Page 1

GE

Automation & Controls

For Public Disclosure

Programmable Control Products

PACSystems* Ethernet Switch GLM Series User Manual GFK-3030

PACSystems* PROFINET

Managed Industrial

Ethernet Switches

User Manual

GFK-3030

December 2017

Page 2

Legal Information

Warnings, Cautions, and Notes as Used in this Publication GFL-002

Warning

Warning notices are used in this publication to emphasize that hazardous voltages,

currents, temperatures, or other conditions that could cause personal injury exist in

this equipment or may be associated with its use.

In situations where inattention could cause either personal injury or damage to

equipment, a Warning notice is used.

Caution

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to understanding

and operating the equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met during installation, operation, and maintenance. The information is supplied

for informational purposes only, and GE makes no warranty as to the accuracy of the information included

herein. Changes, modifications, and/or improvements to equipment and specifications are made periodically

and these changes may or may not be reflected herein. It is understood that GE may make changes,

modifications, or improvements to the equipment referenced herein or to the document itself at any time. This

document is intended for trained personnel familiar with the GE products referenced herein.

GE may have patents or pending patent applications covering subject matter in this document. The furnishing

of this document does not provide any license whatsoever to any of these patents.

GE PROVIDES THE FOLLOWING DOCUMENT AND THE INFORMATION INCLUDED THEREIN AS-IS AND WITHOUT

WARRANTY OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED STATUTORY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

* indicates a trademark of General Electric Company and/or its subsidiaries.

All other trademarks are the property of their respective owners.

©Copyright 2017 General Electric Company.

All Rights Reserved

Page 3

Contact Information

If you purchased this product through an Authorized Channel Partner, please contact the seller directly.

General Contact Information

Online technical support and GlobalCare

www.geautomation.com/support

Additional information

www.geautomation.com

Solution Provider

solutionprovider.ip@ge.com

Technical Support

If you have technical problems that cannot be resolved with the information in this manual, please contact us

by telephone or email, or on the web at www.geautomation.com/support

Americas

Phone

1-800-433-2682

International Americas Direct Dial

1-780-420-2010 (if toll free 800 option is unavailable)

Customer Care Email

digitalsupport@ge.com

Primary language of support

English

Europe, the Middle East, and Africa

Phone

+800-1-433-2682

EMEA Direct Dial

+ 420-296-183-331 (if toll free 800 option is unavailable or if

dialing from a mobile telephone)

Customer Care Email

digitalsupport.emea@ge.com

Primary languages of support

English, French, German, Italian, Czech, Spanish

Asia Pacific

Phone

+86-400-820-8208

+86-21-3877-7006 (India, Indonesia, and Pakistan)

Customer Care Email

digitalsupport.apac@ge.com

Primary languages of support

Chinese, Japanese, English

Page 4

GFK-3030 December 2017 i

Table of Contents

PACSystems* Ethernet Switch GLM Series User Manual GFK-3030

Table of Contents ............................................................................................................................................................... i

Table of Figures ................................................................................................................................................................ iv

Chapter 1 Introduction ................................................................................................................................................ 1

1.1 Revisions in this Manual ........................................................................................................................... 2

1.2 PACSystems Documentation ................................................................................................................... 2

Chapter 2 Overview ...................................................................................................................................................... 3

2.1 System Overview ........................................................................................................................................ 3

IO-Devices on a PROFINET Network .................................................................................................................. 3

Ethernet Devices on an Ethernet Network ..................................................................................................... 4

GLM System Capabilities ......................................................................................................................................... 4

2.2 GLM Product Differentiation .................................................................................................................... 5

2.3 GLM Features .............................................................................................................................................. 5

2.4 GLM LEDS ..................................................................................................................................................... 6

Chapter 3 Installation .................................................................................................................................................. 7

3.1 Mounting ...................................................................................................................................................... 7

DIN-Rail Mounting ....................................................................................................................................................... 7

Panel Mounting ............................................................................................................................................................. 8

3.2 Power Connection ...................................................................................................................................... 9

GLM Switch Current Draw ....................................................................................................................................... 9

3.3 Grounding .................................................................................................................................................. 10

3.4 Alarm Relay Output ................................................................................................................................. 11

3.5 Ethernet Connections .............................................................................................................................. 12

RJ45 Connections ..................................................................................................................................................... 12

SFP Connections ....................................................................................................................................................... 13

3.6 LED Operation ........................................................................................................................................... 14

3.7 System Reset ............................................................................................................................................. 15

3.8 Console Connection ................................................................................................................................. 16

Page 5

Contents

ii PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Chapter 4 Configuration ............................................................................................................................................ 17

4.1 Import the GSDML file ............................................................................................................................. 18

4.2 Associating the IO-Device with its Controller .................................................................................... 21

4.3 PROFINET Cyclic I/O Data ....................................................................................................................... 23

Slot 1: Device Status ................................................................................................................................................ 24

Slot 2: Port Status ...................................................................................................................................................... 24

Slot 3: Port Alarm & Port Settings & Status ................................................................................................. 25

Slot 4: MRP Group 1 Status .................................................................................................................................. 27

Slot 5: MRP Group 2 Status .................................................................................................................................. 28

Slot 6: Ring Group 1 Status .................................................................................................................................. 29

Slot 7: MRE Group 1 Status .................................................................................................................................. 29

Slot 8: MRE Group 2 Status .................................................................................................................................. 29

4.4 PROFINET Acyclic I/O Data ..................................................................................................................... 30

Acyclic Device Data –Subslot 0 ......................................................................................................................... 30

Acyclic Port Data – Subslot 1 .............................................................................................................................. 32

Acyclic MRP Group 1 Data – Subslot 2 .......................................................................................................... 33

Acyclic MRP Group 2 Data – Subslot 3 .......................................................................................................... 33

Acyclic Ring Group 1 Data – Subslot 4 .......................................................................................................... 34

Acyclic MRPe Group 1 Data – Subslot 5 ........................................................................................................ 35

Acyclic MRPe Group 2 Data – Subslot 6 ........................................................................................................ 35

4.5 Assigning Device Name and IP Address .............................................................................................. 36

4.6 MRP Settings for IO-Devices .................................................................................................................. 37

4.7 Download from PME to CPU ................................................................................................................... 38

4.8 Hot Standby CPU Redundancy Considerations .................................................................................. 38

4.9 Discovery Tool .......................................................................................................................................... 39

Chapter 5 Diagnostics................................................................................................................................................ 41

Setting up and Sensing Alarms ......................................................................................................................... 42

Power Alarm ................................................................................................................................................................ 43

5.2 External Alarm Circuit ............................................................................................................................. 44

Appendix A Command Language Interface (CLI) ........................................................................................................ 45

A-1 Operator Interface ................................................................................................................................... 45

Login ................................................................................................................................................................................ 45

Connection Interface .............................................................................................................................................. 45

Login Screen Description ...................................................................................................................................... 45

Execution Modes ....................................................................................................................................................... 46

Getting help ................................................................................................................................................................. 46

Terminal Key Function ........................................................................................................................................... 47

Notation Conventions ............................................................................................................................................. 47

Page 6

Contents

GFK-3030 December 2017 iii

A-2 Summary of Commands Descriptions.................................................................................................. 48

A-3 Command Descriptions .......................................................................................................................... 49

Initialize Mode Commands .................................................................................................................................. 49

Enable Mode Commands ..................................................................................................................................... 50

Configure Mode Commands............................................................................................................................... 71

VLAN Mode Commands ........................................................................................................................................ 91

Interface VLAN Mode Commands ................................................................................................................... 94

RingV2 Group Mode Commands ...................................................................................................................... 97

Spanning Tree Commands .................................................................................................................................. 99

sFlow Configure Commands ............................................................................................................................103

SNMP Configure Commands ............................................................................................................................105

Qos Function Commands...................................................................................................................................109

IGMP Functional Commands ............................................................................................................................113

MVR Functional Commands .............................................................................................................................115

MLD Functional Commands .............................................................................................................................119

Loop-Protection Configure Commands......................................................................................................122

LLDP Configure Commands ..............................................................................................................................123

RFC2544 Testing Configure Commands ....................................................................................................125

GVRP Configure Commands .............................................................................................................................127

Voice VLAN Configure Commands ................................................................................................................128

Profile Alarm Commands ...................................................................................................................................129

Appendix B Supported Ethernet Commands ............................................................................................................. 131

Page 7

Contents

iv PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Table of Figures

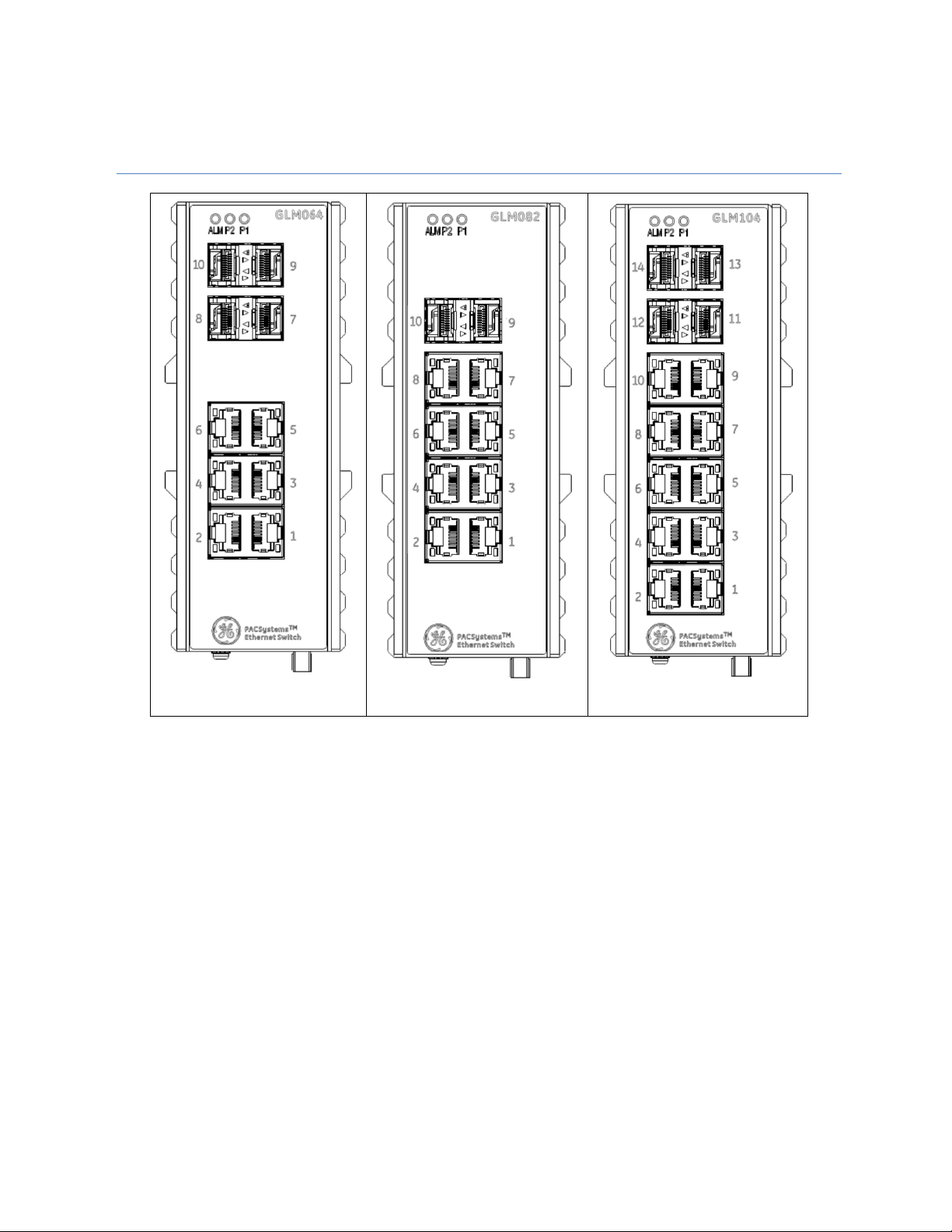

Figure 1: GLM064 ........................................................................................................................................................................................................1

Figure 2: GLM082 ........................................................................................................................................................................................................1

Figure 3: GLM104 ........................................................................................................................................................................................................1

Figure 4: Typical PROFINET System with GLM Switches ..........................................................................................................................3

Figure 5: GLM Switch Bottom Panel...................................................................................................................................................................5

Figure 6: Front-Panel LEDs .....................................................................................................................................................................................6

Figure 7: DIN-Rail Mounting ...................................................................................................................................................................................7

