program segments in this manual or provided on accompanying di sket tes are

included sol ely for illustrative purposes. Due to the many variables and requir em ents associated with any

particular installation, GE Fanuc cannot assume r esponsibility or li ability for actual use based on the

examples and diagram s. It is the sol e r esponsibility of the system designer utilising the Operat or Station

to appropriately design the end system, to appropriately integrate the Operator Station and to make

safety provisions for the end equipment as is usual and c ustom ar y in industr ial applicati ons as def ined in

any codes or standards which apply.

NOTE: The programming examples shown in this manual are illustrative

only. Proper machine operation is the sole responsibility of the system

integrator.

DECLARATION OF EMC CONFORMITY

Manufacturer' s Name: Horner Irel and Ltd.

Manufacturer' s Addr es s: Unit 1, Centr epoint, Centre Park Road, Cork, I r eland

Declares that t he products Models: HE500TI U 050, HE500TIU100, IC300TIU101, HE500TIU102,

HE500TIU110, I C300TIU111, HE500TIU200, I C300TI U201 and

HE500TIU202.

Conforms to the followi ng E M C standar ds:

EMC: EN 55 022, Radiated and Conducted Emissions

EN 50 082-1, RF, EFT/EFB, ES D Imm unity

Supplementary Information:

The above conformi ty only relates to the product s in a stand-alone capacity. The product s are used as

part of a system and are theref or e cl assif ied as a component. As a component, the pr oduc ts are

prohibit ed by EC regul ations to carry a CE Mark for EMC conformity. Stati c discharge tests only apply to

normal operati on of the keyboards via the front panel . We would stress that the use of our products

within your system, while helping to ensure compliance of your system to the same dir ectives, do not

necessarily guar antee that compliance will be ac hiev ed. We would also like to point out that the

interpret ation of the law concerning CE marking and it s appl ic ation to sub-assembli es and components is

open to interpretation.

Date: 31 Mar 1999

Page 4

PREFACE 06 Apr 2000 PAGE 5

GFK-1819

TABLE OF CONTENTS

ABOUT PROGRAMMING EXAMPLES....................................................................................................4

DECLARATION OF EMC CONFORMITY.................................................................................................4

CHAPTER 1: INTRODUCTION................................................................................................................ 7

1.1 Scope....................................................................................................................................... 7

1.2 E quipment Needed ................................................................................................................... 9

1.3 Technical Specifications...........................................................................................................11

1.4 Upgr ade Revision Soft ware & Firmware...................................................................................12

1.4.1 Scope...............................................................................................................................12

1.4.2 Software Upgrade.............................................................................................................12

1.4.3 Firmware Upgrade ............................................................................................................12

CHAPTER 2: TIU050.............................................................................................................................15

2.1 Scope......................................................................................................................................15

2.2 TIU050 Button Selection Actions..............................................................................................15

2.3 TIU050 Contrast Adjustment ....................................................................................................15

2.4 TIU050 Ports............................................................................................................................16

2.4.1 TIU050 Configuration of the RS-485 Por t ..........................................................................16

2.5 TIU050 Dimensions..................................................................................................................17

CHAPTER 3: TIU100/101/ 102/103.........................................................................................................19

3.1 Scope......................................................................................................................................19

3.2 TIU10X Button Selection Actions..............................................................................................19

3.3 TIU10X Contrast Adjustment....................................................................................................19

3.4 TIUX Rear View.......................................................................................................................20

3.5 TIU100 Ports............................................................................................................................20

3.5.1 TIU10X Configuration of the RS-485 P ort..........................................................................21

3.6 TIU10X Dimensions.................................................................................................................22

CHAPTER 4: TIU110/111/ 112/113.........................................................................................................23

4.1 Scope......................................................................................................................................23

4.2 TIU11X Button Selection Actions .............................................................................................23

4.3 TIU11X Contrast Adjustment....................................................................................................23

4.4 TIU11X Rear View...................................................................................................................24

4.5 TIU110 Ports............................................................................................................................24

4.5.1 TIU11X Configuration of the RS-485 P ort..........................................................................26

4.6 TIU11X Dimensions.................................................................................................................26

CHAPTER 5: TIU200/201/ 202/203.........................................................................................................27

5.1 Scope......................................................................................................................................27

5.2 TIU20X Button Selection Actions..............................................................................................27

5.3 TIU20X Contrast Adjustment....................................................................................................28

5.4 TIU20X Rear View...................................................................................................................28

5.5 TIU20X Ports...........................................................................................................................28

5.5.1 TIU20X Configuration of the RS-485 P ort..........................................................................30

5.6 TIU20X Dimensions.................................................................................................................30

CHAPTER 6: COMMUNICATIONS........................................................................................................31

6.1 PC to Operator Station Communications..................................................................................31

6.2 A utomation Equipm ent ( A E) Comm unic ations Connections......................................................31

6.2.1 Recommended Automation Equipm ent Comm unic ation Cables .........................................31

6.3 RS - 232 Connec tion..................................................................................................................31

6.4 RS - 422/485 Four-Wire.............................................................................................................32

6.5 RS - 485 Two-Wire ....................................................................................................................33

6.6 Cur r ent Loop............................................................................................................................34

CHAPTER 7 : GETTING STA RTED........................................................................................................35

7.1 Self-Test..................................................................................................................................35

7.1.1 Contrast Band...................................................................................................................35

Page 5

PAGE 6 06 Apr 2000 PREFACE

GFK-1819

7.1.2 Display Test......................................................................................................................35

7.1.3 Keyboard T est...................................................................................................................35

7.1.4 RAM Test..........................................................................................................................35

7.1.5 Seri al Loop- bac k Tests......................................................................................................35

7.2 Updating the Protocol...............................................................................................................36

7.3 Updating the Operati ng S y stem................................................................................................36

CHAPTER 8 : NETWORKS....................................................................................................................37

8.1 Scope......................................................................................................................................37

8.2 Controller Area Network (CAN) Overview.................................................................................37

8.2.1 CAN Features...................................................................................................................37

8.3 CsCAN Network Overview.......................................................................................................37

8.3.1 CsCAN Network Features.................................................................................................37

8.3.2 CsCAN Network Operation................................................................................................37

8.4 DeviceNe t O verview.................................................................................................................38

8.4.1 D eviceNet Fe a tu re s...........................................................................................................38

8.4.2 DeviceNet Protocol...........................................................................................................39

8.4.3 D eviceNet Op e ra tion.........................................................................................................39

8.5 CAN Wiring Rule s....................................................................................................................40

8.6 Profibus...................................................................................................................................41

8.6.1 Pr ofibus Wir in g..................................................................................................................41

CHAPTER 9: SMARTSTACK .............................................................................................................43

9.1 Scope......................................................................................................................................43

9.2 Installing and Remov i ng a SmartStack Module.........................................................................43

9.2.1 Installing SmartStack Modules...........................................................................................43

9.2.2 Removing SmartStack Modules.........................................................................................43

Page 6

CH.1: INTRODUCTION 06 Apr 2000 PAGE 7

GFK-1819

CHAPTER 1: INTRODUCTION

1.1 Scope

The Operator St ation (TIU050/10X/11X/20X) is an Operator Station (OS) t hat prov ides extensive

monitoring and c ontrol in an extremely small pac k age. The Oper ator Station “OS” product line offers four

distinct categories of products as described i n Table 1.1.

