Page 1

GE

Installation and Maintenance Guide

994-0047

Version 5.10 Revision 4

GE Information

Grid Solutions

iBox/iBox Kit

Page 2

iBox/iBox Kit

Installation and Maintenance Guide

GE Grid Solutions

2

are trademarks and service marks of

COPYRIGHT NOTICE

© 2002-2017, General Electric Company. All rights reserved.

The Software Product described in this documentation may only be used in accordance with the applicable License Agreement. The

Software Product and Associated Material are deemed to be “commercial computer software” and “commercial computer software

documentation,” respectively, pursuant to DFAR Section 227.7202 and FAR Section 12.212, as applicable, and are delivered with

Restricted Rights. Such restricted rights are those identified in the License Agreement, and as set forth in the “Restricted Rights

Notice” contained in paragraph (g) (3) (Alternate III) of FAR 52.227-14, Rights in Data-General, including Alternate III (June 1987).

If applicable, any use, modification, reproduction release, performance, display or disclosure of the Software Product and Associated

Material by the U.S. Government shall be governed solely by the terms of the License Agreement and shall be prohibited except to

the extent expressly permitted by the terms of the License Agreement. Any attached hardware schematics and technical descriptions

are for information purposes only.

The information contained in this online publication is the exclusive property of General Electric Company, except as otherwise

indicated. You may view, copy and print documents and graphics incorporated in this online publication (the “Documents”) subject

to the following: (1) the Documents may be used solely for personal, informational, non-commercial purposes; (2) the Documents

may not be modified or altered in any way; and (3) General Electric Company withholds permission for making the Documents or

any portion thereof accessible via the internet. Except as expressly provided herein, you may not use, copy, print, display,

reproduce, publish, license, post, transmit or distribute the Documents in whole or in part without the prior written permission of

General Electric Company. If applicable, any use, modification, reproduction, release, performance, display, or disclosure of the

Software Product and Associated Material by the U.S. Government shall be governed solely by the terms of the License Agreement

and shall be prohibited except to the extent expressly permitted by the terms of the License Agreement.

The information contained in this online publication is subject to change without notice. The software described in this online

publication is supplied under license and may be used or copied only in accordance with the terms of such license.

TRADEMARK NOTICES

GE and

* Trademarks of General Electric Company.

Windows is a registered trademark of Microsoft Corporation; HyperTerminal is a registered trademark of Hilgreave Inc.; Pentium is a

registered trademark of Intel Corporation; Panduit is a registered trademark of Panduit Corporation; IEC is a registered trademark of

Commission Electrotechnique Internationale; IEEE is a registered trademark of The Institute of Electrical and Electronics Engineers

Inc; Modbus is a registered trademark of RT Schneider Automation Inc.; ADAM is a registered trademark of Advantech Corporation.

Digi One is a registered trademark of Digi International Inc.; and Glyptal is a registered trademark of RT Glyptal Inc.

Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective

companies.

General Electric Company.

994-0047-5.10-4 GE Information

Page 3

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

3

Contents

About This Document 5

Product Support 7

Safety Precautions 8

Section 1: Getting Started ..................................................................................................................................... 13

1.1. What is an iBox? ....................................................................................................................... 14

1.2. Unpacking and Inspection ......................................................................................................... 20

1.3. Storage ...................................................................................................................................... 22

1.4. Installation Tools ...................................................................................................................... 23

Section 2: iBox Installation and Maintenance ..................................................................................................... 24

2.1. Familiarization .......................................................................................................................... 25

2.2. Installing the iBox ..................................................................................................................... 27

2.3. Configuring your iBox .............................................................................................................. 36

2.4. Testing your iBox ..................................................................................................................... 45

2.5. Connecting and Testing Field Wiring ....................................................................................... 51

2.6. Servicing your iBox .................................................................................................................. 58

2.7. Maintaining your iBox Software ............................................................................................... 61

2.8. Troubleshooting your iBox ....................................................................................................... 69

2.9. Replacing your iBox ................................................................................................................. 75

Section 3: iBox Kit Installation and Maintenance .............................................................................................. 77

3.1. Familiarization .......................................................................................................................... 77

3.2. Installing the iBox Kit ............................................................................................................... 82

3.3. Configuring the iBox Kit Components ..................................................................................... 87

3.4. Connecting Field Wiring ......................................................................................................... 132

3.5. Servicing your iBox Kit .......................................................................................................... 134

3.6. Maintaining your iBox Kit Software ...................................................................................... 135

3.7. Troubleshooting your iBox Kit ............................................................................................... 138

3.8. Replacing your iBox Kit ......................................................................................................... 139

Section 4: Removing Configuration Data and Sensitive Information ............................................................. 140

4.1. From the iBox Device ............................................................................................................. 140

4.2. From the PC Running Configuration Software ....................................................................... 141

Appendix A: Technical Specifications ................................................................................................. 143

Appendix B: iBox Kit Default Configurations ................................................................................... 149

Appendix C: Resetting the Digi One Configuration .......................................................................... 153

Appendix D: Setting your PC IP Address ........................................................................................... 155

Appendix E: DPA Default Point Mapping ......................................................................................... 157

Appendix F: Installing and Connecting DNP3 I/O Modules ................................................................................ 163

GE Information

994-0047-5.10-4

Page 4

iBox/iBox Kit

Installation and Maintenance Guide

GE Grid Solutions

4

Appendix G: Error Messages ............................................................................................................... 169

994-0047-5.10-4 GE Information

Page 5

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

5

About This Document

Purpose

What this

document

provides

SGConfig

Online Help

Training Tool

Operating

System

The iBox/iBox Kit Installation and Maintenance Guide contains information about

two products, the iBox and the iBox Kit.

The document is split into three sections. Section 1: Getting Started provides an

overview of the iBox. Section 2: iBox Installation and Maintenance provides

instructions for installing, configuring, using, maintaining and troubleshooting the

iBox. Section 3: iBox Kit Installation and Maintenance provides similar information

for the iBox Kit.

Some iBox configuration procedures provide details on the SGConfig tool. For the

equivalent information when using SGConfig to configure the iBox, refer to the

SGConfig online help.

For topics related to the use of GE Digital Energy's SGConfig* configuration utility,

or details of any software application used in a specific iBox, refer to the SGConfig

online help.

In addition to the primary purpose of this Installation and Maintenance Guide, its

secondary purpose is that of a Training Manual for customer training sessions

provided by GE Digital Energy, or its agents.

The procedures in this guide are based on Windows 2000. Some steps and dialog

boxes may vary slightly if you are using Windows XP or Windows 2003.

Intended Audience

Job Titles

Experience &

Abilities

GE Information

This guide is intended for use by the SCADA system installers and field engineers

who are responsible for the installation, hardware configuration and maintenance of

SCADA systems containing iBox units and iBox Kits.

This guide assumes that anyone working with an iBox or iBox Kit has some prior

knowledge of:

• Electrical utility industry

• Personal computer terminology and interconnection skills

• GE Digital Energy products

• Other industry products such as protective relays, meters, and voltage regulators.

994-0047-5.10-4

Page 6

iBox/iBox Kit

Installation and Maintenance Guide

6

Additional Documentation

GE Grid Solutions

For further information about the iBox and its components, refer to the following

documents:

From GE Digital Energy:

• iBox Product Overview (PRPI-043)

• D20, D25, iBox Automation Applications (PRPI-048)

• SGConfig online help

• WESMAINTII+ User’s Guide (B014-1UG)

• 68K Monitor User’s Guide (SWM0023)

• Application software configuration guides

From other manufacturers

• Digi One User’s Guide (Digi International)

• ADAM 4000 Data Acquisition Modules User’s Manual (Advantech)

• DMMS300+, DMMS350, DMMS425 3-Phase Multifunction Power Monitors

with Advanced Capabilities Installation, Operation and Programming Manual

(Electro Industries/GaugeTech)

994-0047-5.10-4 GE Information

Page 7

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

7

The GE Grid Solutions Web site provides fast access to technical information, such

!

Product Support

Getting Help

Search GE

Grid Solutions

Web Site

Search GE

Grid Solutions

Technical

Support

Contact

Technical

Support

Product

Returns

If you need help with any aspect of your GE Grid Solutions product, you have a few

options.

as manuals, release notes and knowledge base topics.

Visit us on the Web at: http://www.gegridsolutions.com

This site serves as a document repository for post-sales requests. To get access to

the Technical Support Web site, go to:

http://sc.ge.com/*SASTechSupport

GE Grid Solutions Technical Support is open 24 hours a day, seven days a week for

you to talk directly to a GE representative.

In the U.S. and Canada, call toll-free: 1 800 547 8629

International customers, please call: +1 905 927 7070

Or e-mail to multilin.tech@ge.com

Before you return a product, please contact GE Grid Solutions Technical Support to

obtain a Return Merchandise Authorization number and complete instructions for

return shipments.

A Return Merchandise Authorization (RMA) number must accompany all equipment

being returned for repair, servicing, or for any other reason.

Note: Product returns will not be accepted without a Return Merchandise

Authorization number.

If you attempt to resolve problems with your GE product using methods not

recommended by GE Digital Energy, this might result in damage or injury to persons

and property.

GE Information

994-0047-5.10-4

Page 8

iBox/iBox Kit

Installation and Maintenance Guide

8

!

Safety Precautions

Important!

Follow all safety precautions and instructions in this manual:

• Only qualified personnel should work on the iBox/iBox Kit. Maintenance

personnel should be familiar with the hazards associated with electrical

equipment.

• NEVER work alone.

• Before performing visual inspections, tests, or maintenance on this equipment,

isolate or disconnect all hazardous live circuits and

Assume that all circuits are live until they have been completely de-energized,

tested, and tagged. Pay particular attention to the design of the power system.

Consider all sources of power, including the possibility of back feed.

• Turn off all power supplying the equipment in which the iBox/iBox Kit is to be

installed before installing and wiring the iBox/iBox Kit.

• Beware of potential hazards, wear personal protective equipment and carefully

inspect the work area for tools and objects that may have been left inside the

equipment.

• The successful operation of this equipment depends upon proper handling,

installation, and operation. Neglecting fundamental installation requirements

may lead to personal injury as well as damage to electrical equipment or other

property.