Figure 8: Panel-Mounting ........................................................................................................................................................................................8

Figure 9: Dual DC Power Input Connections..................................................................................................................................................9

Figure 10: Ground Connection ........................................................................................................................................................................... 10

Figure 11: Alarm Relay Output .......................................................................................................................................................................... 11

Figure 12: RJ45 Pinout ........................................................................................................................................................................................... 12

Figure 13: Ports 1 & 2 Copper Connections ................................................................................................................................................ 12

Figure 14: Fiber-Optic Cable with LC Duplex Connectors .................................................................................................................... 13

Figure 15: Attach Fiber-Optic Cables to Installed SFP Socket ............................................................................................................ 13

Figure 16: Console Port ......................................................................................................................................................................................... 16

Figure 17: Console Cable Wiring ....................................................................................................................................................................... 16

Figure 18: PME Toolchest Feature .................................................................................................................................................................... 18

Figure 19: Toolchest Data Types ....................................................................................................................................................................... 18

Figure 20: Select PROFINET Device .................................................................................................................................................................. 19

Figure 21: Import GSDML Command ............................................................................................................................................................. 19

Figure 22: Browse to Folder and Select GSDML file for Import ......................................................................................................... 20

Figure 23: Toolchest Displays Newly-Added Device ............................................................................................................................... 20

Figure 24: Add IO-Device to PROFINET Controller .................................................................................................................................... 21

Figure 25: Select IO-Device from PROFINET Device Catalog .............................................................................................................. 21

Figure 26: IO-Device Installed Under PNC001 ........................................................................................................................................... 22

Figure 27: Assign Starting %I & %Q References for Cyclic I/O Data ............................................................................................... 23

Figure 28: Properties of IO-Device ................................................................................................................................................................... 36

Figure 29: Inspector Form for IO-Device ....................................................................................................................................................... 36

Figure 30: Accessing the MRP Parameters of an IO-Device ................................................................................................................ 37

Figure 31: Set up MRP Ring Ports ..................................................................................................................................................................... 37

Figure 32: MRP Group2 Data Tab..................................................................................................................................................................... 37

Figure 33: Launch Discovery Tool .................................................................................................................................................................... 39

Figure 34: Discovery Tool in Progress ............................................................................................................................................................ 39

Figure 35: Listing of all Detected Devices ..................................................................................................................................................... 40

Figure 36: GLM Switch Parameters Set in PME ......................................................................................................................................... 42

Figure 37: Set Port Alarm Active or Inactive Using PME ....................................................................................................................... 42

Figure 38: External Alarm Circuit ...................................................................................................................................................................... 44

Figure 39: Login Constraints ............................................................................................................................................................................... 45

Figure 40: Telnet Login Screen ........................................................................................................................................................................... 46

Page 8

GFK-3030 December 2017 1

Chapter 1 Introduction

Figure 1: GLM064

Figure 2: GLM082

Figure 3: GLM104

The PACSystems GLM series Industrial Ethernet Switches deliver high quality Ethernet operation over a wide

temperature range and can tolerate an extended power input range. These switches are ideal for harsh

environments and mission critical applications. They may be DIN-rail mounted or panel-mounted.

This document includes a product overview and covers installation, configuration, operation and diagnostics.

Page 9

Chapter 1. Introduction

2 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

1.1 Revisions in this Manual

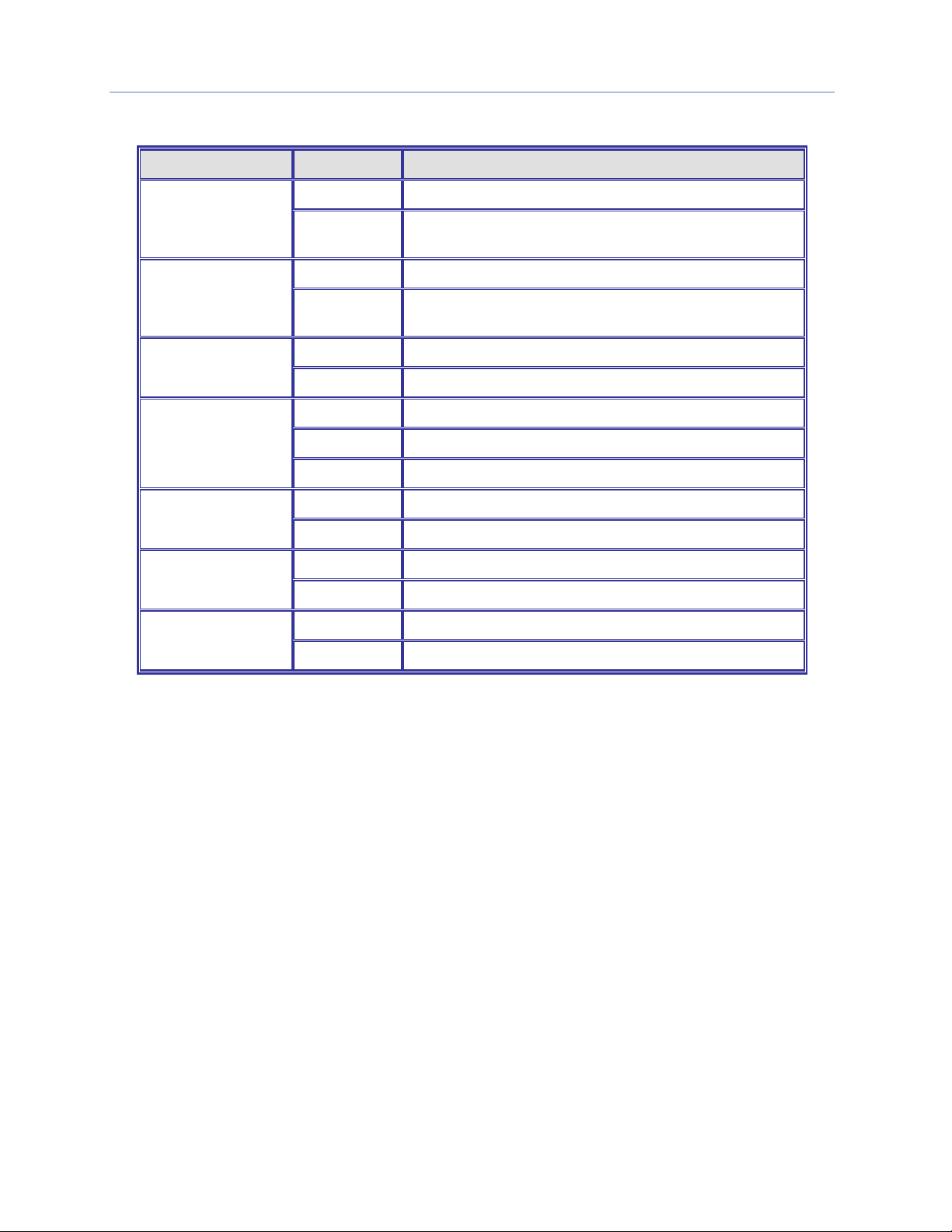

Rev

Date

Description

Dec2017

• Initial release.

1.2 PACSystems Documentation

PACSystems Manuals

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference Manual

GFK-2950

PACSystems RX7i, RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual

GFK-2224

PACSystems TCP/IP Ethernet Communications Station Manager User Manual

GFK-2225

PACSystems Memory Xchange Modules User’s Manual

GFK-2300

PACSystems Hot Standby CPU Redundancy User Manual

GFK-2308

Proficy Machine Edition Logic Developer Getting Started

GFK-1918

Proficy Process Systems Getting Started Guide

GFK-2487

PACSystems RXi, RX3i, RX7i and RSTi-EP Controller Secure Deployment Guide

GFK-2830

PACSystems RX3i & RSTi-EP PROFINET I/O Controller Manual

GFK-2571

RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i Ethernet Network Interface Unit User’s Manual

GFK-2439

PACSystems RX3i PROFINET Scanner Manual

GFK-2737

In addition to these manuals, datasheets and product update documents describe individual modules and

product revisions. The most recent PACSystems documentation is available on the GE Intelligent Platforms

support website http://geautomation.com/support.

Page 10

GFK-3030 December 2017 3

Chapter 2 Overview

2.1 System Overview

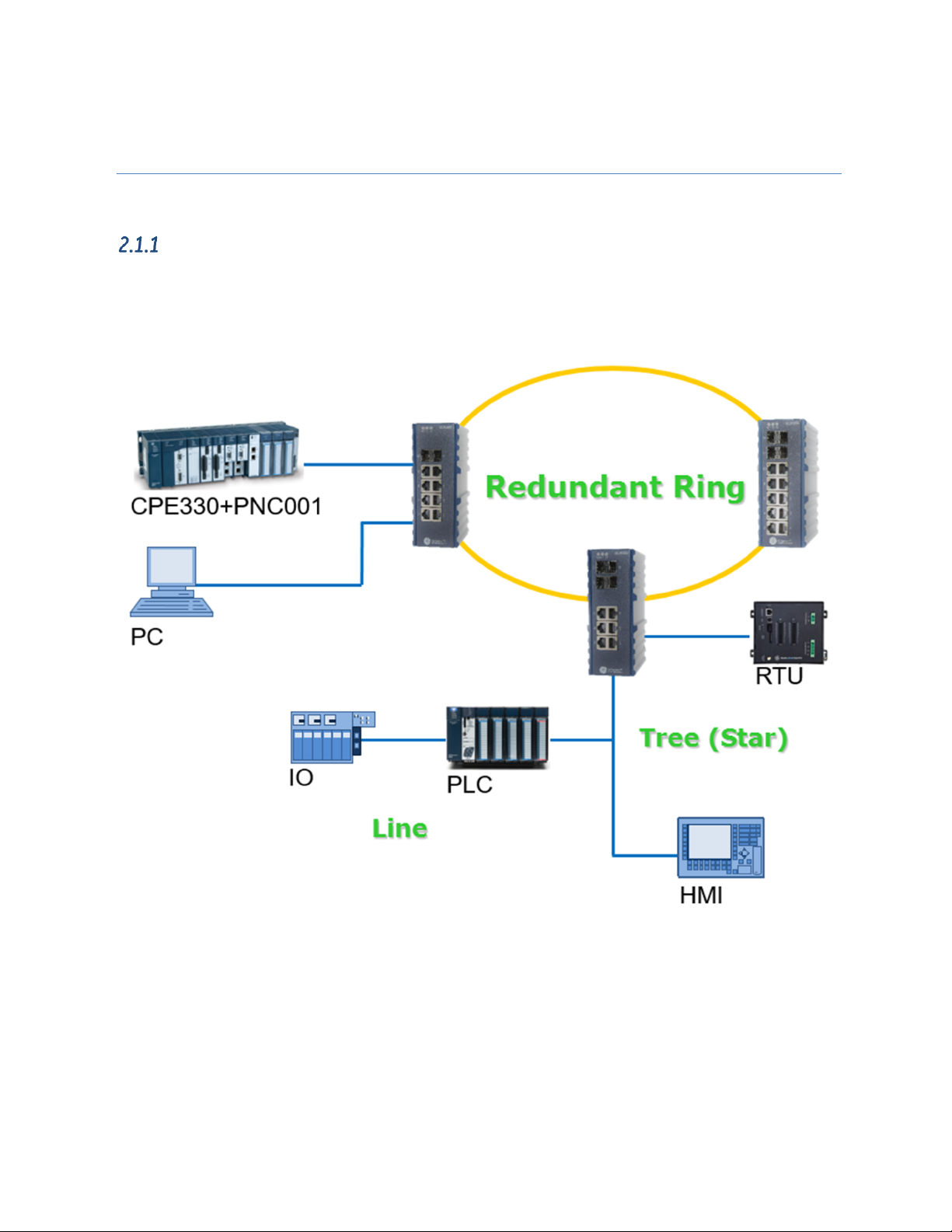

IO-Devices on a PROFINET Network

GLM Switches are treated as PROFINET-IO devices. The host PLC will therefore use an embedded PROFINET

port or a PNC001 PROFINET IO-Controller Module. All physical connections use standard Ethernet connectors

(RJ45 or SFP).

Figure 4: Typical PROFINET System with GLM Switches

Page 11

Chapter 2. Overview

4 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Ethernet Devices on an Ethernet Network

The GLM switches contain a number of features which cannot be accessed over PROFINET, but are available

over Ethernet. The user may choose to install a separate Ethernet network for this purpose, or run both

PROFINET and Ethernet on the same physical network. Refer to Appendix B, Supported Ethernet Commands.