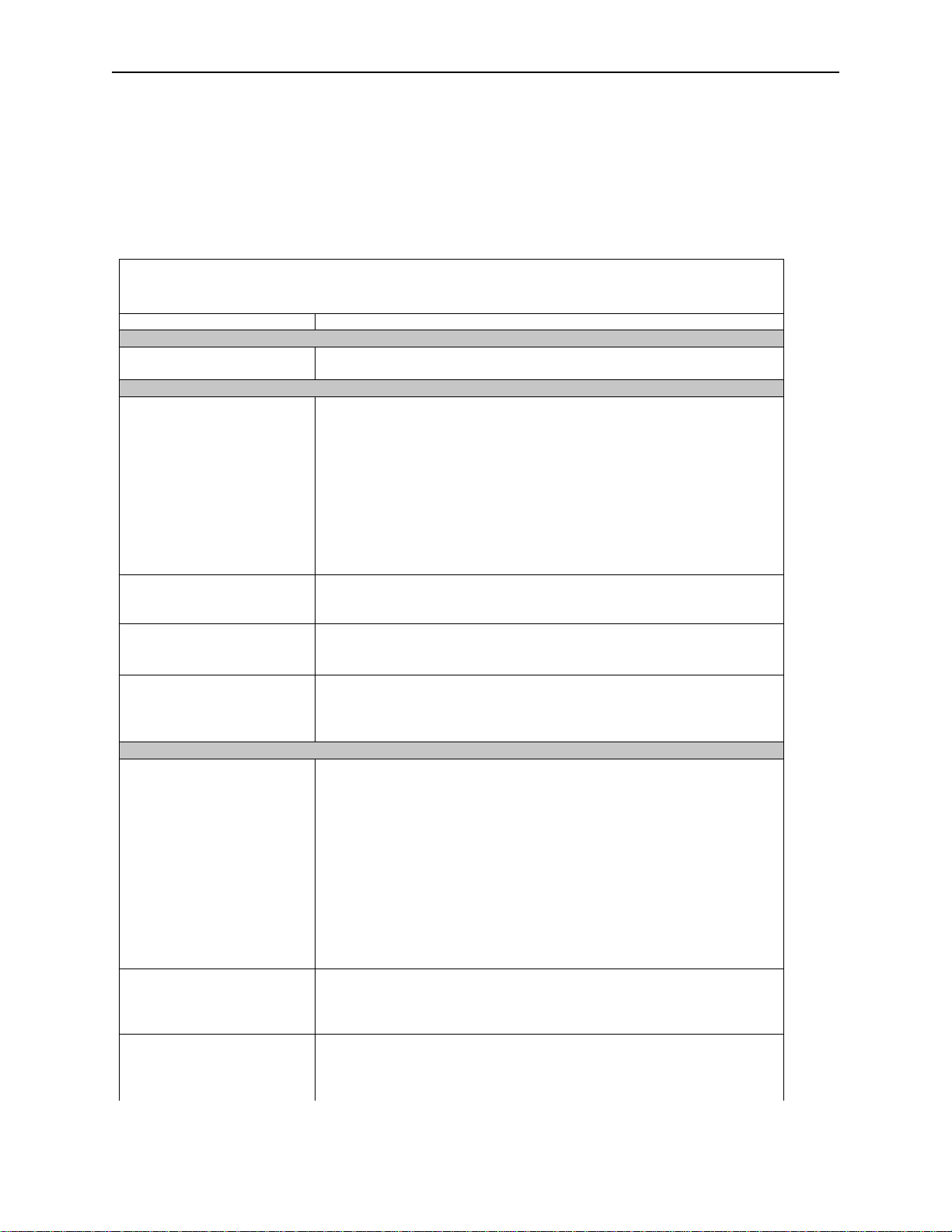

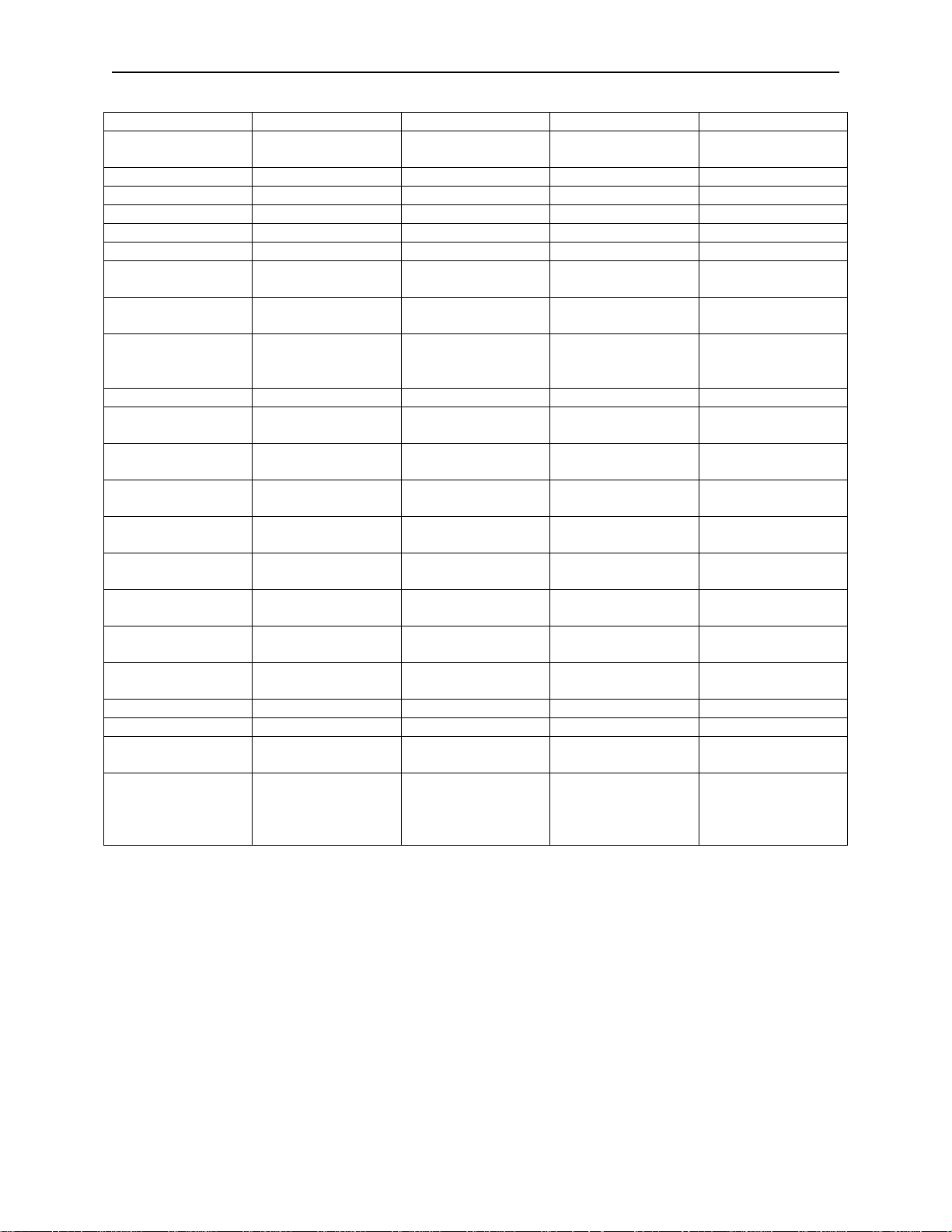

Table 1.1 – Operator St ation (OS ) Prod uct Line

Note: Only IC300 TIU101 / IC300 TIU111 IC300 TIU201 models are available through GE

Fanuc Channels.

Model Description

TIU050: Text Only

HE500TIU050-001

HE500TIU050-002

TIU10x: Text / Semi-Graphics

HE500TIU100-01

HE500TIU100-02

HE500TIU100-03

HE500TIU100-04

HE500TIU100-05

HE500TIU100-06

HE500TIU100-07

HE500TIU100-09

IC300TIU101-01

IC300TIU101-02

HE500TIU102-01

HE500TIU102-02

HE500TIU103-01

HE500TIU103-02

TIU11X: Text / Semi Graphics with Numeric Keypad

HE500TIU110-01

HE500TIU110-02

HE500TIU110-03

HE500TIU110-04

HE500TIU110-05

HE500TIU110-06

HE500TIU110-07

HE500TIU110-09

IC300TIU111-01

IC300TIU111-02

HE500TIU112-01

HE500TIU112-02

2 lines x 20 characters.

2 lines x 20 characters with Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels.

8 Lines x 20 Characters plus 128 x 64 pixels with Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels with Current Loop.

8 Lines x 20 Characters plus 128 x 64 pixels with Current Loop and Real

Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels with Stud Type Metalwork

8 Lines x 20 Characters plus 128 x 64 pixels with wide temperature

display.

8 Lines x 20 Characters plus 128 x 64 pixels with Bezel

8 Lines x 20 Characters plus 128 x 64 pixels with no metal and dill

connectors

8 Lines x 20 Characters plus 128 x 64 pixels with

8 Lines x 20 Characters plus 128 x 64 pixels with

Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels with a

8 Lines x 20 Characters plus 128 x 64 pixels with

and Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels with

Networks

8 Lines x 20 Characters plus 128 x 64 pixels with

Networks

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad.

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

Current Loop.

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

Current Loop and Real Time Clock.

8 Lines x 20 Characters plus 128 x 64 pixels with Stud Type Metalwork.

8 Lines x 20 Characters plus 128 x 64 pixels with wide temperature

display.

8 Lines x 20 Characters plus 128 x 64 pixels with Bezel

8 Lines x 20 Characters plus 128 x 64 pixels with no metal and dill

connectors

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

CsCAN Network

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

CsCAN Network

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

Profibus Network

8 Lines x 20 Characters plus 128 x 64 pixels plus a Numeric keypad with

Profibus Network

.

and Real Time Clock.

.

and Real Time Clock.

.

and Real Time Clock.

CsCAN Network

CsCAN Network

Profibus Network

Profibus Network

DeviceNet

DeviceNet

.

and

.

Page 7

PAGE 8 06 Apr 2000 CH. 1: INTRODUCTION

GFK-1819

HE500TIU113-01

HE500TIU113-02

TIU20X: Text / Full Graphics with Numeric / Function Keypad

HE500TIU200 16 Lines x 40 Characters plus 240 x 128 pixels plus a Numeric keypad /

IC300TIU201 16 Lines x 40 Characters plus 240 x 128 pixels plus a Numeric keypad /

HE500TIU202 16 Lines x 40 Characters plus 240 x 128 pixels plus a Numeric keypad /

HE500TIU203 16 Lines x 40 Characters plus 240 x 128 pixels plus a Numeric keypad /

8 Lines x 20 Characters plus 128 x 64 pixels with

8 Lines x 20 Characters plus 128 x 64 pixels with

and Real Time Clock.

Function keypad. Optional SmartStack I/O.

Function keypad. Optional SmartStack I/O. Can be used with

Network.

Function keypad. Optional SmartStack I/O. Can be used in a

Network

Function keypad. Optional SmartStack I/O. Can be used with

DeviceNet Network.

.

DeviceNet Network

DeviceNet Network

CsCAN

Profibus

.

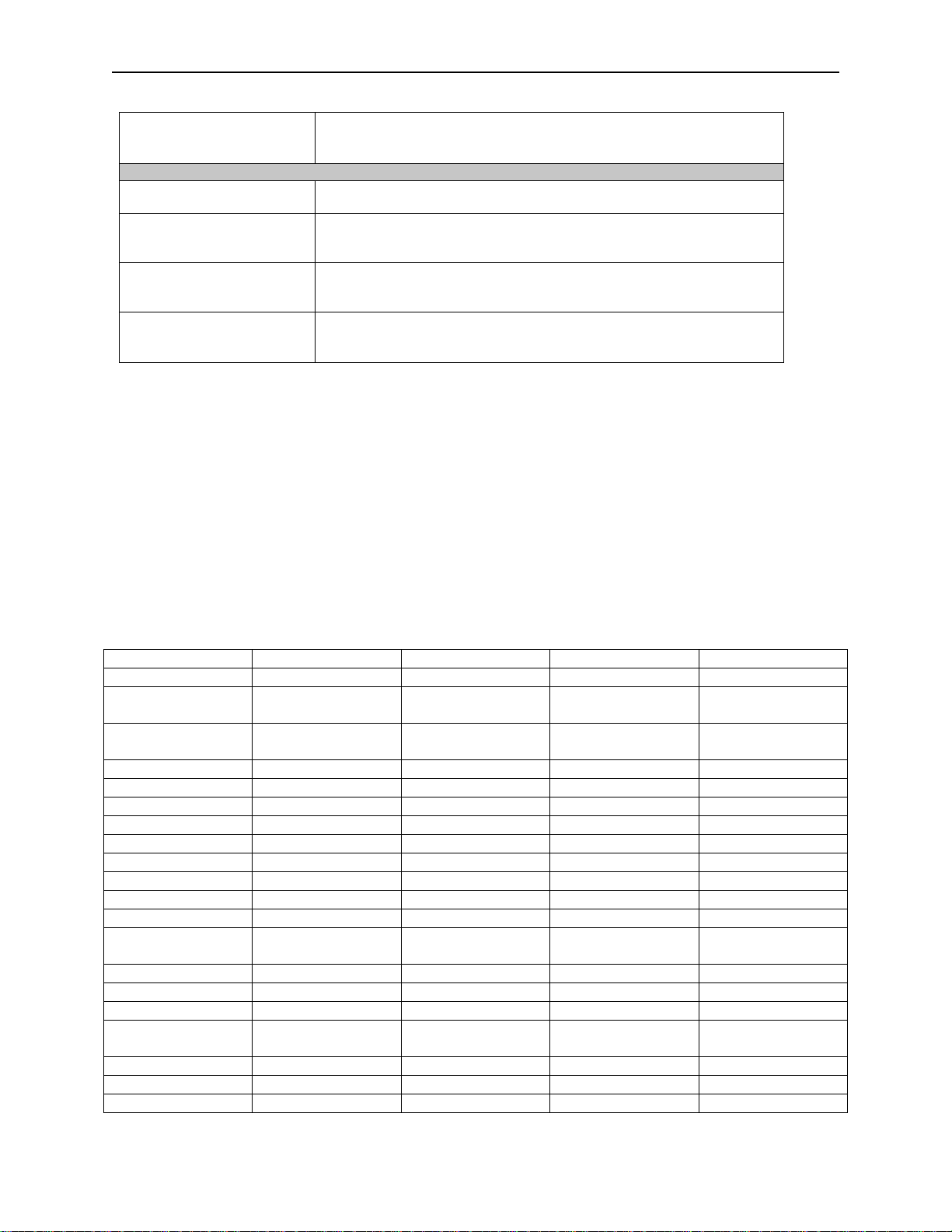

The front panel of the OS has a bright and clear display (LCD with adjustable back lit) and easy-to-use

push buttons. On the back panel ar e c ommunication ports for connection to automation equipm ent

(programm able logic controller, drive, weighing equipment or ot her equipment) and a PC (IBM or

compatible c om puter). Also located on the back panel or end of the bac k panel depending on the model,

the OS has clearly display ed features such as power input, PC and P LC port , Tx and Rx LEDs. Also,

depending on the model , a network port is provided for connec tion to whichever OS network you have

chosen.

The OS supports a variet y of protocols. Various protocols can be downloaded through the PC port and

stored in the unit’s flash memory. The operating system can al so be downloaded thr ough the PC port.

The OS range supports 3 network opt ions. CsCAN (TIUXX1) and Device (TIUXX3) and Profibus with the

TIUXX2 range.