• Many of the components within the iBox/iBox Kits are susceptible to damage

from electrostatic discharge. Observe standard ESD (Electrostatic Discharge)

precautions for handling electronic components at all times.

• Read and thoroughly understand this guide before using the iBox/iBox Kit. Save

these instructions for later use and reference.

GE Grid Solutions

sources of electric power.

Hazardous

Voltages

Failure to observe these instructions may result in death or serious injury.

Hazardous voltages can cause shock, burns or death.

• Disconnect and lock out all power sources before servicing and removing

components.

• Short all current transformer primaries before servicing.

• Do not remove the safety shields that have been installed to prevent accidental

contact with hazardous voltages.

• Avoid touching iBox/iBox Kit power supplies, since these supplies contain

hazardous voltages.

994-0047-5.10-4 GE Information

Page 9

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

9

!

Safety Precautions, continued

Product

Warning

Symbols

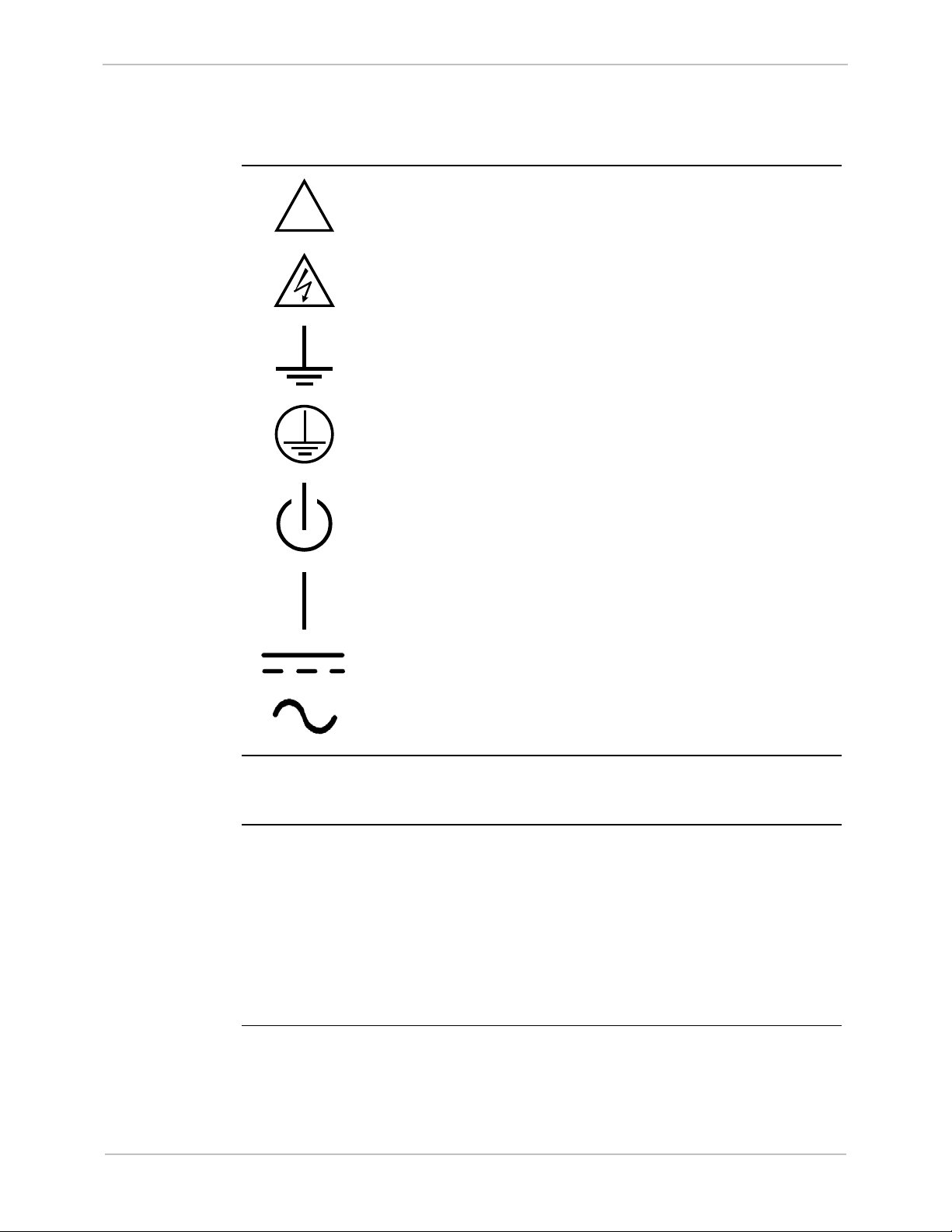

Caution (refer to accompanying documentation)

Caution (risk of electric shock)

Earth/Ground Terminal

Protective Earth Terminal

Power Supply Off (Stand-by Mode)

Power Supply On

Direct Current

Alternating Current

Damaged

Equipment

Operating

Environment

GE Information

Do not operate an iBox or iBox Kit if it has been dropped or damaged. Return it to

GE Digital Energy for inspection and repair.

iBox/iBox Kits are intended for indoor use. Do not place these products in

environments where unusual environmental conditions exist (such as dirt, liquids, or

windblown dust) without a secondary protective enclosure.

For proper fire protection, iBox/iBox Kits must be installed in an enclosure equipped

with a metal floor with no openings.

An IEC

®

60947 compliant main disconnect switch (or other equivalent device

complying with IEC 60947-1 / 60947-3) must be as electrically close as practicable

to the iBox power supply.

994-0047-5.10-4

Page 10

iBox/iBox Kit

Installation and Maintenance Guide

10

!

!

Protection

during

Maintenance

RF

Interference

Rack Spacing

GE Grid Solutions

Ensure iBox/iBox Kits are protected from falling debris during maintenance. Small

metallic particles (such as wire clippings) could fall onto circuit boards and damage

or interfere with the safe and reliable operation of the iBox/iBox Kit.

The iBox/iBox Kit generates radio frequency (RF) energy that can radiate if it is not

installed and used in accordance with the instructions provided in this guide. This RF

energy may cause harmful interference to radio communications or sensitive circuits.

Operating an inadequately shielded iBox or iBox Kit in a residential area may cause

harmful interference, if this happens, you may be liable to correct the interference.

When mounting multiple iBox/iBox Kits in a rack (or when mounting an iBox/iBox

Kit in a rack with other equipment), verify that there is at least one rack unit (RU) of

space above and below the iBox/iBox Kit, to allow for cooling airflow, and for

routing cables between field equipment and the iBox/iBox Kit (1 RU = 1.75 inches).

Power and

Fusing

Grounding

Communication Cables

• For proper operation, input voltages must be within specified limits. Do not

apply voltages outside this range, since this may lead to premature product

failure.

• Always fuse-protect field sources.

• Always replace fuses with fuses of the same type and rating. Fuse types and

ratings are stated in the product specifications.

To ensure voltage transients are properly shunted to ground, you must connect the

iBox’s protective earth terminal to a low-impedance ground point using a braided

cable or heavy solid copper conductor.

When making ground connections, ensure all grounding surfaces are free of dirt,

residue and corrosion. You can use a coating such as Glyptal

®

to protect connections

from oxidation and dirt deposits.

Cable shields should be grounded to either the iBox/iBox Kit ground terminal or to

field equipment, but not to both. Do not ground cable shields at more than one point,

since potential differences between the ground points will result in ground loops and

undesirable noise sources.

• Use shielded cables to prevent electromagnetic interference.

• Route all communication cables away from power-carrying cables, and make

these cables as short as possible.

• Prior to start-up, verify the integrity of all communication cables and

connections.

994-0047-5.10-4 GE Information

Page 11

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

11

!

Safety Precautions, continued

Surge

Protectors

iBox Cover

iBox Jumpers

When connecting the iBox/iBox Kit to communications equipment (for example,

modems or radios), use appropriate surge arrestors to protect the iBox’s

communications ports.

Never operate an iBox without having its protective cover installed, since product

performance may be compromised, and equipment may be damaged if foreign

objects fall into the unit.

Configure the jumpers in your iBox before you connect field inputs and outputs.

Use of the equipment in a manner not recommended or specified by GE Digital

Energy, may impair the protection provided by the equipment.