Caution

Care needs to be taken that connection to an Ethernet networks does not expose

the application to outside interference or monitoring, and does not impose heavy

traffic on the PROFINET network, which is intended to service IO-Devices in a timely

manner. Refer to the PACSystems RXi, RX3i, RX7i and RSTi-EP Controller Secure

Deployment Guide, GFK-2830.

Within the RX3i, the user may install an ETM001 module in a rack controlled by the host PLC CPU, or may use

an embedded Ethernet port within the CPU itself to provide the Ethernet features. .If none of the Ethernet-only

features will be used, no dedicated Ethernet function is required.

The following features, which are outside the scope of this manual, may be accessed over Ethernet, but may

not be accessed over PROFINET:

• Virtual LANs (VLANs)

• Access Control List Security (ACL)

• Quality of Service (QoS) features

• Internet Group Management Protocol (IGMP)

GLM System Capabilities

Function Name

System Max Value

VLAN ID

4096

VLAN Limitation

1024

Privilege Level of User

15

RMON Statistic Entry

65535

RMON Alarm Entry

65

RMON Event Entry

65535

IPMC Profile

64

IPMC Rule / Address Entry

128

ACE

256

ICMP Type / Code

255

MAC-based VLAN Entry

256

IP subnet-based VLAN Entry

128

Protocol-based VLAN Group

125

Voice VLAN OUI

16

QCE

256

IP Interface (for management)

8

IP Route (for management)

32

Security Access Management

16

MVR VLAN

4

MAC Learning table address

8k

IGMP Group

256

Page 12

Chapter 2. Overview

GFK-3030 December 2017 5

2.2 GLM Product Differentiation

Product differentiation within the GLM Series of products lies in the number of standard RJ45 Ethernet

connections and Small Form-Factor Pluggable (SFP) ports offered, as follows:

Product

Number of RJ45 Ports

Number of SFP Ports

Appearance

IC086GLM064 6 4

Figure 1

IC086GLM082 8 2

Figure 2

IC086GLM104

10

4

Figure 3

Note that the final three digits of the GLM part numbers convey the information about the intrinsic port

configuration.

2.3 GLM Features

Each is a stand-alone Ethernet switch that may be mounted on a DIN-rail, or panel-mounted. Refer to Section

3.1.

Operating Temperature Range: -40°C to +75°C (-40°F to +167°F).

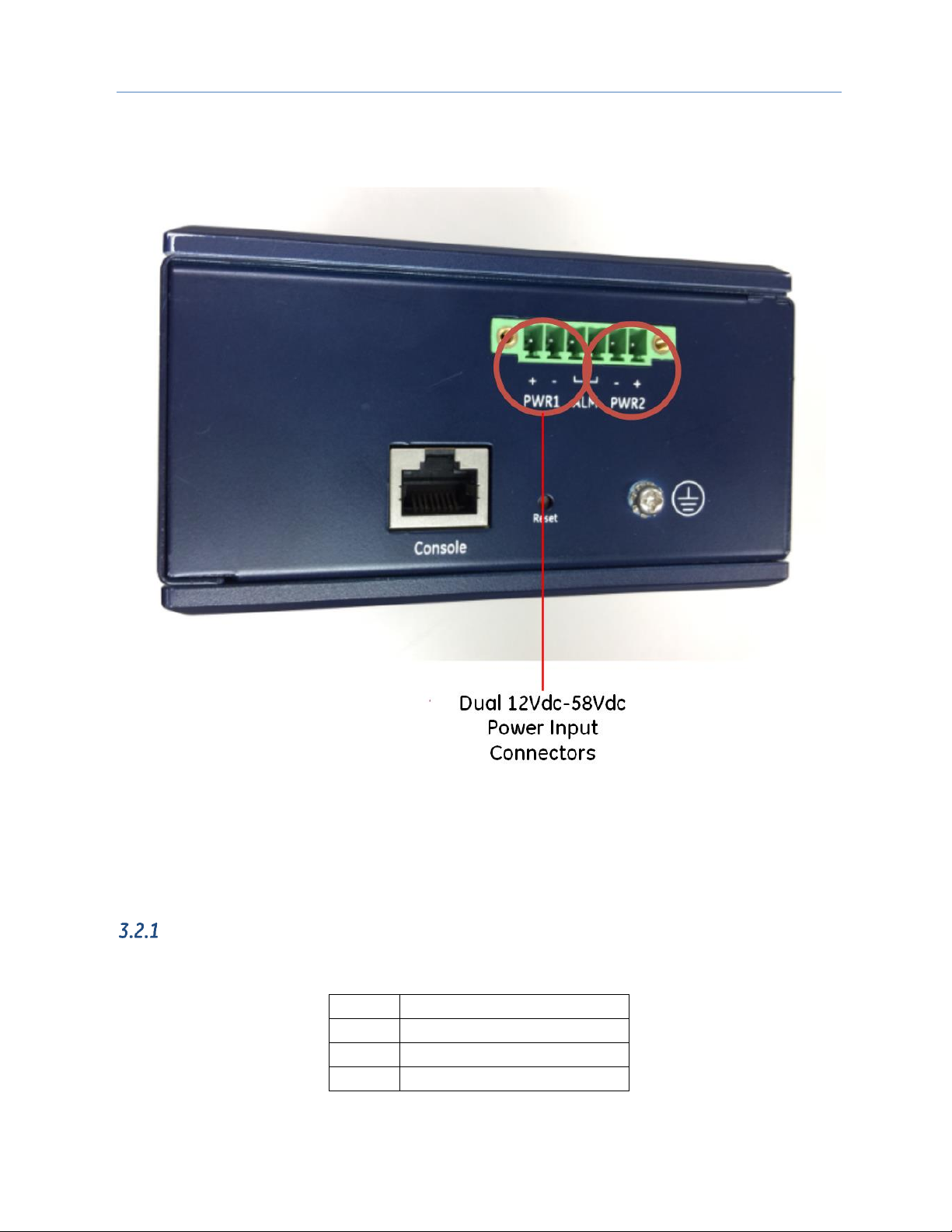

Each is equipped with the same bottom-panel (Figure 5), which includes a dual 12Vdc-58Vdc power input, a

ground stud, an alarm contact, a reset pushbutton and an RJ45 port suitable for attaching a console. Each of

these features is discussed in Chapter 3.

Figure 5: GLM Switch Bottom Panel

Page 13

Chapter 2. Overview

6 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

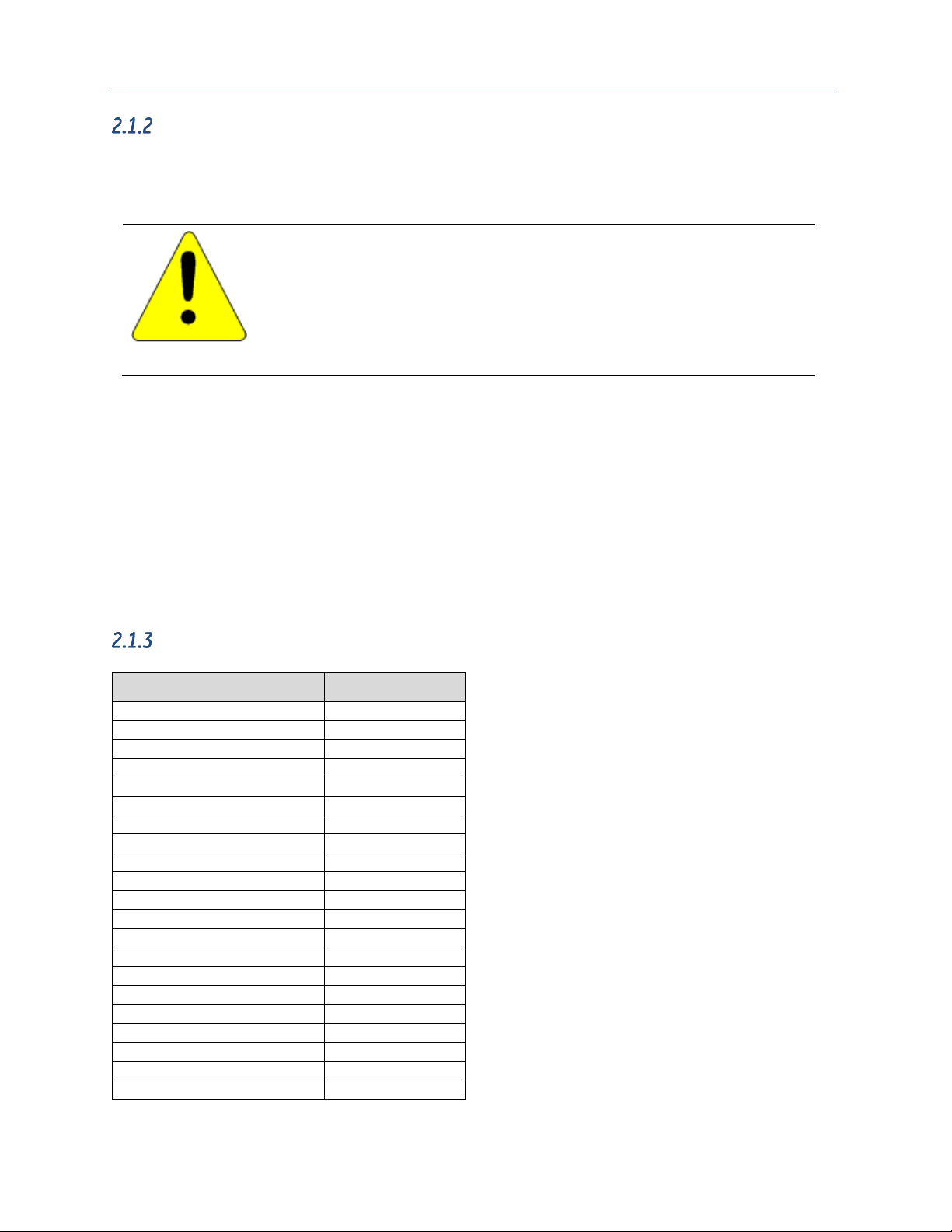

2.4 GLM LEDS

Figure 6: Front-Panel LEDs

Each GLM Switch product is equipped with a common set of LEDs, as shown in Figure 6:

• One LED for each of the two permitted power supply inputs (P1 and P2)

• One LED for the Alarm Contact (ALM)

For each Ethernet port, there is an amber speed LED and a green Link Activity LED. The appearance is different

for the RJ45 ports (suitable for copper cables) versus the SFP connectors, as indicated in Figure 6.

LED Operation is detailed in Section 3.6.

Page 14

GFK-3030 December 2017 7

Chapter 3 Installation

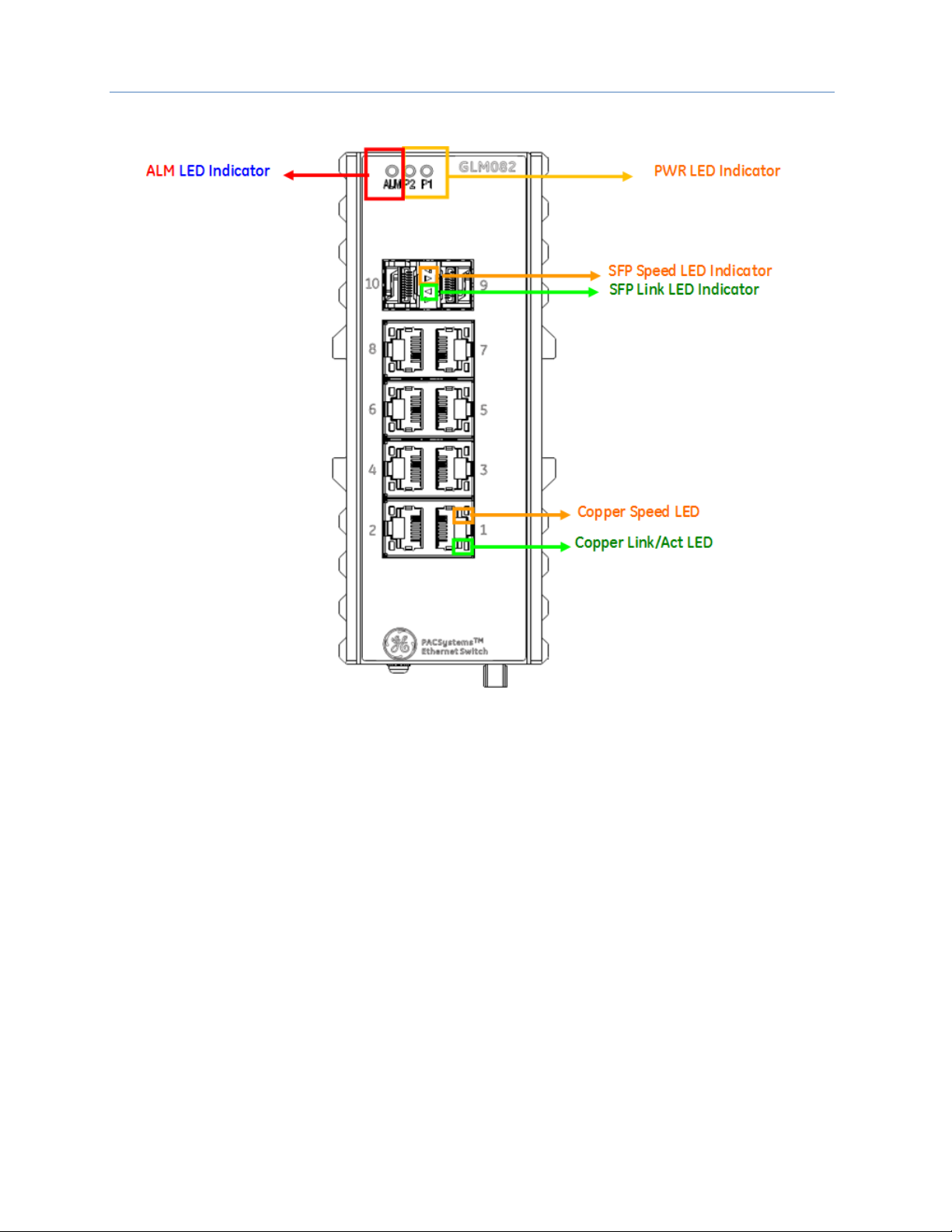

3.1 Mounting

The GLM switches may be DIN-rail mounted or panel-mounted.