HE500TIU050 HE500TIU10X HE500TIU11X HE500TIU20X

Software Cbreeze Included Included Included Included

Programming Port

Standard Standard Standard Standard

RS232

Communication Port

1111

232/485

Flash Ram 64 K Words 256 K Words 256 K Words 512 K Words

Memory UpgradeNoNoNo1 Meg

Words SRam 32 K Bytes 128 K Bytes 128 K Bytes 128 K Bytes

Memory Upgrade No No No 512 K Bytes

Total Pages 300 300 300 300

Characters per Page 2x20 8x20 8x20 16x40

Graphics pixels Text Only 128 x 64 128 x 64 240 x 128

Data fields/page88824

No. of Text tables 249 249 249 249

Text table size Rows

No No No 256

& Columns

Recipe Memory 0 64K 64K 64K

Recipes No Standard Standard Standard

Editable Fonts No Standard Standard Standard

Scaling Range

Standard Standard Standard Standard

checking

Tending No Standard Standard Standard

Graphing No Standard Standard Standard

Editable Graphi cs No No No Standard

Page 8

CH.1: INTRODUCTION 06 Apr 2000 PAGE 9

GFK-1819

Animated BitmapsNoNoNoStandard

Alarm s and Statu s

pages

Numeric keys Stan dard N o Standard S tandard

System keys4444

Function keys *10No1218

LED'sNoNoNo10

SmartStack option No No No Standard

Battery Back Ram +

Real Time Clock

Comprehensive

Math's Facilities

Day & Time

Scheduling,

Background Task

Internal Registers No 1024 %R 1024 %R 1024 %R

Operating

Temper ature C°

Storage TemperatureC°-10 to 70 -10 to 70 -10 to 70 -10 to 70

Standard Standard Standard Standard

Optional Optional Optional Standard

No 1024 lines 1024 lines 1024 li nes

No Standard Standard Standard

0 to 50 0 to 50 0 to 50 0 to 50

Humidity Non

Condensing Storage

Environmental

NEMA4 / IP65

Y2K Certified CE

Approved

Size -Width ,Height

,Depth mm

Cut-out -- Width ,

Height mm

Screen dimensions

mm

Input Voltage Range 9-35 Vdc 9-35 Vdc 9-35 Vdc 9-35 Vdc

Weight (grams) 325 370 450 1855

NetworkDeviceNet, CsCAN

Data xfer from

Automated device

via network Profibus

* System keys can be programmed to be function keys at specific times in the project. See Function keys in

CBREEZE Software Manual MAN0023

** The TIU100/110 is available with two non-standard features: 20mA current loop c ommunication and a

real-tim e cl oc k (RT C). Both can be ordered at the time of purchase. The current l oop c an be re-f it by the

user later. The RTC requires factor re-fit. The TIU050 is only av ailable with the real-time cl oc k opti on.

10-90% 10-90% 10-90% 10-90%

Yes Yes Ye s Yes

Yes Yes Yes Yes

180 X 120 X 60 121 X 105 X 38 172 X 105 X 38 281 X 192 X 58

151 X 89 100 X 85 153 X 85 242 X 158

80 X 17 70 X 38 70 X 38 130 X 75

No Optional Optional Optional

No Optional Optional Optional

*** The TIU20X provides for the display of both text and full gr aphics and has a Numeric/Function

Keypad. It also allows the use of a wide range of SmartStack I/O options.

1.2 Equipment Needed

1. The current v ersion of CBREEZE software install on a PC runni ng Windows 95, Windows 98 or

Windows NT.

2. TIU050/10X/11X/20 X Interface Unit.

Page 9

PAGE 10 06 Apr 2000 CH. 1: INTRODUCTION

GFK-1819

3. PC to TIU Programming Cable HE693CBL232 or equivalent See Chapter on Communications

Page 10

CH.1: INTRODUCTION 06 Apr 2000 PAGE 11

GFK-1819

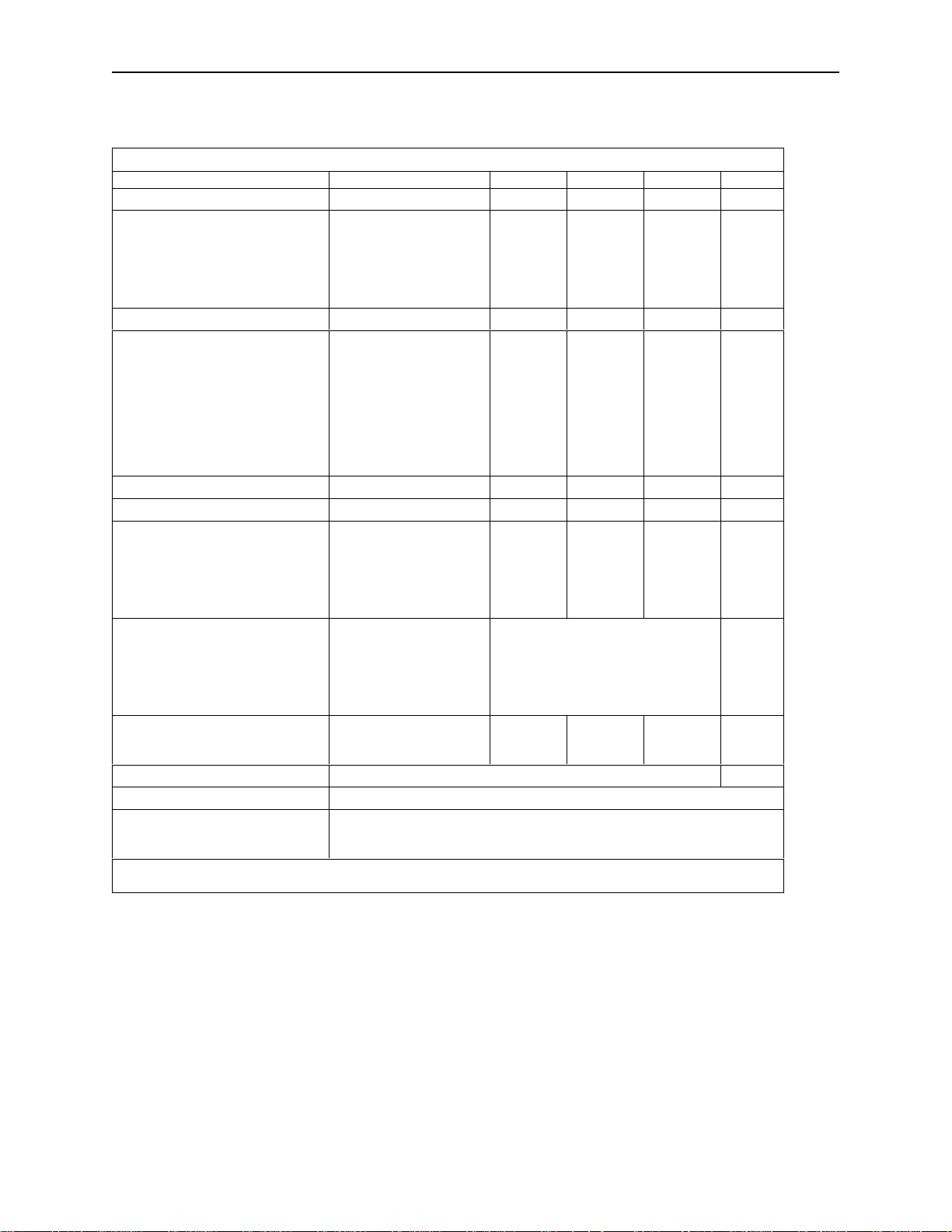

1.3 Technical Specifications

Table 1.2 – Technical Specifications

Parameter Conditions Min. Typical Max. Units

Input voltage (VI)102432VDC

Typical power consumption

= 24VDC

TIU050

TIU10X

TIU11X

TIU20X

V

I

= 24VDC

V

I

= 24VDC

V

I

= 24VDC

V

I

Inrush inp ut cu rrent VI = 24VDC for 4ms 260 mA

Operating temperature

TIU050

TIU10X

TIU10X-6

TIU11X

TIU11X-6

TIU20XA

TIU20XB or higher

0

0

-10

0

-10

0

0

Storag e tempera ture -20 70 °C

Relative Humidity (non-condensing) 10 90 %

Weight

TIU050

TIU10X

TIU11X

TIU20X

130

130

130

350

320

370

470

1870

50

50

60

50

60

45

50

350

400

500

1900

mA

°C

g

Dimensions

TIU050

TIU10X

TIU11X

TIU20X

Cable Lengths

†

RS-232

RS-485 1

179 x 111 x 60

121 x 105 x 38

172 x 105 x 38

282 x 194 x 62

15

1500

IP rating NEMA 4-12/IP65

EN 55 022, Radiated and Conducted Emissions

EMC Conformance

†

Cables beyond the maximum recommended length may create communication problems. Both ends of

EN 61000-4-3, Radiated and Conducted RF Immunity

ENV 50144

an RS-485 network must be properly terminated at 120Ω and grounded.

mm

m

Page 11

PAGE 12 06 Apr 2000 CH. 1: INTRODUCTION

GFK-1819

1.4 Upgrade Revision Software & Firmware

1.4.1 Scope

To avail of any new featur es that are included in this new release on units that were purchased previous

to this release, bot h software and firmware requi r e updating by the user. Any new unit will be set-up for

the latest version released.

1.4.2 Software Upgrade

To update the software requires that the user install the new version of software from the installation CD.

You may install t he new software over any previous version inst alled. See section 1.4 Software

Installation Instructions.

To update existi ng pr ojec ts simple open the project from the newly installed versi on of the software. Once

the project is saved to disk the update is complete. For bac k up r easons we recommend that you save the

new version of your pr ojec t in a different locati on or under a different file name.

1.4.3 Firmware Upgrade

The following steps assum e that a project or confi gur ation is loaded to the Operator Stati on and that the

user is running the latest version of software.

a) Upload the project/configur ation from the unit.

b) If a customised character set is loaded to the unit then upload the character set also.

c) Choose Automation Device from main menu Configure/ Communication Settings.

d) From File menu choose Update TIU Operating System. (See Updating Operating System for more

details).

e) From File menu choose Update TIU Protocol. If you are updat ing from firmware version 2.00 or later

then you just have to update to the latest protocol fil e. However if you are updating from firm ware

version 1.24 or earlier you most update to a Upgrade.1xx pr otocol file first, then update to the latest

firmware revision. See Note. (See updating protocol for further inf ormation).

f) Choose Download Character Sets to TIU from File menu.

g) Choose Download Project to TIU from File menu.

When updating the protocol file t he screen m ay go bl ank after the protocol file is complete.

Note:

Continue with t he procedur e as descri bed and the display will recover.

Page 12

CH.1: INTRODUCTION 06 Apr 2000 PAGE 13

GFK-1819

Page 13

PAGE 14 06 Apr 2000 CH. 1: INTRODUCTION

GFK-1819

NOTES

Page 14

CH.2: TIU050 06 Apr 2000 PAGE 15

P

U

D

E

GFK-1819

CHAPTER 2: TIU050

2.1 Scope

The TIU050 is a 2 line text only displ ay terminal. The hardware descript ion is detailed in this chapter.