GE Information

994-0047-5.10-4

Page 12

iBox/iBox Kit

Installation and Maintenance Guide

12

Connection

Ferrite Clamp

Cable/Wiring

CISPR 11-CE Mark Compliance

GE Grid Solutions

Important

Ferrite Clamp

cabling/wiring

Part Numbers

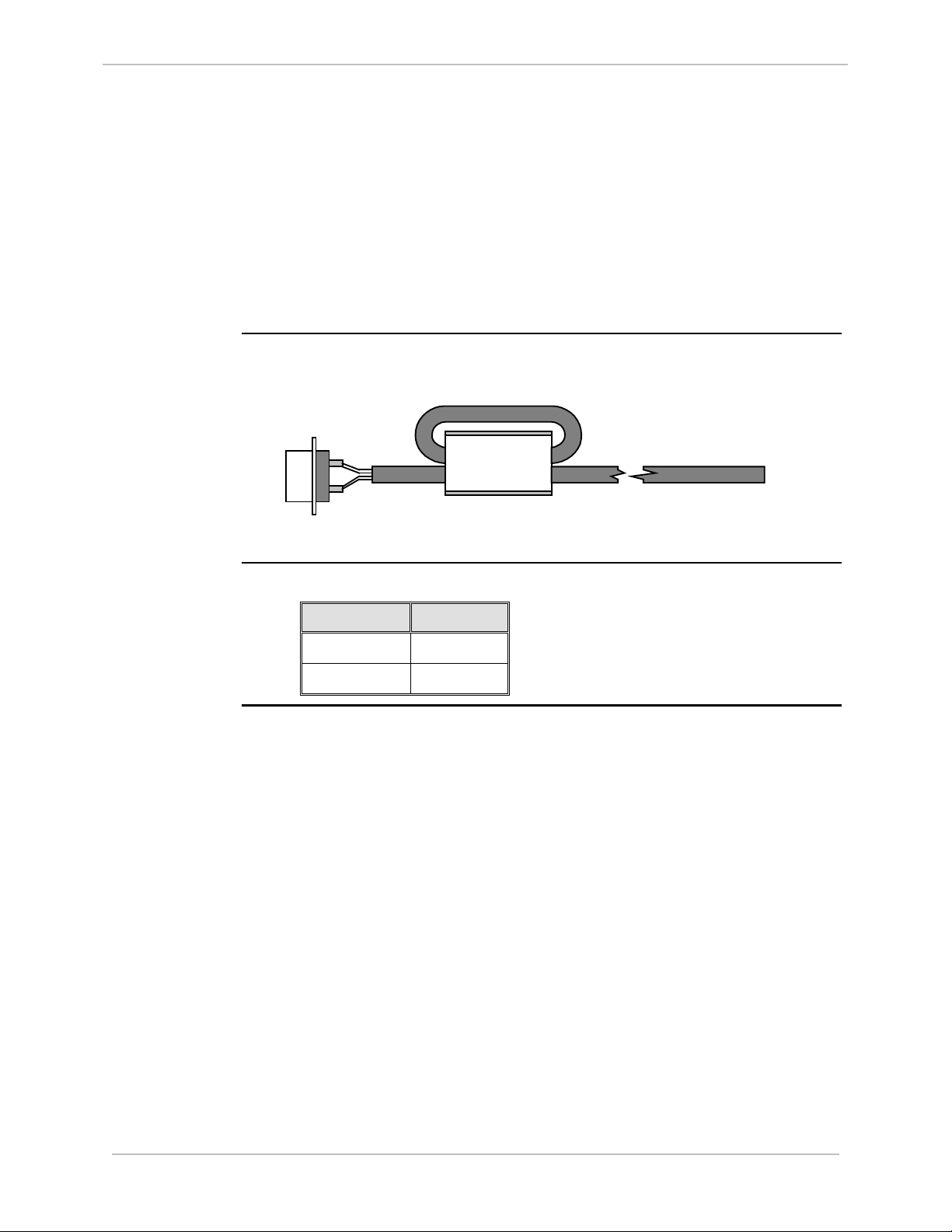

For CISPR 11, Class A-CE Mark compliance on an iBox installed outside of a

protective enclosure, you must use ferrite clamps on the following:

• Serial communication cables attached to J2, J3, and J4

• Wiring connected to TB2-TB15 for digital inputs and control outputs

Note: Although the standalone iBox is CE Marked, GE does not guarantee the CE

Mark of third-party components of the iBox Kits (such as the 10/100BaseT Ethernet

Module or the AC and DC Analog Input Modules).

The following diagram illustrates the cabling/wiring loop through an installed ferrite

clamp.

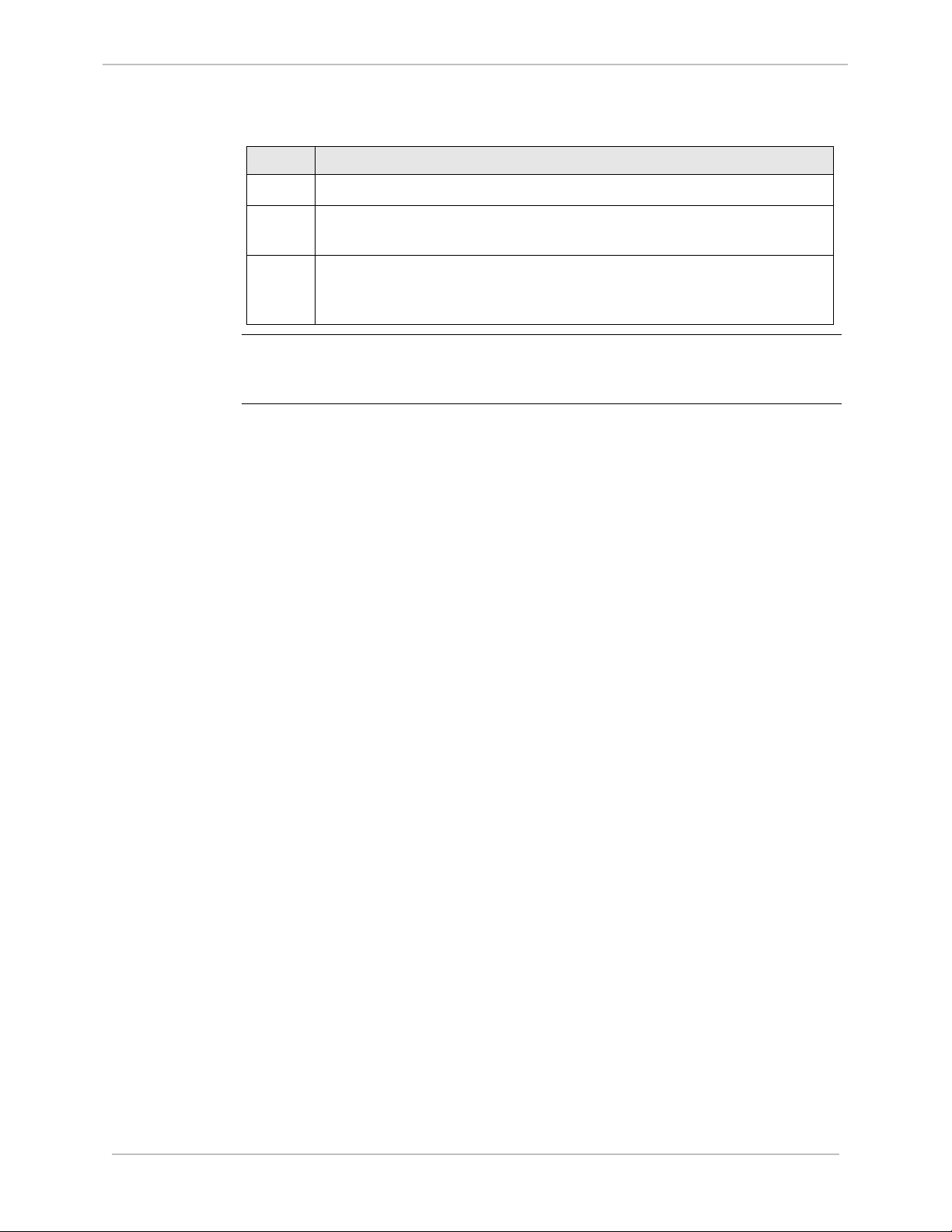

Order the following part number for each of the external ferrite clamps you require.

Part Number Color

460-0031 White body

460-0049 Black body

994-0047-5.10-4 GE Information

Page 13

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

13

Section 1: Getting Started

Overview

Introduction

Before you begin installing the iBox, review the information in this section,

including the following topics:

• Description of the iBox

• Unpacking and inspection

• Storage

• Installation Tools

GE Information

994-0047-5.10-4

Page 14

iBox/iBox Kit

Installation and Maintenance Guide

14

1.1. What is an iBox?

Product Overview

GE Grid Solutions

Introduction

Integrated

Functions

Scalable

Architecture

Features

The iBox is GE Digital Energy small point count Substation Controller. It combines

advanced functionality, multiple communication ports and local I/O in a compact

package.

The iBox processes both digital inputs and digital outputs. It also provides serial

digital data communication ports to facilitate communications with both a masterstation and local communications. The iBox is specifically designed for SCADA

applications.

The iBox Kit is a rack-mounted, pre-wired, pre-configured RTU based on the iBox,

but with additional (optional) power supply, Ethernet and I/O support.

The iBox can function as a:

• Programmable logic controller (PLC)

• IED gateway

• Data concentrator

• Standalone remote terminal unit (RTU).

The iBox’s flexibility makes it an excellent option for:

• Advanced substation monitoring

• Control

• Automation applications.

The iBox has three software-configurable RS-232/485 serial communication ports.

All three RS-232/485 serial ports interface to legacy IEDs or Master stations.

Patent

Protection

An extensive library of application software is available from GE Digital Energy to

enable the iBox to interface with a wide range of IEDs.

A UTC port is available for global satellite time synchronization (however, there

are three serial ports, so if you use one as a UTC port, two serial ports remain for

connecting to IEDs).

Maintenance port support provides access to SGConfig, LogicLinx*, and

WESMAINT* utilities.

Meets the robust requirements of the IEEE

®

, IEC® and CE Mark.

The iBox contains a patent protection label as a formal declaration of the US patents

that protect both the product and the technology developed by GE Digital Energy.

MAY BE PROTECTED BY ONE OR

MORE OF THE FOLLOWING US

PATENTS:

5237511, 5303112, 5513061, 5701226.

994-0047-5.10-4 GE Information

Page 15

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

15

System Software

Overview

Base System

Software

iBox

BootROM

Base

Applications

WIN

The iBox system software consists of two components:

• Base System

• Applications.

The Base System software provides a stable operating environment for applications,

which provide specific functionality for the iBox. The Base System is made up of:

• Boot software, resident in the BootROM, and

• Base applications, required for operating the hardware.

BootROM software is stored in EPROM. The BootROM contains:

• Operating system software

• Device drivers to interface the operating system with the system hardware and

software

• Diagnostic software, to verify the integrity of the iBox

• Monitor interface, for examining the system in a non-operational mode

• Startup code, to verify and initialize the application software

• Low-level maintenance and troubleshooting software

Standard iBox Base Applications, present in every iBox, are:

• WIN, the system database manager

• WESMAINT, which allows the operator to locally examine and control data

• 68K Monitor, which provides low-level system maintenance and diagnostic tools

WIN (for WESDAC Interface Node) is the database manager for the iBox System

Point Database. The System Point Database is the heart of the iBox software system.

All data flowing through the iBox is stored in the System Point Database before it is

passed on to its destination.

GE Information

994-0047-5.10-4

Continued on next page

Page 16

iBox/iBox Kit

Installation and Maintenance Guide

16

System Software, continued

GE Grid Solutions

WESMAINT

Database

Display

Other

WESMAINT

Functions

WESMAINT is the iBox’s primary maintenance and diagnostic tool. You can access

WESMAINT in three ways:

• Through the iBox WESMAINT port

• Through a modem or other serial connection to a programmed COM port

• Over a LAN or serial PPP connection, as a telnet session from a remote network

station

WESMAINT is accessed using a VT100 terminal, or a PC running terminal

emulation software.