DIN-Rail Mounting

Figure 7: DIN-Rail Mounting

1) Attach the DIN-Rail bracket to the mounting surface with the bracket and screws in the included

accessory kit.

2) Hook the top edge of the DIN-Rail latch attached to the GLM switch over the top edge of the DIN rail.

3) Push the bottom of the GLM unit towards the DIN Rail until the bottom latch snaps into place.

Page 15

Chapter 3. Installation

8 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Panel Mounting

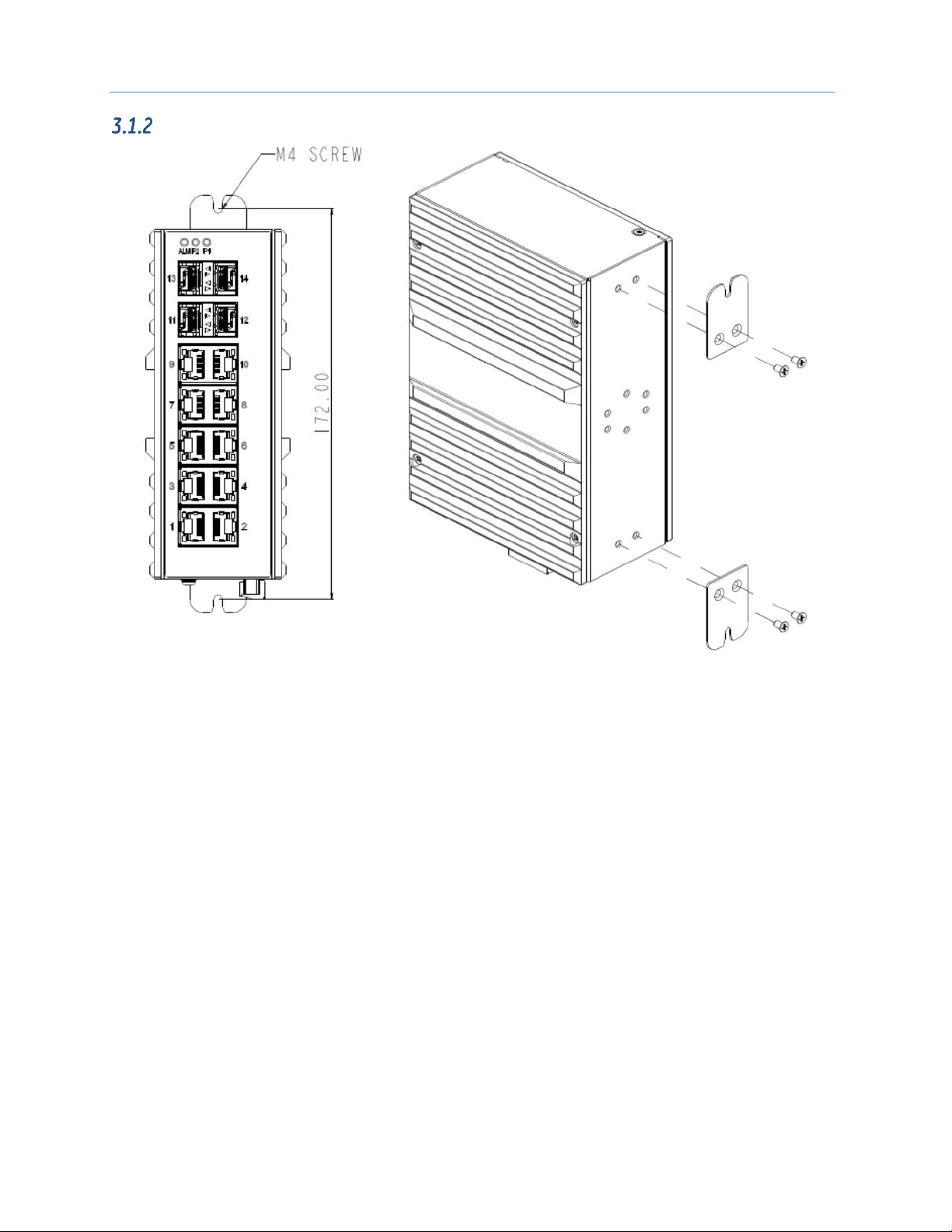

Figure 8: Panel-Mounting

1) Prepare two pilot holes in the mounting surface 172mm apart, per Figure 8.

2) Attach the top and bottom panel-mounting plates to the rear of the GLM switch chassis using the

screws provided in the accessory kit.

3) Secure the GLM switch to the mounting surface with a pair of M4 machine screws.

Page 16

Chapter 3. Installation

GFK-3030 December 2017 9

3.2 Power Connection

The 6-pin terminal block on the bottom panel contains connectors for two DC power inputs. Each is indicated

with polarity signs, as shown.

Figure 9: Dual DC Power Input Connections

The GLM Switch may be powered from one or both power inputs. The specified voltage range is 12Vdc–58Vdc.

The 6-pin terminal strip will accept AWG 28~14. The wire should be stripped back 6~7mm. The screw torque

limit is 2Nm.

The P1 and P2 LEDs on the front panel indicate the status of these two power supply inputs, as shown in

Section 3.6, LED Operation.

GLM Switch Current Draw

The maximum current draw at 24Vdc (nominal) for each of the devices is shown below:

Device

Max Current @ 24Vdc (nominal)

GLM064

580mA

GLM082

521mA

GLM104

709mA

Note: Each DC power input should be connected to a suitably-fused power supply.

Page 17

Chapter 3. Installation

10 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

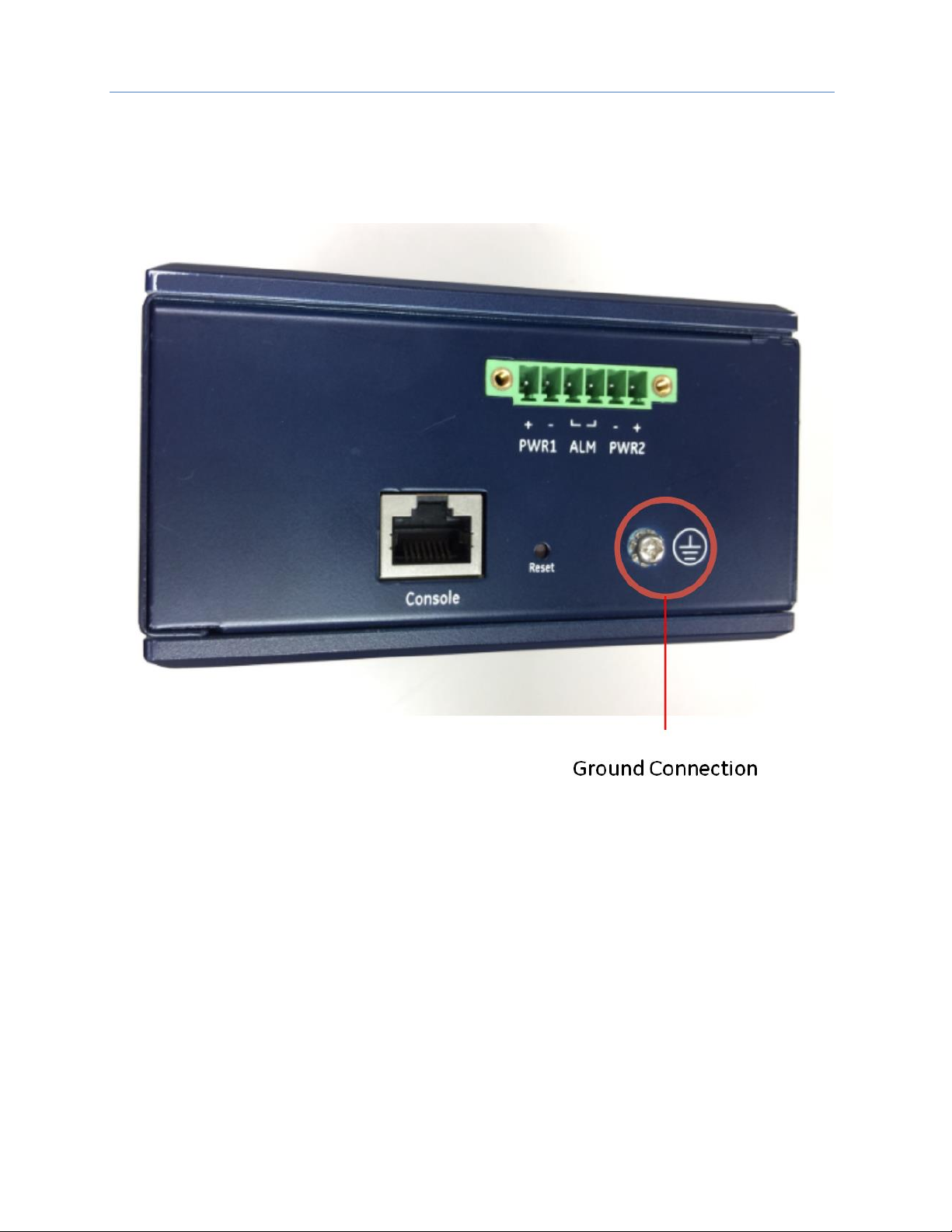

3.3 Grounding

Each GLM switch must be properly grounded for optimal performance. A ground screw (chassis ground) is

provided as part of the bottom panel, as shown below. Loosen the ground screw, insert the stripped end of the

ground strap, then tighten the ground screw to secure the ground strap in place. The other end of the ground

strap (which should be as short as possible) should be securely connected to earth ground.

Figure 10: Ground Connection

Page 18

Chapter 3. Installation

GFK-3030 December 2017 11

3.4 Alarm Relay Output

The Alarm Relay Output is located on the two terminals in the center of the 6-pin terminal strip on the bottom

panel.

Figure 11: Alarm Relay Output

The Alarm Relay Output may be connected to an external device. It is a Normally Open Relay. The state of the

Alarm Relay is indicated on the ALM LED, as documented in Section 3.6, LED Operation.

Refer to Section 3.2 for wire size and stripping information.

Figure 38 diagrams a typical external alarm circuit.

Page 19

Chapter 3. Installation

12 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

3.5 Ethernet Connections

Ethernet connections use either RJ45 (electrical) or mini-GBIC (optical) interfaces. All Ethernet connections are

located on the faceplate. Refer to Figure 1 through Figure 3.The number and type available for each product in

the GLM series is discussed in Section 2.1.3, GLM System Capabilities.

The activity and speed of each port is indicated separately, as documented in Section 3.6, LED Operation.