Alphanumeric

Keypad

Programmable

+(7,8

AUSE Key

P Key

Function Keys

OWN Key

-

1Q Z_F12 ABC 3 DEF 4 GHI 5 JKL

F2 F3 F4 F5

6 MN O 7 PR SF78 TU V

F6

F8

9 WX Y 0

F9

F10

+

NTER Key

Figure 2.1 – Front View of TIU050

2.2 TIU050 Button Selection Action s

a)

PAUSE

b)

PAUSE & DOWN

c)

PAUSE & UP

d)

UP

e)

DOWN

f)

ENTER

g)

ALPHANUMERIC KEYPAD

key selects data f or editing OR exits from data editing.

keys pressed together, enters sub menu pages.

keys pressed together, ex its sub menus to the parent menu pages.

key selects the prev ious menu page, sub menu page, alarms, and increm ents data

key selects the next menu page, sub menu page, alarms and also decrement s data.

key sends data to the automation equipment, accepts alarms, and displays accepted alarms.

and

FUNCTION KEYS

can be used to enter data or can be used to

preform some pr e- pr ogr ammed action.

2.3 TIU050 Contrast Adjustment

On menu page 1 (after the start - up screen) , hold the

ENTER

key and press the UP or

adjust the contrast. The contrast setting is stored and not lost after removi ng power.

DOWN

key to

CONTRAST BAND - allows the user to set the l ower and upper limits of contrast. Adjust the lower limit

using the UP or DOWN key and press Enter when done. Do the same for the upper limit.

WARNING: - Changes to the lower or upper limits may allow the user to set the contrast to a setting

where the display may appear blank. It is recommended that t he factory setting are used (Min 8A, Max

FE).

Page 15

PAGE 16 06 Apr 2000 CH. 2: TIU050

F

P

GFK-1819

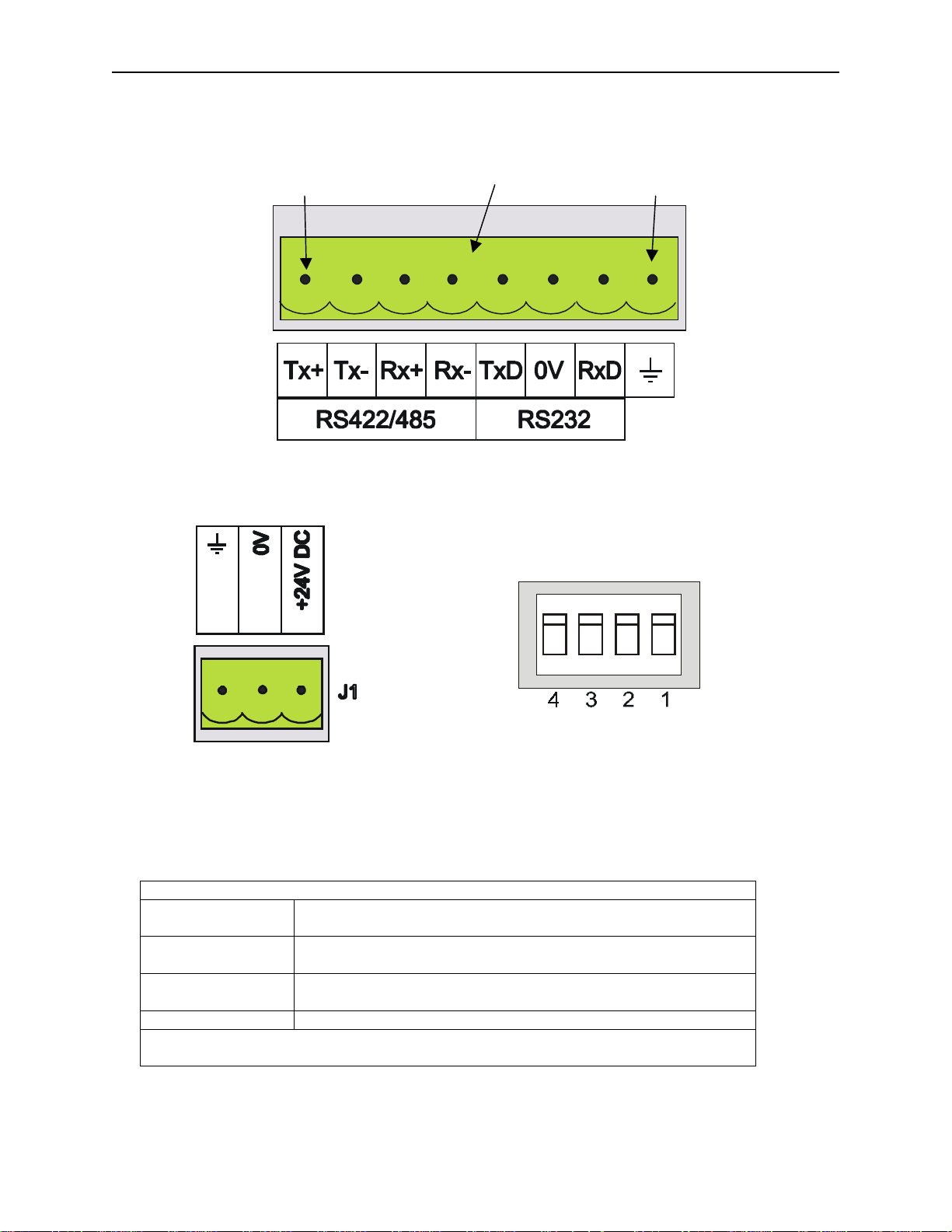

2.4 TIU050 Ports

Pin 1

igure 2.2 – Automation Equipment Serial Port

2.4.1 TIU050 Configuration of the RS-485 Port

in 8TIU050 8-pin Terminal Block

OFF

ON

SW1

Figure 2.3 – Power Connector

Powered by +24VDC and Ground.

The configurat ion bank (shown in Figure 2.5) sets the parameters of the RS-485 port as described in

Table 2.1.

Table 2.1 – Configuration Bank

Switch 1 ON: Pull-up (must be used together with switch 3)

OFF: no Pull-up

Switch 2

Switch 3 ON: Pull-down (must be used together with switc h 1)

Switch 4 Reserved for future use

NOTE:

used or neither i s used.

Switch 1 and 3 must be used together. Either both pull-up and pull-down are

ON: 120Ω termination

OFF: no terminati on

OFF: no Pull-down

Figure 2.4 – Configuration Bank

Page 16

CH.2: TIU050 06 Apr 2000 PAGE 17

GFK-1819

Pull-up

and

Pull-down

switches are used to incr ease the si gnal level on the RS-485 bus. This is usef ul if

there is a long bus and a signifi c ant amount of attenuation i s anti ci pated.

Termination

resistance of 120Ω must be placed across each end of the RS-485 bus. Wit h swit c h 2 ON,

a 120Ω resistance is placed across the bus. This is only used if the TIU050/100/110 is the last device at

either end of the bus.

2.5 TIU050 Dimensions

5.95” [151mm]

+0.02

3.27 ” [83 mm]

-0. 0 0

+0.5

-0. 0

UP TO 0.04”[1mm] CORNER

RADIUS IS ACCEPTABLE

TIU050 CUTO UT D ETAILS

TOLERANCES ARE +/- 0.01” [0.3mm] UNLESS STATED OTHERWISE

Figure 2.5 – TIU050 Cutout

Page 17

PAGE 18 06 Apr 2000 CH. 2: TIU050

GFK-1819

NOTES

Page 18

CH. 3: TIU100/101/102/103 06 Apr 2000 PAGE 19

E

D

GFK-1819

CHAPTER 3: TIU100/101/102/103

3.1 Scope

The TIU10X 128 x 64 pixel display , which allows for some graphics and various fonts to be displayed. .

The hardware description is detailed in thi s chapter.

PAUSE Key

UP Key

Figure 3.1 - Front View of TIU100

3.2 TIU10X Button Selection Actio ns

a)

PAUSE

b)

PAUSE & DOWN

c)

PAUSE & UP

d)

UP

e)

DOWN

f)

ENTER

3.3 TIU10X Contrast Adjustment

On menu page 1 (after the start - up screen) , hold the

adjust the contrast. The contrast setting is stored and not lost after removi ng power.

key selects data f or editing OR exits from data editing.

keys pressed together, enters sub menu pages.

keys pressed together, ex its sub menus to the parent menu pages.

key selects the prev ious menu page, sub menu page, alarms, and increm ents data

key selects the next menu page, sub menu page, alarms and also decrement s data.

key sends data to the automation equipment, accepts alarms, and displays accepted alarms.

OWN Key

ENTER

key and press the UP or

NTER Key

DOWN

key to

CONTRAST BAND - allows the user to set the l ower and upper limits of contrast. Adjust the lower limit

using the UP or DOWN key and press Enter when done. Do the same for the upper limit.

WARNING: - Changes to the lower or upper limits may allow the user to set the contrast to a setting

where the display may appear blank. It is recommended that t he factory setting are used (Min 8A, Max

FE).

Page 19

PAGE 20 06 Apr 2000 CH.3: TIU100/101/102/103

T

GFK-1819

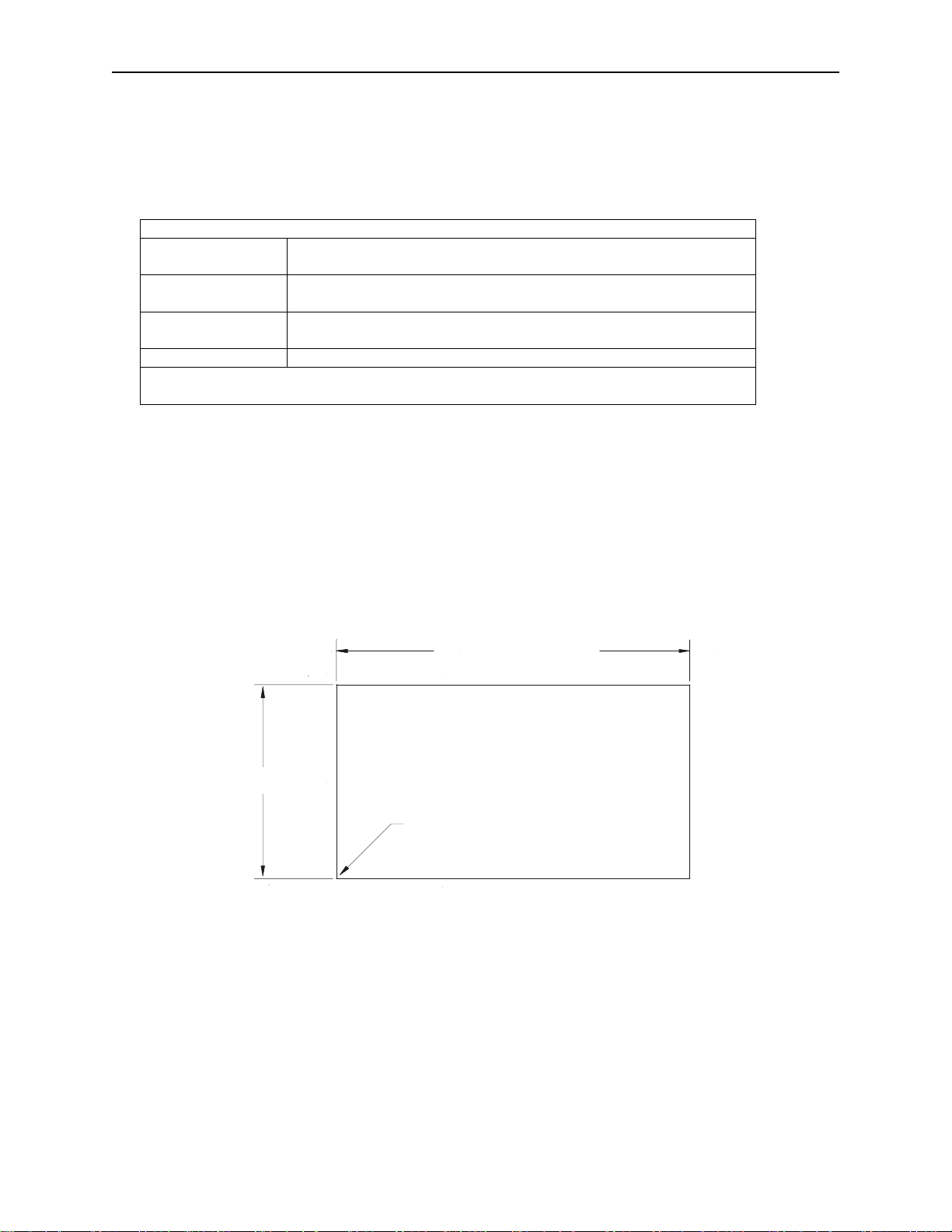

3.4 TIUX Rear View

3.5 TIU100 Ports

Pin 1

Pin 1

Figure 3.2 – Rear View of TIU100/101/102

To P C

Rx Pin 2

Tx Pin 3

0V Pin 5

Pin 1

IU100 13-pin Terminal Bl oc k

Pin 13

Page 20

CH. 3: TIU100/101/102/103 06 Apr 2000 PAGE 21

GFK-1819

Rx

Tx

Serial Port

Figure 3.4 – Automation

Equipment Port Receive &

Transm it L EDs

The LED’s flash when the TIU10X

is communicating with the AE.