Through WESMAINT, you can access the following:

• Digital inputs and outputs

• Counters (or accumulators)

• Device status

• Sequence-of-events (SOE) and change-of-state (COS) data

• System status information

• Error log information

• User login buffer

• Other application-specific information

In addition to displaying information, a WESMAINT user can also:

• Set or clear accumulator counts

• Operate digital outputs

• Clear logged information

• Access the iBox 68K Monitor.

994-0047-5.10-4 GE Information

Page 17

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

17

Note

System Software, continued

68K Monitor

The iBox 68K Monitor, available through WESMAINT, is a diagnostic tool used to

access system-level functions.

The iBox 68K Monitor is resident in both BootROM and flash memory.

When the Monitor is operated from BootROM, the following prompt appears:

D25S>. This mode is accessed only while the iBox is in a maintenance state, since

forcing an iBox into this mode terminates all running applications.

When the Monitor is operated from flash, the following prompt appears: D25A>.

This is the normal mode of operation, and it can be accessed via WESMAINT at any

time without disrupting unit operation.

Using the 68K Monitor requires detailed knowledge of the iBox architecture and

functionality. Refer to the 68K Monitor User’s Guide (SWM0023) for complete

instructions about command usage and availability.

GE Information

994-0047-5.10-4

Page 18

iBox/iBox Kit

Installation and Maintenance Guide

18

Application Software

GE Grid Solutions

Background

Data

Collection

Applications

Data

Processing

Applications

Data

Translation

Applications

Firmware

A wide range of applications can be added to the iBox to enhance its functionality.

Software applications fall into three categories:

• Data Collection Applications (DCA)

• Data Processing Applications (DPA)

• Data Translation Applications (DTA)

Data Collection Applications are used to import (collect) data from external sources,

and to pass this data to WIN (the system point database manager) for storage in the

system database. DCAs also forward output requests from the system database to

external sources.

Data Processing Applications are configured to select and format data from the

system database, and forward this data to a SCADA host or master station

A combination of a DPA and a DCA, Data Translation Applications use data from

the system database to perform logical operations, the results of which create new

data. This new data is then placed back in the system database, where it can be used

as input/output data by another application.

The set of applications installed on an iBox is referred to as its “firmware”.

Firmware is installed in the iBox flash memory prior to shipment. The iBox

operational characteristics can, however, be upgraded at a later date.

Contact your GE Digital Energy representative for more information on firmware

upgrades.

994-0047-5.10-4 GE Information

Page 19

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

19

Plant I/O Subsystem

Plant I/O

Subsystem:

Overview

Plant I/O

Subsystem:

Functions

Fixed Number

of Points

The iBox Plant I/O Subsystem collects, processes, and stores data related to physical

inputs and outputs. Once it is stored in the system database, I/O point data can be

accessed by other applications.

The Plant I/O Subsystem is responsible for scanning of iBox physical I/O points. For

input type points (digital and accumulator), the data of each scan is compared to

previous known data. Changes are recorded in the system database, then reported to

other applications, as needed.

The Plant I/O Subsystem:

• Scans and processes up to 8 digital inputs

• Controls up to two digital outputs and two master trip/close relays.

Requests for digital outputs are accepted and processed as soon as they arrive.

The Plant I/O DCA maintains a fixed number of points in the System Point

Database. The actual number of points is determined by the version of the P097 Plant

I/O Subsystem that has been installed on your iBox.

The hardware options available in the iBox (and the user’s software configuration)

determine if specific system features and data points are available or disabled.

GE Information

994-0047-5.10-4

Page 20

iBox/iBox Kit

Installation and Maintenance Guide

20

Part Number Label

1.2. Unpacking and Inspection

Shipping

Inspection

Unpacking

Inspect the shipping package before opening it to see if it has sustained any damage

from impact or water. If it has, report it immediately to the carrier without opening

it. Carriers may not assume responsibility for damage after the customer accepts

delivery.

Carefully remove the iBox from its shipping package. Visually inspect the unit to

ensure it has not sustained any visible damage during transit.

The figure below shows an iBox removed from the shipping package.

GE Grid Solutions

Package

Contents

Product

Identification

Location

The following items are provided as part of your iBox shipment:

• iBox or iBox Kit unit

• WESMAINT serial cable

• IBOX/iBox Kit Installation and Maintenance Guide (994-0047)

• CD including the software and copy of user documentation

Before installing the unit, check that the unit part number is the same as the part

number on the shipping and ordering documents.