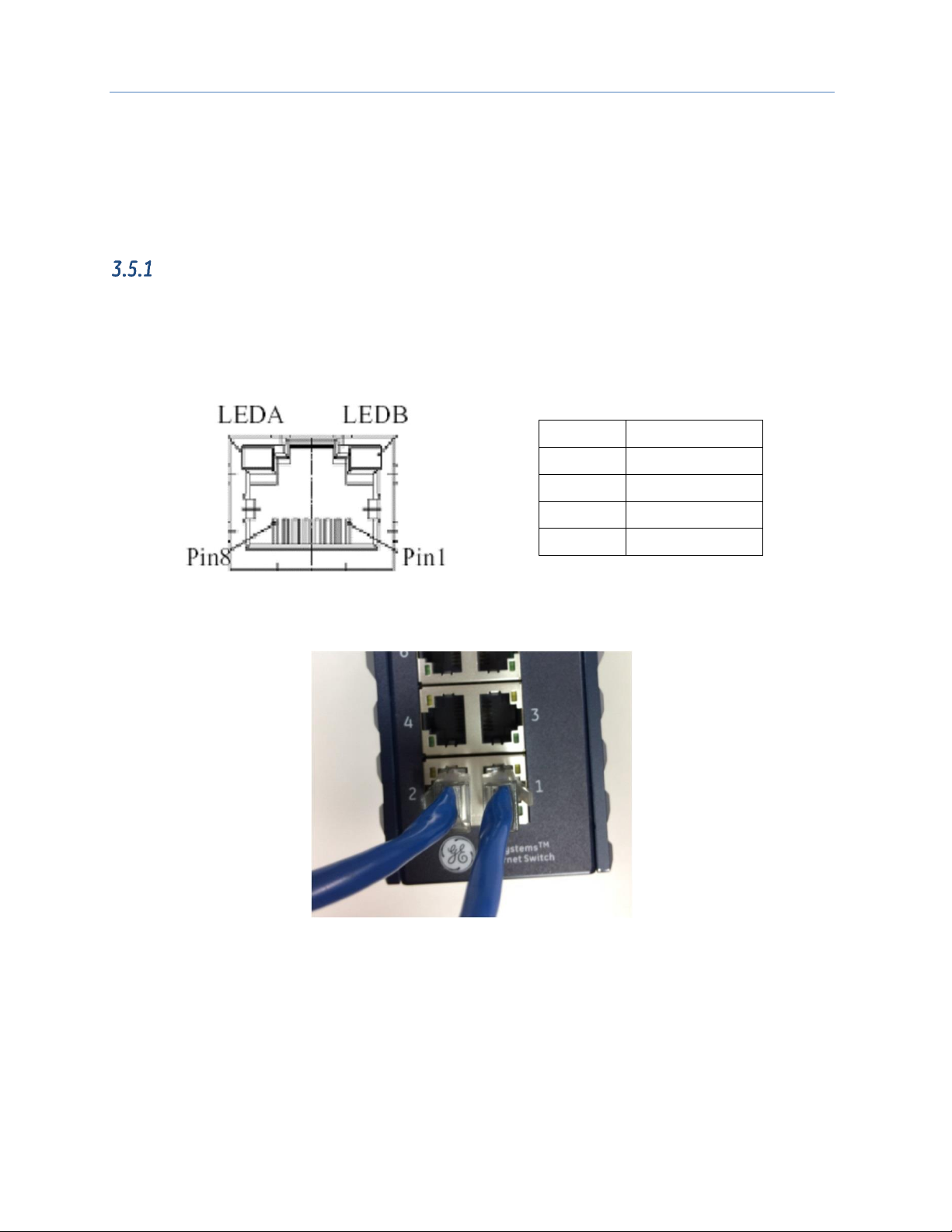

RJ45 Connections

GLM Switches use standard RJ45 connectors for their electrical interfaces. For example, on GLM082, Ports 1-8

are electrical only.

• To connect to a PC, use a straight-through or a cross-over Ethernet cable

• To connect the GLM Switch copper port to an Ethernet device, use UTP (Unshielded Twisted Pair) or

STP (Shielded Twisted Pair) Ethernet cables.

Figure 12: RJ45 Pinout

Pin

Assignment

1,2

T/Rx+, T/Rx-

3,6

T/Rx+, T/Rx-

4,5

T/Rx+, T/Rx-

7,8

T/Rx+, T/Rx-

Figure 13: Ports 1 & 2 Copper Connections

Page 20

Chapter 3. Installation

GFK-3030 December 2017 13

SFP Connections

GLM Switches provide SFP connections using an optical (mini-GBIC) interface. For example, on GLM082, Ports

9 and 10 are SFP ports.

Figure 14: Fiber-Optic Cable with LC Duplex Connectors

Figure 15: Attach Fiber-Optic Cables to Installed SFP

Socket

Prepare a suitable SFP module and install it into the GLM optical port. Then connect the fiber optic cabling that

uses LC connectors (or SC connectors with the use of an optional SC-to-LC adapter) to the fiber optic socket.

Warning

Never attempt to view optical connectors that might be emitting laser energy.

Do not power up the laser product without first connecting the laser to the optical

fiber and properly installing the protective cover.

Laser light, which may cause damage to the eye, will be produced as soon as

power is applied to the laser source.

Warning

When a fiber optic connector is removed during installation, testing, or servicing, or

when an energized fiber is broken, there is a risk of injury to the eye. Exposure to

optical energy may be hazardous to the eye, depending on the laser output power.

The primary hazards of exposure to laser radiation from an optical-fiber

communication system are:

Damage to the eye by accidental exposure to a beam emitted by a laser

source.

Damage to the eye from viewing a connector attached to a broken fiber or an

energized fiber.

Page 21

Chapter 3. Installation

14 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

3.6 LED Operation

LED

STATE

Description

P1

On Green

P1 input power is within specification

Off

P1 power line is disconnected or

supply power is not within specifications

P2

On Green

P2 input power is within specification

Off

P2 power line is disconnected or

supply power is not within specifications

Alarm

On Red

Alarm contact energized

Off

Alarm contact not energized

Copper ports Link/Act

On Green

Ethernet link up but no traffic is detected

Flashing Green

Ethernet link up and there is traffic detected

Off

Ethernet link down

Copper ports Speed

On Yellow

A 100 Mbps or a 1000Mbps connection is detected

Off

No link or a 10 Mbps connection is detected

SFP port Link/Act

On Green

Ethernet link up

Off

Ethernet link down

SFP port Speed

On Yellow

SFP port speed 1000Mbps connection is detected.

Off

No link or a SFP port speed 100Mbps connection is detected

Page 22

Chapter 3. Installation

GFK-3030 December 2017 15

3.7 System Reset

In the event a GLM switch becomes unresponsive, press the recessed Reset button located on the bottom

panel. The reset pushbutton reboots the GLM switch without the need to remove power from that switch.

Resetting a switch is normally not required. The Reset button is recessed in order to avoid accidental use.

Page 23

Chapter 3. Installation

16 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

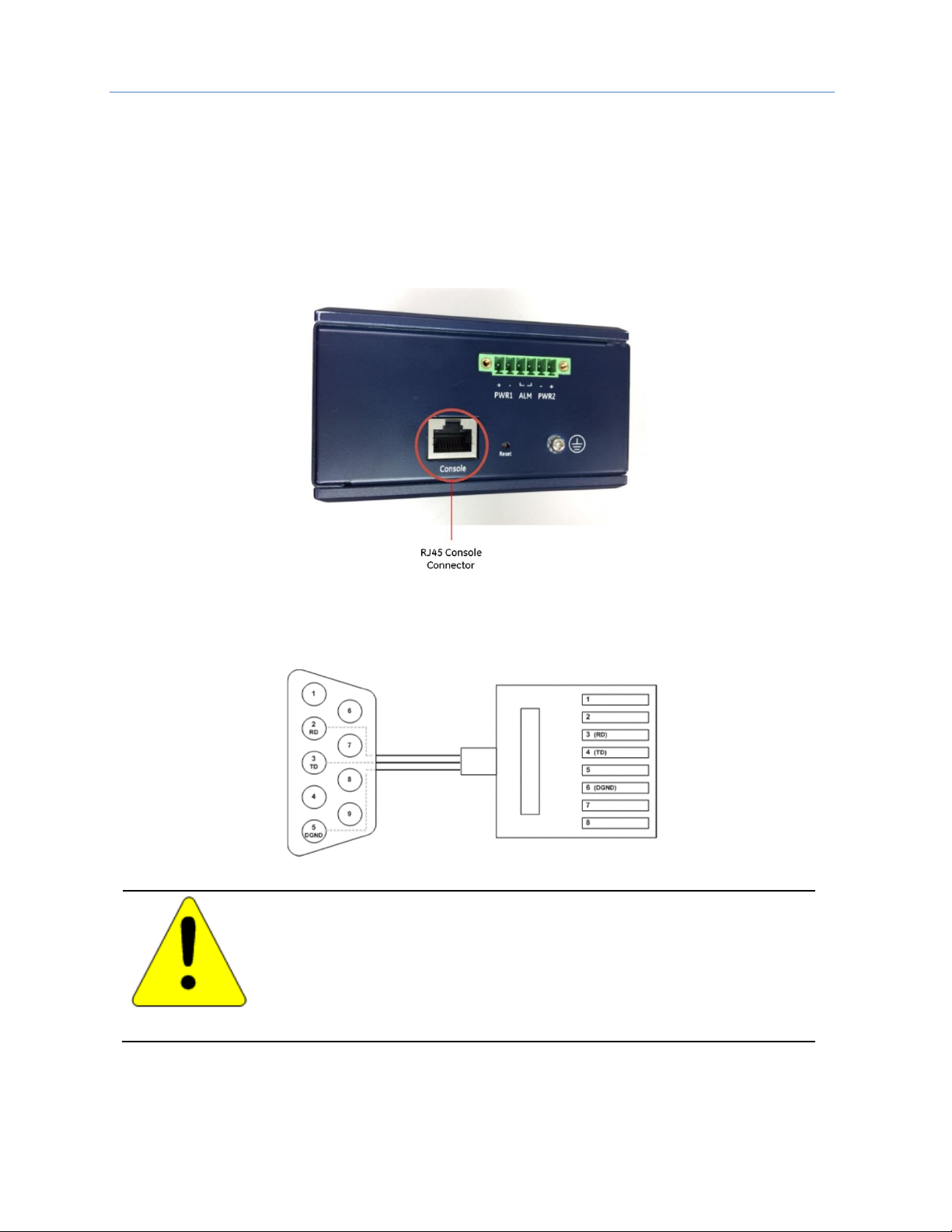

3.8 Console Connection

The Console port, located on the bottom panel (Figure 16), is intended for administrative functions, and its use

is optional. It uses a terminal emulator or a computer with terminal emulation software, connected as follows:

• DB9 connector connected to computer COM port

• Baud rate: 115,200bps

• 8 data bits, 1 stop bit

• No parity

• No flow control

Figure 16: Console Port

To connect the host PC to the Console port, an RJ45 (male) connector-to-RS232 DB9 (female) connector cable

is required. The RJ45 connector of the cable is connected to the Console port of GLM Series; the DB9

connector of the cable is connected to the PC COM port. The wiring for this cable is shown in Figure 17.

Figure 17: Console Cable Wiring

Caution

Console connections should not be permanent. Once any administrative functions

have been performed, disconnect the PC used for that purpose. Leaving a

computer connected would expose the application to security risks. Refer to the

PACSystems RXi, RX3i, RX7i and RSTi-EP Controller Secure Deployment Guide,

GFK-2830.

Refer to Appendix A, Command Language Interface (CLI), for related commands and syntax.

Page 24

GFK-3030 December 2017 17

Chapter 4 Configuration

Configuration is accomplished using Proficy Machine Edition (PME). Each GLM device has a corresponding

GSDML file, which must also be imported.

The GLM Switch Device is always used as a PROFINET IO-Device. Select a suitable PROFINET Controller within

the CPU and “add” a new IO- Device to the corresponding PROFINET Network. The PROFINET Controller may be

an embedded PROFINET Controller Port in the CPU, or a PROFINET Controller module located in a rack

controlled by a CPU. Refer to the corresponding CPU manual for instructions on how to set up an embedded

PROFINET Controller LAN. Refer also to the PACSystems RX3i & RSTi-EP PROFINET I/O Controller Manual,

GFK-2571, which covers further details on embedded PROFINET Controllers and on setting up a PNC001

PROFINET Controller module.

If the GLM Switch Device is to be used as an Ethernet Device, select a suitable Ethernet Controller within the

CPU and “add” a new IO- Device to the corresponding Ethernet Network. The controlling Ethernet Device may

be an embedded Ethernet Port in the CPU, or an Ethernet module located in a rack controlled by a CPU. Refer

to the corresponding CPU manual for instructions on how to set up an embedded Ethernet LAN. Refer to the

PACSystems RX3i Ethernet Network Interface Unit User’s Manual, GFK-2349, for instructions on locating an

ETM001 in a suitable rack/slot location, then setting up its Ethernet LANs and adding devices to those LANs.