Figure 3.3 – Automation Equipment Serial Port

3.5.1 TIU10X Configuration of the RS-485 Port

The configurat ion bank (shown in Figure 3.8) sets the parameters of the RS-485 port as described in

Table 3.1.

Table 3.1 – Configuration Bank

Switch 1 ON: Pull-up (m ust be used together with switch 3)

OFF: no Pull-up

Switch 2

Switch 3 ON: Pull-down (m ust be used together with switch 1)

Switch 4 Reserved for future use

NOTE:

used or neither i s used.

Switch 1 and 3 must be used together. Either both pull-up and pull-down are

ON: 120Ω termination

OFF: no terminati on

OFF: no Pull-down

Figure 3.5 – PC Port Receive &

PC Port

Transm it L EDs

The LED’s flash when the PC is

communicating with the TIU10X

Rx

Tx

Pull-up

there is a long bus and a signifi c ant amount of attenuation i s anti ci pated.

and

Pull-down

switches are used to incr ease the si gnal level on the RS-485 bus. This is usef ul if

Page 21

PAGE 22 06 Apr 2000 CH.3: TIU100/101/102/103

GFK-1819

OFF

ON

SW1

Figure 3.6 – Power Connector

Figure 3.7 – Configuration Bank

Powered by +24VDC and Ground.

Termination

resistance of 120Ω must be placed across each end of the RS-485 bus. Wit h swit c h 2 ON,

a 120Ω resistance is placed across the bus. This should only be used if the TI U050/100/110 is the last

device at either end of the bus.

3.6 TIU10X Dimensions

+0.02

3.94” [100 mm ]

-0.0 0

+0.5

-0.0

+0.02

-0.0 0

+0.5

-0.0

3.27” [83 mm]

UP TO 0.04”[1mm] CORNER

RADIUS IS ACCEPTABLE

TIU10X CUTOUT DETAILS

TOLERANC ES ARE +/- 0 .01” [0.3mm] UNLESS STATED OTHERWISE

Figure 3.8 – TIU10X Cutout

Page 22

CH. 4: TIU110/111/112/113 06 Apr 2000 PAGE 23

N

P

F

GFK-1819

CHAPTER 4: TIU110/111/112/113

4.1 Scope

The TIU11X 128 x 64 pixel display , which allows for some graphics and various fonts to be displayed.

The hardware description is detailed in thi s chapter.

QZ_

GHI

PRS7TUV8WXY

Del

ABC

1

JKL

4

.

DEF

2

5

3

MNO

6

9

+/-

umeric Keypad

rogrammable

unction Keys

Figure 4.1 – Front View of TIU110

4.2 TIU11X Button Selection Actio ns

a)

PAUSE

b)

PAUSE & DOWN

c)

PAUSE & UP

d)

UP

e)

DOWN

f)

ENTER

g)

ALPHANUMERIC KEYPAD

key selects data f or editing OR exits from data editing.

keys pressed together, enters sub menu pages.

keys pressed together, ex its sub menus to the parent menu pages.

key selects the prev ious menu page, sub menu page, alarms, and increm ents data

key selects the next menu page, sub menu page, alarms and also decrement s data.

key sends data to the automation equipment, accepts alarms, and displays accepted alarms.

and

PROGRAMMABLE KEYS

can be used to enter data or can be

used to preform some pr e- pr ogr ammed action.

4.3 TIU11X Contrast Adjustment

On menu page 1 (after the start - up screen) , hold the

ENTER

key and press the UP or

adjust the contrast. The contrast setting is stored and not lost after removi ng power.

DOWN

key to

CONTRAST BAND - allows the user to set the l ower and upper limits of contrast. Adjust the lower limit

using the UP or DOWN key and press Enter when done. Do the same for the upper limit.

WARNING: - Changes to the lower or upper limits may allow the user to set the contrast to a setting

where the display may appear blank. It is recommended that t he factory setting are used (Min 8A, Max

FE).

Page 23

PAGE 24 06 Apr 2000 CH. 4: TIU110/111/112/113

T

GFK-1819

4.4 TIU11X Rear View

4.5

TIU110 Ports

Pin 1

Pin 1

Figure 4.2 – Rear View of TIU11X

To P C

Rx Pin 2

Tx Pin 3

0V Pin 5

Pin 1

IU110 13-pin Terminal Bl oc k

Pin 13

Figure 4.3 – Automation Equipment Serial Port

Page 24

CH. 4: TIU110/111/112/113 06 Apr 2000 PAGE 25

GFK-1819

Rx

Tx

Serial Port

Figure 4.4 – Automation

Equipment Port Receive &

Transm i t LEDs

The LED’s flash when the TIU110

is communicating with the AE.

Rx

Tx

PC Port

Figure 4.5 – PC Port Receive &

Transm i t LEDs

The LED’s flash when the PC is

communicating with the TIU110

OFF

ON

Figure 4.6 – Power Connector

Powered by +24VDC and Ground.

SW1

Figure 4.7 – Configuration Bank

Page 25

PAGE 26 06 Apr 2000 CH. 4: TIU110/111/112/113

GFK-1819

4.5.1 TIU11X Configuration of the RS-485 Port

The configurat ion bank (shown in Figure 4.8) sets the parameters of the RS-485 port as described in

Table 4.1.

Table 4.1 – Configuration Bank

Switch 1 ON: Pull - up (must be used together with switch 3)

OFF: no Pull-up

Switch 2

ON: 120Ω termination

OFF: no terminati on

Switch 3 ON: Pull - down (must be used together with switch 1)

OFF: no Pull-down

Switch 4 Reserved for future use

NOTE:

Switch 1 and 3 must be used together. Either both pull-up and pull-down are

used or neither i s used.

Pull-up

and

Pull-down

switches are used to incr ease the si gnal level on the RS-485 bus. This is usef ul if

there is a long bus and a signifi c ant amount of attenuation i s anti ci pated.

Termination

resistance of 120Ω must be placed across each end of the RS-485 bus. Wit h swit c h 2 ON,

a 120Ω resistance is placed across the bus. This should only be used if the TI U050/100/110 is the last

device at either end of the bus.

4.6 TIU11X Dimensions

5.95” [151mm]

+0.02

3.27” [83 mm]

-0. 0 0

+0.5

-0. 0

UP TO 0.04”[1mm] CORNER

RADIUS IS ACCEPTABLE

TIU11X C UTO UT DE TAILS

TOLERANCES A RE + /- 0.01” [0.3mm] UNLESS STATED OT H ERW ISE

Figure 4.8 – TIU11X Cutout

Page 26

CH. 5: TIU200/201/202/203 06 Apr 2000 PAGE 27

GFK-1819

CHAPTER 5: TIU200/201/202/203

5.1 Scope

The TIU20X is 240 x 128 pixel displ ay whic h allows for full graphic screen. The hardware description is

cover under the followi ng c hapter

F9 F10 F11 F13F12

F14 F15 F16 F17 F18

Figure 5.1 – Front View of TIU20X

5.2 TIU20X Button Selection Actio ns

a)

PAUSE

b)

PAUSE & DOWN

c)

PAUSE & UP

d)

UP

e)

DOWN

f)

ENTER

g)

ALPHANUMERIC KEYPAD

h)

PROGRAMMABLE KEYS

key selects data f or editing OR exits from data editing.

keys pressed together, enters sub menu pages.

keys pressed together, ex its sub menus to the parent menu pages.

key selects the prev ious menu page, sub menu page, alarms, and increm ents data

key selects the next menu page, sub menu page, alarms and also decrement s data.

key sends data to the automation equipment, accepts alarms, and displays accepted alarms.

can be used to enter data

can be used to preform some pre-pr ogr ammed action.

QZ

1

GHI4JKL5MNO

ABC

2

DEF

3

6

PRS7TUV8WXY

9

.

Del

SPACE

0

0

+/-

NEXT

Page 27

PAGE 28 06 Apr 2000 CH. 5: TIU200/201/202/203

P

GFK-1819

5.3 TIU20X Contrast Adjustment

On menu page 1 (after the start - up screen) , hold the

adjust the contrast. The contrast setting is stored and not lost after removi ng power.

CONTRAST BAND - allows the user to set the l ower and upper limits of contrast. Adjust the lower limit

using the UP or DOWN key and press Enter when done. Do the same for the upper limit.

WARNING: - Changes to the lower or upper limits may allow the user to set the contrast to a setting

where the display may appear blank. It is recommended that t he factory setting are used (Min 8A, Max

FE).