994-0047-5.10-4 GE Information

Page 21

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

21

Unpacking and Inspection, Continued

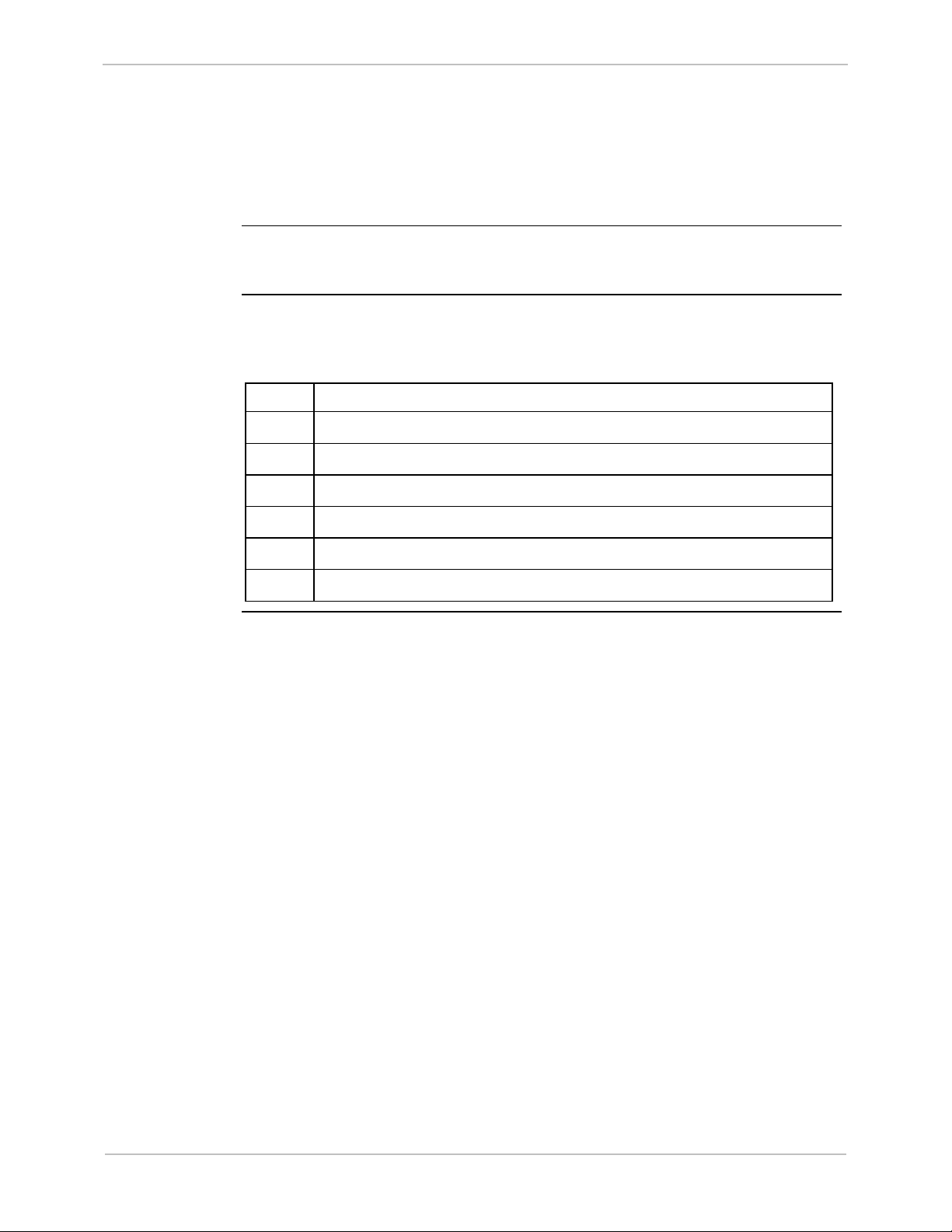

Part Numbers

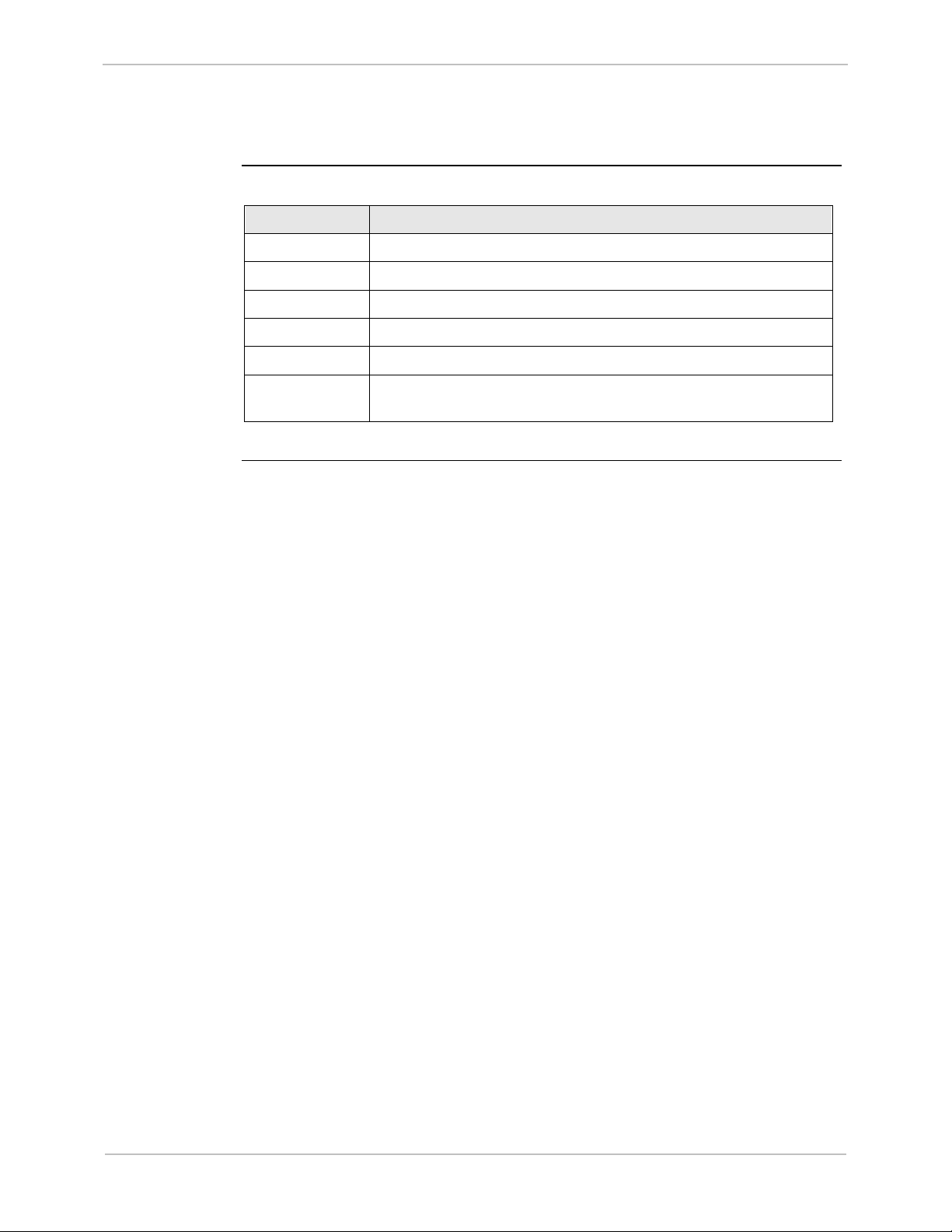

This table contains part numbers and descriptions for each iBox variant:

Part Number iBox Description

505-0100 24 V Digital Input and 4 Trip/Close Control Outputs

505-0101 48 V Digital Input and 4 Trip/Close Control Outputs

505-0102 110/125 V Digital Input and 4 Trip/Close Control Outputs

505-0103 24 V Digital Input and 2 Trip/Close and 2 Form A Control Outputs

505-0104 48 V Digital Input and 2 Trip/Close and 2 Form A Control Outputs

505-0105 110/125 V Digital Input and 2 Trip/Close and 2 Form A Control

Outputs

Note: Part Numbers are subject to change without notice.

GE Information

994-0047-5.10-4

Page 22

iBox/iBox Kit

Installation and Maintenance Guide

22

1.3. Storage

GE Grid Solutions

Environment

Battery Life

Recycling of

Batteries

Specifications for storage are:

• Temperature: -40° to +90°C

• Relative humidity: 0 to 95%, non-condensing

As a general rule, always store your iBox in an environment compatible with

operating conditions. Refer to Appendix A: Technical Specifications for more

detailed environmental specifications

Exposure to excessive temperature or other extreme environmental conditions might

cause damage and/or unreliable operation.

The iBox battery maintains the unit’s NVRAM contents for over five years, with

system power applied.

If you are storing your iBox for extended periods, you should disconnect the battery

by removing the iBox’s top cover and pulling the battery out of the chassis.

If you are storing a new iBox which has the battery “PULL” tab in place, you do not

need to remove the battery for storage; the “PULL” tab disconnects (insulates) the

battery function.

The iBox Lithium battery is recyclable and does not contain mercury, cadmium, or

lead in levels above those regulated by the European Union. Recycle the battery

according to local waste management regulations.

In accordance with European Directive 2006/66/EC, batteries are marked with the

crossed out wheeled bin, which indicates that they cannot be disposed of as unsorted

municipal waste in the European Union. Users of batteries must use the collection

points available to customers for the return, recycling, and treatment of batteries.

Customer participation is important to minimize the negative effects of batteries to

the environment and sustain available natural resources. For more information see

www.weeerohsinfo.com.

994-0047-5.10-4 GE Information

Page 23

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

23

1.4. Installation Tools

Tools for the

Job

ESD

Protective

Gear

Before beginning the installation procedure, ensure you have the following tools and

equipment:

• A Windows PC with HyperTerminal (or any Windows based terminal

emulation software) loaded

• Ethernet Cable[s]

• A flat screwdriver with 0.6 x 3.5 mm blade (for terminal block wiring)

• A #2 Phillip-Server Screwdriver (for rack mounting the unit)

• A #1 Phillip-Server Screwdriver (for removing and installing the communication

boards)

• Needle Nose Pliers

• Wire Cutters

• Wire Strippers

• Wire Crimping Tool (Panduit

• 6 fork connectors

• Fork type Panduit part number PV14-6F for 14-16 AWG wire or PV18-6F for

18-22 AWG wire (or equivalent)

It is recommended that the following ESD gear be used during installation:

• Wrist Straps

• Foot Straps

®

CT-1525 or equivalent).

GE Information

994-0047-5.10-4

Page 24

iBox/iBox Kit

Installation and Maintenance Guide

GE Grid Solutions

24

Section 2: iBox Installation and Maintenance

Overview

Introduction

This section covers the following topics:

• Familiarization of the iBox

• Installing the iBox

• Configuring the iBox

• Testing the iBox

• Connecting and testing field wiring

• Servicing the iBox

• Maintaining the iBox software

• Troubleshooting the iBox

• Replacing the iBox

994-0047-5.10-4 GE Information

Page 25

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

25

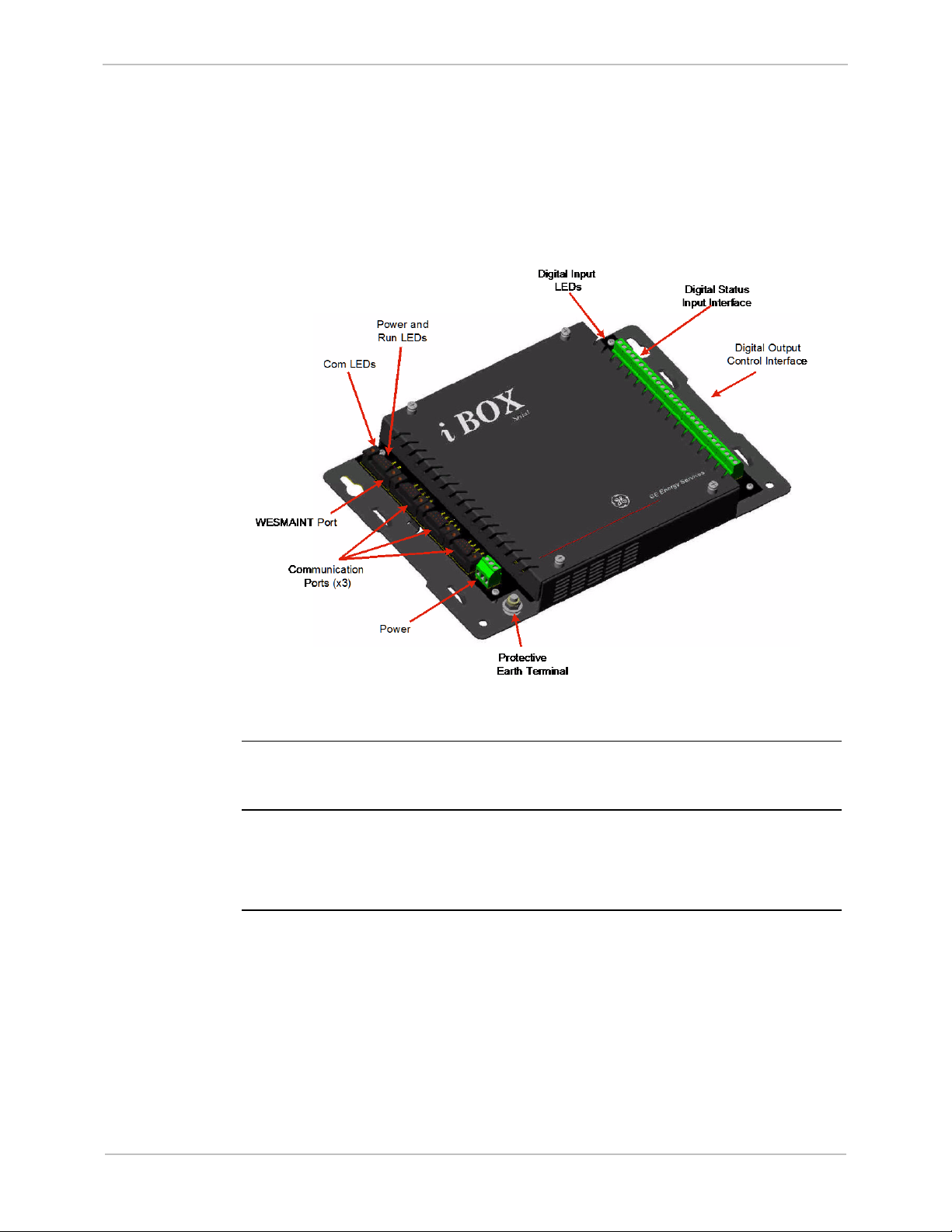

2.1. Familiarization

Front Panel

As you look at the iBox, the:

• Left side has four DB9 connectors (serial ports), a three-position separable

terminal block (power connection), and a protective earth terminal.

• Right side has a 28-position terminal block for field I/O, separable in pairs.

Operation and

Maintenance

Inputs/

Outputs

Digital Inputs

You can operate and maintain the iBox configuration through the WESMAINT port.

The iBox provides the following:

• Eight digital inputs

• Four control outputs

The iBox provides the following digital inputs:

• Eight optically isolated status inputs, 25

VDC or 125 VDC, with 20% overload

• Wetting options

• LED indications

• 4-5 mA typical current burden per input (up to 48

VDC)

• Maximum 0.5 W heat dissipation per input from current burden of inputs at

125

VDC

GE Information

994-0047-5.10-4

Page 26

iBox/iBox Kit

Installation and Maintenance Guide

26

Familiarization, continued

GE Grid Solutions

Continued on next page

Control

Outputs

The iBox provides the following control outputs:

• Four Trip/Close pairs, or two Trip/Close pairs and two Form A contacts.