Page 25

Chapter 4. Configuration

18 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

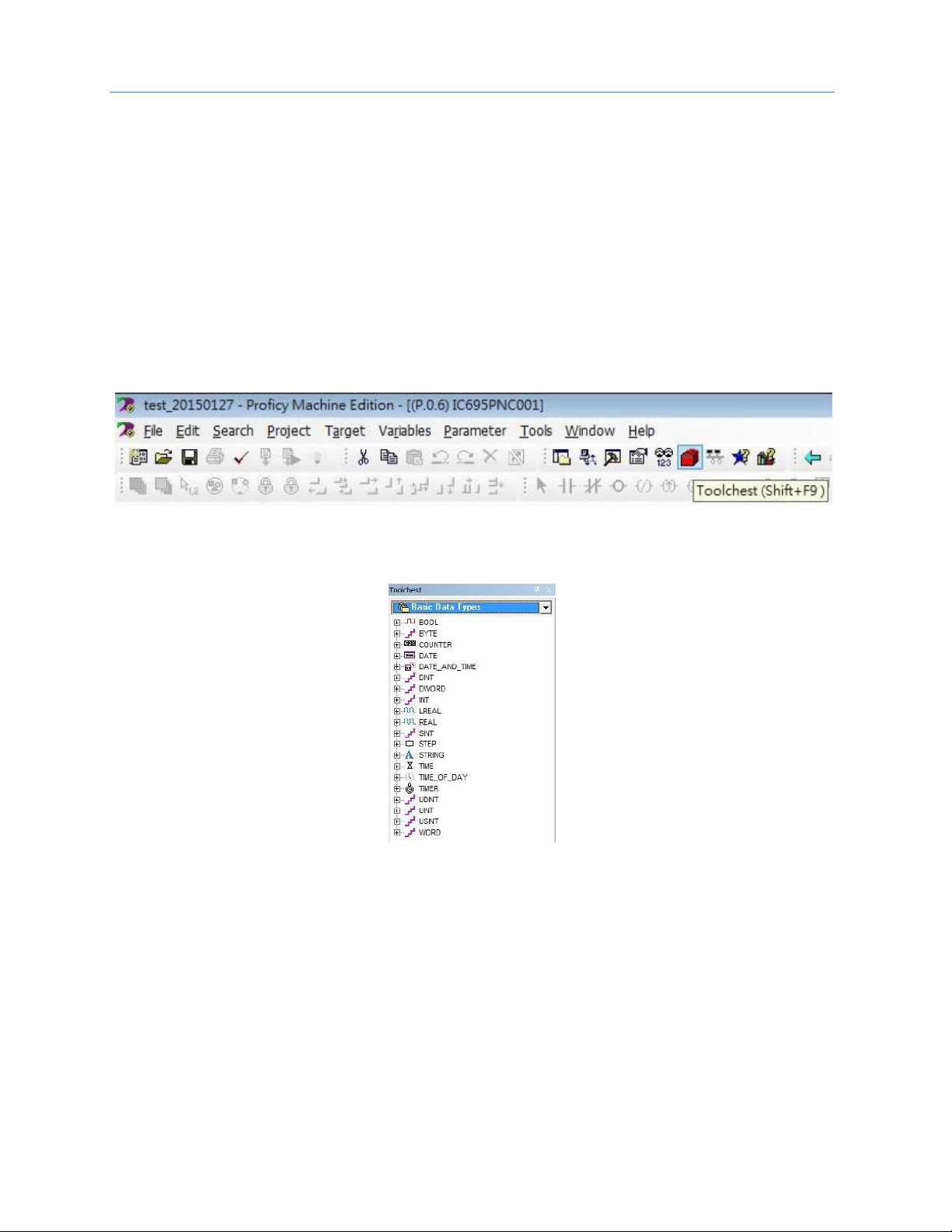

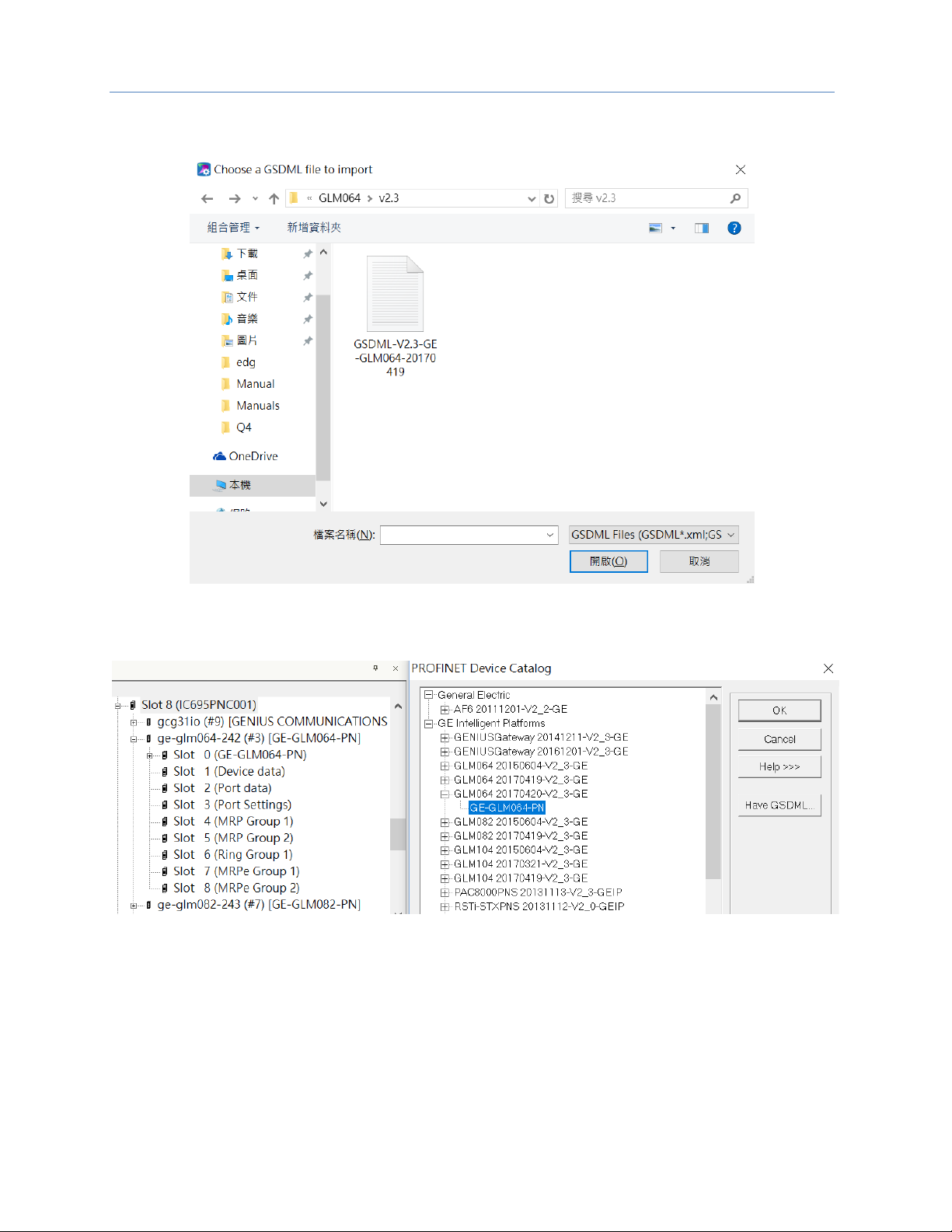

4.1 Import the GSDML file

Browse to the folder containing the GSDML file, then import it using the Toolchest feature of PME, as shown

below. Alternately, use the Have GSDML button shown in Figure 25, and perform the import as configuration

progresses.

Each GLM Switch Catalog Number has a unique GSDML file associated with it.

Note that you will only need to import any given GSDML file once. The file can then be used to define the

parameters associated with each GLM switch of the corresponding type added to the network.

If a newer version of a GSDML file becomes available, it will reside in the Toolchest alongside older versions.

The user has the option to change the version of the GSDML file associated with each installed GLM Switch

device.

If all GLM switches have been associated with a newer version of the GSDLM file, and the older version of the

GSDML file is no longer required, it can be deleted from the Toolchest.

Figure 18: PME Toolchest Feature

The Toolchest offers a drop-down list of various data types:

Figure 19: Toolchest Data Types

Page 26

Chapter 4. Configuration

GFK-3030 December 2017 19

Since the GLM Switch is to be used as a PROFINET Device, select PROFINET Devices from the drop-down list

(Figure 20).

Figure 20: Select PROFINET Device

Right click on the PROFINET Devices line item. At the bottom of the resulting drop-down menu, under

Assistants, select the Import GSDML command.

Figure 21: Import GSDML Command

Page 27

Chapter 4. Configuration

20 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

The resulting dialog box allows you to browse to the desired folder and select the GSDML file.

Figure 22: Browse to Folder and Select GSDML file for Import

The Toolchest now displays the newly-added device:

Figure 23: Toolchest Displays Newly-Added Device

Page 28

Chapter 4. Configuration

GFK-3030 December 2017 21

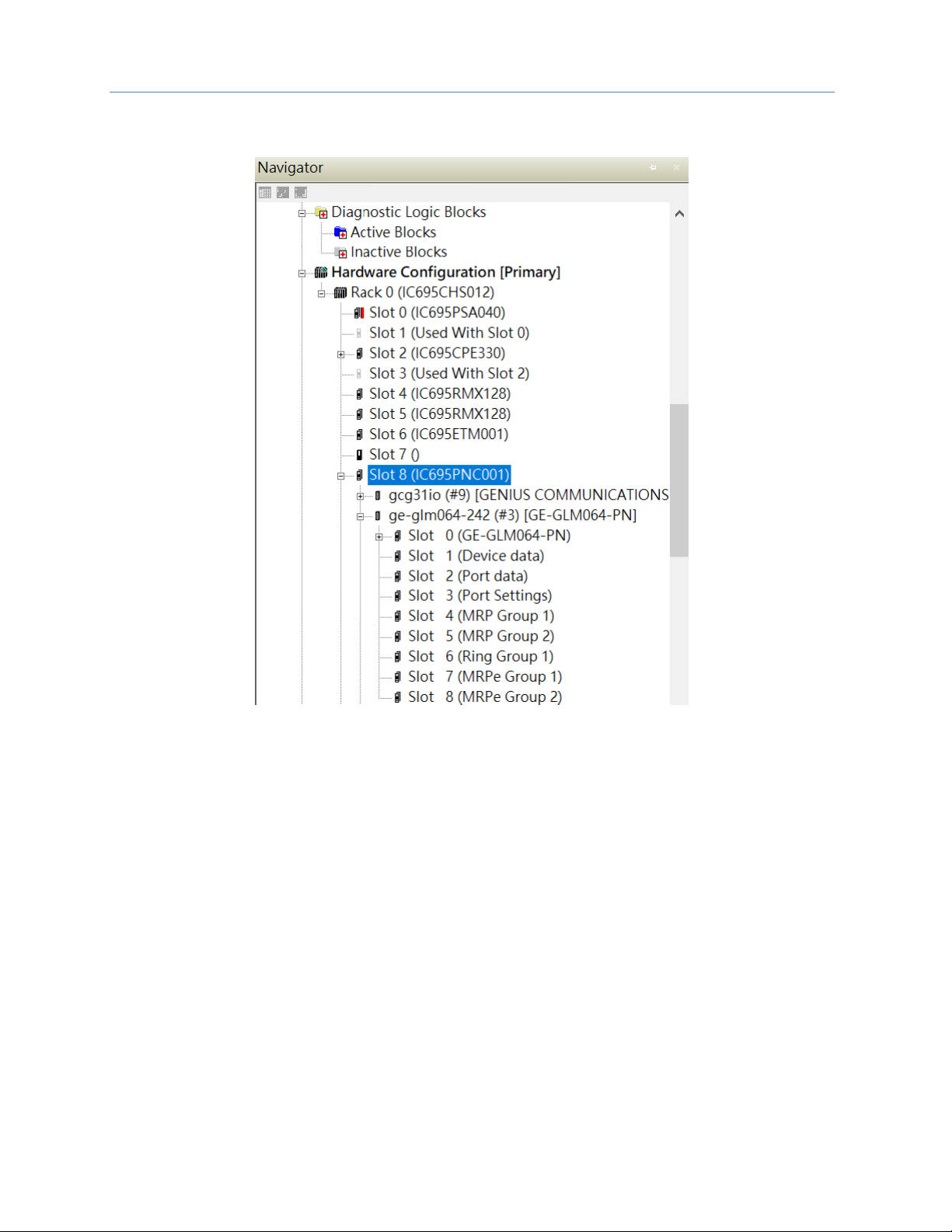

4.2 Associating the IO-Device with its Controller

Each GLM Switch device has to be associated with the PROFINET Controller which will be controlling and

monitoring it. Figure 24 shows that the PNC001 module located in Slot 6 of Rack 0 (the Main CPU Rack) has

been selected. Then with right-click, the menu item Add IO-Device has been selected.