5.4 TIU20X Rear View

ENTER

key and press the UP or

DOWN

key to

5.5 TIU20X Ports

Pin 1

6HULDO 1R

0RGHO 1R

Figure 5.2 – Rear View of TIU20X

in 8TIU20X 8-pin Terminal Block

Figure 5.3 Automated Equipment Serial Port

Page 28

CH. 5: TIU200/201/202/203 06 Apr 2000 PAGE 29

GFK-1819

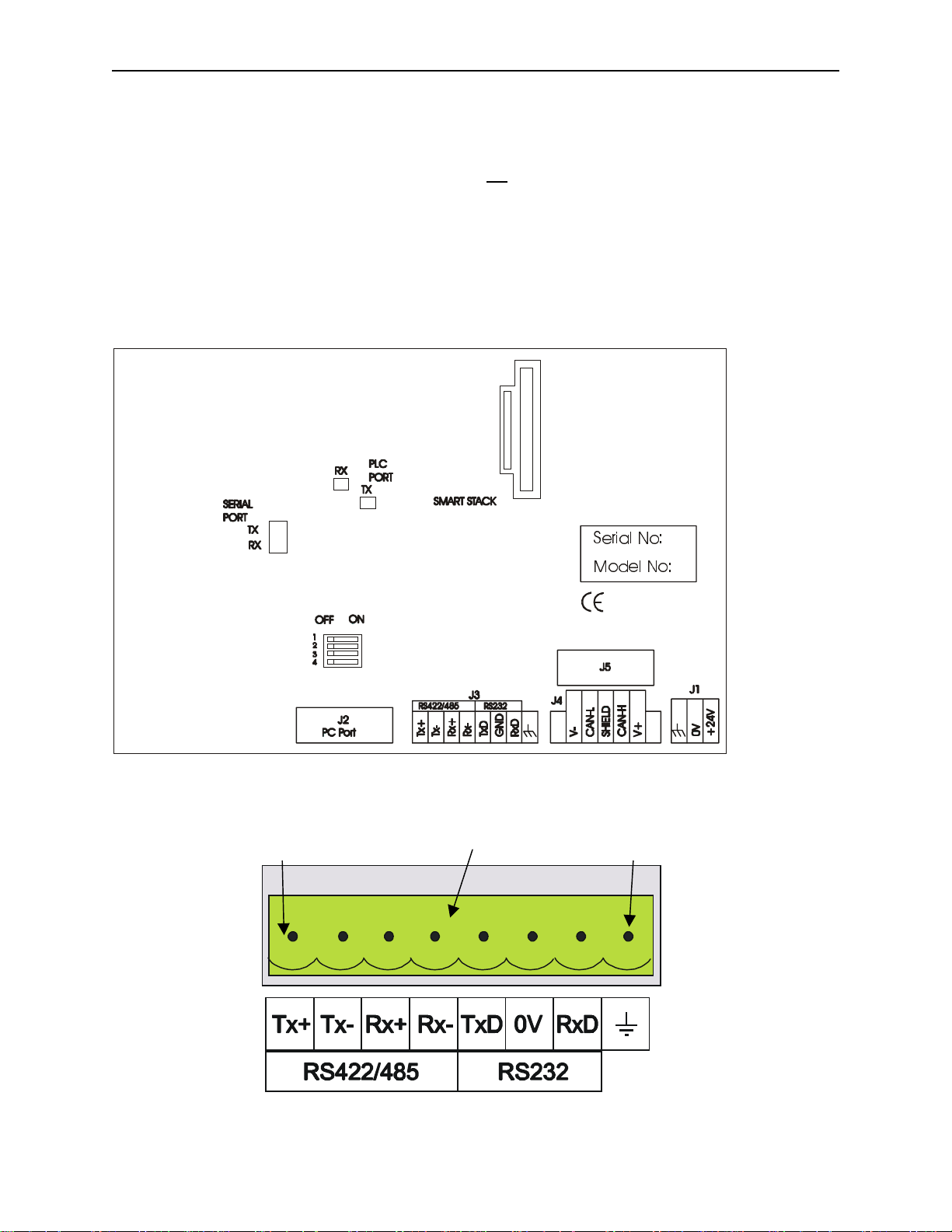

Rx

Tx

Serial Port

Figure 5.4 – Automation

Equipment Port Receive &

Transm i t LEDs

The LED’s flash when the TIU20X

is communicating with the AE.

Rx

Tx

PC Port

Figure 5.5 – PC Port Receive &

Transm i t LEDs

The LED’s flash when the PC is

communicating with the TIU20X

OFF

ON

SW1

Figure 5.6 – Power Connector

Powered by +24VDC and Ground.

Figure 5.7 – Configuration Bank

Page 29

PAGE 30 06 Apr 2000 CH. 5: TIU200/201/202/203

+

-

GFK-1819

5.5.1 TIU20X Configuration of the RS-485 Port

The configurat ion bank (shown in Figure 2.23) sets the parameters of the RS-485 port as described in

Table 5.1.

Table 5.1 – Configuration Bank

Switch 1 O N: Pull-up (must be used together with switch 3)

OFF: no Pull-up

Switch 2

ON: 120Ω termination

OFF: no terminati on

Switch 3 O N: Pull-down (must be used together with switch 1)

OFF: no Pull-down

Switch 4 Reserved for future use

NOTE:

Switch 1 and 3 must be used together. Either both pull-up and pull-down are

used or neither i s used.

Pull-up

and

Pull-down

switches are used to incr ease the si gnal level on the RS-485 bus. This is usef ul if

there is a long bus and a signifi c ant amount of attenuation i s anti ci pated.

Termination

resistance of 120Ω must be placed across each end of the RS-485 bus. Wit h swit c h 2 ON,

a 120Ω resistance is placed across the bus. This should only be used if the TI U050/10X/11X/20X is the

last devic e at eit her end of the bus.

5.6 TIU20X Dimensions

0.02

µ > PP@

0.00

+0.02

µ >

-0.00

+0.5

-0.0

83 72 µ &RUQHU >5$',86 ,6 $&&(37$%/(PP@

7,8; &87287 '(7$,/6

72/(5$1&(6 $5( µ >PP@ 81/(66 67$7(' 27+(5:,6(

Figure 5.8 – TIU20X Cutout

Page 30

CH. 6: COMMUNICATIONS 06 Apr 2000 PAGE 31

GFK-1819

CHAPTER 6: COMMUNICATIONS

6.1 PC to Operator Station Communi cation s

The serial pin connect ions for transmit (Tx ), r ec eiv e (Rx) and ground are displayed below.

1

TIU1X X PC

2 T x 2 Rx

3 R x 3 Tx

5

Figure 6.1 – PC Programming Serial Port & Connect io n Detail

6.2 Automation Equipment (AE) Communications Connections

6.2.1 Recommended Automat i on E quipm ent Communication Cables

Horner Electric r ec ommends the following cables for automation equipment communication:

Belden No. 8105, 9807 or 9832 – Gener al P ur pose

Belden No. 8165 – Heavy Noise Environment

6.3 RS-232 Connection

5 0V 5 0V

TIU 110/100

RS232

(Section of 13-pin

Term inal Block)

RS232

TxD

RxD

0V

6

7

8

AE

Rx

0V

Tx

TIU050/101/102/103/111/112/113/20X

RS232

(Section of 8-pin

Term inal Block)

RS232

TxD

RxD

5

0V

6

7

Figure 6.2 – RS-232 Connection

AE

Tx

Rx

0V

Page 31

PAGE 32 06 Apr 2000 CH. 6: COMMUNICATIONS

GFK-1819

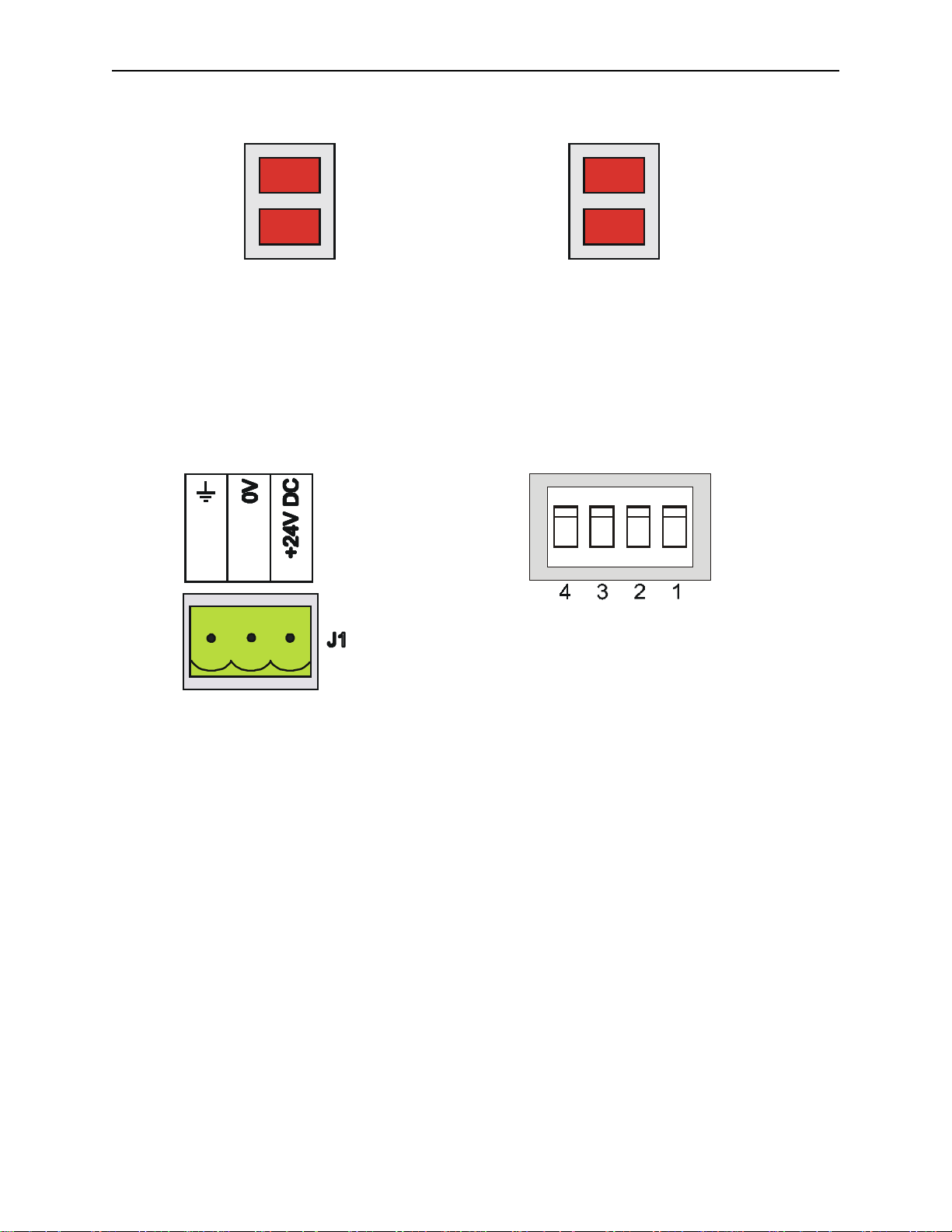

6.4 RS-422/485 Four-Wire

TIU110/100

(Section o f 13 -pin

Term inal Block)

RS422/485

(4 -wire )

TIU050/101/102/103/111/112/113/20X

RS 422 /485

RS232

Tx+

Tx-

Rx+

RxTxD

0V 7

RxD

2

3

4

5

6

8

0.1uF Ce ram ic

Automated E q uipm en t

RS 42 2/48 5 Conn ections

See Note Below

(Section o f 8-pin

Term inal Block)

RS 422 /485

RS422/485

(4 -wire )

The descriptions used by different manuf actur er s f or RS - 422/485 connections vary. Please refer to

Note:

the automation equipment manufactur er s own manuals for connection detail s.

Horner produces appli c ation notes explaining the connection to each of the differ ent aut om ated

Note:

equipment manufactures. These applic ation notes are ongoing, see your installation CD for any released

documentation.