• Separate Master Trip and Master Close relays

• Security features:

− Protection against erroneous operation due to single point of failure

− Select-before-operate (SBO) functionality

• 35

W breaking @ 125 VDC, 180 W breaking @ 30 VDC

• 6

A current handling capability

994-0047-5.10-4 GE Information

Page 27

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

27

2.2. Installing the iBox

Overview

Safety

Precautions

Installation

Steps

Before beginning to install the iBox, thoroughly review the “Safety Precautions” for

guidelines and warnings regarding the safe handling and installation of the product.

Installing the iBox involves the following main steps:

Step Action

1

2

3

4

5

6

Physically install the iBox.

Connect power source and serial interfaces.

Power up the iBox and check for normal operation.

Configure the iBox using SGConfig.

Test the iBox.

Connect and test field wiring.

GE Information

994-0047-5.10-4

Page 28

iBox/iBox Kit

Installation and Maintenance Guide

28

Installation Guidelines

GE Grid Solutions

Installation

Environment

Power Supply

Source

The iBox must be installed in an environment that provides protection against shock

and fire hazard.

The iBox enclosure is intended for indoor use, primarily to provide protection

against accidental contact with the enclosed modules and voltages. Do not place the

product in environments where unusual conditions exist (windblown dust and dirt,

for example) unless you install it in a secondary protective enclosure.

Never operate an iBox in the field with the top cover removed. Operation with the

top cover removed may alter product performance specifications, and result in

component damage from foreign matter entry.

Do not install and/or operate the iBox upside down.

Ensure all nuts and screws are tightened securely.

Ensure that iBox is protected from falling debris during installation.

An IEC

®

60947 compliant main disconnect switch (or other equivalent device

complying with IEC 60947-1 / 60947-3) must be as electrically close as practicable

to the iBox power supply.

For correct iBox power supply operation, the input voltage must be within specified

limits.

The iBox DC power supply draws an inrush current (less than 0.5 A) upon start-up.

Ensure the field source can supply this start-up current without overloading.

Continued on next page

994-0047-5.10-4 GE Information

Page 29

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

29

Installation Guidelines, continued

Power Fusing

Grounding

and Shielding

Communications Ports

and

Connections

Always replace fuses with the same type and rating used by GE Digital Energy. The

fuse types and ratings are stated in “Fuse Replacement” on page 59.

Always fuse-protect field power sources.

To ensure safe operations, you must connect the iBox Protective Earth Terminal to a

low impedance ground using braided cable or heavy solid copper conductor. When

making ground connections, ensure all grounding surfaces are free of dirt, residue

and corrosion.

Ensure cable shields are grounded at either the iBox functional ground terminal or at

the field equipment. Do not ground the shields at more than one point because a

potential difference may exist between grounds, resulting in ground loops and

undesirable noise sources.

To prevent electromagnetic interference from upsetting iBox operation, use cables

with an over-all cable shield. Route all communication cables away from powercarrying cables.

Verify the integrity of all communication cable connections prior to start-up to avoid

damaging the iBox.

Serial ports are protected with surge and noise suppression components.

Always shield communication cables and make them as short as possible.

GE Information

994-0047-5.10-4

Page 30

iBox/iBox Kit

Installation and Maintenance Guide

30

Physical Mounting

GE Grid Solutions

Procedure:

Mounting the

iBox

Mounting and

Clearance

Step Action

1

2

Align the iBox in its proper position on a flat mounting surface.

Install and tighten the four screws, holding the iBox firmly in place on

the mounting surface.

3

Loosen the iBox top cover and remove the battery “PULL” tab. The

iBox is delivered with this tab in place to insulate the battery during

shipment.

Leave at least one rack unit (RU) of space above and below the equipment to allow

for cooling air flow and cable routing (1 RU = 1.75 inches or 44.5

mm).

994-0047-5.10-4 GE Information

Page 31

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

31

!

!

+ – Chassis

TB1

Terminal Connections

Power Supply

Functional

Ground/

Chassis

Internal

Overcurrent

Protection

The iBox’s power supply connection is a three-position terminal block located on the

bottom left side of the iBox. This removable terminal block must be disconnected to

turn off the power supply input. The iBox does not have an ON/OFF switch.

Connect the ground screw terminal to the facility’s ground system before operating

the iBox. Before making this connection, ensure all grounding surfaces are free of

dirt, residue and corrosion. The maximum wire gauge for terminal blocks is 12

AWG.

An internal MDL 0.5 A (slow blow) fuse protects the iBox power supply.

Power

Connection

Procedure

To connect the power source:

Step Action

1

Connect ground wire to the ground terminal. A 12 AWG green and

yellow wire is recommended.

2

Connect the DC power supply, observing the correct polarity, to the

positive and negative connection points on TB1

The chassis ground terminal at the power supply terminal block must not be used as

a protective earth connection.

Make sure the iBox is properly grounded to the protective earth terminal located at

the bottom-left corner of the board. Connection must be provided with a separate

green/yellow wire connected between the iBox and the facility’s ground system.

GE Information

994-0047-5.10-4

Page 32

iBox/iBox Kit

Installation and Maintenance Guide

32

System Diagnostics

GE Grid Solutions

System

Diagnostics

LEDs

Diagnostics

Completed

Once power is applied, the iBox automatically boots and conducts a series of selfdiagnostic tests. If the iBox fails to boot up properly (which indicates that a selfdiagnostic failure has occurred), it might have sustained internal damage during

shipping. Contact GE Digital Energy for assistance.

The POWER and RUN LEDs will both light during the self-diagnostic sequence.

Self-diagnostics have completed successfully when the POWER and RUN LEDs are

on solid.

994-0047-5.10-4 GE Information

Page 33

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

33

Terminal - DB-9 Female

WESMAINT - DB-9 Male

COM

N/C

TXD

RXD

N/C

N/C

N/C

N/C

N/C

N/C

RXD

TXD

N/C

COM

N/C

N/C

N/C

GND

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Connecting Serial Interfaces

WESMAINT

Port

WESMAINT

Cable

The iBox is equipped with a WESMAINT port. By attaching a WESMAINT cable

between the WESMAINT port and your PC, the iBox can:

• Provide local maintenance and diagnostic functionality

• Download configuration data from the optional SGConfig software

With the cable connected, you can also upload diagnostic and operational

information to the PC.

The WESMAINT interface supports RS-232 signaling and normally operates at a

fixed rate of 9600 bps.

To connect to a PC, use a WESMAINT cable (GE part number 977-0048/96), or

equivalent.

The schematic for this cable is shown below:

Standard

Serial

Interfaces

GE Information

The iBox has three serial communications ports: COM1, COM2, and COM3

All COM ports have the following standard characteristics:

• Female DB-9-F style connectors

• RS-232 and RS-485 are supported on the same physical connector.

994-0047-5.10-4

Continued on next page

Page 34

iBox/iBox Kit

Installation and Maintenance Guide

34

Connecting Serial Interfaces, continued

GE Grid Solutions

COM1

Options

COM2

Options

IRIG-B Output

Options

COM Ports

COM Port

Options

In addition to the standard characteristics, COM1 has the following optional

characteristics:

• Jumper-selectable (JP3) radio key, open-collector output

• Communication parameters, determined by the protocol application.

COM2 can optionally be used to connect to a satellite time-code receiver, as follows:

Time code J3 Pin Interface Signal

IRIG-B 8 RS-232 CTS2

Rugby Clock 2 RS-232 RX2

5 RS-232 COM

IRIG-B receivers are available with modulated and/or unmodulated output options. If

the unmodulated output of the receiver is a coaxial connection, a converter will be

required to interface to the iBox.

COM ports provide the following:

• Variable communication parameters

• Optional software flow control

• Optional hardware flow control

• Out-of-sequence transmission of one byte of data

• Support for several I/O timers

• Transmission of break characters

The COM1, COM2 and COM3 serial ports are programmed using SGConfig for:

• RS-232 or RS-485

• RS-485 2-wire or 4-wire (2W/4W)

Note: The 2W/4W selection in SGConfig only affects the interface’s internal

software control (handshaking). It does not change the physical

characteristics of the communication ports.

994-0047-5.10-4 GE Information

Page 35

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

35

Description PIN #

1

2

3

4

5

6

7

8

9

N/C

Data Data -

N/C

Common Ground

N/C

Data +

Data +

Earth Ground

- TX / RX

+ TX / RX

iBox Connectors J2, J3 or J4

Connecting Serial Interfaces, continued

Serial Port

Pinouts

2-Wire RS-485

Cable

The COM port pin-outs, for both RS-232 and RS-485 configurations, are as follows:

DB-9 Pin RS-232 RS-485

1 CD N/C

2 RX RX-

3 TX TX-

4 N/C N/C

5 Com GND Com GND

6 N/C* N/C

7 RTS TX+

8 CTS RX+

9 EARTH GND EARTH GND

* Radio Key Open Collector Output for COM Port 1 only (jumper selected with JP3

installed).

The following schematic shows the cable wiring necessary for 2-wire RS-485

operation.

GE Information

994-0047-5.10-4

Page 36

iBox/iBox Kit

Installation and Maintenance Guide

36

2.3. Configuring your iBox

Overview

GE Grid Solutions

Introduction

Configuration

Template

Configuration

Steps

You can create a project for configuring your iBox device using SGConfig.

A sample configuration is included on the CD with the iBox. You can create the

iBox device configuration starting from the sample configuration or create a new

configuration from scratch.

After you successfully create a device configuration, you can use it as a template for

all subsequent iBox configurations. To do so, copy the original configuration file,

and edit the copied file as necessary.

After creating the device, the remaining procedures are the same, whether you are

working with a copy of an existing configuration or creating a new device

configuration.

The iBox is configured using the SGConfig configuration system.

Configuring the iBox involves the following main steps:

• Create or restore a SGConfig project.

• Create and configure the iBox device in the project.

• Configure the application firmware.

• Configure the Plant I/O.

• Download the configuration to the iBox.

Before you

Start

For the detailed procedures, refer to the SGConfig online help.

To configure the iBox, you will need the following items:

• Factory configuration for your iBox. You can find this on the configuration CD

that shipped with your iBox.