Figure 24: Add IO-Device to PROFINET Controller

Since the device being added is associated with a PROFINET-IO Controller, it will be selected from the catalog

of available PROFINET Devices (upper left portion of Figure 25):

Figure 25: Select IO-Device from PROFINET Device Catalog

Use the Have GSDML button in Figure 25 to select the GSDML file associated with the previously selected GLM

catalog number. This interface allows you to browse to the folder in which the GSDML file is located, and select

the appropriate file. In Figure 25, expand the tree using the “+” icons and select the IO-Device from the catalog

list.

Page 29

Chapter 4. Configuration

22 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Once selected, the IO-Device will display as having been installed under the previously selected PNC001.

Figure 26: IO-Device Installed Under PNC001

Also note that the constituent ports of the new IO-Device are also displayed in Figure 26.

The data from the associated slots (shown in Figure 26) is treated as Cyclic I/O Data (RTC) by the PROFINET

Controller.

Page 30

Chapter 4. Configuration

GFK-3030 December 2017 23

4.3 PROFINET Cyclic I/O Data

Cyclic I/O Data is that data obtained by the PROFINET Controller from each PROFINET IO-Device in a cyclic

manner. The default transfer frequency of PROFINET cyclic data is 128ms. The GSDML file supports three

possible values: 128ms, 256ms and 512ms.

PME is used to assign base references to the Cyclic I/O Data of each GLM IO-Device. Each slot of the GLM

IO-Device has a Settings form, such as that shown in Figure 27. Double-click on the slot to bring up the

corresponding form.

• If the Slot has Output values (as defined by the Direction column in the following tables), it will require

a base reference in %Q. The lowest order bit in the Output table will correspond to the selected %Q

reference value, which must be a multiple of 8, plus 1.

• If the Slot has Input values (as defined by the Direction column in the following tables), it will require a

base reference in %I. The lowest order bit in the Input table will correspond to the selected %I

reference value, which must be a multiple of 8, plus 1.

In the case of slot 3, where there are matching input and output settings, GE recommends selecting the same

%I and %Q references, as this will avoid confusion when debugging and in project documentation. For

instance, if %I00129 is used for the Port Alarm Inputs, then use %Q00129 for the Port Alarm Outputs. Also note

that 16 contiguous %I and %Q references are required to accommodate all the Port Alarm flags (in both %I

and in %Q). Finally, do not allow any other devices or device slots to overlap the selected %I and %Q settings.

If PME is allowed to automatically assign the next available %I and %Q references, there will likely be no

alignment between the %I and %Q bits assigned to any given GLM IO-Device. This will work fine, but may

cause confusion when debugging.

Figure 27: Assign Starting %I & %Q References for Cyclic I/O Data

The constituent data content is documented in the following sections:

• Slot 1 (of the GLM Switch Device) contains Device Status.

• Slot 2 contains Port Status.

• Slot 3 contains Port Alarm Settings & Status.

• Slot 4 contains MRP Group 1 Status.

• Slot 5 contains MRP Group 2 Status.

• Slot 6 contains Ring Group 1 Status

• Slot 7 contains MRE Group 1 Status

• Slot 8 contains MRE Group 2 Status

The Status Flags are discussed in Chapter 5, Diagnostics.

Page 31

Chapter 4. Configuration

24 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Slot 1: Device Status

Category

Direction

Byte#

Bit#

Name

Description

Device Data

(Slot 1)

Input

0

0

Alarm Status

0=No Alarm (ALM Relay Open),

1=Alarm Detected (ALM Relay Closed)

1

Power 1 Status

0=PWR1 not OK, 1=PWR1 OK

2

Power 2 Status

0=PWR2 not OK, 1=PWR2 OK

3

Ring Enabled/Disabled

0=Disabled, 1=Enabled

4

Ring Status

0=Failure, 1=Normal Condition

Slot 2: Port Status

Category

Direction

Byte#

Bit#

Name

Description

Port Status

(Slot 2)

Input

0

0

Port 1 Connection

0=Not Connected, 1=Connected

1

Port 2 Connection

0=Not Connected, 1=Connected

2

Port 3 Connection

0=Not Connected, 1=Connected

3

Port 4 Connection

0=Not Connected, 1=Connected

4

Port 5 Connection

0=Not Connected, 1=Connected

5

Port 6 Connection

0=Not Connected, 1=Connected

6

Port 7 Connection

0=Not Connected, 1=Connected

7

Port 8 Connection

0=Not Connected, 1=Connected

Input

1

0

Port 9 Connection

0=Not Connected, 1=Connected

1

Port 10 Connection

0=Not Connected, 1=Connected

2

Port 11 Connection1

0=Not Connected, 1=Connected

3

Port 12 Connection1

0=Not Connected, 1=Connected

4

Port 13 Connection1

0=Not Connected, 1=Connected

5

Port 14 Connection1

0=Not Connected, 1=Connected

6

Reserved

7

Reserved

1

GLM104 only

Page 32

Chapter 4. Configuration

GFK-3030 December 2017 25

Slot 3: Port Alarm & Port Settings & Status

Category

Direction

Byte#

Bit#

Name

Output

Description

Input Description

Port Settings

(Slot 3)

Input &

Output

0

0

Port 1 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

1

Port 2 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

2

Port 3 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

3

Port 4 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

4

Port 5 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

5

Port 6 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

6

Port 7 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

7

Port 8 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

2

0

Port 9 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

1

Port 10 Alarm

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

2

Port 11 Alarm1

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

3

Port 12 Alarm1

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

4

Port 13 Alarm1

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

5

Port 14 Alarm1

0=Alarm Disabled,

1=Alarm Enabled

0=No Alarm

1=Alarm Condition Detected

6

Reserved

7

Reserved

Note: Bytes 0 and 2 are not contiguous (see next page).

Page 33

Chapter 4. Configuration

26 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Category

Direction

Byte#

Bit#

Name

Output Description

Input Description

Port Settings

(Slot 3)

(continued)

Input &

Output

1

0

Port 1 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

1

Port 2 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

2

Port 3 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

3

Port 4 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

4

Port 5 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

5

Port 6 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

6

Port 7 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

7

Port 8 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

3

0

Port 9 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

1

Port 10 Admin

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

2

Port 11 Admin1

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

3

Port 12 Admin1

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

4

Port 13 Admin1

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

5

Port 14 Admin1

0=Enable Port,

1=Disable Port

0=Port Enabled

1=Port Disabled

6

Reserved

7

Reserved

Note: Bytes 1 and 3 are not contiguous (see previous page).

Page 34

Chapter 4. Configuration

GFK-3030 December 2017 27

Slot 4: MRP Group 1 Status

Category

Direction

Byte#

Bit#

Name

Description

MRP Group 1

(Slot 4)

Input

0

0

MRP Group 1 Mode

0=MRP Disabled, 1=MRP Enabled

1

MRP Group 1 Role

0=MRP Client, 1=MRP Master

MRP Group 1

Ports

(Slot 4)

Input

1

0

Port 1 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

1

Port 2 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

2

Port 3 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

3

Port 4 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

4

Port 5 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

5

Port 6 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

6

Port 7 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

7

Port 8 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

2

0

Port 9 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

1

Port 10 MRP-G1 Status

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

2

Port 11 MRP-G1 Status1

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

3

Port 12 MRP-G1 Status1

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

4

Port 13 MRP-G1 Status1

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

5

Port 14 MRP-G1 Status1

0=Not MRP-G1 Ring Port

1=MRP-G1 Ring Port

6

Reserved

7

Reserved

Page 35

Chapter 4. Configuration

28 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Slot 5: MRP Group 2 Status

Category

Direction

Byte#

Bit#

Name

Description

MRP Group 2

(Slot 5)

Input

0

0

MRP Group 2 Mode

0=MRP Disabled, 1=MRP Enabled

1

MRP Group 2 Role

0=MRP Client, 1=MRP Master

MRP Group 2

Ports

(Slot 5)

Input

1

0

Port 1 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

1

Port 2 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

2

Port 3 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

3

Port 4 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

4

Port 5 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

5

Port 6 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

6

Port 7 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

7

Port 8 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

2

0

Port 9 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

1

Port 10 MRP-G2 Status

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

2

Port 11 MRP-G2 Status1

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

3

Port 12 MRP-G2 Status1

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

4

Port 13 MRP-G2 Status1

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

5

Port 14 MRP-G2 Status1

0=Not MRP-G2 Ring Port

1=MRP-G2 Ring Port

6

Reserved

7

Reserved

Page 36

Chapter 4. Configuration

GFK-3030 December 2017 29

Slot 6: Ring Group 1 Status

Category

Direction

Byte#

Bit#

Name

Description

Ring Group 1

(Slot 6)

Input

0

0

Ring Group 1 Mode

0=Ring Disabled, 1=Ring Enabled

1

Ring Group 1 Role

0=Ring Slave, 1=Ring Master

2

Ring Status

0=Failure, 1=Normal Condition

Ring Group 1

Ports

(Slot 6)

Input

1

0…3

Ring Port 1 Number

Port ID number (1 thru 14)

4…6

Reserved

7 Port 1 Status

0=Forwarded, 1=Blocked

2

0…3

Ring Port 2 Number

Port ID number (1 thru 14)

4…6

Reserved

7

Port 2 Status

0=Forwarded, 1=Blocked

Slot 7: MRE Group 1 Status

Category

Direction

Byte#

Bit#

Name

Description

MRE Group 1

(Slot 7)

Input

0

0

MRE Group 1 Mode

0=Ring Disabled, 1=Ring Enabled

1

MRE Group 1 Role

0=Ring Slave, 1=Ring Master

2

Ring Status

0=Failure, 1=Normal Condition

1

0…3

Ring Port Number

Port ID number (1 thru 14)

4…6

Reserved

7

Port Status

0=Forwarded, 1=Blocked

Slot 8: MRE Group 2 Status

Category

Direction

Byte#

Bit#

Name

Description

MRE Group 2

(Slot 8)

Input

0

0

MRE Group 2 Mode

0=Ring Disabled, 1=Ring Enabled

1

MRE Group 2 Role

0=Ring Slave, 1=Ring Master

2

Ring Status

0=Failure, 1=Normal Condition

1

0…3

Ring Port Number

Port ID number (1 thru 14)

4…6

Reserved

7

Port Status

0=Forwarded, 1=Blocked

Page 37

Chapter 4. Configuration

30 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

4.4 PROFINET Acyclic I/O Data

The GLM Switches also support PROFINET Acyclic I/O Data (RTA). Data of this type has been mapped to the

sub-slots as indicated in this section, and may be retrieved via the assigned %I references.

Acyclic Device Data –Subslot 0

Byte

Name

Access

Value

Description

0

Device Status

read-only

0

Not supported

1

Device OK

2

Device bootup failed

1

Alarm Status

read-only

0

Not supported

1

No Alarm

2

Alarm condition detected

2

Power 1 Status

read-only

0

Not supported

1

PWR1 Input OK

2

PWR1 Input not OK

3

Power 2 Status

read-only

0

Not supported

1

PWR2 Input OK

2

PWR2 Input not OK

4

Redundant Mode

read-only

0

MRP

1

RSTP/MSTP2

2

Ring/Coupling/Dual Homing/Chain/Balancing Chain2

3

Non-Redundant

5

Ring-1 Mode

(config value)

read-only

0

Not supported

1

Enabled

2

Disabled

6

Ring-1 Role

read-only

0

Not supported

1

Ring Master

2

Ring Slave

7

Ring-1 State

read-only

0

Not supported

1

Disabled

2

Normal

3

Failed

2

This feature is not supported by RX3i CPUs.