RS232

Figure 6.2 – RS-422/485 Four-Wir e

Tx+

Tx-

Rx+

RxTxD

0V 6

RxD

1

2

3

4

5

7

0.1uF Ce ram ic

Automated E q uipm en t

RS 42 2/48 5 Conn ections

See Note Below

Page 32

CH. 6: COMMUNICATIONS 06 Apr 2000 PAGE 33

GFK-1819

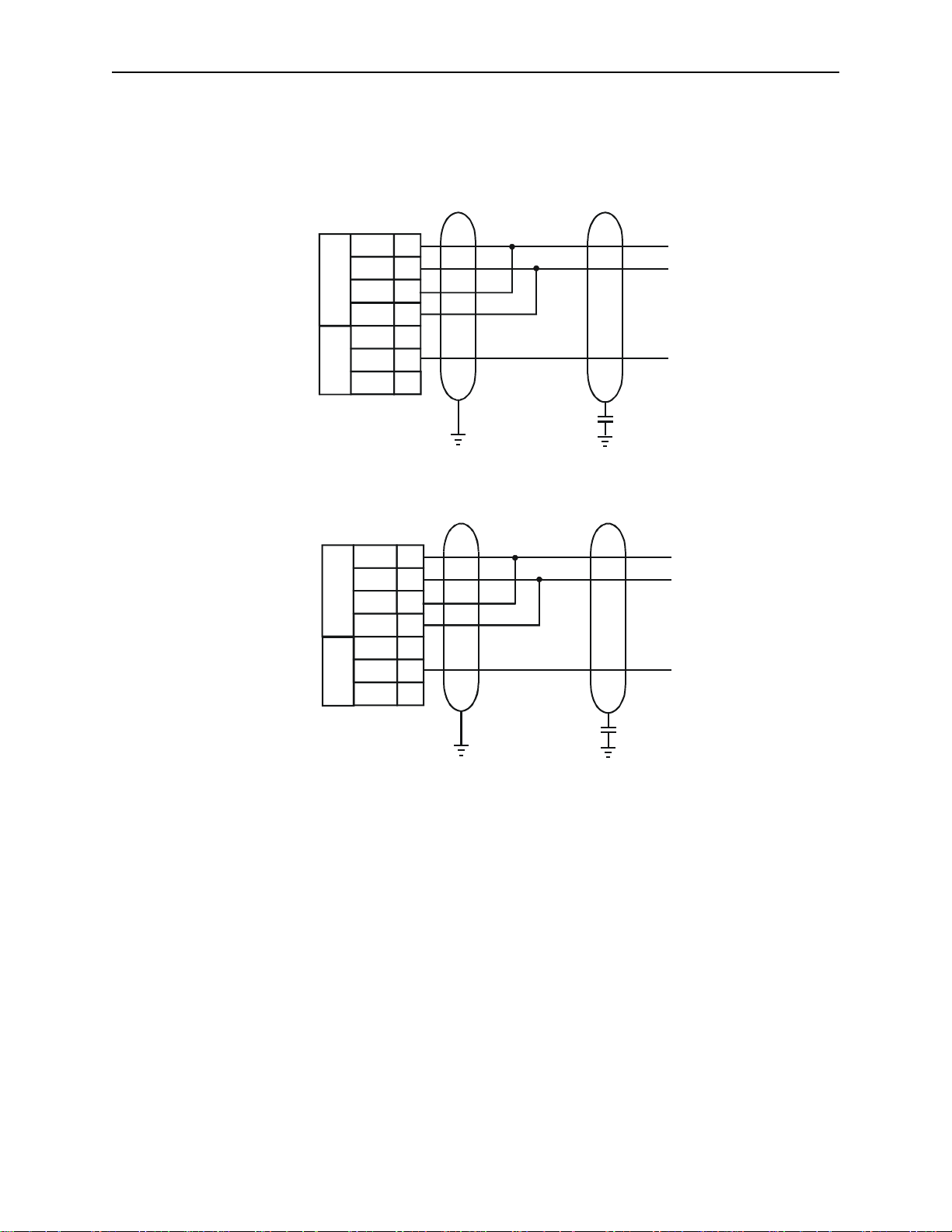

6.5 RS-485 Two-Wire

TIU110/100

RS422/485

(2 -w ire )

TIU050/101/102/103/111/112/113/20X

RS422/485

(2 -w ire )

RS4 22/485

RS232

RS422 /485

RS232

Tx+

TxRx+

RxTxD

0V

RxD 8

Tx+

TxRx+

RxTxD

0V

RxD 7

AE

2

3

4

5

6

7

0.1uF Ceramic

1

2

3

4

5

6

Tx/Rx+

Tx/Rx-

COM

AE

Tx/Rx+

Tx/Rx-

COM

Figure 6.3 – RS-485 Two-Wire

0.1uF Ceramic

Page 33

PAGE 34 06 Apr 2000 CH. 6: COMMUNICATIONS

GFK-1819

6.6 Current Loop

The following diagr am shows the connection to a devic e with an active 20mA current loop. The current

loop on the TIU100/110 is passive. Either the PLC must provide t he 20m A source or an ex ternal current

source must be suppli ed.

20mA Loo p

T+

9

T-

20m A Loop

Note: Current Loop is not a standard option on the T IU100/ 110

specifical ly or can be re-fit into a standard unit. Contact a Horner El ec tric dealer for more information.

Note: Current Loop is not an option with the TIU050/ 101/102/103/111/112/ 113/20X.

10

R+

11

R-

12

Figure 6.4 – Current Loop

. Current loop must be ordered

+

ST

SR

-

Page 34

CH. 7: GETTING STARTED 06 Apr 2000 PAGE 35

GFK-1819

CHAPTER 7: GETTING STARTED

7.1 Self-Test

Power up the unit wit h the UP and

ENTER

mode. The self-test c onsi sts of the following four check s:

7.1.1 Contrast Band

This test allows t he user to set the lower and upper limits of contrast. Adjust the lower limit using the

key and press

Enter

when done. Do the sam e for the upper limit.

WARNING: - Changes to the lower or upp er li mits may allow the user to set the contrast to a

setting where the displ ay may app ear bl ank. It is recommended that the factory setting are used

(Min 8A, Max FE).

7.1.2 Display Test

The display test continuously blinks all pix els on (black) to off. Look for any pixels stuck on or off. Exit

this test by pressing and holding any key for approximately two seconds.

7.1.3 Keyboard Test

As each key is pressed, an indi c ation

keypad, press the key and a message appears indicating the key press. Check for keys indicati ng

multiple presses or not r epor ting presses. Exit this test by pr essing and holding any key for

approximately two seconds.

keys pressed at the same time. The unit ent er s a self - test

UP

appears above that key. In the case of units with a numeric

***

or

DOWN

7.1.4 RAM Test

Test either segment 0000 or segment 1000 (on the TIU100/ 110) of t he RAM. The segment 1000 t est

performs a base 3 repeating test. This test detects shorted addres s l ines and damaged memory bits.

The segment 0000 test performs a Read-Modify-Write test on each byte of RAM, detecting dam aged

memory bits. Exit this test by selecting DONE.

7.1.5 Serial Loop-back Test s

Tests the PC port and the Serial P or t in each of it’s three modes for serial loop-back. Pre-made plugs are

required to link the pins of a particular port. This takes the following form:

Table 7.1 Loop-back Test Plugs

Port Tested Produc t Type of Connector Pins to Short

PC (J2) TIU100/110 Pin male D link connector pin 2 to pin 3

RS-232 (J3) TI U100/110 13-pin phoenix connecti on pin 6 to pin 8

RS-422/485 (J3) TIU100/110 13-pin phoenix connec tion pin 2 to pin 4 and pin 3

to pin 5.

Current Loop TIU100/110 13-pin phoenix connecti on pin 1 to 9, pin 10 to 11

and pin 12 to 7

PC TIU050/101/102/1

Pin male D link connector pin 2 to pin 3

03/112/113/20X

RS-232 TIU050/101/102/1

8-pin phoenix c onnection Pin 5 to pin 7

03/112/113/20X

RS-422/485 TIU050/101/102/1

03/112/113/20X

NOTE:

current loop in not installed on standard models, as such a standard model will fail the

8-pin phoenix c onnection Pin 1 to pin 3, Pin 2 to

pin 4

current loop-back test. Current Loop is not an opti on on the TI U050/20X.

After starting the test, the OK counter begins to count up. Exit this test by selecting

DONE

.

Page 35

PAGE 36 06 Apr 2000 CH. 7: GETTI NG STARTED

_

.

T

GFK-1819

7.2 Updating the Protocol

When the software is i nstalled the user decides where the m ain CB REEZE folder resides. During

install ation the following folder s are cr eated: -

In the protocol directory 3 folders are creat ed, TIU0xx, TIU1xx and TIU2xx. The protoc ol files for the

different t erminal is loaded into these folders. The protocol files for the TIU050 are loaded into Tiu0xx, the

protocol files for the TIU10X are loaded into Tiu10x and the protocol files for t he TIU20X are loaded into

Tiu20x.

The name of the protoc ol file is broken up into three section, the protocol, the main software revsion and

the terminal type that protocol file is for.

Protocol Name

Example

snp_R4.1xx

This is the protocol file for release 4 software for the GE FANUC P LC, for the TIU10X

df1_R4.2xx

This is the protocol file for release 4 software for Allen Brabley PLC, for the TIU20X

To Update Protoc ol File

1. Set Terminal Type

2. Set the required Automation Equipment in Communic ations Settings

3. Select

4. Select the folder of the terminal you have connected to t he PC. The cor r ect file will appear for the

terminal type sel ec ted and the Automation Equipment sel ec ted. Select that file and cli c k OK.

5. A status bar appears indic ating download progress.

6. After the transfer, the TIU050/10X/11X/20X resets itself. The correct P LC type i s di spl ay ed on the

TIU050/10X/11X/20X.

7. Next, the project loaded runs.

7.3 Updating the Operating System

1. Select

2. Choose the updated file with the “BIN” extension. Click OK.

3. A status bar appears indic ating download progress.

4. During the download proc es s, TIU050/10X/11X/20X displays the message “

Update TIU Protocol

Update Operating System

Software Revision

menu.

from the

ile

F

from the

ile

F

erm ina l Ty pe

menu.

SYSTEM SHUTDOWN

”.

Page 36

CH. 8: NETWORKS 06 Apr 2000 PAGE 37

GFK-1819

CHAPTER 8 : NETWORKS

8.1 Scope

This chapter giv es a brief introduction int o the net working hardware available on the Operator Station

range. The part numbers of the various options are av ailable in the Introduction Chapt er of t his manual.

For information on programming the various network options see GFK-1818, User Manual for the

CBREEZE Software.

8.2 Controller Area Netwo rk ( CAN) Overview

The controller area network (or CAN bus) is a serial communications bus that was originall y developed in

the late 1980’s by a German com pany (Robert B osch) for use in the automotive industry. CAN is an ISO

(International Standards Organisation) - defined serial communications bus for real-time appli c ations.

Established i n 1947, the International Standards Or ganisation (I SO) i s a multi national body dedicat ed to

worldwide agreement on international standar ds. S pec ifically, CAN is document ed in ISO 11898 (for

high-speed appli c ations) and ISO 11519 (for lower-speed applications).

8.2.1 CAN Features

CAN-based open autom ation technology successfully competes on the market of distr ibuted automation

systems because of the speci al features of the CAN protocol. T he special features are CAN’s producerconsumer-oriented (or peer-to-peer) principle of data transmi ssion and its multi-master c apability. The

general design of CAN originally specifi ed a high bit rate, high immunity to electri c al interference and an

ability to detect any er r or s produced. CAN networks have the foll owi ng gener al attributes:

•

Automatic er r or detec tion

•

Easily configurable

•

Cost-effective to design and implement

•

Capable of operating in harsh environments

8.3 CsCAN Network Overview

The CsCAN Network was fi r st dev eloped in 1993 by Horner Electric. It was developed for use in a project

that Horner Electr ic completed for the United States Post Office. Horner Electric dev eloped its own

network, because i t needed a network that had a specific set of powerful peer-to-peer and host- to-node

capabiliti es. The CsCAN Net work has a “pass-through” feature whereby PC- base d pr ogr ams access

other nodes connected to a network by passing the programming command through the serial por t to the

network port. (For a more detailed description, see below.) Horner Electric found that by developing its

own network, it sati sfied several important needs. Hor ner Electric continues CsCAN Net work

development t o sati sfy the requirements of today and the requirements of the future.