• SGConfig installed on your PC.

• Serial number of your iBox, from the iBox circuit board

994-0047-5.10-4 GE Information

Page 37

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

37

Restoring your SGConfig Project

Introduction

Procedure:

Restoring

your

SGConfig

Project

This procedure describes how to restore the SGConfig project that includes the

sample configuration provided with the iBox.

Step Action

1 In your Windows desktop, click Start, and then click Programs.

2 Click SGConfig, > SGConfig.

Result: SGConfig opens.

Importing the Factory Configuration

3 Click GE > Archive > Project > Restore.

4 Click Restore.

Result: The Restore Project Details window appears:

5 Insert your configuration CD in the drive.

6 Navigate to the configuration file in the Archive File Name field.

7 Click OK.

Result: The configuration file uploads to your PC, and your project

appears in an SGConfig project tab.

GE Information

994-0047-5.10-4

Page 38

iBox/iBox Kit

Installation and Maintenance Guide

38

Creating a New iBox Device

GE Grid Solutions

Introduction

iBox Device

Icon

Procedure:

Creating a

New iBox

Device

Creating an iBox device in SGConfig has two main steps:

• Create the new device

• Specify the device properties

This procedure assumes that you are using the default firmware already loaded in the

iBox or have created a firmware set.

When you create a new iBox device, select the iBox device template to see the

appropriate configuration screens.

To create a new iBox device:

Step Action

1 Open the project in which you want to create the iBox device.

2 Drag and drop an iBOX device template from Local Repository >

Device Templates into the project tab area.

3 Click Edit group > Properties command.

Result: The iBOX Device Wizard appears.

4 In the Name box, type a unique name for the device.

5 Continue to “Procedure: Setting iBox Device Properties”.

Continued on next page

994-0047-5.10-4 GE Information

Page 39

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

39

Procedure: Creating a New iBox Device, continued

firmware definitions.

esenting your new device, appears in the main proje

iBox Device

Properties

Procedure:

Setting iBox

Device

Properties

Once you have created the iBox device, follow the procedures below for setting the

iBox device properties.

To set the iBox device properties:

Step Action

Hardware Tab

1 In the iBox Device Wizard window, click the Hardware tab.

2 Click the Memory Model tab. You should not need to change the Base

System and Global Variable Area settings. If necessary, change the

NVRAM Area value to suit your specific system.

3 On the Serial I/O tab, configure each com port for RS-232 or RS-485

communications.

Note: The 2W/4W selection in SGConfig only affects the interface’s

internal software control (handshaking). It does not change the

physical characteristics of the communication ports.

New Device

Icon

Processor Tab

4 Click the Processor tab.

5 On the Firmware tab, click the Select button to display the available

6 In the Use Firmware Type field, select the firmware definition that

matches your iBox’s applications.

Result: The Name field shows the name of your firmware selection.

7 From the Memory Model tab, check that Derive From iBox

Hardware Setting is selected.

8 Click Close to complete the creation of the new iBox device.

The wizard closes.

After you complete these steps, an iBox icon, repr

window. The new iBox device is now ready to be configured.

GE Information

994-0047-5.10-4

Page 40

iBox/iBox Kit

Installation and Maintenance Guide

40

Configuring Application Firmware

Overview

Procedure:

Digital Input

Configuration

The iBox uses the D25 Plant I/O Subsystem (P097) Data Collection Application to

configure the digital inputs. Configure the iBox Plant I/O before you configure the

points in the System Point Database application.

To configure the DC digital inputs:

Step Action

1 Configuring the iBox PPP Driver and Internet Data

2 Double-click the D25 Plant I/O Subsystem icon.

Result: The D25 Plant I/O for iBox dialog box appears.

3

Double-click the DC Configuration icon.

Result: The D25 DC Configuration for iBox dialog box appears.

4 On the General tab, select the type of digital input board from the First

Digital Input board list. Select one of:

• C: iBox 8 channels, 24 V wetting

• D: iBox 8 channels, 48 V wetting

• E: iBox 8 channels, 125 V wetting

The other board settings are preset.

GE Grid Solutions

Other

Application

Configuration

Result: The letter in the Device Code changes to match your selection.

Note: Refer to the on-line help in SGConfig for details on configuring

the I/O Configuration and Advanced tabs.

Configure your other applications before continuing to install the iBox. Each

application has its own configuration process. Refer to the documentation for your

specific applications for configuration information.

994-0047-5.10-4 GE Information

Page 41

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

41

Downloading your iBox Configuration

Procedure:

Downloading

your iBox

Configuration

Step Action

1 If you have not already done so, connect your PC to the iBox

WESMAINT port and open SGConfig.

2 In the SGConfig Project window, click the iBox device icon.

3 Click Communications group > Connect > TeraTerm command.

Result: The TeraTerm window appears within an SGConfig tab.

4 Press ENTER.

Result: SGConfig prompts you to enter a user name.

5 Type westronic and press ENTER.

Result: SGConfig prompts you to enter a password.

6 Type your password (the default is rd) and press ENTER.

Result: The following screen appears:

7 Enter “2”.

Result: The following screen appears:

8 Enter “3”.

Result: The 68K Monitor command prompt appears.

9 In the command line, type el /r then press ENTER.

Result: The iBox clears its error log.

Tip: To speed up the configuration download, temporarily change the

baud rate of the WESMAINT serial port from the default 9600 baud to

38400 baud in WESMAINT and SGConfig.

To change the baud rate:

• In WESMAINT, enter baud 38400 at the 68K command line.

• In the SGConfig Terminal Emulator window, on the

Communications menu, click Options. On the Port Settings tab, set

the Baud Rate to 38400 and click OK.

Continued on next page

GE Information

994-0047-5.10-4

Page 42

iBox/iBox Kit

Installation and Maintenance Guide

42

complete.

Downloading your iBox Configuration, continued

GE Grid Solutions

Procedure:

Downloading

your iBox

Configuration

(continued)

Step Action

10 On the SGConfig click Terminal Emulator Connectivity group, click

Connect.

Result: SGConfig connects to the iBox and the 68K Monitor command

line appears.

11 On the SGConfig click Terminal Emulator Actions menu, click Sync To

Device.

Result: The configuration download starts.

A confirmation window appears when the download is

12 Click Reboot.

Result: The iBox reboots.

Note: If you changed the baud rate to 38400, the WESMAINT

communications rate automatically restores to 9600 baud after the

iBox reboots. You need to manually restore the SGConfig

terminal emulator communications rate to 9600.

13 From SGConfig, click the Connectivity group > Disconnect command.

Note: If you changed the baud rate to 38400, the WESMAINT

communications rate automatically restores to 9600 baud after the

iBox reboots. You need to manually restore the SGConfig

terminal emulator communications rate to 9600.

14 On the File menu, click Exit.

15 Physically disconnect your PC from the iBox.

994-0047-5.10-4 GE Information

Page 43

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

43

Configuring the iBox to work with a DNP3 I/O Module

Introduction

Your iBox RTU Master communicates with your DNP3 I/O modules through

the DNP3 Data Collection Application (DCA B023). The DNP DCA collects

data from, and sends control requests to, the DNP3 I/O modules.

Refer to Appendix F: Installing and Connecting DNP3 I/O Modules for

installation and connection instructions.

Use SGConfig to configure the DNP3 DCA in the iBox so that it

communicates with your DNP3 I/O module. There are three tables to

configure:

• Remote Device Table: This table contains one record for each DNP

I/O module in the system. The Remote Device Table specifies the

remote devices with which the DCA communicates, the polling

parameters for each remote device, and the points configured on each

remote device. Each record in the Remote Device Table references the

appropriate Remote Device Point Mapping Table(s) and Remote

Device Polling Table(s).

• Remote Device Point Mapping Table: Specifies the number and type

of data points associated with each DNP I/O module.

• Remote Device Polling Table: Specifies the polling type and frequency

for each DNP I/O module.

Instructions and guidelines for configuring your DNP3 DCA can be found in

the following documentation:

• DNP V3.00 DCA - Configuration Guide (B023-0CG)

• SGConfig online help.

Note: When configuring the Time Sync option:

• Disable Time Sync for the D20A and D20K modules

• If Time Sync is enabled on a D20S module, the polling rate may be a

minimum of 2 seconds (it takes about 850ms to do a Time Sync for each

device).

GE Information

994-0047-5.10-4

Page 44

iBox/iBox Kit

Installation and Maintenance Guide

GE Grid Solutions

44

For example, when configuring your iBox RTU Master to work with a DNP

Configuring the iBox to work with a DNP3 I/O Module, continued

Example

Configuration

Digital Input Module, assume that you have a DNP Digital Input Module:

• That is factory-configured with 64 digital inputs

• That has DNP address 0032

• Which is to be polled every 500 ms.

• With every poll, we want a full status update.

To meet these requirements, you would configure the DNP DCA as shown in

the below table:

Table Parameter Value

Remote Device Table Application Address 0032

Remote Device Point

Mapping Table

Remote Device Polling Table Poll Data Type Integrity

DCA Object Type Binary Input

Number of Device Points 64

Poll Interval 500 ms

994-0047-5.10-4 GE Information

Page 45

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

45

2.4. Testing your iBox

Overview

Introduction

Valid

Configuration

File Required

This section describes a number of system checks that you can perform to verify

your iBox software is functioning properly.

Before performing any of the tests in this section, you must have a valid

configuration file loaded into the iBox’s NVRAM. The iBox is typically shipped

with a valid configuration file loaded during manufacturing, and this file should be

still loaded when the unit is delivered to your site.

In the event that you do not have a valid configuration file loaded into your iBox’s

NVRAM, or the file becomes corrupted before the unit is installed, you must reload

the file before performing these verification tests.

For help restoring your configuration file, refer to the online help in SGConfig.

GE Information

994-0047-5.10-4

Page 46

iBox/iBox Kit

Installation and Maintenance Guide

46

LED Descriptions

GE Grid Solutions

Overview

Description

You can verify the iBox is operating properly by inspecting the LEDs on the iBox

chassis.

The iBox has the following LED indicators, all of which are GREEN.

LED Location Description

PWR Top left The POWER LED remains lit when the iBox is receiving

power.