Page 38

Chapter 4. Configuration

GFK-3030 December 2017 31

Byte

Name

Access

Value

Description

8

Ring-2 Mode

(config value)

read-only

0

Not supported

1

Enabled

2

Disabled

9

Ring-2 Role

read-only

0

Not supported

1

Ring Master2

2

Ring Slave2

3

Coupling Primary2

4

Coupling Backup2

5

Dual Homing2

10

Ring-2 State

read-only

0

Not supported

1

Disabled

2

Normal

3

Failed

11

Ring-3 Mode

(config value)

read-only

0

Not supported

1

Enabled

2

Disabled

12

Ring-3 Role

read-only

0

Not supported

1

Chain Head 2

2

Chain Tail 2

3

Chain Member 2

4

Balancing Chain Terminal 12

5

Balancing Chain Terminal 22

6

Balancing Chain Central Block 2

7

Balancing Chain Member 2

13

Ring-3 State

read-only

0

Not supported

1

Disabled 2

2

Normal 2

3

Failed 2

Page 39

Chapter 4. Configuration

32 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Acyclic Port Data – Subslot 1

Byte

Name

Access

Value

Output Description

Input Description

0

Port Alarm

read-write

0

Do not send alarm

No Port Alarm

1

Send alarm when port link down

Port Alarm Detected

1

Port Setting

State

read-write

0

Not supported

Not supported

1

Off

Off

2

On

On

2

Port Link State

read-only

0 Not supported

1 Link is up

2 Link is down

3

Port Speed

read-only

0 Unavailable (link down)

1 10 Mbps

2 100 Mbps

3 1 Gbps

4

Port Duplex

read-only

0 Unavailable (link down)

1 Half 2

Full

5

Port Autonegotiation

read-only

0 Unavailable (link down)

1 Off

2 On

Page 40

Chapter 4. Configuration

GFK-3030 December 2017 33

Acyclic MRP Group 1 Data – Subslot 2

Byte

Name

Access

Value

Output Description

Input Description

0

MRP Mode

read-write

0

Disable MRP

MRP Disabled

1

Enable MRP (Default)

MRP Enabled

1

MRP Role

read-write

0

MRC (Default)

MRC

1

MRM

MRM

2

Ring Port1 of MRP

read-write

0~7

Assigned Port ID of Ring Port1

(0 corresponds to Port 1,

7 corresponds to Port 8)

0 is default value.

Port ID

3

Ring Port2 of MRP

read-write

0~7

Assigned Port ID of Ring Port 2

(0 corresponds to Port 1,

7 corresponds to Port 8)

1 is default value.

Port ID

Acyclic MRP Group 2 Data – Subslot 3

Byte

Name

Access

Value

Output Description

Input Description

0

MRP Mode

read-write

0

Disable MRP (Default)

MRP Disabled

1

Enable MRP

MRP Enabled

1

MRP Role

read-write

0

MRC (Default)

MRC

1

MRM

MRM

2

Ring Port1 of MRP

read-write

0~7

Assigned Port ID of Ring Port1

(0 corresponds to Port 1,

7 corresponds to Port 8)

2 is default value.

Port ID

3

Ring Port2 of MRP

read-write

0~7

Assigned Port ID of Ring Port 2

(0 corresponds to Port 1,

7 corresponds to Port 8)

3 is default value.

Port ID

Page 41

Chapter 4. Configuration

34 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Acyclic Ring Group 1 Data – Subslot 4

Byte

Name

Access

Value

Output Description

Input Description

0

Ring Mode

read-write

0

Disable Ring (Default)

Ring Disabled

1

Enable Ring

Ring Enabled

1

Ring Role

read-write

0

Slave (Default)

Slave

1

Master

Master

2

Ring Port1

read-write

1~8

Assigned Port ID of Ring Port1

(1 corresponds to Port 1,

8 corresponds to Port 8)

1 is default value.

Port ID

3

Ring Port2

read-write

1~8

Assigned Port ID of Ring Port2

(1 corresponds to Port 1,

8 corresponds to Port 8)

2 is default value.

Port ID

Page 42

Chapter 4. Configuration

GFK-3030 December 2017 35

Acyclic MRPe Group 1 Data – Subslot 5

Byte

Name

Access

Value

Output Description

Input Description

0

MRPe Mode

read-write

0

Disable MRPe (Default)

MRPe Disabled

1

Enable MRPe

MRPe Enabled

1

MRPe Role

read-write

0

Slave (Default)

Slave

1

Master

Master

2

MRPe Port

read-write

1~8

Port ID of MRPe port

(1 corresponds to Port 1,

8 corresponds to Port 8)

5 is default value.

Port ID

Acyclic MRPe Group 2 Data – Subslot 6

Byte

Name

Access

Value

Output Description

Input Description

0

MRPe Mode

read-write

0

Disable MRPe (Default)

MRPe Disabled

1

Enable MRPe

MRPe Enabled

1

MRPe Role

read-write

0

Slave (Default)

Slave

1

Master

Master

2

MRPe Port

read-write

1~8

Port ID of MRPe port

(1 corresponds to Port 1,

8 corresponds to Port 8)

6 is default value.

Port ID

Page 43

Chapter 4. Configuration

36 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

4.5 Assigning Device Name and IP Address

In order to communicate with the newly-added IO-Device, it is necessary to provide it with a unique Device

Name and a unique IP Address. This is performed using the Discovery and Configuration Protocol Tool (DCP).

Figure 28: Properties of IO-Device

As shown in Figure 28, you will need to drill down to the Properties of the highlighted IO-Device. This is done by

double-clicking in the IO-Device of interest. Doing so produces the Inspector form, shown in Figure 29.

Figure 29: Inspector Form for IO-Device

Within the Inspector Form:

• use the Device Number field to provide a unique Device Number for this IO-Device,

• use the Device Name field to provide a unique Device Name for this IO-Device, and

• use the IP Address field to provide a unique IP Address.

Place the cursor in the corresponding data entry box and key in the desired values.

Save the PME project when done.

Page 44

Chapter 4. Configuration

GFK-3030 December 2017 37

4.6 MRP Settings for IO-Devices

Media Redundancy Protocol (MRP) is supported by PACSystems PROFINET Controllers. Refer to the PACSystems

RX3i & RSTi-EP PROFINET I/O Controller Manual, GFK-2571,

To access the MRP parameters associated with a target IO-Device, display the hardware configuration in PME,

then double-click on the IO-Device of interest (Figure 30).

Figure 30: Accessing the MRP Parameters of an IO-Device

The parameters are displayed in the form at right (Figure 30).

In the Media Redundancy tab (Figure 31), change the Media Redundancy field to meet your requirements. The

options are “None”, “Client” and “Manager”.

If “Client” or “Manager” is selected, set up or modify the ring ports in the Media Redundancy tab (Figure 31).

Figure 31: Set up MRP Ring Ports

PME also permits the user to set up dual MRP in a single IO-Device. The two MRP implementations are

independent and use different ports. To modify the parameters of the second group, select the MRP Group2

Data tab (Figure 32).

Figure 32: MRP Group2 Data Tab

Page 45

Chapter 4. Configuration

38 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

4.7 Download from PME to CPU

Once all the devices have been configured, download the resulting configuration from PME to the host CPU.

The CPU will then distribute the configuration elements to its connected devices.

4.8 Hot Standby CPU Redundancy Considerations

The Properties of IO-Devices need to be synchronized between the Primary and Secondary CPUs in a Hot

Standby CPU Redundancy System. To accomplish this, use the Mirror to Secondary Hardware feature. Refer to

the PACSystems Hot Standby CPU Redundancy User Manual, GFK-2308.

Page 46

Chapter 4. Configuration

GFK-3030 December 2017 39

4.9 Discovery Tool

If desired, the operator may use the Launch Discovery Tool of PME to automatically detect all connected

network devices. This operation may only be performed once all network devices have been interconnected

and powered up.

Figure 33: Launch Discovery Tool

As shown in Figure 33, select the network controlling device (here the PNC001 in Slot 6 is highlighted). Then

right-click and select Launch Discovery Tool on the resulting drop-down menu. This initiates a real-time

exploration of the connected network (Figure 34).

Figure 34: Discovery Tool in Progress

When the Discovery Tool scan completes, a listing of all connected devices is produced, along with status

indications.

Page 47

Chapter 4. Configuration

40 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Figure 35: Listing of all Detected Devices

If devices are missing due to incorrect cabling or not having been powered up, correct those situations, then

click on the Refresh Device List button.

Page 48

GFK-3030 December 2017 41

Chapter 5 Diagnostics

The GLM Switches support one alarm per port, plus an independent alarm for each power input circuit (PWR1

and PWR2), and an Alarm Status bit that tracks the state of the ALM relay. There are also status bits relating to

MRP set-up.

Each of the port alarms (i.e. Slot 3 Settings) may be enabled and disabled, as listed in Section 4.3.3. These

alarms may be enabled/disabled by PME setup. The PLC logic may also dynamically enable and disable these

alarms by manipulating the corresponding %Q reference bit.

For details on bit locations and senses, refer to:

• Section 4.3.1 for Slot 1: Device Status

• Section 4.3.2 for Slot 2: Port Status

• Section 4.3.3 for Slot 3: Port Alarm & Port Settings & Status

• Section 4.3.4 for Slot 4: MRP Group 1 Status

• Section 4.3.5 for Slot 5: MRP Group 2 Status

• Section 4.3.6 for Slot 6: Ring Group 1 Status

• Section 4.3.7 for Slot 7: MRE Group 1 Status

• Section 4.3.8 for Slot 8: MRE Group 2 Status

All input status bits listed in the above sections may be tested by logic in the PLC CPU.

In addition, there is an Alarm Contact (Normally Open) (Figure 11) which may be wired to an external device.

The alarm contacts (marked ALM) are located in the middle of the 6-pin terminal strip on the bottom panel.

The Alarm relay closes whenever any of the enabled alarms becomes active. Refer also to Section 4.3.1 Slot 1:

Device Status for the corresponding Alarm Status bit.

The state of the Alarm Relay is indicated on the ALM LED, as documented in Section 3.6, LED Operation.

Page 49

Chapter 5. Diagnostics

42 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

Setting up and Sensing Alarms

Use PME to assign bits in the %Q output table to control whether GLM alarms for a target device will be

enabled or disabled. These are shown as the Port Alarm Outputs in Figure 36.

The Alarm Enabled bits are contiguous and must be assigned a starting location in %Q on a byte boundary.

Figure 36 uses %Q00001 for simplicity, but this starting location can be any multiple of 8, plus 1. For instance,

%Q00401 would be another suitable starting location.

To enable or disable an alarm, refer to Section 4.3.3 for Slot 3: Port Alarm & Port Settings & Status.

Figure 36: GLM Switch Parameters Set in PME

Use PME to assign bits in the %I input table to determine where the PLC may sense the corresponding alarm

conditions associated with the target device. These are shown as the Port Alarm Inputs in Figure 36.

The Port Alarm Input bits are contiguous and must be assigned a starting location in %I on a byte boundary.

The table above uses %I00129 for simplicity, but this starting location can be any multiple of 8, plus 1. For

instance, %I00401 would be another suitable starting location.

When an alarm is present, the corresponding Port Alarm Input bit will register as “1’; when no alarm is present,

it will register as “0”. Refer to Section 4.3.3, Slot 3: Port Alarm & Port Settings & Status for details.

The Port Admin Input and Port Admin Output are used by the console function to read the Alarm Input senses

and enable/disable the alarms as shown in Figure 37. The starting addresses may be assigned to any

available non-conflicting %I and %Q starting references. The corresponding starting location can be any

multiple of 8, plus 1.

Figure 37: Set Port Alarm Active or Inactive Using PME

Page 50

Chapter 5. Diagnostics

GFK-3030 December 2017 43

Power Alarm

As documented in Section 3.2, Power Connection, there are two independent power connections, PWR1 and

PWR2. In the event one of these is powered up and is capable of energizing the target GLM switch device, it is

then possible for that GLM Switch device to sense that the alternate Power Supply Input is within specification,

or otherwise. If not, then the corresponding Power Alarm Input is activated.

The P1 and P2 LEDs on the front panel indicate the status of the two power supply inputs, PWR1 and PWR2, as

shown in Section 3.6, LED Operation. The Power Alarms are always enabled.

The Power Alarm Input bits are located as documented in Section 4.3.1, Slot 1: Device Status.

Page 51

Chapter 5. Diagnostics

44 PACSystems PROFINET Managed Industrial Ethernet Switches User Manual GFK-3030

5.2 External Alarm Circuit

The two ALM contacts in the 6-pin terminal strip located in the bottom panel may be used to drive an external

alarm circuit, as diagrammed in Figure 38. The Alarm Relay is Normally Open, and closes in the event of an

alarm condition. Within the GLM switch, all alarm conditions that have been enabled are OR’d together. Once

any of them becomes active, the Alarm Relay closes.

Figure 38: External Alarm Circuit

Page 52

GFK-3030 December 2017 45

Appendix A Command Language Interface (CLI)