8.3.1 CsCAN Network Features

The CsCAN Network is based on CAN, which has many desi r able features such as ruggedness, ease of

configuration, etc. With Horner Electric Controllers, data is passed at 125Kbp s using a dif ferential pair of

wires plus a ground. It is important to note that the data rate is not limit ed to 125Kbps. The maximum

data rate is 1Mbps (limited by the speed of light). The CAN implementation in the CsCAN controller

allows up to 64 controllers to be networked with no additi onal hardware and up to 253 controllers with

three CAN repeaters.

For the programmer, little knowledge of networking procedures is needed. Howev er for troubleshooting

and optimizing, the following inform ation is helpful. Instead of usi ng m aster /slave or token passing, the

hardware self-arbitrates based on the Network ID.

given a higher prio rity than controllers with higher Netwo rk ID numbers.

Controllers with lower Network ID numbers are

8.3.2 CsCAN Network Operation

When a controller needs to send data over the network, it fir st waits for the network to be idle (curr ently a

maximum of 900uS). If two controllers start broadcasting information on t he network at the same time, the

Page 37

PAGE 38 06 Apr 2000 CH. 8: NETWORKS

GFK-1819

"self-arbitration" causes the controller with the greater Network ID number to cease broadcasting without

affecting t he message-in-progress of the ot her controller.

In applications wit h a large number of networked cont r ollers, better result s may be achieved by assigning

lower Network IDs to contr ollers that have more critical network data than other controllers. By assigning

higher Network IDs to c ontrollers that provide num er ous network updat es, the control lers are prevented

from monopolising the bus time.

Each controll er is capable of broadcasting Gl obal Digital Output bits (%QG) and Global Analog Output

bits (%AQG), which ar e peri odically broadcasted to the other controllers on the net work. The coil

representations %QG and %AQG may be used in CBREEZE like any other coil or i nternal register

reference.

All digital global outputs are broadcast to the net work eac h time one of them has a state change. In

addition, if a cont roller has not transmitted its global data for specifi c tim e peri od, the controller's

programmable network timer may expire, whic h in turn r esul ts in a global data broadcast. Finally, as part

of its power-up initialisation sequence, another controll er can ex plicitly request a controller to broadcast

its global dat a.

8.4 DeviceNet Overview

DeviceNet is an open network. The specification and the protocol are open. Vendors are not required to

purchase hardware, software or licensing rights to connect devic es to a system.

8.4.1 DeviceNet Features

DeviceNet is a low-cost communications li nk to connect i ndustr ial devices. It allows the interchangeabilit y

of simple devi c es whil e making interconnectiv i ty of mor e complex devices possible. Devic eNet is based

on CAN. It is an applicati on lay er pr otocol (ISO layer 7) and is defined i n term s of an abstract object

model, which r epr esents the available communication services and the exter nal v isible behaviour of a

DeviceNet node.

The DeviceNet Model is appl ication independent. Dev ic eNet provides the communication services

needed by various types of applications. Many of today ' s l ower level industrial cont r ol dev ic es must retain

their low cost/low resource characteristics even when directly c onnec ted to a network. DeviceNet takes

this into consider ation by defining a specific instanc e of the DeviceNet Model for comm unic ations typically

seen in a Master/Slave application. Thi s is refer r ed to as the Predefined Master/Slave Connection Set.

Some of the features and functionality of the Devic eNet network are described Tabl e 8.1.

Table 8.1 - DeviceNet F eatures and Functionality

Network Size Up to 64 Nodes

Network Length Selec table end-to end network distanc e v aries with speed

Baud Rate Distance

125 Kbps 500m (1,640 feet)

250 Kbps 250m (820 feet)

500 Kbps 100m (328 feet)

Data Packets 0-8 bytes

Bus Topology Linear (tr unkli ne/dropline); power and signal on the same network cable

Bus Addressing Peer-t o- P eer with Multi-Cast (one-to-many); Multi-Master and Master /Slave

special case; polled or change-of-stat e ( ex ception-based)

System

Features

Removal and replacement of devices from the network under power

Page 38

CH. 8: NETWORKS 06 Apr 2000 PAGE 39

GFK-1819

8.4.2 DeviceNet Protocol

Some of the communication protocol features of Devic eNet consist of the following:

1. A DeviceNet product can behave as a Client, a Server or both.

2. Master/Slave operation.

3. Capable of Peer-to-Peer exchange capability exists in which any Devic eNet product can produce and

consume messages.

4. Capable of supporting 64 node addresses

5. Each node can support an unlim ited number of I/O.

8.4.3 DeviceNet Operat ion

The following r estr ic tions are placed on operations when using an O S that is configured as a

DeviceNet slav e.

1. Currently, c ommunication between the PC and the contr oller is only possible to the device physically

connected to the PCs’ serial por t. Project downloads, upl oads, monitoring, and configuration

currently take place

2. The HE200CGM40x gat eway car d c an not cur r ently be used with DeviceNet communications.

Horner Electric is providing a special Gateway device that is based on the OCS hardware. The

Gateway device m ak es it possible to connect the PC serial port wit h the DeviceNet network.

3. DeviceNet net work nodes are in a range from 0 to 63. The controller is able to observe network

responses (poll ed c onnec tions) from any slave to the Devi ceNet Master. The first 16-words of these

observed responses are made available for mappi ng on the

These correspond to t he av ailable nodes 0 to 63 and registers AQG1 to AQG16. Node 64 is used for

a special case. W hen data is sent to a controller from a DeviceNet Master (via the polled connection)

this data is mapped to node 64. Relative addressing is limited to -64 to +64.

over a DeviceNet network.

Network Input Assignments

cannot

page.

Page 39

PAGE 40 06 Apr 2000 CH. 8: NETWORKS

GFK-1819

8.5 CAN Wiring Rules

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

V+

V-

CN_L

SHIELD

CN_H

V+

121

Ω

121

Ω

+

12-25VDC

-

V+

CN_H

CN_LV-SHIELD

BLK

Ω

BLU

BLK

121

RED

RED

WHT

SH IE LD

BLK

BLU

BLU

WHT

WHT

RED

RED

CN_LV-SHIELD

V+

CN_H

SHIE LD

BLK

BLK

BLU

BLU

WHT

WHT

RED

RED

CN_LV-SHIELD

V+

CN_H

SHIE LD

CN_LV-SHIELD

Ω

121

BLU

BLK

-

+

12-25VDC

1. Wire the CAN network in a daisy-c hained fashion such that there ar e ex actly two physical end-points

on the network.

2. The two nodes at the physical end-points need to have 121 ohm 1% terminating resistors connected

across the CN_L and CN_H terminals.

3. Use data conductors (CN_L and CN_H) that are 24 AWG shielded twisted pair for “thin cable” and 22

AWG shielded twisted pai r for “thick cable”. They must also have 120-ohm c har acteristic impedance.

In typical industrial environments, use a Belden wire #3084A (“thin”). Use #3082A (“thick”) fo r

environment s where noise is a concer n.

4. Use power conductors (V- and V+ ) that are 18 AWG twisted-pair for “thin cable” and 15 AWG twisted-

pair for “thick cable”.

5. Connect the V- power conductor to a good earth ground

physical endpoints.

6. For a section of c able between two nodes, the cable shield is connected to the cable shield input at

one end of the cable only.

7. A CAN network (without r epeaters) is limited to 64 nodes (with 63 cable segments) with a maximum

cable length of 1500 ft.

8. Up to four CAN network segment s, whic h adher e to the above rules, may be connect ed together

using three CAN repeaters. In this manner, a CAN network may be extended to 253 nodes with a

total cable distanc e of 6000 ft.

Figure 8.3 – CAN Network Cabling

at one place only

on the network, preferably

V+

CN_H

RED

WHT

Page 40

CH. 8: NETWORKS 06 Apr 2000 PAGE 41

GFK-1819

8.6 Profibus

Profibus utilises a Master-Slave type of c ommunication with the TIUXX2 functioning as a slave device.

Decentralised Peripherals (Sl av e) Baud r ates of up to 12 MBd can be obtained through Profibus.

Up to 32 devices 9master or sl av es) can be c onnected in one segment without usi ng r epeaters, or up to

64 devices can be connect ed usi ng r epeaters.

Master devices are used to det ermine the data communi c ation on the bus. One master can service

several slav es. S ev er al M aster s can par ticipate on the bus simultaneously, but only one Master can write

outputs to a slave.

The slave devices are peripheral devices. Sl av es do not hav e bus access rights and can only

acknowledge received messages or send messages to the master when requested to do so. Any master

can read data from the sl av e dev ic es. All connected Slaves have the same priority.

For further information on the Profibus Network, visit their website at www.profibus.com

8.6.1 Profibus Wir ing

The TIUXX2 uses a 9 pin D-sub plug connec tor for its Profibus port. T he pin assignment of the plug

connector and the wir ing are show below.

Station 1 Sta tion 2

Rxd/TxD -P 3

V+ 6

D Gnd 5

RxD/TxD -N 8

3

6

5

8

Protective G round

Figure 8.4 Profibus Port Pinout

Page 41

PAGE 42 06 Apr 2000 CH. 8: NETWORKS

GFK-1819

RxD/TxD-N 8

Its is necessary to term inate both ends of the network. B oth terminations must have power to them to

insure proper operation of the network. The following diagram illustrates the correct connection for the

terminati on resistors.

RxD/TxD-P 3

DGND 5

V+ 6

Figure 8.5 – Profibus Network Cabling

RxD/TxD-N 8

DGND 5

V+ 6

RxD/TxD-P 3

RxD/TxD-N 8

RxD/TxD-P 3

DGND 5

V+ 6

VP (6)

Lin e termin ation

390 Oh m

A-Line (3)

220 Oh m

B-Line (8)

390 Oh m

GND (5)

Figure 8.6 – Profibus termination resistors

Page 42

CH. 9: SMARTSTACK 06 Apr 2000 PAGE 43

GFK-1819

CHAPTER 9: SMARTST ACK

9.1 Scope

Horner has now added the Smar tStack modules from the OCS Range to the TIU20X range. The

SmartStack system is a method of allowing I/O expansion on an HM I. A wide range of m odul es i s

available including Digital and Anal ogue.

9.2 Installing and Removing a S mart S t ack Module

The following sect ion describes how to install and r em ove a SmartStack Module.

Caution: To function properly and avoid possible damage, do not install more than four

Smart Stack Modules per TIU20X.

9.2.1 Installing SmartStack Modules

1. Hook the tabs. Each SmartStack Module has two tabs that fit int o sl ots loc ated on the TIU20X. (The

slots on the TIU20X are located on the back cover.)

2. Press the SmartSt ac k Module into the “locked” position, making sure to align the SmartS tack Module

fasteners with t he SmartStack receptacles on t he TI U20X.

9.2.2 Removing SmartS tack Modules

1. Using a Flathead screwdriver, pry up the end of the SmartStack Module (opposite of tabs) and swing

the module out.

2. Lift out the tabs of the module.

Figure 9.1 – Installing a SmartS t ack Module in an OCS.

Page 43

PAGE 44 06 Apr 2000 CH. 9: SMARTSTACK

GFK-1819

NOTES

Loading...

Loading...