RUN Top left The RUN LED flashes to indicate CPU bus activity. Brightness

indicates more CPU bus activity.

TX1 – TX3 Left side The TRANSMIT LED flashes when the iBox is transmitting to

an outside device. There are three transmit LEDs, one for

each communication port.

RX1 – RX3 Left side The RECEIVE LED flashes when the iBox is receiving a signal

from an outside device. There are three receive LEDs, one

for each communication port.

RS1 – RS3 Left side The Request to Send (RTS) LED only works on systems

configured for RS-232 communications. There are three RTS

LEDs, one for each communication port.

CS1 – CS3 Left side The Clear to Send (CTS) LED only works on systems

configured for RS-232 communications. There are three CTS

LEDs, one for each communication port.

CD1 – CD3 Left side The Data Carrier Detect (DCD) LED only works on systems

configured for RS-232 communications. There are three

DCD LEDs, one for each communication port.

I/P1 – I/P8 Right side Each of the iBox’s eight Digital Inputs (DI) has a LED that

remains lit when the DI is receiving a wetting voltage.

994-0047-5.10-4 GE Information

Page 47

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

47

Diagnostic Tools

General

WESMAINT

68K Monitor

To operate the iBox, you require the following system components:

• WESMAINT facility

• iBox monitor facility

• SGConfig configuration system.

Each iBox has a WESMAINT facility that allows users to examine the iBox

database, applications and communications, and to manipulate the data.

You can, for example, use WESMAINT to examine the state of digital input data, or

to force a digital output ON or OFF.

WESMAINT uses a series of menus and screens that display on a VT100 terminal,

or similar terminal emulator, to create a simple interface to the iBox.

With a VT100-compatible terminal emulation program or SGConfig, you can access

the WESMAINT facility directly.

Note: For further information about using WESMAINT software, refer to the

WESMAINTII+ User’s Guide (Document Number B014-1UG).

The iBox’s 68K Monitor is a debugging and diagnostics tool that is accessible in two

ways:

• As a menu selection available through WESMAINT

SGConfig

• Upon start-up of an iBox that has not been previously configured.

Note: For further information about using the iBox Monitor, refer to the 68K

Monitor User’s Guide (Document Number SWM0023).

Use SGConfig to define the iBox’s operating parameters. You can also use

SGConfig to download configuration files to the iBox through a serial connection.

Note: For further information about SGConfig, refer to the SGConfig online help.

GE Information

994-0047-5.10-4

Page 48

iBox/iBox Kit

Installation and Maintenance Guide

48

Boot Test Verification

GE Grid Solutions

System

Diagnostics

(POST)

Terminal

Emulation

Software

WESMAINT

Terminal for

Set-up

The iBox software includes a Power On Self-Test (POST) process, which runs when

the unit is powered ON and determines whether or not the iBox circuitry is working

properly.

Terminal emulation software is not part of the iBox system, but you can use terminal

emulation software such as HyperTerminal

®

or SGConfig terminal utility for these

tests.

Use the following procedure to set up a PC as a WESMAINT terminal:

Step Action

1

Open HyperTerminal (provided with Windows

®

operating system), or

other VT100-compatible terminal emulation software.

2

Verify (or set) the terminal communications settings as follows:

Data Rate

Data Bits

Stop Bits

Parity

Flow Control

9600 bps

8

1

None

XON/XOFF

Connector Settings

COM1, COM2, as required

for your computer

Continued on next page

994-0047-5.10-4 GE Information

Page 49

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

49

Boot Test Verification, continued

Connect to

the

WESMAINT

port

iBox Boot Up

Step Action

1

Connect a WESMAINT cable to the female DB-9 WESMAINT port on

the top left side of your iBox.

2

Attach the other end of the WESMAINT cable to the PC’s selected

communications port.

3

Verify the power cable is properly connected to iBox, and power is

available.

4

The POWER and RUN indicators on the front upper left-hand corner

illuminate when power to the iBox is turned ON.

5

Monitor the VT100 terminal’s display

Result: A series of text scripts displays as the POST routines are

performed. If you do not see the text scripts, check all

connections and repeat the procedure.

The iBox automatically boots as soon as the power is turned on.

If the iBox fails to boot up, it may have sustained damage during shipping. Contact

GE Digital Energy for assistance.

GE Information

994-0047-5.10-4

Page 50

iBox/iBox Kit

Installation and Maintenance Guide

50

Log in to WESMAINT

GE Grid Solutions

General

Procedure:

Logging into

Wesmaint

User Name

and Password

When the POST is complete, you can log in to WESMAINT to continue further

testing.

To log into WESMAINT from a PC:

Step Action

Press

1

ENTER

Result: The Welcome screen appears, as does a login prompt.

Note: If the Welcome banner does not appear, and only a <iBoxS

prompt displays, a valid code or configuration file is not loaded

into the iBox’s memory. Stop this procedure and refer to

“Downloading Code Files” on page 65 for procedures for

restoring files

2

3

Type the User Name: westronic and press

Type the Password: rd and press

ENTER.

ENTER.

Result: The WESMAINT Main Menu appears

4

If a time-out occurs, press

ENTER again, to return to the login prompt

The user name and password shown above are factory defaults. If you cannot log in,

contact your system administrator to obtain the correct user name and password.

Navigating in

WESMAINT

Further

WESMAINT

Information

Use the UP and DOWN arrow keys, or type in the menu number, to select an option

from the Main Menu. Press

CTRL+L at any time to log out of WESMAINT

For further information about using WESMAINT, refer to WESMAINTII+ User’s

Guide (Document Number B014-1UG).

994-0047-5.10-4 GE Information

Page 51

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

51

2.5. Connecting and Testing Field Wiring

Overview

Introduction

This section describes the process for making and testing field connections to the

iBox.

GE Information

994-0047-5.10-4

Page 52

iBox/iBox Kit

Installation and Maintenance Guide

52

Digital Inputs

GE Grid Solutions

Digital Inputs

Wetting Types

Digital Input

Thresholds

The iBox has eight digital inputs (DIs).

All DIs require an input voltage signal large enough to turn on an optical switch. If

the DI is receiving a sufficient wetting voltage, the green LED associated with the DI

will light.

The following table shows the iBox’s ON and OFF state thresholds. Verify that

inputs do not exceed the maximum overload voltage; otherwise, the iBox may be

damaged.

Digital Input

Options

24 VDC >14 VDC <5 VDC 24 VDC + 20%

48 VDC >28 VDC <10 VDC 48 VDC + 20%

110/125 VDC >80 VDC <20 VDC 125 VDC + 20%

On Threshold Off Threshold Max Overload Voltage

Low Voltage Digital Input

High Voltage Digital Input

994-0047-5.10-4 GE Information

Page 53

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

53

!

2

1 1 22 1

Input #1

Input #8

External Wetting

Power Supply

TB2 TB9 TB10

+/- V

Digital Input Configuration

Digital Input

Field

Connections

Digital Input

Wetting

Selection

Wiring

Diagram:

Dry Contact

Operation

Field wiring for all digital input variants are made through the iBox’s terminal

blocks, separable in pairs.

The digital input is wetted (or turned ON) by closing a contact across the two input

termination points. The voltage that is switched at the input terminals is supplied by

an external source. The external power source is connected to terminal block TB-10,

positions 1 and 2, as shown below.

All eight digital inputs are bipolar. Use care when connecting multiple external

power sources, since the digital inputs have common returns.

This diagram illustrates the DC input connections, from Input #1 (TB2) through

Input #8 (TB9). TB10 accepts DC voltages of either polarity. The input voltage level

to TB10 is determined by the purchased option.

GE Information

994-0047-5.10-4

Page 54

iBox/iBox Kit

Installation and Maintenance Guide

54

TB15

TB14

TB13

TB12

TB11

Trip 4

Close 4

Trip 3

Close 3

Trip 2

Close 2

Trip 1

Close 1

1 2 1 2 1 2 1 2 1 2 Master T/C

(+/- V)

GND

TB15

TB14

TB13

TB12

TB11

Trip 2

Close 2

Trip 1

Close 1

1 2 1 2 1 2 1 2 1 2 Master T/C

(+/- V)

GND

Digital Out 2

(Form A)

Digital Out 1

(Form A)

Digital Outputs

GE Grid Solutions

Operating

Modes

Wiring Four

Trip/Close

Outputs

(Part No.

505-0100,

505-0101,

505-0102)

Wiring Two

Trip/Close

and Two

Digital

Outputs

iBox control outputs have two modes of operation:

• Trip/Close (T/C) pairs

• Digital Output (DO) isolation Form A contacts.

Note: Using SGConfig, you must configure the digital outputs for four Trip/Close

outputs or two Trip/Close and two digital outputs, depending on the part number.

You can wire four trip/close outputs, as follows:

You can wire two trip/close and two digital outputs, as follows:

(Part No.

505-0103,

505-0104,

505-0105)

Important

Remote/Local

Operation

iBox digital outputs are not internally fuse-protected.

If: Then operation is:

JP2 is installed Remote (controls are enabled)

JP2 is removed Local (controls are disabled)

994-0047-5.10-4 GE Information

Page 55

GE Grid Solutions

iBox/iBox Kit

Installation and Maintenance Guide

55

The following procedure, accessible through the WESMAINT Main Menu, assumes

• Press N to move to the Next page

Digital Input Verification Test

Testing

Digital Inputs

Note

Procedure:

Testing

Digital Inputs

To view digital input changes through WESMAINT, log in to WESMAINT as

outlined in “Boot Test Verification” on page 48.

The quantity and relative position of data points in the iBox’s System Point Database

is determined by the version of the iBox Plant I/O software application present in

your iBox’s firmware.

You can determine the actual point number that you want to test by viewing the point

descriptions in WESMAINT, or through the SGConfig configuration tables for your

iBox.

The point descriptions viewed in WESMAINT will be modified by changes you

have made to the point descriptions in the iBox configuration file

digital inputs for the iBox are wired and wetted.

Step Action

1

Select 1 — Digital Input Display.

Result: The point numbers and (optionally) point descriptions appear

on the WESMAINT display

2

Use arrow keys to move up or down to highlight the desired point